Page 1

PACOpaQ™

HVAC Packaged Systems

Installation and Operating Instructions

GRUNDFOS INSTRUCTIONS

Page 2

Table of Contents

English (US) Installation and operating instructions

Original installation and operating instructions.

CONTENTS

Page

1. Symbols used in this document 3

2. Terms and Conditions 4

2.1 The contract 4

2.2 Price 4

2.3 Payment terms 4

2.4 Acceptance and inspection 4

2.5 Title and risk of loss 4

2.6 Patent or trademark information 4

2.7 Changes 4

2.8 Cancellation or termination 4

2.9 Delivery and delays 4

2.10 Warranty 5

2.11 Technical documents 5

2.12 Limitation of liability 5

2.13 This company is an equal opportunity 5

employer

2.14 Law and arbitration 5

3. PACOpaQ system installation 6

3.1 General instructions 6

3.2 Lifting and rigging instructions 6

3.3 Storage 6

3.4 Bolt check instruction 6

3.5 Field connection 6

3.6 Assembly of packaged sections (if applicable) 7

3.7 Other package system requirements 7

4. Pump Installation-Mechanical 8

4.1 Pump Identication 8

4.2 Receiving 8

4.3 Temporary storage 8

4.4 Location 8

4.5 Horizontal pump foundation 8

4.6 Securing base plate 9

4.7 Vertical mounting instructions 9

4.8 Piping-general 9

4.9 Suction (inlet) piping 9

4.10 Discharge (outlet) piping 10

4.11 Shaft, sealing-general comments 10

4.12 Packing gland adjustment 10

4.13 Mechanical seals 10

4.14 Coupling alignment (LF) 11

4.15 Coupling alignment (LCS) 11

5. Pump Installation-electrical 11

5.1 Motors general 11

5.2 Installation wiring 11

6. Pump operation 12

6.1 Priming 12

6.2 Pre-start checklist 12

6.3 Motor rotation 12

6.4 Starting the pump 12

6.5 Voltage regulation 13

6.6 Pump shutdown 13

6.7 Short duration shutdown 13

6.8 Extended period shutdown 13

7. Pump Maintenance 13

7.1 Motor lubrication 13

7.2 Pump lubrication 14

7.3 Disassembly of pumps 14

7.3.1 Disassembly of liquid end 14

7.3.2 Disassembly of bearing frame (LF) 14

7.4 Seal replacement (LCS) 14

7.5 Wear ring replacement 15

7.6 Reassembly of pumps 15

7.7 Ordering parts 16

7.8 Type LF, cross section and parts list 17

7.9 Type LC, cross section and parts list 18

7.10 Type LCV, cross section and parts list 19

7.11 Type LCS, cross section and parts list

8. Pump Troubleshooting 21

8.1 Symptom 21

8.2 Possible causes 21

9. Grundfos CUE Variable Frequency Drive 22

9.1 CUE introduction 22

9.2 General description 22

9.3 Applications 23

9.4 References 23

10. CUE safety and warnings 23

10.1 Warning 23

10.2 Safety regulations 23

10.3 Installation requirements 23

10.4 Reduced performance under certain conditions 23

11. Identication 23

11.1 Nameplate 23

11.2 Packaging label 23

12. CUE installation-mechanical 23

12.1 Reception and storage 23

