Page 1

IQAN-LC5-X05

Instruction book

Publ no HY33-8402-IB/UK

Edition 2016-08-09

Page 2

ii

Contents

Instruction book, IQAN-LC5-X05

Contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

General safety regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Construction regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety during installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety during start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety during maintenance and fault diagnosis . . . . . . . . . . . . . . . . . . . 3

3 Product description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

IQAN-LC5-X05 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

The control lever's parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

The IQAN-LC5-X05 control signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

I/O overview, base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

MP handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The handle's parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

I/O overview, MP handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

IQAN-LC5-X05 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Redundant signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Use of limited signal range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting the unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Handle considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Recommended handle specification . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Environmental specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Handle configuration to fit -U2 bellow . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

IQAN-LC5-X05 connector C1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Connector C1 pin assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

G handle connector, 6 position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Connector, 6 position assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

G handle function for 6 position connector. . . . . . . . . . . . . . . . . . . . . . 13

MP handle connector, 6 position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Connector, 6 position assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

MP handle faceplate button numbering for 6 position . . . . . . . . . . . . . 14

MP handle connector, 12 position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Connector, 12 position assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

MP handle faceplate button numbering for 12 position . . . . . . . . . . . . 15

Connector, 12 position assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MP handle faceplate function numbering for 12 position . . . . . . . . . . . 16

Required connectors, based on model code . . . . . . . . . . . . . . . . . . . . . 17

Supply voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Emergency stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting of supply voltage, expansion module . . . . . . . . . . . . . . . . . 18

Output signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Page 3

iii

Contents

Instruction book, IQAN-LC5-X05

Primary and secondary outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting of IQAN-LC5-X05 outputs . . . . . . . . . . . . . . . . . . . . . . . . . 19

Connecting of -MP handle outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Appendix A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

IQAN-LC5-X05 Technical Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

IQAN-LC5-X05, base and -MP handle . . . . . . . . . . . . . . . . . . . . . . . . . 21

IQAN-LC5-X05, base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

IQAN-LC5-X05, -MP handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Thumbwheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Appendix B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dimensioning of the IQAN-LC5-X05 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Page 4

1

Safety symbols

1 Introduction

Instruction book, IQAN- LC5-X05

1Introduction

These instructions are to be used as a reference tool for the vehicle manufacturer’s

design, production, and service personnel.

The user of these instructions should have basic knowledge in the handling of

electronic equipment.

Safety symbols

Sections regarding safety, marked with a symbol in the left margin, must be read and

understood by everyone using the system, carrying out service work or making changes

to hardware and software.

The different safety levels used in this manual are defined below.

WARNING

Sections labeled WARNING with a caution symbol in the left margin, indicate that a

hazardous situation exists. If precautions are not taken, this could result in death, injury,

or property damage.

NOTICE

Sections labeled NOTICE with a notice symbol in the left margin, indicate there is

important information about the product. Ignoring this could result in less than optimal

performance, or damage to the product.

Contact the manufacturer if there is anything you are not sure about or if you have any

questions regarding the product and its handling or maintenance.

The term "manufacturer" refers to Parker Hannifin Corporation.

Page 5

2

General safety regulations

2 Precautions

Instruction book, IQAN- LC5-X05

2 Precautions

General safety regulations

Work on the hydraulics control electronics may only be carried out by trained

personnel who are well-acquainted with the control system, the machine and its safety

regulations.

WARNING

Mounting, modification, repair and maintenance must be carried out in accordance

with the manufacturer's regulations. The manufacturer has no responsibility for any

accidents caused by incorrectly mounted or incorrectly maintained equipment. The

manufacturer does not assume any responsibility for the system being incorrectly

applied, or the system being programmed in a manner that jeopardizes safety.

WARNING

Damaged product may not be used. If the control system shows error functions or if

electronic modules, cabling or connectors are damaged, the system shall not be used.

WARNING

Electronic control systems in an inappropriate installation and in combination with

strong electromagnetic interference fields can, in extreme cases, cause an unintentional

change of speed of the output function.

NOTICE

As much as possible of the welding work on the chassis should be done before the

installation of the system. If welding has to be done afterwards, the electrical

connections on the system must be disconnected from other equipment. The negative

cable must always be disconnected from the battery before disconnecting the positive

cable. The ground wire of the welder shall be positioned as close as possible to the

place of the welding. The cables on the welding unit shall never be placed near the

electrical wires of the control system.

Construction regulations

WARNING

The vehicle must be equipped with an emergency stop which disconnects the supply

voltage to the control system's electrical units. The emergency stop must be easily

accessible to the operator. The machine must be built if possible, so that the supply

voltage to the control system's electrical units is disconnected when the operator leaves

the operator’s station.

Safety during installation

WARNING

Incorrectly positioned or mounted cabling can be influenced by radio signals which can

interfere with the functions of the system.

Page 6

3

General safety regulations

2 Precautions

Instruction book, IQAN- LC5-X05

Safety during start-up

WARNING

The machine's engine must not be started before the control system is mounted and its

electrical functions have been verified.

