Page 1

Grundfos.bk Page 1 Wednesday, September 3, 2008 1:36 PM

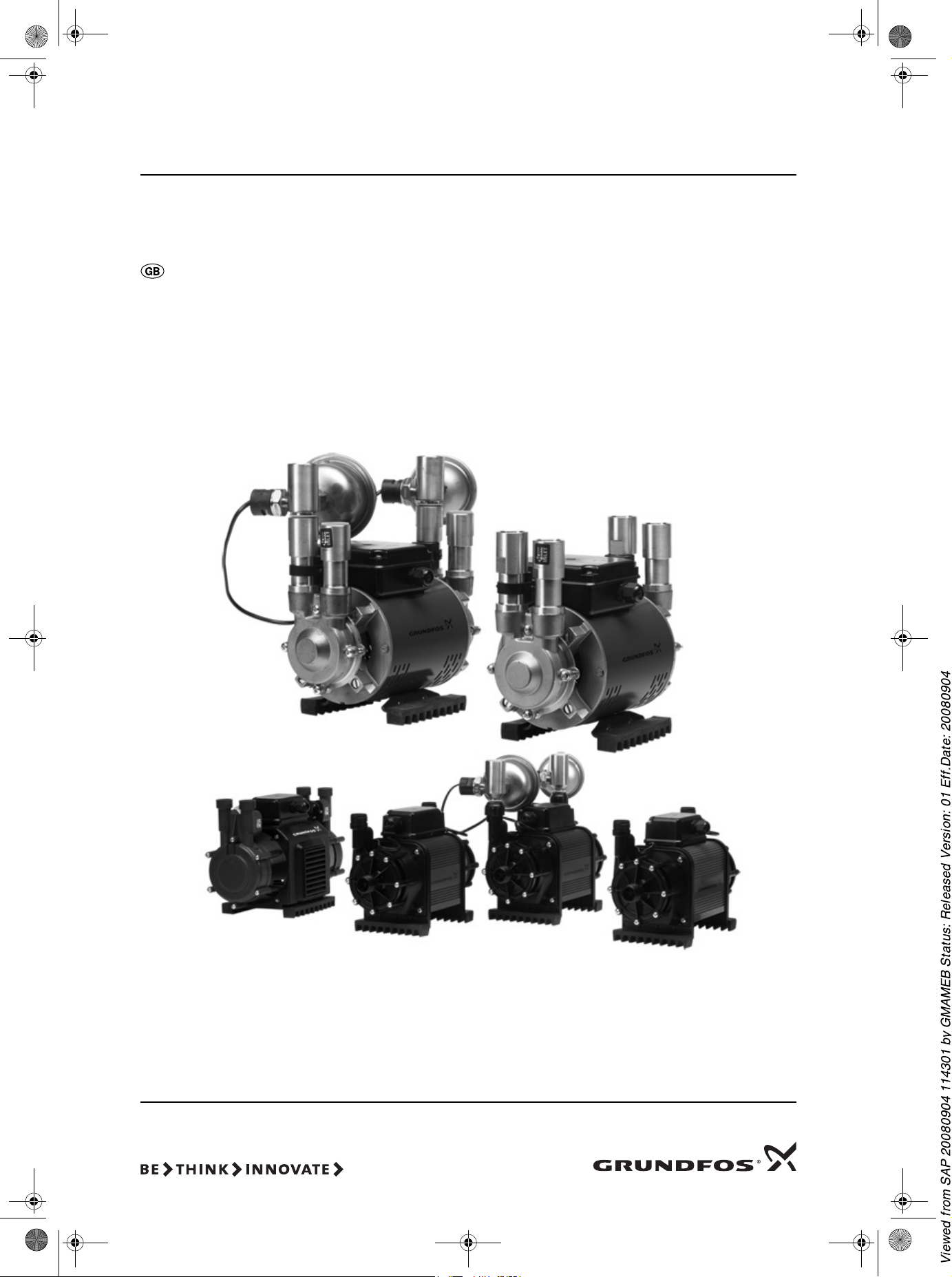

Shower pump

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

Grundfos.bk Page 2 Wednesday, September 3, 2008 1:36 PM

Declaration of Conformity

We Grundfos declare under our sole responsibility that the products SSL,

STL, STC, SSR, STR, SSP, STP, SSN and STN, to which this declaration

relates, are in conformity with the Council Directives on the approximation

of the laws of the EC Member States relating to

— Machinery (98/37/EC).

— Electrical equipment designed for use within certain voltage limits

(2006/95/EC).

Standards used: EN 60335-1: 2002 and EN 60335-2-41: 2003.

— Electromagnetic compatibility (2004/108/EC).

Bjerringbro, 20th December 2007

Svend Aage Kaae

Technical Director

2

Page 3

Grundfos.bk Page 3 Wednesday, September 3, 2008 1:36 PM

CONTENTS

Page

1. Symbols used in this document 3

2. General 3

2.1 Type key 3

3. Important instructions 3

4. Positioning the pump 4

4.1 Negative head 4

5. Hot-water cylinder connections 4

6. Cold-water supply 4

7. Connecting the pump 4

7.1 STC, STR, SSR, STL and SSL pumps 4

8. Electrical connections 5

8.1 Electrical connection, 1 x 230 V, 50 Hz 5

8.2 Electrical connection, low-voltage pumps (STL, SSL and

STL 2.0 CN) 5

9. Before using the pump 5

10. Negative-head pumps 6

10.1 General 6

10.2 Dry-running protection 6

10.3 Connecting the pump 6

10.4 Installation instructions 6

10.5 Pressure and flow control 6

10.6 Operating instructions 6

10.7 Maintenance 6

11. Fault finding chart 7

11.1 Fault finding, negative-head pumps (STN, SSN and STL

2.0 CN) 8

12. Technical data 9

13. Service 11

14. Disposal 11

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

1. Symbols used in this document

Warning

If these safety instructions are not observed,

it may result in personal injury!

