Page 1

GSE

Model

350/355

IS

I

N

TRI

N

SIC

A

LLY

S

A

F

E

INDICATUR

Technical

Reference

Manual

Version

1.0

Page 2

,

--

Model

350/355

IS

Technical Reference

Manual

Version

1.0

Page 3

GSE

3501s

Intrinsically

Safe

Technical

Reference

Manual

Copyright

0

2004

GSE

Scale

Systems.

All

rights

reserved.

Published

by:

GSE

Scale

Systems

42860

Nine

Mile

Road

Novi,

MI

48375

USA

Information

in

this

Operation

Manual

is

subject

to

change

without

notice

due

to

comction

or

enhancement.

The

information

descriw

in

this

manual

is

solely

the

property

of GSE.

No

part

of

this

manual

may

be

reprduced

or

transmittal

in

any

form

or

by

any

means,

electronic

or

mechanical,

including

photocopying

and

recording

and

sold

for

any

monetary

figure

without

the

express

written

permission

of

GSE.

GSE

Locations

GSE

Scale

Systems

42860

Nine

Mile

Road

Novi,

MI

48375

U.S.A.

Phone:

(800)

755-7875

www

.me-inc.com

GSE

Canada,

Inc.

617

East

Lake

Road

Airdrie,

Alberta

Canada

T4B

2B8

Phone:(403)

948-992

I

Fa:

(403)

948-

1449

Page 4

Table

of

Contents

CHAPTER

1:INTRODUCTION

...................................................................................................................................

1

H

A

ZAR

DO

U

S

A

R

E

A

Gu~~E~~Es

....................................................................................................................................

1

Hazard

Grouping

.....................................................................................................................................................

1

Duration

of

Hazard

..................................................................................................................................................

2

Temperature

Codes

..................................................................................................................................................

2

Definitions

................................................................................................................................................................

4

Entity

Evaluation

Concept

.......................................................................................................................................

4

Entity

Rating

Definihons

..........................................................................................................................................

5

Entiry

Rarings

...........................................................................................................................................................

5

APPROVAW

...................................................................................................................................................................

6

S

TANDAR

D

F

U

NCT

ION

S

.................................................................................................................................................

7

S

T

AN

DARD

F~ATURES

...................................................................................................................................................

7

SPECIFICATIONS

............................................................................................................................................................

7

DISPLAY

........................................................................................................................................................................

8

LED

Display

.............................................................................................................................................................

8

LCD

Display

............................................................................................................................................................

9

Annunciators

............................................................................................................................................................

9

350

IS

KEY

PAD

...........................................................................................................................................................

9

Secondaty

Functions

..............................................................................................................................................

10'

355

KEYP .................................................................................................................................................................

11

WEIGH

M

O

D

E

FUNCTIONS

...........................................................................................................................................

f2

CHAFIER

2:

INSTALLATION

..................................................................................................................................

13

S

YSTEM

D

I

A

G

R

AM

S

.....................................................................................................................................................

13

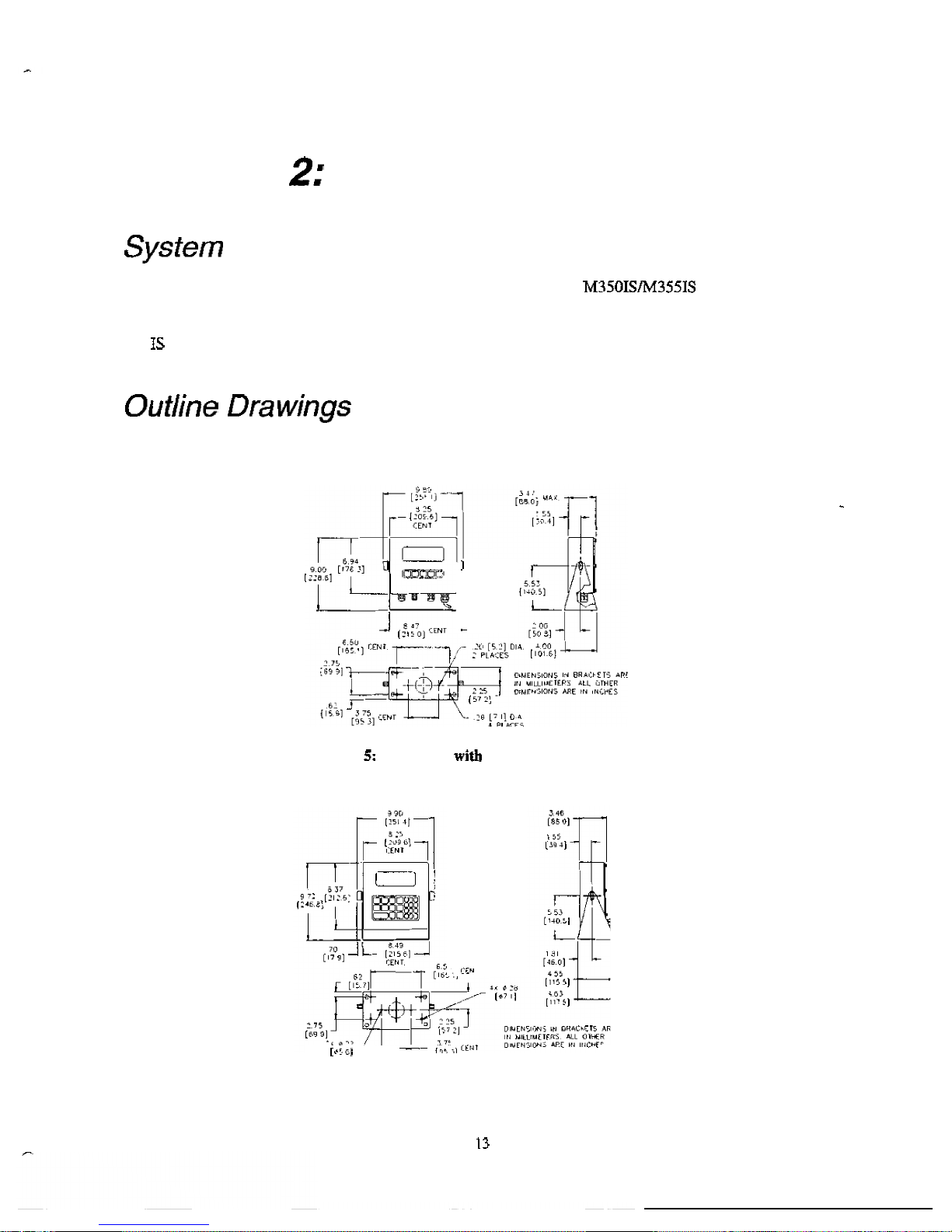

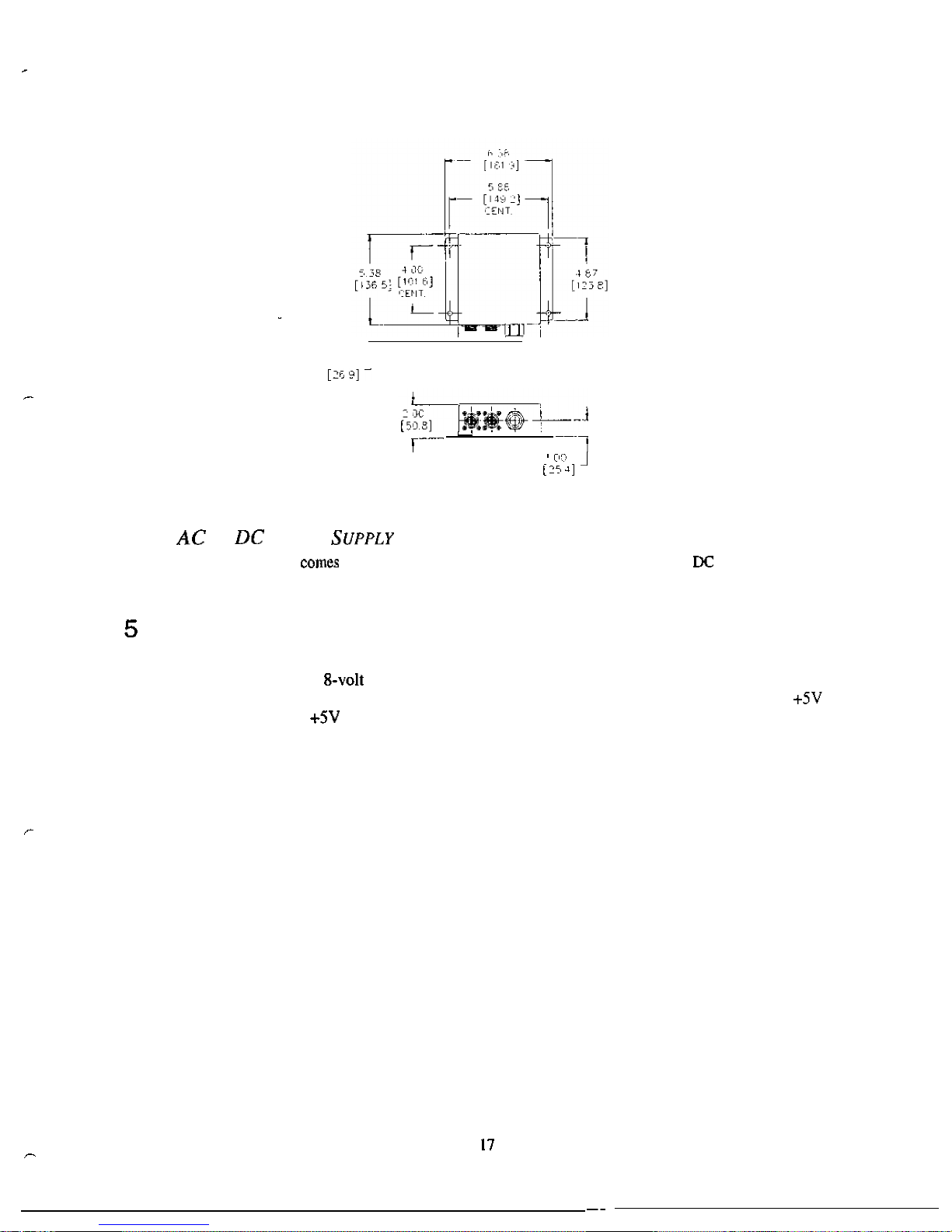

O

UTLIN

E

D

RAW

I

N

G

S

...........!

.......................................................................................................................................

13

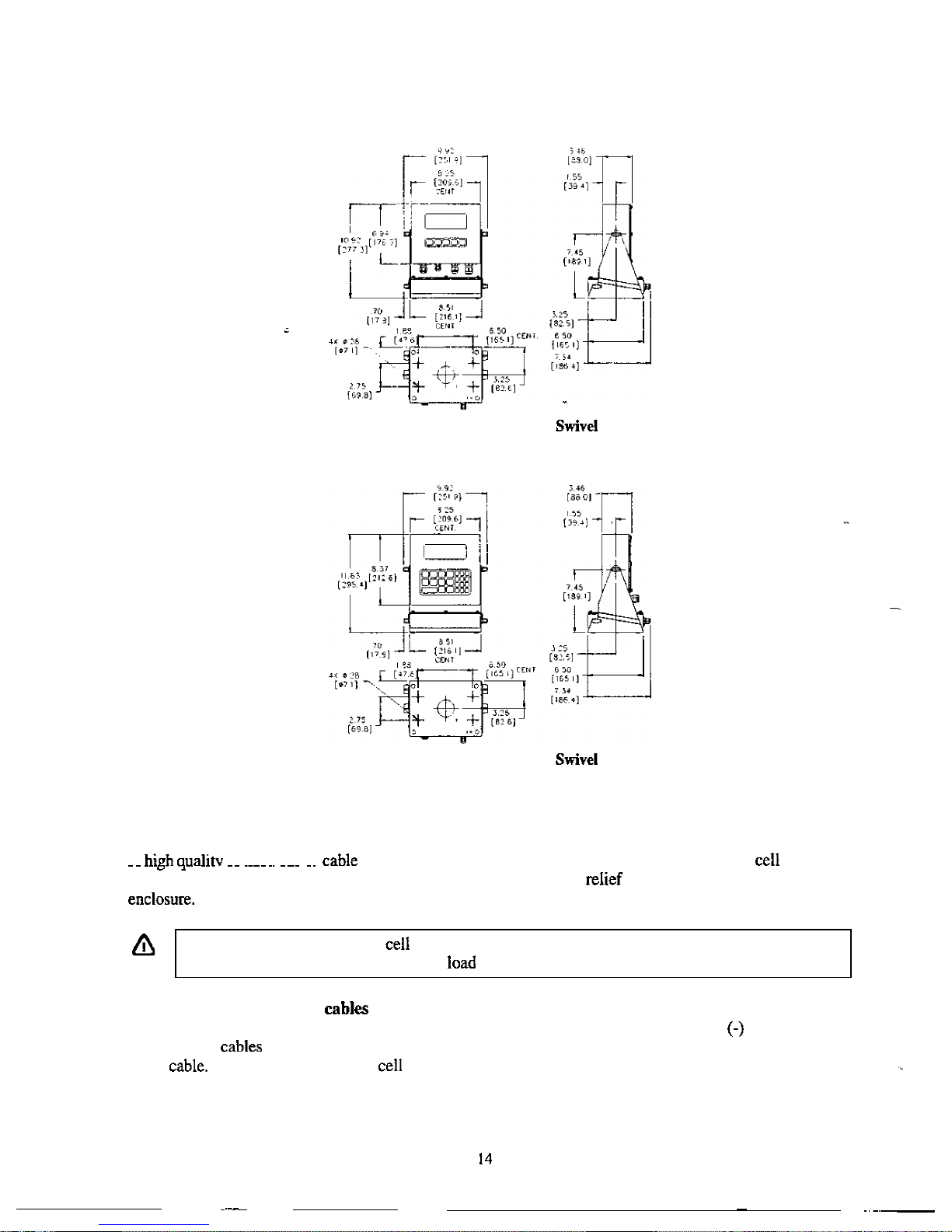

L

O

AD

C

ELL

C

O

N

N

EC

T

I

O

N

S

..........................................................................................................................................

