GSI Group Vane Axial, DF Series, AF Series Owner's Manual

Vane Axial Fan

MODEL # DF __ - __ __ __ - __ __ (W/CONTROLS)

MODEL # AF __ - __ __ __ - __ __ (LESS CONTROLS)

Owner's

Manual

MANUAL # PNEG-010-C

1

FAN CHECK LIST

9OK

_____ 1. All wire connections

_____ 2. Tip clearance on blade

_____ 3. Fan blade torqued to torque specs

_____ 4. Grill guard in place and tight

_____ 5. Fuse in place, extra fuse provided

_____ 6. Motor rotation correct

_____ 7. Contactor engages properly

_____ 8. Running amperage

_____ 9. Vibration

_____ 10. All fasteners tight

_____ 11. Indicator light

_____ 12. All decals and serial number tag

_____ 13. Aesthetic appearance

_____ 14. Manual

Tester Signature___________________________________

Date_________________________

2

VANE AXIAL FAN OPERATING INSTRUCTIONS

TABLE OF CONTENTS

Warranty.......................................................................................................................4

Roof Warning, Operation & Safety................................................................................5

Safety Alert Decals........................................................................................................6

Installation Instructions...................................................................................................7

Fan Pad Location...................................................................................................7

Checklist Before Installing The Fan............................................................................8

Installation.............................................................................................................8

Fan Specifications........................................................................................................9

Fan Installation.............................................................................................................11

Machine To Earth Ground.....................................................................................11

Proper Installation Of The Ground Rod..................................................................11

Previously Installed Units.....................................................................................11

Fan Operation.............................................................................................................12

Start-Up.................................................................................................................12

Maintaining Grain Quality......................................................................................12

Grain Storage........................................................................................................12

Equilibrium Moisture Chart....................................................................................12

Approximate Allowable Holding Time For Field-Shelled Corn..............................12

Approximate Hours Of Fan Time To Change Bin Temperature............................13

Fan Service.................................................................................................................14

Lubrication...........................................................................................................14

Hub Bolt Torque Requirement For Fan Blades....................................................15

Fan Troubleshooting Chart...................................................................................15

Fan Parts....................................................................................................................16

12" Fan.................................................................................................................16

14" Fan.................................................................................................................17

18" Fan.................................................................................................................18

18" 3 HP 1 Phase Control Box Parts....................................................................19

18" 3 HP 3 Phase Control Box Parts....................................................................20

24" Fan..................................................................................................................21

24" 7 HP 1 Phase Control Box Parts....................................................................22

24" 7 HP 3 Phase Control Box Parts....................................................................23

24" 10 HP 1 Phase Control Box Parts..................................................................24

24" 10 HP 3 Phase Control Box Parts..................................................................25

26" Fan.................................................................................................................26

28" Fan.................................................................................................................27

26" & 28" 15 HP 1 Phase Control Box Parts.........................................................28

26" & 28" 15 HP 3 Phase Control Box Parts.........................................................29

240 Volt 1 Phase (3 HP).......................................................................................30

240 Volt 1 Phase (7 And 10 HP)............................................................................31

240 Volt 1 Phase (15HP)......................................................................................32

240 Volt 3 Phase (All Horsepowers).....................................................................33

480 Volt 3 Phase (All Horsepowers).....................................................................34

575 Volt 3 Phase (All Horsepowers).....................................................................35

Notes...........................................................................................................................36

3

THE GSI GROUP, INC. WARRANTY

THE GSI GROUP, INC. (“GSI”) W ARRANTS ALL PRODUCTS WHICH IT MANUF ACTURES TO BE

FREE OF DEFECTS IN MA TERIAL AND WORKMANSHIP UNDER NORMAL USAGE AND

CONDITIONS FOR A PERIOD OF 12 MONTHS AFTER RETAIL SALE T O THE ORIGINAL END

USER. THE PURCHASER’S SOLE REMEDY AND GSI’S ONLY OBLIGA TION SHALL BE TO

REPAIR OR REPLACE, A T GSI’S OPTION AND EXPENSE, PRODUCTS THAT, IN GSI’S SOLE

JUDGMENT , CONT AIN A MA TERIAL DEFECT DUE TO MA TERIALS OR WORKMANSHIP. ALL

DELIVERY AND SHIPMENT CHARGES T O AND FROM GSI’S F ACTOR Y WILL BE

PURCHASER’S RESPONSIBILITY. EXPENSES INCURRED BY OR ON BEHALF OF THE

PURCHASER WITHOUT PRIOR WRITTEN AUTHORIZATION FROM AN AUTHORIZED

EMPLOYEE OF GSI SHALL BE THE SOLE RESPONSIBILITY OF THE PURCHASER.

EXCEPT FOR THE LIMITED W ARRANTY EXPRESSED ABOVE, GSI MAKES NO FURTHER

WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, INCLUDING, WITHOUT LIMIT A TION,

WARRANTIES OF MERCHANT ABILITY OR FITNESS FOR A PARTICULAR PURPOSE OR USE IN

CONNECTION WITH (I) PRODUCT MANUF ACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDA TION OR SUGGESTION PROVIDED BY AN AGENT,

REPRESENTATIVE OR EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION,

INST ALLA TION, LAYOUT, SUIT ABILITY FOR A P ARTICULAR PURPOSE, OR DESIGN OF SUCH

PRODUCTS.

GSI SHALL NOT BE LIABLE FOR ANY DIRECT , INDIRECT, INCIDENT AL OR

CONSEQUENTIAL DAMAGES, INCLUDING, WITHOUT LIMIT A TION, LOSS OF ANTICIP A TED PROFITS

OR BENEFITS. PURCHASER’S SOLE AND EXCLUSIVE REMEDY IS AS SET FORTH IN THE LIMITED

WARRANTY EXPRESSED ABOVE, WHICH SHALL NOT EXCEED THE AMOUNT PAID FOR THE

PRODUCT PURCHASED. THIS WARRANTY IS NOT TRANSFERABLE AND APPLIES ONLY TO THE

ORIGINAL PURCHASER. GSI SHALL HA VE NO OBLIGA TION OR RESPONSIBILITY FOR ANY

REPRESENTATIONS OR WARRANTIES MADE BY OR ON BEHALF OF ANY DEALER, AGENT O R

DISTRIBUTOR OF GSI.

