Grundfos Unilift KP 150, Unilift KP 350, Unilift KP 250 Installation And Operating Instructions Manual

Page 1

Unilift KP 150, KP 250, KP 350

GRUNDFOS INSTRUCTIONS

Installation and operatin g instructi on s

DRAINAGE PUMP

1Z28

Page 2

LIMITED WARRANTY

Products manufactured by GRUNDFOS PUMPS CORPORATION (Grundfos) are

warranted to the original user only to be free of defects in material and workmanship

for a period of 24 months from date of installation, but not more than 30 months from

date of manufacture. Grundfos' liability under this warranty shall be limited to repairing or replacing at Grundfos' option, without charge, F.O.B. Grundfos' factory or

authorized service station, any product of Grundfos' manufacture. Grundfos will not

be liable for any costs of removal, installation, transportation, or any other charges

which may arise in connection with a warranty claim. Products which a re sold but

not manufactured by Grundfos are subject to the warranty provided by the manufacturer of said products and not by Grundfos' warranty. Grundfos will not be liable

for damage or wear to products caused by abnormal operating conditions, accident,

abuse, misuse, unauthorized alteration or repair, or if the product was not installed

in accordance with Grundfos' printed installation and operating instructions.

To obtain service under this warranty, the defective product must be returned to the

distributor or dealer of Grundfos' products from which it was pu rchased togeth er

with proof of purchase and installation date, failure date, and supporting installation

data. Unless otherwise provided, the distributor or dealer will contact Grundfos or

an authorized service station for instructions. Any defective product to be returned

to Grundfos or a service station must be sent freight prepaid; documentation supporting the warranty claim and/or a Return Material Authorization must be included

if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES ARISING FROM INSTALLATION,

USE, OR ANY OTHER CAUSES. THERE ARE NO EXPRESS OR IMPLIED WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE, WHICH EXTEND BEYOND THOSE WARRANTIES DESCRIBED OR

REFERRED TO ABOVE.

Some jurisdictions do not allow the exclusion or limitation of incidental or consequential damages and some jurisdictions do not a llow limit actio ns on how long

implied warranties may last. Therefore, the above limitations or exclusions may not

apply to you. This warranty gives you specific legal rights and you may also have

other rights which vary from jurisdiction to jurisdiction.

2

Page 3

3

Unilift KP 150, KP 250, KP 350

Installation and operating instructions 4

Notice d’installation et d’entretien 9

Instrucciones de instalación y funcionamiento 15

Page 4

4

CONTENTS

Page

1. General description 4

1.1 Applications 4

1.2 Operating conditions 4

1.3 Sound pressure level 5

2. Electrical connection 5

3. Installation 5

3.1 Pipe connection 5

3.2 Basic requirements 5

3.3 Pump location and positioning 5

3.4 Adjustment of float switch 6

3.5 Non-return check valve 6

4. Operation 6

4.1 Starting 6

5. Maintenance 6

5.1 Cleaning the pump 6

5.2 Replacement of parts 7

6. Fault finding chart 8

7. Disposal 8

1. General description

Fig. 1

1. Discharge port 1.25" NPT.

2. Handle.

3. Clamp.

4. Suction strainer.

5. Outer casing.

6. Float switch (optional).

1.1 Applications

The Grundfos Unilift KP 150, KP 250 and KP 350

pumps are single-stage submersible pumps

designed for pumping grey water.

CAUTION: This pump has been evaluated for use

with water, grey wastewater and heated wastewater.

The pump is capable of pumping water which contains a limited quantity of spherical solids up to 3/8"

in diameter without being blocked or damaged.

The pump is suitable for automatic (with float switch)

as well as manual operation and can be installed in a

permanent installation or used as a portable pump.

The pump is suitable for:

• Drainage of basements or buildings prone to

flooding,

• Pumping of wastewater from washing machines,

sinks, baths, showers, etc., up to the sewer level,

• Dewatering of sites or the pumping of water for

fountains,

• Pumping in draining wells,

• Emptying swimming pools, ponds, tanks, or fountains.

The pump is not suitable for pumping:

• sewage

• liquids containing long fibers

• liquids containing solid particles larger than 3/8" in

diameter

• flammable liquids (oil, gasoline, etc.)

• aggressive liquids.

Note: If the pump has been used for very dirty or

chlorinated water it should be flushed thoroughly

with clean water after use.

The pump contains approx. 70 ml of non-poisonous

motor liquid that may pollute the pumped liquid if the

pump should leak.

1.2 Operating conditions

Liquid temperature

Minimum 32°F. The maximum liquid temperature

depends on the rated voltage of the pump, see the

table below.

