Page 1

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 1/16

Warning

Implementation of Safety Technical Tests implies the occurrence of high voltages

which may result in severe injuries or death. Only authorized qualified personnel are

permitted to carry out Safety Technical Tests.

Attention

Safety Technical Tests should only be carried out by authorized personnel with

calibrated measuring equipment and simulators.

Description

Manufacturer or supplier

Model

Part no.

Safety analyzer to perform protective earthing-, device leakage

current-, isolation resistance

measurement and high voltage test

EKU Elektronik GmbH,

D-56291 Leiningen

MTP 6000 (or comparable)

Defibrillator/Pacer analyzer

Fluke Biomedical Division,

Everett, WA 98203, U.S.

Impulse 7000 (or comparable)

Multi parameter/ECG simulator

Fluke Biomedical Division

PS420 (or comparable)

Digital multimeter

Fluke Corporation

Series 80V (or comparable)

Digital fine manometer

GREISINGER electronic GmbH,

D-93128 Regenstauf

GMH 3160-07 (or comparable)

Mains charger with magnetic plug,

12 volts DC / 9 amp.

GS Elektromedizinische Geräte

G. Stemple GmbH,

D-86916 Kaufering

04501.120

Test cable set for Safety Technical

Test Patient Box corpuls³

W0029.14100

Test cable set for Safety Technical

Test Defibrillator Unit corpuls³

W0029.24100

Test cable for Safety Technical

Test Display Unit corpuls³ with LAN

W0029.34100

Paddle holder for leakage current

and H/V testing, corpuls³

W0029.031263

Paddle for leakage current and high

voltage testing corpuls³

(2 pcs. required)

W0029.04326

Test cable Safety Technical Test

Charger with magnetic plug

corpuls³

W0029.04501

Safety Technical Test

For legal requirements and periods of Safety Technical Tests see chapter 9.4.1 of

Operators Instruction.

Implementation of Safety Technical Tests is only accepted when carried out according to

both, this test instruction and the Operators Instruction, and at least documented

according to this test report.

Test equipment, adapters and facilities

Page 2

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 2/16

Adapter for leakage current test

Masimo Rainbow® Module

W4212.00002

T-connector cable

04325.09

1

Check of external mechanical intactness of the device

1.1

Check of mechanical intactness. The device must neither have form cracks

nor fractures. In case of damage, present the device to an authorized

national or local GS representative for repair. Swivel the complete device

about 30°. The mechanisms must neither be too rough-running nor

automatically tilting.

1.2

Check covers and fasteners for completeness.

1.3

Check of shock paddles intactness. The paddles must be free from form

cracks in their synthetic material; the helix cable, the electrode plates and

the safety electrodes must be free of any damage; rubber caps of the

buttons must be available and undamaged, labels must be available. The

connector must easily and surely be lockable with the therapy cable. The

electrode surfaces should be free of gel leftovers and other contamination.

1.4

Check of attached cables and sensors. Check cleading of cables and

sensors for insulating damage; if necessary remove paste-on labels

installed by the operator. Continued use of broken cables and sensors is

forbidden.

1.5

Check printer assembly, lid and locking mechanism. The printer lid should

easily release and lock.

1.6

Check of labels, warning and safety instruction plates for completeness and

readability. Check of type plates for readability. Note the serial numbers of

each single component to be tested in the test report sheet.

1.7

Check interlocking mechanisms between the single components. Therefore

unlock and relock the components. The interlocking mechanism must be

free of damage.

1.8

Check the magnetic connector contact panels of the of the single

components for damage and pollution. Clean the panels if necessary.

1.9

Shaking test. Shake each of the single components to detect loose parts

inside.

Warning

Do not open the device! Inner parts may be under high voltage. Disregarding may

cause severe injuries or death! In case of defect contact your authorized national or

local GS representative for inspection and potential repair.

Test instruction for Safety Technical Test

Page 3

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 3/16

2

Protection against electrical shock hazard

Attention

During following measurements, all single components must be separated from

electrical power supply (power supply pack). Take the batteries out of the single

components!

Attention

Performance of both the leakage current measuring of application parts (item 2.6)

and the high voltage test (item 2.7) requires the application of the specified GSspecific adapters and facilities. Using other adapters and facilities may result in

device damage and termination of warranty rights!