12.2 Transportation and unpacking 23

12.3 Space requirements and air circulation 24

12.4 Mounting 24

13. Electrical connection 24

13.1 Electrical protection 24

13.2 Mains and motor connection 25

13.3 Connecting the signal terminals 30

13.4 Connecting the signal relays 32

13.5

13.6 EMC-correct installation 34

13.7 RFI lters 34

13.8 Output lters 34

14. CUE operating modes 35

15. CUE control modes 35

15.1 Uncontrolled operation (open loop) 35

15.2 Controlled operation (closed loop) 36

16. Menu overview 37

17. Setting by means of the cotnrol panel 40

17.1 Control panel 40

17.2 Back to factory setting 40

17.3 Start-up guide 41

17.4 Menu GENERAL 45

Connecting the MCB 114 sensor input module 33

20

2

Page 3

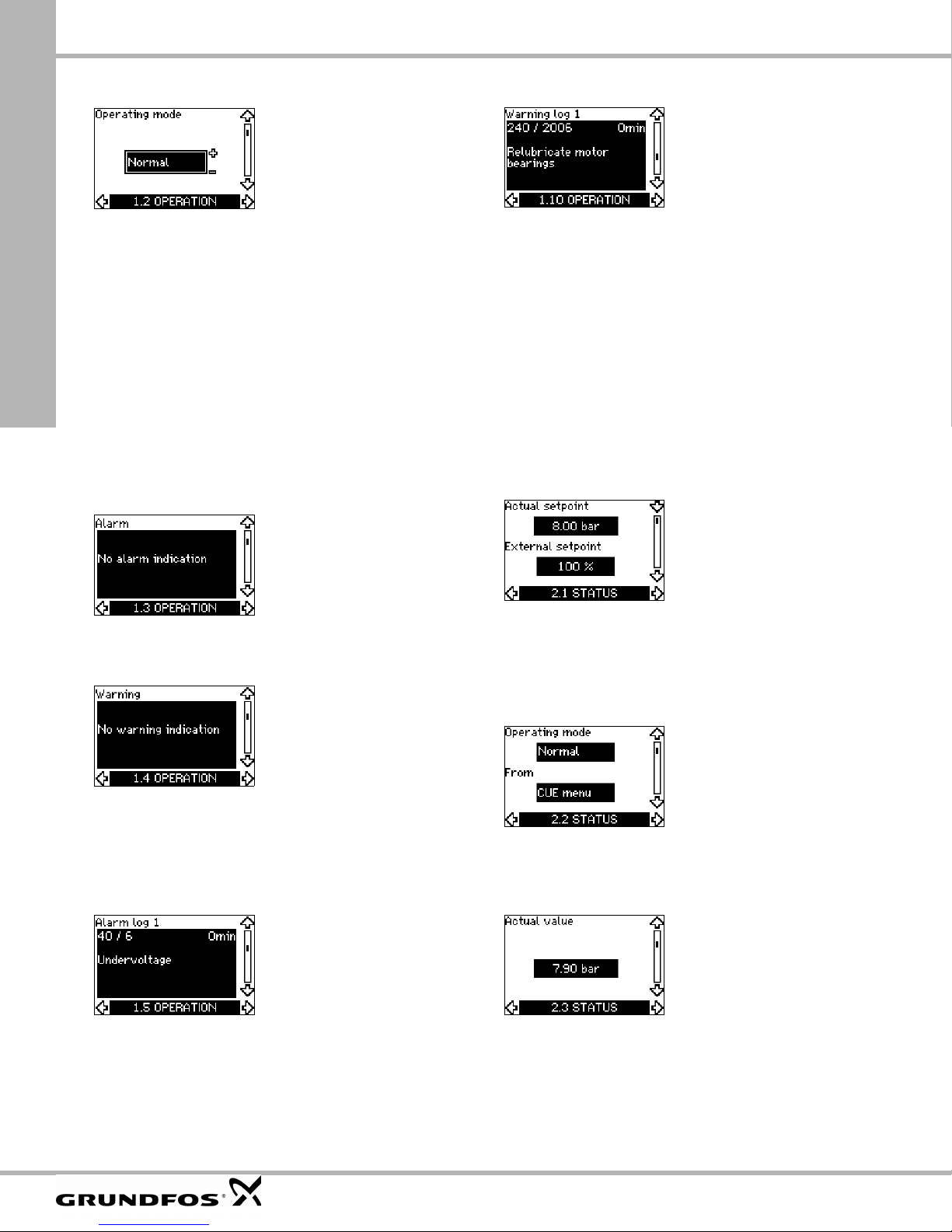

17.5 Menu OPERATION 45

7. Trouble Shooting

18

7.1 Symptom

18

7.2 Possible Causes

18

Caution

Note

Note

17.6 Menu STATUS 46

17.7 Menu INSTALLATION 48

18. Setting by means of PC Tools E-products 55

19. Priority of setttings 56

19.1 Control without bus signal, local operating 56

mode

19.2 Control with bus signal, remote-controlled 56

operating mode

20. External control signals 56

20.1 Digital inputs 57

20.2 External setpoint 57

20.3 GENibus signal 57

20.4 Other bus standards 57

21. CUE Maintenance and service 57

21.1 Cleaning the CUE 57

21.2 Service parts and servie kits 57

22. CUE Troubleshooting 58

22.1 Warning and alarm list 58

22.2 Resetting of alarms 58

22.3 Indicator lights 58

22.4 Signal relays 58

23. Technical data 59

23.1 Enclosure 59

23.2 Main dimensions and weight

23.3 Surroundings 60

23.4 Terminal tightening torques 60

23.5 Cable length 61

23.6 Fuses and cable gauge size 61

23.7 Inputs and putputs 63

23.8 Sound pressure level 63

24. Disposal 63

25. CU 352 product description 64

25.1 Indicator lights 64

25.2 Terminals 64

25.3 Potentially explosive environments

26. Identication

27. CU352 installation 65

27.1 Location 66

27.2 Enclosure class 66

27.3 Terminals 66

27.4 Cables 66

28. CU 352 Installation-Mechanical 66

29. EMC-correct installation 67

29.1 Internal GENibus connection 68

29.2 Fieldbus communication interface 68

modules

29.3 Fitting the CIM module 69

30. CU 352 Startup 70

31. Technical data 70

32. Electrical data 70

32.1 Supply voltage 70

32.2 Power consumption 70

32.3 Circuit breaker 70

32.4 Backup fuse 70

32.5 Short-circuit protection 70

60

64

65

32.6 Digital inputs

32.7 Analog inputs

70

70

32.8 Digital outputs (relay putputs) 70

32.9 Conductors 70

32.10 USB port 70

32.11 Battery backup (UPS) 71

32.12 Terminal groups 71

33. Overview of inputs and outputs 72

34. CU 352 Maintenance 73

35. CU 352 Service

73

