Grundfos UPE 2000 Series, UPED 50-120, UPED 100-60, UPED 65-120, UPED 80-120 Installation And Operating Instructions Manual

Page 1

GRUNDFOS INSTRUCTIONS

UPE Series 2000

UPED 50-120, UPED 65-120, UPED 80-120, UPED 100-60

Installation and operating instructions

Page 2

Декларация о соответствии

Мы, фирма Grundfos, со всей от ветственно стью заявляем, что

изделия UPE серии 2000 к которым и отно сится данное

свид етельст во, отвечают требованиям следующих указаний Совета

ЕС об унификации законодательных предписаний стран-членов ЕС:

– Машиностроение (98/37/ЕС).

– Электрические машины для эксплуатации в пределах

определенного диапазона значений напряжения

(2006/95/ЕС).

Применявшиеся стандарты: Евростандарт EN 60335-1: 2002 и

EN 60335-2-51: 2003.

– Электромагнитная

Применявшиеся стандарты: Евростандарт EN 61800-3.

совместимость (89/336/ЕЭС).

Izjava o usklađenosti

Mi, Grundfos, izjavljujemo uz punu odgovornost, da su proizvodi

UPE serija 2000 na koje se ova izjava odnosi, sukladni smjernicama

Savjeta za prilagodbu propisa država-članica EZ:

– Strojevi (98/37/EZ).

–Električni pogonski uređaji za korištenje unutar određenih granica

napona (2006/95/EZ).

Korištene norme: EN 60335-1: 2002 i EN 60335-2-51: 2003.

– Elektromagnetska kompatibilnost (89/336/EEZ).

Korištena norma: EN 61800-3.

Prohlášení o shodě

My firma Grundfos prohlašujeme na svou plnou odpovědnost, že

výrobky UPE série 2000 na něž se toto prohlášení vztahuje, jsou v

souladu s ustanoveními směrnice Rady pro sblížení právních předpisů

členských států Evropského společenství v oblastech:

– strojírenství (98/37/EG).

– provozování spotřebičů v toleranci napětí (2006/95/EG),

použité normy: EN 60335-1: 2002 a EN 60335-2-51: 2003.

– elektromagnetická kompatibilita (89/336/EWG),

použitá norma: EN 61800-3.

Konformitätserklärung

Wir Grundfos erklären in alleiniger Verantwortung, dass die Produkte

UPE Serie 2000 auf die sich diese Erklärung bezieht, mit den folgenden

Richtlinien des Rates zur Angleichung der Rechtsvorschriften der EGMitgliedstaaten übereinstimmen

– Maschinen (98/37/EG).

– Elektrische Betriebsmittel zur Verwendung innerhalb bestimmter

Spannungsgrenzen (2006/95/EG).

Normen, die verwendet wurden: EN 60335-1: 2002 und

EN 60335-2-51: 2003.

– Elektromagnetische Verträglichkeit (89/336/EWG).

Norm, die verwendet wurde: EN 61800-3.

Izjava o ustreznosti

Mi, Grundfos, pod polno odgovornostjo izjavljamo, da so izdelki

UPE serija 2000 na katere se ta izjava nanaša, v skladu z naslednjimi

smernicami Sveta za uskladitev pravnih predpisov držav članic

Evropske skupnosti:

– Stroji (98/37/EG).

–Električna pogonska sredstva za uporabo v določenih napetostnih

mejah (2006/95/EG).

Uporabljeni normi: EN 60335-1: 2002 in EN 60335-2-51: 2003.

– Elektromagnetna kompatibilnost (89/336/EWG).

Uporabljena norma: EN 61800-3.

Izjava o konformitetu

Mi, Grundfos, izjavljujemo pod potpunom odgovornošću da su

proizvodi UPE serije 2000 na koje se odnosi ova izjava u saglasnosti sa

smernicama i uputstvima Saveta za usaglašavanje pravnih propisa

članica Evropske unije:

– mašine (98/37/EG).

–električna oprema razvijena za korišćenje unutar određenih

naponskih granica (2006/95/EG),

korišćeni standardi: EN 60335-1: 2002 i EN 60335-2-51: 2003.

– elektromagnetna usaglašenost (89/336/EWG),

korišćen standard: EN 61800-3.

Declaration of Conformity

We Grundfos declare under our sole responsibility that the products

UPE Series 2000 to which this declaration relates, are in conformity with

the Council Directives on the approximation of the laws of the EC Member States relating to

– Machinery (98/37/EC).

– Electrical equipment designed for use within certain voltage limits

(2006/95/EC).

Standards used: EN 60335-1: 2002 and EN 60335-2-51: 2003.

– Electromagnetic compatibility (89/336/EEC).

Standard used: EN 61800-3.

Bjerringbro, 15th March 2007

Svend Aage Kaae

Technical Director

2

Page 3

UPE Series 2000

UPED 50-120, UPED 65-120, UPED 80-120, UPED 100-60

Руководство по монтажу и эксплуатации 4

Navodila za montažo in obratovanje 32

Montažne i pogonske upute 55

Uputstvo za montažu i upotrebu 78

Montážní a provozní návod 102

Installation and operating instructions 126

Montage- und Betriebsanleitung 147

3

Page 4

CONTENTS

1. General description 126

1.1 Master pump and slave pump 126

2. Applications 127

2.1 Pumped liquids 127

3. Installation 127

3.1 Terminal box positions 127

3.2 Changing the terminal box position 127

3.3 Changing the nameplate position 128

3.4 Non-return valve 128

3.5 Insulation 128

3.6 Frost protection 128

4. Electrical connection 128

4.1 Supply voltage 128

4.2 Wiring diagram 129

5. Start-up 130

6. Functions 130

6.1 Control of twin-head pumps 130

6.2 Control modes 130

6.3 Selection of control mode 131

6.4 Max. or min. curve duty 132

6.5 Constant curve duty 132

6.6 Temperature influence 133

6.7 Indicator lights 133

6.8 External fault indications 134

6.9 External analog 0-10 V controller 134

6.10 External forced control 135

6.11 Deactivating the control panel 135

6.12 Bus communication 135

6.13 Wireless remote control 135

7. Setting the pump 136

7.1 Factory settings 136

7.2 Control panel 136

7.3 R100 139

7.4 Menu OPERATION 140

7.5 Menu STATUS 140

7.6 Menu INSTALLATION 141

7.7 Priority of settings 143

8. Fault finding chart 143

9. Megging 145

9.1 High-voltage test 145

10. Technical data 145

11. Disposal 146

Page

The desired head can be set on the pump control

panel.

These instructions apply to the pump types

UPED 50-120, UPED 65-120, UPED 80-120 and

UPED 100-60.

The pump offers the following functions:

• Control of twin-head pump:

- Alternating operation,

- Standby operation,

- Synchronous operation,

- Single-pump operation.

• Proportional-pressure control (factory setting).

The head is changed in accordance with the flow

demand. The desired head can be set on the

pump control panel.

• Constant-pressure control. A constant head is

maintained, irrespective of flow demand. The

desired head can be set on the pump control

panel.

• Constant curve duty. The pump runs at a con-

stant speed on or between the max. and min.

curves.

• Temperature influence. The head varies depend-

ing on the liquid temperature.

• External fault signal via a potential-free output.

• External analog control of head or speed from

an external 0-10 V signal transmitter.

• External forced control via inputs for:

- Start/stop,

- Max. curve,

- Min. curve (night-time duty).

• Bus communication. As the UPE Series 2000

incorporates an input for bus communication, the

pump can be controlled and monitored by a

GRUNDFOS Pump Management System 2000 or

a building management system.

