Page 1

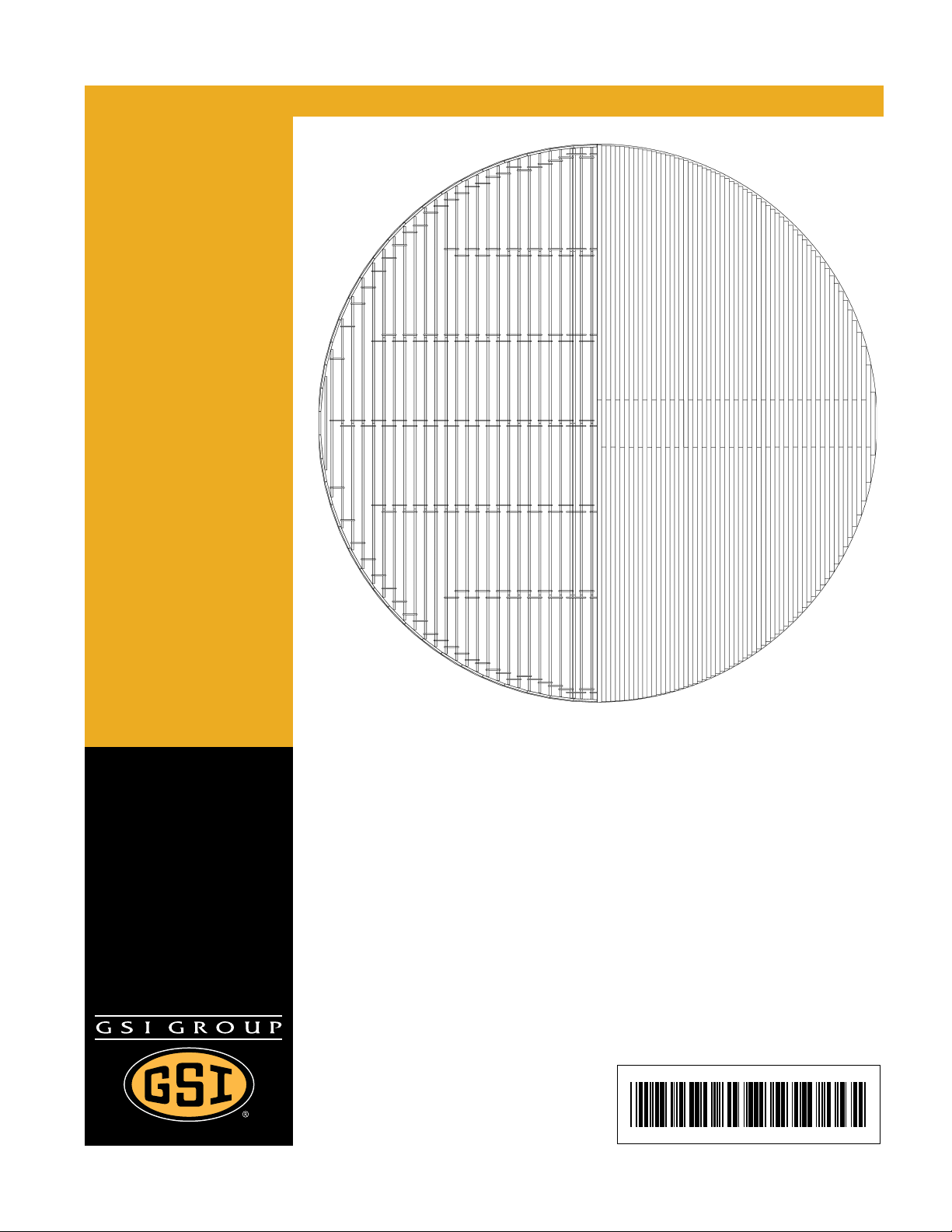

PNEG-1832

72' Dura-Lok Plank and

Support Manual

Owner ’s Manual

PNEG-1832

Version: 1.0

Date: 10-28-11

Page 2

All information, illustrations, photos, and specifications in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any

time without notice.

2 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 3

Table of Contents

Contents

Chapter 1 Introduction ..........................................................................................................................................4

Chapter 2 Safety .....................................................................................................................................................5

Safety Guidelines .................................................................................................................................. 5

General Safety Statement ..................................................................................................................... 6

Safety Instructions ..................... ... .... .......................................... ... ... ..................................................... 7

Safety Sign-Off Sheet ........................................................................................................................... 9

Proper Storage of Grain Bin/Silo Materials Prior to Construction ....................................................... 10

Chapter 3 Decals ..................................................................................................................................................11

Roof Damage Warning and Disclaimer ............................................................................................... 11

Chapter 4 Monorail Installation ..........................................................................................................................14

Fan Placement Diagram ..................................................................................................................... 14

Tie Bar Detail ......................................................... ... .... ... ... ... ............................................................. 15

Tie Strap Detail ......................................................... .... ... ... ... .... ... ... ... ... .... ... ... ... .... ... ... ...................... 16

Assembling Legs to Rail ...................................................................................................................... 17

Outer Perimeter Rail Details ............................................................................................................... 19

Splicing Rails ....................... .......................................... .......................................... ............................ 20

Chapter 5 Flooring - Planks ................................................................................................................................21

Floor Splice Details ... .......................................... ... ... .... .......................................... ... ... ...................... 21

Flashing Installation ............................................................................................................................ 22

Center Well Assembly Details ............................................................................................................. 24

Intermediate Well Assembly Details ....... ... ... .... ... ... ... .... ...................................................................... 25

Chapter 6 Layouts ................................................................................................................................................26

72'-14" Rail Spacing Layout ................................................................................................................ 26

72'-14" Monorail Spacing Layout ........................................................................................................ 27

72'-15" Monorail Spacing Layout ........................................................................................................ 28

72'-15" Rail Spacing Layout ................................................................................................................ 29

72'-16" Rail Spacing Layout ................................................................................................................ 30

72'-16" Monorail Spacing Layout ........................................................................................................ 31

72'-17" Monorail Spacing Layout ........................................................................................................ 32

72'-17" Rail Spacing Layout ................................................................................................................ 33

72'-18" Rail Spacing Layout ................................................................................................................ 34

72'-18" Monorail Spacing Layout ........................................................................................................ 35

72'-20" Monorail Spacing Layout ........................................................................................................ 36

72'-20" Rail Spacing Layout ................................................................................................................ 37

72'-22" Rail Spacing Layout ................................................................................................................ 38

72'-22" Monorail Spacing Layout ........................................................................................................ 39

72'-26" Monorail Spacing Layout ...............................................................................................

72'-26" Rail Spacing Layout ................................................................................................................ 41

72' Floor Bundle Layout ...................................................................................................................... 42

72' Plank Layout .................................................................................................................................. 43

Chapter 7 Warranty ..............................................................................................................................................45

......... 40

PNEG-1832 72' Dura-Lok Plank and Support Manual 3

Page 4

1. Introduction

READ THIS MANUAL carefully to learn how to properly use and install equipment. Failure to do so could

result in personal injury or equipment damage.

INSPECT the shipment immediately upon arrival. The customer is responsible for ensuring that all

quantities are correct. The customer should report and note any damage or shortage on the bill of

lading to justify their claim to the transport company.

THIS MANUAL SHOULD BE CONSIDERED a permanent part of your equipment and should be easily

accessible when needed.

This warranty provides you the assurance that the company will back its products when defects appear

within the warranty period. In some circumstances, the company also provides field improvements, often

without charge to the customer, even if the product is out of warranty. Should the equipment be abused,

or modified to change its performance beyond the factory specifications, the warranty will become void

and field improvements may be denied.

4 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 5

2. Safety

DANGER

WARNING

CAUTION

NOTICE

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a

hazardous situation which, if not avoided, could result in

minor or moderate injury.

NOTICE is used to address practices not related to

personal injury.

DANGER indicates a hazardous situation which, if not

avoided, will result in death or serious injury.

Safety Guidelines

This manual contains information that is important for you, the owner/operator, to know and understand.

This information relates to protecting personal safety and preventing equipment problems. It is the

responsibility of the owner/operator to inform anyone operating or working in the area of this equipment

of these safety guidelines. To help you recognize this information, we use the symbols that are defined

below. Please read the manual and pay attention to these sections. Failure to read this manual and its

safety instructions is a misuse of the equipment and may lead to serious injury or death.