Ensure that no one is in front, behind or nearby the machine when first starting up the

machine.

Follow the instructions for function control in the Start-up section.

Safety during maintenance and fault diagnosis

WARNING

Ensure that the following requirements are fulfilled before any work is carried out on

the hydraulics control electronics.

• The machine cannot start moving.

• Functions are positioned safely.

• The machine is turned off.

• The hydraulic system is relieved from any pressure.

• Supply voltage to the control electronics is disconnected.

Page 7

4

IQAN-LC5-X05

3 Product description

Instruction book, IQAN- LC5-X05

3 Product description

IQAN-LC5-X05

IQAN-LC5-X05 is a large, analogue output, coordinate lever.

The analogue joystick replaces ICL4 (fourth generation) levers and therefore is called

IQAN-LC5 (Lever, Coordinate 5th generation). The designation -X05 (X crossed

outputs, 0 - 5 Vdc) represents the analogue output signals. The joystick has dual,

mirrored outputs per axis in the 0-5V range

.

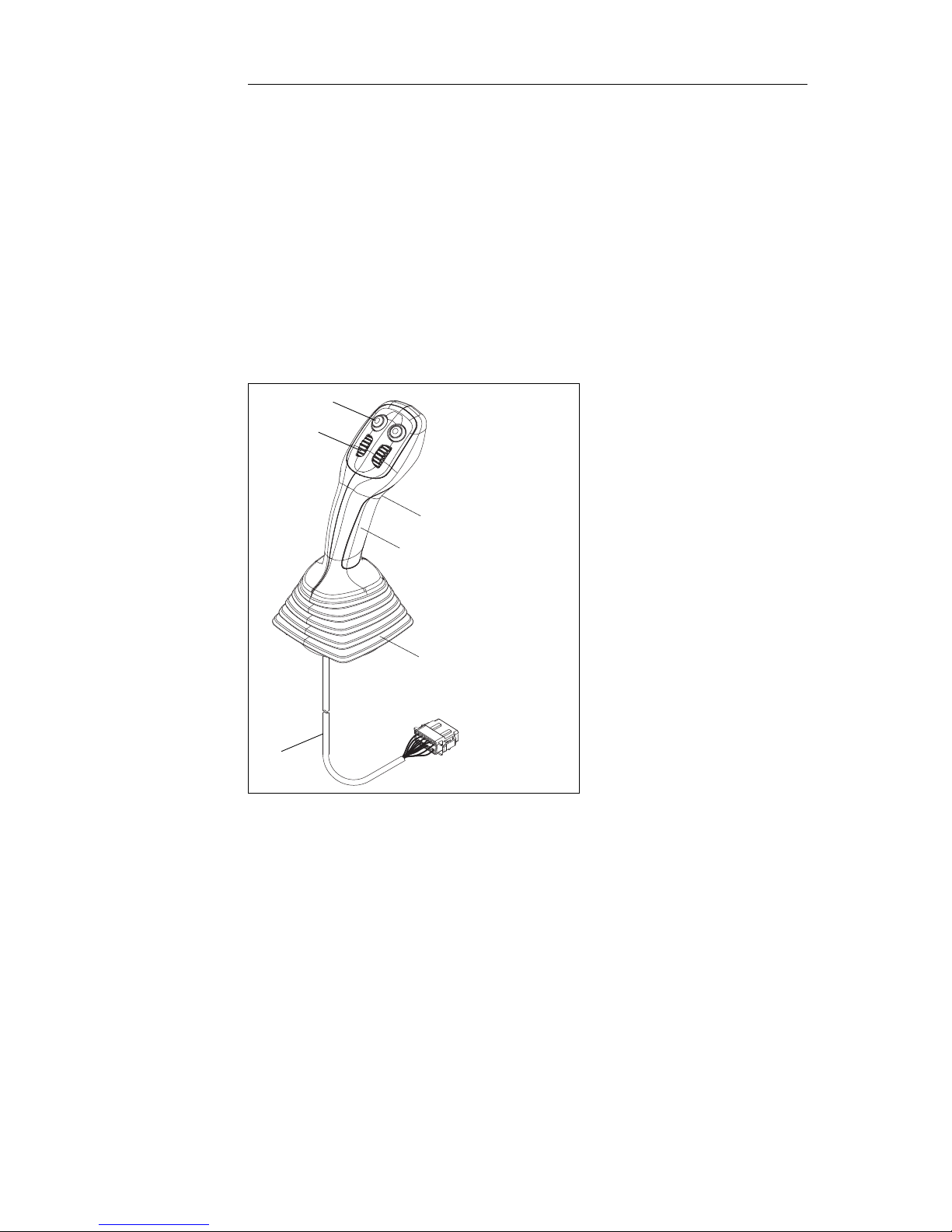

The IQAN-LC5-X05 parts.