GSI ASSUMES NO RESPONSIBILITY FOR CLAIMS RESUL TING FROM ERECTION

DEFECTS OR UNAUTHORIZED MODIFICA TIONS T O PRODUCTS WHICH IT MANUF ACTURED.

MODIFICA TIONS TO PRODUCTS NOT SPECIFICALL Y DELINEA TED IN THE MANUAL

ACCOMP ANYING THE EQUIPMENT A T INITIAL SALE WILL NULLIFY THE PRODUCT WARRANTY

THA T MIGHT HA VE BEEN OTHERWISE A V AILABLE.

THE FOREGOING WARRANTY SHALL NOT EXTEND TO PRODUCTS OR PARTS

WHICH HA VE BEEN DAMAGED BY NEGLIGENT USE, MISUSE, AL TERA TION OR ACCIDENT . THIS

WARRANTY EXTENDS SOLELY TO ONLY PRODUCTS MANUFACTURED BY GSI. THIS W ARRANTY

IS EXCLUSIVE AND IN LIEU OF ALL OTHER W ARRANTIES EXPRESS OR IMPLIED. GSI RESERVES

THE RIGHT TO MAKE DESIGN OR SPECIFICA TION CHANGES A T ANY TIME.

PRIOR TO INST ALLA TION, PURCHASER HAS THE RESPONSIBILITY TO COMPL Y

WITH ALL FEDERAL, STATE AND LOCAL CODES WHICH MA Y APPL Y TO THE LOCATION AND

INST ALLA TION OF PRODUCTS MANUF ACTURED OR SOLD BY GSI.

PHLEGAL: #1832020 v1 (139LG01!.DOC) (revised December 2005)

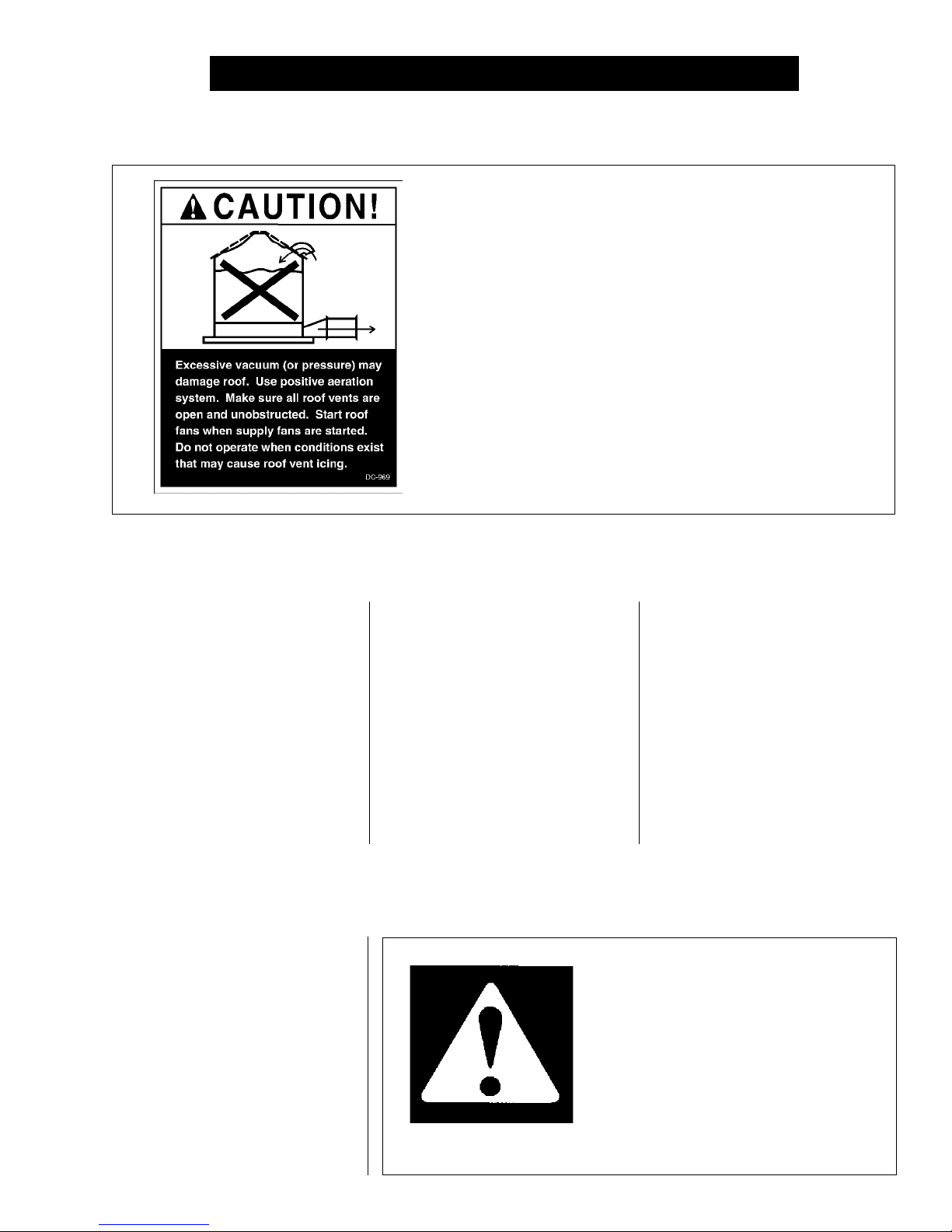

ROOF WARNING, OPERATION & SAFETY

ROOF DAMAGE WARNING AND DISCLAIMER

GSI DOES NOT WARRANT ANY ROOF DAMAGE CAUSED

BY EXCESSIVE VACUUM OR INTERNAL PRESSURE FROM

FANS OR OTHER AIR MOVING SYSTEMS. ADEQUATE

VENTILATION AND/OR "MAKEUP AIR" DEVICES SHOULD

BE PROVIDED FOR ALL POWERED AIR HANDLING SYS-

TEMS. GSI DOES NOT RECOMMEND THE USE OF DOWN-

WARD FLOW SYSTEMS (SUCTION). SEVERE ROOF DAM-

AGE CAN RESULT FROM ANY BLOCKAGE OF AIR PAS-

SAGES. RUNNING FANS DURING HIGH HUMIDITY/COLD

WEATHER CONDITIONS CAN CAUSE AIR EXHAUST OR

INTAKE PORTS TO FREEZE.