PNEG-1832 72' Dura-Lok Plank and Support Manual 5

Page 6

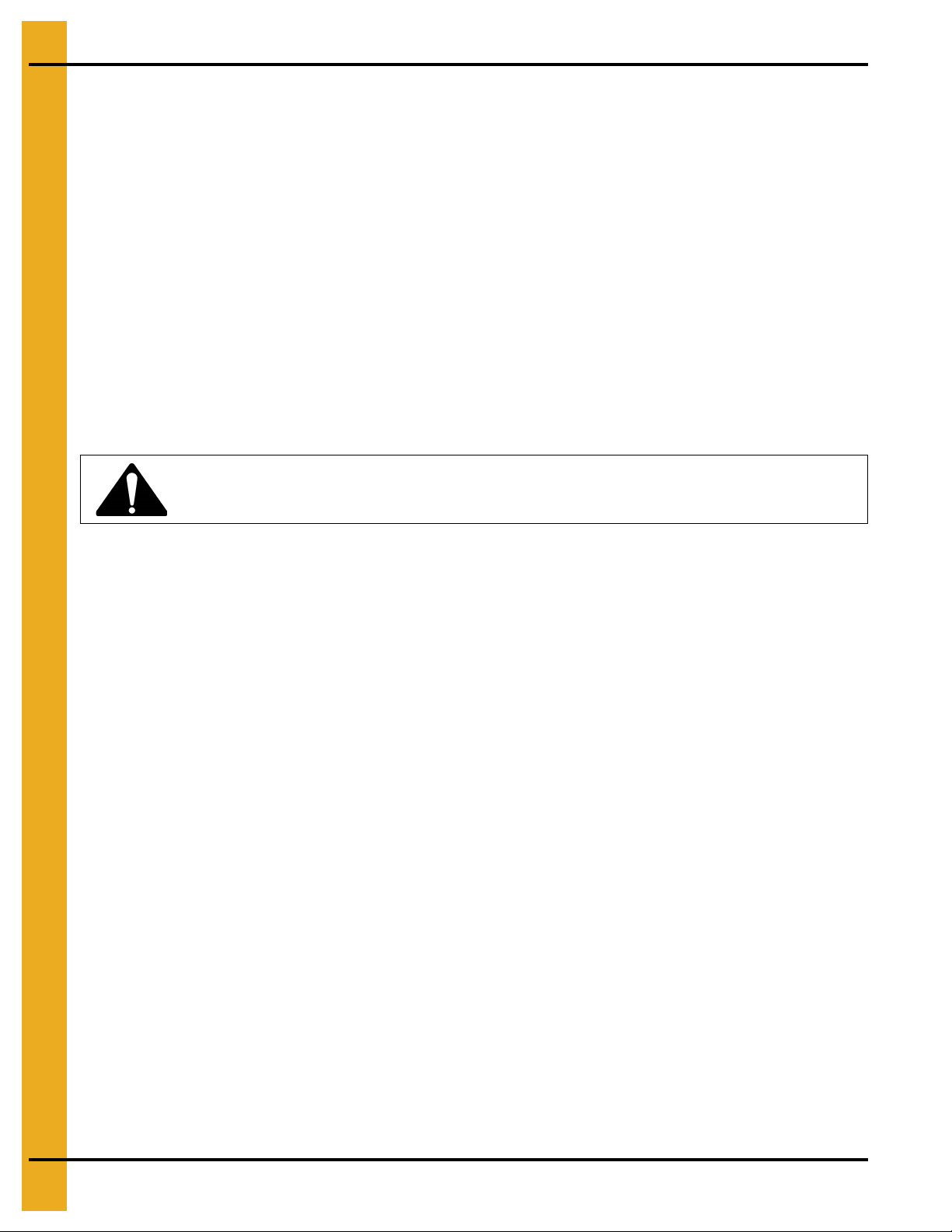

2. Safety

This product has sharp edges, which may cause serious injury. To avoid injury, handle

sharp edges with caution and always use proper protective clothing and equipment.

General Safety Statement

Our foremost concern is your safety and the safety of others associated with grain handling equipment.

This manual is to help you understand safe operating procedures and some problems that may be

encountered by the operator and other personnel.

As owner and/or operator, you are responsible to know what requirements, hazards and precautions exist

and inform all personnel associated with the equipment or in the area. Safety precautions may be required

from the personnel. Avoid any alterations to the equipment, which may produce a very dangerous

situation, where SERIOUS INJURY or DEATH may occur.

You should consider the location of the bin site relative to power line locations or electrical transmission

equipment. Contact your local power company to review your installation plan or for information

concerning required equipment clearance. Clearance of portable equipment that may be taken to the bin

site should also be reviewed and considered. Any electrical control equipment in contact with the bin

should be properly grounded and installed in accordance with National Electric Code provisions and other

local or national codes.

This product is intended for the use of grain storage only. Any other use is a misuse of the product.

Sidewall bundles or sheets must be stored in a safe manner. The safest method of storing sidewall

bundles is laying horizontally with the arch of the sheet upward, like a dome. Sidewall sheets stored on

edge must be secured so that they cannot fall over and cause injury. Use care when handling and moving

sidewall bundles.

Personnel operating or working around equipment should read this manual. This manual must be

delivered with equipment to its owner. Failure to read this manual and its safety instructions is a

misuse of the equipment.

6 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 7

2. Safety

Follow Safety Instructions

Carefully read all safety messages in this manual and

safety signs on your machine. Keep signs in good

condition. Replace missing or damaged safety signs. Be

sure new equipment components and repair parts include

the current safety signs. Replacement safety signs are

available from the manufacturer.

Learn how to operate the machine and how to use controls

properly. Do not let anyone operate without instruction.

Keep your machinery in proper working condition.

Unauthorized modifications to the machine may impair

the function and/or safety and affect machine life.

If you do not understand any part of this manual or need

assistance, contact your dealer.

Read and Understand Manual

Practice Safe Maintenance

Understand service procedures before doing work. Keep area

clean and dry.

Never lubricate, service, or adjust machine while it is in operation.

Keep hands, feet, and clothing away from rotating parts.

Keep all parts in good condition and properly installed. Fix

damage immediately . Replace worn or broken p arts. Remove any

built-up grease, oil, and debris.

Maintain Equipment

and Work Area

Safety Instructions

Our foremost concern is your safety and the safety of others associated with this equipment. We want to

keep you as a customer. This manual is to help you understand safe operating procedures and some

problems that may be encountered by the operator and other personnel.

As owner and/or operator, it is your responsibility to know what requirements, hazards, and precautions

exist, and to inform all personnel associated with the equipment or in the area. Safety precautions may be

required from the personnel. Avoid any alterations to the equipment. Such alterations may produce a very

dangerous situation where SERIOUS INJURY or DEATH may occur.

This equipment shall be installed in accordance with the current installation codes and applicable

regulations, which should be carefully followed in all cases. Authorities having jurisdiction should be

consulted before installations are made.

PNEG-1832 72' Dura-Lok Plank and Support Manual 7

Page 8

2. Safety

Prepare for Emergencies

Be prepared if fire starts.

Keep a first aid kit and fire extinguisher handy.

Keep emergency numbers for doctors, ambulance service,

hospital, and fire department near your telephone.

Keep Emergency Equipment

Quickly Accessible

Wear Protective Clothing

Wear close-fitting clothing and safety equipment appropriate

to the job.

Remove all jewelry.

Tie long hair up and back.

Wear safety glasses at all times to protect eyes from debris.

Wear gloves to protect your hands from sharp edges on

plastic or steel parts.

Wear steel-toed boots to help protect your feet from falling

debris. Tuck in any loose or dangling shoestrings.

A respirator may be needed to prevent breathing potentially

toxic fumes and dust.

Wear a hard hat to help protect your head.

Wear appropriate fall protection equipment when working at

elevations greater than six feet (6').

Eye Protection

Gloves

Steel-Toed Boots

Respirator

Hard Hat

Fall Protection

8 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 9

2. Safety

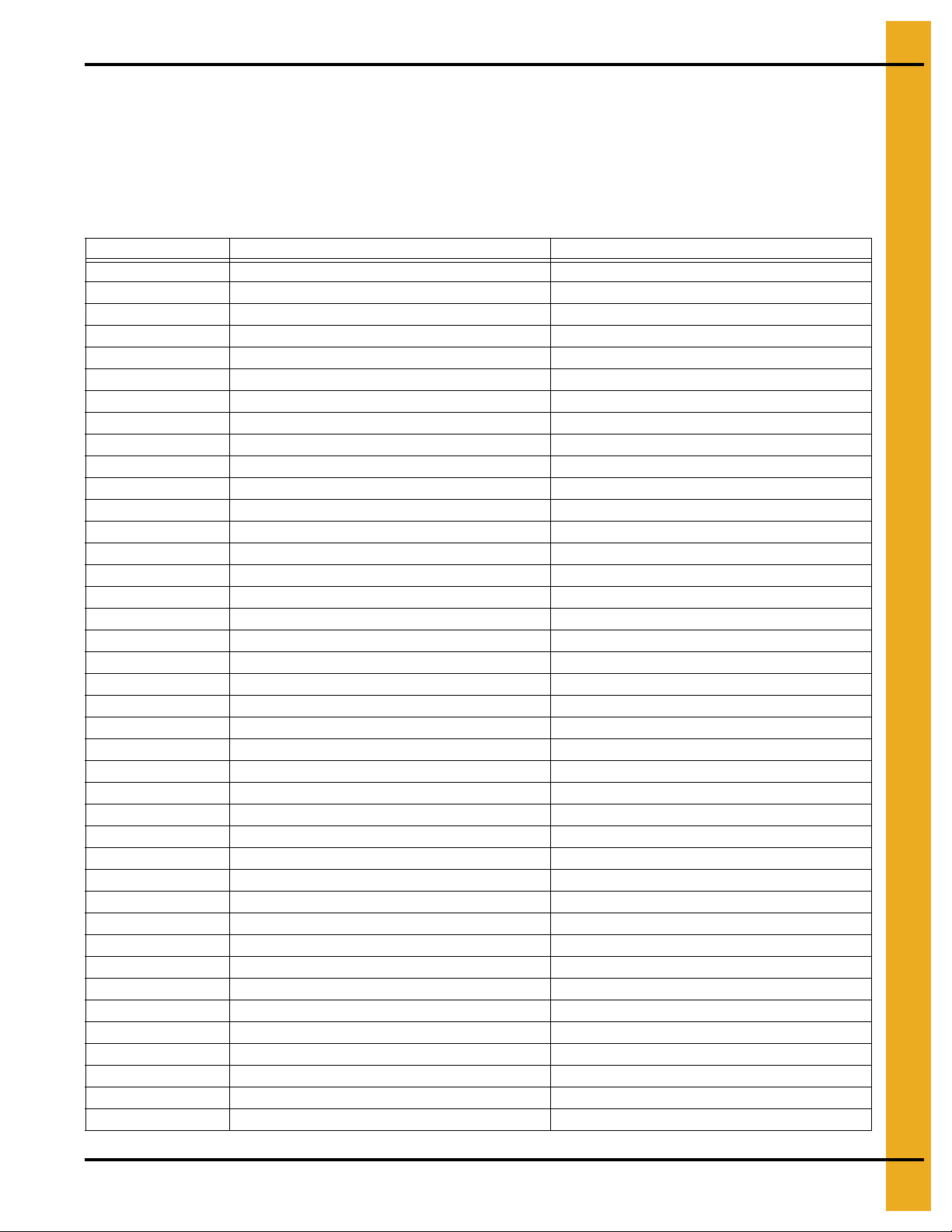

Safety Sign-Off Sheet

As a requirement of O.S.H.A., it is necessary for the employer to train the employee in the safe operating

and safety procedures for this equipment. This sign-off sheet is provided for your convenience and

personal record keeping. All unqualified persons are to stay out of the work area at all times. It is strongly

recommended that another qualified person who knows the shut down procedure be in the area in the

event of an emergency.

Date Employee Name Supervisor Name

PNEG-1832 72' Dura-Lok Plank and Support Manual 9

Page 10

2. Safety

Proper Storage of Grain Bin/Silo Materials Prior to Construction

Wet storage stain (rust) will develop when closely packed bundles of galvanized material, such as sidewall

and roof sheets, have moisture present. Inspect roof and sidewall bundles on arrival for any moisture. If

moisture is present, it must not be allowed to remain between the she ets. Separate the sheets or panels

immediately and wipe them down. Spray with a light oil or diesel fuel.

If possible, sidewall bundles, roof sheets and other closely packed galvanized materials should be stored

in a dry, climate controlled building. If outdoor storage is unavoidable, the materials should be stored so

that they are raised above the ground and vegetation. Any stacking an d spacing mat erials sho uld not be

corrosive or wet. Be sure to protect materials from the weather, but permit air movement around the

bundles if possible.