If these safety instructions are not observed,

Caution

Note

it may result in malfunction or damage to the

equipment!

Notes or instructions that make the job easier

and ensure safe operation.

2. General

These installation and operating instructions apply to the

Grundfos Shower Pumps, types STL, SSL, STC, STR, SSR, STP,

SSP, STN and SSN.

For supplementary instructions regarding negative-head pumps,

see section 10. Negative-head pumps.

Your shower pump has been designed, manufactured and

carefully tested in England.

If correctly installed and not misused, it will give many years of

reliable service.

A shower pump installation requires a cold-water storage tank

and a hot-water cylinder. See fig. 2, page 12.

Low-voltage shower pumps

All transformers are fitted with auto-resetting thermal cut-outs.

If the transformer overheats for any reason, the thermal cut-out

will switch the pump off. The cut-out will automatically switch the

pump on again when the transformer has cooled down.

For the STL 2.0 CN pumps, also read the instructions in section

10. Negative-head pumps.

Please dispose of any packaging supplied with

Note

this pump in an environmentally friendly and

legal manner.

2.1 Type key

Example S T P 2.0 B

S: Shower pump range

T: Twin impeller

S: Single impeller

P: Positive head

N: Negative head

L: Low voltage

C: Centrifugal

R: Regenerative

Maximum head [bar]

Material:

B: Brass

C: Composite

CN: Composite, negative head

3. Important instructions

Do not connect the pump directly to the water

mains supply.

Caution

Note

• A supply head of at least 2 metres is recommended.

• Non-return valves

Do not fit non-return valves in the suction line to the pump.

Make sure that the pump can vent back to the supply tank.

• STC, STR, SSR, STL and SSL pumps

The strainers supplied with the pump must be used on suction

connections. See fig. 1, page 4.

• Push-fit connections (SSN, SSP, STN and STP pumps)

The pump suction and discharge ports are fitted with push-fit

connections. The flexible hoses supplied with the pump must

be used.

Make sure that each hose connection is fully inserted to a

minimum depth of 33 mm.

The hot-water supply to the pump suction port should be

connected from the first outlet from the hot-water cylinder

expansion pipe, i.e use a Surrey flange.

• Disconnecting hose

To disconnect the "push-fit" hose, firmly push down the white

or grey retaining ring, while pulling out the hose.

• No solder flux

Do not allow any solder flux to come into contact with any of

the plastic parts of the pump.

• Do not let the pump run dry

Purge with water thoroughly for 5 minutes before running the

pump.

• Test the system

After completing installation, the whole system must be

thoroughly tested – operating both hot and cold water at

maximum flow.

Maximum hot-water temperature setting must not exceed

60 °C (140 °F) in accordance with BS 6700: 2006.

Finally check that each connection is watertight and not

leaking.

The pump cannot normally be used with

combination boilers.

Make sure that no foreign particles (such as

solder, dust, etc.) are allowed to enter the pump.

The pump cannot operate if the level of the water

in the cold-water storage tank is below the level

of the pump.

3

Page 4

Grundfos.bk Page 4 Wednesday, September 3, 2008 1:36 PM

4. Positioning the pump

Select a position for installing the pump which

Note

Minimum inlet pressure: 2 metres (recommended).

Keep the pump as close as possible to the source of hot and cold

water.

For optimum performance, ensure

• a good water flow to the pump

• sufficient head

• unrestrictive pipework

• provision to prevent air locks.

Place the pump in a well-ventilated location, e.g. on the floor of

the airing cupboard.

Caution

Caution

The pump must be mounted horizontally with discharge ports

vertically upwards to ensure correct operation of the flow

switches.

To reduce noise, we recommend the pump be mounted on a

small concrete foundation of approximately 225 x 225 mm and

40-50 mm thick.

Connect the pump and shower system as shown in fig. 2,

page 12.

To achieve 0.5 l/min. to turn the flow switches on, there must be a

minimum height between the water level in the cold-water storage

tank and the shower outlet of approximately 250 mm. See fig. 2,

page 12.

The pump must be installed in accordance with the Water Supply

(Water Fittings) Regulations 1999.

For installation within a bathroom, locate the pump in accordance

with the IEE Wiring Regulations seventeenth edition (BS 7671:

2008) Part 6 Section 601 for a shower pump with an IPX2

enclosure. The pump must be positioned at least 0.6 metres

horizontally or 3 metres vertically away from any bath, shower

tray or basin.

affords easy access for subsequent servicing

and maintenance.

Do not cover the pump, otherwise the motor will

overheat.

The pump must be placed in a frost-free location.

Warning

The pump may be fitted under a bath, providing

this space is only accessible through the use of

a tool. If in doubt, consult the Wiring Regulations.

