Page 1

1GRUNDIG CUC 1982

Matrix

Item See Model Book

X-Ray Precautions(See Notes)........................................... Grundig G1000 Chassis 4

Service Notes (See Notes). ................................................... Grundig G1000 Chassis 4

AF Amplifier .................................................................................... Grundig CUC 7851 5

IF Amplifier ...................................................................................... Grundig CUC 7861 5

Remote Control .............................................................................. Grundig CUC 6360 5

Recommended Safety Parts

Item Part No. Description

CUC 1951

C 7 8531-505-221 MKT 680PF 20% 12,5KV

C 530 8660-098-219 SI-KERKO B-SS 220PF 20%

C 621, C 622 8660-098-238 SI-KERKO B-SS 2200PF 20%

C 665 8660-098-234 SI-KERKO B-SS 1000PF 20%

D 545 8309-215-045 DIODE 1 N 4148

K 536 29305-119,14 KASKADE BG 2034 642 3206

OK 636,OK 646 8306-000-012 OPTOKOPPLER CNY 17 F1

R 337 8705-279-107 MOW AX 0922-GA 27 KOHM

R 355 8766-302-087 MSW AX 0207 3,9 KOHM

R 371 8701-118-001 KSW SI B 1 OHM 5% -GA

R 408 8765-098-207 MSW AX 0207-GA 2 OHM

R 409 8765-098-208 MSW AX 0207-GA 1,8 OHM

R 414 8765-097-009 MSW AX 0204-GA 2,2 OHM

R 501 8705-221-225 MOW AX 0411-GA 10 OHM

R 502 8705-279-001 MOW AX 0922-GA 1 OHM

R 504 8735-064-039 DRW 4 39 OHM 5% STANDBY, 18

R 523 8705-269-065 MOW AX 0617-GA 470 OHM

R 524 8735-003-022 DW 0,22 OHM 10%

R 525 8735-003—33 DW 0,75W 0,33 OHM 10%

R 527 8730-280-021 DRWS11 7W 6,8 OHM

R 528, R 534 8705-221-225 MOW AX 0411-GA 10 OHM

R 551, R 552,R 553 8705-610-133 MOW AX 0617 330 KOHM 5%

R 571 8701-230-817 NKS 3 4,7 OHM 5% ROE

R 572, R573 8700-007-405 KSW AX 0207-GA 1,5 OHM

R 576 8705-269-015 MOW AX 0617-GA 3,9 OHM

R 577 8735-003-273 DRW 0,75W 1 KOHM 10%

R 622 8730-199-005 DRW 11ST 1,5 OHM 5% V3

R 623 8705-329-127 MOW LI 0411 180 KOHM 5%

R 663 8705-369-113 MOW LI0617 47 KOHM 5%

R 665 8766-349-155 MSW LI 0414 2,7 MOHM

R 667 8735-002-013 DRW 2 W 0,1 OHM 10%

R671 8705-329-321 MOW LI 0411 100 KOHM 10%

R 689 8705-369-079 MOW LI 0617 1,8 KOHM 5%

SI 331 8315-618-200 LOET-SI.-GR 1A/T

SI 630 8315-621-027 LOET-SI.-GR 2,5 A/T

SI 651, SI 661 8315-622-025 LOET-SI.-GR 3,15 A/T

SI 671 8315-623-008 LOET-SI.-GR 4 A/T

SI 6111 8315-613-027 LOET-SI.-GR 400 MA/T

TR 8 29201-447.97 FOKUSIERUEBERTRAGER

TR 501 09245-812.31 TREIBER-UEBERTRAGER

TR 526 29201-025.17 ZEILENTRAFO KPL

TR 651 29201-402.97 SPERRWANDLERTRAFO KPL

TR 6111 29201-385.97 UEBERTRAGER EF20

CUC 1982

C 530 8660-098-219 SI-KERKO.B-SS 220PF 20%

C 621, C 622 8660-098-238 SI-KERKO B-SS 2200PF 20%

C 665 8660-098-234 SI-KERKO B-SS 1000PF 20%

C 6001 8511-793-047 MP 3 0,47 UF 20% 250VW

D 545 8309-215-045 DIODE 1 N 4148

K 536 8324-800-326 KASKADE BG 2034 642 3206

L 6001 29500-820.97 FUNKENTSTOERDROSSEL

OK637, OK646 8306-000-012 OPTOKOPPLER CNY 17 F1

R 337 8705-279-107 MOW AX 0922-GA 27 KOHM

R 355 8766-302-087 MSW AX 0207 3,9 KOHM

R 371 8701-118-001 KSW SI B 1 OHM 5% -GA

R 407 8765-044-049 MSW AX 0414-GA 100 OHM

R 408, R 409 8765-198-006 MSW 0207 1,6 OHM 1% TK 50

R 414 8765-097-009 MSW AX 0204-GA 2,2 OHM

R 501 8705-221-225 MOW AX 0411-GA 10 OHM

R 502 8705-279-001 MOW AX 0922-GA 1 OHM

R 504 8735-064-039 DRW 4 39 OHM 5% STANDB. 18

R 523 8705-269-065 MOW AX 0617-GA 470 OHM

R 524 8735-003-022 DW 0,22 OHM 10%

R 525 8735-003-033 DW 0,75W 0,33 OHM 10%

R 527 8730-280-021 DRWSI 7W 6,8 OHM

R 528, R 534 8705-221-225 MOW AX 0411-GA 10 OHM

R 551, R 552,

R 553 8705-610-133 MOW AX 0617 330 KOHM 5%

R 571 8701-230-817 NKS 3 4,7 OHM 5% ROE

R 572, R 573 8700-007-405 KSW AX 0207-GA 1,5 OHM

R 576 8705-269-015 MOW AX 0617-GA 3,9 OHM

R 577 8735-003-273 DRW 0,75W 1 KOHM 10%

R 622 8730-199-005 DRW 11 ST 1,5 OHM 5% V3

29304-050.97 Mains Interference Unit

09621-113.02 Fuse Holder

Recommended Safety Parts Cont’d.