• Remote control. The pump can be operated by

means of the Grundfos wireless remote control

R100.

1.1 Master pump and slave pump

Slave pump

Master pump

Prior to installation, read these installation

and operating instructions. Installation and

operation must comply with local regulations and accepted codes of good practice.

1. General description

The UPE Series 2000 is a complete range of circulator pumps with integrated differential pressure control enabling adjustment of pump performance to the

actual system requirements. In many systems, this

will mean a considerable reduction in power consumption, prevent noise from thermostatic valves

and similar fittings, and improve the control of the

system.

126

TM02 1389 1101

Fig. 1

Page 5

2. Applications

The UPE Series 2000 is designed for circulating liquids in heating systems. The pumps can also be

used in domestic hot-water systems.

UPE Series 2000 is suitable for:

• systems with a constant flow where it is desira-

ble to optimize the setting of the pump duty point

and

• systems with variable flow-pipe temperatures.

2.1 Pumped liquids

Thin, clean, non-aggressive and non-explosive liquids, not containing solid particles, fibres or mineral

oil.

In heating systems, the water should meet the

requirements of accepted standards on water quality

in heating systems, e.g. the German standard VDI

2035.

In domestic hot-water systems, it is advisable to

use UPED pumps only for water with a degree of

hardness lower than approx. 14°dH.

For water with a higher degree of hardness a directcoupled TPE pump is recommended.

The pump must not be used for the transfer of inflammable liquids such as diesel

oil, petrol or similar liquids.

Liquid flow

direction

→

3. Installation

When installing pumps, types UPED 50-xx and

65-xx, with oval bolt holes in the pump flange,

washers must be used as shown in fig. 2.

Installation

Washer

Fig. 2

See mounting dimensions at the end of these

instructions.

Care should be taken to ensure that persons cannot accidentally come into contact with hot surfaces of the pump.

The pump must be installed with the motor shaft horizontal.

Arrows on the pump housing indicate the liquid flow

direction through the pump.

The permissible liquid flow directions through the

pump are indicated by an "X" in the following table:

Pump

TM01 0683 1997

Pump type

UPED 50-120 X X X

UPED 65-120 X X X

UPED 80-120 X X X

UPED 100-60 X X X

Note: Pumps mounted in horizontal pipes must be

fitted with an automatic air vent in the upper part of

the pump housing.

The automatic air vent is not supplied with the pump.

3.1 Terminal box positions

The terminal box can be turned to the positions

shown in figure 3.

Note: The terminal box must only be turned to the

positions below.

Fig. 3

TM02 1389 1101

TM02 1391 1101

3.2 Changing the terminal box position

Before any dismantling of the pump, the

system must be drained or the isolating

valves on either side of the pump must be

closed as the pumped liquid may be scalding hot and under high pressure.

Change the terminal box position as follows:

1. Remove the four screws holding the pump head.

2. Turn the pump head to the required position.

3. Replace the four screws and tighten securely.

TM02 2104 3401

TM02 1392 1101

TM02 1393 1101

127

Page 6

3.3 Changing the nameplate position

When the terminal box position has been changed,

the pump nameplate must be turned so that the cutout points downwards. This allows water from a possible venting to escape.

To change the nameplate position, ease the outer

edge of the nameplate at the cutout with a screwdriver, turn the nameplate to the new position and

push it into place.

3.4 Non-return valve

If a non-return valve is fitted in the pipe system, see

fig. 4, it must be ensured that the minimum discharge

pressure is always higher than the closing pressure

of the valve. This is especially important in proportional-pressure control mode (reduced head at low

flows).

Fig. 4

3.5 Insulation

If the pump is insulated, it must be ensured that the

differential pressure and temperature sensor in the

pump housing is not covered.

3.6 Frost protection

If the pump is not being used during periods of frost,

the necessary steps must be taken to prevent frost

bursts.

4. Electrical connection

The electrical connection and protection should be

carried out in accordance with local regulations.

Never make any connections in the pump

terminal box unless the electricity supply

has been switched off for at least

5 minutes.

The earth terminal of the pump must be

earthed.

The pump must be connected to an external mains switch with a minimum contact

gap of 3 mm in all poles.

Earthing or neutralization can be used for

protection against indirect contact.

Megging must be carried out as described

in section 9. Megging.

If the pump is connected to an

electric installation where an

earth leakage circuit breaker

(ELCB) is used as an additional

protection, this circuit breaker

must trip out when earth fault

currents with DC content (pul-

TM02 0640 0301

• The pump requires no external motor protection.

• If a classification of the pump to overvoltage prop-

• The operating voltage and frequency are marked

4.1 Supply voltage

3 x 400-415 V ±10%, 50 Hz.

sating DC) and smooth DC

earth fault currents occur.

The earth leakage circuit

breaker must be marked with

the two symbols shown.

erty class 1 or 2 in accordance with

VDE 0160/12.90 is required, a prefilter must be

installed. Contact Grundfos for further information.

on the pump nameplate. Please make sure that

the motor is suitable for the electricity supply on

which it will be used.

128

Page 7

4.2 Wiring diagram

L1L3

321

10987654

L2

1211

Signal output

213

NCNO

C

Differential pres-

sure and temper-

ature sensor

Bus signal

used for

master/slave

communication

AYB

546 987101112

White

Screen

Brown

Fig. 5

Note:

• A possible external controller is to be connected

to the master pump (terminals 7 to 12).

• If the pump is to be connected to a PMU 2000 or

PCU 2000, it must be set to single-pump operation, see supplement to these instructions.

• If no external on/off switch is connected, the connection across terminals 7 and 8 should be maintained.

• If the 0-10 V input is used (terminals 11 and 12),

there must be a connection across terminals

7 and 9 (the input for the min. curve must be

closed).

• All cables used must be heat-resistant up to at

least +85°C.

• All cables used must be installed in accordance

with EN 60204-1.

Mains connection

L2

L3

L1

Start/stop

Min. curve

(night-time duty)

Max. curve

Analog 0-10 V

input

DC 0-10 V

Stop Min. Max.

• Wires connected to

- outputs 1 to 3,

- inputs 4 to 12,

- supply terminals and

- differential pressure and temperature

sensor

must be separated from each other and

from the supply by reinforced insulation.

• All leads connected to a terminal block

must be tied up at the terminals.

Concerning demands on signal wires and signal

transmitters, see section 10. Technical data.

A connection example can be found on page 172.

TM01 1105 3399

129

Page 8

5. Start-up

Do not start the pump until the system has been filled

with liquid and vented. Furthermore, the required

minimum inlet pressure must be available at the

pump inlet, see section 10. Technical data.

The system cannot be vented through the pump.

As the pump is self-venting, it need not be vented

before start-up.

If the inspection screw is to be slackened,

see fig. 6, care should be taken to ensure

that the escaping, scalding hot liquid does

not cause personal injury or damage to

components.

Inspection screw

Fig. 6

The pump may be noisy, when first switched on, due

to air remaining in the chamber. This noise should

cease after a few minutes running.

After start-up, the desired operating mode and possibly pump head are set.

6. Functions

Some functions can only be selected by means of

the remote control R100. Where and how the different settings are made will appear from section

7. Setting the pump.

6.1 Control of twin-head pumps

Factory setting can be changed by means of the

R100.

Twin-head pump

Slave pump

Master pump

If the electricity supply to the pump has been

switched off, any of the pumps may start when

the electricity supply is switched on.

Reaction in case of fault. In case of fault in one

pump head, the operational pump head will operate constantly as a single-head pump.

2. Standby operation. The slave pump is in con-

stant operation. Every 24 hours the master pump

will start up slowly and run for approx. 1 minute to

prevent it from seizing up.

