Page 1

GRUNDFOS INSTRUCTIONS

SMART Digital - DDA

Installation and operating instr uct ions

Page 2

Declaration of conformity

Declaration of conformity

GB Declaration of Conf or mity

We, Grundfos Alldos, declare u nder o ur s ole r es ponsi bilit y t hat the p ro ducts

DDA, DDC and DDE, to w hic h this d ecl arat ion r elate s, ar e in co nf ormit y w ith

these Council directives on the approximation of the laws of the EC member

states:

– Machinery Dir e cti v e ( 2 00 6/ 42 /E C) .

Standards used: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100- 2+A1: 2009.

– Low Voltage Directive (2 006/95/EC) *.

Standard used: EN 60204-1+A1: 2009.

– EMC Directive (20 04/1 0 8/EC).

Standards used: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

* Only for products with operating voltage > 50 VAC or >75 VDC.

Pfinztal, 1 November 2010

Ulrich Stemick

Technical Director

Grundfos Water Treatment GmbH

Reetzstr. 85, D-76327 Pfinztal, Germany

Person aut hori s ed t o compile techn i ca l f i le an d

empowered to sign the EC declaration of conformity.

2

Page 3

English (GB) Installation and operating instructions

Original installation and operating instructions.

CONTENTS

Page

1. Safety instructions

1.1 Identification of saf ety in struc tio ns in

these instructions

1.2 Qualification and training of personnel

1.3 Safety instructions for the operator/

user

1.4 Safety of the system in the event of a

failure in the dos ing pum p

1.5 Dosing chemicals

2. General

2.1 Applications

2.2 Improper operating methods

2.3 Warranty

2.4 Nameplate

2.5 Type key

2.6 Device overvi ew

3. Technical data / dimensions

3.1 Technical data

3.2 Dimensions

4. Assembly a nd in stalla t ion

4.1 Pump assembly

4.1.1 Requirements

4.1.2 Align and install mounting plate

4.1.3 Engage pump in mounting plate

4.1.4 Adjusting control cube position

4.2 Hydraulic co nn ection

4.3 Electrical connection

5. Commissioning

5.1 Setting the menu language

5.2 Deaerating the pump

5.3 Calibrating the pump

6. Operation

6.1 Control ele men ts

6.2 Display and symb ols

6.2.1 Navigation

6.2.2 Operating stat es

6.2.3 Sleep mode (energy-saving mode)

6.2.4 Overview of display symbols

6.3 Main menus

6.3.1 Operation

6.3.2 Info

6.3.3 Alarm

6.3.4 Setup

6.4 Operation m od es

6.4.1 Manual

6.4.2 Pulse

6.4.3 Analog 0/4-20 mA

6.4.4 Batch (pulse-based)

6.4.5 Dosing timer, cycle

6.4.6 Dosing timer, week

6.5 Analog outp ut

6.6 SlowMode

7 FlowControl

6.

6.8 Pressure moni tor ing

6.8.1 Pressure settin g rang es

4

6.8.2 Calibration of pressure sensor

6.9 Flow measurement

4

6.10 AutoFlowAd ap t

4

6.11 Auto deaeratio n

6.12 Key lock

4

6.13 Display Setu p

6.13.1 Units

4

6.13.2 Additional display

5

6.14 Time/date

5

6.15 Bus communic at ion

5

6.16 Inputs/outputs

5

6.16.1 Relay outputs

6

6.16.2 External stop

6

6.16.3 Empt y and low- lev el sign als

7

6.17 Basic settings

8

7. Service

9

7.1 Service system

9

7.2 Perform servic e

11

7.2.1 Dosing head over view

12

7.2.2 Dismantling t he d i ap hr ag m a nd va l ve s

12

7.2.3 Reassembling the diaphragm and

12

12

12

12

13

14

16

16

17

17

19

19

19

19

19

19

20

21

21

21

21

21

22

22

22

23

24

25

25

valves

7.3 Resetting the servic e system

7.4 Repairs

8. Faults

8.1 List of faults

8.1.1 Faults with error me ss age

8.1.2 General faults

9. Disposal

Warning

Prior to instal latio n, read thes e

installation an d ope ra t in g i ns tru c tio ns.

Installation and opera tion mus t comp ly

with local regulations and accepted

codes of good practice.

26

26

27

28

28

28

29

29

29

30

30

30

30

31

31

31

31

32

32

32

33

33

33

34

34

34

34

34

35

36

36

38

38

English (GB)

3

Page 4

1. Safety instructio ns

Caution

Note

Caution

Caution

English (GB)

These installation and operating instructions contain

general instructions that must be observed during

installation, operation and main tenance of the pump.

It must therefor e be rea d by the installation engin ee r

and the relevant qualified operator prior to

installati on an d star t-up , and mus t be av ailab le at the

installation location at all tim es.

1.1 Identifica tion o f saf ety i nstru ctio ns in

these instruction s

The safety instructions are identified by the following

symbols:

Warning

If these safety instructions are not

observed, it m ay r e sult in personal

injury!

If these safety instructions are not

observed, it may resu lt in malf un ctio n

or damage to the equipment!

Notes or instru ctions that make the job

easier and ensure safe operation.

1.2 Qualification and training of personnel

The person ne l responsible f or th e installation,

operation a nd se rvice must b e ap pr op r iately

qualified for these tasks . Ar eas of resp onsib ility,

levels of au th or ity a nd th e su pe rvision of the

personnel must be precisely defined by the operator.

If necessary, the personnel must b e tr ain e d

appropriately.

Risks of not observing the safety instructions

Non-observance of the safety instructions may have

dangerous consequences for the personnel, the

environment an d the pu mp and ma y resu lt in th e loss

of any claims for da mage s.

It may lead to th e following hazards:

• Personal inju ry fr om e xposure to el ect ric al ,

mechanical and chemical influences.

• Damage to the environment and personal injury

from leakage of h ar mf ul su bstances.

1.3 Safety instructions for the

operator/user

The safety instr uc ti o ns de scr ib ed in th es e

instructions, existing national regulations on health

protection, environmental protection and for accident

prevention and an y inter nal working , op erat ing an d

safety regulation s of the op era tor mu st be obse rved .

Information attac he d to th e pu m p m u st be o bse r ved .

Leakages of dangerous substances must be

disposed of in a way that is not harmful to the

personnel or th e en vir on m en t.

Damage caused by electrical energy must be

prevented, see the regulations of the local electricity

supply company.

Before any work to the pump, the pump

must be in the ’Stop’ operational state

or be disconnected from the mains.

The system must be pressureless!

Only orginal accessories and original spare parts

should be use d. Us i ng o the r par ts ca n re sult in

exemption from liability f or a ny resu lti ng

consequences.

1.4 Safety of the system in the event of a

failure in the dosing pump

The dosing p ump was designed a cco rd i n g t o th e

latest technolo gies an d is car efull y manu factu red

and tested.

If it fails regard les s o f th is, th e s af et y o f t he ov era ll

system must be ensured. Use the relevant

monitoring and control functions for this.

Make sure t ha t an y c he m ic al s th at a r e

released fr o m th e p u mp or any

damaged lines do not cause damage to

system parts and buildings.

The installation of leak monitoring

solutions and drip trays is

recommended.

4

Page 5

1.5 Dosing chemica ls

Caution

Caution

Caution

Warning

Before swit ch i ng t h e su ppl y voltage

back on, the dosing lines must be

connected in su ch a wa y that an y

chemicals in the dosi ng he ad ca nnot

spray out and put people at risk.

The dosing medium is pressurised and

can be harmful to health and the

environment.

Warning

When working with chemicals, the

accident prevention regulations

applicable a t t h e in st al la ti on s it e

should be applied (e. g. wearing

protective clothing).

Observe the chemical manufacturer's

safety data sheets and safety

instructions when handling chemicals!

Warning

If the diaphragm leaks or is broken,

dosing liquid will escape from the

discharge opening on the dosing head

(see fig. 3).

Take suitable precautions to prevent

harm to health and damage to property

from escapi ng do sin g li qui d!

Check daily whether liquid is escaping

from the disch arg e ope nin g!

Changing the di aph rag m, se e sect ion

7. S e r vice.

A deaeration hose, which is routed into

a container, e. g. a drip tray, must be

connected to the deaeration valve.

The dosing medium must be in liquid

aggregate stat e!

Observe the free zing and b oiling points

of the dosing medium!

The resistance of the parts that come

into contact with the dosing medium,

such as the dosing head, valve ball,

gaskets and lines, depends on the

medium, media temperature and

operating pressure.

Ensure that parts in contact with the

dosing med ia are resist an t to the

dosing medium under operating

conditions, see data booklet!

Should you have any questions

regarding the material resistance and

suitability o f t he p u mp fo r s p ec if ic

dosing media, please contact

Grundfos.

2. General

The DDA dosing pump is a self-priming

diaphragm pu m p. It co ns i sts o f a h ou si n g

with stepper motor and electronics, a

dosing head with diaphragm and valves and the

control cube.

Excellent dosi ng fe at ur es o f t he p um p:

• Optimal intake even with degassing media, as

the pump always wor ks a t full su ct ion s troke

volume.

• Continuous dosing, as the medium is sucked up

with a short suction str oke, reg ardle ss of the

current dos ing flow, and dosed with t he lo ng est

possible dosing stroke.

2.1 Application s

The pump is suita ble for liquid, no n- ab ra si v e, no n flammable and non-combustible media strictly in

accordance with the inst ructions in these installation

and operating instructions.

Areas of applic at io n

• Drinking water treatment

• Wastewater treatm ent

• Swimming pool water treatment

• Boiler water treatment

• CIP (Clean -In-Place)

• Cooling wate r tr ea tm e nt

• Process wate r tr ea tm en t

• Wash plants

• Chemical industry

• Ultrafiltration processes and reverse osmosis

•Irrigation

• Paper and pulp industry

• Food and beverage industries

2.2 Improper operating methods

The operational safety of the pump is only

guaranteed if it is used in accordance with section

2.1 A pp l ications.

Warning

Other applications or the operation of

pumps in ambient and operating

conditions, which are not approved,

are considered improper and are not

permitted. Grundfos cannot be held

liable for an y da mag e r es u lt in g fr o m

incorrect use.

Warning

The pump is NOT approved for

operation in potentially explosive

areas!

Warning

A sunscreen is required for outdoor

installation !

