Grundfos SL1.40.A60 82, SL1.20.A30.30, SL1.20.A30.40, SLV.25.A25 88, SLV.25.A30 94 Product Manual

...Page 1

GRUNDFOS PRODUCT GUIDE

SL1, SLV pumps

1.5 to 15 hp

60 Hz

Page 2

Contents

Introduction

Introduction 3

Applications 3

Overall construction features 3

Performance range

Performance range, SL1, SLV pumps 4

Identification

Type key 5

Nameplate 6

Selection of product

Ordering a pump 7

Product range

SL1 pump range 8

SLV pump range 11

Variants

List of variants 15

Performance curves

Technical data

SL1.20.A25 40

SL1.20.A30 46

SL1.30.A30 52

SL1.30.A40 64

SL1.40.A40 76

SL1.40.A60 82

SLV.25.A25 88

SLV.25.A30 94

SLV.30.A30 100

SLV.30.A40 120

SLV.40.A40 140

Accessories

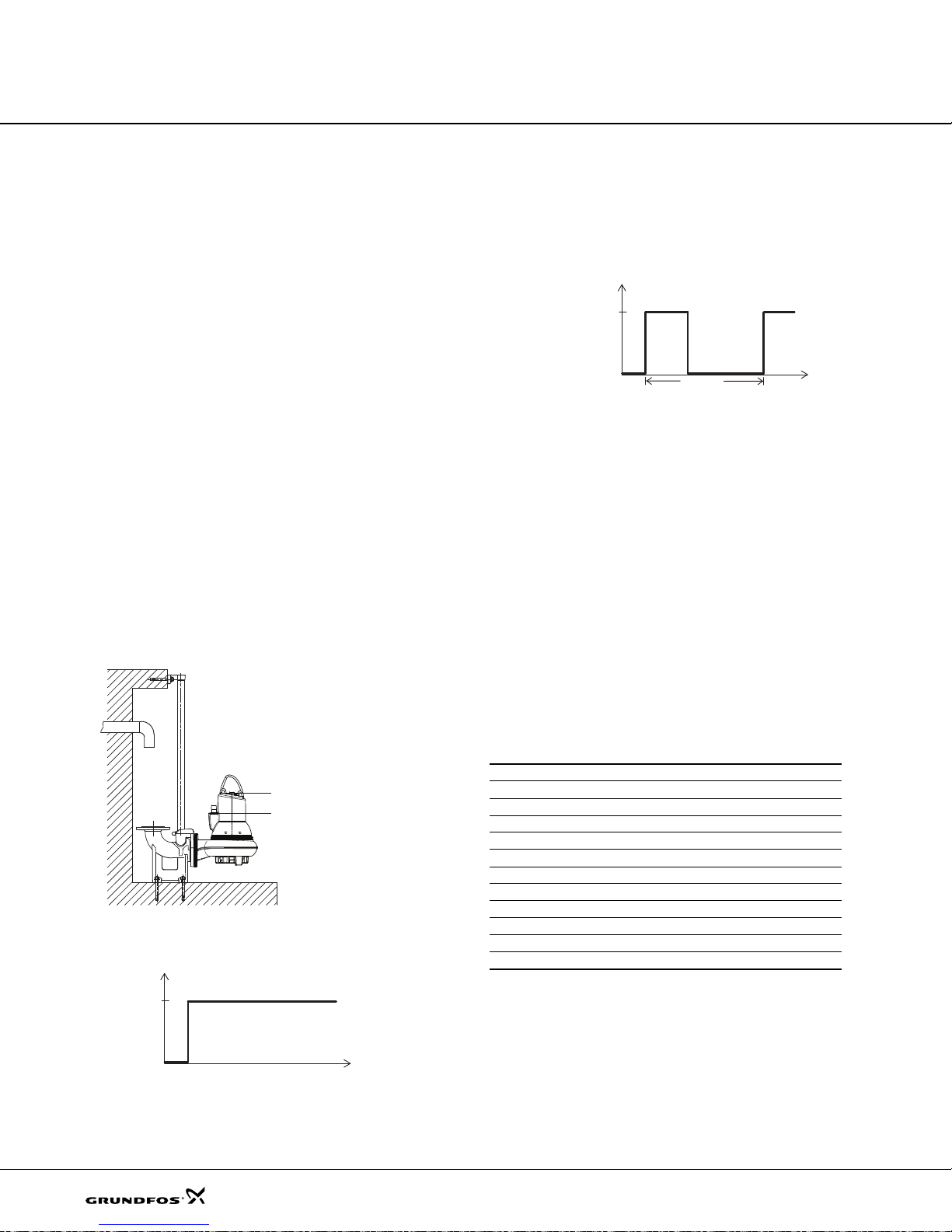

Installati on systems 148

Other accessories 149

Level controllers 150

Further product documentation

WebCAPS 152

WinCAPS 153

Construction

SL1 16

SLV 22

Components and material specification 28

Product description

Features 29

Operating condition s 30

Motor range 30

Pump controllers 31

Variable frequency drive operation 32

Wiring diagrams 33

Curve charts and technical data

How to read the curve charts 38

Curve conditions 39

Performance tests 39

Certificates 39

Witness test 39

2

Page 3

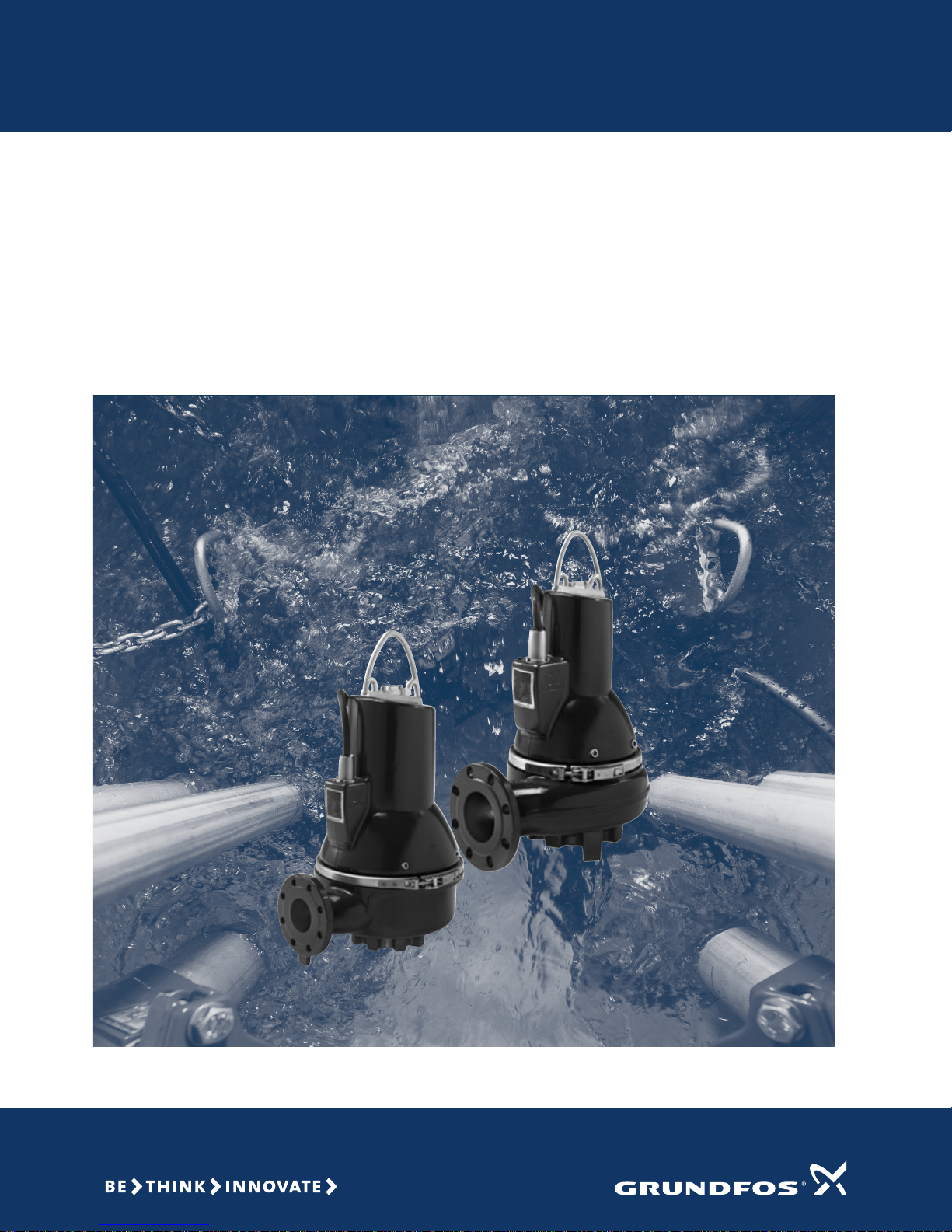

Introduction

SLV

SL1

Introduction

This data booklet deals with Grundfos submersible

sewage pumps, types SL1 and SLV.

Fig. 1 SL1 and SLV pumps

The pumps are free-flow (SuperVo rte x) and single channel impeller pumps specifically designed for

pumping sewage and wastewater in a w ide range of

municipal, private and industrial applications.

The pumps are made of resistant ma teri als, such as

cast iron and stainless steel. These materials ensure a

proper operation.

The pumps are fitted with motors fro m 1.5 hp up to

15 hp (1.1 to 11 kW). The motors are either 2- or 4-pole

motors, depending on the motor size.

The free passage in the pumps is 2 to 4” (50 to

100 mm).

The pumps are available for:

• submerged installation on auto-coupling system

• submerged installation, free-standing.

Applications

Typical applications are transfer of liquids, such as:

• municipal wastewater

• wastewater with high content of fibres (SuperVortex

impeller)

• drainage and groundwater

• domestic wastewater

• industrial wastewater

• process and cooling water.

The pumps are ideal for the pumping of the above

liquids from for instance:

• municipal network pumping stations

• inlet pumping stations in wastewater treatment

plants

• primary clarification in wastewater treatmen t pl ants

• secondary clarification in wastewater treatment

plants

• stormwater pumping stations

• public buildings

• residential buildings

• factories/industry.

Overall construction features

• Cable entry as cable plug, made of corrosionresistant stainless steel with conductors embedded

in polyamide

• Power cable incorporating wires for thermal sensors

in the motor windings

• No extra cable required for sensors in pumps with

sensors

• Monitoring of operating conditions for pumps with

sensors

• Moisture detector for continuous monitoring of

motor enclosure and automatic cut-out in case o f

leakage

• Heavy-duty bearings greased for life

• Built for variable frequency drive oper ation

• Smooth pump surface prevents dirt and impurities

from sticking to the pump

• Self-cleaning channel impeller with long vanes, thus

reducing risk of jamming or clogging, or Sup erVortex impeller with high pumping efficiency and

less downtime

• Explosion-proof motors for potentially explo sive

environments

• Motor in insulation class H (356 °F (180 °C ),

enclosure class IP68 with thermal sensor in each

phase

• Temperature rise class A (1.5 to 8 hp) or class B (10

to 15 hp)

• Service-friendly design:

- clamp connection between motor and pump

- cartridge shaft seal

- cable connection to motor via plug.

• Motor built of highly efficient EFF1 components,

offering lower motor temperature and longer life.

3

Page 4

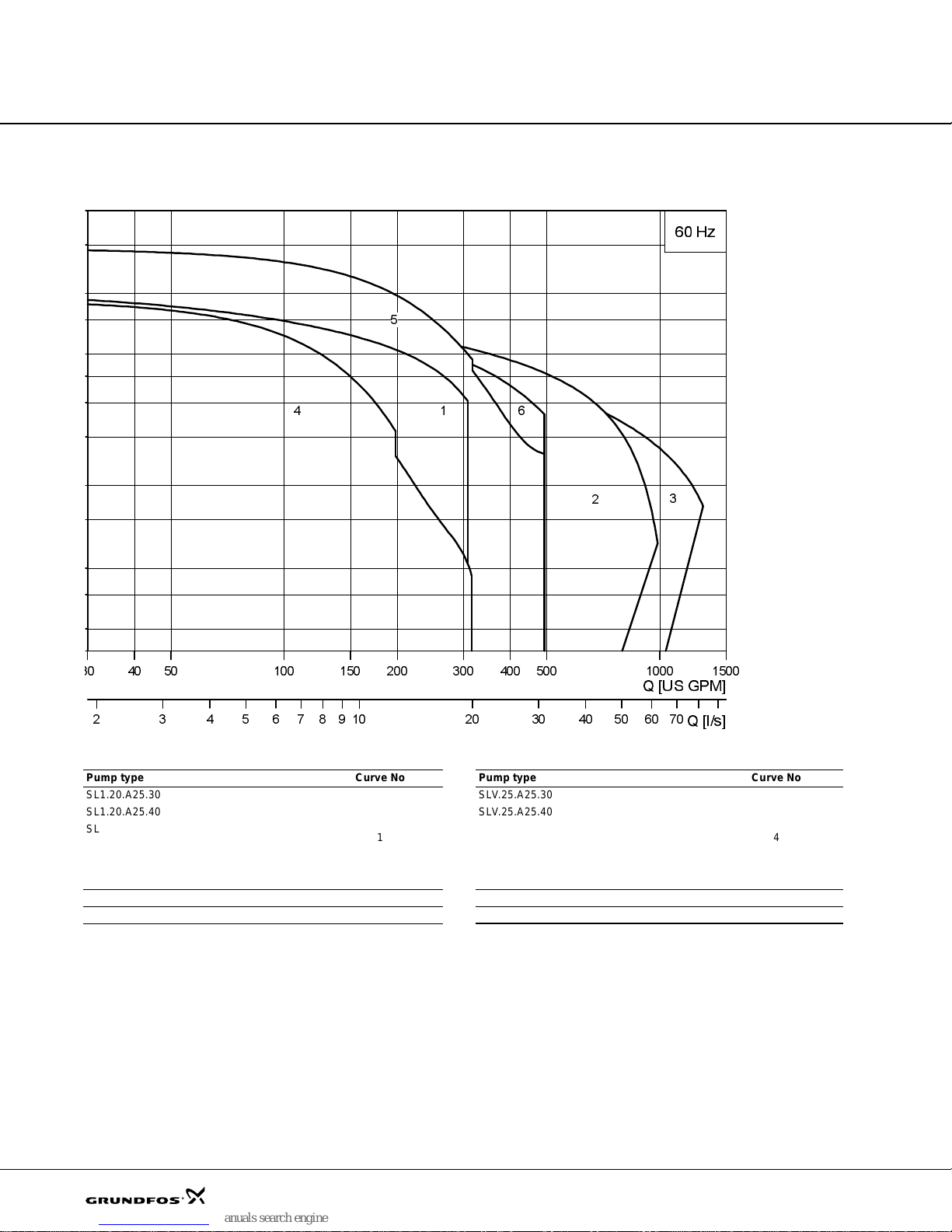

Performance range

Q [US GPM]

2 3 4 5 6 7 8 9 1010 20 30 40 50 60 70

Q [l/s]

60 Hz

1

2

4

5

6

3

Performance range, SL1, SLV pumps

Pump type Curve No Pump type Curve No

SL1.20.A25.30

SL1.20.A25.40 SLV.25.A25.40

SL1.20.A25.55 SLV.25.A25.55

SL1.20.A30.30 SLV.25.A30.30

SL1.20.A30.40 SLV.25.A30.40

SL1.20.A30.55 SLV.25.A30.55

SL1.30 2 SLV.30 5

SL1.40 3 SLV.40 6

1

SLV.25.A25.30

4

TM04 7578 2210

4

Page 5

Identification

Type key

SL1, SLV

Code Example SL 1 30. A30. 55. A. Ex. 4. 6. 0H A. Q.

Pump type:

SL

Grundfos w ast ew ate r pu mp/sewage pump

Impeller type:

1

Single-channel impeller

V

Free-flow impeller (SuperVortex)

Pump passage. C ode number from type key / 10 [inch]:

20

2" (50 mm)

25

2.5" (65 mm)

30

3" (80 mm)

40

4" (100 mm)

Pump discharge (discharge port in inches):

A25

ANSI 2.5" (DN65)

A30

ANSI 3" (DN80)

A40

ANSI 4" (DN100)

A60

ANSI 6" (DN150)

Motor power. Code number from t yp e key / 10 [ hp ]

55

5.5 hp = 4.0 kW

Accessories:

[-]

Standard

A

Sensor

Pump version:

[-]

Non-explosion-proof

Ex

Explosion- pr oo f

Number of poles:

2

2-pole

4

4-pole

Frequency:

6

60 Hz

Voltage and starting method:

0J

3 x 208-230 V Δ DOL

1J

3 x 208-230 V Δ / 460V Y

1H

3 x 460V Δ Y/D

0L

3 x 575V Δ DOL

1L

3 x 575V Δ Y/D

Product generation:

A

1st generation

B

2nd generation

C

3rd generation

Material variant:

[-]

Cast iron impeller, volute and moto r housi ng

Q

Stainless steel impeller

Note: The pump types are not available in all variants.

5

Page 6

Identification

E

4

3

1

2

5

6

8

9

12

7

13

10

15

17

14

18

19

22

16

21

23

20

24

11

Nameplate

Fig. 2 Nameplate

Pos. Description

1 Protection according to FM

2 Type designation

3 Serial number

4 Production code (year/month)

5 Maximum ambient temperature

6 Maxi m um h ea d

7 Maxi m um fl ow rate

8 Rated input/output power

9 Rated voltage, D

10 Rated voltage, Y

11 Frequenc y

12 Country of production

13 CSA mark

14 FM mark

15 Enclosure class to IEC

16 Maximum installation depth

17 Po wer fa ctor

18 Number of phases

19 Rated speed

20 Service factor

21 Full load current, D

22 Full load current, Y

23 Insulation class

24 Weight without cable

TM04 4187 0909

6

Page 7

Selection of product

Ordering a pump

When ordering a pump, you need to take the following

five aspects into consideration:

1. pump type

2. custom-built variation (option)

3. explosion-proof version

4. accessories

5. pump controller.

