Page 1

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

GRUNDFOS INSTRUCTIONS

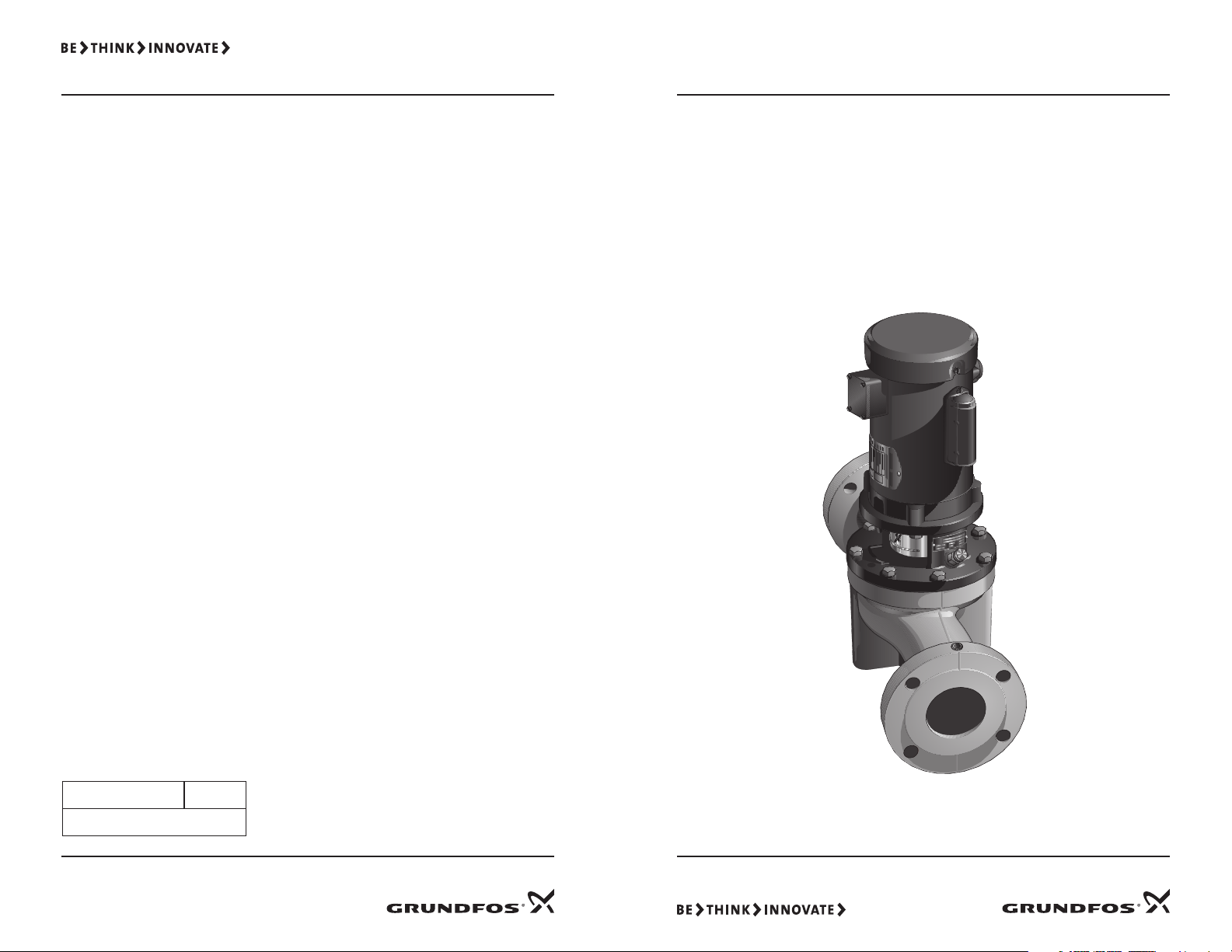

VersaFlo® TP

Direct Coupled In-Line Single Stage

Circulator Pumps

Installation and operating instructions

L-TP-TL-001 10/06

PRINTED IN THE USA

www.grundfos.com

Page 2

LIMITED WARRANTY

Products manufactured by GRUNDFOS PUMPS CORPORATION (GRUNDFOS) are warranted

to the original user only to be free of defects in material and workmanship for a period

of 24 months from date of installation, but not more than 30 months from date of

manufacture. GRUNDFOS' liability under this warranty shall be limited to repairing or

replacing at GRUNDFOS' option, without charge, F.O.B. GRUNDFOS' factory or authorized

service station, any product of GRUNDFOS manufacture. GRUNDFOS will not be liable for

any costs of removal, installation, transportation, or any other charges which may arise

in connection with a warranty claim. Products which are sold but not manufactured by

GRUNDFOS are subject to the warranty provided by the manufacturer of said products and

not by GRUNDFOS' warranty. GRUNDFOS will not be liable for damage or wear to products

caused by abnormal operating conditions, accident, abuse, misuse, unauthorized alteration

or repair, or if the product was not installed in accordance with GRUNDFOS' printed

installation and operating instructions.

