Page 1

Grundfos UP XL

3191277

Maintenance-free circulators

with insulating shell (if equipped)

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Conforms to UL STD 514C

Certified to CSA STD C22.2 No. 18.2

Page 2

English (US)

Note

Caution

English (US) Installation and operating instructions

Original installation and operating

instructions.

CONTENTS

1. Symbols used in this document

2. Limited warranty

3. Safety warning

3.1 Read this booklet

3.2 Electrical work

4. Pre-installation checklist

4.1 Confirm you have the correct pump

4.2 Check the condition of the pump

4.3 Verify electrical requirements

4.4 Pumped liquid requirements

5. Installation procedures

5.1 Piping considerations

5.2 Changing the terminal box position

5.3 Electrical connection

5.4 Insulating shells (if equipped)

6. Starting the pump

6.1 Vent the piping system

6.2 Speed selection

7. Fault finding

7.1 Fault finding chart

7.2 Preliminary checks

7.3 Current measurement

7.4 Insulation resistance (lead-to-ground)

7.5 Winding resistance (line-to-line)

7.6 Resistance tables

8. Replacing components

8.1 Removing the pump head

8.2 Fitting the pump head

8.3 Replacing the terminal box or

capacitor

9. Additional technical data

10. Disposal

Page

10

10

10

11

11

12

12

13

13

13

14

14

15

16

17

17

1. Symbols used in this document

Warning

If these safety instructions are not

observed, it may result in personal

2

3

4

4

4

4

4

4

5

5

6

6

7

8

9

injury.

Warning

If these instructions are not

observed, it may lead to electric

shock with consequent risk of

serious personal injury or death.

Warning

The surface of the product may be

so hot that it may cause burns or

personal injury.

Notes or instructions that

make the job easier and

ensure safe operation.

If these safety instructions are

not observed, it may result in

malfunction or damage to the

equipment.

Warning

Prior to installation, read these

installation and operating

instructions. Installation and

operation must comply with local

regulations and accepted codes of

good practice.

2

Page 3

2. Limited warranty

Products manufactured by GRUNDFOS PUMPS

CORPORATION (Grundfos) are warranted to

the original user only to be free of defects in

material and workmanship for a period of 36

months from date of manufacture. Grundfos'

liability under this warranty shall be limited to

repairing or replacing at Grundfos' option,

without charge, F.O.B. Grundfos' factory or

authorized service station, any product of

Grundfos' manufacture. Grundfos will not be

liable for any costs of removal, installation,

transportation, or any other charges which may

arise in connection with a warranty claim.

Products which are sold but not manufactured

by Grundfos are subject to the warranty

provided by the manufacturer of said products

and not by Grundfos' warranty. Grundfos will not

be liable for damage or wear to products caused

by abnormal operating conditions, accident,

abuse, misuse, unauthorized alteration or repair,

or if the product was not installed in accordance

with Grundfos' printed installation and operating

instructions.

To obtain service under this warranty, the

defective product must be returned to the

distributor or dealer of Grundfos' products from

which it was purchased together with proof of

purchase and installation date, failure date, and

supporting installation data. Unless otherwise

provided, the distributor or dealer will contact

Grundfos or an authorized service station for

instructions. Any defective product to be

returned to Grundfos or a service station must

be sent freight prepaid; documentation

supporting the warranty claim and/or a Return

Material Authorization must be included if so

instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL

DAMAGES, LOSSES, OR EXPENSES ARISING

FROM INSTALLATION, USE, OR ANY OTHER

CAUSES. THERE ARE NO EXPRESS OR

IMPLIED WARRANTIES, INCLUDING

MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, WHICH EXTEND

BEYOND THOSE WARRANTIES DESCRIBED

OR REFERRED TO ABOVE.

Some jurisdictions do not allow the exclusion or

limitation of incidental or consequential

damages and some jurisdictions do not allow

limit actions on how long implied warranties may

last. Therefore, the above limitations or

exclusions may not apply to you. This warranty

gives you specific legal rights and you may also

have other rights which vary from jurisdiction to

jurisdiction.

English (US)

3

Page 4

English (US)

3. Safety warning

4. Pre-installation checklist

3.1 Read this booklet

This booklet is designed to help a certified

installer to install, begin operation of, and

troubleshoot the Grundfos Small UP and UPS

pumps.

Following the instructions will ensure safe,

trouble-free operation.

