Page 1

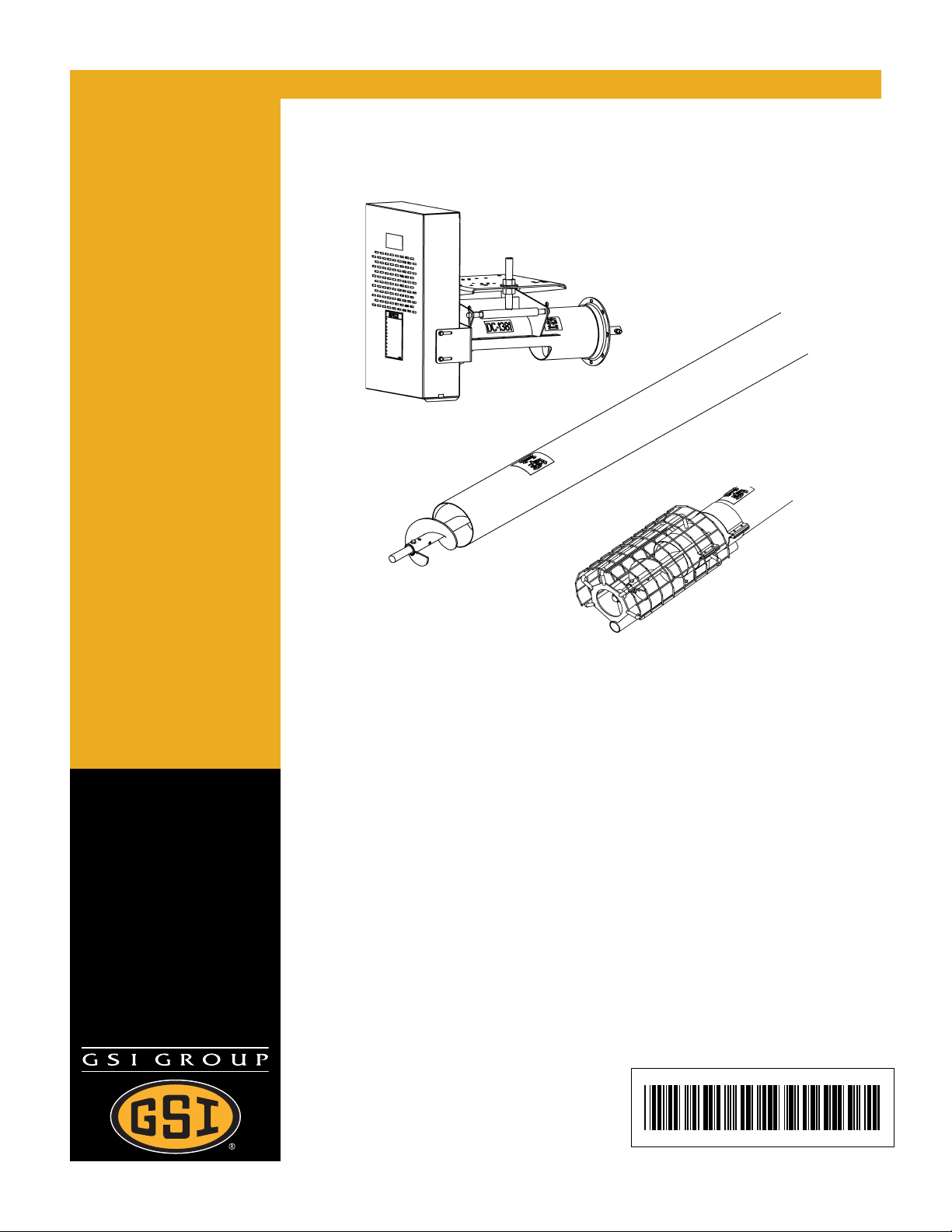

6", 8", 10", & 12" Custom Augers

Assembly & Operation Manual

PNEG-1445

Date: 05-08-07

PNEG-1445

Page 2

2 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 3

Table of Contents

Contents

Chapter 1 Introduction ....................................................................................................................... 4

General Information ............................................................................................................4

Receiving Merchandise and Filing Claims .......................................................................... 4

Capacity .............................................................................................................................. 4

Chapter 2 Safety .................................................................................................................................. 5

Safety Guidelines ................................................................................................................ 5

Safety Instructions ............................................................................................................... 6

Operator Qualifications ....................................................................................................... 9

Chapter 3 Safety Decals ................................................................................................................... 11

Chapter 4 Assembly ......................................................................................................................... 14

Motor Mount Installation Instructions for all 6", 8", 10" & 12" Custom Augers .................. 14

Assembling the Flight Extension for All 6", 8", 10" & 12" Custom Augers ......................... 22

Assembling the Intake Guard for All 6", 8", 10" & 12" Custom Augers ............................. 27

Assembling the Inlet Hopper with Bearings for All 6", 8", 10" & 12" Custom Augers ........ 29

Outlet Cutting Guidelines .................................................................................................. 32

Enclosed Slide Gates with Rack and Pinion Control ......................................................... 33

Basic Inlet Hoppers ........................................................................................................... 34

Spouting, Fittings and Truss Kits ...................................................................................... 34

Sample Custom Auger Configurations .............................................................................. 35

Chapter 5 Electric Drive Motors ...................................................................................................... 36

Power Source .................................................................................................................... 36

Chapter 6 Start-Up ............................................................................................................................ 37

Start-Up and Break-In ....................................................................................................... 37

Chapter 7 Operation/Maintenance ................................................................................................... 39

Operate the Auger ............................................................................................................. 39

Maintain the Auger ............................................................................................................ 40

Chapter 8 Shutdown ......................................................................................................................... 41

Normal Shutdown .............................................................................................................. 41

Emergency Shutdown ....................................................................................................... 41

Lockout .............................................................................................................................. 41

Storage Preparation .......................................................................................................... 41

Chapter 9 Parts List .......................................................................................................................... 43

6" Custom Auger Parts ...................................................................................................... 44

8" Custom Auger Parts ...................................................................................................... 46

8" Internal Bearing Parts ................................................................................................... 48

10" Custom Auger Parts .................................................................................................... 50

10" Internal Bearing Parts ................................................................................................. 52

12" Custom Auger Parts .................................................................................................... 54

12" Internal Bearing Parts ................................................................................................. 56

Chapter 10 Trouble Shooting ........................................................................................................... 58

Chapter 11 Warranty ......................................................................................................................... 59

PNEG-1445 6", 8", 10", & 12" Custom Augers 3

Page 4

1. INTRODUCTION

General Information

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do

so could result in personal injury or equipment damage.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be

easily accessible when needed.

WARRANTY is provided as part of the company’s support program for customers who use and

maintain their equipment as described in the manual. The warranty is explained on the warranty

page located on the inside of the back cover.

Receiving Merchandise and Filing Claims

INSPECT the shipment immediately upon arrival. The Customer is responsible for ensuring that

all quantities are correct. Report any damage or shortages by recording a detailed description

on the Bill of Lading to justify the Customer’s claim from the Transport Firm. When receiving

merchandise, it is important to check both the quantity of parts and their descriptions with the

packing list enclosed within each package. All claims for freight damage or shortage must be

made by the consignee within ten (10) days from the date of the occurrence of freight damage.

The consignee should accept the shipment after noting the damage or loss.

Capacity

1. The capacities may vary greatly under varying conditions. The following factors play a role

in the performance of the auger:

• Speed

• Angle of Operation

• Moisture Content

• Amounts of Foreign Matter

• Different Materials

• Methods of Feeding

2. For example, a twenty-five percent (25%) moisture could cut capacity by as much as 40%

under some conditions.

4 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 5

E

T

2

A

.

F

S

Y

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and

understand. This information relates to protecting personal safety and preventing equipment

problems. It is the responsibility of the owner/operator to inform anyone operating or working in

the area of this equipment of these safety guidelines. To help you recognize this information, we

use the symbols that are defined below. Please read the manual and pay attention to these

sections. Failure to read this manual and it’s safety instructions is a misuse of the equipment and

may lead to serious injury or death.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

DANGER indicates an imminently hazardous situation

which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous

situation which, if not avoided, could result in death or

serious injury.

CAUTION indicates a potentially hazardous situation

which, if not avoided, may result in minor or moderate

injury.

CAUTION used without the safety alert symbol indicates

a potentially hazardous situation which, if not avoided,

may result in property damage.

NOTE indicates information about the equipment that

you should pay special attention to.

PNEG-1445 6", 8", 10", & 12" Custom Augers 5

Page 6

2. SAFETY

Safety Instructions

Our principle concern is your safety and the safety of others associated with grain handling

equipment. We want to keep you as a customer. This manual is to help you understand safe

operating procedures and some problems which may be encountered by the operator and other

personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards and

precautions exist, and to inform all personnel associated with the equipment or in the area.

Safety precautions may be required from the personnel. Avoid any alterations to the equipment.

Such alterations may produce a very dangerous situation, where SERIOUS INJURY or DEATH

may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations which should be carefully followed in all cases. Authorities having jurisdiction should

be consulted before installations are made.

Operate Unload Equipment Properly

Make sure ALL equipment is locked in position before

operating.

NEVER start equipment until ALL persons are clear of the work

area.

Be sure all operators are adequately rested and prepared to

perform all functions of operating this equipment.

NEVER allow any person intoxicated or under the influence of

alcohol or drugs to operate the equipment.

NEVER work alone.

Make sure someone is near by who is aware of the proper

shutdown sequence in the event of an accident or emergency.

ALWAYS think before acting. NEVER act impulsively around

the equipment.

NEVER allow anyone inside a bin, truck or wagon which is

being unloaded by an auger or conveyor. Flowing grain can trap

and suffocate in seconds.

Use ample overhead lighting after sunset to light the work area.

Keep area around intake free of obstacles such as electrical

cords, blocks, etc., that might trip workers.

Operate Unload

Equipment Safely

NEVER drive, stand or walk under the equipment.

Use caution not to hit the auger when positioning the load.

ALWAYS lockout ALL power to the equipment when finished

unloading a bin.

6 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 7

Follow Safety Instructions

Carefully read all safety messages in this manual and

on your machine safety signs. Keep signs in good

condition. Replace missing or damaged safety signs.

