ITALIAN DESIGN

INSTALLATION, COMMISSIONING, USE AND MAINTENANCE MANUAL

Wall-mounted boiler with plate heat exchanger

Monothermal

A brand by G20 ENGINEERING

IVY 24/28/32 KW MR/MN

MONOTHERMAL BOILER MANUAL

VERS. 11/2017 - REV.3

CONTENTS

General requirements 2

-General Information 2

Use and operation 3

-Description of the boiler 3

-Components 3

-Ignition 4

-Interface description 4

-“Stand-by” main menu 5

-Function main menu 6

-Season selection main menu 7

-Temperature regulation 7

-Information menu 8

-Operation with room thermostat 9

-Operation with external sensor 9

-Faults 10

-Fault codes table 11

Installation 12

-Operational diagram 12

-Three-way boiler functional diagram 12

-Wiring diagram 13

-Graphs for the head available to the system 14

-Installation 14

-Fastening the boiler to the wall 15

-Layout of connections 16

-Plumbing the boiler 17

-Connecting CH lling cock 17

-Filling the system 17

-Connection to the gas supply 18

-Connection to the electrical system 19

-Combustion gas evacuation and air intake system:

compatible applications 20

-Combustion gas evacuation and air intake system:

installation 21

-Checking the effectiveness of combustion

gas evacuation 23

-Combustion gas evacuation circuit diaphragms 23

-Combustion gas evacuation system: warnings 24

Adjustment and maintenance 25

-Preliminary maintenance operations 25

-General maintenance operations 25

-SERVICE function 25

-Power adjustment 27

-Gas pressure check 28

-Checking the pressure at the burner 28

-Checking mains gas supply dynamic pressure 29

-Checking pressure at burner at max power 30

-Changing gas type 30

-Conguring the software for a change gas type 31

-Access to conguration menu 32

-Installer menu 33

-Information menu 34

-Room Thermostat/Opentherm installation 35

-Installation of external temperature sensor 36

-External temperature sensor conguration 36

-Conguring the climate curve 37

-Special functions 38

-Thermostat post ventilation function 39

-Technical Data Sheet 40

GENERAL INFORMATION

This manual, supplied with every boiler, should be

considered as an integral component as it contains

instructions for the correct, safe and appropriate

installation, use and maintenance of the system.

The manual must always be kept by the user of

the boiler and made available for the installation

and/or maintenance technicians to consult. It must

also accompany the boiler if it should be moved

or otherwise transferred.

The manufacturer shall not be held responsible

for any damage caused by failure to follow the

instructions contained in this manual, nor:

If the boiler is used for purposes other than those

for which it was built

If any part or circuit of the boiler is modied

If accessories or kits not approved by the

manufacturer are installed

If ordinary and extraordinary maintenance is not

performed by qualied personnel

If applicable technical and legal requirements

have not been observed during installation and

maintenance of the boiler.

WARNING!

If the boiler should cease to function or not function

correctly, deactivate it immediately by turning it off

and then shutting off the gas supply. Do not attempt

any repairs or direct work on the boiler.

Only personnel with the necessary qualications

and licenses must perform maintenance on the

boiler. Any repairs must be performed using only

original parts and accessories.

SYMBOLS USED IN THE MANUAL

Advice, suggestion, note

Important communications, signaling

of modes and operations which could

compromise the correct operation

of the boiler and endanger people.

EC CONFORMITY DECLARATION (ACCORDING TO ISO/IEC 17050-1)

GENERAL REQUIREMENTS

G20 Engineering srl estabilished in Loc. Campogrande, 13 - Carpaneto Piacentino whose processes of design,

manufacturing and after-sales service are in compliance with requirements of UNI EN ISO 9001:2008 - DECLARES

that THEA boilers are in compliance with European Directives and with European Delegates regulations.

Chief Executive Marco Rapaccioli

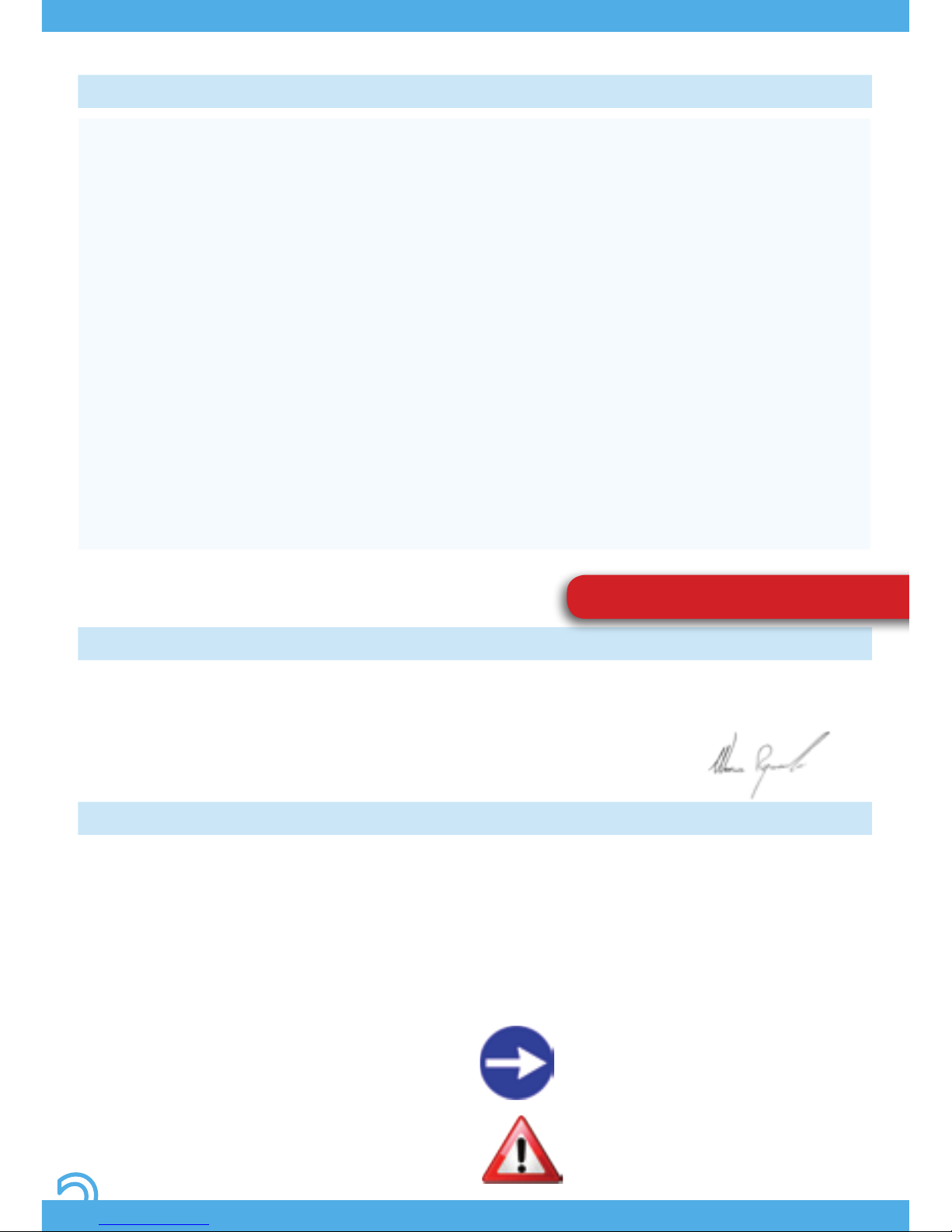

DESCRIPTION OF THE BOILER

COMPONENTS

The Ivy range of boilers represents the best

appliances available for domestic central

heating and hot water production. Their

essential but extremely modern and

elegant lines, compact size, solidity,

performance, reliability and safety place

Ivy boilers in the category of appliances

which are indispensable in every home. In

creating the Ivy range of boilers we chose

to design a system which could satisfy a

wide range of needs, able to adapt itself

to any situation and thus enlarging its

eld of application. Models ranging from

24 to 32 kW power output are indeed

available. The exibility of the Ivy range of

boilers is also increased by the possibility

to congure the management program

of the microprocessor tted to the system.