This booklet should be left with the owner of the

pump for future reference and information

regarding its operation. Should the owner

experience any problems with the pump, a

certified professional should be contacted.

3.2 Electrical work

All electrical work should be performed by a

qualified electrician in accordance with the latest

edition of the National Electrical Code, local

codes and regulations.

Warning

A faulty motor or wiring can cause

electrical shock that could be fatal,

whether touched directly or

conducted through standing water.

For this reason, proper grounding

of the pump to the power supply's

grounding terminal is required for

safe installation and operation.

In all installations, the

above-ground metal plumbing

should be connected to the power

supply ground as described in the

National Electrical Code. All wiring

must comply with the National

Electrical Code, state, and local

regulations.

4.1 Confirm you have the correct pump

• Read the pump nameplate to ensure it is the

one you ordered.

• Compare the pump's nameplate data and its

performance curve (for head, gpm, etc.) with

the application in which you plan to install it.

• Will the pump do what you expect it to do?

4.1.1 Pump to system type recommendations

• Open systems (i.e. potable water): Stainless

steel or bronze volute (pump housing) only.

• Closed systems (i.e. airless, non-potable

water): Cast iron, stainless steel, or bronze

volute (pump housing).

Other considerations regarding Grundfos small

UP and UPS pumps:

• These pumps are intended for indoor use

only.

• If installed outdoors the pump must be

protected by an appropriate, well ventilated,

water-tight enclosure to keep out moisture

and dirt.

• Minimum ambient temperatures must be no

lower than 33 °F ( 1 ° C ).

• For ambient and fluid temperature see

sections 4.4 Pumped liquid requirements

and 9. Additional technical data.

4.2 Check the condition of the pump

The pump's shipping carton is specially

designed around the pump during production to

prevent damage.

As a precaution, it should remain in the carton

until you are ready to install it. At that point, look

at the pump and examine it for any damage that

may have occurred during shipping.

Examine any other parts of the shipment as well

for any visible damage. Once the pump has

been removed from the box, care should be

taken NOT to drop or mishandle the pump.

Box contents:

• one pump

• two gaskets (flanged units only)

• one Installation and Operation Instruction

(I&O).

4

Page 5

4.3 Verify electrical requirements

Note

Caution

Verify the electrical supply to be certain the

voltage, phase and frequency match that of the

pump motor. The proper operating voltage and

other electrical information can be found on the

pump nameplate.

This pump's motor is designed to run on ± 10 %

of the nameplate-rated voltage.

4.4 Pumped liquid requirements

Warning

The Grundfos Small UP/UPS pump

is intended for use with water only.

The pump must not be used for the

transfer of flammable liquids such

as diesel oil, gasoline, and similar

liquids.

The pump is not for pool or marine

use.

The pump can be used to circulate:

• Potable hot water.

• Water containing glycol for hydronic heating

(see section 9. Additional technical data for

additional limitations).

• Cooling water.

In domestic hot-water systems it is advisable to

use stainless steel pump housing versions of

this pump.

All pump types (stainless, bronze or cast iron

pump housing) should not be used in water with

a degree of hardness lower than 14 grains per

gallon of hardness.

Fluids should be clean and should not contain

solid particles, fibers, or mineral oils.

If the pump is installed in a heating system, the

water should meet the requirements of accepted

standards on water quality in heating systems.

The fluid should not contain solid particles,

fibers, or mineral oils.

The pump is lubricated and cooled by the liquid

being pumped. Therefore, the pumped liquid

must always be allowed to circulate through the

pump.

Extended periods without circulation will cause

premature wear to the bearings and excessive

motor heat.

The pumped liquid must meet the temperature

requirements listed in the following charts.

Fluid must never be allowed to

freeze during non-operational

periods.

Open systems

(domestic, potable hot water)

Fluid Ambient

Min. 36 °F (2 °C) 33 °F (1 °C)

Max. < 149 °F (65 °C) 100 °F (38 °C)

In domestic hot-water systems, it is

recommended to keep the liquid

temperature below 149 °F (65 °C) to

eliminate the risk of lime

precipitation.

(non-potable heating or cooling airless

Min. All

Max.

Max. 50 % glycol at 15 °F (-9.5 °C) liquid

(Hydraulic performance change can be

expected.)