Reaction in case of fault. If the slave pump

stops because of fault, the master pump will

operate constantly as a single-head pump.

3. Synchronous operation. Master and slave

pumps are running at the same motor frequency.

This operating mode is suitable if the flow

requirement exceeds the flow of one pump head.

Reaction in case of fault. In case of fault in one

pump head, the operational pump head will operate constantly as a single-head pump.

4. Single-pump operation. See supplement to

these instructions.

The other functions mentioned in sections

TM02 1460 1201TM02 1389 1101

6.2 Control modes to 6.13 Wireless remote control

are all possible in the three operating modes.

6.2 Control modes

UPE Series 2000 pumps can be set to the control

mode which is most suitable for the individual system.

Two control modes are available:

• Proportional pressure (factory setting),

• Constant pressure.

Proportional-pressure control:

Can be set by means of the control panel or the

R100.

The pump head is reduced at falling water demand

and increased at rising water demand, see fig. 8.

This is the factory setting, as in most cases, this is

the optimum control mode, and at the same time it

consumes the least energy.

Constant-pressure control:

Can be set by means of the control panel or the

R100.

The pump maintains a constant pressure, irrespective of water demand, see fig. 8.

Control modes

H

H

Fig. 7

Four operating modes are available. The selection of

operating mode depends on whether reliability, lifetime or performance has top priority.

1. Alternating operation (factory setting). Pump

operation alternates every 24 hours. A manual

change can be made by reducing the setpoint to

stop. Thereby the time is reset, meaning that the

next change will take place after 24 hours.

130

set

H

Hset

2

Fig. 8

Proportional

pressure

H

set

Q

Constant

Q

pressure

TM00 5546 4596

Page 9

6.3 Selection of control mode

Systems with specified control mode:

If the control mode (proportional or constant pressure) and the pump head have been specified for the

system in which the pump is to be installed, the

pump should be set as specified. See section

7. Setting the pump. If problems should arise, see

section 8. Fault finding chart.

Systems with no specified control mode:

If the control mode and the pump head have not

been specified for the system, (for instance, an

uncontrolled standard pump is replaced by the

UPED pump), it is advisable to use the settings in

the following table and in section 6.3.1 Setting in

connection with pump replacement.

In systems

with ...

relatively great

head losses in

the boiler circuit

and the distribution pipes

relatively small

head losses in

the boiler circuit

and the distribution pipes

for instance ...

1. Two-pipe

heating systems with

thermostatic

valves and

with:

2. Underfloor heating systems and one-pipe heating systems with

thermostatic valves and great head losses in the boiler circuit.

3. Primary circuit pumps in systems with great head losses in

the primary circuit.

1. Two-pipe

heating systems with

thermostatic

valves and:

2. Underfloor heating systems with thermostatic valves.

3. One-pipe heating systems with thermostatic valves or pipe balancing valves.

4. Primary circuit pumps in systems with small head losses in the primary circuit.

• a dimensioned pump head higher than 4 metres,

• very long distribution pipes,

• strongly throttled pipe balancing valves,

• differential pressure regulators,

• great head losses in those parts of the system

through with the total quantity of water flows (e.g.

boiler, heat exchanger and distribution pipe up to

the first branching) or

• low differential temperature.

• with a dimensioned pump head lower than

2metres,

• dimensioned for natural circulation,

• with small head losses in those parts of the system

through with the total quantity of water flows

(e.g. boiler, heat exchanger and distribution pipe up

to the first branching) or

• modified to a high differential temperature

(e.g. district heating).

select this control mode ...

Proportional

pressure

Constant

pressure

131

Page 10

6.3.1 Setting in connection with pump

replacement

If an uncontrolled pump is to be replaced with a

UPE Series 2000, settings can be made according to

the tables below.

Existing pump at maximum speed Existing pump at reduced speed

Existing

pump

Maximum

head

[m]

UPE Series 2000

Setting of

head [m]

Setting of

control mode

Existing

pump

Maximum

head

[m]

UPE Series 2000

Setting of

head [m]

Setting of

control mode

3 2 Constant pressure 3 1.5 Constant pressure

4 2 Constant pressure 4 1.5 Constant pressure

5 2.5 Proportional pressure 5 2 Constant pressure

6 3 Proportional pressure 6 2 Constant pressure

7 3.5 Proportional pressure 7 2.5 Proportional pressure

8 4 Proportional pressure 8 3 Proportional pressure

9 4.5 Proportional pressure 9 3.5 Proportional pressure

10 5 Proportional pressure 10 3.5 Proportional pressure

11 5.5 Proportional pressure 11 4 Proportional pressure

12 6 Proportional pressure 12 4 Proportional pressure

Read the tables as follows:

• If the maximum head of the existing pump is

6 metres and the pump is running at maximum

speed under normal operating conditions, it is recommended to set the UPED pump to 3 metres and

to select proportional pressure.

• If, however, the existing pump is running at a

reduced speed, it is recommended to set the

UPED pump to 2 metres and to select constant

pressure.

6.4 Max. or min. curve duty

Can be set by means of the control panel or the

R100.

The pump can be set to operate according to the

max. or min. curve, like an uncontrolled pump,

see fig. 9.

H

Max.

Min.

Q

Fig. 9

The max. curve mode can be selected if an uncontrolled pump is required. In this operating mode, the

pump will operate independently of an external controller, if installed.

The min. curve mode can be used in periods in

which a minimum flow is required. This operating

mode is suitable for night-time duty.

Two different min. curves can be set by means of the

R100.

6.5 Constant curve duty

Can be set by means of the R100.

The pump can be set to operate according to a constant curve, like an uncontrolled pump. Select one of

19 curves between the max. and min. curves, see

fig. 10.

H

Max.

TM00 5547 4596

Fig. 10

Min.

Q

TM00 5548 4596

132

Page 11

6.6 Temperature influence

Can be set by means of the R100.

When this function is activated in proportional or

constant control mode, the setpoint for head will be

reduced according to the liquid temperature. It is

possible to set temperature influence to function at

liquid temperatures below 80°C or below 50°C.

These temperature limits are called T

point is reduced in relation to the head set (= 100%)

according to the characteristics below.

H

100%

actual

30%

H

T

actual

H

805020

°CT

Fig. 11

In the above example, T

selected. The actual liquid temperature T

causes the setpoint for head to be reduced from

100% to H

actual

.

= 80°C has been

max.

The temperature influence function requires:

• Proportional or constant-pressure control mode.

• The pump must be installed in the flow pipe.

• System with flow-pipe temperature control

(e.g. according to outdoor temperature).

Temperature influence is suitable in:

• systems with variable flows (e.g. two-pipe heating

systems), in which the activation of the temperature influence function will ensure a further reduction of the pump performance in periods with small

heating demands and consequently a reduced

flow-pipe temperature, and

• systems with almost constant flows (e.g. one-pipe

heating systems and underfloor heating systems),

in which variable heating demands cannot be registered as changes in the head (as is the case

with two-pipe heating systems). In such systems,

the pump performance can only be adjusted by

activating the temperature influence function.

Selection of T

max.

In systems with a dimensioned flow-pipe temperature of:

• up to and including 55°C, select T

• above 55°C, select T

max.

= 80°C.

max.

max.

. The set-

Q

actual

= 50°C,

6.7 Indicator lights

The two indicator lights are used for fault and operating indication.

For position on pump, see fig. 13, section 7.2 Control

panel.

Master pump indicator lights:

The functions of the master pump indicator lights

apply to both the master pump and the slave pump.

A fault in the slave pump will thus be indicated on the

master pump.