14

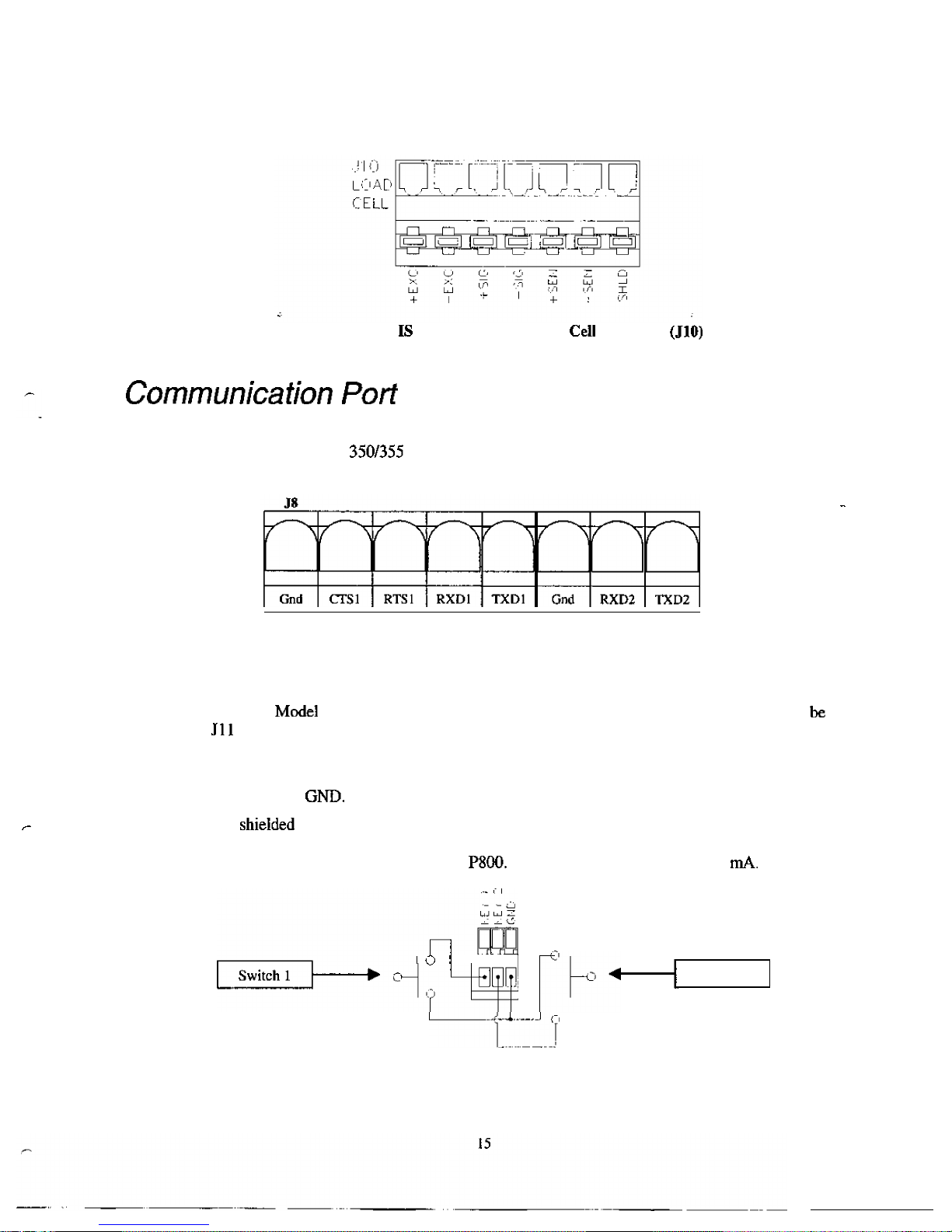

C

O

MM

U

N

I

C

A

T

I

O

N

P

O

R

T

CONN~IONS

.......................................................................................................................

15

REMOTE

KEY

CONNFLTIONS

.......................................................................................................................................

15

H

A

ZAR

DO

U

S

A

R

E

A

O

PTI

O

N

S

.......................................................................................................................................

16

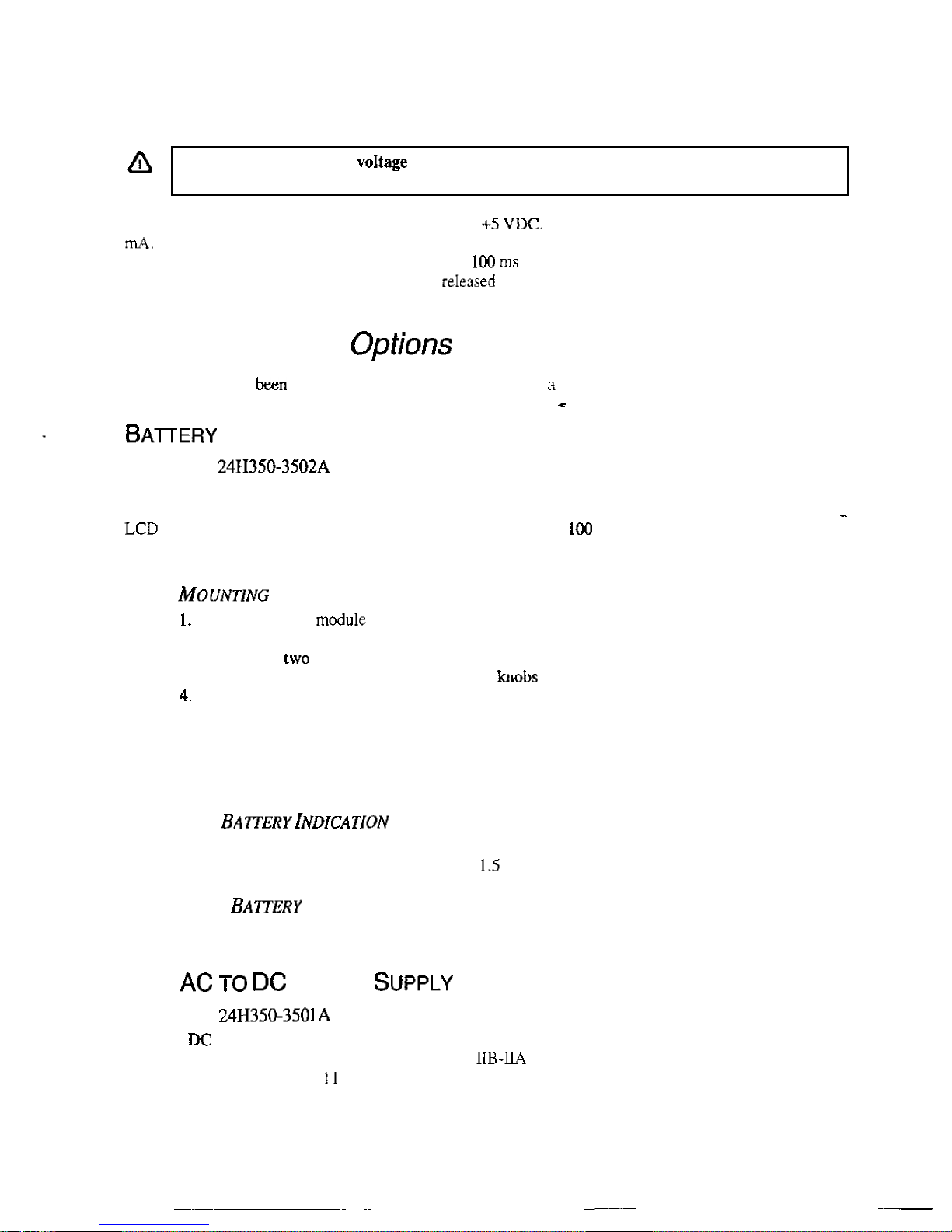

Battery

Power

Supply { Externa

1)

...........................................................................................................................

16

5

Volt

and

8

Volt

Excitation

...................................................................................................................................

17

CHAPTER

3:

CONFIGURATION

..............................................................................................................................

18

-

AC

to

DC

Power

Supply

(External)

.......................................................................................................................

16

E

NTER

IN

G

THE

SETUP

M

O

D

E

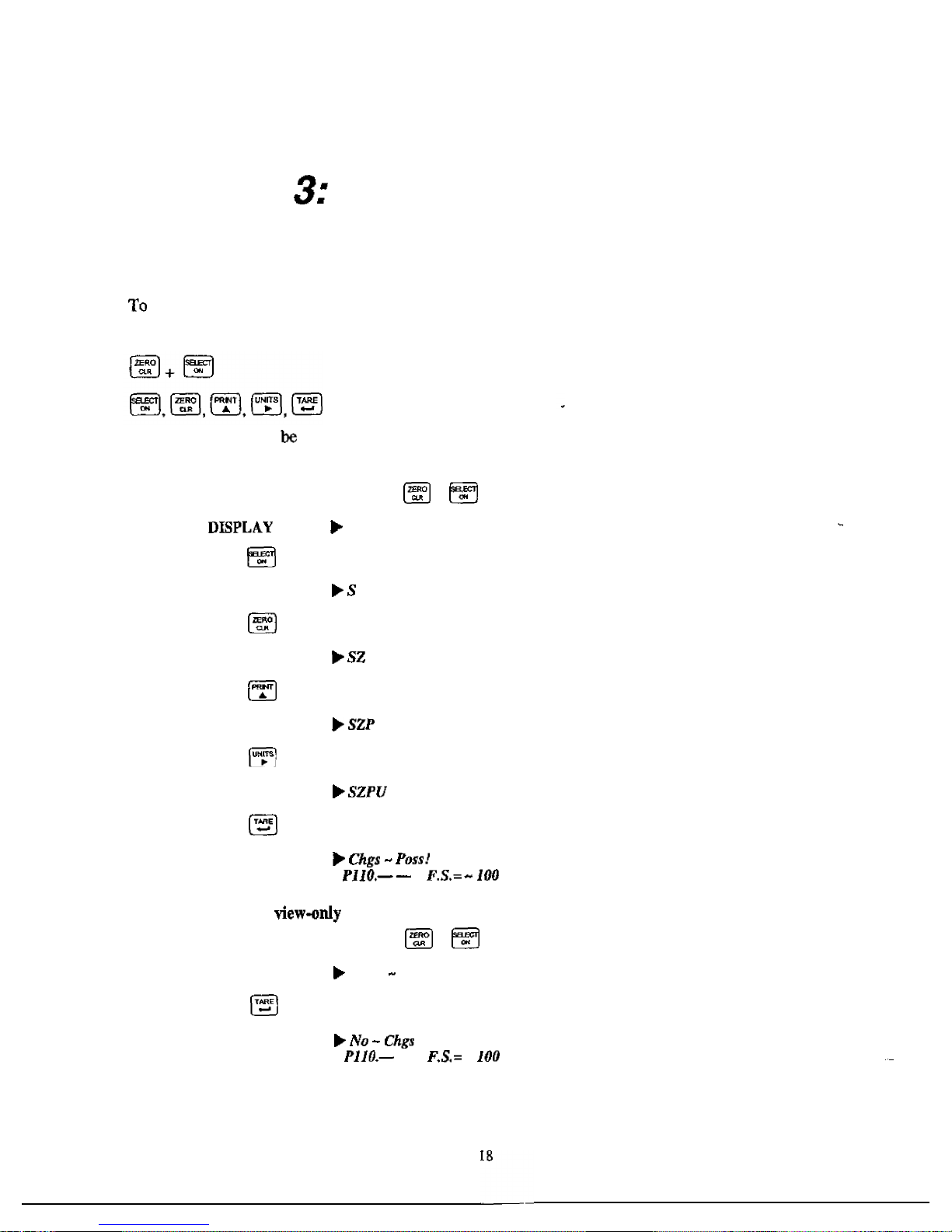

(M

O

DEL

350

1s)

............................................................................................................

18

S

E

LECT

IN

G

A

P

ARAM

ETE

R

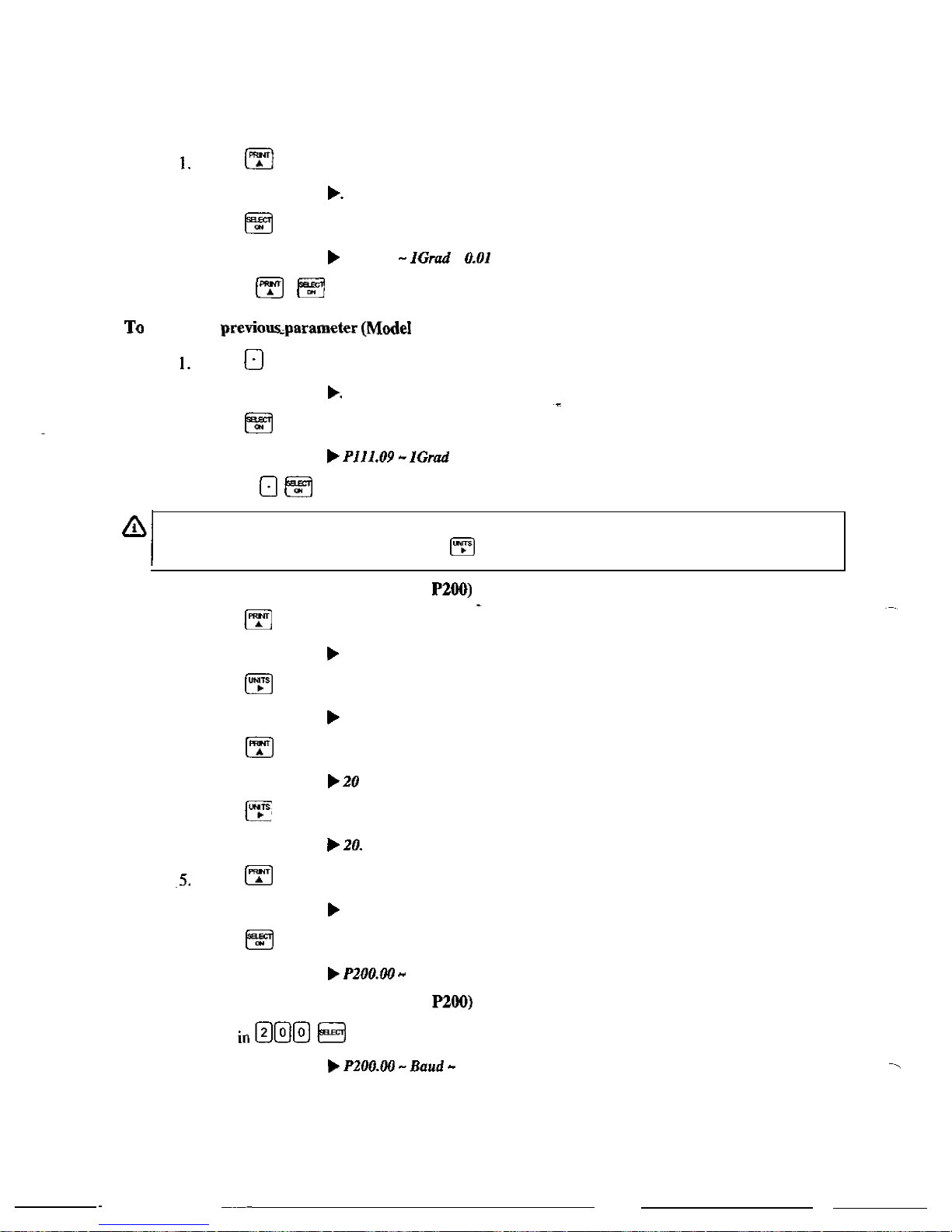

...........................................................................................................................................