Closed systems

fluid)

Pump

models

UPS 26-150

UPS 43-100

UPS 50-60

Water and glycol mix

Liquid Ambient

36 °F

(2 °C)

230 °F

(110 °C)

230 °F

(110 °C)

212 °F

(100 °C)

33 °F

(1 °C)

100 °F

(38 °C)

100 °F

(38 °C)

100 °F

(38 °C)

English (US)

5

Page 6

English (US)

5. Installation procedures

Warning

Never make any connections in the

pump terminal box unless the

electrical supply has been

switched off.

The pump should not be connected

to the electrical system until it has

been properly installed in the

piping system.

Warning

Risk of electrical shock - this pump

has not been investigated for use

in swimming pool or marine areas.

5.1 Piping considerations

When making piping connections, be sure to

follow the piping manufacturer's

recommendations and all code requirements for

piping material.

Thoroughly clean and flush all dirt and sediment

from the system before attempting to install the

pump.

5.1.1 Location in the piping line

The pump should never be located at the lowest

point of the piping system (where dirt and

sediment collect), nor should it be located at the

highest point of the piping system (where air

accumulates).

Warning

The pump must be positioned so

that someone cannot accidentally

come into contact with the hot

surfaces of the pump.

When installing the pump into the piping system,

Grundfos recommends that pressure gauges be

installed in the inlet and discharge flanges or

pipes. This will allow the pump and system

performance to be checked.

Do not block the pipe plugs in the pump housing

flanges by locating the terminal box over these

plugs.

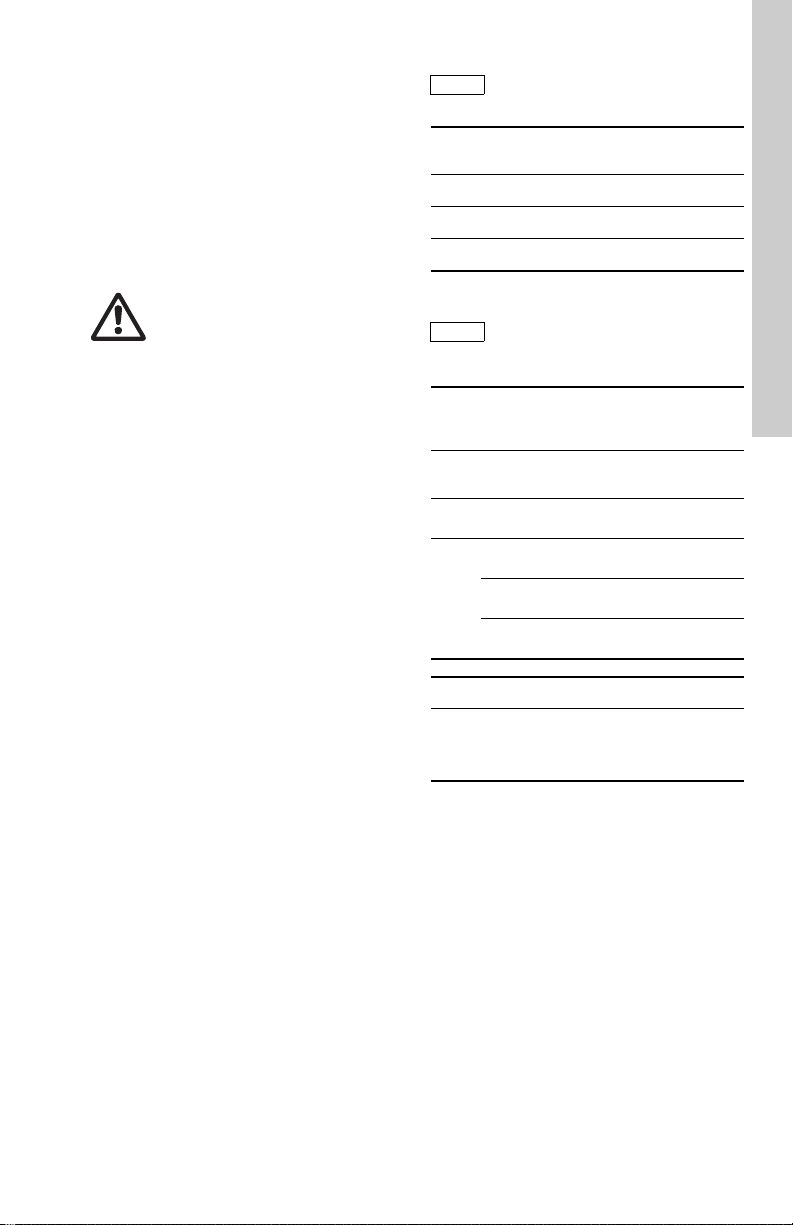

5.1.2 Mounting positions

The arrows on the pump housing indicate the

direction of water flow. The pump may be

installed in vertical or horizontal piping, but the

motor shaft must always remain horizontal,

as shown in fig. 1.

