Page 1

Agrifeed Model 5500

Standard Scale & Supply Company

25421 Glendale Avenue

Redford, MI 48239

313-255-6700

www.standardscale.com

Digital Weight Indicator

Reference Manual

Issue AD

Page 2

Preface

We at GSE wish to thank you for selecting the Agrifeed 5500 Digital

Weight Indicator for your weighing needs. The Agrifeed 5500 continues

the GSE tradition of Excellence in Weighing Technology. When properly

installed and maintained, the Agrifeed 5500 will provide many years of

reliable, accurate performance. Please read the sections on installation

and setup before proceeding with installation.

Warning

The Agrifeed 5500 contains components which could be damaged by

Electrostatic Discharge (ESD) if serviced improperly. Use proper ESD

precautions (wear a wrist strap connected to ground, use grounded work

stations, etc.) when opening the enclosure. ALWAYS unplug the

Agrifeed 5500 when opening the enclosure. Installation and servicing of

the Agrifeed 5500 should be performed by authorized and qualified

service personnel only!

It is important to ensure that the indicator stand is grounded to the truck

frame or the truck battery. If the indicator stand cannot be secured

directly to the truck frame, then it is necessary to provide a grounding

strap from the stand to the frame. Failure to ground the stand can result

in the buildup of a static charge that could damage electrical components

within the indicator, thus voiding the warranty. The indicator power

cable should be run directly to the positive and negative terminals of the

battery.

Proprietary Notice

Information in this Reference Manual is subject to change without notice

due to correction or enhancement. The information described in this

manual is solely the property of GSE. This manual may not be

distributed without written permission of GSE.

This manual is published by:

GSE

1525 Fairlane Circle

Allen Park, MI 48101

http://www.gse-inc.com/

Phone: (313) 253-1300

Fax: (313) 253 - 1301

Page 3

Table of Contents

SECTION 1:

1.1 USING THIS MANUAL ................................................................ 1

1.2 OPERATOR INTERFACE .............................................................. 2

1.3 WEIGH MODE OPERATION ........................................................ 2

1.4 KEYPAD .................................................................................... 3

1.5 STANDARD FUNCTIONS ............................................................. 4

1.6 WARRANTY ............................................................................... 4

1.7 SPECIFICATIONS ........................................................................ 5

SECTION 2: INSTALLATION ........................................................ 7

2.1 UNPACKING ............................................................................... 7

2.2 MOUNTING ................................................................................ 7

2.2.1 Environmental .................................................................. 7

2.2.2 Rear Panel Mounting ........................................................ 7

2.2.3 Swivel Mounting (Optional) ............................................. 8

2.3 LEGAL FOR TRADE .................................................................... 8

2.3.1 Physical Seal..................................................................... 8

2.3.2 Audit Trail ........................................................................ 9

2.4 WIRING ..................................................................................... 9

2.4.1 Load Cell Connection ..................................................... 10

2.4.2 Printer Port Connection ................................................. 10

2.4.3 Comm Port Connection .................................................. 10

2.4.4 Remote Key Connection .................................................. 11

2.4.5 Power Connection .......................................................... 11

2.4.6 Alarm Out Connection .................................................... 12

INTRODUCTION ...................................................... 1

SECTION 3: CONFIGURATION ................................................. 13

3.1 PASSWORD .............................................................................. 13

3.1.1 Entering a password ....................................................... 13

3.1.2 Changing the Default Password ..................................... 13

3.2 QUICK MENU .......................................................................... 14

3.3 SETUP MODE ........................................................................... 14

3.3.1 Print Setup ...................................................................... 15

3.3.2 Scale Setup ...................................................................... 16

3.3.3 Communication Setup ..................................................... 18

3.3.4 Memory Manager Setup ................................................. 23

3.3.5 Remote Display Setup ..................................................... 25

3.3.6 Ingredient Setup .............................................................. 26

3.3.7 Calibrate Mode ............................................................... 31

3.3.8 Mix Timer ....................................................................... 40

i

Page 4

SECTION 4:

4.1 ACCESSING THE RECIPE DATABASE ......................................... 41

4.2 ADDING A RECIPE .................................................................... 42

4.2.1 Recipe Pre-Alarm ............................................................ 43

4.2.2 Weight Entry Method ...................................................... 44

4.2.3 Ingredient Selection ........................................................ 45

4.3 EDITING A RECIPE .................................................................... 46

4.4 DELETING A RECIPE ................................................................. 46

4.5 PRINTING RECIPES ................................................................... 47

SECTION 5: LOAD / UNLOAD OPERATION ............................ 49

5.1 LOADING INGREDIENTS ........................................................... 49

5.1.1 Selecting Individual Ingredients...................................... 49

5.1.2 Selecting a Recipe ........................................................... 49

5.1.3 Loading Process .............................................................. 50

5.1.4 Advancing Ingredients .................................................... 51

5.2 UNLOADING RECIPES ............................................................... 51

5.2.1 Selecting Individual Pens ................................................ 51

5.2.2 Selecting Pens from a List ............................................... 52

5.2.3 Unload Process ............................................................... 52

5.2.4 Advancing Pens ............................................................... 53

5.2.5 Unloading using Weight / Animal ................................... 53

5.2.6 Unfinished Load / Unload ............................................... 53

RECIPE SETUP ........................................................ 41

SECTION 6: TROUBLESHOOTING ........................................... 55

6.1 OPERATIONAL MODE ERROR MESSAGES ................................. 55

6.2 HARDWARE PROBLEM ERROR MESSAGES ............................... 56

6.2.1 Reload Agrifeed 5500 Custom Program ......................... 57

6.3 CALIBRATION ERROR MESSAGES ............................................ 58

6.4 COMMUNICATION ERROR MESSAGES ...................................... 59

6.4.1 Data Transmissions ......................................................... 59

6.4.2 Displayed Weight ............................................................ 59

6.5 A/D CALIBRATION PROCEDURE ............................................... 60

SECTION 7: AGRIFEED 5500 OPTION KITS ........................... 61

7.1 PERIPHERAL OPTIONS FOR THE AGRIFEED 5500 ...................... 61

7.1.1 Swivel Bracket Installation ............................................. 62

7.1.2 Remote Display Option ................................................... 63

7.1.3 Agridata Recipe Management Software .......................... 65

7.1.4 RF Remote Key................................................................ 65

7.1.5 RF Link............................................................................ 65

ii

Page 5

Section 1: Introduction

1.1 Using this Manual

The manual is divided into sections that cover the major features of the

indicator. Each section is then subdivided into smaller reference sections

to provide details of each topic. Where applicable, references will be

made to other sections that contain information pertinent to the current

topic.

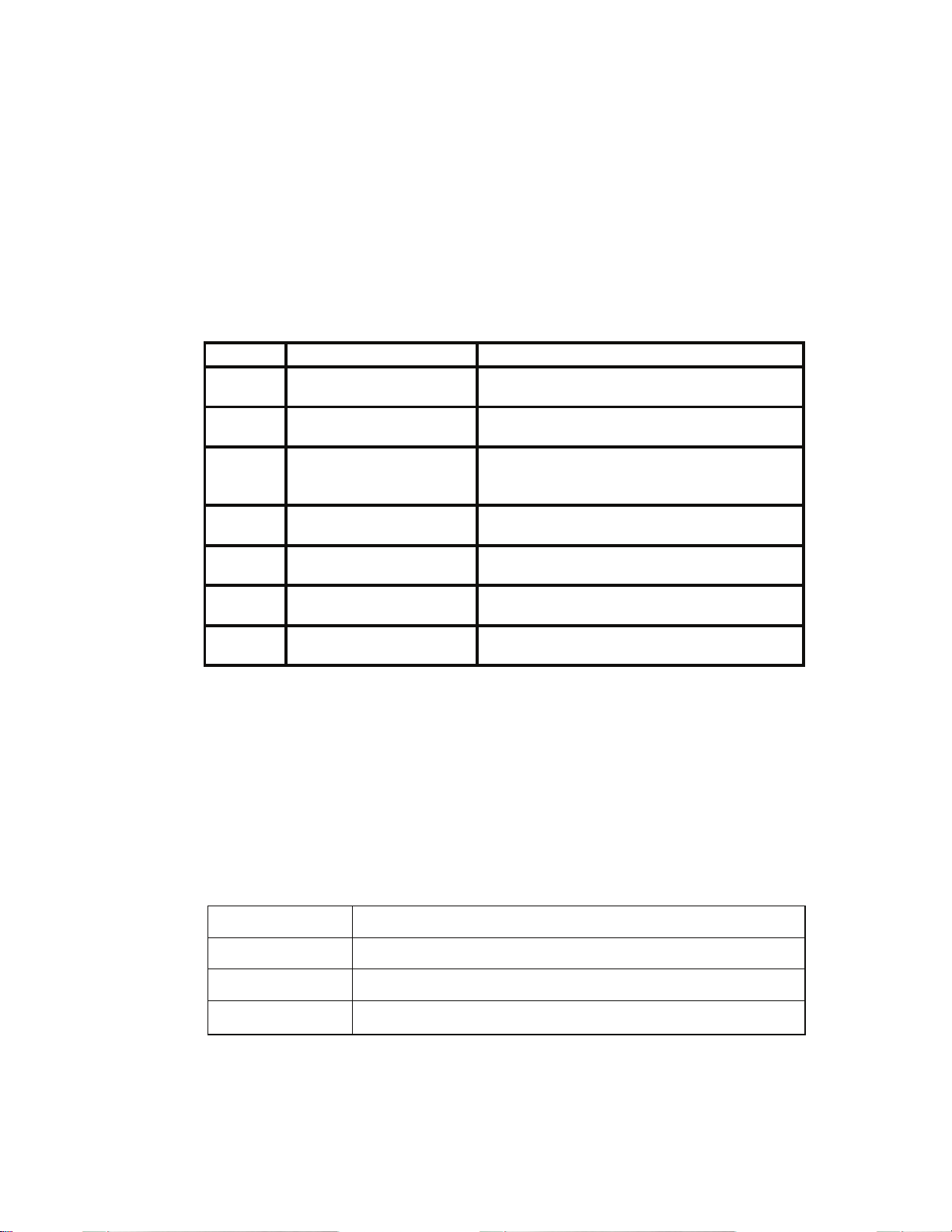

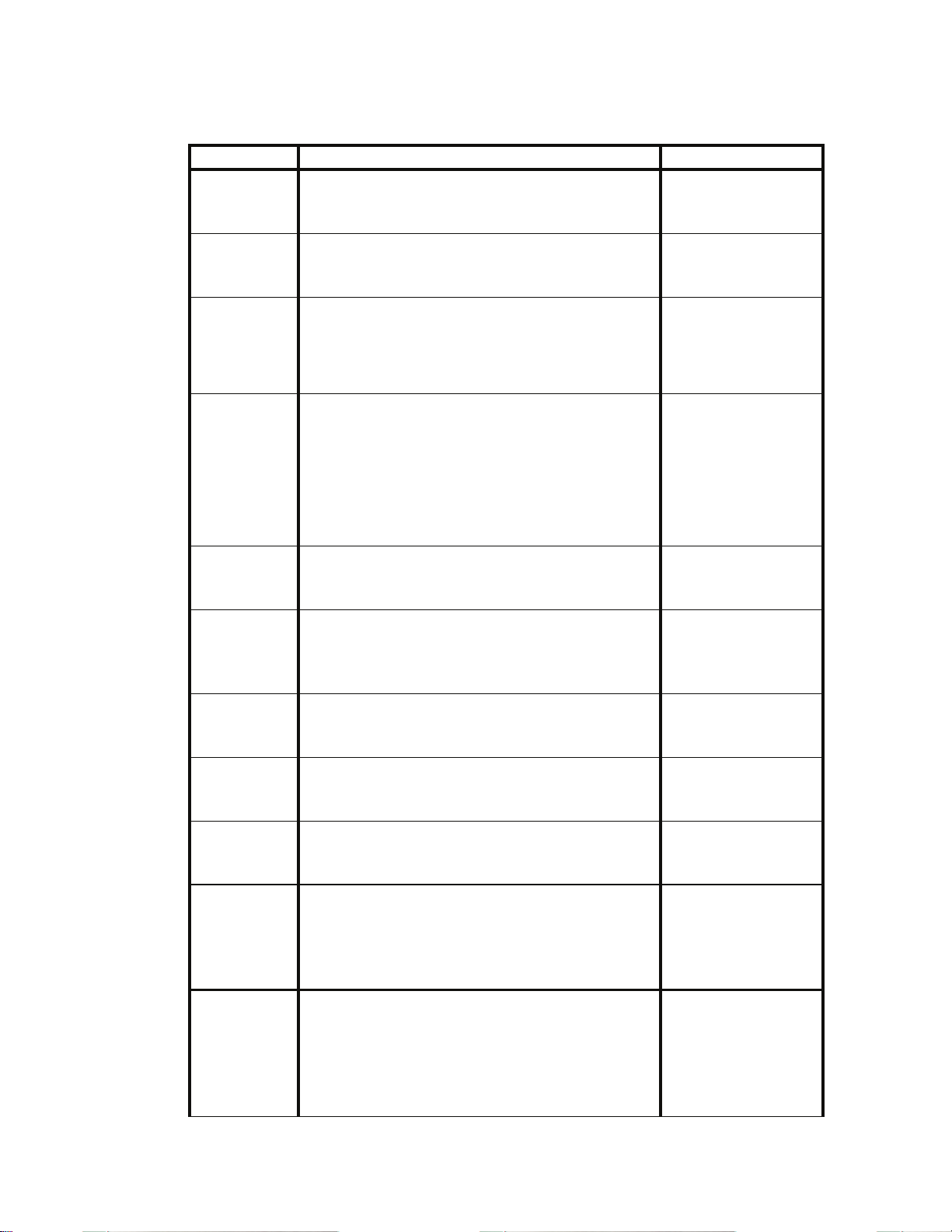

Section Topic Discussion

1 Introduction

2 Installation

3 Configuration

4 Recipe Setup

5 Load/Unload Operation

6 Trouble-shooting

7 Options

Provides an introduction to the Agrifeed

5500 and its basic operation.

