GSI GS832472C-250, GS832472C-225I, GS832472C-225, GS832472C-200I, GS832472C-200 Datasheet

...

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

119- and 209-Pin BGA

2M x 18, 1M x 36, 512K x 72

Commercial Temp

Industrial Temp

36Mb S/DCD Sync Burst SRAMs

Features

• FT pin for user-configurable flow through or pipeline operation

• Single/Dual Cycle Deselect selectable (x36 and x72)

• Dual Cycle Deselect only (x18)

• IEEE 1149.1 JTAG-compatible Boundary Scan

• ZQ mode pin for user-selectable high/low output drive

• 2.5 V or 3.3 V +10%/–5% core power supply

• 2.5 V or 3.3 V I/O supply

• LBO pin for Linear or Interleaved Burst mode

• Internal input resistors on mode pins allow floating mode pins

• Default to SCD x36/x72 Interleaved Pipeline mode

• Byte Write (BW) and/or Global Write (GW) operation

• Internal self-timed write cycle

• Automatic power-down for portable applications

• JEDEC-standard 119- and 209-bump BGA package

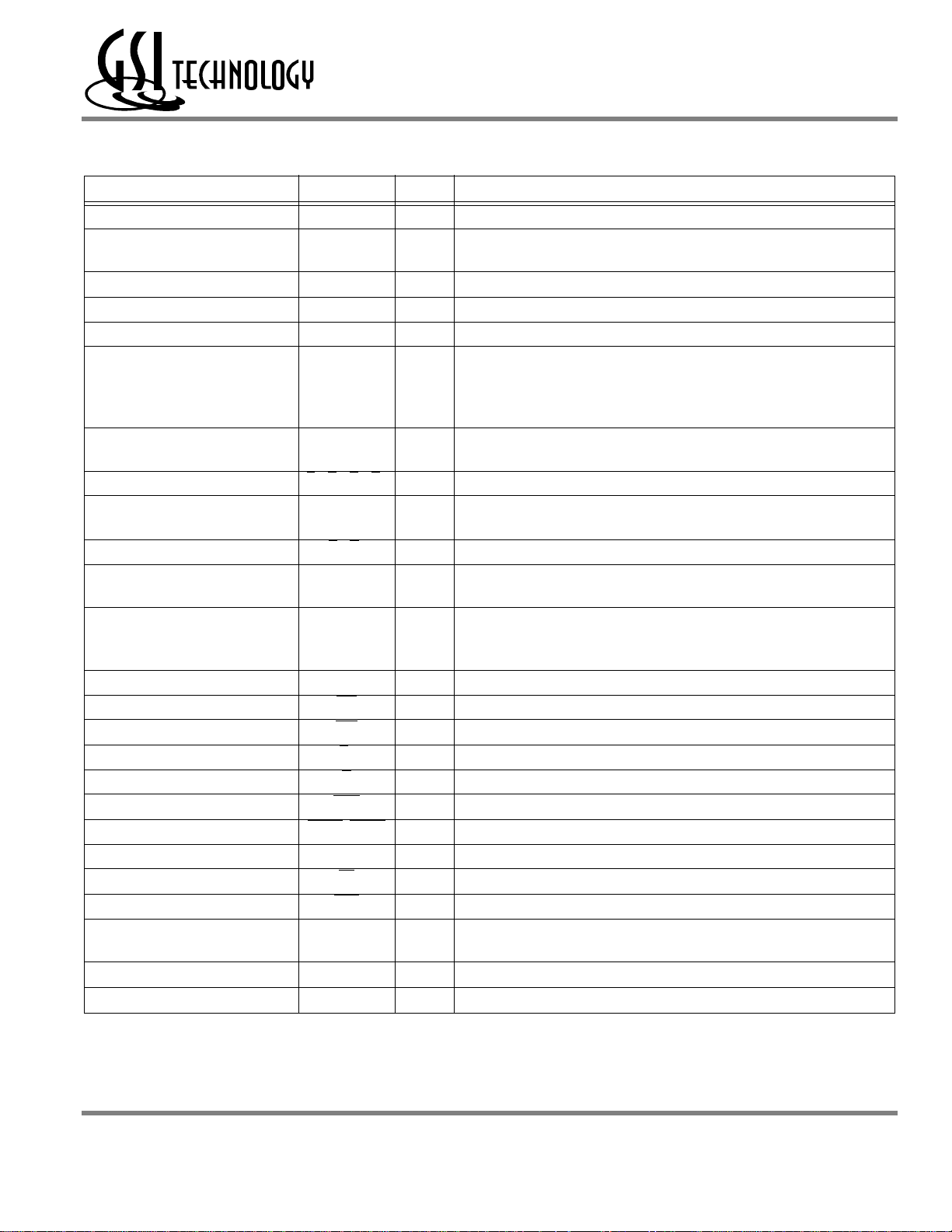

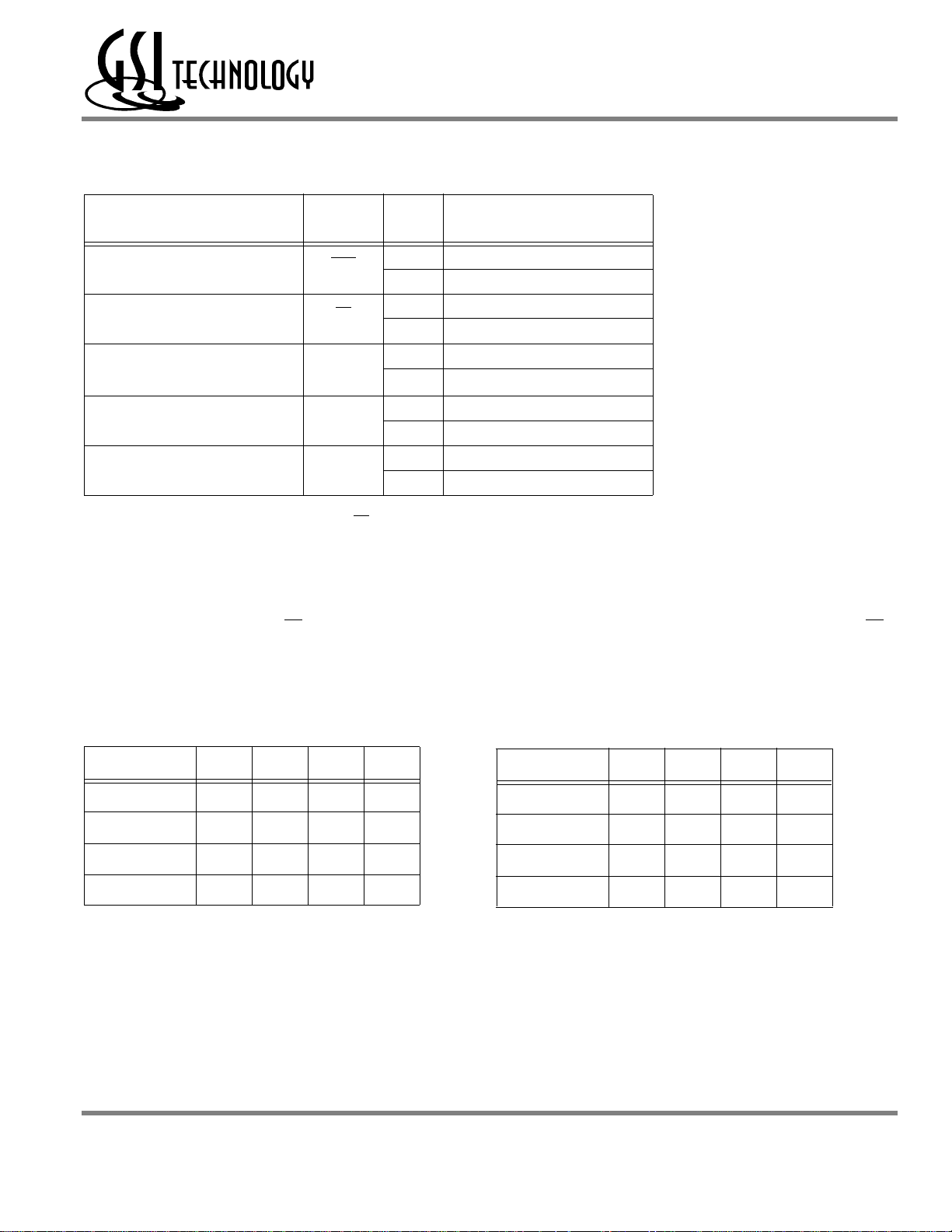

-250 -225 -200 -166 -150 -133 Unit

Pipeline

3-1-1-1

3.3 V

2.5 V

Flow

Through

2-1-1-1

3.3 V

2.5 V

t

KQ

tCycle

Curr (x18)

Curr (x36)

Curr (x72)

Curr (x18)

Curr (x36)

Curr (x72)

t

KQ

tCycle

Curr (x18)

Curr (x36)

Curr (x72)

Curr (x18)

Curr (x36)

Curr (x72)

2.3

4.0

365

560

660

360

550

640

6.0

7.0

235

300

350

235

300

340

2.5

4.4

335

510

600

330

500

590

6.5

7.5

230

300

350

230

300

340

3.0

3.5

5.0

6.0

305

265

460

400

540

460

305

260

460

390

530

450

7.5

8.51010101115ns

8.5

210

200

270

270

300

300

210

200

270

270

300

300

3.8

6.6

245

370

430

240

360

420

195

270

300

195

270

300

4.0

7.5nsns

215

mA

330

mA

380

mA

215

mA

330

mA

370

mA

150

mA

200

mA

220

mA

145

mA

190

mA

220

mA

ns

Functional Description

Applications

The GS832418/36/72 is a 37,748,736-bit high performance 2-die

synchronous SRAM module with a 2-bit burst address counter.

Although of a type originally developed for Level 2 Cache

applications supporting high performance CPUs, the device now

finds application in synchronous SRAM applications, ranging

from DSP main store to networking chip set support.

Controls

Addresses, data I/Os, chip enable (E1), address burst control

inputs (ADSP, ADSC, ADV), and write control inputs (Bx, BW,

GW) are synchronous and are controlled by a positive-edgetriggered clock input (CK). Output enable (G) and power down

control (ZZ) are asynchronous inputs. Burst cycles can be initiated

250 MHz–133MHz

2.5 V or 3.3 V V

DD

2.5 V or 3.3 V I/O

with either ADSP or ADSC inputs. In Burst mode, subsequent

burst addresses are generated internally and are controlled by

ADV. The burst address counter may be configured to count in

either linear or interleave order with the Linear Burst Order (LBO)

input. The Burst function need not be used. New addresses can be

loaded on every cycle with no degradation of chip performance.

Flow Through/Pipeline Reads

The function of the Data Output register can be controlled by the

user via the FT mode . Holding the FT mode pin low places the

RAM in Flow Through mode, causing output data to bypass the

Data Output Register. Holding FT high places the RAM in

Pipeline mode, activating the rising-edge-triggered Data Output

Register.

SCD and DCD Pipelined Reads

The GS832436(B/C) and the GS832472(C) are SCD (Single

Cycle Deselect) and DCD (Dual Cycle Deselect) pipelined

synchronous SRAMs. The GS832418(B/C) is a DCD-only

SRAM. DCD SRAMs pipeline disable commands to the same

degree as read commands. SCD SRAMs pipeline deselect

commands one stage less than read commands. SCD RAMs begin

turning off their outputs immediately after the deselect command

has been captured in the input registers. DCD RAMs hold the

deselect command for one full cycle and then begin turning off

their outputs just after the second rising edge of clock. The user

may configure the x36 or x72 versions of this SRAM for either

mode of operation using the SCD mode input.

Byte Write and Global Write

Byte write operation is performed by using Byte Write enable

(BW) input combined with one or more individual byte write

signals (Bx). In addition, Global Write (GW) is available for

writing all bytes at one time, regardless of the Byte Write control

inputs.

FLXDrive™

The ZQ pin allows selection between high drive strength (ZQ low)

for multi-drop bus applications and normal drive strength (ZQ

floating or high) point-to-point applications. See the Output Driver

Characteristics chart for details.

Sleep Mode

Low power (Sleep mode) is attained through the assertion (High)

of the ZZ signal, or by stopping the clock (CK). Memory data is

retained during Sleep mode.

Core and Interface Voltages

The GS832418/36/72 operates on a 2.5 V or 3.3 V power supply.

All input are 3.3 V and 2.5 V compatible. Separate output power

(V

) pins are used to decouple output noise from the internal

DDQ

circuits and are 3.3 V and 2.5 V compatible.

Rev: 1.00 10/2001 1/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

ByteSafe is a Trademark of Giga Semiconductor, Inc. (GSI Technology).

