Page 1

GSE 351

Checkweigher

Reference Manual 1.0

Page 2

ii

GSE 351

Reference Manual 1.0

Page 3

GSE 351 Checkweigher Reference Manual

Copyright © 2000 GSE Scale Systems. All rights reserved.

Published by:

GSE Scale Systems

42860 Nine Mile Road

Novi, MI 48375

USA

Information in this Reference Manual is subject to change without

notice due to correction or enhancement. The information

described in this manual is solely the property of GSE. No part of

this manual may be reproduced or transmitted in any form or by

any means, electronic or mechanical, including photocopying and

recording and sold for any monetary figure without the express

written permission of GSE.

GSE Locations

GSE Scale Systems

42860 9 Mile Road

Novi, MI 48375

U.S.A.

Phone: (800) 755-7875

www.gse-inc.com

GSE Canada, Inc.

617 East Lake Road

Airdrie, Alberta Canada T4B 2B8

Phone:(403) 948-9921

Fax: (403) 948-1449

Page 4

Page 5

i

Contents

CHAPTER 1: Introduction........................................................................................................1

CONVENTIONS AND SYMBOLS.............................................................................................1

DISPLAY..................................................................................................................................2

LED Display....................................................................................................................2

Annunciators...................................................................................................................2

KEYPAD ..................................................................................................................................3

WEIGH MODE FUNCTIONS...................................................................................................3

SECONDARY FUNCTIONS.......................................................................................................4

SPECIFICATIONS.....................................................................................................................5

Performance ..................................................................................................................5

Electrical.......................................................................................................................5

Operation.......................................................................................................................5

Communication.............................................................................................................5

display...........................................................................................................................5

Enclosure.......................................................................................................................5

Options..........................................................................................................................5

Platform.........................................................................................................................5

CHAPTER 2: Installation ..........................................................................................................7

BENCHTOP MOUNTING.........................................................................................................7

WIRING...................................................................................................................................9

Power Connection..........................................................................................................9

DC Power Connection..................................................................................................9

Serial Port Connection..................................................................................................9

Remote Key Connection..............................................................................................11

Load cell connection....................................................................................................12

CHAPTER 3: Getting Started.................................................................................................13

DEFAULT SETUP ..................................................................................................................13

OPERATION...........................................................................................................................13

Entering a Target Value..............................................................................................14

Entering Tolerances.....................................................................................................17

Status Indication...........................................................................................................18

Counting........................................................................................................................18

Printing out a Ticket....................................................................................................19

CHAPTER 4: Configuration....................................................................................................21

SETUP MODE........................................................................................................................21

Selection Parameters...................................................................................................23

Key-In Parameters........................................................................................................24

PARAMETER MAP ................................................................................................................25

PARAMETER MAP DETAILS................................................................................................27

CUSTOM TRANSMIT SETUP ................................................................................................37

Elements Of A Custom Transmit................................................................................37

Parameters...................................................................................................................38

Page 6

ii

ACSII Text ..................................................................................................................38

Control Codes .............................................................................................................38

Writing A Custom Transmit ASCII Text File...........................................................38

Accessing Setup and Clearing Existing Custom Transmit....................................39

Entering ASCII Text.....................................................................................................39

Entering ASCII Control Codes..................................................................................39

Parameter Selection Numbers....................................................................................41

Exiting Setup Mode And Saving Changes................................................................43

TIME/DATE OPERATION.....................................................................................................43

REMOTE KEY O PERATION..................................................................................................45

REMOTE SERIAL O PERATION.............................................................................................46

Display Capture Utility...............................................................................................46

Example #1.................................................................................................................47

Example #2.................................................................................................................47

TARGET AND TOLERANCE SETUP .....................................................................................47

RS-485 MULTI-DROP NETWORK SETUP AND OPERATION..........................................48

Setup ...............................................................................................................................48

Operation.......................................................................................................................49

Network Protocol .........................................................................................................49

CHAPTER 5: Calibration........................................................................................................51

SETUP MODE CALIBRATION ..............................................................................................51

FAST CALIBRATION.............................................................................................................51

PERFORMING CALIBRATION..............................................................................................52

Select and Calibration Method and Establish Zero ...............................................52

First Zero?...................................................................................................................52

Last Zero .....................................................................................................................53

False Zero....................................................................................................................54

Only Zero ....................................................................................................................55

Reset Calibration.........................................................................................................56

Establishing A Span.....................................................................................................58

Exiting Calibration......................................................................................................58

CHAPTER 6: Legal For Trade................................................................................................61

NTEP REQUIREMENTS.......................................................................................................61

OIML REQUIREMENTS.......................................................................................................62

OTHER REQUIREMENTS......................................................................................................62

SEALING AND AUDIT TRAILS............................................................................................62

Physical Seal.................................................................................................................63

Audit Trails....................................................................................................................64

OIML Audit Trail..........................................................................................................64

Calibration Audit Trail................................................................................................65

Setup Audit Trail.........................................................................................................65

Viewing Audit Trail Parameters .................................................................................65

CHAPTER 7: Model 351 Options...........................................................................................67

RS- 485 NETWORKING.......................................................................................................67

Network Connections...................................................................................................68

Page 7

iii

Half-Duplex (2-wire)..................................................................................................69

Full Duplex (4-wire)...................................................................................................69

Both Half Duplex and Full Duplex.............................................................................69

20 MA CURRENT LOOP O PERATION.................................................................................72

Installation....................................................................................................................72

Bi-Directional...............................................................................................................72

Baud................................................................................................................................72

Active/Passive...............................................................................................................72

Isolation .........................................................................................................................73

Max Voltage..................................................................................................................73

Connections...................................................................................................................73

Cable..............................................................................................................................73

Connected Devices.......................................................................................................74

CHAPTER 8: Troubleshooting................................................................................................75

ERROR MESSAGES...............................................................................................................75

Operational Errors.......................................................................................................75

Setup Mode Errors.......................................................................................................76

Hardware Errors..........................................................................................................77

Calibration Errors........................................................................................................77

Communication Errors................................................................................................78

Miscellaneous Errors...................................................................................................78

V IEWING SETUP ...................................................................................................................78

INFORMATION MODE PARAMETERS.................................................................................79

A/D CALIBRATION PROCEDURE .......................................................................................81

Page 8

Page 9

1

CHAPTER 1: INTRODUCTION

Thank you for selecting the GSE Model 351 Checkweigher. The Model 351

continues the GSE tradition of Excellence in Weighing Technology. A

properly installed and maintained Model 351 will provide many years of

reliable, accurate performance.

The chapters of this manual focus on various aspects of the indicator:

Chapter 1: Introduction Basic operating information.

Chapter 2: Installation Installation instructions.

Chapter 3: Getting Started Enter a target and tolerance limits.

Chapter 4: Configuration Access the Setup Mode and configure the

indicator to a specific application.

Chapter 5: Calibration Access the Calibration Mode and match the

load sensing device to the indicator.

Chapter 6: Legal-for-Trade Legal-for-trade information.

Chapter 7: Options Available options.

Chapter 8: Troubleshooting Troubleshooting help and error messages.

CONVENTIONS AND S YMBOLS

[ZERO] A keypress appears in bold with brackets.

[PRINT]+[UNITS] ‘+’ indicates keys pressed simultaneously.

Setup Display prompts are bold italic.

Setup ~ Enter ~ =Cal! ‘~’ indicates multi-part display prompts.

Fast ~ Cal! Display prompts can appear in sequence.

First ~ 0? ~ 0.00

! Indicates important considerations.

i Provides additional information.

Page 10

Model 351 Checkweigher

2

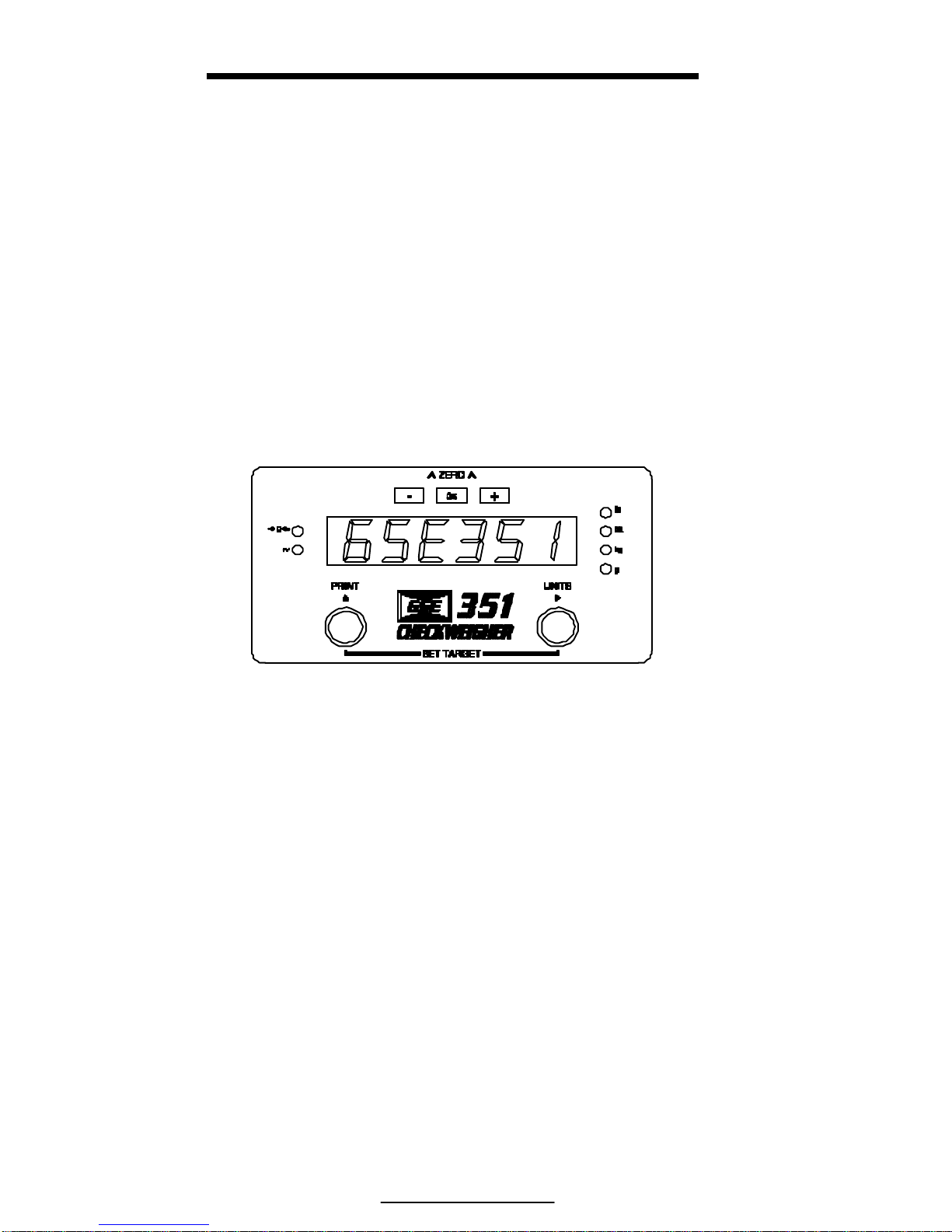

DISPLAY

The M351 displays alpha-numeric data, but due to the nature of 7-segment

LEDs and the limitation of six digits, some information is abbreviated.

All segments and annunciators are illuminated for a brief display test upon

power up. The current gross weight is then displayed in default units.

LED DISPLAY

The LED display is a six digit, 7-segment bright red LED screen with

9 annunciators to show weight and status information. The – (Low

Limit) = Yellow, + (High Limit) = Red and OK (Within tolerance) =

Green. Also there are annunciators for 5 units of measure.

Figure 1: Model 351 LED Display

ANNUNCIATORS

Annunciators provide mode and status information. When illuminated, they

indicate the following conditions:

- (Yellow) Current weight is under the low limit tolerance.

OK (Green) Current weight is within tolerance.

+ (Red) Current weight is over the high limit tolerance.

ÚÚ 0ÙÙ Displayed weight is at center-of-zero (± ¼ display

graduation).

~ Scale is in motion. Motion inhibited transmits will be delayed

until motion ceases.

lb The displayed value is represented in pounds.

oz The displayed value is represented in ounces

Page 11

3

kg The displayed value is represented in kilograms

g The displayed value is represented in grams

lb oz When both the lb and oz annunicators are lit the displayed

value is represented in lb oz.