Instructs how to get the Agrifeed 5500

operating quickly, correctly and safely.

Instructs how to access the Setup Mode

and configure the indicator to a specific

application.

Instructs how to create and edit the recipe

database.

Demonstrates how to load and unload

recipes.

Provides troubleshooting help and

information on error messages.

Describes installation of the Agrifeed 5500

options.

Conventions Used In This Manual

The GSE Agrifeed 5500 Digital Weight Indicator, hereafter referred to as

the Agrifeed 5500, is capable of displaying alpha characters in either

upper or lower case. For ease of reading, this manual uses conventional

capitalization when referencing Agrifeed 5500 prompts. See Table 1 for

the conventions used in this manual.

Table 1: Typographical Conventions

[ZERO] A keypress appears in bold type with brackets.

200 [ZERO] Numeric entries preceding a keypress are also bold.

[CLR]+[ZERO] Keys separated with a ‘+’ must be pressed simultaneously.

“KeyIn CalWt”

Display prompts are bold italic.

1

Page 6

1.2 Operator Interface

G

T

The Agrifeed 5500 makes extensive use of the display and keypad. The

display and keypad perform different functions in the weigh mode, setup

mode and help mode.

Upon power-up, the back-light and all pixels illuminate momentarily for

a display test. The indicator then displays the Agrifeed GSE Model 5500

revision screen followed by the Operator ID? prompt (see Figure 1).

Key in the operator ID number and press [ENTER], or press only

[ENTER] to bypass the prompt. The operator ID will be recorded with

each load or unload transaction saved in the history database.

Operator ID?

Key in ID# and press [ENTER], or

Press [ENTER] to bypass.

Figure 1: Operator ID Entry

Next, the gross weight display appears (see Figure 2). The top right

corner of the display indicates the mode and status (see Table 2). The

lower left corner displays the LOAD/UNLOAD mode as selected by the

[LOAD/UNLOAD] key. The tare weight and recipe number are shown

in the lower right corner.

lbÎοÍ

00

LOAD

Figure 2: Weigh Mode Display

1.3 Weigh Mode Operation

Recipe 00

are 00 lb

ross

Upon power-up, the Agrifeed 5500 will display the gross weight in

default units. The top right of the display provides mode and status

information (see Table 2: Annunciators).

2

Page 7

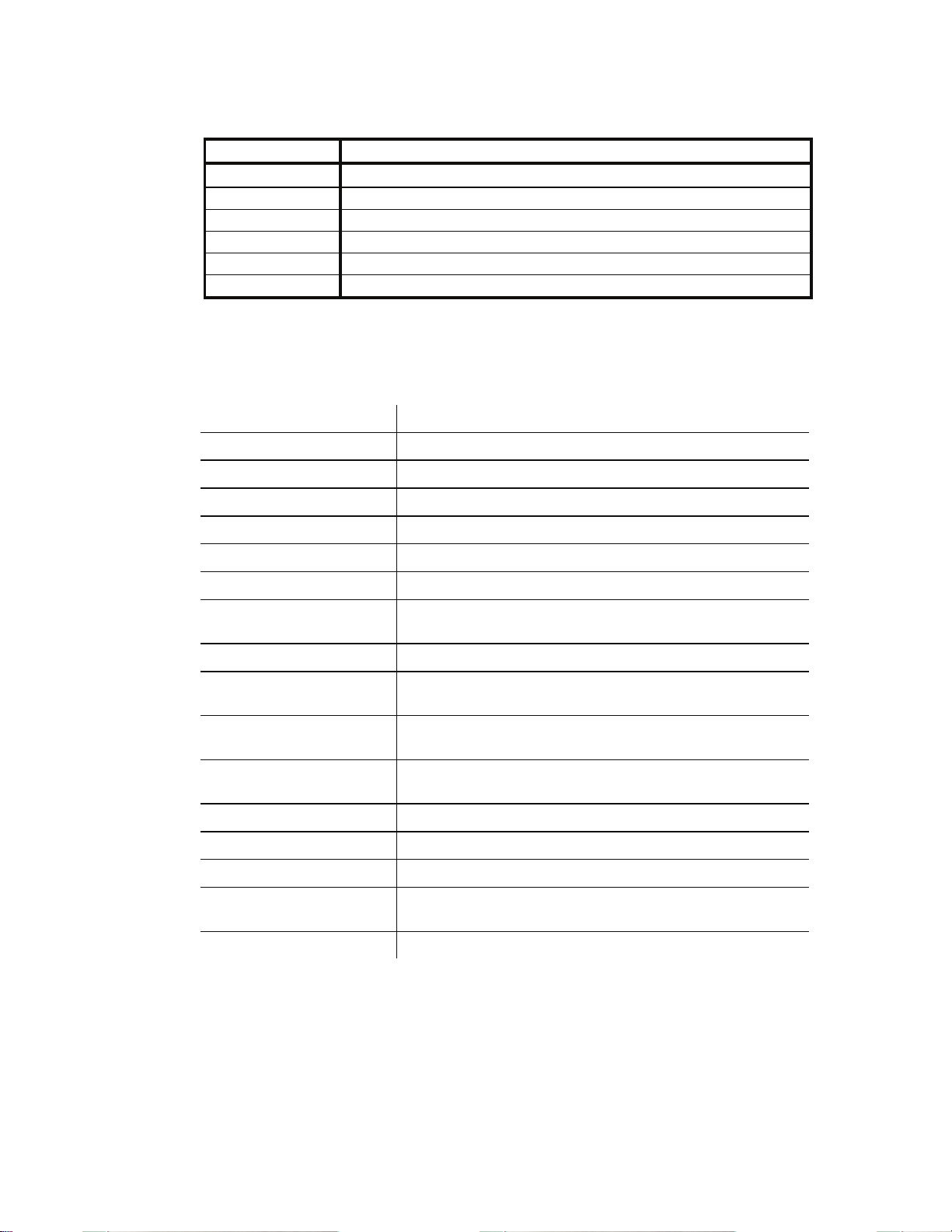

Table 2: Annunciators

Annunciator Indication When Illuminated

→0←

Gross

Net

lb

kg

Tons

Displayed weight is at center-of-zero (± ¼ display graduation).

The displayed value represents the current gross weight.

The displayed value represents the current net weight.

The displayed value is represented in pounds.

The displayed value is represented in kilograms.

The displayed value is represented in tons.

1.4 Keypad

The Agrifeed 5500 keypad provides the following primary functions:

[ON]

[OFF]

[LOAD/UNLOAD]

[MIX TIMER]

[SELECT INGRED]

[TARE]

[NET/GROSS]

[ZERO]

[PRINT]

[ENTER/YES]

[ADD RECIPE]

[EDIT RECIPE]

[SELECT RECIPE]

[START BATCH]

Turns indicator on

Turns indicator off

Toggles between the load and unload process

Initiates the mix timer function

Scrolls ingredients during the load process

Tares the displayed weight and selects the net mode

Toggles the display mode between GROSS and NET

Zeros the scale if pressed immediately after the

[NET/GROSS] key

Initiates data transmission out the printer port

Answers ‘YES’ to prompts or completes operator

entries. Displays time & date in weigh mode

Adds a new recipe to the recipe database using the

first unused recipe number

Invokes the edit routine for the currently selected

recipe

Sets the current recipe number

Used to initiate the [LOAD/UNLOAD] process

[STOP BATCH]

[HELP]

[CLR\NO]

Used to stop/abort the [LOAD/UNLOAD] process

Used to display information about various keys and

access setup parameters

Answers “NO” to prompts. Also used to clear an entry

3

Page 8

1.5 Standard Functions

The Agrifeed 5500 includes several built-in functions that can be enabled

through the indicator setup. These functions include the following:

• Remote key operation

• Selectable data transmission formats

• Mix Timer

• Storage for 100 recipes

• Storage for 100 ingredients

Refer to Section 3.3 on page 14 for setup and operation of these features.

1.6 Warranty

Your Agrifeed 5500 is warranted against defects in

materials and manufacturing for a period of two years from the date of

purchase.

In the event of a product failure due to materials or workmanship,

GSE will, at its discretion, repair or replace the product.

Always ensure proper installation and grounding. Never weld around the

Agrifeed 5500 or load cells. Contact your GSE Agrifeed distributor for

further details.

4

Page 9

1.7 Specifications

PERFORMANCE

Full Scale (F.S.) Selectable 0 to 999,990

Resolution 20-bit A/D converter, 100,000d displayed

±500,000d internal

A/D Conversion 60 Hz

Zero Track 0d – 10.0d

Operating Temperature -30°C to +65°C

Units of Measure lb, kg, tons

ELECTRICAL

Power Requirement Input: 10.5 – 16 VDC, minimum 0.8A

Excitation Voltage 10 VDC

Excitation Current 180 mA max. / (4) 350Ω bridge

Signal Input Sensitivity 0.1 – 20 mV/V

Signal Connection 4 lead

PROCESS CONTROL

Remote Input

COMMUNICATIONS

Serial RS232 bi-directional port

Data Output 1 of 7 selectable fixed-format

Protocol Selectable

Baud Rate 300 – 19200 baud (Print Port)

1200- 19200 baud (Comm Port)

DISPLAY

LCD 240 x 64 DOTS graphic type Liquid

ENCLOSURE

Stainless Steel Wash-down enclosure. NEMA 4X TYPE

OPTIONS

1 momentary contact closure (100ms

minimum)

TARE, PRINT, ZERO, ADVANCE,

PRINT & TARE

transmissions and custom user defined

format.

Crystal Matrix display

(IP66)

.

Wall Mount Kit Swivel bracket/stand

Remote Display 2” (51mm) LCD Back-light

Remote RF Key Wireless remote key functions

Cables Remote display, comm, printer

Data Logger Serial recording device

Agridata Program Windows based interface program

5

Page 10

This page is intentionally left blank

6

Page 11

Section 2: Installation

2.1 Unpacking

When unpacking your new Agrifeed 5500 Indicator, do not discard any

packing material until you are sure you have all the components needed

for your installation. Small bags are included containing parts that may

be required for a complete installation.