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

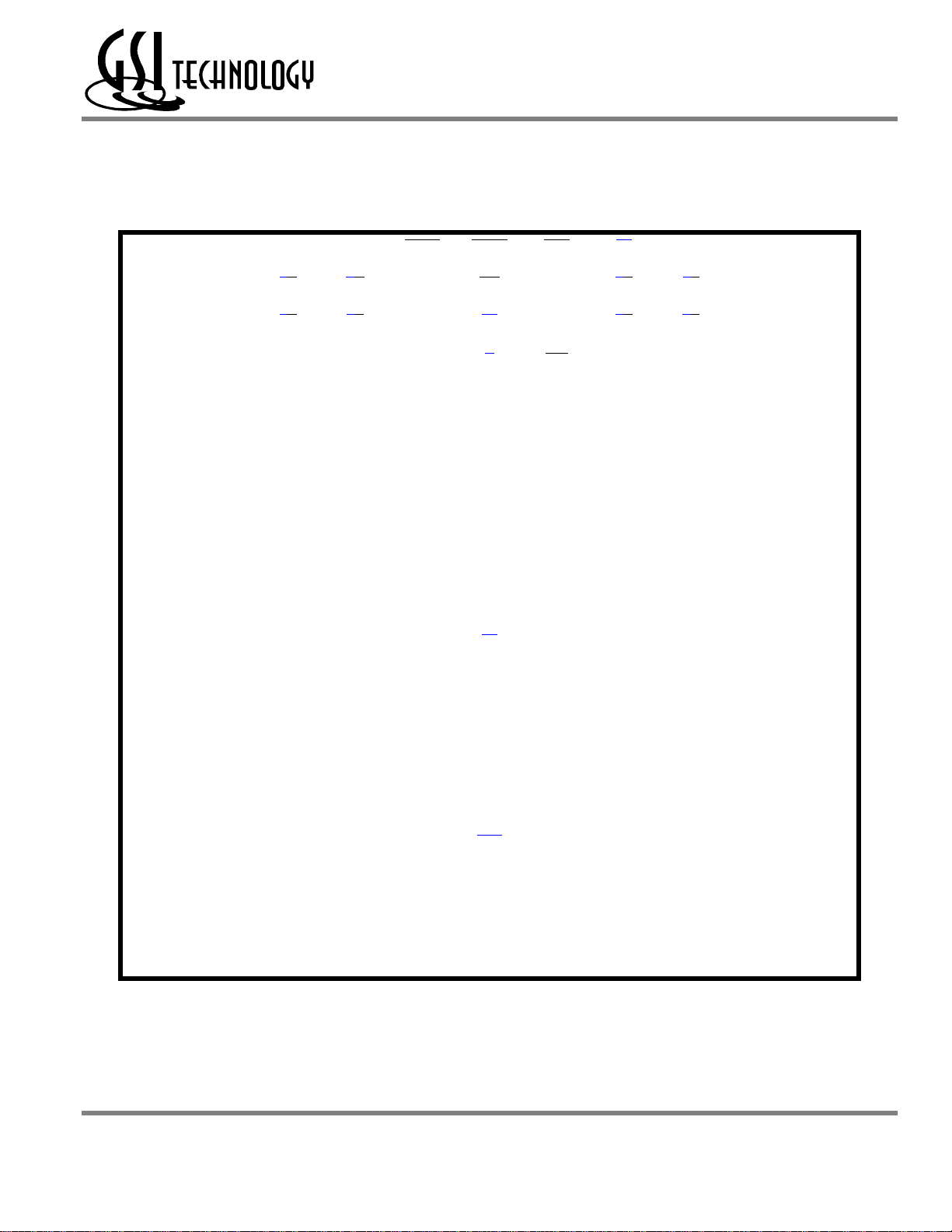

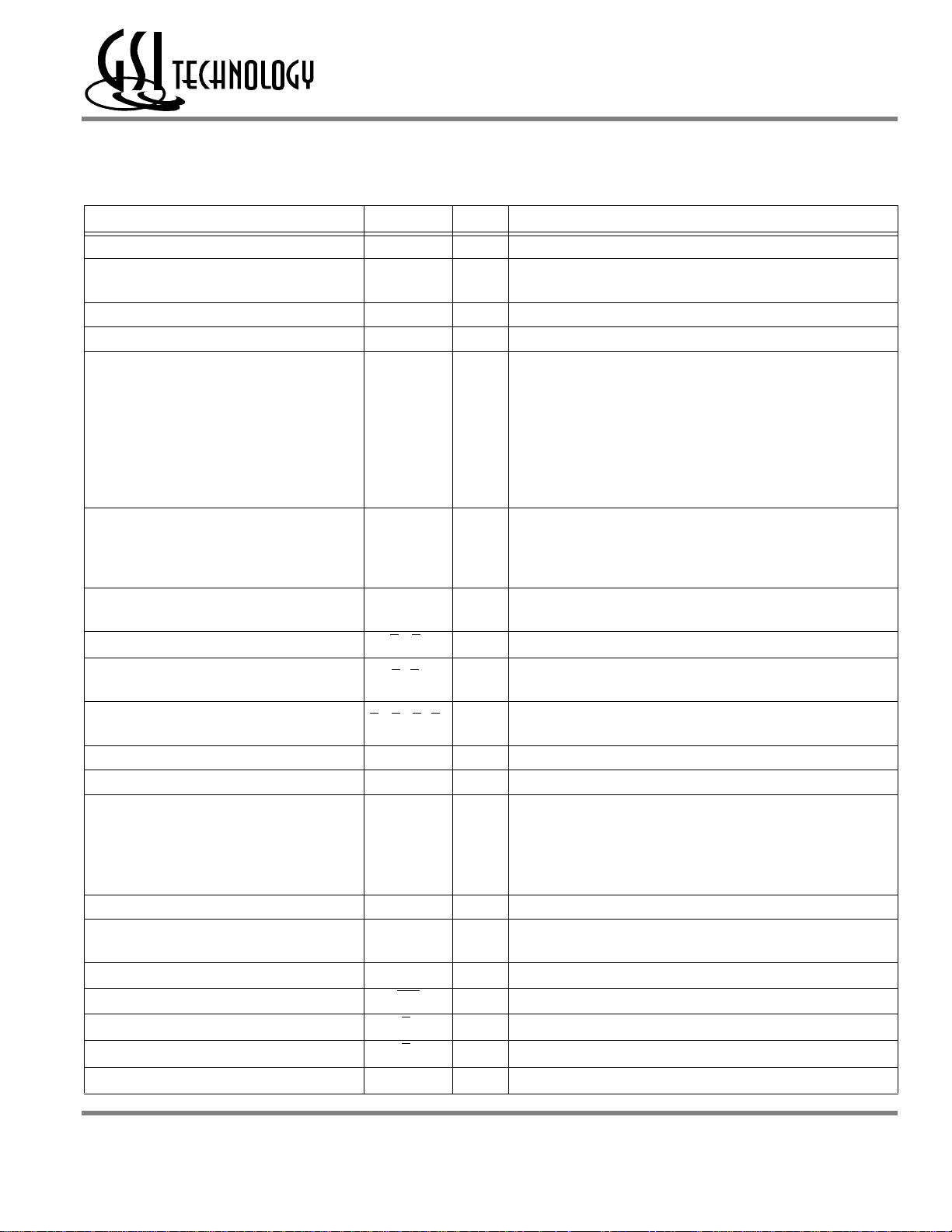

GS832472B Pad Out

209-Bump BGA—Top View

1 2 3 4 5 6 7 8 9 10 11

A DQG5 DQG1 A15 E2 ADSP ADSC ADV E3 A17 DQB1 DQB5 A

B DQG6 DQG2 BC BG NC BW A16 BB BF DQB2 DQB6 B

C DQG7 DQG3 BH BD NC E1 NC BE BA DQB3 DQB7 C

V

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

SS

NC NC G GW NC

V

DDQ

V

V

DDQ

V

V

DDQ

D DQG8 DQG4

E DQPG9 DQPC9

F DQC4 DQC8

G DQC3 DQC7

H DQC2 DQC6

J DQC1 DQC5

K NC NC CK NC

L DQH1 DQH5

M DQH2 DQH6

N DQH3 DQH7

P DQH4 DQH8

R DQPD9 DQPH9

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

SS

SS

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

DD

ZQ

MCH

MCL

MCL

MCL

FT

MCL

SCD

ZZ

V

DD

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

NC NC NC NC K

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

DQB4 DQB8 D

DQPF9 DQPB9 E

DQF8 DQF4 F

DQF7 DQF3 G

DQF6 DQF2 H

DQF5 DQF1 J

DQA5 DQA1 L

DQA6 DQA2 M

DQA7 DQA3 N

DQA8 DQA4 P

DQPA9 DQPE9 R

T DQD8 DQD4

V

SS

NC NC LBO NC NC

V

SS

DQE4 DQE8 T

U DQD7 DQD3 NC A14 A13 A12 A11 A10 A18 DQE3 DQE7 U

V DQD6 DQD2 A9 A8 A7 A1 A6 A5 A4 DQE2 DQE6 V

W DQD5 DQD1 TMS TDI A3 A0 A2 TDO TCK DQE1 DQE5 W

11 x 19 Bump BGA—14 x 22 mm2 Body—1 mm Bump Pitch

Rev: 1.00 10/2001 2/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

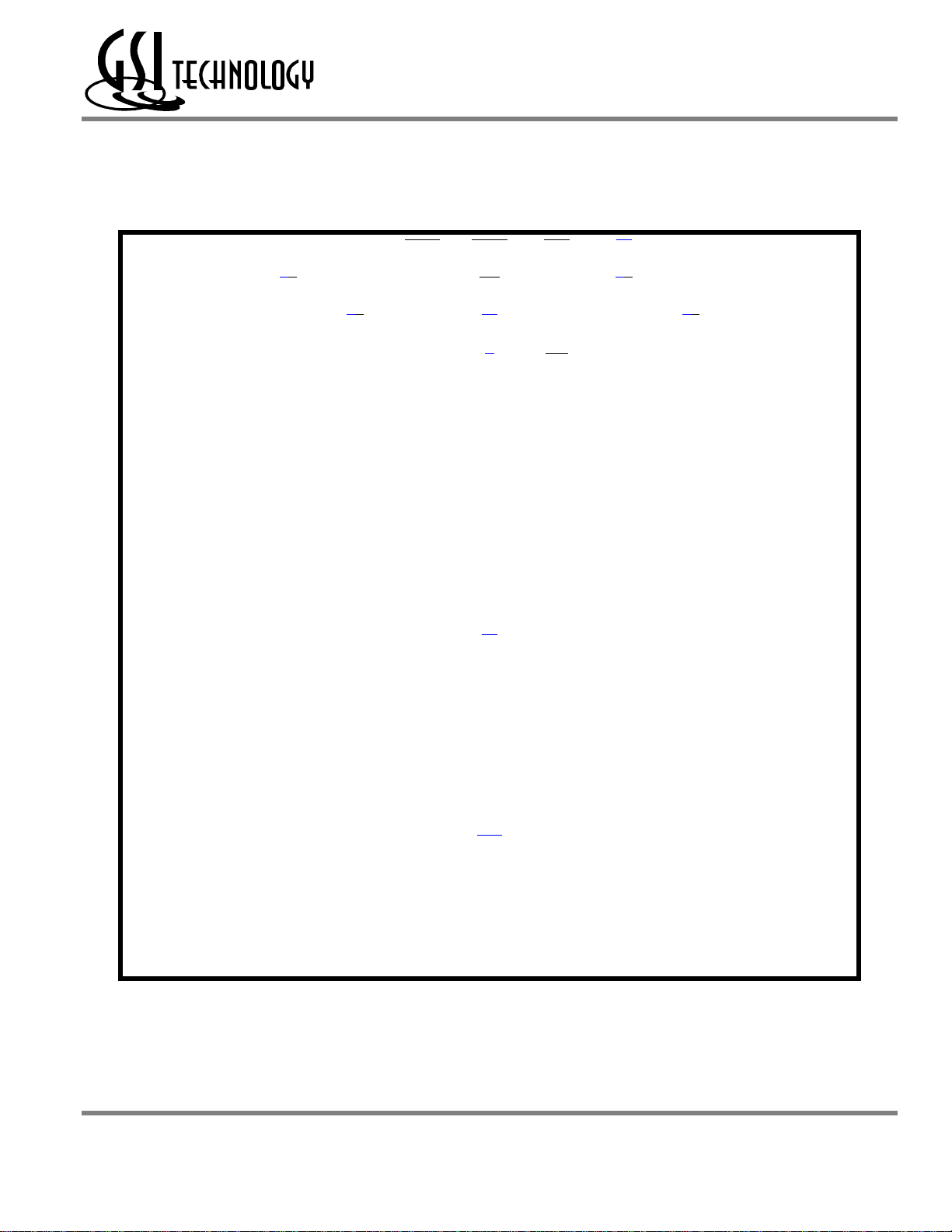

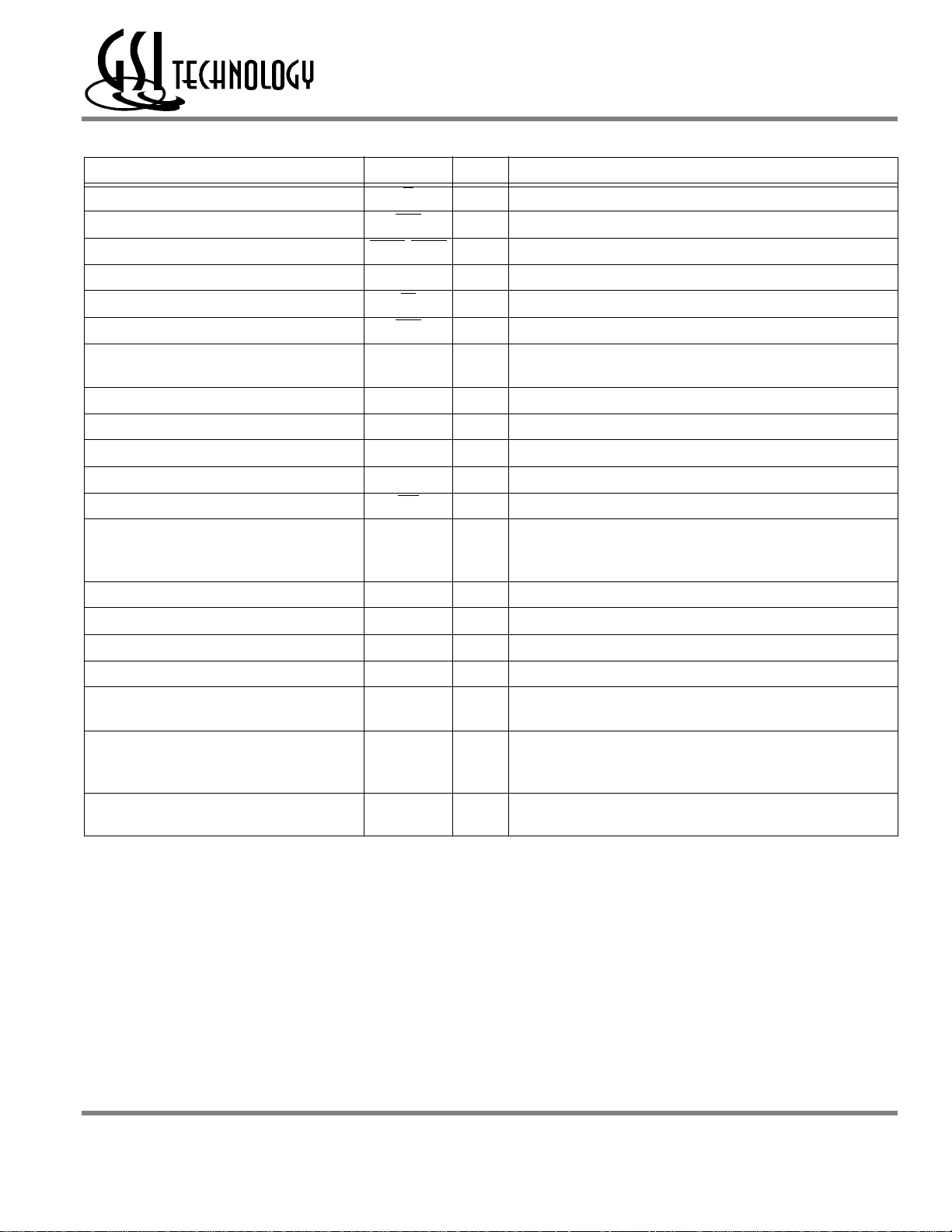

GS832436C Pad Out

209-Bump BGA—Top View

1 2 3 4 5 6 7 8 9 10 11

A NC NC A15 E2 ADSP ADSC ADV E3 A17 DQB1 DQB5 A

B NC NC BC NC A19 BW A16 BB NC DQB2 DQB6 B

C NC NC NC BD NC E1 NC NC BA DQB3 DQB7 C

V

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

SS

NC NC G GW NC

V

DDQ

V

V

DDQ

V

V

DDQ

D NC NC

E NC DQPC9

F DQC4 DQC8

G DQC3 DQC7

H DQC2 DQC6

J DQC1 DQC5

K NC NC CK NC

L NC NC

M NC NC

N NC NC

P NC NC

R DQPD9 NC

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

SS

SS

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

DD

ZQ

MCH

MCL

MCL

MCL

FT

MCL

SCD

ZZ

V

DD

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

NC NC NC NC K

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

DQB4 DQB8 D

NC DQPB9 E

NC NC F

NC NC G

NC NC H

NC NC J

DQA5 DQA1 L

DQA6 DQA2 M

DQA7 DQA3 N

DQA8 DQA4 P

DQPA9 NC R

T DQD8 DQD4

V

SS

NC NC LBO NC NC

V

SS

NC NC T

U DQD7 DQD3 NC A14 A13 A12 A11 A10 A18 NC NC U

V DQD6 DQD2 A9 A8 A7 A1 A6 A5 A4 NC NC V

W DQD5 DQD1 TMS TDI A3 A0 A2 TDO TCK NC NC W

11 x 19 Bump BGA—14 x 22 mm2 Body—1 mm Bump Pitch

Rev: 1.00 10/2001 3/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

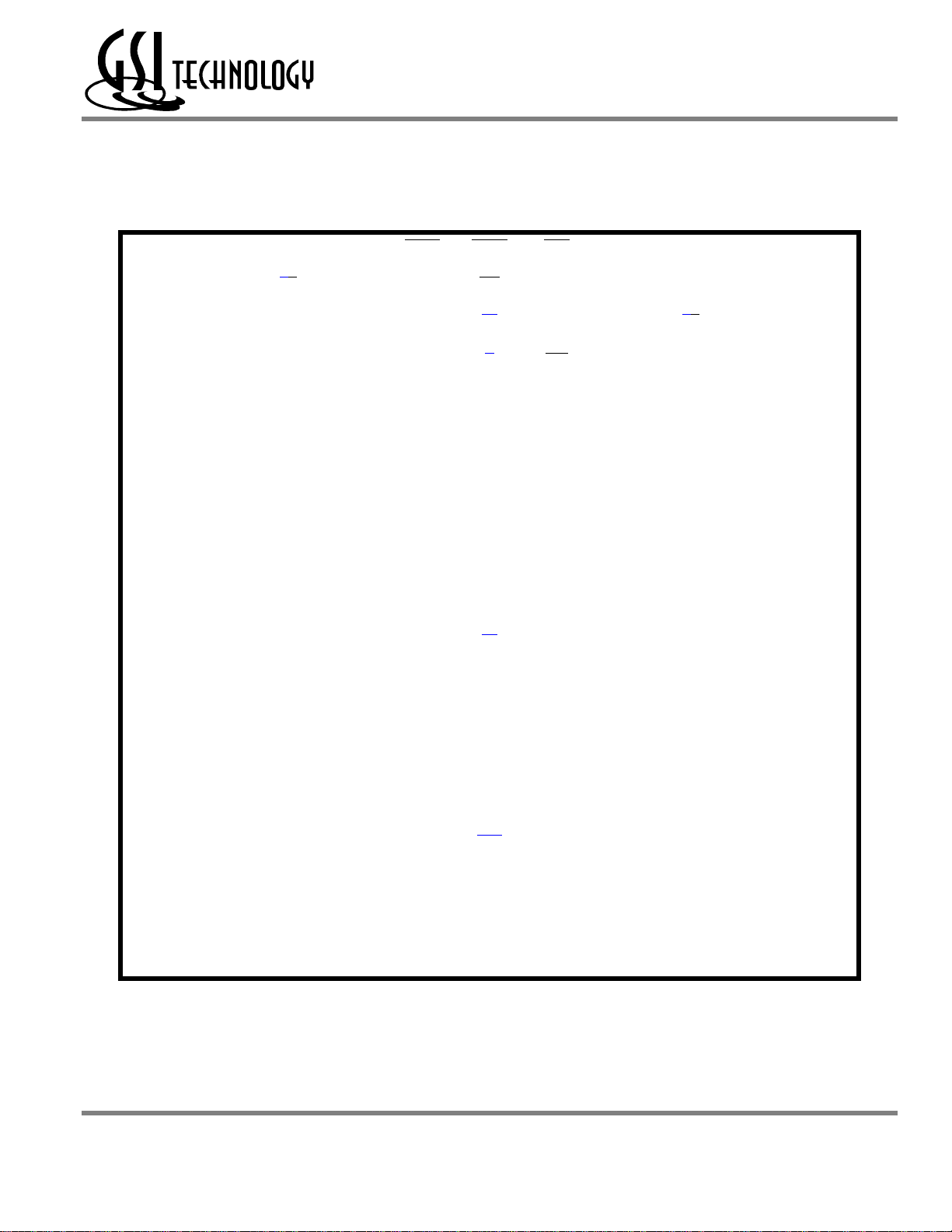

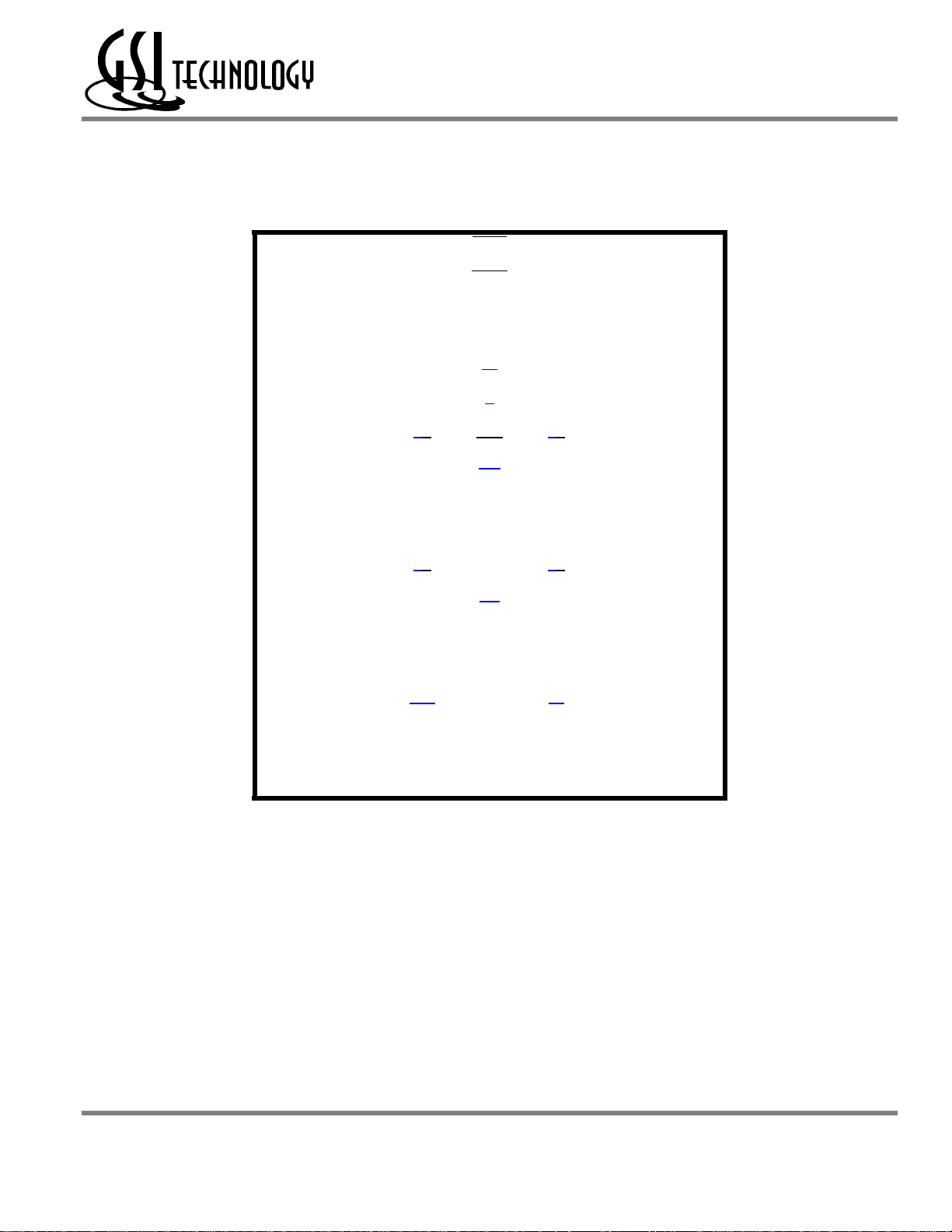

GS832418C Pad Out

209-Bump BGA—Top View

1 2 3 4 5 6 7 8 9 10 11

A NC NC A15 MCH ADSP ADSC ADV MCL A17 NC NC A