The control lever's parts

Control lever -LC5-X05 consists of:

1 Stem, -U2 shown, no handle mounted.

2 Bellows, -U2 shown, no handle mounted.

3 Mounting flange.

4 Lower enclosure.

5 Connector C1 for supply voltage, primary and secondary analogue outputs.

NOTICE

In order to increase the safety of the LC5-X05, the opposing 10%-90% VS and

90%-10% V

S

analogue outputs can be compared e.g. to verify center position.

With a 5 Vdc supply the outputs are typically 0,5-4,5Vdc and 4,5-0,5Vdc

4

3

2

-X05

5

1

Page 8

5

I/O overview, base

3 Product description

Instruction book, IQAN- LC5-X05

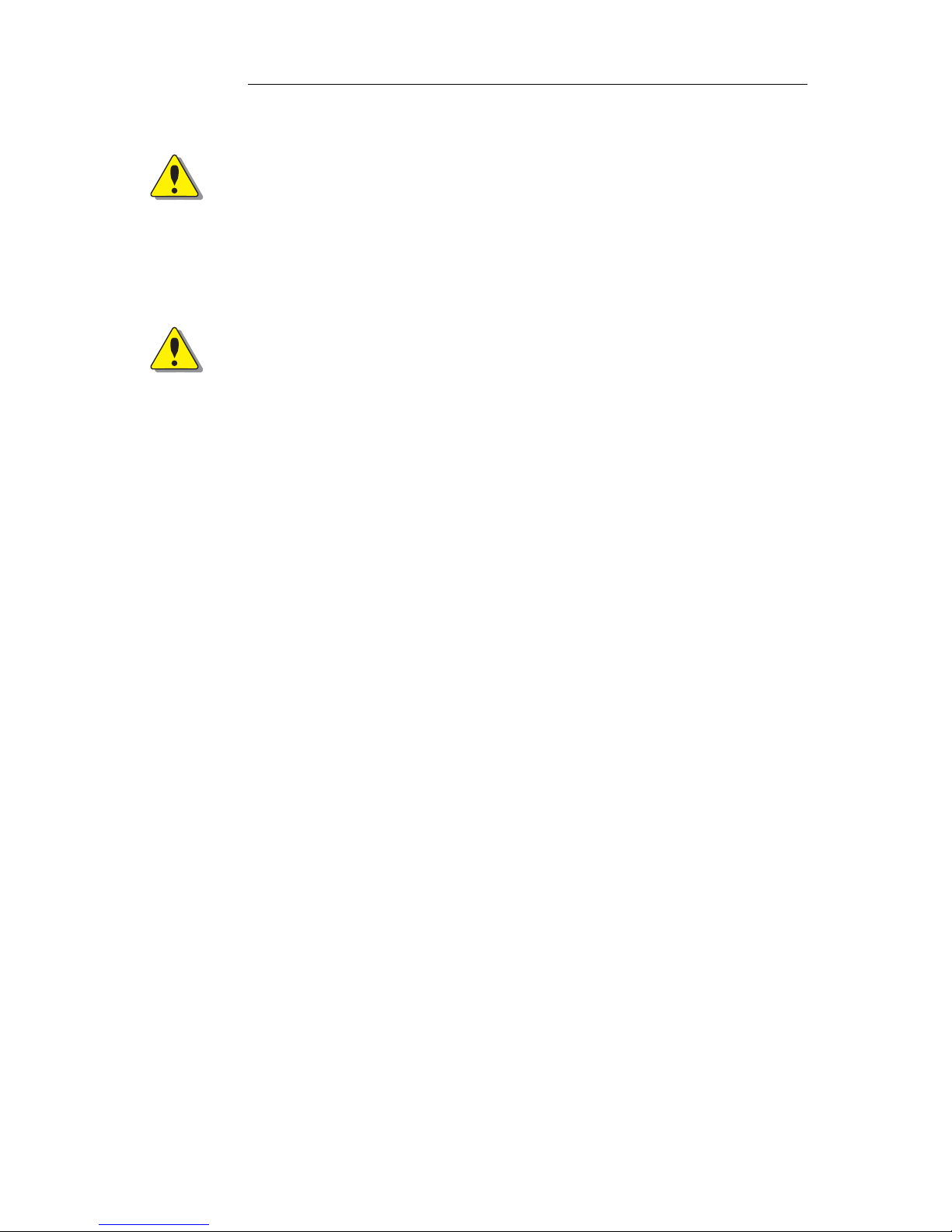

The IQAN-LC5-X05 control signals

The IQAN-LC5 is used to control the object in two directions:

• the lever is moved to the right/left, direction X +/-.

• the lever is moved forward/back, direction Y +/-.

The control signal is proportional to the lever's working range.

The control signal is transferred from the IQAN-LC5-X05 via a cable to the valve

driver electronics (i.e. IQAN-TOC2), an expansion module, or IQAN master unit.

The IQAN-LC5-X05 base has one Deutsch DTM connector, (C1), with 6 positions for

power and analogue output signals.

IQAN-LC5-X05 in a typical system

I/O overview, base

Outputs

The IQAN-LC5-X05 joystick has four (4) analogue outputs for use as command

signals..