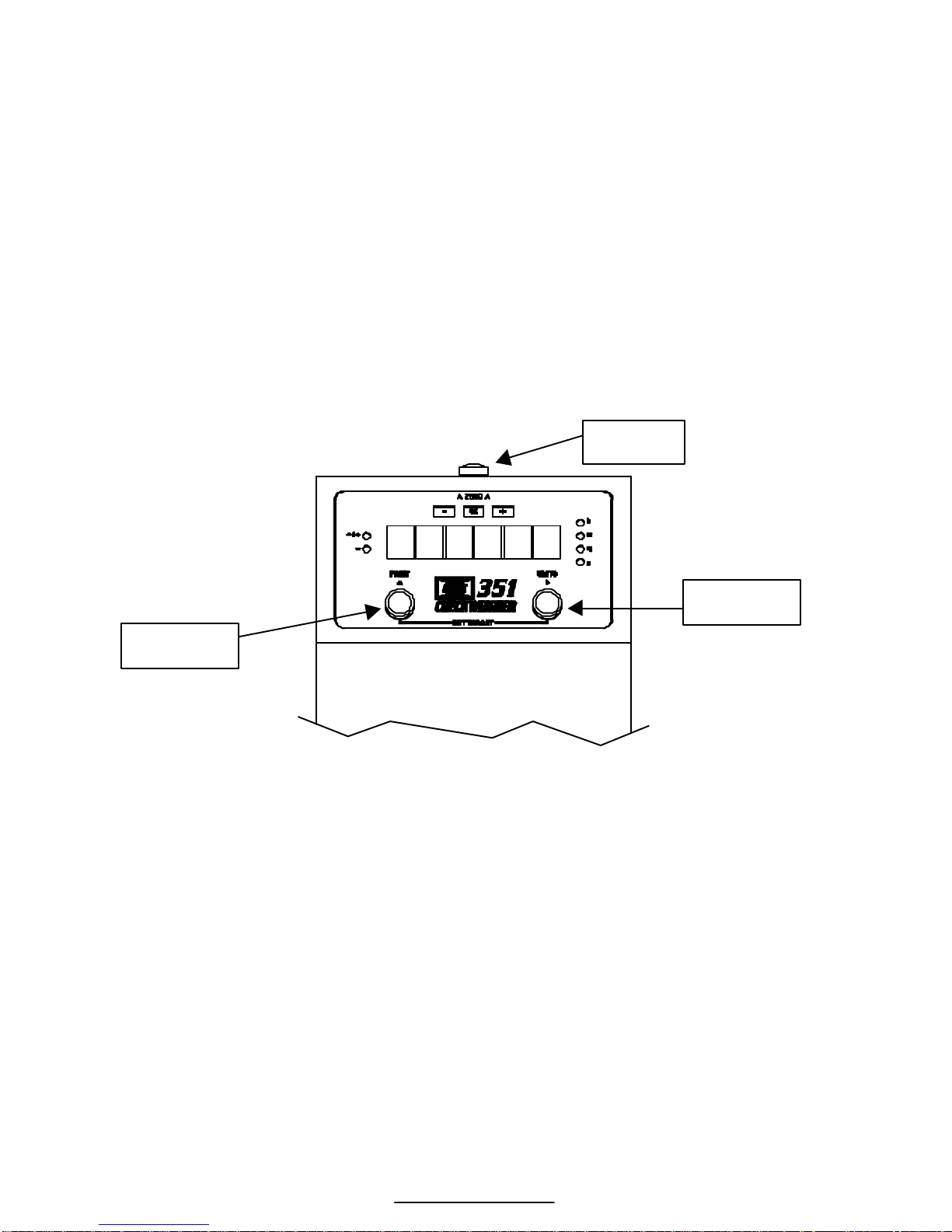

KEYPAD

Three rigid IP67 sealed buttons are used for operator input. Each key is

assigned two distinct functions. Various key combinations are also used.

Each key has secondary functions, allowing an operator to enter target

values, perform piece samples, access setup parameters, etc.

Figure 2: 351 Function Keys

WEIGH MODE FUNCTIONS

The Model 351 Checkweigher has 3 primary Weigh Mode functions:

[ZERO] Performs a gross zero and selects the gross mode.

[PRINT] Initiates data transmission out the communication port.

[UNITS] Toggles the units of measure between ‘lb’, ‘kg’, ‘oz’, ‘lb’

‘oz’ and ‘grams’.

ZERO

UNITS

PRINT

Page 12

Model 351 Checkweigher

4

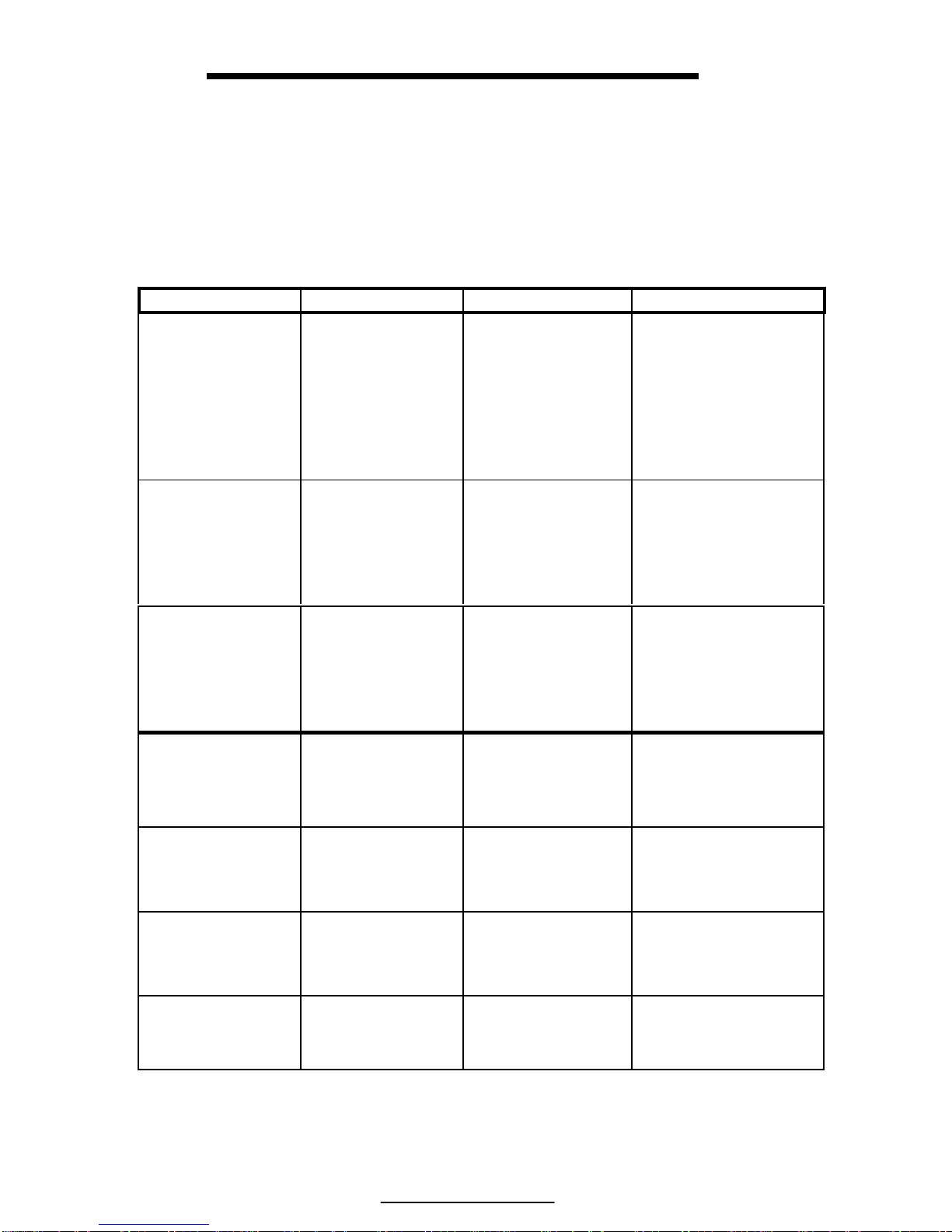

SECONDARY FUNCTIONS

The Model 351 keys perform different functions in the weigh mode, the

setup mode and the calibration mode. Secondary functions for each key

will allow additional tasks to be performed.

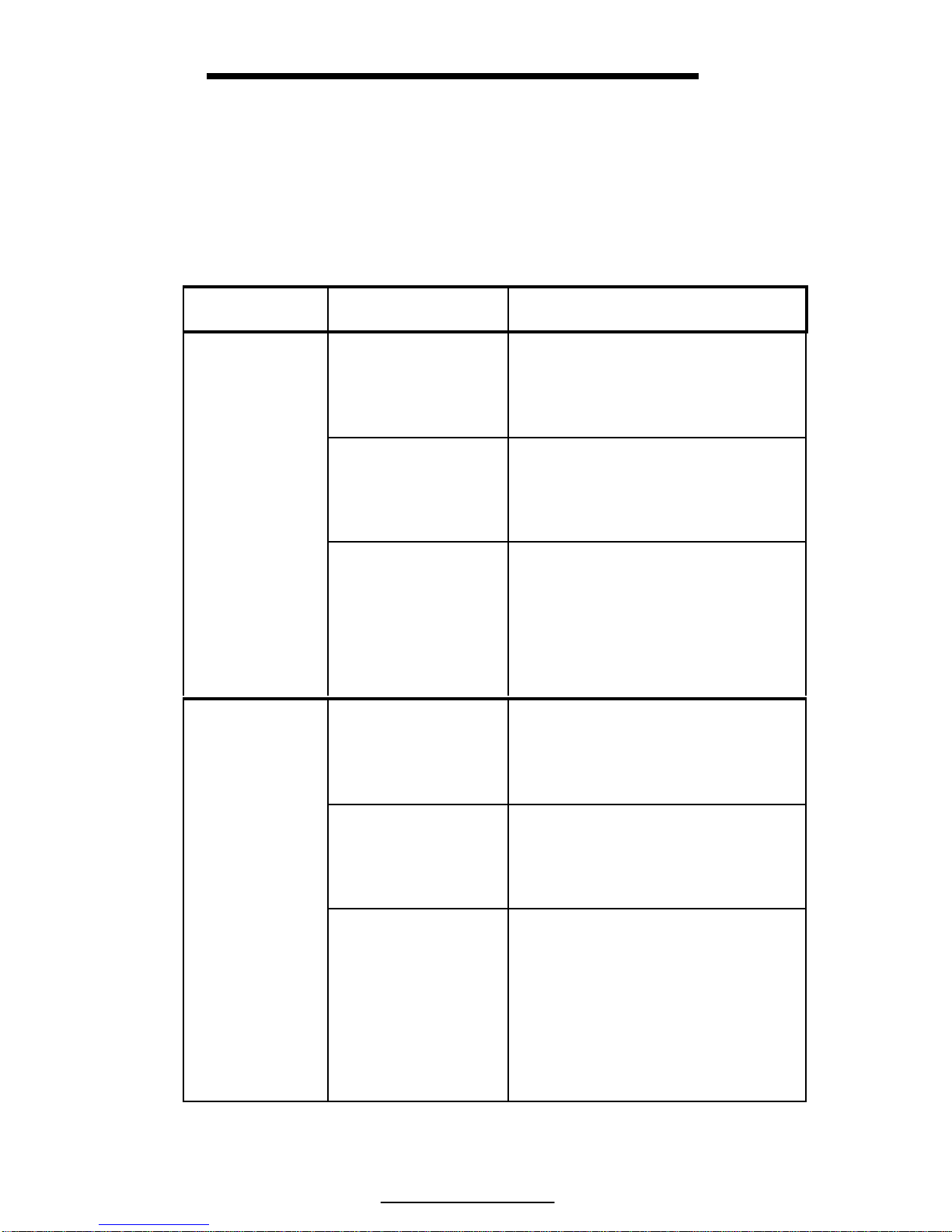

Table 1: Key Functions

Key Press Weigh Mode Count Mode Setup Mode

[ZERO]

Performs a gross

zero function

and/or clears an

entry in progress.

Hold this key on

power-up to turn

on the display

regardless of P420.

Performs a

quantity zero

function and/or

clears an entry in

progress. From

the sample mode,

returns to the

gross weigh mode.

Exits the Setup Mode

and/or answers “NO”

to query prompts

and/or clears an entry

in progress. Also acts

as a [SELECT] key.

[PRINT / p ]

Performs a print

function and/or

‘scrolls’ through

digits during

target or limit

entry.

Performs a print

function and/or

‘scrolls’ through

digits during

target or limit

entry.

‘Scrolls’ through

digits during data

entry.

[UNITS / u ]

Toggles between

‘lb’, ‘kg’, grams,

ounces and lb oz

and/or advances

cursor to next

entry position.

Toggles through

standard sample

sizes and/or begins

a new sample

entry.

Advances cursor to

next entry position

and/or cycles

prompts.

[PRINT]+

[UNITS]

Access target

entry mode.

Access target

entry mode.

Acts as an [ENTER]

keypress.

[ZERO]+

[PRINT]

Decrements the

right-most digit

during data

entry.

Decrements the

right-most digit

during sample

entry.

Decrements the rightmost digit during

sample entry.

[ZERO] +

[UNITS}

Backspace –

erases right-most

digit during data

entry.

Backspace – erases

right-most digit

during data entry.

Backspace – erases

right-most digit

during data entry.

[ZERO]+[PRINT]

+[UNITS]

Access the setup

mode.

Access the setup

mode.

Exit the setup mode.

Page 13

5

SPECIFICATIONS

PERFORMANCE

Full Scale (F.S.) Selectable 0 to 999,990

Resolution 20-bit A/D converter, 100,000d displayed,

+/- 500,000d internal

A/D Conversion 60 Hz

Zero Track Off – 10d

Zero Range 0-100% of F.S. span

Operating Temperature -10 C to +40 C

Warranty 2 year

Units of Measure kg, lb, grams, lb oz, oz

ELECTRICAL

Power Requirement 90-250 VAC / 12-36 VDC

Excitation Voltage 10 VDC

Signal Input Sensitivity 0.1 – 20 mV/V

OPERATION

Modes Selectable modes such as target, count and HI/LO limits.

Remote Input 1 momentary contact closure (100ms minimum)

Keys 3 buttons for easy of setup and operation

COMMUNICATION

Port 1 RS232 bi-directional serial port. RS485 or 20 mA optional

Data Output String Twenty one (21) selectable fixed-format transmissions available,

1 custom format (programmable via RS232)

Protocol Selectable

Baud Rate 150-9600 bps

DISPLAY

LED Bright RED 6-digit weight display, 0.8” (22mm) height with

9 LED annunciators for operational status: Zero indication,

Motion, High, low, accept and units of operation

ENCLOSURE

With Column Both the enclosure and column are NEMA 4X (IP 66) stainless

steel. Durable enough for washdown environments and cleaning

agents

OPTIONS

RS485 Module Isolated multi-drop with 251 devices max, half or full duplex up to

4000 feet, 9600K bps max

20mA Current Loop Isolated TX-Active or Passive, RX-Passive, 9600 bps max,

12VDC, 1000 feet

Stainless Steel Load Cell includes a stainless steel load cell shield

PLATFORM

10 x10 and 12 x 12 Equipped with Shock – Stopper overload and under-load protection.

