Page 1

GRUNDFOS INSTRUCTIONS

LCSE, VLSE

Grundfos E-pumps with MLE frequency-controlled

permanent-magnet motors

Installation and operating instructions

Page 2

English (US)

English (US) Installation and operating instructions

Original installation and operating instructions

These installation and operating instructions describe Grundfos

LCSE, VLSE.

Sections 1-4 give the information necessary to be able to unpack,

install and start up the product in a safe way.

Sections 5-11 give important information about the product, as

well as information on service, fault finding and disposal of the

product.

CONTENTS

Page

1. Limited warranty

2. General information

2.1 Hazard statements

2.2 Notes

2.3 Abbreviations and definitions

3. Receiving the product

3.1 Transporting the product

3.2 Inspecting the product

4. Installing the product

4.1 Mechanical installation

4.2 Electrical installation

4.3 Installing a communication interface module

4.4 Changing the position of the control panel

5. Product introduction

5.1 Product description

5.2 Identification

5.3 Bus signal

5.4 Grundfos Eye

5.5 Signal relays

6. User interfaces

6.1 Advanced control panel

6.2 Grundfos GO

6.3 R100 remote control

7. Description of functions

7.1 "Setpoint"

7.2 "Operating mode"

7.3 "Set manual speed"

7.4 "Control mode"

7.5 "Analog inputs"

7.6 "Pt100/1000 inputs"

7.7 "Digital inputs"

7.8 "Digital inputs/outputs"

7.9 "Signal relays" 1 and 2 ("Relay outputs")

7.10 "Analog output"

7.11 "Controller" ("Controller settings")

7.12 "Operating range"

7.13 "External setpoint function"

7.14 "Predefined setpoints"

7.15 "Limit-exceeded function"

7.16 "LiqTec" ("LiqTec function")

7.17 "Stop function" ("Low-flow stop function")

7.18 "Pipe filling function"

7.19 "Pulse flowmeter" ("Pulse flowmeter setup")

7.20 "Ramps"

7.21 "Standstill heating"

7.22 "Motor bearing monitoring"

7.23 "Service"

7.24 "Number" ("Pump number")

7.25 "Radio communication" ("Enable/disable radio comm.")

7.26 "Language"

7.27 "Date and time" ("Set date and time")

7.28 "Unit configuration" ("Units")

14

15

16

16

17

17

18

19

20

20

25

29

31

31

31

31

31

36

37

37

38

39

40

41

42

42

45

46

47

47

49

49

50

50

50

51

51

51

51

52

52

7.29 "Buttons on product" ("Enable/disable settings")

7.30 "Delete history"

7.31 "Define Home display"

7.32 "Display settings"

7.33 "Store settings" ("Store actual settings")

7.34 "Recall settings" ("Recall stored settings")

7.35 "Pump name"

7.36 "Connection code"

7.37 "Run start-up guide"

7.38 "Alarm log"

7.39 "Warning log"

7.40 "Assist"

3

3

3

4

4

5

5

5

5

5

6

7.41 "Assisted pump setup"

7.42 "Setup, analog input"

7.43 "Setting of date and time"

7.44 "Multi-pump setup" ("Setup of multi-pump system")

7.45 "Description of control mode"

7.46 "Assisted fault advice"

8. Description of settings

8.1 Priority of settings

8.2 Factory settings

9. Servicing the product

9.1 Motor

9.2 Pump

9.3 Cleaning the product

10. Technical data

10.1 Operating conditions

10.2 Megging

10.3 Technical data, single-phase motors

10.4 Technical data, three-phase motors

10.5 Inputs/outputs

10.6 Other technical data

11. Disposing of the product

Prior to installation, read this document. Installation

and operation must comply with local regulations and

accepted codes of good practice.

52

52

53

53

53

53

53

54

54

54

55

55

55

55

55

56

58

58

59

59

60

61

61

61

61

62

62

62

62

63

63

64

65

2

Page 3

1. Limited warranty

New equipment manufactured by seller or service supplied by

seller is warranted to be free from defects and workmanship

under normal use and service for a minimum of twenty-four (24)

months from date of installation, thirty (30) months from date of

shipment, unless otherwise stated in product warranty guide

(available upon request). In the case of spare or replacement

parts manufactured by seller, the warranty period shall be for a

period of twelve months from shipment.

Sellers obligation under this warranty is limited to repairing or

replacing, at its option, any part found to its satisfaction to be so

defective, provided that such part is, upon request, returned to

seller’s factory from which it was shipped, transportation prepaid.

Parts replaced under warranty shall be warranted for twelve

months from the date of the repair, not to exceed the original

warranty period. This warranty does not cover parts damaged by

decomposition from chemical action or wear caused by abrasive

materials, nor does it cover damage resulting from misuse,

accident, neglect, or from improper operation, maintenance,

installation, modification, or adjustment. This warranty does not

cover parts repaired outside seller’s factory without prior written

approval. Seller makes no warranty as to starting equipment,

electrical apparatus or other material not of its manufacture. If

purchaser or others repair, replace, or adjust equipment or parts

without sellers prior written approval, seller is relieved of any

further obligation to purchaser under this paragraph with respect

to such equipment or parts, unless such repair, replacement, or

adjustment was made after seller failed to satisfy within a

reasonable amount of time seller’s obligations under this

paragraph. Sellers liability for breach of these warranties (or for

breach of any other warranties found by a court of competent

jurisdiction to have been given by seller) shall be limited to: (A)

accepting return of such equipment EXW plant of manufacture

and (B) refunding any amount paid thereon by purchaser (less

depreciation at the rate of 15 % per year if purchaser has used

equipment for more than thirty [30] days), and cancelling any

balance still owing on the equipment or (C) in the case of service,

at the sellers option, redoing the service, or refunding the

purchase order amount of the service or portion thereof upon

which such liability is based. These warranties are expressly in

lieu of any other warranties, express or implied, and seller

specifically disclaims any implied warranty of merchantability or

fitness for a particular purpose, and in lieu of any other obligation

or liability on the part of the seller whether a claim is based upon

negligence, breach of warranty, or any other theory or cause of

action. In no event shall seller be liable for any consequential,

incidental, indirect, special or punitive damages of any kind. For

purposes of this paragraph, the equipment warranted shall not

include equipment, parts, and work not manufactured or

performed by seller. With respect to such equipment, parts, or

work, seller’s only obligation shall be to assign to purchaser the

warranties provided to seller by the manufacturer or supplier

providing such equipment, parts or work. No equipment furnished

by seller shall be deemed to be defective by reason of normal

wear and tear, failure to resist erosive or corrosive action of any

fluid or gas, purchaser’s failure to properly store, install, operate,

or maintain the equipment in accordance wtih good industry

practices or specific recommendations of seller, including, but not

limited to seller’s installation and operation manuals, or

purchaser’s failure to provide complete and accurate information

to seller concerning the operational application of the equipment.

2. General information

These installation and operating instructions are a supplement to

the installation and operating instructions for the corresponding

standard pumps LCS and VLS. For instructions not mentioned

specifically in this manual, see the installation and operating

instructions for the standard pump.

2.1 Hazard statements

The symbols and hazard statements below may appear in

Grundfos installation and operating instructions, safety

instructions and service instructions.

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious personal injury.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious personal injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate personal injury.

The hazard statements are structured in the following way:

SIGNAL WORD

Description of hazard

Consequence of ignoring the warning.

- Action to avoid the hazard.

English (US)

3

Page 4

English (US)

2.2 Notes

The symbols and notes below may appear in Grundfos

installation and operating instructions, safety instructions and

service instructions.

Observe these instructions for explosion-proof

products.

A blue or grey circle with a white graphical symbol

indicates that an action must be taken.

A red or grey circle with a diagonal bar, possibly with

a black graphical symbol, indicates that an action

must not be taken or must be stopped.

If these instructions are not observed, it may result in

malfunction or damage to the equipment.

Tips and advice that make the work easier.

2.3 Abbreviations and definitions

AI Analog input.

AL Alarm, out of range at lower limit.

AO Analog output.

AU Alarm, out of range at upper limit.

CIM Communication interface module.

Current sinking

Current

sourcing

DI Digital input.

DO Digital output.

ELCB Earth (ground) leakage circuit breaker.

FM Functional module.

GDS

GENIbus Proprietary Grundfos fieldbus standard.

GFCI

GND Ground.

Grundfos Eye Status indicator light.

LIVE

OC

PE Protective earth (ground).

PELV

RCD Residual-current device

SELV

The ability to draw current into the terminal and

guide it towards GND in the internal circuitry.

The ability to push current out of the terminal

and into an external load which must return it

to GND.

Grundfos Digital Sensor.

Factory-fitted sensor in some Grundfos pumps.

Ground fault circuit interrupter.

(USA and Canada).

Low voltage with the risk of electric shock if the

terminals are touched.

Open collector:

Configurable open-collector output.

Protective extra-low voltage.

A voltage that cannot exceed ELV under

normal conditions and under single-fault

conditions, except earth (ground) faults in

other circuits.

Safety extra-low voltage.

A voltage that cannot exceed ELV under

normal conditions and under single-fault

conditions, including earth (ground) faults in

other circuits.

4

Page 5

3. Receiving the product

D

4.1.2 Mounting

3.1 Transporting the product

WARNING

Falling objects

Death or serious personal injury

- Secure the product during transportation to prevent

it from tilting or falling down.

CAUTION

Crushing of feet

Minor or moderate personal injury

- Wear safety shoes when moving the product.

• Motors from 3 to 5 Hp (2.2 to 5.5 kW): Do not stack more than

two motors in their original packaging.