IQAN-LC5-X05 outputs per axis.

(2) Primary analogue outputs OUT-XA and OUT-YA, 10%-90% Vs

(2) Secondary analogue outputs OUT-XB and OUT-YB, 90% - 10% Vs

CAN

Local I/O

IQAN-MD4

Expansion units

IQAN-LC5-X05 joysticks

POWER +5Vdc

OUT-YA

OUT-YB

GROUND

LC5

-X05

OUT-XA

OUT-XB

Vdc

out

90% Vs

50% Vs

10% Vs

-100%

100%

Neutral

position

Output A

Output B

Deflection

Page 9

6

MP handle

3 Product description

Instruction book, IQAN- LC5-X05

MP handle

The IQAN-LC5-X05 is designed to be used with the Multi-Purpose (MP) handle. The

MP handle together with a IQAN-LC5-X05 base will have a Deutsch DTM connector

for connection to external device (i.e., vehicle wire harness).

In order to reduce operator fatigue, the MP handle incorporates a hand rest, and is

designed for both left and right-handed use.

To extend operating life the housing is made of a corrosive-free material, and is

specially adapted for moisture drainage to protect the the system electronics. The MP

handle uses a bellow that can be quickly changed to simplify field replacement. The

cable between base and handle is routed directly through the base plate, eliminating the

risk of damage and simplifying field service, while the use of a single circuit board and

Hall effect sensors minimise the number of components and moving parts.

The IQAN-LC5-X05 parts.

The handle's parts

MP handle consists of:

1 Bellows, -MP handle.

2 Handle, -MPB2W2T1 shown, (other configurations are possible).

3 Momentary buttons.

4 Proportional thumbwheel (-MP handle thumbwheel has dual, mirrored outputs).

5 Momentary trigger button.

6 Cable and connector for -MP (6 pos. or 12 pos., depending on handle functions).

3

4

2

6

1

5

Page 10

7

I/O overview, MP handle

3 Product description

Instruction book, IQAN- LC5-X05

I/O overview, MP handle

Outputs

Digital

The IQAN-LC5-X05 MP handle has up to nine (9) digital outputs for use as command

signals..

Analogue

The IQAN-LC5-X05 MP handle has up to four (4) thumbwheel analogue outputs for

use as command signals..

MP handle outputs per thumbwheel.

(8) momentary button outputs B1 thru B8

(1) momentary trigger button outputs T1

(2) Primary analogue outputs OUT-W1A and OUT-W2A, 10%-90% Vs

(2) Secondary analogue outputs OUT-W1B and OUT-W2B, 90% - 10% Vs

POWER +5Vdc

OUT-W2A

OUT-W2B

GROUND

MP

OUT-W1A

OUT-W1B

B1

Bn

Vdc

out

90% Vs

50% Vs

10% Vs

-100%

100%

Neutral

position

Output A

Output B

Deflection

Page 11

8

IQAN-LC5-X05

4 Safety

Instruction book, IQAN- LC5-X05

4Safety

IQAN-LC5-X05

Redundant signals

In order to fulfill high safety demands, the analogue joystick IQAN-LC5-X05 uses dual

outputs per axis. The secondary output is the inverse or "mirror image" of the primary

output. These outputs can be compared in the controller and used to detect faults.

Use of limited signal range

The analogue outputs of the IQAN-LC5-X05 use limited signal range to provide an

additional method for error detection. The operating signal range for primary and

secondary outputs are 10%-90% Vs and 90%-10% Vs respectively. Vs (power supply)

is typically 5Vdc. This allows the controller to detect if a wire is pulled loose (open,

result 0V) or making contact with a powered wire (short, result 5V or greater).

Detecting wiring faults can protect against unintended movement.

WARNING

Risk of injury! Do not use in areas with high magnetic fields.

The IQAN-LC5-X05 is based on hall effect sensors. Exposure to high external

magnetic fields may lead to unwanted activation of the output signals.

For maximum allowed external magnetic field, see Appendix A, on page 21.

Page 12

9

Mounting the unit

5 Mounting

Instruction book, IQAN- LC5-X05

5 Mounting

Mounting the unit

NOTICE

The IQAN-LC5-X05 unit should be mounted according to the following instructions.

Mounting considerations

• The control lever must be built in so that it is protected against direct pressurized

liquid spray (above flange) and excessive mechanical forces.

• The machine manufacturer must consider the need of a protective catch, or similar,

to prevent unintentional working of the lever.

NOTICE

Take careful consideration when positioning the unit.

• Mount the unit so that it is not exposed to external heat, e.g. from the engine or

heater.

• Mount the unit so there is no risk that the harness can be folded, crushed, worn or

damaged in any way.

• Locate the harness so there is no pressure on the connector.

• Use ergonomics. The control lever should be mounted at a height so that there is no

pressure on the driver's arm and shoulders. The IQAN-LC5-X05 and a well

designed handle, such as the MP, combined with moveable arm rests, can provide

good ergonomics.

NOTICE

Do not exceed power supply limits for the joystick base and thumbwheel.