2.1

Check of protective earthing of the external power supply pack (IEC

62353:2007, item 5.3.2.2, image 1, protection class I). Connect the mains

plug to the safety tester and measure with the probe at the minus pole of

the corpuls magnet connector using the test cable P/N W0029.04501 to

activate the switch inside the male connector. Testing current must be not

less than 200 mA and must not exceed a limit of 10 A. This step must not

be done for power supplies with part number 04500.1202 and 04501.1201.

2.2

Measuring of device leakage current of external power supply pack (IEC

62353:2007, item 5.3.3.2.3, image 4, protection class I) (direct

measurement).

2.3

Measuring of insulation resistance of the external power supply pack (IEC

62353:2007, item 5.3.4, image 9). Testing voltage 500 V (DC).

2.4

Measuring of line resistance between potential equalization plug and minus

pins of power contact field of the Defibrillator Unit (by using a Hirschmann

clip or an alligator clip). Remove cover if required. Testing current must be

not less than 200 mA and must not exceed a limit of 10 A. The potential

equalization plug may be covert by a plastic cover.

2.5

Measuring of line resistance between safety electrodes of connected shock

paddles and potential equalization plug by using a resistance measuring

gauge. Testing current must not exceed a limit of 1 A.

2.6

Measuring of leakage current of application parts (IEC 62353:2007, item

5.3.3.3.1, image 6, protection class I). Application parts at which is not

currently measured, must be grounded (to the potential equalization plug of

the Defibrillator Unit or to minus contact of the corpuls magnet connector of

the Patient Box). Measure between:

2.6.1

High voltage output of therapy cable/therapy socket with connected

shock paddles and potential equalization plug (connect the shock

paddles to the therapy cable/therapy socket and put on the adapter

P/N w0029.031263).

2.6.2

High voltage output of therapy cable/therapy socket with connected

T-connector cable (P/N 04325.09) and potential equalization plug.

The measuring is only required if internal shock electrodes (shock

spoons) are applied.

2.6.3

High voltage output of test signal connector and potential

equalization plug.

Page 4

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 4/16

2.6.4

Short-wired test contact pins of the paddle trays and potential

equalization plug (if the test contact pins were replaced by

accessory bags Part no. 04322.50 and 04322.51, the original

condition must be restored for the time of measurement).

2.6.5

ECG inputs (4-pole and 6-pole connected) and minus contact of the

corpuls magnet connector of the Patient Box.

2.6.6

SpO

2

input and minus contact of the corpuls magnet connector of

the Patient Box.

2.6.7

CO

2

input and minus contact of the corpuls magnet connector of the

Patient Box.

2.6.8

Input Temp1 and minus contact of the corpuls magnet connector of

the Patient Box.

2.6.9

Input Temp2 and minus contact of the corpuls magnet connector of

the Patient Box.

2.6.10

Input IBP1 and minus contact of the corpuls magnet connector of

the Patient Box.

2.6.11

Input IBP2 and minus contact of the corpuls magnet connector of

the Patient Box.

2.6.12

CPR input and minus contact of the corpuls magnet connector of

the Patient Box.

2.6.13

LAN connector and minus contact of the corpuls magnet connector

of the Display Unit.

2.7

High voltage test of application parts (IEC 60601-2-4:2002, item 20, image

107). Application parts at which is not currently measured, must be

grounded (to the potential equalization plug of the Defibrillator Unit or to

minus contact of the corpuls magnet connector of the Patient Box). Set the

current limiter of the high voltage generator to 500 µA. No high voltage

flashover must appear; no release of the current limiter. Apply 5 kV (DC) for

30 sec each between:

2.7.1

High voltage output of therapy cable/therapy socket with connected

shock paddles and potential equalization plug (connect the shock

paddles to the therapy cable and put on the adapter P/N

w0029.031263).

2.7.2

High voltage output of test signal connector and potential

equalization plug.

2.7.3

Short-wired test contact pins of the paddle trays and potential

equalization plug (if the test contact pins were replaced by

accessory bags Part no. 04322.50 and 04322.51, the original

condition must be restored for the time of measurement).

2.7.4

ECG inputs (4-pole and 6-pole connected) and minus contact of the

corpuls magnet connector of the Patient Box.

2.7.5

SpO

2

input and minus contact of the corpuls magnet connector of

the Patient Box.

2.7.6

CO

2

input and minus contact of the corpuls magnet connector of the

Patient Box.

2.7.7

Input Temp1 and minus contact of the corpuls magnet connector of

the Patient Box.

2.7.8

Input Temp2 and minus contact of the corpuls magnet connector of

the Patient Box.