Fig. 1 Installation positions

5.1.3 Terminal box positions

At the bottom of the stator, closest to the pump

housing, there are three drain holes to allow

condensed water to escape. The drain holes

shall not be blocked for any reason and one

drain hole must always point downward.

There is not a drain hole directly below the

terminal box; therefore the terminal box must be

positioned in one of the positions shown in fig. 1

or fig. 2.

TM04 5646 3609

6

Page 7

Caution

Terminal box

position A

Terminal box

position B

Terminal box

position C

5.2 Changing the terminal box position

Warning

Before starting any work on this

circulator, be sure electrical supply

has been switched off and it cannot

be accidentally switched on.

If the pump is already installed in the system,

the system must be drained or the isolation

valves on both sides of the pump must be closed

and the pressure released/relieved by removing

the vent plug.

Warning

Exercise caution when draining the

system or removing the vent plug

as the fluid in the system may be

scalding hot and under pressure.

Only after the pressure has been relieved and

the pump drained should you proceed with the

next steps.

5.2.1 Rotating the terminal box

To change the position of the terminal box,

follow these steps:

1. Remove the four (5 mm) allen-head screws

holding the pump head onto the pump

housing.

2. Carefully lift/slide the pump head out and

away from the pump housing. Next rotate the

pump head and locate the terminal box in the

desired position. The terminal box can be

rotated in steps of 90 °. Review fig. 1 and

fig. 2 for possible/permissible positions.

DO NOT locate the terminal box beneath the

pump.

Use caution as the rotor assembly

can fall out of the pump head or

pump housing if the pump head is

pulled too far away from the pump

housing.

3. Make sure the O-ring is properly seated in

the pump housing.

4. Replace the pump head onto the pump

housing.

5. Diagonally tighten the 5 mm allen-head

screws evenly.

Torque to: 7 ft lbs. / 9.5 Nm.

6. Check to ensure the rotor turns freely. Do

this by removing the vent plug in the middle

of the pump nameplate. Insert a

medium-size, flat-blade screwdriver into the

slot at the exposed end of the shaft. Gently

turn the shaft. If it does not turn easily,

repeat steps 1 through 5 above. If the rotor

spins freely, proceed to step 7. Do not put

the vent plug back into the pump until the

end of step 9.

7. The position of the nameplate can be

changed by easing the outer edge of the

plate at the cutout with a screwdriver. Turn

the nameplate to the required position and

push into place.

8. Follow electrical instructions in section

5.3 Electrical connection.

9. Refill the system, open the isolation valves

and vent the system. Also allow air to vent

out of the pump; once water flows out the

vent hole, replace the vent plug removed in

step 6. See additional instructions in section

6.1 Vent the piping system.

10.Figure 2 shows acceptable terminal box

positions along with recommended drip

loops (dashed lines) in the electrical wiring

harness based on entry point.

Fig. 2 Acceptable terminal box positions

English (US)

TM04 5636 3609

7

Page 8

English (US)

Black

White

Green

Speed

switch

Capacitor

Black

White

Green

Capacitor

5.3 Electrical connection

Warning

Risk of electrical shock! The

electrical connection and

protection should be carried out in

accordance with the latest edition

of the National Electrical Code,

local codes and regulations by a

qualified electrician.

The safe operation of this pump

requires that it be grounded in

accordance with the National

Electrical Code and any state, local

governing codes and regulations.

Ground wires should be copper

conductors of at least the size of

the circuit conductor supplying

power to the pump. Connect the

ground wire to the grounding point

in the terminal box and then to an

acceptable ground. Do not ground

to gas or water supply line.

All wire sizes should be copper and

size-based on the ampacity

(current carrying properties of a

conductor) as required by the

National Electrical Code or local

regulations. Additionally UL

requires the following wire sizes to

be used: 18-12 Solid or 14-12

Stranded.

Both the power and grounding

wires must be suitable for at least

194 °F (90 °C).

Proper operating voltage and other electrical

information can be found on the pump

nameplate attached to the top of the motor.

• The motor is thermally protected on all three

speeds and no additional external protection

is needed.