English (GB)

5

Page 6

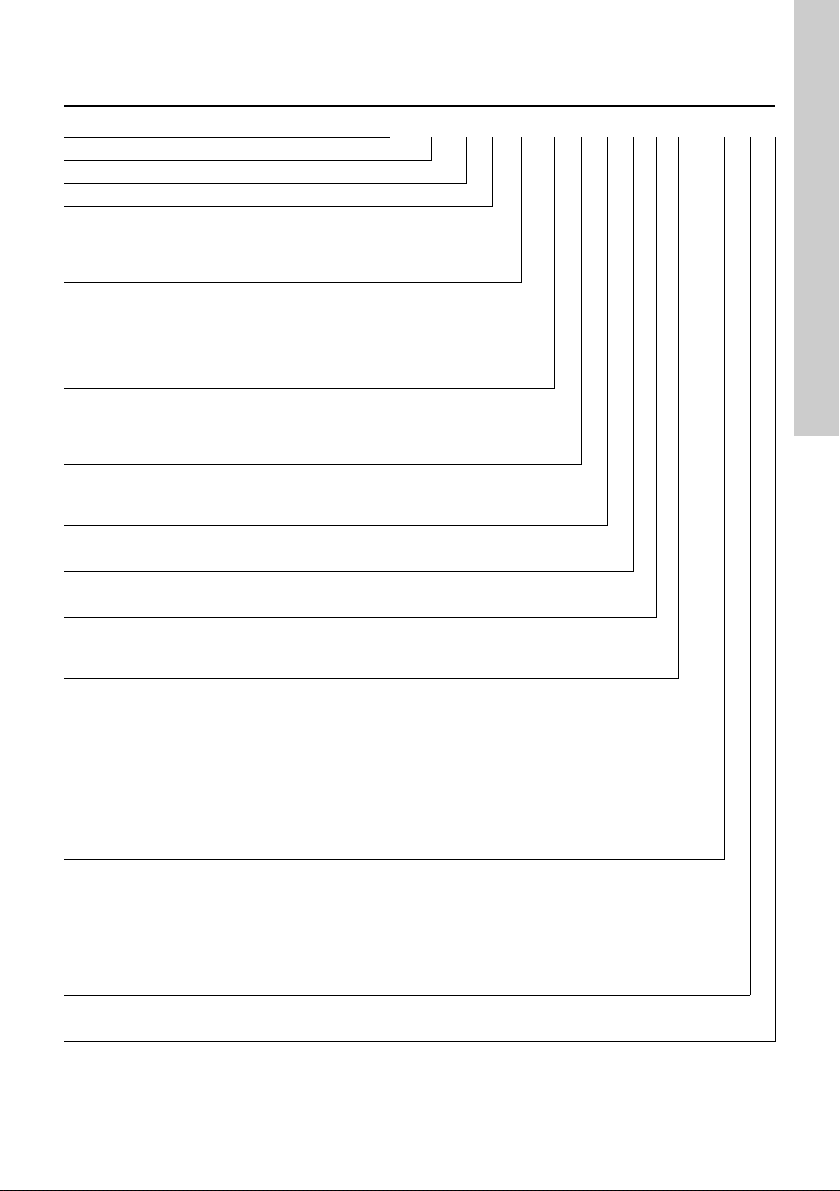

2.3 Warranty

psi

gphl/h

P

Type designation

Voltage

Frequency

Max. dosing flow

Power consumption

Enclosure class

Mark of approval, CE mark, etc.

Model

Current consumption

Country of production

Max. operating pressure

English (GB)

A guarantee claim in acco rd ance wit h our gene ral t erms o f s ale a nd deli ver y is only va lid if the fo llow ing

requiremen ts are ful fille d:

• The pump is use d in accordance wit h t he information w ith i n th is m a nu al .

• The pump is not dismantled or incorrectly handled.

• The maintenance is carried out by authorised and qualified personnel.

• Original spare parts are used for repairs during maintenance.

2.4 Nameplate

Fig. 1 Nameplate

TM04 1116 1110

6

Page 7

2.5 Type key

The type key i s us ed t o identify the p r eci se pump and is n ot us ed f or co nf i gu r ati on p ur po se s.

Code Example DDA 7.5- 16 AR- PP/ V/ C- F- 3 1 U2U2 F G

Pump type

Max. flow [l/h]

Max. pressure [bar]

Control variant

AR

Standard

FC

AR with FlowControl

FCM

FC with integrated flow measurement

Dosing head material

PP

Polypropylene

PVC

PVC (polyvinyl chloride) (PVC dosing heads onl y up to 1 0 bar)

PV

PVDF (polyvinylidene fluoride)

SS

Stainless steel DIN 1.4401

PVC-P3

PVC with Plus

Gasket material

E

EPDM

V

FKM

T

PTFE

Valve ball material

C

Ceramic

SS

Stainless steel DIN 1.4401

Control cube position

F

Front-mounted (can be changed to the right o r left)

Voltage

3

1 x 100-240 V, 50/60 Hz

Valve type

1

Standard

2

Spring-loaded (HV version)

Suction/discharge side connection

U2U2

Hose, 4/6 mm, 6/9 mm, 6/12 mm, 9/12 mm

U7U7

Hose 1/8" x 1/4"; 0.17" x 1/4"; 1/4" x 3/8"; 3/8" x 1 /2"

AA

Threaded Rp 1/4", female (stainless steel)

VV

Threaded 1/4" NPT, female (stainless steel)

XX

No connection

Installation set*

I001

Hose, 4/6 mm (up to 7.5 l/h, 16 bar)

I002

Hose, 9/12 mm (up to 60 l/h, 13 bar)

I003

Hose 0.17" x 1/4" (up to 7.5 l/h, 16 bar)

I004

Hose, 3/8" x 1/2" (up to 60 l/h, 10 bar)

Power plug

F

EU (Schuko)

B

USA, Canada

G

UK

I

Australia, New Zealand, Taiwan

E

Switzerland

J

Japan

L

Argentina

Design

G

Grundfos Alldos

*) including: 2 pump connections, foot valve, injection unit, 6 m PE discharge hose, 2 m PVC suction hose,

2 m PVC deaeration hose (4/6 mm)

3

English (GB)

7

Page 8

2.6 Device overview

Start/stop key

(Sect. 6.1)

Mains connection

Control cube

Graphic LC display

(Sect. 6.2.2)

Click wheel (Sect. 6.1)

100 % key (Sect.6.1)

Signal inputs, outputs

(Sect. 4.3)

Mounting plate

100%100%

FlowControl connection

FC/FCM

Deaeration valve

Dosing head

Valve, suction side

Connection, deaeration

hose

Valve, discharge side

Control cube assembly

screws

Drain opening in cas e of

diaphragm breakage

English (GB)

Fig. 2 Front view of the pump

TM04 1129 0110

Fig. 3 Rear view of th e pu m p

8

TM04 1133 0110

Page 9

3. Technical data / dimensions

3.1 Technical data

Data

Mechanica l

data

DDA pump type

7.5 - 16 12-10 17-7 30-4

Turndown ration (setting range) [1:X] 3000 1000 1000 1000

Max. dosing flow

Max. dosing flow with SlowMode 50 %

Max. dosing flow with SlowMode 25 %

Min. dosing flow

Max. operatin g pr es sur e

Max. stroke freq ue ncy

1)

[l/h] 7.5 12.0 17.0 30.0

[gph] 2.0 3.1 4.5 8.0

[l/h] 3.75 6.00 8.50 15 .0 0

[gph] 1.00 1.55 2.25 4.00

[l/h] 1.88 3.00 4.25 7.50

[gph] 0.50 0.78 1.13 2.00

[l/h] 0.0025 0.0120 0.0170 0.0 30 0

[gph] 0.0007 0.0031 0.0045 0.0080

[bar] 16 10 7 4

[psi] 230 150 100 60

[Strokes/

min]

190 155 205 180

Stroke volume [ml] 0.74 1.45 1.55 3.10

Accuracy of repeatability [%] ±1

Max. suction lift during operation

Max. suction lift when pr imi ng wit h wet

2)

valves

Min. pressure difference between suction

and discharge side

2)

[m] 6

[m] 2 3 3 2

[bar] 1 (FC and FCM: 2)

Max. pressure, suctio n side [bar] 2

Max. viscosity in S lowMode 25 % with

spring-loaded valves

Max. viscosity in S lowMode 50 % with

spring-loaded valves

Max. viscosity without Slow Mode with

spring-loaded valves

Max. viscosity without spring-loaded

3)

valves

Min. diameter of hose/pipe on suction/

discharge side

Min. diameter of hose/pipe on suction

side for highly viscous media (HV)

Min. diameter of hose/pipe on discharge

side for highly viscous media (HV)

3)

3)

3)

2) 4)

4)

4)

[mPa s]

(= cP)

[mPa s]

(= cP)

[mPa s]

(= cP)

[mPa s]

(= cP)

2500 2500 2000 1500

1800 1300 130 0 600

600 500 500 200

50 300 300 150

[mm] 4 6 6 9

[mm] 9

[mm] 9

Max. media te mp er ature [°C] 45

Min. media temp erat ur e [°C] -10

Max. ambient tem p er at ur e [°C] 45

Min. ambient tem per atur e [°C] 0

Max. storage te mp er at ur e [°C] 70

Min. storage temperature [°C] -20

English (GB)

9

Page 10

English (GB)

DDA pump type

Data

7.5 - 16 12-10 17-7 30-4

Voltage [V] 100-240 V, 50-60 Hz

Length of ma ins ca ble [m] 1.5

Max. current co nsu m pti on ( 10 0 V ) [A] 8

Electrical

data

Max. current co nsu m pti on ( 23 0 V ) [A] 25

Max. power co nsu m ption P

1

[W] 18 / 24

Enclosure class IP 65, Nema 4X

Electrical safety cla ss II

Max. load for level input 12 V, 5 mA

Max. load for pu ls e in pu t 12 V, 5 mA

Max. load for external stop 12 V, 5 mA

Signal input

Min. pulse length [ms] 5

Max. pulse frequency [Hz] 100

Impedance at 0/ 4-20 mA analo g input [Ω]15

Max. resistance in level circuit [Ω]1000

Max. resistance in pulse circuit [Ω]1000

Max. ohmic load on r elay o ut pu t [A] 0.5

Signal

output

Max. voltage on relay output [V] 30 VDC / 30 VAC

Impedance at 0/ 4-20 m A a nalog output [Ω]500

Weight (PVC, PP, PVDF) [kg] 2.4 2.4 2.6

Weight/ size

Weight (stainless steel) [kg] 3.2 3.2 4.0

Diaphragm diameter [mm] 44 50 74

Sound

pressure

level

Max. sound pr es su re le vel [dB(A)] 60

Approvals CE, CSA-US, NSF61, G HOS T, C-Tick

5)

1)

The maximum stroke frequency varies depending on calibration

2)

Data is based on measu rements wi th water

3)

Maximum suction lift: 1 m, dosing flow reduced (approx. 30 %)

4)

Length of suction line: 1.5 m / length of discharge line: 10 m (at max. viscosity)

5)

With E-Box.