Pump

Use the following table to ident ify w hich type of pu mp

that best meets your needs. The table is f or g uidance

only.

Application SL1 SLV

Storm water x x

Groundwater x x

Drainage and surface water x x

Drainage and surface water with small impurities x x

Abrasive surface water x x

Wastewater with long fibres, e.g. from laundries x x

Domestic wastew a ter w ith discharge from to ilets x x

Municipal sewage x x

Sewage from commercial buildings x x

Industrial pr oces s water w ith fibr es /solid s x

Industrial pr oces s wate r with s olids x x

Industrial process water without solids and fibres x

When you have selected the pump type, you can

identify the specific pump that best meets your needs in

section Product range on page 8 a nd T ype key on

page 5. The list below is a detaile d descr iptio n of the

product you get if you order the follo wing pump:

Custom-built variants

The pumps can be customized to meet individual

requirements. Many pump features and o ption s are

available for customization, such as explosion-proof

versions, various cable lengths or special materials.

Variants can be seen in the table in sect ion List of

variants on page 15. For requir ements or d esigns

outside the mentioned table, contact Grundf os.

Accessories

Depending on the installation type, accessories may be

required. See section Installation systems on page 148

for selection of the correct accessor ies.

Note: Ordered accessories are not fitted from factory.

Controller

The following controllers a re available:

• CU361 - Grundfos Dedicated Controls

Grundfos Dedicated Controls is a control system

designed for installation in either commercial buildings

or network pumping stations with one to six pumps.

Advanced control and data communication ar e al so

possible with the Grundfos Dedicated Controls system.

The Dedicated Controls system is desig ned to cont rol

and monitor Grundfos wastewater pumps.

See also section Pump controllers on page 31.

Explosion-proof version

The entire range is available in exp losion-proof

versions.

The SL1 and SLV pumps have the foll owing explosi on

protection classification: Class I, Division 1, Groups C

and D, T4, T3, IP68.

Pump Product no

SLV.25.A25.30.2.61H 96970895

• Pump as specified in the type key

• 33 ft (10 m) cable

• Paint: NSC 8005-R80B (dark gr ey), gloss co de 35,

thickness 100 μ

• Thermal switch in stator

• Tested according to Hydraulic Institute Centrifugal

pump test 1.6-2000 acceptance level B.

See section Performance curves Technical data for

selection of a standard pump.

Note: Product-specific dat a fo r the pu mp can a lso be

found in WebCAPS using the pr oduct number

96970895.

7

Page 8

Product range

SL1 pump range

Pump type Sensor

SL1.20.A25.30

SL1.20.A25.40

SL1.20.A25.55

SL1.20.A30.30

SL1.20.A30.40

SL1.20.A30.55

SL1.30.A30.20

SL1.30.A30.30

Single channel Q versions will be available from 3rd quarter of 2011. Contact Grundfos for more information.

Explosio n

proof

[.A] [.EX ] [.2] [.6 ] [0J] [1J] [1H] [0L] [1L] [.Q]

No No 2 6 - 96970713 96970715 - 96970716 No

Yes No 2 6 - 96971178 96971180 - 96971181 No

No Yes 2 6 - 96971644 96971646 - 969716 47 No

Yes Yes 2 6 - 96972111 96972113 - 96 972114 No

NoNo26-----Yes

YesNo26-----Yes

No No 2 6 - 96970719 96970724 - 96970722 No

Yes No 2 6 - 96971184 96971189 - 96971187 No

No Yes 2 6 - 96971650 96971655 - 969716 53 No

Yes Yes 2 6 - 96972117 96972122 - 96972120 No

NoNo26-----Yes

YesNo26-----Yes

No No 2 6 - 96970727 96970732 - 96970730 No

Yes No 2 6 - 96971192 96971197 - 96971195 No

No Yes 2 6 - 96971658 96971663 - 969716 61 No

Yes Yes 2 6 - 96972125 96972130 - 96972128 No

NoNo26-----Yes

YesNo26-----Yes

No No 2 6 - 96970735 96970737 - 96970738 No

Yes No 2 6 - 96971200 9697 12 02 - 9 69 71203 No

No Yes 2 6 - 96971666 96971668 - 969716 69 No

Yes Yes 2 6 - 96972133 96972135 - 96972136 No

NoNo26-----Yes

YesNo26-----Yes

No No 2 6 - 96970741 96970746 - 96970744 No

Yes No 2 6 - 96971206 96971211 - 96971209 No

No Yes 2 6 - 96971672 96971677 - 969716 75 No

Yes Yes 2 6 - 96972139 96972144 - 96972142 No

NoNo26-----Yes

YesNo26-----Yes

No No 2 6 - 96970749 96970754 - 96970752 No

Yes No 2 6 - 96971214 9697 12 19 - 9 69 71217 No

No Yes 2 6 - 96971680 96971685 - 969716 83 No

Yes Yes 2 6 - 96972147 96972152 - 97622851 No

NoNo26-----Yes

YesNo26-----Yes

No No 4 6 96970757 96970765 - 96970760 96970762 No

Yes No 4 6 96971222 96971230 - 96971225 96971227 No

No Yes 4 6 96971688 96971696 - 96971691 96971693 No

Yes Yes 4 6 96972155 96972163 - 96972158 96972160 No

No No 4 6 97662094 97662095 - 97661961 97661962 Yes

Yes No 4 6 97662139 97662140 - 97662005 97662006 Yes

No No 4 6 - 96970763 96970759 - 96970766 No

Yes No 4 6 - 96971228 9697 12 24 - 9 69 71231 No

No Yes 4 6 - 96971694 96971690 - 969716 97 No

Yes Yes 4 6 - 96972161 96972157 - 96972164 No

No No 4 6 - 97662096 97662101 - 97661963 Yes

Yes No 4 6 - 97662151 97662156 - 97662007 Yes

Poles Hz

3x208-230V

DOL

3x208-230V Δ

/ 460V Y

Voltage

3x460V Y/D 3x575V DOL 3x575V Y/D

Stainless steel

impeller

8

Page 9

Product range

Pump type Sensor

SL1.30.A30.40

SL1.30.A30.55

SL1.30.A30.75

SL1.30.A30.100

SL1.30.A40.20

SL1.30.A40.30

SL1.30.A40.40

SL1.30.A40.55

Single channel Q versions will be available from 3rd quarter of 2011. Contact Grundfos for more information.

Explosio n

proof

[.A] [.EX ] [.2] [.6 ] [0J] [1J] [1H] [0L] [1L] [.Q]

No No 4 6 - 96970769 96970774 - 96970772 No

Yes No 4 6 - 96971234 9697 12 39 - 9 69 71237 No

No Yes 4 6 - 96971700 96971705 - 969717 03 No

Yes Yes 4 6 - 96972167 96972172 - 96972170 No

No No 4 6 - 97662097 97662102 - 97661964 Yes

Yes No 4 6 - 97662152 97662157 - 97662008 Yes

No No 4 6 - 96970777 96970782 - 96970780 No

Yes No 4 6 - 96971242 9697 12 47 - 9 69 71245 No

No Yes 4 6 - 96971708 96971713 - 96 97 17 11 No

Yes Yes 4 6 - 96972175 96972180 - 96972178 No

No No 4 6 - 97662098 97662103 - 97661965 Yes

Yes No 4 6 - 97662153 97662158 - 97662009 Yes

No No 4 6 - 96970785 96970790 - 96970788 No

Yes No 4 6 - 96971250 9697 12 55 - 9 69 71253 No

No Yes 4 6 - 96971716 96971721 - 969717 19 No

Yes Yes 4 6 - 96972183 96972188 - 96972186 No

No No 4 6 - 97662099 97662104 - 97661966 Yes

Yes No 4 6 - 97662154 97662159 - 97662010 Yes

No No 4 6 - 96970793 96970798 - 96970796 No

Yes No 4 6 - 96971258 9697 12 63 - 9 69 71261 No

No Yes 4 6 - 96971724 96971729 - 969717 27 No

Yes Yes 4 6 - 96972191 96972196 - 96972194 No

No No 4 6 - 97662100 97662105 - 97661967 Yes

Yes No 4 6 - 97662155 97662160 - 97662011 Yes

No No 4 6 96970801 96970808 - 96970804 96970806 No

Yes No 4 6 96971266 96971273 - 96971269 96971271 No

No Yes 4 6 96971732 96971739 - 96971735 96971737 No

Yes Yes 4 6 96972199 96972206 - 96972202 96972204 No

No No 4 6 97662106 97662107 - 97661968 97661969 Yes

Yes No 4 6 97662161 97662162 - 97662012 97662013 Yes

No No 4 6 - 96970807 96970809 - 96970810 No

Yes No 4 6 - 96971272 9697 12 74 - 9 69 71275 No

No Yes 4 6 - 96971738 96971740 - 969717 41 No

Yes Yes 4 6 - 96972205 96972207 - 96972208 No

No No 4 6 - 97662108 97662113 - 97661970 Yes

Yes No 4 6 - 97662163 97662168 - 97662014 Yes

No No 4 6 - 96970813 96970818 - 96970816 No

Yes No 4 6 - 96971278 9697 12 83 - 9 69 71281 No

No Yes 4 6 - 96971744 96971749 - 969717 47 No

Yes Yes 4 6 - 96972211 96972216 - 96972214 No

No No 4 6 - 97662109 97662114 - 97661971 Yes

Yes No 4 6 - 97662164 97662169 - 97662015 Yes

No No 4 6 - 96970821 96970826 - 96970824 No

Yes No 4 6 - 96971286 9697 12 91 - 9 69 71289 No

No Yes 4 6 - 96971752 96971757 - 969717 55 No

Yes Yes 4 6 - 96972219 96972224 - 96972222 No

No No 4 6 - 97662110 97662115 - 97661972 Yes

Yes No 4 6 - 97662165 97662170 - 97662016 Yes

Poles Hz

3x208-230V

DOL

3x208-230V Δ

/ 460V Y

Voltage

3x460V Y/D 3x575V DOL 3x575V Y/D

Stainless steel

impeller

9

Page 10

Product range

Pump type Sensor

SL1.30.A40.75

SL1.30.A40.100

SL1.40.A40.55

SL1.40.A40.75

SL1.40.A40.100

SL1.40.A60.55

SL1.40.A60.75

SL1.40.A60.100

Single channel Q versions will be available from 3rd quarter of 2011. Contact Grundfos for more information.

Explosio n

proof

[.A] [.EX ] [.2] [.6 ] [0J] [1J] [1H] [0L] [1L] [.Q]

No No 4 6 - 96970829 96970834 - 96970832 No

Yes No 4 6 - 96971294 9697 12 99 - 9 69 71297 No

No Yes 4 6 - 96971760 96971765 - 969717 63 No

Yes Yes 4 6 - 96972227 96972232 - 96972230 No

No No 4 6 - 97662111 97662116 - 97661973 Yes

Yes No 4 6 - 97662166 97662171 - 97662017 Yes

No No 4 6 - 96970837 96970842 - 96970840 No

Yes No 4 6 - 96971302 9697 13 07 - 9 69 71305 No

No Yes 4 6 - 96971768 96971773 - 969717 71 No

Yes Yes 4 6 - 96972235 96972240 - 96972238 No

No No 4 6 - 97662112 97662117 - 97661974 Yes

Yes No 4 6 - 97662167 97662172 - 97662018 Yes

No No 4 6 - 96970845 96970855 - 96970848 No

Yes No 4 6 - 96971310 9697 13 15 - 9 69 71313 No

No Yes 4 6 - 96971776 96971781 - 969717 79 No

Yes Yes 4 6 - 96972243 96972248 - 96972246 No

No No 4 6 - 97662118 97662121 - 97661975 Yes

Yes No 4 6 - 97662173 97662176 - 97662019 Yes

No No 4 6 - 96970853 96970858 - 96970856 No

Yes No 4 6 - 96971318 9697 13 23 - 9 69 71321 No

No Yes 4 6 - 96971784 96971789 - 969717 87 No

Yes Yes 4 6 - 96972251 96972256 - 96972254 No

No No 4 6 - 97662119 97662122 - 97661976 Yes

Yes No 4 6 - 97662174 97662177 - 97662020 Yes

No No 4 6 - 96970861 96970866 - 96970864 No

Yes No 4 6 - 96971326 9697 13 31 - 9 69 71329 No

No Yes 4 6 - 96971792 96971797 - 969717 95 No

Yes Yes 4 6 - 96972259 96972264 - 96972262 No

No No 4 6 - 97662120 97662123 - 97661977 Yes

Yes No 4 6 - 97662175 97662178 - 97662021 Yes

No No 4 6 - 96970869 96970874 - 96970872 No

Yes No 4 6 - 96971334 9697 13 39 - 9 69 71337 No

No Yes 4 6 - 96971800 96971805 - 969718 03 No

Yes Yes 4 6 - 96972267 96972272 - 96972270 No

No No 4 6 - 97662124 97662127 - 97661978 Yes

Yes No 4 6 - 97662179 97662182 - 97662022 Yes

No No 4 6 - 96970877 96970882 - 96970880 No

Yes No 4 6 - 96971342 9697 13 47 - 9 69 71345 No

No Yes 4 6 - 96971808 96971813 - 96 97 18 11 No

Yes Yes 4 6 - 96972275 96972280 - 96972278 No

No No 4 6 - 97662125 97662128 - 97661979 Yes

Yes No 4 6 - 97662180 97662183 - 97662023 Yes

No No 4 6 - 96970885 96970890 - 96970888 No

Yes No 4 6 - 96971350 9697 13 55 - 9 69 71353 No

No Yes 4 6 - 96971816 96971821 - 969718 19 No

Yes Yes 4 6 - 96972283 96972288 - 96972286 No

No No 4 6 - 97662126 97662129 - 97661980 Yes

Yes No 4 6 - 97662181 97662184 - 97662024 Yes

Poles Hz

3x208-230V

DOL

3x208-230V Δ

/ 460V Y

Voltage

3x460V Y/D 3x575V DOL 3x575V Y/D

Stainless steel

impeller

10

Page 11

Product range

SLV pump range

Pump type Sensor

SLV.25.A25.30

SLV.25.A25.40

SLV.25.A25.55

SLV.25.A30.30

SLV.25.A30.40

SLV.25.A30.55

SLV.30.A30.15

SLV.30.A30.18

Vortex Q versions are available from june 2010. Contact Grundfos for more information.

Explosio n

proof

[.A] [.EX ] [.2] [.6 ] [0J] [1J] [1H] [0L] [1L] [.Q]

No No 2 6 - 96970893 96970895 - 96970896 No

Yes No 2 6 - 96971358 9697 13 60 - 96971361 No

No Yes 2 6 - 96971824 96971826 - 96971827 No

Yes Yes 2 6 - 96972291 969722 93 - 96972294 No

No No 2 6 - --Yes

Yes No 2 6 - - Yes

No No 2 6 - 96970899 96970904 - 96970902 No

Yes No 2 6 - 96971364 9697 13 69 - 96971367 No

No Yes 2 6 - 96971830 96971835 - 96971833 No

Yes Yes 2 6 - 96972297 969723 02 - 96972300 No

No No 2 6 - - Yes

Yes No 2 6 - - Yes

No No 2 6 - 96970907 96970912 - 96970910 No

Yes No 2 6 - 96971372 9697 13 77 - 96971375 No

No Yes 2 6 - 96971838 96971843 - 96971841 No

Yes Yes 2 6 - 96972305 969723 10 - 96972308 No

No No 2 6 - ----Yes

Yes No 2 6 - ----Yes

No No 2 6 - 96970915 96970917 - 96970918 No

Yes No 2 6 - 96971380 9697 13 82 - 96971383 No

No Yes 2 6 - 96971846 96971848 - 96971849 No

Yes Yes 2 6 - 96972313 969723 15 - 96972316 No

No No 2 6 - - Yes

Yes No 2 6 - - Yes

No No 2 6 - 96970921 96970926 - 96970924 No

Yes No 2 6 - 96971386 9697 13 91 - 96971389 No

No Yes 2 6 - 96971852 96971857 - 96971855 No

Yes Yes 2 6 - 96972319 969723 24 - 9697

No No 2 6 - - Yes

Yes No 2 6 - - Yes

No No 2 6 - 96970929 96970934 - 96970932 No

Yes No 2 6 - 96971394 9697 13 99 - 96971397 No

No Yes 2 6 - 96971860 96971865 - 96971863 No

Yes Yes 2 6 - 96972327 969723 32 - 96972330 No

No No 2 6 - - Yes

Yes No 2 6 - - Yes

No No 4 6 96970937 96970935 - 96970940 96970956 No

Yes No 4 6 96971402 96971400 - 96971405 96971421 No

No Yes 4 6 96971868 96971866 - 96971871 96971887 No

Yes Yes 4 6 96972335 96972333 - 96972338 96972354 No

No No 4 6 97638699 97638722 - 97638628 97638641 Yes

Yes No 4 6 97639015 97639018 - 97638669 97638672 Yes

No No 4 6 96970943 96970941 - 96970946 96970958 No

Yes No 4 6 96971408 96971406 - 96971411 96971423 No

No Yes 4 6 96971874 96971872 - 96971877 96971889 No

Yes Yes 4 6 96972341 96972339 - 96972344 96972356 No

No No 4 6 97638700 97638723 - 97638629 97638642 Yes

Yes No 4 6 97639016 97639019 - 97638670 97638673 Yes

Poles Hz

3x208-230V

DOL

3x208-230V Δ

/ 460V Y

Voltage

3x460V Y/D 3x575V DOL 3x575V Y/D

2322 N

Stainles s steel

impeller

o

11

Page 12

Product range

Pump type Sensor

SLV.30.A30.20

SLV.30.A30.30

SLV.30.A30.55

SLV.30.A30.55

SLV.30.A30.80

SLV.30.A30.100

SLV.30.A30.125

SLV.30.A30.150

Vortex Q versions are available from june 2010. Contact Grundfos for more information.