• Motors from 7.5 to 15 Hp (5.5 to 11 kW): Do not stack the

motors.

3.2 Inspecting the product

Before you install the product, do the following:

1. Check that the product is as ordered.

2. Check that no visible parts have been damaged.

3. If parts are damaged or missing, contact your local Grundfos

sales company.

4. Installing the product

4.1 Mechanical installation

4.1.1 Handling the product

Observe local regulations setting limits for manual lifting or

handling. The motor weight is stated on the nameplate.

CAUTION

Back injury

Minor or moderate personal injury

- Use lifting equipment.

CAUTION

Crushing of feet

Minor or moderate personal injury

- Secure the product to a solid foundation by bolts

through the holes in the flange or the base plate.

In order to maintain the UL mark, additional

requirements apply to the equipment. See Appendix,

page 66.

4.1.3 Cable entries

See the size of the cable entries in section 10.6 Other technical

data.

4.1.4 Cable glands

The number and size of cable glands delivered with the pump

depends on the motor size. See section 10.6 Other technical

data.

4.1.5 Ensuring motor cooling

Leave at least 2 in. (50 mm) between the end of the fan cover and

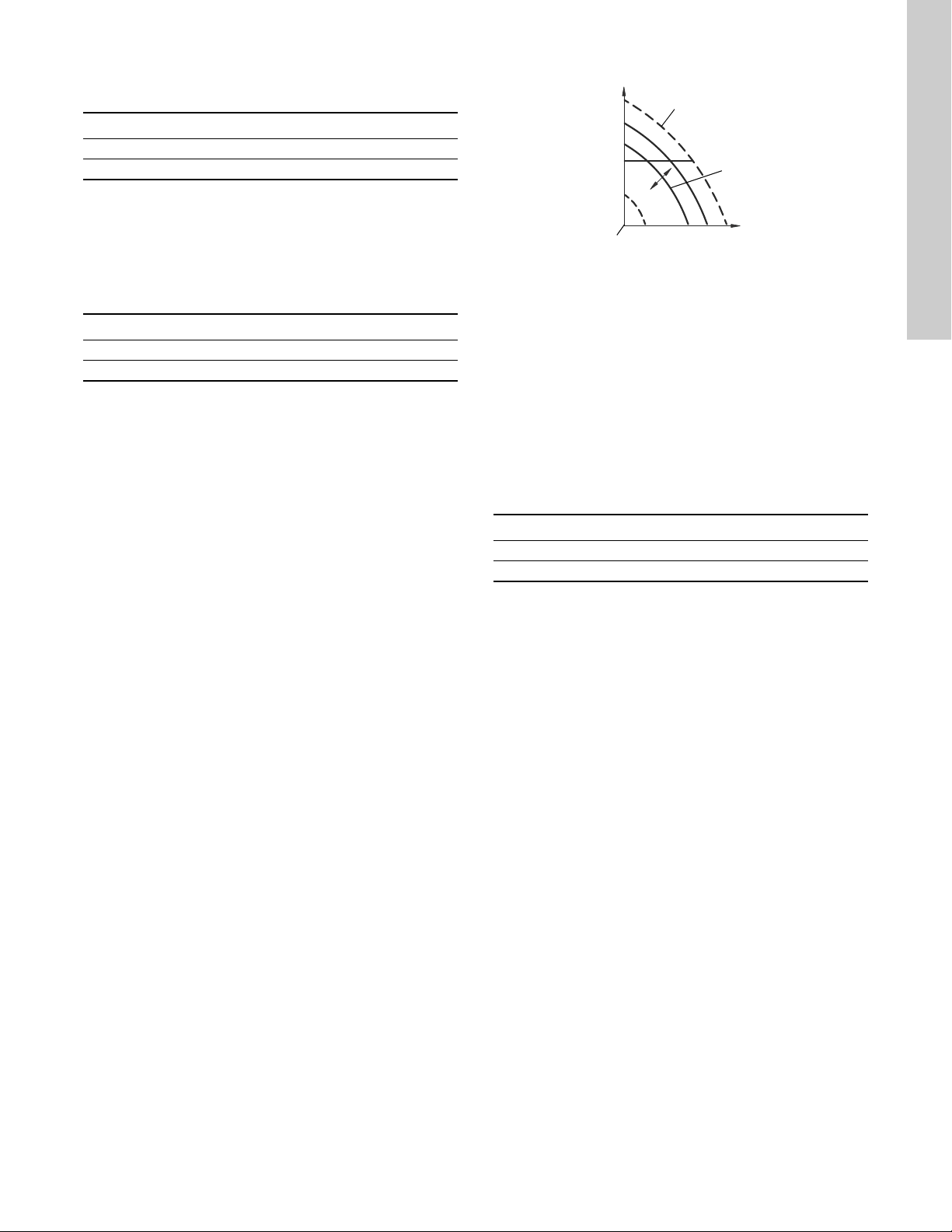

a wall or other fixed objects. See fig. 1.

Fig. 1 Minimum distance (D) from the motor to a wall or other

fixed objects

English (US)

TM05 5236 3512

CAUTION

Crushing of feet

Minor or moderate personal injury

- Wear safety shoes and attach lifting equipment to

the motor eyebolts when handling the product.

Do not lift the product by the terminal box.

5

Page 6

English (US)

B3 B14 B5

4.1.6 Outdoor installation

The enclosure class of MLE motor is a NEMA 3 rating. If you

install the motor outdoors, provide the motor with a suitable cover

and open the drain holes to avoid condensation on the electronic

components. See figs 2 and 3.

When fitting a cover to the motor, observe the

guideline in section 4.1.5 Ensuring motor cooling.

The cover must be sufficiently large to ensure that the motor is

not exposed to direct sunlight, rain or snow. Grundfos does not

supply covers. We therefore recommend that you have a cover

built for the specific application. In areas with high humidity, we

recommend that you enable the built-in standstill heating

function. See section 7.21 "Standstill heating".

Fig. 2 Examples of covers (not supplied by Grundfos)

In order to maintain the UL mark, additional

requirements apply to the equipment. See Appendix,

page 66.

4.1.7 Drain holes

When the motor is installed in moist surroundings or areas with

high humidity, the bottom drain hole must be open. The enclosure

class of the motor will then be lower. This helps prevent

condensation in the motor as the motor becomes self-venting,

and it allows water and humid air to escape.

The motor has a plugged drain hole on the drive side. You can

turn the flange 90 ° to both sides or 180 °.

Fig. 3 Drain holes

4.2 Electrical installation

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply to the motor and to the

signal relays. Wait at least 5 minutes before you

make any connections in the terminal box. Make

sure that the power supply cannot be accidentally

switched on.

DANGER

Electric shock

Death or serious personal injury

- Check that the supply voltage and frequency

correspond to the values stated on the nameplate.

If the power supply cable is damaged, it must be replaced by the

manufacturer, the manufacturer's service partner or a similarly

qualified person.

The user or the installer is responsible for the installation of

TM05 3496 3512

correct grounding and protection according to local regulations.

All operations must be carried out by a qualified electrician.

4.2.1 Protection against electric shock, indirect contact

WARNING

Electric shock

- Death or serious personal injury

- Connect the motor to a protective ground and

provide protection against indirect contact in

accordance with local regulations.

Protective-ground conductors must always have a yellow/green

(PE) or yellow/green/blue (PEN) color marking.

Protection against power supply voltage transients

The motor is protected against power supply voltage transients in

accordance with EN 61800-3.

Motor protection

The motor requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking.

TM02 9037 1604

6

Page 7

4.2.2 Cable requirements

RCD, type B

Cable cross-section

DANGER

Electric shock

Death or serious personal injury

- Always comply with local regulations as to cable

cross-sections.

Single-phase supply

Conductor type

Solid

Stranded 0.5 - 2.5 30-12

Three-phase supply

Conductor

material

Copper

Cross section

2

[mm

][AWG]

0.5 - 2.5 28-12

Single-phase supply voltage

• 1 x 200-240 V - 10 %/+ 10 %, 50/60 Hz, PE.

Check that the supply voltage and frequency correspond to the

values stated on the nameplate.

If you want to supply the motor through an IT

network, make sure that you have a suitable motor

variant. If you are in doubt, contact Grundfos.

The wires in the motor terminal box must be as short as possible.

Excepted from this is the separated ground conductor which must

be so long that it is the last one to be disconnected in case the

cable is inadvertently pulled out of the cable entry.

For maximum backup fuse, see section 10.3.1 Supply voltage.

English (US)

Conductor type

Solid

Stranded 0.5 - 10 18-8

Conductors

Typ e

Stranded or solid copper conductors.

Temperature rating

Temperature rating for conductor insulation: 140 °F (60 °C).

Temperature rating for outer cable sheath: 167 °F (75 °C).

4.2.3 Power supply

Conductor

material

Copper

Cross section

2

][AWG]

[mm

0.5 - 10 18-8

DANGER

Electric shock

- Death or serious personal injury

- Use the recommended fuse size. See section

10.3.1 Supply voltage.

TM05 4034 1912TM05 3494 1512

Fig. 4 Example of a power supply-connected motor with

power supply switch, backup fuse and additional

protection

Fig. 5 Power supply connection, single-phase motors

7

Page 8

English (US)

L1

L2

L3

L2

L1

L3

PE

RCD, type B

Three-phase supply voltage

• 3 x 440-480 V - 10 %/+ 10 %, 50/60 Hz, PE.

Check that the supply voltage and frequency correspond to the

values stated on the nameplate.

The wires in the motor terminal box must be as short as possible.