Storage temperature

Not lower than –4°F.

Minimum water level

Water level must be above strainer inlet.

Maximum installation depth

30 feet below liquid level.

Prior to installation, read these installation

and operating instructions. Installation and

operation must comply with local regulations and accepted codes of good practice.

TM03 4327 2006

With float switch

Do not use the pump in or at swimming

pools, garden ponds, etc. when there are

persons in the water.

Voltage

Maximum

liquid temperature

1 x 115 V, 60 Hz +122°F (+113°F KP 350)

At intervals of at least 30 minutes, the pump is

allowed, however, to run at maximum +158°F for

periods not exceeding 2 minutes.

Page 5

5

1.3 Sound pressure level

The sound pressure level of the pump is lower than

the limiting values stated in the EC Council Directive

98/37/EC relating to machinery.

A-weighted sound pressure level

< 65 dB(A) in accordance with ISO 3743.

2. Electrical connection

The electrical connection should be carried out in

accordance with local regulations and following the

National Electrical Code. The pump should be

grounded. The operating voltage and frequency are

marked on the nameplate. Make sure that the motor

is suitable for the electricity supply on which it will be

used.

When connecting the pump for manual operation,

the 115V plug is inserted into a 115V outlet. If a float

switch is included for automatic operation it will be of

the "Piggy-back" design. Plug the 115V plug on the

float switch into the 115V outlet, and plug the 115V

plug from the pump into the float switch plug.

Fig. 2

3. Installation

3.1 Pipe connection

Steel or rigid plastic pipe can be screwed directly into

the 1.25" NPT discharge port. For permanent installation, it is recommended to fit a union, a non-return

valve and an isolating valve in the discharge pipe.

Other recommendations:

• For portable or temporary installations, plastic discharge pipe can be used in conjunction with a

suitable screwed/hose connector.

• Removal of the pump should be by a cable

secured to the pump handle and not by the discharge pipework.

• Screwed threads should be sealed using Teflon

®

tape.

Note: The pump must not be installed hanging from

the discharge pipe.

3.2 Basic requirements

When the pump is installed in a permanent installation with a float switch, and the cable length is set to

the minimum length of at least 2.5" inches, the minimum dimensions of the well should be as shown in

fig. 3.

Furthermore, the well should be sized according to

the relation between the water flow to the well and

the pump capacity.

Fig. 3

3.3 Pump location and positioning

Pumps without or with float switch can be used in

vertical position with the discharge port uppermost or

in horizontal or tilted position with the discharge port

as the highest point of the pump. See fig. 4.

When used in horizontal position, the pump must be

completely covered by liquid.

Fig. 4

When the pipe/hose has been connected, the pump

is ready for use.

Note: Do not lift the pump by means of the electric

cable. Lift the pump by means of a cable secured to

the handle of the pump.

The Unilift KP pumps have built-in thermal

overload protection and require no additional motor protection. If the motor is

overloaded, it will stop automatically.

When it has cooled to normal temperature

it will start automatically.

TM03 4461 2106

As a precaution, the pump must be connected to a socket with earth connection.

It is recommended to fit the permanent

installation with a ground fault circuit interrupter (GFCI) with a tripping current

<30mA.

115V outlet

Float switch plug

("Piggy-back")

Pump plug

TM03 4330 2006TM00 1548 0493

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹‹‹‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

ø 350 mm

400 mm

16 inches

With float switch

14 inches

Page 6

6

Before positioning the pump, make sure that the suction strainer will not be blocked or partly blocked by

silt, mud or similar materials.

This can be avoided by positioning the pump on

bricks, an iron plate, etc. See fig. 5.

Fig. 5

3.4 Adjustment of float switch

The float switch can automatically turn the pump on

and off. Switching the adjustment is possible by

repositioning the float switch in the handle of the

pump.

The free cable length must always be:

• at least 2.5 inches

• no more than 6 inches.

Fig. 6

The start/stop level varies according to the cable

length.

For manual operation, unplug both the pump and

float switch from the 115V outlet. Plug the 115V plug

on the pump into the outlet.

3.5 Non-return check valve

Whenever the pump is installed in a permanent

installation with a float switch, a non return valve

must be fitted in the discharge pipe or hose.

4. Operation

4.1 Starting

Before starting the pump, check:

• whether the pump is submerged in liquid. During

normal operation, the strainer of the pump must

be below the surface of the liquid

• whether the pump is positioned on a base so that

the strainer is not blocked by silt, mud or similar

materials

• whether the pipe/hose connection is tight

• whether the discharge pipe is open (bend of hose,

etc.)

• whether the pump is connected to the electric supply in accordance with the instructions

• check the float switch for free movement.

