Page 1

GRUNDFOS INSTRUCTIONS

SP-G

Installation and operating instructions

Page 2

Declaration of conformity

We, Grundfos, declare under our sole responsibility that the products SP-G, to which this

declaration relates, are in conformity with these Council directives on the approximation of the laws

of the EC member states:

— Machinery Directive (2006/42/EC).

Standard used: EN 809: 2009.

— Low Voltage Directive (2006/95/EC).

Standards used: EN 60335-1: 2002 and EN 60335-2-41: 2003, except sections 25.1 and 25.8.

Bare shaft pump

We, Grundfos, declare under our sole responsibility that the products SP-G, to which this

declaration relates, are in conformity with these Council directives on the approximation of the laws

of the EC member states:

— Machinery Directive (2006/42/EC).

Standard used: EN 809: 2009.

Before the pump is taken into operation, the complete machinery into which the pump is to be

incorporated must be declared in accordance with all relevant regulations.

Déclaration de conformité

Nous, Grundfos, déclarons sous notre seule responsabilité, que les produits SP-G, auxquels se

réfère cette déclaration, sont conformes aux Directives du Conseil concernant le rapprochement

des législations des Etats membres CE relatives aux normes énoncées ci-dessous :

— Directive Machines (2006/42/CE).

Norme utilisée : EN 809 : 2009.

— Directive Basse Tension (2006/95/CE).

Normes utilisées : EN 60335-1 : 2002 et EN 60335-2-41 : 2003, sauf pour paragraphes 25.1

et 25.8.

Pompe à arbre nu

Nous, Grundfos, déclarons sous notre seule responsabilité, que les produits SP-G, auxquels se

réfère cette déclaration, sont conformes aux Directives du Conseil concernant le rapprochement

des législations des Etats membres CE relatives aux normes énoncées ci-dessous :

— Directive Machines (2006/42/CE).

Norme utilisée : EN 809 : 2009.

Avant que la pompe ne soit mise en service, la machine complète, dans laquelle sera incorporée la

pompe, doit être en accord avec toutes les réglementations en vigueur.

Declaración de conformidad

Nosotros, Grundfos, declaramos bajo nuestra entera responsabilidad que los productos SP-G,

a los cuales se refiere esta declaración, están conformes con las Directivas del Consejo en la

aproximación de las leyes de las Estados Miembros del EM:

— Directiva de Maquinaria (2006/42/CE).

Norma aplicada: EN 809: 2009.

— Directiva de Baja Tensión (2006/95/CE) .

Normas aplicadas: EN 60335-1: 2002 y EN 60335-2-41: 2003, excepto las secciones 25.1 y

25.8.

Bomba a eje libre

Nosotros, Grundfos, declaramos bajo nuestra entera responsabilidad que los productos SP-G,

a los cuales se refiere esta declaración, están conformes con las Directivas del Consejo en la

aproximación de las leyes de las Estados Miembros del EM:

— Directiva de Maquinaria (2006/42/CE).

Norma aplicada: EN 809: 2009.

Antes de la puesta en marcha de la bomba, todo el sistema en que la bomba va a incorporarse,

debe estar de acuerdo con todas las normativas en vigor.

Δήλωση συμμόρφωσης

Εμείς, η Grundfos, δηλώνουμε με αποκλειστικά δική μας ευθύνη ότι τα προϊόντα SP-G στα οποία

αναφέρεται η παρούσ α δήλωση, συμμορφώνονται με τις εξής Οδηγίες του Συμβουλίου περί

προσέγγισης των νομοθεσιών των κρατών μελώ ν της ΕΕ:

— Οδηγία για μηχανήματα (2006/42/EC).

Πρότυπο που χρησιμοποιήθηκε: EN 809: 2009.

— Οδηγία χαμ ηλής τάσης (2006/95/EC).

Πρότυπα που χρησιμοποιήθηκαν: EN 60335-1: 2002 και EN 60335-2-41: 2003, εκτός των

παραγράφ ων 25.1 και

Αντλία ελεύθερου άξονα

Εμείς, η Grundfos, δηλώνουμε με αποκλειστικά δική μας ευθύνη ότι τα προϊόντα SP-G στα οποία

αναφέρεται η παρούσ α δήλωση, συμμορφώνονται με τις εξής Οδηγίες του Συμβουλίου περί

προσέγγισης των νομοθεσιών των κρατών μελώ ν της ΕΕ:

— Οδηγία για μηχανήματα (2006/42/EC).

Πρότυπο που χρησιμοποιήθηκε: EN 809: 2009.

Πριν η αντλία τεθεί σε λειτουργία, όλο το μηχάνημα στο οποίο

πρέπει να δηλωθεί σύμφωνα με όλους το υς σχετικούς κανονισμούς.

25.8.

η αντλία πρόκειται να ενσωματωθεί

Försäkran om överensstämmelse

Vi, Grundfos, försäkrar under ansvar att produkterna SP-G, som omfattas av denna försäkran,

är i överensstämmelse med rådets direktiv om inbördes närmande till EU-medlemsstaternas

lagstiftning, avseende:

— Maskindirektivet (2006/42/EG).

Tillämpad standard: EN 809: 2009.

— Lågspänningsdirektivet (2006/95/EG).

Tillämpade standarder: EN 60335-1: 2002 och EN 60335-2-41: 2003, förutom avsnitt 25.1 och

25.8.

Pump utan koppling och motor

Vi, Grundfos, försäkrar under ansvar att produkterna SP-G, som omfattas av denna försäkran,

är i överensstämmelse med rådets direktiv om inbördes närmande till EU-medlemsstaternas

lagstiftning, avseende:

— Maskindirektivet (2006/42/EG).

Tillämpad standard: EN 809: 2009.

Före igångkörning av pumpen måste hela applikationen, som pumpen kommer att vara en del av,

stämma överens med samtliga relevanta föreskrifter.

Overensstemmelseserklæring

Vi, Grundfos, erklærer under ansvar at produkterne SP-G som denne erklæring omhandler,

er i overensstemmelse med disse af Rådets direktiver om indbyrdes tilnærmelse til EFmedlemsstaternes lovgivning:

— Maskindirektivet (2006/42/EF).

Anvendt standard: EN 809: 2009.

— Lavspændingsdirektivet (2006/95/EF).Anvendte standarder: EN 60335-1: 2002 og

EN 60335-2-41: 2003, undtagen afsnit 25.1 og 25.8.

Pumpe uden kobling og motor

Vi, Grundfos, erklærer under ansvar at produkterne SP-G som denne erklæring omhandler,

er i overensstemmelse med disse af Rådets direktiver om indbyrdes tilnærmelse til EFmedlemsstaternes lovgivning:

— Maskindirektivet (2006/42/EF).

Anvendt standard: EN 809: 2009.

Før pumpen tages i brug, skal det komplette maskinanlæg hvori den skal inkorporeres, erklæres

i overensstemmelse med alle relevante bestemmelser.

Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung, dass die Produkte SP-G, auf die sich diese

Erklärung bezieht, mit den folgenden Richtlinien des Rates zur Angleichung der Rechtsvorschriften

der EU-Mitgliedsstaaten übereinstimmen:

— Maschinenrichtlinie (2006/42/EG).

Norm, die verwendet wurde: EN 809: 2009.

— Niederspannungsrichtlinie (2006/95/EG).

Normen, die verwendet wurden: EN 60335-1: 2002 und EN 60335-2-41: 2003, ausgenommen

Abschnitt 25.1 und 25.8.

Pumpe mit freiem Wellenende

Wir, Grundfos, erklären in alleiniger Verantwortung, dass die Produkte SP-G, auf die sich diese

Erklärung bezieht, mit den folgenden Richtlinien des Rates zur Angleichung der Rechtsvorschriften

der EU-Mitgliedsstaaten übereinstimmen

— Maschinenrichtlinie (2006/42/EG).

Norm, die verwendet wurde: EN 809: 2009.

Vor der Inbetriebnahme der Pumpe ist eine Konformitätserklärung für die gesamte Anlage, in die die

Baugruppe "Pumpe mit freiem Wellenende" eingebaut ist, auszustellen.

Dichiarazione di conformità

Grundfos dichiara sotto la sua esclusiva responsabilità che i prodotti SP-G, ai quali si riferisce

questa dichiarazione, sono conformi alle seguenti direttive del Consiglio riguardanti il

riavvicinamento delle legislazioni degli Stati membri CE:

— Direttiva Macchine (2006/42/CE).

Norma applicata: EN 809: 2009.

— Direttiva Bassa Tensione (2006/95/CE).

Norme applicate: EN 60335-1: 2002 e EN 60335-2-41: 2003, eccetto per i paragrafi 25.1 e

25.8.

Pompa ad asse nudo

Grundfos dichiara sotto la sua esclusiva responsabilità che i prodotti SP-G, ai quali si riferisce

questa dichiarazione, sono conformi alle seguenti direttive del Consiglio riguardanti il

riavvicinamento delle legislazioni degli Stati membri CE:

— Direttiva Macchine (2006/42/CE).

Norma applicata: EN 809: 2009.

Si ricorda che se la pompa è inserita in un sistema, prima di avviare la pompa stessa, è necessario

che tutto il sistema sia in accordo alle norme di riferimento.

Declaração de conformidade

A Grundfos declara sob sua única responsabilidade que os produtos SP-G, aos quais diz respeito

esta declaração, estão em conformidade com as seguintes Directivas do Conselho sobre a

aproximação das legislações dos Estados Membros da CE:

— Directiva Máquinas (2006/42/CE).

Norma utilizada: EN 809: 2009.

— Directiva Baixa Tensão (2006/95/CE).

Normas utilizadas: EN 60335-1: 2002 e EN 60335-2-41: 2003, excepto nos pontos 25.1 e

25.8.

Bomba com ponta de veio livre

A Grundfos declara sob sua única responsabilidade que os produtos SP-G, aos quais diz respeito

esta declaração, estão em conformidade com as seguintes Directivas do Conselho sobre a

aproximação das legislações dos Estados Membros da CE:

— Directiva Máquinas (2006/42/CE).

Norma utilizada: EN 809: 2009.

Antes de colocar a bomba em operação, o equipamento no qual a mesma irá ser incorporada deve

ser declarado de acordo com todas as regulamentações relevantes.

Overeenkomstigheidsverklaring

Wij, Grundfos, verklaren geheel onder eigen verantwoordelijkheid dat de producten SP-G waarop

deze verklaring betrekking heeft, in overeenstemming zijn met de Richtlijnen van de Raad in zake

de onderlinge aanpassing van de wetgeving van de EG Lidstaten betreffende:

— Machine Richtlijn (2006/42/EC).

Gebruikte norm: EN 809: 2009.

— Laagspannings Richtlijn (2006/95/EC).

Gebruikte normen: EN 60335-1: 2002 en EN 60335-2-41: 2003, behalve hoofdstukken 25.1

en 25.8.

Pomp met vrije aseinde

Wij, Grundfos, verklaren geheel onder eigen verantwoordelijkheid dat de producten SP-G waarop

deze verklaring betrekking heeft, in overeenstemming zijn met de Richtlijnen van de Raad in zake

de onderlinge aanpassing van de wetgeving van de EG Lidstaten betreffende:

— Machine Richtlijn (2006/42/EC).

Gebruikte norm: EN 809: 2009.

Voordat de pomp in gebruik wordt genomen, moet de gehele installatie waarin de pomp zich bevindt

overeenstemmend zijn met alle relevante wetgevingen.

Vaatimustenmukaisuusvakuutus

Me, Grundfos, vakuutamme omalla vastuullamme, että tuotteet SP-G, joita tämä vakuutus koskee,

ovat EY:n jäsenvaltioiden lainsäädännön yhdenmukaistamiseen tähtäävien Euroopan neuvoston

direktiivien vaatimusten mukaisia seuraavasti:

— Konedirektiivi (2006/42/EY).

Sovellettu standardi: EN 809: 2009.

— Pienjännitedirektiivi (2006/95/EY).

Sovellettavat standardit: EN 60335-1: 2002 ja EN 60335-2-41: 2003, lukuun ottamatta

kappaleita 25.1 ja 25.8.

Erillinen pumppu

Me, Grundfos, vakuutamme omalla vastuullamme, että tuotteet SP-G, joita tämä vakuutus koskee,

ovat EY:n jäsenvaltioiden lainsäädännön yhdenmukaistamiseen tähtäävien Euroopan neuvoston

direktiivien vaatimusten mukaisia seuraavasti:

— Konedirektiivi (2006/42/EY).

Sovellettu standardi: EN 809: 2009.

Ennen pumpun käyttöönottoa koko järjestelmä, jossa pumppua tullaan käyttämään, on osoitettava

kaikkien soveltuvien säädösten mukaiseksi.

Bjerringbro, 1st July 2011

Jan Strandgaard

Technical Director

Grundfos Holding A/S

Poul Due Jensens Vej 7

8850 Bjerringbro, Denmark

Person authorised to compile technical file and

empowered to sign the EC declaration of conformity.

2

Page 3

SP-G

Installation and operating instructions 4

Montage- und Betriebsanleitung 14

Notice d'installation et d'entretien 24

Istruzioni di installazione e funzionamento 34

Instrucciones de instalación y funcionamiento 43

Instruções de instalação e funcionamento 52

Οδηγίες εγκατάστασης και λειτουργίας 62

Installatie- en bedieningsinstructies 72

Monterings- och driftsinstruktion 82

Asennus- ja käyttöohjeet 91

Monterings- og driftsinstruktion 100

3

Page 4

Original installation and operating instructions.