Storing roof bundles and sidewall sheets at a slight incline can also help minimize the presence of

moisture. Storing the bundles with the center of the dome up (like an arch) is one option for minimizing

moisture during storage. Sidewall bundles can also be stored on edge but must be secured so that they

do not fall over and cause injury.

If “white rust” or “wet storage stain” occurs, contact the manufacturer imme diately about ways to minimize

the adverse effect upon the galvanized coating.

10 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 11

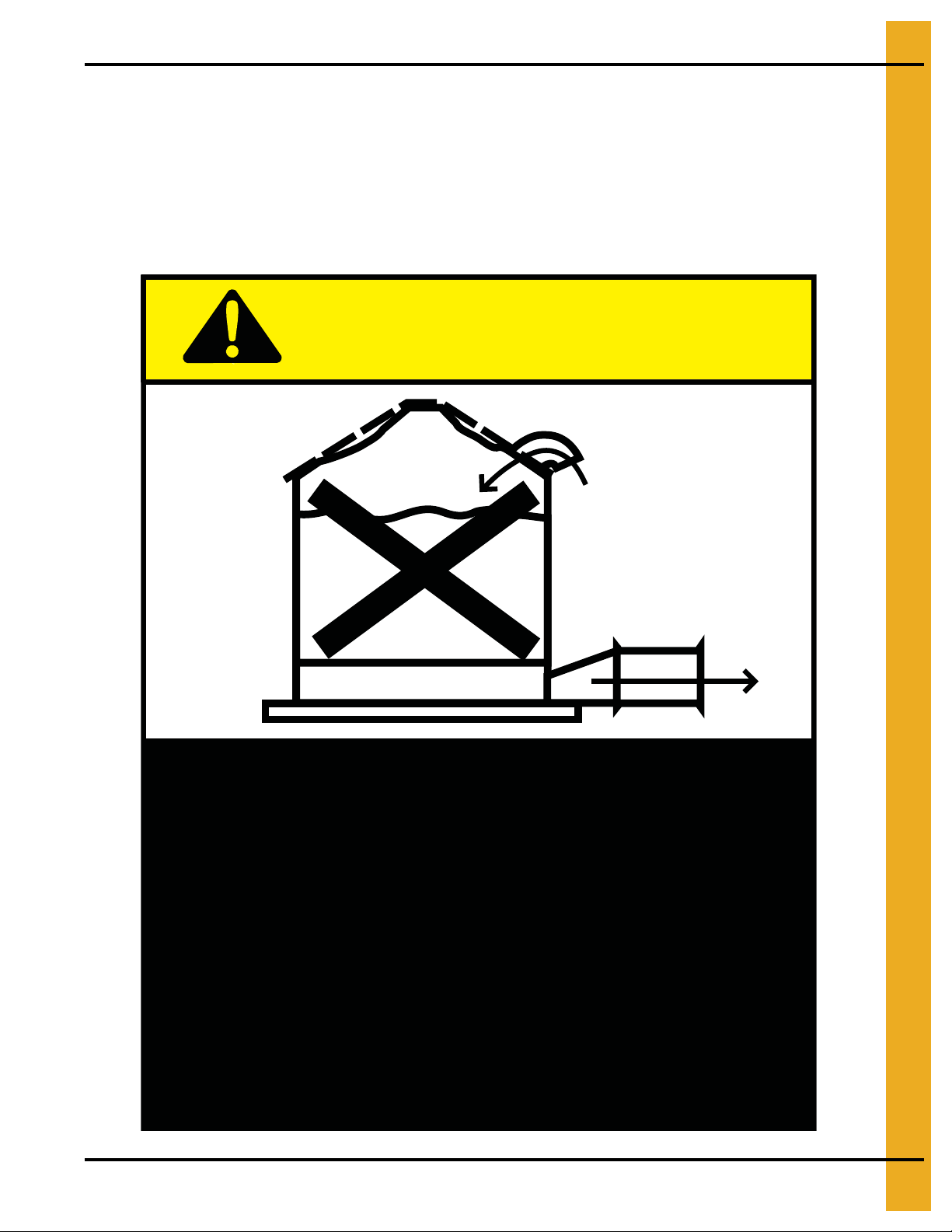

Roof Damage Warning and Disclaimer

The manufacturer does not warrant any roof damage caused by excess ive v acuum or internal

pressure from fans or other air moving systems. Adequate ventilation and/or “makeup air”

devices should be provided for all powered air handling systems. The manufacturer does not

recommend the use of downward flow systems (suction). Severe roof damage can result from

any blockage of air passages. Running fans durin g high humidity/cold weather conditions can

cause air exhaust or intake ports to freeze.

CAUTION!

3. Decals

Excessive vacuum (or pressure) may

damage roof. Use positive aeration

system. Make sure all roof vents are

open and unobstructed. Start roof

fans when supply fans are started.

Do not operate when conditions exist

that may cause roof vent icing.

DC-969

PNEG-1832 72' Dura-Lok Plank and Support Manual 11

Page 12

3. Decals

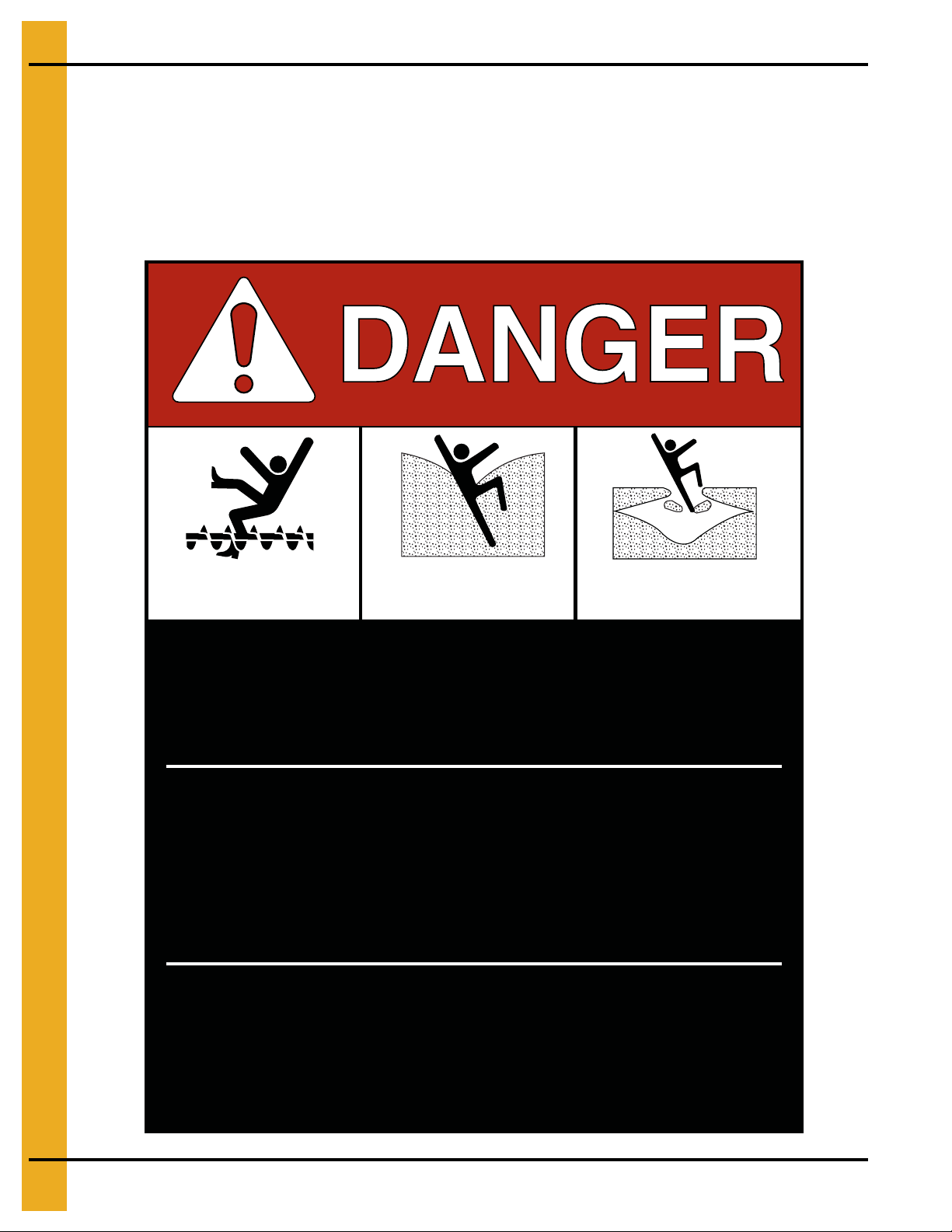

Rotating flighting will

kill or dismember.

Flowing material will

trap and suffocate.

Crusted material will

collapse and suffocate.

Keep clear of all augers.

DO NOT ENTER this bin!

Failure to heed these

warnings will result in

serious injury or death.

If you must enter the bin:

1. Shut off and lock out all power.

2. Use a safety harness and safety line.

3. Station another person outside the bin.

4. Avoid the center of the bin.

5. Wear proper breathing equipment or respirator.

DC-GBC-1A

ATTENTION: The decal shown below should be present on the outside of the door cover of the 2 ring,

24" porthole door cover and the roof manway cover. If a decal has been damaged or is missing in any of

these locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

12 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 13

3. Decals

ATTENTION: The decal shown below should be present on the outside of the door cover of the 2 ring,

24" porthole door cover and the roof manway cover. If a decal has been damaged or is missing in any of

these locations, contact the manufacturer for a free replacement decal.