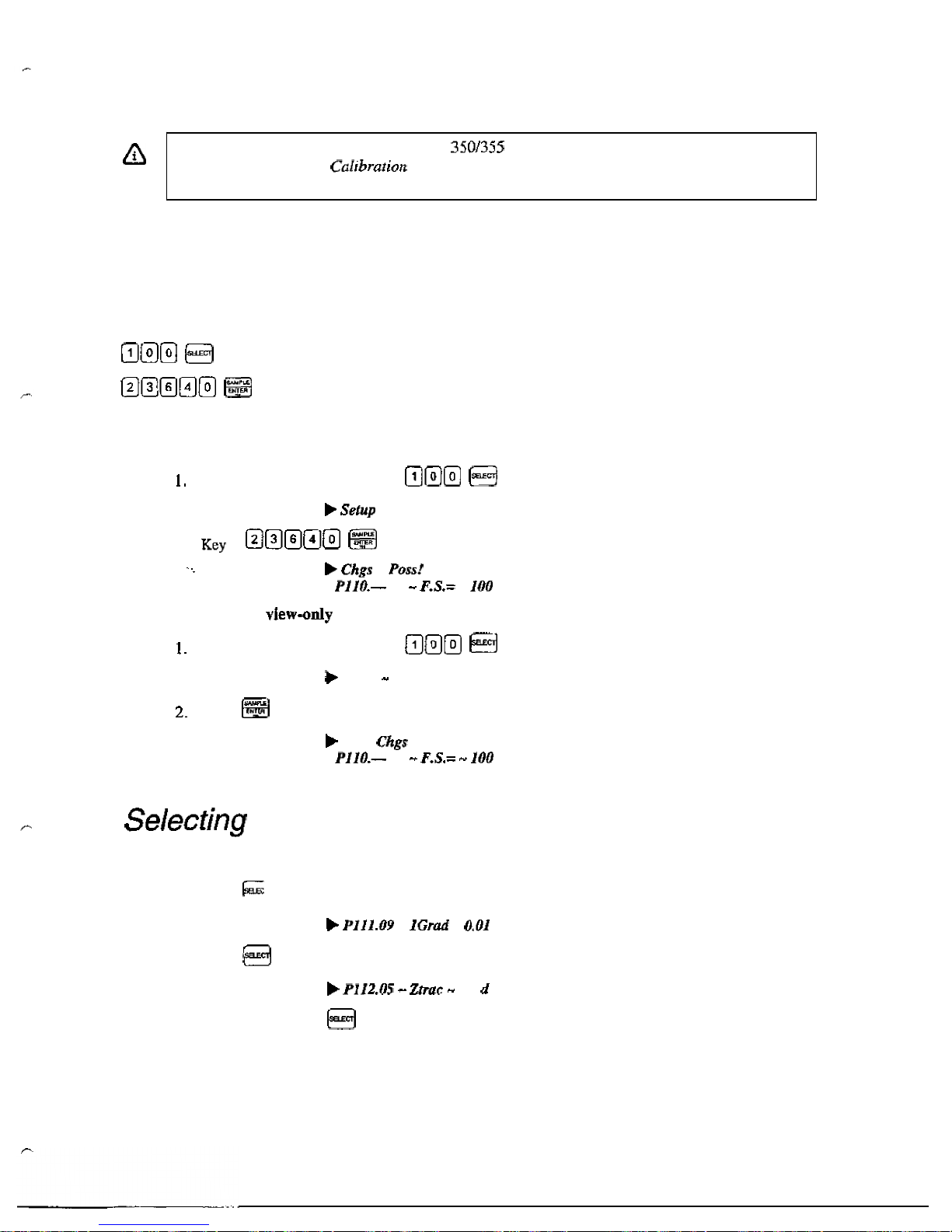

19

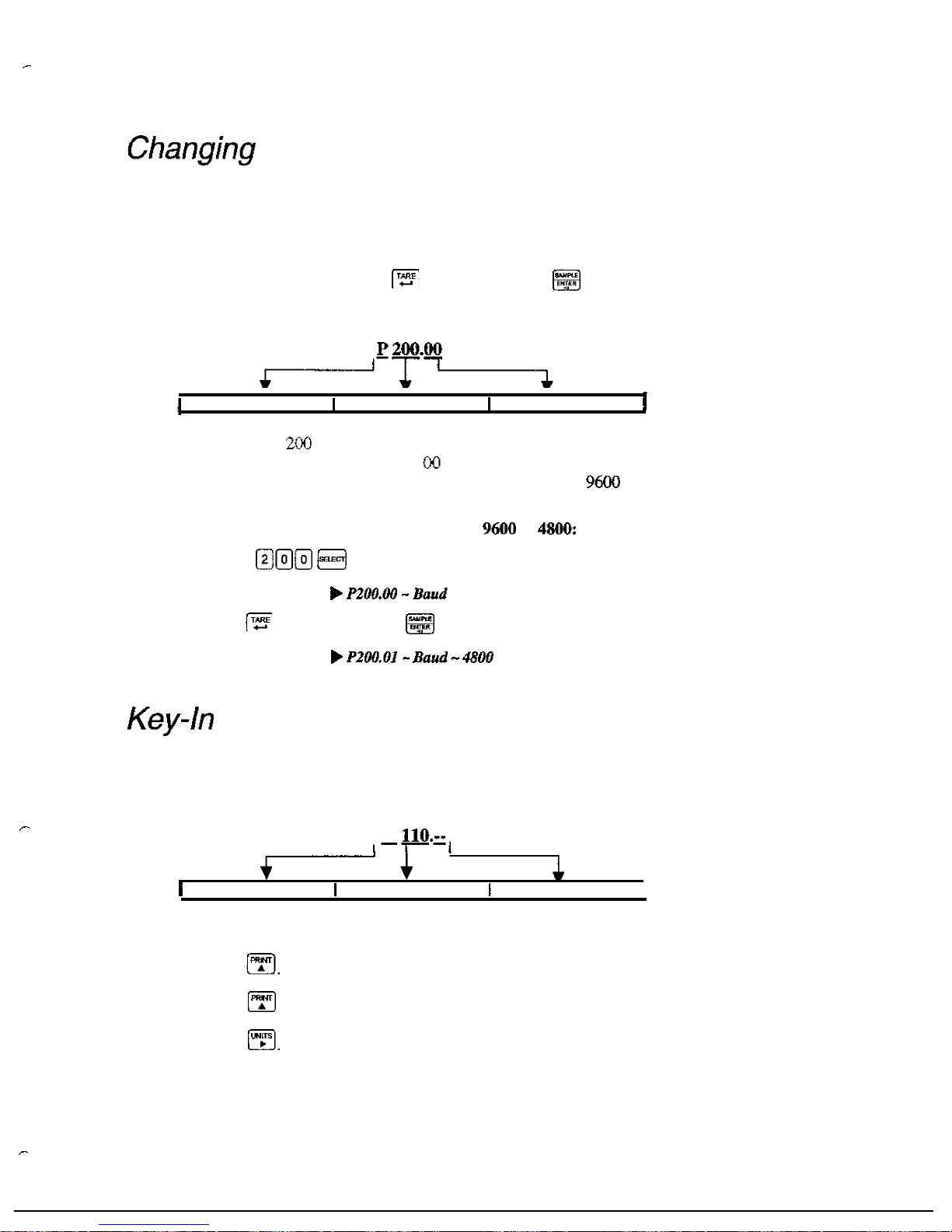

C

H

A

NGIN

G

A

P

A

RAMETE

R

V

ALU

E

...............................................................................................................................

21

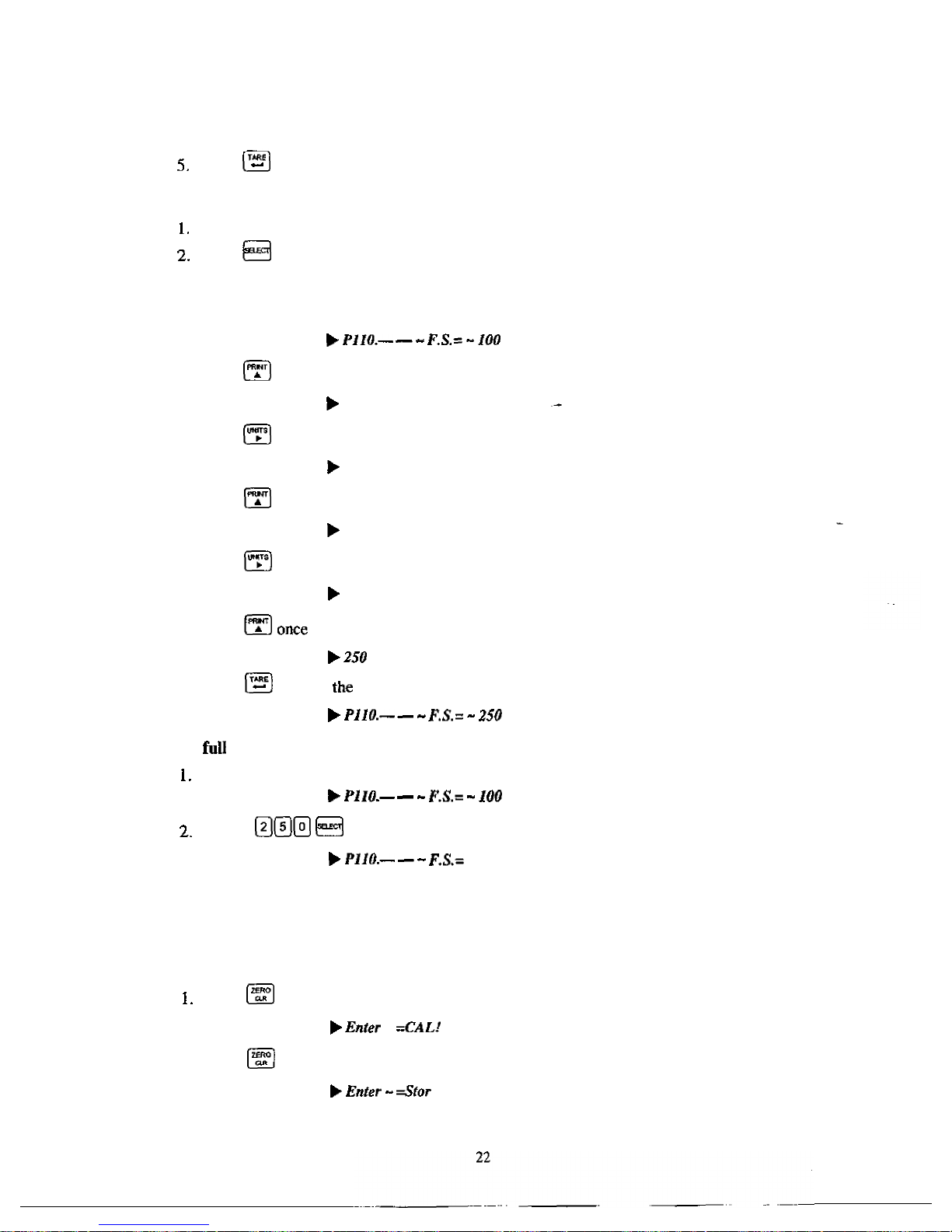

Selection

Parameters

.............................................................................................................................................

21

K

E

Y

-

I

N

P~AMETERS

..................................................................................................................................................

21

S

AVI

N

G

P

A

R

AMETE

R

S

.................................................................................................................................................

22

F

A

CTOR

Y DE

F

A

U

L

T

.....................................................................................................................................................

24

L

IST

O

F

PARAMETERS

..................................................................................................................................................

25

E

NTE

R

IN

G

THE

SEIWP

M

O

D

E

(MODEL

355

1s)

............................................................................................................

19

Parameter

Map

Details

..........................................................................................................................................

27

Elements

of

a

Custom

Transmit

.............................................................................................................................

34

Writing

a

custom

transmit

ASCZZ

textfile

..............................................................................................................

34

Entering

ASCII

Text

...............................................................................................................................................

35

Entering

ASCII

Control

Codes

...............................................................................................................................

35

PREsET

TRANSMIT

SELECTIONS

..................................................................................................................................

32

CUSTOM

TR~SM

rr

..................................................................................................................................................... 34

Accessing

Setup

and

Clearing

Existing

Custom

Transmit

.....................................................................................

34

Parameter

Selecrion

Numbers

................................................................................................................................

37

I

Page 5

..

Exiting

Setup

Mode

and

Saving Changes

..............................................................................................................

38

PARTS

COUNTING

........................................................................................................................................................

38

SETPOINT

SrrUP

..........................................................................................................................................................

40

Activation Methods (General)

................................................................................................................................

40

Pre-acls

(General)

.................................................................................................................................................

41

ham

Feature

(General)

........................................................................................................................................

41

Pause Fearure

{General)

.......................................................................................................................................

41

Changing

Targets

from the

Weigh

Mode (General)

..............................................................................................

42

Bargraph

(General)

...............................................................................................................................................

43

P

E

RCENT

AGE

CHECK-WEIGAING

.................................................................................................................................

46

Setpoint

Activation {Percentage

Check

-

Weighing)

................................................................................................

46

Changing

Targets

from

the

Weigh

Mode

(Percentage

Check- Weighing)

..............................................................

46

Example

(Percentage Check- Weighing)

................................................................................................................

47

FLL

.............................................................................................................................................................................

48

Activation

Merhod

(Fill)

.........................................................................................................................................

48

Pre-acts

(Fill)

.........................................................................................................................................................

48

Learn

Feature

(Fill)

...............................................................................................................................................

49

Pause

Feature

(Fill)

...............................................................................................................................................

49

Changing Targets

from

the

Weigh

Mode

(Fill)

......................................................................................................

49

Example

(Fill)

........................................................................................................................................................

49

B

A

TC

H

49-

Activation Method (Batch)

.....................................................................................................................................

50

Pre-acts

(Batch)

.....................................................................................................................................................

50

ham

Feature

(Batch)

...........................................................................................................................................

50

Pause

Feature

(BatchJ

...........................................................................................................................................

50

Exumple

(Eatchl

.....................................................................................................................................................

51

D

IS

C

H

ARGE

.................................................................................................................................................................

51

Activation

Method

(Discharge)

..............................................................................................................................

52

Pre-acts

(Discharge)

..............................................................................................................................................

52

Learn

Feature

(Discharge)

....................................................................................................................................

52

Pause

Feature (Discharge)

....................................................................................................................................

53

Example

(Discharge)

.............................................................................................................................................

53

B

O

T

H

...........................................................................................................................................................................

53

Activation

Method

(Both)

.......................................................................................................................................

54

Pre-acts (Both)

.......................................................................................................................................................

54

Change

Target

Weight

Example

(General)

............................................................................................................

43

<

.........................................................................................................................................................................

Changing

Targets

from the

Weigh

Mode

(Batch)

..................................................................................................

50

...

