Page 1

GRUNDFOS

INSTRUCTIONS

http://waterheatertimer.org/Water-heater-recirculation-system.html

Comfort System

Hot Water Recirculation System

US Installation and operating instructions

ANSI/NSF61 and

IAPMO listed

Page 2

Shipment Inspection page 1.

Pre-Installation Checklist page 1.

Pump Mounting page 2.

Electrical page 5.

Timer Control Technical Data and Application page 5.

Timer Operation page 6.

Warranty page 7.

CONGRATULATIONS! You are now the owner of a Grundfos Comfort System. It has

been carefully inspected and tested before shipment. It should give you long, efficient,

trouble-free service. For maximum performance and reliability, please follow the

simple instructions in this manual. NOTE: Please understand this is not an anti-scald

device. You may have some warm water in your cold water line under the sink where

the valve is installed. Once the cold water line is opened, the warm water will dissipate

in a very short time.

Shipment Inspection

Examine the components carefully to make sure no damage has occurred to the

pump during shipment. Care should be taken to ensure the pump is NOT dropped or

mishandled; dropping will damage the pump.

Grundfos Hot Water Package Includes:

• One Grundfos UP15 circulator with timer and linecord

• One Under Sink, Thermal By-Pass Valve

• Two Valve mounting screws

• Installation and Operating Instructions

Items that must be supplied by Installer:

• 2- 1/2” NPT X 3/8” compression flex hoses

• 2- 1/2” NPT X 1/2” NPT flex hoses

• Hand Tools

Pre-Installation Checklist

Before beginning installation procedures, the following checks should be made. They

are all important for proper installation of the circulator pump.

Maximum Water Temperature:

UP15 pump with line cord and timer only; The maximum allowable water temperature

is 150°F.

In a pressurized system, the required inlet pressure is the minimum allowable system

pressure.

page 1

Page 3

Pump Mounting: For Indoor Use

Note: Do not energize pump

until properly installed

1. Close the supply water valve to the water

heater located, in most cases, above the hot

water heater on the cold water inlet to the

hot water heater.

2. Drain the water from the hot water pipe

by opening a hot water faucet in the house.

Let the water run until it stops flowing.

Then drain remaining water from hot water

heater spigot. Leave the faucet open until

pump installation is complete. If water does

not stop flowing, check to make sure the

water to the hot water heater has been

completely shut off.