Excepted from this is the separated ground conductor which must

be so long that it is the last one to be disconnected in case the

cable is inadvertently pulled out of the cable entry.

In order to avoid loose connections, make sure that you have

pressed home the terminal block for L1, L2 and L3 in its socket

when you connect the supply cable.

For maximum backup fuse, see section 10.4.1 Supply voltage.

4.2.4 Additional protection

DANGER

Electric shock

Death or serious personal injury

- Only use residual-current circuit breakers (ELCB,

GFCI, RCD) of type B.

The residual-current circuit breaker must be marked with the

following symbol:

If you want to supply the motor through an IT

network, make sure that you have a suitable motor

variant. If you are in doubt, contact Grundfos.

Corner grounding is not allowed for supply voltages

above 3 x 480 V, 50/60 Hz.

Fig. 6 Example of a power supply-connected motor with

power supply switch, backup fuses and additional

protection

Fig. 7 Power supply connection, three-phase motors

The total leakage current of all the electrical equipment in the

installation must be taken into account. You find the leakage

current of the motor in sections 10.3.2 Leakage current and

10.4.2 Leakage current (AC).

This product can cause a direct current in the protective ground

conductor.

Overvoltage and undervoltage protection

Overvoltage and undervoltage may occur in case of unstable

power supply or a faulty installation. The motor is stopped if the

voltage falls outside the permissible voltage range. The motor

restarts automatically when the voltage is again within the

permissible voltage range. Therefore, no additional protection

relay is required.

The motor is protected against transients from the

TM05 3942 1812TM05 3495 1512

power supply according to EN 61800-3. In areas with

high lightning intensity, we recommend external

lightning protection.

Overload protection

If the upper load limit is exceeded, the motor automatically

compensates for this by reducing the speed and stops if the

overload condition persists.

The motor remains stopped for a set period. After this period, the

motor automatically attempts to restart. The overload protection

prevents damage to the motor. Consequently, no additional motor

protection is required.

Overtemperature protection

The electronic unit has a built-in temperature sensor as an

additional protection. When the temperature rises above a certain

level, the motor automatically compensates for this by reducing

the speed and stops if the temperature keeps rising. The motor

remains stopped for a set period. After this period, the motor

automatically attempts to restart.

Protection against phase unbalance

Three-phase motors must be connected to a power supply with a

quality corresponding to IEC 60146-1-1, class C, to ensure

correct motor operation at phase unbalance. This also ensures

long life of the components.

8

Page 9

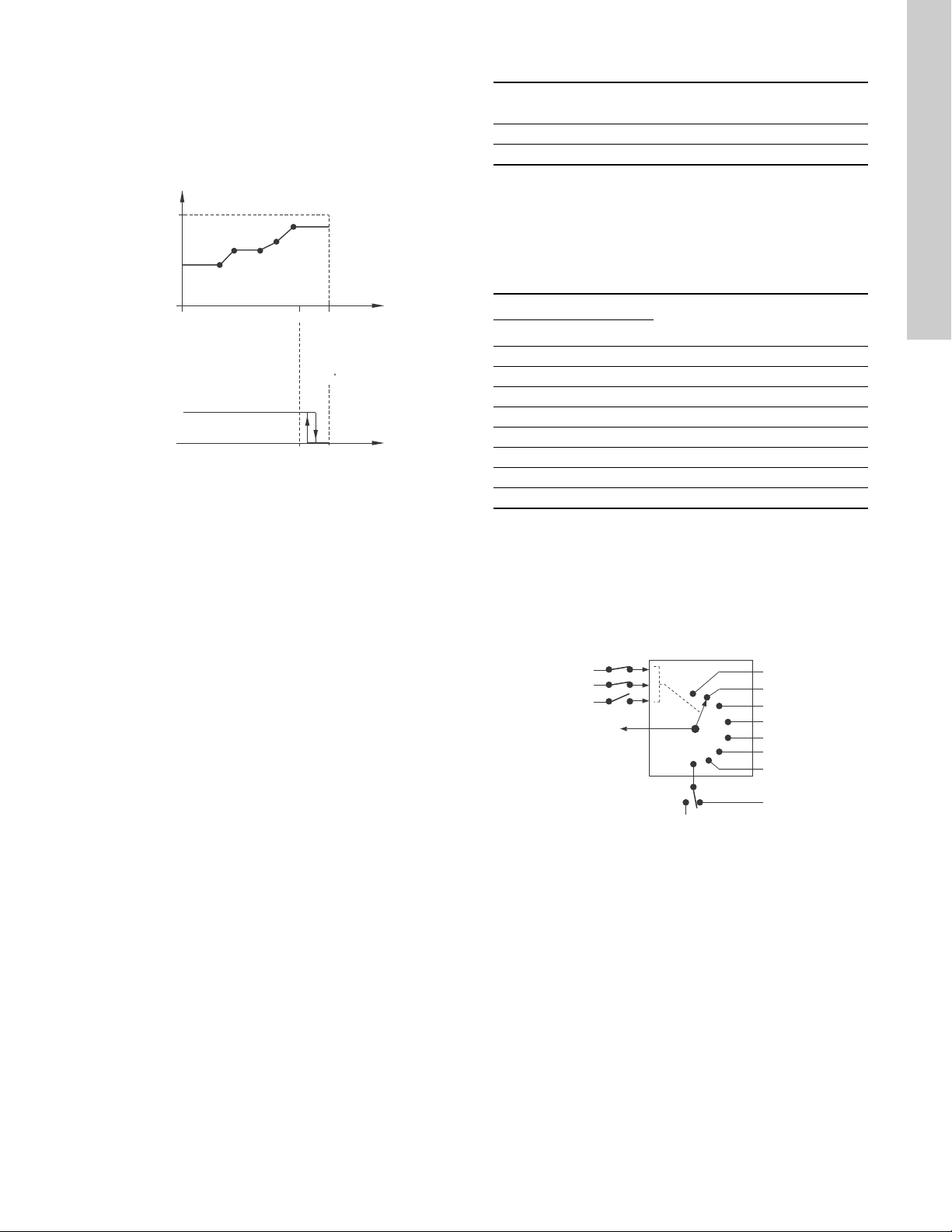

4.2.5 Connection terminals

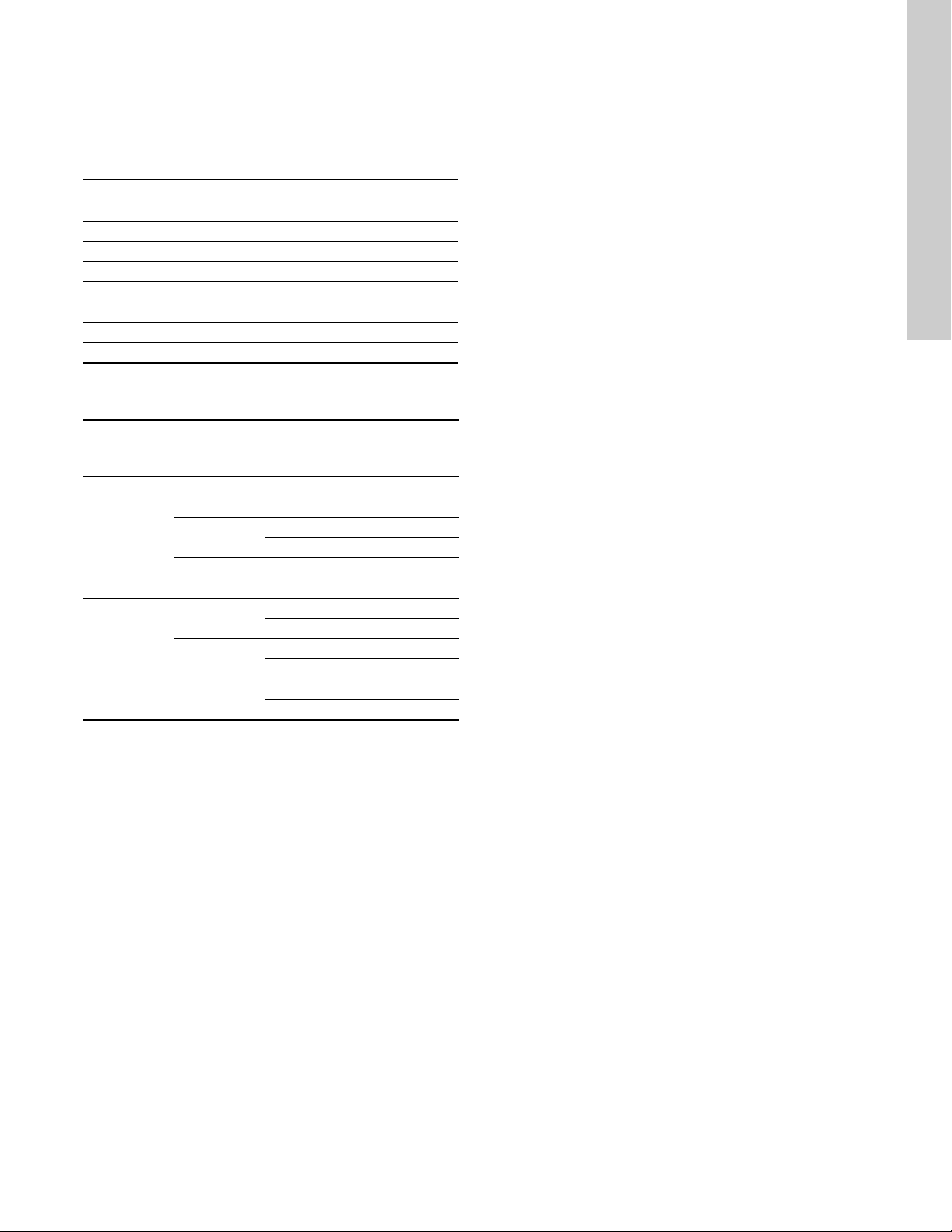

The descriptions and terminal overviews in this section apply to

both single- and three-phase motors.