Page 5

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 5/16

2.7.9

Input IBP1 and minus contact of the corpuls magnet connector of

the Patient Box.

2.7.10

Input IBP2 and minus contact of the corpuls magnet connector of

the Patient Box.

2.7.11

CPR input and minus contact of the corpuls magnet connector of

the Patient Box.

2.7.12

LAN connector and minus contact of the corpuls magnet connector

of the Display Unit.

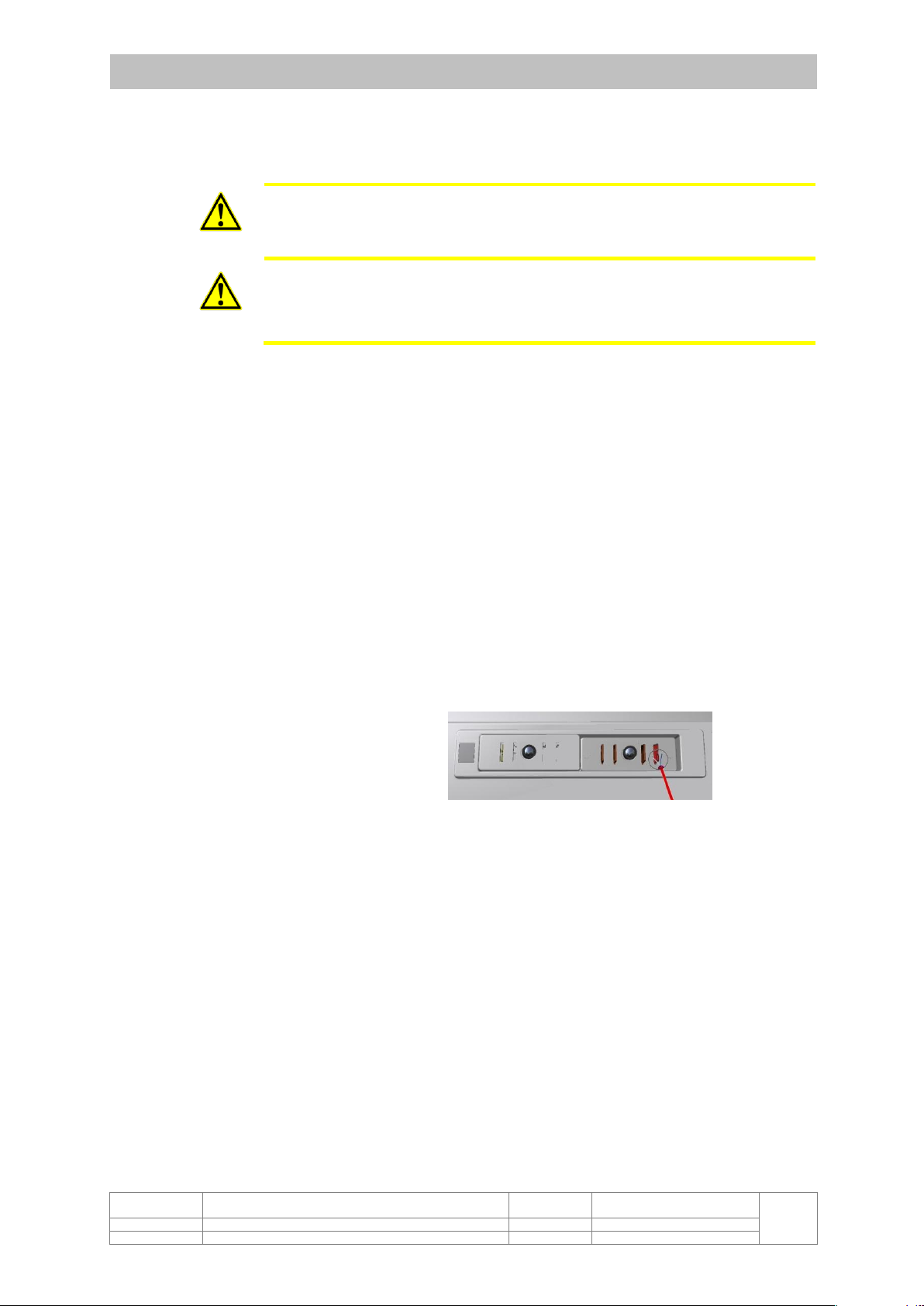

3

General functions (charging, network connection)

For all following checks reinstall the batteries to the single components. The

single components will automatically switch on. Shutdown the single components

by operating the PWR on/off buttons and reassemble them to a compact device.