Open platform design for ease of cleaning

Page 14

Page 15

7

CHAPTER 2: INSTALLATION

This chapter contains information necessary for proper installation of the

Model 351 Checkweigher. Please review these instructions before installing

your scale.

High voltages may exist within the enclosure. To prevent the risk of

electrical shock, ALWAYS unplug the Model 351 when opening the

enclosure. Installation and servicing of the Model 351 should be performed

only by authorized and qualified service personnel.

For information on installing options, see Chapter 7: Model 351 Options. For

NTEP and OIML details, see Chapter 6: Legal For Trade

!!

IMPORTANT! The Model 351 does not include an on/off switch and

therefore must be installed near a power outlet socket that is easily

accessible and in keeping with UL/CSA Safety Standards.

INFORMATION IMPORTANT! Prendre note que les contrôleurs de

serie 351 ne sont pas munis d'interrupteurs "Marche / Arrêt". Par

conséquent, il devront être installés près d'une source d'alimentation secteur

accessible pour demeurer sous les exigences des normes de sécurité

UL/CSA.

BENCHTOP MOUNTING

The Model 351 enclosure and column meet NEMA 4X type specifications.

When choosing a mounting location, make sure the unit is level (a level

bubble is located under the platform shroud) and free from obstructions.

Figure 3: Model 351 with 10x10 platform

Page 16

Model 351 Checkweigher

8

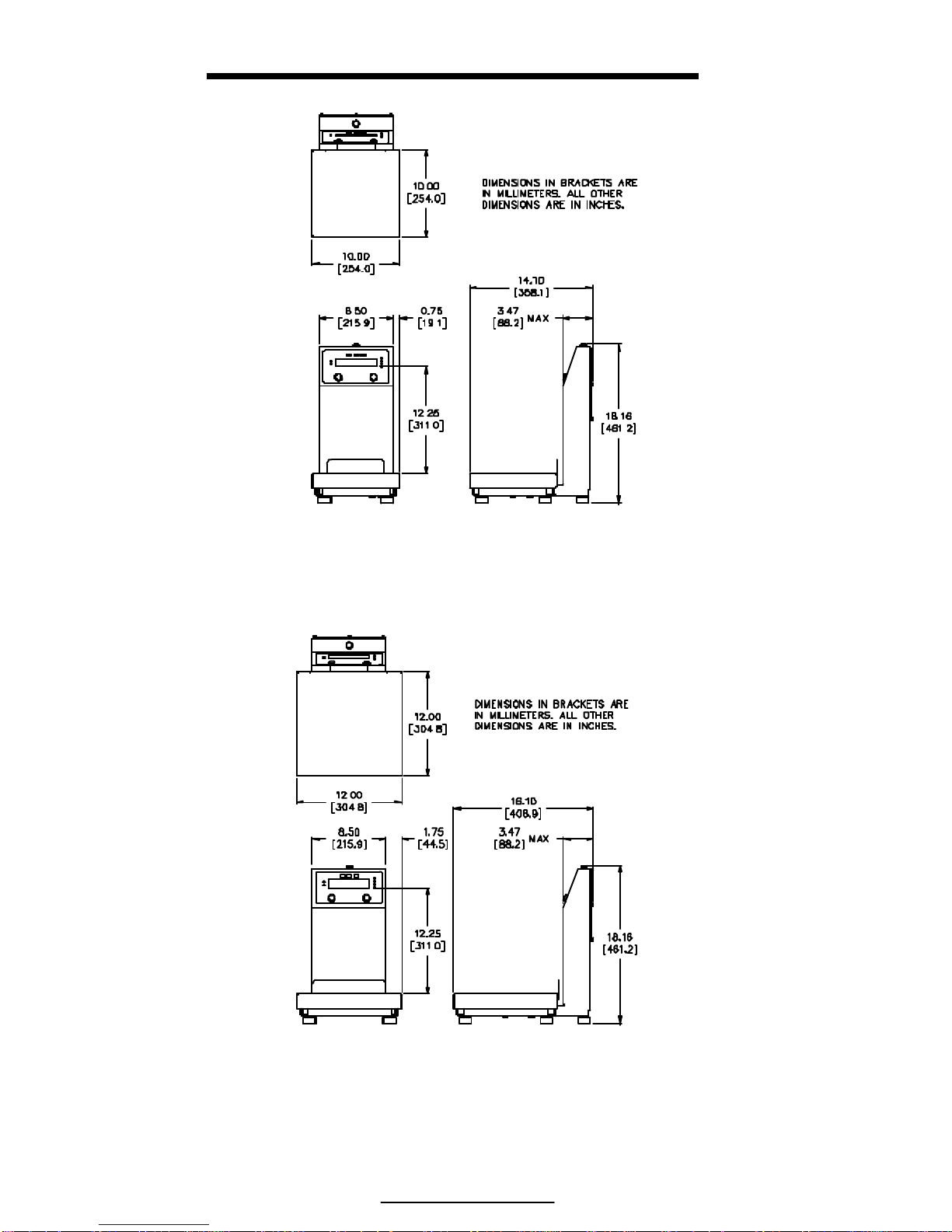

Figure 4: Model 351 with 10x10 Platform Dimensions

Figure 5: Model 351 with 12x12 Platform Dimensions

Page 17

Chapter 2: Installation

9

WIRING

POWER CONNECTION

There are two ways to power the Model 351, with a 90-250 Volt line cord

(U.S. Style standard) or with a 12-36 VDC external source.

i

The Model 351 does not include an on/off switch. In keeping with

UL/CSA Safety Standards it must be installed near an easily accessible

power outlet.

DC POWER CONNECTION

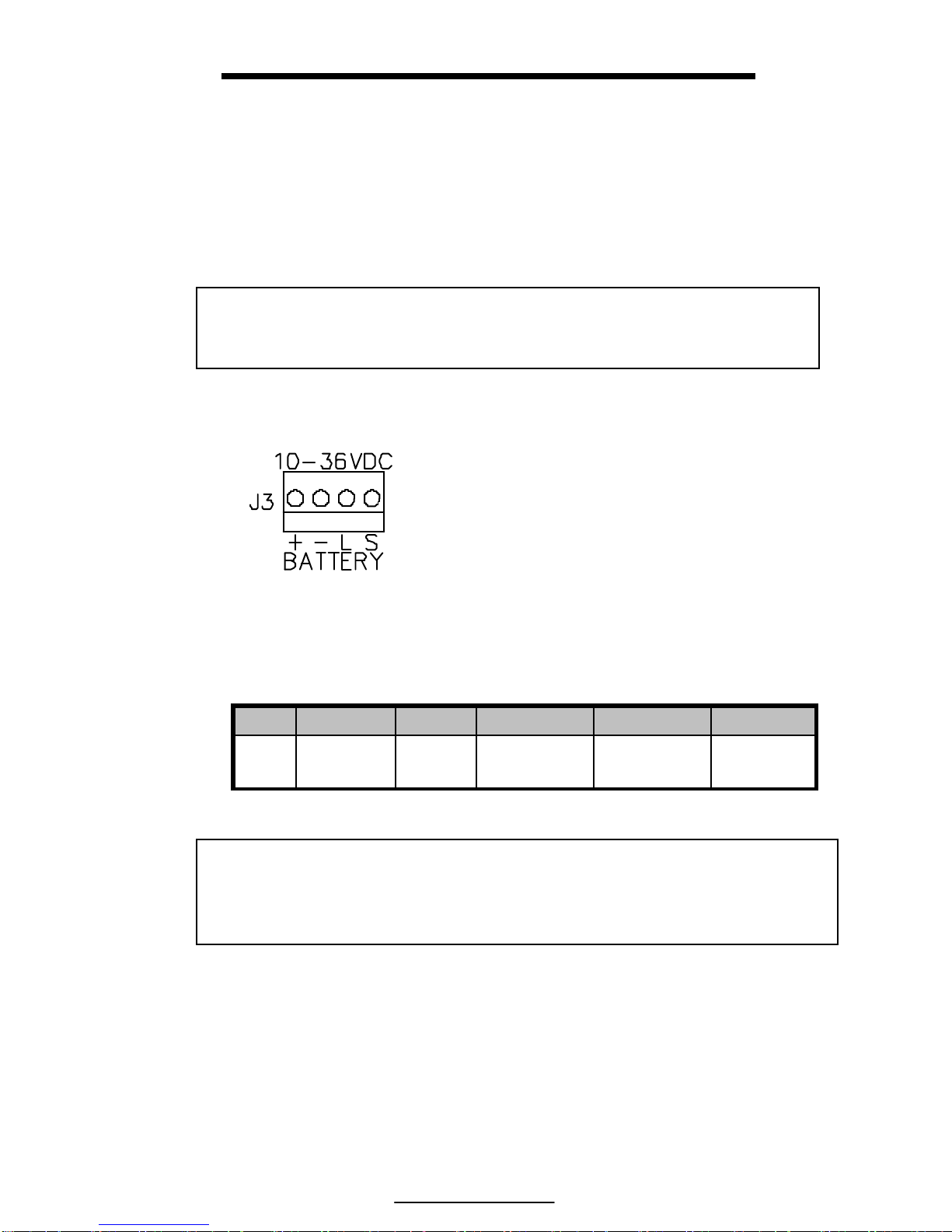

Wire the DC supply to the J3 connector

on the Model 351 main board. Do not

connect pins 3 or 4. The mating

connector can be purchased from a local

electronics supplier. Recommended

connectors are GSE PN: 26-20-3365 (24

AWG) or GSE PN: 26-20-3366 (22

AWG) / AMP PN: 640441-3 (24 AWG)

or AMP PN: 640440-3 (22 AWG).

Connector cover GSE PN: 26-20-3389

or AMP PN: 643075-3.

!!

CAUTION: Do not apply AC power through the line cord when a DC

source is attached. When AC is supplied, the voltage at J3 is 24 VDC.

This voltage can damage batteries attached to J3 unless a protection

diode is used to prevent backfeeding.

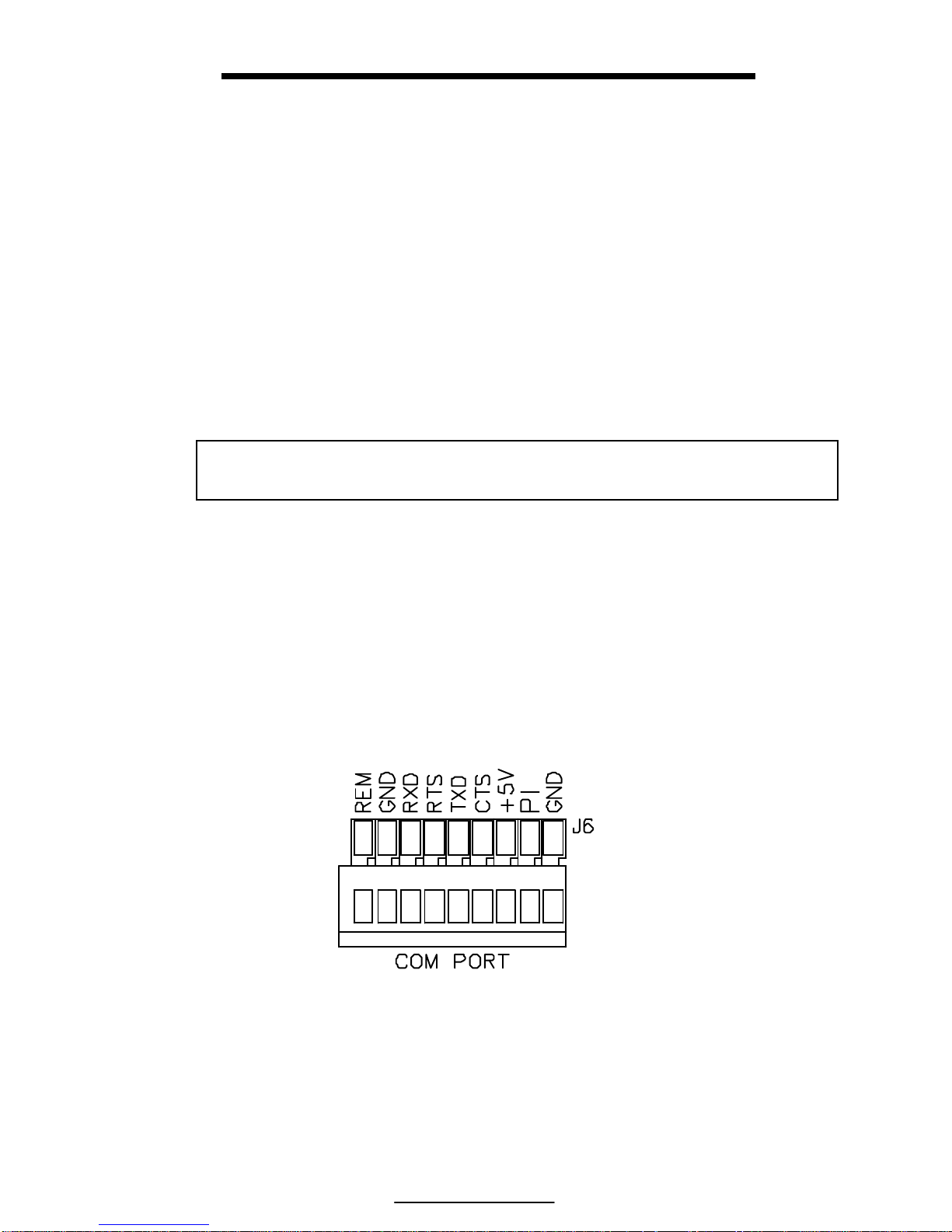

SERIAL PORT CONNECTION

Before connecting to the serial port, consideration should be given to the

communication protocol and to any remote key requirements. For

information on remote key operation, refer to Remote Key Operation on page

11. Use Table 2 to determine proper wiring to the communication port.

Figure 6: DC Power

Connector

Pin 1 Pin 2 Pin 3 Pin 4 Range

DC + - Do not use Do not use 12 - 36 VDC

Page 18

Model 351 Checkweigher

10

Communication connections are made with a pigtailed cable through a strain

relief. The cable should be 20 to 28 AWG with a braided or foil shield for

either model type. The maximum recommended cable length is 50 feet (15

meters). However, much longer connections are possible if using a properly

shielded, low-capacitance cable.