10

Page 11

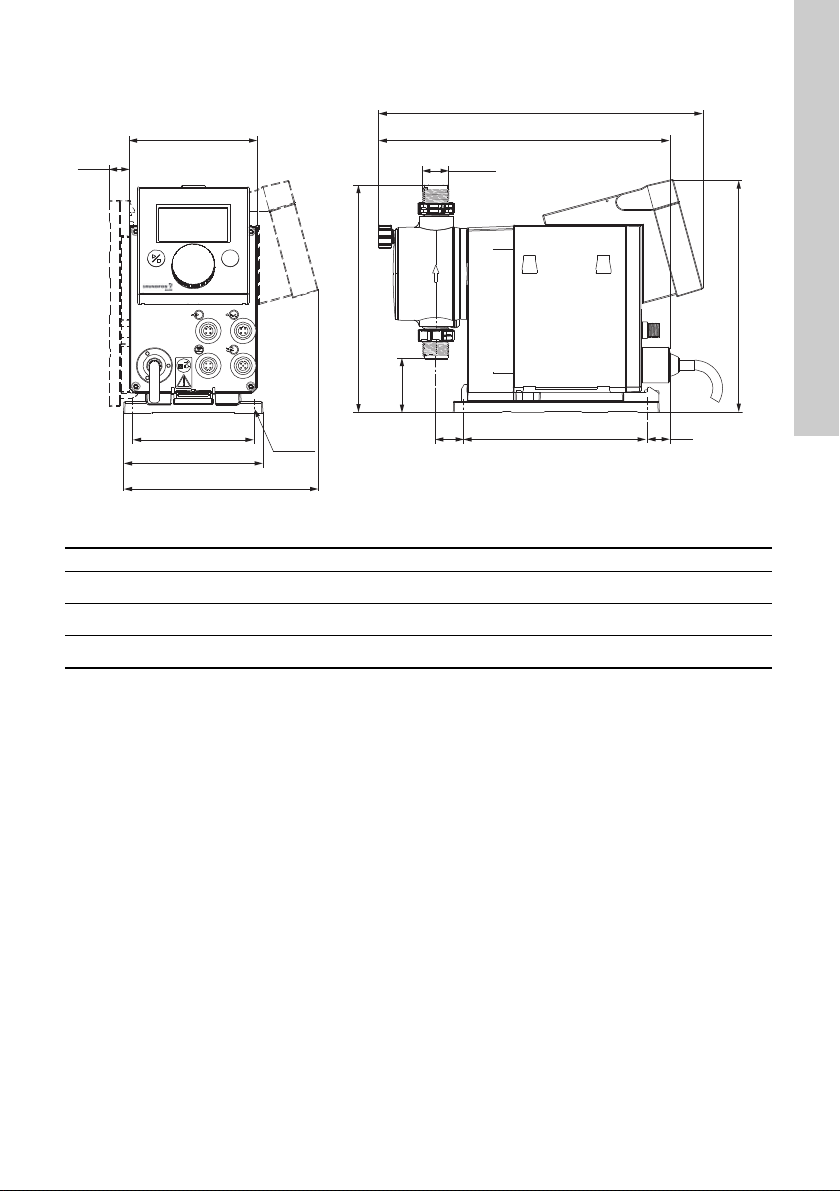

3.2 Dimensions

161

17

D

B

C

A1

G 5/8"

A

200.8

100%

110

4 x Ø6

105

120

17.5

168

Fig. 4 Dimensional draw ing

Pump type A [mm] A1 [mm] B [mm] C [mm] D [mm]

DDA 7.5 - 16 280 251 196 46.5 24

DDA 12-10/17-7 280 251 200.5 39.5 24

DDA 30-4 295 267 204.5 35.5 38.5

English (GB)

TM04 1103 0110

11

Page 12

4. Assembly and installation

Caution

Caution

IP65, Nema 4X

English (GB)

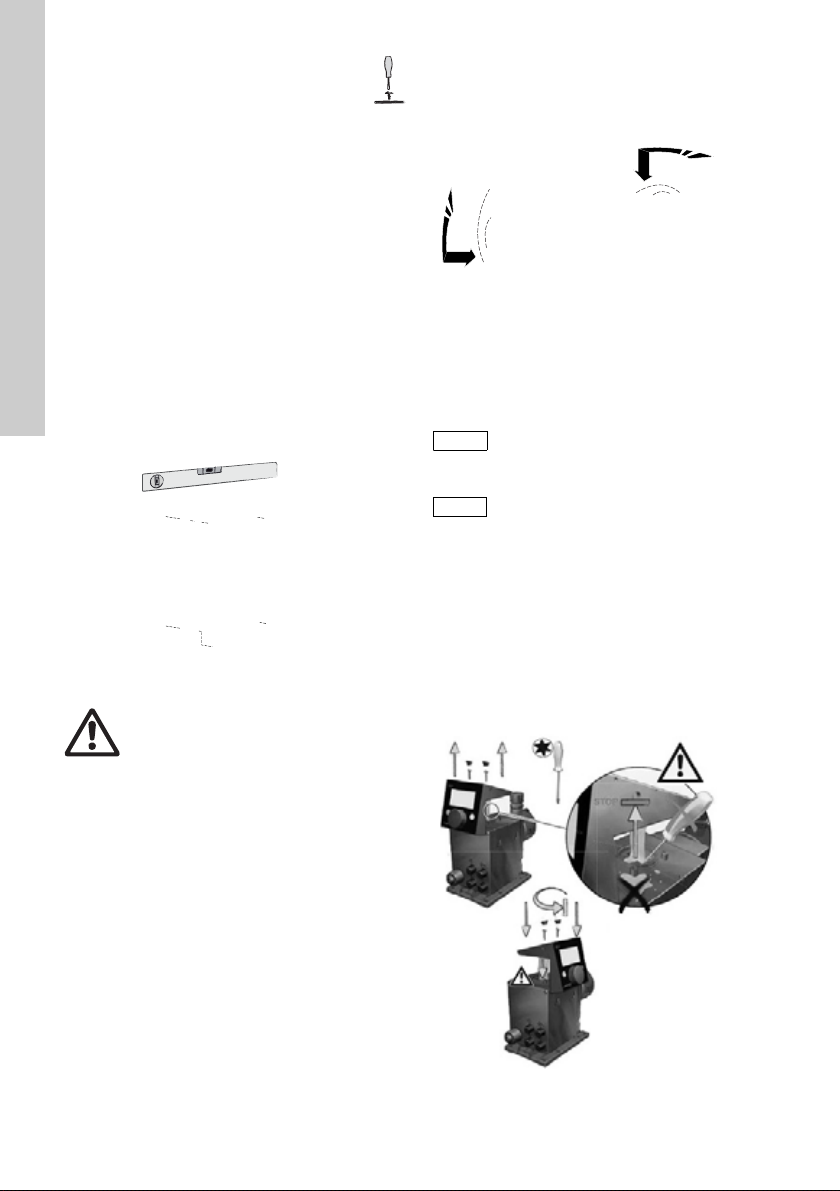

4.1 Pump assembly

The pump is deli vered with a moun tin g plat e.

The mountin g pl a te c an b e m ounted vertic al ly

e. g. on a wall or hor i zo ntally e. g. on a tank. It take s

just a few quick ste ps to f i rmly se cur e th e pu m p t o

the mounting plate by means of a slot mechanism.

The pump can easily be released from the mounting

plate for maintenance.

4.1.1 Requirements

• The mounting surface must be stable and must

not vibrate.

• Dosing must flow upwards vertically.

4.1.2 Align and install mounting plate

• Vertical installation: Mounting plate slot

mechanism must be above.

• Horizontal installatio n : Mounting plate slot

mechanism mu st be o pp os ite th e do si n g he ad .

• The mounting plate can be used as a drill

template, please see fig. 4 for drill hole distances.

Fig. 5 Locate mounting plate

Warning

Make sure that you do no t damage any

cables and lines during installation!

1. Indicate drill holes.

2. Dr ill h ol es.

3. Secure mounting plate u sin g fo ur screws,

diameter 5 mm, to the wa ll, o n th e b ra ck et or th e

tank.

4.1.3 Engage pump in mounting plate

1. Attach the pump to the mounting plate support

clamps and slide under slight pressure until it

engages.

Fig. 6 Engaging the pump

4.1.4 Adjusting control cube position

The control cub e is f i tt ed to t he fr o nt of th e pu m p on

delivery. It can be turned by 90 ° so that the user can

select to oper at e th e pump from th e r ig ht or left side.

The enclos ur e c lass (IP65 / Nema 4X)

and shock protection are only

guaranteed if the control cube is

installed correctly!

Pump must be disconnected from the

power supply!

1. Carefully remove both pr o t ec tive caps on the

control cube using a thin screwdriver.

2. Loosen screws.

3. Carefully lift off control cube on ly s o fa r f ro m th e

pump housing that no tensile stress is produced

on the flat band cable.

4. Turn control cube by 90 ° and re-attach.

TM04 1162 0110

– Make sure th e O- r ing is se cur e .

5. Tighten screws slightly and attach protective

caps.

TM04 1159 0110

12

TM04 1182 0110

Fig. 7 Adjusting contro l c ube

Page 13

4.2 Hydraulic connection

Caution

Caution

Caution

Note

Caution

Union nut

Tensioning ri ng

Cone part

Hose

Deaeration

hose

Tank

Multifunction

valve

Suction line

with empty

signal

Warning

Risk of chemical b urns!

Wear protective clothing (gloves and

goggles) when working on the dosing

head, connections or lines!

The dosing head may contain water

from the factory check!

When dosing media which should not

come into co n ta ct w ith wa ter, another

medium must be dosed beforehand!

Faultless function can only be

guaranteed in conjunction with lines

supplied by Grundfos!

The lines used must comply with the

pressure lim it s as per sectio n

3.1 Tech nica l dat a!

Important information on installation

• Observe suction lift and line diameter, see

section 3.1 Technical data.

• Shorten hos es a t r i gh t an gle s .

• Ensure that th er e ar e no lo o ps or kinks in the

hoses.

• Keep suction line as short as possible.

• R oute suctio n line up towards the suctio n valve.

• Installing a filter in the su cti on li n e pr ot ec ts th e

entire installatio n again st di rt and re duce s the

risk of leakage.

• Only control varia n t FC/ FC M: For disch ar g e

quantities < 1 l/h we recommend the use of an

additional spring-loaded valve (approx. 3 bar) on

the discharge side for the saf e gene rati on of the

necessary differential pressure.

Hose connection procedure

1. Push union nut and te nsioning ring a cr oss h ose .

2. Push cone part fully into ho se , s ee fig . 8.

3. Attach cone part with ho se to co rr e spo nding

pump valve.

4. Tighten union nut manual l y.

– do not use tools!

5. Tighten up union nuts after 2-5 operating hours if

using PTFE gaske ts!

6. Attach deaeration hose to the corresponding

connection ( see fig. 3) and ru n i nt o a c on tai ne r

or a collec ting tray.