2.2 Mounting

This section contains information necessary for proper installation of the

Agrifeed 5500. The standard enclosure is designed to allow wiring

without opening the enclosure. All wiring is accessible through bottom

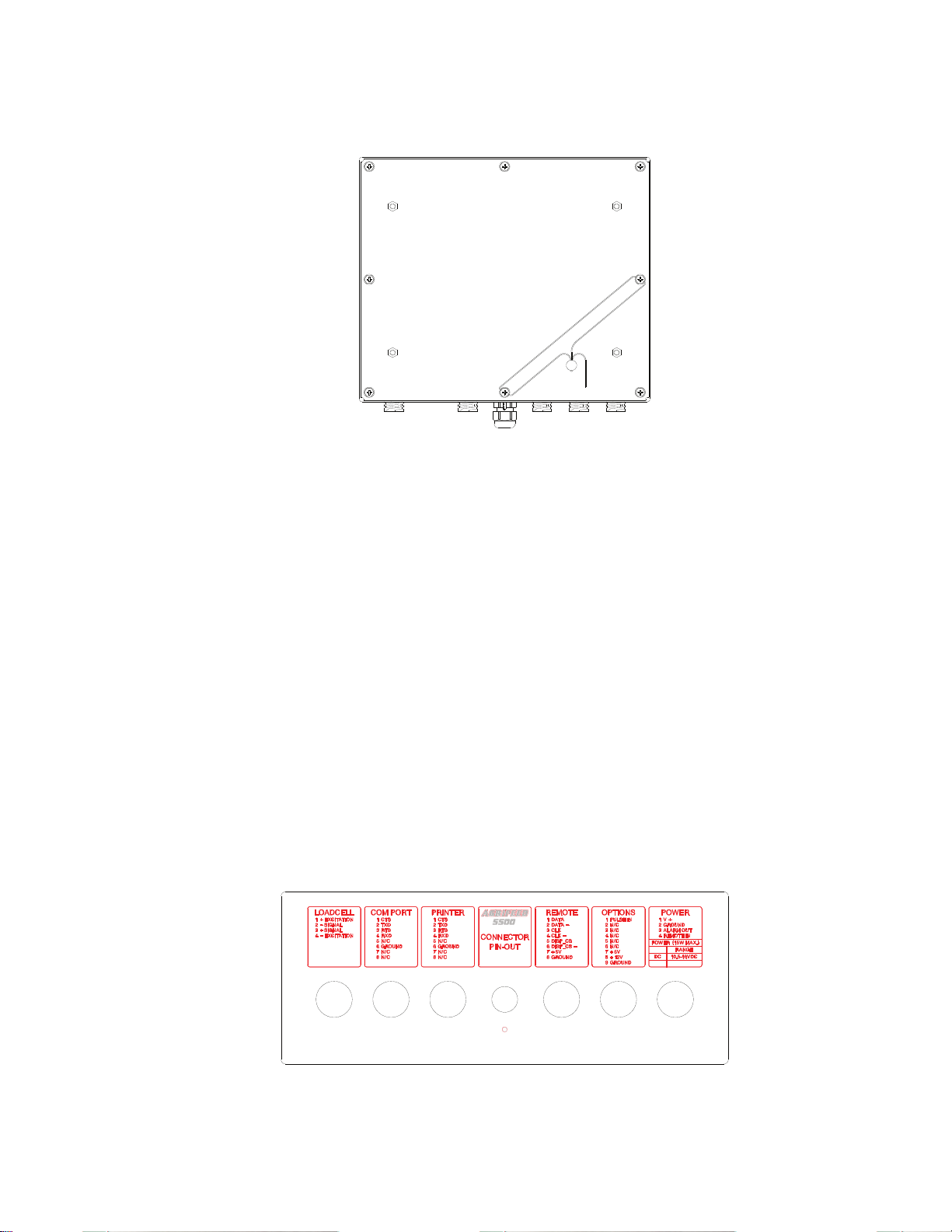

connectors (see Figure 6: Agrifeed 5500 Connector Label).

2.2.1 Environmental

The Agrifeed 5500 Stainless Steel enclosure is designed to NEMA 4X

(IP66) type specifications.

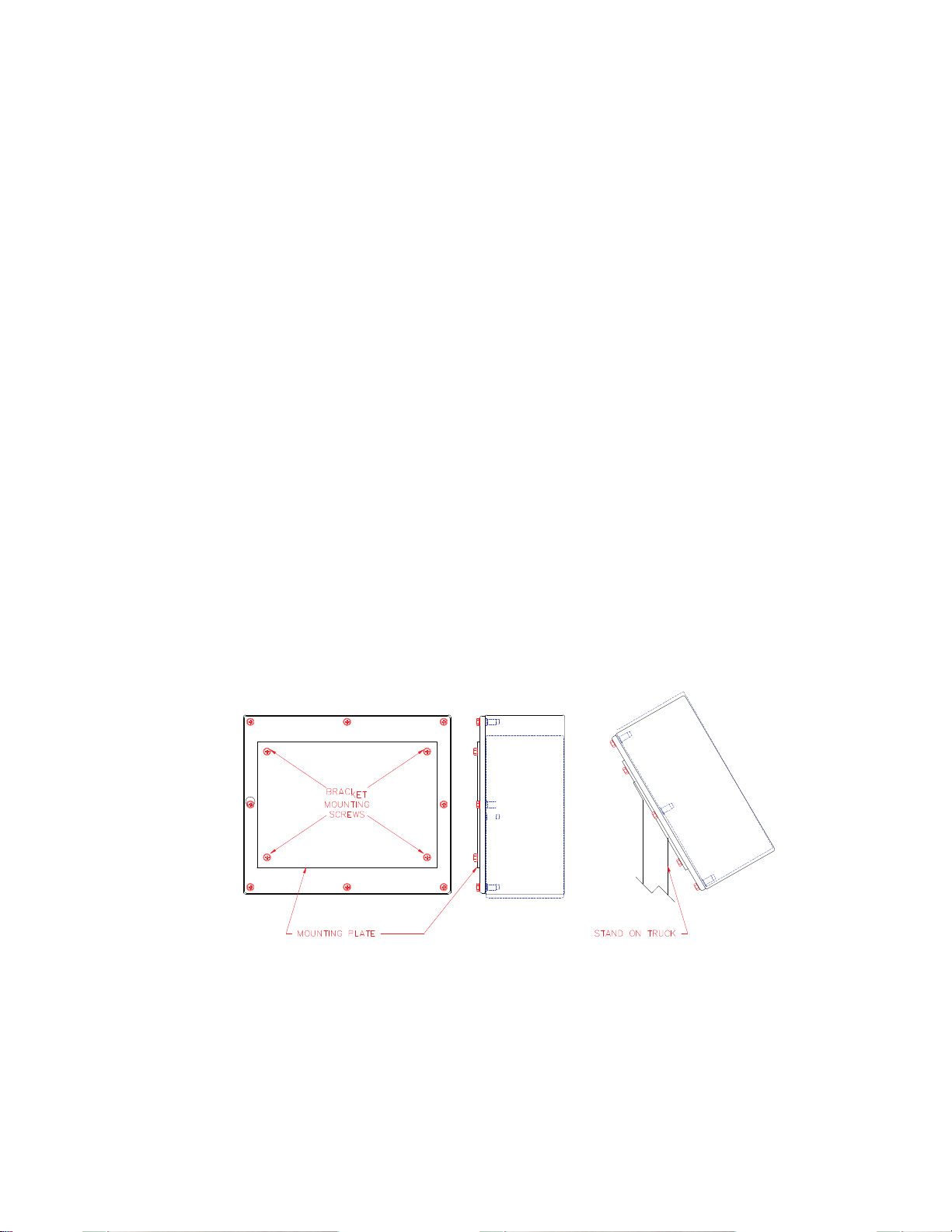

2.2.2 Rear Panel Mounting

The standard enclosure is designed to attach to an existing stand for

mounting. Note that the stand shown in Figure 3 is not supplied by GSE.

Figure 3: Rear Panel Mounting Screws

7

Page 12

2.2.3 Swivel Mounting (Optional)

The optional swivel mounting bracket allows the enclosure to be securely

fastened to another surface. The bracket is attached to the indicator with

four thumbscrews two of which are used to lock the swivel for optimal

viewing angle.

2.3 Legal for Trade

Most legal-for-trade installations will require the Agrifeed 5500 to be

sealed. A sealed indicator cannot be accessed for setup or calibration

changes without breaking a physical seal or incrementing an event

counter, thus providing evidence of tampering.

The Agrifeed 5500 has two types of sealing provisions, a physical seal

and a three event audit trail counter. Check with your local weights and

measures authority to determine your requirements.

2.3.1 Physical Seal

The most common sealing method is a lead-wire seal. Before applying a

wire seal, move the program jumper to the ‘NO’ position as shown in

Figure 4. Doing this will prevent access to the Setup and Calibration

Modes.

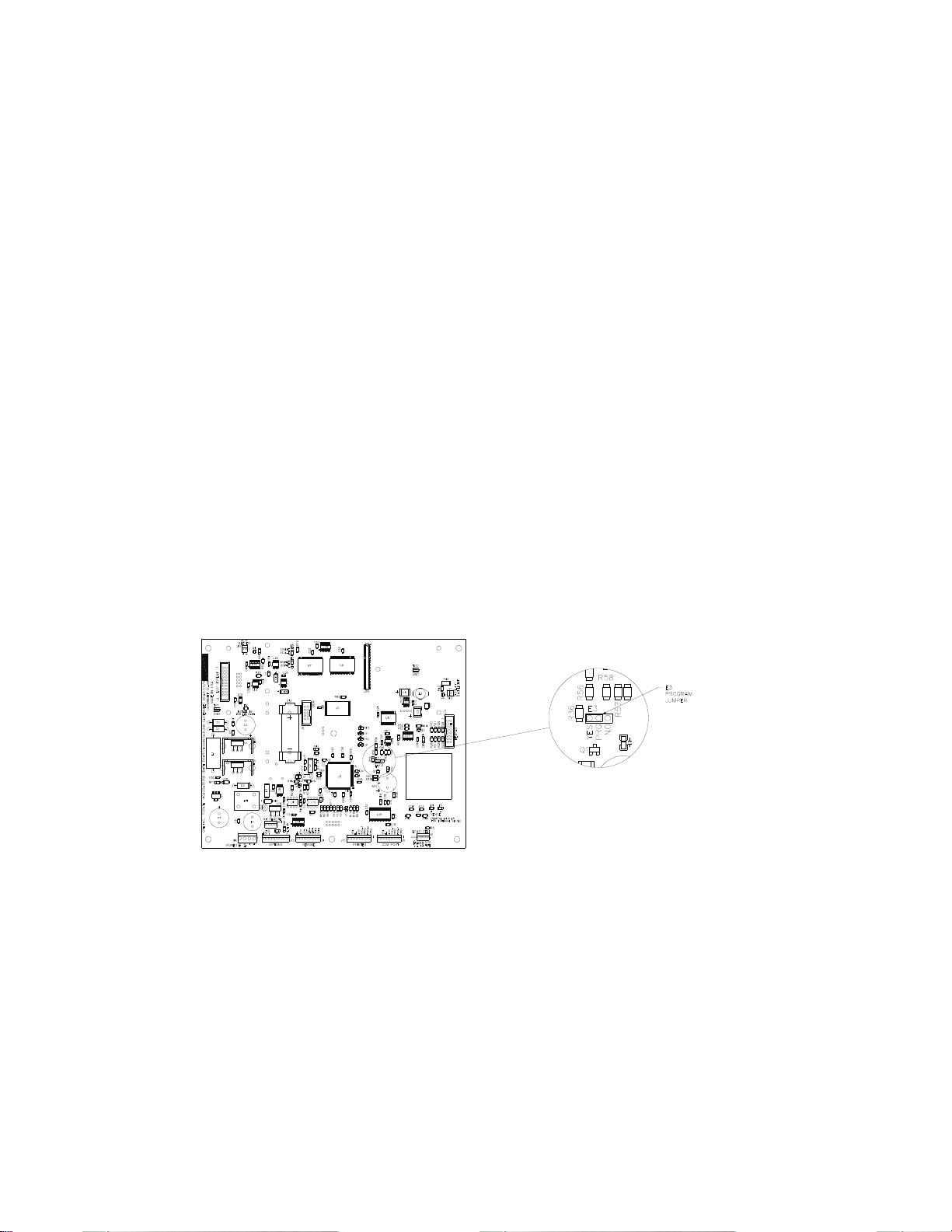

Figure 4: Program Jumper

8

Page 13

The seal will pass through two back panel screws as shown in Figure 5.

Figure 5: Legal for Trade Sealing Method

2.3.2 Audit Trail

Three separate incrementing, non-resetable audit trail parameters are

used to indicate changes to various parameters, P60201 – OIML, P60203

– Calibration , and P60204 – Setup. An audit trail counter will increment

only once upon exiting the Setup Mode and saving changes regardless of

how many settings were changed.

With the indicator off, press and hold [CLR] key and turn power on.

Continue to hold [CLR] until "Macro Disbl" is displayed. Key in

"60203" and press [NET/GROSS] to view the calibration event counter,

or key in "60204" and press [NET/GROSS] to view the configuration

event counter. To return to the normal weigh mode from either parameter

"60203" or "60204", press the [ZERO] key.

2.4 Wiring

A description of all wiring terminals is included on the bottom label of

the enclosure as shown in Figure 6.

Figure 6: Agrifeed 5500 Connector Label

9

Page 14

2.4.1 Load Cell Connection

A high quality cable with braided shield is recommended. Use a fourconductor, 16 to 24 AWG stranded wire cable for load cell or summing

box connections.

2.4.2 Printer Port Connection

The printer port is a RS232 bi-directional serial port that can be

connected to a printer or computer. Use the custom print formats

described in section 3.3.3 to configure the printer port output.

When making the printer port connections, consideration should be given

to the communication protocol. Refer to Table 3 in order to determine

proper wiring for the printer port.