3.1

Switch on the compact device by operating the PWR button of the Display

Unit. Wait for boot-up (approx. 20 sec) then check network status.

3.2

Separate Defibrillator Unit, and then separate Patient Box from Display Unit

(modular mode). Check network status.

3.3

Check network status on the LCD of Patient Box.

3.4

Connect power supply pack to corpuls magnet connector of Defibrillator

Unit. Check charging control lamp of Defibrillator Unit.

3.5

Connect power supply pack to corpuls magnet connector of Patient Box.

Check charging control lamp of Patient Box.

3.6

Reassemble Patient Box with Display Unit (semi-modular mode). Check

charging control lamp of Display Unit.

3.7

Connect power supply pack to corpuls magnet connector of the Display

Unit. Check charging control lamp of Display Unit.

3.8

Reassemble all single components to a compact device; connect power

supply pack to corpuls magnet connector of Defibrillator Unit. Check

charging control lamp of Display Unit.

4

Device function Display Unit

For following tests operate the device in modular mode.

4.1

Check acoustics and keyboard of the Display Unit. Push every button of the

keyboard. The speaker must answer with a tone.

4.2

Check printer functionality. Select menu item “Test page“.

4.3

Check alarm and printer stop in case of lack of paper. Remove paper reel

and start printer operation.

4.4

Check visual alarm indication. In case of an alarm, the alarm lamp in the

jogdial must light up.

4.5

Check GSM function. Install SIM and establish a connection to a fax

recipient. Transmit a diagnosis ECG to the fax recipient.

4.6

Check the Health Insurance Card Reader. Insert an applicable card into the

card reader slot; patient’s data must appear on the screen.

4.7

Check the LAN function. Compare the MAC address of the device with the

papers of the device. Connect the device to a DHCP server. Dial the

assigned IP address of the device using the ping networking utility.

Page 6

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 6/16

5

Device function Patient Box

For following tests operate the device in modular mode.

5.1

ECG Monitoring

5.1.1

Connect the 4-pole ECG cable to an ECG simulator and to the

Patient Box. Select a sinus waveform and call-up the function

„Resting ECG“ at the Display Unit. The derivations I, II, III, aVR,

aVL and aVF must appear.

5.1.2

Connect a 6-pole ECG cable additionally to the ECG simulator and

to the Patient Box. The derivations V1 up to V6 must appear as

well.

5.1.3

Check alarm function “ECG electrode off”. Disconnect each single

wire from simulator and check the alarm. The alarm may fail to

appear if the black wire is disconnected.

5.1.4

Operate the button at the Patient Box as often until the LCD of

the Patient Box indicates the heart rate.

5.2

Pulse oximeter

5.2.1

Depending on the Masimo Rainbow® SET/Masimo® SET module,

connect the appropriate SpO2 /SpCO/SpHb/SpMet finger sensors to

the Patient Box. Apply the sensor to a proband. The parameters

listed below must be indicated on the Display Unit (curves or vital

parameter view boxes must be configured if necessary):

- the arterial oxygen saturation SpO2 (>90 %),

- the peripheral pulse rate PP,

- the perfusion index PI,

- the plethysmogram,

- the carboxyhemoglobin concentration SpCO (< 10%),

- the hemoglobin SpHb (10-17 g/dl),

- the methemoglobin concentration SpMet (< 3%)

Note: Reading of SpHb value takes about 2 ½ minutes.

5.2.2

Check alarm functions “SpO2

sensor off” and “SpO2 cable off”. First

pull out the finger from the sensor, and then after release of the

alarm, pull the cable out from the Patient Box.

5.3

Capnometer

5.3.1

Fix an airway adapter to the CO2 sensor, then connect the CO2

sensor to the Patient Box. Breathe through the airway adapter. The

parameters listed below must be indicated on the Display Unit

(curves or vital parameter view boxes must be configured if

necessary):

- the CO2 partial pressure,

- the respiratory rate,

- the capnogram.

5.3.2

Check alarm function “CO2

apnoea” and “CO2 cable off”. First,

discontinue breathing through the airway adapter, and then after

release of the alarm, pull the cable out from the Patient Box.

5.4

Temperature measurement

Page 7

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 7/16

5.4.1

Connect a temperature sensor to the Patient Box. The ambient

temperature must be indicated on the Display Unit (vital parameter

view boxes must be configured if necessary). Retake the test with

the 2

nd

temperature input.