• See fig. 3 for proper grounding and supply

power connection locations (115 V and

208-230 V).

• The terminal connections are toggle/lever

push design. Push the lever down and insert

the field wiring. Push the lever down and pull

to remove wires.

• Next, use care when installing the terminal

box cover with speed switch. Insert the

Phillips head screw through the cover and

tighten to a snug fit.

• An external "Drip Loop" is recommended in

the electrical wiring harness; see fig. 2.

• Where an external "Drip Loop" is not

possible, or if the wiring enters through the

upward facing (top) surface of the box, then

an internal "Drip Loop" is recommended; see

fig. 3.

Fig. 3 Examples of ground and power

supply connections (115 V and

108-230 V) with internal drip loop

TM04 5634 3609

8

Page 9

5.4 Insulating shells (if equipped)

Insert flange bolts

toward pump

Insert flange bolts

toward pump

Do not block weep slots

Do not block weep slots

For pumps with provided insulation shell, the

following procedures are required to insure safe

and proper installation.

1. Pump and mating piping flange bolts need to

be installed towards the pump as illustrated

in fig. 4.

2. Apply water proof, heat resistant, silicon

based sealant to insulation shell. Care

should be taken to not block weep slots for

pump motor when applying sealant. Failure

to follow proper sealant location procedures

could damage motor and insulation shell.

See fig. 5 for proper locations when applying

sealant.

3. Mate the two insulation shells over the pump

volute as illustrated in fig. 6. If the shells do

not mate; flange bolts are installed in the

wrong direction, review step one and or

switch mating shell location.

4. Proper amount of time should be allowed for

sealant to set-up before any additional

installation work is performed. See sealant

manufactures recommended time for sealant

set-up. See fig. 7 for final configuration.

English (US)

TM05 1889 3811TM05 1890 2515TM05 1891 2515

Fig. 5 Applying silicon sealant (dotted

areas indicate sealant)

Fig. 4 Connect pump to piping, installing

Fig. 6 Insulating shell installation (dotted

areas indicate sealant)

TM05 1888 2515

flange bolts toward the pump

Fig. 7 Ready for insulation wrap

9

Page 10

English (US)

Caution

Inspection screw/

Low

HHH

Medium

High

QQ Q

H = Head and Q = Flow

6. Starting the pump

6.1 Vent the piping system

After the pump has been installed and the

electrical connections made, the piping system

must be vented.

Never operate the pump dry - the

system must first be filled with

liquid and vented.

NOTE: Do not vent the piping system through

the pump. Instead, follow these steps:

1. Fill and pressurize the system with liquid,

and vent all trapped air from the piping by

suitable means.

2. If any isolation valves are used, make sure

they are OPEN.

Warning

If the vent screw/plug is to be

loosened, care should be taken to

ensure that the escaping scalding

hot liquid does not cause personal

injury or damage to components.

3. Vent the pump by removing the vent plug.

When water exists through the port, the

pump is fully vented / primed.

4. Reinstall the vent plug.

6.2 Speed selection

UPS models

Speeds can be changed via the speed switch on

the terminal box cover. Power must be turned off

before changing speeds. The speed in the three

positions appears in the following table; also see

fig. 10.

UP models

Speed is fixed on Speed 3 (High) and cover

does not have a switch (cover is solid).

Fig. 9 Terminal box cover with speed

Switch position

Low (Speed 1) approx. 60 %

Medium (Speed 2) approx. 80 %

High (Speed 3) 100 %

Changing to lower speeds offers considerable

reduction in energy consumption and less noise

in the system.

switch in medium speed (Speed 2)

Speed in % of max.

speed

TM04 5641 2515

Fig. 8 Vent screw/plug removal for pump

10

venting

TM04 5644 3609

Fig. 10 Pump performance at speed

settings

TM04 5640 3609

Page 11

7. Fault finding

7.1 Fault finding chart

Warning

Before removing the terminal box cover, make sure that the electrical supply has

been switched off and that it cannot be accidentally switched on.

Warning

The pumped liquid may be scalding hot and under high pressure. Before any

removal or dismantling of the pump, the system must be drained or the isolation

valves on both sides of the pump must be closed.

Fault Cause Remedy

1. The pump does not

run.

2. The pump does not

run.