B NC NC BB NC A19 BW A16 NC NC NC NC B

C NC NC NC NC NC E1 A20 NC BA NC NC C

V

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

SS

NC NC G GW NC

V

DDQ

V

V

DDQ

V

V

DDQ

D NC NC

E NC DQPB9

F DQB4 DQB8

G DQB3 DQB7

H DQB2 DQB6

J DQB1 DQB5

K NC NC CK NC

L NC NC

M NC NC

N NC NC

P NC NC

R NC NC

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

SS

SS

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

DD

ZQ

MCH

MCL

MCL

MCL

FT

MCL

MCL

ZZ

V

DD

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

SS

V

DD

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

NC NC NC NC K

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

V

V

V

DDQ

V

DDQ

V

DDQ

SS

SS

NC NC D

NC NC E

NC NC F

NC NC G

NC NC H

NC NC J

DQA5 DQA1 L

DQA6 DQA2 M

DQA7 DQA3 N

DQA8 DQA4 P

DQPA9 NC R

T NC NC

V

SS

NC NC LBO NC NC

V

SS

NC NC T

U NC NC NC A14 A13 A12 A11 A10 A18 NC NC U

V NC NC A9 A8 A7 A1 A6 A5 A4 NC NC V

W NC NC TMS TDI A3 A0 A2 TDO TCK NC NC W

11 x 19 Bump BGA—14 x 22 mm2 Body—1 mm Bump Pitch

Rev: 1.00 10/2001 4/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

GS832418/36/72 209-Bump BGA Pin Description

Pin Location Symbol Type Description

W6, V6 A0, A1 I Address field LSBs and Address Counter Preset Inputs.

W7, W5, V9, V8, V7, V5, V4, V3, U8, U7, U6,

U5, U4, A3, B7, A9, U9

B5 A19 I Address Inputs (x36/x18 Versions)

C7 A20 I Address Inputs (x18 Version)

L11, M11, N11, P11, L10, M10, N10, P10, R10

A10, B10, C10, D10, A11, B11, C11, D11, E11

J1, H1, G1, F1, J2, H2, G2, F2, E2

W2, V2, U2, T2, W1, V1, U1, T1, R1

W10, V10, U10, T10, W11, V11, U11, T11, R11

J11, H11, G11, F11, J10, H10, G10, F10, E10

A2, B2, C2, D2, A1, B1, C1, D1, E1

L1, M1, N1, P1, L2, M2, N2, P2, R2

L11, M11, N11, P11, L10, M10, N10, P10, R10

A10, B10, C10, D10, A11, B11, C11, D11, E11

J1, H1, G1, F1, J2, H2, G2, F2, E2

W2, V2, U2, T2, W1, V1, U1, T1, R1

L11, M11, N11, P11, L10, M10, N10, P10, R10

J1, H1, G1, F1, J2, H2, G2, F2, E2

C9, B8

B3, C4

C8, B9, B4, C3

B5 NC — No Connect (x72 Version)

C7 NC — No Connect (x72/x36 Versions)

W10, V10, U10, T10, W11, V11, U11, T11, R11

J11, H11, G11, F11, J10, H10, G10, F10, E10

A2, B2, C2, D2, A1, B1, C1, D1, E1

L1, M1, N1, P1, L2, M2, N2, P2, R2, C8, B9,

B4, C3

B3, C4 NC — No Connect (x18 Version)

C5, D4, D5, D8, K1, K2, K4, K8, K9, K10, K11,

T4, T5, T7, T8, U3

K3 CK I Clock Input Signal; active high

D7

C6

A8

A4

An I Address Inputs

DQA1–DQA9

DQB1–DQB9

DQC1–DQC9

DQD1–DQD9

DQE1–DQE9

DQF1–DQF9

DQG1–DQG9

DQH1–DQH9

DQA1–DQA9

DQB1–DQB9

DQC1–DQC9

DQD1–DQD9

DQA1–DQA9

DQB1–DQB9

BA, BB

BC,BD

BE, BF, BG,BH

NC — No Connect (x36/x18 Versions)

NC — No Connect

GW

E1

E3

E2

I/O Data Input and Output pins (x72 Version)

I/O Data Input and Output pins (x36 Version)