Be sure new equipment components and repair parts

include the current safety signs. Replacement safety

signs are available from the manufacturer.

Learn how to operate the machine and how to use

controls properly. Do not let anyone operate without

instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may

impair the function and/or safety and affect machine

life.

2. SAFETY

If you do not understand any part of this manual and

need assistance, contact your dealer.

Install & Operate Electrical Equipment Properly

To avoid serious injury or death, stay away from unit

and make sure everyone is clear of all augers before

starting or operating the unit.

Electrical controls should be installed by a qualified

electrician and must meet the standards set by the

national electrical code and all local and state codes.

Disconnect and lock out all power sources before

installing wires/cables or servicing equipment.

Do not operate electric motor equipped units until

motors are properly grounded.

Disconnect power on electrical driven units before

resetting motor overloads.

Read and Understand Manual

Electric Shock Hazard

Do not repetitively stop and start the drive in order to

free a plugged condition. Jogging the drive in this type

of condition can damage the equipment.

PNEG-1445 6", 8", 10", & 12" Custom Augers 7

Page 8

2. SAFETY

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher

handy.

Keep emergency numbers for doctors,

ambulance service, hospital, and fire

department near your telephone.

Wear Protective Clothing

Wear close fitting clothing and safety

equipment appropriate to the job.

Safety glasses should be worn at all times

to protect eyes from debris.

Keep Emergency Equipment Quickly

Accessible.

Eye Protection

Wear gloves to protect your hands from

sharp edges on plastic or steel parts.

Wear steel toe boots to help protect your

toes from falling debris.

A respirator may be needed if a hog house

has poor ventilation. Waste fumes can be

toxic.

Remove all jewelry.

Tuck in any loose or dangling shoe strings.

Long hair should be tied up and back.

Gloves

Steel Toe Boots

Respirator

Wear hard hat to help protect your head.

Hard Hat

8 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 9

2. SAFETY

Operator Qualifications

1. The User/Operator must be competent and experienced to operate auger equipment.

Anyone who works with or around augers must have good common sense in order to be

qualified. These persons must also know and meet all other qualifications, such as:

A. Any person who has not read and/or does not understand all operation and safety

instructions is not qualified to operate any auger systems.

B. Certain regulations apply to personnel operating power machinery. Personnel under

the age of 18 years may not operate power machinery, including augers. It is your

responsibility, as owner and/or supervisor, to know what these regulations are in your

area or situation.

C. Unqualified or incompetent persons are to remain out of work area.

D. O.S.H.A. (Occupational Safety & Health Administration) regulations state: “At the time

of initial assignment and at least annually thereafter, the employer shall instruct every

employee in the safe operation and servicing of all equipment with which the employee

is, or will be involved”. Federal Occupational Safety & Health Standards for Agriculture.

Sub part D, Section 19287.57 (a) (6).

2. As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the

safe operating and safety procedures for this auger. We included this sign-off sheet for your

convenience and personal record keeping. All unqualified people are to stay out of the work

area at all times. It is strongly recommended that another qualified person who knows the

shutdown procedure is in the area in the event of an emergency. A person who has not read

this manual and understands all operating and safety instructions, is not qualified to operate

the machine.

Date

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Employees Name (Printed) Employees Signature

PNEG-1445 6", 8", 10", & 12" Custom Augers 9

Page 10

2. SAFETY

st

SAFETY

Replace missing guards and shields

FREE OF CHARGE!

Our equipment is built to provide many years of dependable service to our customers through

durable craftsmanship.

One of the most important aspects of our engineering is SAFETY 1

product lines. Safety is NO ACCIDENT!

That is why we are implementing its SAFETY 1st program. Should you ever need guards,

shields, safety decals, or owner/operator manuals, simply contact us, and we will supply you with

them FREE OF CHARGE!

While it is our main goal to be the world leader in auger manufacturing, it is always our first

priority to keep our customers safe.

If you need any of the above listed safety items or have safety questions, please contact:

The GSI Group

PO Box 20

1004 E. Illinois Street

Assumption, IL 62510

Ph: 1-217-226-4421

st

design throughout all

10 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 11

A

L

E

E

T

Y

.

3

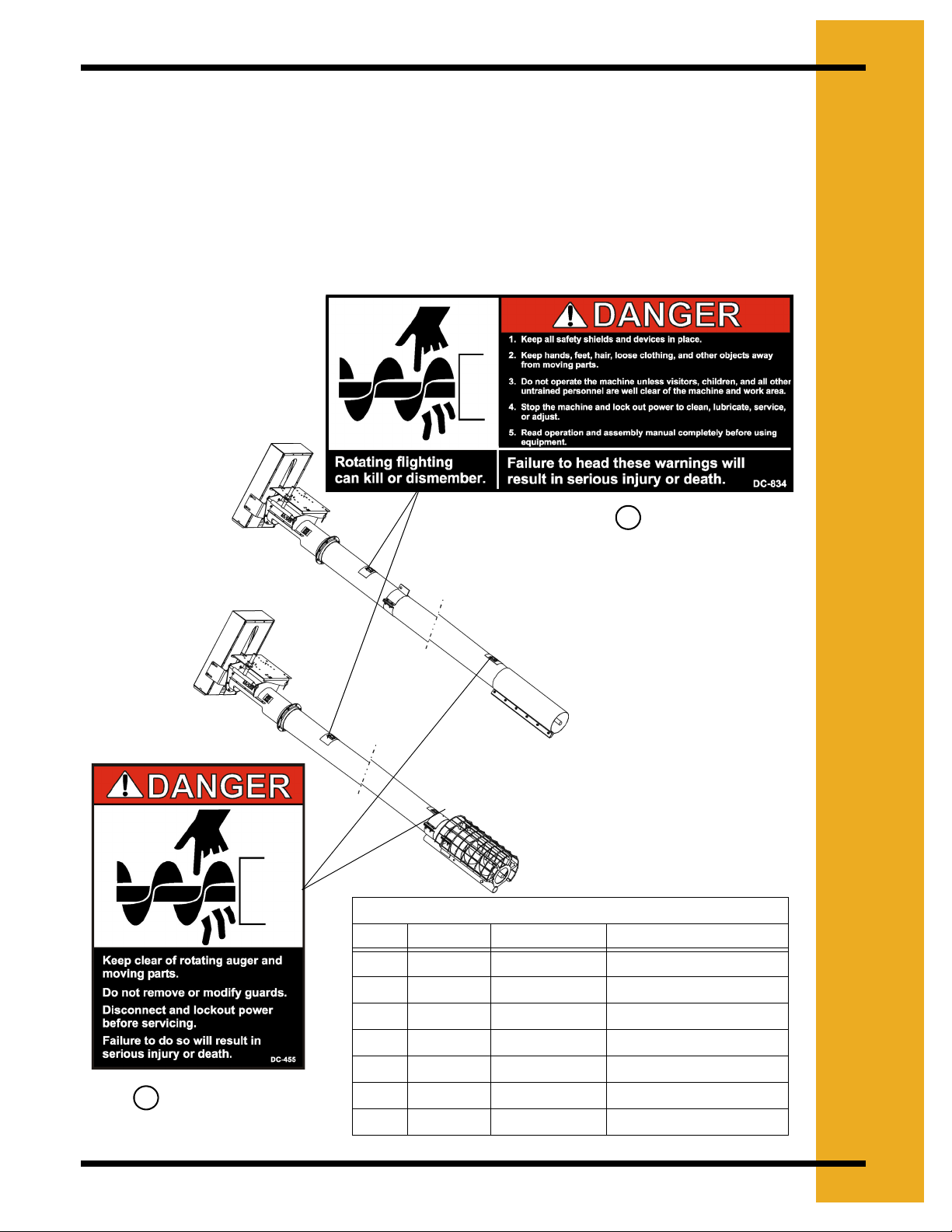

The Decal List below has all the safety decals that should be included with your equipment. The

following pages show what the decals look like and where they should be located on the

equipment. Inspect all decals and replace any that are illegible, worn, or missing. Contact your

local dealer or the manufacturer to order replacement decals free of charge.

Contact:

The GSI Group

1004 E. Illinois Street

Assumption, IL 62510

Ph: (217)-226-4421

F

S

A

C

D

S

DC-834

3

3

Bulk Auger

Utility Auger

6'', 8'', & 10'' Roof Auger Decal List

Ref # Part # Size Description

1 DC-1381 4-1/2'' x 2'' Danger - Shear Point

2 DC-994 4-1/2'' x 2'' Danger - Shear Point

3 DC-834 9'' x 3-3/4'' Danger - Unloading

4 DC-1379 5-1/8'' x 7-3/8'' Notice -1 - 11

5 DC-455 4'' x 5-3/4'' Danger - Rotating Flight

DC-455

5

PNEG-1445 6", 8", 10", & 12" Custom Augers 11

6 DC-12L34 2-1/4'' x 2-3/4'' Caution

7 DC-1395 4-1/4'' x 6-1/4'' Danger - Rotating Flight

Page 12

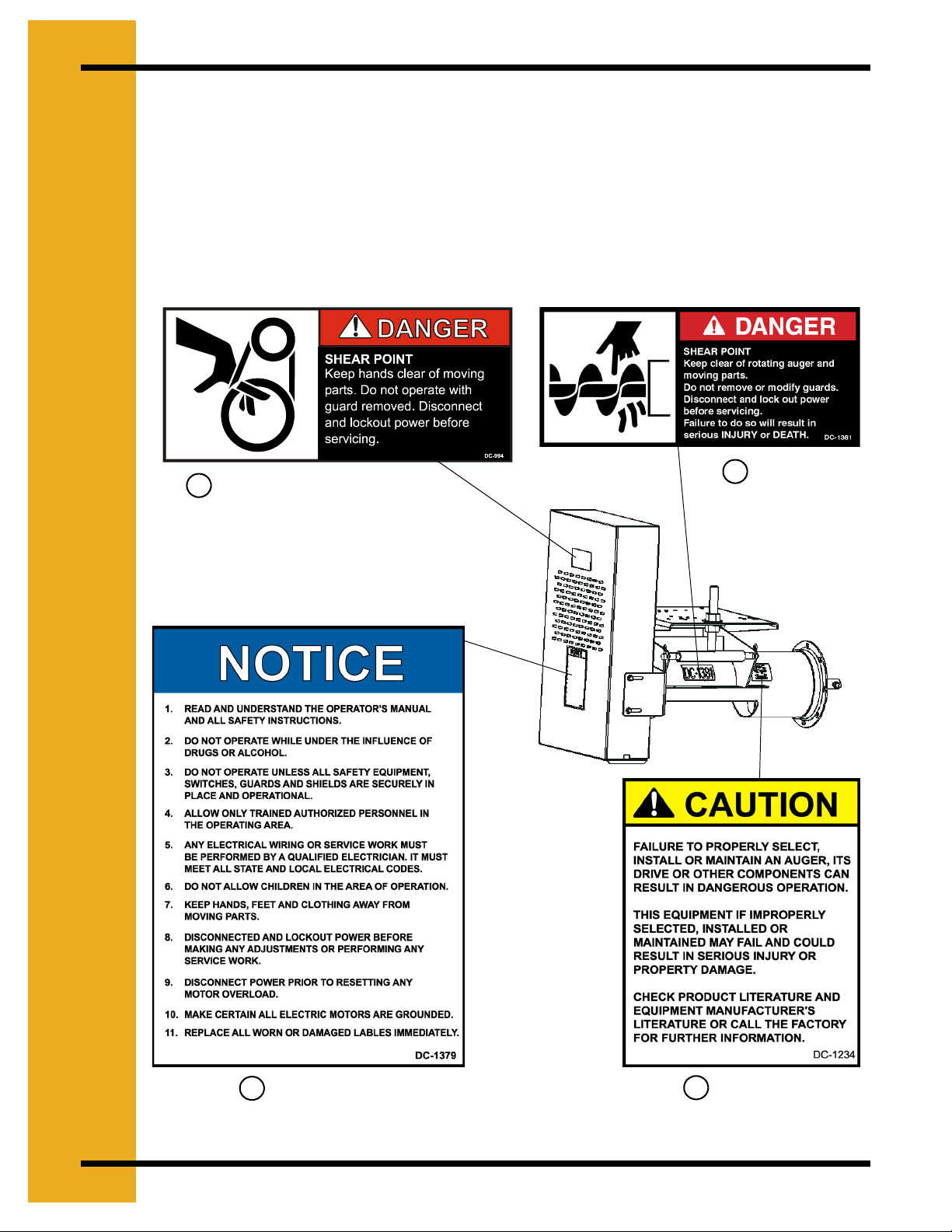

3. SAFETY DECALS

Check components shown below to insure that the safety decals are in place and in good

condition. If a decal cannot be easily read for any reason or has been painted over, replace it

immediately. Contact your dealer or the manufacturer to order a replacement Decal free of

charge.

Contact:

The GSI Group

1004 E. Illinois Street

Assumption, IL 62510

Ph: (217)-226-4421

DC-994

5

1

DC-994

DC-1381

DC-1379

4

6

DC-1234

12 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 13

3. SAFETY DECALS

Check components shown below to insure that the safety decals are in place and in good

condition. If a decal cannot be easily read for any reason or has been painted over, replace it

immediately.

Contact your dealer or the manufacturer to order a replacement Decal free of charge.

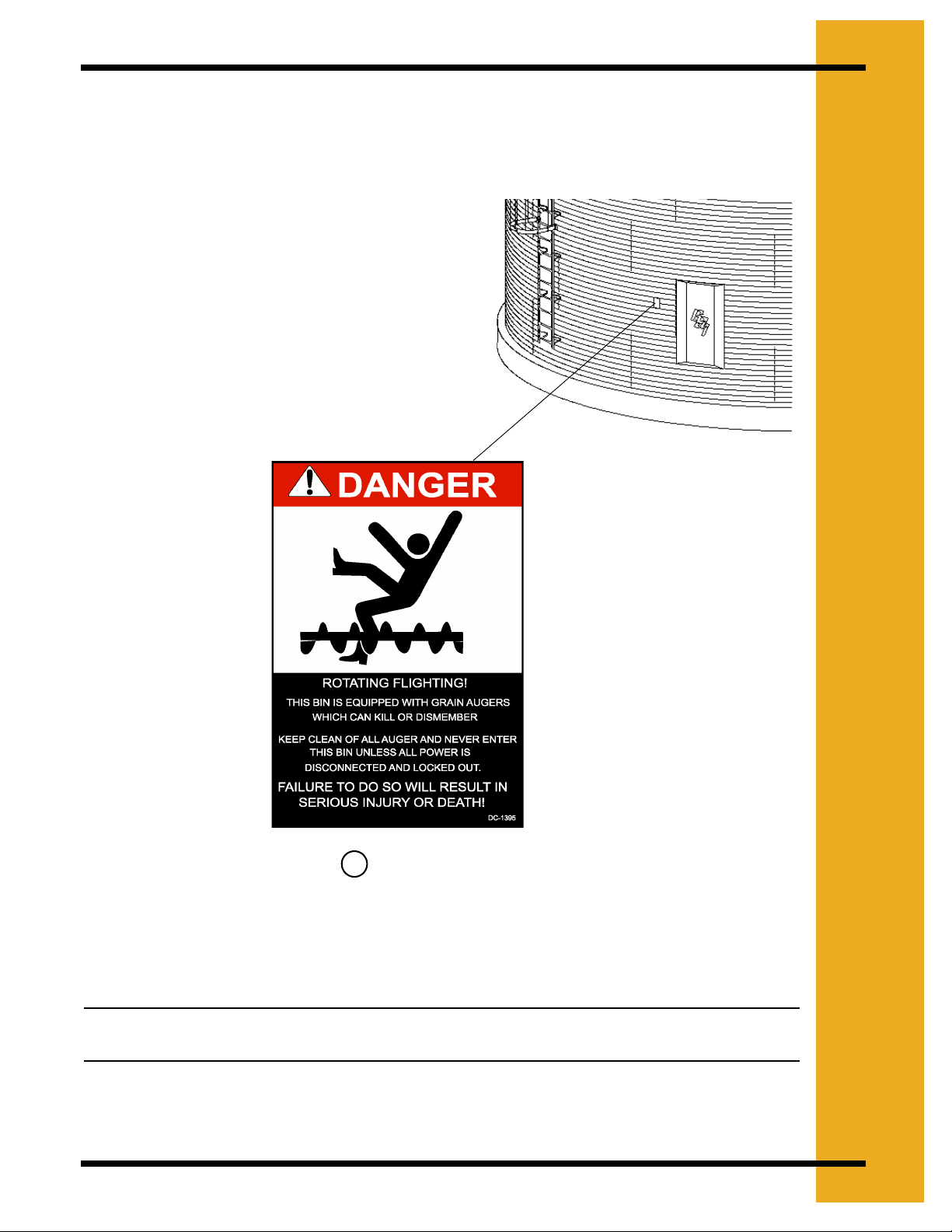

DANGER Sign No. DC-1395 was supplied with

your bin unloading equipment. This safety sign

should be applied to the side of the bin near the bin

opening, so it will be viewed by people entering into

the bin storage building. Do not cover any safety

signs or any other signs that are already there.

.

6

DC-1395

Note: Please remember, safety signs provide important safety information for people

working near bin unloading equipment that is in operation.

PNEG-1445 6", 8", 10", & 12" Custom Augers 13

Page 14

4. ASSEMBLY

Motor Mount Installation Instructions for all 6", 8", 10" & 12" Custom

Augers

1. Installing Drive Shaft

A. Insert the Drive Shaft into the opposite end of flight with keyway facing outward.

Align the holes in the shaft and secure with Grade 8 bolts and stover nuts.

(See Chart for Bolt Sizes), (See Figure 4A).

Figure 4A

Flight Hardware

6" 3/8" - 16 x 2" Grade 8 Hex Bolts

8" 7/16" - 14 x 3" Grade 8 Hex Bolts

10" 1/2" - 13 x 3-1/2" Grade 8 Hex Bolts

12" 5/8" - 11 x 4" Grade 8 Hex Bolt

14 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 15

2. Mounting Bearing to Bearing Plate

A. Align bolt holes on Bearing Flange with bolt holes on Bearing Plate.

B. Secure Bearing to Bearing plate using appropriate bolts, lock washers, and nuts.

(See Chart for Bolt Sizes), (See Figure 4B).

4. ASSEMBLY

Figure 4B

Bearing Bolts

6" 7/16" - 14 x 1-1/2" Bolt

8" & 10" 1/2" - 13 x 1-1/2" Bolt

12" 5/8" - 11 x 2" Bolt

PNEG-1445 6", 8", 10", & 12" Custom Augers 15

Page 16

4. ASSEMBLY

3. Installing Bearing Plate onto Tube

A. Align Bearing with Drive Shaft and slip Shaft through bearing.

B. Rotate Plate until bolt holes in tube flange and plate align. Secure with appropriate

bolts, and Serrated Flange nut (See Chart for Bolt Sizes).

C. Only Secure with UPPER and LOWER four (4) bolts (See Figure 4G). The other

four (4) bolts will be installed later with the Belt Guard Mounting Brackets.

(See Chart for Bolt Sizes).

(See Chart for Bolt Sizes)

Figure 4C

Bearing Plate Bolts

6" & 8" 5/16" - 18 x 1" Bolt

10" & 12" 3/8" - 16 x 1" Bolt

Note: On the 10" & 12" systems use the four (4) 3/8" x 1" –16 bolts in this step, the longer

bolts will be used to attach the Belt Guard Mounting Brackets in a future step.