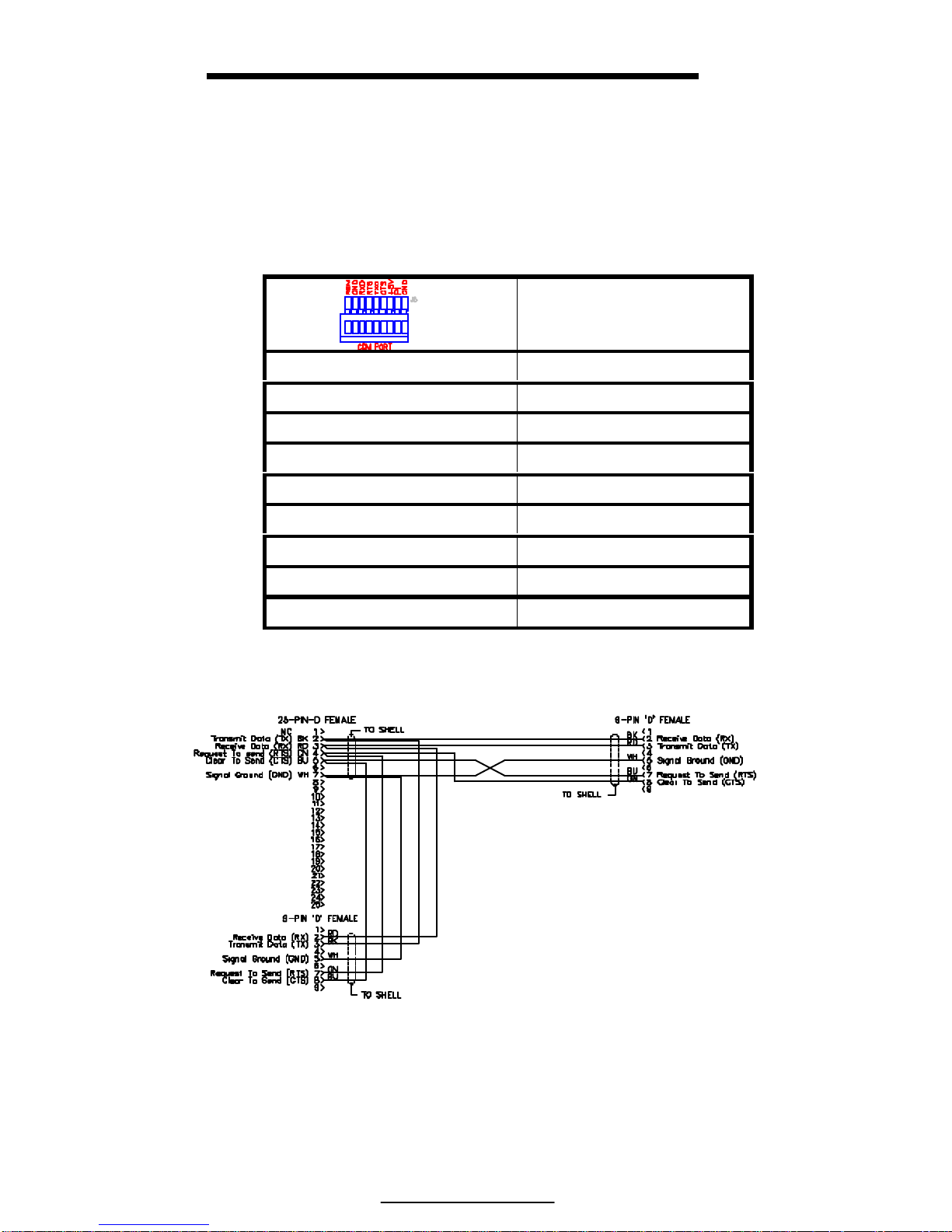

Table 2: Serial Port Connections

Description

REM Remote Key

GND Digital Ground

RXD Receive

RTS Request-to-Send

TXD Transmit

CTS Clear-to-Send

+5V +5 VDC

PI Do Not Connect

GND Digital Ground

Figure 7: : GSE Serial Cable, Part Number 22-30-29752

Page 19

Chapter 2: Installation

11

A communication cable (P/N: 22-30-29752) may be purchased from

GSE

REMOTE KEY CONNECTION

A remote key may be connected to the Model 351 communication port to

provide remote activation of print or zero functions.

The connection for the remote key input is between pin 1 and pin 2. A twoconductor shielded cable between 28 and 20 AWG is recommended. The

input requires a contact closure from a push-button switch, a ‘dry’ relay

contact, a photo-eye, and a proximity sensor or other such device. A closure

initiates the operation specified at P800.

!!

Do not apply an external voltage to remote key terminals! Only a

contact closure is required to activate the remote key input.

The open circuit voltage across the remote key pins is +5 VDC. A closed

switch will conduct about 0.25 mA. Therefore, a low-voltage switch with

gold-plated contacts is recommended. A Mercury-wetted switch will also

work well. A minimum contact duration of 100 ms is required. Once

invoked, the selected remote key operation will not repeat until the contact is

released and closed again.

Figure 8: Remote Key Connection

Page 20

Model 351 Checkweigher

12

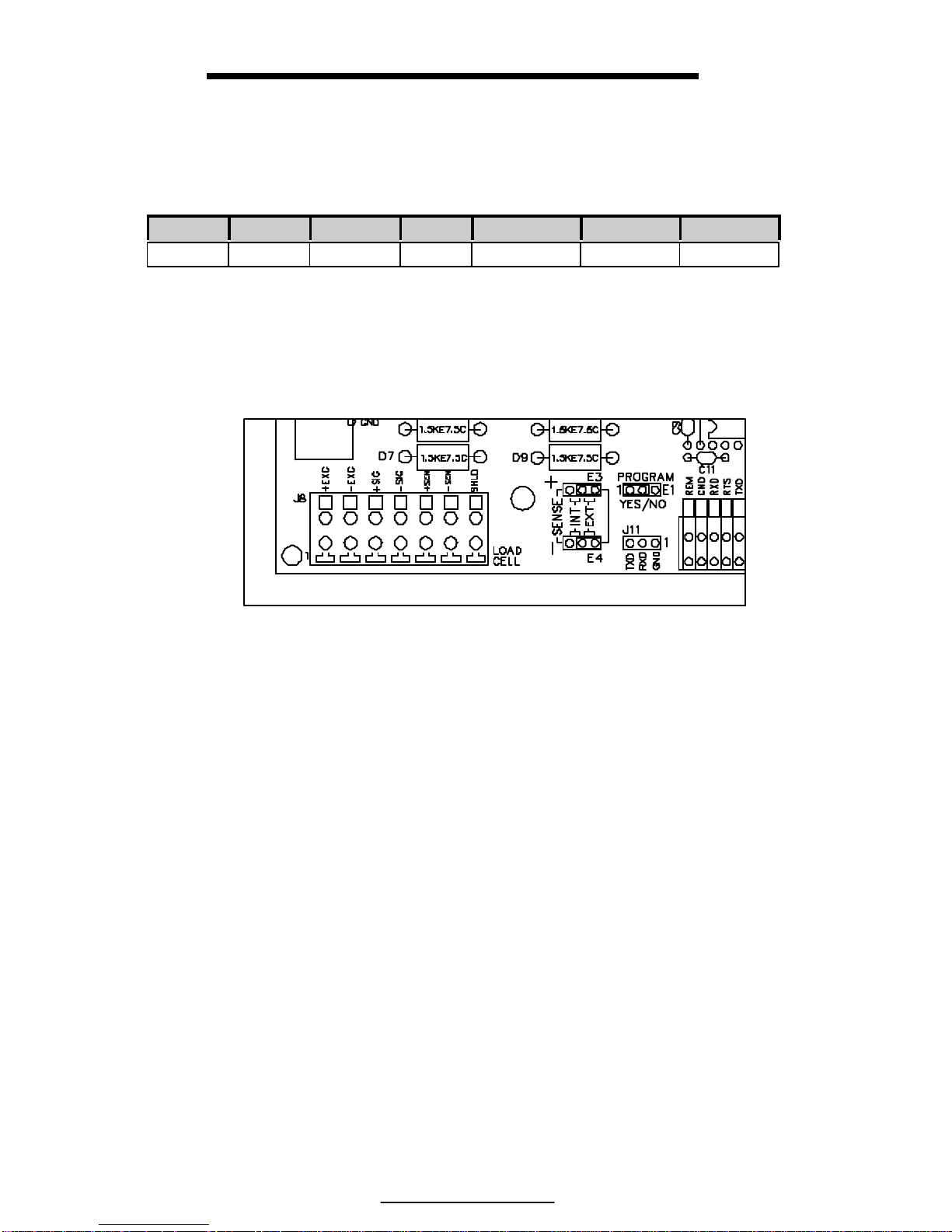

LOAD CELL CONNECTION

The Model 351 will come equipped with either an aluminum or stainless

steel load cell. The load cells used have 7 wires.

+ EX - EX + SIG - SIG + SENSE - SENSE SHIELD

Green Black White Red Orange Blue Wire

When replacing a load cell or main board, be sure to use the proper

connections. The load cell is connected to J8 on the main board. Make sure

the sense jumpers E3 and E4 are set to external (EXT).

Figure 9: Model 351 Load Cell Connector and Sense Jumpers

Page 21

13

CHAPTER 3: GETTING STARTED

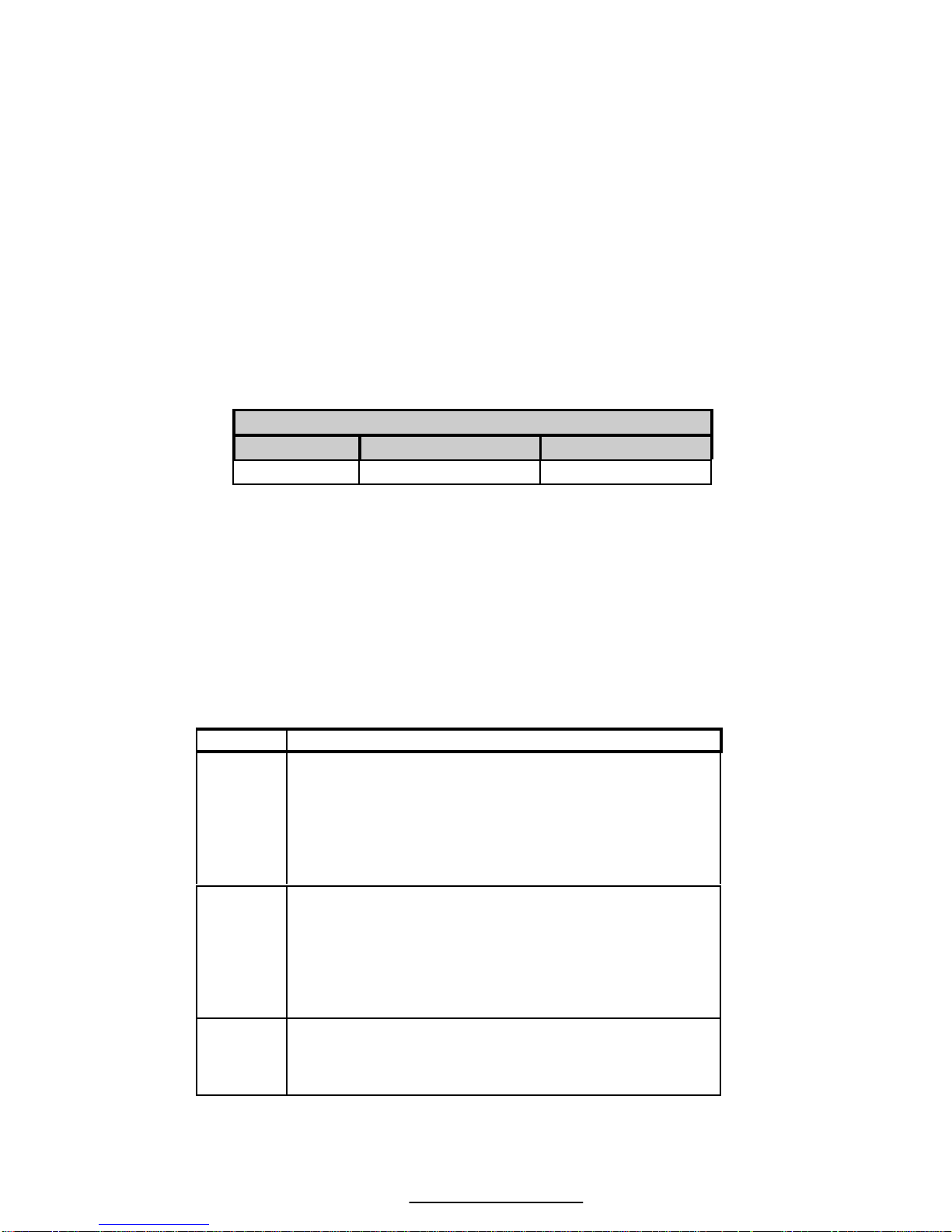

DEFAULT S ETUP

If a factory default is performed at parameter 65001, the target values and

tolerances will have default values. Below is the default values and

checkeweighing method. These are also set when the unit is delivered from

the factory.