Thank you for choosing a GSI/

Airstream product. It is designed

to give excellent performance

and service for many years.

This manual describes the

operation of the Airstream Vane

Axial Fan. It is designed for me-

dium to high static pressures,

and comes equipped with a 3450

RPM motor.

The symbol shown is used to call

your attention to instructions con-

cerning your personal safety. Watch

for this symbol; it points out impor-

tant safety precautions. It means

"ATTENTION", "WARNING", "CAU-

TION", and "DANGER". Read the

message and be cautious to the

possibility of personal injury or

death.

FAN OPERATION

The principal concern of the GSI

Group, Inc. ("GSI") is your safety and

the safety of others associated with

grain handling equipment. This

manual is written to help you under-

stand safe operating procedures,

and some of the problems that may

be encountered by the operator or

other personnel.

As owner and/or operator, it is

SAFETY ALERT SYMBOL

WARNING! BE ALERT!

Personnel operating or working around

electric fans should read this manual.

This manual must be delivered with the

equipment to its owner. Failure to read

this manual and its safety instructions is

a misuse of the equipment.

your responsibility to know what

requirements, hazards and pre-

cautions exist, and to inform all

personnel associated with the

equipment, or who are in the area.

Avoid any alterations to the equip-

ment. Such alterations may pro-

duce a very dangerous situation,

where serious injury or death may

occur.

5

Grain Systems, Inc. recommends

contacting your local power company,

and having a representative survey

your installation so the wiring is com-

patible with their system, and ad-

equate power is supplied to your unit.

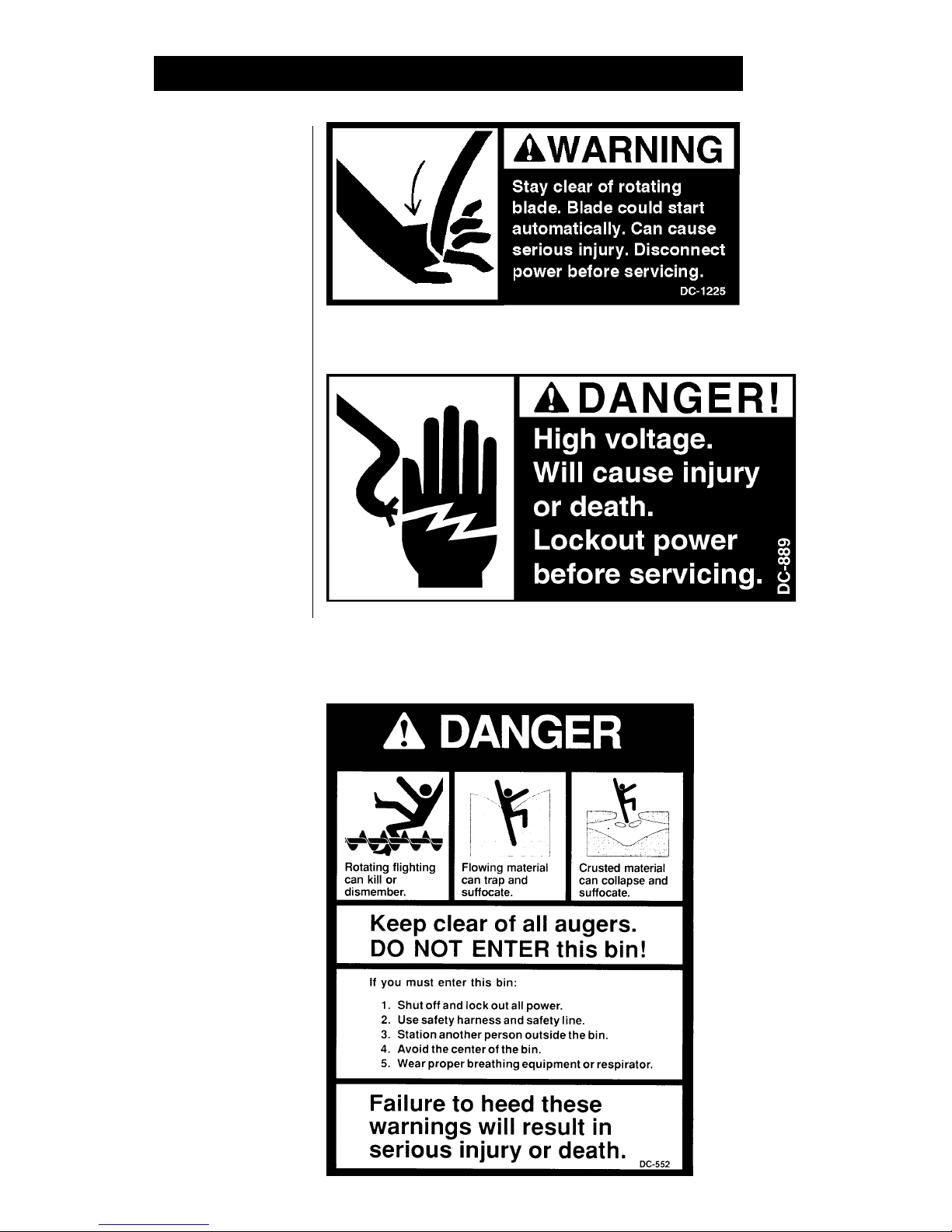

Safety decals should be read

and understood by all people in the

grain handling area. The bottom

right decal should be present on the

inside bin door cover of the two ring

door, 24" porthole door cover and

the roof manway cover.

If a decal is damaged or is miss-

ing contact:

Grain Systems, Inc.

1004 E. Illinois St.

Assumption, IL 62510

217-226-4421

A free replacement will be sent to you.