I/O Data Input and Output pins (x18 Version)

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

I Byte Write Enable for DQA, DQB I/Os; active low

I

I

I Global Write Enable—Writes all bytes; active low

I Chip Enable; active low

I Chip Enable; active low (x72/x36 Versions)

I Chip Enable; active high (x72/x36 Versions)

Byte Write Enable for DQC, DQD I/Os; active low

(x72/x36 Versions)

Byte Write Enable for DQE, DQF, DQG, DQH I/Os; active low

(x72 Version)

Rev: 1.00 10/2001 5/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

GS832418/36/72 209-Bump BGA Pin Description

Pin Location Symbol Type Description

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

D6

A7

A5, A6

P6

L6

T6

N6

G6

A4

H6, J6, K6, M6

A8, N6

B6

F6

W3

W4

W8

W9

E5, E6, E7, G5, G7, J5, J7, L5, L7, N5, N7, R5,

R6, R7

D3, D9, F3, F4, F5, F7, F8, F9, H3, H4, H5, H7,

H8, H9, K5, K7, M3, M4, M5, M7, M8, M9, P3,

P4, P5, P7, P8, P9, T3, T9

E3, E4, E8, E9, G3, G4, G8, G9, J3, J4, J8, J9,

L3, L4, L8, L9, N3, N4, N8, N9, R3, R4, R8, R9

G

ADV

ADSP, ADSC

ZZ

FT

LBO

SCD

MCH

MCH

MCL

MCL

BW

ZQ

TMS

TDI

TDO

TCK

V

DD

V

SS

V

DDQ

I Output Enable; active low

I Burst address counter advance enable; active low

I Address Strobe (Processor, Cache Controller); active low

I Sleep Mode control; active high

I Flow Through or Pipeline mode; active low

I Linear Burst Order mode; active low

I

I Must Connect High

I Must Connect High (x18 version)

I Byte Enable; active low

I

I Scan Test Mode Select

I Scan Test Data In

O Scan Test Data Out

I Scan Test Clock

I Core power supply

I I/O and Core Ground

I Output driver power supply

Single Cycle Deselect/Dual Cycle Deselect Mode Control (

x72/x36 Versions)

Must Connect Low

Must Connect Low (x18 version)

FLXDrive Output Impedance Control

(Low = Low Impedance [High Drive], High = High Impedance [Low

Drive])

Rev: 1.00 10/2001 6/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

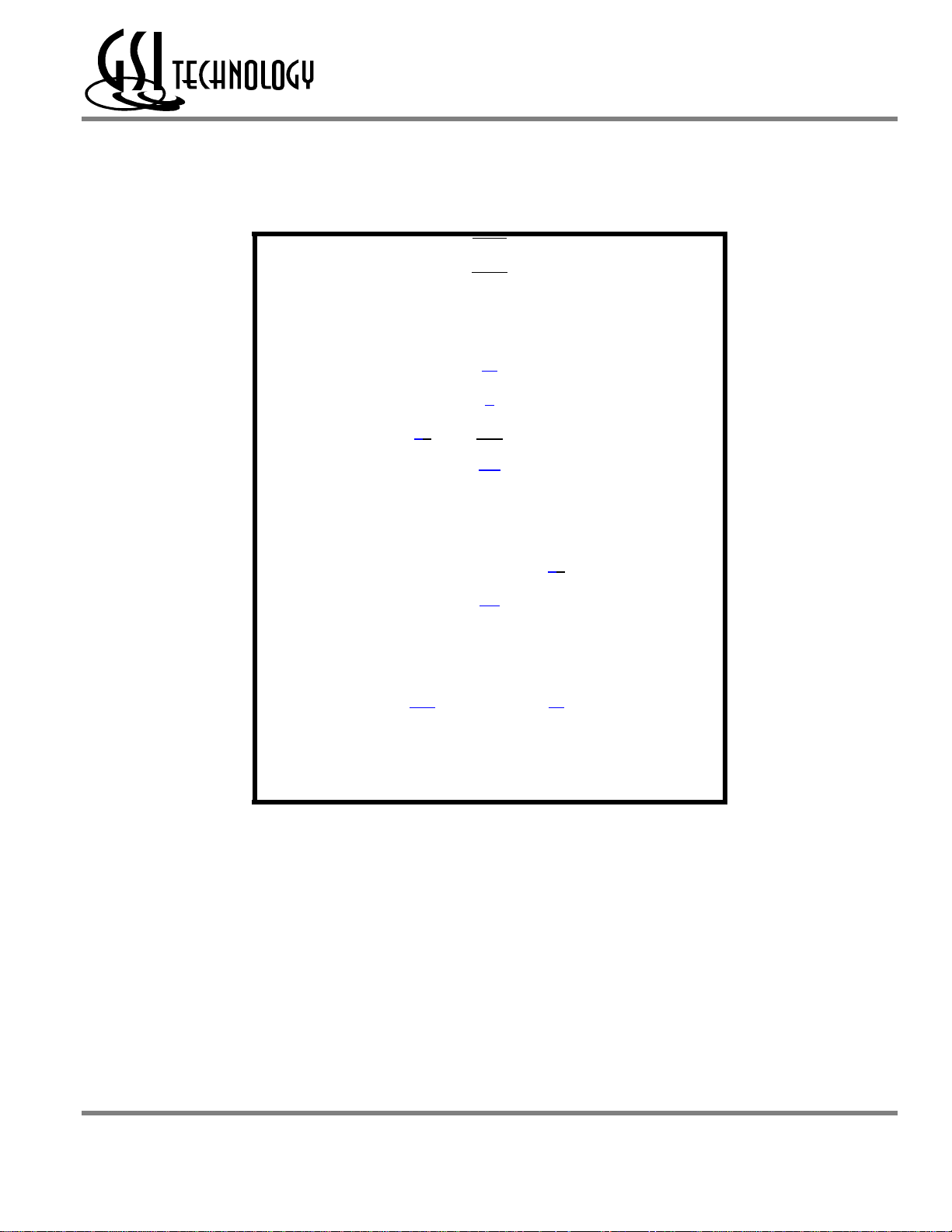

GS832418(B/C)/GS832436(B/C)/GS832472(C)

GS832436B Pad Out

119-Bump BGA—Top View

1 2 3 4 5 6 7

Preliminary

A V

DDQ

A6 A7 ADSP A8 A9 V

DDQ

B NC A18 A4 ADSC A15 A17 NC B

C NC A5 A3 V

D DQC4 DQPC9 V

E DQC3 DQC8 V

F V

DDQ

DQC7 V

SS

SS

SS

DD

ZQ V

E1 V

G V

A14 A16 NC C

SS

SS

SS

DQPB9 DQB4 D

DQB8 DQB3 E

DQB7 V

DDQ

G DQC2 DQC6 BC ADV BB DQB6 DQB2 G

H DQC1 DQC5 V

J V

DDQ

V

DD

K DQD1 DQD5 V

SS

NC V

SS

GW V

DD

CK V

SS

NC V

SS

DQB5 DQB1 H

DD

V

DDQ

DQA5 DQA4 K

L DQD2 DQD6 BD SCD BA DQA6 DQA3 L

M V

DDQ

N DQD3 DQD8 V

P DQD4 DQPD9 V

DQD7 V

SS

SS

SS

BW V

A1 V

A0 V

SS

SS

SS

DQA7 V

DDQ

DQA8 DQA2 N

DQPA9 DQA1 P

A

F

J

M

R NC A2 LBO V

DD

FT A13 NC R

T NC NC A10 A11 A12 A19 ZZ T

U V

DDQ

TMS TDI TCK TDO NC V

DDQ

U

7 x 17 Bump BGA—14 x 22 mm2 Body—1.27 mm Bump Pitch

Rev: 1.00 10/2001 7/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

GS832418(B/C)/GS832436(B/C)/GS832472(C)

GS832418B Pad Out

119-Bump BGA—Top View

1 2 3 4 5 6 7

Preliminary

A V

DDQ

A6 A7 ADSP A8 A9 V

DDQ

B NC A18 A4 ADSC A15 A17 NC B

C NC A5 A3 V

D DQB1 NC V

E NC DQB2 V

F V

DDQ

NC V

SS

SS

SS

DD

ZQ V

E1 V

G V

A14 A16 NC C

SS

SS

SS

DQPA9 NC D

NC DQA8 E

DQA7 V

DDQ

G NC DQB3 BB ADV NC NC DQA6 G

H DQB4 NC V

J V

DDQ

V

DD

K NC DQB5 V

SS

NC V

SS

L DQB6 NC NC V

M V

DDQ

N DQB8 NC V

P NC DQPB9 V

DQB7 V

SS

SS

SS

GW V

DD

CK V

SS

BW V

A1 V

A0 V

SS

NC V

SS

DQA5 NC H

DD

V

DDQ

NC DQA4 K

BA DQA3 NC L

SS

SS

SS

NC V

DDQ

DQA2 NC N

NC DQA1 P

A

F

J

M

R NC A2 LBO V

DD

FT A13 NC R

T NC A10 A11 A20 A12 A19 ZZ T

U V

DDQ

TMS TDI TCK TDO NC V

DDQ

U

7 x 17 Bump BGA—14 x 22 mm2 Body—1.27 mm Bump Pitch

Rev: 1.00 10/2001 8/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

GS832418/36 119-Bump BGA Pin Description

Pin Location Symbol Type Description

P4, N4 A0, A1 I Address field LSBs and Address Counter Preset Inputs

R2, C3, B3, C2, A2, A3, A5, A6, T3,

T5, R6, C5, B5, C6, B6, B2

T4, T6 An Address Input (x36 Version)

T2 NC — No Connect (x36 Version)

T2, T6, T4 An I Address Input (x18 Version)

K7, L7, N7, P7, K6, L6, M6, N6

H7, G7, E7, D7, H6, G6, F6, E6

H1, G1, E1, D1, H2, G2, F2, E2

K1, L1, N1, P1, K2, L2, M2, N2

P6, D6, D2, P2

L5, G5, G3, L3 BA, BB, BC, BD I Byte Write Enable for DQA, DQB, DQC, DQD I/Os; active low (x36 Version)

P7, N6, L6, K7, H6, G7, F6, E7, D6

D1, E2, G2, H1, K2, L1, M2, N1, P2

L5, G3 BA, BB I Byte Write Enable for DQA, DQB I/Os; active low (x18 Version)

B1, C1, R1, T1, U6, B7, C7, J3, J5,

R7

P6, N7, M6, L7, K6, H7, G6, E6, D7,

D2, E1, F2, G1, H2, K1, L2, N2, P1,

G5, L3

K4 CK I Clock Input Signal; active high

M4 BW I Byte Write—Writes all enabled bytes; active low

H4 GW I Global Write Enable—Writes all bytes; active low

E4 E1 I Chip Enable; active low

F4 G I Output Enable; active low

G4 ADV I Burst address counter advance enable; active low

A4, B4 ADSP, ADSC I Address Strobe (Processor, Cache Controller); active low

T7 ZZ I Sleep mode control; active high

R5 FT I Flow Through or Pipeline mode; active low

R3 LBO I Linear Burst Order mode; active low

D4 ZQ I

L4 SCD I Single Cycle Deselect/Dual Cyle Deselect Mode Control (x36 version)

U2

An I Address Inputs

DQA1–DQA8

DQB1–DQB8

DQC1–DQC8

DQD1–DQD8

DQA9, DQB9,

DQC9, DQD9

DQA1–DQA9

DQB1–DQB9

NC — No Connect

NC — No Connect (x18 Version)

TMS

I/O Data Input and Output pins. (x36 Version)

I/O Data Input and Output pins. (x36 Version)

I/O Data Input and Output pins (x18 Version)

I Scan Test Mode Select

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

FLXDrive Output Impedance Control (Low = Low Impedance [High Drive],

High = High Impedance [Low Drive])