For maximum torques, see section Torques, page 64.

Connection terminals, LCSE and VLSE

LCSE and VLSE pumps have a number of inputs and outputs

enabling the pumps to be used in advanced applications where

many inputs and outputs are required.

The pumps have these connections:

• three analog inputs

• one analog output

• two dedicated digital inputs

• two configurable digital inputs or open-collector outputs

• Grundfos Digital Sensor input and output

• two Pt100/1000 inputs

• two LiqTec sensor inputs

• two signal relay outputs

• GENIbus connection.

See fig. 8.

Digital input 1 is factory-set to be start-stop input

where open circuit results in stop. A jumper has been

factory-fitted between terminals 2 and 6. Remove the

jumper if digital input 1 is to be used as external

start-stop or any other external function.

English (US)

DANGER

Electric shock

Death or serious personal injury

- Make sure that the wires to be connected to the

connection groups below are separated from each

other by reinforced insulation in their entire

lengths.

• Inputs and outputs

All inputs and outputs are internally separated from the power

supply-conducting parts by reinforced insulation and galvanically

separated from other circuits. All control terminals are supplied by

protective extra-low voltage (PELV), thus ensuring protection

against electric shock.

• Start-stop: (Digital input 1) = Terminals 2 and 6

• Pressure sensor: (Analog input 1) = Terminals 4 and 8

• Pressure switch: (Digital input 3) = Terminals 6 and 10

• External analog signal input: (Analog input 2) = Terminals 7

and 23

• GENIbus Terminals A, Y and B

• Signal relay outputs

– Signal relay 1:

LIVE:

You can connect supply voltages up to 250 VAC.

PELV:

The output is galvanically separated from other circuits.

Therefore, you can connect the supply voltage or protective

extra-low voltage to the output as desired.

– Signal relay 2:

PELV:

The output is galvanically separated from other circuits.

Therefore, you can connect the supply voltage or protective

extra-low voltage to the output as desired.

• Power supply (terminals N, PE, L or L1, L2, L3, PE).

9

Page 10

English (US)

3

15

8

26

23

25

24

7

21

20

22

B

Y

6

5

2

4

10

A

+24 V*

1

14

9

12

17

19

11

18

+24 V*

+

+24 V*

OC

DI

+24 V*/5 V*

+24 V*

+

+

+

+24 V*/5 V*

+24 V*

+24 V*

+

+

+24 V*/5 V*

+24 V*

+5 V*

AI2

GDS RX

GDS TX

GND

GENIbus A

GENIbus B

+5 V

+24 V

+24 V

GND

GENIbus Y

GND

+5 V

DI1

AI1

DI3/OC1

LiqTec

AI3

GND

DI2

LiqTec

GND

AO

Pt100/1000

Pt100/1000

DI4/OC2

GND

+24 V*

OC

DI

GND

NC

C2

NO

NC

C1

NO

+5 V*

Terminal Type Function

Normally closed

NC

contact

C1 Common

Normally open

NO

contact

Normally closed

NC

contact

C2 Common

Normally open

NO

contact

Signal relay 1

(LIVE or PELV)

Signal relay 2

(PELV only)

18 GND Ground

Digital input/output,

11 DI 4/O C2

configurable.

Open collector: Max. 24 V

resistive or inductive.

19 Pt100/1000 input 2 Pt100/1000 sensor input

17 Pt100/1000 input 1 Pt100/1000 sensor input

Analog output:

12 AO

0-20 mA / 4-20 mA

0-10 V

9 GND Ground

Analog input:

14 AI3

0-20 mA / 4-20 mA

0-10 V

1 DI2 Digital input, configurable

* If you use an external supply source, there must be a

connection to GND.

Fig. 8 Connection terminals, LCSE and VLSE pumps

10

21 LiqTec sensor input 1

20 GND

22 LiqTec sensor input 2

LiqTec sensor input

(white conductor)

Ground (brown and black

conductors)

LiqTec sensor input

(blue conductor)

Digital input/output,

10 DI3/OC1

configurable.

Open collector: Max. 24 V

resistive or inductive.

Analog input:

4AI1

0-20 mA / 4-20 mA

0.5 - 3.5 V / 0-5 V / 0-10 V

2 DI1 Digital input, configurable

5+5 V

Supply to potentiometer and

sensor

6 GND Ground

TM05 3509 3512

A GENIbus, A GENIbus, A (+)

Y GENIbus, Y GENIbus, GND

B GENIbus, B GENIbus, B (-)

3 GND Ground

15 +24 V Supply

8 +24 V Supply

26 +5 V

Supply to potentiometer and

sensor

23 GND Ground

25 GDS TX

Grundfos Digital Sensor

output

24 GDS RX Grundfos Digital Sensor input

Analog input:

7AI2

0-20 mA / 4-20 mA

0.5 - 3.5 V / 0-5 V / 0-10 V

Page 11

Digital input 1 is factory-set to be start-stop input

where open circuit results in stop. A jumper has been

factory-fitted between terminals 2 and 6. Remove the

jumper if digital input 1 is to be used as external

start-stop or any other external function.

DANGER

Electric shock

Death or serious personal injury

- Make sure that the wires to be connected to the

connection groups below are separated from each

other by reinforced insulation in their entire

lengths.

• Inputs and outputs

All inputs and outputs are internally separated from the power

supply-conducting parts by reinforced insulation and galvanically

separated from other circuits. All control terminals are supplied by

protective extra-low voltage (PELV), thus ensuring protection

against electric shock.

• Start-stop: (Digital input 1) = Terminals 2 and 6

• Pressure sensor: (Analog input 1) = Terminals 4 and 8

• Pressure switch: (Digital input 3) = Terminals 6 and 10

• External analog signal input: (Analog input 2) = Terminals 7

and 23

GENIbus Terminals A, Y and B

• Signal relay outputs

– Signal relay 1:

LIVE:

You can connect supply voltages up to 250 VAC to the

output.

PELV:

The output is galvanically separated from other circuits.

Therefore, you can connect the supply voltage or protective

extra-low voltage to the output as desired.

– Signal relay 2:

PELV:

The output is galvanically separated from other circuits.

Therefore, you can connect the supply voltage or protective

extra-low voltage to the output as desired.

• Power supply (terminals N, PE, L or L1, L2, L3, PE).

English (US)

11

Page 12

English (US)

3

15

8

26

23

25

24

7

B

Y

6

5

2

4

10

A

AI2

GDS RX

GDS TX

GND

GENIbus A

GENIbus B

+5 V

+24 V

+24 V

GND

GENIbus Y

GND

+5 V

DI1

AI1

DI3/OC1

+24 V*

+

+

+24 V*/5 V*

+24 V*

+5 V*

NC

C2

NO

NC

C1

NO

+24 V*

+

+

+24 V*/5 V*

+24 V*

+24 V*

OC

DI

GND

Terminal Type Function

NC

C1 Common

NO

Normally closed

contact

Normally open

contact

Signal relay 1

(LIVE or PELV)

* If you use an external supply source, there must be a

connection to GND.

Fig. 9 Connection terminals, optional for LCSE and VLSE

pumps

NC

C2 Common

NO

Normally closed

contact

Normally open

contact

Signal relay 2

(PELV only)

Digital input/output,

10 DI3/OC1

configurable.

Open collector: Max. 24 V

resistive or inductive.

Analog input:

4AI1

0-20 mA / 4-20 mA

0.5 - 3.5 V / 0-5 V / 0-10 V

2 DI1 Digital input, configurable

5+5 V

Supply to potentiometer and

sensor

6 GND Ground

A GENIbus, A GENIbus, A (+)

Y GENIbus, Y GENIbus, GND

B GENIbus, B GENIbus, B (-)

3 GND Ground

15 +24 V Supply

8 +24 V Supply

26 +5 V

Supply to potentiometer and

sensor

23 GND Ground

TM05 3510 3512

25 GDS TX

24 GDS RX

Grundfos Digital Sensor

output

Grundfos Digital Sensor

input

Analog input:

7AI2

0-20 mA / 4-20 mA

0.5 - 3.5 V / 0-5 V / 0-10 V

12

Page 13

4.2.6 Signal cables

A

Y

B

A

Y

B

1

2

3

1

2

3

Motor

A

Y

B

A

Y

B

1

2

1

2

Motor

• Use screened cables with a cross-sectional area of minimum

28 AWG and maximum 16 AWG for the external on/off switch,

digital inputs, setpoint and sensor signals.

• Connect the screens of the cables to the frame at both ends

with good connection. The screens must be as close as

possible to the terminals. See fig. 10.

Fig. 10 Stripped cable with screen and wire connections

• Always tighten screws for frame connections whether a cable

is fitted or not.

• The wires in the motor terminal box must be as short as

possible.

Connection of E+pump to Danfoss pressure sensor MBS3000

The blue wire of the pressure sensor is connected to the #4

terminal of the E-pump. The brown wire of the pressure sensor is

connected to the #8 terminal of the E-pump.

See section 4.2.6 Signal cables for additional details.

4.2.7 Bus connection cable

New installations

For the bus connection, use a screened 3-core cable with a

cross-sectional area of minimum 28 AWG and maximum 16 AWG.

If the motor is connected to a unit with a cable clamp which is

identical to the one on the motor, connect the screen to this cable

clamp.