CONTENTS

Page

1. Delivery and storage 4

1.1 Delivery 4

1.2 Storage and handling 4

2. General data 4

2.1 Applications 4

2.2 Pumped liquids 4

2.3 Sound pressure level 5

3. Preparation 5

3.1 Checking of liquid in motor 5

3.2 Positional requirements 5

3.3 Diameter of pump/motor 6

3.4 Liquid temperatures/cooling 6

4. Electrical connection 6

4.1 General 6

4.2 Motor protection 7

4.3 Lightning protection 7

4.4 Cable sizing 7

4.5 Connection of motor 8

5. Pump installation 9

5.1 Assembly of motor and pump 9

5.2 Fitting of submersible drop cable 9

5.3 Riser pipe 9

5.4 Maximum installation depth below water level 9

5.5 Cable fitting 10

5.6 Lowering the pump 10

5.7 Installation depth 10

6. Start-up and operation 10

6.1 Start-up 10

6.2 Operation 10

7. Maintenance and service 11

8. Fault finding chart 12

9. Checking of motor and cable 13

10. Disposal 13

Before beginning installation procedures, these

installation and operating instructions should be

studied carefully. The installation and operation

should also be in accordance with local regulations

and accepted codes of good practice.

These instructions apply to GRUNDFOS submersible motors,

types MS and MMS, and GRUNDFOS submersible pumps, types

SP 55, SP 90, SP 270, SP 300 and SP 360, fitted with submersible motors, types MS or MMS.

If the pump is fitted with a motor of another motor make than

GRUNDFOS MS or MMS, please note that the motor data may

differ from the data stated in these instructions.

1. Delivery and storage

1.1 Delivery

GRUNDFOS submersible pumps are supplied from the factory in

proper packing in which they should remain until they are to be

installed.

During unpacking and prior to installation, care must be taken

when handling the pump to ensure that misalignment does not

occur due to bending.

The loose data plate supplied with the pump should be fixed

close to the installation site.

The pump should not be exposed to unnecessary impact and

shocks.

1.2 Storage and handling

Storage temperature: Pump: –20°C to +60°C.

Motor: –20°C to +70°C.

The motors must be stored in a closed, dry and well ventilated

room.

Note: If MMS motors are stored for more than one year, the shaft

must be turned by hand at least once a month.

If a motor has been stored for more than one year before installation, the rotating parts of the motor must be dismantled and

checked before use.

The pump should not be exposed to direct sunlight.

If the pump has been unpacked, it should be stored horizontally,

adequately supported, or vertically to prevent misalignment of the

pump. Make sure that the pump cannot roll or fall over. During

storage, the pump can be supported as shown in fig. 1.

TM00 1349 2495TM01 4349 0199

Fig. 1

If the pump is not handled in vertical position, it must be lifted in

the motor part and the pump part at the same time, see fig. 2.

Note that the centre of gravity will vary, depending on pump type.

Fig. 2

1.2.1 Frost protection

If the pump has to be stored after use, it must be stored on a

frost-free location, or it must be ensured that the motor liquid is

frost-proof.

2. General data

2.1 Applications

GRUNDFOS submersible pumps, type SP, are designed for a

wide range of water supply and liquid transfer applications, such

as the supply of fresh water to private homes or waterworks,

water supply to nursery gardens or farms, drawdown of groundwater and pressure boosting, and various industrial jobs.

The pump must be installed so that the suction interconnector is

completely submerged in the liquid. The pump can be installed

either horizontally or vertically, see also section 3.2 Positional

requirements.

2.2 Pumped liquids

Clean, thin, non-explosive liquids without solid particles or

fibres.

The maximum sand content of the water must not exceed

50 g/m³. A larger sand content will reduce t he life o f the pum p and

increase the risk of blockin g.

When pumping liquids with a density higher than that of water,

motors with correspondingly higher outputs must be used.

Note: When pumping liquids with a viscosity and aggressiveness

higher than that of drinking water, please contact GRUNDFOS.

The maximum liquid temperature appears from section 3.4 Liquid

temperatures/cooling.

4

Page 5

2.3 Sound pressure level

1 2

3

The sound pressure level has been measured in accordance with

the rules laid down in the EC machinery directive 2006/42/EC.

Sound pressure level of pumps:

Applies to pumps submerged in water, without external regulating

valve.

Pump type L

SP 55 71

SP 90 71

SP 270 77

SP 300 77

SP 360 77

Sound pressure level of motors:

The sound pressure level of GRUNDFOS MS and MMS motors is

lower than 70 dB(A).

Other motor makes: See installation and operating instructions

for these motors.

pA

[dB(A)]

3. Preparation

Before starting work on the pump, make sure that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

3.1 Checking of liquid in motor

3.1.1 General

The submersible motors are factory-filled with a special non-poisonous liquid, which is frost-proof down to –20°C.

Note: The level of the liquid in the motor must be checked and

the motor must be refilled, if required.

Note: If there is a risk of frost, special GRUNDFOS liquid must be

used to refill the motor. Otherwise clean water may be used for

refilling (however, never use distilled water).

3.1.2 Refilling - GRUNDFOS submersible motors MS 6000

• If the motor is delivered from stock, the liquid level must be

checked before the motor is fitted to the pump, see fig. 3.

• On pumps delivered directly fro m GRUNDFOS, th e liqu id le vel

has already been checked.

• In the case of service, the liquid level must be checked, see

fig. 3.

To refill the motor, proceed as follows:

The filling hole for motor liquid is placed at the top of the motor.

1. Position the submersible pump as shown in fig. 3. The filling

screw must be at the highest point of the motor.

2. Remove the screw from the filling hole.

3. Inject liquid into the motor with the filling syringe, fig. 3, until

the liquid runs back out of the filling hole.

4. Replace the screw in the filling hole and tighten securely

before changing the position of the pump.

Torque: 3.0 Nm.

The submersible pump is now ready for installation.

TM01 2391 1698TM01 4986 1299

Fig. 3

3.1.3 Refilling - GRUNDFOS submersible motors MMS 6000,

MMS 8000, MMS 10000 and MMS 12000

To refill the motor, proceed as follows:

1. Position the submersible pump as shown in fig. 4.

2. Remove the screw (A) from the filling hole and fit the nipple

with pipe and funnel supplied with the motor.

3. Remove the air vent screw (B) to allow possible air in the

motor to escape.

4. Hold the funnel higher than the vent hole and pou r clean wa ter

into the motor until the liquid starts dripping out of the motor.

5. Stop pouring water into the motor. Refit the screw (B) to the

vent hole and remove pipe and funnel. Replace the screw (A)

in the filling hole and tighten securely.

The submersible pump is now ready for installation.

Fig. 4

3.2 Positional requirements

If the pump is to be installed in a position where it is

accessible, the coupling must be suitably isolated

from human touch. The p ump can for inst ance b e

built into a flow sleeve.

Depending on motor type, the pump can be installed either vertically or horizontally. A complete list of motor types suitable for

horizontal installation is shown in section 3.2.1.