Fig. 8 Hydraulic connection

Pressure differential between suction

and discharge side must be at least

1 bar / 14.5 psi!

Tighten up the dosing head screws

once before commissioning and after

2-5 operating hours at 3 Nm.

Installation ex ample

The pump offers various installation options. In the

picture below, the pump is installed in conjunction

with a suction line, l evel s witch and multifunction

valve on a Grundfos tank.

English (GB)

TM04 1155 0110

TM04 1183 0110

Fig. 9 Installation example

13

Page 14

4.3 Electrical connection

2

1

3

4

2

1

3

4

5

2

3

4

1

2

1

3

►

2

1

GND

GND

BUS

BUS

GND

12

34

12

34

12

5

34

34

12

English (GB)

Warning

The enclosure class (IP65 / Nema 4X) is only guaranteed if plugs or protective caps are

correctly ins ta lle d!

Warning

The pump c an s ta r t au t oma tically when t h e ma in s v ol ta g e is switched on !

Do not manipulate mains plug or cable!

The rated voltage of the pump, see section 2.4 Nameplate , mu st confor m to local conditions .

Signal connections

Fig. 10 Wiring diagram of the electrical connections

14

TM04 1121 0110

Page 15

Analog, external stop and pulse input

Sensor

Function

Analog GND/ (-) mA (+) mA mA signal

External stop GND X Pulse

Pulse GND X Pulse

Level signals: empty and low-level signal

Function

Low-level signal X GND Pu lse

Empty signal X GND Pulse

GENIbus, analog output

Function

GENIbus +30 V

Analog output (+) mA GND/ (-) mA mA signal

Relay outputs

Function

Relay 1 X X Pulse

Relay 2 X X Pulse

1/brown 2/white 3/blue 4/black

1/brown 2/white 3/blue 4/black

1/brown 2/white 3/blue 4/black

GENI bus

TXD

1/brown 2/white 3/blue 4/black

Pins

Pins

Pins

GENI bus

RXD

Pins

5/yellow/

green

GND Bus

Plug type

English (GB)

Plug type

Plug type

Plug type

FlowControl signal connection

Fig. 11 FlowControl connec ti o n

TM04 1158 0110

15

Page 16

5. Commissioning

Operation

English >

Manual >

Actual flow

Off

❑

Language

Operation mode

Analog output

SlowMode

FlowControl active

Operation

Setup

Setup

Setup

Setup

Setup

l/h

Manual

7.50

l/h

Manual

English >

Manual >

Actual flow

Off

❑

Language

Operation mode

Analog output

SlowMode

FlowControl active

❑

❑

❑

❑

English

Deutsch

Francais

Espanol

Italiano

❑

❑

❑

❑

English

Deutsch

Francais

Espanol

Italiano

Confirm

settings?

7.50

English (GB)

5.1 Setting the menu language

For description of control elements, see Section 6.

1. Turn click wheel to highlight the cog symbol.

2. Press the click wheel to op en the ’Setup’ menu.

3. Turn the click wheel to highlight the ’Language’

menu.

4. Press the click wheel to op en the ’Langu ag e’

menu.

5. Turn the click wheel to highlight the desired

language.

6. Press the click wheel to se lec t the hi ghlig hted

language.

7. Press the click wheel a gain to c onfir m the

’Confirm settings’ prompt and apply the setting.

16

TM04 1184 1110

Fig. 12 Set menu language

Page 17

5.2 Deaerating the p ump

Note

Warning

The deaeration hose must be

connected corr ectl y a nd i ns ert ed int o a

suitable tank !

1. Open deaeration screw by approximately half a

turn.

2. Press and hold down the 100 % key (deaeration

key) until liqui d f lows continuously wit ho ut any

bubbles from th e de ae ra tio n ho se.

3. Close deaeration screw.

Press the 10 0 % ke y an d

simultaneously t u rn t h e clickwheel

clockwise to i nc rease the dur at io n of

the process to up to 3 00 s ec onds . Af ter

setting the seconds, do not press the

key any longer.

5.3 Calibrating the pump

The pump is calibrated in the factory for media with a

viscosity similar to water at maximum pump

backpressure (se e sec tio n 3. 1 Technical data) .

If the pump is op er at ed with a backp r ess ur e th at

deviates or if dosing a medium whose viscosity

deviates, the pump must be calibrated.

For pumps with FCM c ontr ol varia nt , it is not

necessary to ca libr a te th e pu mp if t he re is de via tin g

or fluctuating backpressure as long as the

’AutoFlowA da pt’ function has been enabled

(see section 6.10 AutoFlowAd ap t).

Requirements

• The hydraulic s a nd e l ec tr ics of th e pump are

connected (se e se ctio n 4. Assembly and

installation).

• The pump is integrated into the dosing process

under operating conditions.

• The dosing h ea d an d suc ti o n ho se ar e filled with

dosing medium.

• The pump has been dea erat ed.

English (GB)

17

Page 18

Calibration process - example for DDA 7.5 - 16

V2 = 170 ml

V

d

= V1-V2= 130 ml

V

1

= 300 ml

Calibration

Calibration

Strokes

Calibrat. volu m e

200

STOP

START

0.0 ml

Strokes

Calibrat. volume

200

125 ml

Calibration

Calibrat. volu me

STOP

START

ml

Strokes

200

130

Actual dosed volum e V

d

English (GB)

1. Fill a measuring beaker with dosing med ium .

Recommended filling volumes:

DDA type 7.5 - 16 1 2-10 17-7 30-4

Medium V

2. Read off and note down the fill vo lu me V

(e.g.300ml).

0.3 l 0.5 l 1.0 l 1.5 l

1

1

3. Place the suction hose in the measuri ng beak er.

4. Start the calibration process in the ’Setup >

5. The pump executes 200 dosing strok es and

6. Remove the suction hose from the measuring

7. From V

Calibration’ menu.

displays the fa ctory ca lib ra tio n val ue

(e.g.125ml).

beaker and check the remaining volume V

(e.g.170ml).

and V2 , calculate th e ac tu al dosed

1

volume V

(e. g. 300 ml - 170 ml = 130 ml).

= V1-V

d

2

2

8. Set and apply V

– The pump is calibrated.

18

in the calibration menu.

d

TM04 1154 1110

Page 19

6. Operation

100%

7.49 l/h

Manual

7.50

l/h

Operation

Start/stop key

Graphical LC

display

Click wheel

100 % key

6.1 Control elements

The pump control p an el inc lud es a di spl ay

and the foll o wi n g con tr ol elements.

Fig. 13 Control panel

Keys

Key Function

Start/stop

key

100 % key

Click wheel

The click wheel is u sed t o navig at e thr oug h t he

menus, select setting s and con firm them.

Turning the clickwheel clockwise moves the cursor

clockwise in increments in the d isp l ay. Turning the

clickwheel anti-clockw ise move s the curso r anticlockwise.

Starting and stopping the pump.

The pump doses at maximum flow

regardless of the operation mode.

6.2 Display and symb ols

6.2.1 Naviga tion

In the ’Info’, ’Alarm’ and ’Setup’ main menus, the

options and submenus are displayed in the rows

below. Use the ’Back’ s ym bo l to r et ur n to th e higher

menu level. The scroll bar at the right edge of the

display indicates that there are further menu items

which are not shown.

The active symbol (current cursor position) flashes.

Press the click wheel to co nfirm you r s elect ion a nd

open the next menu level. The active main menu is

displayed as text, the other main menus are

displayed as sy mb ols. The positi on o f t he cu rsor is

highlighted in bla ck in the sub- menu s.

When you posit i on t he cu rs or o n a value and press

the click wheel, a value is selected. Turning the

clickwheel clockwise increases the value, turning the

clickwheel anti-clockwise reduces the value. When

you now press the click wheel, the cursor will be

released again.

6.2.2 Operati ng states

TM04 1104 1120

The operating state of the pump is indicated by a

symbol and display c olour.

Display Fault Operating state

White -

Green -

Yellow Warning

Red Alarm

6.2.3 Sleep mo de (e ner gy-sa vi ng mod e)

If in the ’Operation’ main menu the pump is not

operated for 30 seconds, the header disappears.

After 2 minutes, the display switc hes to the

’Operation’ main menu and the display brightness is

reduced. This state will be cancelled when the pump

is operated or a fault oc cu rs.

Stop Standby

Stop Standby Running

Stop Standby

English (GB)

Running

19

Page 20

6.2.4 Overview of display symbols

100%

Operation

Operation

Operating state (Sect. 6.2) and

dosing flow

7.48

l/h

Manual

7.48l/h

Operation mode

Activated functions

Top row with main menus (Sect. 6.3)

Info

Alarm

Setup

Back

SlowMode (Sec t. 6.6)

FlowControl ( Sect. 6. 7)

Key lock (Sect. 6.12)

Bus (Sect.6.15)

Auto deaeration (Sect. 6.11)

Manual (Sect . 6.4.1)

Pulse (Sect. 6.4.2)

Analog 0/4-20 mA (Sect.6.4.3)

Batch (Sect. 6.4.4)

Timer (Sect. 6.4.5, 6.4. 6)

Running

Standby

Stop

Deaerating

Diaphragm position 'out’ (Sect. 7.)

Additional display (Sect. 6.13.2)

AR, FC variant: Target flow

FCM variant: Actual flow

Remaining batch volume (Batch/Timer)

Time until next dosing process (Timer)

Input current ( A na log )

Blocked driv e - f l as hin g sym b ol

Run display

Running - rotates when pump is dosing

External stop ( Sect . 6.16.2)

Empty signal (Sect. 6.16.3)

Low-level signal (Sect. 6.16.3)

Cable break (Sect. 6.4.3)

E-box (Sect.6.15)

Service (Sect.7.)

Total dosed volume

Actual backpress ure

Signal and error display

Diaphragm position ’in’ (Sect. 7.)

English (GB)

The following d isplay symbols m ay ap pe ar i n t he m enu s .

Fig. 14 Overview of display symbols

20

TM04 1161 1710

Page 21

6.3 Main menus

Operation

7.48

l/h

Manual

7.48l/h

Th

Backpressure

Counters

Service

ServiceKit

Reset service syste m

Software rev.

Serial no.:

Product no.:

Typ e K e y

Info

18.02.2010 12:34

15.0bar

>

-

❑

V0.20

Alarm

12.02.2010

12.02.2010

1

Empty

2

Low level

12:34

12:34

Delete alarm

messages

❑

Setup

Deutsch >

Pulse >

❑

>

1.06 l

7:50

>

>

Actual flow >

Off >

❑

>

>

❑

❑

>

Off >

>

>

>

>

>

Language

Operation mode

Pulse memory *

Analog scaling *

Batch volume *

Dosing time *

Dos. Timer Cycle *

Dos. Timer Week *

Analog output

SlowMode

FlowControl active *

FlowControl *

Pressure moni torin g *

AutoFlowAdapt *

Auto deaerati on

Calibration

Key lock

Display

Time+date

Bus *

Inputs/Outputs

Basic settings

Section

5.1

6.4

6.4.2

6.4.3

6.4.4

6.4.4

6.4.5

6.4.6

6.5

6.6

6.7

6.7

6.8

6.10

6.11

5.3

6.12

6.13

6.14

6.15

6.16

6.17

The main menus are dis pl aye d as sy m bols at the t op

of the displa y. The curren tly active main me nu i s

displayed as text.