Explosio n

proof

[.A] [.EX ] [.2] [.6 ] [0J] [1J] [1H] [0L] [1L] [.Q]

No No 4 6 96970949 96970947 - 96970952 96970970 No

Yes No 4 6 96971414 96971412 - 96971417 96971435 No

No Yes 4 6 96971880 96971878 - 96971883 96971901 No

Yes Yes 4 6 96972347 96972345 - 96972350 96972368 No

No No 4 6 97638721 97638724 - 97638630 97638643 Yes

Yes No 4 6 97639017 97639020 - 97638671 97638674 Yes

No No 4 6 - 96970955 96970963 - 96970953 No

Yes No 4 6 - 96971420 9697 14 28 - 96971418 No

No Yes 4 6 - 96971886 96971894 - 96971884 No

Yes Yes 4 6 - 96972353 969723 61 - 96972351 No

No No 4 6 - 97638725 97638732 - 97638644 Yes

Yes No 4 6 - 97639031 97639038 - 97638675 Yes

No No 2 6 - 96970961 96970966 - 96970964 No

Yes No 2 6 - 96971426 9697 14 31 - 96971429 No

No Yes 2 6 - 96971892 96971897 - 96971895 No

Yes Yes 2 6 - 96972359 969723 64 - 96972362 No

No No 2 6 - 97638727 97638734 - 97638646 Yes

Yes No 2 6 - 97639033 97639040 - 97638677 Yes

No No 4 6 - 96970969 96970974 - 96970972 No

Yes No 4 6 - 96971434 9697 14 39 - 96971437 No

No Yes 4 6 - 96971900 96971905 - 96971903 No

Yes Yes 4 6 - 96972367 969723 72 - 96972370 No

No No 4 6 - 97638726 97638733 - 97638645 Yes

Yes No 4 6 - 97639032 97639039 - 97638676 Yes

No No 2 6 - 96970977 96970982 - 96970980 No

Yes No 2 6 - 96971442 9697 14 47 - 96971445 No

No Yes 2 6 - 96971908 96971913 - 96971911 No

Yes Yes 2 6 - 96972375 969723 80 - 96972378 No

No No 2 6 - 97638728 97638735 - 97638647 Yes

Yes No 2 6 - 97639034 97639041 - 97638678 Yes

No No 2 6 - 96970985 96970990 - 96970988 No

Yes No 2 6 - 96971450 9697 14 55 - 96971453 No

No Yes 2 6 - 96971916 96971922 - 96971920 No

Yes Yes 2 6 - 96972383 969723 88 - 96972386 No

No No 2 6 - 97638729 97638736 - 97638648 Yes

Yes No 2 6 - 97639035 97639042 - 97638679 Yes

No No 2 6 - 96970993 96970998 - 96970996 No

Yes No 2 6 - 96971458 9697 14 63 - 96971461 No

No Yes 2 6 - 96971925 96971930 - 96971928 No

Yes Yes 2 6 - 96972391 969723 96 - 96972394 No

No No 2 6 - 97638730 97638737 - 97638649 Yes

Yes No 2 6 - 97639036 97639043 - 97638680 Yes

No No 2 6 - 96971001 96971006 - 96971004 No

Yes No 2 6 - 96971466 9697 14 71 - 96971469 No

No Yes 2 6 - 96971933 96971938 - 96971936 No

Yes Yes 2 6 - 96972399 969724 04 - 96972402 No

No No 2 6 - 97638731 97638738 - 97638650 Yes

Yes No 2 6 - 97639037 97639044 - 97638681 Yes

Poles Hz

3x208-230V

DOL

3x208-230V Δ

/ 460V Y

Voltage

3x460V Y/D 3x575V DOL 3x575V Y/D

Stainles s steel

impeller

12

Page 13

Product range

Pump type Sensor

SLV.30.A40.15

SLV.30.A40.18

SLV.30.A40.20

SLV.30.A40.30

SLV.30.A40.55

SLV.30.A40.55

SLV.30.A40.80

SLV.30.A40.100

Vortex Q versions are available from june 2010. Contact Grundfos for more information.

Explosio n

proof

[.A] [.EX ] [.2] [.6 ] [0J] [1J] [1H] [0L] [1L] [.Q]

No No 4 6 96971009 96971007 - 96971012 96971026 No

Yes No 4 6 96971474 96971472 - 96971477 96971491 No

No Yes 4 6 96971941 96971939 - 96971944 96971958 No

Yes Yes 4 6 96972407 96972405 - 96972410 96972424 No

No No 4 6 97638739 97638742 - 97638651 97638654 Yes

Yes No 4 6 97639045 97639048 - 97638682 97638685 Yes

No No 4 6 96971015 96971013 - 96971018 96971029 No

Yes No 4 6 96971480 96971478 - 96971483 96971494 No

No Yes 4 6 96971947 96971945 - 96971950 96971961 No

Yes Yes 4 6 96972413 96972411 - 96972416 96972427 No

No No 4 6 97638740 97638743 - 97638652 97638655 Yes

Yes No 4 6 97639046 97639049 - 97638683 97638686 Yes

No No 4 6 96971021 96971019 - 96971024 96971040 No

Yes No 4 6 96971486 96971484 - 96971489 96971505 No

No Yes 4 6 96971953 96971951 - 96971956 96971972 No

Yes Yes 4 6 96972419 96972417 - 96972422 96972438 No

No No 4 6 97638741 97638744 - 97638653 97638656 Yes

Yes No 4 6 97639047 97639050 - 97638684 97638687 Yes

No No 4 6 - 96971027 96971043 - 96971025 No

Yes No 4 6 - 96971492 9762 28 56 - 96971490 No

No Yes 4 6 - 96971959 96971975 - 96971957 No

Yes Yes 4 6 - 96972425 969724 41 - 96972423 No

No No 4 6 - 97638745 97638752 - 97638657 Yes

Yes No 4 6 - 97639051 97639058 - 97638688 Yes

No No 2 6 - 96971033 96971038 - 96971036 No

Yes No 2 6 - 96971498 9697 15 53 - 96971551 No

No Yes 2 6 - 96971965 96971970 - 96971968 No

Yes Yes 2 6 - 96972431 969724 36 - 96972434 No

No No 2 6 - 97638747 97638754 - 97638659 Yes

Yes No 2 6 - 97639053 97639060 - 97638690 Yes

No No 4 6 - 96971041 96971046 - 96971044 No

Yes No 4 6 - 96971556 96971511 - 96971559 No

No Yes 4 6 - 96971973 96971978 - 96971976 No

Yes Yes 4 6 - 96972439 969724 44 - 96972442 No

No No 4 6 - 97638746 97638753 - 97638658 Yes

Yes No 4 6 - 97639052 97639059 - 97638689 Yes

No No 2 6 - 96971049 96971054 - 96971052 No

Yes No 2 6 - 96971514 9697 15 19 - 96971517 No

No Yes 2 6 - 96971981 96971986 - 96971984 No

Yes Yes 2 6 - 96972447 969724 53 - 96972450 No

No No 2 6 - 97638748 97638755 - 97638660 Yes

Yes No 2 6 - 97639054 97639061 - 97638691 Yes

No No 2 6 - 96971057 96971062 - 96971060 No

Yes No 2 6 - 96971522 9697 15 27 - 96971525 No

No Yes 2 6 - 96971989 96971994 - 96971992 No

Yes Yes 2 6 - 96972456 969724 62 - 96972460 No

No No 2 6 - 97638749 97638756 - 97638661 Yes

Yes No 2 6 - 97639055 97639062 - 97638692 Yes

Poles Hz

3x208-230V

DOL

3x208-230V Δ

/ 460V Y

Voltage

3x460V Y/D 3x575V DOL 3x575V Y/D

Stainles s steel

impeller

13

Page 14

Product range

Pump type Sensor

SLV.30.A40.125

SLV.30.A40.150

SLV.40.A40.40

SLV.40.A40.55

SLV.40.A40.75

SLV.40.A40.100

Vortex Q versions are available from june 2010. Contact Grundfos for more information.

Explosio n

proof

[.A] [.EX ] [.2] [.6 ] [0J] [1J] [1H] [0L] [1L] [.Q]

No No 2 6 - 96971065 96971070 - 96971068 No

Yes No 2 6 - 96971530 9697 15 35 - 96971533 No

No Yes 2 6 - 96971997 96972002 - 96972000 No

Yes Yes 2 6 - 96972465 969724 70 - 96972468 No

No No 2 6 - 97638750 97638757 - 97638662 Yes

Yes No 2 6 - 97639056 97639063 - 97638693 Yes

No No 2 6 - 96971073 96971078 - 96971076 No

Yes No 2 6 - 96971538 9697 15 43 - 96971541 No

No Yes 2 6 - 96972005 96972010 - 96972008 No

Yes Yes 2 6 - 96972473 969724 78 - 96972476 No

No No 2 6 - 97638751 97638758 - - Yes

Yes No 2 6 - 97638751 97638758 - 97638663 Yes

No No 4 6 - 97639057 97639064 - 97638694 No

Yes No 4 6 - 96971546 9762 28 57 - 96971549 No

No Yes 4 6 - 96972013 96972018 - 96972016 No

Yes Yes 4 6 - 96972481 969724 86 - 96972484 No

No No 4 6 - 97638759 97638763 - 97638664 Yes

Yes No 4 6 - 97639065 97639069 - 97638695 Yes

No No 4 6 - 96971089 96971094 - 96971092 No

Yes No 4 6 - 96971554 9762 28 60 - 96971557 No

No Yes 4 6 - 96972021 96972026 - 96972024 No

Yes Yes 4 6 - 96972489 969724 94 - 96972492 No

No No 4 6 - 97638760 97638764 - 97638665 Yes

Yes No 4 6 - 97639066 97639070 - 97638696 Yes

No No 4 6 - 96971097 96971102 - 96971100 No

Yes No 4 6 - 96971562 9697 15 67 - 96971565 No

No Yes 4 6 - 96972029 96972034 - 96972032 No

Yes Yes 4 6 - 96972497 969725 02 - 96972500 No

No No 4 6 - 97638761 97638765 - 97638666 Yes

Yes No 4 6 - 97639067 97639071 - 97638697 Yes

No No 4 6 - 96971105 96971110 - 96971108 No

Yes No 4 6 - 96971570 9697 15 75 - 96971573 No

No Yes 4 6 - 96972037 96972043 - 96972041 No

Yes Yes 4 6 - 96972505 969725 10 - 96972508 No

No No 4 6 - 97638762 97638766 - 97638667 Yes

Yes No 4 6 - 97639068 97639072 - 97638698 Yes

Poles Hz

3x208-230V

DOL

3x208-230V Δ

/ 460V Y

Voltage

3x460V Y/D 3x575V DOL 3x575V Y/D

Stainles s steel

impeller

14

Page 15

Variants

List of variants

Motor

50 ft (15 m)

Various cable lengths

EMC power c ab l es Screened p o wer cables for vari a ble - s pe ed d ri v es

Special motor Special voltage

Tests

Test at specified duty on standard impeller curve

Trimmed impeller for sp ecifi ed du ty test

Additional test of entire QH curve (including report) Duty points from pump performance curve

Different tes t s tand ar d Efficiency guar an te ed b y Grundfos

Customer requested duty point

Vibration test ( incl ud i ng r ep ort) According to Gr un dfos factory qual ity standard

String test Contact Grundfos

Witness test Contact Grundfos

Note: When using a different cable length than

standard, a new cable cross section must be

calculated

Test according to customer specified duty poin t o n

standard pump curve

Hydraulic Institute 1.6-2000

acceptance level B

Hydraulic Institute 1.6-2000

acceptance level B

65 ft (20 m)

80 ft (25 m)

100 ft (30 m)

130 ft (40 m)

165 ft (50 m)

33 ft (10 m)

50 ft (15 m)

65 ft (20 m)

80 ft (25 m)

100 ft (30 m)

130 ft (40 m)

165 ft (50 m)

Certificates

ATEX-aproved pump report Special Grundfos report. Contact Grundfos

Certificate of compliance with order According to EN10204 2.1. accordi ng to annex A grade 1 and 2

Pump certificate According to EN10204 2.2 according to annex A grade 1 and 2

Insepction certificate According to EN10204 3.1 according to annex A grade 1 and 2

Material specification report According to EN10204 3.1B

Material report with certificate According to EN10204 3.2 Material supplier information