5.4.2

Check alarm “Sensor T

(x)

off”. Therefore, pull the temperature

sensor out from the respective temperature socket.

5.5

Non-invasive blood pressure measurement

Connect a cuff to the Patient Box and measure the blood pressure of a

proband. The measuring cycle shall be passed completely and the values

of systolic, diastolic and mean effective arterial pressure must be indicated

on the Display Unit (one vital parameter view box must be configured if

necessary).

5.6

Invasive blood pressure measurement

5.6.1

Connect an invasive blood pressure simulator via an adapter cable

to the Patient Box. Set atmospherical pressure and calibrate

channel P

(x)

. Turn to an arterial pressure progression. The values of

systolic, diastolic and mean effective arterial pressure (max.

tolerance of ± 2 mmHg) as well as the pressure curve must be

indicated on the Display Unit (curves or vital parameter view boxes

must be configured if necessary). Retake the test with the three

remaining pressure channels.

5.6.2

Check alarm function “IBP sensor P

(x)

off”. Therefore, pull the

adapter cable out from the respective input or pull the sensor cable

out from the intermediate adapter cable.

5.7

Audiovisual CPR Feedback

5.7.1

Connect a CPR sensor to the Patient Box. Move the CPR sensor

up and down with a frequency of about 100 min-1. Vary the swivel

altitude of sensor. The parameters as listed below must be

indicated on the Display Unit (curves or vital parameter view boxes

must be configured if necessary):

- the compression rate (CPR rate),

- course of curve of the actual thorax compression.

5.7.2

Check alarm function “CPR sensor loose”. Therefore, remove the

sensor from the plugged CPR cable and, after release of the alarm,

reconnect the sensor.

Check alarm function “CPR cable loose”. Therefore, pull the CPR

cable out from the Patient Box.

5.8

Data recording

Insert CompactFlash™ memory card to the slot of the Patient Box and start

a new mission. Alternatively, the record can be started at the beginning of

the functional test. Using the Operation Browser check the mission is

recorded.

Page 8

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 8/16

6

Device function Defibrillator/Pacer

For the following tests, operate the device in modular mode. The battery of the

Defibrillator Unit must be charged sufficiently for the following tests. If the device

is operated w/o shock paddles, shock paddles must be provided for the following

tests.

6.1

Function of defibrillator (IEC 60601-2-4:2003, 50)

6.1.1

Check ECG derivation of the Defibrillator/Pacer Unit. Therefore,

connect the shock paddle electrodes/the therapy cable/the therapy

socket to the defibrillator tester. Set up the analyzer to a sinus wave

rhythm of 60 min-1 and check the indication at the Display Unit.

6.1.2

Check output of test signal at the contact pins of the shock paddle

trays. Therefore, insert the shock paddles to the trays (if the test

contact pins were replaced by accessory bags Part no. 04322.50

and 04322.51, the original condition must be restored for the time of

test).

6.1.3

Functional test of the discharging resistors of the shock paddle

trays. Insert the shock paddles to the trays and release a shock

with maximum energy (if the test contact pins are replaced by

accessory bags Part no. 04322.50 and 04322.51, the original

condition must be restored for the time of test).

6.1.4

Check output of test signal at the test contacts of the cable base.

Therefore plug the therapy cable into the test contact connector of

the cable base.

6.1.5

Functional test of the discharging resistors of the cable base test

contacts. Plug the therapy cable into the test contact connector of

the cable base and release a shock with maximum energy.

6.1.6

Functional test of impedance measuring. Apply the shock paddles

to the test pads of a Defibrillator/Pacer analyzer with an impedance

of 50 Ω. If no shock paddles are used, perform this test using the Tconnector cable P/N 04325.09.

6.1.7

Test of energy output. Set advised energy level, charge, and

release the shock immediately after reaching shock readiness

asynchronously to the defibrillator tester. Release three shocks of

each energy level and note the highest value.

6.1.8

Check of energy output of the baby shock electrodes. Place the

baby shock electrodes at the adult shock paddles according to

Operators Instruction. Release one shock with maximum energy

level and note the value.

6.1.9

Check synchronous defibrillation. Supply a sinus rhythm of the

simulator of the defibrillator tester and release a shock. Note the

delay time.