6. Cold-water supply

Do not connect the pump directly to the water

Caution

The cold-water supply to the pump must be connected using

22 mm pipe to the cold-water storage tank. See fig. 2, page 12.

The tank connector should be positioned at least 25 mm (1”)

lower than the cold-water supply to the hot-water cylinder to

prevent the supply of hot water only.

mains supply.

Do not use any jointing compounds or tape.

7. Connecting the pump

Caution

For ease of installation, subsequent servicing and cleaning of

strainers, full-bore isolating gate valves should be fitted in the

pump suction and discharge ports.

Note

The flexible hoses supplied with the pump must be used for

connecting the pump to the pipework. Use of these hoses will

ensure strain- and vibration-free watertight connections. The

maximum bend angle should not exceed 45 °.

After initial installation, run the pump for a few minutes, switch off,

drain down and clean the suction strainers.

For SSN, SSP, STN and STP pumps, remove the suction hose

from the pump, and the strainer basket can be removed by hand

or with long-nosed pliers.

Line up pipework, and fit hoses to the pump before connecting to

pipes. Position pipework accurately so that the pump is not

subject to mechanical strain.

Plastic nuts should be finger-tight plus 1/4 turn. The nuts should

be retightened after hot water has been pumped for the first time.

Note

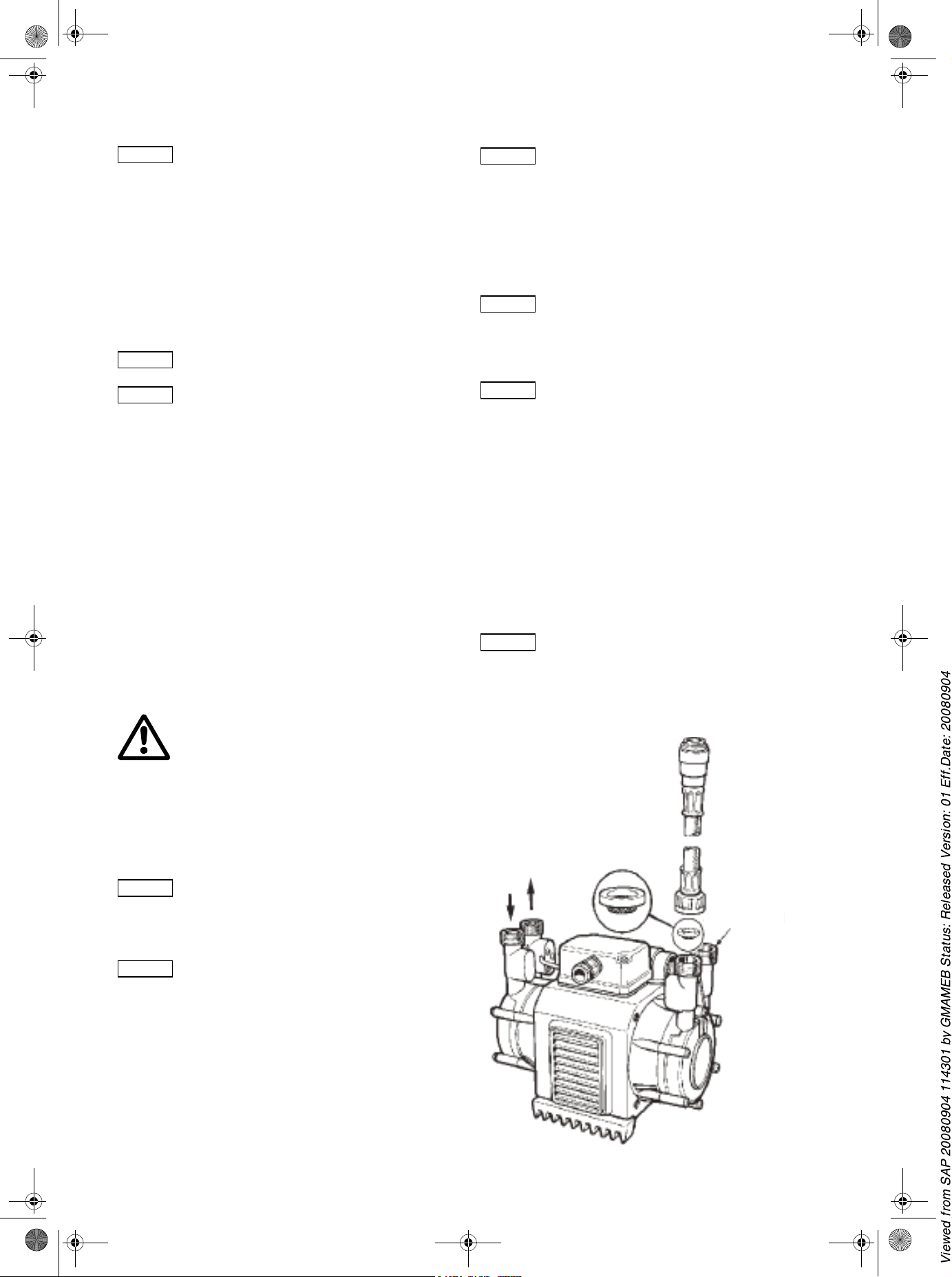

7.1 STC, STR, SSR, STL and SSL pumps

The strainers supplied with the pump must be fitted to the pump

suction connections only with the wire dome towards the pump.