Target Changesfrom

(he

Weigh

Mode

(Discharge)

..............................................................................................

53

bum

Feature

(Both)

.............................................................................................................................................

54

Pause

Feature

(Borh)

.............................................................................................................................................

55

Target

Changesfrom

the

Weigh Mode

(BothJ

.......................................................................................................

55

Setpoinr

Activation

(Absolute

Check

-

Weighing)

....................................................................................................

56

Changing

Targetsfrom

the

Weigh

Mode

(Absolute

Check

-

Weighing)

.................................................................. 56

Setpoint Activation {Independent)

..........................................................................................................................

58

Changing Targets

from

the

Weigh

Mode

(Independent)

........................................................................................

58

Example

(Independent)

..........................................................................................................................................

59

TARGET

DEVIATION

CHECK-WEIGHING

......................................................................................................................

59

Setpoint

Activation

(Target Deviaiion

Check

-

Weighing}

.......................................................................................

60

Changing

Targets

from

rhe

Weigh

Mode

(Target Deviation Check- Weighing)

.....................................................

60

Example

(Target Deviation

Check

-

Weighing)

.......................................................................................................

61

BARGRAPH

SETUP

(LCD)

............................................................................................................................................

61

T

IM

E

AND

D

A

TE

SEiTl.JP

(MODEL

350

1s)

.....................................................................................................................

63

Example

(Borh)

......................................................................................................................................................

55

ABSOLUTE

C

HECK

-

W

E

IGH

IN

G

.....................................................................................................................................

55

Example

(Absolure

Check-Weighing)

.....................................................................................................................

57

I

NDEPENDENT

SETPOINT

O

P

E

RAT

I

O

N

..........................................................................................................................

57

7

.....

..

Page 6

TIME

AND

D

A

T

E

SETUP

(MODEL

355

1s)

.....................................................................................................................

65

66

R

E

M

O

TE

KEY

O

PERAT

I

O

N

R

E

MOT

E

S

E

RIAL OPER

A

TION

.......................................................................................................................................

66

Display

Capture

Ufdity

..........................................................................................................................................

67

U

P

G

RAD

E

I

N

D

I

C

A

TOR

F

IR

M

W

A

R

E

................................................................................................................................

67

Prepare

for

upgrade

...............................................................................................................................................

68

Load

Flash

File

......................................................................................................................................................

68

...........................................................................................................................................

CHAPTER

4:

CALIBRATION.

...................................................................................................................................

69

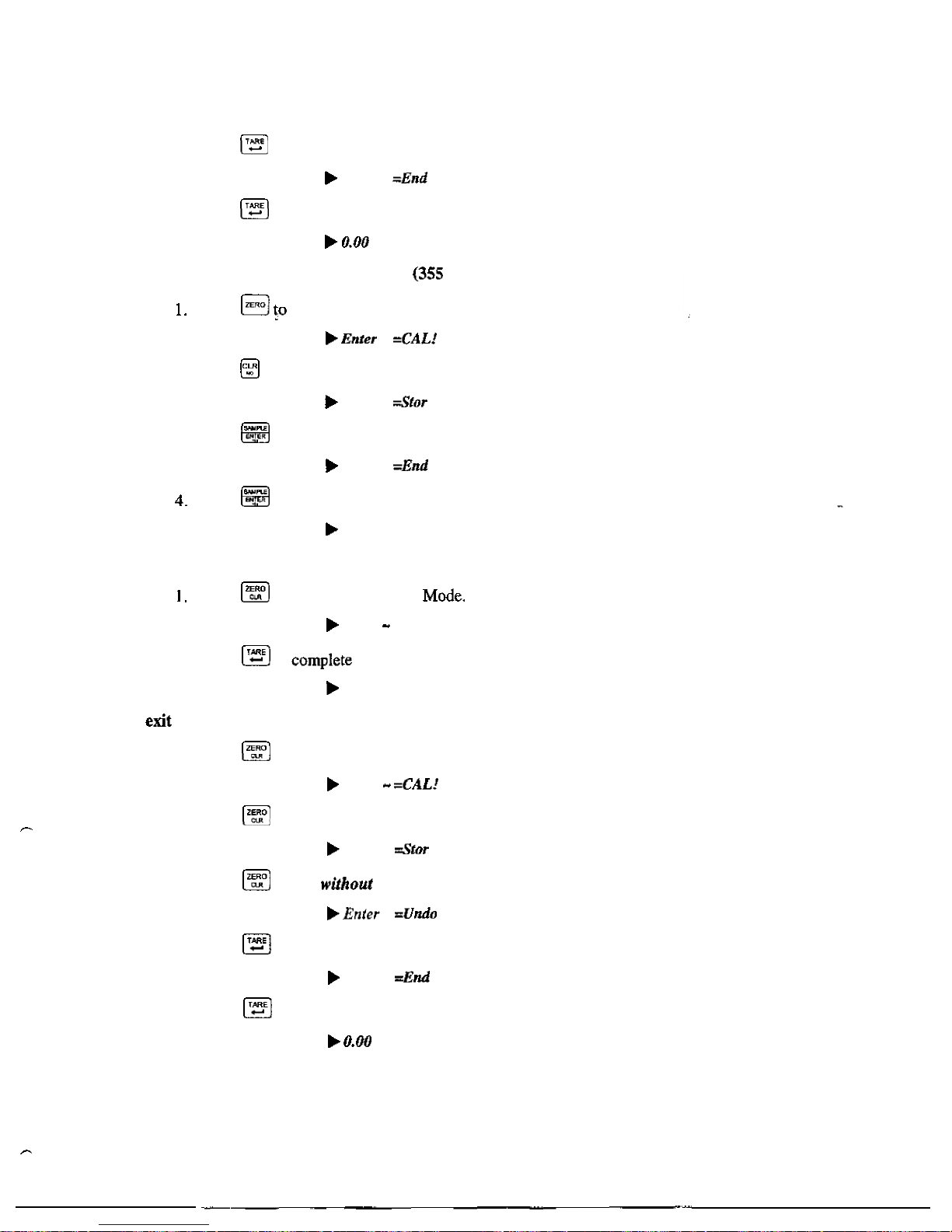

S~P

M

O

D

E

CALIBRATION

........................................................................................................................................

69

F

A

S

T

C

A

LIBRAT

I

O

N

.....................................................................................................................................................

69

P

E

RFOR

M

IN

G

C

A

LIB

R

A

T

I

O

N

........................................................................................................................................

69

First

Zero

...............................................................................................................................................................

70

Last

Zero

................................................................................................................................................................

72

ESTABLISHNG

ZERO

...................................................................................................................................................

70

c

False

Zero

..............................................................................................................................................................

74

Only

Zero

............................................................................................................................................................... 76

E

S

T

A

BLISH

IN

G

A

SPAN

................................................................................................................................................

79

Reset

Calibration

...................................................................................................................................................

77

E

X

IT

IN

G

C

A

LIBRAT

I

O

N

................................................................................................................................................

80

CHAPTER

5:

LEGAL

FOR

TRADE

.......................................................................................................................... 82

.

NTEP

R

E

Q

U

IREM

ENT

S

................................................................................................................................................

82

OML

R

E

Q

U

IR

EM

ENT

S

................................................................................................................................................

82

O

THER

RE~uIREMENTs

...............................................................................................................................................

83

S

EALIN

G

A

N

D

A

U

D

IT

TRAU

......................................................................................................................................

83

Physical

Seal

..........................................................................................................................................................

84

Audit

Trails

............................................................................................................................................................

84

CHAPTER

7:

TROUBLESHOOTING

.......................................................................................................................

86

E

RROR

MESSAGE^

.......................................................................................................................................................

86

Operation

a

1

Err0

rs ................................................................................................................................................

86

Setup

Mode Errors

.................................................................................................................................................

87

Calibration

Errors

.................................................................................................................................................

88

Communication

Errors

..........................................................................................................................................

88

Miscellaneous

Errors

.............................................................................................................................................

88

VIEWING

SrrUP

...........................................................................................................................................................

89

IN~RMATION

M

O

D

E

PARAMETERS

.............................................................................................................................

89

A/D

C

A

LIBRAT

I

O

N

P

ROCE

DUR

E

..................................................................................................................................

91

Hardware

Errors

................................................................................................................................................... 87

Page 7

Page 8

CHAPTER

I~INTRODUCTION

4

Thank

you

for

selecting

the

GSE

Model

3501355

Intrinsically

Safe

Indicator.

The

Model

350

and

Model

355

IS

continue

the

GSE

tradition

of

Excellence

in

Weighing. A properly

installed

and

maintained

Model

350

or

Model

355

IS

will

provide

many

years

of

reliable, accurate

performance.

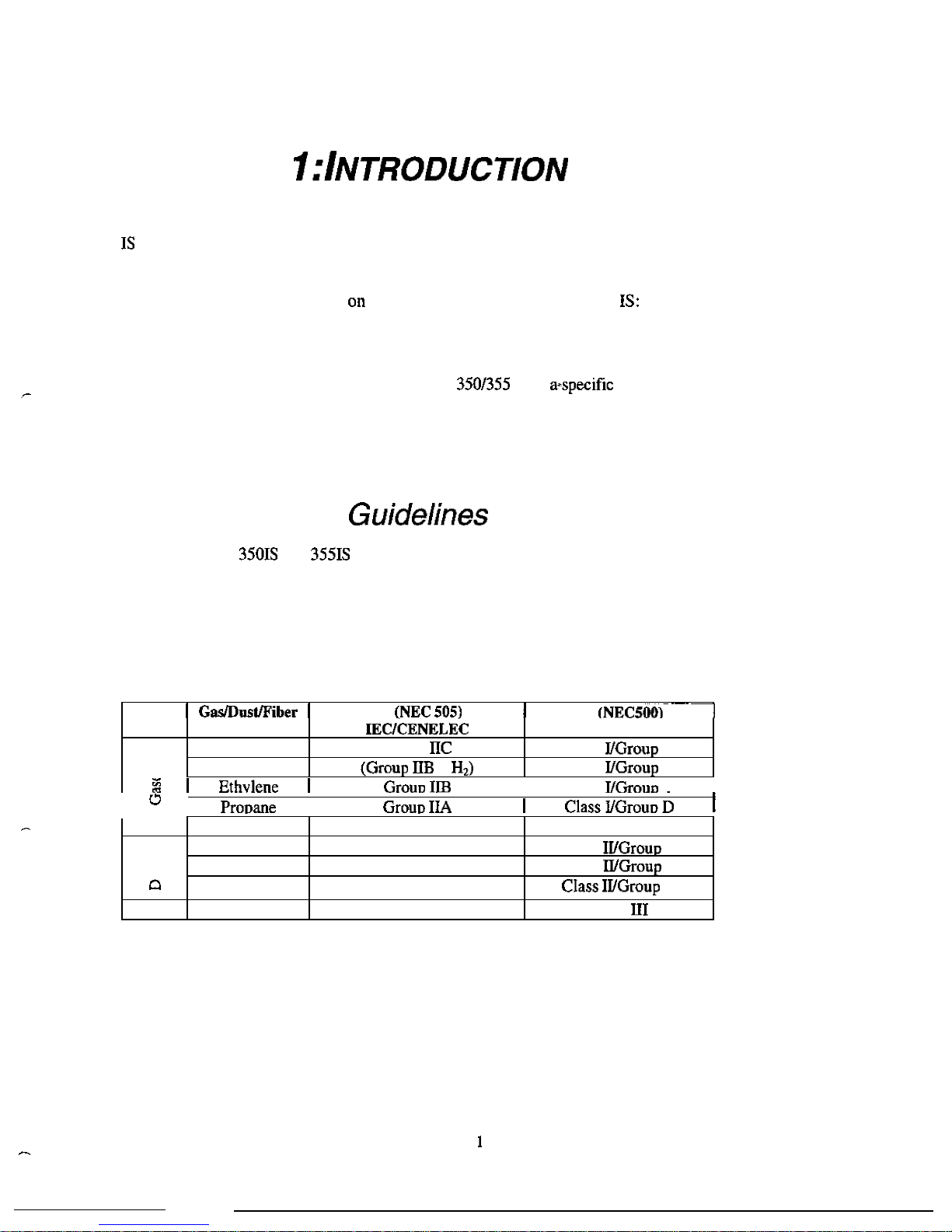

IEUCENELEC

Acetylene Group

IIC

Class

XlGroup

A

Hydrogen

(Group

IIB

+

Hz)

Class

YGroup

B

The

chapters

of

this

manual

focus

on

various

aspects

of

the

Model

3501355

IS:

Methane

Metal

Dust

Coal Dust

Grain

Dust

Fibers

4

CI

Chapter

1:

Introduction

Chapter

2:

Installation

Chapter

3:

Configuration

Chapter

4:

Operation

Chapter

5:

Calibration

Chapter

6:

Troubleshooting

Group

I

*

Mining

*

None

Class

IYGroup

E

None

Class

IyGroup

F

None

CIass

IYGroup

G

None

Class

UI

Hazardous

Area

Hazardous

Area

Guidelines,

Features

and

Specifications.

Installation

of

Indicator

and

Options.

Setup the

350/355

IS

to

a*specific

application.

Using

the

Model

3501355

IS.

Calibrate

the

indicator

to

a

scale.

Troubleshooting

help

and

error

messages.

Guidelines

The

GSE

Models

3501s

and

3551s

instruments

are

approved

by

FM

Approvals

as

intrinsically

safe

for

use

in

hazardous

areas.

An intrinsically

safe

device

has

been

proven

through

calculation

and

testing that

it

cannot

produce

enough electric

or

thermal

energy

under

normal

or

fault

conditions

to

cause ignition

of

flammable

material

present

in

the

atmosphere.

The

hazardous

area

is

defined

in

terms

of

how

long

the

hazard

is

present,

how

easily

it

is

ignited,

and

what

maximum temperature

can

be

present.

H

AZAR

D

G

R

O

U

PIN

G

I I

GadDustlFiber

I

US

[NEC

505)

1

US

(NEC5001-

1

I

2

I

Ethvlene

I

Groua

IIB

t

Class

IlGroun

c

I

..