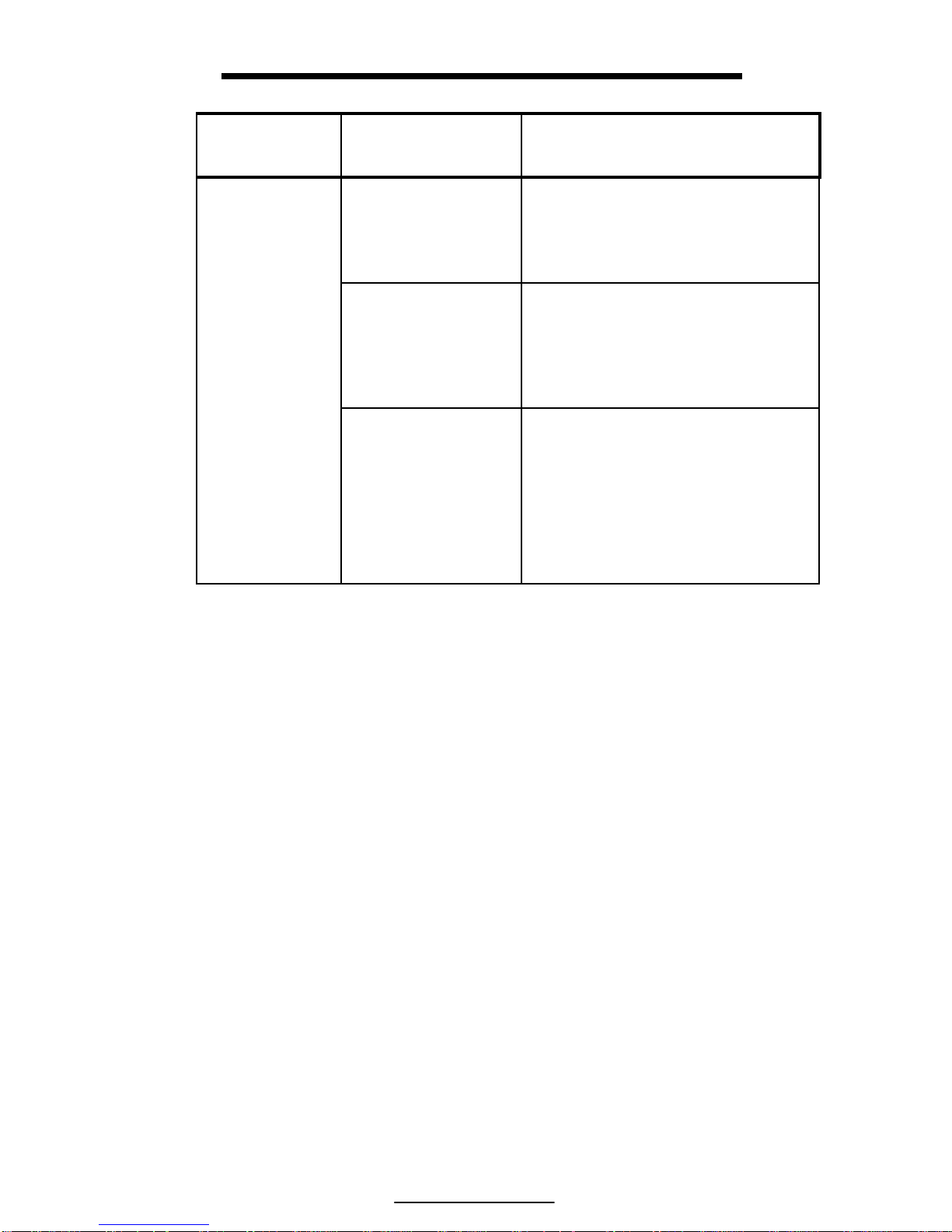

Checkweighing Method - Checb

TARGET LO TOLERANCE HI TOLERANCE

5.00 1.00 1.00

OPERATION

The Model 351 Checkweigher offers easy of operation. Entering target and

tolerance values is simply done by pressing [PRINT] + [UNITS]. Below is a

table with the different checkweighing methods available. The operation of

the Model 351 depends on the method chosen. Refer to Table 3 for

examples of the available methods.

Table 3: Checkweighing Methods

Choice Description

Checb

The target is varied by the Hi/Lo limits

Example: Target = 20, Hi limit = .8, Lo

Limit= .5

20 + .8 = 20.8 and 20 - .5 = 19.5

Accept Window = 19.5 to 20.8

ChecP

Hi/lo limits are used as a percentage deviation.

Example: Target = 20, Hi Limit = 5, Lo

Limit = 5

20 + 5% = 21 and 20 – 5% = 19

Accept Window = 19 to 21

ChecA

The values are absolute, Target is not used.

Example: TargH = 21.3, TargL = 19.8

Accept Window = 19.8 to 21.3

Page 22

Model 351 Checkweigher

14

ENTERING A TARGET VALUE

Entering a target depends on the checkweighing method chosen and the

access setting. Refer to Table 4 for a comparison of the available methods

and access settings.

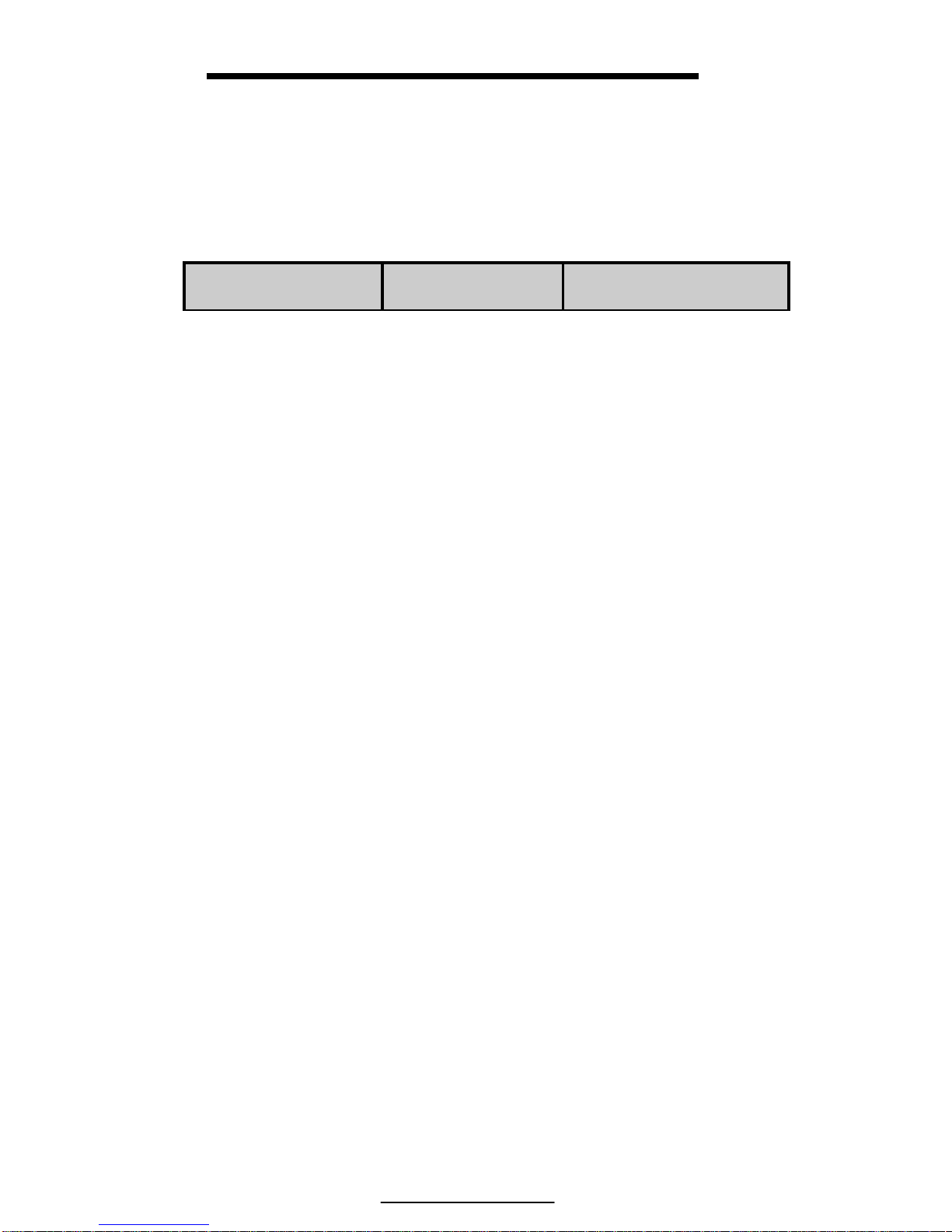

Table 4: Entering Targets and Tolerances

Checkweighing

Method (P5100)

Access Setting

(P5020)

Weigh Mode

Disbl – This choice

assures the target and

tolerances cannot be

changed from the

weigh mode.

When the [PRINT] + [UNITS] keys

are pressed the Target, lo Limit and

Hi Limit values are shown for one

second each but not changeable

Targ – This choice

allows only the target

value to be changed

in the weigh mode.

When the [PRINT] + [UNITS] keys

are pressed only the Target can be

changed. HI/LO limits can be viewed

by pressing the [UNITS] key during

target entry mode.

Checkb

All – This choice

allows the target and

tolerance limits to be

changed from the

weigh mode.

Press [PRINT] + [UNITS] to view

the Target first. Either accept the

weight on the scale or scroll in a

target. Press [PRINT] + [UNITS]

again for the LO limit and [PRINT]

+ [UNITS] for the HI limit.

Disbl – This choice

assures the target and

tolerances cannot be

changed from the

weigh mode.

When the [PRINT] + [UNITS] keys

are pressed the Target, lo Limit and

Hi Limit values are shown for one

second each but not changeable

Targ – This choice

allows only the target

value to be changed

in the weigh mode.

When the [PRINT] + [UNITS] keys

are pressed only the Target can be

changed. HI/LO limits can be viewed

by pressing the [UNITS] key during

target entry mode.

Checkp

All – This choice

allows the target and

tolerance limits to be

changed from the

weigh mode

Press [PRINT] + [UNITS] to view

the Target first. Either accept the

weight on the scale or scroll in a

target. Press [PRINT] + [UNITS]

again for the LO limit and [PRINT]

+ [UNITS] for the HI limit.

Page 23

Chapter 3: Getting Started

15

Checkweighing

Method (P5100)

Access Setting

(P5020)

Weigh Mode

Disbl – This choice

assures the absolute

values cannot be

changed from the

weigh mode.

When the [PRINT] + [UNITS] keys

are pressed the TargeL and targH

values are shown for one second each

but not changeable

Targ – This choice

allows the absolute

low target value and

the absolute high

target to be changed

in the weigh mode.

When the [PRINT] + [UNITS] keys

are pressed targL will be displayed.

Press [PRINT] + [UNITS] again and

targH will be displayed.

CheckA

All – This choice

allows the absolute

low target value and

the absolute high

target to be changed

in the weigh mode.

When the [PRINT] + [UNITS] keys

are pressed targL will be displayed.

Press [PRINT] + [UNITS] again and

targH will be displayed.

EXAMPLE 1: the checkweighing method is set to checp (percentage) and

the access setting is set to targ (Target).

To set a target of 6.5 from the weigh mode:

1. Press [PRINT] + [UNITS]

Targ1 ~ 5.00

2. Press the [PRINT] key until 6 is displayed

6

3. Press the [UNITS] key to move over a character

6 .

4. Press the [UNITS] key again to accept the .

6.

5. Press the [PRINT] key until 5 is displayed

6.5

6. Press the [PRINT] + [UNITS] to accept the entry

Targ1 ~ 6.50

7. Press the [PRINT] + [UNITS] to exit to the weigh mode

0.00

Page 24

Model 351 Checkweigher

16

EXAMPLE 2: enter a target with an acceptable weight on the scale. The

access setting is set to targ (Target).

To set a target of 2.10 lbs with a known weight:

1. Press [PRINT] + [UNITS] with the weight on the scale

Targ1 ~ 5.00

2. Press [PRINT] + [UNITS]. NOTE: The [ZERO] key may be pressed to

exit out of the entry process.

Accept ~ 2.10

3. Press the [PRINT] + [UNITS] to accept the target

2.10

EXAMPLE 3: the checkweighing method is set to checA (absolute) and the

access setting is set to All (Hi/Lo limits).

To set the low target to 4.5 and the high target to 5.8 from the weigh

mode:

1. Press [PRINT] + [UNITS]

TargL ~ 0.50

2. Press the [PRINT] key until 4 is displayed

4

3. Press the [UNITS] key to move over a character

4 .

4. Press the [UNITS] key again to accept the .

4.

5. Press the [PRINT] key until 5 is displayed

4.5

6. Press [PRINT] + [UNITS] to accept the entry

TargL ~ 4.50

7. Press [PRINT] + [UNITS] to show the high target

TargH ~ 1.50

8. Press the [PRINT] key until 5 is displayed

5

9. Press the [UNITS] key to move over a character

5 .