If the pump is installed horizontally, the discharge port should

never fall below the horizontal plane, see fig. 5.

5

Page 6

Fig. 5

Allowed

Not allowed

If the pump is installed horizontally, e.g. in a tank, it is recommended to fit it in a flow sleeve.

3.2.1 Motors suitable for horizontal installation

Installation

Motor

GRUNDFOS

MS and MMS

GRUNDFOS

MS

GRUNDFOS

MMS

TM00 1355 5092

Flow past

the motor

Free

convection

0 m/s

0.15 m/s

0.15 m/s

Vertical Horizontal

20°C

(~68°F)

recommended

40°C

(~105°F)

25°C

(~77°F)

Note: By free convection is meant that the borehole diameter is

at least 2" larger than the diameter of the submersible motor.

Other motor makes: See motor specifications.

4. Electrical connection

Flow sleeve

40°C

(~105°F)

25°C

(~77°F)

Motor type

Power output

50 Hz

Power output

60 Hz

[kW] [kW]

MS 6000 All sizes All sizes

MMS 6000 3.7 to 18.5 3.7 to 18.5

MMS 8000 22.0 to 55.0 22.0 to 55.0

MMS 10000 75.0 to 110.0 75.0 to 110.0

MMS 12000 147.0 to 190.0 –

Note: During operation, the suction interconnector of the pump

must always be completely submerged in the liquid.

In special conditions, it may be necessary to submerge the pump

even deeper, depending on the operating conditions of the actual

pump and the NPSH value.

Note: If the pump is used for pumping hot liquids (40° to 60°C),

care should be taken to ensure that persons cannot come into

contact with the pump and the installation, e.g. by installing a

guard.

3.3 Diameter of pump/motor

The maximum diameter of the pump/motor is as shown in the

table on page 109.

It is recommended to check the borehole with an inside calliper to

ensure unobstructed passage.

3.4 Liquid temperatures/cooling

The maximum liquid temperature and the minimum liquid velocity

over the motor appear from the following table.

It is recommended to install the motor above the well screen in

order to achieve proper motor cooling.

Note: In cases where the stated liquid velocity cannot be

achieved, a flow sleeve must be installed.

If there is a risk of sediment build-up, such as sand, around the

motor, a flow sleeve should be used in order to ensure proper

cooling of the motor.

3.4.1 Maximum liquid temperature

Out of consideration for the rubber parts in pump and motor, the

liquid temperature must not exceed 40°C (~105°F). See also the

following table.

The pump can operate at liquid temperatures between 40°C and

60°C (~105°F and 140°F) provided that all rubber parts are

replaced every third year.

Before starting work on the pump, make sure that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

4.1 General

The electrical connection should be carried out by an authorize d

electrician in accordance with local regulations.

The supply voltage, rated maximum current and cos appear

from the loose data plate that must be fitted close to the installa-

tion site.

The required voltage quality for GRUNDFOS MS submersible

motors, measured at the motor terminals, is +6%/–10% of the

nominal voltage during continuous operation (including variation

in the supply voltage and losses in cables).

The required voltage quality for GRUNDFOS MMS submersible

motors, measured at the motor terminals, is +5%/–5% of the

nominal voltage during continuous operation (including variation

in the supply voltage and losses in cables).

Furthermore, it must be checked that there is volt age symmetry in

the electricity supply lines, i.e. same difference of voltage

between the individual phases, see also section 9. Checking of

motor and cable, point 2

.

The pump must be earthed.

The pump must be connected to an external mains

switch.

In order that the GRUNDFOS MS motors with a built-in and operational temperature transmitter can meet the EC EMC Directive

(2004/108/EC), a 0.47 F capacitor (in accordance with IEC 384-

14) must always be connected over the two phases to which the

temperature transmitter is connected, see fig. 6.

6

Page 7

0,47 µF

1

2

3

4

1. Black

2. Blue

3. Yellow/green

4. Brown

0.47 F

82 50 45

PE

L3

L2

L1

Fig. 6

The motors are wound for direct-on-line starting or star-delta

starting and the starting current is between 4 and 6 times the full

load current of the motor.

The run-up time of the pump is only about 0.1 second. Direct-online starting is therefore normally approved by the electricity supply authorities.

4.1.1 Frequency converter operation

GRUNDFOS motors:

Three-phase GRUNDFOS motors can be connected to a frequency converter.

Note: If a GRUNDFOS MS motor with temperature transmitter is

connected to a frequency converter, a fuse incorporated in the

transmitter will melt and the transmitter will be inactive. The transmitter cannot be reactivated. This means that the motor will operate like a motor without a temperature transmitter.

If a temperature transmitter is required, a Pt100 sensor for fitting

to the submersible motor can be ordered from GRUNDFOS.

During frequency converter operation, it is not advisable to run

the motor at a frequency higher than the nominal frequency (50 or

60 Hz). In connection with pump operation, it is importan t never to

reduce the frequency (and consequently the speed) to such a

level that the necessary flow of cooling liquid past the motor is no

longer ensured.

To avoid damage to the pump part, it must be ensured that the

motor stops when the pump flow falls below 0.1 x nominal flow.

Depending on the frequency converter type, it may expose the

motor to detrimental voltage peaks.

The above disturbance can be abated by installing an RC filter

between the frequency converter and the motor.

Possible increased acoustic noise from the motor can be abated

by installing an LC filter which will also eliminate voltage peaks

from the frequency converter.

For further details, please contact your frequency converter supplier or GRUNDFOS.

4.2 Motor protection

GRUNDFOS MS motors are available with or without a built-in

temperature transmitter.

Motors with a built-in and operational temperature transmitter

must be protected by means of:

• a motor starter with thermal relay or

• an MTP 75 and a motor starter with thermal relay or

• a CU 3 and contactor(s).

Motors without or with a non-operational temperature transmitter must be protected by means of:

• a motor starter with thermal relay or

• a CU 3 and contactor(s).

GRUNDFOS MMS motors have no built-in temperature transmit-

ter. A Pt100 sensor is available as an accessory.

Motors with a Pt100 sensor must be protected by means of:

• a motor starter with thermal relay or

• a CU 3 and contactor(s).

Motors without a Pt100 sensor must be protected by means of:

• a motor starter with thermal relay or

• a CU 3 and contactor(s).

4.2.1 Required motor starter settings

For cold motors, the tripping time for the motor starter must be

less than 10 seconds at 5 times the rated maximum current of the

motor.

Note: If this requirement is not met, the motor warranty will be

invalidated.

In order to ensure the optimum protection of the submersible

motor, the starter overload unit should be set in accordance with

TM00 7100 0696

the following guidelines:

1. Set the starter overload to the rated maximum current of the

motor.

2. Start the pump and let it run for half a n hou r at n ormal pe rformance.

3. Slowly grade down the scale indicator until the motor trip point

is reached.