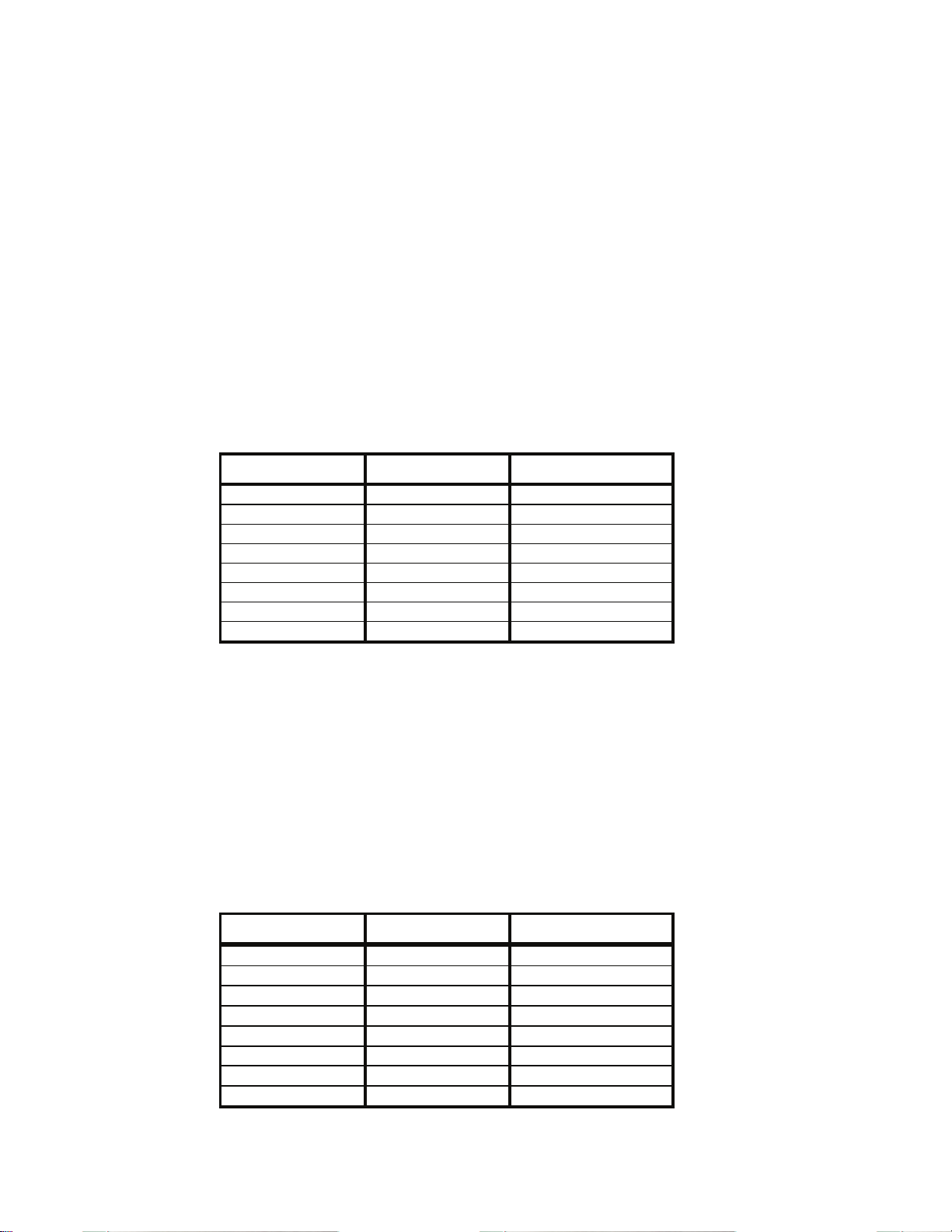

Table 3: Printer Port Connections

Pin Name Description

1 CTS Clear-to-Send

2 TXD Transmit

3 RTS Request-to-Send

4 RXD Receive

5 N/C -

6 GND Digital Ground

7 N/C -

8 N/C -

2.4.3 Comm Port Connection

The Comm port is a RS232 bi-directional serial port that can be

connected to a computer or any other serial device. This port can be used

for bi-directional communications with a serial device, through an RF

link or data logger, for recipe and transaction data exchange.

Before connecting to the comm port, consideration should be given to the

communication protocol. To determine proper wiring to the comm port,

refer to Table 4.

Table 4: Communication Port Connections

Pin Name Description

1 CTS Clear-to-Send

2 TXD Transmit

3 RTS Request-to-Send

4 RXD Receive

5 +5V + 5 Volts DC

6 GND Digital Ground

7 N/C -

8 N/C -

10

Page 15

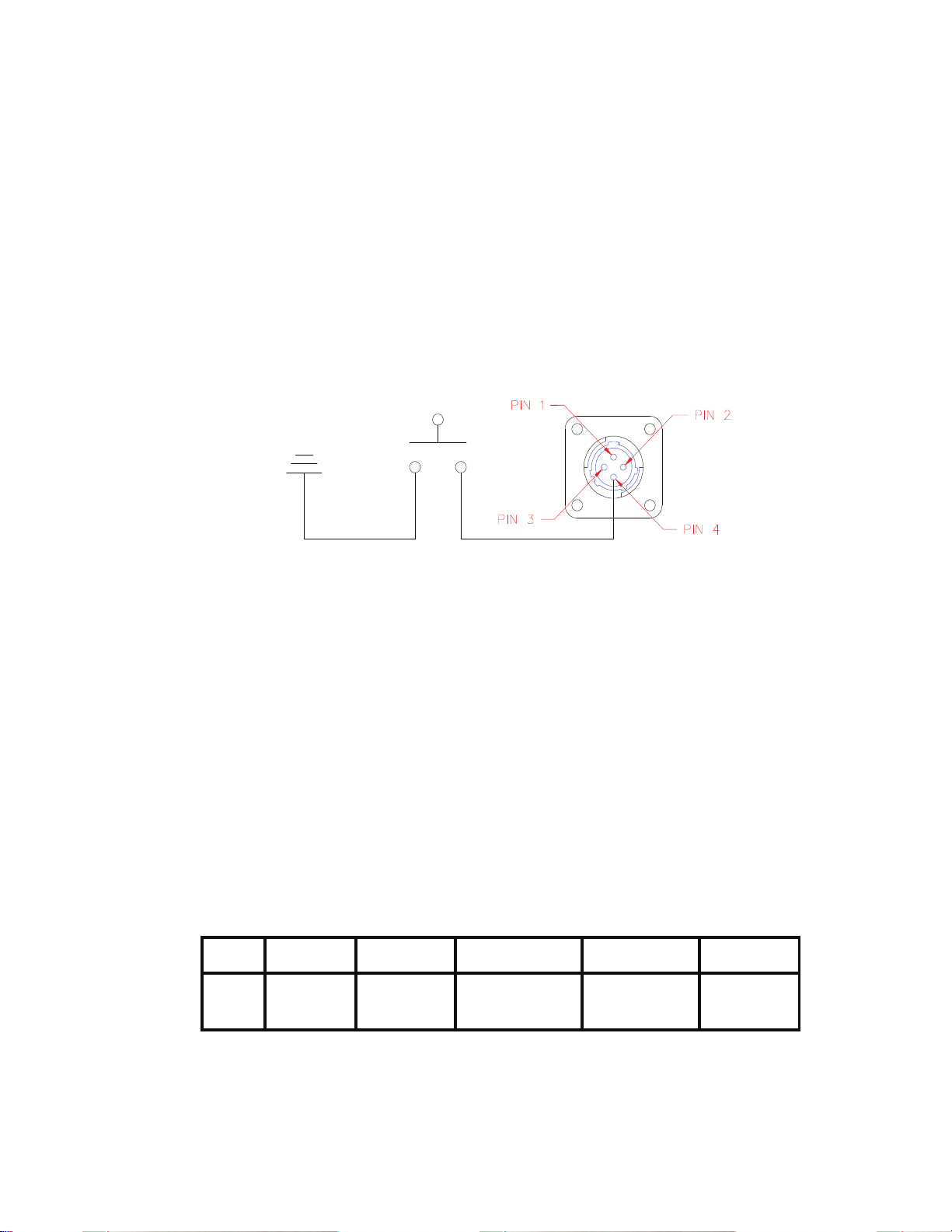

2.4.4 Remote Key Connection

A remote key may be connected to the Agrifeed 5500 to provide remote

activation of TARE, ZERO, PRINT/ADVANCE and PRINT & TARE

functions.

The connection for the remote key input is between pin 4 of the power

connector and ground (pin 2). A two-conductor cable between 28 and 20

AWG is recommended. The input requires a contact closure from a

push-button switch, a mechanical relay contact or other such device.

Do NOT apply an external voltage to the remote key terminal! Only a

contact closure is required to activate the remote key input.

Figure 7: Remote Key Connection

The open circuit voltage across the Remote Key pins is +5 VDC. A

closed switch will conduct about 0.25 mA. Therefore, a low-voltage

switch with gold-plated or mercury wetted contacts is recommended.

The input may also be activated remotely with a RF remote key. A

minimum contact duration of 100 ms is required. Once invoked, the

selected remote key operation will not repeat until the contact is released

and closed again.

2.4.5 Power Connection

The Agrifeed 5500 is powered by an external 10.5-16 VDC power

source. The power supply should have a minimum current rating of

800mA. Table 5 shows the power connector pin locations.

Table 5: Power Connector Pin Chart

Pin 1 Pin 2 Pin 3 Pin 4 Range

DC

+

GND

ALARM

OUT

REMOTE

IN

10.5-16

VDC

11

Page 16

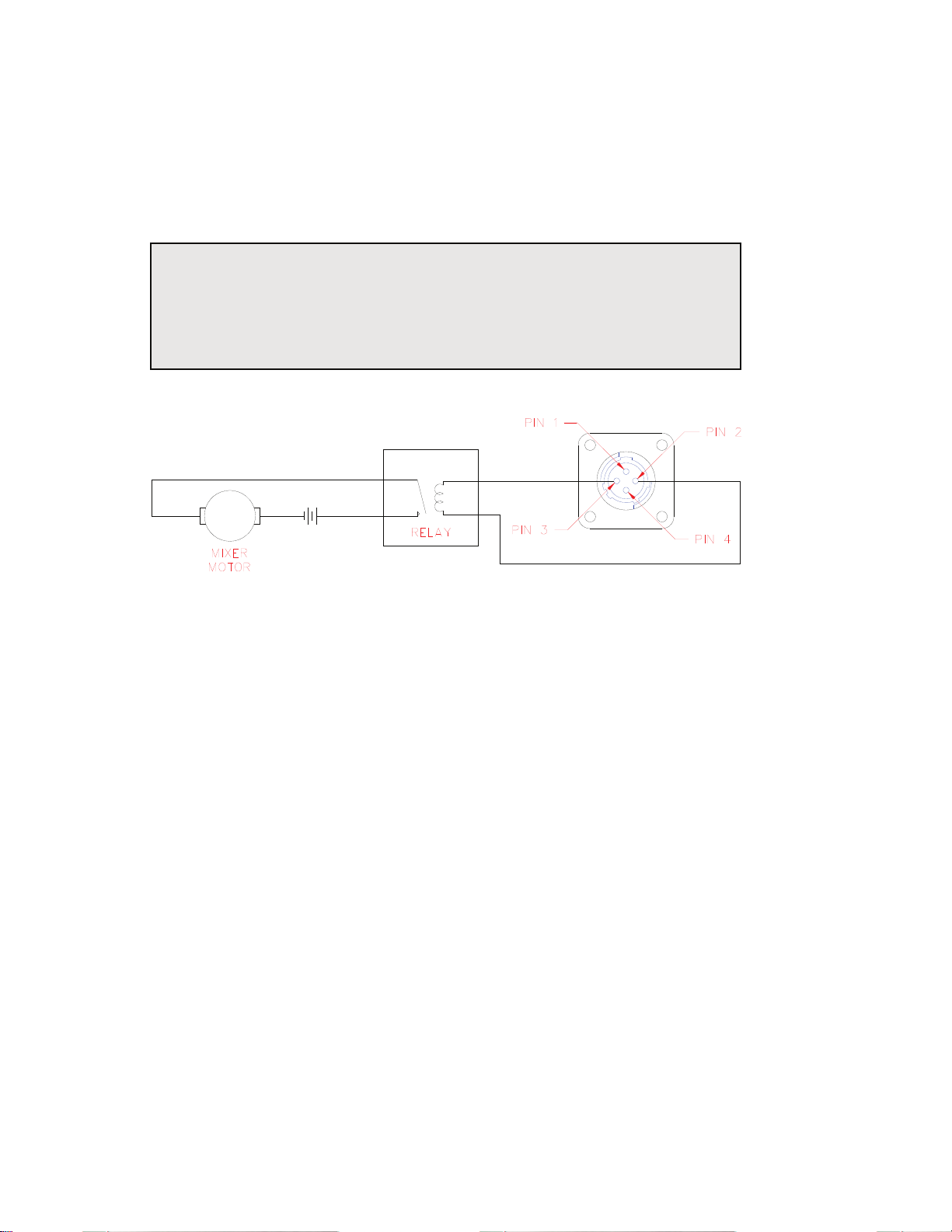

2.4.6 Alarm Out Connection

This connection is used in conjunction with the [MIX TIMER] key.

When the mix timer is not active pin 3 has a floating output. When the

mix timer is active (i.e. counting down) pin 3 is pulled high to the supply

voltage.

Example:

The indicator power is supplied by a truck battery, typically 13.8

volts. The output from pin 3 is 13.8 volts when the mix timer is

active.

Figure 8: Alarm Out Connection

12

Page 17

Section 3: Configuration

3.1 Password

A password must be entered for full access to all setup parameters. The

password routine may be bypassed by pressing [ENTER] without

entering a password. Bypassing the password allows access to only

Quick Menu items listed in section 3.2.