3. Noise in the system. a) Air in the system. Vent the system.

4. Noise in the pump. a) Air in the pump. Vent the pump.

5. Insufficient heat in

some places in the

heating system.

a) External circuit breaker is

switched off.

b) Current-/voltage-operated

ground fault circuit

interrupter has tripped.

a) Rotor is blocked. Switch off the electrical supply and

b) The speed switch is not

fully positioned (is

between speeds)

c) The pump has been cut

out by the thermal

overload switch due to

high liquid temperature.

b) The pump flow is too

high.

c) The pressure is too high. Reduce the pump performance.

b) The inlet pressure is too

low.

a) The pump performance

is too low.

b) The performance is too

high.

Switch the circuit breaker on.

Repair the insulation defects and reset

the interrupter.

clean/repair the pump.

Switch off the electrical supply at the

external circuit breaker and change

speed switch into position.

Check that the liquid temperature falls

within the specified range. The pump will

restart automatically when it has cooled

to normal temperature.

Reduce the pump performance.

Increase the inlet pressure and/or check

the air volume in the expansion tank (if

installed).

Increase the pump performance, if

possible. Flow too fast through the

boiler/heat exchanger may not allow for

the proper BTU transfer to the fluid. If

fluid is too slow, fluid may be cooling too

much before returning from the system.

If changing speeds does not resolve the

problem, replacing the pump with a

properly sized pump may be required.

English (US)

11

Page 12

English (US)

7.2 Preliminary checks

Supply voltage

To check the voltage being supplied to the

motor, use a voltmeter.

Warning

Be careful, since power is still

being supplied to the pump. Do not

touch the voltmeter leads together

while they are in contact with the

power lines.

Single-phase motors

Touch one voltmeter lead to each of the lines

supplying power to the pump as shown in fig. 11:

• L and N for 115 V and 208-230 V circuits

These tests should give a reading of full line

voltage.

Evaluation

When the motor is under load, the voltage

should be within 10 % (+ or -) of the nameplate

voltage.

Any variation larger than this may indicate a

poor electrical supply and can cause damage to

the motor windings. The motor should not be

operated under these conditions. Contact your

power supplier to correct the problem or change

the motor to one requiring the voltage you are

receiving.

and N = L2 for 208-230 V circuits in

(L = L

1

the US)

Fig. 11 Testing with voltmeter

7.3 Current measur emen t

To check the current using an ammeter, follow

these steps:

1. Make sure the pump is operating.

2. Set the ammeter to the proper scale.

3. Place the tongs of the ammeter around the

leg to be measured.

4. Compare the results with the amp draw

information on the motor nameplate.

5. Repeat for the other legs.

Fig. 12 Current measurement

Evaluation

If the current draw exceeds the listed nameplate

amps, or if the current imbalance is greater than

5 % between each leg, then check the following:

• The voltage supplied to the pump may be too

high or too low.

• The terminals/wires in the terminal box or to

circuit breaker may be loose.

• The contacts on the motor starter may be

burned.

TM04 5645 3609

• The terminals in the starter or terminal box

may be loose.

• There may be a winding defect. Check the

winding and insulation resistance; see

section 7.6 Resistance tables.

• The motor windings may be shorted or

grounded.

• The pump may be damaged in some way

and may be causing a motor overload.

• A voltage supply problem may exist.

TM04 5639 3609

12

Page 13

7.4 Insulation resistance

L

N

(lead-to-ground)

To check the insulation resistance

(lead-to-ground) of the motor and leads, use a

megohmmeter and follow these steps:

1. Turn the POWER OFF.

2. Disconnect all electrical leads to the motor.

3. Set the scale selector on the megohmmeter

to R x 100K, touch its leads together, and

adjust the indicator to zero.

4. Touch the leads of the megohmmeter

individually to each of the motor leads and to

ground (i.e. L to ground; N to ground, etc.).

7.6 Resistance tables

Checking connections in the terminal box at the

power connections L and N; see fig. 14 for 1 15 V

and 208-230 V.

Connection

115 V

L to N

(Speed 3)

L to N

(Speed 2)

L to N

(Speed 1)

Ohm value

range

= 6.9 - 8.01 7.55

= 9.7 - 11.38 10.54

= 12.97 - 15.23 14.10

Nominal

English (US)

Fig. 13 Insulation resistance measurement

Evaluation

The resistance values for new motors must

exceed 1,000,000 ohms. If they do not, replace

power head.

7.5 Winding resistance (line-to-line)

To check the winding resistance of the motor

windings, use a megohmmeter and follow these

steps.