Slave pump indicator lights:

The green indicator light on the slave pump will flash

on and off 20 times per minute to indicate correct

communication with the master pump.

The indicator lights of the slave pump can be activated briefly by pressing a button on the slave pump

control panel. Fault indication will then only apply to

the slave pump.

Note: When the R100 remote control communicates

with the master pump, the red indicator light will flash

TM01 0626 1797

rapidly.

Functions of indicator lights:

Indicator lights

Opera-

(red)

(green)

Off Off

Off

Perma-

nently on

Off Flashing

Perma-

nently on

Perma-

nently on

Perma-

nently on

Perma-

nently on

Flashing

See also section 8. Fault finding chart.

DescriptionFault

tion

The electricity supply has

been switched off.

The pump is operating.

The pump has been set to

stop.

The pump has stopped because of a fault. Restarting

will be attempted. (It may

Off

be necessary to restart the

pump manually by resetting

the fault indication.)

The pump is operating, but

it has been stopped because of a fault.

Note: If there is no differential pressure or temperature sensor signal, the

pump will continue operating according to the max.

curve.

The pump has been set to

stop, but it has been

stopped because of a fault.

133

Page 12

6.8 External fault indications

The pump incorporates a fault signal output for a

potential-free fault signal via terminals 2 and 3.

The signal output of both the master pump and the

slave pump can be used.

• The function of the master pump signal output

applies to both the master pump and the slave

pump.

• The function of the slave pump signal output

applies only to the slave pump.

Functions of signal output:

Signal output Description

The electricity supply has been

132

132

NC NO C

132

NC NO C

12 3

NC NO C

12 3

NC NO C

12 3

NC NO C

Resetting of fault indications:

A fault indication can be reset in one of the following

ways:

• Briefly press "+" or "–" on the pump. This will not

influence the pump performance set.

• Briefly switch off the electricity supply to the

pump.

• By means of the R100, see section 7.3 R100.

The fault indication cannot be reset until the cause of

the fault has disappeared.

switched off.

The pump is operating.

The pump has been set to stop.

The pump has stopped because

of a fault. Restarting will be attempted. (It may be necessary to

restart the pump manually by

resetting the fault indication.)

The pump is operating, but it has

been stopped because of a fault.

Note: If there is no differential

pressure or temperature sensor

signal, the pump will continue

operating according to the max.

curve.

The pump has been set to stop,

but it has been stopped because

of a fault.

6.9 External analog 0-10 V controller

The pump has an input for an external 0-10 VDC

analog signal transmitter (terminals 11 and 12 in

master pump). Via this input, the pump can be controlled by an external controller if the pump has been

set to one of the following control modes:

• Constant curve.

The external analog signal will set the pump curve

within the range from the min. curve to the constant curve selected according to the characteristic in fig. 12.

• Pressure control.

The external analog signal will control the setpoint

for the pump head between the setpoint corresponding to the min. curve and the setpoint

selected according to the characteristic in fig. 12.

At an input voltage lower than 0.5 V, the pump will

operate according to the min. curve. The setpoint

cannot be changed.

The setpoint can only be changed when the input

voltage is higher than 0.5 V.

Head set/constant curve

Max. head/constant curve

mVH

Min.

curve

0

8 9 107654321

Fig. 12

Note:

• The max. curve input, terminals 7 and 10, must be

open.

• The min. curve input, terminals 7 and 9, must be

closed.

U

TM03 1648 2505

134

Page 13

6.10 External forced control

The pump incorporates inputs for external signals for

the forced-control functions:

• Start/stop of pump (terminals 7 and 8 in master

pump).

• Max. curve duty (terminals 7 and 10 in master

pump).

• Min. curve duty (terminals 7 and 9 in master

pump).

During forced control, the light fields/indicator lights

on the pump will show which function is active.

Functional diagram: Start/stop input:

Start/stop

H

Q

H

Q

Functional diagram: Max. curve input:

The max. curve input is only active if the start/stop

input is closed.

Max. curve

H

Q

H

Q

Normal duty

Stop

Normal duty

Max. curve

6.12 Bus communication

If the pump is to be connected to a PMU 2000 or

PCU 2000, it must be set to single-pump operation,

see supplement to these instructions.

The pump enables serial communication via an

RS-485 input. The communication is carried out

according to the Grundfos bus protocol, GENIbus,

and enables connection to the GRUNDFOS Pump

Management System 2000, a building management

system or another type of external control system.

Via the bus signal, it is possible to remote-set pump

operating parameters, such as desired head, temperature influence, operating mode, etc. At the same

time, the pump can provide status information about

important parameters, such as actual head, actual

flow, power input, fault indications, etc.

For further details, consult the operating instructions

for the GRUNDFOS Pump Management System

2000 or contact Grundfos.

Note: When the pump is controlled via a bus signal,

the number of settings available on the pump control

panel or via the R100 will be reduced.

The pump head and control mode can only be set via

the bus signal. The pump control panel or the R100

can only set the pump to max. curve and to stop.

However, an R100 is required if a number is to be

allocated to the pump. See also section 7.7 Priority

of settings.

6.13 Wireless remote control

For wireless operation and reading of data, use the

Grundfos remote control R100.

For application of the remote control, see section

7.3 R100.

Functional diagram: Min. curve input:

The min. curve input is only active if the start/stop

input is closed and the max. curve input is open.

Min. curve

H

Q

H

Q

Normal duty

Min. curve

(night-time duty)

6.11 Deactivating the control panel

Can be set by means of the R100.

The buttons on the master pump control panel can

be deactivated to prevent unauthorized persons from

operating the pump.

135

Page 14

7. Setting the pump

All control of the twin-head pump is carried out by

the master pump except when the pump is running

single-pump operation.

The slave pump will not respond to commands

(unless when in single-pump operation) from the

control panel, the R100 nor from external signal

transmitters but only to commands from the master

pump. All setting and reading of data must therefore

be done via the master pump.

The green slave pump indicator light will flash on and

off 20 times per minute to indicate correct communication between master and slave pump.

For the setting of the pump, use:

• Control panel.

• R100 remote control.

• Bus communication (not described in detail in

these instructions. Contact Grundfos).

The following table shows the application of the individual operating units and in which section the function has been described.

7.2 Control panel

Note: Only the control panel of the master pump is

active unless the pump is running single-pump operation.

At high liquid temperatures, the pump may

be so hot that only the buttons should be

touched to avoid burns.

The control panel, fig. 13, incorporates the following:

• Buttons, "+" and "–", for setting.

• Light fields, yellow, for indication of control mode

and pump head.

• Indicator lights, green and red, for operating and

fault indication, see section 6.7 Indicator lights.

Buttons

Light fields

Function

Proportional-pressure

control

Constant-pressure control 7.2.1 7.6.1

Setting of pump head 7.2.2 7.4.1

Max. curve duty 7.2.3 7.4.2

Min. curve duty 7.2.4 7.4.2

Constant curve duty – 7.4.2

Temperature influence – 7.6.3

Resetting of fault indications 7.2.6 7.4.3

Activation/deactivation of

pump buttons

Allocation of pump number – 7.6.5

Reading of various data –

Star t/ stop 7.2.5 7.4.2

Control of twin-head pumps

(change of factory setting)

"–" = not available with this operating unit.

Control

panel

7.2.1 7.6.1

– 7.6.4

7.5.1 -

7.5.7

– 7.6.6

7.1 Factory settings

UPED xx-60 UPED xx-120

Control mode

Head

Control of

twin-head

pump

136

Proportional

pressure

3 m at maximum

flow, see fig. 15

Alternating Alternating

Proportional

pressure

6 m at maximum

flow, see fig. 17

R100

Fig. 13

7.2.1 Setting of control mode

Description of function, see section 6.2 Control

modes.