SAFETY ALERT DECALS

6

INSTALLATION INSTRUCTIONS

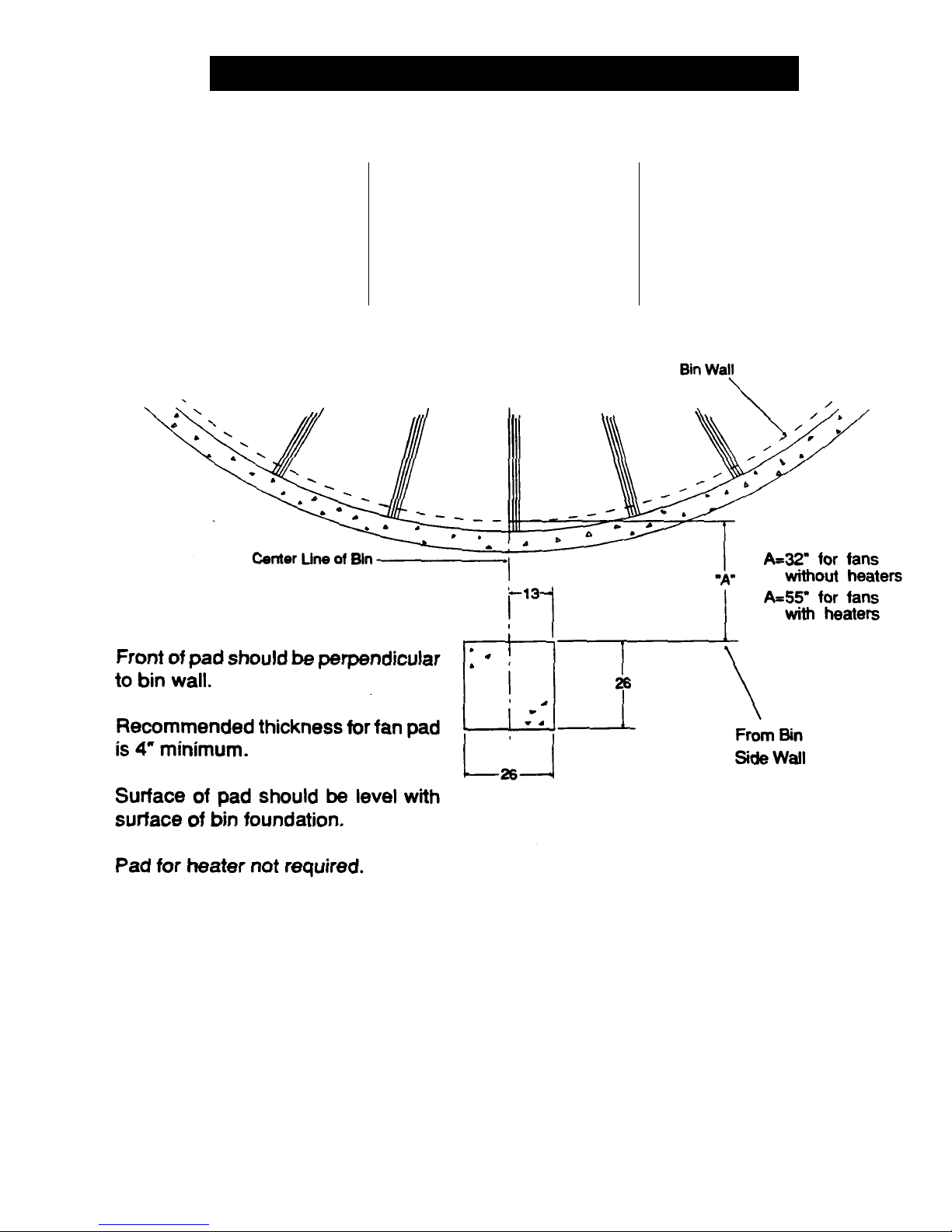

FAN PAD LOCATION

FOR USE WITH

TR-6918 & TR-6919

OVAL TRANSITION

Fan pad should be poured level with

top of bin foundation for all vane

axial fans 18" through 26" diameter.

The pad for Airstream heaters is not

required. If a vane axial heater may

be installed at a later date, then it

would be recommended to pour fan

pad 26" wide and 52" long. Fan should

be centered on center line of bin.

IMPORTANT! FAN PAD AND FAN

MUST BE LEVEL AND SMOOTH

FOR PROPER OPERATION. VI-

BRATION PROBLEMS CAN RE-

SULT FROM IMPROPER FAN LEV-

ELING.

Figure 1: Fan pad installation guidelines.

7

INSTALLATION INSTRUCTIONS

CHECKLIST BEFORE

INSTALLING THE FAN

1. One of the most important fac-

tors for installation is providing

adequate power to run the unit.

Undersized wire can lead to

voltage drop and can cause

motor overheating and short-

ened life. Therefore, it is neces-

sary to know the distance from

the unit to available transformer

and the horsepower of your fan

unit. These two factors will de-

termine the size of wire needed

for efficient operation. See Fan

ALWAYS DISCONNECT

Specifications on the following

page.

2. Grain Systems, Inc. recommends

contacting your local power com-

pany, and having a representa-

tive survey your installation so

the wiring is compatible with

their system, and adequate power

is supplied to your unit.

3. Each fan motor should be wired

through a fused or circuit

breaker disconnect switch.

4. Refer to Fan Specifications on

page 9 for the recommended

slow blow fuse or breaker size

to use when installing your par-

ticular fan.

5. Standard electrical safety prac-

tices and codes should be used.

(Refer to National Electrical Code

Standard Handbook by National

Fire Protection Association).

INSTALLATION

1. Be sure that the disconnect and

the fan are well grounded. See

machine to earth ground on

page 11.

2. Rotate the fan blade to be sure

that it revolves easily and does

not rub the housing.

3. Check all fasteners on motor

mounts, fan blades and other

bolted items to make sure they

are tight. If any are loose, check

for proper clearance and re-

tighten fasteners. They may

have loosened in shipping.

4. Fans should be mounted to set

level and solid. It may be nec-

essary to shim one or more cor-

ners of the foot mount to achieve

a solid mounting. Fans not sol-

idly mounted and properly

shimmed may have excess vi-

bration in them.