4. Increase the overload setting by 5%.

The highest permissible setting is the rated maximum current of

the motor.

For motors wound for star-delta starting, the starter overload unit

should be set as above, but the maximum setting should be as

follows:

Starter overload setting = Rated maximum current x 0.58.

The highest permissible start-up time for star-delta starting or

autotransformer starting is 2 seconds.

4.3 Lightning protection

The installation can be fitted with a special overvolt age prote ctive

device to protect the motor from voltage surges in the electricity

supply lines when lightning strikes somewhere in the area, see

fig. 7.

Fig. 7

The overvoltage protective device will not, however, protect the

motor against a direct stroke of lightning.

The overvoltage protective device should be connected to the

installation as close as possible to the motor and always in

accordance with local regulations.

Ask GRUNDFOS for lightning protective devices.

4.4 Cable sizing

Make sure that the submersible drop cable can withstand permanent submersion in the actual liquid and at the actual temperature.

GRUNDFOS can supply submersible drop cables for a wide

range of installations.

TM001 4700 0799

7

Page 8

The cross-section (q) of the cable should meet the following

L2 L3

M

L1 PE

UVWPE

3

requirements:

1. The submersible drop cable should be dimensioned to the

rated maximum current (I) of the motor.

2. The cross-section should be sufficient to make a voltage drop

over the cable acceptable.

Use the largest of the cross sections found under points 1. and 2.

Re 1: The following table specifies the current value of GRUND-

FOS submersible drop cables (i.e. the maximum current tolerated

by the drop cable) at an ambient temperature of maximum 30°C.

Please contact GRUNDFOS if the ambient temperature lies

above 30°C.

When sizing the submersible drop cable, make sure that the rated

maximum current does not exceed the current value (I

For star-delta starting, however, size the cables so that 0.58 x the

rated maximum current of the motor does not exceed the current

value (I

) of the cables.

s

q [mm²] I

[A] q [mm²] Is [A]

s

1.5 18 50 153

2.5 25 70 196

4 34 95 238

6 43 120 276

10 60 150 319

16 80 185 364

25 101 240 430

35 126 300 497

If GRUNDFOS submersible drop cables are not used, the crosssection should be selected on the basis of the current values of

the actual cables.

Re 2:

Note: The cross-section of the submersible drop cable must be

large enough to meet the voltage quality requirements specified

in section 4.1 General.

Determine the voltage drop for the cross-section of the submersible drop cable by means of the diagrams on pages 110 and 111,

where

I = Rated maximum current of the motor.

For star-delta starting

I = rated maximum current of the motor x 0.58.

Lx = Length of cable converted to a voltage drop of 1% of the

nominal voltage.

Lx =

length of drop cable

permissible voltage drop in %

q = Cross-section of submersible drop cable.

Draw a straight line between the actual I-value and the Lx-value.

Where the line intersects the q-axis, select the cross-section that

lies right above the intersection.

The diagrams are made on the basis of the formula:

L =

I x 1.73 x 100 x (cosx+ sinx Xl)

U x U

q

where

L = Length of submersible drop cable [m]

U = Nominal voltage [V]

U = Voltage drop [%]

I = Rated maximum current of the motor [A]

cos =0.9

= Specific resistance: 0.02 [mm²/m]

q = Cross-section of submersible drop cable [mm²]

sin = 0.436

-3

Xl = Inductive resistance: 0.078 x 10

[/m]

4.5 Connection of motor

Three-phase submersible motors must be protected, see section

4.2 Motor protection.

For electrical connection by means of the CU 3, see the separate

installation and operating instructions for this unit.

When a conventional motor starter is being used, the electrical

connection should be carried out as described below.

4.5.1 Checking of direction of rotation

Note: The pump must not be started until the suction intercon-

nector has been completely submerged in the liquid.

When the pump has been connected to the electricity supply,

determine the correct direction of rotation as follows:

).

s

1. Start the pump and check the quantity of water and head

developed.

2. Stop the pump and interchange two of the phase connections.

In the case of motors wound for star-delta starting, exchange

U1 by V1 and U2 by V2.

3. Start the pump and check the quantity of water and head

developed.

4. Stop the pump.

5. Compare the results taken under points 1. and 3. The connection which gives the larger quantity of water and the higher

head is the correct connection.

4.5.2 GRUNDFOS motors, direct-on-line starting

The connection of GRUNDFOS submersible motors wound for

direct-on-line starting appears from the following table and fig. 8.

Cable/connection

Mains

GRUNDFOS 6", 8", 10" and 12" motors

L1 U

L2 V

L3 W

PE PE

Check the direction of rotation as described in section

4.5.1 Checking of direction of rotation.

TM00 1364 5092

Fig. 8

4.5.3 GRUNDFOS motors, star-delta starting

The connection of GRUNDFOS submersible motors wound for

star-delta starting appears from the following table and fig. 9.

Connection GRUNDFOS 6" motors

U1 Brown

V1 Blue

W1 Black

W2 Brown

U2 Blue

V2 Bla ck

PE Yellow/green

8

Page 9

Check the direction of rotation as described in section

L2 L3

M

L1 PE

W2 U2 V2

PE

U1 W1V1

3

L2 L3

M

L1 PE

W2 U2 V2

PE

U1 W1V1

3

U2

V2

W1W2

U1

V1

4.5.1 Checking of direction of rotation.

5. Pump installation

Before starting any work on the pump/motor, make

sure that the electricity supply has been switched off

and that it cannot be accidentally switched on.

5.1 Assembly of motor and pump

The bolts and nuts securing the straps to the pump must be tightened diagonally to the torques stated in the following table:

Fig. 9

If star-delta starting is not required, but direct-on-line starting is,

the submersible motors should be connected as shown in fig. 10.

Fig. 10

4.5.4 Connection in the case of unidentified cable marking/

connection

If it is unknown where the individual leads are to be connected to

the mains in order to ensure the correct direction of rotation, proceed as follows:

Motors wound for direct-on-line starting:

Connect the pump to the mains as is expected to be right.

Then check the direction of rotation as described in section

4.5.1 Checking of direction of rotation.

Motors wound for star-delta starting:

The windings of the motor are determined by means of an ohmmeter, and the lead sets for the individual windings are named

accordingly: U1-U2, V1-V2 and W1-W2, see fig. 11.

Pump type

Number of

impellers

Straps

Bolt/nut

SP 55 / SP 90 10 to 17 M20 180

The bolts holding the chambers together on pumps type s SP 270,

TM00 1365 5092TM00 1366 5092TM00 1367 5092

SP 300 and SP 360 must be tightened to 60 Nm.

Make sure that the coupling between the pump and motor

engages properly.

When assembling the motor and the pump, the nuts must be

tightened diagonally to the torques stated in the following table:

Pump/motor

Torque

Staybolt diameter

M8 18

M10 35

M12 60

M14 95

M16 145

M18 200

Note: Make sure that the pump chambers are aligned when

assembly has been completed.