This allows to pass from a reduced number

of functions and configurations which

make using the device easy, immediate

and effective to a complete conguration

with many specic options enabled as

well as the possibility to interface with

external control and regulation devices.

Ivy MR (whit rapid heat exchanger)

1) FUME EXTRACTOR

2) SAFETY THERMOSTAT

5) HEATING SENSOR

7) BURNER

8) IGNITION MONOELECTRODE

9) EARTH ELECTRODE

10) PRESSURE GAUGE

11) CIRCULATOR UNIT

12) DHW PRIORITY VALVE

13) PRESSURE SENSOR (TRANSMITTER)

14) SAFETY VALVE

15) GAS VALVE

16) EXPANSION TANK

17) COMBUSTION GAS PRESSURE SWITCH

18) PRIMARY HEAT EXCHANGER

19) IMMERSION DHW SENSOR

20) THREE-WAYS GROUP

21) SECONDARY HEAT EXCHANGER

Pic. 1

Pic. 2

USE AND OPERATION

152

63748

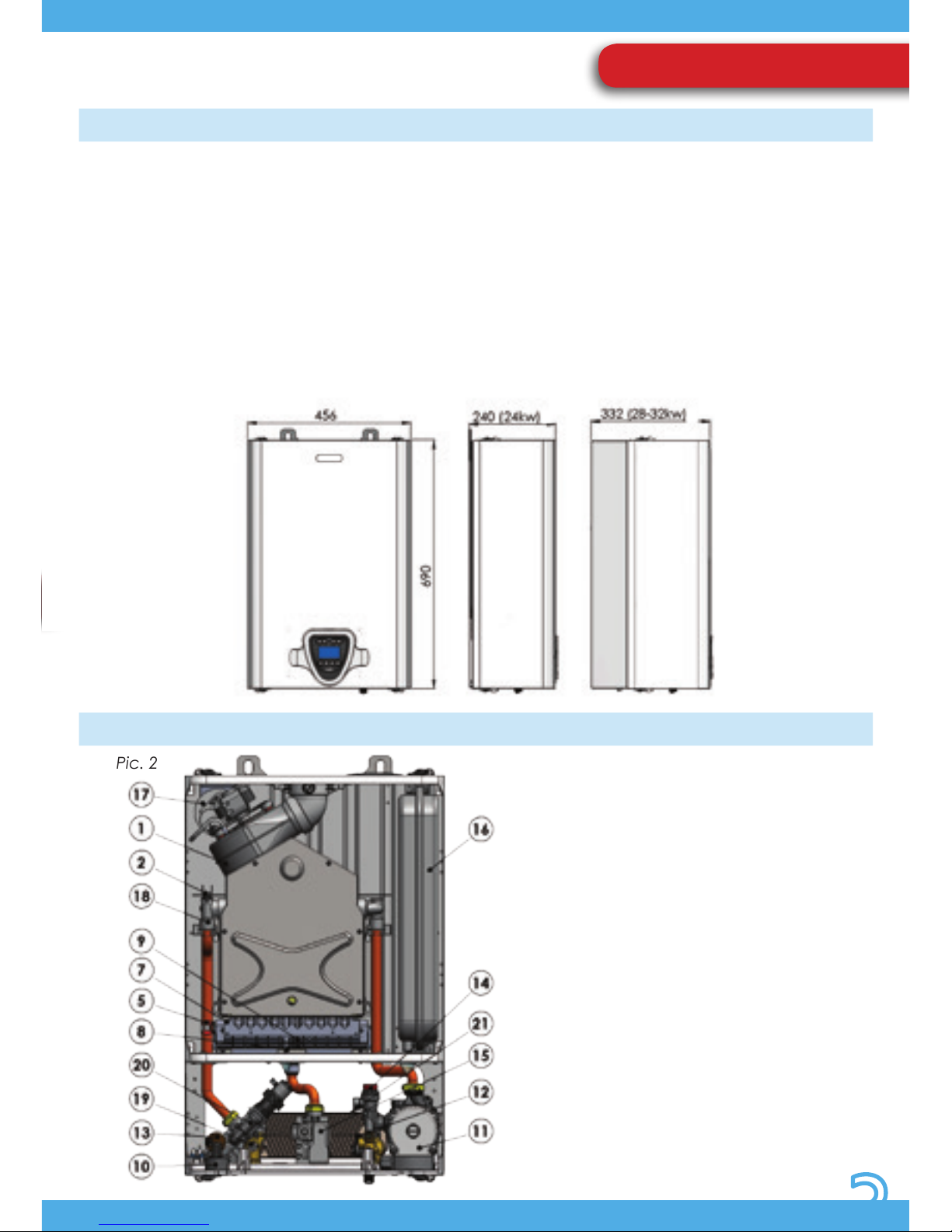

INTERFACE DESCRIPTION

IGNITION

Turn on the boiler’s electrical supply at the

switch, which must be installed on the power

supply line to the boiler. The LCD display (with

blue backlight) will turn on immediately,

showing the two-digit software version

number loaded on the microprocessor for

a few seconds, while an automatic check is

performed on the conditions of the system

and installed devices. When this stage

has nished, if no faults are detected, the

last page of the MAIN menu to be stored

is displayed on the LCD (the one being

displayed when the power was turned off).

The interface allowing all operating parameters to

be selected and modied as well as their relative

values to be displayed is extremely simple. It is

composed of a large backlit LCD which displays all

symbols necessary for communicating the boiler’s

status in a simple and immediate way, together

with a series of BUTTONS each one having a specic

function shown on the display.

Read the relevant chapters for more information

about the symbols and the available operation

modes.