When the buttons "+" and "–" are pressed simultaneously, the light fields will indicate the selected control

mode:

Light fields Control mode

Top + bottom

light fields flashing

Middle light fields

flashing

None of the light

fields are on

If the buttons are pressed for more than 5 sec., the

control mode will change over to constant pressure

and proportional pressure respectively. This means

that constant curve duty is deactivated if selected by

means of the R100.

Indicator lights

Proportional pressure

Constant pressure

Constant curve

TM00 4431 0603

Page 15

7.2.2 Setting of pump head

The desired pump head is set by pressing the button

"+" or "–".

The light fields on the control panel will indicate the

head set.

The table below shows examples of pump head settings indicated by the light fields.

Constant-pressure control Proportional-pressure control

mH

5

4

3

2

UPED 100-60

1

0

Fig. 14

Light field 5 is activated, indicating a desired head of 3 metres.

H m

10

8

6

UPED 50-120

UPED 65-120

UPED 80-120

4

2

1

0

Fig. 16

Light fields 5 and 6 are activated, indicating a desired head

of 5.5 metres.

mH

5

4

3

2

1

QQ

0

TM00 4435 1597

QQ

TM00 4434 1597

Fig. 15

Light fields 5 and 6 are activated, indicating a desired head

of 3 metres at maximum flow.

H m

10

8

6

4

2

QQ

0

TM00 4433 1597

Fig. 17

QQ

TM00 4432 2297

Light fields 7 and 8 are activated, indicating a desired head

of 6 metres at maximum flow.

137

Page 16

7.2.3 Setting to max. curve duty

Description of function, see section 6.4 Max. or min.

curve duty.

Press "+" continuously to change over to the max.

curve of the pump (top light field flashes), see fig. 18.

To change back, press "–" continuously until the

desired head is indicated.

H

Max. curve

QQ

Fig. 18

7.2.4 Setting to min. curve duty

Description of function, see section 6.4 Max. or min.

curve duty.

Press "–" continuously to change over to the min.

curve of the pump (bottom light field flashes), see

fig. 19. To change back, press "+" continuously until

the desired head is indicated.

H

QQ

Min. curve

Fig. 19

7.2.5 Start/stop of pump

Stop the pump by continuously pressing "–" until

none of the light fields are activated. When the pump

is stopped, the green indicator light will be flashing.

Start the pump by continuously pressing "+" until the

desired head is indicated.

If the pump is to be inoperative for a period, it is

recommended to use the start/stop input, the R100

or to switch off the electricity supply. In this way, the

pump head setting will remain unchanged when the

pump is to be started again.

7.2.6 Resetting of fault indications

To reset fault indications, briefly press "+" or "–".

This will not influence the pump performance set.

If the fault has not disappeared, the fault indication

will reappear.

TM00 4436 4596TM00 4437 4596

138

Page 17

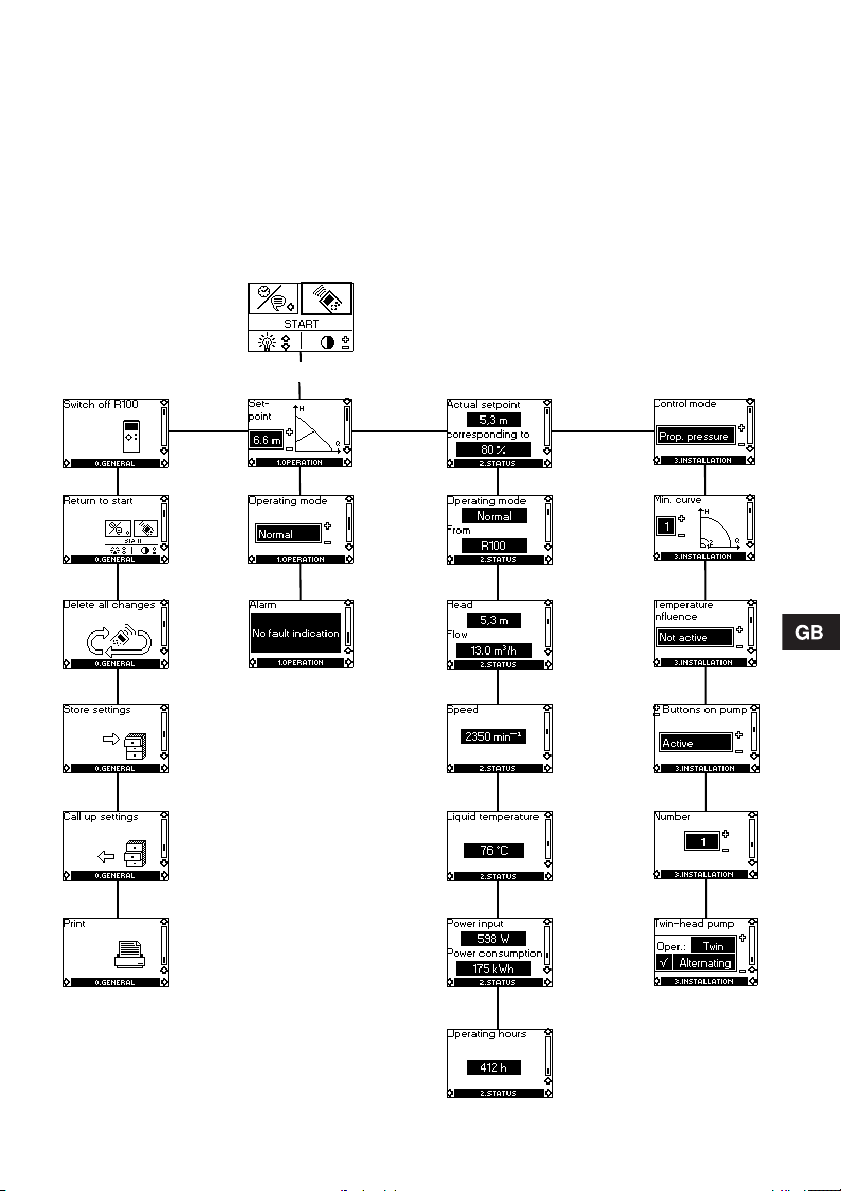

7.3 R100

The pump is designed for wireless communication

with the Grundfos remote control R100. The R100

communicates with the pump via infra-red light.

During communication, the R100 must be pointed at

the control panel on the master pump. When the

R100 is communicating with the pump, the red indicator light will flash rapidly.

The R100 offers additional possibilities of setting and

status displays for the pump.

The displays are divided into four parallel menus,

see fig. 20:

0. GENERAL, see operating instructions for R100

1. OPERATION

2. STATUS

3. INSTALLATION

The number stated at each individual display in

fig. 20 refers to the section in which the display is

described.

0. GENERAL

1. OPERATION 2. STATUS

7.4.1

7.4.2

7.4.3

7.5.1

7.5.2

7.5.3

7.5.4

7.5.5

7.5.6

3. INSTALLATION

7.6.1

7.6.2

7.6.3

7.6.4

7.6.5

7.6.6

Fig. 20

7.5.7

139

Page 18

7.4 Menu OPERATION

When communication has been established, menu

OPERATION appears in the display.

7.4.1 Setpoint

This display depends on the control mode selected

in the display "Control mode" in menu INSTALLATION.

If the pump is remote- or forced-controlled via external signals, the number of possible settings will be

reduced, see section 7.7 Priority of settings.

Attempts to change the settings will result in an indication in the display saying that the pump is remotecontrolled and changes therefore cannot be made.