If the unit has no cable clamp leave the screen unconnected at

this end. See fig. 11.

TM02 1325 4402 TM05 1533 2911

Fig. 11 Connection with screened 3-core cable

Replacing a motor

• If a 2-core cable is used in the installation, connect it as shown

in fig. 12.

Fig. 12 Connection with screened 2-core cable

English (US)

TM05 3973 1812TM02 8842 0904

• If a screened 3-core cable is used in the installation, follow the

instructions in section New installations.

13

Page 14

English (US)

A

B

B

C

D

A

A

A

B

A

4.3 Installing a communication interface module

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply to the motor and to the

signal relays. Wait at least 5 minutes before

starting any work on the motor. Make sure that the

power supply cannot be accidentally switched on.

Always use an antistatic service kit when handling

electronic components. This prevents static electricity

from damaging the components.

When unprotected, place the component on the

antistatic cloth.

3. Remove the securing screw (fig. 16, A).

TM06 4082 1515TM06 4083 1515TM06 4195 1615

Fig. 16 Removing the securing screw

4. Fit the CIM module by aligning it with the three plastic holders

(fig. 17, A) and the connecting plug (fig. 17, B). Press home

the module using your fingers.

Fig. 13 Antistatic service kit

1. Loosen the four screws (fig. 14, A) and remove the terminal

box cover (fig. 14, B).

Fig. 14 Removing the terminal box cover

2. Remove the CIM cover (fig. 15, A) by pressing the locking tab

(fig. 15, B) and lifting the end of the cover (fig. 15, C). Then lift

the cover off the hooks (fig. 15, D).

TM06 4462 2315TM06 4081 1515TM06 4084 1515

Fig. 17 Fitting the CIM module

5. Fit and tighten securing screw (fig. 16, A) to 1.3 Nm.

6. Make the electrical connections to the CIM module as

described in the instructions delivered with the module.

7. Connect the cable screens of the bus cables to ground via

one of the ground clamps (fig. 18, A).

Fig. 18 Connecting the cable screens to ground

Fig. 15 Removing the CIM cover

14

Page 15

8. Route the wires for the CIM module. See the example in fig.

FCC

19.

Fig. 19 Example of wire routing

9. Fit the CIM cover.

10. If the CIM module is supplied with an FCC label, then place

this on the terminal box. See fig. 20.

4.4 Changing the position of the control panel

DANGER

Electric shock

Death or serious personal injury

- Switch off the power supply to the motor and to the

signal relays. Wait at least 5 minutes before

starting any work on the motor. Make sure that the

power supply cannot be accidentally switched on.

You can turn the control panel 180 °. Follow the instructions

below.

1. Loosen the four screws (TX25) of the terminal box cover.

TM06 4085 1515TM05 7028 0413

Fig. 21 Loosening the screws

2. Remove the terminal box cover.

English (US)

TM05 5351 3612TM05 5352 3612TM05 5353 3612

Fig. 20 FCC label

11. Fit the terminal box cover (fig. 14, B) and cross-tighten the

four mounting screws (fig. 14, A) to 6 Nm.

Make sure that the terminal box cover is aligned with

the control panel. See section 4.4 Changing the

position of the control panel.

Fig. 22 Removing the terminal box cover

3. Press and hold in the two locking tabs (fig. 23, A) while gently

lifting the plastic cover (fig. 23, B).

Fig. 23 Lifting the plastic cover

15

Page 16

English (US)

4. Turn the plastic cover 180 °.

Do not twist the cable more than 90 °.

Fig. 24 Turning the plastic cover

5. Position the plastic cover correctly on the four rubber pins (fig.

25, C). Make sure that the locking tabs (fig. 25, A) are placed

correctly.

Fig. 25 Positioning the plastic cover

6. Fit the terminal box cover, and make sure that it is also turned

180 ° so that the buttons on the control panel are aligned with

the buttons on the plastic cover.

7. Tighten the four screws (TX25) with 5 Nm.

Fig. 26 Fitting the terminal box cover

5. Product introduction

5.1 Product description

Grundfos E-pumps are fitted with frequency-controlled

permanent-magnet motors for single-phase or three-phase power

supply connection.

5.1.1 Pumps without factory-fitted sensor

The pumps have a built-in PI controller and can be set for an

external sensor enabling the control of the following parameters:

• constant pressure

• constant differential pressure

• constant temperature

• constant differential temperature

TM05 5354 3612TM05 5355 3612TM05 5356 3612

• constant flow rate

• constant level

• constant curve

• constant other value.

The pumps have been factory-set to constant-curve control

mode. You can change the control mode with R100 or Grundfos

GO.

5.1.2 Pumps with factory-fitted pressure sensor

The pumps have a built-in PI controller and are set for a pressure

sensor enabling the control of the outlet pressure.

The pumps have been factory-set to constant-pressure control

mode. The pumps are typically used to keep a constant pressure

in variable-demand systems.

5.1.3 Settings

The description of settings applies both to pumps without

factory-fitted sensor and to pumps with a factory-fitted pressure

sensor.

Setpoint

You can set the desired setpoint in three ways:

• on the pump control panel

• via an input for external setpoint signal

• with the Grundfos wireless R100 remote control or Grundfos

GO.

Other settings

Make all other settings with R100 or Grundfos GO.

You can read important parameters, such as the actual value of

the control parameter and power consumption, via R100 or

Grundfos GO.

If special or customized settings are required, use Grundfos PC

Tool. Contact your local Grundfos company for more information.

16

Page 17

5.1.4 Radio communication

Env.Type :

Serial no :

SF CL:

PF:

PB

FM

HMIEff

n max:

CIMWgt

:

DE

:

kg

NDE

:

T

amb

:

:

FAA

V

~

P.C.

:

Made in Hungary

OUTPUT

VARIANT

INPUT

TEFC

Type

:

P.N.

:

U

in

:

I

1/1

:

f

in

HpHzP2

I

SF Amp:

rpm

:::

:

:

:

:

Xxxxxxxxxxx

E.P. Motor

DK - 8850 Bjerringbro, Denmark

Env.T

yyp

p

:

S

a

o

:

SF

C

:

P

:

Effn W

g

g

t

:

DE

:

k

g

g

NDE:T

amb

:

:

FAAVP

.C.

:

PU

TTE

C

T

yp

yp

e

:

P.N.

:

U

n

:

I

1/1

:

finHzP

I

S

p

p

:

:

PB

FM

HMI

CIM

VARIANT

Hp

rpm

:

:

:

:

PB

:

HMI

:

C

:

H

prpm

Env.Type :

Serial no :

SF CL:

PF:

PB

FM

HMIEff

n max:

CIMWgt

:

DE

:

kg

NDE

:

T

amb

:

:

FAA

V

~

P.C.

:

Made in Hungary

OUTPUT

VARIANT

INPUT

TEFC

Type

:

P.N.

:

U

in

:

I

1/1

:

f

in

HpHzP2

I

SF Amp:

rpm

:::

:

:

:

:

Xxxxxxxxxxx

E.P. Motor

DK - 8850 Bjerringbro, Denmark

Env.T

yyp

p

:

S

a

l

n

o

:

SF

C

:

P

:

Eff

n

W

g

g

t

:DE:

k

g

g

NDE

:

T

amb

:

:

FAAVP

.C.

:

PU

TTE

C

T

yp

yp

e

:

P.N.

:

U

n

:

I

1/1

:

f

n

HzP

I

S

p

p

:

:

PB

FM

HMI

CIM

VARIANT

Hp

rpm

:

:

:

:

PB

:

C

:

H

prpm

FM

:

This product incorporates a radio module for remote control

which is a class 1 device and which you can use anywhere in the

EU without restrictions.

For use in USA and Canada, see page 66.

Some variants of the product and products sold in China and

Korea have no radio module.

This product can communicate with Grundfos GO and other

products of the same type via the built-in radio module.

In some cases, an external antenna may be required. Only

Grundfos-approved external antennas may be connected to this

product, and only by a Grundfos-approved installer.

5.1.5 Battery

A Li-ion battery is fitted in LCSE and VLSE pumps. The Li-ion

battery complies with the Battery Directive (2006/66/EC). The

battery does not contain mercury, lead and cadmium.

5.2 Identification

5.2.1 Identification of functional module

You can identify the fitted module in one of the following ways:

Grundfos GO

You can identify the functional module in the "Fitted modules"

menu under "Status".

Pump display

For pumps fitted with the advanced control panel, you can identify

the functional module in the "Module type" menu under "Status".

Motor nameplate

You can identify the fitted module on the motor nameplate. See

fig. 27.

5.2.2 Identification of control panel

You can identify the fitted module in one of the following ways:

Grundfos GO

You can identify the control panel in the "Fitted modules" menu

under "Status".

Pump display

For pumps fitted with the advanced control panel, you can identify

the control panel in the "Module type" menu under "Status".

Motor nameplate

You can identify the fitted control panel on the motor nameplate.

See fig. 28.

IN

i

eri

e

F

i

L

F Am

F

IM

Fig. 28 Identification of control panel

Variant Description

HMI 300 Advanced control panel

English (US)

TM06 4013 1415

5.3 Bus signal

IN

i

eri

e

F

L

F Am

F

IM

Fig. 27 Identification of functional module

Variant Description

FM 300 Advanced functional module

The pump supports serial communication via an RS-485 input.

The communication is carried out according to the Grundfos

GENIbus protocol and enables connection to other pumps as well

as a building management system or another external control

system.

Via a bus signal, you can remote-set pump operating parameters,

such as setpoint and operating mode. At the same time, the pump

can, via the bus, provide status information about important

parameters, such as actual value of control parameter, input

power and fault indications.