IVY MN (Heat only)

1) FUME EXTRACTOR

2) SAFETY THERMOSTAT

5) HEATING SENSOR

7) BURNER

8) IGNITION MONOELECTRODE

9) EARTH ELECTRODE

10) PRESSURE GAUGE

11) CIRCULATOR UNIT

13) PRESSURE SENSOR (TRANSDUCER)

14) SAFETY VALVE

15) GAS VALVE

16) EXPANSION TANK

17) COMBUSTION GAS PRESSURE SWITCH

18) PRIMARY HEAT EXCHANGER

Pic. 3

1. ON/OFF BUTTON

2. SUMMER/WINTER BUTTON

3. RESET BUTTON

4. INFO/CONFIGURATION BUTTON

5. DHW TEMPERATURE DECREASE

6. DHW TEMPERATURE INCREASE

7. CH TEMPERATURE DECREASE

8. CH TEMPERATURE INCREASE

Pic. 4

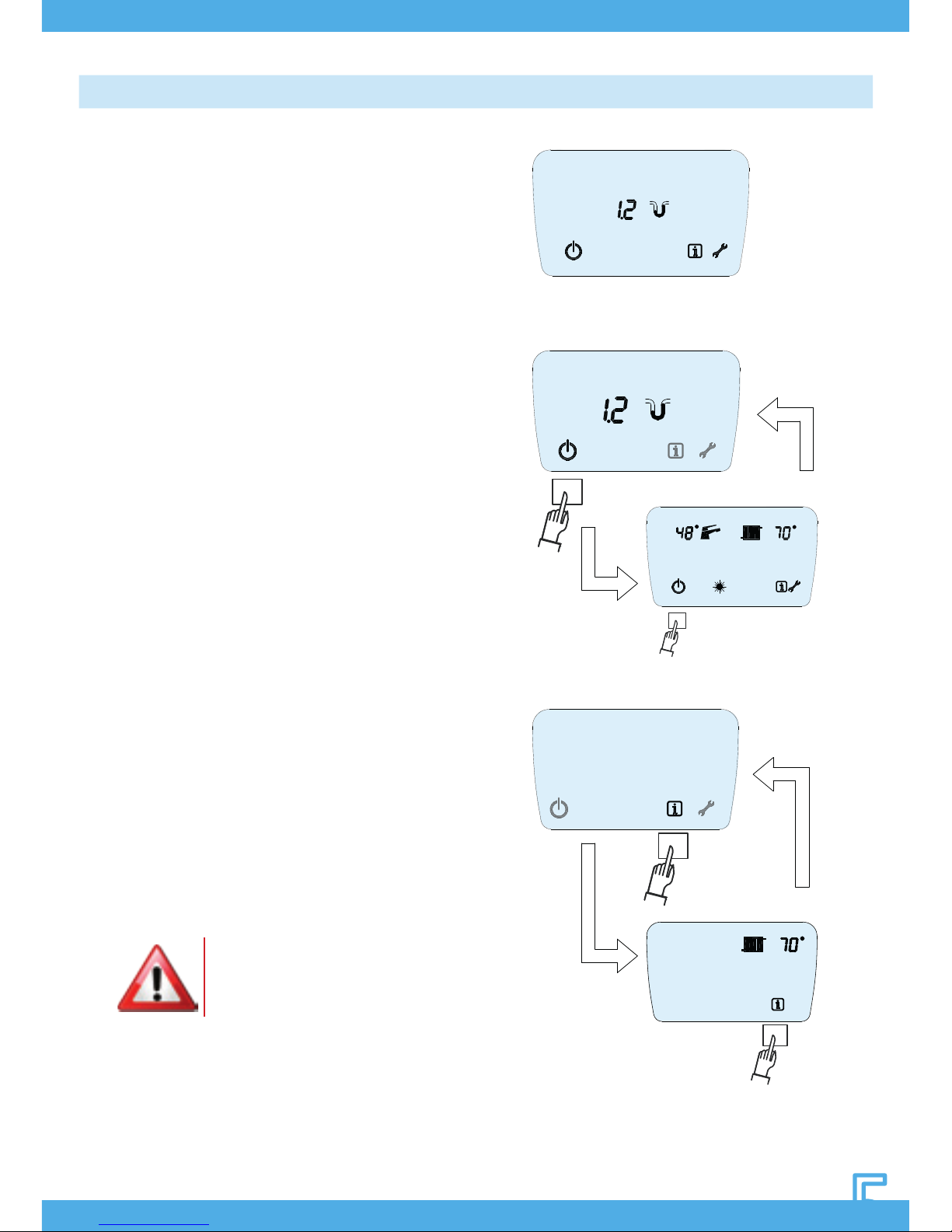

“STAND-BY” MAIN MENU

When the boiler is turned on, two operating

modes are possible. These constitute the

MAIN MENU from which it is possible to set

any operating mode required or view the

boiler status at any time. The characteristics

of the possible options for each page of the

MAIN MENU are here listed:

Page 1 – STAND-BY (Pic. 5.1)

In this mode the device is powered but all

functions regarding the supply of domestic

hot water or central heating are inactive. In

this mode the central heating system pressure

is displayed (in boilers with transducer) and

it is possible to turn the boiler on by pressing

BUTTON 1, at the MAIN MENU page :

In order to go back to the rst page (standby), press again BUTTON 1. (Pic. 5.2)

By pressing BUTTON 4, the INFORMATION

MENU can be accessed; by pressing BUTTON

4 again, the rst page is displayed (Pict. 5.3).

Read the relevant chapters for more

information about the functions in each

menu: “FUNCTION, PARAMETERS MENU”

While in the stand-by mode, all fault

indication modes remain active as do the

main maintenance functions for the diverter

valve (when tted) and the circulator unit

together with the ANTI-FROST function.

Pic. 5.1

Pic. 5.2

Pic. 5.3

WARNING: In standby/off

mode the boiler is inactive

but its electricity supply is still

connected!