GSI Decals

1004 E. Illinois St.

Assumption, IL. 62510

Phone: 1-217-226-4421

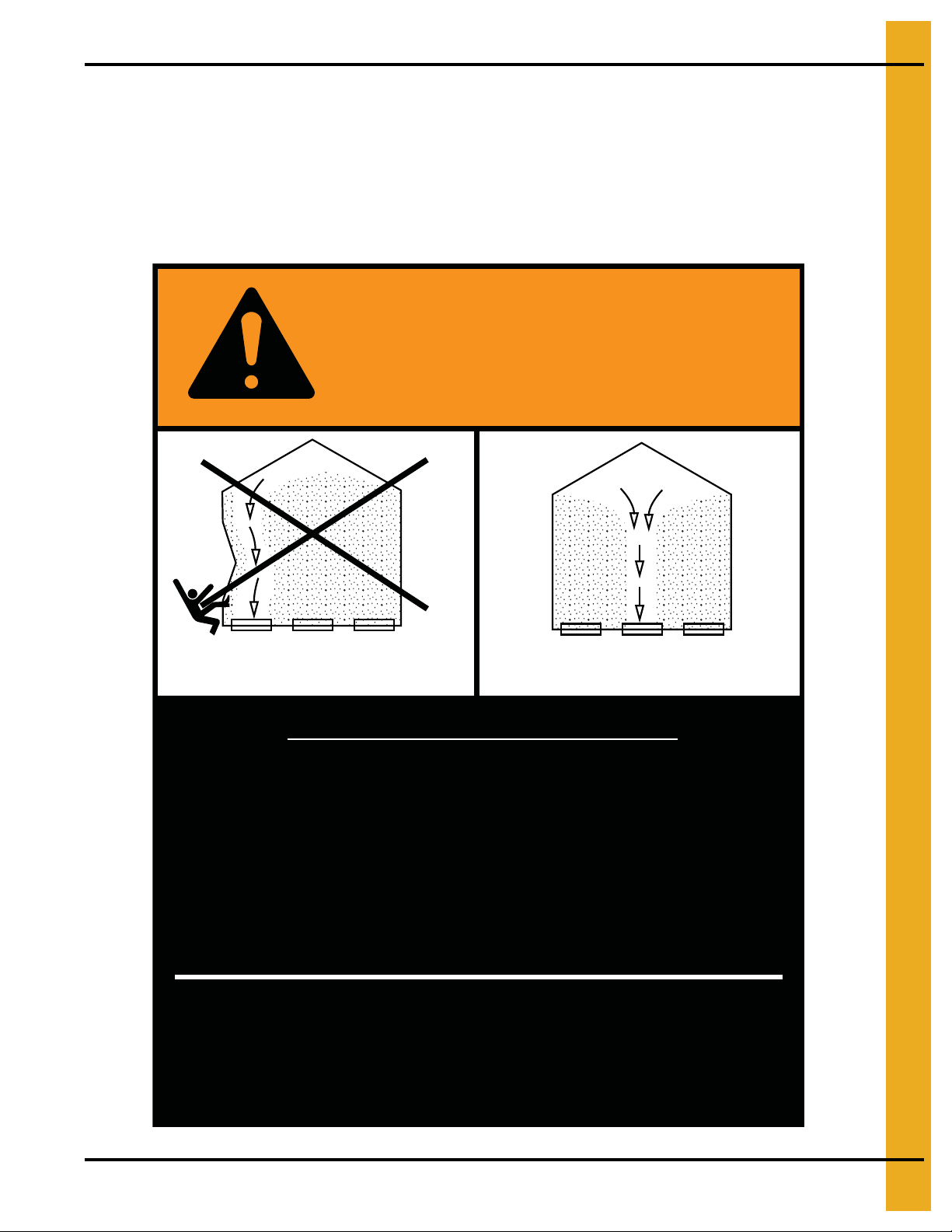

WARNING

DON’T

DO

UNLOADING INSTRUCTIONS:

1. Use CENTER FLOOR OUTLET ONLY until NO grain

remains above this outlet.

2. Side floor outlets to be used ONLY when above

condition is satisfied.

3. Lock all side floor outlets to avoid accidental

premature use.

4. See manufacturers instructions for proper use of

factory supplied sidedraw (wall) discharge systems.

Failure to heed these warnings

could result in serious injury, death,

structural damage or collapse of tank.

DC-GBC-2A

PNEG-1832 72' Dura-Lok Plank and Support Manual 13

Page 14

4. Monorail Installation

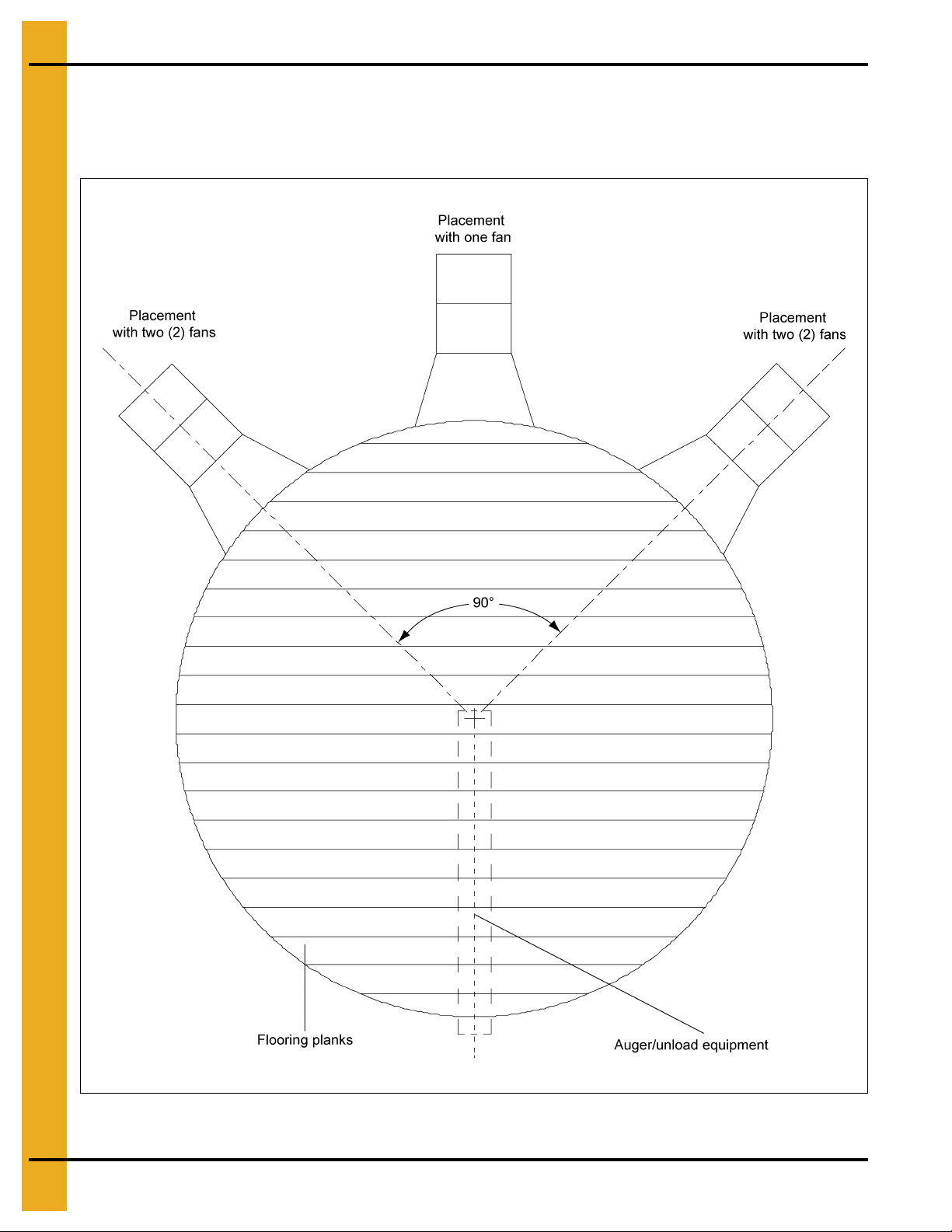

Fan Placement Diagram

For uniform air flow, place the fans in relation to the unloading tube as shown in Figure 4A. Floor planks

should be perpendicular to the unloading tube.

Figure 4A

14 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 15

4. Monorail Installation

Tie Bar Detail

1. Locate the tie bars between the rails. (Spaced evenly throughout the system.)

NOTE: Tie bars are to be placed at the end of monorail, at each splice and in the middle of the rail

if it is over 16' long. (Not necessarily evenly spaced.) Rail spacing details on Pages 26-41,

detail tie bar placements in each layout.

2. A single #10 x 5/8" self-drilling screws may be used to fasten the tie bars at each end to the rails

as necessary. (See Figure 4B.)

Figure 4B Tie Bar Detail

3. Tie bars should overlap and connect each rail to the next rail. Tie bars should be located along

each side of a rail splice and around the perimeter of the bin, no more than 6" from the end of the rail.

(See Figure 4C.)

Figure 4C Tie Bar Dimension Detail

PNEG-1832 72' Dura-Lok Plank and Support Manual 15

Page 16

4. Monorail Installation

Tie Strap Detail

1. Tie straps should be used when a tie bar cannot be used to connect rails together due to special

spacing of monorail. Tie strap should be connected to all three (3) rails using self-drilling screws.

(See Figure 4D.)

2. Tie straps are to be located in the same places as a tie bar would be used.

NOTE: Some tie straps will be used to support center well and intermediate well assembly.

(See Figure 5F on Page 24 and Figure 5G on Page 25.)

Figure 4D Strap Detail

16 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 17

4. Monorail Installation

See chart on Page 18.

Spacing depends on

eave height.

Assembling Legs to Rail

1. Place two (2) corners of the monorail leg into the rails as shown.

2. By twisting the leg it will spread the rail enough to get the other corners inside.

3. The leg can then be pushed down into the rail until the tabs lock it into place. (See Figure 4E.)

PNEG-1832 72' Dura-Lok Plank and Support Manual 17

Figure 4E Assembly Leg Rail

Page 18

4. Monorail Installation

Monorail “Rail and Leg Spacing”/“Full Floor Leg Quantity” for 72' Bin Diameter

4.00"

Ring

3 4 11 26 See Page 41 22 1288

46 16 26See Page 41 20 1409

5 8 22 22 See Page 38 20 1616

710 27 22See Page 38 19 1696

9 12 33 22 See Page 38 18 1786

10 14 38 20 See Page 37 18 1941

11 16 43 20 See Page 37 17 2049

13 18 48 18 See Page 34 17 2248

14 20 54 18 See Page 34 16 2382

16 22 59 17 See Page 33 16 2498

17 24 64 17 See Page 33 16 2498

19 26 70 16 See Page 30 16 2638

20 28 75 16 See Page 30 15 2806

22 30 81 15 See Page 29 15 2840

2.66"

Ring

Eave Height (ft.) Rail Spacing

Reference

Page

Leg Spacing Leg Qty

23 32 86 15 See Page 29 15 2840

25 34 92 15 See Page 29 15 2840

27 37 100 14 See Page 26 15 2984

18 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 19

4. Monorail Installation

Outer Perimeter Rail Details

3' Sections of monorail should be placed around the perimeter of the bin. Monorail legs for perimeter rails

should be spaced 16" apart on center. (See Figure 4F.)