Item Part No. Description

R 623 8705-329-127 MOW LI 0411 180 KOHM 5%

R 663 8705-369-113 MOW LI 0617 47 KOHM 5%

R 665 8766-349-155 MSW LI 0414 2,7 MOHM

R 667 8735-002-013 DRW 2 W 0,1 OHM 10%

R 671 8705-329-321 MOW LI 0411 100 KOHM 10%

R 689 8705-369-079 MOW LI 0617 1,8 KOHM 5%

R 6009 8311-200-010 DUO-PTC

SI 331 8315-618-200 LOET-SI.-GR 1 A/T

SI 630 8315-617-006 FS.2,5 A/T L 250V

SI 651, SI 661 8315-622-025 LOET-SI.-GR 3,15 A/T

SI 671 8315-623-008 LOET-SI.-GR 4 A/T

SI6001 8315-622-503 FS.3,15 A/T H 250V

SI6111 8315-613-027 LOET-SI.-GR 400 MA/T

TR 8 29201-447.97 FOKUSIERUEBERTRAGER

TR501 09245-812.31 TREIBER-UEBERTRAGER

TR526 29201-025.17 ZEILENTRAFO KPL

TR651 29201-402.97 SPERRWANDLERTRAFO KPL

TR6010 09032-301.02 NETZTRAFO

WW. 29201-601.97 TRAFO NETZ

TR6111 29201-385.97 UEBERTRAGER EF20

WW. =Optional

M 70-169/9

C 6001 8511-793-047 MP 3 0,47 UF 20% 250VW

C 6002 8511-793-033 MP 3 0,22 UF 20% 250VW

L 6001 29500-820.97 FUNKENTSTOERDROSSEL

R 6009 8311-200-010 DUO-PTC

SI 6001 8315-622-003 FS.3,15 A/T L 250V

TR6010 09032-301.02 NETZTRAFO

WW. 29201-601.97 TRAFO NETZ

WW. = Optional

M 82-169/9

R 6000 8765-049-157 MSW AX 0414-GA 3,3 MOHM

09246-188.31 Degaussing Coil

09246-188.71 Degaussing Coil

8300-066-697 Pict. Tube W 66 KZA 696X99

29305-165.04 Power Switch Unit

29703-291.32 Power Switch

29303-452.02 Mains Plug Lower Part

09621-113.02 Fuse Holder

8290-991-307 Power Cable

09246-120.71 Degaussing Coil

8300-076-690 Pict. Tube W76 KYR 690X96

29303-452.02 Mains Plug Lower Part

29703-291.32 Power Switch

8290-991-307 Power Cable

Service Adjustments

Service and Special Functions

1: Switching-on Options

Initialisation of the µP (IC850)

Connect Pin 1 of the processor to chassis and

switch the TV on with the mains switch to load

the EEPROM in the processor IC850.

Display: “CONFIG” bzw “CO”.

After replacement of IC840 the ATS (see ATS

EURO Plus) must be re-started.

Loading the Average Values/Emergency Data

(ROM Data)

If µPIC850 fails (is replaced) or the data has

been changed, the TV receiver must be

switched on with the emergency data set.

Mains button “ON” and press the P- button on

the local keyboard simultaneously —> ROM

data are loaded. In doing so the following data

are read out from IC860:

- white value blue, green and white balance.

picture geometry and deflection.

- TV set up (switching on with programme / AV,

frequency-channel mode, PIP frame colour,

PIP position).

- national identification of the location.

- volume offset.

- last programme.

- analog average values and the Luminance

Delay (“0”) and loaded into RAM memories of

IC850.

Having entered the individual values via the

Info. Menu they will be stored automatically

when switching off (see alignment).

ATS Reset

Mains button “ON” and press the L+ button on

the local keyboard.

- default values are loaded.

- either optimum analog values of the factory

- or, analog values from the EPROM.

- This option activates the ATS function

- Black Stretch on (if provided)

- Cinema Picture Format.

ATS Start

Pressing the button “P/C” (for approx. 4 secs.)

—> and confirming “Restart” or “Update” with

“OK” —> starts the Auto Tuning System (ATS).

The ATS-system determines the VPS-signal for

the station identification. Additionally, for the

programmes 1 - 99, the volume offset is reset

and the optimum values, Colour Match and

Picture Sharpness are stored together with the

Peri-bit for the respective country.

I2C-Bus, IC Test, (for fault finding in the I2C-Bus)

These error messages refer only to interference’s in the I2C-bus, that is modules which do

the next time the receiver is switched

on. The previously stored programmes

(channels) are cancelled.

not return an Acknowledge bit via the I2C-bus.

For example no operating voltage present on

the module, break in the circuit path or defective

I2C-interface.

Service-Mode Programme for Sets with

Display

Mains button “ON” and press the P+ button on

the local keyboard simultaneously = I2C-Bus

Test.

With this diagnostic programme the microprocessor in the control unit interrogates the

modules connected to the I2C-Bus and indicates

defective modules by an error message or a

code number on the display and LED, respectively.