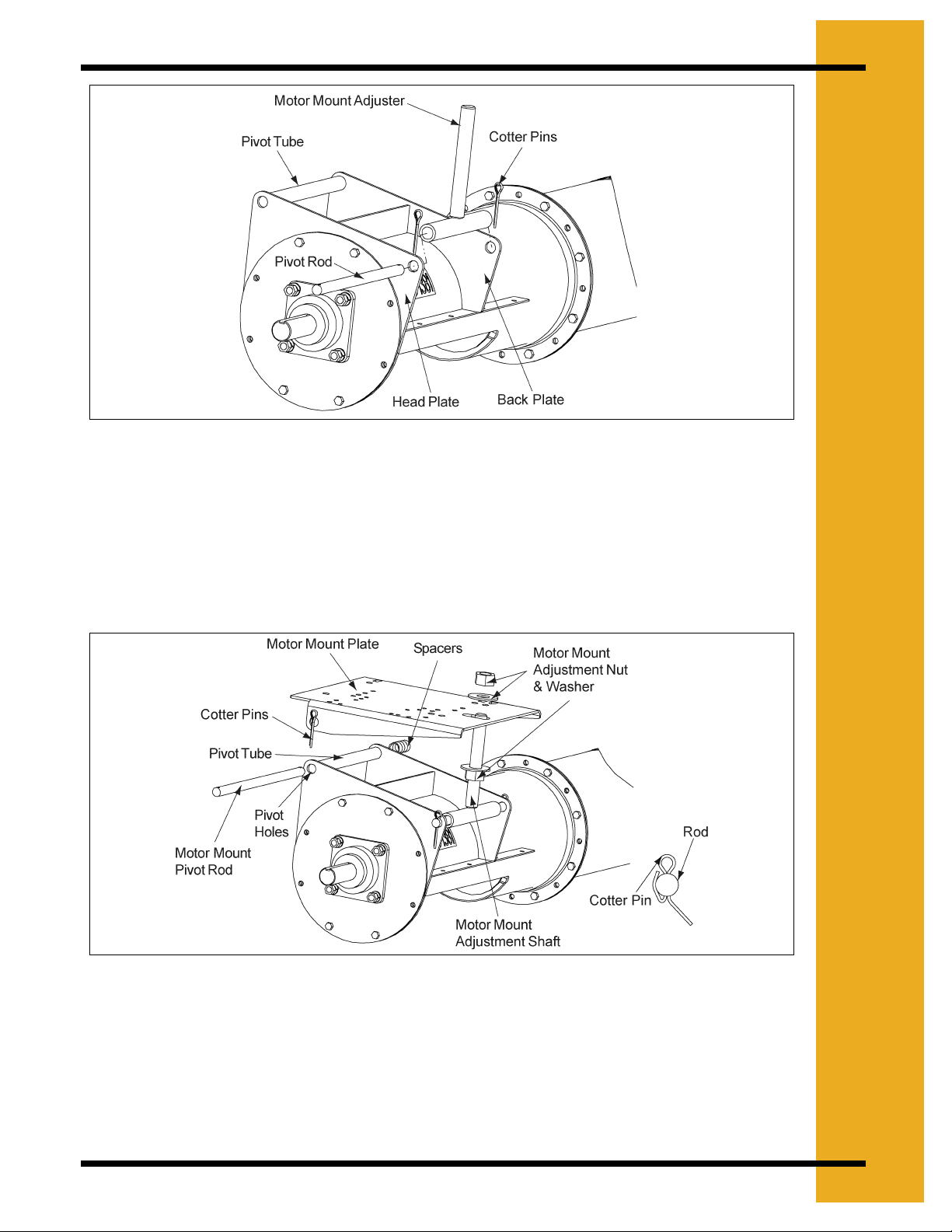

4. Installing the Motor Mount Adjuster

A. Place Motor Mount Adjuster between the Back Plate and Head Plate on the

Discharge Tube.

B. Insert Pivot Rod through the Tube plates and Motor Mount Adjuster. Secure in place

with two (2) 3/16" x 2" cotter pins. (See Figure 4D).

16 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 17

5. Installing the Motor Mount Plate

4. ASSEMBLY

Figure 4D

A. Secure one (1) of the motor mount adjustment nuts and one (1) the motor mount

adjustment washers approximately 3/4 of the way down the motor mount adjuster’s

threaded shaft.

B. Once the nut and washer is secure, slip the Motor Mount Plate over the adjuster and

align the pivot holes with the pivot tube. (See Figure 4E).

Figure 4E

C. Slide the Motor Mount Pivot Rod through the pivot tube on the Discharge Tube.

D. When the pivot rod begins to extend through the pivot tube install the spacers,

BETWEEN the Back Plate and the inner face of the Motor Mount Plate.

(See Figure 4F).

PNEG-1445 6", 8", 10", & 12" Custom Augers 17

Page 18

4. ASSEMBLY

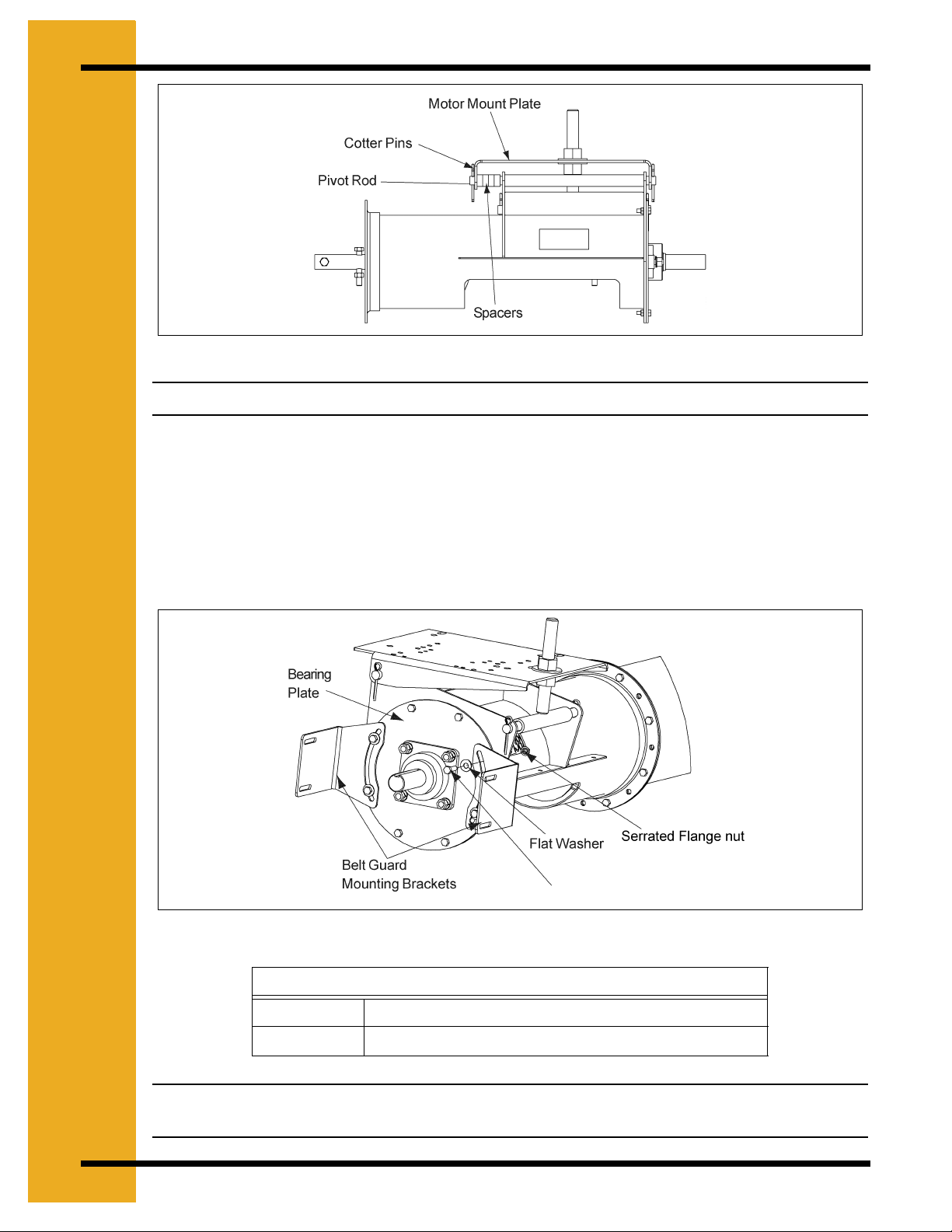

Figure 4F

Note: The number of spacers will vary between each size of unloader.

6. Installing the Belt Guard Brackets

A. Align the holes on the Bearing Plate with the slots on the Belt Guard Mounting

Brackets.

B. Secure the Brackets with proper bolts, flat washers, and Serrated Flange nut .

(See Chart for Bolt Sizes), (See Figure 4G).

(See Chart for Bolt

Figure 4G

Belt Guard Bracket Bolts

6" & 8" 5/16" - 18 x 1" Bolt

10" & 12" 3/8" - 16 x 1-1/4" Bolt

Note: DO NOT tighten the bolts completely. The brackets will need to be rotated to align

the slot in the Belt Guard with the shafts on the motor and flight.

18 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 19

7. Installing the Lock Collar

A. Slide the Lock Collar over the Drive Shaft, positioning it against the bearing. Do not

tighten the lock collar at this time as it will be tightened later in the assembly.

(See Figure 4H).

4. ASSEMBLY

8. Installing the Pulley

A. Place and position the key into the keyway located on the Drive Shaft.

B. Place the pulley onto the Drive Shaft with the setscrew side of the pulley facing

away from the Bearing Plate. Position the pulley so that it is as close to the lock

collar as possible, but not touching it.

C. Once the pulley is appropriately positioned, tighten the setscrew with a hex head

wrench to secure it to the drive shaft. (See Figure 4I).

Figure 4H

Figure 4I

PNEG-1445 6", 8", 10", & 12" Custom Augers 19

Page 20

4. ASSEMBLY

9. Tightening the Lock Collar

A. Using a punch and hammer, drive the lock collar clockwise (the same direction as

the shaft rotation). Once the lock collar is set in place, use a hex head wrench to

tighten the lock collar by tightening the setscrew.

Note: If the lock collar is not turned far enough, the setscrew will not lock it into place.

10. Installing the Motor (Not Provided)

A. Attach the Motor to the Motor Mount Plate using appropriate bolts, lock washers,

and hex nuts. (See Chart for Bolt Sizes).

B. Install pulley onto motor shaft making sure that it is aligned with the flight pulley. It

may be necessary to move spacers to gain shaft alignment. (See Figure 4J).

Figure 4J

Motor Bolt Chart

Motor Size Hex Bolt Size Qty

56 5/16" -18 x 1-1/4" 4

143T

145T

182T 3/8" - 16 x 1-1/4" 4

184T

213T

215T

254T 1/2" -13 x 1-3/4" 4

256T

20 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 21

11. Installing the Belts

A. Place the belts onto the pulleys.

B. First screw the lower Motor Mount Adjustment Nut upward, raising the Motor Mount

Plate, putting tension on the belts.