Rev: 1.00 10/2001 9/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

GS832418/36 119-Bump BGA Pin Description

Pin Location Symbol Type Description

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

U3

U5

U4

J2, C4, J4, R4, J6

D3, E3, F3, H3, K3, M3, N3, P3, D5,

E5, F5, H5, K5, M5, N5, P5

L4

A1, F1, J1, M1, U1, A7, F7, J7, M7,

U7

TDI

TDO

TCK

V

V

V

V

DDQ

DD

SS

SS

I Scan Test Data In

O Scan Test Data Out

I Scan Test Clock

I Core power supply

I I/O and Core Ground

I I/O and Core Ground

I Output driver power supply

Rev: 1.00 10/2001 10/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

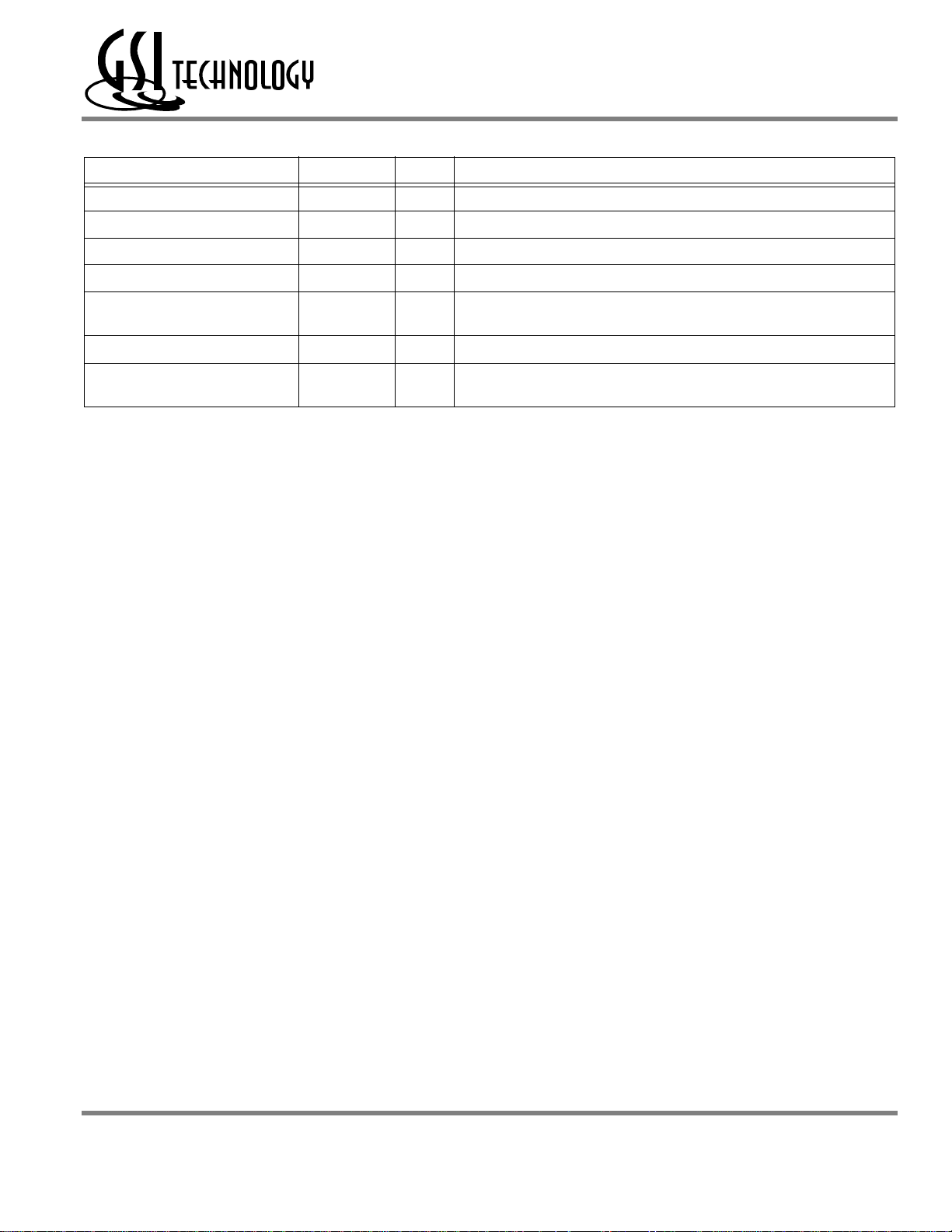

GS832418/36/72 Block Diagram

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

A0–An

LBO

ADV

CK

ADSC

ADSP

GW

BW

BA

BB

BC

BD

Register

D Q

A0

A1

D0

D1

Counter

Load

Register

D Q

Register

D Q

Register

D Q

Register

D Q

Q0

Q1

A0

A1

A

Memory

Array

Q D

36

4

DQ

Register

36

Register

DQ

E1

FT

G

ZZ

Note: Only x36 version shown for simplicity.

Power Down

Control

Register

D Q

Register

D Q

Register

D Q

SCD

36

36

36

DQx0–DQx9

36

Rev: 1.00 10/2001 11/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

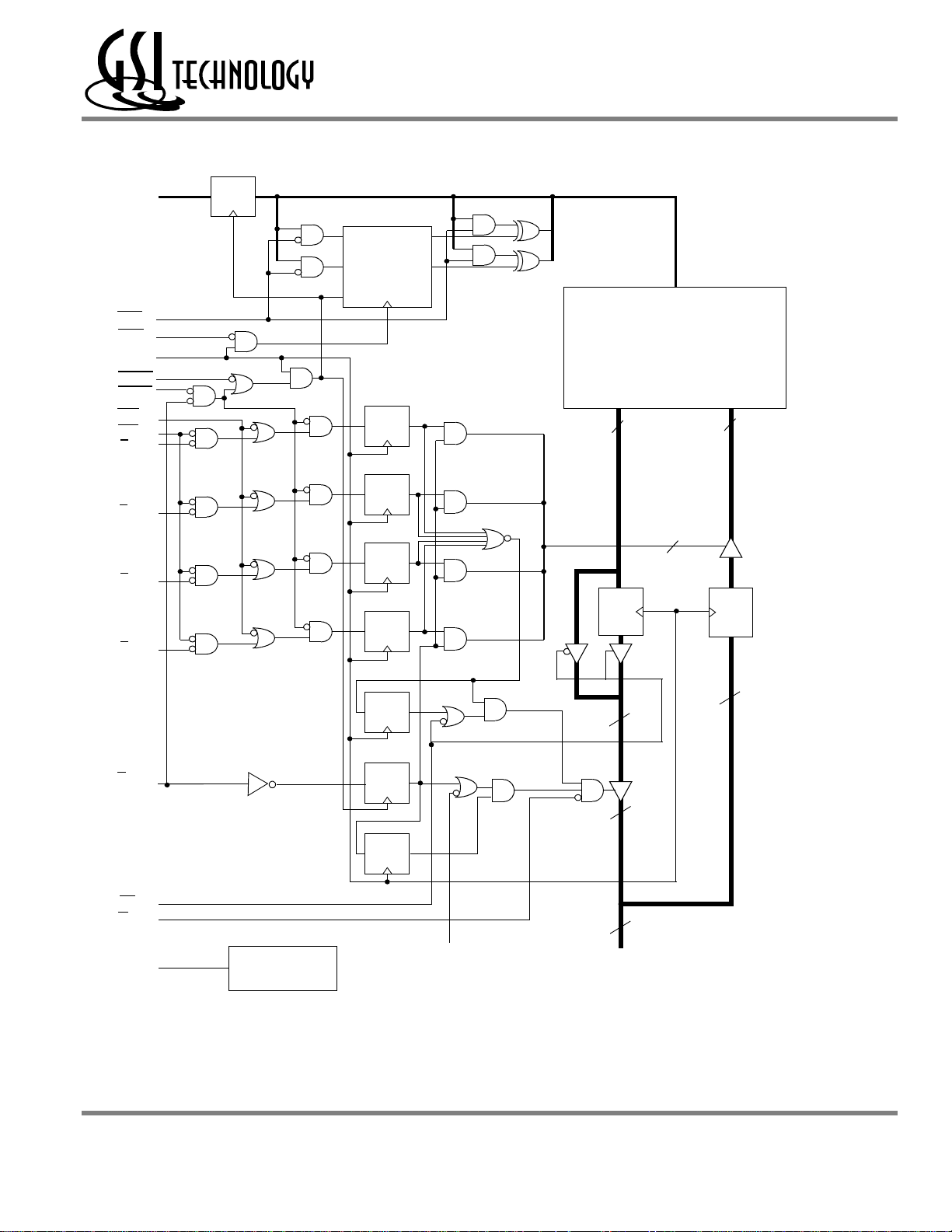

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

GS832418 Die Layout

GS832436 Die Layout

Die A

x18

16Mb

Die A

x18

16Mb

Inputs

TDO TDI TDOTDI

Die B

x18

16Mb

18 I/Os

Inputs

TDO TDI TDOTDI

Die B

x18

16Mb

18 I/Os 18 I/Os

GS832472 Die Layout

Inputs

Die A

TDO TDI TDOTDI

x36

32Mb

36 I/Os 36 I/Os

Rev: 1.00 10/2001 12/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Die B

x36

32Mb

Linear Burst Sequence

I

Mode Pin Functions

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Mode Name

Burst Order Control LBO

Output Register Control FT

Power Down Control ZZ

Single/Dual Cycle Deselect Control SCD

FLXDrive Output Impedance Control ZQ

Note:

There are pull-up devices on the ZQ, SCD and FT pins and a pull-down device on the ZZ pin, so those input pins can be unconnected and the

chip will operate in the default states as specified in the above tables.

Pin

Name

State Function

L Linear Burst

H Interleaved Burst

L Flow Through

H or NC Pipeline

L or NC Active

H

L Dual Cycle Deselect

H or NC Single Cycle Deselect

L High Drive (Low Impedance)

H or NC Low Drive (High Impedance)

Standby, IDD = I

SB

Enable / Disable Parity I/O Pins

This SRAM allows the user to configure the device to operate in Parity I/O active (x18, x36, or x72) or in Parity I/O inactive (x16,

x32, or x64) mode. Holding the PE bump low or letting it float will activate the 9th I/O on each byte of the RAM. Grounding PE

deactivates the 9th I/O of each byte, although the bit in each byte of the memory array remains active to store and recall parity bits

generated and read into the ByteSafe parity circuits.

Burst Counter Sequences

nterleaved Burst Sequence

A[1:0] A[1:0] A[1:0] A[1:0]

1st address 00 01 10 11

2nd address 01 10 11 00

3rd address 10 11 00 01

4th address 11 00 01 10

Note: The burst counter wraps to initial state on the 5th clock.

Rev: 1.00 10/2001 13/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

1st address 00 01 10 11

2nd address 01 00 11 10

3rd address 10 11 00 01

4th address 11 10 01 00

Note: The burst counter wraps to initial state on the 5th clock.

A[1:0] A[1:0] A[1:0] A[1:0]

BPR 1999.05.18

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Byte Write Truth Table

Function GW BW BA BB BC BD Notes

Read H H X X X X 1

Read H L H H H H 1

Write byte a H L L H H H 2, 3

Write byte b H L H L H H 2, 3

Write byte c H L H H L H 2, 3, 4

Write byte d H L H H H L 2, 3, 4

Write all bytes H L L L L L 2, 3, 4

Write all bytes L X X X X X

Notes:

1. All byte outputs are active in read cycles regardless of the state of Byte Write Enable inputs.

2. Byte Write Enable inputs BA, BB, BC, and/or BD may be used in any combination with BW to write single or multiple bytes.

3. All byte I/Os remain High-Z during all write operations regardless of the state of Byte Write Enable inputs.

4. Bytes “C” and “D” are only available on the x36 version.

Preliminary

Rev: 1.00 10/2001 14/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Synchronous Truth Table (x72 and x36 209-Bump BGA)

State

Operation Address Used

Deselect Cycle, Power Down None X H X X L X X High-Z

Deselect Cycle, Power Down None X L F L X X X High-Z

Deselect Cycle, Power Down None X L F H L X X High-Z

Read Cycle, Begin Burst External R L T L X X X Q

Read Cycle, Begin Burst External R L T H L X F Q

Write Cycle, Begin Burst External W L T H L X T D

Read Cycle, Continue Burst Next CR X X H H L F Q

Read Cycle, Continue Burst Next CR H X X H L F Q

Write Cycle, Continue Burst Next CW X X H H L T D

Write Cycle, Continue Burst Next CW H X X H L T D

Read Cycle, Suspend Burst Current X X H H H F Q

Read Cycle, Suspend Burst Current H X X H H F Q

Write Cycle, Suspend Burst Current X X H H H T D

Write Cycle, Suspend Burst Current H X X H H T D

Note:

1. X = Don’t Care, H = High, L = Low.

2. E = T (True) if E2 = 1 and E3 = 0; E = F (False) if E2 = 0 or E3 = 1.

3. W = T (True) and F (False) is defined in the Byte Write Truth Table preceding.

4. G is an asynchronous input. G can be driven high at any time to disable active output drivers. G low can only enable active drivers (shown

as “Q” in the Truth Table above).

5. All input combinations shown above are tested and supported. Input combinations shown in gray boxes need not be used to accomplish

basic synchronous or synchronous burst operations and may be avoided for simplicity.

6. Tying ADSP high and ADSC low allows simple non-burst synchronous operations. See BOLD items above.

7. Tying ADSP high and ADV low while using ADSC to load new addresses allows simple burst operations. See ITALIC items above.

Diagram

5

Key

E1

E

2

ADSP ADSC ADV

W

3

DQ

4

Rev: 1.00 10/2001 15/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Synchronous Truth Table (x18 209-Bump BGA and x36/x18 119-Bump BGA)

State

Operation Address Used

Deselect Cycle, Power Down None X H X L X X High-Z

Read Cycle, Begin Burst External R L L X X X Q

Read Cycle, Begin Burst External R L H L X F Q

Write Cycle, Begin Burst External W L H L X T D

Read Cycle, Continue Burst Next CR X H H L F Q

Read Cycle, Continue Burst Next CR H X H L F Q

Write Cycle, Continue Burst Next CW X H H L T D

Write Cycle, Continue Burst Next CW H X H L T D

Read Cycle, Suspend Burst Current X H H H F Q

Read Cycle, Suspend Burst Current H X H H F Q

Write Cycle, Suspend Burst Current X H H H T D

Write Cycle, Suspend Burst Current H X H H T D

Notes:

1. X = Don’t Care, H = High, L = Low

2. W = T (True) and F (False) is defined in the Byte Write Truth Table preceding

3. G is an asynchronous input. G can be driven high at any time to disable active output drivers. G low can only enable active drivers (shown

as “Q” in the Truth Table above).

4. All input combinations shown above are tested and supported. Input combinations shown in gray boxes need not be used to accomplish

basic synchronous or synchronous burst operations and may be avoided for simplicity.

5. Tying ADSP high and ADSC low allows simple non-burst synchronous operations. See BOLD items above.

6. Tying ADSP high and ADV low while using ADSC to load new addresses allows simple burst operations. See ITALIC items above.