List of Error Messages and Code Numbers:

Interface Error Code Defective Module

NVM Control Unit E0, E1,E2, E3 IC840, Control Unit

Box DDC E4 IC1410, Feature Box

Box MSC E5 IC1455, Feature Box

Box CSG E6 IC1430, Feature -Box

Box PP E7 IC1550, Feature-Box

Box DP E8 IC1560, Feature-Box

Colour Dec RGB Chip E9 IC5122, Video Module

IF Stereo Sound IC EA IC2250, IF Amplifier

TDA 8443 EC IC5021, Video Module

TDA 9160 EE IC5001, Video Module

ATA Tuner PLL EF CIC2140, Tuner

Tuner NVM EH CIC2100, Tuner

Audio Matrix EL IC7560, Socket Board

TEA6420

Video Matrix EP IC7660,

TEA6415 Socket Board

The L+ button can be used to discover other

defective interfaces.

Service-Mode Programme for sets without

Display

Mains button “ON” and press the P+ button on

the local keyboard simultaneously = I2C-Bus

Test.

In this fault finding programme, the microprocessor on the tuning module (control unit) scans

the individual modules connected to the I2C-Bus

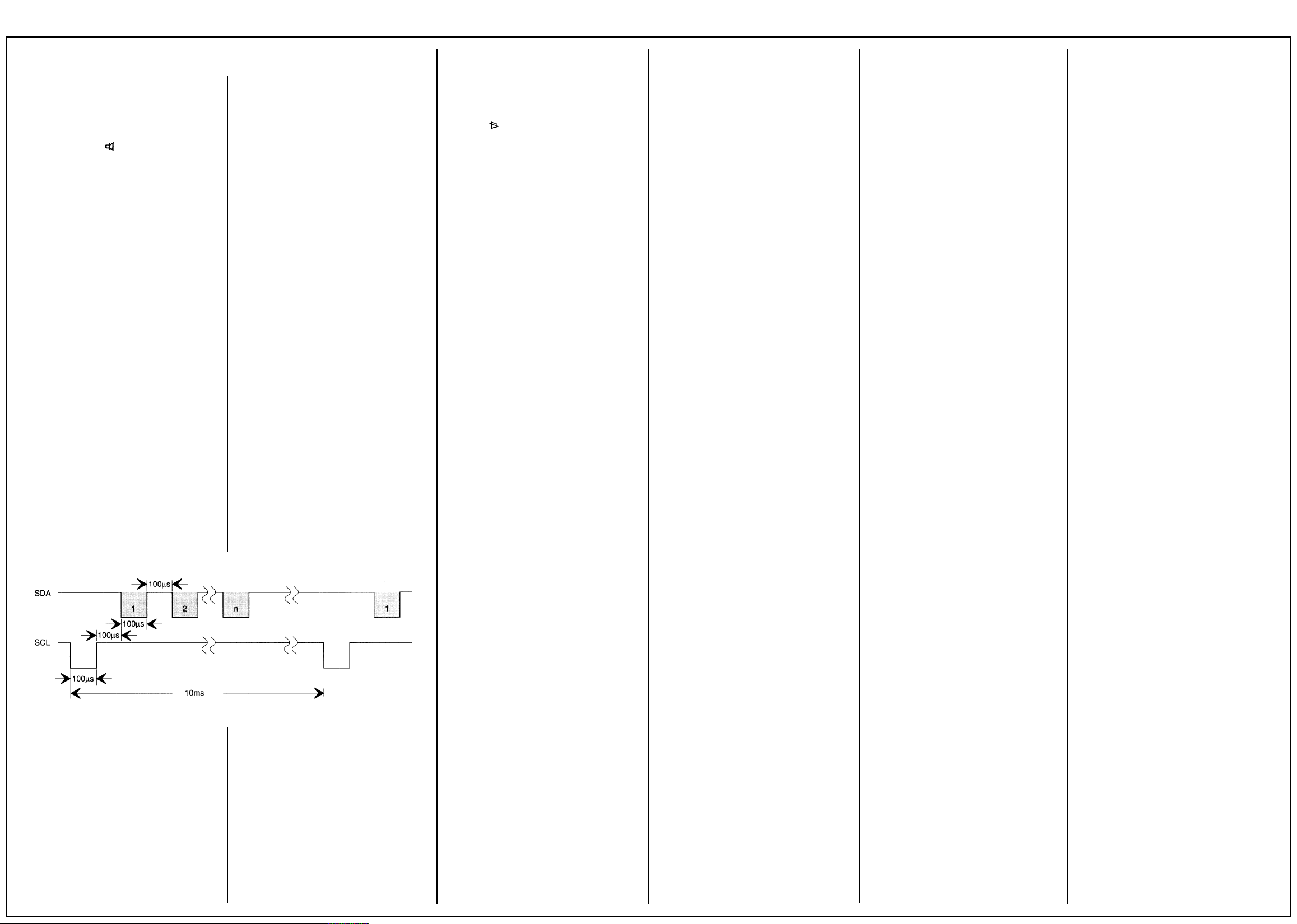

and indicates them as countable pulse sequence (see fig 1).

1:Connect a double-beam oscilloscope to I2C-

Bus, trigger “SCL” on the oscilloscope.

2:Press and hold P+ on the keyboard and

switch on with the mains button. The number

of clock pulses indicates the defective module

as shown in the table. If there is no fault in the

I2C-Bus communication the pulses SDA and

SCL cannot be synchronised on the screen.

Interface Number Defective

of Clocks Module

NVM Control Unit 1, 2, 3, 4 IC840, Control Unit

Box DDC 5 IC1410, Feature-Box

Box MSC 6 IC1455, Feature-Box

Box CSG 7 IC1430, Feature-Box

Box PP 8 IC1550, Feature-Box

Box DP 9 IC1560, Feature-Box

Colour Dec RGB Chip 10 IC5122, Video Module

IF Stereo Sound IC 11 IC2250, IF-Amplifier

TDA 8443 12 IC5021,V ideo Module

TDA 9160 13 IC5001, Video Module

ATA Tuner

PLL 14 CIC2140, Tuner

Tuner NVM 15 CIC2100, Tuner

Audio Matrix 16 IC7560, Socket Board

TEA6420

Video Matrix 17 IC7660, Socket Board

TEA6415

2: Settings via the Info. Centre Menu

Programme Lock (security system)

You can cancel your personal code number by

pressing + , - , , sequentially.