Reversed polarity, or supply voltage dif ferent from recommended operating conditions,

see Appendix A, on page 21, will seriously damage the unit.

Mounting methods

• Control lever IQAN-LC5-X05 must only be mounted using screws through the

flange.

Mounting the IQAN-LC5-X05 with screws.

4x

Page 13

10

Handle considerations

5 Mounting

Instruction book, IQAN- LC5-X05

• Allow sufficient space beneath the unit to provide for unplugging the connector.

Required space for connector.

Please refer to the IQAN-LC5-X05 installation sheet for mounting dimensions.

Handle considerations

Recommended handle specification

In addition to the MP handle, the IQAN-LC5-X05 will accept OEM specified handles.

These handles will need to be adapted to mount on the joystick stem. The maximum

weight of any handle fitted to the IQAN-LC5-X05 combined with its center of gravity

(COG), shall not cause more force than the minimum activation moment. For the

minimum activation force, see Appendix A, on page 29. Any tilting of the lever by

armrest movement or possible machine levelin g or orientation should be taken into

consideration when specifying a suitable handle.

WARNING

Risk of injury! Exceeding the recommended handle specifications could cause

unintended movement of the joystick.

Environmental specification

Any handle used with the IQAN-LC5-X05 should be a sealed type that is rated IP65 for

outdoor use. Additionally, the joystick must always have a bellow installed to ensure

that it will meet the environmental specification for sealing above the flange. When

using a handle from a different manufacturer than Parker, be sure to include a suitable

bellow made of a material that is able to withstand the stresses of outdoor use in mobile

hydraulic machinery.

NOTICE

Failure to use a properly fitted bellow of the correct material will cause the unit to not

meet its environmental specification and may result in damage to the IQAN-LC5-X05

joystick.

75

Page 14

11

Handle considerations

5 Mounting

Instruction book, IQAN- LC5-X05

Handle configuration to fit -U2 bellow

The IQAN-LC5-X05 is offered without a handle, either no bellow (-U1) is supplied, or

a standard bellow with Ø40mm opening is supplied (-U2). A handle of customer design

or from a 3rd party handle manufacturer may use this standard boot if the mounting

bushing is properly designed.

The LC5 handle mount consists of a Ø10mm stem and M12 thread, for dimensions, see

section Dimensioning of the IQAN-LC5-X05, on page 24. To fit the -U2 bellow, a disc

with a groove to hold the top of the bellow needs to be an integral part of the handle

mount.

Disc dimension guidelines for -U2 bellow interface.

Depending on the mount design, the disc may be plastic if desired, however, the

threaded part of the handle mount that is tightened to the LC5 stem should be metal for

strength.

NOTICE

The design shown above is a guideline only!

The customer is responsible for developing a suitable handle interface when mounting

a non-Parker handle to an IQAN-LC5-X05-U2 joystick base.

min Ø 18.0 (2x)

Ø 45±0.3

Ø 55±0.5

THREAD

LENGTH

min 15

Ø 10.1

M12x1.25

+0.2

-0.0

SECTION A-A

A

A

1±0.2

2±0.2

2.5±0.2

6±0.3

CUSTOMER DESIGN

R 1±0.3

Page 15

12

IQAN-LC5-X05 connector C1

6 Installation

Instruction book, IQAN- LC5-X05

6 Installation

IQAN-LC5-X05 connector C1

Connector C1 pin assignments

Connector kit Parker 20072408

Housing Deutsch no. DTM06-6S

C1

Pin type Deutsch no. 1062-20-0222

Wedge type Deutsch no. WM6S

Sealing plug Deutsch no. 0413-204-2005

Recommended

cable

0.75-1 mm

2

(18 AWG)

Symbol Pin No. Function

Power 6 Power supply Vs, +5Vdc

GND 1 Power supply ground, 0Vdc

OUT-XA 2 X primary signal, 10%-90% Vs

OUT-XB 5 X secondary signal, 90%-10% Vs

OUT-YA 3 Y primary signal, 10%-90% Vs

OUT-YB 4 Y secondary signal, 90%-10% Vs

5

4

3

2

1

6

POWER +5Vdc

OUT-YA

OUT-YB

GROUND

LC5

-X05

OUT-XA

OUT-XB

Page 16

13

G handle connector, 6 position

6 Installation

Instruction book, IQAN- LC5-X05

G handle connector, 6 position

Connector, 6 position assignments

G handle function for 6 position connector

G handle proportional rocker.

Connector parts Parker 5035017

Housing Deutsch no. DTM04-6P

C1

Pin type Deutsch no. 1060-20-0222

Wedge type Deutsch no. WM6P

Sealing plug Deutsch no. 0413-204-2005

Supplied on

handle type

G

Symbol Color

G handle

Pin No.

-Vref-B Black 1

OUT-ZA White 2

OUT-ZB Green 3

--

--

+Vref-B Red 6

1

6

POWER +5Vdc

GROUND

G

OUT-Z1

A

OUT-Z1B

Z-axis

Page 17

14

MP handle connector, 6 position

6 Installation

Instruction book, IQAN- LC5-X05

MP handle connector, 6 position

Connector, 6 position assignments

MP handle faceplate button numbering for 6 position

MP button numbering. (Note: legacy N handle 4 button numbering is different).