AND LOCK OUT POWER

BEFORE WORKING ON OR

AROUND HEATER

8

6. A qualified electrician should

make all electrical wiring instal-

lations.

5. Check and retighten all electri-

cal connections. They may have

loosened in shipping.

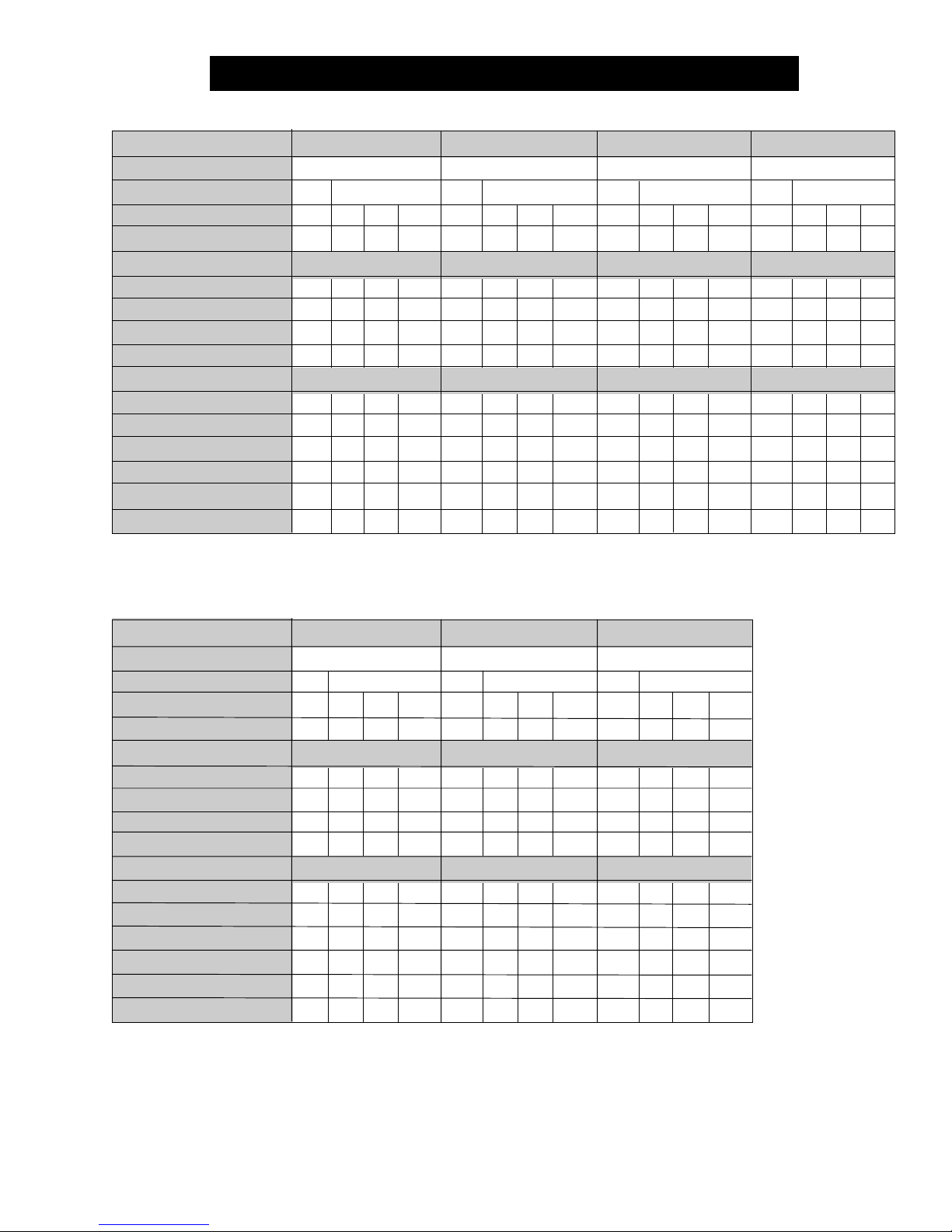

FAN SPECIFICATIONS

FAN HORSEPOWER

RPM

PHASE

VOLTS

FULL LOAD AMPS

MINIMUM WIRE SIZE

50' RUN

100' RUN

200' RUN

300' RUN

MINIMUM WIRE SIZE

50' RUN

100' RUN

200' RUN

300' RUN

FUSE SIZE (SLOW BLOW)

BREAKER SIZE

3/4

3450

230

2.6

14

14

14

14

14

14

14

12

10

15

3

460

1.3

14

14

14

14

14

14

14

14

5

10

1

230

5.5

Copper Wire

14

14

12

10

Aluminum Wire

14

14

10

8

15

20

575

1.0

14

14

14

14

14

14

14

14

5

10

1

3450

230

3.0

14

14

14

14

14

14

14

12

10

15

3

460

1.5

14

14

14

14

14

14

14

14

5

10

1

230

5.5

Copper Wire

14

14

12

10

Aluminum Wire

14

14

10

8

15

20

575

1.2

14

14

14

14

14

14

14

14

5

10

1.1/2

3450

230

4.6

14

14

12

10

12

12

10

10

10

15

3

460

2.3

14

14

14

12

14

12

12

12

5

10

1

230

7.5

Copper Wire

14

12

8

6

Aluminum Wire

12

10

6

4

15

20

575

1.8

14

14

14

12

14

14

12

12

5

10

3

3450

230

7.4

12

12

10

8

12

10

10

8

15

20

3

460

3.7

14

12

12

10

12

12

10

10

10

15

1

230

15

Copper Wire

12

10

8

6

Aluminum Wire

12

8

6

4

30

40

575

3

14

12

12

10

12

12

10

10

10

15

FAN HORSEPOWER

RPM

PHASE

VOLTS

FULL LOAD AMPS

MINIMUM WIRE SIZE

50' RUN

100' RUN

200' RUN

300' RUN

MINIMUM WIRE SIZE

50' RUN

100' RUN

200' RUN

300' RUN

FUSE SIZE (SLOW BLOW)