I

I-,

I

I

I

"

I

Pronane

I

Grow

IIA

I

ClassllGrou~D

1

h

Page 9

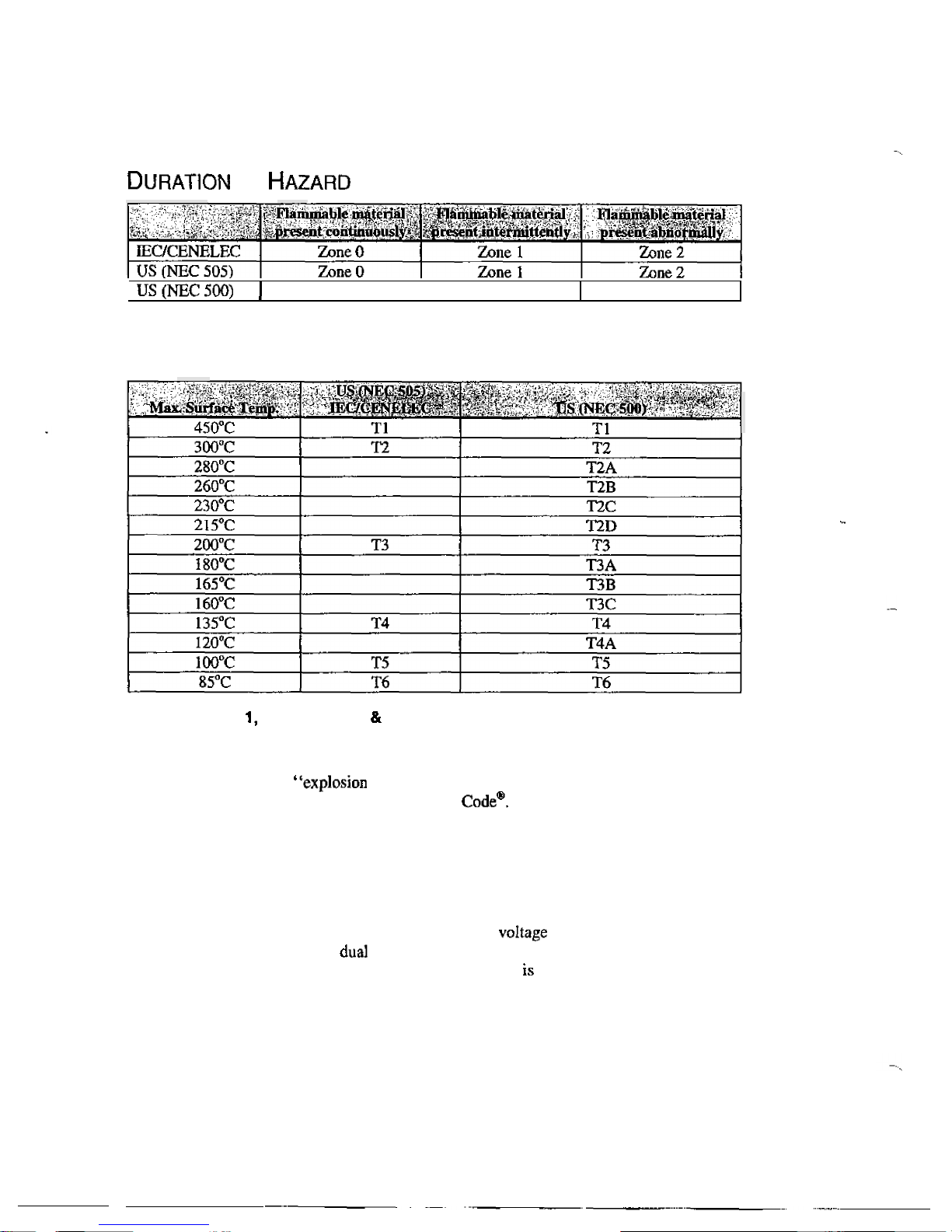

DURATlON

OF

HAZARD

US(NEC500)

I

Division

1

Division

2

T

EMP

ERA

T

U

R

E

C

O

D

E

S

Class

I,

Division

I,

Groups

A,

B,

C

&

D

Class

I,

Division

1

locations

are

those

in

which

hazardous

concentrations

of

flammable

gases

or

vapors

exist

continuously, intermittently

or

periodically

under

normal

operating

conditions.

Electrical equipment

for

use

in

such

locations

may

be

“explosion

proof,”

“intrinsically

safe,”

“purged”

or

otherwise

protected

to

meet

the intent

of

Articles

500

of

the

National

Electrical

Code@.

Explosion

proof

protection consists

of

equipment

designed

to

be

capable

of

containing

an

internal

explosion

of

a

specified

flammable

vapor-air

mixture.

In

addition,

the

equipment must operate at

a

safe

temperature

with

respect

to

the

surrounding

atmosphere.

Intrinsically

safe

electrical

equipment

and

associated

wiring

are

incapable

of

releasing sufficient

electrical

or

thermal

energy

to

cause

ignition

of

a

specific

hazardous

material

under

“normal”

or

“fault”

operating

conditions.

Normal

operation

assumes

maximum

supply

voftage

and

rated

environmental

extremes;

fault

conditions

assume

any

single

or

dud

independent

electrical

faults

plus

field

wiring

open,

shorts

or

connections

to

ground. Equipment

rated

as

intrinsically

safe

is

recognized

by

Article

500

as

safe

for

use

in

hazardous

locations

without

special

enclosures

or

physical

protection that

would

otherwise

be

required.

Purged

systems

have

fresh

air

or

an

inert

gas

under positive

pressure

to

exclude

ignitable

quantities

of

flammables

from

the

electrical

equipment

enclosure.

Equipment

Approved

for

Division

1

locations

shall

be

permitted

in Division

2

locations

of

the

same

class,

group

and

temperature

class.

2

Page 10

Class

I,

Division

2,

Groups

A,

8,

C

&

D

Class

I,

Division

2

locations

are

those in which hazardous concentrations

of

flammables exist only

under

unlikely

conditions

of operation.

As

such,

equipment

and

associated

wiring

which

are

incapable

of

reIeasing

sufficient electrical

and

thermal

energy

to

ignite

flammable

gases

or

vapors

under

“normal”

operation

and

environmental conditions

are

safe

to

use

in

Class

I,

Division

2

locations.

Class

I,

Zone

0,

Groups

IIC,

fIB & IIA

A

Class

I,

Zone

0

location

is

a

location

(I)

in which ignitible concentrations

of

flammable

gases

or

vapors

are

present continuously;

or

(2)

in which ignitible concentrations

of

flammable gases

or

vapors

are

present

for

long

periods

of

time. Electrical apparatus for

use

in

such

locations

may

be

type

of

protection “ia”

Intrinsic Safety.

Class

I,

Zone

1,

Groups IIC,

1IB & IIA

A

Class

I,

Zone

1

location is a location

(I)

in

which

ignitible concentrations

of

flammable

gases

or

vapors

are

likely

to

exist

under

normal

operating conditions;

or

(2)

in

which

ignitible concentrations

of

flammable

gases

or

vapors

may

exist

frequently

because

of

repair

or maintenance operations

or

because

of

leakage;

or

(3)

in

which

equipment

is

operated

or

processes

are

carried

on,

of

such

a

nature

that

equipment

breakdown

or

faulty operations could

result

in

the

release

of

ignitible concentrations of flammable

gases

or

vapors

and

also

cause

simultaneous

failure

of

electrical

equipment

in

a

mode

to

cause

the electrical equipment

to

become a source

of

ignition;

or

(4)

that

is

adjacent to

a

Class

I,

Zone

0

location

from

which

ignitible

concentrations

of

vapors

could

be

communicated, unless communication

is

prevented

by

adequate

positive

-

pressure

ventilation

from a source

of

clean air

and

effective

safeguards

against ventilation failure

are

provided. Electrical apparatus

for

use

in

such

locations

may

be

type

of

protection

“d”

Flameproof,

“e”

Increased

Safety,

“ib”

Intrinsic

Safety,

“m”

Encapsulation,

“0”

Oil Immersion,

“p”

Pressurized

or

“q”

Pow

der-Fil

led.

Note:

Electrical

apparatus

Approved

for

use

in

Class

I,

Zone

0

locutions

shall

be

permitted

in

Class

I,

Zone

1

locations

of

the

same

gas

group

and

temperature

class.

Class

I,

Zone

2,

Groups

IIC,

IIB

&

tlA

A

Class

I,

Zone

2

location

is

a

lmation

(I)

in

which

ignitible concentrations

of

flammable

gases

or

vapors

are

not

likely

to

occur

in

normal

operation

and

if

they

do

occur

will

exist

only

for

a

short

period;

or

(2)

in

which volatile

flammable

liquids, flammable

gases

or flammable

vapors

are

handled,

processed

or

used,

but

in which

the

liquids,

gases

or

vapors

normally

are

confined within

closed

containers

or

closed

systems

from

which

they

can

escape

only

as

a

result

of

accidental

rupture

or

breakdown

of

the

containers

or

system

or

as

the

result

of

the

abnormal

operation

of

the

equipment

with

which

the liquids

or

gases

are

handled,

processed

or

used;

or

(3)

in

which

ignitible concentrations

of

flammable

gases

or

vapors normally

are

prevented

by

positive

mechanical

ventilation,

but

which

may

become

hazardous

as

the

result

of

failure

or

abnormal

operation

of

the ventilation equipment;

or

(4)

that is adjacent

to

a

Class

I,

Zone

1

location,

from

which

ignitible

concentrations

of

flammable

gases

or

vapors

could

be

communicated. unless

such

communication

is prevented

by

adequate positive-pressure ventilation

from

a

source

of

clean

air

and

effective

safeguards

against

ventilation

failure

are

provided.

Electrical

apparatus

for

use

in such locations

may

be

type

of

protection

“nA”

Non-Sparking, “nC” Protected contacts,

“nR”

Restricted Breathing

or

“p”

Pressurized.

Note:

Electrical

apparatus

Approved

for

use

in

Class

I,

Zone

0

or

Zone

I

locations

shall

be

permitted

in

Class

I,

Zone

2

locations

of

rhe

same

gas

gruup

and

temperature

class.

Class

II,

Divisions

1 & 2,

Groups

E,

F

&

G

Electrical equipment suitable

for

use

in

Class

11

locations,

as

defined

by

the

National

Electrical

Code@,

is

constructed to

exclude

ignitable

amounts

of

dust

from

the equipment enclosure.

Approved

equipment

of

this

type

has

also

been

evaluated

to

assure

that

hazardous

sudace

temperatures

do

not

exist.

Equipment

listed

as

3

Page 11

suitable

for

Class

II

locations

is

“dust-ignitionproof”

or

otherwise designed

to

meet

the

intent

of

Articles

500

and

502

of

the National

Electrical

Code@.

Class

111,

Divisions 1 &

2

Class

HI

lccations

are

those

which

are

hazardous

because

of

the

presence

of

ignitable

fibers

or

flyings.

Equipment listed for installation in

Class

ID

locations is

designed

to

exclude

the

fibers

and

flyings

from

the

equipment enclosure

and

to

function without developing excessive

surface

temperatures.

D

EFINITION

S

Associated

Apparatus - Apparatus, including

Category

ia

and

ib apparatus,

in

which

the

circuits

are

not

necessarily

intrinsically

safe

themselves, but

which

affect

the

energy

in the intrinsically

safe

circuits

and

are

relied

upon

to maintain intrinsic

safety.

Associated

electrical

apparatus

may

be

either:

a)

Electrical

apparatus

that

has

an

alternative type

of

protection

for

use

in

the appropriate potentialiy

flammable

atmosphere.;

or

b) Electrical

apparatus

not

so

protected

and thus not suitable

for

use

in

a

potentially flammable

atmosphere.

ContruZ

Drawing

-

A

drawing

or

other

document

provided

by

the

manufacturer

of

the

intrinsically

safe

or

associated

apparatus

that details

the

allowed

interconnections

to

other

circuits

or

apparatus.

If

the

intrinsi

-

cally

safe

ox

associated apparatus

is

investigated

under

the

entity

concept.

the

control

drawing

will

indude

the applicable electrical

parameters

to

permit

selection

of

apparatus

for

interconnection.

Entity

Evaludion

Concept

-

A

method used

to

determine acceptable combinations

of

intrinsically

safe

apparatus

and

connected

associated

apparatus

that

have

not

been

investigated

in

such

combination.

Harardous

(Clrassiflcation)

Lmation:

A

location

in

which

fire

or

explosion

hazards

may

exist

due

to

an

explosive atmosphere

of

flammable

gases

or

vapors,

flammable

liquids. combustible

dust.

or

easily

ignitable

fibers

or

flyings.

Intrinsically

Safe

Circuit

-

A

circuit in

which

any

spark

or

thermal

effect,

produced

either normally

or

in

specified fault conditions,

is

incapable,

under

the

test conditions

prescribed

in

this

standard,

of

causing

ignition

of

a

mixture

of

flammable

or

combustible

material

in

air

in

the

mixture’s

most

easily

ignited

concentration.

Nonincendive

Circuit

-

A

circuit,

other

than

field

wiring,

in which

any

arc

or

thermal

effect

produced

under

intended operating conditions

of

the

equipment

is

not

capable, under specified test conditions,

of

igniting

the

flammable

gas-air,

vapor-air,

or

dust-air mixture.

._

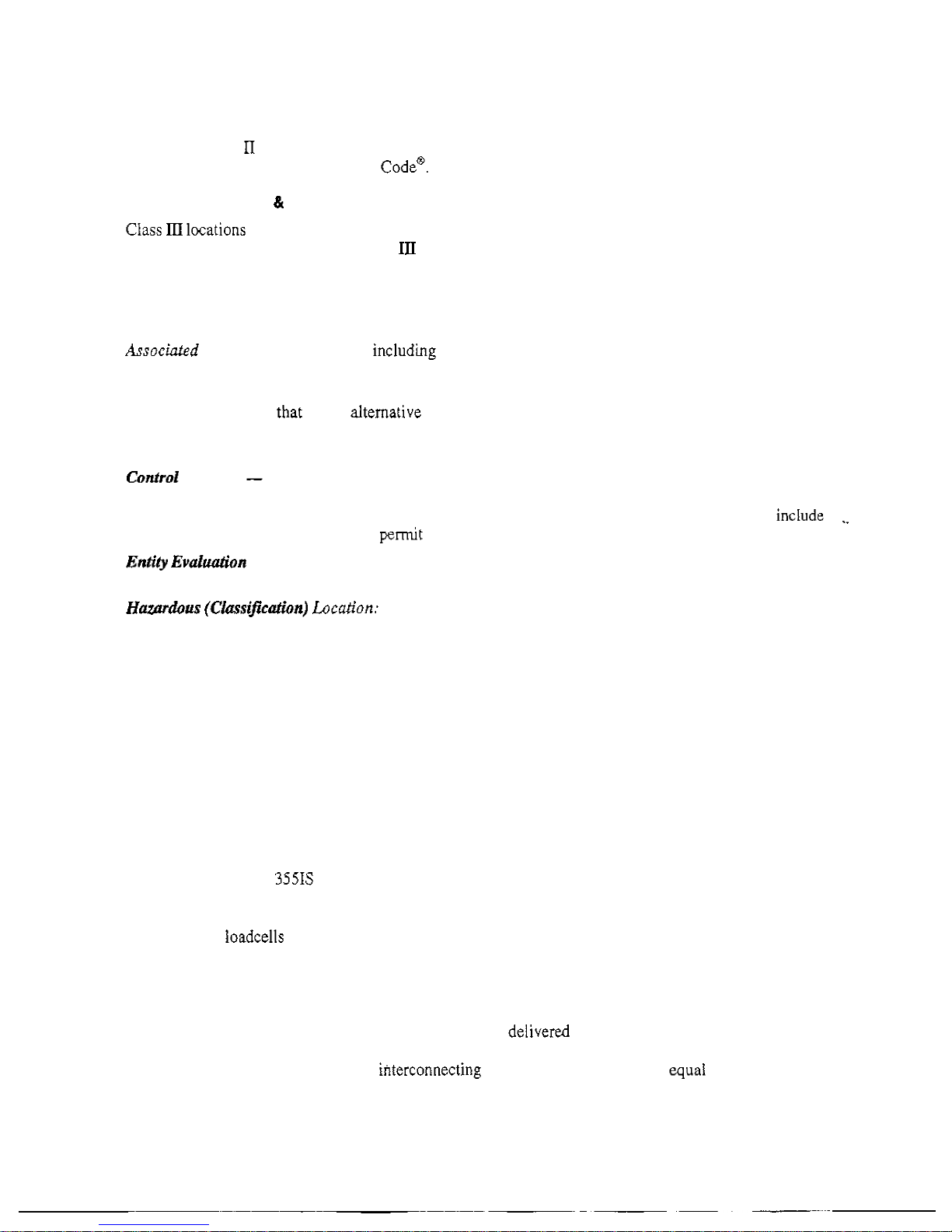

E

NTITY

E

VALUATION

C

ONCEPT

The

Model

35015

and

3551s

indicators

have

been

approved

under

the

entity

evaluation

concept,

which

allows

the

interconnection

of

intrinsically

safe

devices

in

hazardous

areas

even though these devices

were

not specifically

approved

in

this combination. This

means

that not only

can

the instrument

be

used with

GSE

FM

Approved Ioadcells

and

peripherals, but

they

can

also

be used with

any

manufacturer’s

FM

Approved

loadcells and

peripherals

provided

that they

have

matching

entity ratings

and

are

approved

for

the

appropriate

hazardous

area.