Connector parts Parker 5035017

Housing Deutsch no. DTM04-6P

C1

Pin type Deutsch no. 1060-20-0222

Wedge type Deutsch no. WM6P

Sealing plug Deutsch no. 0413-204-2005

Supplied on

handle types

MPB0W0T1, MPB2W0T0,

MPB2W0T1, MPB4W0T0

Symbol Color

MPB0W0T1

Pin No.

MPB2W0T0

Pin No.

MPB2W0T1

Pin No.

MPB4W0T0

Pin No.

+Vref-BRed6666

B1Grey 222

B2Green 333

B3 Brown 4

B4 Violet 5

T1 Pink 4 4

16

POWER +5Vdc

to

32 Vdc

MP

B1

Bn

B2W0T0

B2W0T1

B4W0T0

B0W0T1

1

2

2

3

1

4

Page 18

15

MP handle connector, 12 position

6 Installation

Instruction book, IQAN- LC5-X05

MP handle connector, 12 position

Connector, 12 position assignments

MP handle faceplate button numbering for 12 position

MP button numbering. (Note: legacy N handle 4 button numbering is different).

Types with thumbwheels continued in separate table.

Connector parts Parker 5035018

Housing Deutsch no. DTM04-12PA

Pin type Deutsch no. 1060-20-0222

Wedge type Deutsch no. WM12P

Sealing plug Deutsch no. 0413-204-2005

Supplied on

handle types

MPB4W0T1, MPB8W0T0,

MPB8W0T1, MPB2W2T0,

MPB2W2T1, MPB4W1T0,

MPB4W1T1

Symbol Color

MPB4W0T1

Pin No.

MPB8W0T0

Pin No.

MPB8W0T1

Pin No.

+Vref-A Red 12 12 12

B1Grey444

B2Green555

B3 Brown 6 6 6

B4 Violet 8 8 8

B5 Yellow 2 2

B6 Orange 3 3

B7 White 10 10

B8 Blue 11 11

T1 Pink 9 9

6

1

7

12

B4W0T1 B8W0T0

B8W0T1

2

3

1

4

4

5

3

6

2

7

1

8

Page 19

16

MP handle connector, 12 position

6 Installation

Instruction book, IQAN- LC5-X05

Connector, 12 position assignments

MP handle faceplate function numbering for 12 position

MP button and thumbwheel numbering.

Symbol Colour

MPB2W2T0

Pin No.

MPB2W2T1

Pin No.

MPB4W1T0

Pin No.

MPB4W1T1

Pin No.

+Vref-A Red 12 12 12 12

-Vref-ABlack1111

B1Grey4444

B2Green5555

B3 Brown 6 6

B4 Violet 8 8

T1 Pink 9 9

OUT-W1PYellow2222

OUT-W1SOrange3333

OUT-W2P White 10 10

OUT-W2S Blue 11 11

POWER +5Vdc

OUT-W2

A

OUT-W2B

GROUND

MP

OUT-W1

A

OUT-W1B

B1

Bn

Vdc

out

90% Vs

50% Vs

10% Vs

-100%

100%

Neutral

position

Output A

Output B

Deflection

B2W2T0

B2W2T1

B4W1T0

B4W1T1

2

3

1

4

1

2

1

2

1

Page 20

17

MP handle connector, 12 position

6 Installation

Instruction book, IQAN- LC5-X05

Required connectors, based on model code

Model code 20072408 5035017 5035018

IQAN-LC5-X05-U1 X - -

IQAN-LC5-X05-U2 X - -

IQAN-LC5-X05-G X X

IQAN-LC5-X05-MPB0W0T0 X - -

IQAN-LC5-X05-MPB0W0T1 X X -

IQAN-LC5-X05-MPB2W0T0 X X -

IQAN-LC5-X05-MPB2W0T1 X X -

IQAN-LC5-X05-MPB4W0T0 X X -

IQAN-LC5-X05-MPB4W0T1 X - X

IQAN-LC5-X05-MPB8W0T0 X - X

IQAN-LC5-X05-MPB8W0T1 X - X

IQAN-LC5-X05-MPB4W1T0 X - X

IQAN-LC5-X05-MPB4W1T1 X - X

IQAN-LC5-X05-MPB2W2T0 X - X

IQAN-LC5-X05-MPB2W2T1 X - X

Page 21

18

Supply voltage

6 Installation

Instruction book, IQAN- LC5-X05

Supply voltage

WARNING

Before any installation of an IQAN system can take place, make sure the ignition lock

is turned off and the battery is disconnected.

Emergency stop

Make sure an Emergency Stop disconnecting the system power supply, is easily

accessible at any time. The IQAN module and standalone controller instruction books

show how to connect an emergency stop.

Connecting of supply voltage, expansion module

The supply voltage, should be within the operating range, see Appendix A, on page 21 .