Inspection certificate Lloyds Register According to EN10204 3.2

Inspection certificate DNV (Det Norske Veritas) According to EN10204 3.2

Inspection certificate Germanisher Lloyd According to EN10204 3.2

Inspection certificate American Bureau of shipping According to EN10204 3.2

Inspection certificate Bureau Veritas According to EN10204 3.2

Registro Itali an o Navale Argenture According t o EN 10 20 4 3. 2

Other 3rd-party test certificate Contact Grundfos

Miscellaneous

FKM sealing (optional) Contact Grundfos

Cable protection hose Contact Grundfos

Stainless steel impe lle r Contact Grundfos

Ceramic coating of impeller and pump housing Contact Grundfos

Extra epoxy coating 300 micron Contact Grundfos

Top coating (black RAL9005, red RAL 3000 and other colors Contact Grundfos

Special packaging Contact Grundfos

Special nameplate Contact Grundfos

Other variants Contact Grundfos

15

Page 16

Construction

SL1

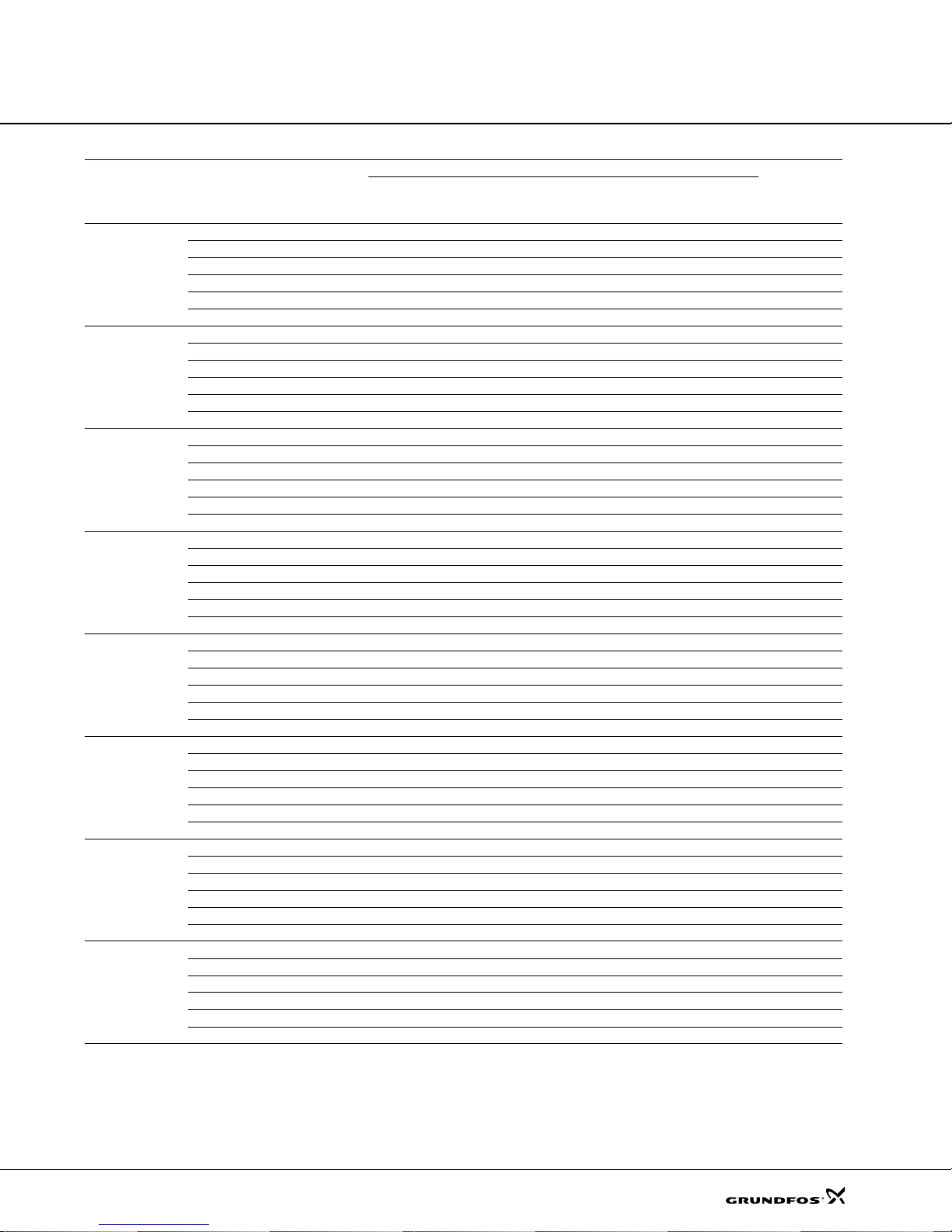

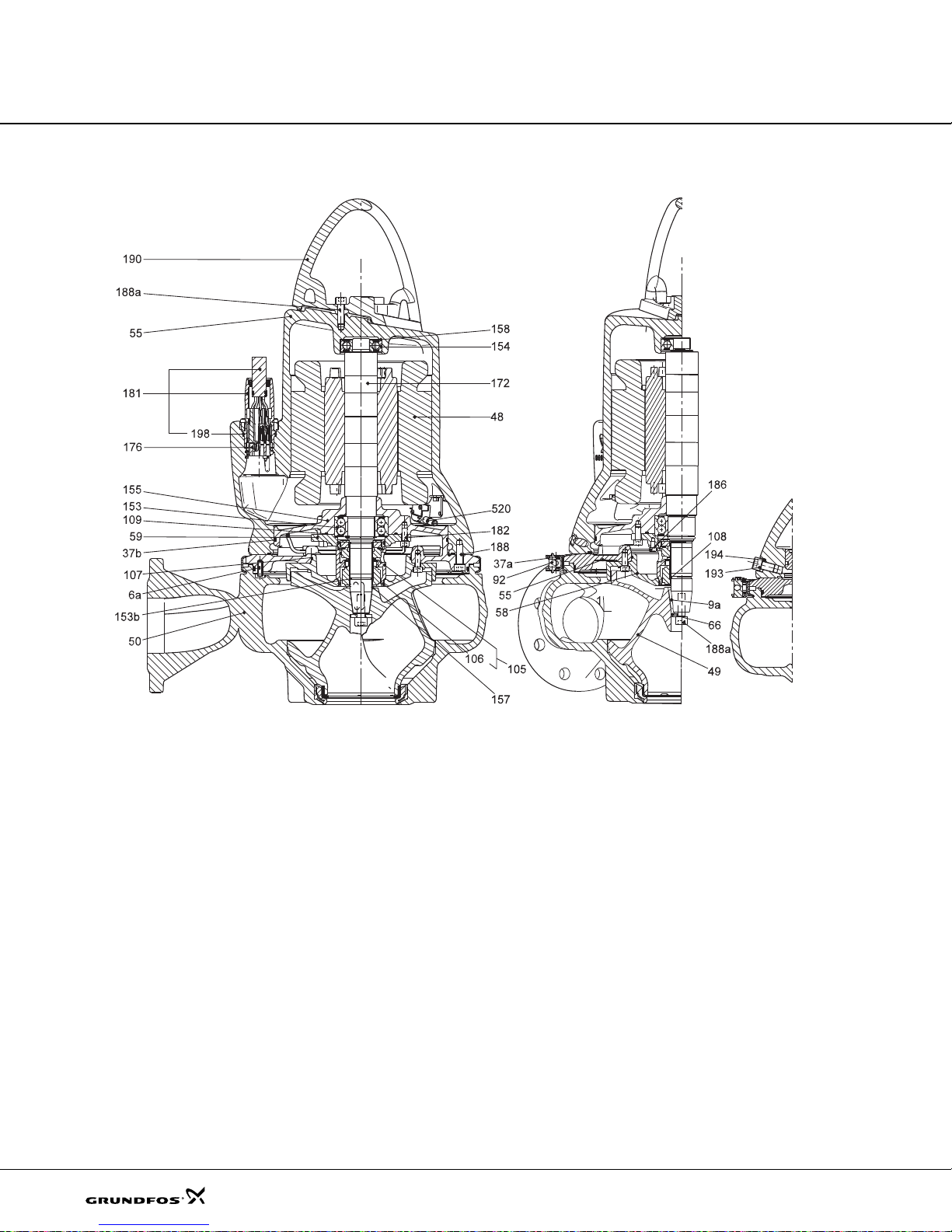

Fig. 3 Sectional drawing , SL1 pu mps w ithou t sens or

16

TM04 2787 2908

Page 17

Construction

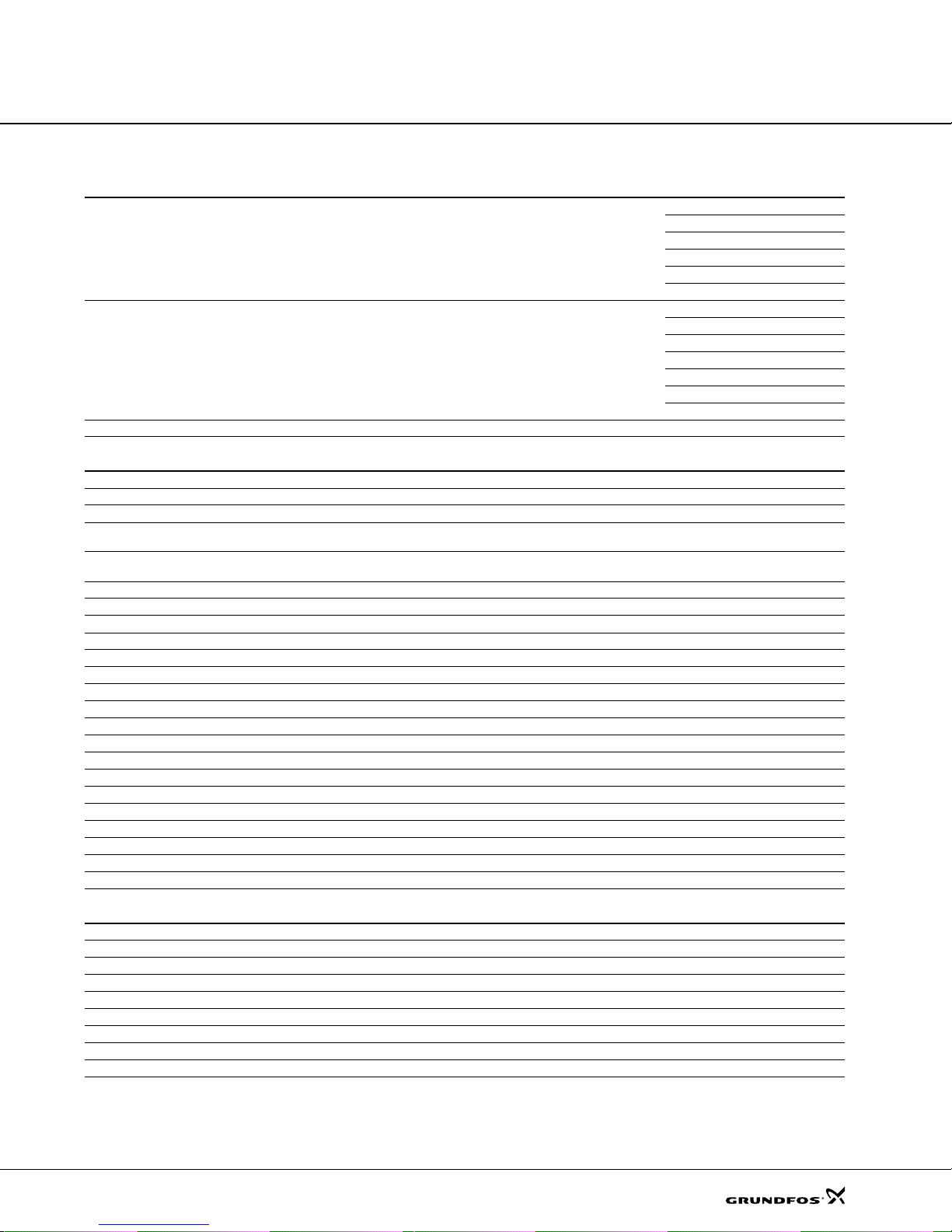

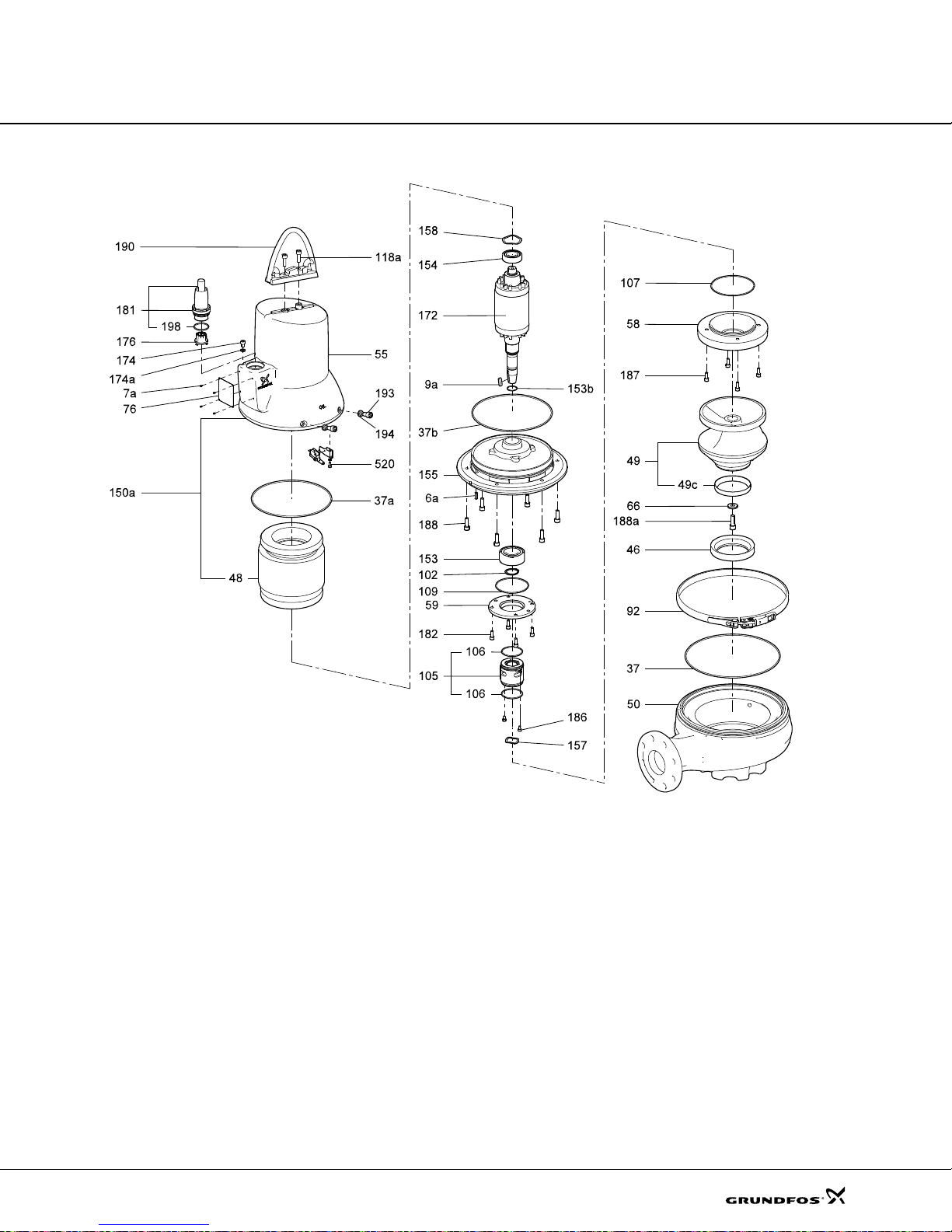

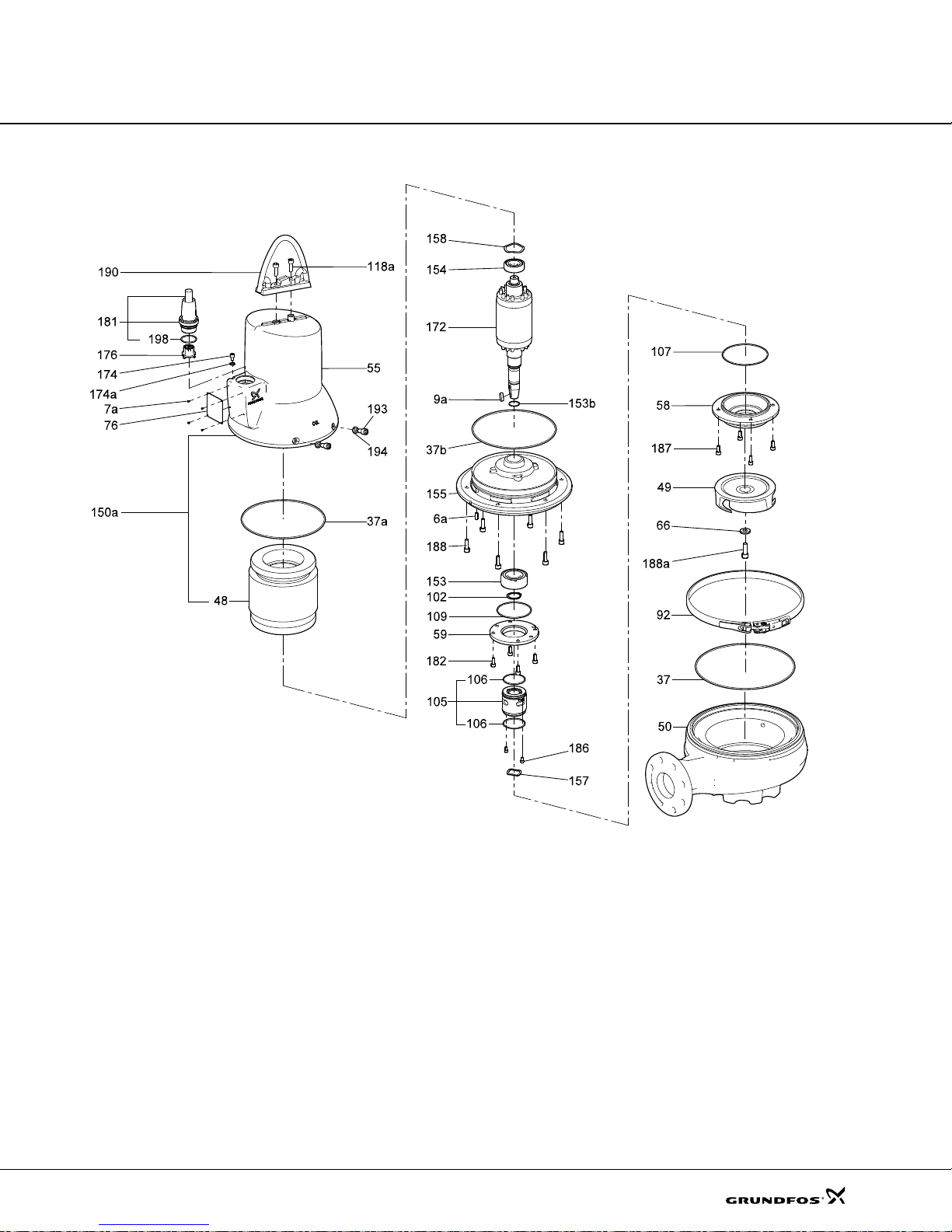

Fig. 4 Exploded view, SL1 pumps without sensor

TM04 2777 2908

17

Page 18

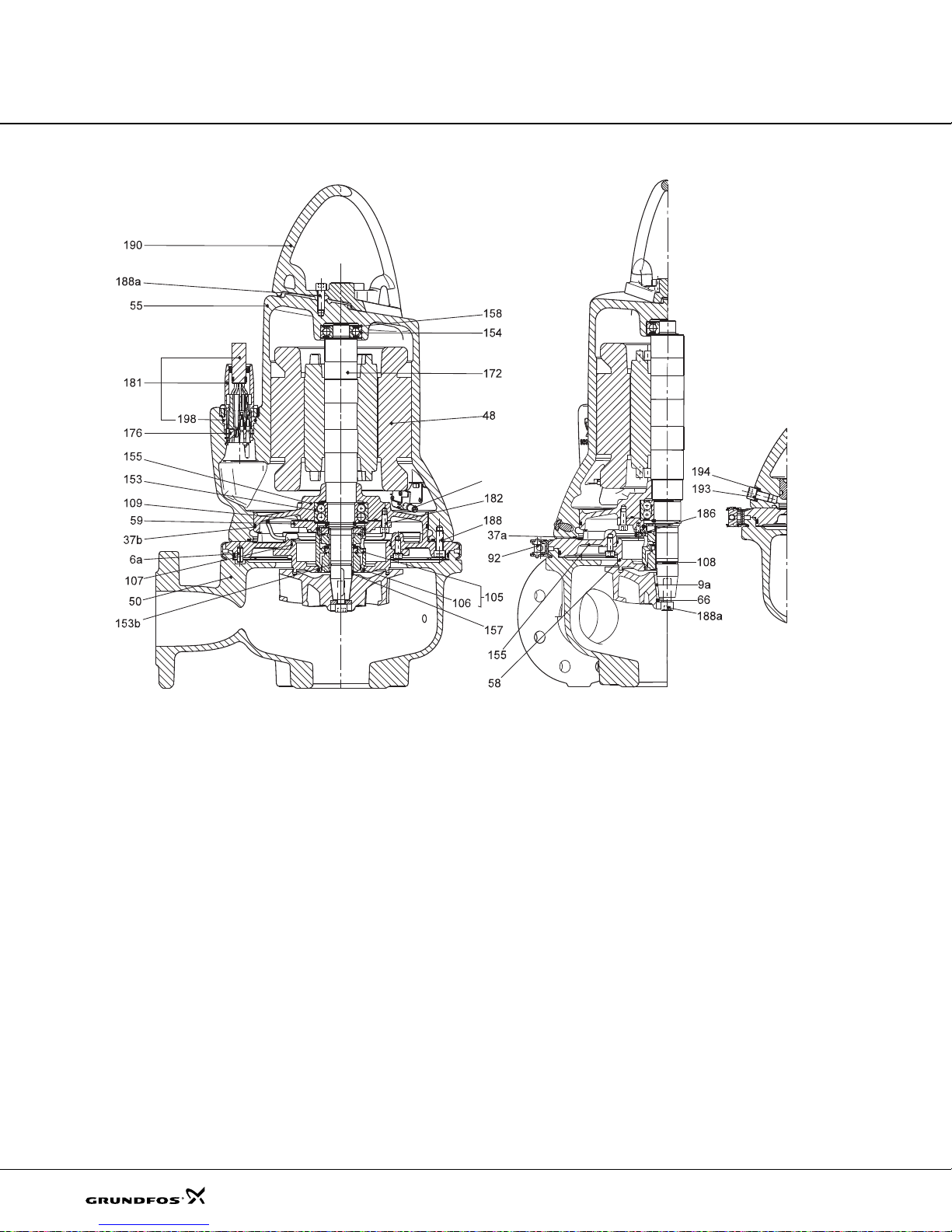

Construction

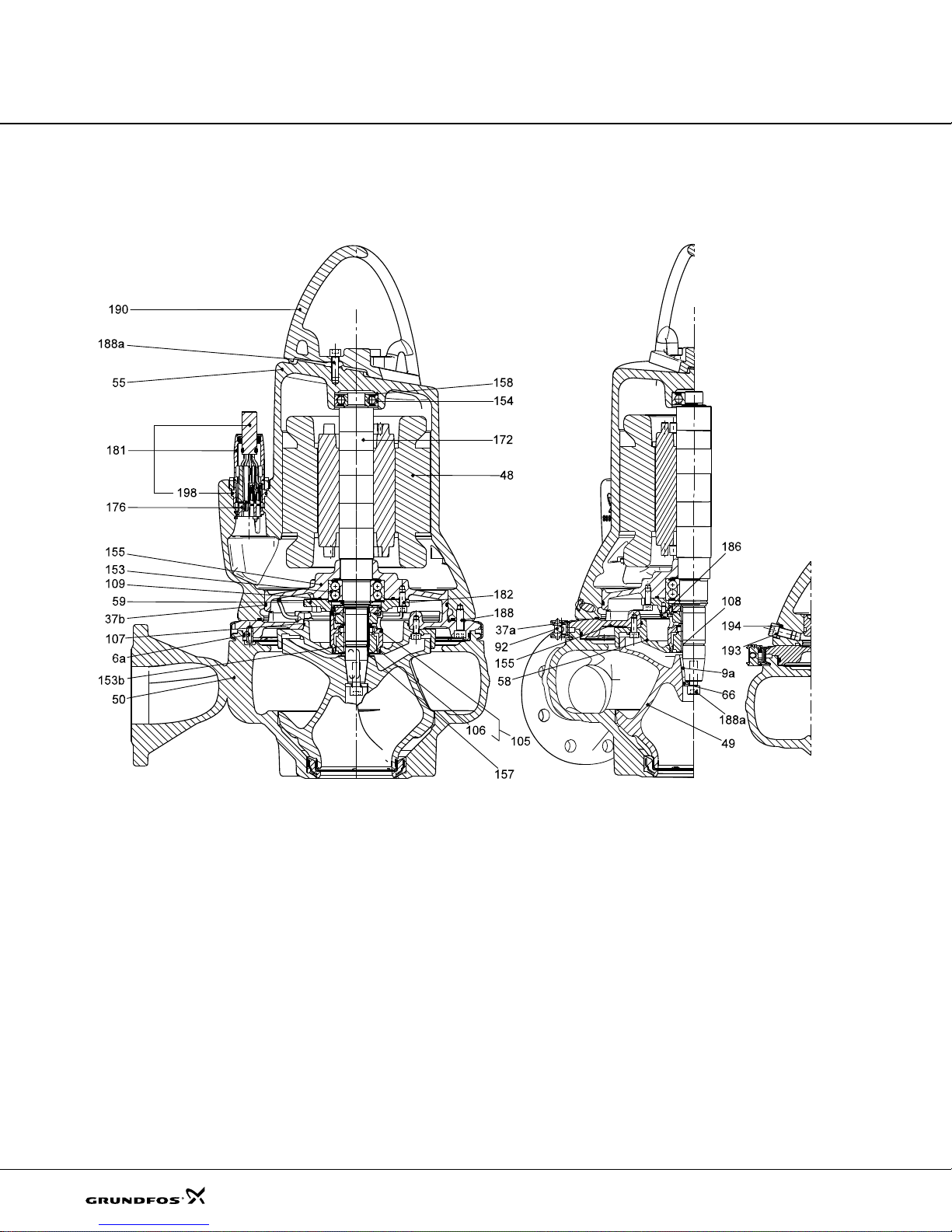

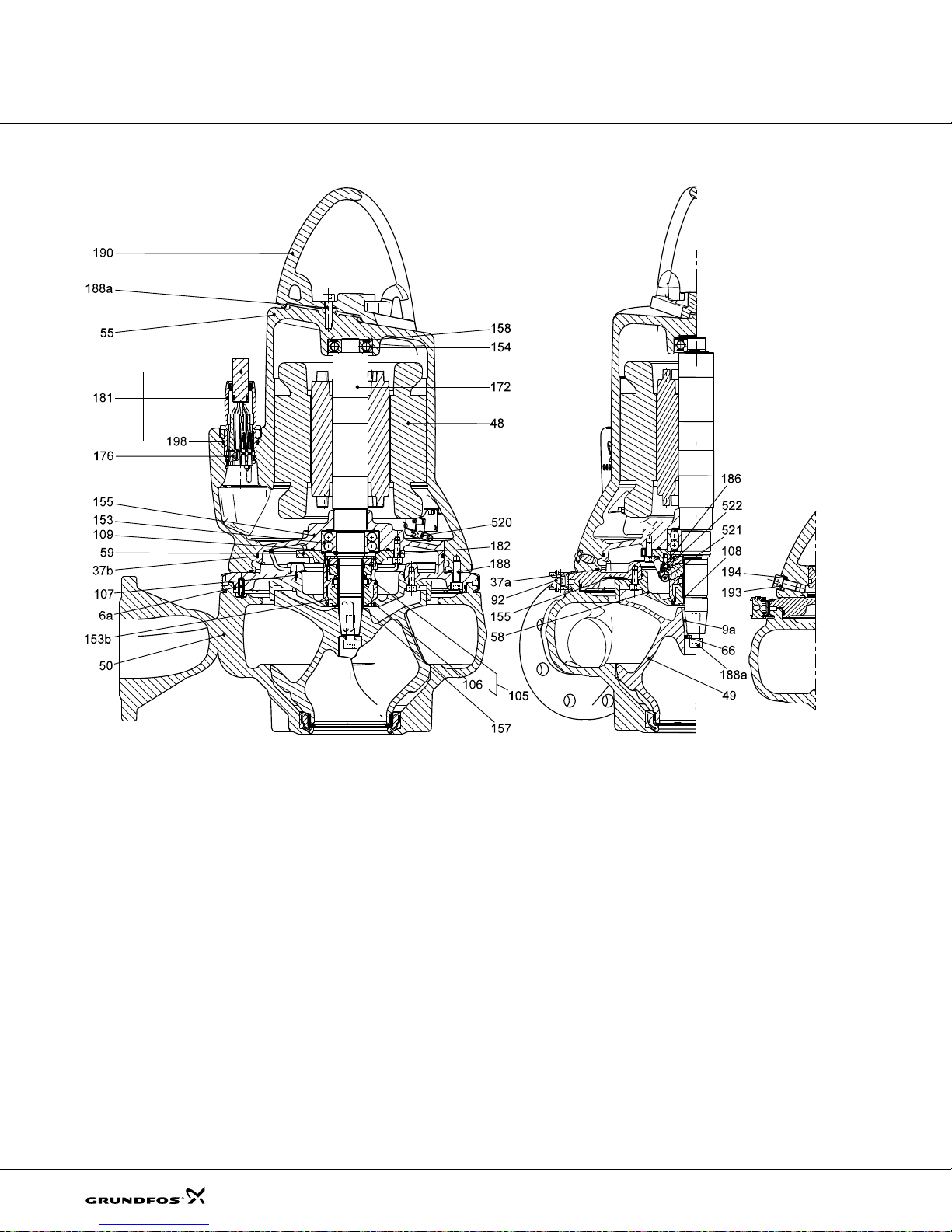

Fig. 5 Sectional drawing , SL 1 pumps E X ve rsion

TM04 7575 2110

18

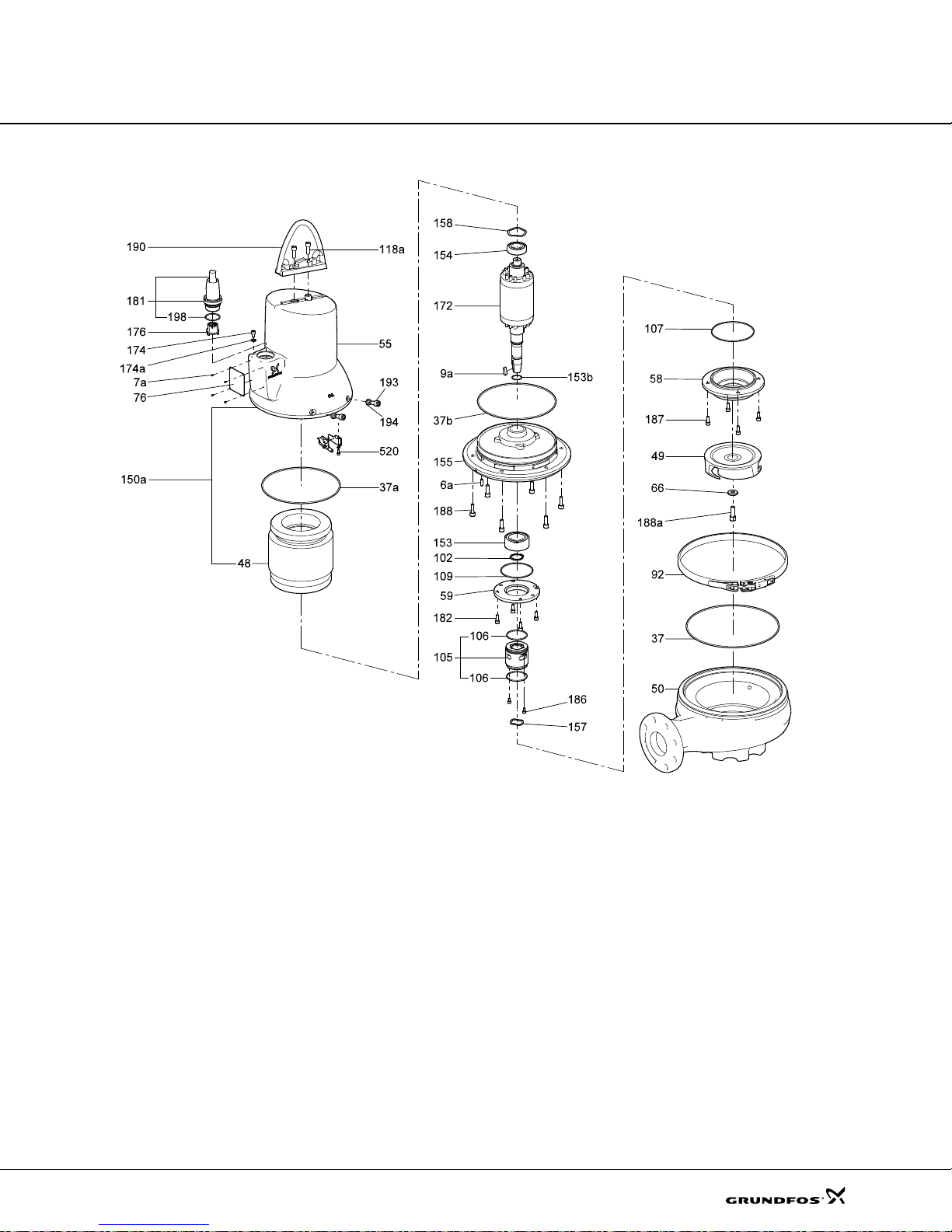

Page 19

Construction

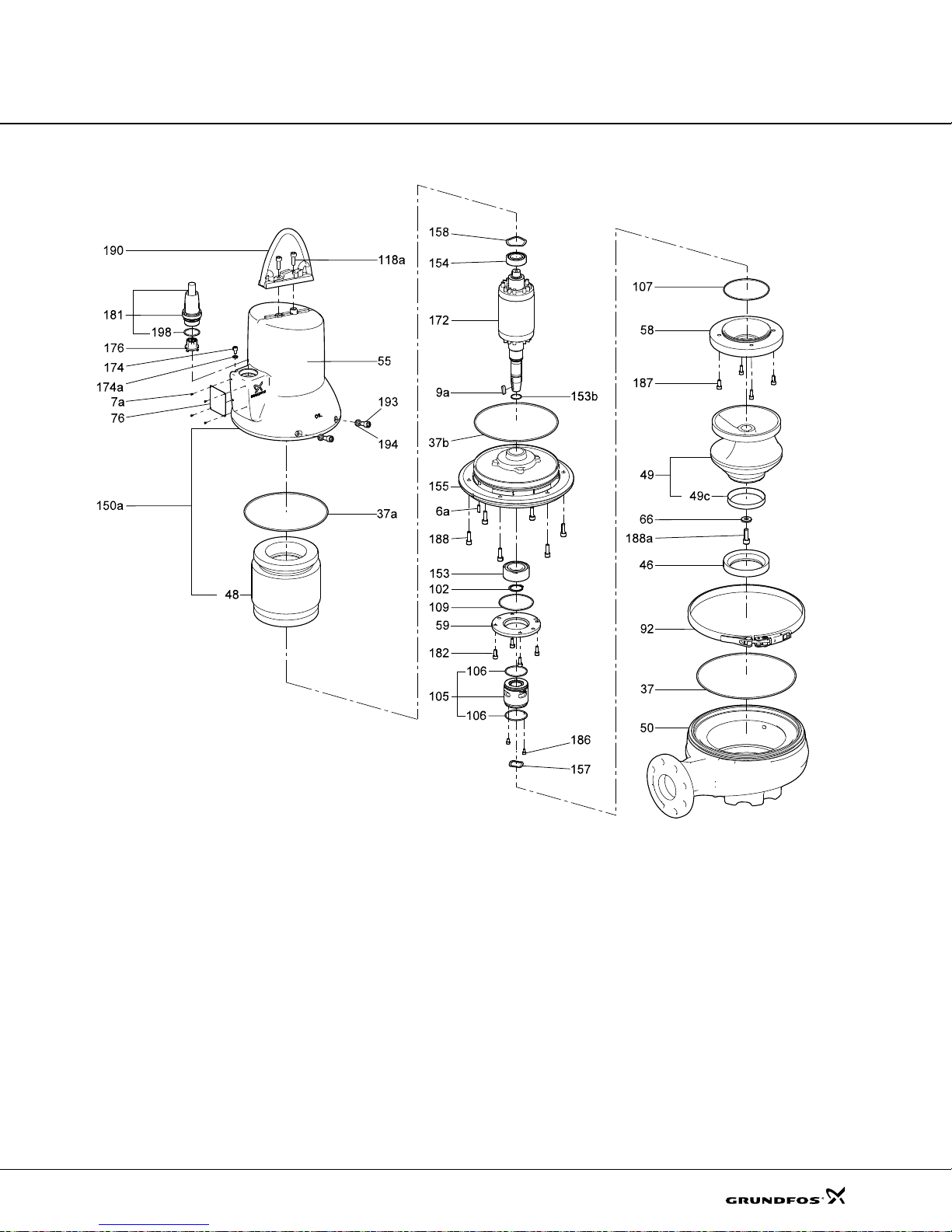

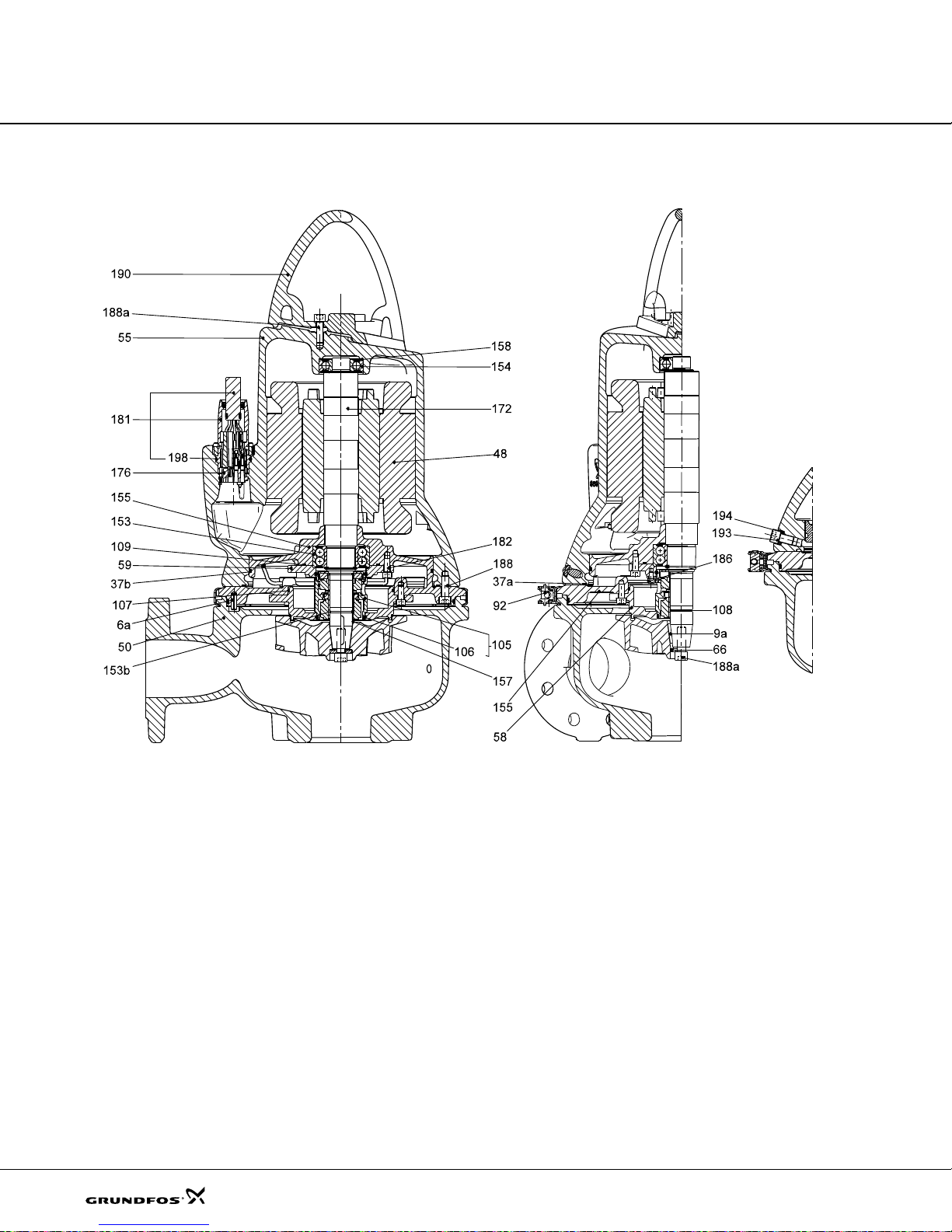

Fig. 6 Exploded view, SL1 pumps EX version

TM047077 1610

19

Page 20

Construction

Fig. 7 Sectional drawing , SL1 pu mps w ith sens or

TM04 2788 2908

20

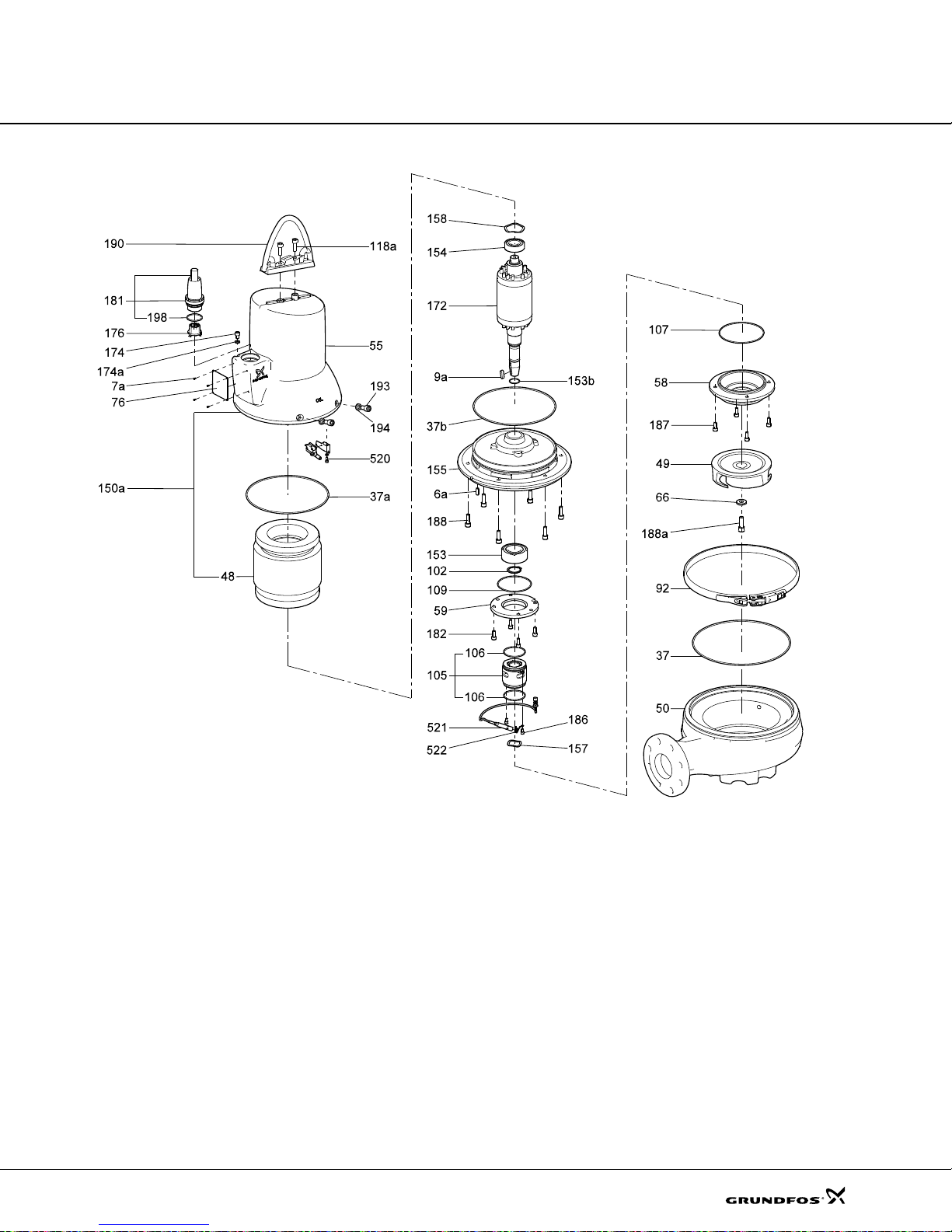

Page 21

Construction

Fig. 8 Exploded view, SL1 pumps with sens or

TM02 2778 0904

21

Page 22

Construction

SLV

Fig. 9 Exploded view, SLV pumps without sensor

TM04 2785 2908

22

Page 23

Construction

Fig. 10 Sectional drawin g, S LV pumps without sensor

TM04 2779 2908

23

Page 24

Construction

520

Fig. 11 Exploded view, SLV pumps EX version

TM04 7576 2110

24

Page 25

Construction

Fig. 12 Sectional dra wing, S LV pumps EX version

TM04 2779 2908

25

Page 26

Construction

Fig. 13 Sectional drawin g, S LV pumps with sensor

TM04 2786 2908

26

Page 27

Construction

Fig. 14 Exploded view, SLV pumps with sensor

TM04 2780 2908

27

Page 28

Construction

Components and material specification

Pos. Component Material

6a Tubular pin D 8 x 22 A2 Stainless steel 1.4301 304

7a Blank rive t 2.4 x 6 A 2 Stainless steel 1.4301 304

37 O-Ring NBR rubber

37a O-Ring NBR rubber

48 Stator package

49 Impeller Cast iron GG20 EN-JL 1030

55 Stator housing Cast iron GG20 EN-JL 1030

58 Cover fo r oil chamber Cast iron GG 2 0 EN-JL 1030

59 Bearing cover Cast iron GG25 EN-JL 1040

76 Nameplate Stainless steel 1.4401 316

92 Clamp Stainless steel 1.4401 316