EPROM Version Number

The version number can be called up in the

Menu Info. Centre with the “AUX” button. The

index 01 of the part number (19798-277.01)

indicates the EPROM version.

Switch on with Programme “1” or “AV”

Via the Menu Info. Centre —> Special Functions

—> Settings programme —> AV. When switching power “On”, programme position “AV” has

priority.

On-Place/Two-Place Programme Selection

Via the menu Info Centre —> Special Functions

—> Settings Programme selection can be

switched over between 1 - 9 and 1-99.

Volume Offset

Via the Menu Info. Centre —> Special Functions

—> Settings —> the “Volume” level can be

changed in 16 steps on a pre-programme basis.

Colour Match

Via Menu Info. Centre —> Special Functions —>

Settings —> the “Colour Match” can be changed

in 8 steps on a pre-programme basis.

Station Ident

Via the Menu Info. Centre —> Special Functions

—> Settings —> the station ident can be

switched off, displayed for a short period or

continuously on the screen.

OSD-ON/OSD/OFF for all Programmes

The on screen display can be switched “on” or

“off” via the Menu Info. Centre —> Special

Functions —> Settings —> Pict/Sound Options.

When selecting the “off” option the scales for the

analog values is switched off.

RGB-Sync-Level

Via the Menu Info. Centre —> Special Functions

—> Settings —> the RGB-Sync-Level can be

changed to On or Off.

PIP-Menu

Via the Menu Info. Centre —> Special Functions

—> Settings —> the frame colour and small

picture position can be selected.

Maximum Programme Number

Via the Menu Info. Centre —> TV-Station Table

—> OK. When storing the channel number “00”

at any programme position, programme

selection with the , , buttons is limited to the

numbers lower than this position.

3: Settings via the Audio Menu

Hi-Fi-output off, linear, controlled

Via Audio Menu —> Hi-Fi-output and the - / +

buttons the AF at the Hi-Fi-output can be:

- switched “off” normal operation.

- set to “var”, the volume level of the

Hi-Fi system can be varied via the

remote of the TV. The loudspeakers in

the TV receiver are switched off in

Page 2

GRUNDIG CUC 1982

2

Service Adjustments Cont’d

this case.

- switched to “lin”, the volume level of

the Hi-Fi-system is constant.

Switching Over the Sound: Stereo, Mono,

FM, NICAM, NICAM B

Select Audio Menu —> Sound. With the - +

buttons switch the stereo decoder over to the

desired reception.

FM - sound stereo broadcast:

- switchable between Stereo <—> Mono.

- Two-channel sound: switchable

between Mono A <—> Mono B.

The sound for the loudspeakers and headphones can be switched over independently of

each other.

NICAM - sound mono broadcast:

- switchable between NICAM-Mono

<—> FM

NICAM - sound stereo broadcast:

- switchable between NICAM-Stereo

<—> FMo

NICAM - sound dual-sound broadcast:

- switchable to NICAM-sound 1 —>

NICAM-sound 2 —> FM

NICAM not relating to the picture:

- switchable to NICAM-sound 1 —>

NICAM-sound 2 —> FM- preferred

sound is FM-Mono

AV mode

- Stereo (preferred setting) —> Mono A

—> Mono B.

- With the options Sound 1 and Sound

2, the sound for the loudspeakers and

headphones can be switched over

independently of each other.

Headphones dual-sound broadcast:

- switchable between Sound 1 <—>

Sound 2

Fig 1.

4: Settings via the Station Ident

Settings entered in the station identification

effect forced switching of the TV set to an

operating mode; as a result, the automatic

evaluation function is suppressed.

Select the Menu Info. Centre —> TV-Station

Table.

Activate the desired TV station and enter a

comma at the 4th place from the left. The places

5 and 6 are reserved for the actual switching

information (see table).

The first three places (from the left) of the

station ident may be filled with any characters.

Example: ARD, MO only mono sound.

The final setting of the station ident shows only

the first three places, the switching information

will not be indicated.

Indication: ARD.

Possible switch settings:

station ident XXX, MO -> forced mono

station ident XXX, 2T -> sound 2 select (preferred

with dual-sound broadcasts)

station ident XXX, AF -> AFC- Nachregelung aktiv

station ident XXX, AV -> VCR time constant and AFC

Senderkennung AV... -> VCR time constant and AFC

station ident XXX, P5 -> 50Hz

station ident XXX, N5 -> 50Hz

station ident XXX, S5 -> 0Hz

station ident XXX, P6 -> 60Hz

station ident XXX, N6 -> 60Hz

station ident XXX, S6 -> 60Hz

5: Settings via the “AUX” Function

The “AUX” command initialises an input mode in

which certain commands are interpreted

differently. This mode remains active for about 4

secs. unless another command is entered. The

indication “AUX” is shown on the screen for

about 4 secs.

Setting the Peri Bit

“AUX” —> 0/AV.

With the Peri Bit set, the control processor

evaluates the switching voltage on Pin 8 of the

EURO-AV socket AV1 (black) and switches the

TV receiver to this input, (eg. on descrambler

operation).

The Peri symbol illuminates in the display of the

keyboard unit.

Switching over the Descrambler

Descrambler off

Descrambler on Auto (Peri Bit set)

Descrambler on Stereo (Peri Bit set)

Descrambler on mono - L (Peri Bit set)

Descrambler on mono - R (Peri Bit set)

Copy Function

In operating mode:

Firstly select the AV signal source, eg. AV1, AV2

etc.