5.2 Fitting of submersible drop cable

Before fitting the submersible drop cable to the motor, make sure

that the cable socket is clean and dry.

To facilitate the fitting of the cable, lubricate the rubber parts of

the cable plug with non-conducting silicone paste.

Tighten the screws holding the cable to the torques stated:

MS 6000: 4.0 Nm.

MMS 6000: 10 Nm.

MMS 12000: 15 Nm.

5.3 Riser pipe

If a tool, e.g. a chain pipe wrench, is used when the riser pipe is

fitted to the pump, the pump must only be gripped by the pump

discharge chamber.

The threaded joints on the riser pipe must all be well cut and fit

together to ensure that they do not work loose when subjected to

torque reaction caused by the starting and stopping of the pump.

The thread on the first section of the riser pipe which is to be

screwed into the pump should not be longer than the threads in

the pump.

Where flanged pipes are used, the flanges should be slotted to

take the submersible drop cable and a water indicator hose, if fitted.

Torque

[Nm]

[Nm]

Fig. 11

If star-delta starting is required, the leads should be connected as

shown in fig. 9.

If direct-on-line starting is required, the leads should be connected as shown in fig. 10.

Then check the direction of rotation as described in section

4.5.1 Checking of direction of rotation.

5.4 Maximum installation depth below water level

GRUNDFOS MS 6000: 600 m.

GRUNDFOS MMS 6000: 200 m.

GRUNDFOS MMS 8000: 200 m.

GRUNDFOS MMS 10000: 200 m.

GRUNDFOS MMS 12000: 200 m.

9

Page 10

5.5 Cable fitting

L2

L3

L1

L5

L4

Cable clips must be fitted every 3 metres to fix the submersible

drop cable and the straining wire, if fitted, to the riser pipe of the

pump.

GRUNDFOS supplies cable clip sets on request. The set consists

of a 1.5 mm thick rubber band and 16 buttons.

Cable fitting: Cut off the rubber band so that the piece with no

slit becomes as long as possible.

Insert a button in the first slit.

Position the wire alongside the submersible drop cable, fig. 12.

Fig. 12

Wind the band once around the wire and the cable.

Then wind it tightly at least twice around the pipe, wire and the

cable.

Push the slit over the button and then cut off the band.

Where large cable cross-sections are used, it will be necessary to

wind the band several times.

When flanged pipes are used, the cable clips should be fitted

above and below each joint.

5.6 Lowering the pump

It is recommended to check the borehole by means of an inside

calliper before lowering the pump to ensure unobstructed passage.

Lower the pump carefully into the borehole, taking care not to

damage the motor cable and the submersible drop cable.

Note: Do not lower or lift the pump by means of the motor cable.

5.7 Installation depth

The dynamic water level should always be above the suction

interconnector of the pump, see section 3.2 Positional require-

ments and fig. 13.

Minimum inlet pressure is indicated in the NPSH curve for the

pump.

The minimum safety margin should be 1 metre head.

It is recommended to install the pump so that the motor part is

above the well screen in order to ensure optimum cooling, see

section 3.4 Liquid temperatures/cooling.

When the pump has been installed to the required depth, the

installation should be finished by means of a borehole seal.

6. Start-up and operation

6.1 Start-up

When the pump has been connected correctly and it is submerged in the liquid to be pumped, it should be started with the

discharge valve closed off to approx. 1/3 of its maximum volume

of water.

Check the direction of rotation as described in section

4.5.1 Checking of direction of rotation.

If there are impurities in the water, the valve should be opened

gradually as the water becomes clearer. The pump should not be

stopped until the water is completely clean, as otherwise the

pump parts and the non-return valve may choke up.

As the valve is being opened, the drawdown of the water level

should be checked to ensure that the pump always remains submerged.

The dynamic water level should always be above the suction

interconnector of the pump, see section 3.2 Positional require-

ments and fig. 13.

Fig. 13

L1: Minimum installation depth below dynamic water level.

Minimum 1 metre is recommended.

TM00 1369 5092

L2: Depth to dynamic water level.

L3: Depth to static water level.

L4: Drawdown. This is the difference between the dynamic

and the static water levels.

L5: Installation depth.

If the pump can pump more than yielded by the well, it is recom-

mended to fit the GRUNDFOS control unit, type CU 3, or some

other type of dry-running protection.

If no water level electrodes or level switches are installed, the

water level may be drawn down to the suction interconnector of

the pump and the pump will then draw in air.

Long time operation with water containing air may damage the

pump and cause insufficient cooling of the motor.

6.2 Operation

6.2.1 Minimum flow rate

To ensure the necessary cooling of the motor, the pump should

never be set so low that the cooling requirements specified in

section 3.4 Liquid temperatures/cooling cannot be met.

6.2.2 Frequency of starts and stops

Motor type Number of starts

MS 6000

MMS 6000

MMS 8000

MMS 10000

MMS 12000

Minimum 1 per year is recommended.

Maximum 30 per hour.

Maximum 300 per day.

Minimum 1 per year is recommended.

Maximum 15 per hour.

Maximum 360 per day.

Minimum 1 per year is recommended.

Maximum 10 per hour.

Maximum 240 per day.

Minimum 1 per year is recommended.

Maximum 8 per hour.

Maximum 190 per day.

Minimum 1 per year is recommended.

Maximum 5 per hour.

Maximum 120 per day.

TM00 1041 3695

10

Page 11

7. Maintenance and service

The pumps are maintenance-free.

All pumps are easy to service.

Service kits and service tools are available from GRUNDFOS.

The GRUNDFOS Service Manual is available on request.

The pumps can be serviced at a GRUNDFOS service centre.

If a pump has been used for a liquid which is injurio us

to health or toxic, the pump will be classified as contaminated.

If GRUNDFOS is requested to service the pump, GRUNDFOS

must be contacted with details about the pumped liquid, etc.

before the pump is returned for service. Otherwise GRUNDFOS

can refuse to accept the pump for service.

Possible costs of returning the pump are paid by the customer.

11

Page 12

8. Fault finding chart

Fault Cause Remedy

1. The pump does not run. a) The fuses are blown. Replace the blown fuses. If the new ones blow too,

b) The ELCB or the voltage-operated ELCB

has tripped out.

c) No electricity supply. Contact the electricity supply authorities.

d) The motor starter overload has tripped out. Reset the motor starter overload (automatically or

e) Motor starter/contactor is defective. Replace the motor starter/contactor.

f) Starter device is defective. Repair/replace the starter device.

g) The control circuit has been interrupted or is

defective.

h) The dry-running protection has cut off the

the electricity supply to the pump, due to low

water level.

i) The pump/submersible drop cable is defec-

tive.

2. The pump runs but

gives no water.

3. The pump runs at

reduced capacity.