See fig. 1.

Do not use any jointing compounds or tape.

Isolating valves greatly assist draining down,

strainer cleaning and refilling, which will result in

much lower service costs.

Do not bend hoses as this will cause restriction

of flow.

4.1 Negative head

If the water level in the cold-water storage tank is below the level

of the shower outlet, this is called a negative-head system. To

enable the pump to operate, a negative-head pump must be

used. See section 2.1 Type key.

If the pump is positioned above the outlet of

Note

the hot-water storage cylinder, ensure that the

pipework to the pump from the cylinder has a

downward loop. This will help prevent air locks.

5. Hot-water cylinder connections

Caution

The use of a Surrey flange (see fig. 2, page 12) is recommended

to ensure a free-flowing supply of air-free hot water.

The hot-water supply may be taken directly from the top of the

hot-water cylinder, but entrapped air may cause problems.

22 mm copper pipe should be used to ensure an adequate flow to

the pump. Where high flows are expected, 28 mm is

recommended.

Do not use any jointing compounds.

Discharge

Suction

Fig. 1 Fitting the strainer

Suction

strainer

Discharge

connection

TM04 02 0203 5107

4

Page 5

Grundfos.bk Page 5 Wednesday, September 3, 2008 1:36 PM

8. Electrical connections

Warning

The pump must be earthed.

The pump must be connected to an external

mains switch with a contact separation gap

of at least 3 mm in each pole.

The pump must be connected to a 230 V, 50 Hz,

supply with a switched spur fused at 5 A

(10 A on models STP 4.0 B and STN 4.0 B).

Metal pipes must be earthed by the use of

earthing clamps to BS 951 and 4 mm earthing

wire.

Complete all pipework before making electrical

Caution

If in doubt, consult a qualified electrician or call your local

electricity board engineer.

8.1 Electrical connection, 1 x 230 V, 50 Hz

Observe colour coding as follows:

• Brown to terminal L.

• Yellow/green to terminal E (PE).

Ensure that the earth lead is at least as long as the other two

leads.

• Blue to terminal N (neutral).

Insert the lead fully into the terminal connector and tighten the

screw firmly. Ensure that the connection is secure. Be sure to

tighten the cable restraint.

Ensure compliance with IEE Regulations. In the interests of

safety, it is recommended that a residual current device (RCD)

be installed in the supply circuit.

The pump switch should be left "on" at all times for normal

operation of the system.

connections.

Do not allow any water to enter into the electric

terminal box.

Warning

Do not operate the pump without terminal box

cover in place.

Ensure compliance with IEE Regulations.

Observe colour coding as follows:

• Brown to terminal L.

• Blue to terminal N.

For normal operation of the shower, the transformer can be left

permanently switched on – very little power is used when the

pump is not running.

Copper pipes should have supplementary earth bonding. Where

the earth continuity has been broken, the pump suction and

discharge pipework should be connected with earthing clamps to

BS 951 and 4 mm earthing wire.

9. Before using the pump

Warning

Do not let the pump run dry.

Purge water thoroughly through the system

before switching on the electricity supply to

the pump.

Do not switch on the electricity supply.

1. Turn on the water supply. Allow the system to fill.

2. Immediately inspect for any leaks.

3. With pump not running, allow maximum water flow, for

example remove handset from shower hose, letting the

shower hose hang into the shower tray or bath. Operate

maximum hot and cold flow for at least 2 minutes, to flush out

all debris and ensure air is thoroughly purged from the system.

4. Switch on the electricity supply to the pump. Again operate the

pump in both full hot and cold modes for about 2 minutes.

5. With the pump operating, carefully inspect again for any leaks

from all connections on both hot- and cold-feed pipes to the

pump and to the system.

After hot water has been run for several minutes, check all

hot-water connections and make sure that there are no leaks.

6. The first few times the pump is used, the insulating varnish

used on the pump motor may give off an odour. This is

perfectly normal and will diminish with use.

8.2 Electrical connection, low-voltage pumps

(STL, SSL and STL 2.0 CN)

Use the transformer supplied.

Caution

The low-voltage pump has added electrical protection via a safety

isolating transformer. See fig. 3, page 13, or fig. 4, page 14.

For installations where the pump has to be placed in the

bathroom (for example under the bath), we recommend that

the safety isolating transformer is placed outside the bathroom or

shower area.

The low-voltage leads from the transformer must be connected to

the two terminals marked "T" in the terminal box. As the supply is

AC, the leads can be connected to either terminal on the pump.

The low-voltage pump installation kits are supplied with 3 metres

of connecting lead. The connecting leads between the pump and

the isolating transformer can be extended up to about 15 metres.

Use 1.0 mm cable.

The safety isolating transformer must be connected to a

230-240 V, 50 Hz, supply voltage with a switched spur fused

at 5 A. The switch must have a double-pole disconnection with

a separation gap of at least 3 mm. See fig. 3, switched spur.

Do not connect the pump directly to 240 V.

Electrical hazard will result and the motor will be

irreparably damaged.

Warning

Do not locate 230-240 V connections, plugs or

switches within the "wet" area in accordance

with IEE Regulations.