Diagram

5

Key

E1 ADSP ADSC ADV

W

3

DQ

4

Rev: 1.00 10/2001 16/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

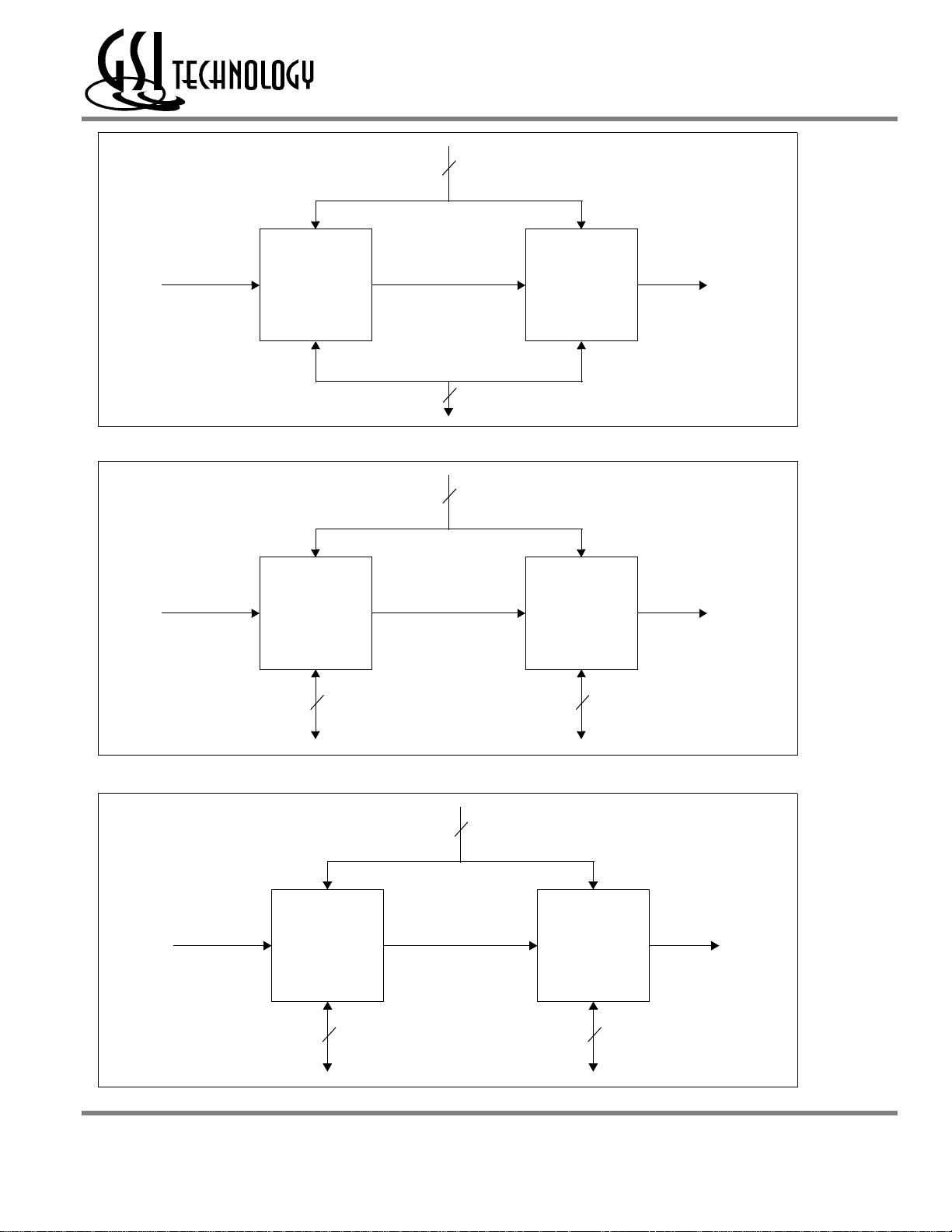

Simplified State Diagram

GS832418(B/C)/GS832436(B/C)/GS832472(C)

X

Deselect

W R

W

X

Simple Synchronous OperationSimple Burst Synchronous Operation

First Write

W R

Burst Write

CW CR

R

CR

R

CR

R

First Read

Burst Read

X

CRCW

XX

Notes:

1. The diagram shows only supported (tested) synchronous state transitions. The diagram presumes G is tied low.

2. The upper portion of the diagram assumes active use of only the Enable (E1) and Write (BA, BB, BC, BD, BW, and GW) control inputs, and

that ADSP is tied high and ADSC is tied low.

3. The upper and lower portions of the diagram together assume active use of only the Enable, Write, and ADSC control inputs and

assumes ADSP is tied high and ADV is tied low.

Rev: 1.00 10/2001 17/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Simplified State Diagram with G

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

X

Deselect

W R

W

X

X

First Write

W

Burst Write

CW CR

R

CR

R

CR

W

CW

W

CW

R

First Read

R

Burst Read

X

CRCW

X

Notes:

1. The diagram shows supported (tested) synchronous state transitions plus supported transitions that depend upon the use of G.

2. Use of “Dummy Reads” (Read Cycles with G High) may be used to make the transition from read cycles to write cycles without passing

through a Deselect cycle. Dummy Read cycles increment the address counter just like normal read cycles.

3. Transitions shown in grey tone assume G has been pulsed high long enough to turn the RAM’s drivers off and for incoming data to meet

Data Input Set Up Time.

Rev: 1.00 10/2001 18/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Absolute Maximum Ratings

(All voltages reference to VSS)

Symbol Description Value Unit

V

DD

V

DDQ

V

CK

V

I/O

V

IN

I

IN

I

OUT

P

D

T

STG

T

BIAS

Note:

Permanent damage to the device may occur if the Absolute Maximum Ratings are exceeded. Operation should be restricted to Recommended

Operating Conditions. Exposure to conditions exceeding the Absolute Maximum Ratings, for an extended period of time, may affect reliability of

this component.

Voltage on VDD Pins

Voltage in V

DDQ

Pins

–0.5 to 4.6 V

–0.5 to 4.6 V

Voltage on Clock Input Pin –0.5 to 6 V

Voltage on I/O Pins

Voltage on Other Input Pins

–0.5 to V

–0.5 to V

+0.5 (≤ 4.6 V max.)

DDQ

+0.5 (≤ 4.6 V max.)

DD

V

V

Input Current on Any Pin +/–20 mA

Output Current on Any I/O Pin +/–20 mA

Package Power Dissipation 1.5 W

Storage Temperature –55 to 125

Temperature Under Bias –55 to 125

o

o

C

C

Rev: 1.00 10/2001 19/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Power Supply Voltage Ranges

Parameter Symbol Min. Typ. Max. Unit Notes

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

3.3 V Supply Voltage

2.5 V Supply Voltage

3.3 V V

2.5 V V

Notes:

1. The part numbers of Industrial Temperature Range versions end the character “I”. Unless otherwise noted, all performance specifications quoted are

evaluated for worst case in the temperature range marked on the device.

2. Input Under/overshoot voltage must be –2 V > Vi < V

I/O Supply Voltage V

DDQ

I/O Supply Voltage V

DDQ

V

DD3

V

DD2

DDQ3

DDQ2

+2 V not to exceed 4.6 V maximum, with a pulse width not to exceed 20% tKC.

DDn

3.0 3.3 3.6 V

2.3 2.5 2.7 V

3.0 3.3 3.6 V

2.4 2.5 2.7 V

V

Range Logic Levels

DDQ3

Parameter Symbol Min. Typ. Max. Unit Notes

VDD Input High Voltage V

V

Input Low Voltage V

DD

V

I/O Input High Voltage V

DDQ

V

I/O Input Low Voltage V

DDQ

Notes:

1. The part numbers of Industrial Temperature Range versions end the character “I”. Unless otherwise noted, all performance specifications quoted are

evaluated for worst case in the temperature range marked on the device.

2. Input Under/overshoot voltage must be –2 V > Vi < V

3. V

(max) is voltage on V

IHQ

pins plus 0.3 V.

DDQ

DDn

IH

IL

IHQ

ILQ

+2 V not to exceed 4.6 V maximum, with a pulse width not to exceed 20% tKC.

1.7 —

–0.3 — 0.8 V 1

1.7 —

–0.3 — 0.8 V 1,3

VDD + 0.3

V

+ 0.3

DDQ

V 1

V 1,3

V

Range Logic Levels

DDQ2

Parameter Symbol Min. Typ. Max. Unit Notes

VDD Input High Voltage V

V

Input Low Voltage V

DD

V

I/O Input High Voltage V

DDQ

V

I/O Input Low Voltage V

DDQ

Notes:

1. The part numbers of Industrial Temperature Range versions end the character “I”. Unless otherwise noted, all performance specifications quoted are

evaluated for worst case in the temperature range marked on the device.

2. Input Under/overshoot voltage must be –2 V > Vi < V

3. V

(max) is voltage on V

IHQ

pins plus 0.3 V.

DDQ

DDn

IH

IL

IHQ

ILQ

+2 V not to exceed 4.6 V maximum, with a pulse width not to exceed 20% tKC.

Rev: 1.00 10/2001 20/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

0.6*V

DD

–0.3 —

0.6*V

DD

–0.3 —

—

—

VDD + 0.3

0.3*V

DD

V

+ 0.3

DDQ

0.3*V

DD

V 1

V 1

V 1,3

V 1,3

Recommended Operating Temperatures

Parameter Symbol Min. Typ. Max. Unit Notes

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Ambient Temperature (Commercial Range Versions)

Ambient Temperature (Industrial Range Versions)

Note:

1. The part numbers of Industrial Temperature Range versions end the character “I”. Unless otherwise noted, all performance specifications quoted are

evaluated for worst case in the temperature range marked on the device.

2. Input Under/overshoot voltage must be –2 V > Vi < V

T

A

T

A

+2 V not to exceed 4.6 V maximum, with a pulse width not to exceed 20% tKC.

DDn

0 25 70 °C 2

–40 25 85 °C 2

Undershoot Measurement and Timing Overshoot Measurement and Timing

V

– 2.0 V

SS

V

50%

IH

V

+ 2.0 V

DD

SS

20% tKC

50%

V

DD

V

IL

20% tKC

Capacitance

(TA = 25oC, f = 1 MHZ, V

DD

= 2.5 V)

Parameter Symbol Test conditions Typ. Max. Unit

Input Capacitance

Input/Output Capacitance (x36/x72)

Input/Output Capacitance (x18)

Note: These parameters are sample tested.

C

IN

C

I/O

C

I/O

V

V

V

IN

OUT

OUT

= 0 V

= 0 V

= 0 V

6.5 7.5 pF

6 7 pF

8.5 9.5 pF

Package Thermal Characteristics

Rating Layer Board Symbol Max Unit Notes

Junction to Ambient (at 200 lfm) single

Junction to Ambient (at 200 lfm) four

Junction to Case (TOP) —

Notes:

1. Junction temperature is a function of SRAM power dissipation, package thermal resistance, mounting board temperature, ambient. Temperature air flow, board density, and PCB thermal resistance.

2. SCMI G-38-87

3. Average thermal resistance between die and top surface, MIL SPEC-883, Method 1012.1

Rev: 1.00 10/2001 21/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

R

R

R

ΘJA

ΘJA

ΘJC

40 °C/W 1,2

24 °C/W 1,2

9 °C/W 3

AC Test Conditions

Parameter Conditions

Input high level 2.3 V

Input low level 0.2 V

Input slew rate 1 V/ns

Input reference level 1.25 V

Output reference level 1.25 V

Output load Fig. 1& 2

Notes:

1. Include scope and jig capacitance.

2. Test conditions as specified with output loading as shown in Fig.

1 unless otherwise noted.

3. Output Load 2 for tLZ, tHZ, t

4. Device is deselected as defined by the Truth Table.

DQ

and t

OLZ

Output Load 1

OHZ

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Output Load 2

2.5 V

DC Electrical Characteristics

Parameter Symbol Test Conditions Min Max

Input Leakage Current

(except mode pins)

ZZ and PE Input Current

FT, SCD, ZQ, DP Input Current

Output Leakage Current (x36/x72)

Output Leakage Current (x18)