6.3.1 Operation

Status information such as th e dosin g flow,

selected operation mode and operating state

is displayed in the ’Operation’ main menu.

6.3.2 Info

You can find the date, time and informati on

about the active dosing process, various

counters, product data and the service system status

in the ’Info’ main menu. The information can be

accessed during operation.

The service syst em c an a lso b e r e set fr o m he re.

6.3.3 Alarm

You can view errors in the ’Alarm’ main menu.

Up to 10 warning s a n d a la rm s, to ge th er wi th th eir

date, time and cause , are lis ted in chrono logica l

TM04 1157 1010TM04 1106 1010

order. If the list is full, the old est e nt ry will be

overwritten, see Section 8. Faul ts.

6.3.4 Setup

The ’Setup’ main menu contains menus for

pump configuration. These menus are

described in the followin g s ec tions.

English (GB)

TM04 1109 1010TM04 1110 1010

Counters

The ’Info > counters’ menu contains the fol lowing

counters:

Counters resettable

Volume

Total dosed volume [l] or US gallons

Operating hours

Accumulated operating hours (pump

switched on) [h]

Motor runtime

Accumulated motor runtime [h]

Stroke s

Accumulated number of dosing

strokes

Power on/off

Accumulated frequency of switching

mains voltage on

Yes

No

No

No

No

* These submenus are only displayed for specific

default settings and control variants. The contents of

the ’Setup’ menu also vary depending on the

operation mode.

21

Page 22

6.4 Operation mod es

Operation

3.40

l/h

Manual 3.40l/h

Note

Operation

0.040

ml/

Pulse 3.40l/h

English (GB)

Six different operation modes can be set in the

’Setup > Operation mode’ menu.

• Manual, see section 6.4.1

• Pulse, see section 6.4.2

• Analog 0 - 20 mA, see section 6.4 .3

• Analog 4 - 20 mA, see section 6.4 .3

• Batch, see section 6.4.4

• Dosing timer, cycle, see section 6.4.5

• Dosing timer, week, see section 6.4.6

6.4.1 Manual

In this operation mode, the pump constantly

doses the dosing flow set with the click wheel.

The dosing flow is se t in l/h or ml/h . The pu mp

automatically switches between the units.

Alternatively, the display can be reset to US units

(gph).

Fig. 15 Manual mode

The setting rang e depe nds on the pum p type:

Type

DDA 7.5 - 16 0.0025 - 7.5 0.0007 - 2.0

DDA 12-10 0.012 - 12 0.0031 - 3.1

DDA 17-7 0.017 - 17 0.0045 - 4.5

DDA 30-4 0.03 - 30 0.0080 - 8.0

* When the SlowMode function is active, the maximum

dosing flow is reduced, see section 3.1 Technical

data.

Setting range*

l/h gph

6.4.2 Pulse

In this operatio n m o de , the p um p d ose s the

set dosing vo lu me for each in c o min g (p otential-fre e)

pulse, e. g. f rom a wat er met er. There is no direct

connection betwe en inco min g pulse s and do sin g

strokes. The pump automa tica lly cal culate s the

optimum strok e fr eq ue nc y f or d osing the set v olu m e

per pulse.

The calculation is based on:

• the frequency of external pulses

• the set dosing volume/ pulse .

TM04 1126 1110

Fig. 16 Pulse operation mode

The dosing volume per pulse is set in ml/pulse using

the click wheel. The setting range for the dosing

volume depends on the pump type:

TM04 1125 1110

Type Setting range [ml/pulse]

DDA 7.5 - 16 0.0013 - 12.8

DDA 12-10 0.0026 - 25.8

DDA 17-7 0.00 27 - 2 6.8

DDA 30-4 0.00 58 - 5 8.4

The frequencyof incoming pulses is multiplied by the

set dosing vol um e. If th e pu mp recei v es more pu ls es

than it can pr oc ess at the maxi m um dosing flow, it

runs at the maximum stroke frequency in continuous

operation. Excess pulses will be ignored if the

memory funct ion i s no t en ab l e d.

Memory function

When the ’Setup > Pulse me m or y ’ function is

enabled, up to 65,000 unprocessed pulses can be

saved for subsequent processing.

The contents of the mem ory wil l be

deleted when:

– Switching off the power supply

– By switching the operating mode

– Interruption (e . g. alarm,

external stop).

22

Page 23

6.4.3 Analog 0/4-20 mA

0

Q [%]

0 - 20 mA

4 - 20 mA

[mA]

4

2081216

100

80

0

60

40

20

Operation

6.5

ml/h

0-20 mA 17.14 mA

Q [l/h]

16

1.5

6

7.5

5

0

020I [mA]

(I2 / Q2)

(I

1

/ Q1)

0

0

20

16

1,3

2

7,5

I [mA]

Q [l/h]

(I2 / Q2)

(I

1

/ Q1)

In this operation mode, the pump doses

according to the ex tern al an alog sig nal. Th e

dosing volume is proportional to the signal input

value in mA.

Operation

mode

4 - 20 mA

0 - 20 mA

If the input value in operation mode 4-20 mA falls

below 2 mA, an alarm is displayed and the pump

Input value Dosing flow

≤ 4.1 mA 0 %

≥ 19 .8 mA 100 %

≤ 0.1 mA 0 %

≥ 19 .8 mA 100 %

stops. A cable break or signal transmitter error has

occured. The ’Cable break’ symbol is displayed in

the ’Signal and er ror dis pla y’ area of the di splay.

Fig. 17 Analog scaling

Set analog scaling

Analog scaling refers to the assignment of the

current input valu e to the do sing flo w.

Analog scaling passes through the two reference

points (I

/ Q1) and (I2 / Q2), which are set in the

1

’Setup > Analog scaling’ menu. The dosing flo w i s

controlled according to th is settin g.

Example 1 (DDA 7.5 - 16)

Analog scaling with positive gradient:

Fig. 19 Analog scaling w it h po s. gradient

In example 1, the refe ren ce points I

Q

= 1.5 l/h and I2= 16 mA, Q2= 7.5 l/h ha ve be en

1

set.

From 0 to 6 mA anal og sc alin g i s des c r ibe d by a li ne

that passes thr ou gh Q = 0 l/ h, b etween 6 mA and

=6mA,

1

16 mA i t r i ses p ro p or tio nally from 1.5 l/h to 7.5 l/h

and from 16 mA onwards it passes through

Q=7.5l/h.

TM04 1120 2010

Example 2 (DDA 7.5-16)

Analog scaling with negative gradient

(Operation m od e 0 - 20 m A):

English (GB)

TM04 1160 2010

Fig. 18 Analog operatio n mode

TM04 1127 1110

TM04 1101 2010

Fig. 20 Analog scaling w it h neg. gradient

In example 2, the refe ren ce points I

Q

= 7.5 l/h and I2= 16 mA, Q2= 1.3 l/h have be en

1

set.

From 0 to 2 mA anal og sc alin g i s des c r ibe d by a li ne

that passes thr ou gh Q = 0 l/ h, b etween 2 mA and

= 2 mA,

1

16 mA it drops proportionally from 7.5l/h to 1.3l/h

and from 16 mA onwards it passes through

Q

=1.3l/h.

2

23

Page 24

Set analog scaling in the ’Operation’ menu

Caution

4020

100

0

Q [%]

I [mA]

new

actual mA

(I

2

/ Q2)

(I

1

/ Q1)

(I

2

/ Q2)

Pulse

Batch volume

Pulse

Time

t

1

t

1

Setup

Batch >

Input >

75.0 ml

0:32

Off >

Operation mo de

Analog output

Batch volume

Dosing time [mm:ss]

SlowMode

Operation

75.0

ml

Batch 43 ml

English (GB)

Analog scaling ca n also be m odifi ed after a s ecur ity

prompt directly in the ’Operation’ menu. This is how

the dosing flow is directly modified for the current

flow input v al u e.

Please observe that changes also have

a direct effect on point I

(see fig. 21)!

2

Fig. 21 Set analog scaling (’Operation’ menu)

6.4.4 Batch (pulse-based)

In this operation mode, the pump doses the

set batch volume in the set dosing time (t

A batch is dosed with each incoming pulse.

/ Q2

The batch volume (e. g. 75 ml) is se t in t he ’Setup >

Batch volume’ menu. The minimum dosing time

required for th is (e . g. 32 seconds) is displayed an d

can be increased.

TM04 1134 1110TM04 1135 1110

Fig. 23 Batch mode

If the batch v olu m e i s m od ifi ed , the dosing ti me

resets to the m ini mum dosing time.

Signals received during a batch process or an

interruption (e. g. alarm, ex ternal stop) will be

ignored. If the pump is r es tarted f ollo wing an

interruption, th e ne xt batch volume is dosed on the

TM04 1132 2010

next incoming pu lse .

).

1

Fig. 24 Batch mode

In the ’Operation’ me nu, th e total batc h volume

(e. g. 75 m l) and th e rem ainin g ba tch volu me st ill t o

be dosed (e. g. 43 ml) are shown in the display.

Fig. 22 Batch (pulse-based)

The setting rang e depe nds on the pum p type:

Type

DDA 7.5 - 16 0.74 999 0.0925

DDA 12-10 1.45 999 0.1813

DDA 17-7 1.55 999 0.1938

DDA 30-4 3.10 999 0.3875

* Thanks to the digital motor control, dosing quantities

with a resolution of up to 1/8 of the dosing stroke

volume can be dosed.

24

from [ml] t o [ l]

Setting range per batch

Resolution*

TM04 1105 2010

[ml]

Page 25

6.4.5 Dosing timer, cycle

t

1

t

1

t

2

t

3

Batch volume

Timer

125 ml

1:54

3 min

2 min

Batch volume

Dosing time [mm :ss ]

Cycle time

Start delay

Note

Operation

125

ml

Timer

1:21

0:00

6:00

12:00

18:00

0:00

3333333

22

1

4

4

11 1

MO TU WE TH FR SA SU

Timer

Procedure

Batch volume

Dosing time [ mm:ss]

Start time [hh:mm]

1

80.5 ml

0:34

05:00

M ❑ T T W ❑ F ❑ S ❑ S

In this operation mode, the pump doses the

set batch volume in regula r cycles. Dosing

starts when the pump is starte d after a sing ul ar start

delay. The setting range for the batch volume

corresponds to the values in section 6.4.4 Batch

(pulse-based).