To obtain service under this warranty, the defective product must be returned to the

distributor or dealer of GRUNDFOS products from which it was purchased together

with proof of purchase and installation date, failure date, and supporting installation

data. Unless otherwise provided, the distributor or dealer will contact GRUNDFOS or

an authorized service station for instructions. Any defective product to be returned to

GRUNDFOS or a service station must be sent freight prepaid; documentation supporting

the warranty claim and/or a Return Material Authorization must be included if so

instructed.

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Canada

GRUNDFOS Canada, Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905-829-9533

Telefax: +1-905-829-9512

Mexico

Bombas GRUNDFOS de Mexico S.A. de C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

C.P. 66600 Apodaca, N.L. Mexico

Phone: +1-52-81-8144 4000

Telefax: +1-52-81-8144 4010

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES,

LOSSES, OR EXPENSES ARISING FROM INSTALLATION, USE, OR ANY OTHER CAUSES. THERE

ARE NO EXPRESS OR IMPLIED WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, WHICH EXTEND BEYOND THOSE WARRANTIES DESCRIBED OR

REFERRED TO ABOVE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential

damages and some jurisdictions do not allow limitations on how long implied warranties

may last. Therefore, the above limitations or exclusions may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary from

jurisdiction to jurisdiction.

Please leave these instructions with the pump for future reference.

Page 3

Notes

14

Contents

Page

1. Pre-Installation Checklist 4

1.1 Confirm You Have the 4

Right Pump

1.2 Check the Condition of 4

the Pump

1.3 Electrical Requirements 4

1.4 Is the Application Correct 4

for This Pump?

1.5 Read This Guide Thoroughly 5

2. Installation Procedures 5

2.1 Electrical Preparation 5

2.1.1 Terminal Box Position 5

2.1.2 Single-Phase Motors 5

2.1.3 Three-Phase Motors 5

2.1.4 Other Wiring Considerations 5

2.2 Piping Considerations 5

2.3 Installing the Pump 6

2.3.1 Pump Location 6

2.3.2 Position in Piping System 6

2.3.3 Proper Orientation 6

2.3.4 Direction of Flow for 6

Specific Applications

2.3.5 Suggested Accessories 6

2.4 Electrical Hookup 6

3. Starting the Pump the 6

First Time

3.1 Prime the Pump 6

3.1.1 In Closed/Open System 6

Where Water Source is

Above the Pump

3.1.2 In Open Systems 7

3.2 Check the Direction of 7

Rotation

3.3 Starting and Adjusting 7

4. Maintenance 7

4.1 Servicing the Pump Head 7

4.1.1 Step 1: Remove the Pump 7

Head

4.1.1.1 Assembly 8

4.1.2 Step 2: Re-Install the Pump 8

Head

4.1.3 Motor Replacement 9

4.1.3.1 Disassembly 9

Page

4.1.4 Pump Lubrication 9

4.1.5 Motor Lubrication 9

4.1.6 Lubrication Schedule 9

4.1.7 Periodic Safety Checks 9

4.1.8 Service Conditions 10

4.1.9 Rapid Cycling 10

4.1.10 Freeze Protection 10

5. Troubleshooting 10

5.1 Preliminary Checks 10

5.1.1 Supply Voltage 10

5.1.1.1 How to Measure 10

5.1.1.2 Evaluation 10

5.1.2 Current Measurement 10

5.1.2.1 How to Measure 10

5.1.2.2 Evaluation 10

5.1.3 Winding Resistance 11

5.1.3.1 How to Measure 11

5.1.3.2 Evaluation 11

5.1.4 Insulation Resistance 11

(Lead to Ground)

5.1.4.1 How to Measure 11

5.1.4.2 Evaluation 11

5.2 Diagnosing Specific Problems 12

Page 4

Safety Warning

Nominal diameter (suction

& discharge) of ports in mm

Circulator Pump

Maximum head in dm

Bronze

TP 50 80 B

SPEC

FRAME

H.P.