The following example of display will appear if the

pump is in constant-pressure control mode.

In this display, the desired head is set.

Furthermore, it is possible to choose between the

following operating modes:

• Stop,

• Min. (min. curve),

• Max. (max. curve).

This display will be a little different in the case of pro-

portional-pressure control or constant curve duty.

The actual duty point of the pump is indicated by a

square in the Q/H field. The pump cannot register

very low flow rates, and the square will therefore disappear.

7.4.2 Operating mode

Select one of the following operating modes:

• Stop,

• Min. (min. curve),

• Normal (proportional pressure, constant pressure

or constant curve),

• Max. (max. curve).

7.4.3 Fault indications

If the pump is faulty, the cause will appear in this

display.

Possible causes:

• Phase failure,

• Pump blocked,

• Undervoltage,

• Defective pressure/temperature sensor,

• Internal fault (fault in electronics),

• Fault in master/slave communication.

The fault indication can be reset in this display. If the

fault cause has not disappeared when resetting is

attempted, this will be indicated in the display.

7.5 Menu STATUS

The displays appearing in this menu are status displays only. It is not possible to change or set values.

The actual values in the display are stated as a

guide.

7.5.1 Actual setpoint

Field "Actual setpoint":

Actual setpoint of pump.

Field "corresponding to":

Actual setpoint in % of the setpoint set if the pump is

connected to an external analog 0-10 V signal transmitter or if temperature influence or proportionalpressure control is activated.

7.5.2 Operating mode

This display shows the actual operating mode (Stop,

Min., Normal or Max.) and where is was selected

(Pump, R100, BUS or External).

140

Page 19

7.5.3 Head and flow

Very low flows cannot be registered, and the R100

will show "<" in front of the lowest possible value of

the pump in question.

7.5.4 Speed

The actual pump speed.

7.5.5 Liquid temperature

The actual temperature of the pumped liquid.

Because of the physical position of the sensor,

deviations in the temperature measuring may occur,

e.g. at high liquid temperatures and/or low ambient

temperatures.

7.5.6 power input and power consumption

7.6 Menu INSTALLATION

In this menu, the settings are chosen that should be

considered when installing the pump.

7.6.1 Control mode

Description of function, see section 6.2 Control

modes or section 6.5 Constant curve duty.

Select one of the following control modes:

• Prop. pressure (proportional pressure),

• Const. pressure (constant pressure),

• Const. curve (constant curve).

Setting of setpoint or curve is carried out in display

7.4.1 Setpoint in menu OPERATION.

7.6.2 Min. curve

Description of function, see section 6.4 Max. or min.

curve duty.

In this display, it is possible to choose between two

min. curves. The curve is used when the operating

mode "min. curve" is selected.

7.6.3 Temperature influence

Description of function, see section 6.6 Temperature

influence.

.

Actual power input and power consumption of the

pump.

The value of power consumption is an accumulated

value and cannot be set to zero.

7.5.7 Operating hours

Operating hours of the pump.

The value of operating hours is an accumulated

value and cannot be set to zero.

The temperature influence function can be activated

in this display.

In the case of temperature influence, the pump must

be installed in the flow pipe. It is possible to choose

between maximum temperatures of 50°C and 80°C.

The temperature influence function will be active

only in constant or proportional-pressure control

mode.

When the temperature influence is active, a small

thermometer is shown in the display "Setpoint" in

menu OPERATION, see 7.4.1 Setpoint.

Note: If the pump is controlled via bus, temperature

influence cannot be set by means of the R100.

141

Page 20

7.6.4 Buttons on pump

To prevent unauthorized persons from operating the

pump, the function of the buttons "+" and "–" can be

deactivated in this display. The buttons can be reactivated only by means of the R100.

The buttons can be set to:

• Active,

• Not active.

7.6.5 Pump number

A number between 1 and 64 can be allocated to a

pump or can be changed so that the R100 or Pump

Management System 2000 can distinguish between

two or more pumps.

The Pump Management System 2000 can, however,

only accept the numbers 1 to 8.

7.6.6 Twin-head pump

3

This display offers the following options:

Selection of operating mode for twin-head pump:

If field 1 reads "Twin", field 2 offers the choice

between three operating modes:

• Alternating (alternating operation),

• Synchron. (synchronous operation),

• Standby (standby operation).

Description of function, se section 6.1 Control of

twin-head pumps.

Setting the pump to single-pump operation:

In the single-pump operation mode, the master and

slave pumps run independently of each other without

internal communication and with a sensor each.

To set the pump to this operating mode, the communication between master and slave is to be disconnected in one of the following ways:

1

2

1. If the master and slave pumps are connected

correctly:

1. Point the R100 at the master pump.

2. Choose "Single" in field 1.

3. Press "OK".

2. If there is a fault in the master-slave commu-

nication (red indicator lights of both pumps

are on):

1. Point the R100 at the master pump.

2. Choose "Single" in field 1.

3. Press "OK".

The master pump will now be running like

an ordinary single-head pump and the red

indicator light will go out.

4. Switch the R100 off and on again.

5. Point the R100 at the slave pump.

Field 1 is already reading "Single".

6. Press "OK" twice in field 1.

The slave pump is now running like a

The slave pump will now be running according to the

factory settings unless its settings have been

changed.

Setting the pump to twin-pump operation:

If the pump is running like a single-head pump, the

communication can be restored in the following way:

1. Check that the bus cable between master and

2. Check that both pump heads are connected to

3. Check that the operating mode of the slave pump

4. Check that the slave pump has been set to

5. Point the R100 at the master pump.

6. Choose "Twin" in field 1.

7. Press "OK".

8. Press "+" or "–" on the control panel of the

* If correct connection was not established because

single-head pump.

slave pump is connected to the pump heads.

the mains supply.

is "Normal".

"Single" in the display "Twin-head pump".

After a short while, the green indicator light on

the slave pump will start flashing rapidly for

5 seconds, indicating that the pump is ready to

be the slave pump of a twin-head pump. (If the

pump is installed in a bus system with many

pumps, the green indicator lights of all possible

slave pumps in the system will start flashing.)

selected slave pump (while the light is flashing *).

The light fields of the slave pump will go out and

the green indicator light will be flashing 20 times

per minute to indicate that correct connection has

been established.

5 seconds passed before "+" or "–" was pressed,

the red indicator light of the master pump will be

on. Go through the procedure all over again to

establish connection.

142

Page 21

Confirmation of correct connection:

1. Point the R100 at the master pump.

2. Press "OK" in field 3.

If the connection has been correctly established,

the green indicator light on the slave pump will be

flashing rapidly to indicate this.

7.7 Priority of settings

The forced-control signals will influence the settings

available on the pump and with the R100. By means

of the pump control panel or the R100, the pump can

always be set to max. curve duty or to stop.

If two or more functions are activated at the same

time, the pump will operate according to the function

with the highest priority.

The priority of the settings is as shown in the following table:

Without bus signal:

:

Possible settings

Priority

1Stop

2Max. curve

3 Stop

4 Max. curve

5 Min. curve Min. curve

6 Setting of head Setting of head

Example: If, via an external signal, the pump has

been forced to operate according to the max. curve,

the pump control panel or the R100 can only set the

pump to stop.

With bus signal:

:

Priority

1 Stop

2 Max. curve

3 Stop Stop

4

5 Min. curve Min. curve

6

Example: If, via an external signal, the pump has

been forced to operate according to the max. curve,

the pump control panel, the R100 or the bus signal

can only set the pump to stop.