5

Page 6

Grundfos.bk Page 6 Wednesday, September 3, 2008 1:36 PM

10. Negative-head pumps

Pump types: STN, SSN and STL 2.0 CN.

10.1 General

Automatic negative-head shower pumps are designed to operate

automatically in installations where the pumped system outlets

are above the stored water level.

Shower pumps, types STN and SSN, feature independent

pressure and flow controls, with built-in non-return valves and

stainless-steel expansion tanks in each pump end. This system

ensures complete hot- and cold-water system isolation with

stable control over a very wide flow range.

The pump is fitted with dry-running protection. Should the water

supply fail, the pump will stop to prevent damage to the shaft

seals.

10.2 Dry-running protection

STN, SSN and STL 2.0 CN negative-head pumps feature dryrunning protection to avoid damage to seals caused by water

starvation. This condition is possible if there is insufficient stored

water or the pump strainers are blocked.

If the pump runs for 60 seconds with an insufficient water supply,

the pump will stop and "lock out".

Resetting the "lock out"

To reset the pump, switch the electricity supply off for

10 seconds.

When the electricity supply is switched on again, the pump will

run for a few seconds to recharge the tanks. If it continues to run

and there is no demand, this would indicate that one of the

following is still present:

• No water in the system.

• Blocked strainer.

• Air which has not yet cleared.

Caution

10.3 Connecting the pump

Caution

For the pump to work correctly, it must have:

• Air-free supply of hot water – the use of Surrey flanges is

recommended.

• 22 mm (minimum) feed pipes, gate valves and flexible hoses.

• Minimum head of water to supply the pump 2 metres (6'6").

However, the STN and SSN pumps will function with a supply

head as low as 600 mm (2 ft), providing the water make-up

system has unrestrictive pipework, and provision is made to

avoid air locks.

• Maximum hot-water temperature of 60 °C conforming to

BS 6700: 2006.

• Maximum static head of 8 m, i.e. the highest point of the

system must be less than 8 m above the pump. See fig. 4,

page 14.

10.4 Installation instructions

• The hot-water cylinder must have an expansion pipe or be

fitted with a vent pipe connected to the pump hot-water supply,

to allow air from the hot-water cylinder to escape.

Excessive air entering the pump will cause faulty operation

and damage to the pump seals which will cause serious water

leaks.

• Feed pipes, hot and cold, must be minimum 22 mm with

22 mm service isolating gate valves. The flexible hoses

supplied must be used. The hoses must be connected without

kinks which will restrict water flow. The maximum bend angle

is 45 °.

Continued dry running will lead to overheating of

the shaft seals and eventually to a water leak.

Do not connect the pump directly to the water

mains supply.

• Ensure an adequate head of water and non-restrictive makeup pipework.

Inadequate feed head will cause pump cavitation, unstable

water temperature, noise and ultimately pump and seal

damage.

• All air must be thoroughly purged from the system. If air is

present in the pump, it will be unable to generate sufficient

pressure to operate the pressure switch. This will cause the

pump to run or pulse continuously.

• Lavatory cisterns

If the pump is to supply a lavatory cistern, certain precautions

should be taken to avoid frequent starting and stopping of the

pump due to low flow rates.

If possible, best practice is to supply the cistern from the

mains water supply. Failing this, a "Torbeck" or equilibrium

valve is recommended. If either of these are not possible, the

following instructions should be followed:

– A: The pump is supplied with two expansion or pressure

tanks. They have capacities of 500 ml and 160 ml.

The larger tank must be used on the cold side of the

pump.

– B: The cistern filling pipework must be as free-flowing as

possible with all flow restrictors removed.

It is possible to change the tanks from one side of the pump

to the other. When doing so, take care to ensure that none

of the fibre washers are lost.

• Washer dryers

Only brass pumps must be used for these applications.

10.5 Pressure and flow control

Shower pumps for negative-head applications are controlled by

both water pressure and water flow.

Twin-impeller pumps incorporate two separate pressure and flow

control systems, one on each pump end, ensuring complete

isolation of hot- and cold-water systems and consistent operation

over a wide range of unbalanced flow rates.

The control system manifold includes an integral non-return valve

to maintain system pressure when water is not flowing.

Operation

The pressure switches start the pump on falling pressure.

The switch point is factory-set.

It is important that the total head on the pump

Note

Once the pump has been started by the pressure switches, the

flow switches maintain the pump running, providing the flow rate

is above 0.4 l/min. When the flow rate drops below 0.4 l/min. or

the demand is turned off, the pump will stop after first running on

for 3 seconds to recharge the pressure tanks.

is less than 8 metres. Otherwise the pressure

switch can never operate and hence the pump

will fail to start.

10.6 Operating instructions

Taps and valves used on the "pressure system" must be fully

turned off when not in use.

10.7 Maintenance

Washers and seals must be replaced when necessary to prevent

leaks or drips.

Any leak or drip will cause the pump to operate periodically, the

frequency dependent on the rate of the leak.

Tank air-pressure setting

The pressures are factory-set. In the event of a leak, they should

be set as follows:

The smaller tank (160 ml) should be set at a pressure between

0.9 and 1.0 bar. The larger tank (500 ml) should be set at a

pressure between 0.5 and 0.6 bar.

In certain applications, e.g. steam cabinets, it

Note

For further information regarding general maintenance and

service, see section 13. Service.

may be necessary to increase the pressure.