1. Turn the POWER OFF.

2. Disconnect all electrical leads to the motor.

3. Set the scale selector on the megohmmeter

to R x 1, touch its leads together and adjust

the indicator to zero.

4. Using the charts in section 7.6 Resistance

tables for reference, touch the leads of the

megohmmeter to the appropriate pair of

connectors. Check all pairs that are present

and write down and label (RA1, RS1, RS2)

all readings.

– In T-box at L & N: UP will = Speed 3/High

– In T-box at L & N: UPS value depends on

the selected speed (Speed 1, 2, or 3)

– For both UP and UPS: with the terminal

box removed, check all combinations RA,

S1, S2.

5. Compare your readings to the matching

model, phase and voltage listed in the charts

in section 7.6 Resistance tables.

Evaluation

The resistance values must fall within the

tolerances listed in section 7.6 Resistance

tables. If they do not, replace the power head.

Connection

L to N

(Speed 3)

208 V

230 V

TM04 5638 3609

* T can only be checked with the terminal box

removed; if the thermiks is open the pump will

not run.

Fig. 14 Power connections L and N

-

L to N

(Speed 2)

L to N

(Speed 1)

Ohm value

range

= 34.63 - 40.66 37.65

= 41.57 - 48.81 45.19

= 56.67 - 66.53 61.60

Nominal

TM04 5633 3609

13

Page 14

English (US)

Checking at the pin connection behind the

terminal box (see section 8.3 Replacing the

terminal box or capacitor for terminal box

removal):

Stator pin

connection

Winding groups

1 to 2 RA: Main winding

4 to 5 RS

6 to 7 RS

: Auxiliary winding

1

: Auxiliary winding

2

2 to 8 T: Thermiks

Connection

Ohm value

range

RA (1 to 2) = 6.7 - 7.9 7.3

RS

(4 to 5) = 3.0 - 3.6 3.3

115 V

1

RS

(6 to 7) = 3.0 - 3.6 3.3

2

T (2 to 8) = 0

Connection

Ohm value

range

RA (1 to 2) = 30.4 - 35.6 33

208 V

RS

(4 to 5) = 12.0 - 14.0 13

1

-

RS

(6 to 7) = 12.0 - 14.0 13

230 V

2

T (2 to 8) = 0

Figure 15 shows terminal plug-in stator

relationship to the top / nameplate end of the

stator.

Nominal

Nominal

8. Replacing components

Warning

Before starting any work on this

circulator, make sure electrical

supply has been switched off and

that it cannot be accidentally

switched on.

8.1 Removing the pump head

1. Disconnect or TURN OFF the power supply.

2. Close any isolating valves on either side of

the pump to avoid draining the system of

liquid.

3. Remove the vent plug to relieve any system

pressure retained in the pump. Exercise

caution as the fluid may be scalding hot

and under pressure. Only after the

pressure has been relieved and the pump

drained should you proceed with the next

steps.

4. Disconnect the electrical leads from the

terminal box.

5. Disconnect and remove the conduit from the

terminal box.

6. Loosen and remove the four 5 mm

allen-head screws which connect the pump

head housing to the pump housing.

7. Remove the pump head from the pump

housing. Exercise care as the rotor may

fall out of the stator or pump housing.

8. Clean the machined surfaces in the pump

housing of any foreign material.

Fig. 15 Stator socket

Fig. 16 Internal wiring

14

TM04 5643 3609TM04 5637 3609

Page 15

8.2 Fitting the pump head

Terminal box

Stator housing Rotor assembly

ImpellerBearing plate

O-ring

Pump housing

Thrust bearing

Allen

screws (4)

5 mm

1. Carefully remove the new pump head

assembly from its packaging. Separate the

impeller/rotor assembly from the new pump

head.

2. While holding the thrust bearing plate,

carefully place the impeller/rotor assembly

into the pump housing. The bearing plate

should fit snugly into the lowest machined

surface in the pump housing.

3. Ensure that the impeller/rotor assembly can

rotate freely.

4. Place the O-ring over the rotor and locate it

into the inner diameter of the pump housing.

5. Carefully place the pump head housing over

the rotor and rotate it so the terminal box is

in the position you wish; see section

5.2.1 Rotating the terminal box.

6. Ensure that the pump head housing is

properly seated on the pump housing. Do

not force the two together - if there is

binding, disassemble them and repeat steps

2 to 6. Cross-tighten the allen-head screws

evenly.

Torque to: 7 ft lb / 9.5 Nm.