VOLTS

AMPS

R.P.M.

HZ

SE R F

RATING

CAT. NO.

FULL LOAD EF F.

SER

P.F.

PH

DES

CLASS

CODE

LO

W

VOLTAGE

HOOKUP

HIGH

VOLTAGE

HOOKUP

®

Nameplate

Wiring

Diagram

(in this case, for

a dual voltage

motor)

Read This Booklet

This booklet is designed to help a certified

installer begin operation of and troubleshoot Grundfos VersaFlo™ TP pumps. This

booklet should be left with the owner of

the pump for future reference and information regarding its operation. Should the

owner experience any problems with the

pump, a certified professional should be

contacted.

Electrical Work

All electrical work should be performed by

a qualified electrician in accordance with

the latest edition of the National Electrical

Code, local codes and regulations.

Shock Hazard

through standing water. For this reason,

proper grounding of the pump to the power supply's grounding terminal is required

for safe installation and operation.

The ground wire should be a copper

conductor at least the size of the circuit

conductors supplying power to the motor.

Do not ground to a gas supply line.

In all installations, the above-ground metal

plumbing should be connected to the

power supply ground as described in Article

250-80 of the National Electrical Code.

1. Pre-Installation Checklist

1.1 Confirm You Have the Right Pump

• Read the pump nameplate to make sure

that it is the correct one.

• Compare the pump's nameplate data

and its performance curve (for head,

GPM, etc.) with the application in which

you plan to install it.

• Will the pump do what you expect it to

do?

• The nomenclature for the VersaFlo TP

line of Grundfos pumps is:

A faulty motor or wiring can

cause electrical shock that

could be fatal, whether

touched directly or conducted

1.2 Check the Condition of the Pump

The shipping carton your pump came in

is designed around your pump during production to prevent damage. As a precaution, it should remain in the carton until

you are ready to install it. At that point,

look at the pump and examine it for any

damage that may have occurred during

shipping. Examine any other parts of the

shipment as well for any visible damage.

1.3 Electrical Requirements

Check the motor nameplate to determine

the proper voltage, phase, and frequency

required. The voltage must be within ± 10%

of the specified motor nameplate voltage.

Dual volt-age motors must be internally

wired to match the electrical supply. A

wiring connection diagram is affixed to the

motor.

Fig. 1

1.4 Is the Application Correct for This Pump?

Compare the pump's nameplate data or its

performance curve with the application in

which you plan to install it. Will it perform

the way you want it to perform? Also,

make sure the application falls within the

following limits:

Approved applications:

• Open or closed water systems

• Glycol solutions up to 50% (requires

optional RUVV mechanical seal)

• HVAC hot and cooled water

• Condenser or cooling tower heat

exchanger circulation

• Commercial solar

• Commercial heating and fan coil

systems

• Geothermal systems

• Agricultural temperature conditioning

• Snow melting

Correct it by...

If no voltage at motor, check feeder panel for tripped circuits.

Replace blown fuses or reset circuit breaker. If new fuses blow or circuit breaker trips, the terminal box wiring must be

checked.

Replace burned heaters or reset. Inspect starter for other damage. If heater trips again, check the supply voltage and

starter holding coil.

If no voltage, check the control circuit fuses. If there is voltage, check the holding coil for shorts. Replace bad coil.

Replace worn or defective parts.

If the motor windings are open or grounded, replace the motor.

When the meter is connected, the needle should jump toward “0” ohms and slowly drift back to infinity. Replace

capacitor if defective.

Correct wiring and change leads as required.

Refill the pump, replace lug and start the pump. Long suction lines must be filled before starting the pump.

Clean and replace. Re-prime the pump.

Reduce suction lift by lowering pump, increasing suction line size or by removing high friction-loss fittings.

Repair all leaks and retighten all loose fittings.

Convert PSI to feet (PSI x 2.31 = _____ ft.). Refer to the specific pump curve for shutoff head for that pump model. If

actual head is close to curve, the pump is probably OK. If not, remove pump and inspect.

Readjust switch or replace if defective.

Readjust setting (refer to level control manufacturer’s data). Replace if defective.

Check diaphragm for leak. Check tank and piping for leaks with soap and water solution. Check air-to-water volume.