C. Once the desired tension is reached tighten the Upper Motor Mount Adjustment Nut

down onto the Motor Mount Plate locking it into place.

12. Installing the Belt Guard

A. With the belts properly tensioned remove the bottom Belt Guard cover and slip Belt

Guard down over motor shaft.

B. Bolt the Belt Guard to the Belt Guard Mounting Brackets, the brackets should still

be loose at this time.

C. Align the motor shaft and the Flight Drive Shaft in the Belt Guard’s slot, making sure

that the Belt Guard DOES NOT contact either pulley, and tighten down the Belt

Guard Mounting Brackets to the Bearing Plate. (See Figure 4K).

4. ASSEMBLY

D. Once the brackets are tightened slide the bottom cover back into place and secure

with supplied bolt.

Figure 4K

PNEG-1445 6", 8", 10", & 12" Custom Augers 21

Page 22

4. ASSEMBLY

Assembling the Flight Extension for All 6", 8", 10" & 12" Custom

Augers

13. Standard Assembly without Bearings

Note: If your auger does not include an extension skip ahead to Step - 13E.

A. Begin by sliding the extension connecting band onto the main auger tube.

(See Figure 4L).

Figure 4L

22 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 23

4. ASSEMBLY

B. Slide the flight connecting shaft into the main section of flight and bolt together with

Grade 8 Hex Bolt and Stover nut. Next slide extension flight onto connecting shaft

and bolt together using proper grade 8 bolts and stover nuts. (See Chart for Bolt

Sizes), (See Figure 4M).

Figure 4M

Flight Hardware

6" 3/8" - 16 x 2" Grade 8 Hex Bolts

8" 7/16" - 14 x 3" Grade 8 Hex Bolts

10" 1/2" - 13 x 3-1/2" Grade 8 Hex Bolts

12" 5/8" - 11 x 4" Grade 8 Hex Bolt

C. Slide the extension tube over the extension flight, making sure the tube is pressed

securely against the main auger tube. (See Figure 4N).

Figure 4N

PNEG-1445 6", 8", 10", & 12" Custom Augers 23

Page 24

4. ASSEMBLY

D. Slide the extension connecting band over the two sections of tube, making sure the

connecting band is centered over the mated surfaces of the tubes. Tighten the

connecting band down using the correct Hex Bolts and Nylock nuts.

(See Chart for Bolt Sizes), (See Figure 4O).

Figure 4O

Connecting Band Bolts

6" & 8" 5/16" -18 x 1" Hex Bolt

10" & 12" 3/8" - 16 x 1" Hex Bolt

E. Insert the intake shaft into the flight and connect with proper grade 8 bolt and stover

nut. (See Chart for Bolt Sizes), (See Figure 4P).

Figure 4P

Flight Hardware

6" 3/8" - 16 x 2" Grade 8 Hex Bolts

8" 7/16" - 14 x 3" Grade 8 Hex Bolts

10" 1/2" - 13 x 3-1/2" Grade 8 Hex Bolts

12" 5/8" - 11 x 4" Grade 8 Hex Bolt

24 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 25

14. Assemblies with Internal Bearings

A. Slide Connecting Band onto main auger tube, and attach Connecting Stub to main

auger flight using the assigned hardware. (See Chart for Bolt Sizes), (See Figure

4Q).

4. ASSEMBLY

Figure 4Q

Flight Hardware

6" 3/8" - 16 x 2" Grade 8 Hex Bolts

8" 7/16" - 14 x 3" Grade 8 Hex Bolts

10" 1/2" - 13 x 3-1/2" Grade 8 Hex Bolts

12" 5/8" - 11 x 4" Grade 8 Hex Bolt

B. Slide Hanger Bearing onto Connecting Stub, followed by Extension Flight. Bolt

Extension Flight to Connecting Stub using assigned hardware.

(See Chart Above), (See Figure 4R).

Figure 4R

PNEG-1445 6", 8", 10", & 12" Custom Augers 25

Page 26

4. ASSEMBLY

C. With flight sections bolted together slide Extension Tube flush against Main Auger

Tube. (See Figure 4S).

D. With tube sections pressed flush against each other slide Connecting Band over the

tubes aligning the holes. Reach through the Access Hole and align Hanger Bearing

with the bolt hole. Attach the Hanger Bearing to the tube using assigned hardware.

(See Chart for Bolt Sizes), (See Figure 4T).

Figure 4S

Figure 4T

Hanger Bearing Bolt

8" 5/8" -11 x 1-3/4" Grade 8 Bolt

10" 5/8" -11 x 1-3/4" Grade 8 Bolt

12" 3/4" -10 x 2" Grade 8 Bolt

26 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 27

4. ASSEMBLY

E. With Hanger Bearing secured bolt connecting band to tubes using the

3/8" -16 x 1-1/2" Hex Bolts and attach Access Cover using included Nylock Nuts.

(See Figure 4U).

Figure 4U

Assembling the Intake Guard for All 6", 8", 10" & 12" Custom Augers

15. Installing the Intake Guard

Note: For Utility Augers Only.

A. Slide the Intake guard onto the Auger Tube aligning the intake shaft with the bronze

bushing. (See Figure 4V).

Figure 4V

PNEG-1445 6", 8", 10", & 12" Custom Augers 27

Page 28

4. ASSEMBLY

B. With the Intake Shaft inserted in the bushing make sure to leave approximately

1/2" of clearance between the end of the Flight and the face of the bushing.

(See Figure 4W).

Figure 4W

C. Attach the Intake Guard to the Tube using the proper hex bolts and Nylock nuts

through the half bands that are welded to the Intake Guard.

(See Chart for Bolt Sizes), (See Figure 4X).

Figure 4X

Intake Guard Bolts

6" 5/16" - 18 x 1-3/4" GR5 Hex Bolt

8" 5/16" - 18 x 1-3/4" GR5 Hex Bolt

10" 3/8" - 16 x 1-1/2" GR5 Hex Bolt

28 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 29

4. ASSEMBLY

D. Place Intake Guard Half Band above the lower half band on the Intake Guard and

attach using proper hex bolts and Nylock nuts. (See Chart Above), (See Figure 4Y).

Figure 4Y

Assembling the Inlet Hopper with Bearings for All 6", 8", 10" & 12"

Custom Augers

16. Installing Intake Shaft

A. Begin by assembling the intake shaft to the flight using the required Grade 8 bolts

and stover nuts. (See Chart for Bolt Sizes), (See Figure 4Z).

Figure 4Z .

Flight Hardware

6" 3/8" - 16 x 2" Grade 8 Hex Bolts

8" 7/16" - 14 x 3" Grade 8 Hex Bolts

10" 1/2" - 13 x 3-1/2" Grade 8 Hex Bolts

PNEG-1445 6", 8", 10", & 12" Custom Augers 29

Page 30

4. ASSEMBLY

B. Next bolt the bearing with flangette to the studs on the hopper using the required

lock washer and nut. (See Chart for Bolt Sizes), (See Figure 4AA).

Figure 4AA

Hopper Bearing Nut

6" 5/16" - 18 Hex Nut

8" 3/8" - 16 Hex Nut

10" 1/2" - 13 Hex Nut

30 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 31

17. Attach Hopper

A. Slide the hopper onto the tube and align the end of the flight approximately 1/2" from

the surface of the bearing. With the proper distance set, install the proper bolt, lock

washer and nut, and secure the hopper to the tube.

(See Chart for Bolt Sizes), (See Figure 4AB).

4. ASSEMBLY

Figure 4AB

Hopper Connecting Band Bolt

6" & 8" 5/16" - 18 x 1" Hex Bolt

10" 5/16" - 18 x 1-1/2" Hex Bolt

PNEG-1445 6", 8", 10", & 12" Custom Augers 31

Page 32

4. ASSEMBLY

Outlet Cutting Guidelines

1. Before ordering, predetermine the location of the outlet drops. Make sure the outlet drops

do not interfere with the connecting band locations.

2. When an outlet opening is cut, that section of tube loses much of it’s strength therefore

additional support may be necessary.

3. If you have internal bearing flighting, outlets may be cut below internal bearings but a hole

must cut in the spout halfband allow access to internal hanger bearing.

4. We recommend removing flight before cutting the tube otherwise flight will be notched and/

or rough edges will occur. This may not significantly impact the performance of the auger,

but burrs and metal chips should be removed or abnormal wear will result. Also, grind down

any rough edges on tubing for a better fit and smoother operation.

5. Carefully measure your outlet before cutting. Follow the recommended guidelines as shown

below. It is very important that the opening be large enough not to reduce capacity, but

small enough so the outlet can be covered securely by the spout.

Figure 4AC

32 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 33

4. ASSEMBLY

Enclosed Slide Gates with Rack and Pinion Control

1. Follow cutting guidelines on Page - 34.

2. Attach spout to tube with backband.

3. Remove smaller outside nut from the rack and pinion connecting rod and insert rod through

the hole in the angle on the slide gate and secure with the smaller outside nut.

4. Fully close slide gate. Using the pulley, adjust the halfbands so they are located at the end

of the control rod farthest from the spout. Then tighten the halfbands to the tube.

5. Wrap rope or cable around the pulley, doubling it to prevent slippage.

Figure 4AD

PNEG-1445 6", 8", 10", & 12" Custom Augers 33

Page 34

4. ASSEMBLY

Basic Inlet Hoppers

1. Follow the cutting guidelines on on Page - 34.

2. Attach hoppers to tube as shown below.

3. Follow the instructions below before cutting and installing inlet hopper.

a. Slide ring flange onto the end of tube and weld, making sure the flange is mounted

squarely.

b. Bolt end plate to flange.

c. Bolt bearing to end plate.

d. Guide intake stub through bearing and tighten the lock collar.

e. Install any covers if applicable.

Figure 4AE

Spouting, Fittings and Truss Kits

Spouting and Fittings

To connect sections of spouting or to connect fittings to spouting, use one or all of the following

procedures:

1. Spouting to Spouting

place. Make sure flanges are mounted squarely. Join flanges and bolt together.

2. Spouting to Fitting

(valve, dead head, slip joints, etc.,).

3. Flange Clamps

4. Quick-Connect Flange Clamps

location where permanent unions are required.