The

criteria

for

interconnection

is

that

the maximum input

voltage

and

current, which intrinsically

safe

apparatus

can

receive

and

remain intrinsically

safe,

considering faults, must

be

equal

to

or

greater than the

maximum

output

voltage

and

current

levels

which

can

be

delivered by the associated

apparatus,

considering

faults

and

applicable factors.

In

addition,

the

maximum

internal

capacitance

and

inductance

of

the

intrinsically

safe

apparatus, including ihterconnecting wiring,

must

be

less

than

or

equal

to

the

maximum

allowed capacitance

and

inductance which

can

be

safely

connected

to

the

associated

apparatus.

If

these

4

Page 12

criteria

are

met,

then

the

combination

may

be

connected

and

remain intrinsically

safe.

If

the

specific

capacitance

and

inductance

ratings

of

the

wiring

are

unknown,

use

a

capacitance

of

6OpF/ft

and

an

inductance

of

0.2uWft.

When

connecting

a

Model

350IS

or

3551s

to

another

intrinsically

safe

device,

the

entity

ratings

must

be

compared

and satisfy

the

conditions

shown

in

the

following

table.

voc

ISC

Ca

1

.

35OIS3551S

Indlcatoc

IC

Condition

1,.

Intrinsicall$f$afq@evice

\I

<=

Vmax

or

Ui

<=

Imax

or

Ti

>=

Ci

+

cable

caDacitance

La

>=

I

Li

+

cable

inductance

E

NTITY

R

A

T

I

N

G

D

E

FI N

ITI

O

N

s

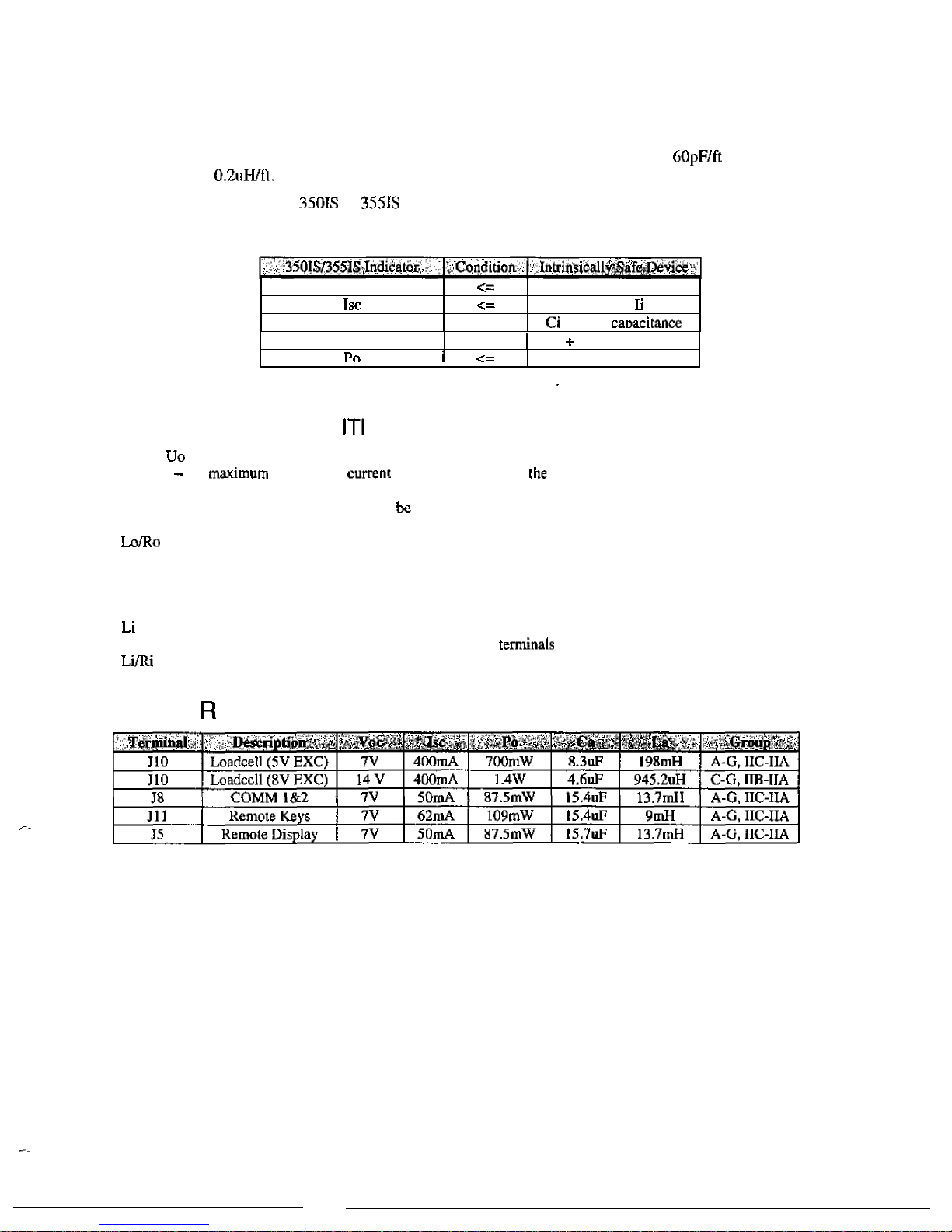

Pn

I

<=

Voc

or

Uo

-

the

maximum

open

circuit

voltage

that

may

be

present

at

the

specified terminals

Isc

or

Io

-

the mimum

short

circuit

current

that

may

be

present

at

the

specified

terminals

Ca

or

Co

-

the

maximum

capacitance

that

may

be

connected

to

the

specified

terminals

La

or

Lo

-

the

maximum

inductance

that

may

be

connected

to

the

specified

terminals

Po

-

the

maximum output

power

from

the

specified

terminals

LolRo

-

inductance to resistance

ratio

that

indicates the maximum

inductance

per

ohm

of

resistance

that

can be

connected

to

the

specified

terminals

Vmax

or

Ui

-

the

maximum

voltage

that

may

be

connected

to

the

specified

terminals

Imax

or

Ii

-

the

maximum

current

that

may

be

connected

to

the

specified

terminals

Ci

-

the

capacitance

present

at

the

specified

terminals

Li

-

the

inductance

present

at

the

specified

terminals

Pi

-

the

maximum

power

that

may

be

supplied

to

the

specified terminals

LilRi

-

the

maximum

internal

inductance

to

resistance

ratio

at

the

specified

terminals

Pi

E

NTITY

R

A

T

I

N

G

s

5

Page 13

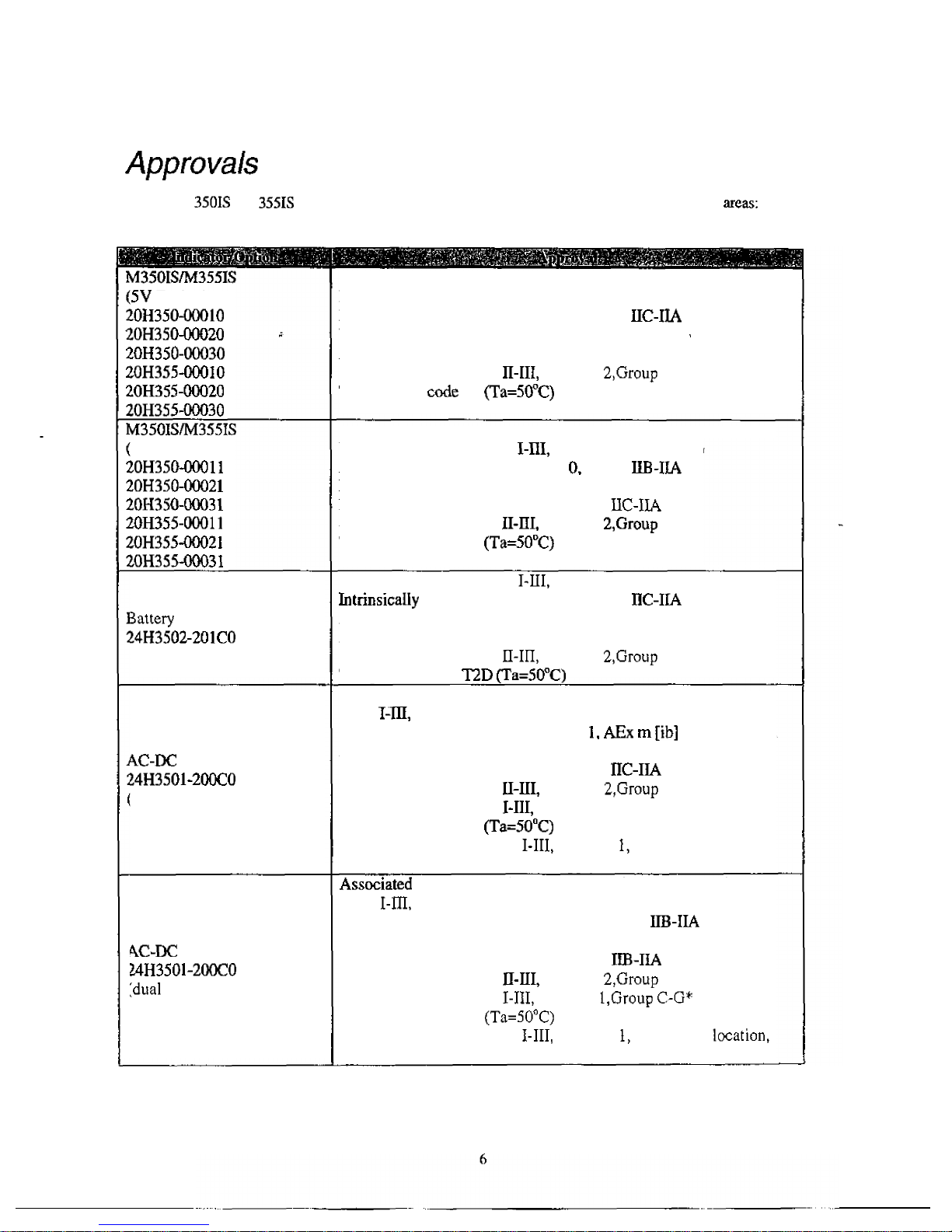

Approvals

The

Model

3501s

and

3551s

indicators

and

options

have

been

approved

for

the

following

hazardous

areas:

5V

Excitation)

!OH35MK3010

!OH350-04)020

!OH355-000IO

30H355-00030

vi3501StM355IS

8V

Excitation)

!OH350-00011

!OH350-00030

!OH35

5-00020

30H350-0002

1

!OH350-0003

I

!OH355-00011

lOH355-0002

1

lOH355-00031

3attery

Power

Supply

Option

14B3502-201CO

4C-DC

Power

Supply

Option

:single output

used)

Z4H3501-200CO

4C-DC

Power

Supply

Option

:dual

outputs

used)

24H350

1

-2OOCO

Intrinsically

Safe

for Class

I-BI,

Division

1 , Group

A-G

Intrinsically

Safe

for

Class

I,

Zone

0,

Group

LIC-IIA

Nonincendive

for

Class

I,

Division

2,

Group

A-D

Nonincendive

for

Class

I,

Zone

2,

Group

IIC-IIA

Suitable

for

use

in

Class

II-111,

Division

2,Group F-

G

Temperature

ccde

T4

(Ta=50°C)

Intrinsically

Safe

for

Class

I-III,

Division

1,

Group

C-G

Intrinsically

Safe

for

Class

I,

Zone

0.

Group

ILB-ILA

Nonincendive

for

Class

I,

Division

2,

Group

A-D

Nonincendive

for

Class

I,

Zone

2,

Group

IlC-II.4

Suitable

for

use

in

Class

11-III,

Division

2,Group F-

G

Temperature

code

T4

(Ta=50DC)

Intrinsically

Safe

for

Class

I-LII,

Division

1,

Group

A-G

IntrinsicaIIy

Safe

for

Class

I,

Zone

0,

Group

XXC-IL4

Nonincendive

for

Class

I,

Division

2,

Group

A-D

Nonincendive

for

Class

I,

Zone

2,

Group

IIC-IIA

Suitable

for

use

in

Class

D-III,

Division

2,Group

F-G

Temperature

code

T2D

(Ta=SO"C)

Associated

Apparatus

with

Intrinsically

Safe

Connections

for

Class

T-m,

Division

1,

Group A-

G

Encapsulated

for

use

in

Class

I,

Zone

I,

AEx m lib]

Group

IIC-IIA

Nonincendive

for

Class

I,

Division

2,

Group A-

D

Nonincendive

for

Class

I,

Zone

2,

Group

UC-IIA

Suitable

for

use

in

Class

II-HI,

Division

2,Group

F-G

Suitable

for

use

in

Class

1-111,

Division

I

,Group

A-G*

Temperature

code

T4

(Ta=SO"C)

*

When

installed

in

a

Class

1-111,

Division

I,

Group

A-G

location,

conduit must

be

used

on

the

AC

supply cable.