Contact Grundfos for further information.

TM06 1889 3314

If you use a bus signal, the number of settings

available via R100 or Grundfos GO are reduced.

17

Page 18

English (US)

A

5.4 Grundfos Eye

The operating condition of the pump is indicated by Grundfos Eye

on the control panel. See fig. 29, A.

Fig. 29 Grundfos Eye

Grundfos Eye Indication Description

No lights are on.

The two opposite green indicator lights are rotating in

the direction of rotation of the pump when seen from

the non-drive end.

The two opposite green indicator lights are

permanently on.

One yellow indicator light is rotating in the direction

of rotation of the pump when seen from the non-drive

end.

One yellow indicator light is permanently on.

The two opposite red indicator lights flash

simultaneously.

The green indicator light in the middle flashes quickly

four times.

TM05 5993 4312

The power is off.

The pump is not running.

The power is on.

The pump is running.

The power is on.

The pump is not running.

Warning.

The pump is running.

Warning.

The pump is stopped.

Alarm.

The pump is stopped.

This is a feedback signal which the pump gives in

order to ensure identification of itself.

The green indicator light in the middle flashes

continuously.

Grundfos GO or another pump is trying to

communicate with the pump. Press on the

pump control panel to allow communication.

The green indicator light in the middle is permanently

on.

Remote control with Grundfos GO via radio.

The pump is communicating with Grundfos GO via

radio connection.

The green indicator light in the middle flashes quickly

while Grundfos Go is exchanging data with the

pump. It takes a few seconds.

Remote control with Grundfos GO via infrared

light.

The pump is receiving data from Grundfos GO via

infrared communication.

18

Page 19

5.5 Signal relays

NCNO

C

NCNOCNCNOCNCNOCNCNO

C

C

NO NCCNO NCCNO NC

NCNOCNCNO

C

C

NO NCCNO NC

NCNOCNCNOCNCNO

C

NCNOCNCNO

C

C

NO NC

NCNOCNCNO

C

C

NO NCCNO NCCNO NCCNO NC

C

NO NCCNO NC

NCNO

C

NCNO

C

C

NO NC

NCNOCNCNO

C

C

NO NC

NCNO

C

C

NO NC

C

NO NCCNO NC

NCNO

C

C

NO NC

NCNO

C

C

NO NCCNO NC

NCNO

C

C

NO NC

NCNO

C

NCNOCNCNOCNCNO

C

C

NO NC

NCNO

C

C

NO NC

NCNO

C

C

NO NC

NCNOCNCNO

C

The pump has two outputs for potential-free signals via two

internal relays.

You can set the signal outputs to "Operation", "Pump running",

"Ready", "Alarm" and "Warning".

The functions of the two signal relays appear from the table

below:

English (US)

Description Grundfos Eye

The power is off.

Off

The pump runs in

"Normal" mode.

Green, rotating

The pump runs in

"Manual" mode.

Green, rotating

The pump is in

operating mode

"Stop".

Green, steady

Warning, but the

pump is running.

Yellow, rotating

Warning, but the

pump runs in "Manual"

mode.

Yellow, rotating

Warning, but the

pump was stopped via

a "Stop" command.

Yellow, steady

Alarm, but the pump is

running.

Red, rotating

Contact position of signal relays when activated

"Operation"

"Pump

running"

"Ready" "Alarm" "Warning"

"Operating

mode"

-

"Normal",

"Min." or

"Max."

"Manual"

"Stop"

"Normal",

"Min." or

"Max."

"Manual"

"Stop"

"Normal",

"Min." or

"Max."

Alarm, but the pump

runs in "Manual"

mode.

The pump is stopped

due to an alarm.

The pump is stopped

due to "Low-flow stop

function".

"Manual"

Red, rotating

"Stop"

Red, flashing

"Normal"

Green, steady

19

Page 20

English (US)

1

2

3

4

5

6

6. User interfaces

WARNING

Hot surface

Death or serious personal injury

- Only touch the buttons on the display as the

product may be very hot.

You can make the pump settings by means of the following user

interfaces:

Control panels

• Advanced control panel.

See section 6.1 Advanced control panel.

Remote controls

• Grundfos GO.

See section 6.2 Grundfos GO.

• Grundfos R100 remote control.

See section 6.3 R100 remote control.

If the power supply to the pump is switched off, the settings are

stored.

6.1 Advanced control panel

The pumps can be fitted with the advanced control panel as an

option.

Fig. 30 Advanced control panel

Pos. Symbol Description

1

2 - Graphical color display.

3 It goes one step back.

4

TM05 4849 1013

5

Grundfos Eye

This shows the operating status of the pump.

For further information, see section 4.4 Changing

the position of the control panel.

With these buttons you can navigate between

main menus, displays and digits.

When you change the menu, the display always

shows the top display of the new menu.

With these buttons you can navigate between

submenus.

They change value settings.

Note: If you have disabled the possibility to make

settings with the "Enable/disable settings"

function, then you can enable it again temporarily

by pressing these buttons simultaneously for at

least 5 seconds. See section 7.29 "Buttons on

product" ("Enable/disable settings").

It saves changed values, resets alarms and

expands the value field.

It enables radio communication with Grundfos

GO and other products of the same type.

When you try to establish radio communication

between the pump and Grundfos GO or another

pump, the green indicator light in Grundfos Eye

flashes. A note also appears in the pump display

stating that a wireless device wants to connect to

the pump. Press on the pump control panel to

allow radio communication with Grundfos GO and

other products of the same type.

This makes the pump ready for operation/starts

and stops the pump.

Start:

If you press the button when the pump is

stopped, the pump only starts if no other

functions with higher priority have been enabled.

See section 8. Description of settings.

Stop:

If you press the button when the pump is running,

the pump is always stopped. When you stop the

pump via this button, the

icon appears in the

bottom of the display.

6 This button goes to the "Home" menu.

20

Page 21

6.1.1 Home display

Fig. 31 Example of "Home" display

Pos. Symbol Description

"Home"

This menu shows up to four user-defined

parameters. You can select parameters

1

2-

3-

4-

5

6

7

8

9

6.1.2 Startup guide

The pump incorporates a startup guide which is started at the first

startup. See section 7.37 "Run start-up guide". After the startup

guide, the main menus appear in the display.

shown as shortcut icon , and when

pressing you go directly to the

"Settings" display for the selected

parameter.

"Status"

This menu shows the status of the pump

and system as well as warnings and

alarms.

"Settings"

This menu gives access to all setting

parameters. You can make detailed

settings of the pump in this menu.

See section 7. Description of functions.

"Assist"

This menu enables assisted pump setup,

provides a short description of the control

modes and offers fault advice.

See section 7.40 "Assist".

This symbol indicates that the pump has

been stopped via the

This symbol indicates that the pump is

functioning as master pump in a multipump

system.

This symbol indicates that the pump is

functioning as a slave pump in a multipump

system.

This symbol indicates that the pump is

operating in a multipump system. See

section 7.44 "Multi-pump setup" ("Setup of

multi-pump system").

This symbol indicates that the possibility to

make settings has been disabled for

protective reasons. See section

7.29 "Buttons on product" ("Enable/disable

settings").

button.

English (US)

TM06 8915 0417

21

Page 22

English (US)

6.1.3 Menu overview for advanced control panel

"Home"

"Home" VLSE LCSE

Multipump

system

●●●

"Status"

"Status" VLSE LCSE

Multipump

system

"Operating status" ●●●

"Operating mode, from" ●●●

"Control mode" ●●●

"Pump performance" ●●●

"Actual controlled value" ●●●

"Resulting setpoint" ●●●

"Speed" ●●●

"Acc. flow and specific energy" ●●●

"Power and energy consumption" ●●●

"Measured values" ●●●

"Analog input 1" ●●●

"Analog input 2" ●●●

"Analog input 3" ●●●

"Pt100/1000 input 1" ●●●

"Pt100/1000 input 2" ●●●

"Analog output" ●●●

1)

1)

1)

1)

"Warning and alarm" ●●●

"Actual warning or alarm" ●●●

"Warning log" ●●●

"Alarm log" ●●●

"Operating log" ●●●

"Operating hours" ●●●

"Module type" ●●●

"Date and time" ●●●

"Product identification" ●●●

"Motor bearing monitoring" ●●●

"Multi-pump system" ●

"System operating status"" ●

"System performance"" ●

"System input power and energy"" ●

"Pump 1, multi-pump system"" ●

"Pump 2, multi-pump system"" ●

"Pump 3, multi-pump system"" ●

"Pump 4, multi-pump system"" ●

1)

Only available if an advanced functional module, type FM 300, is fitted.