Tank volume should be approximately 10 gal. for each gpm of pump capacity. The normal air volume is 2/3 of the total

tank volume at the pump cut-in pressure.

If voltage varies more than ±10%, contact power company. Check wire sizing.

Increase heater size or adjust trip setting.

Must be within ±5%. If not, check motor and wiring.

If an open or grounded winding is found, repair or replace the motor.

Tighten loose terminals. Replace damaged wire.

If shaft does not rotate, remove pump and inspect. Disassemble and repair.

When the ohmmeter is connected to the capacitor, the needle should jump towards “0” ohms and slowly drift back to

infinity; or, with the capacitor meter the UF reading should be ±10% of capacitor rating. Replace if defective.

134

Page 5

5.2 Diagnosing Specific Problems

If the pump... It may be caused by... Check this by...

1. No power at motor. Check for voltage at terminal box.

Does not run

Pump runs, but at

a reduced capacity

or

Doesn’t deliver

water

Pump cycles too

much

Fuses blow

or

Circuit breakers

trip

2. Fuses are blown or circuit

breakers are tripped.

3. Motor starter overloads are

burned or have tripped.

4. Starter does not energize. Energize control circuit and check for voltage at the

5. Defective controls. Check all safety and pressure switches for operation.

6. Motor is defective. Turn off power. Disconnect the wiring. Measure the

7. Defective capacitor.

(Single-phase motors)

1. Wrong rotation

(Three-phase only)

2. Pump is not primed or is airbound.

3. Strainers, check valves, or foot

valves are clogged.

4. Suction lift too large. Install compound pressure gauge at the suction side

5. Suction and/or discharge piping

leaks.

6. Worn pump. Install pressure gauge, start the pump, gradually close

1. Pressure switch is not properly

adjusted or is defective.

2. Level control is not properly set

or is defective.

3. Three-phase current is unbalanced.

4. Tank is too small. Pump air into tank or diaphragm chamber. Check tank

1. High or low voltage. Check voltage at the starter panel or terminal box.

2. Starter overloads are set too low. Cycle pump and measure amperage.

3. Three-phase current is unbalanced.

4. Motor is shorted or grounded Turn off power and disconnect incoming power supply

5. Wiring or connections are faulty. Check for proper wiring and loose terminals.

6. Pump is stuck. Turn off power and manually rotate pump shaft.

7. Defective capacitor.

(Single-phase only)

Turn off power and remove fuses and check for

continuity with an ohmmeter.

Check for voltage on the line and load side of the starter.

holding coil.

Inspect contact in control devices.

lead-to-lead resistance with an ohmmeter (set at R x 1).

Measure lead-to-ground values with a megohmmeter

(R x 100K). Record the measured values.

Turn off the power, then discharge the capacitor.

Disconnect the leads and check them with an ohmmeter

(R x 100K).

Check for proper electrical connections in terminal box.

Turn pump off, close isolation valves, remove priming

plug. Check fluid level.

Remove strainer, screen, or valve and inspect.

of the pump. Start pump and compare reading to

performance data.

Pump shaft spins backwards when turned off. Air in

suction pipe.

the discharge valve and read pressure at shut-off.

Check pressure setting on switch and operation.

Check voltage across closed contacts.

Check setting and operation.

size and air volume in tank.

Check the current draw on each lead to the motor.

from terminal box. Measure winding and lead-to-ground

resistance as explained on the previous page.

Turn off power, discharge capacitor and check with

ohmmeter set at highest R value or check with capacitor

meter.

Temperature range

• Minimum +5°F (-15°C)

• Maximum +284°F (140°C)

Maximum working pressure:

145 PSI (10 bars)

1.5 Read This Guide Thoroughly

Even if you are very familiar with the

installation of this pump, a quick glance

through the remaining sections of this

guide may help you avoid a potential

problem.

For TPE pump installation, see Grundfos

Pumps publication L-EC-TL-001.

2. Installation Procedures

2.1 Electrical Preparation

2.1.1 Terminal Box Position

Before installing the pump, you must determine the most convenient position for

the terminal box, which can be rotated in

90° increments. To rotate the terminal box,

remove the four bolts securing the motor

to the pump, lift and rotate the motor, and

retighten the bolts. (See page 9.)

Fig. 2

Capacitor

(single-phase only)

2.1.2 Single-Phase Motors

These motors are multi-voltage with builtin automatic resetting thermal protection

to prevent overheating.