102 Circlip

Shaft seal cpl.

(rotating part of M G1 /2 5- G6 0 Q1 Q1 P GG

105

stationary part of MG1/25-G60 Q1Q1PGG;

rotating part of BT-AR/25 BXPFF

stationary par t of B T-AR/25 BX PF F )

106 O-ring for shaft seal NBR rubber

107 O-ring (cover for oil chamber/cover for oil chamber) NBR rubber

109 O-ring for bearing cover D-end NBR rubber

150a Stator housing co m pl e te wit h stator

153 Bearing, D-end Stainless steel

153b O-ring NBR rubber

154 Bearing, N-end Stainless steel

155 Oil chamber Cast iron GG25 EN-JL1040

157 Corrugated spring (b eari ng D-en d) Stainless steel

158 Corrugated spring (b eari ng N-en d) Stainless steel

172 Shaft with rotor Regular iron/stainless steel 1.0570 1.4401 316

174 Earth screw, external Stainless steel

174a Washer for external earth screw Stainless steel

176 Connector set (internal part)

181 Cable with outer plug part 7G AWG 14 + 3G AWG 16

182 Screw Stainless steel 1.4436 316

186 Screw Stainless steel 1.4436 316

188 Screw Stainless steel 1.4436 316

190 Lifting handle Stainless steel 1.4308

193 Plug Stainless steel 1.4436 316

194 Gasket

198 O-ring NBR rubber

520 Moisture switch (only sensor versions)

521 WIO sensor (only sensor versions)

522 Bracket for WIO sensor (only sensor versions) Stainless steel

Stainless steel, SiC/SiC

Carbon/ceram i c

DIN W. –Nr. /

EN standard

AISI / ASTM

28

Page 29

Product description

Features

Ball bearings

The bearings are greased for life .

Main bearings:

10 hp (7.5 kW) 4-pole,

12 hp (9.2 kW) 2-pole,

15 hp (11kW) 2-pole:

4 hp (3 kW) 4-pole to

10 hp (7.5 kW) 2-pole:

Support bearings: Single-r ow deep-groove ball

bearing.

Shaft seal

The shaft seal consists of two mechanical seals and

separates the motor from the pumped liquid.

The shaft seal is a cartridge seal for easy service. The

combination of the primary and secondary seals in a

cartridge results in shorter assembly l ength compare d

to traditional shaft seals. Fu rth ermore, t his desi gn

minimises the risk of incorrect fitting.

The primary seal is SiC/SiC and the secondar y is

carbon/ceramic.

Motor

The motor is a watertight, to tally encapsulated mot or.

Insulation class: H (356 °F (180 °C)).

Motor insulation fullfils NEMA MG1 par t 31 fo r

frequency converter duty.

Temperature rise class: A (1.5 to 8 hp) or class B (10 to

15 hp).

Enclosure class: IP68.

For motor protection and sensors, see section Sensors

below.

Angular contact bearing

3209B.2RS.C3.SYN.

Angular contact bearing

3208B.2RS.C3.SYN.

Power cables

Standard cable

Cable type

7 G AWG 16 0.523 (13.3) 1.25 (31.8) 1.875 (47.6)

4 G AWG 14 + 3 G 16 AWG 0.636 (16.2) 1.25 (31.8) 1.875 (47.6)

7 G AWG 14 + 3 G 16 AWG 0.811 (20.6) 1.5 (38.1) 2.25 (57.2)

Outer cable

diameter

[inch(mm)]

EMC cable

Cable type

2

]

[mm

4 G AWG 14 + 3 G 16 AWG

screened cable

Outer cable

diameter

[inch (mm)]

0.695 (17.7) 1.5 (38.1 ) 2.25 (57.2)

The cables are 33 ft (10 m) long as st andard. Oth er

cable lengths are available on request. See sect ion

List of variants on page 15.