22

Page 23

"Settings"

"Settings" VLSE LCSE

Multipump

system

"Setpoint" ●●●7.1 "

"Operating mode" ●●●7.2 "

"Set manual speed" ●●●7.3 "

Section Page

Setpoint"

Operating mode"

Set manual speed"

"Control mode" ●●●7.4 "Control mode" 31

"Analog inputs" ●●●

"Analog input 1, setup" ●●●

"Analog input 2, setup" ●●●

"Analog input 3, setup" ●●●

"Pt100/1000 inputs" ●●●

"Pt100/1000 input 2, setup" ●●●

1)

1)

1)

1)

Analog inputs"

7.5 "

7.6 "

Pt100/1000 inputs"

"Digital inputs" ●●●

Digital inputs"

"Digital input 2, setup" ●●●

1)

7.7 "

"Digital inputs/outputs" ●●●

Digital inputs/outputs"

"Digital input/output 4, setup" ●●●

1)

7.8 "

"Relay outputs" ●●●

7.9 "Signal relays" 1 and 2 ("

outputs"

)

Relay

"Relay output 2" ●●●

"Analog output" ●●●

"Function of analog output" ●●●

"Controller settings" ●●●7.11 "Controller" ("

"Operating range" ●●●7.12 "

1)

1)

1)

7.10 "

Analog output"

Controller settings"

) 41

Operating range"

"Setpoint influence" ●●●7.13 "External setpoint function" 42

"Ext. setpoint infl." ●●●7.13 "External setpoint function" 42

"Predefined setpoints" ●●●

1)

7.14 "Predefined setpoints" 45

"Monitoring functions" ●●●

"Motor bearing monitoring" ●●●7.22 "

"Motor bearing maintenance" ●●●

Motor bearing monitoring"

"Bearings replaced" ("Motor bearing

maintenance")

"Limit-exceeded function" ●●●7.15 "Limit-exceeded function" 46

"LiqTec function" ●●●7.16 "LiqTec" ("LiqTec function") 47

1)

Only available if an advanced functional module, type FM 300, is fitted.

Continued on page 24.

31

31

31

36

37"Pt100/1000 input 1, setup" ●●●

37"Digital input 1, setup" ●●●

38"Digital input/output 3, setup" ●●●

39"Relay output 1" ●●●

40"Output signal" ●●●

42

50

51

English (US)

23

Page 24

English (US)

Continued from page 23.

"Settings" VLSE LCSE

"Special functions" ●●●

"Low-flow stop function" ●●●

"Pipe filling function" ●●●7.18 "Pipe filling function" 49

"Pulse flowmeter setup" ●●●

"Ramps" ●●●7.20 "Ramps" 50

"Standstill heating" ●●●7.21 "Standstill heating" 50

"Communication" ●●●

"Pump number" ●●●7.24 "Number" ("Pump number") 51

"Enable/disable radio comm." ●●●

"General settings" ●●●

"Language" ●●●7.26 "

"Set date and time" ●●●

"Units" ●●●7.28 "Unit configuration" ("Units") 52

"Enable/disable settings" ●●●

"Delete history" ●●●7.30 "Delete history" 52

"Define Home display" ●●●7.31 "Define Home display" 53

"Display settings" ●●●7.32 "Display settings" 53

"Store actual settings" ●●●

"Recall stored settings" ●●●

"Run start-up guide" ●●●7.37 "Run start-up guide" 54

1)

Only available if an advanced functional module, type FM 300, is fitted.

"Assist"

Multipump

system

Section Page

7.17 "Stop function" ("Low-flow st op

function")

7.19 "Pulse flowmeter" ("Pulse

flowmeter setup")

7.25 "Radio communication"

("Enable/disable radio comm.")

Language"

7.27 "Date and time" ("Set date and

time")

7.29 "Buttons on product"

("Enable/disable settings")

7.33 "Store settings" ("Store actual

settings")

7.34 "Recall settings" ("Recall stored

settings")

47

49

51

51

52

52

53

53

"Assist" VLSE LCSE

"Assisted pump setup" ●●●7.41 "Assisted pump setup" 55

"Setup, analog input" ●●●7.42 "Setup, analog input" 55

"Setting of date and time" ●●●7.43 "Setting of date and time" 55

"Setup of multi-pump system" ●●●

"Description of control mode" ●●●7.45 "Description of control mode" 58

"Assisted fault advice" ●●●7.46 "Assisted fault advice" 58

Multipump

system

Section Page

7.44 "Multi-pump setup" ("Setup of

multi-pump system")

56

24

Page 25

6.2 Grundfos GO

+

+

1

2

The pump is designed for wireless radio or infrared

communication with Grundfos GO.

Grundfos GO enables setting of functions and gives access to

status overviews, technical product information and actual

operating parameters.

Grundfos GO offers the following mobile interfaces (MI).

Fig. 32 Grundfos GO communicating with the pump via radio

or infrared connection (IR)

Pos. Description

Grundfos MI 204:

Add-on module enabling radio or infrared

communication. You can use MI 204 in conjunction

with an Apple iPhone or iPod with Lightning connector,

1

such as fifth generation or later iPhone or iPod.

MI 204 is also available together with an Apple iPod

touch and a cover.

Grundfos MI 301:

Separate module enabling radio or infrared

communication. You can use the module in

2

conjunction with an Android or iOS-based smart

device with Bluetooth connection.

6.2.1 Communication

When Grundfos GO initiates communication with the pump, the

indicator light in the middle of Grundfos Eye flashes green. See

section 4.4 Changing the position of the control panel.

Furthermore, on pumps fitted with an advanced control panel a

text appears in the display saying that a wireless device is trying

to establish connection. Press on the pump in order to

establish connection with Grundfos GO or press

connection.

Establish communication using one of these communication

types:

• radio communication

• infrared communication.

Radio communication

Radio communication can take place at distances up to 30

meters. The first time Grundfos GO communicates with the pump,

you must enable communication by pressing or on the

pump control panel. Later when communication takes place, the

pump is recognized by Grundfos GO and you can select the

pump from the "List" menu.

Infrared communication

When communicating via infrared light, Grundfos GO must be

pointed at the pump control panel.

to reject

English (US)

TM06 6256 0916

25

Page 26

English (US)

6.2.2 Menu overview for Grundfos GO

Dashboard VLSE LCSE

Multipump

system

●●●

"Status" VLSE LCSE

"System mode" ●

Multipump

system

2)

"Resulting setpoint" ●●

"Resulting system setpoint" ●

"Actual controlled value" ●●●

2)

2)

"Motor speed" ●●

"Power consumption" ●●

"Power cons., sys." ●

2)

"Energy consumption" ●●

"Energy cons., sys." ●

"Acc. flow, specific energy" ●●●

2)

2)

"Operating hours" ●●

"Operating hours, system" ●

2)

"Pt100/1000 input 1" ●●

"Pt100/1000 input 2" ●●

"Analog output" ●●

"Analog input 1" ●●

"Analog input 2" ●●

"Analog input 3" ●●

"Digital input 1" ●●

"Digital input 2" ●●

"Digital in/output 3" ●●

"Digital in/output 4" ●●

"Fitted modules" ●●

"Pump 1" ●

"Pump 2" ●

"Pump 3" ●

"Pump 4" ●

1)

Only available if an advanced functional module, type FM 300, is fitted.

2)

Only available if Grundfos GO is connected to a multipump system.

2)

2)

2)

2)

26

Page 27

"Settings" VLSE LCSE

"Setpoint" ●●●7.1 "

"Operating mode" ●●●7.2 "

"Control mode" ●●●7.4 "Control mode" 31

"Pipe-filling function" ●●●7.18 "Pipe filling function" 49

"Buttons on product" ●●

"LiqTec" ●● 7.16 "LiqTec" ("LiqTec function") 47

"Stop function" ●●●

"Controller" ●●●7.11 "Controller" ("

"Operating range" ●●●7.12 "

"Ramps" ●● 7.20 "Ramps" 50

"Number" ●● 7.24 "Number" ("Pump number") 51

"Radio communication" ●●

"Analog input 1" ●●

"Analog input 3" ●●

"Pt100/1000 input 1" ●●

"Pt100/1000 input 2" ●●

"Digital input 1" ●●

"Digital input 2" ●●

"Digital in/output 3" ●●

"Digital in/output 4" ●●

"Pulse flowmeter" ●●

"Predefined setpoint" ●●●7.14 "Predefined setpoints" 45

"Analog output" ●● 7.10 "

"External setpoint funct." ●● 7.13 "External setpoint function" 42

"Signal relay 1" ●●

"Signal relay 2" ●●

1)

Only available if an advanced functional module, type FM 300, is fitted.

Multipump

system

Section Page

Setpoint"

Operating mode"

7.29 "Buttons on product" ("Enable/disable

settings")

7.17 "Stop function" ("Low-flo w stop

function")

Controller settings"

) 41

Operating range"

7.25 "Radio communication"

("Enable/disable radio comm.")

7.5 "

Analog inputs"

Pt100/1000 inputs"

7.6 "

7.7 "

Digital inputs"

7.8 "

Digital inputs/outputs"

7.19 "Pulse flowmeter" ("Pulse flowmeter

setup")

Analog output"

7.9 "Signal relays" 1 and 2 ("

outputs"

)

Relay

Continues on page 28.

31

31

English (US)

52

47

42

51

36"Analog input 2" ●●

37

37

38

49

40

39

27

Page 28

English (US)

Continued from page 27.

"Settings" VLSE LCSE

Multipump

system

"Limit 1 exceeded" ●●●

"Limit 2 exceeded" ●●●

"Alternating operation, time" ●

"Time for pump changeover" ●

2)

1) + 2)

Section Page

7.15 "Limit-exceeded function" 46

7.44 "Multi-pump setup" ("Setup of

multi-pump system")

"Standstill heating" ●● 7.21 "Standstill heating" 50

"Motor bearing monitoring" ●● 7.22 "

Motor bearing monitoring"

"Service" ●● 7.23 "Service" 51

"Date and time" ●● 7.27 "Date and time" ("Set date and time") 52

"Store settings" ●●

"Recall settings" ●●

7.33 "Store settings" ("Store actual

settings")

7.34 " Recal l setting s" ("Re call stored

settings")

"Undo" ●●●7.34.1 "Undo" 53

"Pump name" ●●●7.35 "Pump name" 53

"Connection code" ●●●7.36 "Connection code" 54

"Unit configuration" ●● 7.28 "Unit configuration" ("Units") 52

1)

Only available if an advanced functional module, type FM 300, is fitted.