Fig. 25 Dosing timercycle

t1Dosing time

t

Start delay

2

t

Cycle time

3

The cycle time must be long er tha n the do sing tim e,

otherwise the following dosin g will be ignor ed. In the

event of an interruption (e. g. interruption of the

mains voltage, external sto p), th e do sing will be

stopped while the time continues running. After

suspending the inte rruptio n, th e pu m p will c on tinue

to dose according to the actual timeline position.

The following sett ings a r e re qu ired in th e ’Setup >

Dos. Time r Cycle’ me nu:

The total batch vo lu me ( e. g. 125 m l) a nd th e

remaining batch volume st ill t o be d os ed a re

displayed in the ’Oper ation ’ m e nu . D ur ing b re ak s in

dosing, the tim e u nti l th e ne xt do si n g pr o ces s

(e.g.1:21) is displayed.

Fig. 27 Dos. Timer Cycle mode

6.4.6 Dosing t im e r, week

In this opera tion mode, up to 1 6 do si n g

procedures are defined for a week. These

TM04 1107 1109

dosing proced ur e s m ay take place re gu la rl y on o ne

or several week days. The setting range for the

batch volume cor r esp on ds t o t he v alu es in se ction

6.4.4 Batch (pulse-ba sed) .

Fig. 28 Week timer dosing

English (GB)

TM04 1136 1110

TM04 1108 1109

Fig. 26 Dos. Timer Cycle mode

The batch volume to be dosed (e. g. 125 ml) is set in

the ’Setup > Dos. Timer Cycle’ menu. The minimum

dosing time required for this (e. g. 1:54) is displayed

and can be increased.

If several procedures overlap, the

process with the higher dosing flow has

priority!

In the event of an interruption (e. g. disconnection of

the mains voltag e, external st op ), th e dosing is

stopped whil e the t i me c on tin ue s r u nning. After

TM04 1137 1110

suspending the int errupt ion, th e pump continu es to

dose according to th e actua l timel ine po siti on.

The following settings ar e re q uired in t he ’Setup >

Dos. Timer Week’ menu for each dosing procedure:

TM04 1138 1110

Fig. 29 Setting the timer

25

Page 26

The batch volu me ( e. g. 80.5 ml) is set in th e ’S etup

Operation

80.5

ml

Timer

43:32

Output = Input

Actual flow

Backpressure

Bus control

❑

❑

❑

Analog out

Note

Caution

Off

SlowMode [50 % m a x.]

SlowMode [25 % m a x.]

❑

❑

SlowMode

English (GB)

> Dos. Timer Week’ menu. The mini mum dos ing time

required for thi s (e. g. 0:34) is displayed an d can be

increased.

In the Operation mode, the total batch volume

(e. g. 80.5 ml) and the remaining batch vol ume to be

dosed is dis pl aye d. D ur ing br ea ks i n dos i ng , th e ti me

(e. g . 43:32) u nti l th e ne xt do sin g is disp la yed .

Fig. 30 Weekly timer dosing /br e ak in do si n g

6.5 Analog output

Fig. 31 Configure analo g ou tp ut

The analog output of the pump is parametrised in the

’Setup > Analo g ou tp ut’ menu. The following setting s

are possible:

Setting

Output

=Input

Actual

flow

Backpres

sure

Bus

control

* Output signal is based on motor speed and pump

status (target flow).

26

Description

Analog output signal

The analog input signal is

mapped 1:1 to the an alog

output (e. g. to control

several pumps using on e

signal)

Current actual flow

• 0/4 mA = 0 %

• 20mA=100%

see section

6.8.2 Calibration o f

pressure sensor

Backpressure, meas ured

in the dosing head

• 0/4 mA = 0 %

• 20mA=100%

see section 6.8 Pressure

monitoring

Enabled by command in

Bus control, see section

6.15 Bu s commun icatio n

Control

variant

FC

AR

FCM

XXX

XX*X*

XX

XXX

Wiring diagram see section 4.3 Electrical

connection.

In all modes, the analog output has a

range of 4-20 mA. Exc eption: Operation

mode 0-20 mA. Here, the analog output

range is 0-20 mA.

6.6 SlowMode

When the ’SlowMode’ function is enabled, the

pump slows down the suction stroke. The function is

enabled in the ’ Setup > SlowMo de ’ menu and is

used to prevent ca vita tion in the following cases:

• for dosing media with a high viscosity

• for degas sin g dosing media

• for long suction li nes

TM04 1136 1110

• for large suction lift.

In the ’Setup > SlowMode’ menu, the speed of the

suction stroke can be reduced to 50 % or 25 %.

Enabling the 'SlowMode' fu nc ti on

reduces the maximum dosing flow of

the pump to the set percentage value!

TM04 1153 1110

Fig. 32 SlowMode menu

TM04 1153 1110

Page 27

6.7 FlowControl

1

2

3

4

Pressure

Stroke

length

Trouble-free dosin g

stroke

Faulty dosing st ro ke : Air

bubbles in the dosing

head

FC/FCM control varian t.

This functi on is used to monit or th e do sin g pr oc ess.

Although the pump is runnin g , v ar i ou s inf lue nces

e. g. air bu bb l es , c an cause a redu ce d f low or even

stop the dosing process. In order to guarantee

optimum process safety, the enabled FlowControl

function directl y det ects an d ind ica te s t he fo llo win g

errors and devia tio ns:

• Overpressure

• Damaged discharge line

• Air in the do sin g ch am be r

•Cavitation

• Suction valve leakage

• Discharge valve leakage.

The occurrence of a fault is indica ted by the 'eye'

symbol flas hin g. T he f au l ts ar e di spl a ye d in th e

’Alarm’ menu (see section 8. Faults).

FlowControl works with a main te nanc e-fr ee se n sor

in the dosing head. During the dosing process, the

sensor measur es the cu rren t press ure an d

continuously sends the measured value to the

microprocessor in the pump. An internal indicator

diagram is creat ed fr om the curr ent me asu red va lue s

and the current diaphragm position (stroke length).

Causes for deviations can be identified immediately

by aligning th e cu rr en t ind i ca to r d ia gr am with a

calculated optimum indica tor diagram. Air bubbles in

the dosing h ea d re du ce e. g. the disc ha rg e phase

and consequently the stroke volume (see fig. 33).

Setting FlowControl

The ’FlowControl’ function is set using the two

parameters ’Sen sit ivity ’ and ’Dela y’ in t he ’Setup >

FlowControl’ menu.

Sensitivity

In 'Sensitivity’ the deviation in strok e volume, which

will result in an error message, is set in percent.

Sensitivity Devia tio n

Low approx. 70 %

Medium approx. 50 %

High approx. 30 %

Delay

The ’Delay’ parameter is use d to d efine the time

period until an error message is generated: ’short’,

’medium’ or ’long’. The delay depends on the set

dosing flow and therefore cannot be measured in

strokes or time.

English (GB)

Fig. 33 Indicator diagram

1 Comp ressio n phas e

2 Discharge phase

3 Expansi on phase

4 Suct ion p ha se

TM04 1610 1710

27

Page 28

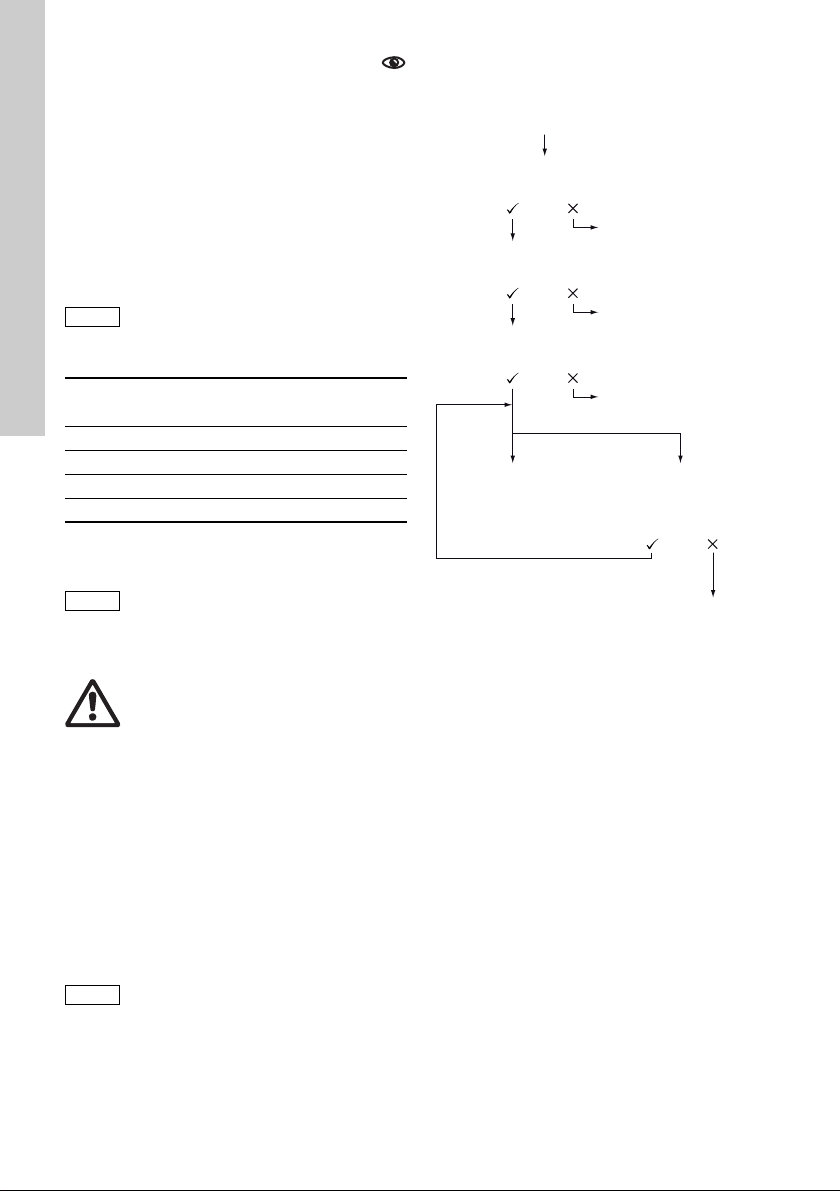

6.8 Pressure monit orin g

Caution

Caution

Caution

Plug in pressur e s enso r pl u g or se lec t

’Setup > FlowControl active’ me nu

Prompt:

’Activate FlowContr.?’

FlowControl not

activated

FlowControl active,

Sensor not calibrated.

Prompt:

’Sensor calibration?’

Prompt:

’Suction valv e re mo ve d? ’

Sensor not calibrated.

OK

Calibration error

Message:

’Sensor cal ib . OK

Current pressure: X bar’

Message:

’Sensor calib. failed!

’Repeat?’

Sensor not calibr ated .

English (GB)

FC/FCM control varian t.