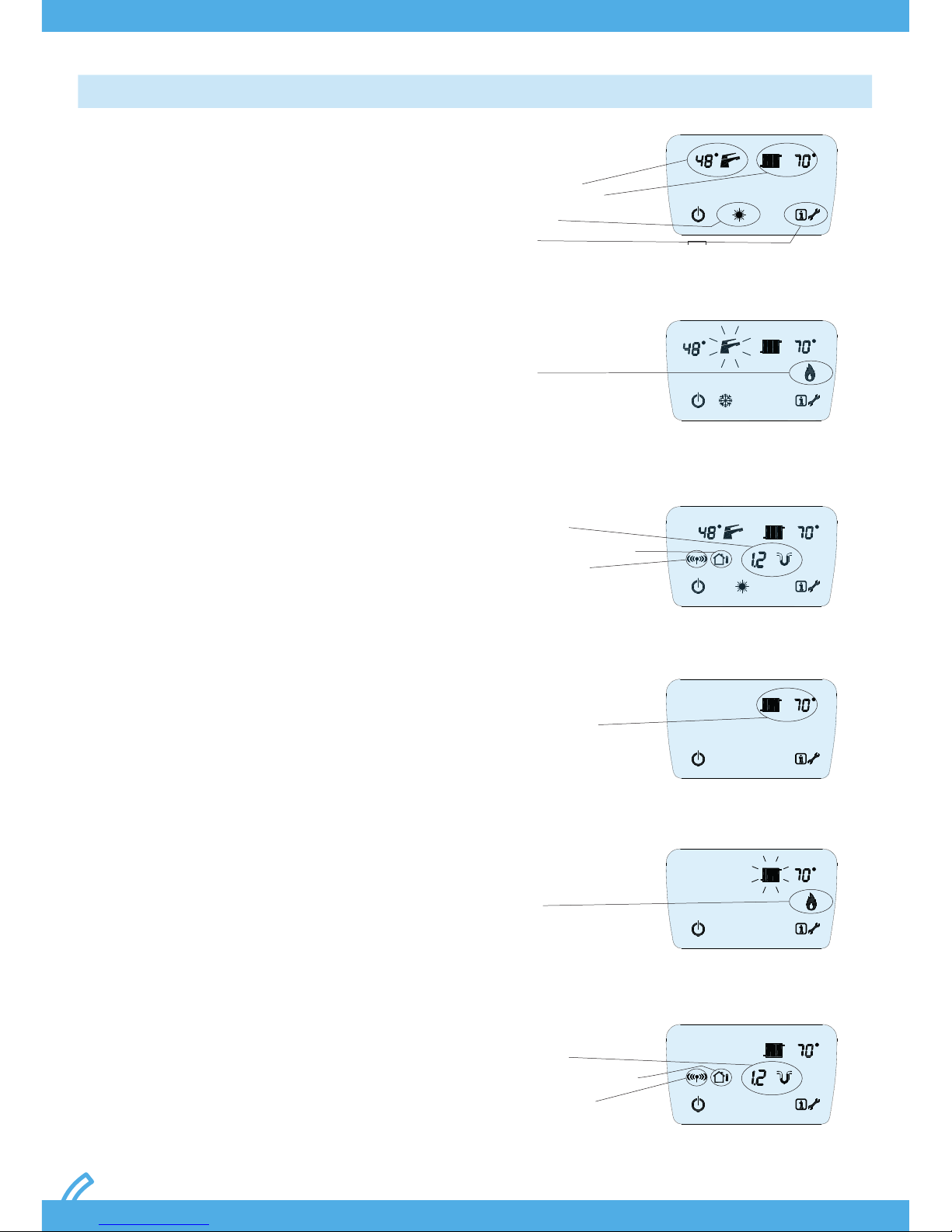

“FUNCTION” MAIN MENU

The FUNCTION page is always displayed during

the normal operation of the boiler. Symbols

regarding the following items are always

displayed:

Boilers for domestic hot water production

• The selected season

• The DHW temperature set

• The temperature of the water in the CH circuit

• The INFORMATION menu access symbol

• The INSTALLER menu access symbol

• The standby/off menu access symbol (Pic. 6.1).

When the burner is lit and running in order to

produce domestic hot water, the tap symbol

ashes and the temperature of the supplied

domestic hot water is displayed. During heating

of the CH circuit water, the radiator symbol

and the CH temperature ash. In both cases,

the ame symbol is always displayed (Pict. 6.2).

Based on whether devices such as the pressure

sensor, external temperature sensor and OT

timer thermostat are installed, the following

are displayed, respectively: the pressure of the

central heating circuit with relative symbol, the

external sensor present symbol and the OT timer

thermostat present symbol. (Pic. 6.3).

Boilers for central heating only

• The temperature of the water in the CH circuit

• The INFORMATION menu access symbol

• The standby/off menu access symbol (Pic. 6.4).

When the burner is operating the ame signal

is displayed, with the radiator symbol ashing

(Pict. 6.5). Based on whether devices such

as the pressure sensor, external temperature

sensor and OT timer thermostat are installed,

the following are displayed respectively: the

pressure of the central heating circuit with

relative symbol and the OT timer thermostat

present symbol. (Pic. 6.6).

Pic. 6.1

DHW temperature

CH water temperature

Season select

Info Menu

Heating temperature

Pressure sensor

External temperature sensor

OT timer thermostat

Pressure sensor

External temperature sensor

OT timer thermostat

Burner on

Burner on

Pic. 6.2

Pic. 6.3

Pic. 6.4

Pic. 6.5

Pic. 6.6

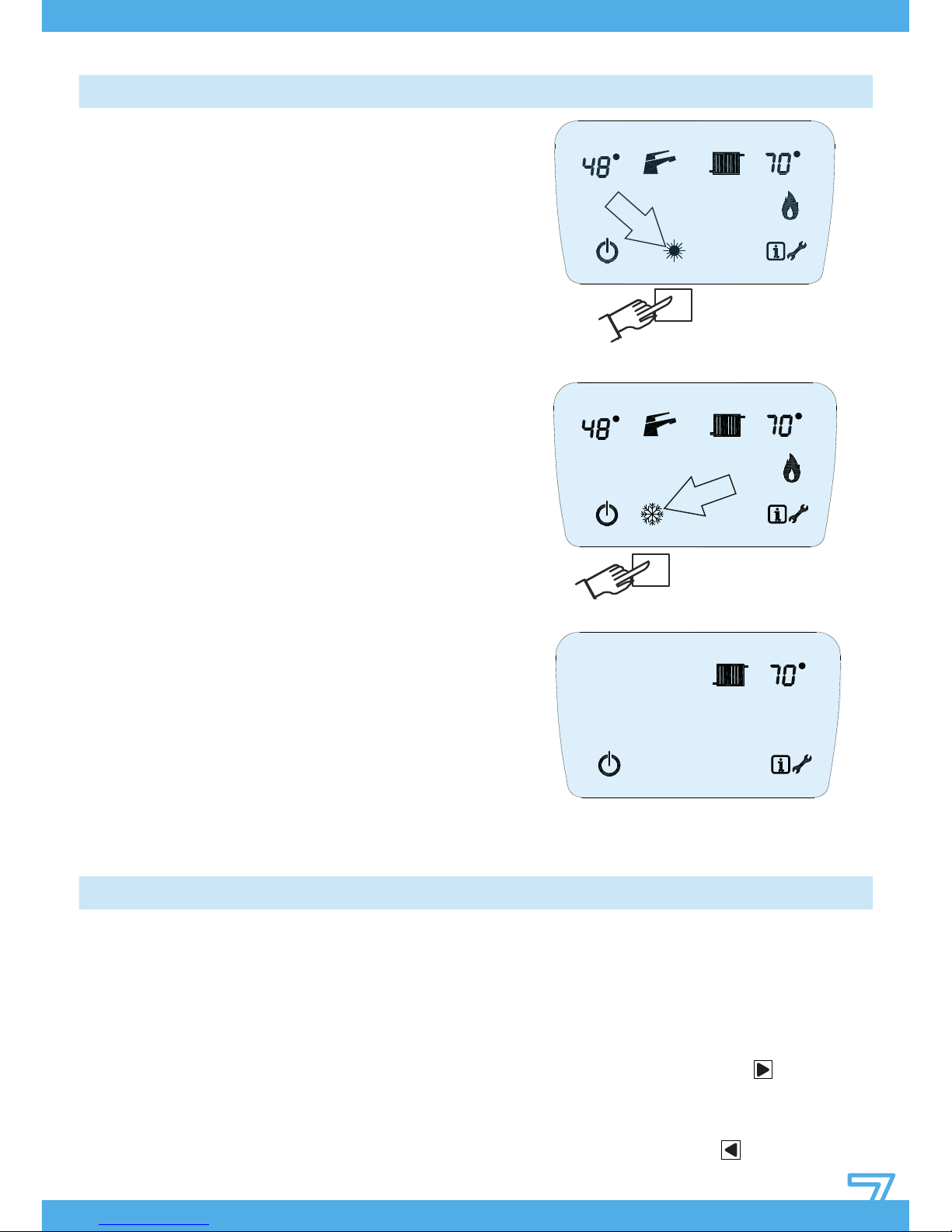

The boiler has two operating modes, which

depend on the basic conguration, in response to

the external temperature or the user requirements.

These modes can be selected from the FUNCTION

page:

Boilers for domestic hot water production

• SUMMER mode deactivates all central heating

functions, maintaining only domestic hot water

production. When the boiler is in this mode the SUN

symbol is displayed on the function page (Pict. 7.1)

• WINTER mode, in which all central heating

and domestic hot water production functions

are active. When the boiler is in this mode the

SNOWFLAKE symbol is displayed on the function

page (Pict. 7.2)

In order to select one of the modes above, press

BUTTON 2.