After start-up, chec k th at:

• the pump operates properly, that water is being

pumped, and the pump operates through the control sequence

• the float switch will allow the pump to pump down

to a level of approximately 4". To pump out below

this level secure the switch in the manual position.

See 3.4 Adjustment of float switch.

5. Maintenance

Under normal operating conditions, the pump is

maintenance-free.

If the pump has been used for liquids other than

clean water, it should be flushed through with clean

water immediately after use.

5.1 Cleaning the pump

If the pump does not deliver a sufficient quantity of

water because of sediment, dismantle and clean the

pump.

The dismantling of the pump is carried out as follows:

1. Disconnect the electricity supply.

2. Allow the pump to drain.

3. Carefully loosen the suction strainer by inserting

a screwdriver in the recess between the outer

casing and the strainer and pressing it hard.

Repeat the procedure until the strainer is free

and can be removed, see fig. 7.

TM00 1549 0493TM03 4331 2006

Cable length

Min. 2.5"

Cable length

Max. 6"

Start Stop Start Stop

Unilift KP 150

Unilift KP 250

11.5" 5.5" 12,5" 3.5"

Unilift KP 350 12" 6" 13 4"

‹‹‹‹‹‹‹‹

‹‹‹‹‹‹‹

‹‹‹‹‹‹

‹‹‹‹‹‹

‹‹‹‹‹‹

‹‹‹‹‹

‹‹‹‹‹

‹‹‹‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

‹

••••••••••••••

••••••••••••

•••••••••••

••••••••••••

•••••••••••

••••••••••

•••••••••••

••••••••••

••••••••••

••••••••••

•••••••••

••••••••

••••••••

Min./max.

cable length

Start

Stop

As a precaution, the suction strainer must

always be fitted to the pump during operation.

Never dismantle the pump unless the electricity supply has been switched off.

During dismantling, caution should be

exercised as there will be access to sharp

edges, etc. which may cut.