2.1.3 Three-Phase Motors

A motor starter is required to ensure the

motor is protected from damage caused by

low voltage, phase failure, current imbalance, and overloads.

• Motor starter — should be properly

sized, have a manual reset, and ambi-

ent-compensated extra quick trip in all

three legs.

• Overload — should be sized and adjusted to trip at the full-load current rating of the motor. If the motor is lightly

loaded, the overload should be re-sized

or adjusted to a lower value. Under no

circumstances should the overloads be

set to a higher value than the full load

current shown on the motor nameplate. Overloads for auto transfers and

resistant starters should be sized in

accordance with the recommendations

of the manufacturer.

• Fused disconnect — recommended for

each pump where service and standby

pumps are installed. An alternating

switch should be used so each pump

can be equally operated to even the

wear.

2.1.4 Other Wiring Considerations

The pump must be grounded. Wire sizes

should be based on the ampacity (current

carrying properties of a conductor) as required by the latest edition of the National

Electrical Code or local regulations.

In most cases, direct on line (D.O.L.) starting is approved due to the extremely fast

run-up time of the motor and the low

moment of inertia of the pump and motor.

If D.O.L starting is not acceptable, an auto

transformer or resistant starter should be

used.

2.2 Piping Considerations

Whenever possible, avoid high pressureloss fittings (elbows, branch tees, etc)

directly on either side of the pump. The

pump and piping should be adequately

supported on both sides to reduce thermal

and mechanical stresses on the pump.

Pipe, valves, and fittings should be at least

the same diameter as the discharge pipe

to reduce excessive fluid velocities and

friction losses. They should also have a

pressure rating equal to or greater than

the maximum system pressure.

A bypass or pressure relief valve should

be installed in the discharge pipe if there

is any possibility the pump may operate

against a closed valve in the discharge line.

Circulation through the pump is required

to ensure adequate cooling and lubrication

of the pump.

512

Page 6

Minimum Pumping Rates:

TP32,TP40,TP50 . . . . . . . . . . . . . . . . . . . .8 GPM

TP80 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 GPM

TP100 . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 GPM

The bypass should be routed back to a heat

dissipating source or to drain, depending

on the liquid being pumped and local codes.

2.3 Installing the Pump

2.3.1 Pump Location

The pump should be installed in a dry,

well-ventilated area which is not subject to

freezing or large variations in temperature.

The pump should never be mounted

within six inches of any obstruction or hot

surface.

Pumps to be installed outdoors or in a

dusty environment should be ordered with

a totally-enclosed-fan-cooled motor (TEFC)

attached to prevent motor failure.

2.3.2 Position in Piping System

Do not mount the pump at the highest or

lowest point in the piping system.

If the pump is installed at the highest point

in the piping system, it may experience

reduced performance and increased noise

due to air trapped in the pump.

If the pump is located at the lowest point

in the piping system, the dirt and sediment

in the system may collect inside the pump,

causing premature wear to the shaft seal.

2.3.3 Proper Orientation

VersaFlo TP pumps can be mounted either

vertically or horizontally, and all positions

in between. However, the motor shaft

must never fall below the horizontal plane.

Recommended

DO NOT mount motor

with shaft below

horizontal plane

X

2.3.4 Direction of Flow for Specific

Applications

Arrows on the flanges of the pump volute

show the flow direction of water through

the pump.

Pumps used to circulate domestic water

should ALWAYS be installed in a vertical

section of the circulating pipe and pump

upwards, and an effective air vent should

be used in the same vertical section of pipe.

If the pump must be installed in a vertical

pipe pumping down, an air vent should be

installed at the highest point before the

pump.

2.3.5 Suggested Accessories

Isolation valves — should be installed on

each side of the pump to avoid having to

drain the system if the pump needs to be

cleaned or repaired.

Check valve — should be installed in the

discharge pipe.

Plugged tee or capped pipe — should be

installed in the suction line to fill the pump

and pipe before start-up, especially if the

system is not pressurized.

Vibration isolators — should be used in

noise-sensitive areas to prevent vibra-tion

from being transmitted to the structure.

Relief valve of bypass line — should be

installed to allow sufficient water to

circulate through the pump to provide

adequate cooling and lubrication of the

pump's bearings and seals.

2.4 Electrical Hookup

Turn the incoming POWER OFF and make

the proper electrical connections according

to the diagram on the motor and the latest

edition of the National Electrical Code.