34 PNEG-1445 6", 8", 10", & 12" Custom Augers

- Slide flange rings over ends of spouting to be joined and weld in

- Install ring flange on spouting as in Step 1. Join to flange on fitting

- Fit each half over flanges and tighten with bolts provided.

- Fit each half over flange and tighten bolt. Do not use in

Page 35

4. ASSEMBLY

Truss Kits

Truss rod kits are designed to provide support for support for spouting and certain auger

sections. There are two different kits available for trussing. 20' to 30' Span Kits and 30' to 40'

Span kits for spouting only. See the Instructions that are included with your kit for proper

installation.

Sample Custom Auger Configurations

Figure 4AF

PNEG-1445 6", 8", 10", & 12" Custom Augers 35

Page 36

5. ELECTRIC DRIVE MOTORS

Power Source

1. Use electric motors that operate at 1750 R.P.M

2. Electric motors and controls should be installed by a qualified electrician and must meet the

standards set by the National Electrical Code and all local and state codes.

3. A magnetic starter should be used to protect your motor when starting and stopping. It

should stop the motor in case of power interruption, conductor fault, low voltage, circuit

interruption, or motor overload. Then the motor must be restarted manually. Some motors

have built-in thermal overload protection. If this type motor is used, use only those with a

manual reset.

WARNING

A main power disconnect switch capable of being locked only in the OFF position shall

be provided. This shall be locked whenever work is being done on the auger.

CAUTION

Disconnect power before resetting motor overloads.

WARNING

Make sure all electrical motors are grounded.

WARNING

Reset and motor starting and stopping controls must be located so that the operator has

full view of the entire operation.

DANGER

Shut off power to adjust, service, or clean the machinery.

DANGER

Keep all safety guards and shields in place.

36 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 37

-

6

A

.

T

S

R

T

U

Start-Up and Break-In

DANGER

ALWAYS keep ALL guards and shields in place, until all the power is disconnected and

locked out.

1. Make sure all belts are tensioned properly.

2. Make sure ALL shields are in place and that the belt(s) and pulley(s) are able to move

freely.

3. Double check the assembly instructions to see that all parts have been assembled properly.

4. During operation of equipment, one person should be in a position to monitor the entire

operation.

Note: During the initial start-up and break-in period, the operator should note any

unusual vibrations or noises and take the appropriate action.

P

WARNING

Make certain everyone is clear before operating or moving the machine.

5. The bin well inside the bin should have a control gate. The gate should be closed before

start-up and closed before shutdown to allow the machine to clean out.

6. The controls for the control gate should either pull or push open, depending on the type of

well you have. Use the control gate to regulate a flow of less than full capacity until several

hundred bushels of grain have been augered to polish the flighting assembly and tube.

7. Any new screw conveyor or one that has set idle for a season should go through a

“break-in" period. This “break-in" consists of running the auger at half capacity until the

screw becomes polished and smooth before attempting to run at full capacity. It is

recommended that several hundred bushels of grain be augered at partial capacity.

CAUTION

Failure of your auger is very likely to occur if it is run at full capacity before the screw has

become polished.

PNEG-1445 6", 8", 10", & 12" Custom Augers 37

Page 38

6. START-UP

CAUTION

NEVER operate augers empty for any length of time as excessive wear will result.

8. Do not stop or start augers under load, especially before the flight and tube become well

polished, as this may cause the auger to “lockup”.

CAUTION

Excessive wear will result if auger is run at speeds in excess of what is recommended.

9. Do not run auger at to slow speed, this will load up or over load the auger. An loading up of

the auger will cause the motor to over load and a higher torque will be required to turn the

auger, which in turn may cause damage to the auger.

38 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 39

N

C

N

E

A

/

M

I

A

O

E

P

R

.

O

7

Operate the Auger

Note: The auger capacity can fluctuate greatly under varying conditions. Moisture

content, different commodities, amount of foreign matter and speeds all play a part

in the performance of the auger. Twenty-five percent(25%) moisture may cut

capacity by as much as 40% under some conditions.

1. Make certain there are at least two (2) people in the work area to monitor operations at all

times.

2. Visually inspect the auger periodically during operation.

N

T

I

N

T

A

E

WARNING

Be alert for any unusual vibrations, noises and the loosening of any fasteners. If anything

unusual is detected, immediately shutdown the auger, disconnect and lockout the power

source before servicing.

3. Consideration should be given to the proper size auger for a batch drying or any intermittent

type operations. When augers are stopped and restarted under full load, it may result in

damage to the auger. Using a larger diameter auger and reducing its load level will be far

better than subjecting a smaller diameter auger to big loads. If an auger is kept from

absolute filling, it will make startup easier and will convey more efficiently.

PNEG-1445 6", 8", 10", & 12" Custom Augers 39

Page 40

7. OPERATION/MAINTENANCE

Maintain the Auger

DANGER

ALWAYS shutdown and disconnect the power supply before adjusting, servicing or cleaning the

equipment.

1. Use caution when repairing or replacing equipment parts.

2. Make sure ALL decals are legible and tightly attached to the auger. If necessary, replace

them FREE OF CHARGE by contacting your dealer or the manufacturer.

3. Ensure that ALL electric motors, etc. are operating at the proper speed.

4. Maintain proper adjustments on the belt(s).

5. Mount controls for any electric motors at a safe distance from the machine and in a location

accessible in case of an emergency.

6. Make sure ALL electrical wiring is not damaged, and that it meets proper wiring codes.

7. Make sure ALL components are in good working condition before use.

8. Check the auger flighting to make sure it is in good working condition.

9. Check the internal bearing bracket, bearing and universal joint to make sure they are in

good working order.

10. Grease bearing at least two (2) times each season.

40 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 41

N

W

D

T

8

H

.

U

S

O

Normal Shutdown

1. Make certain unloading tubes are empty before stopping the unit.

2. Disconnect and lockout the power source before leaving the work area.

Emergency Shutdown

1. Know how to shutdown the auger in case of an emergency.

2. Disconnect and lockout the power source.

3. Close bin well control gates.

4. Clear out as much grain from the auger and hopper as you can.

CAUTION

Never restart when under a full load. Starting unit under load may result in damage to the

machine. Such damage is considered abuse of the equipment.

5. Reconnect and unlock the power source.

6. Gradually clear the auger until there is no grain or obstructions.

Lockout

1. Always stop and disconnect the power source whenever the operator must leave the work

area or for maintenance of the machinery.

2. Make sure equipment is locked out and that the machinery cannot be started while the

operator is not in the work area.

WARNING

Use the type of main power disconnect switch that is capable of being locked only in the

off position.

Storage Preparation

1. Close all wells to discharge auger tube.

2. Be sure the unload tube is empty.

3. Make sure power source is disconnected and locked out.

4. Check to see that all fasteners are secure.

PNEG-1445 6", 8", 10", & 12" Custom Augers 41

Page 42

NOTES

42 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 43

1. 6" Custom Auger Parts

2. 8" Custom Auger Parts

3. 8" Internal Bearing Parts

4. 10" Custom Auger Parts

5. 10" Internal Bearing Parts

6. 12" Custom Auger Parts

7. 12" Internal Bearing Parts

9

L

I

S

S

T

A

.

R

P

T

PNEG-1445 6", 8", 10", & 12" Custom Augers 43

Page 44

9. PARTS LIST

6" Custom Auger Parts

44 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 45

6" Custom Auger Parts

Ref # Part # Description

1 GK7005 Belt Guard Assembly

S-1323 B48 V-Belt (12'' Sheaves)

2

GK2349 B54 V-Belt (15'' Sheaves)

3 GK-7062 Belt Guard Mounting Bracket

4 S-9065 3/8" - 16 x 1" Flange Bolt

5 S-1196 5/16" - 18 x 1" Bolt

6 S-845 5/16" Flat Washer

7 GK-6996 Horizontal Power Head Tube

8 S-3611 5/16" - 18 Serrated Flange Nut

9 S-275 5/16" - 18 x 3/4" Bolt

10 S-3611 5/16" - 18 Serrated Flange Nut

11 S-234 3/4" - 10 Hex Nut

12 S-866 3/4" Flat Washer

13 GK-7060 Motor Mount Adjuster

14 GK6994 3*16" x 2" Cotter Pin

15 S-7052 Motor Plate

16 S-1117 1" x 7" Intake Shaft

17 S-7058 Motor Mount Pivot Rod

18 S-7837 7/16" - 14 x 1-1/2" Bolt

19 GK7061 Bearing Plate

20 S-1196 5/16" - 18 x 1" Bolt

21 GK1049 1" ID w/ 2 Hole Flangette Bearing

22 S-7014 7/16" Lock Washer

23 S-7332 7/16" - 14 Nut

GK1309 12" x 1.0" 1 Belt Sheave

GK1321 12" x 1.0" 2 Belt Sheave

24

GK2544 15" x 1.0" 2 Belt Sheave

GK4643 12" x 1.0" 3 Belt Sheave

GK2545 15" x 1.0" 3 Belt Sheave

25 S-3727 3/18" - 16 x 1-3/4" Grade 8 Bolt

26 GK2025 1" x 10" Drive Shaft

27 S-4513 1/4" x 1/4" x 2" Square Key

28 S-8251 3/8" - 16 Stover Nut

GK2854 6" x 11' Discharge Flight

29

GK2855 6" x 16' Discharge Flight

GK-2856 6" x 21' Discharge Flight

30 GK-7082 6" x 9' Tube

GK7083 6" x 14' Tube

30

GK7084 6" x 19' Tube

9. PARTS LIST

PNEG-1445 6", 8", 10", & 12" Custom Augers 45

Page 46

9. PARTS LIST

8" Custom Auger Parts

46 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 47

8" Custom Auger Parts

Ref # Part # Description

Belt Guard Assembly

1

GK7005 12" & 15" Sheaves

GK7068 18.4" Sheaves

GK1952 B50 V-Belt (12" Sheaves)

2

GK-1346 B57 V-Belt (15" Sheaves)

MHC00160 B64 V-Belt (18.4" Sheaves)