7. Check to make sure the rotor turns freely. Do

this by removing the vent plug in the middle

of the pump nameplate. Insert a

medium-size, flat-blade screwdriver into the

slot at the exposed end of the shaft. Gently

turn the shaft. If it does not turn easily,

repeat steps 1 through 6 above. If the rotor

spins freely, proceed to step 8. Do not put

the vent plug back into the pump until the

end of step 10.

8. The position of the nameplate can be

changed by easing the outer edge of the

plate at the cutout with a screwdriver. Turn

the nameplate to the required position and

push into place.

9. Follow electrical instructions in section

5.3 Electrical connection.

10.Refill the system, open the iso lation valves

and vent the system. Also allow air to vent

out of the pump, once water flows out the

vent hole, replace the vent plug removed in

step 7. See additional instructions in section

6.1 Vent the piping system.

English (US)

Fig. 17 Removing and fitting the pump head

TM04 5635 3609

15

Page 16

English (US)

Terminal box

holding screws

8.3 Replacing the terminal box or capacitor

Warning

Before starting any work on this

circulator, make sure electrical

supply has been switched off and

that it cannot be accidentally

switched on.

Removal

1. Before replacing the terminal box and

capacitor, make sure the power is OFF.

2. Remove the terminal box cover/lid by

completely loosening the Phillips head screw

in the center of the cover/lid.

3. Disconnect all wiring. Move the capacitor to

allow access to the screws.

4. Remove the two T15 Torx head screws

holding the terminal box in place.

5. Pull firmly and evenly on both sides of the

terminal box to free it from the stator / pump

head.

Installation

1. Carefully press the terminal box into the

stator socket.

2. Replace the two T15 Torx head screws and

torque to 1.5 ft.-lbs / 2 Nm.

3. Replace the wiring (refer to section

5.3 Electrical connection).

4. Use care when installing the terminal box

cover with speed switch. Next insert the

Phillips head screw through the cover and

tighten to a snug fit.

5. Restore power.

TM04 5641 2515TM04 5642 3609

Fig. 18 Terminal box lid / cover

Fig. 19 Terminal box holding screws

16

Page 17

9. Additional technical data 10. Disposal

Caution

Supply voltage:

Motor protection: Thermally protected

Enclosure class: CSA Type 2

Insulation class: H

Max. discharge

pressure:

Max. sound

pressure level:

Water hardness: 14 dH

(domestic, potable hot water)

Fluid A mbient

Min. 36 °F (2 °C) 33 °F (1 °C)

Max. < 149 °F (65 °C) 100 °F (38 °C)

1 x 115 V ± 10 %, 60 Hz

1 x 208-230 V ± 10 %, 60 Hz

145 psi (10 bar)

30 dB(A)

Open systems

In domestic hot-water systems, it is

recommended to keep the liquid

temperature below 149 °F (65 °C) to

eliminate the risk of lime

precipitation.

This product or parts of it must be disposed of in

an environmentally sound way:

1. Use the public or private waste collection

service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

English (US)

Subject to alterations.

(non-potable heating or cooling airless

Min. All

Max.

Max. 50 % glycol at 15 °F (-9.5 °C) liquid

(Hydraulic performance change can be

expected.)

Closed systems

fluid)

Pump

models

UPS 26-150

UPS 43-100

UPS 50-60

Water and glycol mix

Fluid Ambient

36 °F

(2 °C)

230 °F

(110 °C)

230 °F

(110 °C)

212 °F

(100 °C)

33 °F

(1 °C)

100 °F

(38 °C)

100 °F

(38 °C)

100 °F

(38 °C)

17

Page 18

18

Page 19

GRUNDFOS Kansas City

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: (913) 227-3400

Fax: (913) 227-3500

www.grundfos.us

GRUNDFOS Canada

2941 Brighton Road

Oakville, Ontario L6H 6C9 Canada

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

www.grundfos.ca

GRUNDFOS México

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

C.P. 66600 Apodaca, N.L. México

Phone: 011-52-81-8144 4000

Fax: 011-52-81-8144 4010

www.grundfos.mx

Grundfos companies

Page 20

L-UP-TL-062

98419789 0715

ECM: 1161312

www.grundfos.com

© Copyright Grundfos Holding A/S

owned by Grundfos Holding A/S or Grundfos A/S, Denmark. All rights reserved worldwide.

The name Grundfos, the Grundfos logo, and be think innovate are registered trademarks

Loading...

Loading...