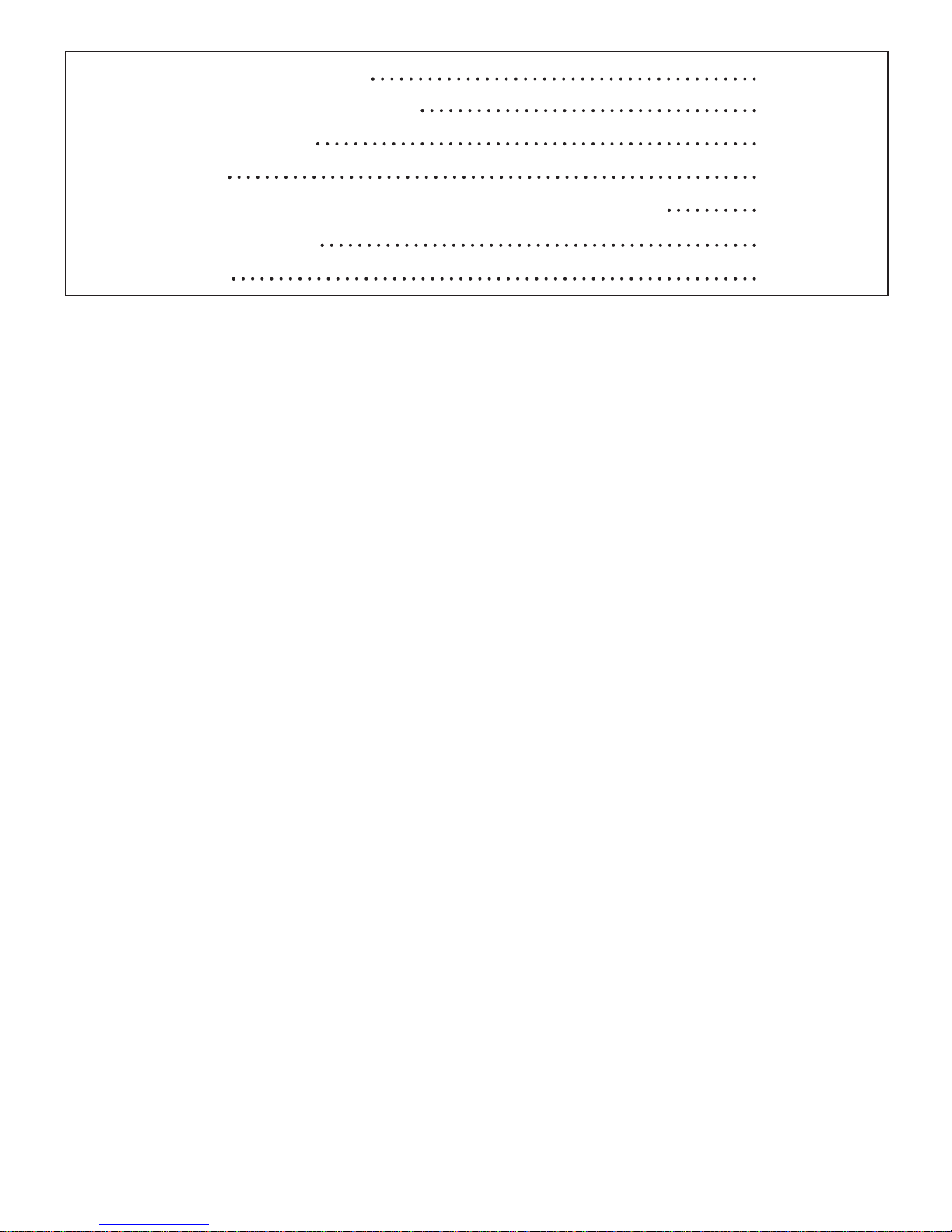

Picture 1

Disconnect

3. Disconnect the hot water heater at the hot water discharge. (see Picture #1)

4. Install pump onto the water heater discharge, using the 3/4” female fitting and

gasket supplied on the pump ensuring that the pump shaft is horizontal. The pump

should be installed so that the pump is pumping away from the hot water heater,

towards the house. Confirm the direction of pumping by observing the flow arrow on

the side of the pump housing. Be sure that the pump is not touching the exhaust vent

piping (chimney) of a gas or oil fired hot water heater. (See Picture #2)