Belt Guard Mounting Bracket

3

GK7006 12" & 15" Sheaves

GK7100 18.4" Sheaves

4 S-9065 3/8" - 16 x 1" Flange Bolt

5 S-1196 5/16" - 18 x 1" Bolt

6 S-845 5/16" Flat Washer

7 GK6997 Horizontal Power Head Tube

8 S-2611 5/16" - 18 Serrated Flange Nut

9 S-275 5/16" - 18 x 3/4" Bolt

10 S-3611 5/16" - 18 Serrated Flange Nut

11 S-240 1" - 8 Hex Nut

12 S-7835 1" Flat Washer

13 GK7060 Motor Mount Adjuster

14 GK7012 Motor Mount Adjustment Rod

15 S-6994 3*16" x 2" Cotter Pin

16 GK6986 Motor Plate

17 GK7014 Pivot Tube Spacer

18 GK7013 Motor Mount Pivot Rod

19 S-8760 1/2" - 13 x 1-1/2" Bolt

20 GK6987 Bearing Plate

21 S-1196 5/16" - 18 x 1" Bolt

22 GK1330 1-1/4" ID w/ 2 Hole Flangette Bearing

23 S-236 1/2" Lock Washer

24 S-7510 1/2" - 13 Nut

GK1335 12" x 1.25" 2 Belt Sheave

GK1869 15" x 1.25" 2 Belt Sheave

GK2567 18.4" x 1.25" 2 Belt Sheave

25

GK2234 15" x 1.25" 3 Belt Sheave

GK2570 18.4" x 1.25" 3 Belt Sheave

26 GCO7674 1-1/4" Bushing for 18.4" Sheaves

27 S-8316 7/16" - 14 x 3" Grade 8 Bolt

28 GK1331 1-1/4" x 10" Drive Shaft

29 S-4513 1/4" x 1/4" x 2" Square Key

30 S-8317 7/16" - 14 Stover Nut

GK2879 8" x 11' Discharge Flight

31

GK2880 8" x 16' Discharge Flight

GK2881 8" x 21' Discharge Flight

32 GK1884 1-1/4" x 9" Intake Shaft

GK7079 8" x 8' Tube

33

GK7080 8" x 13' Tube

GK7081 8" x 18' Tube

9. PARTS LIST

PNEG-1445 6", 8", 10", & 12" Custom Augers 47

Page 48

9. PARTS LIST

8" Internal Bearing Parts

48 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 49

8" Internal Rearing Parts

Ref # Part # Description

Belt Guard Top Assembly

1

GK7005 12" & 15" Sheaves

GK7068 18.4" Sheaves

GK1952 B50 V-Belt (12" Sheaves)

2

GK1346 B57 V-Belt (15" Sheaves)

MHC00160 B64 V-Belt (18.4" Sheaves)

3

GK7006 12" & 15" Sheaves

3 GK7100 18.4" Sheaves

4 S-9065 3/8" - 16 x 1" Flange Bolt

5 S-1196 5/16" - 18 x 1" Bolt

6 S-845 5/16" Flat Washer

7 GK6997 Horizontal Power Head Tube

8 S-3611 5/16" - 18 Serrated Flange Nut

9 S-275 5/16" - 18 x 3/4" Bolt

10 S-3611 5/16" - 18 Serrated Flange Nut

11 S-240 1" - 8 Hex Nut

12 S-7835 1" Flat Washer

13 GK7060 Motor Mount Adjuster

14 GK7012 Motor Mount Adjustment Rod

15 S-6994 3*16" x 2" Cotter Pin

16 GK6986 Motor Plate

17 GK7014 Pivot Tube Spacer

18 GK7013 Motor Mount Pivot Rod

19 S-8760 1/2" - 13 x 1-1/2" Bolt

20 GK6987 Bearing Plate

21 S-1196 5/16" - 18 x 1" Bolt

22 GK1330 1-1/4" ID w/ 2 Hole Flangette Bearing

23 S-236 1/2" Lock Washer

24 S-7510 1/2" - 13 Nut

GK1335 12" x 1.25" 2 Belt Sheave

GK1869 15" x 1.25" 2 Belt Sheave

25

GK2567 18.4" x 1.25" 2 Belt Sheave

GK2234 15" x 1.25" 3 Belt Sheave

GK2570 18.4" x 1.25" 3 Belt Sheave

26 GC07674 1-1/4" Bushing for 18.4" Sheaves

27 S-8316 7/16" - 14 x 3" Grade 8 Bolt

28 GK1331 1-1/4" x 10" Drive Shaft

29 S-4513 1/4" x 1/4" x 2" Square Key

30 S-8317 7/16" - 14 Stover Nut

31 GK3735 8" x 10' 10-1/2" Discharge Flight

32 GK1884 1 - 1/4" x 9" Intake Shaft

GK4349 8" x 4' 9-3/8" Extension Flight

33

GK3736 8" x 9' 9-3/4" Extension Flight

34 S-3208 5/8" Lock Washer

35 S-7886 5/8" -11 x 1-3/4" Grade 8 Bolt

36 GC06394 8" Hanger Bearing Assembly

37 GK1736 1-1/4" x 11-1/2" Connecting Shaft

38 GK3669 8" Inspection Cover

39 S-7382 5/16" - 18 Nylock Nut

40 S-7149 5/16" - 18 x 1-3/4" Bolt

GK7093 8" x 13' Tube

41

GC06394 8" x 18' Tube

Belt Guard Mounting Bracket

9. PARTS LIST

PNEG-1445 6" , 8", 10" , & 12" Custom A ug ers 49

Page 50

9. PARTS LIST

10" Custom Auger Parts

50 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 51

10'' Custom Auger Parts

Ref # Part # Description

Belt Guard Top Assembly

1

GK7005 15" Sheaves

GK7068 18.4" Sheaves

GK1346 B57 V-Belt (15" Sheaves)

2

MHC00160 B64 V-Belt (18.4" Sheaves)

GK4441 B60 V-Belt (15" 4 BeltSheave)

Belt Guard Mounting Bracket

3

GK7018 15" Sheaves

GK7101 18.4" Sheaves

4 S-9065 3/8" - 16 x 1" Flange Bolt

5 S-2071 3/8" - 16 x 1-1/4" Bolt

6 S-248 3/8" Flat Washer

7 GK6998 Horizontal Power Head Tube

8 S-968 3/8" - 16 Serrated Flange Nut

9 S-7520 3/8" - 16 x 1" Bolt

10 S-456 3/8" - 16 Nut

11 S-240 1" - 8 Hex Nut

12 S-7835 1" Flat Washer

13 GK6942 Motor Mount Adjuster

14 GK7012 Motor Mount Adjustment Rod

15 S-6994 3*16" x 2" Cotter Pin

16 GK6986 Motor Plate

17 GK7014 Pivot Tube Spacer

18 GK7013 Motor Mount Pivot Rod

19 S-8760 1/2" - 13 x 1-1/2" Bolt

20 GK7017 Bearing Plate

21 S-7469 3/8" - 16 x 1" Bolt

22 GK1343 1-1/2" ID w/ 4 Hole Flangette Bearing

23 S-236 1/2" Lock Washer

24 S-7510 1/2'' - 13 Nut

GK1345 15" x 1-1/2" 2 Belt Sheave

GK2567 18.4" 2 Belt Sheave

25

GK1304 15" x 1-1/2" 3 Belt Sheave

GK2570 18.4" 3 Belt Sheave

GK4248 18.4" Sheave Bushing

26

D03-0264 15" 4 Belt Sheave Bushing

27 S-8314 1/2" - 13 x 3-1/2" Grade 8 Bolt

28 GK1289 1-1/2" x 11.5" Drive Shaft

29 S-9181 3/8" x 3/8" x 3" Square Key

30 S-8315 1/2" - 13 Stover Nut

GK5143 10" x 11' Discharge Flight

31

GK5144 10" x 16' Discharge Flight

GK5130 10" x 21' Discharge Flight

32 GK2907 1-1/2" x 9-1/2" Intake Shaft

GK7095 10" x 7' 6" Tube

33

GK7096 10" x 12' 6" Tube

GK7097 10" x 17' 6" Tube

9. PARTS LIST

PNEG-1445 6", 8", 10", & 12" Custom Augers 51

Page 52

9. PARTS LIST

10" Internal Bearing Parts

52 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 53

10" Internal Bearing Parts

Ref # Part # Description

Belt Guard Top Assembly

1

GK7005 15" Sheaves

GK7068 18.4" Sheaves

GK1346 B57 V-Belt (15" Sheaves)

2

MHC00160 B64 V-Belt (18.4" Sheaves)

GK4441 B60 V-Belt (15" 4 BeltSheave)

Belt Guard Mounting Bracket

3

GK7018 15" Sheaves

GK7101 18.4" Sheaves

4 S-9065 3/8" - 16 x 1" Flange Bolt

5 S-2071 3/8" - 16 x 1-1/4" Bolt

6 S-248 3/8" Flat Washer

7 GK6998 Horizontal Power Head Tube

8 S-968 3/8" - 16 Serrated Flange Nut

9 S-7520 3/8" - 16 x 1" Bolt

10 S-456 3/8" - 16 Nut

11 S-240 1" - 8 Hex Nut

12 S-7835 1" Flat Washer

13 GK6942 Motor Mount Adjuster

14 GK7012 Motor Mount Adjustment Rod

15 S-6994 3*16" x 2" Cotter Pin

16 GK6986 Motor Plate

17 GK7014 Pivot Tube Spacer

18 GK7013 Motor Mount Pivot Rod

19 S-8760 1/2" - 13 x 1-1/2" Bolt

20 GK7017 Bearing Plate

21 S-7469 3/8" - 16 x 1" Bolt

22 GK1343 1-1/2" ID w/ 4 Hole Flangette Bearing

23 S-236 1/2" Lock Washer

24 S-7510 1/2" - 13 Nut

GK1345 15" x 1-1/2" 2 Belt Sheave

GK2567 18.4" 2 Belt Sheave

25

GK1304 15" x 1-1/2" 3 Belt Sheave

GK2570 18.4" 3 Belt Sheave

26 GK4248 18.4'' Shave Bushing

D03-0264 15'' 4 Belt Shave Bushing

27 S-8314 1/2" - 13 x 3-1/2" Grade 8 Bolt

28 GK1289 1-1/2" x 11.5" Drive Shaft

29 S-9181 3/8" x 3/8" x 3" Square Key

30 S-8315 1/2" - 13 Stover Nut

31 GK5143 10" x 11' Discharge Flight

32 GK2907 1-1/2" x 9-1/2" Intake Shaft

33 GK3708 10" x 4' 9-15/16" Extension Flight

33 GK3706 10" x 9' 9-3/4" Extension Flight

34 S-3208 5/8" Lock Washer

35 S-7886 5/8" -11 x 1-3/4" Grade 8 Bolt

36 GC06396 10" Hanger Bearing Assembly

37 GK1951 1-1/2" x 11-1/2" Connecting Shaft

38 GK3670 10" Inspection Cover

39 S-7382 5/16" - 18 Nylock Nut

40 S-7149 5/16" - 18 x 1-3/4" Bolt

GK7098 10'' x 12' 6'' Tube

41

GK7099 10'' x 17' 6'' Tube

9. PARTS LIST

PNEG-1445 6", 8", 10", & 12" Custom Augers 53

Page 54

9. PARTS LIST

12" Custom Auger Parts

54 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 55

12" Custom Auger Parts

Ref # Part # Description

1 GK7068 Belt Guard Top Assembly

GK4129 B58 V-Belt (15" Sheaves)