Boilers for central heating only

The season selection option is not available in

central heating only boilers. The device can

therefore be either in stand-by mode (Pict. 5.1)

or in operational mode, i.e. ready to supply the

only service which it has been manufactured for

(Pict. 7.3).

SEASON SELECTION

TEMPERATURE REGULATION

Pic. 7.1

Pic. 7.2

Pic. 7.3

Boilers for domestic hot water production

It is possible to regulate the temperature

of the domestic hot water supplied as well

as that for the central heating. The set

temperature will be reached, if possible,

when supplying these services and

maintained at the set value, allowing the

user requests to be satised in both cases.

The temperature supplied for both modes

is continuously displayed near the relative

symbol when the functions are active: the

radiator for the central heating and the tap

for domestic hot water.

When the boiler is in standby the DHW

temperature displayed is the set value.

Setting DHT temperature

Press one of the two buttons upon the tap

symbol (5-6). The numbers indicating the

temperature ash, then press the button

(6) to increase the temperature of DHW.

Each time this button is pressed, an increase

by 1°C is obtained. In order to decrease the

DHW temperature, press the button (5).

Each time this button is pressed, a decrease

by 1°C is obtained.

Once the needed temperature value is

set, do not press the (5-6) buttons anymore.

The new DHW temperature value will ash

for 5 seconds, then it will be stored and

displayed.

The minimum hot water temperature which

can be set is 30°C, the maximum 60°C.

Setting CH temperature

PPress one of the two buttons upon the tap

symbol (7-8). The numbers indicating the

temperature ash, then press the button

(8) to increase the temperature of CH. Each

time this button is pressed, an increase by

1°C is obtained. In order to decrease the CH

temperature, press the button (7). Each

time this button is pressed, a decrease by

1°C is obtained.

Once the needed temperature value is

set, do not press the (7-8) buttons anymore.

The new CH temperature value will ash

for 5 seconds, then it will be stored and

displayed.

The CH temperature values depend on the

type of installation.

For boilers used for high temperature

systems, the temperature range is 50°C –

80°C, while for the ones used for low teZ

mperature systems, the temperature range

is 27°C – 55°C.

Setting heating temperature

If the “Summer” mode is active (the

sun symbol is displayed), the device for

modifying the CH temperature is disabled.

Boilers for central heating only

Only the temperature value for the single

option which can be viewed on the

display can be adjusted in central heating

only boilers. Setting the central heating

temperature is performed as previously

described.

DHW temperature CH temperature

Pic. 8

THE USE OF TOO HIGH DHW

TEMPERATURES CAUSES THE

PREMATURE WEAR OF THE DHW

HEAT EXCHANGER.

ASK YOUR AREA INSTALLER FOR

INFORMATION ON THE TYPE

OF SYSTEM CONNECTED AND

RESPECTIVE ADJUSTMENTS

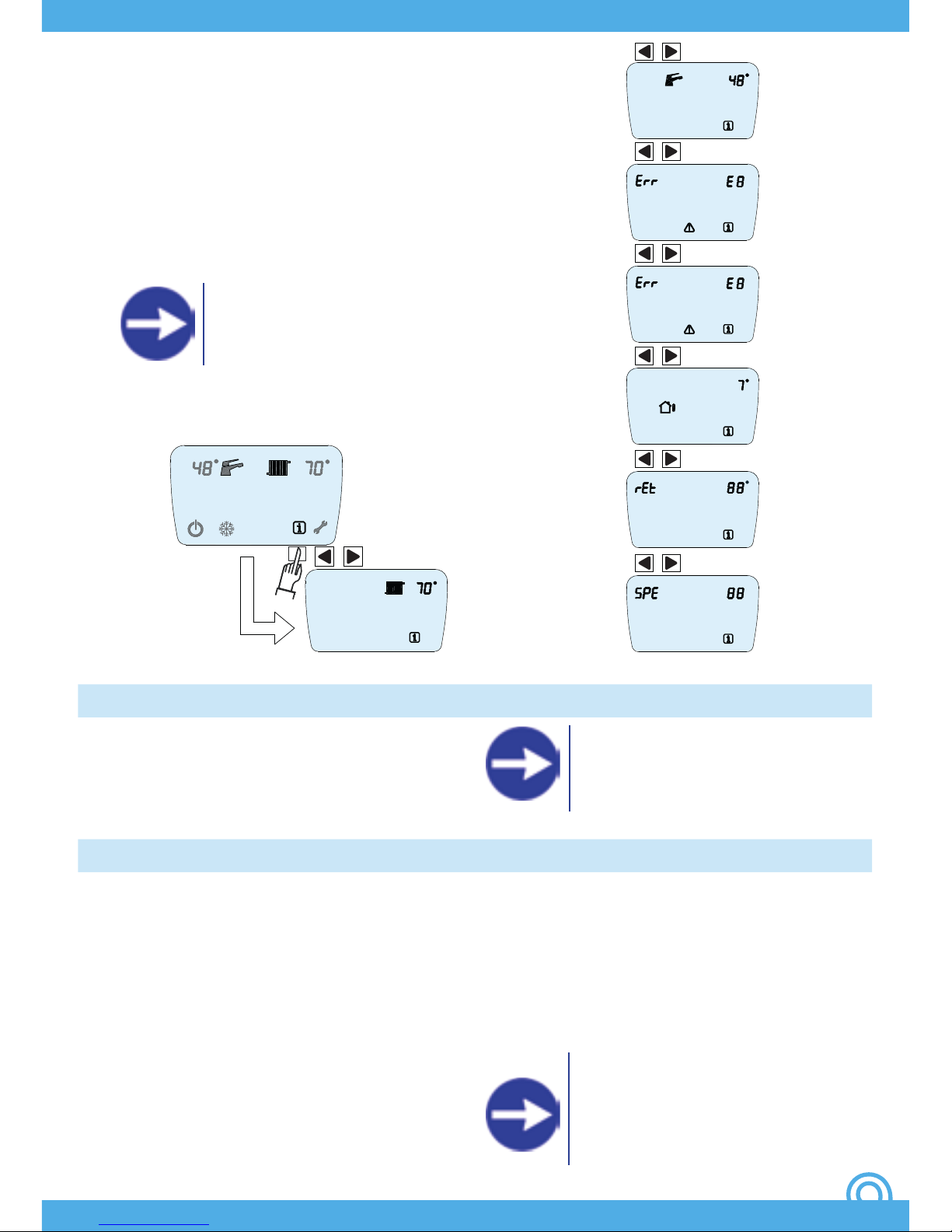

INFORMATION MENU

Accessing the INFORMATION MENU allows

various important parameters regarding the

boiler adjustments and status to be viewed,

allowing the state determining its operation

to be known at any time. The displayed

parameters cannot be modied.

To access the menu pages, press BUTTON 4.

The menu can be accessed both when the

boiler is in stand-by and when it is operating.