5. Connect the hot water line to the 3/4”

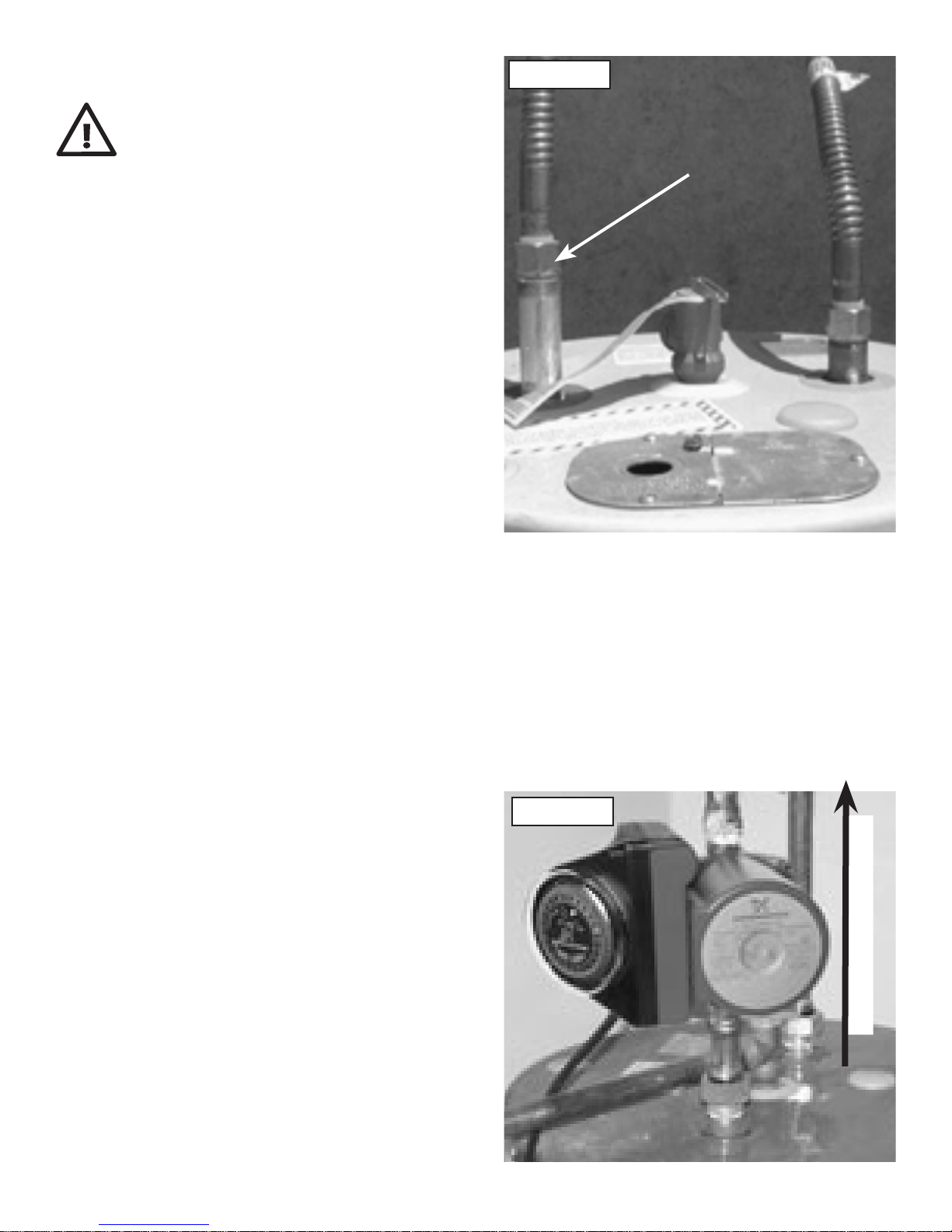

Picture 2

NPT discharge of the pump. Use pipe

dope or Teflon tape to seal threads when

connecting to a 3/4 female NPT connection.

If a gasketed flexible copper water heater

connector is used pipe dope or Teflon tape is

not required

6. Reopen the supply valve to the hot water

heater and allow the water to run until all

the air has been purged from the piping.

Direction of water

7. Close faucet inside the house.

page 2

Page 4

8. Plug the line cord of pump into a 115V

outlet. Be sure to route the power cord

so that it does not touch the exhaust vent

piping of a gas or oil fired hot water heater.

9. Using the timer (see pg. 6), set the pump

to operate around your peak use times. (eg

30 minutes before the first shower until 15

minutes after last shower).

Valve Location

For the greatest effect, the valve should

be located at a faucet with the greatest

piping distance from the hot water heater.

If your home has a branched hot water line,

more than one valve may be necessary.