Do not start the pump — even to check

the direction of rotation — until it has

been filled with water. The pump may be

seriously damaged if it is run dry.

3. Starting the Pump the First Time

3.1 Prime the Pump

3.1.1. In Closed/Open System Where Water

Source is Above the Pump

1. Close the pump isolation valves and

open the air vent screw.

2. Gradually open the suction isolation

valve until a steady stream of airless

water runs out the air vent hole.

Fig. 7

1. Burned contacts on motor starter.

2. Loose terminals in starter/terminal box

or possible wire defect.

3. Too high or too low supply voltage.

4. Motor windings are shorted or

grounded. Check winding and insulation

resistances.

5. Pump is damaged causing a motor

overload.

5.1.3 Winding Resistance

5.1.3.1 How to Measure

Turn off power and disconnect the

supply power leads in the pump terminal

box. Using an ohmmeter, set the scale

selector to R x 1 and zero adjust the meter

by touching the two ohmmeter leads

together.

Touch the leads of the ohmmeter to two

motor leads.

Fig. 8

Single phase motors - touching the leads

of the ohmmeter to the two outgoing "hot"

motor leads (either a single motor lead or

combination of leads joined together) will

measure the main winding's resistance.

Three phase motors - touching the leads

of the ohmmeter to any two hot leads will

measure that winding's resistance. Repeat

for all three possible lead combinations (L1

and L2, L2 and L3, L1 and L3).

5.1.3.2 Evaluation

If all ohm values are normal, the motor

windings are neither shorted nor open.

If any one ohm value is less than normal

(-25%), that motor winding may be starting

too short. If any one ohm value is greater

than normal (+25%), the winding may

be starting too open. If some values are

high and some are low, the leads may be

connected incorrectly, or they may have a

break in the insulating jacket.

5.1.4 Insulation Resistance (Lead to

Ground)

5.1.4.1 How to Measure

Turn off power and disconnect the supply

power leads in the pump terminal box.

Using an ohmmeter, set the scale selector

to R x 100 and zero adjust the meter

by touching the two ohmmeter leads

together. Touch one ohmmeter lead to a

motor lead and one to ground. Repeat for

each lead.

Fig. 9

5.1.4.2 Evaluation

The resistance values for new motors must

exceed 1,000,000 ohms. If they do not,

replace the motor.

116

Page 7

C

O

U

N

T

E

R

C

L

O

C

K

W

I

S

E

4.1.8 Service Conditions

Severity of

Service

Ambient

Temperature

(maximum)

Atmospheric

Contamination

Grease

Interval

(hrs.)

Approved

Types of Grease

Standard 104°F (40°C) Clean, little corrosion 5500 Shell Dolium R

Severe 122°F (50°C) Moderate dirt, corrosion 2750 Chevron SR#2

Extreme >122°F (50°C)

or class H ins.

If the pump fails to operate or there

is a loss of performance, refer to the

Troubleshooting section on pages 11

through 14.

4.1.9 Rapid Cycling

Pump cycling should be monitored to

make sure the pump is not starting more

than 20 times per hour. If it is, premature

motor failure is quite likely, due to the

increased heat build-up in the motor. Make

any adjustments to controls ne-cessary to

reduce the frequency of stops and starts.

Severe dirt, abrasive

dust, corrosion

Evaluation

When the motor is under load, the voltage

should be within ±10% of the nameplate

voltage. Larger voltage variation may

cause winding damage and indicate a poor

electrical supply. The pump should not be

operated until these variations have been

corrected.

If the voltage constantly remains high or

low, the motor should be changed to the

correct supply voltage.

Fig. 6

550 Or compatible

equivalent grease

4.1.10 Freeze Protection

If the pump is installed in an area where

freezing could occur, the pump and

system should be drained during freezing

temperatures to avoid damage.

To drain the pump, close both isolation

valves and loosen the suction and discharge flanges. Allow water to flow out of

the pump before reconnecting the pump

to the flanges. Do not tighten the flanges

completely until the pump is ready to be

used again.

5. Troubleshooting

5.1 Preliminary Checks

5.1.1 Supply Voltage

5.1.1.1 How to Measure

Use a volt meter, (set to the proper scale)

measure the voltage at the pump terminal

box or starter.