Figure 4F

PNEG-1832 72' Dura-Lok Plank and Support Manual 19

Page 20

4. Monorail Installation

Splicing Rails

1. A leg must be centered at each rail splice.

2. The closest leg may be moved a few inches over to center it under the splice. If more than 3" of

movement is required to center the leg under the splice, add an additional leg.

3. Fasten the rail to the leg with two (2) #10 self-drilling screws (splice locations o nly). (See Figure 4G.)

Figure 4G

20 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 21

5. Flooring - Planks

Two (2) splices located at each splice location.

(See Figure 5B on Page 22.)

Floor Splice Details

Some of the floor planks will need to be spliced together. (See Figure 5F on Page 24 and plank layout

on Page 43 and plank length chart on Page 44.) Install plank length A first, then in stall the corresponding

plank length B. Continue until floor is complete. Center and install two (2) splices (PCL-7009) at each plank

splice location using self-drilling screws. Use eight (8) screws at the end of the splice for each plank,

four (4) on each side. (See Figure 5A below and Figure 5B on Page 22.)

Figure 5A Floor Splice Layout

PNEG-1832 72' Dura-Lok Plank and Support Manual 21

Page 22

5. Flooring - Planks

Figure 5B Splice Assembly View

Flashing Installation

Figure 5C

Formed Flashing Installation

If bin sweep auger is to be used, overlap flashing such that rotation (usually clockwise) of the sweep will

climb up on the next flashing section. (See detail C in Figure 5C.) This will prevent the rotating/slipping

outer wheel of the sweep from catching on the flashing edges.

After the floor is in place, lay the flashing pieces on top of the floor place over the 1-1/4" bin bolts.

See Figure 5D and Figure 5E on Page 23 to determine the correct sequence for placing the nuts and

washers. Finger tighten the nuts. While holding flashing flat, fasten the flashing to the floor with sheet

metal screws. Now tighten flashing nuts.

22 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 23

Flashing Installation (Continued)

Figure 5D 2.66" Corrugation

5. Flooring - Planks

Figure 5E 4.00" Corrugation

PNEG-1832 72' Dura-Lok Plank and Support Manual 23

Page 24

5. Flooring - Planks

Center Well Assembly Details

Figure 5F 72' Diameter Bin Center Well Position

24 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 25

Intermediate Well Assembly Details

5. Flooring - Planks

Figure 5G 72' Diameter Bin Intermediate Well Position

PNEG-1832 72' Dura-Lok Plank and Support Manual 25

Page 26

6. Layouts

NOTE: This depicts monorail spacings only. Leg spacing is dependant

on eave height. See Page 18 for leg and rail spacing chart.

Tie bar (See Page 15 for

installation detail.)

72'-14" Rail Spacing Layout

Figure 6A 72' Diameter 14" Rail Spacing

26 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 27

72'-14" Monorail Spacing Layout

Part # Description Qty

FL-404-14 14" Monorail Tie Bar 350

S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 1170

FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 70

NOTE: Seventy four (74) total outer perimeter 3' monorail

pieces. See Page 17 for leg support details.

Bill of Materials

Part # Length Qty

A-22MONO 264 70

A-21.67MONO 260 4

A-21.25MONO 255 4

A-20.75MONO 249 4

A-20.67MONO 248 4

A-20MONO 240 4

A-19.33MONO 232 4

A-19MONO 228 4

A-18.67MONO 224 4

A-17.83MONO 214 4

A-17MONO 204 8

A-16MONO 192 4

A-15.7MONO 188 2

A-15MONO 180 4

A-14.67MONO 176 4

A-13.83MONO 166 4

A-13.42MONO 161 4

A-13.33MONO 160 4

A-13.25MONO 159 4

A-13.17MONO 158 4

A-13MONO 156 4

A-12.75MONO 153 4

A-12.67MONO 152 4

A-12.58MONO 151 4

A-12.25MONO 147 4

A-11.92MONO 143 4

A-11.83MONO 142 4

A-11.58MONO 139 4

A-11.25MONO 135 4

A-11.17MONO 134 4

A-3MONO 36 100

72' Diameter 14" Spacing

Measurement in Inches

Rail # Section 1 Section 2 Section 3 Section 4

1 161 264 264 161

2 160 264 264 160

3 159 264 264 159

4 158 264 264 158

5 156 264 264 156

6 153 264 264 153

7 151 264 264 151

8 147 264 264 147

9 143 264 264 143

10 139 264 264 139

11 134 264 264 134

12 260 264 260 0

13 255 264 255 0

14 248 264 248 0

15 240 264 240 0

16 232 264 232 0

17 224 264 224 0

18 214 264 214 0

19 204 264 204 0

20 192 264 192 0

21 180 264 180 0

22 166 264 166 0

23 152 264 152 0

24 135 264 135 0

25 249 249 0 0

26 228 228 0 0

27 204 204 0 0

28 176 176 0 0

29 142 142 0 0

30 188 0 0 0

21.95 m Diameter 35.56 cm Spacing

Measurement in Centimeters

Rail # Section 1 Section 2 Section 3 Section 4

1 408.94 670.56 670.56 408.94

2 406.4 670.56 670.56 406.4

3 403.86 670.56 670.56 403.86

4 401.32 670.56 670.56 401.32

5 396.24 670.56 670.56 396.24

6 388.62 670.56 670.56 388.62

7 383.54 670.56 670.56 383.54

8 373.38 670.56 670.56 373.38

9 363.22 670.56 670.56 363.22

10 353.06 670.56 670.56 353.06

11 340.36 670.56 670.56 340.36

12 660.4 670.56 660.4 0

13 647.7 670.56 647.7 0

14 629.92 670.56 629.92 0

15 609.6 670.56 609.6 0

16 589.28 670.56 589.28 0

17 568.96 670.56 568.96 0

18 543.56 670.56 543.56 0

19 518.16 670.56 518.16 0

20 487.68 670.56 487.68 0

21 457.2 670.56 457.2 0

22 421.64 670.56 421.64 0

23 386.08 670.56 386.08 0

24 342.9 670.56 342.9 0

25 632.46 632.46 0 0

26 579.12 579.12 0 0

27 518.16 518.16 0 0

28 447.04 447.04 0 0

29 360.68 360.68 0 0

30 477.52 0 0 0

PNEG-1832 72' Dura-Lok Plank and Support Manual 27

6. Layouts

Figure 6B 72' Diameter Bin with 14" Monorail Spacing

Page 28

6. Layouts

Part # Description Qty

FL-404-15 15" Monorail Tie Bar 350

S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 1130

FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 70

NOTE: Seventy four (74) total outer perimeter 3' monorail

pieces. See Page 17 for leg support details.

Bill of Materials

Part # Length Qty

A-22MONO 264 64

A-21.83MONO 262 4

A-21.33MONO 256 8

A-20.67MONO 248 4

A-20.08MONO 241 4

A-19.58MONO 235 4

A-19.3MONO 232 4

A-18.63MONO 223 4

A-17.66MONO 212 4

A-17.5MONO 210 4

A-16.75MONO 201 4

A-16MONO 192 2

A-15.7MONO 188 4

A-15.17MONO 182 4

A-14.58MONO 175 4

A-13.42MONO 161 4

A-13.3MONO 160 4

A-13.25MONO 159 8

A-13.1MONO 157 4

A-12.9MONO 155 4

A-12.7MONO 152 4

A-12.42MONO 149 4

A-12.17MONO 146 4

A-12.1MONO 145 4

A-11.92MONO 143 4

A-1 1 .8MONO 141 4

A-11.3MONO 136 4

A-3MONO 36 100

72' Diameter 15" Spacing

Measurement in Inches

Rail # Section 1 Section 2 Section 3 Section 4

1 161 264 264 161

2 160 264 264 160

3 159 264 264 159

4 157 264 264 157

5 155 264 264 155

6 152 264 264 152

7 149 264 264 149

8 145 264 264 145

9 141 264 264 141

10 136 264 264 136

11 262 264 262 0

12 256 264 256 0

13 248 264 248 0

14 241 264 241 0

15 232 264 232 0

16 223 264 223 0

17 212 264 212 0

18 201 264 201 0

19 188 264 188 0

20 175 264 175 0

21 159 264 159 0

22 143 264 143 0

23 256 256 0 0

24 235 235 0 0

25 210 210 0 0

26 182 182 0 0

27 146 146 0 0

28 192 0 0 0

21.95 m Diameter 38.10 cm Spacing

Measurement in Centimeters

Rail # Section 1 Section 2 Section 3 Section 4

1 408.94 670.56 670.56 408.94

2 406.4 670.56 670.56 406.4

3 403.86 670.56 670.56 403.86

4 398.78 670.56 670.56 398.78

5 393.7 670.56 670.56 393.7

6 386.08 670.56 670.56 386.08

7 378.46 670.56 670.56 378.46

8 368.3 670.56 670.56 368.3

9 358.14 670.56 670.56 358.14

10 345.44 670.56 670.56 345.44

11 665.48 670.56 665.48 0

12 650.24 670.56 650.24 0

13 629.92 670.56 629.92 0

14 612.14 670.56 612.14 0

15 589.28 670.56 589.28 0

16 566.42 670.56 566.42 0

17 538.48 670.56 538.48 0

18 510.54 670.56 510.54 0

19 477.52 670.56 477.52 0

20 444.5 670.56 444.5 0

21 403.86 670.56 403.86 0

22 363.22 670.56 363.22 0

23 650.24 650.24 0 0

24 596.9 596.9 0 0

25 533.4 533.4 0 0

26 462.28 462.28 0 0

27 370.84 370.84 0 0

28 487.68 0 0 0

72'-15" Monorail Spacing Layout

28 PNEG-1832 72' Dura-Lok Plank and Support Manual

Figure 6C 72' Diameter Bin with 15" Monorail Spacing

Page 29

72'-15" Rail Spacing Layout

NOTE: This depicts monorail spacings only. Leg spacing is dependant

on eave height. See Page 18 for leg and rail spacing chart.

Tie bar (See Page 15 for

installation detail.)

6. Layouts

Figure 6D 72' Diameter 15" Rail Spacing

PNEG-1832 72' Dura-Lok Plank and Support Manual 29

Page 30

6. Layouts

Tie bar (See Page 15 for

installation detail.)

Tie strap (See Page 16

for installation detail.)

NOTE: This depicts monorail spacings only. Leg spacing is dependant

on eave height. See Page 18 for leg and rail spacing chart.