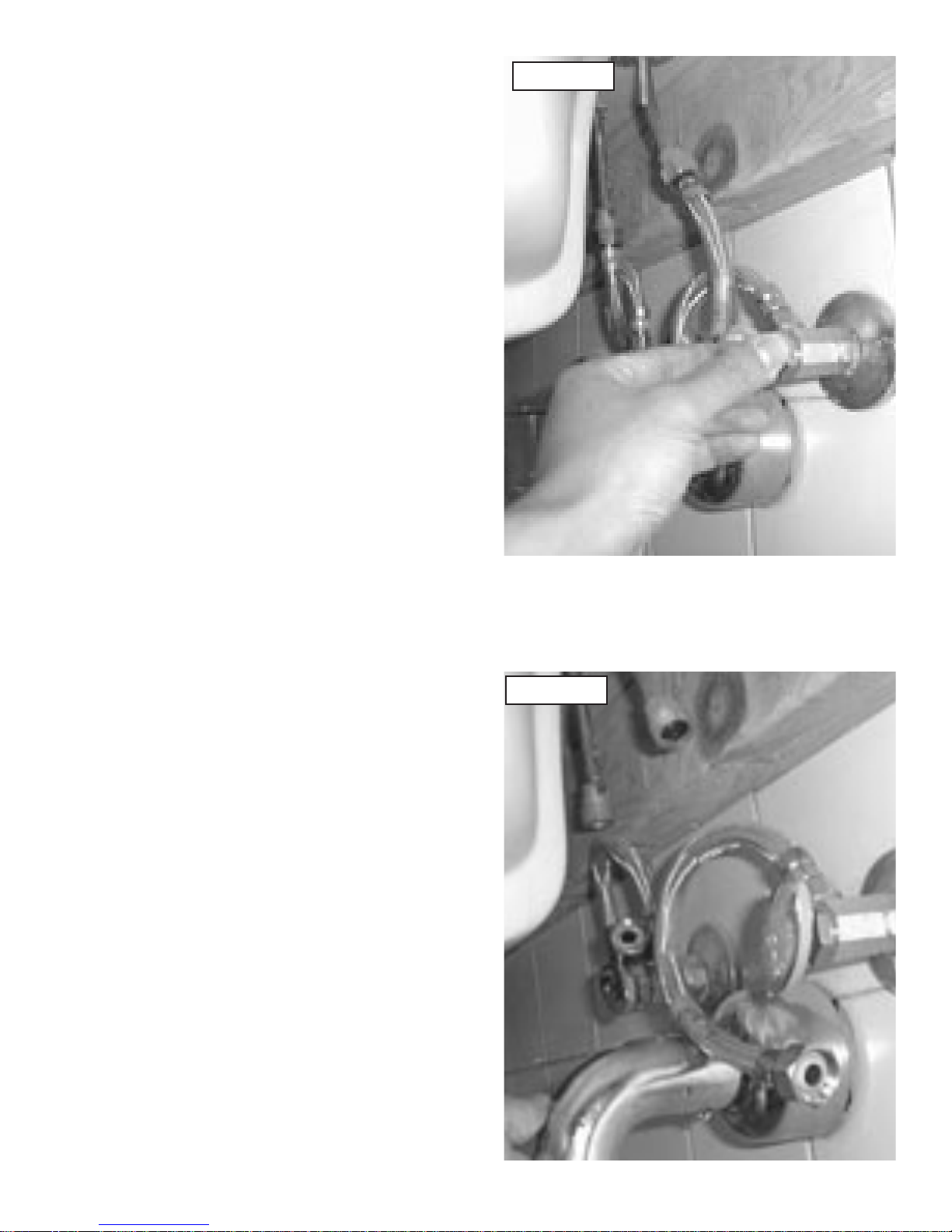

Picture 3

Valve Installation

Note: Do not use teflon tape or pipe dope on

the valve threads.

1. Close both the hot and cold water angle

stop valves below the sink. (see Picture #3)

2. Disconnect the risers. (see Picture #4)

3. Connect the 1/2”X1/2” flex hoses to the

ports on the valve marked “Hot Out” and

“Cold Out”. (see Picture #5)

4. Connect the 1/2”X3/8” flex hoses to the

ports on the valve marked “Hot In” and

“Cold In”. (see Picture #5)

Picture 4

Please note: By plumbing convention, the

hot water is on the left side and cold water

on the right, when looking at the sink. Your

piping may be different.

page 3

Page 5

5. Connect the 1/2” hose fitting from the “Hot Out” port to the left side of the faucet.

(see Picture #5)

6. Connect the 1/2” hose fitting from the “Cold Out” port to the right side of the faucet.

(see Picture #5)

7. Connect the 3/8” hose fitting from the “Hot In” port to the left angle stop valve. (see

Picture #5)

8. Connect the 3/8” hose fitting from the “Cold In” port to the right angle stop valve.

(see Picture #5)

9. Open both hot and cold water angle stop valves.

10. Valve may be mounted to the wall with supplied mounting screws if desired.

Valve Operation

If there is no hot water

at the faucet or there

appears to be too much

hot water on the cold

water side the following

steps will determine if

the valve is operating

correctly:

1. Close the cold water

angle stop valve below

the sink.