Assdated

Apparatus

with

Intrinsically

Safe

Connections

for

Class

I-III,

Division 1,

Group

C-G

*

Encapsulated

for

use

in

Class

I.

Zone

0,

Group

IIB-IIA

*

Nonincendive

for

Class

I,

Division

2,

Group

C-D

Nonincendive

for

Class

I,

Zone

2,

Group

1B-IIA

Suitable

for

use

in

Class

II-111,

Division

2,Group

F-G

Suitable

for

use

in

Class

1-111,

Division

1,Group

C-G*

Temperature

code

T4

(Ta=50°C)

*

When

installed

in

a

Class

1-111,

Division

€,

Group

C-G

lmation,

conduit must

be

used

on

the

AC

supply

cable.

Page 14

r

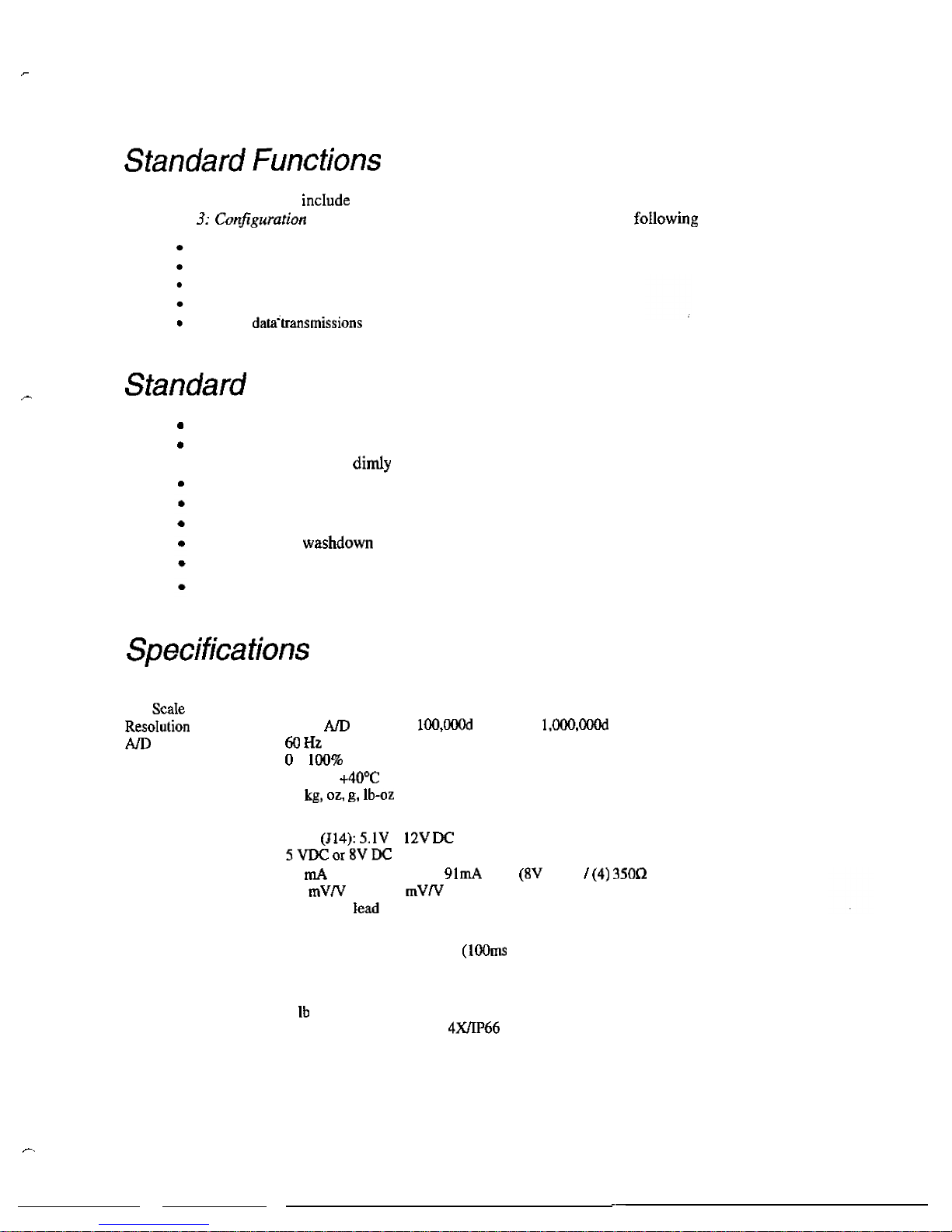

Standard

Functions

/-

r

-

The

Model

350

and

355

IS

indude

built-in

functions

that

you

can

enable

through

the

Indicator

Setup.

Refer

to

Chapter

3:

Configuration

for

information

on

the

setup

and

operation

of

the

foIlowing

standard

functions:

Check-weighing

Parts

counting

Remote

key

operation

Custom

data'transmissions

Selectable,

built-in

data

transmission

formats

Standard

Features

a

Three

display

choices

(LCD,

LCD

backlit

and

LED).

LED

model

uses

low

current

high

efficiency

display

digits

and

annunciators

to

save

battery

life

and

adds

brightness

to

dimly

lit

areas.

Real

time clock

with

battery

backed

time

and

date.

Two

RS-232

communication

ports.

Model

355

has

a

numeric

keypad

Stainless

Steel

washdown

enclosure

Up

to

(4)

350

ohm

loadcells

Easily

update

firmware

via

the

RS-232

port

Specifications

PERFORMANCE

Full

ScaIe

(F.S.)

ResoIution

AID

Conversion

Zero

Track

Operating

Temperature

Units

of

Measure

ELECTRICAL

Power

Requirement

Excitation

Voltage

Excitation

Current

F.S.

Signal

Input

Signal

Connection

Selectable

0

to

999,999

20-bit

AID

converter,

100,ooW

displayed,

l,MH),OOOd

internal

60

HZ

0 - 100%

of

Full

Scale

-

10°C

to

+40T

Ib,

kg,

02,

g,

Ib-02

Input

(J14):

5.1V

-

12V

DC

5WXor8VDC

57

mA

max.

(5V

EXC)

or

91mA

max.

(8V

EXC)

/

(4)

350a

bridge

0.1

mVN

min

-

10

mVN max

4

lead

or

6

lead

with

sense

PROCESS

CONTROL

Remote

Input

EN

CLOSURE

Shipping

Weight

Material

Mounting

2

momentary

contact

closure

(1OOms

minimum)

TARE,

PRINT,

ZERO

7

Ib

(3

kg)

304

Stainles

Steel,

NEMA

4xflP66

Design

2

swivel

brackets

are

available

for

battery

or

AC

operation

7

r.

Page 15

DISPLAY

LED

LCD

COMMUNICATION

KEYPAD

350

IS

355

IS

RS-232

6-digit

weight

display,

0.8'

(22mm) height

12

LED

annunciators

for

operational

status

&digit

weight

display,

1.0'

(25.4")

height

12

LCD

anhunciators for

operational

status.

Built

in

LCD

status

bargraph.

Also

available

with

backlight

(2)

RS232

communication

ports,

1

with

hardware

handshaking

.-Five

key,

durable

elastomeric

(rubber)

22

key,

full

numeric,

durable elastomeric

(rubber)

SAFE

AREA

OPTIONS

Battery

Charger

HAZARDOUS

AREA

OPTIONS

Battery

Charges

completely discharged

battery

option

in

3.5

hours

Universal

AC

input

85-265VAC

50160

Hz

Stainless

steel

enclosure,

mounts

to

indicator

swivel

bracket.

200

hours

continuous

use

with

LCD

display

3-

1

loadcell,

and

100

hours

continuous

use

with

LED

display + 1

loadcell.

Charge

time

3.5

hours

with

battery

charger

option.

AC

to

DC

Power

Supply

Stainless

steel

enclosure.

Powers

up

to

2

indicators

(2

indicators

can

only

be

powered

in

Groups C-

G

hazardous

area).

Wall

mount.

Universal

AC

input

90-250VAC,

50/60

Hz.

Power

Extension

Cable

Allows

the

AC-DC

power

supply

to

be

mounted

away

from

the

indicator.

25

feet

and

50

feet

lengths

available.

..

Display

The

Model

350

and

355

intrinsically

safe

indicators

are

available

with

a

six

digit,

7-segment

red

LED

display,

six

digit,

7-segment

black

LCD

display

or

7-segment

backlit

LCD

display.

The

Model

350

and

355

IS

will

display

alphanumeric

data,

but

due

to

the

nature

of

7-segment

LEDs/LCD

and

the

limitation

of

six

digits,

some

information

is

abbreviated.

All

segments

and

annunciators

are

illuminated

for

a

brief

display

test

upon

power

up.

The

current

gross

weight

is

then

displayed

in

default

units.

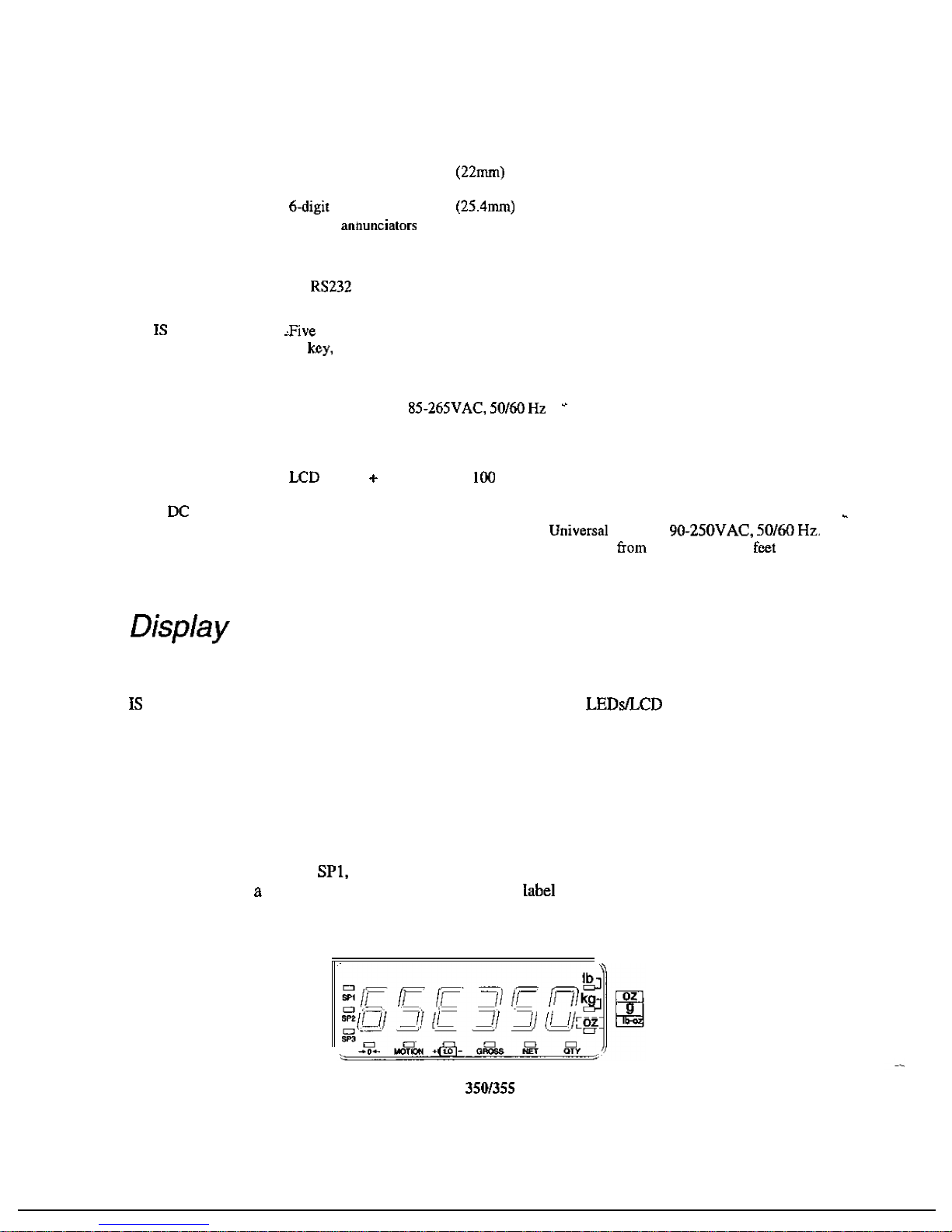

LED

D

ISPLA

Y

The

LED

display

is

a

six

digit, 7-

segment

bright

red

LED

screen

with

12

annunciators

to

show

weight

and

status

information.

The

SP1,

SP2,

and

SP3

annunciators

are

red,

green,

and

yellow.

Also

there

is

an

annunciator

for

a

third unit under

kg.

Place

the

third

unit

label above

the

third annunciator

(the

third

unit

is

available

on

both

the

LED

and

LCD

displays).

See

page

28

for

third

unit

setup.

Figure

1:

Model

3501355

IS

LED

Display

a

Page 16

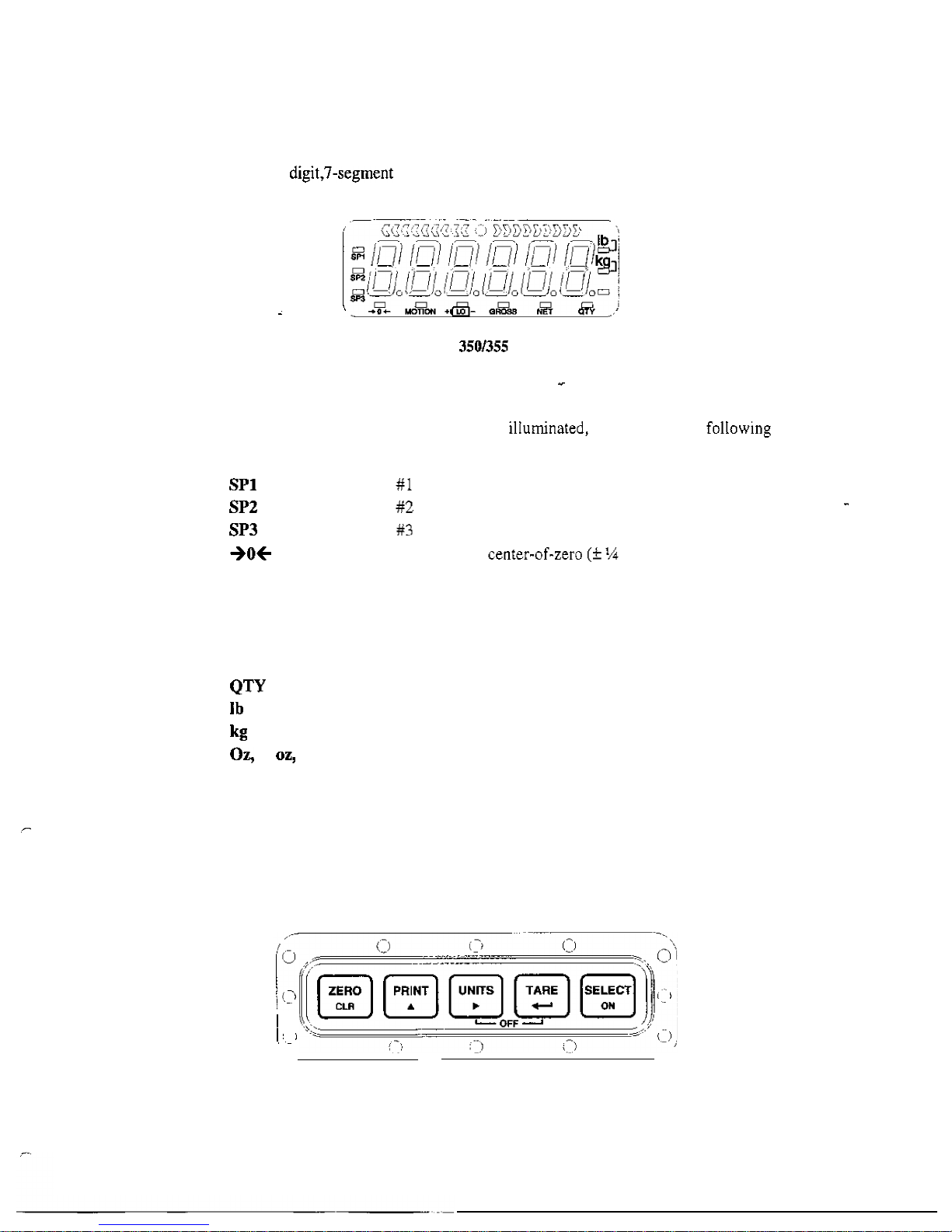

LCD

D

ISPLA

Y

The

LCD

display

is

a

six digit,7-segment

black

LCD

screen

with

12

annunciators

and

a

bargraph

to

show

the

operational

status.