2

PT1172 B73 V-Belt (18.4" Sheaves)

3 GK7101 Belt Guard Mounting Bracket

4 S-9065 3/8" - 16 x 1" Flange Bolt

5 S-2071 3/8" - 16 x 1-1/4" Bolt

6 S-248 3/8" Flat Washer

7 GK6999 Horizontal Power Head Tube

8 S-968 3/8" - 16 Serrated Flange Nut

9 S-7520 3/8" - 16 x 1" Bolt

10 S-456 3/8" - 16 Nut

11 S-240 1" - 8 Hex Nut

12 S-7835 1" Flat Washer

13 GK6942 Motor Mount Adjuster

14 GK7012 Motor Mount Adjustment Rod

15 S-6994 3*16" x 2" Cotter Pin

16 GK6986 Motor Plate

17 GK7014 Pivot Tube Spacer

18 GK7013 Motor Mount Pivot Rod

19 S-8399 5/8" - 11 x 2" Bolt

20 GK7064 Bearing Plate

21 S-7469 3/8" - 16 x 1" Bolt

22 GK2004 2" ID w/ 4 Hole Flange Bearing

23 S-3208 5/8" Lock Washer

24 S-4110 5/8" - 11 Nut

GK2567 18.4" 2 Belt Sheave

25

GK2570 18.4" 3 Belt Sheave

GK3541 15" 4 Belt Sheave

GK4248 18.4" Sheave Bushing

26

D03-0264 15" 4 Belt Sheave Bushing

27 S-7893 5/8" - 11 x 4" Grade 8 Bolt

28 GK2006 2" x 12" Drive Shaft

29 S-9181 3/8" x 3/8" x 3" Square Key

30 S-8606 5/8" - 11 Stover Nut

GK5501 12" x 11' Discharge Flight

31

GK6567 12" x 16' Discharge Flight

GK5633 12" x 21' Discharge Flight

32 GK5313 2" x 7-3/4" Intake Shaft

GK7243 12" x 7' 6" Tube

33

GK7244 12" x 12' 6" Tube

GK7245 12" x 17' 6" Tube

9. PARTS LIST

PNEG-1445 6", 8", 10", & 12" Custom Augers 55

Page 56

9. PARTS LIST

12" Internal Bearing Parts

56 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 57

12'' Internal Bearing Parts

Ref # Part # Description

1 GK7068 Belt Guard Top Assembly

GK4129 B58 V-Belt (15" Sheaves)

2

PT1172 B73 V-Belt (18.4" Sheaves)

3 GK7101 Belt Guard Mounting Bracket

4 S-9065 3/8" - 16 x 1" Flange Bolt

5 S-2071 3/8" - 16 x 1-1/4" Bolt

6 S-248 3/8" Flat Washer

7 GK6999 Horizontal Power Head Tube

8 S-968 3/8" - 16 Serrated Flange Nut

9 S-7520 3/8" - 16 x 1" Bolt

10 S-456 3/8" - 16 Nut

11 S-240 1" - 8 Hex Nut

12 S-7835 1" Flat Washer

13 GK6942 Motor Mount Adjuster

14 GK7012 Motor Mount Adjustment Rod

15 S-6994 3*16" x 2" Cotter Pin

16 GK6986 Motor Plate

17 GK7014 Pivot Tube Spacer

18 GK7013 Motor Mount Pivot Rod

19 S-8399 5/8" - 11 x 2" Bolt

20 GK7064 Bearing Plate

21 S-7469 3/8" - 16 x 1" Bolt

22 GK2004 2" ID w/ 4 Hole Flange Bearing

23 S-3208 5/8" Lock Washer

24 S-4110 5/8" - 11 Nut

GK2567 18.4" 2 Belt Sheave

25

GK2570 18.4" 3 Belt Sheave

GK3541 15" 4 Belt Sheave

GK4248 18.4" Sheave Bushing

26

D03-0264 15" 4 Belt Sheave Bushing

27 S-7893 5/8" - 11 x 4" Grade 8 Bolt

28 GK2006 2" x 12" Drive Shaft

29 S-9181 3/8" x 3/8" x 3" Square Key

30 S-8606 5/8" - 11 Stover Nut

31 GK5501 12" x 11' Discharge Flight

32 GK5313 2" x 7-3/4" Intake Shaft

GK5566 12" x 4' 9-3/4" Extension Flight

33

GK4482 12" x 9' 9-3/4" Extension Flight

34 S-233 3/4" Lock Washer

35 S-869 3/4" -10 x 2" Grade 8 Bolt

36 GC06398 12" Hanger Bearing Assembly

37 GK2222 2" x 11-1/2" Connecting Shaft

38 GK5599 12" Inspection Cover

39 S-7382 5/16" - 18 Nylock Nut

40 S-7149 5/16" - 18 x 1-3/4" Bolt

GK7249 12" x 12' 6" Tube

41

GK7250 12" x 17' 6" Tube

9. PARTS LIST

PNEG-1445 6", 8", 10", & 12" Custom Augers 57

Page 58

10. TROUBLE SHOOTING

Problem Possible Cause Corrective Action

1. The Auger is vibrating. 1. Damage can occur to the auger

flighting, causing noise.

Damage usually is caused from

foreign material being run

through the auger.

2. Drive belt may be overtightened,

putting head stub and flight in a

bind.

2. Capacity is too low. 1. There may not be enough grain

reaching the auger.

2. The auger is moving too slowly. 2. Check the auger speed. Low

3. The Auger plugs. 1. The auger may be “jamming”

because too much grain is

reaching the auger.

2. The grain may be wet. 2. If wet grain or other

1. It may be necessary to remove

the flighting for inspection.

2. Loosen the drive belts.

1. Make sure the intake has not

bridged over, restricting flow.

The flighting at the intake should

be covered with grain for

maximum capacity.

capacity will result from speeds

slower than recommended.

1. Use the control gates to

decrease the amount of grain the

auger is gathering.

hard-to-move material is being

augered, use a larger size motor

than recommended for normal

use.

3. The auger may be jammed with

foreign material.

4. The motor may be to small or

wired incorrectly.

3. Remove any foreign material in

the auger.

4. Check wiring or consider using

the next larger size motor.

58 PNEG-1445 6", 8", 10", & 12" Custom Augers

Page 59

A

R

W

1

1

.

THE GSI GROUP, INC. (GSI) WARRANTS ALL PRODUCTS WHICH IT MANUFACTURES TO

BE FREE OF DEFECTS IN MATERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE TO THE ORIGINAL

END USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGATION SHALL BE

TO REPAIR OR REPLACE, AT GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S

SOLE JUDGMENT, CONTAIN A MATERIAL DEFECT DUE TO MATERIALS OR

WORKMANSHIP. ALL DELIVERY AND SHIPMENT CHARGES TO AND FROM GSI’S

FACTORY WILL BE PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON

BEHALF OF THE PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN

AUTHORIZED EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE

PURCHASER.

EXCEPT FOR THE LIMITED WARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMITATION,

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR

USE IN CONNECTION WITH (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (I) ANY

ADVICE, INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN

AGENT, REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE

CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY FOR A PARTICULAR

PURPOSE, OR DESIGN OF SUCH PRODUCTS.

T

Y

N

A

R

GSI SHALL NOT BE LIABLE FOR ANY DIRECT, INDIRECT, INCIDENTAL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMITATION, LOSS OF

ANTICIPATED PROFITS OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY

IS AS SET FORTH IN THE LIMITED WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT

EXCEED THE AMOUNT PAID FOR THE PRODUCT PURCHASED. THIS WARRANTY IS NOT

TRANSFERABLE AND APPLIES ONLY TO THE ORIGINAL PURCHASER. GSI SHALL HAVE

NO OBLIGATION OR RESPONSIBILITY FOR ANY REPRESENTATIONS OR WARRANTIES

MADE BY OR ON BEHALF OF ANY DEALER, AGENT OR DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESULTING FROM ERECTION

DEFECTS OR UNAUTHORIZED MODIFICATIONS TO PRODUCTS WHICH IT

MANUFACTURED. MODIFICATIONS TO PRODUCTS NOT SPECIFICALLY DELINEATED IN

THE MANUAL ACCOMPANYING THE EQUIPMENT AT INITIAL SALE WILL NULLIFY THE

PRODUCT WARRANTY THAT MIGHT HAVE BEEN OTHERWISE AVAILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS WHICH

HAVE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, ALTERATION OR ACCIDENT. THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS

WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES EXPRESS OR

IMPLIED. GSI RESERVES THE RIGHT TO MAKE DESIGN OR SPECIFICATION CHANGES

AT ANY TIME.

PRIOR TO INSTALLATION, PURCHASER HAS THE RESPONSIBILITY TO COMPLY WITH

ALL FEDERAL, STATE AND LOCAL CODES WHICH MAY APPLY TO THE LOCATION AND

INSTALLATION OF PRODUCTS MANUFACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

PNEG-1445 6", 8", 10", & 12" Custom Augers 59

Page 60

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations which should be carefully followed in all

cases. Authorities having jurisdiction should be

consulted before installations are made.

Internet: http://www.grainsystems.com

Copyright © 2007 by the GSI Group

Printed in the USA

GSI Group, Inc.

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

Loading...

Loading...