Output High Voltage

Output High Voltage

Output Low Voltage

50Ω

VT = 1.25 V

I

IL

I

IN1

I

IN2

I

OL

I

OL

V

OH2

V

OH3

V

OL

*

30pF

* Distributed Test Jig Capacitance

V

IN

V

DD ≥ VIN ≥ VIH

0 V ≤ V

V

DD ≥ VIN ≥ VIL

0 V ≤ V

Output Disable, V

Output Disable, V

I

= –8 mA, V

OH

I

= –8 mA, V

OH

I

OL

= 0 to V

IN

IN

OUT

OUT

DDQ

DDQ

= 8 mA

DQ

DD

≤ V

IH

≤ V

IL

= 0 to V

= 0 to V

= 2.375 V

= 3.135 V

5pF

DD

DD

225Ω

*

225Ω

–2 uA 2 uA

–1 uA

–1 uA

–100 uA

–1 uA

1 uA

100 uA

1 uA

1 uA

–1 uA 1 uA

–2 uA 2 uA

1.7 V —

2.4 V —

— 0.4 V

Rev: 1.00 10/2001 22/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Unit

to

–40

0

to

to

–40

0

to

to

–40

0

to

to

–40

0

to

to

–40

mA

360

85°C

340

70°C

400

85°C

380

70°C

430

85°C

410

70°C

500

85°C

480

70°C

550

85°C

mA

40

220

40

200

50

290

50

270

50

290

50

270

60

290

60

270

70

330

mA

20

330

20

310

30

360

30

340

30

390

30

370

30

450

30

430

40

490

mA

20

200

20

180

30

270

30

250

30

270

30

350

30

270

30

250

40

300

mA

20

220

20

205

20

245

20

230

20

265

20

250

20

305

20

290

20

330

mA

10

150

10

135

15

190

15

175

15

190

15

175

15

190

15

175

20

215

mA

10

360

10

340

10

400

10

380

10

430

10

410

10

500

10

480

10

550

mA

30

220

30

200

40

290

40

270

40

290

40

270

50

290

50

270

60

330

mA

20

330

20

310

30

360

30

340

30

390

30

370

30

450

30

430

30

490

mA

20

200

20

180

20

270

20

250

20

270

20

250

30

270

30

250

30

300

mA

10

220

10

205

20

245

20

230

20

265

20

250

20

305

20

290

20

330

mA

mA

mA

mA

mA

10

10

10

10

10

10

15

15

15

5

150

5

135

10

190

10

175

10

190

10

175

10

190

10

175

10

215

0

to

70°C

to

–40

85°C

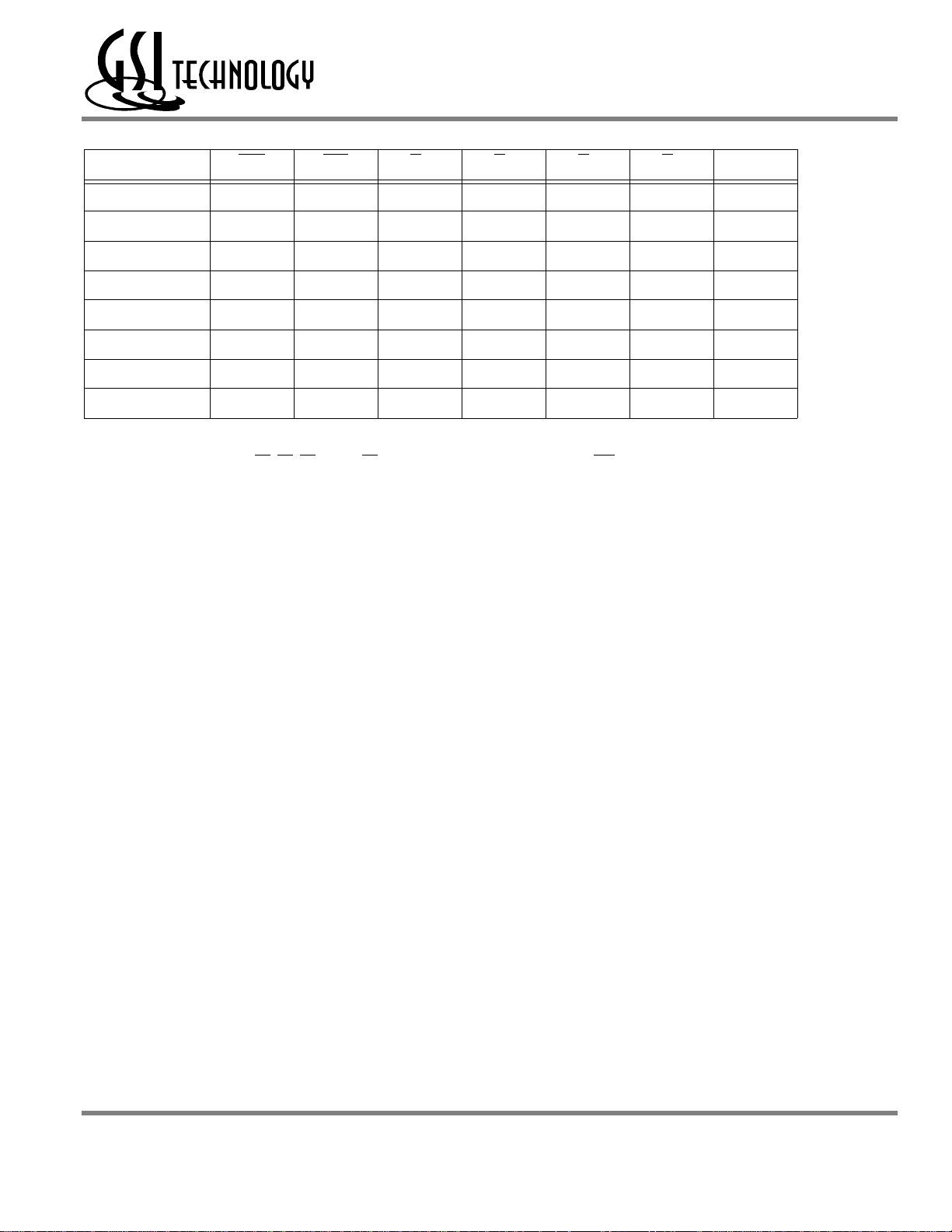

-250 -225 -200 -166 -150 -133

0

to

70°C

70

530

80

560

80

580

40

340

40

330

40

310

40

470

40

540

40

520

20

280

20

300

20

280

20

315

20

360

20

345

10

200

10

215

10

200

60

530

60

600

60

580

30

310

30

330

30

310

30

470

30

540

30

520

20

280

20

300

20

280

15

315

15

360

15

345

10

200

10

215

10

40 60 40 60 40 60 40 60 40 60 40 60

200

40 60 40 60 40 60 40 60 40 60 40 60

170 180 160 170 150 160 130 140 120 130 100 110

120 130 120 130 100 110 100 110 100 110 90 100

operation.

DDQ2

, and V

SB

DD

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DD

I

DDQ

I

DDQ

I

SB

DD

I

I

DD

I

I

DDQ3

, V

DD2

, V

Flow

Pipeline

Through

(x72)

Flow

Pipeline

Through

(x36)

IL

Flow

Pipeline

Through

(x18)

Flow

Pipeline

Through

(x72)

Flow

Pipeline

Through

(x36)

IL

Flow

Pipeline

Through

(x18)

Flow

Pipeline

Through

—

Flow

Pipeline

Through

—

IL

DD3

– 0.2 V

or ≤ V

IH

≥V

Device Selected;

Output open

All other inputs

or ≤ V

IH

≥V

Device Selected;

Output open

All other inputs

DD

ZZ ≥ V

or ≤ V

IH

≥ V

All other inputs

Device Deselected;

apply to any combination of V

DDQ

and I

Operating Currents

Parameter Test Conditions Mode Symbol

Operating

Operating

3.3 V

Current

2.5 V

Current

Current

Standby

Current

Deselect

DD

Notes:

1. I

2. All parameters listed are worst case scenario.

Rev: 1.00 10/2001 23/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

AC Electrical Characteristics

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Pipeline

Flow

Through

Parameter Symbol

-250 -225 -200 -166 -150 -133

Min Max Min Max Min Max Min Max Min Max Min Max

Clock Cycle Time tKC 4.0 — 4.4 — 5.0 — 6.0 — 6.7 — 7.5 — ns

Clock to Output Valid tKQ — 2.3 — 2.5 — 3.0 — 3.4 — 3.8 — 4.0 ns

Clock to Output Invalid tKQX 1.5 — 1.5 — 1.5 — 1.5 — 1.5 — 1.5 — ns

Clock to Output in Low-Z

tLZ

1

1.5 — 1.5 — 1.5 — 1.5 — 1.5 — 1.5 — ns

Clock Cycle Time tKC 7.0 — 7.5 — 8.5 — 10.0 — 10.0 — 15.0 — ns

Clock to Output Valid tKQ — 6.0 — 6.0 — 7.5 — 8.5 — 10.0 — 10.0 ns

Clock to Output Invalid tKQX 3.0 — 3.0 — 3.0 — 3.0 — 3.0 — 3.0 — ns

Clock to Output in Low-Z

tLZ

1

3.0 — 3.0 — 3.0 — 3.0 — 3.0 — 3.0 — ns

Clock HIGH Time tKH 1.3 — 1.3 — 1.3 — 1.3 — 1.5 — 1.7 — ns

Clock LOW Time tKL 1.5 — 1.5 — 1.5 — 1.5 — 1.7 — 2 — ns

Clock to Output in

High-Z

tHZ

1

1.5 2.3 1.5 2.5 1.5 3.0 1.5 3.5 1.5 3.8 1.5 4.0 ns

G to Output Valid tOE — 2.3 — 2.5 — 3.2 — 3.5 — 3.8 — 4.0 ns

G to output in Low-Z

G to output in High-Z

tOLZ

tOHZ

1

0 — 0 — 0 — 0 — 0 — 0 — ns

1

— 2.3 — 2.5 — 3.0 — 3.5 — 3.8 — 4.0 ns

Setup time tS 1.5 — 1.5 — 1.5 — 1.5 — 1.5 — 1.5 — ns

Hold time tH 0.5 — 0.5 — 0.5 — 0.5 — 0.5 — 0.5 — ns

ZZ setup time

ZZ hold time

tZZS

tZZH

2

5 — 5 — 5 — 5 — 5 — 5 — ns

2

1 — 1 — 1 — 1 — 1 — 1 — ns

ZZ recovery tZZR 100 — 100 — 100 — 100 — 100 — 100 — ns

Unit

Notes:

1. These parameters are sampled and are not 100% tested.

2. ZZ is an asynchronous signal. However, in order to be recognized on any given clock cycle, ZZ must meet the specified setup and hold

times as specified above.

Rev: 1.00 10/2001 24/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Write Cycle Timing

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

CK

ADSP

ADSC

ADV

A0–An

GW

BW

Single Write

tH

tS

tH

tS

WR1

Burst Write

ADSP is blocked by E inactive

tKC

tKL

tKH

tH

tS

tH

tS

ADV must be inactive for ADSP Write

WR2 WR3

tS tH

tH

tS

tS

tH

Write

ADSC initiated write

Deselected

BA–BD

tS

WR1 WR2 WR3

WR1

tH

WR2 WR3

E1 masks ADSP

E1

E1 only sampled with ADSP or ADSC

G

tS

tH

DQA–DQD

Hi-Z

D1A

Rev: 1.00 10/2001 25/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Write specified byte for 2A and all bytes for 2B, 2C& 2D

D2A D2B

D2C D2D D3A

Preliminary

Flow Through Read Cycle Timing

GS832418(B/C)/GS832436(B/C)/GS832472(C)

CK

ADSP

ADSC

ADV

A0–An

GW

BW

Single Read

tS

tH

tS

tS

tH

RD1

tS

tS

tKL

tKH

tS

tH

tH

RD2 RD3

Burst Read

ADSP is blocked by E inactive

tKC

Suspend Burst

ADSC initiated read

Suspend Burst

tH

tH

BA–BD

tH

tS

E1 masks ADSP

E1

tOE

tOHZ

G

DQA–DQD

tOLZ

Hi-Z

Q1A

tLZ

tKQ

Q2A

tKQX

Q2cQ2B

Q2D

Rev: 1.00 10/2001 26/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

tKQX

Q3A

tHZ

Flow Through Read-Write Cycle Timing

Single Read

CK

tH

tS

ADSP

ADSC

tH

tS

ADV

tS

tH

tKH

tKL

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Single Write

tKC

tS

tH

ADSP is blocked by E inactive

ADSC initiated read

Burst Read

A0–An

GW

BW

BA–BD

E1

DQA–DQD

G

Hi-Z

tS

RD1

tH

tOE

tKQ

tS tH

tS

tOHZ

Q1A D1A

tH

tS

tS

WR1

WR1

tH

tH

RD2

E1 masks ADSP

Q2A

Q2B Q2c

Q2D

Q2A

Burst wrap around to it’s initial state

Rev: 1.00 10/2001 27/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Pipelined SCD Read Cycle Timing

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

CK

ADSP

ADSC

ADV

A0–An

GW

BW

Single Read

tH

tS

tS

tH

tS

RD1

tS

tS

tH

tS

RD2

tKH

tH

tKL

Burst Read

tKC

ADSP is blocked by E inactive

ADSC initiated read

Suspend Burst

RD3

tH

tH

BWA–BWD

tH

tS

E1 masks ADSP

E1

tOE

G

tOHZ

tKQX

Q2A

Q2B

Q2c

DQA–DQD

Hi-Z

tOLZ

Q1A

tLZ

tKQ

Rev: 1.00 10/2001 28/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Q2D

tKQX

Q3A

tHZ

Pipelined SCD Read-Write Cycle Timing

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

CK

ADSP

ADSC

ADV

A0–An

GW

BW

tKL

Single Write

tKC

tS tH

WR1

tH

tS

ADSP is blocked by E inactive

ADSC initiated read

RD2

Single Read Burst Read

tH

tS

tS

RD1

tS tH

tH

tS

tH

tS tH

tKH

BWA– BWD

tS

tH

WR1

E1 masks ADSP

E1

tOE tOHZ

G

tS

DQA–DQD

Hi-Z

tKQ

Q1A

Rev: 1.00 10/2001 29/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

tH

D1A Q2A

Q2B Q2c

Q2D

Pipelined DCD Read Cycle Timing

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

CK

ADSP

ADSC

ADV

A0–An

GW

BW

BA–BD

Single Read

tH

tS

tS

tH

RD1

tS

tS

tS

tH

RD2

tKH

tKL

Burst Read

ADSP is blocked by E1 inactive

tKC

tS

tH

ADSC initiated read

Suspend Burst

RD3

tH

tH

tH

tS

E1 masks ADSP

E1

tOE

G

tOHZ

Q1A

DQA–DQD

Hi-Z

tOLZ

tLZ

tKQ

Rev: 1.00 10/2001 30/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Q2A

tKQX

Q2B

Q2c

Q2D

tKQX

Q3A

tHZ

Preliminary

Pipelined DCD Read-Write Cycle Timing

GS832418(B/C)/GS832436(B/C)/GS832472(C)

CK

ADSP

ADSC

ADV

A0–An

GW

BW

tKL

tS

Single Write

tKC

tH

ADSC initiated read

WR1

tS

tH

Single Read

tS

tH

tS

tH

tS

tH

RD1 RD2

tS

tH

tS tH

tKH

Burst Read

ADSP is blocked by E1 inactive

BA–BD

E1

G

DQA–DQD

Hi-Z

tS

tH

tOE tOHZ

tKQ

Q1A

WR1

E1 masks ADSP

tS

tH

D1A Q2A

Q2B Q2c

Q2D

Rev: 1.00 10/2001 31/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Sleep Mode

During normal operation, ZZ must be pulled low, either by the user or by its internal pull down resistor. When ZZ is pulled high,

the SRAM will enter a Power Sleep mode after 2 cycles. At this time, internal state of the SRAM is preserved. When ZZ returns to

low, the SRAM operates normally after 2 cycles of wake up time.

Sleep mode is a low current, power-down mode in which the device is deselected and current is reduced to ISB2. The duration of

Sleep mode is dictated by the length of time the ZZ is in a High state. After entering Sleep mode, all inputs except ZZ become

disabled and all outputs go to High-Z The ZZ pin is an asynchronous, active high input that causes the device to enter Sleep mode.

When the ZZ pin is driven high, ISB2 is guaranteed after the time tZZI is met. Because ZZ is an asynchronous input, pending

operations or operations in progress may not be properly completed if ZZ is asserted. Therefore, Sleep mode must not be initiated

until valid pending operations are completed. Similarly, when exiting Sleep mode during tZZR, only a Deselect or Read commands

may be applied while the SRAM is recovering from Sleep mode.

Sleep Mode Timing Diagram

~

CK

ADSP

tS

tH

tKC

tKH

tKL

~

~

~

~

~

~

ADSC

tZZS

ZZ

~

~

~

~

~

Snooze

tZZH

tZZR

Application Tips

Single and Dual Cycle Deselect

SCD devices (like this one) force the use of “dummy read cycles” (read cycles that are launched normally, but that are ended with

the output drivers inactive) in a fully synchronous environment. Dummy read cycles waste performance, but their use usually

assures there will be no bus contention in transitions from reads to writes or between banks of RAMs. DCD SRAMs do not waste

bandwidth on dummy cycles and are logically simpler to manage in a multiple bank application (wait states need not be inserted at

bank address boundary crossings), but greater care must be exercised to avoid excessive bus contention.

JTAG Port Operation

Due to the fact that this device is built from two die, the two JTAG parts are chained together internally. The following describes

the behavior of each die.