Figure

2:

Model

350/355

IS

LCD

Display

<

A

N

NUNCI

A

T

ORS

Annunciators

provide

mode

and

status

information. When ilIuminated,

they

indicate

the

folIowing

conditions:

SPl

SP2

SP3

+Ot

MOTION

LO

GROSS

NET

QTY

kg

Ib

Ox,

lb

02,

g

350

IS

KEYPAD

Setpoint

#1

activated

(relay

1

closed).

Setpoint

#2

activated (relay 2 closed).

Setpoint

#3

activated (relay 3 closed).

Displayed

weight

is

at

center-of-zero

(5

'/4

display

graduation).

Scale

is

in

motion. Motion inhibited

transmits

and motion inhibited setpoint

activation will

be

delayed

until

motion

ceases.

Lights when

the

battery

reaches a low

tolerance.

Displayed

value

represents

the

current

gross

weight.

Displayed value

represents

the

current net weight.

Displayed

value

represents

the

current

piece

quantity (Count).

The

displayed

value

is

represented

in pounds.

The

displayed value

is

represented in

kilograms.

The

displayed

value

is

represented

in

either

ounces,

pound

ounces

or

grams.

The

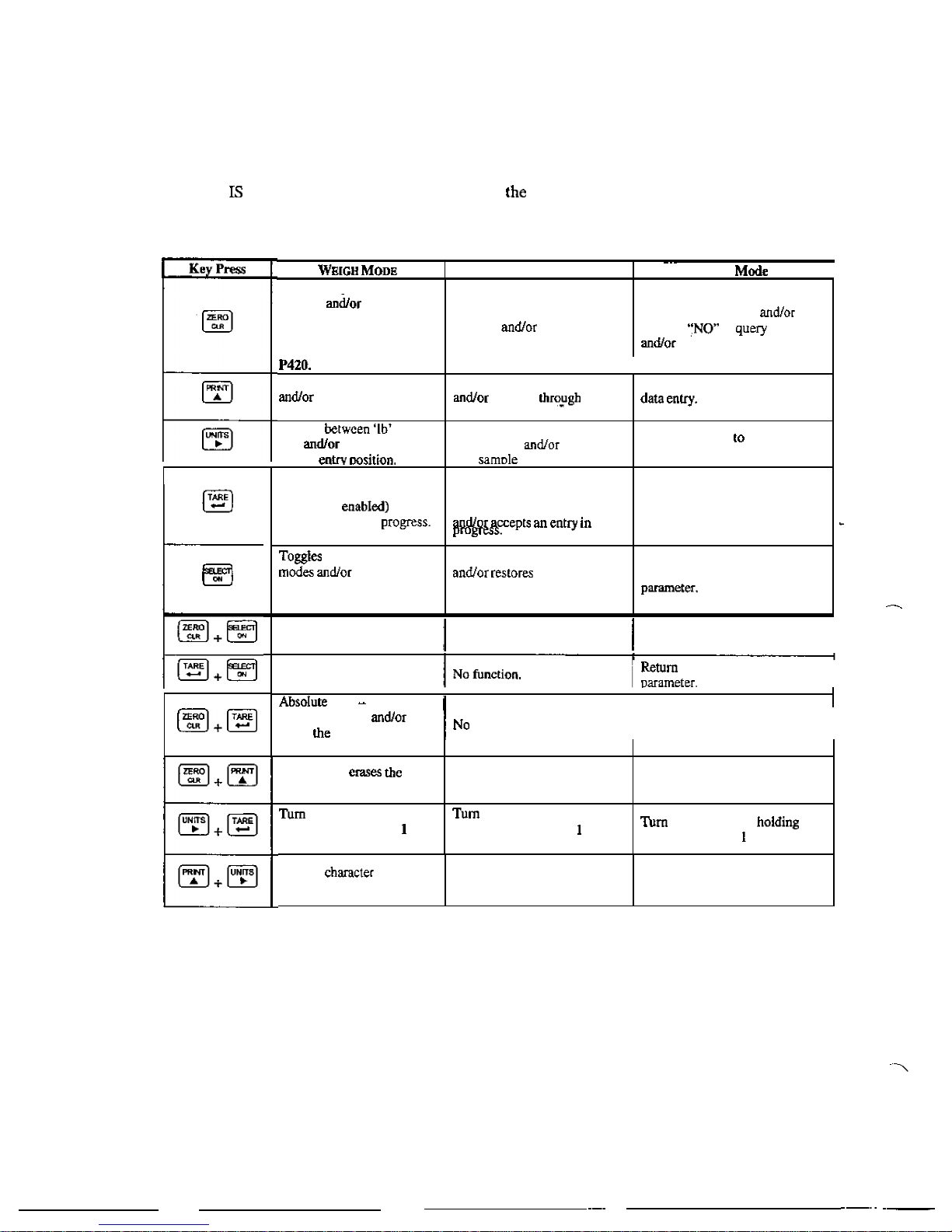

Model

350

IS

offers

a

sealed

5-button

elastomer

keypad

is

used

for

operator

input.

Each

key

is

assigned

two distinct functions.

Various

key

combinations

are

also

used.

Each

key

has

secondary functions; allowing

an

operator

to

enter

target

values,

perform

piece

samples,

access

setup

parameters,

etc.

I

I

Figure

3:

Model

350

IS

Keypad

9

Page 17

S

E

C

O

NDA

R

Y

F

U

NCT

I

ONS

.

-..

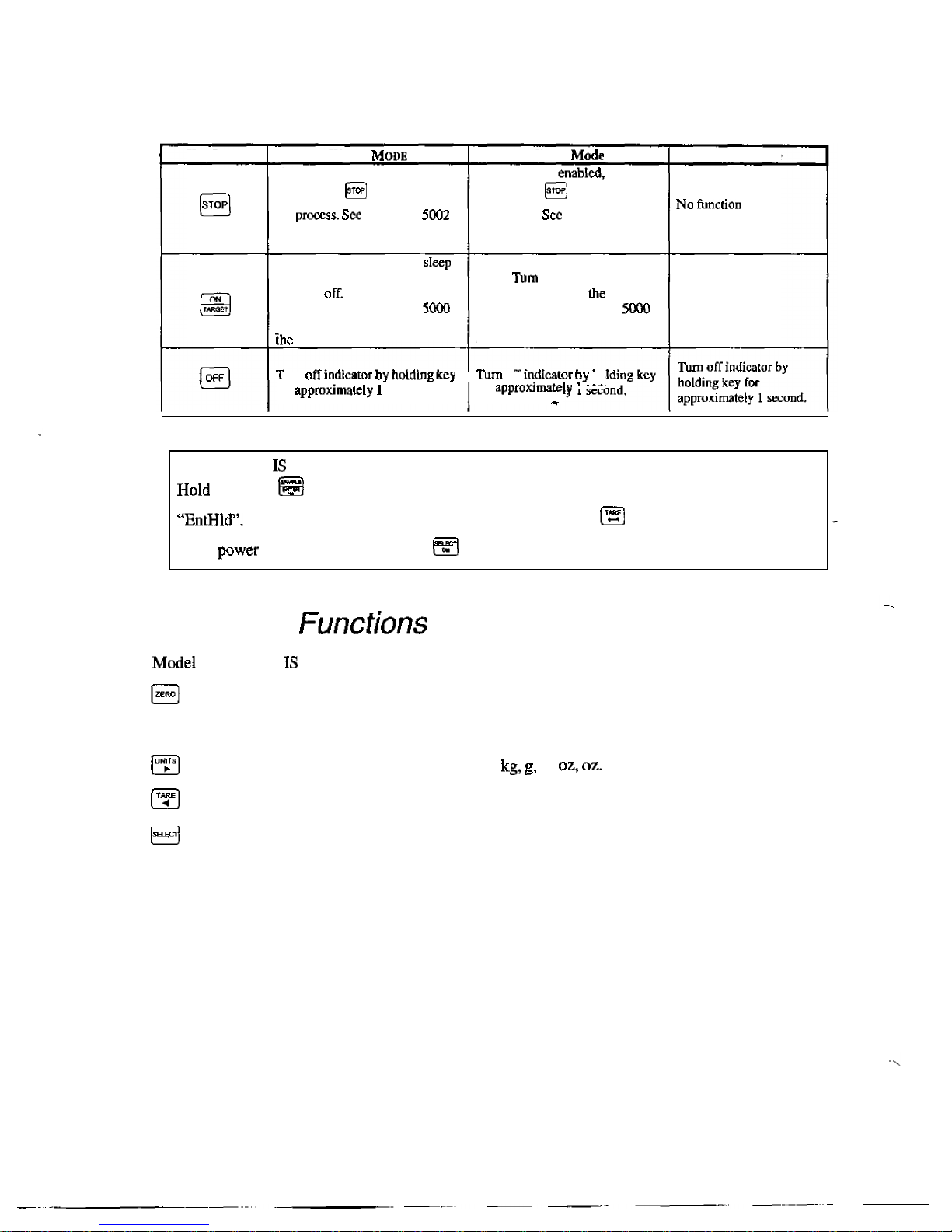

The

Model

350

IS

keypad

performs

different functions

in

the

Weigh

Mode,

the

Setup

Mode,

and

the

Calibration

Mode.

Secondary

functions

for

each

key

allow

you

to

perform

additional

tasks.

Wmn

MODE

Count

Mode

Setup

Mde

function

andlor

clears

an

entry

in

progress.

Hold

this

key

on

power-up

to

turn

on

the

display

regardless

of

Performs

a

quantity

zero

function

andor

clears

an

entry

in

progress.

Exits

the

Setup

Mode

and/or

answers

';NO

to

query

prompts

andor

clears

an

entry in

progress.

P420.

Performs

a

print

function

andor

'scrolls'

through

digits

during

setpoint entry.

Toggles

betwcen

'Ib'

and

'kg'

andor

advances

cursor

to

next

entrv

aosition.

Performs

a

print

function

and/or

'scrolls'

throygh

digits

during

setpoint

entry.

Toggles

through

standard

sample

sizes

andor

begins

a

new

samde

entrv.

data

'Scrolls'

entry.

through

digits

during

Advances

cursor

to

next

entry

position

andor

cycles

prompts.

No

function.

I

Access

Setup

Mode.

1

Access

Setup

Mode.

I

Perform

an

auto-tare

function

(if

enabIed)

andlor

accepts

an

entry

in

progmss.

No

function.

Accepts

an

entry

in

progress

andlor

'scrolls'

through

parameter

sub-sct selections

andlor

answers

'YES'

to

query

prompts.

Performs

an

auto-tare

function

and

requests a piece

sample

andlor

accepts

an

entry

in

P"S.

+

Return

to

the

previous

setup

oarameter.

I

ToggIes

between display

modw

andlor

restores

power

to

the

indicator (if

auto

-

shutoff

enabled).

I

I'

AbsoIute

clear

-

clears

an

1

Toggles

between

display

modes

andor

restores

power

to

the

enabled).

Advances

to

the

next

setup

indicator

(if

auto-shutoff

pXNlIetf3.

1

No

function.

entry

in

progress

and/or

clears

the

value

of

a

parameter.

Backspace

-

erases

thc

right

-

most

digit

during

data

entry.

Clears

any

entry

in

progress.

I

Backspace

-

erases

the

right

-

most digit during sample

entry.

Backspace

-

erases

right-most

digit during data entry.

Turn

off

indicator

by

holding

key

for

approximately

1

second.

Turn

off

indicator

by

holding

key

for

approximately

1

second.

Turn

off

indicator

by

hoIding

key

for

approximately

1

second.

Reverse

character

scroll

during data

entry.

10

.

.-

Reverse

character

scroll

during

sample

entry.

data

entry.

Reverse

character

scroll

during

Page 18

355

Keypad

The

Model

355

IS

keypad

performs

different

functions

in

the

Weigh

Mode,

the Setup

Mode,

and

the

Calibration

Mode.

The

number

keys

make

entering

a

tare

value

or

average

piece

weight

easier.

Key

Prw

-

-

W

E

IGH

M

O

D

E

Performs

a

gross

zero

function

andor

clears

an

entry

in

progress.

Performs

a

print

function

andlor

‘scrolls’

through

digits

during

setpoint entry.

Toggles

between

’Ib’

and

‘kg’

andor

advances

cursor

to

next

entry

position.

Performs

an

auto-tare

function

(if

enabled)

andor

accepts

an

entry

in

progress.

If

the

tare

weight

is

known,

key

in

the

value

and

press

El.

~~

Toggles

between

display

modes

andor

restores

power

to

the

indicator

(if

auto-shutoff

enabled).

Performs

a

sample.

If

a

number

is

keyed

in

kfore

hand,

it

will

be

used

as

the

sample

size.

Accepts

an

entry.

Clears

an

entry in

progress.

Hold

this

key

on

power-up

to

turn

on

the

display

regardla

of

P420.

If

setpoints

are

enabled, causes

a

process

to

start

or

resume.

See

parameter

5003

on

page