72'-16" Rail Spacing Layout

Figure 6E 72' Diameter 16" Rail Spacing

30 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 31

72'-16" Monorail Spacing Layout

Part # Description Qty

FL-404-16 16" Monorail Tie Bar 310

FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 90

S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 1070

Bill of Materials

Part # Length Qty

A-22MONO 264 68

A-21.5MONO 258 4

A-20.83MONO 250 4

A-20.58MONO 247 4

A-20.2MONO 242 4

A-19.42MONO 233 4

A-18.92MONO 227 2

A-18.67MONO 224 4

A-18.63MONO 223 4

A-17.66MONO 212 4

A-16.6MONO 200 4

A-16.25MONO 195 4

A-15.5MONO 186 4

A-14.25MONO 171 4

A-13.42MONO 161 8

A-13.3MONO 160 4

A-13.25MONO 159 8

A-13.1MONO 157 4

A-12.9MONO 155 8

A-12.58MONO 151 4

A-12.3MONO 148 4

A-12MONO 144 2

A-11.92MONO 143 4

A-1 1 .5MONO 138 4

A-11.3MONO 136 4

A-3MONO 36 100

72' Diameter 16" Spacing

Measurement in Inches

Rail # Section 1 Section 2 Section 3 Section 4

1 161 264 264 161

2 160 264 264 160

* 3 159 264 264 159

4 159 264 264 159

5 157 264 264 157

6 155 264 264 155

7 151 264 264 151

8 148 264 264 148

9 143 264 264 143

10 138 264 264 138

11 264 264 264 0

12 258 264 258 0

13 250 264 250 0

14 242 264 242 0

15 233 264 233 0

16 223 264 223 0

17 212 264 212 0

18 200 264 200 0

19 186 264 186 0

20 171 264 171 0

21 155 264 155 0

22 136 264 136 0

23 247 247 0 0

24 224 224 0 0

25 195 195 0 0

26 161 161 0 0

27 227 0 0 0

28 144 0 0 0

21.95 m Diameter 40.64 cm Spacing

Measurement in Centimeters

Rail # Section 1 Section 2 Section 3 Section 4

1 408.94 670.56 670.56 408.94

2 406.4 670.56 670.56 406.4

* 3 403.86 670.56 670.56 403.86

4 403.86 670.56 670.56 403.86

5 398.78 670.56 670.56 398.78

6 393.7 670.56 670.56 393.7

7 383.54 670.56 670.56 383.54

8 375.92 670.56 670.56 375.92

9 363.22 670.56 670.56 363.22

10 350.52 670.56 670.56 350.52

11 670.56 670.56 670.56 0

12 655.32 670.56 655.32 0

13 635 670.56 635 0

14 614.68 670.56 614.68 0

15 591.82 670.56 591.82 0

16 566.42 670.56 566.42 0

17 538.48 670.56 538.48 0

18 508 670.56 508 0

19 472.44 670.56 472.44 0

20 434.34 670.56 434.34 0

21 393.7 670.56 393.7 0

22 345.44 670.56 345.44 0

23 627.38 627.38 0 0

24 568.96 568.96 0 0

25 495.3 495.3 0 0

26 408.94 408.94 0 0

27 576.58 0 0 0

28 365.76 0 0 0

NOTE: Seventy four (74) total outer perimeter 3' monorail

pieces. See Page 17 for leg support details.

* NOTE: This special monorail run is used

to support the floor plank at the split.

6. Layouts

PNEG-1832 72' Dura-Lok Plank and Support Manual 31

Figure 6F 72' Diameter Bin with 16" Monorail Spacing

Page 32

6. Layouts

Part # Description Qty

FL-404-17 17" Monorail Tie Bar 290

FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 90

S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 1020

Bill of Materials

Part # Length Qty

A-22MONO 264 62

A-21.67MONO 260 4

A-21.08MONO 253 4

A-20.3MONO 244 4

A-20.08MONO 241 4

A-19.58MONO 235 4

A-18.67MONO 224 4

A-17.83MONO 214 4

A-17.75MONO 213 4

A-16.6MONO 200 4

A-15.7MONO 188 2

A-15.5MONO 186 4

A-15.17MONO 182 4

A-14.17MONO 170 4

A-13.42MONO 161 4

A-13.3MONO 160 4

A-13.25MONO 159 4

A-13.2MONO 158 4

A-13MONO 156 4

A-12.83MONO 154 4

A-12.7MONO 152 4

A-12.5MONO 150 4

A-12.17MONO 146 4

A-1 1 .8MONO 141 4

A-11.67MONO 140 4

A-11.25MONO 135 4

A-11MONO 132 4

A-3MONO 36 100

72' Diameter 17" Spacing

Measurement in Inches

Rail # Section 1 Section 2 Section 3 Section 4

1 161 264 264 161

2 160 264 264 160

* 3 159 264 264 159

4 158 264 264 158

5 156 264 264 156

6 154 264 264 154

7 150 264 264 150

8 146 264 264 146

9 141 264 264 141

10 135 264 264 135

11 260 264 260 0

12 253 264 253 0

13 244 264 244 0

14 235 264 235 0

15 224 264 224 0

16 213 264 213 0

17 200 264 200 0

18 186 264 186 0

19 170 264 170 0

20 152 264 152 0

21 132 264 132 0

22 241 241 0 0

23 214 214 0 0

24 182 182 0 0

25 140 140 0 0

26 188 0 0 0

21.95 m Diameter 43.18 cm Spacing

Measurement in Centimeters

Rail # Section 1 Section 2 Section 3 Section 4

1 408.94 670.56 670.56 408.94

2 406.4 670.56 670.56 406.4

* 3 403.86 670.56 670.56 403.86

4 401.32 670.56 670.56 401.32

5 396.24 670.56 670.56 396.24

6 391.16 670.56 670.56 391.16

7 381 670.56 670.56 381

8 370.84 670.56 670.56 370.84

9 358.14 670.56 670.56 358.14

10 342.9 670.56 670.56 342.9

11 660.4 670.56 660.4 0

12 642.62 670.56 642.62 0

13 619.76 670.56 619.76 0

14 596.9 670.56 596.9 0

15 568.96 670.56 568.96 0

16 541.02 670.56 541.02 0

17 508 670.56 508 0

18 472.44 670.56 472.44 0

19 431.8 670.56 431.8 0

20 386.08 670.56 386.08 0

21 335.28 670.56 335.28 0

22 612.14 612.14 0 0

23 543.56 543.56 0 0

24 462.28 462.28 0 0

25 355.6 355.6 0 0

26 477.52 0 0 0

NOTE: Seventy four (74) total outer perimeter 3' monorail

pieces. See Page 17 for leg support details.

* NOTE: This special monorail run is used

to support the floor plank at the split.

72'-17" Monorail Spacing Layout

32 PNEG-1832 72' Dura-Lok Plank and Support Manual

Figure 6G 72' Diameter Bin with 17" Monorail Spacing

Page 33

72'-17" Rail Spacing Layout

Tie bar (See Page 15 for

installation detail.)

Tie strap (See Page 16

for installation detail.)

NOTE: This depicts monorail spacings only. Leg spacing is dependant

on eave height. See Page 18 for leg and rail spacing chart.

6. Layouts

Figure 6H 72' Diameter 17" Rail Spacing

PNEG-1832 72' Dura-Lok Plank and Support Manual 33

Page 34

6. Layouts

Tie bar (See Page 15 for

installation detail.)

Tie strap (See Page 16

for installation detail.)

NOTE: This depicts monorail spacings only. Leg spacing is dependant

on eave height. See Page 18 for leg and rail spacing chart.

72'-18" Rail Spacing Layout

Figure 6I 72' Diameter 18" Rail Spacing

34 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 35

72'-18" Monorail Spacing Layout

Part # Description Qty

FL-404-18 18" Monorail Tie Bar 270

FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 90

S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 950

Bill of Materials

Part # Length Qty

A-22MONO 264 60

A-21.83MONO 262 4

A-21.33MONO 256 4

A-20.83MONO 250 2

A-20.67MONO 248 4

A-19.83MONO 238 4

A-19.75MONO 237 4

A-18.92MONO 227 4

A-17.9MONO 215 4

A-17.3MONO 208 4

A-16.8MONO 202 4

A-15.58MONO 187 4

A-14.4MONO 172 4

A-14.17MONO 170 4

A-13.42MONO 161 6

A-13.3MONO 160 4

A-13.25MONO 159 4

A-13.2MONO 158 4

A-13MONO 156 4

A-12.8MONO 153 4

A-12.7MONO 152 4

A-12.42MONO 149 4

A-12MONO 144 4

A-1 1 .5MONO 138 4

A-3MONO 36 100

72' Diameter 18" Spacing

Measurement in Inches

Rail # Section 1 Section 2 Section 3 Section 4

1 161 264 264 161

2 160 264 264 160

* 3 159 264 264 159

4 158 264 264 158

5 156 264 264 156

6 153 264 264 153

7 149 264 264 149

8 144 264 264 144

9 138 264 264 138

10 264 264 264 0

11 256 264 256 0

12 248 264 248 0

13 238 264 238 0

14 227 264 227 0

15 215 264 215 0

16 202 264 202 0

17 187 264 187 0

18 170 264 170 0

19 152 264 152 0

20 262 262 0 0

21 237 237 0 0

22 208 208 0 0

23 172 172 0 0

24250000

25 161 0 0 0

21.95 m Diameter 45.72 cm Spacing

Measurement in Centimeters

Rail # Section 1 Section 2 Section 3 Section 4

1 408.94 670.56 670.56 408.94

2 406.4 670.56 670.56 406.4

* 3 403.86 670.56 670.56 403.86

4 401.32 670.56 670.56 401.32

5 396.24 670.56 670.56 396.24

6 388.62 670.56 670.56 388.62

7 378.46 670.56 670.56 378.46

8 365.76 670.56 670.56 365.76

9 350.52 670.56 670.56 350.52

10 670.56 670.56 670.56 0

11 650.24 670.56 650.24 0

12 629.92 670.56 629.92 0

13 604.52 670.56 604.52 0

14 576.58 670.56 576.58 0

15 546.1 670.56 546.1 0

16 513.08 670.56 513.08 0

17 474.98 670.56 474.98 0

18 431.8 670.56 431.8 0

19 386.08 670.56 386.08 0

20 665.48 665.48 0 0

21 601.98 601.98 0 0

22 528.32 528.32 0 0

23 436.88 436.88 0 0

24 635 0 0 0

25 408.94 0 0 0

NOTE: Seventy four (74) total outer perimeter 3' monorail

pieces. See Page 17 for leg support details.