10. Press the [UNITS] key again to accept the .

5.

11. Press the [PRINT] key until 8 is displayed

5.8

Page 25

Chapter 3: Getting Started

17

12. Press the [PRINT] + [UNITS] to accept the high target value

0.00

ENTERING TOLERANCES

Tolerances are the bases for the acceptance window (OK). Checkb

(deviation) and Checkp (percentage) use tolerances and the target to

determine the accepted target. Refer to Table 3 for more details. Check A

operates differently by using two values and anything in between those

values is acceptable.

For Example, the checkweighing method is set to checb (deviation) and the

access setting is set to ALL (Target and Tolerances).

To set a target of 6.0, low limit of .5 and high limit of .6 from the weigh

mode (Acceptance Window 5.5 – 6.6):

Press [PRINT] + [UNITS]

Targ1 ~ 5.00

1. Press the [PRINT] key until 6 is displayed

6

2. Press [PRINT] + [UNITS] to accept the target

Targ1 ~ 6.00

3. Press [PRINT] + [UNITS] to display the Lo tolerance

1.00

4. Press the [PRINT] key once to display the .

.

5. Press [UNITS] to move the cursor. Press [UNITS] until 5 is displayed

.5

6. Press [PRINT] + [UNITS] to accept the Lo tolerance entry

Lo ~ 0.50

7. Press [PRINT] + [UNITS] to display the Hi tolerance

1.00

8. Press the [PRINT] key once to display the .

.

9. Press [UNITS] to move the cursor. Press [UNITS] until 6 is displayed

.6

10. Print [PRINT] + [UNITS] to accept the Hi tolerance entry

Hi ~ 0.60

11. Press [PRINT] + [UNITS] to accept the values and exit to the weigh

mode

0.00

Page 26

Model 351 Checkweigher

18

STATUS INDICATION

The status annunciators are located above the weight display. This allows

ease in checkweighing by simply looking at a status light. Only one light will

illuminate at a time. The status annunicators can be turned off (refer to page

37).

Below Target

-

Within Tolerance

OK

Above Target

+

COUNTING

It is possible to checkweigh in the counting mode. Parameter 179 must be

set for enabled (refer to page 29 for details). Operation is similar to the other

checkweigh methods. Target and tolerances may be entered or locked out.

EAMPLE 1: Doing A Sample

1. From the count mode press [UNITS]

Add 10

2. Add the sample pieces to the scale then press [PRINT] + [UNITS].

The OK status indicator should also be lit.

10

3. From the count mode press [UNITS]

EXAMPLE 2: To sample using selectable fixed counts:

1. From the Quantity Mode, press [UNITS]. The scale prompts to add 10

pieces.

Add ~ 10

2. Press [UNITS] to toggle sample amounts between 5, 10, 20, 50 and 100.

Add ~ 20

3. Add sample pieces to scale

Add ~ 20

4. Press [PRINT] + [UNITS] to sample and display the current quantity.

20.

Page 27

Chapter 3: Getting Started

19

EXAMPLE 3: To sample using variable counts (36 pieces):

1. From the Quantity Mode, press [UNITS]. The scale prompts to add 10

pieces.

Add ~ 10

2. Key in 36, then press [PRINT] + [UNITS] to sample as 36 pieces and

display the current quantity.

Add ~ 36

3. Add 36 pieces and press [PRINT] + [UNITS] to accept the quantity.

36.

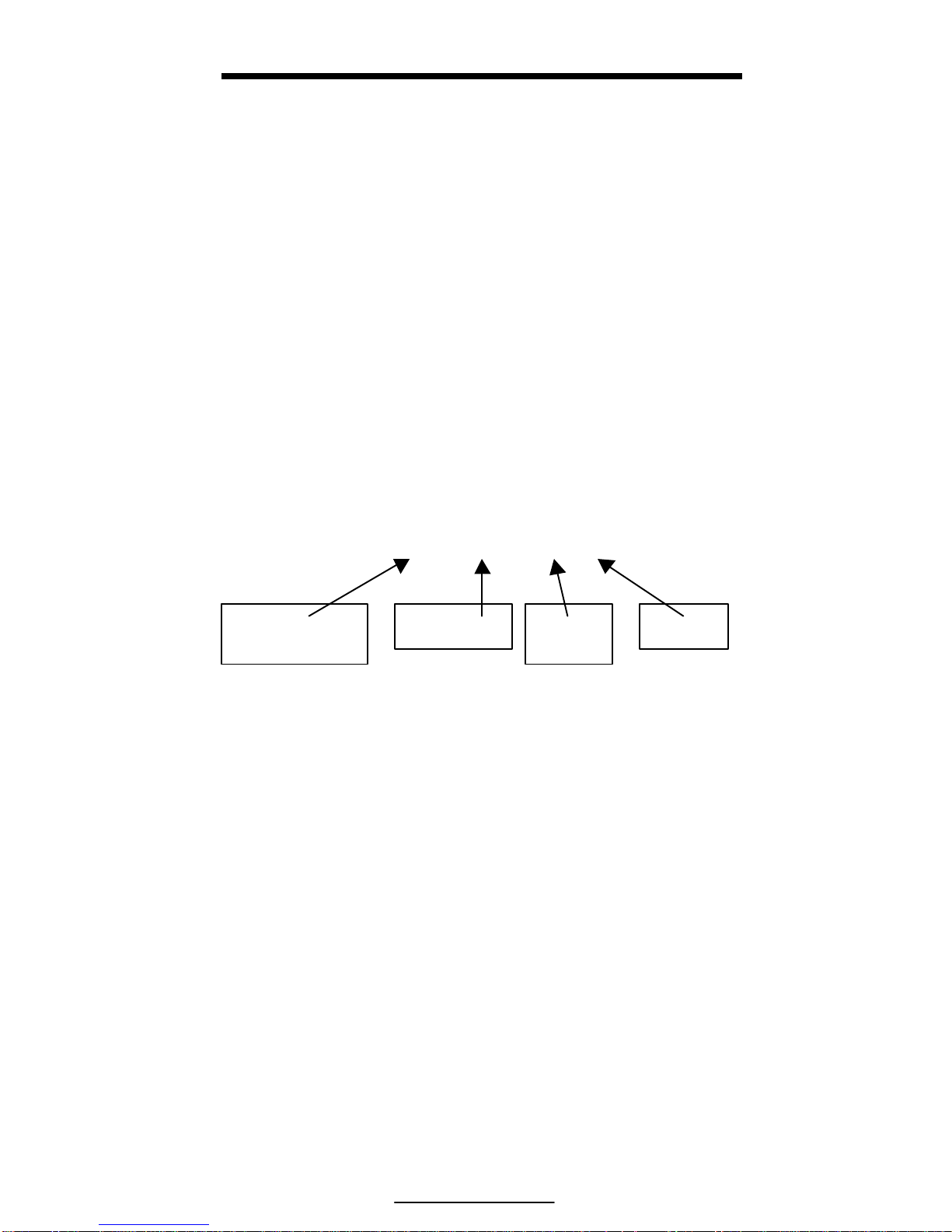

PRINTING OUT A TICKET

Depending on the Comm Port configuration, printing a ticket is as simple as

pressing the [PRINT] key (refer to page 29).

U -0.68 0.32 lb

Figure 10: Sample Print Out

Check Status

(Under)

Deviation

Gross

Weight

Unit

Page 28

Page 29

21

CHAPTER 4: CONFIGURATION

SETUP MODE

To prevent accidental changes to the indicator setup, a sequence of

keystrokes is used to gain access to the setup mode.

To access the setup mode:

1. From the weigh mode press [ZERO] + [PRINT] + [UNITS]

Setup ~ Enter Code

The following keystrokes must be made within five seconds or the indicator

will return to the weigh mode.

2. Press [PRINT]

P

3. Press [PRINT]

PP

4. Press [UNITS]

PPu

5. Press [UNITS]

PPuu

6. Press [PRINT] + [UNITS]

Chgs ~ Poss!

P110.— — ~ F.S.= ~ 50.00

To access setup in a view-only mode:

1. From the weigh mode press [ZERO] + [PRINT] + [UNITS]

Setup ~ Enter Code

2. Press [PRINT] + [UNITS]

No ~ Chgs

P110.— — ~ F.S.= ~ 50.00

Page 30

Model 351 Checkweigher

22

To advance to the next parameter:

4. Press [ZERO]

P111.09 ~ 1Grad ~ 0.01

5. Press [ZERO]

P112.05 ~ Ztrac ~ 0.5 d

6. Continue pressing [ZERO] to advance through all setup parameters.

To access the previous parameter:

1. Press [PRINT]

.

2. Press [ZERO]

P111.09 ~ 1Grad ~ 0.01

3. Repeat [PRINT] [ZERO] to back up one parameter

i

When accessing a parameter, the parameter number appears briefly. The

display then toggles between the parameter name and selection. Pressing

[UNITS] will again briefly display the parameter number.

To access a specific parameter from the setup mode (for example P150):

1. Press [PRINT] three times to select the first digit.

1

2. Press [UNITS] to advance to the next digit.

1.

3. Press [PRINT] six times to select the next digit.

15

4. Press [UNITS] to advance to the next digit.

15.

5. Press [PRINT] once to select the next digit.

150

6. Press [ZERO] to advance to the parameter.

P111.0 ~ Units ~ Lb

i

For information on accessing information parameters (P60000 – P65002),

see Information Mode Parameters on page 79.

Page 31

Chapter 4: Configuration

23

To exit the setup mode and save changes:

1. Press [ZERO] + [PRINT] + [UNITS] to begin exiting the setup mode.

Enter ~ =CAL!

2. Press [ZERO] to bypass the calibration mode.

Enter ~ =Stor

3. Press [PRINT] + [UNITS] to save setup changes.

Enter ~ =End

4. Press [PRINT] + [UNITS] to complete exit.

0.00

To exit the setup mode from the view-only mode:

1. Press [ZERO] + [PRINT] + [UNITS] to begin exiting the setup mode.

Enter ~ =End

2. Press [PRINT] + [UNITS] to complete exit.

0.00

To exit the setup mode without saving changes:

1. Press [ZERO] + [PRINT] + [UNITS] to begin exiting the setup mode.

Enter ~ =CAL!

2. Press [ZERO] to bypass the calibration mode.

Enter ~ =Stor

3. Press [ZERO] to exit without saving changes

Enter ~ =Undo

4. Press [PRINT] + [UNITS] to undo changes.

Enter ~ =End

5. Press [PRINT] + [UNITS] to complete exit.

0.00

SELECTION PARAMETERS

Selection parameters have a pre-defined list of choices to pick from. Each

choice is numbered and corresponds to a certain value. The choice number is

shown to the right of the decimal point within the parameter number.

Repeatedly pressing [PRINT] + [UNITS] while viewing a selection

parameter cycles through the available choices, or you can key in the choice

number.

Page 32

Model 351 Checkweigher

24

P 200.00

Indicates Parameter Parameter Number Choice Number

For example, parameter 200 is a selection parameter that holds the baud rate

for the serial. This is a selection parameter because a choice number between

00 and 06 must be used. Each choice number corresponds to a different baud

rate. To change the baud rate from the default value of 9600 to 4800,

perform the following steps from the Setup Mode.

To change the baud rate from the default value of 9600 to 4800:

1. Press 200 [ZERO].

P200.00 ~ Baud ~ 9600

2. Press [PRINT] + [UNITS] once.

P200.01 ~ Baud ~ 4800

KEY-IN PARAMETERS

Key-In Parameters are not limited to a list of choices, although there may be

upper and lower value limits. A Key-In Parameter requires that a numeric

value be entered using the front panel keys. Key-In Parameters are shown

with two hyphens after a decimal point within the parameter number.

P 110.--

Indicates Parameter Parameter Number Denotes “Key In”

To enter a Key-In Parameter:

1. Press [PRINT]. A decimal point is used to represent the entry position.

2. Press [PRINT] until the desired character appears.

3. Press [UNITS]. Another decimal point indicates the next entry position.

4. Repeat steps 1 and 2 until your desired entry value is shown.

5. Press [PRINT] + [UNITS] to enter your numerical value.

To setup a full target value of 10 lbs:

Page 33

Chapter 4: Configuration

25

1. Press 5101 [ZERO].

P5101.— — ~ TARG= ~ 5.00

2. Press [PRINT] three times to select the first digit.

1

3. Press [UNITS] to advance to the next digit.

1.