3.1.1 Entering a password

An asterisk (*) is displayed in place of each password keypress. When

four digits have been pressed, the entry is automatically accepted and

compared to the stored password. The default user password is "0000".

To enter a password:

1. From the weigh mode press [HELP], then [ENTER/YES] to

display the password screen (see Figure 9).

2. Key in the 4-digit password.

KEY-IN PASSWORD

_ _ _ _

PASSWORD REQUIRED FOR FULL ACCESS

[ENTER]= Limited Access [HELP] =Exit

Figure 9: Key - In Password Screen

3.1.2 Changing the Default Password

To change the existing password:

1. From the weigh mode press [HELP], then [ENTER/YES] to

display the password screen (see Figure 9).

2. Enter 9999 as the password. The display will prompt Enter

OLD Password.

3. Key in the existing password. If the indicator is new and a new

password has not yet been set, the default password will be

"0000".

4. Next, enter the new password at the Enter NEW Password.

5. Enter the new password a second time at the ReEnter NEW

Password prompt to verify the password entry.

13

Page 18

6. If the password entered in step 5 is correct, “New Password

Saved!” is displayed briefly before returning to the weigh mode.

3.2 Quick Menu

The Quick Menu provides access to data logger, display contrast, display

back-light and remote display back-light settings. A password is not

required to access the Quick Menu.

To access the Quick Menu:

1. From the weigh mode, press [HELP], then [ENTER].

2. At the password prompt, press only the [ENTER] key.

To navigate Quick Menu:

1. Press [YES] to advance to the next parameter.

2. Press [NO] to select options within a parameter.

3. Press [HELP] to save changes and exit the Quick Menu.

3.3 Setup Mode

The Setup Mode provides access to all setup parameters and calibration.

To access the Setup Mode:

1. Press [HELP], then [ENTER] as prompted in the Help screen.

2. Key in the 4-digit password to access the Setup Mode as shown

in Figure 9 (see section 3.1.1 for password information).

SETUP MENU SELECTION

J SCALE SETUP I

[YES]=Access [NO]=Next [HELP]=Exit

Figure 10: Setup Menu Selection Screen

To navigate the main category headings of the Setup Menu:

1. Press [NO] to advance to the next setup category (see Figure 11

for setup category headings).

2. Press [YES] to access setup parameters for the displayed

category.

3. Press [HELP] to save changes and exit the Setup Mode.

14

Page 19

J SCALE SETUP I

J COMM SETUP I

J MEMORY MANAGER I

J REMOTE SETUP I

J INGREDIENT SETUP I

J CALIBRATION I

Figure 11: Setup Category Headings

3.3.1 Print Setup

A print setup may be done from the SCALE SETUP, COMM SETUP,

MEMORY MANAGER, REMOTE SETUP and INGREDIENT SETUP.

If the print key is pressed from any of these menus, the parameters within

that menu will be printed.

Below is an example of the MEMORY MANAGER SETUP print out:

MEMORY MANAGER SETUP PARAMETERS

----------------------------------------------------------- UNLOAD DATA LOGGER DATA LOGGER

ENABLED RECORD HISTORY

500 TOTAL HISTORY ROWS

2 ROWS USED

498 ROWS AVAILABLE

15:43 02/04/08 DATE HISTORY CLEARED

The SCALE SETUP, COMM SETUP, MEMORY MANAGER and

REMOTE SETUP menus can all be printed from the quick menu. Simply

press the print key after accessing the quick menu setup.

15

Page 20

3.3.2 Scale Setup

Access the Scale Setup as described in section 3.3. Table 6 describes the

Scale Setup parameters.

SETUP MENU SELECTION

J SCALE SETUP I

[YES]=Access [NO]=Next [HELP]=Exit

Figure 12: Setup Menu Selection - Scale Setup

To navigate the Scale Setup selections:

1. Press [YES] to advance to the next parameter.

2. Press [NO] to select options within a parameter.

3. Press [HELP] to return to the Setup Menu Selection screen.

4. Press [HELP] again to save changes and exit the setup mode.

Example

To change the PRE-ALARM METHOD:

1. From the SCALE SETUP screen, press [YES] 3 times.

2. Press [NO] to toggle between COMMON & RECIPE PRE-

ALARM.

3. Press [HELP] twice to save changes and exit the setup mode

16

Page 21

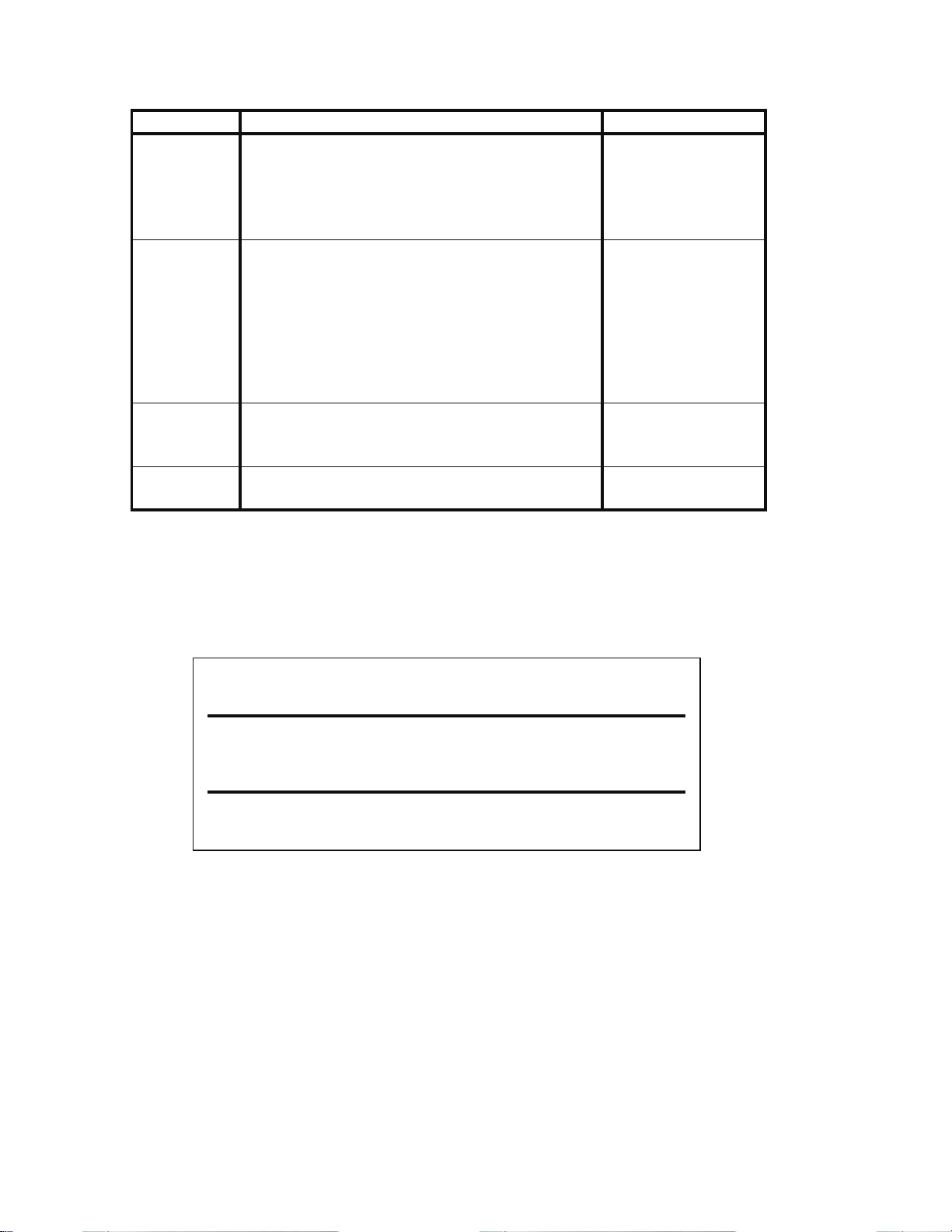

Table 6: Scale Setup Menu Parameters

(

)

Parameter Description Selections

LCD

CONTRAS

T SETUP

LCD

BACKLIG

HT SETUP

PRE-

ALARM

METHOD

PRE-

ALARM

WEIGHT

ADVANCE

TOLERAN

CE

ADVANCE

DELAY

REMOTE

INPUT

ACTION

TIME&DA

TE

CAPACITY

SETUP

DIVISON

SIZE

ZERO

TRACK

Sets the level of contrast (or darkness) of

characters on the display.

Sets the display back-light brightness.

RECIPE PRE-ALARM: Pre-Alarm based on

individual recipes/ingredients.

COMMON PRE-ALARM: Pre-Alarm based

on the PRE-ALARM WEIGHT in setup.

Sets the weight at which the alarm sounds

prior to reaching the load/unload target

weight.

This parameter can only be set if the PRE-

ALARM METHOD is set to COMMON

PRE-ALARM.

see section 4.2.1for more details

Sets the tolerance requirement for loading

before auto-advancing ingredients.

Sets the time requirement for auto-advancing

ingredients. The weight must be in tolerance

and stable within the ADVANCE DELAY

time before and auto-advance will occur.

Defines the remote key function.

PRINT/ADVANCE is the default

*

Sets the time and date. Key in Time/Date

Sets the scale capacity.

Sets the scale division size (count by). If the

capacity or division size is changed such that

the number of divisions is not between 1 and

100000, then an appropriate division size is

automatically selected.

Sets the Zero Track Aperture. Weight

deviations that remain within the Zero Track

range for more than 1 second are tracked off

(zeroed).

0-100%

in 5% intervals.

*55%

0-100%

in 10% intervals.

*50%

*COMMON PRE-

ALARM, and

RECIPE PREALARM

Key in value:

0-999990

*00 lb

*OFF, 0.5%,

1-10%

1-5,10,

15, 30, 45 sec.,

1, 2 min.,

*Manual

TARE, ZERO,

PRINT & TARE,

PRINT/ADVANCE

Key in value:

0.02-999990

*40000 lb

.0001 to 500

*000010

0.5, 1-5, 10

divisions,

OFF

*1.0

17

Page 22

Parameter Description Selections

MOTION

SETUP

Defines the amount of instability in terms of

number of divisions that will constitute

motion. Presence of motion will delay ZERO,

TARE or ingredient Auto-Advance until

motion ceases.

0.5, 1-5, 10

divisions,

OFF

*1.0

Determines how quickly the indicator will

FILTER

SETUP

DISPLAY

UPDATE

RATE

UNITS

SETUP

respond to a change in weight. A low

filter setting results in fast response, while

a heavier filter setting will ‘dampen’ the

response. Filtering is used to help

stabilize weight fluctuations due to wind,

vibration, etc.

Sets the rate at which the weight display is

refreshed.

Sets the default weight units.

MINIMUM,

LOW,

*MEDIUM,

HEAVY,

MAXIMUM

5/sec, 2/sec,

1 sec, 2 sec

*2/SEC

lb, kg, Tons

*lb

* indicates default setup

3.3.3 Communication Setup

Access the Communication Setup as described in section 3.3. Table 7

describes the Communication Setup parameters.

SETUP MENU SELECTION

J COMM SETUP I

[YES]=Access [NO]=Next [HELP]=Exit

Figure 13: Setup Menu Selection - Comm Setup

To navigate the Communication Setup selections:

1. Press [YES] to advance to the next parameter.

2. Press [NO] to select options within a parameter.

3. Press [HELP] to return to the Setup Menu Selection screen.

4. Press [HELP] again to save changes and exit the setup mode.

18

Page 23

Example:

To enable the CUSTOM PRINT HEADER:

1. From the COMM SETUP screen, press [YES] twice.

2. Press [NO] to toggle between ENABLED and DISABLED

3. Press [HELP] twice to save changes and exit the setup mode.

Table 7: Communication Setup Parameters

Parameter Description Selections

CUSTOM

PRINT

HEADER

PRINT

HEADER LINE

#

(1 - 4)

CUSTOM

PRINT

FORMAT

TICKET

NUMBER

AUTO PRINT

COMM BAUD

RATE

WAGON

NUMBER

Enabled to print custom header on

each ticket.

Permits entry of a custom print

header (up to 4 lines).

This parameter can only be set if

the CUSTOM PRINT HEADER is

ENABLED.

Sets unload print format. Choose

from 7 pre- set formats or select

“CUSTOM” format (contact your

Agrifeed distributor for

information on creating custom

transmits).

Reset printed ticket number.

Assigns an event for auto-printing.

Sets the baud rate for the comm

port.

Sets truck or wagon ID number.

Numbers 1-247 are valid wagon

numbers for use with Agridata

software. A wagon number of zero

(000) will disable the RF link.

ENABLED,

*DISABLED

Refer to section 3.3.3.1

for instructions on

entering print headers.

Refer to section 3.3.3.2

for print styles.