- ON: “AUX” —> 0/AV (indication “Copy On”)

- OFF: “AUX” —> 0/AV (no indication)

Copying possibilities from —> to:

- AV1 (black Scart socket) —> AV2

(orange Scart socket).

- AV2 (orange Scart socket) —> AV1 (black

Scart socket).

- AV3 (S-Video and Cinchbuchse) —>AV2

(orange Scart socket).

- AV3 (S-Video and Cinchbuchse) —>AV1

(black Scart socket).

Headphone Volume Control

The headphone volume level can be changed

by ““AUX”” —> - +.

Switching between Mono —> Stereo Sound

“AUX” —> activates the sound switching

function: Mono —> Stereo —> Mono A —>

Mono B etc.

6: IR-Data Programmer

With this menu and the IR-Data Programmer 2,

it is possible to store a maximum of 99 programme positions with the data for the channel,

TV norm, Peri, 6-place station identification, the

fine tuning centre frequency and the volume

offset “0”.

The Programmer AP transfers only channels

and 4-place station identifications with fine

tuning centre frequency and volume offset “0”.

Call up via the Menu Info. Centre —> Special

Functions —> IR-Data Programmer.

Attention: The data transfer can be affected by

interference’s from electrical lighting fixtures.

7: Setting the Analog Values

When exceeding the minimum possible values

for the brightness, colour contrast, B/W-contrast

and volume level as specified in the table below,

the appropriate optimum value is initialised

when switching the TV on or changing from RF

—> AV.

Minimum Optimum

Value Value

Brightness 15 31

Colour contrast 11 32

B/W contrast 15 31

Volume 11 11

Alignment

All adjustment controls not mentioned in this

description are pre-set at the factory and must

not be re-adjusted in the case of repairs.

1. Chassis Board

Measuring instruments:

Dual-channel oscilloscope.

10:1 test probe.

Digital voltmeter.

Service works after replacement or repair of the

following modules:

Chassis: alignment 1.1

Tuner, IF amplifier: alignment 1.2, 1.3

Display/Control Unit: alignment 1.2...1.13

Video Module: 1.5

1.1: Alignment:

+A voltage

+B voltage

+N voltage

+F voltage

Preparation

Brightness: Minimum

These voltages must be checked after every

repair and before every adjustment.

Alignment Process

Set control R654 to 150V.

Set control R673 to 12V on contact 36 of the

Feature-Box.

Set control R683 to 5V on contact 32/33 of the

feature-Box.

Set control R697 to 5V on contact 9/10 of the

Feature-Box.

1.2: Alignment

Tuner-AGC Automatic

Preparation

Feed in a standard test pattern in the upper

range of the UHF band; the RF must be ≥1.5mV

(64dBm V, noise-free picture) at least.

Infocenter —> Special Functions —> Service —

> Code 8500 —> Tuner AGC —> Automatic.

Alignment Process

The control processor IC850 will set the

optimum value for the delayed gain control

voltage. Activate with button “OK”.

1.2 (ii): Alignment

Tuner-AGC Manual.

Preparation

Feed in a standard test pattern in the upper

range of the UHF band; the RF must be ≥1.5mV

(64dBm V, noise-free picture) at least.

Infocentre —> Special Functions —> Service —

> Code 8500 —> Tuner-AGC —> Manual.

or

Digitalvoltmeter: Tuner-Contact 9.

Alignment Process

Press “OK”. With buttons - + tune the TV station

so that noise just starts to appear on the picture.

Then tune in reverse direction until the picture

just becomes noise free. Store with “OK”

With buttons - + adjust ≥3.3V.

1.3: Alignment

(i) AFC-Reference Automatic

Preparation

Infocentre —> Special Functions —> Service —

> Code 8500 —> AFC-Reference Æ Automatic.

Tune to a local station on a channel as low as

possible at the desired programme position with

standard channel spacing without fine tuning.

Alignment Process

On activation of AFC Reference Automatic a

rectified IF-voltage is measured at the AFC

output of the IF amplifier which is used on

station search as a comparative value for VCRHF playback (station identification “AV”) to

readjust the modulator drift.

Activate with “OK”

(ii): AFC-Reference Def. Value.

Preparation

Not for Servicing.

Alignment Process

The AFC Reference Def. Value contains only

average values stored during production.

1.4: Alignment

Text RGB-Level

Preparation

Infocentre —> Special Functions —> Service —

> Code 8500 —> Text RGB-Level.

Alignment Process

Change the value with buttons - + to “Full level”

or “Half level”.

1.5: Alignment

White balance.

Preparation

Black Stretch “off” (Picture Menu).

Infocentre —> Special Functions —> Service —

> Code 8500 —> White balance.

Alignment Process

With the - + buttons set the VG (amplification

green) and VB (amplification blue) values so

that the white rectangular area in the middle of

the picture becomes achromatic.

Store with “OK” .

1.6: Alignment

Bottom flutter gate.

Preparation

Connect the video recorder and play back the

recording.

Infocentre —> Special Functions —> Service —

> Code 8500 —> Bottom flutter gate.

Alignment Process

With the - + buttons adjust for minimum flutter at

the top or bottom picture edge.

1.7: Alignment

Type of picture tube.

Preparation

Infocentre —> Special Functions —> Service —

> Code 8500 —> Tube type.

Alignment Process

With the - + buttons select T82/16:9 or T70/16:9.

1.8: Alignment

Video processor

Preparation

Infocentre —> Special Functions —> Service —

> Code 8500 —> Video processor.

Alignment Process

With the - + buttons switch the Video processor

to TDA 4686 or TDA 4780 which may be fitted to

the TV set. TDA 4780 contains the features for

Black Stretch, Blue Stretch and Gamma Control.

1.9: Alignment

RGB Sync-level.