6.2

Function of pacer

6.2.1

Connect a terminating resistor of 700 Ω to the therapy cable using

the T-connector cable P/N 04325.09. Call up the pacemaker

function and set the parameters as advised below:

- Mode FIX,

- Intensity 30 mA,

- Frequency 150 min-1.

Measure the preset parameters and note the results.

6.2.2

Increase intensity to 150 mA and note the output current.

Page 9

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 9/16

6.2.3

Increase the terminating resistor to 1000 Ω and note the output

current.

6.2.4

Short the electric circuit. The alarm “Short circuit“ must appear on

the Display Unit.

6.2.5

Disconnect the electric circuit. The alarm “Circuit open“ must

appear on the Display Unit.

7

Device function charging brackets

7.1

Check available charging brackets for mechanical intactness. Perform a

visual inspection of connector plugs and cables of charging brackets with

power supply.

7.2

Check operational capability of interlocking mechanisms of the brackets.

Therefore insert the single components (Display Unit, Patient Box,

Defibrillator Unit) to the brackets, then lock and unlock them.

7.3

Check power supply of the charging brackets (only charging brackets with

available power connector). Insert the single components to the brackets,

connect the brackets to the 12 volts power supply and check the charging

lamps of the single components.

Page 10

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 10/16

8

Leak tightness test of the pressure system and measuring accuracy test of

indication

For Metrological Control of the non-invasive blood pressure module the

device under test must be connected to a calibrated pressure gauge, to a

hand pump with nonreturn valve and release valve, further to a testing

volume (inelastic metal tank of 1 liter volume) by using a four-way

connector. Alternatively, a blood pressure simulator can be used. All tests

require operation in calibration mode (Call up via menu items „NIBP“

„Test“). The calibration mode is automatically left after 3 minutes.

8.1

Generate a pressure of approx. 200 mmHg by using the hand pump. Run a

pressure compensation sequence of approx. 30 seconds. Memorize the

indicated value. After a delay of 60 seconds, read the indicated value;

calculate and note the difference.

8.2

Successively generate the pressures 250 mmHg, 200 mmHg, 150 mmHg,

100 mmHg and 50 mmHg by using the hand pump. Wait a few seconds

each for pressure compensation. Note values indicated on both, pressure

gauge and device under test.

9

Measuring accuracy test of indication

9.1

Successively plug test jack connectors with calibrated resistors in

temperature socket Temp1 and note the indicated value. Alternatively, a

temperature simulator can be used.

9.2

Repeat this sequence for socket Temp2.

Metrological Controls

For legal requirements and periods of Metrological Controls see chapter 9.4.2 of

Operators Instruction. Alternative legal regulation of other countries provided.

Implementation of Metrological Controls is only accepted when carried out according to

both this test instruction and the Operators Instruction, and at least documented

according to this test report.

Instruction of Metrological Control of function Non-invasive

Blood Pressure Measurement (NIBP)

Instruction of Metrological Control of function Temperature

measuring

Page 11

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 11/16

Operator

Ambulance service/hospital

Nr, street

City code

City

Accessories:

Battery S/N

4-pole ECG cable

CO2 sensor

Battery S/N

6-pole ECG cable

Temperature probe(s)

Battery S/N

SpO2 sensor

Mounting Defibrillator Unit

Shock paddles

SpO2/SpCO/SpMet sensor

Mounting Monitor Unit

Baby shock electrodes

SpO2/SpHb/SpMet sensor

Mounting Patient Box

Pos

Test description

required result

realized result

passed

failed

1

Check of external mechanical intactness of the device

1.1

Check of mechanical intactness,

swivel mechanism

no damages,

30° swiveling

1.2

Covers and fastening parts

complete

1.3

Shock paddles

undamaged

1.4

Cables and sensors

undamaged

1.5

Printer (locking mechanism)

fully functional

1.6

Labels, safety instruction plates,

type plates

complete,

legibly

1.7

Locking mechanism between the

single modules

fully functional

1.8

Magnetic plug connector

undamaged

unpolluted

1.9

Shaking test

no loose parts

Single module

Serial nr

Inventory nr

Software

Display Unit

Patient Box

Defibrillator Unit

Power supply

Nr of test report

Test report of Safety Technical Test corpuls

³

Delete items where inapplicable!

Page 12

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 12/16

Pos

Test description

required result

realized result

passed

failed

2

Protection against electrical shock hazard

2.1

Check of protective earthing of pwr supply

< 0.3 Ω

__________Ω

2.2

Device leakage current of power supply

< 500 µA S.F.C.