Page 7

7

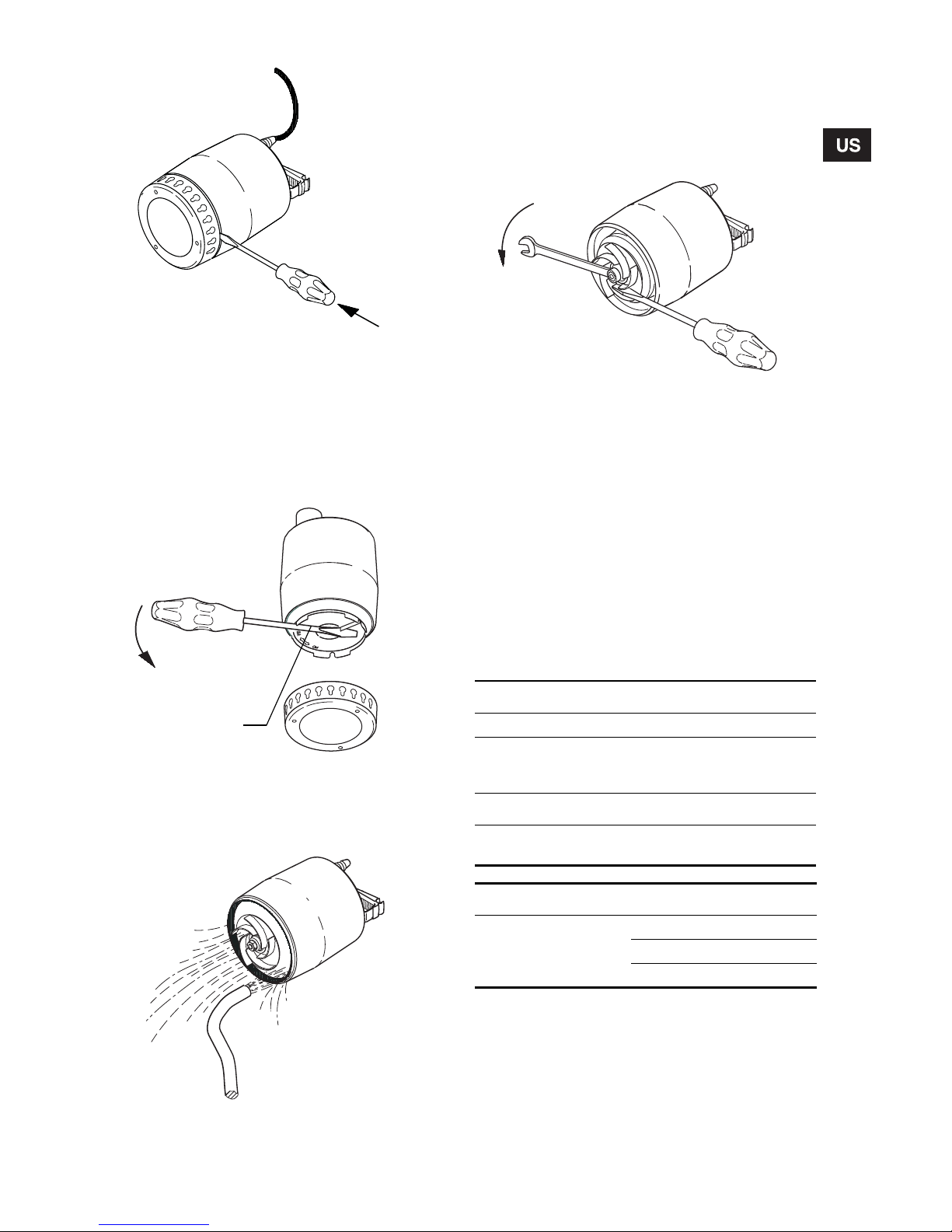

Fig. 7

4. Clean the suction strainer and refit it.

If the pump still does not deliver a sufficient quantity

of water, dismantle the pump as follows:

1. Disconnect the electricity supply.

2. Turn the pump housing 90° counter-clockwise

using a screwdriver, see the arrow on the pump

housing. Pull off the housing, see fig. 8.

Fig. 8

3. Clean and flush the pump with water to remove

possible impurities between the motor and the

outer casing. Clean the impeller, see fig. 9.

Fig. 9

4. Check that the impeller can rotate freely. If not,

remove the impeller:

• Slacken and remove the nut on the motor shaft

(13 mm). Prevent the impeller from rotating by

means of a screwdriver, see fig. 10.

• Clean the impeller and around the shaft.

Fig. 10

5. Check the impeller, the pump housing and the

sealing part. Replace possible defective parts.

6. Assemble the pump in reverse order of dismantling.

Note: Check before and when fitting the pump housing that the sealing part is positioned correctly, see

fig. 11. Moisten the sealing part with water to facilitate the fitting.

5.2 Replacement of parts

The impeller assembly and electric cord can be

replaced.

The part numbers and the components included in

the service kits will appear from the tables below and

fig. 11.

If pump components other than those mentioned

above are damaged or defective, please contact

your pump supplier.

TM03 4329 2006TM03 1168 1205TM03 1169 1205

Pump housing

TM03 1170 1205

Pump type Part number

Impeller kit

KP 150, 60 Hz

KP 250, 60 Hz

KP 350, 60 Hz

015783

015784

015786

Replacement cords

10' 60HZ

25' 60HZ

016728

016729

Service kit Description Qty.

Impeller kit

Impeller 1

Nut 1

Gasket 1

Page 8

8

Fig. 11

6. Fault finding chart

7. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

Use the public or private waste collection service.

TM03 4328 2006

Impeller

Nut

Gasket

Pump housing

Strainer

Electrical cord

Fault Cause

1. Motor does not start. a) Supply failure.

b) Pump switched off by float switch/vertical level switch.

c) Fuses are blown.

d) Thermal relay has cut out the electricity supply to the motor

(see 2. Electrical connection).

e) Check cable for defects.

2. Thermal relay trips out

after short time of

operation.

a) Temperature of pumped liquid higher than that stated in 1.2 Operating con-

ditions.

b) Pump partly blocked by impurities (see 4. Operation).

c) Pump mechanically blocked (see 4. Operation).

d) Check volts and amperage.

e) Check cable for defects.

3. Pump runs but gives

insufficient water.

a) Pump partly blocked by impurities (see 4. Operation).

b) Discharge pipe/hose partly blocked. Check the non-return valve, if fitted.

c) Check the impeller, the pump housing and the sealing part (see

4. Operation).

4. Pump runs but gives no

water.

a) Pump blocked by impurities (see 4. Operation).

b) Non-return valve, if fitted, in discharge pipe/hose blocked in closed position.

c) Liquid level is too low. During normal operation, the liquid level must be

above the strainer.

d) Pumps with float switch: The free cable of the float switch is too long

(see 3.4 Adjustment of float switch).

Subject to alterations.

Page 9

21

Page 10

22

Page 11

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

Mexico

Bombas GRUNDFOS de Mexico

S.A. de C.V.

Boulevard TLC No. 15

Parque Industrial Stiva

Aeropuerto

Apodaca, N.L.C.P. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Addresses revised 22.09.2005

Page 12

www.grundfos.com

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

L-KP-TL-002 1/07

US

Loading...

Loading...