4. Frequent starts and

stops.

a) The discharge valve is closed. Open the valve.

b) No water or too low water level in borehole. See item 3 a).

c) The non-return valve is stuck in its shut posi-

tion.

d) The inlet strainer is choked up. Pull out the pump and clean the strainer.

e) The pump is defective. Repair/replace the pump.

a) The drawdown is larger than anticipated. Increase the installation depth of the pump, throttle

b) Wrong direction of rotation. See section 4.5.1 Checking of direction of rotation.

c) The valves in the discharge pipe are partly

closed/blocked.

d) The discharge pipe is partly choked by

impurities (ochre).

e) The non-return valve of the pump is partly

blocked.

f) The pump and the riser pipe are partly

choked by impurities (ochre).

g) The pump is defective. Repair/replace the pump.

h) Leakage in the pipework. Check and repair the pipework.

i) The riser pipe is defective. Replace the riser pipe.

a) The differential of the pressure switch

between the start and stop pressures is too

small.

b) The water level electrodes or level switches

in the reservoir have not been installed

correctly.

c) The non-return valve is leaking or stuck

half-open.

d) The volume of air in the pressure/diaphragm

tank is too small.

e) The pressure/diaphragm tank is too small. Increase the capacity of the pressure/diaphragm tank

f) The diaphragm of the diaphragm tank is

defective.

the electric installation and the submersible drop cable

should be checked.

Cut in the circuit breaker.

possibly manually). If it trips out again, check the

voltage. Is the voltage OK, see items e) - h).

Check the electric installation.

Check the water level. If it is OK, check the water level

electrodes/level switch.

Repair/replace the pump/cable.

Pull out the pump and clean or replace the valve.

the pump or replace it by a smaller model to obtain a

smaller capacity.

Check and clean/replace the valves, if necessary.

Clean/replace the discharge pipe.

Pull out the pump and check/replace the valve.

Pull out the pump. Check and clean or replace the

pump, if necessary. Clean the pipes.

Increase the differential. However, the stop pressure

must not exceed the operating pressure of the pressure tank, and the start pressure should be high

enough to ensure sufficient water supply.

Adjust the intervals of the electrodes/level switches to

ensure suitable time between the cutting-in and

cutting-out of the pump. See Installation and Operating

Instructions for the automatic devices used. If the

intervals between stop/start cannot be changed via the

automatics, the pump capacity may be reduced by

throttling the discharge valve.

Pull out the pump and clean/replace the non-return

valve.

Adjust the volume of air in the pressure/diaphragm

tank in accordance with its Installation and Operating

Instructions.

by replacing or supplementing with another tank.

Check the diaphragm tank.

12

Page 13

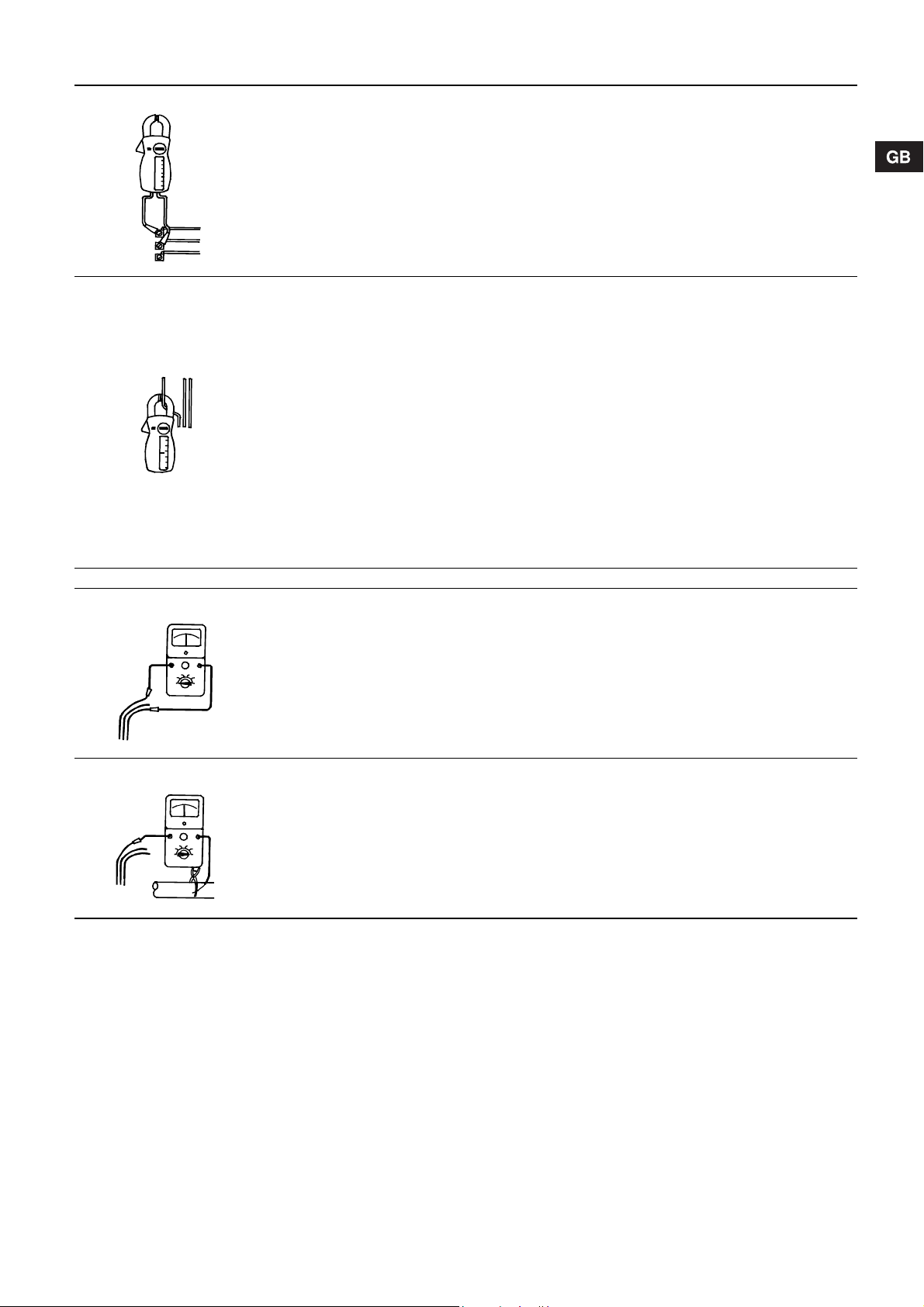

9. Checking of motor and cable

TM00 1371 5092

TM00 1372 5092

TM00 1373 5092

TM00 1374 5092

Subject to alterations.

1. Supply voltage Measure the voltage between the

phases by means of a voltmeter.

Connect the voltmeter to the terminals

in the motor starter.

The voltage should, when the motor is loaded, be within the

range specified in section 4.1 General.

The motor may burn if there are larger variations in voltage.

Large variations in voltage indicate poor electricity supply, and

the pump should be stopped until the defect has been remedied.