Connect the supply voltage to POWER +5Vdc, pin C1:6. The regulated 5Vdc is

supplied from an IQAN module’s +VREF. The ground connection is made from GND

pin C1:1 to the IQAN module’s -VREF.

NOTICE

Maximum load for the VREF position is different between types of IQAN modules.

Refer to the appropriate instruction book.

EXAMPLE

Connecting an IQAN-LC5-X05 to expansion module.

+5 Vdc

GND

IQAN module

+VREF

-VREF

LC5-X05

Page 22

19

Output signals

6 Installation

Instruction book, IQAN- LC5-X05

Output signals

Primary and secondary outputs

The IQAN-LC5-X05 has dual outputs for each axis. The redundant outputs allow the

user to set up controller logic that monitors the integrity of the dual joystick signals.

The secondary signal for each axis is a mirror of the primary signal. Use of the

secondary output is optional and determined by the user’s requirements.

Connecting of IQAN-LC5-X05 outputs

When you connect the IQAN-LC5-X05 joystick to a module or standalone controller,

you may use both OUT-[axis]A and OUT-[axis]B signals from the joystick. The

primary signal for the axis is connected to a VIN, voltage input and the secondary

signal for the axis, if used, is connected to a separate VIN on the controller module.

Connect each primary axis 10%-90% Vs output signal to VIN, and optionally connect

the corresponding secondary axis 90%-10% Vs output signal to another VIN.

WARNING

The previous example is presented with limited information to explain the use of

primary and secondary signals from the IQAN-LC5-X05. Safety considerations such as

the use of an ’operator present’ switch to enable outputs etc. are always recommended.

EXAMPLE

Connecting an IQAN-LC5-X05 to a module.

to valve section controlled

to valve section controlled

OUT-YB(optional)

OUT-XB(optional)

OUT-XA

OUT-YA

by Y axis of joystick

by X axis of joystick

IQAN module

LC5-X05

VIN

VIN

VIN

VIN

Page 23

20

Output signals

6 Installation

Instruction book, IQAN- LC5-X05

Connecting of -MP handle outputs

When you connect the IQAN-LC5-X05 joystick handle functions to a module or

standalone controller you may have proportional outputs from thumbwheels, or on-off

outputs from buttons. For the proportional outputs, you may use both OUT-A and

OUT -B signals from the thumbwheels. The primary signal for the axis is connected to a

VIN, voltage input and the secondary signal for the axis, if used, is connected to a

separate VIN on the controller module.

Connect each primary output 10%-90% Vs output signal to VIN, and optionally

connect the corresponding secondary output 90%-10% Vs output signal to another

VIN.

WARNING

The previous example is presented with limited information to explain the use of

primary and secondary signals from the -MP handle thumbwheels. Safety

considerations such as the use of an ’operator present’ switch to enable outputs etc. are

always recommended.

EXAMPLE

Connecting -MP thumbwheel outputs to a module.

to valve section controlled

to valve section controlled

OUT-W1B (optional)

OUT-W2B (optional)

OUT-W1A

OUT-W2A

by thumbwheel 2 of joystick

by thumbwheel 1 of joystick

IQAN module

MP handle

VIN

VIN

VIN

VIN

Page 24

21

IQAN-LC5-X05 Technical Overview

Appendix A

Instruction book, IQAN-LC5-X05

Appendix A

IQAN-LC5-X05 Technical Overview

IQAN-LC5-X05, base and -MP handle

Absolute Maximum Ratings

a

a.The “Absolute Maximum Ratings” table lists the maximum limits to which the device can be subjected without damage. This doesn´t

imply that the device will function at these extreme conditions, only that, when these conditions are removed and the device operated

within the “Recommended Operating Conditions”, it will still be functional and its useful life won’t have been shortened.

Param eter

Limit values

Unit Remark

min. typ. max.

Ambient temperature, T

A

Storage temperature

– 40

– 40

+85

+100

°C

Maximum over voltage on any pin 8.5 V

External magnetic fields 2.5 mT Risk for exceeding maxi-

mum difference on output

signal from ideal value.

Environmental ratings

Parameter Remark

EMI

ISO 13766/ISO 14982, radiated emission

ISO 11452-4:2005, conducted susceptability

ISO 11452-2:2004, radiated susceptability

ISO 7637-3:2007, conducted transients susceptability

30 - 1000 MHz

1 -200 MHz, 1 KHz, 80%AM, 100 mA

200 -2000 MHz, 1 KHz, 80%AM, 100 V/m

Level 3

ESD

ISO 10605:2001, ESD, operation

ISO 10605:2001, ESD, operation

ISO 10605:2001, ESD, handling

15kV air

8 kV contact

4 kV contact

Mechanical environment

IEC 60068-2-64:1993 Fh, random vibration

IEC 60068-2-29:1987 Eb, bump

15-1000 Hz, 11.6 grms, 3 x10 hours

40g, 6 ms, 1000 x 6 directions

Climate environment

IEC 600529:2001 IP65, (with sealed handle and bellow)