* NOTE: This special monorail run is used

to support the floor plank at the split.

6. Layouts

PNEG-1832 72' Dura-Lok Plank and Support Manual 35

Figure 6J 72' Diameter Bin with 18" Monorail Spacing

Page 36

6. Layouts

Part # Description Qty

FL-404-20 20" Monorail Tie Bar 250

FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 90

S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 870

Bill of Materials

Part # Length Qty

A-22MONO 264 56

A-21.42MONO 257 4

A-20.58MONO 247 4

A-19.83MONO 238 4

A-19.67MONO 236 4

A-18.67MONO 224 6

A-17.5MONO 210 4

A-17.2MONO 206 4

A-16.25MONO 195 4

A-14.75MONO 177 4

A-13.75MONO 165 4

A-13.42MONO 161 4

A-13.3MONO 160 4

A-13.25MONO 159 4

A-13.2MONO 158 4

A-13.1MONO 157 4

A-12.9MONO 155 4

A-12.58MONO 151 4

A-12.17MONO 146 4

A-1 1 .7MONO 140 4

A-11.08MONO 133 4

A-3MONO 36 100

72' Diameter 20" Spacing

Measurement in Inches

Rail # Section 1 Section 2 Section 3 Section 4

1 161 264 264 161

* 2 160 264 264 160

3 159 264 264 159

4 158 264 264 158

5 155 264 264 155

6 151 264 264 151

7 146 264 264 146

8 140 264 264 140

9 264 264 264 0

10 257 264 257 0

11 247 264 247 0

12 236 264 236 0

13 224 264 224 0

14 210 264 210 0

15 195 264 195 0

16 177 264 177 0

17 157 264 157 0

18 133 264 133 0

19 238 238 0 0

20 206 206 0 0

21 165 165 0 0

22224000

21.95 m Diameter 50.80 cm Spacing

Measurement in Centimeters

Rail # Section 1 Section 2 Section 3 Section 4

1 408.94 670.56 670.56 408.94

* 2 406.4 67 0.56 670.56 406.4

3 403.86 670.56 670.56 403.86

4 401.32 670.56 670.56 401.32

5 393.7 670.56 670.56 393.7

6 383.54 670.56 670.56 383.54

7 370.84 670.56 670.56 370.84

8 355.6 670.56 670.56 355.6

9 670.56 670.56 670.56 0

10 652.78 670.56 652.78 0

11 627.38 670.56 627.38 0

12 599.44 670.56 599.44 0

13 568.96 670.56 568.96 0

14 533.4 670.56 533.4 0

15 495.3 670.56 495.3 0

16 449.58 670.56 449.58 0

17 398.78 670.56 398.78 0

18 337.82 670.56 337.82 0

19 604.52 604.52 0 0

20 523.24 523.24 0 0

21 419.1 419.1 0 0

22 568.96 0 0 0

NOTE: Seventy four (74) total outer perimeter 3' monorail

pieces. See Page 17 for leg support details.

* NOTE: This special monorail run is used

to support the floor plank at the split.

72'-20" Monorail Spacing Layout

36 PNEG-1832 72' Dura-Lok Plank and Support Manual

Figure 6K 72' Diameter Bin with 20" Monorail Spacing

Page 37

72'-20" Rail Spacing Layout

Tie bar (See Page 15 for

installation detail.)

Tie strap (See Page 16

for installation detail.)

NOTE: This depicts monorail spacings only. Leg spacing is dependant

on eave height. See Page 18 for leg and rail spacing chart.

6. Layouts

Figure 6L 72' Diameter 20" Rail Spacing

PNEG-1832 72' Dura-Lok Plank and Support Manual 37

Page 38

6. Layouts

Tie bar (See Page 15 for

installation detail.)

Tie strap (See Page 16

for installation detail.)

NOTE: This depicts monorail spacings only. Leg spacing is dependant

on eave height. See Page 18 for leg and rail spacing chart.

72'-22" Rail Spacing Layout

Figure 6M 72' Diameter 22" Rail Spacing

38 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 39

72'-22" Monorail Spacing Layout

Part # Description Qty

FL-404-22 22" Monorail Tie Bar 220

FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 90

S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 810

Bill of Materials

Part # Length Qty

A-22MONO 264 48

A-21.58MONO 259 4

A-21MONO 252 4

A-20.75MONO 249 4

A-19.75MONO 237 4

A-19.5MONO 234 2

A-18.67MONO 224 4

A-18.2MONO 218 4

A-17.3MONO 208 4

A-15.83MONO 190 4

A-14.67MONO 176 4

A-14.17MONO 170 4

A-13.42MONO 161 4

A-13.3MONO 160 4

A-13.25MONO 159 4

A-13.1MONO 157 4

A-12.8MONO 153 4

A-12.42MONO 149 4

A-12.25MONO 147 4

A-11.92MONO 143 4

A-11.3MONO 136 4

A-3MONO 36 100

72' Diameter 22" Spacing

Measurement in Inches

Rail # Section 1 Section 2 Section 3 Section 4

1 161 264 264 161

* 2 160 264 264 160

3 159 264 264 159

4 157 264 264 157

5 153 264 264 153

6 149 264 264 149

7 143 264 264 143

8 136 264 264 136

9 259 264 259 0

10 249 264 249 0

11 237 264 237 0

12 224 264 224 0

13 208 264 208 0

14 190 264 190 0

15 170 264 170 0

16 147 264 147 0

17 252 252 0 0

18 218 218 0 0

19 176 176 0 0

20 234 0 0 0

21.95 m Diameter 55.88 cm Spacing

Measurement in Centimeters

Rail # Section 1 Section 2 Section 3 Section 4

1 408.94 670.56 670.56 408.94

* 2 406.4 67 0.56 670.56 406.4

3 403.86 670.56 670.56 403.86

4 398.78 670.56 670.56 398.78

5 388.62 670.56 670.56 388.62

6 378.46 670.56 670.56 378.46

7 363.22 670.56 670.56 363.22

8 345.44 670.56 670.56 345.44

9 657.86 670.56 657.86 657.86

10 632.46 670.56 632.46 0

11 601.98 670.56 601.98 0

12 568.96 670.56 568.96 0

13 528.32 670.56 528.32 0

14 482.6 670.56 482.6 0

15 431.8 670.56 431.8 0

16 373.38 670.56 373.38 0

17 640.08 640.08 0 0

18 553.72 553.72 0 0

19 447.04 447.04 0 0

20 594.36 0 0 0

NOTE: Seventy four (74) total outer perimeter 3' monorail

pieces. See Page 17 for leg support details.

* NOTE: This special monorail run is used

to support the floor plank at the split.

6. Layouts

PNEG-1832 72' Dura-Lok Plank and Support Manual 39

Figure 6N 72' Diameter Bin with 22" Monorail Spacing

Page 40

6. Layouts

Part # Description Qty

FL-404-26 26" Monorail Tie Bar 180

FL-7411 Monorail Strap 1-1/2" x 30" x 0.061" 90

S-280 #10-16 x 5/8" Zinc Self-Drilling Screw 670

72' Diameter 26" Spacing

Measurement in Inches

Rail # Section 1 Section 2 Section 3 Section 4

1 160 264 264 160

* 2 160 264 264 160

3 159 264 264 159

4 156 264 264 156

5 150 264 264 150

6 144 264 264 144

7 135 264 264 135

8257 264 257 0

9 245 264 245 0

10 230 264 230 0

11 212 264 212 0

12 192 264 192 0

13 168 264 168 0

14 140 264 140 0

15 237 237 0 0

16 193 193 0 0

17 261 0 0 0

21.95 m Diameter 66.04 cm Spacing

Measurement in Centimeters

Rail # Section 1 Section 2 Section 3 Section 4

1 406.4 670.56 670.56 406.4

* 2 406.4 67 0.56 670.56 406.4

3 403.86 670.56 670.56 403.86

4 396.24 670.56 670.56 396.24

5 381 670.56 670.56 381

6 365.76 670.56 670.56 365.76

7 342.9 670.56 670.56 342.9

8 652.78 670.56 652.78 0

9 622.3 670.56 622.3 0

10 584.2 670.56 584.2 0

11 538.48 670.56 538.48 0

12 487.68 670.56 487.68 0

13 426.72 670.56 426.72 0

14 355.6 670.56 355.6 0

15 601.98 601.98 0 0

16 490.22 490.22 0 0

17 662.94 0 0 0

NOTE: Seventy four (74) total outer perimeter 3' monorail

pieces. See Page 17 for leg support details.

* NOTE: This special monorail run is used

to support the floor plank at the split.

Bill of Materials

Part # Length Qty

A-22MONO 264 42

A-21.75MONO 261 2

A-21.42MONO 257 4

A-20.42MONO 245 4

A-19.75MONO 237 4

A-19.17MONO 230 4

A-17.66MONO 212 4

A-16.08MONO 193 4

A-16MONO 192 4

A-14MONO 168 4

A-13.3MONO 160 8

A-13.25MONO 159 4

A-13MONO 156 4

A-12.5MONO 150 4

A-12MONO 144 4

A-1 1 .7MONO 140 4

A-11.25MONO 135 4

A-3MONO 36 100

72'-26" Monorail Spacing Layout

40 PNEG-1832 72' Dura-Lok Plank and Support Manual

Figure 6O 72' Diameter Bin with 26" Monorail Spacing

Page 41

72'-26" Rail Spacing Layout

Tie bar (See Page 15 for

installation detail.)

Tie strap (See Page 16

for installation detail.)

NOTE: This depicts monorail spacings only. Leg spacing is dependant

on eave height. See Page 18 for leg and rail spacing chart.

6. Layouts

Figure 6P 72' Diameter 26" Rail Spacing

PNEG-1832 72' Dura-Lok Plank and Support Manual 41

Page 42

6. Layouts

NOTE: 72' Floor is split up into two (2) bundles, two (2) of which are identical to each other. The split of the

floor is staggered from one 7" plank to the next. The bundle is arranged, so that the AB1 planks are installed

together and AB2 planks are installed together.