The number and dimension of cables depend on t he

motor size.

Cable entry

The stainless steel plug is fastene d with a unio n nut.

The nut and O-rings provide sealing a gainst liquid

penetration.

The plug is filled with a special material that is cast into

the plug around the condu ctors of the cable to prevent

water penetrating into the motor through the cable in

case of cable breakage or in case water enters the free

cable end due to careless handling in con nection wi th

installation or service.

Sensors

As standard the pump is equipped with t hree the rmal

switches, one in each phase.

Customised analog sensor options

1. PT1000 sensors in motor phases for stator

temperature measurements.

2. WIO (water-in-oil) sensor

The WIO sensor measures the water content in t he

oil and converts the value into an analog curr ent

signal. The two sensor conductors are for power

supply as well as for carrying the sign al t o the

measuring device or controller. The sensor

measures the water content from 0 to 20 %. It also

sends a signal if the water content is outside t he

normal range (warning), or if the re is air in the o il

chamber (alarm). The sensor is fitte d in a stainless

steel tube for mechanical protection.

The WIO sensor is connected to a Grundfos IO 111

module.

3. One moisture switch.

Bending radius

Fixed

[inch(mm)]

Bending radius

Fixed Free

Free

[inch(mm)]

29

Page 30

Product description

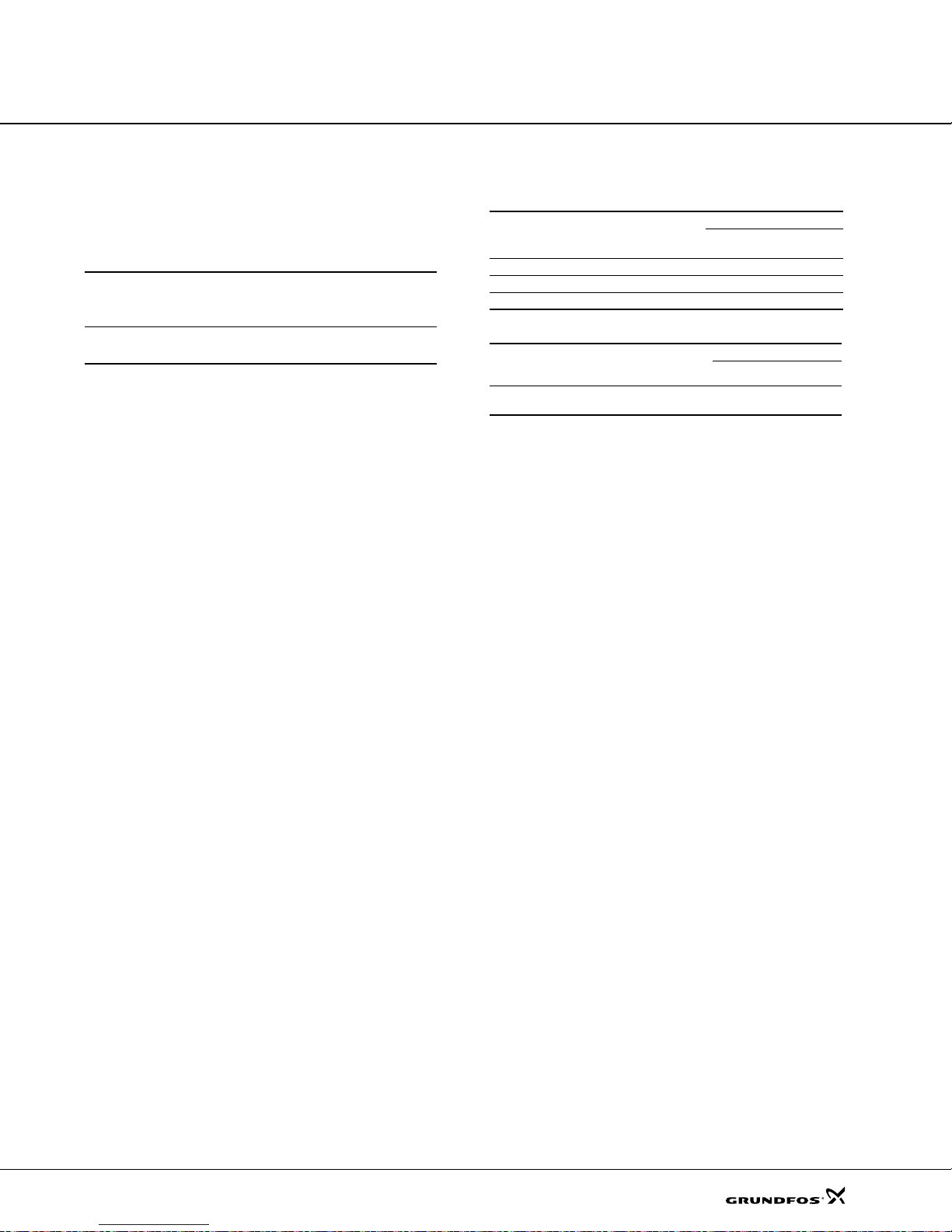

S1 operation

S3 operation

P

t

Stop

Operation

10 min

P

t

4 min 6 min

Operation

Stop

Max.

4 min.

Min. 6

min.

10 min.

IO 111 sensor module

The module collects the following signals from sensors

in the pump:

• Stator temperature

• Stator insulation resistance

• Water in oil chamber

• Moisture in motor.

Note: All pump versions with analog sensor come with

an IO 111 sensor module. It is therefore not necessary

to order an IO 111 separately.

Testing

All pumps are tested before leaving the f actory. T he

factory test report is based on HI 1.6-2000 acceptance

level B. Test reports can be ordered directly with the

pump or separately based on the pump ser ial n umber.

Other tests or third-party inspect ion certif icates a re

available on request. See section List of variants on

page 15.

Operating conditions

The SL1 and SLV pumps are only fo r sub merged

installation.

• Intermittent operation S3 with max. 20 starts per

hour when pump is submerged to the bo ttom of t he

cable plug. The pump must run for max. 4 minut es

and stop for min. 6 minutes. Se e fi g. 16.

Note: Explosion-proof pumps must always be full y

submerged.

TM04 2656 2808

Fig. 16 Intermittent operation

Pumped liquids

pH value: 4-10.

Liquid temperature: 32 °F to + 104 °F

(0 °C to + 40 °C)

When pumping liquids with a density and/or a kinematic

viscosity higher than that of wate r, use mot ors with

correspondingly higher outputs.

For short periods (max. 3 minutes), temperatures up to

140°F (60°C) are permissible (non-Ex versions only).