IEC 60068-2-52:1996 Kb, salt mist

IEC 60068-2-30:1985 Db, damp heat, cyclic

IEC 60068-2-78:2001, damp heat, steady state

IEC 60068-2-2:1993-01 Bb, heat, operation

IEC 60068-2-2:1993-01 Bb, heat, storage

IEC 60068-2-1:1993-02 Ab, cold

IEC 60068-2-14:1984 Nb, change of temperature

12.5 l/minute, 3 minutes

72 hours

+55°C, 95% RH, 6 cycles

+40°C, 93% RH, 21 days

+70°C, 72 hours

+100°C, 72 hours

-40°C, 16 hours

-30°C to +85°C, 100 x 4 hours

Page 25

22

IQAN-LC5-X05 Technical Overview

Appendix A

Instruction book, IQAN-LC5-X05

IQAN-LC5-X05, base

System

TA = -40 to +85 °C, unless otherwise specified

Param eter

Limit values

Unit Remark

min. typ. max.

Weight, base unit

Weight, base unit + MP handle

380

750

g

Ambient temperature, T

ROC

– 40 +85 °C recommended operating

Voltage supply, V

S

4.55.05.5V

Current consumption, base only 33 46 mA V

S

= 5.0 V

Electrical characteristics

Param eter

Limit values

Unit Remark

min. typ. max.

Number of VOUT 4 antivalent signals

VOUT, minimum position 400 500 600 mV over life of unit

VOUT, center position 2400 2500 2600 mV over life of unit

VOUT, maximum position 4400 4500 4600 mV over life of unit

VOUT linearity error 300 mV Max difference on output

signal A or B from ideal

VOUT A and B difference 375 mV Max difference between

output signals A/B

VOUT resolution 12 bits =1.22 mV

Response time 6 ms

Load, resistive 4.5 kohm

Load, capacitive 1 µF

Continuous voltage 5.5 V

Protection SCG

Mechanical ratings

Param eter

Limit values

Unit Remark

min. typ. max.

Angle of movement ±18 deg.

Deflection moment, neutral 0.6 Nm

Deflection moment, fully actuated 1.4 Nm

One time loading 100 Nm Exceptional condition

Expected life

5x10

6

cycles One cycle: Neutral to full +

direction to neutral to full direction and back to neutral

Page 26

23

IQAN-LC5-X05 Technical Overview

Appendix A

Instruction book, IQAN-LC5-X05

IQAN-LC5-X05, -MP handle

Thumbwheel

Electrical characteristics

Param eter

Limit values

Unit Remark

min. typ. max.

Number of VOUT 2 antivalent signals

VOUT minimum position 400 500 600 V V

S

= 5.0 V

VOUT center position 2400 2500 2600 V V

S

= 5.0 V

VOUT maximum position 4400 4500 4600 V V

S

= 5.0 V

VOUT linearity error 300 mV Max difference on output

signal A or B from ideal

VOUT A and B difference 375 mV Max difference between

output signal A/B

VOUT resolution 12 bits =1.22 mV

Response time 6 ms

Load, resistive 4.5 kohm

Load, capacitive 1 µF

Continuous voltage 5.5 V

Current supply, per thumbwheel 16 23 mA Vs=5,0V,

Protection SCG

Mechanical ratings

Param eter

Limit values

Unit Remark

min. typ. max.

Angle of movement ±25 deg.

Deflection moment, neutral 10 Nmm

Deflection moment, fully actuated 15 Nmm

Expected life

5x10

6

cycles One cycle: Neutral to full +

direction to neutral to full direction and back to neutral

Buttons

Param eter

Limit values

Unit Remark

min. typ. max.

Max current 400

100

mA 32 VAC, resistive load

50 VDC, resistive load

Total travel 1.5 mm

Switching point 1.2 mm

Expected life

.5x10

6

cycles electrical

Mechanical life

1x10

6

cycles

Operating force 2 5 N activation

Page 27

24

Dimensioning of the IQAN-LC5-X05

Appendix B

Instruction book, IQAN-LC5-X05

Appendix B

Dimensioning of the IQAN-LC5-X05

90

105

105

49

80

Ø 6 (8x)

80

M12 x 1.25

(Ø 108)

Alternative mounting holes

28

10

12

158

unit = mm

stem detail

G handle

Page 28

25

Dimensioning of the IQAN-LC5-X05

Appendix B

Instruction book, IQAN-LC5-X05

101

240

unit = mm

-MP handle

Page 29

For latest information visit our website www.iqan.com

Information in this instructionbook is subject to change without notice

Parker Hannifin

Electronic Controls Division

SE-435 35 Mölnlycke

Sweden

Tel +46 31 750 44 00

Fax +46 31 750 44 21

www.parker.com/ecd

Parker Hannifin

Electronic Controls Division

1651 N. Main Street

Morton, IL 61550

USA

Tel +1 309 266 2200

Fax +1 309 266 6674

Publ no HY33-8402-IB/UK

Edition 2016-08-09

Loading...

Loading...