BREAKER SIZE

7

3450

1

230

30

Copper Wire

10

8

4

4

Aluminum Wire

8

6

3

2

40

60

3

23018460

9

12

12

10

12

8

10

6

8

10

12

8

10

6

10

4

8

25

15

30

15

575

6.9

12

12

12

10

12

12

10

10

15

15

10

3450

1

230

47

Copper Wire

10

6

4

2

Aluminum Wire

8

4

2

0

60

80

3

23025460

13

10

12

8

10

6

10

4

8

10

12

8

10

4

8

2

6

30

20

40

20

575

9.6

12

12

10

8

12

10

10

8

15

20

15

3450

1

230

57

Copper Wire

8

6

2

0

Aluminum Wire

6

4

0

00

75

100

3

23032460

16

8

12

6

10

4

10

4

8

8

10

6

8

4

6

2

4

40

20

60

30

575

14

12

12

10

10

10

10

8

6

20

20

9

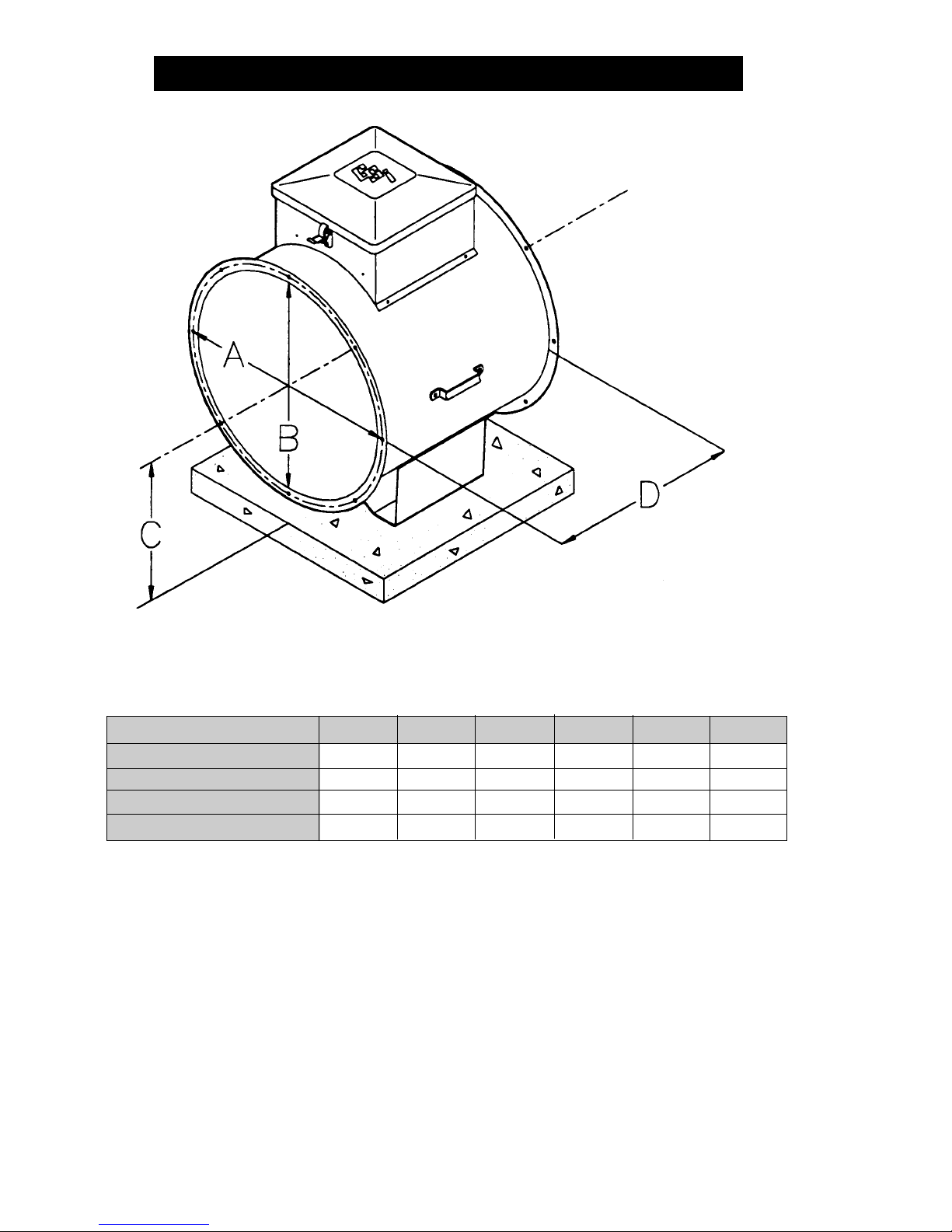

FAN SPECIFICATIONS

FAN

A (BOLT CIRCLE)

B (INSIDE DIA)

C (CL TO BOTTOM OF LEG)

D (LENGTH)

Note: All Dimensions in inches.