72' Floor Bundle Layout

35'-6"

Critical starting

dimension for

first plank

Bundle AB1

Bundle AB2

Bundle AB2

Bundle AB1

Figure 6Q 72' Plank Layout Bundles

42 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 43

72' Plank Layout

6. Layouts

Figure 6R Plank Layout for 72' Diameter Bin

PNEG-1832 72' Dura-Lok Plank and Support Manual 43

Page 44

6. Layouts

72' Plank Layout for Manual

Plank #

1 8'-0" 96 243.84

2A 4' - 6-1/2" 54-1/2 138.43 2B 10' - 6-1/2" 126-1/2 321.31

3A 12' - 10-1/2" 154-1/2 392.43 3B 6' - 10-1/2" 82-1/2 209.55

4A 8'-8" 104 264.16

5A 16'-2" 194 492.76 5B 10'-2" 122 309.88

6A 11' - 6-1/2" 138-1/2 351.79

7A 18' - 9-1/2" 225-1/2 572.77 7B 12' - 9-1/2" 153-1/2 389.89

8A 13'-11" 167 424.18

9A 20' - 11-1/2" 251-1/2 638.81 9B 14' - 11-1/2" 179-1/2 455.93

10A 15'-11" 191 485.14

11A 22'-10" 274 695.96 11B 16'-10" 202 513.08

12A 17'-8" 212 538.48

13A 24' - 4-1/2" 292-1/2 742.95 13B 18' - 4-1/2" 220-1/2 560.07

14A 19' - 1-1/2" 229-1/2 582.93

15A 25'-10" 310 787.4 15B 19'-10" 238 604.52

16A 20' - 6-1/2" 246-1/2 626.11

17A 27'-2" 326 828.04 17B 21'-2" 254 645.16

18A 21' - 9-1/2" 261-1/2 664.21

19A 28' - 4-1/2" 340-1/2 864.87 19B 22' - 4-1/2" 270-1/2 687.07

20A 22'-11" 275 698.5

21A 29' - 5-1/2" 353-1/2 897.89 21B 23' - 5-1/2" 281-1/2 715.01

22A 23' - 11-1/2" 287-1/2 730.25

23A 30' - 5-1/2" 365-1/2 928.37 23B 24' - 5-1/2" 293-1/2 745.49

24A 24'-11" 299 759.46

25A 31' - 4-1/2" 376-1/2 956.31 25B 25' - 4-1/2" 304-1/2 773.43

26A 25'-10" 310 787.4

27A 32'-3" 387 982.98 27B 26'-3" 315 800.1

28A 26' - 7-1/2" 319-1/2 811.53

29A 33'-0" 396 1005.84 29B 27'-0" 324 822.96

30A 27' - 4-1/2" 328-1/2 834.39

31A 33'-9" 405 1028.7 31B 27'-9" 333 845.82

32A 28'-1/2" 336-1/2 854.71

33A 34' - 4-1/2" 412-1/2 1047.75 33B 28' - 4-1/2" 340-1/2 864.87

34A 28'-8" 344 873.76

35A 34' - 11-1/2" 419-1/2 1065.53 35B 28' - 11-1/2" 347-1/2 882.65

36A 29'-3" 351 891.54

37A 35'-6" 426 1082.04 37B 29'-6" 354 899.16

38A 29'-9" 357 906.78

39A 36'-0" 432 1097.28 39B 30'-0" 360 914.4

40A 30'-3" 363 922.02

41A 36' - 5-1/2" 437-1/2 1111.25 41B 30' - 5-1/2" 365-1/2 928.37

42A 30'-8" 368 934.72

43A 36' - 10-1/2" 442-1/2 1123.95 43B 30' - 10-1/2" 370-1/2 941.07

44A 31'-1/2" 372-1/2 946.15

45A 37'-3" 447 1135.38 45B 31'-3" 375 952.5

46A 31' - 4-1/2" 376-1/2 956.31

47A 37' - 6-1/2" 450-1/2 1144.27 47B 31' - 6-1/2" 378-1/2 961.39

48A 31'-8" 380 965.2

49A 37'-10" 454 1153.16 49B 31'-10" 382 970.28

50A 31' - 11-1/2" 383-1/2 974.09

51A 38'-1/2" 456-1/2 1159.51 51B 32'-1/2" 384-1/2 976.63

52A 32'-2" 386 980.44

53A 38'-3" 459 1165.86 53B 32'-3" 387 982.98

54A 32'-4" 388 985.52

55A 38'-5" 461 1170.94 55B 32'-5" 389 988.06

56A 32' - 5-1/2" 389-1/2 989.33

57A 38'-6" 462 1173.48 57B 32'-6" 390 990.6

58A 32' - 6-1/2" 390-1/2 991.87

59A 38'-7" 463 1176.02 59B 32'-7" 391 993.14

60A 32'-7" 391 993.14

61A 38'-8" 464 1178.56 61B 32'-8" 392 995.68

Length

Plank A

In Inch I n Met ric Plank #

4B 14' - 8-1/2" 176-1/2 448.31

6B 17' - 6-1/2" 210-1/2 534.67

8B 19'-11" 239 607.06

10B 21'-11" 263 668.02

12B 23'-8" 284 721.36

14B 25' - 1-1/2" 301-1/2 765.81

16B 26' - 6-1/2" 318-1/2 808.99

18B 27' - 9-1/2" 333-1/2 847.09

20B 28'-11" 347 881.38

22B 29' - 11-1/2" 359-1/2 913.13

24B 30'-11" 371 942.34

26B 31'-10" 382 970.28

28B 32' - 7-1/2" 391-1/2 994.41

30B 33' - 4-1/2" 400-1/2 1017.27

32B 34'-1/2" 408-1/2 1037.59

34B 34'-8" 416 1056.64

36B 35'-3" 423 1074.42

38B 35'-9" 429 1089.66

40B 36'-3" 435 1104.9

42B 36'-8" 440 1117.6

44B 37'-1/2" 444-1/2 1129.03

46B 37' - 4-1/2" 448-1/2 1139. 19

48B 37'-8" 452 1148.08

50B 37' - 11-1/2" 455-1/2 1156.97

52B 38'-2" 458 1163.32

54B 38'-4" 460 1168.4

56B 38' - 5-1/2" 461-1/2 1172. 21

58B 38' - 6-1/2" 462-1/2 1174. 75

60B 38'-7" 463 1176.02

Length

Plank B

In Inch I n Met ri c

44 PNEG-1832 72' Dura-Lok Plank and Support Manual

Page 45

7. Warranty

9101239_1_CR_rev7.DOC (revised July 2009)

GSI Group, LLC Limited Warranty

The GSI Group, LLC (“GSI”) warrants products which it manufactures to be free of defects in materials and workmanship

under normal usage and conditions for a period of 12 months after sale to the original end-user or if a foreign sale,

14 months from arrival at port of discharge, whichever is earlier. The end-user’s sole remedy (and GSI’s only obligation)

is to repair or replace, at GSI’s option and expense, products that in GSI’s judgment, contain a material defect in materials

or workmanship. Expenses incurred by or on behalf of the end-user without prior written authorization from the GSI

Warranty Group shall be the sole responsibility of the end-user.

Warranty Extensions:

The Limited Warranty period is extended for the following products:

Product Warranty Period

Performer Series Direct Drive Fan Motor 3 Years

AP Fans and Flooring

Cumberland

Feeding/Watering

Systems

Grain Systems Grain Bin Structural Design 5 Years

Grain Systems

Farm Fans

Zimmerman

All Fiberglass Housings Lifetime

All Fiberglass Propellers Lifetime

Feeder System Pan Assemblies 5 Years **

Feed Tubes (1-3/4" and 2.00") 10 Years *

Centerless Augers 10 Years *

Watering Nipples 10 Years *

Portable and Tower Dryers 2 Years

Portable and Tower Dryer Frames and

Internal Infrastructure †

5 Years

* Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 25%

5 to 7 years - end-user pays 50%

7 to 10 years - end-user pays 75%

** Warranty prorated from list price:

0 to 3 years - no cost to end-user

3 to 5 years - end-user pays 50%

† Motors, burner components

and moving parts not included.

Portable dryer screens included.

Tower dryer screens not included.

GSI further warrants that the portable and tower dryer frame and basket, excluding all auger and auger drive components,

shall be free from defects in materials for a period of time beginning on the twelfth (12

and continuing until the sixtieth (60

th

) month from the date of purchase (extended warranty period). During the extended

th

) month from the date of purchase

warranty period, GSI will replace the frame or basket components that prove to be defective under normal conditions

of use without charge, excluding the labor, transportation, and/or shipping costs incurred in the performance of this

extended warranty.

Conditions and Limitations:

THERE ARE NO WARRANTIES THAT EXTEND BEYOND THE LIMITED WARRANTY DESCRIPTION SET FORTH

ABOVE. SPECIFICALLY, GSI MAKES NO FURTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED,

INCLUDING, WITHOUT LIMITATION, WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE OR USE IN CONNECTION WITH: (I) PRODUCT MANUFACTURED OR SOLD BY GSI OR (II) ANY ADVICE,

INSTRUCTION, RECOMMENDATION OR SUGGESTION PROVIDED BY AN AGENT, REPRESENTATIVE OR

EMPLOYEE OF GSI REGARDING OR RELATED TO THE CONFIGURATION, INSTALLATION, LAYOUT, SUITABILITY

FOR A PARTICULAR PURPOSE, OR DESIGN OF SUCH PRODUCTS.

GSI shall not be liable for any direct, indirect, incidental or consequential damages, including, without limitation, loss of

anticipated profits or benefits. The sole and exclusive remedy is set forth in the Limited Warranty, which shall not exceed

the amount paid for the product purchased. This warranty is not transferable and applies only to the original end-user. GSI

shall have no obligation or responsibility for any representations or warranties made by or on behalf of any dealer, agent

or distributor.

GSI assumes no responsibility for claims resulting from construction defects or unauthorized modifications to products

which it manufactured. Modifications to products not specifically delineated in the manual accompanying the equipment at

initial sale will void the Limited Warranty.

This Limited Warranty shall not extend to products or parts which have been damaged by negligent use, misuse, alteration,

accident or which have been improperly/inadequately maintained. This Limited Warranty extends solely to products

manufactured by GSI.

Prior to installation, the end-user has the responsibility to comply with federal, state and local codes which apply to the

location and installation of products manufactured or sold by GSI.

PNEG-1832 72' Dura-Lok Plank and Support Manual 45

Page 46

This equipment shall be installed in accordance with

the current installation codes and applicable

regulations, which should be carefully followed in

all cases. Authorities having jurisdiction should be

consulted before installations are made.

Copyright © 2011 by GSI Group

Printed in the USA

GSI Group

1004 E. Illinois St.

Assumption, IL 62510-0020

Phone: 1-217-226-4421

Fax: 1-217-226-4420

www.gsiag.com

CN-205168

Loading...

Loading...