Preparation

Infocentre —> Special Functions —> Service —

> Code 8500 —> RGB Sync-level.

Alignment Process

In RGB operation it is possible to set the RGB

level to “on” or “off” with the buttons - + to

eliminate line tearing for example in this mode.

1.10: Alignment

VM (Velocity Modulation).

Preparation

Infocentre —> Special Functions —> Service —

> Code 8500 —> Velocity Modulation.

Alignment Process

With the - + buttons switch the Velocity Modulation on or off.

1.11: Alignment

Picture Sharpness.

Preparation

Infocentre —> Picture Menu —> Sharpness.

Alignment Process

Adjust with - + buttons for optimal picture

sharpness.

1.12: Alignment

Colour Match.

Alignment Process

Infocentre —> Special Functions —> Settings

—> Colour Match.

1.13: Alignment

Picture Geometry.

Preparation

Infocentre —> Special Functions —> Service —

> Code 8500 —> Geometry.

Feed in a test generator pattern or a standard

test pattern in 16:9 format via the aerial or use

the integrated test pattern. Feed in the geometry

test pattern in Cinema mode.

Attention:

The “Line Shift” alignment influences the line

phase. Before this adjustment, set the horizontal

amplitude to minimum and if necessary correct

the raster position with the “Shift Plug”.

Reset:

The “Reset” menu contains:

either the optimum picture geometry data

entered during production or the average data

set read out from the ROM if the TV is switched

on with the emergency data set. If the TV has

been adjusted wrongly, these basic values can

be loaded at any time as follows:

Call up Infocentre —> Special Functions —>

Service —> Code 8500 —> Geometry —>

Reset and confirm with “OK”.

Alignment Process

Via the menu, select the geometry values for the

vertical deflection, then set the values for the

horizontal deflection, first at 50Hz then at 60Hz

field frequency. Now with - or + button, move the

picture into the centre of the raster. Re-adjust

the horizontal amplitude according to the test

pattern.

Store:

Call up “End without memory” and change with

the button - or + to “End with memory”.

Store the setting with the “OK” button.

Whenever the TV is switched on the picture

geometry is set to the value stored last.

1.14: Alignment

Adjustment of the bridge coil L573.

Preparation

Infocentre —> Special Functions —> Service —

> Code 8500 —> Geometry.

Set the horizontal amplitude (width) to minimum.

Connect channel 1 of the oscilloscope to the

collector of the transistor T572.

Connect channel 2 of the oscilloscope between

diodes D571 and D572.

Alignment Process

Set the coil L573 so that the pulse width of both

oscillograms is the same.

1.15: Alignment

Line Sharpness.

Preparation

Select the convergence test pattern:

Contrast to maximum, set the brightness so that

the black background of the test pattern is just

brightening.

Alignment Process

With focus control on the CRT panel adjust the

horizontal lines for maximum sharpness.

Subsequently, with the focus control on the

focusing panel, adjust the vertical lines for

maximum sharpness. Repeat.

Attention:

For measurements on the focusing panel use

only sufficiently insulated measuring cables and

test probes with adequate electric strength

(eg. 100:1).

2: Picture Tube Panel

Measuring instruments:

Oscilloscope with 10:1 test probe, high resistance voltmeter.

Service works after replacement or repair of the

picture tube panel:

Alignments no. 2:1 and 2:2.

Page 3

Service Adjustments Cont’d.