2. Current consumption Measure the amps of each phase while

the pump is operating at a constant

discharge head (if possible, at the

capacity where the motor is most heavily loaded).

For maximum operating current, see

nameplate.

The difference between the current in the phase with the

highest consumption and the current in the phase with the

lowest consumption should not exceed 5%.

If so, or if the current exceeds the full load current, there are

the following possible faults:

• The contacts of the motor starter burnt. Replace the contacts.

• Poor connection in leads, possibly in the cable joint. See

item 3.

• Too high or too low supply voltage. See item 1.

• The motor windings are short-circuited or partly disjointed.

See item 3.

• Damaged pump is causing the motor to be overloaded. Pull

out the pump for overhaul.

• The resistance value of the motor windings deviates too

much. Move the phases in phase order to a more uniform

load. If this does not help, see item 3.

Items 3 and 4: Measurement is not necessary when the supply voltage and the current consumption are normal.

3. Winding resistance Disconnect th e submersible drop cable

at the motor starter.

Measure the winding resistance

between the leads of the drop cable.

The difference between the highest and the lowest value

should not exceed 5%.

If the deviation is higher, pull out the pump.

Measure motor, motor cable and drop cable separately, and

repair/replace defective parts.

4. Insulation resistance Disconnect the submersible drop cable

at the motor starter.

Measure the insulation resistance from

each phase to earth (frame).

Make sure that the earth connection is

made carefully.

10. Disposal

Disposal of this product or parts of it must be carried out according to the following guidelines:

1. Use the local public or private waste collection service.

2. In case such waste collection service does not exist or cannot

handle the materials used in the product, please deliver the

product or any hazardous materials from it to your nearest

GRUNDFOS company or service workshop.

If the insulation resistance is less than 0.5 M, the pump

should be pulled out for motor or cable repair.

Local regulations may specify other values for the insulation

resistance.

13

Page 14

Pump

Pumpe

Pompe

Pompa

Bomba

Bomba

Αντλία

Pomp

Pump

Pumppu

Pumpe

Maximum Diameter of Pump/Motor [mm]

Max. Pumpen-/Motordurchmesser [mm]

Diamètre maximum de la pompe/du moteur [mm]

Massimo diametro della pompa/motore [mm]

Máximo diámetro de bomba/motor [mm]

Diâmetro máximo da bomba/motor [mm]

Μέγιστη Διάμετρος Αντλίας /Κινητήρα [mm]

Maximale diameter van de pomp/motor [mm]

Max. pump-/motordiameter [mm]

Pumpun/moottorin suurin halkaisija [mm]

Maks. pumpe-/motordiameter [mm]

Motor - Motor - Moteur - Motore - Motor - Motor - Κινητήρας

Type

Typ

Type

Tipo

Tipo

Tipo

Τύπ ος

Type

Typ

Tyyppi

Type

SP 55 DN 100 242 242 242 242

SP 90 DN 100 242 242 242 242

SP 270 DN 175 290 290 290 290 290 290

SP 300 DN 175 290 290 290 290 290 290

SP 360 DN 175 290 290 290 290 290 290

Flange

Flansch

Bride

Flangia

Brida

Flange

Φλάντζα

Flens

Fläns

Laippa

Flange

Direct-On-Line Starting

Direktanlauf

Démarrage direct

Avviamento diretto

Arranque directo

Arranque directo

Απευθείας Εκκίνηση

Directe aanloop

Direktstart

Suorakäynnistys

Direkte start

6" 8" 10" 12" 6" 8" 10" 12"

Motor - Motor - Moottori - Motor

Star-Delta Starting

Stern-Dreieck-Anlauf

Démarrage étoile-triangle

Avviamento Y/

Arranque estrella-triángulo

Arranque estrela-triângulo

Εκκίνηση Αστέρα-Τριγώνου

Ster/driehoek-aanloop

Y/-start

Y/-käynnistys

Y/-start

109

Page 15

Example:

U = 3 x 400 V

I=40 A

L = 140 m

U=2%

Lx

L

U

------- -

140

2

------------

70 m q25mm

2

== = =

TM00 1346 5092

I = 40 A

U = 2%

U = 3 x 400 V

L = 140 m

Example:

U = 3 x 380 V

I=10 A

L = 120 m

U=2%

Lx

L

U

------- -

120

2

------------

60 m q6mm

2

== = =

TM00 1345 5092

I = 10 A

U = 2%

U = 3 x 380 V

L = 120 m

110

Page 16

Example:

U = 3 x 220 V

I=5 A

L = 105 m

U=3%

Lx

L

U

------- -

105

3

------------

35 m q25,mm

2

== = =

TM00 1348 5092

I = 5 A

U = 3%

U = 3 x 220 V

L = 105 m

Example:

U = 3 x 415 V

I=100 A

L = 150 m

U=3%

Lx

L

U

------- -

150

3

------------

50 m q50mm

2

== = =

TM00 1347 5092

I = 100 A

U = 3%

U = 3 x 415 V

L = 150 m

111

Page 17

112

Page 18

113

Page 19

114

Page 20

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belorussia

Представительство ГРУНДФОС в

Минске

220123, Минск,

ул. В. Хоружей, 22, оф. 1105

Тел.: +(37517) 233 97 65,

Факс: +(37517) 233 97 69

E-mail: grundfos_minsk@mail.ru

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Trg Heroja 16,

BiH-71000 Sarajevo

Phone: +387 33 713 290

Telefax: +387 33 659 079

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

50/F Maxdo Center No. 8 XingYi Rd.

Hongqiao development Zone

Shanghai 200336

PRC

Phone: +86-021-612 252 22

Telefax: +86-021-612 253 33

Croatia

GRUNDFOS CROATIA d.o.o.

Cebini 37, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.grundfos.hr

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-3066 5650

Telefax: +358-3066 56550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Bo x 7 1

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg., 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

México

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Velu wezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

România

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундфос

Россия, 109544 Москва, ул. Школьная

39

Тел. (+7) 495 737 30 00, 564 88 00

Факс (+7) 495 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47 496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS d.o.o.

Šlandrova 8b, SI-1231 Ljubljana-Črnuče

Phone: +386 1 568 0610

Telefax: +386 1 568 0619

E-mail: slovenia@grundfos.si

South Africa

Corner Mountjoy and George Allen Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölndal

Tel.: +46(0)771-32 23 00

Telefax: +46(0)31-331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС УКРАЇНА

01010 Київ, Вул. Московська 8б,

Тел.:(+38 044) 390 40 50

Фах.: (+38 044) 390 40 59

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Usbekistan

Представительство ГРУНДФОС в

Ташкенте

700000 Ташк ент ул.Усм ана Носира 1-й

тупик 5

Телефон: (3712) 55-68-15

Факс: (3712) 53-36-35

Revised 29.09.2010

Page 21

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

96432078 0711

Repl. 96432078 0506

ECM: 1078259

www.grundfos.com

Loading...

Loading...