Press [PRINT] to

preview format

*STYLE #7

Press [CLR\NO] then

key in value

* LOAD & UNLOAD,

LOAD,

UNLOAD,

DISABLED

1200,2400,4800,

9600,*19200,38400

Baud

*000

Press [CLR\NO] then

key in value

COMM

PROTOCOL

Sets the protocol for the

communication port.

(data bits / parity / stop bits)

19

*8/NONE/1, 8/ODD/1,

8/EVEN/1, 8/NONE/2,

7/NONE/1, 7/ODD/1,

7/EVEN/1, 7/NONE/2

Page 24

Parameter Description Selections

-

*

*XON/XOFF,

COMM

HANDSHAKE

PRINT BAUD

RATE

PRINT

PROTOCOL

PRINT

HANDSHAKE

Sets handshaking for the

communications port.

Sets the baud rate for the printer

port.

Sets the protocol for the printer

port.

(data bits / parity / stop bits)

Sets the handshaking for the

printer port.

BOTH,

NONE,

CTS/RTS

300,600,1200,2400,480

0, *9600,19200 baud.

*8/NONE/1,

8/ODD/1,

8/EVEN/1, 8/NONE/2,

7/NONE/1, 7/ODD/1,

*XON/XOFF,

BOTH,

NONE,

CTS/RTS

* indicates default setup

3.3.3.1 Custom Print Headers

4 lines of up to 20 characters each may be assigned to the header. The

CUSTOM PRINT HEADER parameter must be enabled before it is

possible to assign text to the print header.

To create or change a Custom Print Header:

1. Access the PRINT HEADER LINE #1 parameter as described

in section 3.3.3.1.

2. Press [NO] to access the header entry screen (see Figure 14).

ENTER HEADER #1

L

ABCDEFGHIJKLMNOPQRSTUVWXYZ +

Figure 14: Custom Header Entry Screen

3. Use the cursor keys to key in the header text. Use the numeric

portion of the keypad to enter numbers.

/=#$()<>&@

20

Page 25

r

§

Moves left to

previous

¨

Moves right

to next

characte

¯

Selects the

character under

the cursor arrow

Enters header text

and completes entry

Deletes the last

character of the

header text

3.3.3.2 Print Styles

There are seven selectable print styles and one custom print format

available within the Agrifeed 5500.

1. Print style #1 prints the TICKET#, Time, Date, RECIPE#,

PEN#, and amount of product loaded or unloaded.

2. Print style #2 prints the Time, Date, Pen ID number, Gross,

Tare, and Net weights.

3. Print style #3 prints the Gross, Tare and Net weights.

4. Print style #4 prints the current Time, Date and Gross weight.

5. Print style #5 prints the TICKET #, Time, Date, PEN #,

RECIPE # and the amount of product loaded or unloaded in

comma delimited format.

6. Print style #6 prints the current Time, Date, Pen ID number, and

displayed weight.

7. Print style #7 prints the PEN #, Gross weight, Time and Date.

21

Page 26

TICKET# 1234567

03:30 pm 04/04/07

RECIPE# 13

PEN# 12345

AMOUNT 2010 lb

03:31 pm 04/04/07

ID#: 12345

----------------- 2090 lb Gross

00 lb Tare

2090 lb Net

Style #1 Style #2

2090 lb Gross

00 lb Tare

2090 lb Net

03:33 pm 04/04/07

2090 lb Gross

Style #3 Style #4

Time 03:03 pm Date 04/04/07

Style #5

1234567,03:33 pm 04/04/07,12345,13,2010

Style #6

Pen# 12345 016100 13:17 04/04/07

Style #7

22

Page 27

3.3.4 Memory Manager Setup

Access the Memory Manager Setup as described in section 3.3. Table 8

describes the Memory Manager Setup parameters.

SETUP MENU SELECTION

J MEMORY MANAGER I

[YES]=Access [NO]=Next [HELP]=Exit

Figure 15: Setup Menu Selection - Memory Manager

To navigate the Memory Manager Setup selections:

1. Press [YES] to advance to the next parameter.

2. Press [NO] to select options within a parameter.

3. Press [HELP] to return to the Setup Menu Selection screen.

4. Press [HELP] again to save changes and exit the setup mode.

Example:

To enable the RECORD HISTORY:

1. From the MEMORY MANAGER SETUP screen, press [YES] twice.

2. Press [NO] to toggle between ENABLED and DISABLED.

3. Press [HELP] twice to save changes and exit the setup mode.

23

Page 28

Table 8: Memory Manager Setup Menu Parameters

Parameter Description Selections

DATA

LOGGER

RECORD

HISTORY

Used to transfer recipe/pen information

from the data logger to the Agrifeed 5500

(unload data logger), or to transfer history

information to the data logger from the

AGRIFFEED 5500 (load data logger).

Press [LOAD/UNLOAD] to initiate data

transfer routine.

Used for managing the history

database. WHEN THIS

PARAMETER IS DISABLED, NO

DATA WILL BE STORED TO

UNLOAD

DATA

LOGGER,

*LOAD DATA

LOGGER

ENABLED,

DISABLED,

THE HISTORY DATABASE!

TOTAL

HISTORY

Shows the total history rows

available for data storage. EXAMPLE:

500

ROWS

ROWS

USED

Shows the number of records that are

stored in the history database. Also

the database may be cleared from this

selection. Press [CLR\NO] and

EXAMPLE:

182

follow the display prompts.

ROWS

AVAILABLE

DATA

HISTORY

CLEARED

Shows the number of unused rows in

the history database.

Shows the time and date the history

database was last cleared.

EXAMPLE:

318

EXAMPLE:

04:56 pm 02/04/00

When the history is 90% full, the following warning will appear on

the display:

MEMORY WARNING

THE HISTORY DATABASE IS 90% FULL!

Download the history database to avoid

losing data once the database is full.

PRESS [ENTER] TO CONTINUE.

Additional warning screens will be displayed when the memory is 95%

and 100% full. If the memory is not cleared, the oldest history data will

24

Page 29

be lost as new information is recorded. Refer to the MEMORY

MANAGER section to clear the history database.

3.3.5 Remote Display Setup

Access the Remote Display Setup as described in section 3.3. Table 9

describes the Remote Display Setup parameters.

SETUP MENU SELECTION

J REMOTE SETUP I

[YES]=Access [NO]=Next [HELP]=Exit

Figure 16: Setup Menu Selection - Remote Setup

To navigate the Remote Setup selections:

1. Press [YES] to advance to the next parameter.

2. Press [NO] to select options within a parameter.

3. Press [HELP] to return to the Setup Menu Selection screen.

4. Press [HELP] again to save changes and exit the setup mode.

Table 9: Remote Display Setup Parameters

Parameter Description Selections

REMOTE

BACKLIGHT

REMOTE

MIRROR IMAGE

3.3.5.1 Remote Display Operation

Enables the Model 1500 remote

display back-light.

Enables the Model 1500 remote

display reverse image feature

allowing it to be viewed with a

mirror. Select ‘UNLOAD ONLY’ to

enable the mirror imaging only while

unloading.

DISABLED,

ENABLED

DISABLED,

ENABLED,

UNLOAD

ONLY

Upon power-up, the remote display shows ID ? indicating that the

operator ID has not yet been entered.

25

Page 30

During normal operation the remote display will echo the gross or net

|

[

|

K

|

P

|

-

|

[

|

[

|

[

weight as displayed on the Agrifeed 5500.

During the load/unload process the remote display will show the gross

for two seconds between the change of ingredients or pens. It will then

toggle between the name of the current ingredient or pen and the target

net weight until motion occurs.

The [NET\GROSS] key may be pressed at any time during the

load/unload process to display the gross weight for 2 seconds.

3.3.6 Ingredient Setup

The Ingredient Setup Mode provides the ability to create, edit, delete and

view ingredients. Access the Ingredient Setup as described in section

3.3.

SETUP MENU SELECTION

J INGREDIENT SETUP I

[YES]=Access [NO]=Next [HELP]=Exit

Figure 17: Setup Menu Selection - Ingredient Setup

Press [YES] to access the Ingredient Selection Screen (see Figure 18).

INGREDIENTS

00 *PRESET*

01 ALFALFA

02 BARLEY

03 FLAKED BARLEY

04 CORN

Figure 18: Ingredient Selection Screen

3.3.6.1 Viewing Ingredients

ey-in Ingred#,

ress [Enter].

---------ADD RECIPE]

START BATCH]

HELP] = Exit

00]

↑

↓

There are two ways to access ingredients from the Ingredient Selection

Screen – by keying in the two-digit ingredient number or by scrolling

through the ingredient list.

26

Page 31

|

[

1

|

K

|

P

|

-

|

[

|

[

|

[

|

[

|

K

|

P

|

-

|

[

|

[

|

[

To key in an ingredient number, simply type the two-digit ingredient

number to display the selected ingredient.

EXAMPLE:

To access ingredient #8, key in [0] [8] or [8] [ENTER].

To access ingredient #15, key in [1] [5].

INGREDIENTS

ey-in Ingred#,

15 OATS

16 FLAKED OATS

17 SORGHOM

18 SOY BEAN

19 SOY HULLS

Figure 19: Ingredient Selection (Key-in)

To scroll ingredients, use the scroll keys as shown below.

ress [Enter].

---------ADD RECIPE]

START BATCH]

HELP] = Exit

INGREDIENTS

ey-in Ingred#,

11 HAY

12 HAYLAGE

13 LINSEED MEAL

14 MOLASSES

15 OATS

ress [Enter].

----------

ADD RECIPE]

START BATCH]

HELP] = Exit

5]

↑

↓

11]

↑

↓

Figure 20: Ingredient Selection (Scroll)

27

Page 32

-

*

Scroll

Scroll

Down

3.3.6.2 Naming Ingredients

Ingredients must be named before they can be selected for a recipe. To

name or rename an ingredient:

1. Access the Ingredient Setup as described in section 3.3.

2. Select the desired ingredient number as described in section

3.3.6.1.

3. Press [ENTER] to display the Name Ingredient screen (see

Figure 21). If a name already exists for the selected ingredient,

the name will appear in the entry screen for editing.

©

Up

ª

NAME INGREDIENT #21

L

ABCDEFGHIJKLMNOPQRSTUVWXYZ +

Figure 21: Ingredient Name Entry Screen

4. Use the cursor keys to key in the ingredient name. Use the

numeric portion of the keypad to enter numbers.

/=#$()<>&@

28

Page 33

¨

r

§

Moves left to

previous

Moves right

to next

characte

¯

Selects the

character under

the cursor arrow

Enters name and

completes entry

Deletes the last

character of the

ingredient name

5. Press [ENTER] to save the name and proceed to the Ingredient

Pre-Alarm screen (see Figure 22).

3.3.6.3 Ingredient Pre-Alarm

The Ingredient Pre-Alarm is used during the loading process to sound an

alarm and flash the display when the pre-alarm weight is achieved. A

unique pre-alarm value can be assigned to each ingredient. Pre-alarm

values are assigned immediately after naming an ingredient as described

in the previous section.

To assign or change an Ingredient Pre-Alarm:

1. Access the Ingredient Setup as described in section 3.3.

2. Select the desired ingredient number as described in section

3.3.6.1.

3. Press [ENTER] to display the Name Ingredient screen (see

Figure 21). If a name does not exist for the selected ingredient,

a name must be assigned before a pre-alarm value can be

entered.

4. Press [ENTER] to accept the ingredient name and proceed to

the Ingredient Pre-Alarm screen (see Figure 22).

5. Key in the pre-alarm weight value and press [ENTER]. The

display will then revert back to the Ingredient Selection screen.

29

Page 34

INGREDIENT PRE-ALARM

000000 lb

KEY-IN PRE-ALARM VALUE

[ENTER]=Accept Value [CLR]=Delete

Figure 22: Ingredient Pre-Alarm Screen

NOTE:

If the PRE-ALARM METHOD parameter in the scale setup is set to

“COMMON PRE-ALARM”, then the indicator disregards the Ingredient

Pre-alarm weight and instead uses the PRE-ALARM WEIGHT

specified in the scale setup for all ingredients. See Table 6 for more

details on the Pre Alarm setup.

3.3.6.4 Deleting Ingredients

Deleting an ingredient does not remove the ingredient number from the

ingredient list; however it will clear the ingredient name and make it

unavailable for recipe configuration.

To delete an ingredient:

1. Access the Ingredient Setup as described in section 3.3.

2. Select the desired ingredient number as described in section

3.3.6.1.

3. Press [CLR] to display the DELETE INGREDIENT? prompt.

4. Press [YES] to confirm the intent to delete, or [NO] to cancel

deletion. The display will then revert back to the Ingredient

Selection screen.

3.3.6.5 Printing Ingredients

A list of all named ingredients can be printed from the Ingredient

Selection screen.

To print ingredients:

1. Access the Ingredient Setup as described in section 3.3.

2. Press [PRINT]. A list of all named ingredients will be

transmitted out the printer port.

30

Page 35

3.3.7 Calibrate Mode

The Calibration Mode is used to calibrate the Agrifeed 5500 scale system

to a known weight value, thus establishing an accurate weight indication

throughout the weighing range. Access the Calibration selection as

described in section 3.3. From the Calibration Setup Menu Selection,

press [YES] to access the calibration routines (see Figure 24).