Sound pressure

The sound pressure level of the pump is lower than the

limiting values stated in the EC C ouncil directive 2006/

42/EC relating to machinery (Mach inery Directive) .

• Continuous operation S1 when the pump is fully

submerged to the top of the moto r.

Fig. 15 Continuous ope ration

30

Motor range

Shaft power [hp (kW)] No of poles

1.5 (1.1) 4

1.8 (1.3) 4

2.0 (1.5) 4

3.0 (2.2) 2/4

4.0 (3.0) 2/4

5.5 (4.0) 2/4

TM04 2649 2808TM02 7776 4003

7.5 (5.5) 4

8.0 (6.0) 4

10.0 (7.5) 2/4

12.5 (9.2) 2

15.0 (11) 2

Page 31

Product description

Pump controllers

The pumps must be connected to a control box w ith a

motor protection relay with IEC t rip class 10 or 15.

Note: Pumps for hazardous locatio ns must be

connected to a control box with a motor protection relay

with an IEC trip class 10 .

The pumps can be controlled by Grundf os Dedicat ed

Controls that enables control of one u p to six pumps.

The Dedicated Controls system starts/stops the SL1

and SLV pumps by means of:

• float switches

• pressure sensor

• ultrasonic sensor.

The Grundfos Dedicated Controls system offe rs the

following features and benefi ts:

Basic features

• Pump start/stop

• alternating operation of two pumps

• overflow detection

• overflow measurement

• alarms and warnings

• advanced alarm schedules

• start and stop delays

• free language selection.

Advanced features

• Daily emptying

• foam draining

• anti-seizing

• safety after-run delay

• mixer or flush valve

• maximum number of running pumps

• pump flow measurement

• system flow measurement

• pump flow calculation

• system flow calculation.

Additional features

• Insulation resistance alarm

• moisture-in-motor alarm.

These features are directly related to the actual system

configuration and the modules insta lled.

Communication features

• Complete overview of the pump installation

• setpoint change, resetting of system and start/stop

of pumps

• access to complete alarm/warning log

• automatic redirection of alarms and warnings to t he

on-duty staff

• optimisation of your maintenance and service

program

• reduction in energy consumption of the system

• Modbus RTU communication via cable

• Modbus RTU communication via GSM/GPRS

• SMS messaging

• VNC connection for migration of user inte rface to

a web browser.

PC-T ool featu res

Used for

• commissioning

• monitoring pump condition

• adjusting settings

• start/stop of pumps

• acquiring data logs

• creating operation reports

• creating service reports.

Benefits

• Easy installation and configuration.

• Configuration wizard that helps the user to configure

the system during start-up.

• Electrical overview via the CU 361 operator display,

for easy maintenance.

• Help texts for settings shown on the operator

display.

• Advanced data communication.

• Advanced alarm and warning priority.

• PC-Tool support.

• VNC (Virtual Network Computing).

• GSM/GPRS, SMS (tran smit and rece iv e), SC AD A,

BMS and PLC support.

• Data logging such as alarms, runtime, flow,

overflow, volume, energy, etc.

• Service-cost-optimised installation.

• Use of easy-to-configure rotating week schedules to

plan ahead.

31

Page 32

Product description

Variable frequency drive operation

In principle, all three-phase motors can be connected to

a frequency converter.

However, frequency converter operation w ill often

expose the motor insulation system to a hea vier load

and cause the motor to be more noisy than usual due to

eddy currents caused by voltage peaks.

In addition, large motors dr iven via a freque ncy

converter will be loaded by bearing currents.

For more information, please se e the Installati on an d

operation manual US-P/N 97640137 at

www.grundfos.com

Approvals

The SL1 and SLV pumps have been approved by CSA

and FM, and the explosion-proof versions hold an F M

type examination certificate no.: 3035318

Approval standards

These pumps are approved by CSA and FM according

to UL778, C22.2 no 108 and FM 3600, FM3615 and

FM3615.80.

Explanation to FM approval

The SL1 and SLV pumps have the following explosion

protection classification: Class I, Division 1, Gr oups C

and D, T4, T3, IP68

Standards Code Description

Explosive atmo sp he re is

caused by gas or

=

vapours.

Area classificatio n

=

Classification of gases

=

maximum surface

temperature is 275 °F

=

(135 °C) and 392 °F

(200 °C)

Enclosure class

=

according to IEC 60 529.

FM3600

FM3615

FM3615.80

Class I

Division 1

Groups C

and D

T4/T3

IP68

32

Page 33

Product description

Standard version

Thermal switches

CSA approved

Ex. version

Thermal switch and moistur e switch

CSA and FM appro ve d

Sensor version

Thermal switch and PT1000 resistor

Moisture switch and water-in -oil se nsor

CSA approved, with/without FM approval

Wiring diagrams

Fig. 17 Wiring diagram, 7-core cable, DO L

tm04 6689 0710

33

Page 34

Product description

Standard version

Thermal switches

CSA approved

Ex. version

Thermal switch and mo istu re sw itch

CSA and FM approved

Sensor version

Thermal switch an d PT10 00 res isto r

Moisture switch and wate r-in-oil s enso r

CSA approved, with/without FM approval

Fig. 18 Wiring diagram, 10-core c able, star/de lta (Y/D )

tm04 6690 0710

34

Page 35

Product description

Standard version

Thermal switches

CSA approved

Ex. version

Thermal switch and moistur e switch

CSA and FM appro ved

Sensor version

Thermal switch and PT10 00 r esisto r

Moisture switch and wate r-in- oil sen sor

CSA approved, with/w ithou t FM a pproval

Fig. 19 Wiring diagram, 10-core c able , star-co nne cte d (Y)

tm04 6691 0710

35

Page 36

Product description

Standard version

Thermal switches

CSA approved

Ex. version

Thermal switch and moisture switch

CSA and FM approved

Sensor version

Thermal switch an d PT 1000 r esist or

Moisture switch and water - in- oil sensor

CSA approved, wit h/with out FM appr oval

Fig. 20 Wiring diagram, 10-core c able, delta-con nect ed (D)

tm04 6692 0710

36

Page 37

Curve charts and

technical data

The following pages are divided into sections:

Pages 38 and 39 give a brief expla nation of how to read the curve chart s, t he curve condi tions, etc.

Performance curves and technical data:

Page Pump curves Page Pump curves Page Pump curves Page Pump curves

Performance curves

40

SL1.20.A25. 30

Performance curves

42

SL1.20.A25. 40

Performance curves

44

SL1.20.A25. 55

Performance curves

46

SL1.20.A30. 30

Performance curves

48

SL1.20.A30. 40

Performance curves

50

SL1.20.A30. 55

Performance curves

52

SL1.30.A30. 20

Performance curves

54

SL1.30.A30. 30

Performance curves

56

SL1.30.A30. 40

Performance curves

58

SL1.30.A30. 55

Performance curves

60

SL1.30.A30. 75

Performance curves

62

SL1.30.A30. 10 0

Performance curves

64

SL1.30.A40. 20

Performance curves

66

SL1.30.A40. 30

Performance curves

68

SL1.30.A40. 40

Performance curves

70

SL1.30.A40. 55

Performance curves

72

SL1.30.A40. 75

Performance curves

74

SL1.30.A40. 10 0

Performance curves

76

SL1.40.A40. 55

Performance curves

78

SL1.40.A40. 75

Performance curves

80

SL1.40.A40. 10 0

Performance curves

82

SL1.40.A60. 55

Performance curves

84

SL

Performance curves

86

SL1.40.A60. 10 0

Performance curves

88

SLV. 25.A25.30

Performance curves

90

SLV. 25.A25.40

Performance curves

92

SLV. 25.A25.55

Performance curves

94

SLV. 25.A30.30

1.40.A6

0.75

40 96

40 98

40 100

40 102

40 104

40 106

40 108

40 110

40 112

40 114

40 116

40 118

40 120

40 122

Performance curves

SLV. 25.A30.40

Performance curves

SLV. 25.A30.55

Performance curves

SLV. 30.A30.15

Performance curves

SLV. 30.A30.18

Performance curves

SLV. 30.A30.20

Performance curves

SLV. 30.A30.30

Performance curves

SLV.30.A30.55, 2- pol e

Performance curves

SLV.30.A30.55, 4- pol e

Performance curves

SLV. 30.A30.80

Performance curves

SLV.30.A30.100

Performance curves

SLV.30.A30.125

Performance curves

SLV.30.A30.150

Performance curves

SLV. 30.A40.15

Performance curves

SLV. 30.A40.18

124

126

128

130

132

134

136

138

140

142

144

146

Performanc e curve s

SLV.30.A40.20

Performanc e curve s

SLV.30.A40.30

Performanc e curve s

SLV.30.A40.55, 2- p ole

Performanc e curve s

SLV.30.A40.55, 4- p ole

Performanc e curve s

SLV.30.A40.80

Performanc e curve s

SLV.30.A40.100

Performanc e curve s

SLV.30.A40.125

Performanc e curve s

SLV.30.A40.150

Performanc e curve s

SLV.40.A40.40

Performanc e curve s

SLV.40.A40.55

Performanc e curve s

SLV.40.A40.75

Performanc e curve s

SLV.40.A40.100

37

Page 38

Curve charts and

0 50 100 150 200 250 300 350 Q [US GPM]

0

5

10

15

20

25

30

35

40

45

[ft]

H

0 2 4 6 8 10 v [ft/s]

10

15

20

25

30

35

40

45

50

[%]

Eff

0 1 2 3 4 v [ft/s]

0 2 4 6 8 10 12 14 16 18 20 22 24 Q [l/s]

0

2

4

6

8

10

12

14

[m]

H

SLV.30.A40.30.4.6

60 Hz

ISO 9906 Annex A

Eff 2

Eff 1

QH

ANSI 4 / DN 100

ANSI 6 / DN 150

0 50 100 150 200 250 300 350 Q [US GPM]

0.5

1.0

1.5

2.0

2.5

3.0

3.5

[hp]

P

0 2 4 6 8 10 12 14 16 18 20 22 24 Q [l/s]

0

10

20

[ft]

NPSH

0.5

1.0

1.5

2.0

2.5

[kW]

P

0

2

4

6

[m]

NPSH

P2

P1

Pump typeQH curve

Eta1 and Eta 2 curves of

the individual pump

Total pump he ad

H = H

total

Power curves

indicating input power

(P

1

) and output power

(P

2

) of the pump

NPSH cuves. When

sizing the pumps, ad d a

safety margin of at least

0.5 m.

technical data

How to read the curve charts

38

TM04 7268 1810

Page 39

Curve charts and

H

total

H

geoHstatHdyn

++=

technical data

Curve conditions

The guidelines below apply to the curves shown in the

performance charts on page 40 to pag e 147.

• Tole rances accordi ng t o: HI 1.6- 2000 a cceptance

level B

• The curves show pump performance w ith different

impeller diameters at the nominal speed .

• The bold part of the curves show the

recommended operating range.

• The curves apply to the pumping of airless water at

a temperature of +68 °F (+ 20 ° C) and a kine matic

viscosity of 1 cSt (1.076 (ft2/s)x10-5).

• ETA: The lines show values of the hydraulic

efficiency of the pump for the different impeller

diameters.

• NPSH: The curves show average values measured

under the same conditions as the per forman ce

curves.

When dimensioning the pump, add a safety margin

of at least 1.6 ft (0.5 m).

• In case of other densities than 13 3.5 o unces/gallon

(1000 kg/m

to the density.

• When pumping liquids with a density h igher than

133.5 ounces/gallon (1000 kg/m

correspondingly higher outputs must be used.

Calculation of total head

The total pump head consists of th e hei ght d ifference

between the measuring points + the differential head +

the dynamic head.

3

), the discharge pressure is proportional

3

), motors with

Performance tests

The requested duty point for ever y pump is te sted

according to HI 1.6-2000 acceptance level B, and

without certification.

In case of pumps ordered on the basi s of impeller

diameter only (no requested duty po int) , the pump wil l

be tested at a duty point which is 2/3 of the maximum

flow of the published performance curve which is

related to the ordered impeller diameter (according to

Hydraulic Institute 1.6-2000 accept ance l evel B).

If the customer requires either more points on the curve

to be checked or certain minimum perfor mances o r

certificates, individual measurements must b e made,

and a certificate can be ordered.

Certificates

Certificates have to be confirmed for every ord er a nd

are available on request. See secti on List of variants

on page 15

Witness test

It is possible for the customer to witness t he te sting

procedure according to Hydraulic I nstitu te 1.6-2 000.

The witness test is not a certificate and will not result in

a written statement from Grundfos. The witness itself is

the only guarantee that everything is car ried out as

prescribed in the testing procedure.

If the customer wants to witness the test of pump

performance, this request must be st ated on t he order.

H

: Height diffe rence between measuring points.

geo

: Differential head between suction and the

H

stat

discharge side of the pump.

H

: Calculated values based on the velocity of the

dyn

pumped liquid on the suction and the discharge

side of the pump.

39

Page 40

0 50 100 150 200 250 Q [US GPM]

0

10

20

30

40

50

60

70

80

[ft]

H

0 2 4 6 8 10 12 14 16 18 v [ft/s]

0

10

20

30

40

50

60

70

[%]

Eff

0 2 4 6 8 10 12 v [ft/s]

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

5

10

15

20

25

[m]

H

SL1.20.A25.30.2

60 Hz

ISO 9906 Annex A

Eff 2

Eff 1

QH

Ansi 2½ / DN 65

ANSI 3 / DN 80

0 50 100 150 200 250 Q [US GPM]

0

1

2

3

4

[hp]

P

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

10

20

30

[ft]

NPSH

0

1

2

3

[kW]

P

0

2

4

6

8

[m]

NPSH

P2

P1

Performance curves

Technical data

SL1.20.A25

Performance curves SL1.20.A25.30

SL1, SLV pumps

40

TM04 7833 2310

Page 41

Performance curves

Technical data

Dimensional sketches SL1.20.A25.30

SL1, SLV pumps

A C D E F H DN1 Dc1 DØ1 D1n DN2 Dc2 DØ2 D2n Weight [lb/kg]

[inch] 25.236 14.409 6.732 8.504 1 2.6 38 3.661 2.5 5.5 4xM16 2.5 5.5 4x0. 75 190. 9

[mm] 641 366 171 216 321 93 65 139.7 4xM16 65 139.7 4x19.1 86.6

Z2 Z3 Z4 Z6 Z7 Z8 Z9 Z10 Z11 Z12a Z14 Z15 Z16 ZDN1 ZM

[inch] 8.270 3.740 5.510 27.56 20.2 14.290 3.19 1.5" 29.13 3.898 0.04 6.89 10.472 2.5 4XM16

[mm] 210 9 5 140 700 513 363 81 1.5" 740 99 1 17 5 266 65 4XM16

V1 V2 V3 V4 V5 V6 V7 VØ

[inch] 30.354 13.346 5.118 12.795 10.63 19.331 2.559 0.709

[mm] 771 339 130 325 270 491 65 18

Electrical data

0.17

0.17

0.17

Breakdown

2

2

)]

torque

M

max

[lbf*ft

(Nm)]

14.01 (19)

18.44 (25)

16.96 (23)

Pump type

SL1.20.A25.30.2.61J

SL1.20.A25.30.2.61H 3x460V D

SL1.20.A25.30.2.61L 3x575V D

Voltage

[V]

3x208-230V D

/ 460V Y

P1

[kW]

3.9

(2.9)

3.9

(2.9)

3.9

(2.9)

I

NIstart

P2

No of

[kW]

poles

3.0

2 3480 SD 8.8 68.7 67.7 7 2.8 74.3

(2.2)

3.0

2 3520 SD 4.3 44.0 66.7 7 3.3 76.1

(2.2)

3.0

2 3510 SD 3.2 32.1 67.7 7 3.0 75.8

(2.2)

RPM

Starting

method

[A] [A] 1/2 3/4 1/1 1/2 3/4 1/1

η

motor

[%]

Cos ϕ

0.8

0.89 0.91 1.15

5

0.7

0.85 0.88 1.15

7

0.8

0.87 0.89 1.15

1

SF

Moment

of inertia

[lb*ft

(kgm

(0.00704)

(0.00704)

(0.00704)

Pump data

Max. solids

Impeller type

Channel 2 / 50 10 20 65 / 2 0 IP68 H A 104 / 40 4-10

size

[Inch / mm] PN [Feet / m] [°F / °C]

Pump housing

pressure

Max . number of

starts per hour

Max. installation

depth

Enclosure

class

Insulation

class

Temperature

rise class

Max. liquid

temperatur e

TM04 2794 3008/TM04 2795 3008/TM04 3473 4608

pH

41

Page 42

0 50 100 150 200 250 Q [US GPM]

0

10

20

30

40

50

60

70

80

90

[ft]

H

0 2 4 6 8 10 12 14 16 18 v [ft/s]

0

10

20

30

40

50

60

70

[%]

Eff

0 2 4 6 8 10 12 v [ft/s]

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

5

10

15

20

25

[m]

H

SL1.20.A25.40.2

60 Hz

ISO 9906 Annex A

Eff 2

Eff 1

QH

Ansi 2½ / DN 65

ANSI 3 / DN 80

0 50 100 150 200 250 Q [US GPM]

0

1

2

3

4

5

[hp]

P

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

10

20

30

[ft]

NPSH

0

1

2

3

[kW]

P

0

2

4

6

8

[m]

NPSH

P2

P1

Performance curves

Technical data

Performance curves SL1.20.A25.40

SL1, SLV pumps

TM04 7834 2310

42

Page 43

Performance curves

Technical data

Dimensional sketches SL1.20.A25.40

A C D E F H DN1 Dc1 DØ1 D1n DN2 Dc2 DØ2 D2n Weight [lb /kg]