4. Press [PRINT] one time to select the next digit.

10

5. Press [PRINT] + [UNITS] to accept and enter the value.

P5101.— — ~ TARG= ~ 10.00

PARAMETER MAP

Table 5: Parameter Map

Parameter

Number

Display

Name

Default

Value

Valid Range/

Choices

Parameter

Description

Page

P110.-- F.S.= 10.00 .01 – 999,999

(Keyed In)

Full Scale 27

P111.09 1Grad .01 .00001 – 500

(24 Selections)

Count By 27

P112.05 Ztrac 0.5d Off - 20.0d

(200 Selections)

Zero Track

Aperture

27

P114.10 Stabl 1.0d Off – 20.0d

(200 Selections)

Stability

Window

27

P116.04 Filtr 1 Sec .065 – 8.00 Sec

(8 Selections)

Filter Setting 28

P117.01 Rate= 0.1 Sec 0.05 – 20.0 Sec

(201 Selections)

Display

Update

28

P118.12 Zrang 100% .01 – 100%

(13 Selections)

Zero Button

Range

28

P150.00 Units lb lb / kg

(Toggle)

Default

(Calibration)

Units

28

Page 34

Model 351 Checkweigher

26

Parameter

Number

Display

Name

Default

Value

Valid Range/

Choices

Parameter

Description

Page

P151.01 Unbut Enable Enable / Disable

(Toggle)

Units Button 28

P152.00 Lb Enable Enable / Disable

(Toggle)

Pounds

indication

28

P154.00 OZ Enable Enable / Disable

(Toggle)

Ounces

indication

29

P155.00 G Enable Enable / Disable

(Toggle)

Grams

indication

29

P156.00 Lb_OZ Enable Enable / Disable

(Toggle)

Pounds -

Ounces

indication

29

P179.00 Count Disable Enable / Disable

(Toggle)

Counting

Functions

29

P200.00 Baud 9600 150 – 9600

(7 Selections)

Comm Baud

Rate

29

P201.01 Data 8 Bits 7 – 8 Bits

(2 Selections)

Comm Data

Bits

29

P202.00 Par’y None None – Odd

(3 Selections)

Comm Parity 29

P203.00 Stop 1 Bit 1 – 2 Bits

(2 Selections)

Comm Stop

Bits

29

P204.02 HndSh Soft None – Both

(4 Selections)

Comm

Handshake

29

P210.01 Send Press Off – Cycle

(4 Selections)

Comm

Transmit

29

P212.01 Stabl Delay Off – Delay

(Toggle)

Comm Motion 30

P213.01 TrTyp --1-- 0 – 13

(Selection)

Print

Transmission

30

P250.00 RS485 Disable Enable / Disable

(Toggle)

Network

Option

34

P251.00 Addr Disable Disabled and 4 –

254 (Key In)

Network

Address

35

P410.-- Euro Disable Enable / Disable

9991/9990 (Key In)

OIML

Enforce

35

P420.01 Dsply On Off – Auto

(3 Selections)

Display

Function

35

P440.00 rStrc Disable Enable / Disable

(Toggle)

NTEP

Enforce

36

Page 35

Chapter 4: Configuration

27

Parameter

Number

Display

Name

Default

Value

Valid Range/

Choices

Parameter

Description

Page

P502.01 disbl

t-dAt

Disable Enable / Disable

(Toggle)

Time/Date

Function

36

P504.00 Style U.S.A U.S.A or

International

Time/Date

Function

36

P800.00 R-But None None – Zero

(3 Selections)

Remote

Button

Function

36

P1000.-- Cust.

Trans

-- -- Custom

Transmit

36

P5010.00 SPAnn Enable Enable / Disable

(Toggle)

Acceptance

Annunciators

37

P5020.00 Hi-Lo Disable Targ, Hi/LO, All

(Selectable)

Tolerance

Display

37

P5100.00 SetPt Check b None – Check A

(3 Selections)

Checkweigh

Operation

37

P5101.00 Target 5.00 .01 – 50.00

(Keyed In)

Target Entry 37

P5102.00 Lot 1.00 .01 – 50.00

(Keyed In)

Lo Tolerance

Entry

37

P5103.00 Hit 1.00 .01 – 50.00

(Keyed In)

Hi Tolerance

Entry

37

PARAMETER MAP DETAILS

P110 Full Scale Value (Key in)

Denotes the full scale capacity. This value should not exceed the rated

capacity of the weighing device.

P111 Division Size (Selection)

Indicates the count-by and decimal point.

P112 Zero Track Aperture (Selection)

Set in terms of number of divisions. Zero tracking eliminates small weight

deviations at or near zero. Weight deviations within the selected window that

have been stable for more than one second are tracked off, maintaining a

gross or net zero condition.

The sum of weight values zeroed with auto zero tracking and [ZERO] cannot

exceed the allowable zero range (P118).

P114 Stability (Selection)

Stability is defined as weight fluctuations within an aperture that can be

regarded as being a stable weight. Deviations outside this aperture are

considered motion, and the motion annunciator on the front panel will light

Page 36

Model 351 Checkweigher

28

accordingly. Once the scale settles within the stability aperture, the indicator

will wait one second before the indicator is considered stable.

Print operations configured as motion delayed (P114) will not send the

specified data until the weight reflects a stable reading as designated by this

setting.

P116 Filter (Selection)

Sets the indicator response time in terms of seconds. Filtering determines

how quickly the indicator will respond to changing input signals. A low filter

setting speeds the response, a higher filter setting will ‘dampen’ the

response.

Filtering is used to filter out weight fluctuations caused by outside sources,

such as vibrations or air currents.

P117 Rate (Selection)

Specifies how often the display is updated with new data. For example, if

0.05 is selected, the controller will write data to the display every time an

analog/digital conversion is made. Since the A/D converter updates every

0.05 sec, selections from 0.05 to 20.0 seconds are available. This parameter

also affects the transmission rate for continuous transmit. Actual

transmission intervals are dependent upon system setup.

P118 Zero Range (Selection)

Specifies how many divisions can be zeroed in terms of a percentage of full

scale (P110). The sum of weight values zeroed through the [ZERO] key and

auto zero tracking cannot exceed this range.

P150 Units (Toggle)

Set default units to ‘lb’, ‘kg’, ‘lb oz’, ‘grams’ or ‘oz’. The indicator must use

the default units during calibration procedures (see ). The default units are

the displayed units upon indicator power-up.

P151 Units Button (Toggle)

When enabled, this parameter will allow [UNITS] to toggle the units. When

disabled, the indicator will show only the calibration units as determined by

P150.

P152 Pounds (Toggle)

This parameter will allow the ‘lb’ units to be disabled individually. It is still

possible to have ‘lb’ as default calibration units.

P153 Kilograms (Toggle)

This parameter will allow the ‘kg’ (1000 g) units to be disabled individually.

It is still possible to have ‘kg’ as default calibration units.

Page 37

Chapter 4: Configuration

29

P154 Ounces (Toggle)

This parameter will allow the ‘oz’ units to be disabled individually. It is still

possible to have ‘oz’ as default calibration units.

P155 Grams (Toggle)

This parameter will allow the ‘g’ units to be disabled individually. It is still

possible to have ‘g’ as default calibration units.

P156 Lb oz (Toggle)

This parameter will allow the ‘lb oz’ units to be disabled individually. It is

still possible to have ‘lb oz’ as default calibration units.

P179 Count (Toggle)

When enabled, the counting mode becomes accessible. See page 18 for

details on counting.

P200 Baud (Selection)

Set the desired baud rate for the communication port.

P201 Data Bits (Toggle)

Select 7 or 8 data bits for the transmission.

P202 Parity (Selection)

Select Odd, Even or None for the transmission parity.

P203 Stop Bits (Toggle)

Select 1 or 2 stop bits for communication port transmissions.

P204 Comm Handshake (Selection)

Select from None, Software (Xon/Xoff), Hardware (CTS/RTS), or Both.

P210 Send (Selection)

Transmission Send options:

Choice Number

Selection

Name

Description

P210.00 Off All transmissions disabled.

P210.01 Press Sends transmission with [PRINT] key.

P210.02 Cont. Sends transmissions continuously.

P210.03 Cycle

Send single transmission after weight is

reached and motion ceases. Must return

display value below 0.1% of F.S. to reset for

next transmission.

Page 38

Model 351 Checkweigher

30

P212 Send Stability (Toggle)

Enabling Send Stability will delay any transmissions until a no-motion

condition exists.

P213 Transmit Selection (Selection)

Select desired print output (0 – 21). The transmission will be initiated by the

selected print operation (P210) and / or the Remote Key selection (P800).

Fixed Transmit # 1

Fixed Transmit # 2

Fixed Transmit # 3 – Condec Clone NOTE: + is shown with a space

Fixed Transmit # 4 Fixed Transmit # 5

Fixed Transmit # 6

Fixed Transmit # 6

GROSS WEIGHT

LEADING SPACES

S

P

A

C

E

UNIT

lb, kg

oz, g

S

P

A

C

E

G r o s s

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

±

GROSS WEIGHT

Leading Zeros

S

P

A

C

E

UNIT

lb, kg

oz, g

S

P

A

C

E

G r o s s

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Example: +0000.48 lb Gross

S

T

X

-

GROSS WEIGHT

Leading Spaces

L

or

K

G

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13

Example: +0000.48 LG

S

T

X

±

GROSS WEIGHT

Leading Zeros

CR LF

1 2 3 4 5 6 7 8 9 10 11

Example: +0000.48

S

T

X

±

DEVIATION

Leading Zeros

CR LF

1 2 3 4 5 6 7 8 9 10 11

Example: -0000.52

C

H

E

C

K

±

DEVIATION

Leading Zeros

±

GROSS WEIGHT

Leading Zeros

S

P

A

C

E

UNIT

lb, kg

oz, g

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

Example: U-0000.52+0000.48 lb

Page 39

Chapter 4: Configuration

31

Fixed Transmit #7

Fixed Transmit # 8

Fixed Transmit # 9

Fixed Transmit # 10

F

i

C

H

E

C

K

DEVIATION

Leading Spaces with

‘+’ for positive data

GROSS WEIGHT

Leading Spaces

S

P

A

C

E

UNIT

lb, kg

oz, g

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

Example: U -0.52 0.48 lb

S

T

X

±

GROSS WEIGHT

Leading Zeros

±

DEVIATION

Leading Zeros

S

P

A

C

E

UNIT

lb, kg

oz, g

S

P

A

C

E

C

H

E

C

K

S

T

A

T

U

S

CR LF

1 2 3 4 5 6 7 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26

Example: +0000.48-0000.52 lb U

S

T

A

T

U

S

,

C

H

E

C

K

,

GROSS WEIGHT

Leading Zeros

S

P

A

C

E

UNIT

lb, kg

oz, g

,

DEVIATION

Leading Zeros

S

P

A

C

E

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25

UNIT

lb, kg

oz, g

,

TIME

*

HH:MM am/pm

,

DATE

*

MM/DD/YY

CR LF

26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47

Example: ,U,00000.41 lb,-0000.59 lb,10:52 pm,01/01/70

HIGH LIMIT

Leading Zeros

,

LOW LIMIT

Leading Zeros

,

TARGET WEIGHT

Leading Zeros

S

P

A

C

E

UNI

T

lb, kg

oz, g

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31

Example: 00000.20,00000.50,00001.00 lb

Page 40

Model 351 Checkweigher

32

Fixed Transmit # 11

Fixed Transmit # 12

Fixed Transmit # 13

GROSS WEIGHT

LEADING SPACES

S

P

A

C

E

UNIT

lb, kg

oz, g

SPACE

G r o s s

CR LF

TARGET WEIGHT

LEADING SPACES

S

P

A

C

E

UNIT

lb, kg

oz, g

SPACE

T a r g 1

CR LF

DEVIATION

LEADING SPACES WITH ‘+’

FOR POSITIVE DATA

S

P

A

C

E

UNIT

lb, kg

oz, g

SPACE

D e v

CR LF

1 2 3 4 5 6 7 8 9 10 11

1

2

13 14 15 16 17 18 19

Example:0.41 lb Gross

1.00 lb Targ1

-0.59 lb Dev

TIME

*

HH:MM am/pm

S

P

A

C

E

DATE

*

MM/DD/YY

CR LF

GROSS WEIGHT

LEADING SPACES

S

P

A

C

E

UNIT

lb, kg

oz, g

G r o s s

CR LF

TARGET WEIGHT

LEADING SPACES

S

P

A

C

E

UNIT

lb, kg

oz, g

T a r g 1

CR LF

DEVIATION

LEADING SPACES WITH ‘+’

FOR POSITIVE DATA

S

P

A

C

E

UNIT

lb, kg

oz, g

D e v

CR LF

1 2 3 4 5 6 7 8 9 10 11 13 14 15 16 17 18 19

Example:11:58 pm 01/01/70

0.41 lb Gross

1.00 lb Targ1

-0.59 lb Dev

TIME

*

HH:MM am/pm

S

P

A

C

E

DATE

*

MM/DD/YY

CR LF

GROSS WEIGHT

LEADING SPACES

S

P

A

C

UNIT

lb, kg

oz, g

S

P

A

C

G r o s s

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Example: 11:40 pm 01/01/70

0.41 lb Gross

Page 41

Chapter 4: Configuration

33

Fixed Transmit # 14

Fixed Transmit # 15

Fixed Transmit # 16 Fixed Transmit # 17

Fixed Transmit # 18

TIME

*

HH:MM am/pm

S

P

A

C

E

DATE

*

MM/DD/YY

CR LF

GROSS WEIGHT

LEADING SPACES

S

P

A

C

E

UNIT

lb, kg

oz, g

S

P

A

C

E

G r o s s

CR LF

DEVIATION

LEADING SPACES WITH

‘+’ FOR POSITIVE DATA

S

P

A

C

E

UNIT

lb, kg

oz, g

S

P

A

C

E

D e v

S

P

A

C

E

C

H

E

C

K

CR LF

1 2 3 4 5 6 789 10 11 12 13 14 15 16 17 18 19 20 21

Example:12:04 am 01/02/70

0.41 lb Gross

-0.59 lb Dev U

QUANTITY

LEADING SPACES

S

P

A

C

E

C o u n t

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Example:10 Count

±

QUANTITY

Leading Zeros

S

P

A

C

E

C o u n t

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Example:+0000010 Count

S

T

X

-

QUANTITY

Leading Zeros

CR LF

1 2 3 4 5 6 7 8 9 10 11

Example:+0000010

S

T

A

T

U

S

,

C

H

E

C

K

,

QUANTITY

Leading Zeros

, ±

DEVIATION

Leading Zeros

,

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22

TIME

*

HH:MM am/pm

,

DATE

*

MM/DD/YY

CR LF

23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41

Example: ,O,00000010,-0004.59,01:00 am,01/02/70

Page 42

Model 351 Checkweigher

34

Fixed Transmit # 19

Fixed Transmit # 20

Fixed Transmit # 21

HIGH LIMIT

Leading Zeros

,

LOW LIMIT

Leading Zeros

,

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

TARGET QUANTITY

Leading Zeros

,

APW

Leading Zeros

S

P

A

C

E

UNIT

lb, kg

oz, g

CR LF

19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40

Example: 0.20, 0.50,00005.00,+0.041059 lb

TIME

*

HH:MM am/pm

S

P

A

C

E

DATE

*

MM/DD/YY

CR LF

QUANTITY

LEADING SPACES

S

P

A

C

E

C o u n t

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Example: 01:16 am 01/02/70

10 Count

TIME

*

HH:MM am/pm

S

P

A

C

E

DATE

*

MM/DD/YY

CR LF

QUANTITY

LEADING SPACES

S

P

A

C

E

C o u n t

CR LF

DEVIATION

LEADING SPACES WITH ‘+’

FOR POSITIVE DATA

S

P

A

C

E

D e v

S

P

A

C

E

C

H

E

C

K

CR LF

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19

Example: 01:18 am 01/02/70

10 Count

-4.59 Dev O

Page 43

Chapter 4: Configuration

35

When printing with ‘pounds & ounces’ as the current units, the gross weight

is transmitted in two parts, pounds followed by ounces. Each weight

followed by a space and two units characters. Polarity will apply to both the

pounds field and ounces field in the same manner as it applies to the other

single units of measure. Below is an example of fixed transmit #1 with the

current units of lb oz .