Selecting the menu pages

In order to visualize the values of all the

INFORMATION MENU parameters, after

activating the initial page which immediately

displays the central heating temperature,

press the

button (6) to scroll forward the

pages and press the

button (5) to scroll

backward the pages. The pages which can

be displayed are:

1. CH temperature

2. DHW temperature

3. Last error code

4. Second to last error code

5.Temperature measured by external

temperature sensor (if present*)

REQUEST INFORMATION ON

CONNECTED DEVICES FROM AREA

AUTHORISED INSTALLER

ASK YOUR AREA INSTALLER

FOR INFORMATION ON THE

INSTALLATION AND OPERATION

OF A ROOM THERMOSTAT.

REQUEST INFORMATION ON

INSTALLATION OF THE EXTERNAL

SENSOR AND OPTIMAL REGULATION

OF THE BOILER TO YOUR AUTHORISED

AREA INSTALLER.

OPERATION WITH ROOM THERMOSTAT

OPERATION WITH EXTERNAL SENSOR

Energy savings regulations REQUIRE

the boiler to be connected to a room

thermostat in order to optimally regulate

and maintain the temperature in domestic

environments.

The boiler can be connected to an EXTERNAL

sensor. In this mode, the system can regulate

the central heating circuit temperature

automatically based on the temperature

measured by the suitably located sensor on

the outside of the building.

Adjustments are made automatically to the

central heating circuit temperature using

a pre-loaded mathematical algorithm.

Different “climate curves” can be selected by

modifying the correct parameters, allowing

the boiler to be optimized for a specific

climatic area or season.

It is possible, in any case, to customize the

central heating circuit temperature; by

increasing or decreasing the central heating

circuit temperature, the temperature itself

(temperature offset) adapts to the selected

climate curve.

6. Return sensor temperature

7. Fan Speed

The automatic exit from the menu happens

after 60 seconds of device inactivity, or by

pressing any button.

The display will return to last menu page

active when the INFORMATION MENU was

accessed.

Fig. 9

Fig. 9

“1”

“3”

“2”

“4”

“5”

“6”

“7”

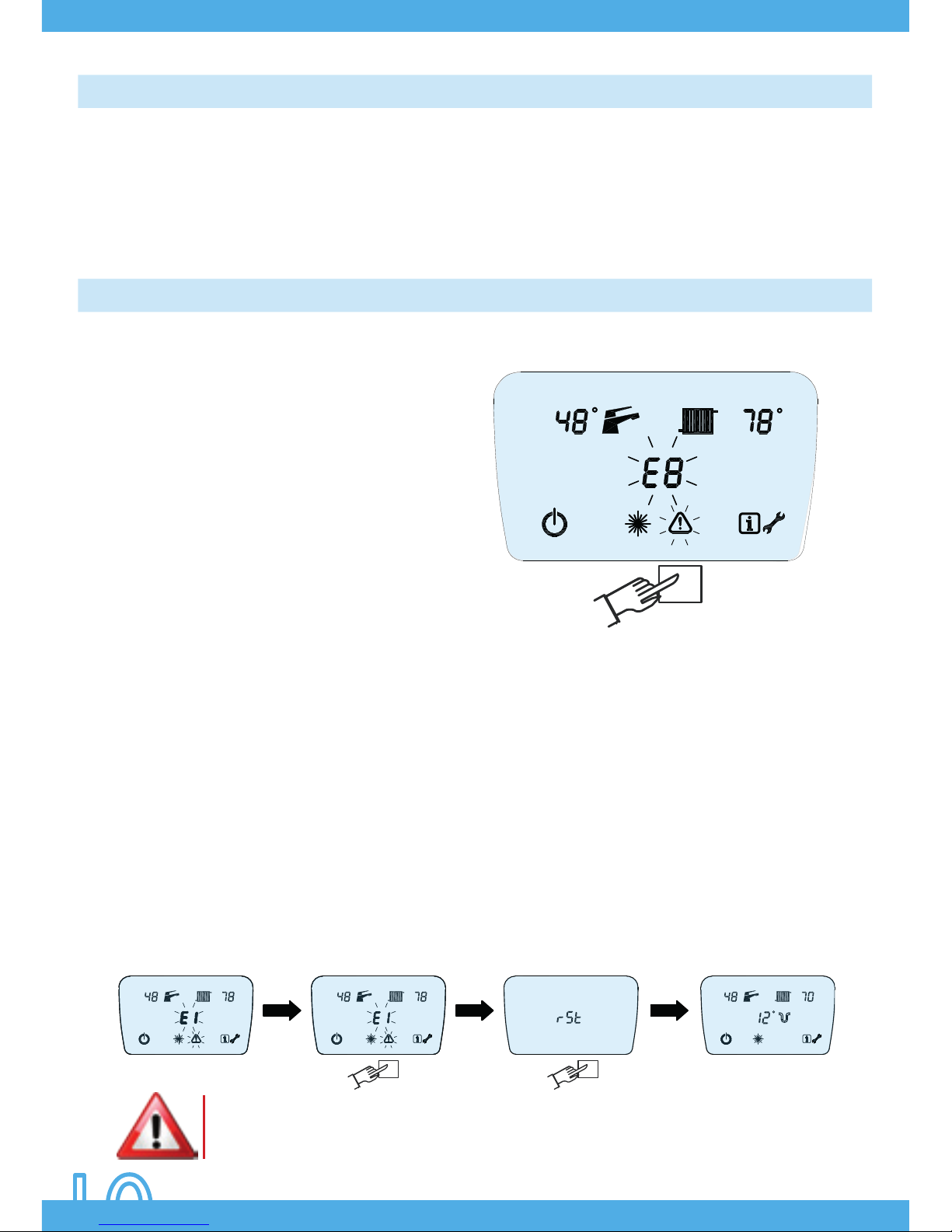

FAULTS

OPERATION WITH OPENTHERM TIMER THERMOSTAT

All functions supported by the boiler are

managed by a microprocessor-based system

which, aside from allowing the system to run

perfectly in order to maintain the greatest

level of comfort possible, constantly monitors

the functional parameters, ensuring they

fall within the necessary safety interval by a

wide margin, and therefore that all devices

present are functioning perfectly.

Whenever the malfunction of any component

or conditions which could compromise safe

operation of the system are detected, the

microprocessor system places the device

into a limited operation mode or even

completely prevents it from operating. The

microprocessor system is able to detect and

issue warnings for the main fault conditions

to allow the system to be brought back to

normal conditions as soon as possible. Fault

warnings are given on the LCD display. The

malfunction is detected and an intermittent

warning displayed immediately, consisting

of a number preceded by the error symbol E

(Pict. 10). Faults are displayed on any screen

of the main menu.

Conditions causing transitory faults are

possible. Many of these are recognized

and cause a temporary block which is

automatically reset once the condition

causing the fault has stopped. Some of these

provide for the possibility to attempt to restore

operation manually.

Manual error reset, recovery attempt

To manually reset the system following a

fault condition, press BUTTON 3: the symbol

RST (reset) will be displayed on the LCD

display. Then press BUTTON 3 again (Pict. 11).

The microprocessor will attempt to recover

the system by resetting all the conditions

presumed to have caused the fault. If the

operation is successful the boiler will return

to normal operation; if not, the error code

causing the malfunction will be displayed.

Pic. 11

Pic. 10

IF A FAULT IS NOT SOLVED AFTER 2 MANUAL RESET ATTEMPTS THEN THE AUTHORISED

TECHNICAL ASSISTANCE CENTRE MUST BE CALLED.