A pressure se nsor monitors th e pr e ssu re in t he

dosing head. If the pressure during the discharge

phase falls below 2 bar, a warning is generated

(pump continues running). If in the ’Setup > Pressure

monitoring’ menu the func tio n ’ Min . pres sur e alarm’

is activated, an alarm is generated and the pump is

stopped.

If the pressure exceeds the cut-off pressure set in

the ’ Set up > Press ur e mo nit ori n g’ me nu, th e pu mp i s

shut down, ent er s the st a nd by st at e a nd i n dic at es an

alarm.

The pump restarts automatically once

the backpressure fal ls below the cut-of f

pressure!

6.8.1 Pressure setting ranges

4. Proceed as described below to calibrate:

Type

Fixed min.

pressure (bar)

DDA 7.5 - 16 < 2 3 ... 17

DDA 12-10 < 2 3 ... 11

DDA 17-7 < 2 3 ... 8

DDA 30-4 < 2 3 ... 5

The pressure measured in the dosing

head is slightly higher than the actual

system pressure.

Therefore the cut-off pressure should

be set min. 0.5 bar higher than the

system pressure.

6.8.2 Calibration of pressure sensor

The pressure sensor is calibrated in the factory. As a

rule, it does not need to be re-calibrated . If specific

circumstances (e. g. pressure senso r excha nge,

extreme air pressure values at the location of the

pump) necessitate a calibration, the sensor can be

calibrated as follows:

1. Set pump to ’Stop’ operational state.

2. Make system pressureless and flu sh.

3. Dis ma ntle suc tion line a nd s uct ion v alv e.

Warning

Install a pres su r e -re lie f valve in the

pressure line to provide protection

against impermissibly high pressure!

Calibrating w h en t h e su ct io n v al ve is

installed produ ces inc orrect calibr ation

and can cause personal injuries and

damage to property!

Only carry out a calibration if this is

technically r e qui re d !

Settable max.

pressure [bar]

If a calibration i s n ot su ccessfully possible, ch eck

plug connectio ns, cab le and se nsor an d repl ace

defective parts wher e necessa ry.

TM04 1145 2510

28

Page 29

6.9 Flow measurem ent

Note

Note

Note

FCM control variant

The pump accu r ate l y me as ur es the actual fl o w a nd

displays it. Via the 0/4 - 20 mA analog output, the

actual flow signal can easily be integrated into an

external process control without additional

measuring equipment (see section 6.5 Analog

output).

The flow measurement is based on the indicator

diagram as described in section 6.7 FlowCon trol.

The accumulated length of the discharge phase

multiplied by the stroke frequency produces the

displayed actual flow. Faults e. g. air bubbles or

backpressure that i s t oo lo w r esult in a smal ler or

larger actual flow. When the ’ AutoFlowAdapt’

function is activa ted (s ee secti on

6.10 AutoFlowAdapt), the pump compensates f or

these influences by correction of the stroke

frequency.

Strokes which canno t be an alys ed

(partial strokes, pressure differential

which is too lo w) a re p r ovis io n al ly

calculated b a se d o n th e s et po i nt v al ue

and displayed.

6.10 AutoFlowAdapt

FCM control variant.

The ’AutoFlowAdapt ’ fun ction is activate d in the

’Setup’ menu. It detects changes in various

parameters and responds accordingly in order to

keep the set target flow cons tant.

Dosing accuracy is increased when

’AutoFlowAdapt’ is activated.

This function processes information from the

pressure senso r in the do sing he ad. Err ors det ect ed

by the sensor are processed by the software. The

pump responds immediately regardless of the

operation mode by adjusting the stroke frequency or

where necessary compensating for the deviations

with a corres po nding indicator d i a gram .

If the target flow cannot be achieved by the

adjustments, a warning is issued.

’AutoFlowA da pt’ operates on the basis of the

following functions:

• FlowControl: malfunctions are identified (see

section 6.7 FlowContr ol).

• Pressure moni t or in g: pressu re fl uct ua ti o ns a re

identified (s ee s ect ion 6.8 Pressure monitoring).

• Flow measurement: deviations from the target

flow are identified (see section 6.8.2 C alibration

of pressure sensor).

Examples of ’AutoFlowAdapt’

Pressure fluctuations

The dosing volu me d ecr e ases as backpressure

increases and conversely the dosing volume

increases as the b ack pr es sur e de crea se s.

The ’AutoFlowAdapt’ function identifies p re ssur e

fluctuations and responds by adjusting the stroke

frequency. The actua l f l ow i s th us m ai n taine d at a

constant level.

Air bubbles

The ’AutoFlowAdapt’ function identifies a ir bu bb le s.

The pump responds with a special indicator diagram

due to which the air bubbles are removed as a top

priority (deaeration).

If the air bubbles have not been eliminated after a

maximum of 6 0 s tr ok es, th e pu m p swit che s to th e

’Air bubble’ warning status and returns to the norm al

indicator diagram.

6.11 Auto deaeration

Dosing degassing media can result in air

pockets in the d osi ng head during br ea ks in

dosing. This can result in no medium being dosed

when restarting the pump. The ’Setup > Auto

deaeration’ function performs pump deaeration

automatically a t re gu lar in te rv als . S o ftwa re controlled diaphragm movements encourage any

bubbles to rise and gather at the discharge valve so

that they can be r em o ve d o n th e ne xt do sin g str oke.

The function works:

• when the pump is not in the ’Stop’ mode

• during brea ks in dosin g (e. g. External stop, no

incoming pulses, etc. ).

Low volumes can be displaced into the

discharge line by the diaphragm

movements. W h en do sing strong ly

degassing media, this is however

virtually impos sib l e.

English (GB)

29

Page 30

6.12 Key lock

Operation

1.30

l/h

Manual

1.28 l/h

Additional display

English (GB)

The key lock is set in th e ’Setup > Key lock’

menu by ent eri ng a f ou r- di git code. It protects the

pump by preventing changes to settings. Two levels

of key lock can b e se lec te d:

Level Description

All settings can on ly be c hange d by

Settings

Settings +

keys

It is still possible to n avi gate in th e ’Alarm’ and ’I nf o’

main menu and reset alarms.

Temporary deactivation

If the key lock function is activated but settings need

to be modified, th e k eys c a n be un loc ke d tem por ar i l y

by entering the deactivation code. If the code is not

entered within 10 seconds, the display automatically

switches to the ’Operation’ main menu. The key lock

remains active.

Deactivation

The key lock can b e de ac tivated in the ’S et up > Key

lock’ menu via the ’Off’ menu point. The key lock is

deactivated after the general code ’2583’ or a predefined custom code has been entered.

entering the lock code.

The start/stop key and the 100 %

key are not locked.

The start/stop key and the 100 %

key and all settings are locke d.

6.13 Display Se tup

Use the followi ng se tt ing s in the ’Setup > Display’

menu to adjust th e display proper tie s:

• Units (metric/US)

• Display contrast

• A dditional dis play.

6.13.1 Units

Metric units (litres/millilitr es /bar ) or US units (U S

gallons/PSI) can be selected. According to the

operation mode and menu, the following units of

measurement ar e dis playe d:

Operation mode/

function

Manual contro l ml/h or l/h gph

Pulse control ml/ ml/

0/4-20 mA

Analogue control

Batch (pulse- or timer-

controlled)

Calibration ml ml

Volume counter l gal

Pressure monito ri ng bar psi

Metric units US units

ml/h or l/h gph

ml or l gal

6.13.2 Additional display

Additional display provides additional information

about the cu rr en t p um p s t at us . The v alu e i s sho wn i n

the display w ith th e co rr esponding sym bo l.

In ’Manual’ mode the ’Actual flow ’ information can be

displayed with Q = 1.28 l /h (se e fig. 3 4).

TM0 4 1151 111 0

Fig. 34 Display with ad dit i on al display

The additional display can be set as follows:

Setting D escription

Depending on the operation

mode:

Actual flow (manual, pulse)

Target flow (pulse)

Default display

Dosed volume

Actual flow Current actual flow

Backpressure

1)

only DDA-FCM control variant

2)

only DDA-FCM/FC control variant.

Input current (analog)

Remaining batch volume

(Batch, Dos. Timer)

Period until next dosing

(Dos. Timer)

Dosed vol. since las t reset

(see Counters on page 21)

Current back pr es sur e in th e

dosing head

2)

1)

1)

30

Page 31

6.14 Time/date

Caution

Bus

Bus control active

Bus address

127

In/Output

Relay 1

Relay 2

External stop

Empty signal

Low-level signal

>

>

NO

NO

NO

The time and date can be set in the ’Set up >

Time+date’ menu .

The conversion between summer and

winter time does not take place

automatically!

6.15 Bus commu nicati on

The pump is supplied with a n int eg rated

module for GENIbu s commun icatio n. The

pump identif ies the bus con tr ol afte r co nn ecting to

the corresponding signal input. The "Activate

Genibus?"prompt is displayed. After confirmation,

the ’Bus’ submenu appears in the ’Setup’ menu.

Fig. 35 ’Setup > Bus’ menu

The correspon d i ng sy mb ol ap pears in the ’Activated

functions’ area in the ’Operation’ menu.

The pump c an a lso be in tegrated into a Pr of i bu s D P

network using the additional E-box module

(retrofitting possib le) .

The bus communication enables remote monitoring

and setting of the pu mp vi a a fiel dbus sys tem. The

accompanyin g fiel dbus do cume ntatio n an d the

Profibus GSD file can be downloaded from the

Internet.

www.grundfosalldos.com

6.16 Inputs/outputs

In the ’Setup > In pu ts/o ut pu ts’ m enu, yo u ca n

configure the two outputs ’Relay 1+2’ and the signal

inputs ’External st op ’, ’E m pty si gn al ’ an d ’Low l evel

signal’.

Fig. 36 ’Setup > Inputs/out p uts’ me nu

6.16.1 Relay ou t p uts

The pump can switch two external signals using

installed relays. The relays are switched by potentialfree pulses. The connection diagram of the relays is

shown in sec tio n 4.3 Electrical connection. Both

relays can be allocate d with t he fo llowin g s ign als:

TM04 1139 2410

Relay 1

signal

Alarm* Alarm

Προειδοποί

ηση*

Stroke

signal

Pump

dosing

Bus control Bus control

Contact type

NO* NO* Normally open contact

NC NC

Relay 2

signal

Warning

Stroke

signal*

Pump

dosing

Timer, cycle see follo win g sec tio n

Timer, week see following sectio n

Description

Display red, pump

stopped (e. g. empty

signal, etc. )

Display yellow, pump is

running (e. g. low-level

signal, etc. )

each full stroke

Pump running and

dosing

Activated by a

command in the bus

communication

Normally closed

contact

English (GB)

TM04 1152 1110

* Factory setting

31

Page 32

Timer, cycl e (relay 2)

Caution

t

2

t

3

t

1

t

1

English (GB)

For the ’Relay 2 > Timer cycl e ’ function, set the

following param eter s:

•Dosing time (t

• Start delay (t

•Cycle time (t

)

1

)

2

)

3

Fig. 37 Diagram

Timer, week (relay 2)

This function saves up to 16 relay on-times for a

week. The following settings can be made for each

relay switching operation in the ’Relay 2 >

Timer Week’ menu:

• Procedure (No.)