Figure 2: Fan dimensions

12" Dia

12.3/4

11.7/8

8

14.1/8

14" Dia

15.1/8

14.1/8

10

14.1/8

18" Dia

19.1/2

18.1/4

13.5/16

22

24" Dia

25.3/4

24.1/4

15.3/8

23.1/2

26" Dia

27.11/16

26.5/16

16.7/8

20.1/4

28" Dia

29.5/8

28.1/8

18.1/8

26

10

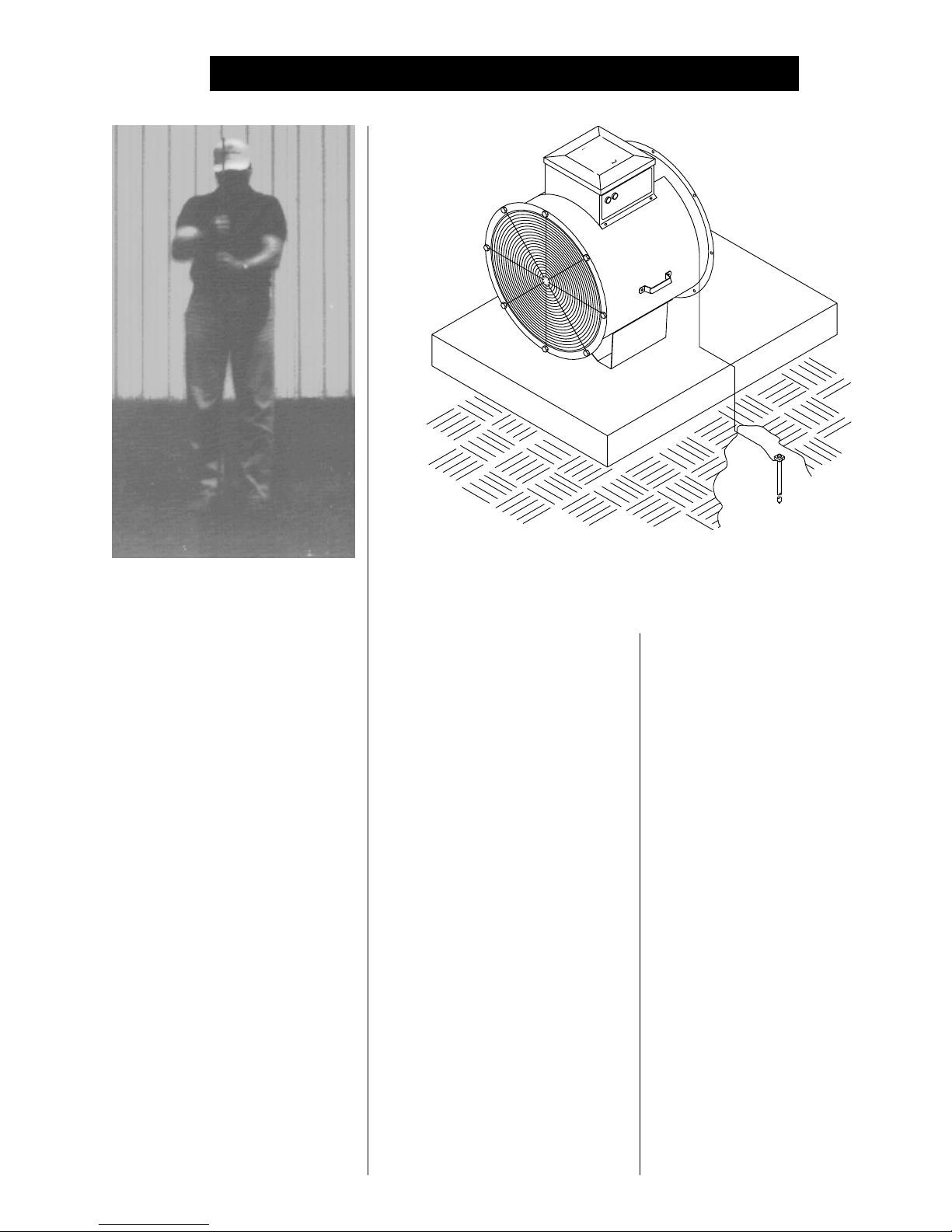

FAN INSTALLATION

Dig a hole large enough to hold 1

or 2 gallons of water. Work the

ground rod into the earth until it is

completely in the ground.

MACHINE TO EARTH

GROUND

It is very important that a machine

to earth ground rod be installed at

the fan. This is true even if there is

a ground at the pole 15 feet away.

This ground needs to be as close to

the fan as possible, but no more than

8 feet away. The ground rod should

be connected to the fan control panel

with at least a #6 solid bare copper

ground wire, or in accordance with

local requirements. The machine to

earth ground provides additional

safety if there is a short. It also pro-

vides the grounding necessary for

long life and operation of the solid

state circuit boards used on control

circuits and the electronic ignition

systems.

Figure 3: Use a #6 or approved size bare copper ground wire. Install a 5/8"

diameter 8' long copper-clad ground rod, 2' away from the foundation and 1'

below the surface of the ground or in accordance with local requirements.

PROPER INSTALLATION

OF THE GROUND ROD

(Ground rods and wires are not sup-

plied by Airstream). It is recom-

mended that the rod not be driven into

dry ground. The following steps en-

sure proper ground rod installation:

1. Dig a hole large enough to hold

1 to 2 gallons of water.

2. Fill hole with water.

3. Insert rod through water and jab

it into the ground.

4. Continue jabbing the rod up and

down, the water will work its way

down the hole, making it pos-

sible to work the rod completely

into the ground. This method of

installing the rod gives a good

conductive bond with the sur-

rounding soil.

5. Connect the bare copper ground

wire to the rod with the proper

ground rod clamp.

6. Connect the bare ground wire to

the fan control boxes with a

grounding lug. See Figure 3.

7. Ground wire must not have any

breaks or splices. Insulated

wire is not recommended for

grounding.

PREVIOUSLY INSTALLED

UNITS

It is recommended that previously

installed units be checked to see that

a machine to earth ground has been

installed by an electrician.

11

FAN OPERATION

START-UP

On initial start-up of the fan, run it

momentarily to make sure that the

fan blade is rotating in the proper

direction and airflow is correct. If not,

change motor direction using in-

structions on the motor.

Proper installation and start-up

ensures many years of trouble-free

operation.

MAINTAINING GRAIN

QUALITY

To properly maintain the quality of

stored grain, it is necessary to keep

the grain dry, cool and insect free.

Any one of these problems can con-

tribute to spoilage. Wet, warm grain

promotes insect growth as well as

grain spoilage. Cool, dry grain can

keep for long periods of time.

It is recommended that the grain

be kept cool (avoid freezing as freez-

ing can reduce quality). Grain should

be cooled through the fall and winter,

warmed in the spring and summer.

GRAIN STORAGE

Average grain temperature should

be above 35°F in the winter and below 65°F in the summer. Always try

to keep the grain within 10-15°F of

the average monthly outside tem-

perature. This means grain may

need to be aerated on warm days

during the winter to stay above 35°F

when freezing temperatures are pre-

dominate. During the summer it may

be necessary to aerate the grain on

cool nights, so the 65°F temperature

is not exceeded during the hot days

of summer.

Conditions and requirements may

vary from area to area. We suggest

that you contact your local Agriculture

Extension Office or State Ag. Univer-

sity for more exact guidelines.