EXAMPLE: 1 lb 6.6 oz Gross

Time fields will follow the format set by the selection at P503 (Hours). If

P503 is set for 12-hour format, the time will be transmitted as HH:MM

followed by a space, followed by either ‘am’ or ‘pm’. If P503 is set for 24hour format, the time will only be transmitted as HH:MM.

Date fields will follow the format set by the selection a P504 (Style). If P504

is set for USA style, the date will appear as MM/DD/YY. If P504 is set for

international style, the date will appear as DD/MM/YY.

Polarity (±) indicates positive data will be transmitted with a fixed position

plus sign (+); negative date will be transmitted with a fixed position minus

sign (-).

P250 RS-485 Multi-Drop Network (Toggle)

Enable / disable the RS-485 multi-drop network option. Requires that an RS485 option board be installed. This option allows up to 250 RS-485 devices

to be networked together in either a half duplex or full duplex wiring

scheme. See the RS-485 Multi-Drop Network Setup and Operation section

beginning on page 48 for complete details on RS-485 setup and operation.

P251 Address (Key in)

Specifies the address of the controller for RS-485 multi-drop

communications. Allowed choices are 0 (disabled) and 4 – 254.

P410 Euro (Toggle)

Enable OIML legal-for-trade restrictions (see Chapter 6: Legal For Trade).

P420 Display (Selection)

Select display control option. Choose from On, Off or Auto. The auto setting

helps conserve power for extended battery life. When the indicator display is

off, the load cell(s) are still powered.

If P420 is set to Off or selection 0, you can turn on the display by holding

down the [ZERO] key upon power up. This does not set P420 to On; it only

temporarily turns on the display.

Page 44

Model 351 Checkweigher

36

Parameter

Setting

Choice Description

P420.00 Off Shuts off the display.

P420.01 On Normal display operation.

P420.02 Auto

Shuts off the display when weight has stabilized

within 6 divisions for 5 minutes. Pressing [ON] or

changing weight more than 6 divisions will re-enable

the display. NOTE: The display will turn back on if

data is received via the RS-232 Port.

P440 Legal For Trade Restrictions (Toggle)

Enable NTEP legal-for-trade restrictions. See Chapter 6: Legal For Trade.

P502 Time/Date (toggle)

Enables or disables the time and date feature. If enabled the

indicator will prompt the user to enter the correct date and time

upon power up. Note: if disabled P503-P505 will not be accessible,

however, their current settings will be retained for future use.

P503 Hours (toggle)

Determines the TIME format style, 12 hour or 24 hour. If in 12 hour

mode the right most decimal point on the LED display will become

the PM indicator. Note: The time must be entered as military time.

If the mode is set for 12 hour, the time will be converted to a 12

hour clock.

P504 Style (toggle)

Determines the DATE format style, U.S.A. or Int’l. If set for

U.S.A, the date will resemble 01/26/01. If set for international, the

date will resemble 26/01/01.

P800 Remote Key Operation (Selection)

Select function for Remote Key closure. Choose from None, Print or Zero.

The Remote Key Operation section on page 45 details the remote key

operation. See Remote Key Connection on page for remote key electrical

connections.

P1000 Custom Transmit

A custom transmit is a user-defined string of data that can be sent to the

serial port. Parameter P1000 is the beginning of the custom transmit table

and must be enabled for transmit by selecting choice 0 at P213. Parameters

use three bytes of memory; ASCII characters and control codes use one byte.

See P60001 for available memory. The custom transmit cannot be viewed or

altered from the indicator. A custom transmit must be entered via the serial

Page 45

Chapter 4: Configuration

37

port. See Custom Transmit Setup on page 37 for details on designing and

loading a custom transmit.

P5010 Setpoint Annunciators (Toggle)

Enables or disables the checkweigh status annunciators above the main 7segment display.

P5020 Target/Hi/Lo limit (Selection)

Allows the ability to determine whether the Target/Hi/lo tolerance settings

are changeable from the weigh mode. See P5100 for

P5100 Checkweighing method (Selection)

Choose the method in which checkweighing will be performed.

P5101 Target Entry (Key-in)

Ability to enter a target value from the setup mode. Particularly helpful for a

supervisor that does not want operators changing the value from the weigh

mode. See Parameter 5020 for details on locking out target and tolerance

changes from the weigh mode.

P5102 Low Tolerance Entry (Key-in)

Ability to enter a low tolerance value from the setup mode. Particularly

helpful for a supervisor that does not want operators changing the value from

the weigh mode. See Parameter 5020 for details on locking out tolerances.

P5103 High Tolerance Entry (Key-in)

Ability to enter a high tolerance value from the setup mode. Particularly

helpful for a supervisor that does not want operators changing the value from

the weigh mode. See Parameter 5020 for details on locking out tolerances.

CUSTOM TRANSMIT SETUP

The serial output of the Model 351 can be configured for a custom

application such as a remote display format, a customized computer program

format, or a customized ticket format. The custom transmit must be designed

in a computer-transmittable ASCII text file. The custom transmit can only be

loaded into the indicator through the serial port. P213 must be set to 0 to

select the custom transmit format for transmission.

ELEMENTS OF A CUSTOM TRANSMIT

Parameters, ASCII text, and control codes are the elements of a custom

transmit.

Page 46

Model 351 Checkweigher

38

PARAMETERS

Certain parameters related to weight, quantity, setpoints and status can be

sent out of the comm port. Gross Weight, Target 1 and Quantity are

examples of printable parameters.

ACSII TEXT

ASCII text can be entered into a custom transmit to provide further detail of

a transaction. “P”, “@” and “+” are examples of ASCII text.

CONTROL C ODES

You can custom transmit ASCII control codes to control a printing device.

<CR> (carriage return) and <FF> (form feed) are examples of control codes.

WRITING A CUSTOM TRANSMIT ASCII TEXT FILE

Any text editor may be used to construct a custom transmit (Notepad,

Wordpad, etc.), but you must save the custom transmit as a text (.txt) file.

Instructions can also be sent keystroke by keystroke from a communications

program. To do so, ignore the 351 display and enter the characters in the

correct order. Figure 11 shows a custom transmit written in Wordpad.

Figure 11: Custom Transmit File

Access Setup and clear old custom

transmit

ASCII Text

ASCII Control Codes

Gross and Time/Date Parameters

Extended ASCII (<ALT>0 246). Start

exit and %c%e%e will complete the

exit from the weigh mode.

Page 47

Chapter 4: Configuration

39

ACCESSING SETUP AND CLEARING EXISTING CUSTOM TRANSMIT

Every custom transmit file must start with:

1999%s%s%z%p%u%e

%c%e

This accesses the Setup Mode at the end of the existing transmit and then

clears the transmit so that a new one may be entered.

ENTERING ASCII TEXT

ASCII text is defined as printable characters, including alpha-numerics as

well as punctuation and symbols. See Table 6: ASCII/HEXADECIMAL

CONVERSION CHART for a complete listing of ASCII characters. ASCII

text can be entered directly into a custom transmit with a %e (enter

command). For example, Johnsons’s Meat Packing%e.

ENTERING ASCII CONTROL CODES

Some ASCII characters are known as control codes, non-printable characters

that instruct a printing device to perform certain functions. For example, a

carriage return <CR> forces a printer to move the print head to the left-most

position of the current line. A line feed <LF> forces the print head to move

down one line. Enter control codes with a decimal point, a 3-digit ASCII

code, and a %e. For example, .013%e.

ii

Most printers require a carriage return (.013) and/or a line feed (.010) to

print preceding data and avoid leaving data in the printer buffer. See Table

6 for a list of ASCII codes.

Page 48

Model 351 Checkweigher

40

Table 6: ASCII/HEXADECIMAL CONVERSION CHART

HEX

CHAR

DEC

00 NUL 000

1A

SUB

026 34

4

052

N

078 68

h

104

01

SOH

001 1B

ESC

027 35

5

053 4F

O

079 69

i

105

02

STX

002 1C

FS

028 36

6

054 50

P

080 6A

j

106

03

ETX

003 1D

GS

029 37

7

055 51

Q

081 6B

k

107

04

EOT

004 1E

RS

030 38

8

056 52

R

082 6C

l

108

05

ENQ

005 1F

US

031 39

9

057 53

S

083 6D

m

109

06

ACK

006 20

SP

032 3A

:

058 54

T

084 6E

n

110

07

BEL

007 21

!

033 3B

;

059 55

U

085 6F

o

111

08

BS

008 22

“

034 3C

<

060 56

V

086 70

p

112

09

HT

009 23

#

035 3D

=

061 57

W

087 71

q

113

0A

LF

010 24

$

036 3E

>

062 58

X

088 72

r

114

0B

VT

011 25

%

037 3F

?

063 59

Y

089 73

s

115

0C

FF

012 26

&

038 40

@

064 5A

Z

090 74

t

116

0D

CR

013 27

‘

039 41

A

065 5B

[

091 75

u

117

0E

SO

014 28

(

040 42

B

066 5C

\

092 76

v

118

0F

SI

015 29

)

041 43

C

067 5D

]

093 77

w

119

10

DLE

016 2A

*

042 44

D

068 5E

^

094 78

x

120

11

DC1

017 2B

+

043 45

E

069 5F

_

095 79

y

121

12

DC2

018 2C

‘

044 46

F

070 60

`

096 7A

z

122

13

DC3

019 2D

-

045 47

G

071 61

a

097 7B

{

123

14

DC4

020 2E

.

046 48

H

072 62

b

098 7C

|

124

15

NAK

021 2F

/

047 49

I

073 63

c

099 7D

}

125

16

SYN

022 30

0

048 4A

J

074 64

d

100 7E

~

126

17

ETB

023 31

1

049 4B

K

075 65

e

101 7F

DEL

127

18

CAN

024 32

2

050 4C

L

076 66

f

102

19

EM

025 33

3

051 4D

M

077 67

g

103

Page 49

Chapter 4: Configuration

41

PARAMETER SELECTION NUMBERS

The following sequence enters parameters into a custom transmit: %e , the

parameter number, %e%e , a format code, and then %e%e with no

intervening spaces.

%e 0 %e%e 0 %e%e

Initiates

Parameter

Entry

Parameter

Number

(Table 7)

Enters Parameter

and Initiates

Format Entry

Format

Choice

(Table 8)

Enters Format

and Ends Entry

Table 7: Custom Transmit Parameter Selection Numbers

Parameter Name Parameter Number Sample Print Output

Gross Weight 0 27.49 lb Gross

Time / Date 11 10:01:01 am 01/26/01

Quantity 30 58 Qty

APW 34 0.25 lb APW

APW * K 35 250 lb APW * K

Targ1 60 50 lb Targ1

LO

64

.5 lb LO

HI 66 .5 lb Hi

Check

96

A,U,O

Stability Status 97 Stat M

Displayed Value

98

16.34 lb Gross

The default format code for all parameters is 0. This prints all numeric data

with 8 characters, right justified, left spaces filled., the units (if applicable)

and the parameter name. The format choices for all parameters are shown in

Table 8.

Page 50

Model 351 Checkweigher

42

Table 8: Format Codes

Choice Sample Print Result Description

Weight Parameter Format Codes

0 “ 27.49 lb Gross”

Fixed width (8 characters), right

justified, left spaces filled.

1 “000027.49 lb Gross”

Fixed width (8 characters), right

justified, left zeroes filled.

2 “27.49 lb Gross”

Fixed width, left justified, right spaces

filled.

3 “27.49 lb Gross” Minimum possible width.

8 “400. lb Gross”

Print decimal point, even if data has no

fractional portion.

16 “+400 lb Gross” Print “+” for positive numbers.

32 “336.52 Gross”

Do NOT print parameter units

(lb or kg).

64 “336.52 lb Gross”

Print value in “default” units (as opposed

to current viewed units).

128 “336.52 lb” Do NOT print parameter name.

Time/Date Format Codes

1 “10:07:40 am 01/26/01 Includes seconds with time.

2 “10:08 01/26/01” 24 hour time format.

4

“10:11 am Jan 26,

2001”

Print date spelled out.

8

“10:12 am Fri

01/26/01”

Print day of the week.

16 “10:12 am 26/01/01” International date format.

32 “980503984 Tm/Dt” # of seconds since 12:00 AM Jan 1, 1970.