SETUP MENU SELECTION

J CALIBRATION I

[YES]=Access [NO]=Next [HELP]=Exit

Figure 23: Setup Menu Selection - Calibration

Notes on Calibration:

Press [CLR] at any point in the calibration routine to move back one

step.

Pressing [CLR] at the New Zero? prompt will exit the calibration

mode.

If a calibration weight is less than 5% of capacity, or if there was a

large change in the calibration, the display prompts ReCal Req'd

suggesting that the calibration process be repeated. Press [YES] to

repeat the calibration procedure, or press [NO] accept the

calibration and obtain the CAL OK? prompt.

If a calibration weight exceeds full scale by +4% or is less than 0.1%

of full scale, an error message is displayed

A calibration weight may be applied before or after the calibration

weight is entered. The display will prompt you to Keyin CalWT (key

in calibration weight) or Add CalWT (add calibration weight) at the

appropriate time.

31

Page 36

Z

New

00

ero?

Calibration Mode

Figure 24: Calibration Mode

There are six Calibration Mode selections as described below:

Most common calibration procedure used to

"New Zero?"

"Last Zero?"

"Temp Zero?"

"Only Zero?"

"Cal Reset"

"Known LCOut"

Press [NET/GROSS] to scroll through and select a calibration method.

Press [ENTER] to begin the calibration method selected and refer to the

appropriate section for calibration instructions:

establish a new zero (no load) and span (test

load) calibration reference.

Allows a span re-calibration without removing

the test load.

Allows calibration without removing the

current gross weight. The zero reference

determined during the last calibration is

maintained.

Establishes a new zero reference without

affecting span. Useful when changing the

scale's dead load, for example adding safety

rails to a scale platform.

Adjusts the zero and gain factors of the A/D

amplifier to default values for maximum

sensitivity.

Method of calibrating without the use of test

weights. The loadcell mV/V value and full

scale capacity must be known.

New Zero? See section 3.3.7.1

Last Zero? See section 3.3.7.2

Temp Zero? See section 3.3.7.3

Only Zero? See section 3.3.7.4

Cal Reset See section 3.3.7.5

Known LCOut See section 3.3.7.6

32

Page 37

3.3.7.1 New Zero

This is the most common calibration procedure used to establish a new

zero (no load) and span (test load) calibration reference. Use this method

for first-time calibration and complete re-calibration.

To access "New Zero?" calibration from the weigh mode:

1. Access the Calibration Setup Menu Selection as described in

section 3.3.

2. Press [YES] to access the calibration routines (see Figure 24).

3. Remove all weight from the scale.

4. Press [ENTER] at the “New Zero?” prompt to establish the

zero reference.

If “New Zero?” is not the displayed selection, press

[NET/GROSS] until it is displayed, then press [ENTER].

5. After establishing the zero reference, "Keyin CalWt" is

displayed. Place the calibration weight on the platform, key in

the calibration weight and press [ENTER] to establish span.

6. After establishing the span, “CAL OK?” is displayed suggesting

that the calibration is acceptable, or “ReCal ???” is displayed

suggesting that the calibration procedure be repeated.

Press [YES] at the “CAL OK?” prompt or [NO] at the “ReCal

???” prompt to accept the calibration.

OR

Press [NO] at the “CAL OK?” prompt or [YES] at the “ReCal

???” prompt to repeat the calibration.

7. Once the calibration is accepted in step 6, press [ENTER] at the

ENTER=SAVE prompt and again at the ENTER=EXIT prompt

to save the new calibration and exit the calibration mode.

8. To exit the calibration mode without

saving the new calibration,

press [CLR] at the ENTER=SAVE prompt. Then press

[ENTER] at the ENTER=UNDO prompt and again at the

ENTER=EXIT prompt to exit the calibration mode.

33

Page 38

3.3.7.2 Last Zero

This procedure allows span re-calibration without removing the

applied test weight. The last zero established by pressing [ZERO]

from the weigh mode will be used as the zero reference for this

procedure.

To access " Last Zero?" calibration from the weigh mode:

1. Remove all weight and press [NET\GROSS] then [ZERO]

to establish a gross zero reference.

2. Access the Calibration Setup Menu Selection as described

in section 3.3.

3. Press [YES] to access the calibration routines (see Figure

24).

4. Press [NET/GROSS] to scroll to the “Last Zero?”

calibration method.

5. With the test weight still on the scale, press [ENTER] to

initiate span calibration. The display then shows "Keyin

CalWt" .

5. Place the calibration weight on the platform, key in the

calibration weight and press [ENTER] to establish span.

6. After establishing the span, “CAL OK?” is displayed

suggesting that the calibration is acceptable, or “ReCal

???” is displayed suggesting that the calibration procedure

be repeated.

Press [YES] at the “CAL OK?” prompt or [NO] at the

“ReCal ???” prompt to accept the calibration.

OR

Press [NO] at the “CAL OK?” prompt or [YES] at the

“ReCal ???” prompt to repeat the calibration.

7. Once the calibration is accepted in step 7, press [ENTER]

at the ENTER=SAVE prompt and again at the

ENTER=EXIT prompt to save the new calibration and exit

the calibration mode.

To exit the calibration mode without

saving the new

calibration, press [CLR] at the ENTER=SAVE prompt.

Then press [ENTER] at the ENTER=UNDO prompt and

again at the ENTER=EXIT prompt to exit the calibration

mode.

34

Page 39

3.3.7.3 Temporary Zero

This procedure is used to recalibrate without establishing a new zero.

Calibration can be performed without removing the currently applied

gross load. A temporary zero is established so additional test weight can

be added during calibration. The original zero reference determined

during the previous calibration is not affected.

To access " Temp Zero?" calibration from the weigh mode:

1. Access the Calibration Setup Menu Selection as described in

section 3.3.

2. Press [YES] to access the calibration routines (see Figure 24).

3. Press [NET/GROSS] to scroll to the “Temp Zero?” calibration

method.

4. Press [ENTER] to establish a temporary zero reference. The

display then shows "Keyin CalWt".

5. Place the calibration weight on the platform, key in the

calibration weight and press [ENTER] to establish span.

6. After establishing the span, “CAL OK?” is displayed suggesting

that the calibration is acceptable, or “ReCal ???” is displayed

suggesting that the calibration procedure be repeated.

Press [YES] at the “CAL OK?” prompt or [NO] at the “ReCal

???” prompt to accept the calibration.

OR

Press [NO] at the “CAL OK?” prompt or [YES] at the “ReCal

???” prompt to repeat the calibration.

7. Once the calibration is accepted in step 6, press [ENTER] at the

ENTER=SAVE prompt and again at the ENTER=EXIT prompt

to save the new calibration and exit the calibration mode.

8. To exit the calibration mode without

saving the new calibration,

press [CLR] at the ENTER=SAVE prompt. Then press

[ENTER] at the ENTER=UNDO prompt and again at the

ENTER=EXIT prompt to exit the calibration mode.

35

Page 40

3.3.7.4 Only Zero

This procedure is used for zero calibration only and is primarily used for

correcting the zero reference after adding or removing dead-load from

the scale.

To access " Only Zero?" calibration from the weigh mode:

1. Access the Calibration Setup Menu Selection as described in

section 3.3.

2. Press [YES] to access the calibration routines (see Figure 24).

3. Press [NET/GROSS] to scroll to the “Only Zero?” calibration

method.

4. With no weight on the scale, press [ENTER] to establish the

new zero reference.

5. After establishing zero, “CAL OK?” is displayed suggesting

that the calibration is acceptable, or “ReCal ???” is displayed

suggesting that the calibration procedure be repeated.

6. Press [YES] at the “CAL OK?” prompt or [NO] at the “ReCal

???” prompt to accept the calibration.

7. Press [NO] at the “CAL OK?” prompt or [YES] at the “ReCal

???” prompt to repeat the calibration.

8. Once the calibration is accepted in step 5, press [ENTER] at the

ENTER=SAVE prompt and again at the ENTER=EXIT prompt

to save the new calibration and exit the calibration mode.

9. To exit the calibration mode without

saving the new calibration,

press [CLR] at the ENTER=SAVE prompt. Then press

[ENTER] at the ENTER=UNDO prompt and again at the

ENTER=EXIT prompt to exit the calibration mode.

36

Page 41

3.3.7.5 Calibration Reset

This procedure adjusts the zero and gain factors of the A/D amplifier.

Normally, a Cal Reset is performed if the amplifier is locked in at an

extremely high gain factor and will not allow a new calibration to be

performed due to an over-load or under-load condition.

To access "Cal Reset" from the weigh mode:

1. Access the Calibration Setup Menu Selection as described in

section 3.3.

2. Press [YES] to access the calibration routines (see Figure 24).

3. Press [NET/GROSS] to scroll to the “Cal Reset” calibration

method.

NOTE:

If an over-load or under-load condition exists at the time of calibration,

the calibration method prompts will not appear. Press [CLR] to proceed

directly to the Cal Reset procedure.

4. Press [ENTER] to reset the A/D amplifier. The display then

shows the "New Zero?" prompt.

5. Following a Cal Reset, a re-calibration should be performed

before exiting the calibration or setup modes. Press

[NET\GROSS] to toggle to the desired calibration routine.

37

Page 42

3.3.7.6 Known Load Cell Out

This procedure is used to calibrate without test weights. The mV/V

rating and capacity for each loadcell must be known.

To access "Known LCOut" from the weigh mode:

1. Access the Calibration Setup Menu Selection as described in

section 3.3.

2. Press [YES] to access the calibration routines (see Figure 24).

3. Press [NET/GROSS] to scroll to the “Known LCOut”

calibration method.

4. Press [ENTER] to display the "#ofLC" prompt. The number of

load cells specified during the last calibration will also be

displayed (a value of 0 indicates that this calibration method has

not yet been performed).

5. Key in the number of load cells and press [ENTER], or press

only [ENTER] to accept the displayed value.

6. Display prompts "LC #x mVv" (where “x” is the load cell

number) and shows the mV/V value (0.1 – 5.0) last entered for

the specified load cell.

7. Key in the load cell’s mV/V value and press [ENTER], or press

only [ENTER] to accept the displayed value.

8. Steps 6 – 7 will be repeated for as many load cells as specified

in step 5.

9. Display briefly shows the calibration units, pounds, then

prompts "LC FS" showing the value last entered for the load

cell full scale.

10. Key in the load cell’s full scale capacity in pounds and press

[ENTER], or press only [ENTER] to accept the displayed

value.

11. Display briefly shows "Calc Gains" as it calculates new gains,

then prompts "CurWT Zero?".

Press [ENTER] to establish the current input signal as the zero

reference,

or…

…press [NET/GROSS] t

o scroll the zero method to

“Zero=0mV/V” (uses 0mV/V load cell output as the zero

reference) and press [ENTER],

or…

…press [NET/GROSS] again to scroll the zero method to

“Keyin CurWt”, key in the known gross weight already applied

to the scale and press [ENTER],

or...

…press [CLR] to bypass the zeroing operation.

38

Page 43

12. The display shows “CAL OK?” suggesting that the calibration

is acceptable.

Press [YES] at the “CAL OK?” prompt to accept the

calibration.

13. Press [NO] at the “CAL OK?” prompt to repeat the calibration.

14. Once the calibration is accepted in step 5, press [ENTER] at the

ENTER=SAVE prompt and again at the ENTER=EXIT prompt

to save the new calibration and exit the calibration mode.

15. To exit the calibration mode without

press [CLR] at the ENTER=SAVE prompt. Then press

[ENTER] at the ENTER=UNDO prompt and again at the

ENTER=EXIT prompt to exit the calibration mode.

saving the new calibration,

39

Page 44

3.3.8 Mix Timer

This feature provides an output to control a mixer and audible alarm at

the end of a mixing procedure (see Figure 25).

00:00:00

Enter Mix Time

Figure 25: Mix Time Entry

1. Press [MIX TIMER] after loading a recipe. Display shows

“Enter Mix Time”.

2. Key in the desired mix time (hh:mm:ss) and press [ENTER] or

[MIX TIMER] to start the countdown.

3. Pressing [CLR] during the mix time entry will clear the mix

timer.

4. Pressing [CLR] a second time will exit the mix time entry

mode.

5. Pressing [CLR] or [MIX TIMER] during the countdown will

abort.

6. During the countdown, the output of pin 3, of the power

connector, is set high equaling the supply voltage. See section

2.4.6 for more details.

7. After the count down is complete, the alarm will activate. Press

[CLR] or [MIX TIMER] to stop the alarm.

After the desired mix time has been entered and the [ENTER] key is

press, the MIX TIME REMAINING will be displayed on the M1500

Remote Display. When the time is complete, the M1500 display will

flash.

40

Page 45

Section 4: Recipe Setup

|

[

|

K

|

P

|

-

|

[

|

[

|

[

This section describes how to setup the recipe database. The Agrifeed

5500 is capable of storing a combination of 500 recipes/ingredients.