__________µA

2.3

Isolation resistance of power supply

> 70 MΩ

__________MΩ

2.4

Protective conductor potential

equalization Ground contact

Defibrillator Unit

< 0.1 Ω

__________Ω

2.5

Resistance of safety electrodes

< 0.6 Ω

__________Ω

2.6

Leakage currents between device ground (potential equalization) and following application parts:

2.6.1

– Therapy cable with shock paddles (BF)

< 500 µA S.F.C.

__________µA

2.6.2

– Therapy cable/therapy socket (CF)

< 100 µA S.F.C.

__________µA

2.6.3

– Test signal output (BF)

< 500 µA S.F.C.

__________µA

2.6.4

– Test contact pins (BF)

< 500 µA S.F.C.

__________µA

2.6.5

– ECG inputs (4-pole + 6-pole) (CF)

< 50 µA S.F.C.

__________µA

2.6.6

– SpO2 input (BF)

< 500 µA S.F.C.

__________µA

2.6.7

– CO2 input (BF)

< 500 µA S.F.C.

__________µA

2.6.8

– Input Temp1 (BF)

< 500 µA S.F.C.

__________µA

2.6.9

– Input Temp2 (BF)

< 500 µA S.F.C.

__________µA

2.6.10

– Input IBP1 (CF)

< 50 µA S.F.C.

__________µA

2.6.11

– Input IBP2 (CF)

< 50 µA S.F.C.

__________µA

2.6.12

– CPR input (BF)

< 500 µA S.F.C.

__________µA

2.6.13

– LAN connector

< 500 µA S.F.C.

__________µA

2.7

High voltage test 5 kV (30 sec) between device ground (potential equalization) and:

2.7.1

– Therapy cable/therapy socket

no flashover

2.7.2

– Test signal output

no flashover

2.7.3

– Test contact pins

no flashover

2.7.4

– ECG inputs (4-pole + 6-pole)

no flashover

2.7.5

– SpO2 input

no flashover

2.7.6

– CO2 input

no flashover

2.7.7

– Input Temp1

no flashover

2.7.8

– Input Temp2

no flashover

2.7.9

– Input IBP1

no flashover

2.7.10

– Input IBP2

no flashover

2.7.11

– CPR input

no flashover

2.7.12

– LAN female connector

no flashover

3

General functions (Charging, network connection)

3.1

IrDA network connection as compact

device

Indication Display

Page 13

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 13/16

Pos

Test description

required result

realized result

passed

failed

3.2

Radio network connection in modular

mode

Indication Display

3.3

Radio network connection in modular

mode

Indication Patient

Box

3.4

Power supply connected to Defibrillator

Unit (modular mode)

Charging indicator

Defibrillator Unit

on

3.5

Power supply connected to Patient Box

Charging indicator

Patient Box on

3.6

Power supply connected to Patient Box

Charging indicator

Display Unit on

3.7

Power supply connected to Display Unit

Charging indicator

Display Unit on

3.8

Power supply connected to Defibrillator

Unit (compact device)

Charging indicator

Display Unit on

4

Device function Display Unit

4.1

Acoustics/keyboard

Sound audible

4.2

Test printout

Total printing span

readable

4.3

Paper deficiency function

Printer stops,

alarm appears

4.4

Visual alarm indication

Alarm lamp on

4.5

GSM function

Fax transmission

successful

4.6

Function of Health Insurance Card

Reader

Data appear on

the screen

4.7

LAN function

MAC address

LAN connection is

established

5

Device function Patient Box

5.1

ECG Monitoring

5.1.1

Resting ECG with 4-pole ECG cable

Derivations I, II,

III, aVR, aVL, aVF

5.1.2

Resting ECG with 4+6-pole ECG cables

Derivations

V1 to V6

5.1.3

Alarm „ECG Electrode off“

Practicable with

each wire

5.1.4

Indication Patient Box

Heart rate

5.2

Pulse oximeter

5.2.1

Indication Display Unit

SpO2 value

Pulse rate

PI value

Plethysmogram

Page 14

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 14/16

Pos

Test description

required result

realized result

passed

failed

SpCO value

SpHb value

SpMet value

5.2.2

Alarms

SpO2 Sensor off

SpO2 cable off

5.3

Capnometer

5.3.1

Indication Display Unit

CO2 partial

pressure

Respiratory rate

Capnogram

5.3.2

Alarms

CO2 Apnoea

CO2 cable off

5.4

Temperature measuring

5.4.1

Indication of room ambient temperature

Indication T1

Indication T2

5.4.2

Alarm „Sensor T

(x)