On single-phase units, measure between

power leads L1 and L2 (or L1 and N for 115

volt units). On three-phase units, measure

between:

• Power leads L1 and L2

• Power leads L2 and L3

• Power leads L3 and L1

5.1.2 Current Measurement

5.1.2.1 How to Measure

Use an ammeter, (set on the proper scale)

to measure the current on each power lead

at the terminal box or starter.

Current should be measured when the

pump is oper-ating at constant discharge

pressure.

5.1.2.2 Evaluation

If the amp draw exceeds the listed

service factor amps (SFA) or if the current

imbalance is greater than 5% between

each leg on three-phase units, check the

following:

3. Tighten the air vent screw and

completely open the isolation valves.

3.1.2 In Open Systems

1. The suction pipe and pump must be

filled and vented of air before starting

the pump.

2. Close the discharge side isolation valve

and open the air vent screw and suction

valve.

3. Fill the suction line through the plugged

tee or capped pipe (if one is installed). If

not possible, remove one of the gauge

tapping plugs in the pump flanges and

pour water into the hole using a funnel

or hose with an adapter.

Fig. 3

Air

venting

screw

Gauge

Tapping

plugs (2)

All air in the pump and suction line must

be purged before starting the pump.

3.2 Check the Direction of Rotation

a. Switch the POWER OFF.

b. Check to make sure the pump has been

filled and vented.

c. Remove the coupling guard and rotate

the pump shaft to be certain it turns

freely. Replace the coupling guard.

d. Verify that the

electrical connections

are in accordance with

the wiring diagram on

the motor.

e. Switch the power

on and observe the

direction of rotation.

When viewed from the motor end, the

pump should rotate counter-clockwise.

f. To reverse the direction of rotation,

TURN OFF the power supply and

complete the following which applies.

• On three-phase motors, interchange

any two power leads at the load

side of the starter. On single-phase

motors, refer to the connection

diagram on the motor nameplate.

Change the wiring as required.

g. TURN ON the power and again check for

proper motor rotation.

3.3 Starting and Adjusting

a. Make sure that:

• The pump has been primed.

• The rotation is counter-clockwise

when viewed from the motor end.

• The piping connections are tight and

adequately supported.

b. Open the suction line valve completely

(if one is installed).

c. Close the isolation valve in the discharge

pipe. It should be opened gradually

after the pump is turned on. Opening

the valve too fast may result in water

hammer in the discharge pipe.

d. Start the pump.

e. Gradually open the isolation valve in the

discharge piping as explained in step c.

Open the valve completely.

f. Check the voltage and amperage at

the motor and record them. Adjust the

motor overloads if required.

g. If pressure gauges have been installed,

check and record the values as the pump

operates.

h. Check all controls for proper operation.

If the pump is controlled by a pressure

switch, check and adjust the cut-in and

cut-out pressures. If low-water level

controls are used, be sure the low-level

switch is properly adjusted so the pump

cannot run if the pump breaks suction.

4. Maintenance

4.1 Servicing the Pump Head

4.1.1 Step 1: Remove the Pump Head

1. Turn OFF the power to the motor.

2. Close any isolation valves on either

side of the pump.

710

Page 8

Powerhead

Terminal

Box

Motor

Stool

Hex

Screws

O-Ring

Impeller

Stainless Steel

Seal Ring

(inside)

Pump

Housing

Fig. 4

Pump Head

3. Disconnect the electrical leads and

conduit from the terminal box.

4. Loosen and remove the hex bolts

connecting the pump head assembly to

the pump housing. Note the position

of the motor terminal box relative

to the pump housing.

5. Remove the pump head assembly

from the pump housing.

6. Clean the machined surfaces in the

pump housing.

7. Inspect the pump housing and stainless

steel ring for any damage. Check to be

sure the seal ring is mounted securely in

the pump housing.

8. Repair or replace parts as needed.

4.1.1.1 Assembly

With the motor/motor stool assembly

upside down as shown (fig. 5)

1. Carefully pass the shaft with the

rotating shaft seal and impeller through

the shaft hole in the motor stool (the

seal rings must not be exposed to blows

or knocks).

2. Fit the shaft pin in the shaft pin hole.

3. Fit the coupling halves and the coupling

allen bolts loosely to the pump and

motor shafts so that the gaps on both

sides of the coupling halves are even.

4. Insert a screwdriver above the coupling,

push the pump shaft towards the motor

as far as possible. The pump and motor

shaft should touch each other. Tighten

coupling allen bolts to the following

specifications:

M6 . . . . . . . . . . . . . . . . .9.6 ft lbs

M8. . . . . . . . . . . . . . . . .22.6 ft lbs

5. Clean the recess of the pump housing/

motor stool lubricate o-ring with soapy

water if necessary.