• On-time (dur ation )

• Start time

• Weekdays.

6.16.2 External stop

The pump can be stopped via an external

pulse, e. g. from a control room. When activating the

external stop pulse, the pump switches from the

operational stat e ’ Ru nn in g’ in to th e ope ra tional state

’Standby’. The co rr es po nd i ng s ym bo l a pp ea rs i n th e

Signal/error di spla y (see se ction 6.2.2 Op er ating

states).

Frequent disengagement from the

mains voltage, e. g. via a relay, can

result in damage to the pump

electronics and to the breakdown of the

pump. The dosing accuracy is also

reduced as a re su l t o f i nt ern al start

procedures.

Do not control the pump via the mains

voltage for dosing purposes!

Only use the ’External stop’ func tion to

start and stop the pump!

The contact ty pe is fa cto r y-s et to closed contact

(=>NO). In the ’Setup > Inputs/outputs > External

stop’ menu, the setting can be changed to open

contact (=>NC).

6.16.3 Empty a n d lo w- le ve l si gn a ls

In order to monitor t he filling level in the

tank, a dual-level senso r can be connec ted to th e

pump. The pum p re sp on ds to the sign als as follows:

Sensor signa l Pump status

• Display is yellow

Low level

• flashes

• Pump continues

running

• Display is red

Empty

• flas hes

• Pump stops

Both signal i n pu ts ar e a l loc at ed to th e c los ed c ont ac t

(=>NO) in the f actory. They can be re- al located in

TM04 1124 2110

the ’Setup > In pu ts/ou tp uts’ menu to open contact

(=>NC).

6.17 Basic settin gs

All settings can be reset to the se tting s defau lt upon

delivery in the ’Setup > Basic set tings ’ menu.

Selecting ’Save customer settings’ saves the current

configuration to the memory. This can then be

activated using ’Load customer settings’ .

The memory alw ays contains the pr ev iou sl y sa ved

configuration. Older mem or y d a ta i s ov er w ri tte n.

32

Page 33

7. Service

Service soon!

Please exchan ge

diaphragm and valves!

Service kit:

97xxxxxx

Service now!

Please exchan ge

diaphragm and valves!

Service kit:

97xxxxxx

Caution

In order to ensure a long service life and

dosing accuracy, wearing parts such as

diaphragms and valves must be regularly checked

for signs of w ea r. Where ne ce ssa ry, replace worn

parts with original spare parts made from suitable

materials.

Should you have an y qu es tio ns, pl e as e co nta ct yo ur

service partner.

Warning

If the diaphragm leaks or is broken,

dosing liquid will escape from the

discharge opening on the dosing head

(see fig. 3).

Take suitable precautions to prevent

harm to health and damage to property

caused by escaping dosing liquid!

Check daily whether liquid is escaping

from the disch arg e ope nin g!

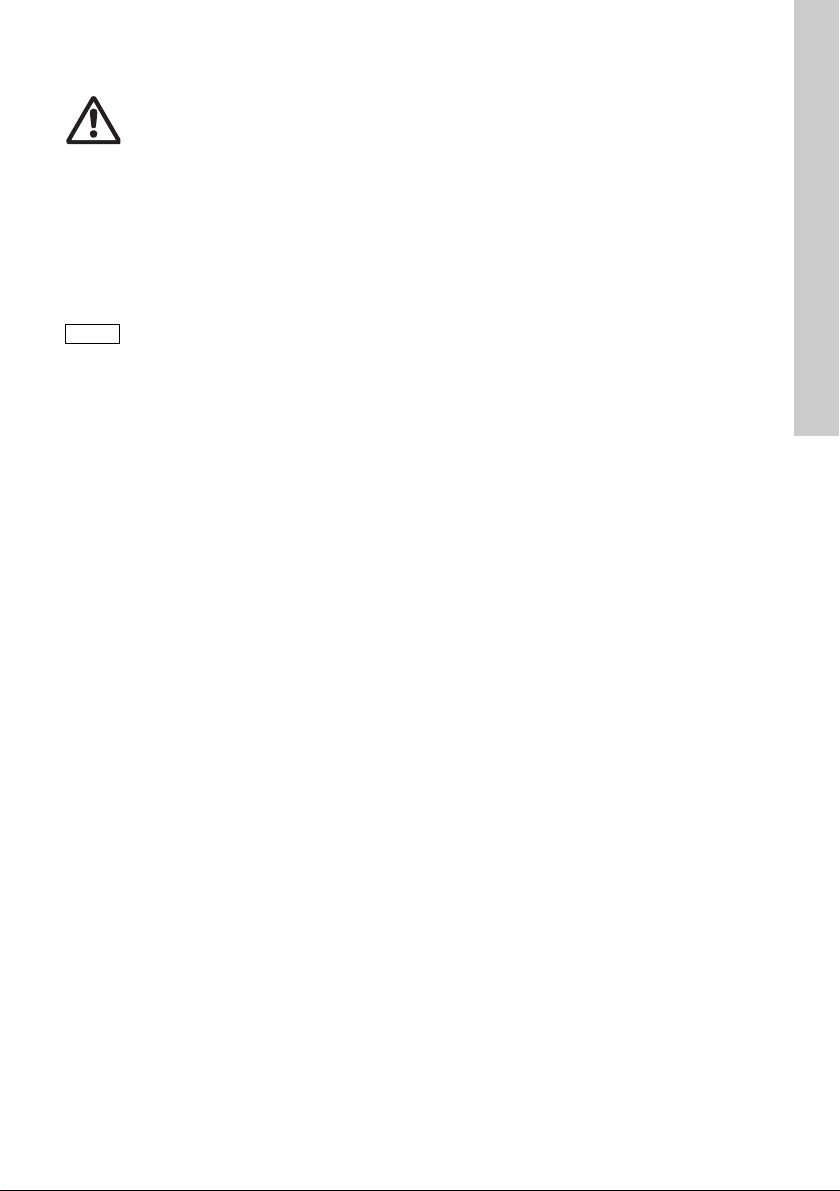

7.1 Service system

According to the motor runtime or after a defined

period of op e ra tio n, service req ui r em en ts wi l l

appear. Service requirements appear regardless of

the current operational state of the pump and do not

affect the dosing process.

Service requirement

’Service soon’ 7500 23

’Service now’ 8000 24

* Since the last service system reset

Motor

runtime

[h]*

Time interval

[months]*

The service requirement signals when the

replacement of wearing parts is due and displays the

number of the se rvi ce kit. Press the cli ck w he el to

temporarily hide the service prompt.

When the ’Service now’ message appears (displayed

daily), the pump must be serviced immediately. To

signalise in the ’Operation’ menu, the symbol

appears in the ’Signal/error display’ area of the

display.

The number of the service kit required is also

displayed in the ’Info’ menu.

For media whic h resul t in i nc reased wear, the service

interval must be sh or te ne d.

7.2 Perform service

Only spare parts and accesso ries f rom Grun dfos

should be used for maintenance. The usage of nonoriginal spare parts and accessories renders any

liability for resulting dama ges n ull and vo id.

Information about carrying out maintenance can be

found in the servic e kit catalog on our ho mepag e

(www.grundfosalldos.com).

Warning

When dosing dangerous media,

observe the cor responding p recautions

in the safety data sheets!

Risk of chemical burns!

Wear protective clothing (gloves and

goggles) when working on the dosing

head, connections or lines!

Do not allow any chemicals to leak

from the pump. Collect and dispose of

all chemical s co rr ec tl y!

Before any work to the pump, the pump

must be in the ’Stop’ operational state

or be disconnected from the mains.

The system must be pressureless!

English (GB)

Fig. 38 ’Service soon’

Fig. 39 ’Service now’

TM0 4 1131 111 0TM04 1131 1110

33

Page 34

7.2.1 Dosing head overview

123 57 8

46 10

9

Caution

English (GB)

Fig. 40 Changing the diap hr ag m an d va l ve s

1 Safety d iap hr ag m

2Flange

3O-ring

4 Diaphragm

5 Valve on discharge side

6 Valve on suction side

7 Dosing head

8 Screws with discs

9 Cover

10 Deaeration v alv e

7.2.2 Disma ntli ng th e diap hr agm an d valv es

1. Make system pressureless.

2. Empty dosing head before m ai n te na n ce an d

flush it if necessa ry.

3. Set pump to ’Stop’ operational state using the

’Start/stop key’.

4. Press the ’Start/stop’ and ’100 %’ keys at the

same time to put the diaphragm into ’out’

position.

– Symbol must b e di s pla ye d as the

operational stat e (s ee fi g . 14 ).

5. Take suitable s te ps to e ns ur e that the returning

liquid is safely collect ed.

6. Dismantle suction, pressure and deaeration

hose.

7. Dismantle valves on suction an d disc harg e

side (5, 6) .

8. Remove the cover (9).

9. Undo screws (8) on the dosing head (7) and

remove with d iscs .

10.Remove the dosing head (7).

11.Un scr ew diaphragm (4 ) co un te r- clo ckwise and

remove with fla n ge ( 2).

7.2.3 Reassembling the diaphragm and valves

1. Attach flange (2) correctly and screw on new

diaphragm (4) clockwise.

– Make sure that the O-ring (3) is seated

correctly!

2. Press the ’Start/stop’ and ’100%’ keys at the

same time to put the dia phr agm int o ’in’ position .

– Symbol must be displayed as the

operational state (see fig. 14).

3. Attach the dosing head ( 7) .

4. Install screws with discs (8) and cross-tighten.

– Torque: 3 Nm.

5. Attach the cover (9).

6. Install new valves (5, 6).

TM04 1123 2110

– Do not interchang e va l ve s an d pay attention to

direction of arrow.

7. C onnect suction, pressure and deaeration hose

(see section 4.2 Hydraulic connection)

8. Press the ’Start/Stop’ key to leave the service

mode.

9. Deaerate dosing pump (see sec tio n

5.2 Deaerating the pump).

10.Please observe t he n ot es on commissioning i n

section 5. Commissi oning!

7.3 Resetting the service system

After performing the ser vice, th e servic e system

must be reset u s ing t he ’Info > Reset service system’

function.

7.4 Repairs

Warning

The pump housing must only be

opened by personnel authorised by

Grundfos!

Repairs must only be carried out by

authorised and qualified personnel!

Switch off the pump and disconnect it

from the voltage supply before carry ing

out maintenance work and repairs!

After consultin g G r un df os, p l ea se se nd t he p um p,