Overview

The JTAG Port on this RAM operates in a manner that is compliant with IEEE Standard 1149.1-1990, a serial boundary scan

interface standard (commonly referred to as JTAG). The JTAG Port input interface levels scale with VDD. The JTAG output

drivers are powered by V

DDQ

.

Rev: 1.00 10/2001 32/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Disabling the JTAG Port

It is possible to use this device without utilizing the JTAG port. The port is reset at power-up and will remain inactive unless

clocked. TCK, TDI, and TMS are designed with internal pull-up circuits.To assure normal operation of the RAM with the JTAG

Port unused, TCK, TDI, and TMS may be left floating or tied to either VDD or VSS. TDO should be left unconnected.

JTAG Pin Descriptions

Pin Pin Name I/O Description

TCK Test Clock In

TMS Test Mode Select In

TDI Test Data In In

TDO Test Data Out Out

Note:

This device does not have a TRST (TAP Reset) pin. TRST is optional in IEEE 1149.1. The Test-Logic-Reset state is entered while TMS is

held high for five rising edges of TCK. The TAP Controller is also reset automaticly at power-up.

Clocks all TAP events. All inputs are captured on the rising edge of TCK and all outputs propagate

from the falling edge of TCK.

The TMS input is sampled on the rising edge of TCK. This is the command input for the TAP

controller state machine. An undriven TMS input will produce the same result as a logic one input

level.

The TDI input is sampled on the rising edge of TCK. This is the input side of the serial registers

placed between TDI and TDO. The register placed between TDI and TDO is determined by the

state of the TAP Controller state machine and the instruction that is currently loaded in the TAP

Instruction Register (refer to the TAP Controller State Diagram). An undriven TDI pin will produce

the same result as a logic one input level.

Output that is active depending on the state of the TAP state machine. Output changes in

response to the falling edge of TCK. This is the output side of the serial registers placed between

TDI and TDO.

JTAG Port Registers

Overview

The various JTAG registers, refered to as Test Access Port orTAP Registers, are selected (one at a time) via the sequences of 1s

and 0s applied to TMS as TCK is strobed. Each of the TAP Registers is a serial shift register that captures serial input data on the

rising edge of TCK and pushes serial data out on the next falling edge of TCK. When a register is selected, it is placed between the

TDI and TDO pins.

Instruction Register

The Instruction Register holds the instructions that are executed by the TAP controller when it is moved into the Run, Test/Idle, or

the various data register states. Instructions are 3 bits long. The Instruction Register can be loaded when it is placed between the

TDI and TDO pins. The Instruction Register is automatically preloaded with the IDCODE instruction at power-up or whenever the

controller is placed in Test-Logic-Reset state.

Bypass Register

The Bypass Register is a single bit register that can be placed between TDI and TDO. It allows serial test data to be passed through

the RAM’s JTAG Port to another device in the scan chain with as little delay as possible.

Boundary Scan Register

The Boundary Scan Register is a collection of flip flops that can be preset by the logic level found on the RAM’s input or I/O pins.

The flip flops are then daisy chained together so the levels found can be shifted serially out of the JTAG Port’s TDO pin. The

Boundary Scan Register also includes a number of place holder flip flops (always set to a logic 1). The relationship between the

device pins and the bits in the Boundary Scan Register is described in the Scan Order Table following. The Boundary Scan

Register, under the control of the TAP Controller, is loaded with the contents of the RAMs I/O ring when the controller is in

Rev: 1.00 10/2001 33/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Capture-DR state and then is placed between the TDI and TDO pins when the controller is moved to Shift-DR state. SAMPLE-Z,

SAMPLE/PRELOAD and EXTEST instructions can be used to activate the Boundary Scan Register.

JTAG TAP Block Diagram

0

Bypass Register

012

Instruction Register

TDI

TMS

TCK

ID Code Register

31 30 29

· · · ·

Boundary Scan Register

n

Test Access Port (TAP) Controller

· · ·· · ·

012

· · ·

012

TDO

Identification (ID) Register

The ID Register is a 32-bit register that is loaded with a device and vendor specific 32-bit code when the controller is put in

Capture-DR state with the IDCODE command loaded in the Instruction Register. The code is loaded from a 32-bit on-chip ROM.

It describes various attributes of the RAM as indicated below. The register is then placed between the TDI and TDO pins when the

controller is moved into Shift-DR state. Bit 0 in the register is the LSB and the first to reach TDO when shifting begins.

ID Register Contents

Die

Revision

Code

Bit # 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

x72 X X X X 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 1 0 0 0 1 1 0 1 1 0 0 1 1

x36 X X X X 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 1 1 0 1 1 0 0 1 1

x32 X X X X 0 0 0 0 0 0 0 0 0 0 0 0 1 1 0 0 0 0 0 1 1 0 1 1 0 0 1 1

x18 X X X X 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 0 0 0 0 1 1 0 1 1 0 0 1 1

x16 X X X X 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 0 0 0 0 1 1 0 1 1 0 0 1 1

Not Used

I/O

Configuration

GSI Technology

JEDEC Vendor

ID Code

Presence Register

Tap Controller Instruction Set

Overview

There are two classes of instructions defined in the Standard 1149.1-1990; the standard (Public) instructions, and device specific

(Private) instructions. Some Public instructions are mandatory for 1149.1 compliance. Optional Public instructions must be

Rev: 1.00 10/2001 34/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

implemented in prescribed ways. The TAP on this device may be used to monitor all input and I/O pads, and can be used to load

address, data or control signals into the RAM or to preload the I/O buffers.

When the TAP controller is placed in Capture-IR state the two least significant bits of the instruction register are loaded with 01.

When the controller is moved to the Shift-IR state the Instruction Register is placed between TDI and TDO. In this state the desired

instruction is serially loaded through the TDI input (while the previous contents are shifted out at TDO). For all instructions, the

TAP executes newly loaded instructions only when the controller is moved to Update-IR state. The TAP instruction set for this

device is listed in the following table.

JTAG Tap Controller State Diagram

Test Logic Reset

1

0

Run Test Idle

0

1 1 1

Select DR

1

Capture DR

Shift DR

1

Exit1 DR

Pause DR

Exit2 DR

Update DR

1

Select IR

0

1

0

0

Capture IR

0

Shift IR

1

0

0

1

1

Exit1 IR

0

Pause IR

1

1

0

0 0

1

Exit2 IR

1

Update IR

0

1 0

0

0

Instruction Descriptions

BYPASS

When the BYPASS instruction is loaded in the Instruction Register the Bypass Register is placed between TDI and TDO. This occurs when

the TAP controller is moved to the Shift-DR state. This allows the board level scan path to be shortened to facilitate testing of other devices

in the scan path.

SAMPLE/PRELOAD

SAMPLE/PRELOAD is a Standard 1149.1 mandatory public instruction. When the SAMPLE / PRELOAD instruction is loaded in the Instruction Register, moving the TAP controller into the Capture-DR state loads the data in the RAMs input and I/O buffers into the Boundary Scan

Register. Boundary Scan Register locations are not associated with an input or I/O pin, and are loaded with the default state identified in the

Rev: 1.00 10/2001 35/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

Boundary Scan Chain table at the end of this section of the datasheet. Because the RAM clock is independent from the TAP Clock (TCK) it

is possible for the TAP to attempt to capture the I/O ring contents while the input buffers are in transition (i.e. in a metastable state). Although

allowing the TAP to sample metastable inputs will not harm the device, repeatable results cannot be expected. RAM input signals must be

stabilized for long enough to meet the TAPs input data capture set-up plus hold time (tTS plus tTH). The RAMs clock inputs need not be

paused for any other TAP operation except capturing the I/O ring contents into the Boundary Scan Register. Moving the controller to ShiftDR state then places the boundary scan register between the TDI and TDO pins.

EXTEST

EXTEST is an IEEE 1149.1 mandatory public instruction. It is to be executed whenever the instruction register is loaded with all logic 0s.

The EXTEST command does not block or override the RAM’s input pins; therefore, the RAM’s internal state is still determined by its input

pins.

Typically, the Boundary Scan Register is loaded with the desired pattern of data with the SAMPLE/PRELOAD command. Then the EXTEST

command is used to output the Boundary Scan Register’s contents, in parallel, on the RAM’s data output drivers on the falling edge of TCK

when the controller is in the Update-IR state.

Alternately, the Boundary Scan Register may be loaded in parallel using the EXTEST command. When the EXTEST instruction is selected,

the sate of all the RAM’s input and I/O pins, as well as the default values at Scan Register locations not associated with a pin, are transferred in parallel into the Boundary Scan Register on the rising edge of TCK in the Capture-DR state, the RAM’s output pins drive out the

value of the Boundary Scan Register location with which each output pin is associated.

IDCODE

The IDCODE instruction causes the ID ROM to be loaded into the ID register when the controller is in Capture-DR mode and places the ID

register between the TDI and TDO pins in Shift-DR mode. The IDCODE instruction is the default instruction loaded in at power up and any

time the controller is placed in the Test-Logic-Reset state.

SAMPLE-Z

If the SAMPLE-Z instruction is loaded in the instruction register, all RAM outputs are forced to an inactive drive state (high-Z) and the

Boundary Scan Register is connected between TDI and TDO when the TAP controller is moved to the Shift-DR state.

RFU

These instructions are Reserved for Future Use. In this device they replicate the BYPASS instruction.

Rev: 1.00 10/2001 36/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

JTAG TAP Instruction Set Summary

Instruction Code Description Notes

EXTEST 000 Places the Boundary Scan Register between TDI and TDO. 1

IDCODE 001 Preloads ID Register and places it between TDI and TDO. 1, 2

Captures I/O ring contents. Places the Boundary Scan Register between TDI and

SAMPLE-Z 010

RFU 011

SAMPLE/

PRELOAD

GSI 101 GSI private instruction. 1

RFU 110

BYPASS 111 Places Bypass Register between TDI and TDO. 1

Notes:

1. Instruction codes expressed in binary, MSB on left, LSB on right.

2. Default instruction automatically loaded at power-up and in test-logic-reset state.

100

TDO.

Forces all RAM output drivers to High-Z.

Do not use this instruction; Reserved for Future Use.

Replicates BYPASS instruction. Places Bypass Register between TDI and TDO.

Captures I/O ring contents. Places the Boundary Scan Register between TDI and

TDO.

Do not use this instruction; Reserved for Future Use.

Replicates BYPASS instruction. Places Bypass Register between TDI and TDO.

1

1

1

1

Rev: 1.00 10/2001 37/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

GS832418(B/C)/GS832436(B/C)/GS832472(C)

JTAG Port Recommended Operating Conditions and DC Characteristics

Parameter Symbol Min. Max. Unit Notes

3.3 V Test Port Input High Voltage

3.3 V Test Port Input Low Voltage

2.5 V Test Port Input High Voltage

2.5 V Test Port Input Low Voltage

TMS, TCK and TDI Input Leakage Current

TMS, TCK and TDI Input Leakage Current

TDO Output Leakage Current

Test Port Output High Voltage

Test Port Output Low Voltage

Test Port Output CMOS High

Test Port Output CMOS Low

Notes:

1. Input Under/overshoot voltage must be –2 V > Vi < V

2. V

3. 0 V ≤ V

4. Output Disable, V

5. The TDO output driver is served by the V

6. I

7. I

8. I

9. I

ILJ

OHJ

OLJ

OHJC

OHJC

≤ V

IN

IN

= –4 mA

= + 4 mA

= –100 uA

= +100 uA

≤ V

≤ V

DDn

ILJn

OUT

= 0 to V

DDn

DDQ

supply.

+2 V not to exceed 4.6 V maximum, with a pulse width not to exceed 20% tTKC.

DDn

V

V

V

V

I

I

V

V

V

V

IHJ3

ILJ3

IHJ2

ILJ2

INHJ

INLJ

I

OLJ

OHJ

OLJ

OHJC

OLJC

V

DDQ

0.6 * V

Preliminary

V

2.0

–0.3 0.8 V 1

DD2

–0.3

–300 1 uA 2

–1 100 uA 3

–1 1 uA 4

1.7 — V 5, 6

— 0.4 V 5, 7

– 100 mV

— 100 mV V 5, 9

DD3

V

DD2

0.3 * V

+0.3

+0.3

DD2

V 1

V 1

V 1

— V 5, 8

JTAG Port AC Test Conditions

Parameter Conditions

Input high level 2.3 V

Input low level 0.2 V

Input slew rate 1 V/ns

Input reference level 1.25 V

Output reference level 1.25 V

Notes:

1. Include scope and jig capacitance.

2. Test conditions as as shown unless otherwise noted.

Rev: 1.00 10/2001 38/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

DQ

JTAG Port AC Test Load

50Ω

VT = 1.25 V

* Distributed Test Jig Capacitance

30pF

*

JTAG Port Timing Diagram

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

tTKQ

tTKL

tTS tTH

tTKC

tTKH

TCK

TMS

TDI

TDO

JTAG Port AC Electrical Characteristics

Parameter Symbol Min Max Unit

TCK Cycle Time tTKC 50 — ns

TCK Low to TDO Valid tTKQ — 20 ns

TCK High Pulse Width tTKH 20 — ns

TCK Low Pulse Width tTKL 20 — ns

TDI & TMS Set Up Time tTS 10 — ns

TDI & TMS Hold Time tTH 10 — ns

Rev: 1.00 10/2001 39/46 © 2001, Giga Semiconductor, Inc.

Specifications cited are subject to change without notice. For latest documentation see http://www.gsitechnology.com.

Preliminary

GS832418(B/C)/GS832436(B/C)/GS832472(C)

GS832418/36/72 Boundary Scan Chain Order

Bump

Order x72 x36 x18

x72 x36 x18

1(TBD)

Notes:

1. Depending on the package, some input pads of the scan chain may not be connected to any external pin. In such case: LBO = 1, ZQ = 1,

PE = 0, SD = 0, ZZ = 0, FT = 1, DP = 1, and SCD = 1.

2. Every DQ pad consists of two scan registers—D is for input capture, and Q is for output capture.

3. A single register (#194) for controlling tristate of all the DQ pins is at the end of the scan chain (i.e., the last bit shifted in this tristate control

is effective after JTAG EXTEST instruction is executed.