Consult the appliance manufacturer.

6

Page 7

Grundfos.bk Page 7 Wednesday, September 3, 2008 1:36 PM

11. Fault finding chart

Before starting work on the pump, make sure that the electricity supply has been switched off and that it cannot be

accidentally switched on.

Fault Possible cause Remedy

1. The pump fails to start. a) The electricity supply is switched off. Switch on the electricity supply.

b) The fuses are blown. Replace the blown fuses. If the new ones blow too,

the electric installation should be checked.

c) The built-in thermal protection has switched

off the motor.

d) Isolating valves are closed. Open the isolating valves.

e) Strainers are blocked. Close the service isolating gate valves, clean the

f) Pump installed with non-vertical discharge

ports (flow switches).

g) Insufficient water flow, below 0.5 l/min. Increase the water flow to at least 0.5 l/min.

2. The flow from the

shower drops.

3. The pump runs

continuously.

4. The pump pulses. a) The use of other taps in the house may

5. Unstable water

temperature/noisy

pump.

a) Blocked strainers. Clean the pump strainers.

a) A tap or outlet is turned on. Ensure there are no leaks and that all taps and

b) Flow switch or reed switch faulty or

incorrectly set.

c) Air in the system. Vent the system.

d) The float in the flow switch is stuck in the

up (on) position.

cause the pump to start momentarily.

a) Air entering the pump, most commonly from

the hot-water cylinder.

b) Too high water temperature. Reduce hot-water temperature. The maximum

c) Debris caught in the impeller casing. Remove debris.

The thermal protection resets automatically within

1 to 2 hours.

strainers and re-open the service isolating gate valves.

The pump must be installed with vertical discharge ports

(flow switches).

appliances are off.

Adjust or replace as appropriate.

Make sure that the flow switch can operate correctly and

there is no debris in the flow switch.

Contact your installer.

Fit a Surrey flange and study the pipework layout.

There should be no high points where air can collect.

recommended hot-water temperature setting is 60 ºC

(140 ºF).

7

Page 8

Grundfos.bk Page 8 Wednesday, September 3, 2008 1:36 PM

11.1 Fault finding, negative-head pumps (STN, SSN and STL 2.0 CN)

Before starting work on the pump, make sure that the electricity supply has been switched off and that it cannot be

accidentally switched on.

Fault Possible cause Remedy

1. The pump fails to start. a) The electricity supply is switched off. Switch on the electricity supply.

b) The fuses are blown. Replace the blown fuses. If the new ones blow too, the

electric installation should be checked.

c) The built-in thermal protection has switched

off the motor.

d) Isolating valves are closed. Open the isolating valves.

e) Strainers are blocked. Close the service isolating gate valves, clean the

f) Pump installed with non-vertical discharge

ports (flow switches).

g) Dry-running protection operated. Switch off the electricity supply for 10 seconds to reset.

2. The flow from the

shower drops.

3. The pump runs

continuously.

4. The pump pulses. a) The use of other taps in the house may

5. Pump stops when there

is a demand.

6. Pump hunts when

shutting down.

7. Pump hunts when

starting up.

a) Blocked strainers. Clean the pump strainers.

a) A flow demand still exists. Check the installation for leaks.

b) Flow switch or reed switch faulty or

incorrectly set.

c) Faulty pressure switch. Check the pressure switch.

d) The float in the flow switch is stuck in the

up (on) position.

cause the pump to start momentarily.

b) Leaks in the system. Check the system for leaks.

c) Faulty non-return valve. Check the non-return valves and replace, if necessary.

a) Flow demand below 0.4 l/min. Increase the flow demand.

b) Flow switch or reed switch faulty. Replace the flow switch or reed switch.

a) Incorrect tank air-pressure setting. Adjust the tank air-pressure setting.

b) Insufficient run-on time. Replace the printed-circuit board (PCB).

a) Flow rate below 0.4 l/min. Increase the flow rate.

b) Flow switch or reed switch faulty or

incorrectly set.

The thermal protection resets automatically within

1to2hours.

strainers and re-open the service isolating gate valves.

The pump must be installed with vertical discharge ports

(flow switches).

Adjust or replace as appropriate.

Make sure that the flow switch can operate correctly and

there is no debris in the flow switch.

Contact your installer.

Adjust or replace as appropriate.

8

Page 9

Grundfos.bk Page 9 Wednesday, September 3, 2008 1:36 PM

12. Technical data

Data

Supply voltage 1 x 230 V, 50 Hz

Power consumption 400 W 435 W 370 W 525 W 640 W 850 W 920 W

Rated current 1.7 A 1.9 A 1.6 A 2.3 A 2.8 A 4.0 A 4.3 A

Rating* Continuous operation

Enclosure class ** IPX2

Motor 2-pole induction

Inlet head (min. - max.) 1 to 20 m

Maximum developed pump

head

Maximum operating pressure 6 bar

Minimum starting flow rate 0.5 l/min.

Length 178 mm 178 mm 230 mm 245 mm 243 mm 266 mm 296 mm

Width 135 mm 135 mm 135 mm 135 mm 135 mm 135 mm 135 mm

Height 225 mm 225 mm 225 mm 225 mm 225 mm 225 mm 225 mm

Weight 7.1 kg 7.1 kg 7.4 kg 8.4kg 9.9 kg 12.0 kg 14.5 kg

Sound pressure level (1 m) < 70 dB(A)

* Recommended minimum flow rate: 5 l/min.