Pump control

panel or R100

Possible settings

Pump

control

panel or

R100

External

signals

Max.

curve

External

signals

Bus

signal

Max.

curve

Setting of

head

8. Fault finding chart

Before removing the terminal box cover,

make sure that the electricity supply has

been switched off for at least 5 minutes.

The pumped liquid may be scalding hot

and under high pressure. Before any

removal or dismantling of the pump, the

system must therefore be drained or the

isolating valves on either side of the pump

must be closed.

• Only the indicator lights of the master pump are

active and they will therefore indicate fault no matter if the fault is in the master or the slave pump.

• The indicator lights of the slave pump can be activated briefly by pressing a button on the slave

pump control panel. Fault indication will then only

apply to the slave pump.

• The indicator lights mentioned in the fault finding

chart are the indicator lights of the master pump.

143

Page 22

Fault Cause Remedy

None of the pumps are

running.

None of the indicator

lights are on.

The pump is not running.

The green indicator light

is flashing.

Both pumps have stopped

due to a fault.

The red indicator light is

on and the green indicator light is off.

The pump is running, but

has been stopped due to

a fault.

The red and green indicator lights are on.

The pump has been set to

stop, but has been

stopped due to a fault.

The red indicator light is on

and the green indicator

light is flashing.

Noise in the system.

The green indicator light

is on.

One fuse in the installation is blown. Replace the fuse.

The current-operated or voltage-operated

circuit breaker has tripped out.

The pump is defective. Repair or replace the pump.

The pump has been stopped in one of the

following ways:

1. With the button "–".

2. With the R100.

3. External on/off switch in position off.*

4. Via bus signal.*

* The fault can be temporarily corrected by selecting max. curve duty on the

pump or with the R100, as external forced-control signals will be ignored.

Electricity supply failure (e.g. undervoltage).

Missing phase (the pump runs for 2 minutes and then stops).

The pumps are blocked and/or impurities

in the pumps.

Fault in electronics. Contact Grundfos.

The differential pressure and temperature

sensor is defective.

The master and slave pumps have been

stopped due to a fault. One or both

pumps have restarted automatically.

The master pump is or has been stopped

due to a fault.

The slave pump is or has been stopped

due to a fault.

The differential pressure and temperature

sensor is defective.

The master and slave pumps have been

stopped due to a fault.

The master pump is or has been stopped

due to a fault.

The slave pump is or has been stopped

due to a fault.

Air in the system. Vent the system.

The flow is too high. Reduce the head (setpoint) and pos-

The pressure is too high. Reduce the head (setpoint) and pos-

Cut in the circuit breaker.

1. Start the pump by pressing "+".

2. Start the pump with the R100 or

by pressing "+".

3. Switch on the on/off switch.*

4. Start the pump via bus signal.*

Check that the electricity supply falls

within the specified range.

Check fuse and connections.

Remove the inspection screw and

turn the rotor by means of a screwdriver inserted into the slot in the

shaft end, and/or dismantle and

clean the pump.

Check sensor connection. Replace,

if necessary.

Reset fault indication.

Check sensor connection.

Replace, if necessary.

Reset fault indication.

sibly change over to constant pressure.

sibly change over to proportional

pressure.

144

Page 23

Fault Cause R emedy

Noise in the pump.

The green indicator light

is on.

Insufficient heat in some

places in the heating system.

See also section 6.7 Indicator lights.

Note: The R100 can also be used for fault finding.

Air in the pump. Vent the pump.

The inlet pressure is too low. Increase the inlet pressure and/or

The flow is too low. Increase the head (setpoint) and/or

check air volume in the expansion

tank (if installed).

change over to constant pressure.

9. Megging

Megging of an installation incorporating an UPED

pump is not allowed, as the built-in electronics may

be damaged. If megging of the pump is necessary,

the pump should be electrically separated from the

installation.

The master and slave pumps must be megged separately.

Megging of the pump can be carried out as

described below.

Megging of UPED pumps

1. Switch off the electricity supply.

2. Remove the wires from terminals L1, L2 and L3 and

the earth wire (see B).

3. Short-circuit terminals L1, L2 and L3 using two short

wires (see D).

4. Remove the wire for electronics frame connection

(see A).

5. Test between terminals L1/L2/L3 and earth (see C).

Maximum test voltage: 1500 VAC/DC.

Note: Never test between supply terminals (L1, L2 and

L3).

Maximum permissible leakage current: < 20 mA.

6. Fit the wire for electronics frame connection (see A).

7. Remove the short wires between terminals L1, L2 and

L3 (see D).

8. Fit the supply wires to terminals L1, L2 and L3 and

the earth wire (see B).

9. Switch on the electricity supply.

D

A

C

B

TM00 9122 4596

9.1 High-voltage test

If it is necessary to high-voltage test the UPED

pump, the megging instructions must be followed,

see section 9. Megging.

10. Technical data

Supply voltage

3 x 400-415 V ±10%, 50 Hz.

Motor protection

The pump requires no external motor protection.

Enclosure class

IP 42.

Relative air humidity

Maximum 95%.

Ambient temperature

0°C to +40°C.

145

Page 24

Temperature class

TF110 to CEN 335-2-51.

Liquid temperature

Maximum +110°C.

Continuously: +15°C to +95°C.

Pumps in domestic hot-water systems:

Continuously: +15°C to +60°C.

To avoid condensation in the terminal box and the

stator, the pumped liquid temperature must always

be higher than the ambient temperature. See the

table below:

Ambient

temperature

[°C]

15 15 110

20 20 110

25 25 110

30 30 110

35 35 90

40 40 70

System pressure

The system pressure is indicated on the pump

flanges:

Pump type PN 6 PN 10

UPED 50-120 z 4

UPED 65-120 z 4

UPED 80-120

UPED 100-60

Inlet pressure

The following minimum pressures must be available

at the pump inlet during operation:

Liquid temperature

Min. [°C] Max. [°C]

Number

PN 6/

PN 10

z 4

z 8

z 4

z 8

of bolt

holes

EMC (electromagnetic compatibility)

EN 61800-3.

Sound pressure level

The sound pressure level of the pump is lower than

54 dB(A).

Leakage current

The pump mains filter will cause a discharge current

to earth during operation. I

Inputs and outputs

Start/stop input External potential-free switch.

Max. curve input

Min. curve input

Input for analog

0-10 V signal

Signal output Internal potential-free change-

Bus input Grundfos bus protocol,

Contact load:

5 V, 0.1 mA.

Screened cable.

Loop resistance:

Maximum 130 Ω/km.

Logical levels:

Logical zero: U < 1.5 V.

Logical one: U > 4.0 V.

External signal: 0-10 VDC.

Maximum load: 1 mA.

Screened cable.

over contact.

Maximum load:

250 V, 2 A AC1.

Minimum load: 5 V, 1 mA.

Screened cable.

GENIbus protocol, RS-485.

Screened cable.

Lead cross section:

0.25 - 1 mm².

Cable length:

Maximum 1200 m.

leakage

< 3.5 mA.

11. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

Liquid temperature

Pump type

UPED 50-120 0.4 0.7

UPED 65-120 0.9 1.2

UPED 80-120 1.6 1.9

UPED 100-60 0.95 1.25

146

75°C 90°C

[bar] [bar]

Subject to alterations.