For optimum and even more economical

management of the domestic premises it is

possible to use the EASY CONTROL

programmable timer thermostat. EASY

CONTROL allows all main boiler functions to

be managed remotely,

allowing it to be fully managed from a

different room to that where the boiler is

installed.

EASY CONTROL can also be used to schedule

daily and weekly room temperatures and

manage reduced demand periods (holidays,

anti-frost and maintenance modes).

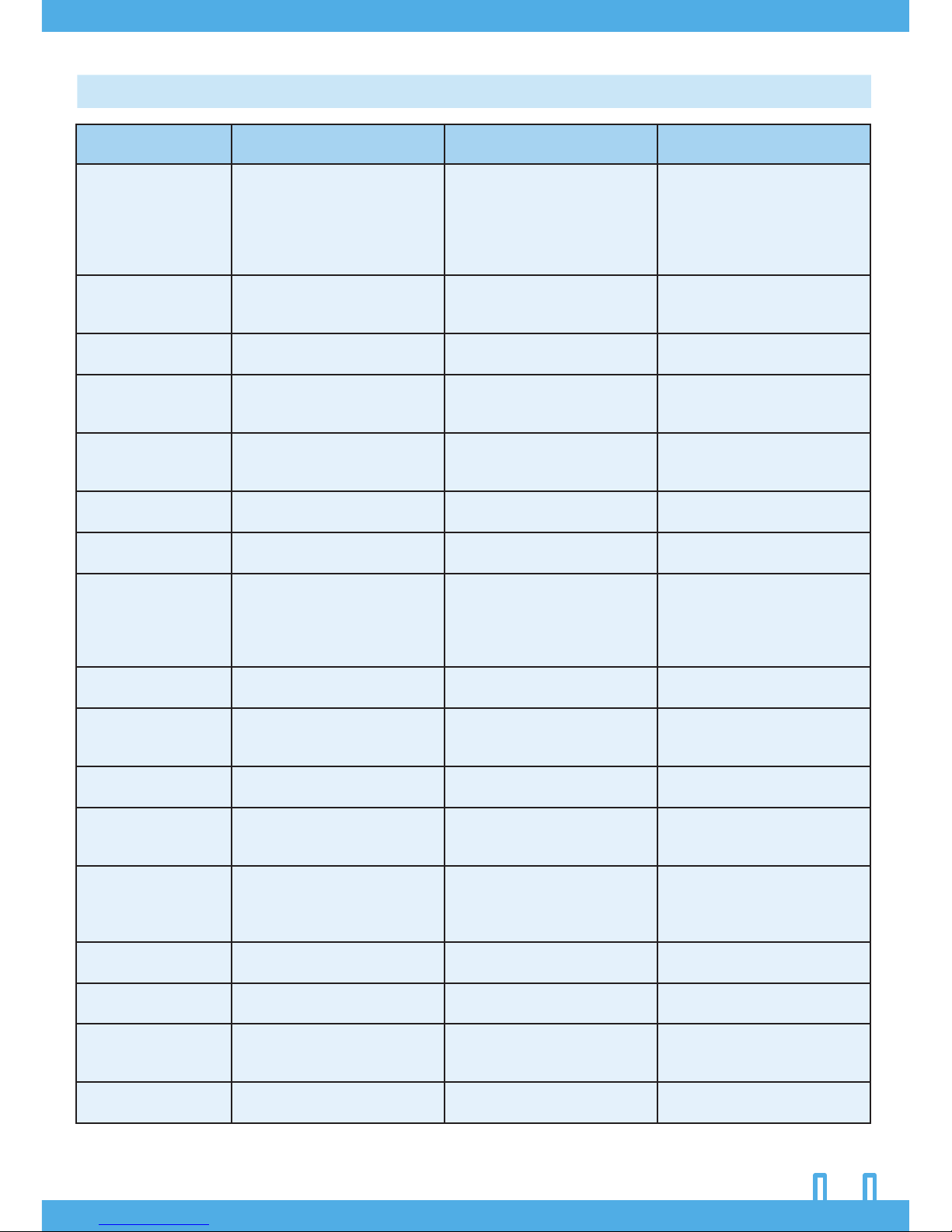

FAULT CODES TABLE (ALL MODELS)

Code Possible cause Behaviour Possible actions

E1 Ignition failed Boiler locked

Check gas presence

Check gas line pressure

Check ignition/detection

electrodes

Check electronic cable

Check igniter

E2 Air pressure switch failure Boiler locked

Check ue draught / ue

pipes

Check fan

E3

Heating system temperature

sensor fault

Boiler locked Replace CH sensor

E4

Domestic hot water system

temperature sensor fault

DHW supplied in provisional

mode

Heating functions normally

Replace CH sensor

E5 Gas regulation valve fault Boiler locked

Check wire connection to

modulator

Replace gas valve

E6

High temperature detected

by heating system sensor

Device in stand-by

Normal DHW supply

Wait for automatic unlocking

E8

Central heating system

pressure too low

Boiler locked Check pressure to CH system

E9

Central heating system

water temperature too high

Boiler locked

Degas CH system

Check CH system pressure

Check CH system circulation

Check combustion

adjustmen

E10

Central heating system

pressure too HIGH (> 2.7 bar)