2. Open the cold water

faucet.

3. Water should slowly

flow from the faucet

until hot water reaches

the valve. The flow

should gradually decrease to a trickle of

water until no water is

coming from the faucet.

Picture 5

Hot Water

IN

Hot Water

OUT

Cold Water

OUT

Cold Water

IN

page 4

Page 6

Electrical

SAFETY WARNING

Warning - Risk of electrical shock - This pump is supplied with a grounding conductor.

To reduce the risk of electric shock, be certain that it is connected only to a properly

grounded grounding type receptacle. The safe operation of this pump requires that it

be grounded in accordance with the National Electrical Code and local governing codes

and regulations.

Electrical Requirements

The operating voltage and other electrical data are marked on the motor label. Make

sure that the motor is suitable for the electrical supply on which it will be used.

Electrical Connection

Insert the 115V plug on the line cord from the pump into a properly grounded 115V

outlet.

Timer Technical Data

TIMER CONTROL

Supply Voltage: 115-120 VAC, 60 hertz

Contact Rating: 16 amps

Ambient Temperature: -4°F to 175°F

Shortest Switching Interval: 15 minute increment

Switch Modes: “Timer”, “ON” Override, “OFF” Override

Protection: Clear plastic cover for dust and moisture protection of the clock face.

Timer Technical Application

The Grundfos timer control is designed only for use with specified Grundfos Series UP

circulators installed in indoor hot water service systems.

The timer control is designed to turn the circulator on and off at preset times, allowing

the user to select operation of the circulator during high use periods of the day.

page 5

Page 7

Timer Operation

Setting & Operating

The Timer Control

Starting the Pump

NOTE:

the system must be filled with liquid

and vented.

1. Set the timer switch to the actual time by turning the programming ring in the

direction of the arrow until the timing arrow points to the actual time on the ring.

2. Plug in the power cord from the circulator and set the manual switch to the “ON”

position. The circulator will now start.

3. Set the required “ON”/“OFF” times on the programming ring by pushing the

programming tabs either away from or toward the center of the ring. Tabs pushed

away from the center indicate the

circulator is switched “ON” while tabs

pushed toward the center indicate the

circulator is switched “OFF”.

4. Set the manual switch to the “TIMER”

position. The circulator will now start/

stop according to the settings of the

programming tabs.

Before the circulator is started,

5. For continuous operation, set the

manual switch to the “ON” position. To switch the circulator off, set the manual switch

to the “OFF” position. The “ON”/“OFF” modes may be used without affecting the

function of either the programming ring or the timer switch.

6. In case of power outage the timer will not keep time. After power has been restored,

the correct time of day must be reset by rotating the programming ring in the direction

of the arrow until the timing arrow points to the actual time on the ring.

page 6

Page 8

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 Q [US GPM]

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

4.5

5.0

[ft]

H

0.0 0.2 0.4 0.6 0.8 1.0 1.2 Q [m³/h]

0.0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

[m]

H

UP15-10SU7P/TLC

60 Hz

http://waterheatertimer.org/Water-heater-recirculation-system.html

UP Series

5

Comfort System

The Comfort System uses a patented Comfort Valve®

and pump to provide instant availability of hot water at

the point of use.

Operation

The Comfort Valve® is installed at the fixture furthest

away from the hot-water tank. With a built-in timer, the

pump allows hot water to circulate along the loop

through the valve using the cold-water side as a return

line. As the temperature rises to 100 °F (38 ° C), the

valve closes directing hot water to the tap, thus

resulting in a constant availability of hot water.

Savings

The Comfort System saves up to 16,000 gallons

(60,566 liters) of water per year and per household

(based on average modern household usage) and

uses less energy than a 25 W light bulb.

Applications

• Domestic hot-water recirculation systems in singleand two-family houses.