6. Fit the pump head in the pump housing

with the terminal box in the required

position, be careful to align impeller

with neck ring.

7. Replace the motor stool bolts and

tighten to the following specifications.

M8. . . . . . . . . . . . . . . . . . . . 18.4 ft lbs

M10 . . . . . . . . . . . . . . . . . . 34.7 ft lbs

8. Check the shaft for free rotation and

replace the coupling guards.

9. The pump is now completely assembled.

Fig. 5

4.1.2 Step 2: Re-Install the Pump Head

1. Lubricate the O-ring with soapy water.

2. With the motor terminal box in the

desired position, carefully place the

pump head assembly into the pump

housing. Be careful not to damage the

impeller or mating seal ring. Once the

pump head O-ring is engaged with the

pump housing, do not attempt to rotate

the pump head, since doing so may

damage the O-ring.

3. Make sure the pump head assembly is

properly seated on the pump housing.

DO NOT force the two together.

4. Tighten two of the hex bolts opposite

each other until the pump head is

secure to the pump housing.

5. Check to make sure the motor shaft

turns freely.

6. Insert and tighten the rest of the hex

bolts evenly to secure the pump head

assembly.

Hex Bolt Torque

13 mm . . . . . . . . . . . . . . 19 ft lbs

17 mm . . . . . . . . . . . . . . . 35 ft lbs

4.1.3 Motor Replacement

If the motor is damaged due to bearing

failure, or electrical failure, the following

instructions detail how to remove the

motor for replacement. It must be

emphasized that motors used on VersaFlo

TP pumps are specifically selected to our

rigid specifications.

Replacement motors must be of the same

NEMA frame size, should be equipped with

the same or better bearings and have the

same service factor. Failure to follow these

recommendations may result in premature

motor failure.

4.1.3.1 Disassembly

1. Remove the coupling guard screens.

2. Using the proper metric allen wrench,

loosen the four cap screws in the

coupling, fully remove coupling halves.

3. With the correct size wrench, loosen and

remove the four bolts which hold the

motor to the discharge section of the

pump end.

4. Lift the motor straight up until the shaft

is free from the coupling.

4.1.4 Pump Lubrication

Grundfos VersaFlo TP in-line centrifugal

pumps installed in accordance with

these instructions and sized for correct

performance will operate efficiently and

provide years of service.

The pumps are lubricated by the fluid they

pump, and do not require any additional

lubrication. However, this also means the

pump should never be operated for any

prolonged periods of time without fluid

flowing through the pump. The motors will

require periodic lubrication as noted in the

following paragraphs.

4.1.5 Motor Lubrication

Electric motors are prelubricated at the

factory and do not require additional

lubrication at start-up. Motors without

external grease fittings have sealed

bearings that cannot be relubricated.

Motors with grease fittings should only be

lubricated with approved types of grease.

Do not over grease the bearings. Over

greasing will cause increased bearing heat

and can result in bearing/motor failure.

Do not mix petroleum grease and silicon

grease in motor bearings.

Bearing Grease will lose its lubricating

ability over time, not suddenly. The

lubricating ability of the grease (over time)

depends primarily on the type of grease,

the size of the bearings, the speed at which

the bearings operate and the severity of

the operating conditions.

Good results can be obtained if the

following recommendations are used in

your maintenance program.

4.1.6 Lubrication Schedule

For motor frame sizes smaller than 210TC,

add 0.3 oz. (8.4g) or 0.6 in.3 (2 tsp.) at the

intervals listed above.

4.1.7 Periodic Safety Checks

At regular intervals depending on the

conditions and time of operation, the

following checks should be made:

1. Pump meets required performance and

is operating smoothly and quietly.

2. There are no leaks, particularly at the

shaft seal.

3. The motor is not overheating.

4. Remove and clean all strainers or filters

in the system.

5. Verify the tripping of the motor

overload protection.

6. Check the operation of all controls.

Check unit control cycling twice and

adjust if necessary.

7. If the pump is not operated for

unusually long periods, the unit should

be maintained in accordance with these

instructions. In addition, if the pump

is not drained, the pump shaft should be

manually rotated or run for short

periods of time at monthly intervals.

98

Loading...

Loading...