Page 25

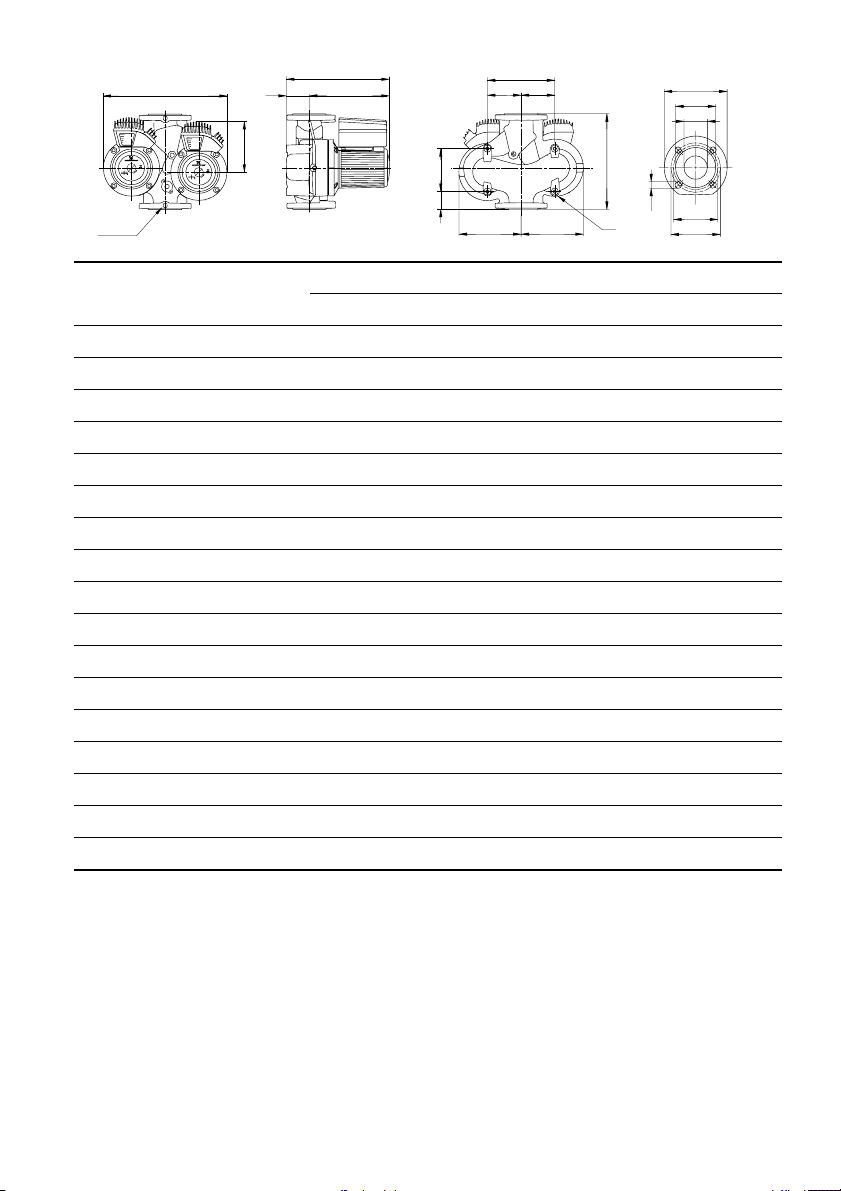

Rp 1/4

B3

B2

H3

H2

H1

L2

L3

B7

B6

B6

L1

B4

B5

M

UPED 50-120 UPED 65-120

PN 6 / PN 10 PN 6 / PN 10

L1 280 340

L2 126 153

L3 60 63

B2 205 205

B3 450 450

B4 225 225

B5 225 225

B7 240 240

H1 75 82

H2 277 290

H3 352 372

D1 50 65

D2 102 122

D3 110/125 130/145

D4 165 185

D5 14 /19 14/19

M M12 M12

D4

D2

D1

D5

D3

D3

TM02 0696 5000

170

Page 26

B3

H3

H2

H1

B7

B6

B6

D4

D3

D1

Rp 1/4

B2

L2

L3

B4

L1

B5

M

UPED 80-120 UPED 100-60

PN 6 PN 10 PN 6 PN 10

L1 360 360 450 450

L3 53 53 83 83

B2 205 205 205 205

B3 460 460 595 595

B4 225 225 280 280

B5 235 235 315 315

B7 240 240 280 280

H1 97 97 122 122

H2 294 294 313 313

H3 391 391 435 435

D1 80 80 100 100

D2 138 138 158 158

D3 150 160 170 180

D4 200 200 220 220

D5 19 19 19 19

M M16 M16 M16 M16

D2

D5

PN 6

PN 10

TM02 0695 5000

171

Page 27

3 x 400-415 V, UPED 50-120, UPED 65-120, UPED 80-120, UPED 100-60

L2

L1L3

10987654

321

1211

TM01 6419 2399TM01 6421 2399

172

Page 28

173

Page 29

174

Page 30

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-8750 5050

Telefax: +45-87 50 51 51

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461 4611

Telefax: +61-8-8346 7434

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246 883 0

Telefax: +43-6246 883 60 / 883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belorussia

Представительство ГРУНДФОС в Минске

220090 Минск ул.Олешева 14

Теле фон: (8632) 62-40-49

Факс: (8632) 62-40-49

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Paromlinska br. 16,

BiH-71000 Sarajevo

Phone: +387 33 713290

Telefax: +387 33 231795

Bulgaria

GRUNDFOS Bulgaria

BG-1421 Sofia

105-107 Arsenalski blvd.

Тел.: +359 2963 3820, 2963 5653

Факс: +359 2963 1305

Croatia

GRUNDFOS predstavništvo Zagreb

Cebini 37, Buzin

HR-10000 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

Czech Republic

GRUNDFOS s.r.o.

Čapkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 44

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-3066 5650

Telefax: +358-3066 56550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O . B ox 7 1

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

Ireland

GRUNDFOS (Ireland) Ltd.

Unit 34, Stillorgan Industrial Park

Blackrock

County Dublin

Phone: +353-1-2954926

Telefax: +353-1-2954739

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-2-95838112

Telefax: +39-2-95309290 / 95838461

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga

Tālr.: + 371 7 149 640, 7 149 641

Fakss: + 371 9 149 646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Netherlands

GRUNDFOS Nederland B.V.

Postbus 104

NL-1380 AC Weesp

Tel.: +31-294-492 211

Telefax: +31-294-492244 / 492299

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-229 047 00

Telefax: +47-223 221 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Phone: (+48-61) 650 13 00

Telefax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS (Portugal) Lda.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2780 Paço de Arcos

Tel.: +351-1-4407600

Telefax: +351-1-4407690

România

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундф ос

Росс ия, 10954 4 Москва, Школьная 39

Тел. (+7) 095 737 30 00, 564 88 00

Факс (+7) 095 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381-11-2647-877, 11-2647-496

Telefax: +381-11-2648-340

Slovenia

GRUNDFOS PUMPEN VERTRIEB Ges.m.b.H.,

Podružnica Ljubljana

Blatnica 1, SI-1236 Trzin

Phone: +386 1 563 5338

Telefax: +386 1 563 2098

E-mail: slovenia@grundfos.si

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Lunnagårdsgatan 6

431 90 Mölndal

Tel.: +46-0771-32 23 00

Telefax: +46-31-331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС Украина

ул. Владимирская, 71, оф. 45

г. Киев, 01033, Украин а,

Тел. +380 44 289 4050

Факс +380 44 289 4139

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4-8815166

Telefax: +971-4-8815136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1 913 227 3400

Telefax: +1 913 227 3500

Usbekistan

Представительство ГРУНДФОС в Ташкент е

700000 Ташкен т ул.Усм ан а

тупик 5

Телеф он: (3712) 55-68-15

Факс: (3712) 53-36-35

Носира 1-й

Addresses revised 10.01.2007

Page 31

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

96421914 0307

Repl. V7140345 0801

www.grundfos.com

247

Loading...

Loading...