[inch] 25.236 14.409 6.732 8.504 1 2.6 3 8 3.661 2.5 5.5 4xM16 2. 5 5.5 4x0.75 197.8

[mm] 641 366 171 216 321 93 65 139.7 4xM16 65 139.7 4x19.1 89.7

Z2 Z3 Z4 Z6 Z7 Z8 Z9 Z10 Z11 Z12a Z14 Z15 Z16 ZDN1 ZM

[inch] 8.270 3.74 5.51 27.56 20.2 14.29 3.19 1.5" 29.13 3.898 0.04 6.89 10.472 2.5 4XM16

[mm] 210 95 140 700 513 363 81 1.5" 740 99 1 175 2 66 65 4XM16

V1 V2 V3 V4 V5 V6 V7 VØ

[inch] 30.354 13.346 5.118 12.795 10.63 19.331 2.559 0.709

[mm] 771 339 130 325 270 491 65 18

Electrical data

Pump type

SL1.20.A25.40.2.61J

SL1.20.A25.40.2.61L 3x575V D

SL1.20.A25.40.2.61H 3x460V D

Voltage

[V]

3x208-230V D

/ 460V Y

P1

[kW]

5.1

(3.8)

5.1

(3.8)

5.1

(3.8)

I

P2

No of

[kW]

poles

4.0

2 3510 SD 11.6 99.5 72.9 77.2 78.4 0.79 0.86 0. 89 1.15

(3.0)

4.0

2 3510 SD 4.5 47.9 72.9 77.8 79.6 0.74 0.82 0.87 1.15

(3.0)

4.0

2 3510 SD 5.9 63.5 72.5 77.4 79.7 0.66 0.77 0.83 1.15

(3.0)

RPM

Starting

method

NIstart

[A] [A] 1/2 3/4 1/1 1/2 3/ 4 1/1

η

motor

[%]

Cos ϕ

SF

Moment

of inertia

2

[lb*ft

2

(kgm

)]

0.23

(0.00956)

0.23

(0.00956)

0.23

(0.00956)

Breakdown

torque

M

[lbf*ft (Nm)]

22.86 (31)

28.03 (38)

29.5 (40)

max

Pump data

Max. solids

Impeller type

Channel 2 / 50 10 20 65 / 2 0 IP68 H A 104 / 40 4-10

size

[Inch / mm] PN [Feet / m] [°F / °C]

Pump housing

pressure

Max . number of

starts per hour

Max. installation

depth

Enclosure

class

Insulation

class

Temperature

rise class

Max. liquid

temperatur e

TM04 2794 3008/TM04 2795 3008/TM04 3473 4608

pH

43

Page 44

0 50 100 150 200 250 Q [US GPM]

0

10

20

30

40

50

60

70

80

90

100

[ft]

H

0 2 4 6 8 10 12 14 16 18 v [ft/s]

0

10

20

30

40

50

60

70

[%]

Eff

0 2 4 6 8 10 12 v [ft/s]

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

5

10

15

20

25

30

[m]

H

SL1.20.A25.55.2

60 Hz

ISO 9906 Annex A

Eff 2

Eff 1

QH

Ansi 2½ / DN 65

ANSI 3 / DN 80

0 50 100 150 200 250 Q [US GPM]

2

3

4

5

6

7

[hp]

P

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

10

20

30

[ft]

NPSH

2

3

4

5

[kW]

P

0

2

4

6

8

[m]

NPSH

P2

P1

Performance curves

Technical data

Performance curves SL1.20.A25.55

SL1, SLV pumps

TM04 7835 2310

44

Page 45

Performance curves

Technical data

Dimensional sketches SL1.20.A25.55

SL1, SLV pumps

A C D E F H DN1 Dc1 DØ1 D1n DN2 Dc2 DØ2 D2n Weight [lb /kg]

[inch] 26.654 16.024 7.874 8.937 1 4.9 2 1 3.661 2.5 5.5 4xM16 2. 5 5.5 4x0.75 254.9

[mm] 677 407 200 227 379 93 65 139.7 4xM16 65 139.7 4x19.1 115.6

Z2 Z3 Z4 Z6 Z7 Z8 Z9 Z10 Z11 Z12a Z14 Z15 Z16 ZDN1 ZM

[inch] 8.270 3.740 5.510 29.17 21.81 14.76 3.19 1.5" 30.47 3.819 0.04 6.89 10.472 2.5 4XM16

[mm] 210 95 140 741 5 54 375 81 1.5" 774 97 1 175 2 66 65 4 X M1 6

V1 V2 V3 V4 V5 V6 V7 VØ

[inch] 31.772 13.425 5.118 12.795 10.63 20.433 2.559 0.709

[mm] 807 341 130 325 270 519.000 65 18

Electrical data

Pump type

SL1.20.A25.55.2.61J

SL1.20.A25.55.2.61L 3x575V D

SL1.20.A25.55.2.61H 3x460V D

Voltage

[V]

3x208-230V D

/ 460V Y

P1

[kW]

6.6

(4.9)

6.6

(4.9)

6.6

(4.9)

I

P2

No of

[kW]

poles

5.5

2 3530 SD 14.8 152 75.0 79.9 81.7 0.78 0.86 0.90 1.15

(4.0)

5.5

2 3535 SD 5.8 70.8 74.1 79.6 82.0 0.71 0.82 0.87 1.15

(4.0)

5.5

2 3540 SD 7.4 96.8 73.6 79.2 82.0 0.68 0.80 0.85 1.15

(4.0)

RPM

Starting

method

NIstart

[A] [A] 1/2 3/4 1/1 1/2 3/ 4 1/1

η

motor

[%]

Cos ϕ

SF

Moment

of inertia

2

[lb*ft

2

(kgm

)]

0.38

(0.0159)

0.38

(0.0159)

0.38

(0.0159)

Breakdown

torque

M

[lbf*ft (Nm)]

53.84 (73)

44.99 (61)

37.62 (51)

max

Pump data

Max. solids

Impeller type

Channel 2 / 50 10 20 65 / 2 0 IP68 H A 104 / 40 4-10

size

[Inch / mm] PN [Feet / m] [°F / °C]

Pump housing

pressure

Max . number of

starts per hour

Max. installation

depth

Enclosure

class

Insulation

class

Temperature

rise class

Max. liquid

temperatur e

TM04 2794 3008/TM04 2795 3008/TM04 3474 4608

pH

45

Page 46

0 50 100 150 200 250 Q [US GPM]

0

10

20

30

40

50

60

70

80

[ft]

H

0 2 4 6 8 10 12 v [ft/s]

0

10

20

30

40

50

60

70

[%]

Eff

0 2 4 6 8 v [ft/s]

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

5

10

15

20

25

[m]

H

SL1.20.A30.30.2

60 Hz

ISO 9906 Annex A

Eff 2

Eff 1

QH

Ansi 3 / DN 80

ANSI 4 / DN 100

0 50 100 150 200 250 Q [US GPM]

0

1

2

3

4

[hp]

P

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

10

20

30

[ft]

NPSH

0

1

2

3

[kW]

P

0

2

4

6

8

[m]

NPSH

P1

P2

Performance curves

Technical data

SL1.20.A30

Performance curves SL1.20.A30.30

SL1, SLV pumps

46

TM04 7836 2310

Page 47

Performance curves

Technical data

Dimensional sketches SL1.20.A30.30

SL1, SLV pumps

A C D E F H DN1 Dc1 DØ1 D1n DN2 Dc2 DØ2 D2n Weight [lb /kg]

[inch] 25.236 14.409 6.732 8.504 1 2.6 3 8 3.937 2.5 5.5 4xM16 3 6 8 x 0. 75 192.7

[mm] 641 366 171 216 321 100 65 139.7 4xM16 80 152.4 8x19.1 87.4

Z2 Z3 Z4 Z6 Z7 Z8 Z9 Z10 Z11 Z12a Z14 Z15 Z16 ZDN1 ZM

[inch] 8.66 3.74 6.3 28.31 20.71 14.8 3.19 1.5" 30.47 5.236 0.51 6.73 13.583 2.5 4XM16

[mm] 220 95 160 719 5 26 376 81 1.5" 774 133 13 171 345 65 4XM16

V1 V2 V3 V4 V5 V6 V7 VØ

[inch] 30.354 13.346 5.118 12.795 10.63 19.528 3. 15 0.709

[mm] 771 339 130 325 270 496 80 18

Electrical data

Pump type

SL1.20.A30.30.2.61J

SL1.20.A30.30.2.61H 3x460V D

SL1.20.A30.30.2.61L 3x575V D

Voltage

[V]

3x208-230V D

/ 460V Y

P1

[kW]

3.9

(2.9)

3.9

(2.9)

3.9

(2.9)

I

P2

No of

[kW]

poles

3.0

2 3480 SD 8.8 68.7 67.7 72.8 74.3 0.85 0.89 0.91 1.15

(2.2)

3.0

2 3520 SD 4.3 44.0 66.7 73.3 76.1 0.77 0.85 0.88 1.15

(2.2)

3.0

2 3510 SD 3.2 32.1 67.7 73.0 75.8 0.81 0.87 0.89 1.15

(2.2)

RPM

Starting

method

NIstart

[A] [A] 1/2 3/4 1/1 1/2 3/ 4 1/1

η

motor

[%]

Cos ϕ

SF

Moment

of inertia

2

[lb*ft

2

(kgm

)]

0.17

(0.00704)

0.17

(0.00704)

0.17

(0.00704)

Breakdown

torque

M

[lbf*ft (Nm)]

14.01 (19)

18.44 (25)

16.96 (23)

max

Pump data

Max. solids

Impeller type

Channel 2 / 50 10 20 65 / 2 0 IP68 H A 104 / 40 4-10

size

[Inch / mm] PN [Feet / m] [°F / °C]

Pump housing

pressure

Max . number of

starts per hour

Max. installation

depth

Enclosure

class

Insulation

class

Temperature

rise class

Max. liquid

temperatur e

TM04 2793 3008/TM04 2794 3008/TM04 2795 3008

pH

47

Page 48

0 50 100 150 200 250 Q [US GPM]

0

10

20

30

40

50

60

70

80

90

[ft]

H

0 2 4 6 8 10 12 v [ft/s]

0

10

20

30

40

50

60

70

[%]

Eff

0 2 4 6 8 v [ft/s]

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

5

10

15

20

25

[m]

H

SL1.20.A30.40.2

60 Hz

ISO 9906 Annex A

Eff 1

Eff 2

QH

Ansi 3 / DN 80

ANSI 4 / DN 100

0 50 100 150 200 250 Q [US GPM]

0

1

2

3

4

5

[hp]

P

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

10

20

30

[ft]

NPSH

0

1

2

3

[kW]

P

0

2

4

6

8

[m]

NPSH

P2

P1

Performance curves

Technical data

Performance curves SL1.20.A30.40

SL1, SLV pumps

TM04 7837 2310

48

Page 49

Performance curves

Technical data

Dimensional sketches SL1.20.A30.40

SL1, SLV pumps

A C D E F H DN1 Dc1 DØ1 D1n DN2 Dc2 DØ2 D2n Weight [lb /kg]

[inch] 25.236 14.409 6.732 8.504 1 2.6 3 8 3.937 2.5 5.5 4xM16 3 6 8 x 0. 75 199.5

[mm] 641 366 171 216 321 100 65 139.7 4xM16 80 152.4 8x19.1 90.5

Z2 Z3 Z4 Z6 Z7 Z8 Z9 Z10 Z11 Z12a Z14 Z15 Z16 ZDN1 ZM

[inch] 8.66 3.74 6.3 28.31 20.71 14.8 3.19 1.5" 30.47 5.236 0.51 6.73 13.583 2.5 4XM16

[mm] 220 95 160 719 5 26 376 81 1.5" 774 133 13 171 345 65 4XM16

V1 V2 V3 V4 V5 V6 V7 VØ

[inch] 30.354 13.346 5.118 12.795 10.630 19.528 3.15 0.709

[mm] 771 339 130 325 270 496 80 18

Electrical data

Pump type

SL1.20.A30.40.2.61J

SL1.20.A30.40.2.61L 3x575V D

SL1.20.A30.40.2.61H 3x460V D

Voltage

[V]

3x208-230V D

/ 460V Y

P1

[kW]

5.1

(3.8)

5.1

(3.8)

5.1

(3.8)

I

P2

No of

[kW]

poles

4.0

2 3510 SD 11.6 99.5 72.9 77.2 78.4 0.79 0.86 0 .8 9 1.15

(3.0)

4.0

2 3510 SD 4.5 47.9 72.9 77.8 79.6 0.74 0.82 0.87 1.15

(3.0)

4.0

2 3510 SD 5.9 63.5 72.5 77.4 79.7 0.66 0.77 0.83 1.15

(3.0)

RPM

Starting

method

NIstart

[A] [A] 1/2 3/4 1/1 1/2 3/ 4 1/1

η

motor

[%]

Cos ϕ

SF

Moment

of inertia

2

[lb*ft

2

(kgm

)]

0.23

(0.00956)

0.23

(0.00956)

0.23

(0.00956)

Breakdown

torque

M

[lbf*ft (Nm)]

22.86 (31)

28.03 (38)

29.5 (40)

max

Pump data

Max. solids

Impeller type

Channel 2 / 50 10 20 65 / 2 0 IP68 H A 104 / 40 4-10

size

[Inch / mm] PN [Feet / m] [°F / °C]

Pump housing

pressure

Max . number of

starts per hour

Max. installation

depth

Enclosure

class

Insulation

class

Temperature

rise class

Max. liquid

temperatur e

TM04 2793 3008/TM04 2794 3008/TM04 2795 3008

pH

49

Page 50

0 50 100 150 200 250 Q [US GPM]

0

10

20

30

40

50

60

70

80

90

100

[ft]

H

0 2 4 6 8 10 12 v [ft/s]

0

10

20

30

40

50

60

70

[%]

Eff

0 2 4 6 8 v [ft/s]

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

5

10

15

20

25

30

[m]

H

SL1.20.A30.55.2

60 Hz

ISO 9906 Annex A

Eff 2

Eff 1

QH

Ansi 3 / DN 80

ANSI 4 / DN 100

0 50 100 150 200 250 Q [US GPM]

2

3

4

5

6

7

[hp]

P

0 2 4 6 8 10 12 14 16 18 Q [l/s]

0

10

20

30

[ft]

NPSH

2

3

4

5

[kW]

P

0

2

4

6

8

[m]

NPSH

P2

P1

Performance curves

Technical data

Performance curves SL1.20.A30.55

SL1, SLV pumps

TM04 7838 2310

50

Page 51

Performance curves

Technical data

Dimensional sketches SL1.20.A30.55

SL1, SLV pumps

A C D E F H DN1 Dc1 DØ1 D1n DN2 Dc2 DØ2 D2n Weight [lb /kg]

[inch] 26.654 16.024 7.874 8.937 1 4.9 2 1 3.937 2.5 5.5 4xM16 3 6 8 x 0. 75 256.6

[mm] 677 407 200 227 379 100 65 139.7 4xM16 80 152.4 8x19.1 116.4

Z2 Z3 Z4 Z6 Z7 Z8 Z9 Z10 Z11 Z12a Z14 Z15 Z16 ZDN1 ZM

[inch] 8.66 3.74 6.3 29.92 22.32 15.24 3.19 1.5 31.81 5.197 0.51 6.73 13.583 2.5 4XM16

[mm] 220 95 160 760 567 387 81 1.5 80 8 132 13 171 345 65 4XM16

V1 V2 V3 V4 V5 V6 V7 VØ

[inch] 31.772 13.425 5.118 12.795 10.63 20.669 3. 15 0.709

[mm] 807 341 130 325 270 525 80 18

Electrical data

Pump type

SL1.20.A30.55.2.61J

SL1.20.A30.55.2.61L 3x575V D

SL1.20.A30.55.2.61H 3x460V D

Voltage

[V]

3x208-230V D

/ 460V Y

P1

[kW]

6.6

(4.9)

6.6

(4.9)

6.6

(4.9)

I

P2

No of

[kW]

poles

5.5

2 3530 SD 14.8 152 75.0 79.9 81.7 0.78 0.86 0.90 1.15

(4.0)

5.5

2 3535 SD 5.8 70.8 74.1 79.6 82.0 0.71 0.82 0.87 1.15

(4.0)

5.5

2 3540 SD 7.4 96.8 73.6 79.2 82.0 0.68 0.80 0.85 1.15

(4.0)

RPM

Starting

method

NIstart

[A] [A] 1/2 3/4 1/1 1/2 3/ 4 1/1

η

motor

[%]

Cos ϕ

SF

Moment

of inertia

2

[lb*ft

2

(kgm

)]

0.38

(0.0159)

0.38

(0.0159)

0.38

(0.0159)

Breakdown

torque

M

[lbf*ft (Nm)]

53.84 (73)

44.99 (61)

37.62 (51)

max

Pump data

Max. solids

Impeller type

Channel 2 / 50 10 20 65 / 2 0 IP68 H A 104 / 40 4-10

size

[Inch / mm] PN [Feet / m] [°F / °C]

Pump housing

pressure

Max . number of

starts per hour

Max. installation

depth

Enclosure

class

Insulation

class

Temperature

rise class

Max. liquid

temperatur e

TM04 2793 3008/TM04 2794 3008/TM04 2795 3008

pH

51

Page 52

0 50 100 150 200 250 300 350 400 Q [US GPM]

0

5

10

15

20

25

30