36. Replacing the CU 352 73

36.1 Replacing the CIM module

73

37. CU 352 Dimensions 73

38. CU 352 Disposal 73

39. Suctiondiuser-IOM 74

39.1 Installation 74

39.2 Operation and maintenance 74

39.3 Sectional drawing and components 74

1. Symbols used in this document

The following symbols may be used in this document.

Warning

If these safety instructions are not observed,

it may result in personal injury.

Warning

If these instructions are not observed, it may lead

to electric shock with consequent risk of serious

personal injury or death.

Warning

When pumping hazardous liquids, special

attention must be paid to the risk of personal

injury.

Warning

The surface of the product may be so hot that

it may cause burns or personal injury.

Warning

The sound pressure level is so high that hearing

protection must be used.

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment.

Notes or instructions that make the job easier

and ensure safe operation.

Table of Contents

3

Page 4

English (US)

Terms and Conditions

2. Terms and Conditions

2.1 The contract

The Contract shall be comprised of the following terms, together

with such terms and conditions as are set forth in Seller's written

proposal or quotation (the "Quotation"), including any documents,

drawings or specifications incorporated t

any additional or different terms proposed in Buyer's purchase

order (the "Purchase Order") that are accepted by Seller in

writing, which together shall constitute the entire agreement

between the parties, provided, however, that preprinted terms on

Buyer's purchase order or invoice shall not apply and Seller gives

notice of objection to such terms. An offer by Seller in its

Quotation that does not stipulate an acceptance date is not

binding. This Contract shall be deemed to have been entered into

upon written acknowledgment of the Purchase Order by an officer

or authorized representative of Seller, which may not be modified,

supplemented, or waived except in a writing executed by an

authorized representative of the party to be bound.

2.2 Price

The price quoted in the Quotation shall be the Purchase Price

unless otherwise agreed in the Purchase Order. The Purchase

Price for equipment shall include packing for shipment. Field

Services shall be provided at Seller's standard rates. All other

costs, including packing for storage, freight, insurance, taxes,

customs duties and import/export fees, or any other item not

specified in the Contract, shall be paid by Buyer unless

separately stated in the Quotation and included in the price

quoted. Any sales, use, or other taxes and duties imposed on the

transaction or the equipment supplied shall be paid or reimbursed

by Buyer.