2)

Only available if Grundfos GO is connected to a multipump system.

56

50

53

53

"Alarms and warnings" VLSE LCSE

Multipump

system

"Alarm log" ●●●7.38 "

"Warning log" ●●●7.39 "

Section Page

Alarm log"

Warning log"

"Reset alarm" button ●●●

"Assist" VLSE LCSE

Multipump

system

Section Page

"Assisted pump setup" ●● 7.41 "Assisted pump setup" 55

"Assisted fault advice" ●●●7.46 "Assisted fault advice" 58

"Multi-pump setup" ●●●

7.44 "Multi-pump setup" ("Setup of

multi-pump system")

54

55

56

28

Page 29

6.3 R100 remote control

The pumps are designed for wireless communication with the

Grundfos R100 remote control.

Fig. 33 R100 communicating with the pump via infrared light

6.3.1 Menu overview for R100

"General" VLSE LCSE

"Switch off R100" ●●

"Return to start" ●●

"Delete all changes" ●●

"Store settings" ●●

"Call up settings" ●●

"Store status data" ●●

"Call up status data" ●●

During communication, point R100 at the control panel. When

R100 communicates with the pump, the indicator light in the

middle of the Grundfos Eye flashes green. See page 18.

R100 offers additional possibilities of setting and status displays

for the pump.

The displays are divided into four parallel menus:

"0. GENERAL" (see operating instructions for the R100)

"1. OPERATION"

"2. STATUS"

"3. INSTALLATION."

TM05 3933 1712

See section 6.3.1 Menu overview for R100.

It may be necessary to update R100 to access the new menus.

Multipump

system

English (US)

"Operation" VLSE LCSE

Multipump

system

Section Page

"Setpoint" ●● 7.1 "

"Operating mode" ●● 7.2 "

"Manual speed" ●● 7.3 "

"Alarm" ●●

"Warning" ●●

"Alarm log 1 to 5" ●● 7.38 "

"Warning log 1 to 5" ●● 7.39 "

"Status" VLSE LCSE

"Actual setpoint and external

setpoint"

●●

Multipump

system

"Operating mode" ●●

"Actual controlled value" ●●

"Analog input 1, 2 and 3" ●●

"Pt100/1000 input 1 and 2" ●●

"Speed" ●●

"Power input and power

consumption"

●●

"Operating hours" ●●

"Replace motor bearings" ●●

Setpoint"

Operating mode"

Set manual speed"

Alarm log"

Warning log"

31

31

31

54

55

29

Page 30

English (US)

"Installation" VLSE LCSE

"Control mode" ●● 7.4 "Control mode" 31

"Controller" ●●

"Signal relay 1 and 2" ●●

"Buttons on pump" ●●

"Number" ●● 7.24 "Number" ("Pump number") 51

"Digital input 1 and 2, Function" ●● 7.7 "

"Digital input/output 3 and 4, State" ●●

"Digital input/output 3 and 4,

Function"

"Analog input 1, 2 and 3, Function" ●●

"Analog input 1, 2 and 3,

Measured parameter"

"Analog input 1, 2 and 3" ●●

"Pt100/1000 input 1 and 2,

Function"

"Pt100/1000 input 1 and 2,

Measured parameter"

"LiqTec function" ●● 7.16 "LiqTec" ("LiqTec function") 47

"Operating range" ●● 7.12 "

"Ramps" ●● 7.20 "Ramps" 50

"Motor bearing monitoring" ●● 7.22 "

"Motor bearings" ●● 7.23 "Service" 51

"Standstill heating" ●● 7.21 "Standstill heating" 50

●●

●●

●●

●●

Multipump

system

Section Page

7.11 "Controller" ("

settings"

7.9 "Signal relays" 1 and 2 ("

outputs"

7.29 "Buttons on product"

("Enable/disable settings")

)

)

Controller

Relay

Digital inputs"

Digital inputs/outputs"

7.8 "

7.5 "

Analog inputs"

7.6 "

Pt100/1000 inputs"

Operating range"

Motor bearing monitoring"

41

39

52

38

36

37

42

50

30

Page 31

7. Description of functions

QHQ

H

"Max."

"Min."

"Normal"

"Normal"

"Manual"

"Stop"

7.1 "Setpoint"

Pump variant "Setpoint"

LCSE ●

VLSE ●

You can set the setpoint for all control modes when you have

selected the desired control mode. See section 7.4 "Control

mode".

Factory setting

See section 10. Technical data.

All operating modes are illustrated in fig. 34.

English (US)

TM06 4024 1515

Fig. 34 Operating modes

7.2 "Operating mode"

Pump variant "Operating mode"

LCSE ●

VLSE ●

Possible operating modes:

•"Normal"

The pump runs according to the selected control mode.

•"Stop"

The pump stops.

•"Min."

You can use the minimum curve mode in periods in which a

minimum flow is required. When operating according to the

minimum curve, the pump is operating like an uncontrolled

pump.

•"Max."

You can use the maximum curve mode in periods in which a

maximum flow is required. When operating according to the

maximum curve, the pump is operating like an uncontrolled

pump.

•"Manual"

The pump is operating at a manually set speed. In "Manual"

the setpoint via bus is over-ruled. See section 7.3 "

speed"

.

Set manual

Factory setting

See section 10. Technical data.

7.3 "Set manual speed"

This menu is only available in the advanced control panel. With

Grundfos GO, you set the speed via the "Setpoint" menu.

You can set the pump speed in % of the maximum speed. When

you have set the operating mode to "Manual", the pump runs at

the set speed.

Factory setting

See section 10. Technical data.

7.4 "Control mode"

Pump variant "Control mode"

LCSE ●

VLSE ●

Possible control modes:

• "Constant pressure" ("Const. pressure")

• "Constant temperature" ("Const. temp.")

• "Constant differential pressure" ("Con. diff. press.")

• "Constant differential temperature" ("Con. diff. temp.")

• "Constant flow rate" ("Const. flow rate")

• "Constant level" ("Const. level")

• "Constant other value" ("Const. other val.")

• "Constant curve" ("Const. curve".")

• "Proportional pressure" ("Prop. pressure".) (VLSE only).

Factory setting

See section 10. Technical data.

31

Page 32

English (US)

H

Q

p

p

H

Q

t

t

t

7.4.1 "Constant pressure"

7.4.2 "Constant temperature"

Pump variant

"Constant

pressure"

LCSE ●

VLSE ●

We recommend this control mode if the pump is to deliver a

constant pressure, independently of the flow in the system. See

fig. 35.

Fig. 35 "Constant pressure"

This control mode uses the factory-fitted pressure sensor, if any,

which measures the outlet pressure of the pump.

For pumps without a factory-fitted sensor, you must connect a

pressure sensor to one of the analog inputs of the pump. You can

set the pressure sensor in the "Assist" menu. See section

7.41 "Assisted pump setup".

Examples

• One external pressure sensor.

Pump variant

"Constant

temperature"

LCSE ●

VLSE ●

This control mode ensures a constant temperature. Constant

temperature is a comfort control mode that you can use in

domestic hot-water systems to control the flow to maintain a fixed

temperature in the system. See fig. 37.

TM05 7901 1613

Fig. 37 "Constant temperature"

This control mode requires a temperature sensor placed at the

location where the temperature is to be controlled. See the

examples below:

Examples

TM05 7900 1613

Fig. 36 "Constant pressure"

"Controller settings"

For recommended controller settings, see section

7.11 "Controller" ("

Controller settings"

).

Factory setting

See section 10. Technical data.

Fig. 38 "Constant temperature"

"Controller settings"

For recommended controller settings, see section

7.11 "Controller" ("

Controller settings"

).

Factory setting

See section 10. Technical data.

32

Page 33

7.4.3 "Constant differential pressure"

H

Q

p

p

p

pp

p

p

p

H

Q

△t

t

t

t

t

7.4.4 "Constant differential temperature"

"Constant

Pump variant

differential

pressure"

LCSE ●

VLSE ●

The pump maintains a constant differential pressure,

independently of the flow in the system. See fig. 39.

Fig. 39 "Constant differential pressure"

This control mode requires either a differential-pressure sensor or

two external pressure sensors. See the examples below:

Examples

• One differential-pressure sensor.

The pump uses the input from the sensor to control the

differential pressure.

You can set the sensor manually or by using the "Assist"

menu. See section 7.41 "Assisted pump setup".

• Two pressure sensors.

Constant differential-pressure control is achievable with two

pressure sensors. The pump uses the inputs from the two

sensors and calculates the differential pressure.

Both sensors must have the same unit and must be set as

feedback sensors. You can set the sensors manually, sensor

by sensor, or by using the "Assist" menu. See section

7.41 "Assisted pump setup".

Fig. 40 "Constant differential pressure"

"Controller settings"

For recommended controller settings, see section

7.11 "Controller" ("

Controller settings"

).

Factory setting

See section 10. Technical data.

"Constant

Pump variant

differential

temperature"

LCSE ●

VLSE ●

The pump maintains a constant differential temperature in the

system and the pump performance is controlled according to this.

See fig. 41.

TM05 7901 1613

Fig. 41 "Constant differential temperature"

This control mode requires either two temperature sensors or one

differential-temperature sensor. See the examples below. The

temperature sensors can either be analog sensors connected to

two of the analog inputs or two Pt100/Pt1000 sensors connected

to the Pt100/1000 inputs, if these are available on the specific

pump.

Set the sensor in the "Assist" menu under "Assisted pump setup".

See section 7.41 "Assisted pump setup".

Examples

• One differential-temperature sensor.

The pump uses the input from the sensor to control the

differential temperature.