Boiler locked Check pump functioning

E11 Pressure transmitter failure Boiler locked

Check integrity of

connection

Replace pressure trasmitter

E12

Remote control

reset used-up

Boiler locked

Reset system

Switch off power

E13 SYSTEM error Boiler locked

Reset system

Switch off power

Replace electronic board

E23*

Fault on external

temperature sensor

Resumption of operation

without external sensor

Check position of external

probe

Check communication line

Replace external sensor

E28

Water cylinder / water

heater probe failure

Boiler locked Replace probe

E70 Supply voltage too low Boiler locked

Controlling the supply of the

boiler

E77 System error Boiler locked

Reset system

Switch off power

Replace electronic board

E99

Parameter

conguration error

Boiler locked

Check and recongure the

parameters

*Can be displayed only if the relative devices are installed

GAS

INTAKE

DOMESTIC

HOT WATER

WATER

INTAKECHRETURN

1

2

CH FLOW

3

4

10

9

8

7

6

5

AB

B

A

1

2

3

BOILER

FLOW

BOILER

RETURN IN

HOT

WATER

OUTLET

COLD

WATER

INTAKE

Pic. 12

Pic. 13

Pic. 14

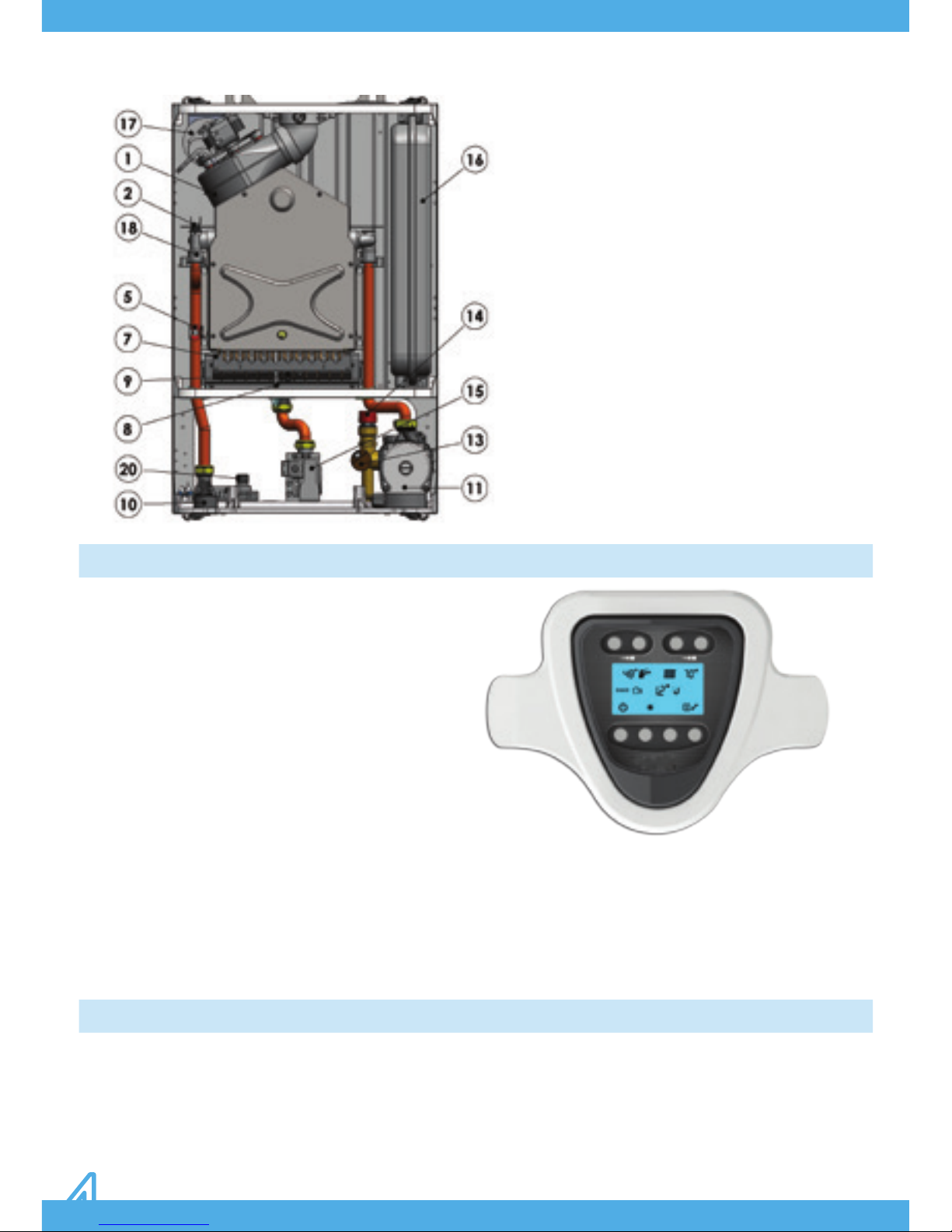

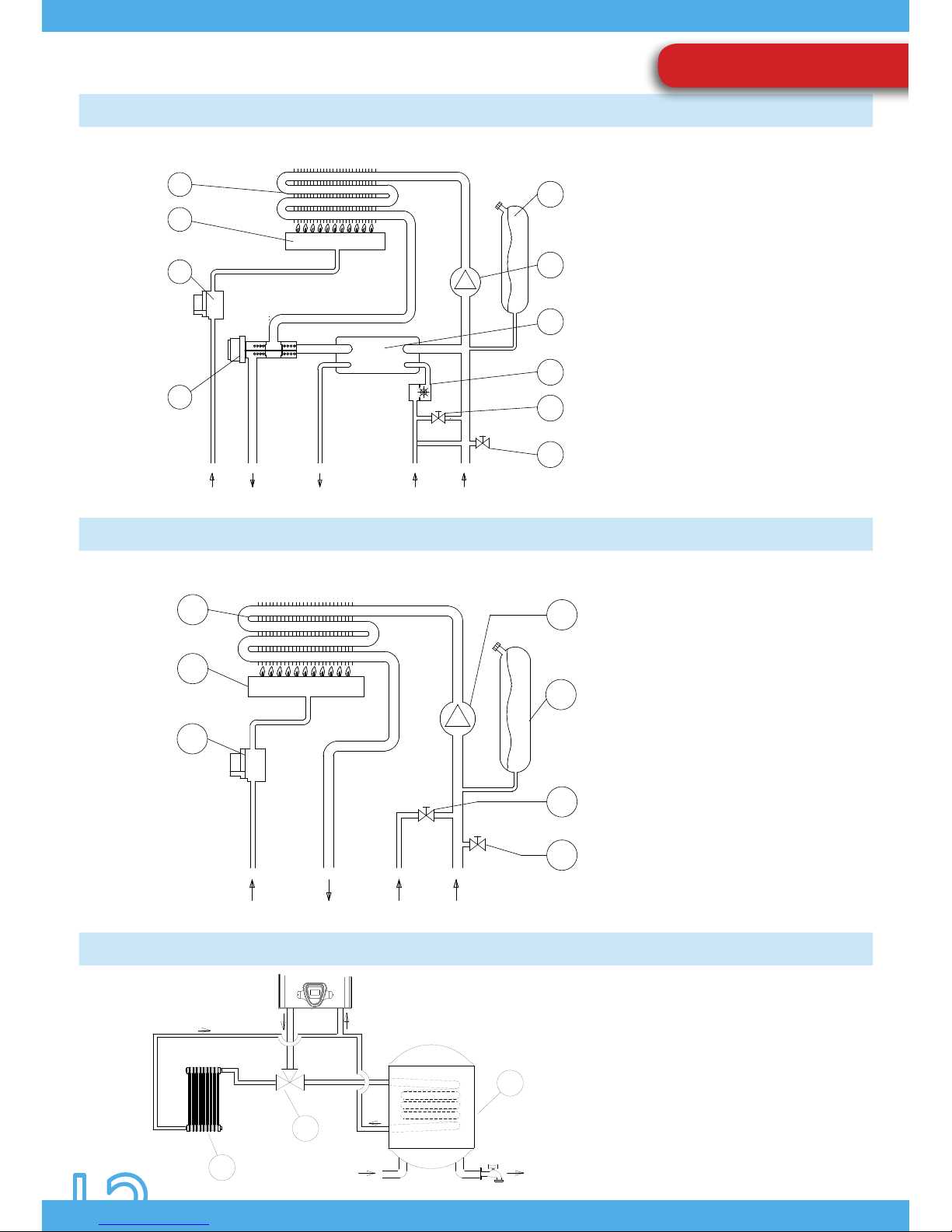

OPERATING DIAGRAM (MR)

OPERATING DIAGRAM (MN)

DHW STORAGE TANK- THREE WAY VALVE OPERATIONAL DIAGRAM

INSTALLATION

1) Primary heat exchanger

2) Burner

3) Gas valve

4) Three-way valve

5) Safety valve

6) Filling loop cock

7) Hot water priority turbine

8) Secondary heat exchanger

9) Circulator unit

10) Expansion tank

1) Primary heat exchanger

2) Burner

3) Gas valve

5) Safety valve

6) Filling loop cock

9) Circulator unit

10) Expansion tank

1) Central heating circuit

2) Three-way valve

3) DHW storage tank

COMBINATION: DOMESTIC HOT WATER + CENTRAL HEATING

CENTRAL HEATING ONLY

1

2

3

10

5

6

9

GAS

INTAKE

DOMESTIC

HOT WATER

WATER

INTAKECHRETURN

Loading...

Loading...