** When mounted on a flat horizontal surface.

Data

Supply voltage 1 x 230 V, 50 Hz

Power consumption 270 W 350 W

Rated current 1.5 A 1.8 A

Rating* 20 min. on / 40 min. off

Enclosure class** IPX2

Motor Universal

Inlet head (min. - max.) 2 to 10 m

Maximum developed pump

head

Maximum operating pressure 3.0 bar

Minimum starting flow rate 0.5 l/min.

Length 300 mm 305 mm

Width 120 mm 120 mm

Height 185 mm 185 mm

Weight 2.9 kg 3.3 kg

Sound pressure level (1 m) < 70 dB(A)

* At flow rates between 5 and 20 l/min.

** When mounted on a flat horizontal surface.

SSP 2.0 B SSP 3.0 B STP 1.0 B STP 1.5 B STP 2.0 B STP 3.0 B STP 4.0 B

23 m 31 m 13 m 18 m 24 m 34 m 41 m

Pump type

STC 1.5 C STC 2.0 C

15 m 20 m

Pump type

9

Page 10

Grundfos.bk Page 10 Wednesday, September 3, 2008 1:36 PM

Data

Supply voltage (transformer) 1 x 230 V, 50 Hz

Transformer output 29 VDC 37 VDC 38 VDC 39 VDC 39 VDC

Power consumption 170 W 270 W 160 W 380 W 380 W

Rated current 5.4 A 7.0 A 4.0 A 10 A 10 A

Rating*

Enclosure class** IPX2 IPX2

Motor Permanent magnet, low voltage, DC

Inlet head (min. - max.) 2 to 10 m 2 to 8 m

Maximum developed pump

head

Maximum operating pressure 3 bar

Minimum starting flow rate 0.5 l/min.

Length [mm] 275 mm 275 mm 225 mm 285 mm 285 mm

Width [mm] 120 mm 120 mm 120 mm 120 mm 215 mm

Height [mm] 185 mm 185 mm 185 mm 185 mm 256 mm

Weight [kg] 4.6 kg 5.8 kg 4.0 kg 6.9 kg 8.3 kg

Sound pressure level (1 m) < 70 dB(A)

* At flow rates between 5 and 20 l/min.

** When mounted on a flat horizontal surface.

STL 1.0 C STL 1.5 C SSL 1.4 C STL 2.0 C STL 2.0 CN

20 min. on /

40 min. off

9.5 m 15 m 14 m 19.5 m 19.5 m

Pump type

30 min. on / 30 min. off

Data

Supply voltage 1 x 230 V, 50 Hz

Power consumption 350 W 390 W 270 W

Rated current 1.5 A 1.7 A 1.2 A

Rating* 20 min. on / 40 min. off 20 min. on / 40 min. off 20 min. on / 40 min. off

Enclosure class** IPX2

Motor 4 pole, induction

Inlet head (min. - max.) 1 to 10 m

Maximum developed pump

head

Maximum working pressure 3 bar

Minimum starting flow rate 0.5 l/min.

Length 250 mm 250 mm 230 mm

Width 140 mm 140 mm 140 mm

Height 190 mm 190 mm 190 mm

Weight 5.8 kg 5.8 kg 5.4 kg

Sound pressure level (1 m) < 70 dB(A)

* Recommended minimum flow rate: 5 l/min.

** When mounted on a flat horizontal surface

STR 1.2 C STR 1.5 C SSR 1.5 C

12 m 15 m 16 m

Pump type

10

Page 11

Grundfos.bk Page 11 Wednesday, September 3, 2008 1:36 PM

Data

Supply voltage (transformer) 1 x 230 V, 50 Hz

Power consumption 400 W 435 W 525 W 640 W 850 W 920

Rated current 1.7 A 1.9 A 2.3 A 2.8 A 4.0 A 4.3

Rating* Continuous operation

Enclosure class** IPX2

Motor 2-pole induction

Inlet head (min. - max.) 1 to 8 m

Maximum developed pump

head

Maximum operating pressure 6 bar

Minimum starting flow rate 0.5 l/min.

Length [mm] 178 mm 178 mm 245 mm 243 mm 266 mm 296 mm

Width [mm] 225 mm 225 mm 225 mm 225 mm 225 mm 225 mm

Height [mm] 283 mm 283 mm 283 mm 283 mm 283 mm 283 mm

Weight [kg] 7.6 kg 7.6 kg 9.7 kg 11.3 kg 13.3 kg 15.8 kg

Sound pressure level (1 m) < 70 dB(A)

* Recommended minimum flow rate: 5 l/min.

** When mounted on a flat horizontal surface

SSN 2.0 B SSN 3.0 B STN 1.5 B STN 2.0 B STN 3.0 B STN 4.0 B

23 m 31 m 21 m 24 m 34 m 41 m

13. Service

• The flexible pump hoses, dependent on water temperature

and mechanical stress, can deteriorate with age. We

recommend that all flexible hoses and connections are

inspected at least every 6 months. Replace as necessary to

prevent leaks.

• If the flow from the shower drops below its normal

performance, it may be necessary to clean the pump strainers.