3GRUNDIG CUC 1982

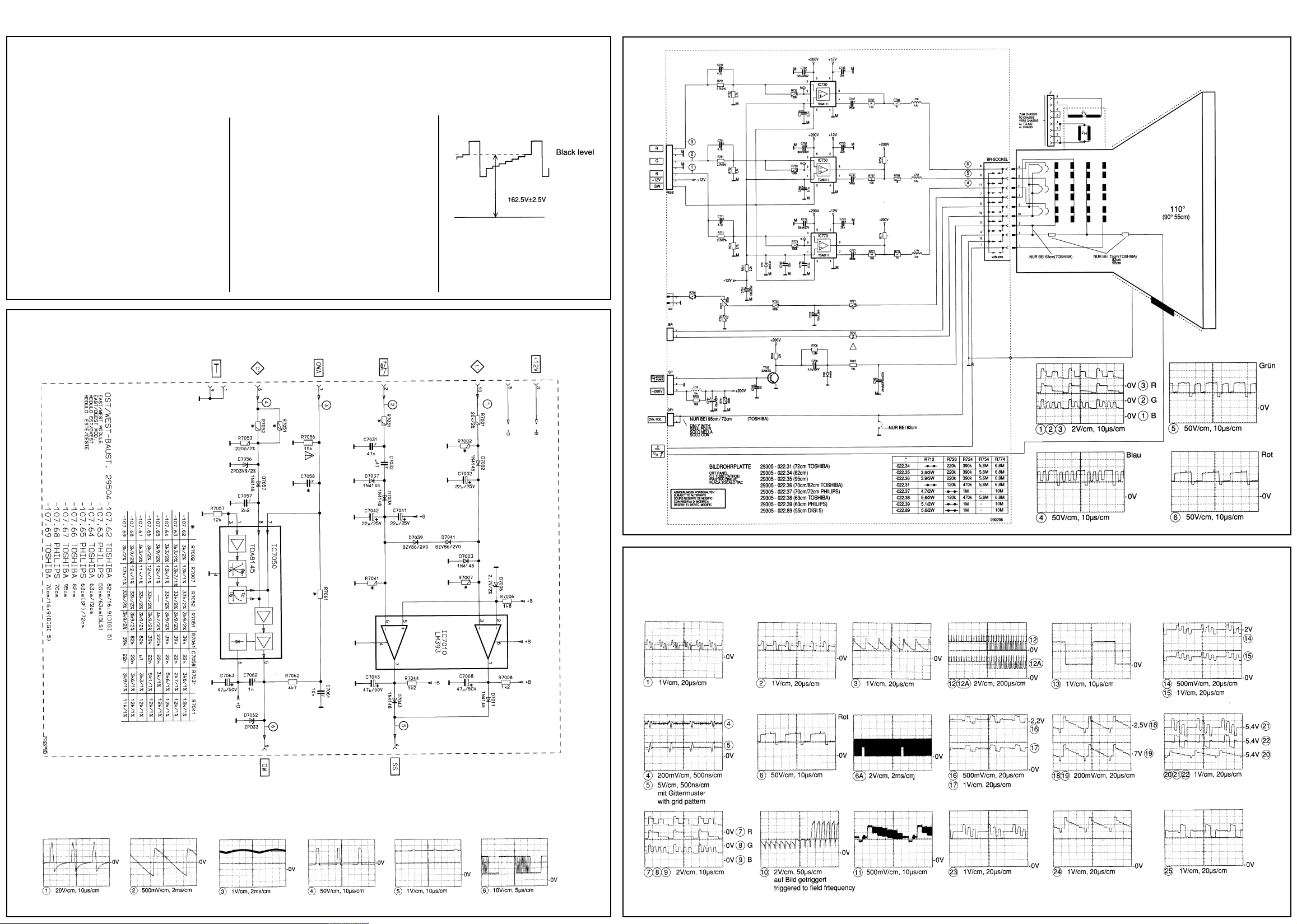

CRT Diagram

2.1: Alignment

White balance.

Preparation

Black Stretch set to “off” (Picture Menu).

Infocentre —> Special Functions —> Service —

> Code 8500 —> White Balance.

Alignment Process

With the - + buttons set the VG (amplification

green) and VB (amplification blue) values so

that the white rectangular area in the middle of

the picture becomes achromatic.

Store with “OK”.

2.2: Alignment

Screen grid voltage.

Preparation

- Feed in the test pattern.

- Switch the TV receiver to AV mode.

- Adjust the screen brightness with the remote

control handset so that the grey areas just

become dark.

- Connect the voltmeter (200 kW series

resistance) to the test points R,G,B to

determine the test point with the highest

voltage level.

- Oscilloscope: measured test point.

Alignment Process

With the control SG on the picture tube panel

set the voltage to 162.5V±2.5V.

If flyback lines are visible on the screen reduce

the voltage by 10V approximately.

East West Diagram

Fig 2.