4.1 Accessing the Recipe Database

Press [SELECT RECIPE] and the display will change from the weigh

mode to the Main Recipe screen (see Figure 26: Main Recipe Screen

). On a new indicator, the recipe database will be empty, thus no recipe

names will appear.

RECIPES

00 Horse Feed

01 Pig Meal

02 Chicken Meal

03 Dog food

04 Rabbit Feed

Figure 26: Main Recipe Screen

00]

ey-in Recipe#,

ress [Enter].

---------ADD RECIPE]

START BATCH]

HELP] = Exit

↑

↓

©

Scroll

Up

Scroll

Down

ª

To view the recipes, use the [ADD RECIPE] and [START BATCH] to

scroll up and down through the recipe names one screen at a time. Note

that the recipe number in the upper-right corner changes to identify the

currently selected recipe. To access a specific recipe number, simply key

in the 2-digit recipe number and it will appear at the top of the scroll list.

41

Page 46

Press [HELP] to exit the Main Recipe screen. The recipe identified in

-

*

the upper-right corner becomes the recipe selected for loading and

unloading.

4.2 Adding a Recipe

To add a recipe to the recipe database:

1. Press [ADD RECIPE] from the weigh mode.

2. The display shows ‘Searching…’ while looking for the next

available recipe number. When an unused (unnamed) recipe is

found the Recipe Name Entry screen appears (see Figure 27).

3. Up to 100 recipes can be defined. Recipe #00 is permanently

assigned as a “Preset” recipe that serves as a simple, single

ingredient recipe. Recipe #01 - #99 can be must be assigned a

custom name before they can be configured and used.

NAME RECIPE #01

L

ABCDEFGHIJKLMNOPQRSTUVWXYZ +

Figure 27: Recipe Name Entry Screen

Use the cursor keys to key in the recipe name. Use the numeric portion

of the keypad to enter numbers.

/=#$()<>&@

42

Page 47

§

Moves left to

previous

¨

Moves right

to next

character

¯

Selects the

character under

the cursor arrow

Enters name and

completes entry

Deletes the last

character of the

recipe name

Press [ENTER] to save the name and proceed to the Recipe Pre-Alarm

screen as described in the following section.

4.2.1 Recipe Pre-Alarm

The Recipe Pre-Alarm is used during the unloading process to sound an

alarm and flash the display when the pre-alarm weight is achieved. A

unique pre-alarm value can be assigned to each recipe. Pre-alarm values

are assigned immediately after naming a recipe as described in the

previous section.

To assign or change a Recipe Pre-Alarm:

1. Select a recipe number as described in section 4.1 and press

[EDIT RECIPE], or press [ADD RECIPE] to assign a new

recipe number.

2. Enter the recipe name as described in section 4.2. A name must

be assigned before a pre-alarm value can be entered.

3. Press [ENTER] to accept the recipe name and proceed to the

Recipe Pre-Alarm screen (see Figure 28).

4. Key in the pre-alarm weight value and press [ENTER]. The

display will then proceed to the Weight Entry Method screen as

described in the following section.

43

Page 48

RECIPE PRE-ALARM

000000 lb

KEY-IN PRE-ALARM VALUE

[ENTER]=Accept Value [CLR]=Delete

Figure 28: Recipe Pre-Alarm

NOTE:

If the PRE-ALARM METHOD parameter in the scale setup is set to

“COMMON PRE-ALARM”, then the indicator disregards the Recipe

Pre-alarm weight and instead uses the PRE-ALARM WEIGHT

specified in the scale setup for all recipes. See Table 6 for more details on

the Pre Alarm setup.

4.2.2 Weight Entry Method

The weight entry method is selected after entering the recipe pre-alarm

when adding new recipes (see section 4.2). The weight entry method

cannot be changed when editing a recipe. There are 3 weight entry

methods used for loading ingredients:

WEIGHT/LOAD

Target weight entered as the actual ingredient weight to be

loaded.

WEIGHT/ANIMAL

Target weight entered as the amount of each ingredient to be

feed to a single animal.

PERCENT/LOAD

Target percentage of each ingredient. Target weight will be

calculated as a percentage of the total load amount.

Press [YES] to accept the displayed weight entry method and proceed

with ingredient selection as described in the following section.

Press [NO] to scroll to the next weight entry method.

44

Page 49

4.2.3 Ingredient Selection

Ingredients are assigned when adding or editing recipes. The Ingredient

Selection screen (see Figure 29) will appear immediately after selecting

the weight entry method described in the previous section.

1st Ingredient

CORN SILAGE

USE [SELECT INGRED] TO ASSIGN/CHANGE

[ENTER]=Next [HELP]=Exit

Figure 29: Ingredient Selection Screen

There are two ways to select ingredients:

1. If the 2-digit ingredient number is known, key in the ingredient

number and press [SELECT INGRED].

2. To search for an ingredient, press [SELECT INGRED] to view

the ingredient list as described in section 3.3.6.1. Choose the

desired ingredient and press [ENTER] to select it for the recipe.

When the desired ingredient is displayed in the Ingredient Selection

screen (see Figure 29) press [ENTER] to accept it and proceed to the

Ingredient Target Entry screen (see Figure 30).

1st Ingredient

000000 lb

KEY-IN NEW TARGET VALUE

[ENTER]=Accept Value [HELP]=Delete

Figure 30: Ingredient Target Entry Screen

The ingredient target value will be entered either as a weight value or

percentage depending on the selected weight entry method. Key in the

desired target value and press [ENTER].

45

Page 50

Following the target entry, the display prompts for the selection of

G

T

another ingredient. Repeat the Ingredient Selection procedure for each

additional ingredient required. After all required ingredients have been

entered, press [HELP] at the Ingredient Selection screen (without

selecting another ingredient) to exit and save the recipe.

4.3 Editing a Recipe

The procedure for editing a recipe is much the same as adding one.

When editing a recipe, it is possible to change the recipe name, pre-alarm

weight, ingredients and ingredient targets. Additional ingredients can

also be appended to a recipe. It is not

method.

To edit a recipe from the weigh mode (see Figure 31):

1. Key-in the desired recipe number and press [SELECT

RECIPE]. The selected recipe number will appear in the

lower-right corner of the display.

2. Press [EDIT RECIPE] to display the Recipe Name Entry

screen.

3. Refer back to Figure 27 in section 4.2 Adding a Recipe to

continue the editing process.

00

LOAD

possible to change the weight entry

lbÎοÍ

Recipe 01

are 00 lb

ross

Figure 31: Agrifeed 5500 Weigh Mode

4.4 Deleting a Recipe

If you wish to add another recipe but all 100 recipes have already been

configured, a message is displayed indicating that you must first delete

an existing recipe.

To delete a recipe from the weigh mode:

1. Press [SELECT RECIPE].

2. Key in the 2-digit recipe number to be deleted and press [CLR].

The display prompts “Delete Recipe?”.

3. Press [YES] to delete the recipe.

46

Page 51

4.5 Printing Recipes

A list of all named recipes can be printed from the Recipe Selection

screen.

To print recipes:

1. Press [SELECT RECIPE] to access the recipe list.

2. Press [PRINT] then,

3. Press [1] as prompted to print only the current recipe.

4. Press [2] as prompted to print all recipes.

Recipes will be transmitted out the printer port.

47

Page 52

This page is intentionally left blank

48

Page 53

Section 5: Load / Unload Operation

The Agrifeed 5500 is capable of loading and unloading recipes by the

touch of the button. Also the indicator is also capable of loading a single

ingredient batch using a default recipe ‘RECIPE 00’.

5.1 Loading Ingredients

When loading, ingredients can be specified individually or recalled from

a recipe.

5.1.1 Selecting Individual Ingredients

To load ingredients individually:

1. Make sure the Agrifeed 5500 is in the LOAD mode – if it is in

the UNLOAD mode, press [LOAD].

2. Key in the ingredient target weight and press [LOAD].

3. The display shows the batch target and prompts “Enter Ing#:”.

4. Key in the ingredient number (optional), and press [ENTER].

5. Begin the loading process (see section 5.1.3).

5.1.2 Selecting a Recipe

1. To load ingredients of a recipe:

2. Make sure the Agrifeed 5500 is in the LOAD mode – if it is in

the UNLOAD mode, press [LOAD].

3. Select a recipe to load as follows:

Key in the recipe number and press [SELECT RECIPE], or

View the recipe list by pressing [SELECT RECIPE]. Refer to

section 4.2 for instructions on accessing the recipe database.

4. Press [START BATCH].

5. Enter the total recipe target value and press [ENTER].

Consider the recipe’s Weight Entry Method:

WEIGHT/ANIMAL - Key in the number of animals to feed.

The target weight for each ingredient is automatically

calculated.

WEIGHT/LOAD – The total recipe weight as determined by

the individual ingredient targets is shown as the batch target.

Press [ENTER] to accept this target, or key in a new target and

press [ENTER]. If a new target is entered, all ingredient targets

are adjusted in direct proportion to the new target (for this batch

only).

49

Page 54

PERCENT/LOAD – Key in the desired batch target. The

target weight for each ingredient is automatically calculated

based on the ingredient’s percentage of load.

6. The display shows the first ingredient to load.

7. Press [START BATCH] to begin the loading process (see

section 5.1.3).

lbÎοÍ

-1250

Ing’t #05

CORN SILAGE

Figure 32: Start Load Window

NOTE:

If the operator does not wish to weigh the ingredient displayed, press

[SELECT INGRED] before pressing the [START BATCH] to scroll

through the remaining ingredients of the current recipe/batch.

5.1.3 Loading Process

When loading, the target weight is displayed as a negative net weight.

Fill each ingredient to a net weight of zero (0).

During the loading process, the bottom-right of the display gives an

UNDER/GOOD/OVER annunciation. This serves as a visual aide,

indicating that loaded weight is over, under or within the desired

tolerance.

Net

START

The Pre-Alarm also provides a visual and audible alarm during the

loading process. When the pre-alarm weight is reached, the display

back-light flashes slowly, accompanied by a series of warning beeps.

When the target weight is reached, the display back-light flashes rapidly

along with another series of beeps.

50

Page 55

5.1.4 Advancing Ingredients

To manually advance ingredients:

Press [SELECT INGRED]. This records the loaded net weight of the

previous ingredient, deletes the ingredient from the loading list, then

waits for you to press [START] to begin the loading process for the next

ingredient. It is possible to temporarily skip ingredients by pressing

[SELECT INGRED] before pressing [START].

Pressing [STOP] during the loading process will record the weight

already loaded for the current ingredient, but will not delete it from the

loading list. Thus it is possible to load the remaining weight out of

sequence at a later time.

Pressing [STOP] twice consecutively during the loading process aborts

the batch.

To advance ingredients automatically:

Enable the ADVANCE TOLERANCE parameter in the Scale Setup

mode. When the loaded weight is within the specified tolerance for the

amount of time specified by the ADVANCE DELAY, the next ingredient

is automatically selected. The weight of the previous ingredient is

recorded and the ingredient is deleted from the loading list.

To Advance Ingredients with Remote Key:

Disable the ADVANCE TOLERANCE in the Scale Setup mode and set

the REMOTE INPUT ACTION to ‘PRINT/ADVANCE’. Activating the

remote key will print a ticket and then advance to the next ingredient

similar to the automatic method.

5.2 Unloading Recipes

A pen number can be assigned to each location that a recipe is unloaded.

When using the AGRIDATA Recipe Management PC software, a pen

routing list can be created providing a driver with pen location and

unload weight information for multiple pens.

5.2.1 Selecting Individual Pens

To unload a recipe to a single pen:

1. Make sure the Agrifeed 5500 is in the UNLOAD mode – if it is

in the LOAD mode, press [UNLOAD].

2. Key in the unload target weight and press [UNLOAD].

3. The display shows the batch target and prompts “Enter

PEN/ID:”.

4. Key in the pen number (optional), and press [ENTER].

5. Begin the unload process (see section 5.2.3).

51

Page 56

5.2.2 Selecting Pens from a List

This procedure is only used in conjunction with a pen routine list

configured by the AGRIDATA Recipe Management PC software.

1. To unload pens from a routine list:

2. Make sure the Agrifeed 5500 is in the UNLOAD mode – if it is

in the LOAD mode, press [UNLOAD].

3. Press [START BATCH].

4. The display shows the recipe target for the first pen (see Figure

33: Start Unload Screen

5. ).

6. Press [START BATCH] to begin the unload process for the

displayed pen number (see section 5.2.3).

- OR -

7. Press [SELECT INGRED] to temporarily skip the current pen

and display the next pen in sequence.

lbÎοÍ

700

Pen #01 Cow Barn

Special Cow Feed

Figure 33: Start Unload Screen

5.2.3 Unload Process

When unloading, the target weight is initially displayed. Unload material

to a net weight of zero (0).

During the unloading process, the bottom-right of the display gives an

UNDER/GOOD/OVER annunciation. This serves as a visual aide,

indicating that unloaded weight is over, under or within the desired

tolerance.