Blocked strainers are common on initial installation of pumps,

or in new buildings where the use of jointing compounds,

tapes, flux and other debris can be flushed through the

system.

In this event, close the service valves, remove and clean the

strainers. See section 7. Connecting the pump.

• A common cause of poor shower performance is a clogged

shower head/handset, so regular cleaning and descaling is

important – this applies particularly to hard-water areas.

Pump type

14. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest Grundfos company

or service workshop.

Subject to alterations.

11

Page 12

r

Grundfos.bk Page 12 Wednesday, September 3, 2008 1:36 PM

System vent

Cold-water storage tank

of at least 50 gallon

capacity

Shower outlet

250 mm (10 inches)

below water level

Shower

valve

Cold-wate

supply

min.

22 mm

Expansion pipe

22 mm

Hot-water supply

Surrey

flange

min.

22 mm

service

gate

valves

Hot

Supply to

Full-bore gate valve

Water mains

Cold-water supply to cylinder, min. 22 mm, 28 mm recommended

Hot-water

cylinder

Cold

another shower,

if required

Fig. 2 Installation of STP, SSP, STC and STR pumps

Pump

230 V

switched spur

TM04 0201 5107

12

Page 13

Grundfos.bk Page 13 Wednesday, September 3, 2008 1:36 PM

System vent

Cold-water supply to cylinder, min. 22 mm, 28 mm recommended

Cold-water storage tank

of at least 50 gallon

capacity

Expansion pipe

Hot-water supply

Surrey

flange

Hot-water

min.

22 mm

cylinder

Cold-water

supply

min.

22 mm

Anti-scald valve

(optional)

Shower

valve

Low-voltage

transformer

Shower outlet

250 mm (10 inches)

below water level

(Except STL 2.0 CN)

22 mm

service

gate

valves

Hot

Supply to

another shower,

Cold

if required

Min. 2 metres (6 ft. 6 in.)

max. 10 metres (33 ft)

supply head from water

level to pump suction port

Water mains

Full-bore gate valve

Fig. 3 Installation of STL and SSL pumps

230 V

switched spur

Pump

TM04 0202 5107

13

Page 14

Grundfos.bk Page 14 Wednesday, September 3, 2008 1:36 PM

Shower

valve

Max.

8 m

Cistern

Basin

Bath

System vent

Negative

Cold-water storage tank

of at least 50 gallon

capacity

Hot-water supply

min.

Surrey

22 mm

flange

Cold-water

supply

min.

22 mm

22 mm

service

gate

valves

Hot

Cold

Supply to another shower,

bath or basin, if required

Positive

Hot-water

cylinder

Min. 22 mm

Water mains

230 V switched spur

Low-voltage pumps must be

connected via transformer only

Fig. 4 Installation of STN, SSN and STL 2.0 CN pumps

Pump

TM04 0200 5107

14

Page 15

Grundfos.bk Page 15 Wednesday, September 3, 2008 1:36 PM

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote

34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb

Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belorussia

Представительство ГРУНДФОС в

Минске

220090 Минск ул.Олешева 14

Теле фо н: (8632) 62-40-49

Факс: (8632) 62-40-49

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Paromlinska br. 16,

BiH-71000 Sarajevo

Phone: +387 33 713290

Telefax: +387 33 231795

Brazil

Mark GRUNDFOS Ltda.

Av. Humberto de Alencar Castelo

Branco, 630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

GRUNDFOS Pumpen Vertrieb

Representative Office - Bulgaria

Bulgaria, 1421 Sofia

Lozenetz District

105-107 Arsenalski blvd.

Phone: +359 2963 3820, 2963 5653

Telefax: +359 2963 1305

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

51 Floor, Raffles City

No. 268 Xi Zang Road. (M)

Shanghai 200001

PRC

Phone: +86-021-612 252 22

Telefax: +86-021-612 253 33

Croatia

GRUNDFOS predstavništvo Zagreb

Cebini 37, Buzin

HR-10000 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-3066 5650

Telefax: +358-3066 56550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O . B o x 7 1

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg., 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

México

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

e-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

România

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Гру нд фо с

Росс ия, 109544 Москва, ул. Школьная

39

Тел. (+7) 495 737 30 00, 564 88 00

Факс (+7) 495 737 75 36, 564 88 11

E-mail

grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47

496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS PUMPEN VERTRIEB

Ges.m.b.H.,

Podružnica Ljubljana

Blatnica 1, SI-1236 Trzin

Phone: +386 01 568 0610

Telefax: +386 01 568 0619

E-mail: slovenia@grundfos.si

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölndal

Tel.: +46(0)771-32 23 00

Telefax: +46(0)31-331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Tai ch u ng, Taiwan, R. O . C .

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd.

Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС УКРАЇНА

01010 Київ, Вул. Московська 8б,

Тел.:(+38 044) 390 40 50

Фах.: (+38 044) 390 40 59

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Usbekistan

Представительство ГРУНДФОС в

Ташкенте

700000 Ташкент ул.Усм ана Носира 1-й

тупик 5

Телеф он : (3712) 55-68-15

Факс: (3712) 53-36-35

Addresses revised 09.07.2008

Page 16

Grundfos.bk Page 16 Wednesday, September 3, 2008 1:36 PM

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

96787913 0908

Repl. 96787913 1207

www.grundfos.com

GB

Loading...

Loading...