Waveforms

- Video Diagram

Page 4

GRUNDIG CUC 1982

4

Video Diagram

1

Continued at 1

Page 5

5GRUNDIG CUC 1982

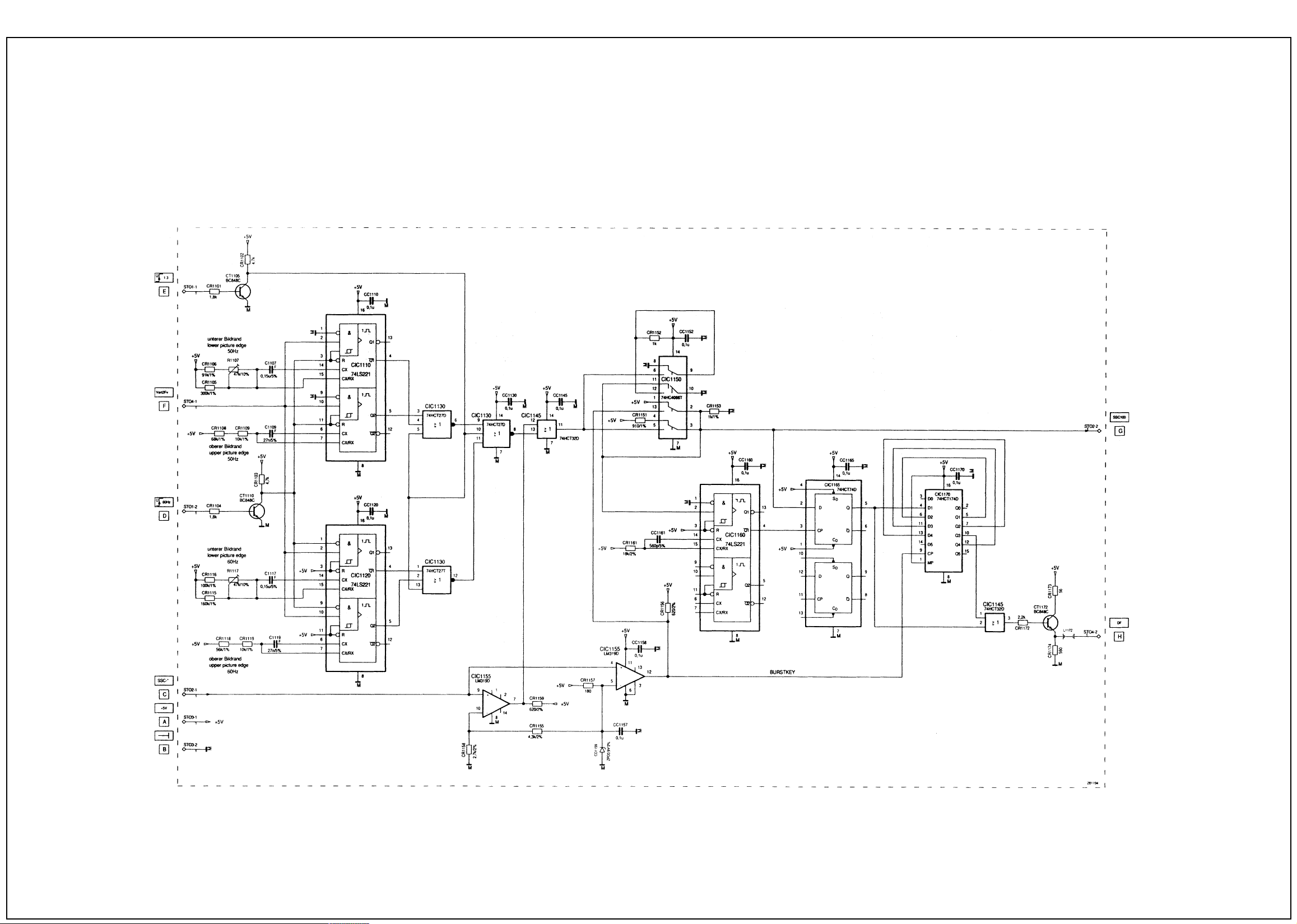

Sandcastle Diagram

Page 6

GRUNDIG CUC 1982

6

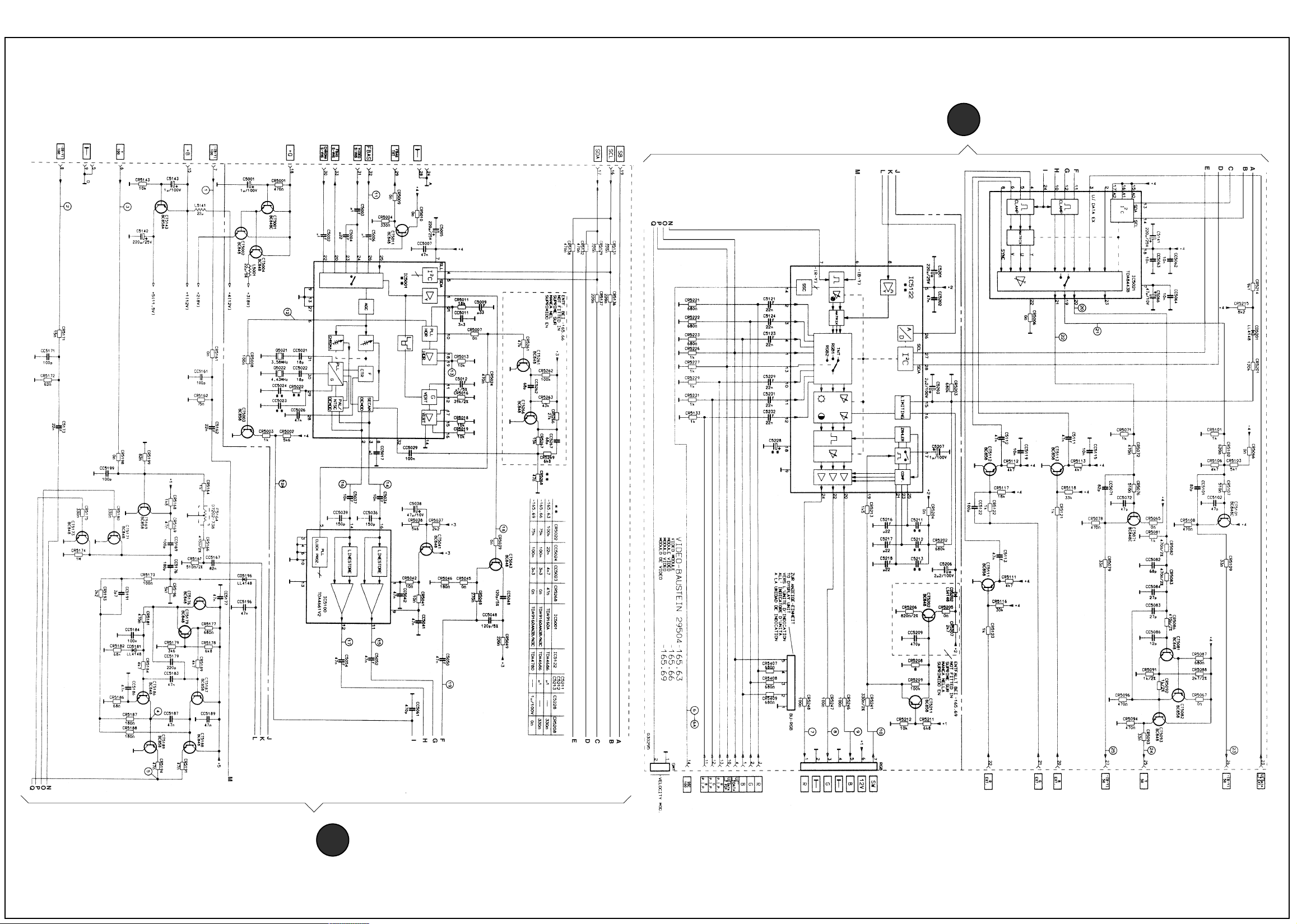

Control Diagram

Continued at 2

Page 7

Control Diagram Cont’d

7GRUNDIG CUC 1982

2

Page 8

GRUNDIG CUC 1982

8

Feature Box Diagram

Continued at 3

Page 9

Feature Box Diagram Cont’d

9GRUNDIG CUC 1982

3

Page 10

GRUNDIG CUC 1982

10

Focussing Diagram

Power Supply Diagram

Interference Diagram

Page 11

11GRUNDIG CUC 1982

Main Diagram

Continued at 4

Page 12

GRUNDIG CUC 1982

12

Main Diagram Cont’d

4

Page 13

13GRUNDIG CUC 1982

Velocity Diagram

Socket Diagram

Continued at 5

Page 14

GRUNDIG CUC 1982

Socket Diagram Cont’d

14

5

Page 15

15GRUNDIG CUC 1982

Tuner Diagram

Continued at 6

Page 16

GRUNDIG CUC 1982

Tuner Diagram Cont’d

16

6

Loading...

Loading...