If the grain is to be stored more

than one year, it has to be recooled

the following fall and winter, repeat-

ing the process as long as the grain

is in storage. Frequent and regu-

lar inspection (at least weekly

during fall and spring) is the best

prevention against grain spoilage).

EQUILIBRIUM MOISTURE CHART

Air

Temperature

°°

20

°F

°°

°°

30

°F

°°

°°

40

°F

°°

°°

50

°F

°°

°°

60

°F

°°

°°

70

°F

°°

°°

80

°F

°°

Safe moisture for normal winter storage of shelled corn is about 15%. Grain to be stored through the summer or

long term, needs to be 1 to 3 points dryer.

35

11.2

10.8

10.5

10.1

9.7

9.0

8.3

40

11.7

11.3

11.0

10.6

10.2

9.7

9.1

45

12.7

12.2

11.7

11.3

10.9

10.4

9.8

50

13.7

13.1

12.5

12.0

11.6

11.1

10.5

14.5

13.9

13.3

12.7

12.1

11.5

10.8

Percentage Relative Humidity

55

60

15.1

14.6

14.0

13.3

12.7

12.0

11.2

65

16.2

15.5

14.8

14.1

13.4

12.8

12.1

17.1

16.4

15.5

14.8

14.2

13.5

13.0

70

75

18.0

17.4

16.6

15.8

15.0

14.5

13.9

80

19.6

18.7

17.8

16.9

16.0

15.4

14.8

85

21.2

20.2

19.4

18.6

17.8

16.8

15.8

90

23.5

22.5

21.5

20.5

19.5

18.5

17.4

95

25.8

25.0

24.2

23.4

22.6

21.3

20.0

100

29.1

28.3

27.5

26.7

25.9

24.5

22.8

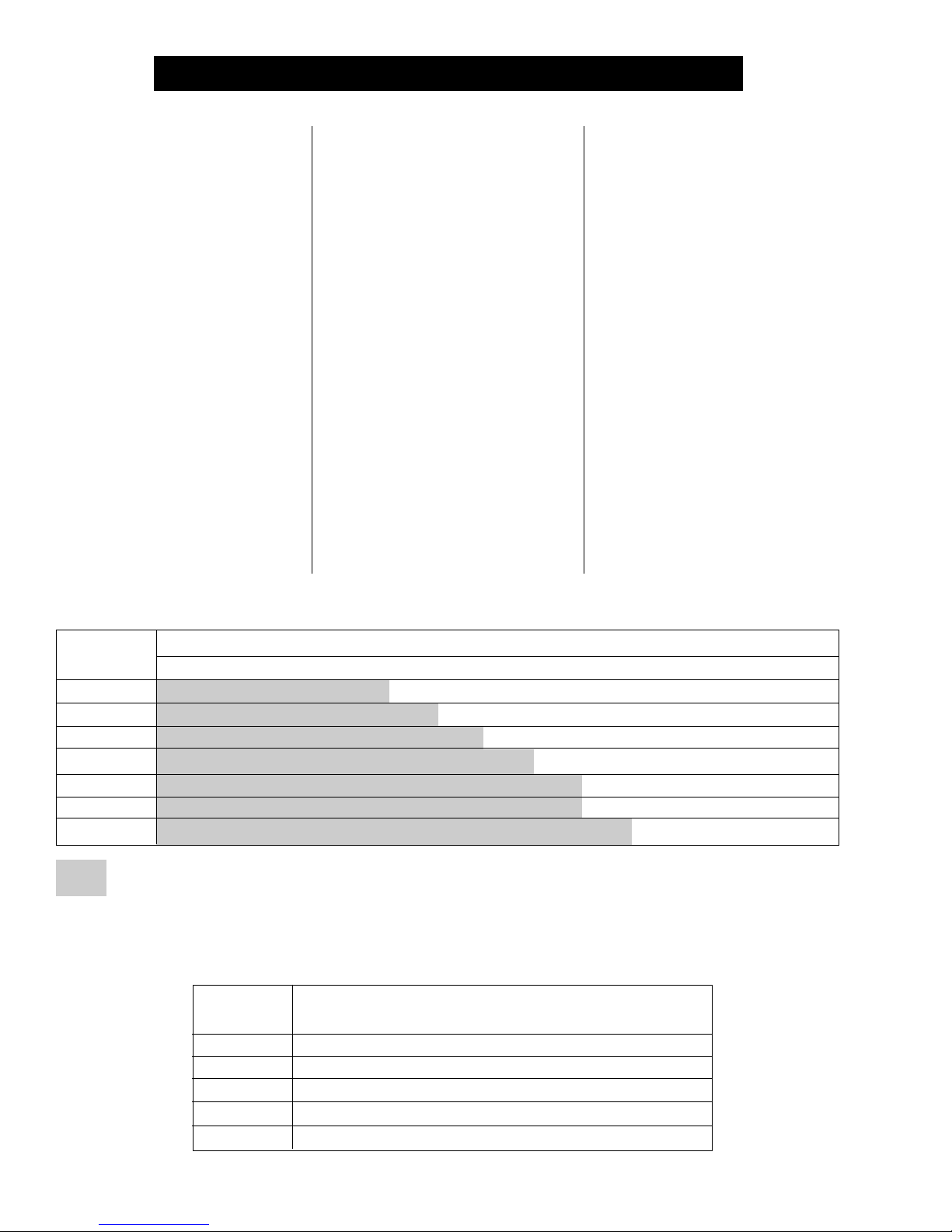

APPROXIMATE ALLOWABLE HOLDING TIME FOR FIELD-SHELLED CORN,

TO MAINTAIN GRADE*

°°

Grain (

°F)

°°

Temperature

°°

40

°F

°°

°°

50

°F

°°

°°

60

°F

°°

°°

70

°F

°°

°°

80

°F

°°

15%

days

898

451

242

147

109

18%

days

195

102

63

37

27

20%

days

85

46

26

13

10

22%

days

54

28

16

8

6

24%

days

38

19

10

5

4

26%

days

28

16

8

4

3

28%

days

24

13

6.5

3.5

2.5

30%

days

20

11

5.5

3

2

*Allowable holding time for field-shelled corn at various grain temperatures and moisture

12

Loading...

Loading...