off“

Sensor T1 off

Sensor T2 off

5.5

Not invasive blood pressure measuring

realistic results

5.6

Invasive blood pressure measuring

5.6.1

Values and pressure curve

Channel P1

Channel P2

Channel P3

Channel P4

5.6.2

Alarm „IBP Sensor P

(x)

off“

Sensor P1 off

Sensor P2 off

Sensor P3 off

Sensor P4 off

5.7

CPR Feedback

5.7.1

Indication Display Unit

CPR curve

CPR rate

5.7.2

Alarms

CPR sensor loose

CPR cable loose

5.8

Data recording on CompactFlash™ card

Data available

6

Device function Defibrillator Unit

6.1

Function of defibrillator

6.1.1

Heart rate

59…61 min

-1

__________min-1

Page 15

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 15/16

Pos

Test description

required result

realized result

passed

failed

6.1.2

Test signal via shock paddles mounting

differentiated

rectangular signal

6.1.3

Discharging resistors of shock paddles

mounting

Shock released

6.1.4

Test signal via test contacts cable base

differentiated

rectangular signal

6.1.5

Discharging resistors of test contacts

cable base

Shock released

6.1.6

Impedance measuring

Indication OOKO

6.1.7

Energy output

20 J (16…24 J)

__________J

100 J (90…110 J)

__________J

200 J (180…220 J)

__________J

6.1.8

Energy output baby shock electrodes

20 J (18…22 J)

__________J

6.1.9

Delay synchronous defibrillation

< 35 msec

__________msec

6.2

Pacer function

6.2.1

Rate

148…152 min

-1

__________min-1

Impulse width

22.4…23.5 msec

__________msec

Output current (30 mA @ 700 Ω)

27…33 mA

__________mA

6.2.2

Output current (150 mA @ 700 Ω)

143…157 mA

__________mA

6.2.3

Output current (150 mA @ 1000 Ω)

143…157 mA

__________mA

6.2.4

Alarm „Pacer short circuit“

Alarm appears

6.2.5

Alarm „Pacer circuit open“

Alarm appears

7

Device function charging mountings

7.1

Check of mechanical intactness

undamaged

7.2

Interlocking mechanisms

fully functional

7.3

Power conveyance

Charging indicator

on

8

Metrological Control of non-invasive blood pressure measuring module

(valid to:____________)

8.1

Tightness of pressure system

Difference

< 6 mmHg

_________mmHg

8.2

Accuracy of indication

- 250 mmHg (± 3 mmHg)

- 200 mmHg (± 3 mmHg)

- 150 mmHg (± 3 mmHg)

- 100 mmHg (± 3 mmHg)

- 50 mmHg (± 3 mmHg)

Indication

Display

_________mmHg

_________mmHg

_________mmHg

_________mmHg

_________mmHg

Indication

pressure gauge

_________mmHg

_________mmHg

_________mmHg

_________mmHg

_________mmHg

Page 16

Document name

and location:

S:\Reparaturen\STK_Protokolle\STK_c³_with_test_instruction

_EN.docx

Release

identification:

Software version 2.1.0

Creation date:

2013-05-07

Release date:

2013-05-15

Originator name:

Carsten Fuchs

Release name:

Udo Franke

corpuls

³

Safety Technical Test, Test instruction and test report 16/16

9

Metrological Control of temperature module

(valid to:____________)

9.1

Input Temp1

- 24 °C or 30 °C or ________°C

- 37 °C

- 40 °C or 42 °C or ________°C

± 0.1 K

Indication Display

__________°C

__________°C

__________°C

9.2

Input Temp2

- 24 °C or 30 °C or ________°C

- 37 °C

- 40 °C or 42 °C or ________°C

± 0.1 K

Indication Display

__________°C

__________°C

__________°C

Result of Safety Technical Test

Device is free of defects.

Slight defects which should be

occasionally fixed by an

authorized service

representative:

- _______________________

- _______________________

- _______________________

Serious safety-related

deficiencies which forbid any

continued operation. The

device must be repaired by an

authorized service

representative before restart of

operation.

Appointed date for next Safety Technical Test:

____________________________

The Safety Technical Test has been carried out by

(Name of the examiner):

____________________________

Date:

____________________________

Signature:

____________________________

Name and address of the responsible company (company stamp)

Loading...

Loading...