Pumped liquids

• Domestic hot water

• Potable and non-potable water

Description

(UP open systems)

Inlet cone, bearing plate, bearing

retainers, rotor can, rotor

cladding, shaft retainer

Volute retainer (SU & SF models)

and stator housing

Shaft, upper and lower radial

bearings

Thrust bearing

Pump housing (volute)

O-ring and gaskets

Impeller PES composite (30 % glass-filled)

Terminal box Noryl® with EPDM gasket

Material

Stainless steel

Aluminium

Aluminium oxide ceramic

Carbon bearing and EPDM

retainer

Silicon bronze C875 or stainless

steel 300 series.

EPDM (ethylene propylene

rubber)

Grundfos Comfort Valve body materials

Description Trade name Material

Springs, pins, screens 300 Series Stainless steel

Valve body Ryton PPS

Thermal actuator

body

Check valve O-ring EPDM

Check valve body Acetal

Check valves plunger Thermoplastic

300 Series Stainless steel

Ambient and liquid temperatures

Liquid temperature: 36 °F (2 °C) to 150 °F (66 °C).

It is recommended to keep the operating temperature

as low as possible (e.g. 140 °F (60 °C)) to avoid

calcium precipitation.

Applications

Fig. 7 Comfort System

Motor

• Insulation class: F.

• Power consumption: 25 W.

• Voltage: 115 V.

• Current 0.23 A.

• Phase: 1.

The ambient temperature should always be lower than

the liquid temperature, as otherwise condensatio n may

form in the stator housing.

Maximum system pressure

145 psi (10 bar).

TM03 9126 3407

TM03 5547 3806

Fig. 8 Performance curve for the Comfort System

33

Page 9

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

Limited Warranty

Products manufactured by GRUNDFOS PUMPS CORPORATION (GRUNDFOS) are warranted to

the original user only to be free of defects in material and workmanship for a period of 24 months

from date of installation, but not more than 30 months from date of manufacture. GRUNDFOS’

liability under this warranty shall be limited to repairing or replacing at GRUNDFOS’ option, without

charge, F.O.B. GRUNDFOS’ factory or authorized service station, any product of GRUNDFOS

manufacture. GRUNDFOS will not be liable for any costs of removal, installation, transportation,

or any other charges which may arise in connection with a warranty claim. Products which are sold

but not manufactured by GRUNDFOS are subject to the warranty provided by the manufacturer

of said products and not by GRUNDFOS’ warranty. GRUNDFOS will not be liable for damage or

wear to products caused by abnormal operating conditions, accident, abuse, misuse, unauthorized

alteration or repair, or if the product was not installed in accordance with GRUNDFOS’ printed

installation and operation instructions.

To obtain service under this warranty, the defective product must be returned to the distributor

or dealer of GRUNDFOS products from which it was purchased together with proof of purchase

and installation date, failure date, and supporting installation data. Unless otherwise provided,

the distributor or dealer will contact the GRUNDFOS factory or authorized service station for

instructions. Any defective product to be returned to the factory or service station must be sent

freight prepaid; documentation supporting the warranty claim and/or a Return Authorization must

be included if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES,

LOSSES, OR EXPENSES ARISING FROM INSTALLATION, USE, OR ANY OTHER CAUSES.

THERE ARE NO EXPRESS OR IMPLIED WARRANTIES, INCLUDING MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE, WHICH EXTEND BEYOND THOSE WARRANTIES

DESCRIBED OR REFERRED TO ABOVE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages

and some jurisdictions do not allow limitations on how long implied warranties may last. Therefore,

the above limitations or exclusions may not apply to you. This warranty gives you specic legal

rights and you may also have other rights which vary from jurisdiction to jurisdiction.

LUPTL043 Rev. 10/05 (US)

Grundfos Pumps Corporation

17100 W. 118th Terrace

Olathe, Kansas 66061

Telephone: (913) 227-3400

Fax: (913) 227-3500

Grundfos Canada, Inc.

2941 Brighton Rd.

Oakville, Ontario L6H 6C9

Telephone: (905) 829-9533

Fax: (905) 829-9512

www.grundfos.com

Bombas Grundfos de Mexico, S.A. de C.V.

Boulevard TLC #15, Parque Industrial Stiva Aeropuerto

C.P. 66600 Apodaca, N.L. Mexico

Telephone: 52-81-8144-4000

Fax: 52-81-8144-4010

Loading...

Loading...