2.3 Payment terms

Payment shall be due within 30 days of the date of Seller's

invoice in U.S. funds unless otherwise agreed. If Buyer does not

observe the agreed dates of payment, Buyer shall pay interest to

Seller on overdue amounts at a rate that is the higher of: 9 % per

annum or a rate 5 % in excess of the rate borne from time to time

by new issues of six-month United States Treasury bills. Seller

shall be entitled to issue its invoice for the Purchase Price for

equipment upon the earlier of shipment, or notice to Buyer that

Seller is ready to ship, and for services, upon completion. If the

Purchase Price exceeds $250,000 USD, Buyer shall pay the

Purchase Price in Progress payments as follows: Fifteen percent

(15 %) upon submittal of general arrangement drawings, thirty

five percent (35 %) after receipt of first Bowl Casting, twenty

percent (20 %) after first case/bowl hydro test or bowl machining

and thirty percent (30 %) after notification of ready to ship.

2.4 Acceptance and inspection

All equipment shall be finally inspected and accepted by Buyer

within 14 days after delivery or such other period of time as is

agreed in the Purchase Order. Buyer shall make all claims

(including claims for shortages), excepting only those provided

for under the warranty clause contained herein, in writing within

such 14 day period or they are waived. Services shall be

accepted upon completion. Buyer shall not revoke its acceptance.

Buyer may reject the equipment only for defects that substantially

impair its value, and Buyer's remedy for lesser defects shall be in

accordance with Section 10, Warranty. If tests are made by Buyer

to demonstrate the ability of the equipment to operate under the

contract conditions and to fulfill the warranties in Section 10,

Buyer is to make all preparations and incur all expenses

incidental to such tests. Seller will have the right of representation

at such tests at its expense, and the right to technically direct the

operation of the equipment during such tests, including requiring

a preliminary run for adjustments.

herein by reference, and

2.5 Title and risk of loss

Full risk of loss (including transportation delays and losses) shall

pass to Buyer upon delivery, regardless of whether title has

passed to Buyer, transport is arranged or supervised by Seller, or

start-up is carried out under the direction or supervision of Seller.

Delivery shall be ex works, INCOTERMS 2000. Loss or

destruction of the equipment or injury or damage to the

equipment that occurs while the risk of such loss or damage is

borne by Buyer does not relieve Buyer of its obligation to pay

Seller for the equipment.

2.6 Patent or trademark information

If the equipment sold he

manufactured according to Buyer's specifications, Buyer shall

indemnify Seller and hold it harmless from any claims or liability

r patent or trademark infringement on account of the sale of

fo

such goods.

reunder is to be prepared or

2.7 Changes

Buyer may request, in writing, changes in the design, drawings,

specifications, shipping instructions, and shipment schedules of

the equipment. As promptly as practicable after receipt of such

request, Seller will advise Buyer what amendments to the

Contract, if any, may be necessitated by such requested

changes, including but not limited to amendment of the Purchase

Price, specifications, shipment schedule, or date of delivery. Any

changes agreed upon by the parties shall be evidenced by a

Change Order signed by both parties.

2.8

Buyer shall have the right to cancel the Contract upon 15 day

prior

upo

Buyer. If Buyer cancels the Contract, it shall pay: (a) the agreed

unit price for equipment or components completed and delivered,

(b) additional material and labor costs incurred, and for

engineering services supplied by Seller with respect to the

canceled items, which shall be charged to Buyer at Seller's rates

n effect at the time of cancellation, but which shall not exceed the

i

contract price for such items, and (c) such other costs and

expenses, including cancellation charges under subcontracts, as

Seller may incur in connection with such cancellation or

termination.

ellation or

Canc

en notice

writt

n the receipt of such notice except as otherwise agreed with

ermination

t

s'

to Seller, and Seller shall stop its performance

2.9 Delivery and delays

Seller shall use its best efforts to meet quoted delivery dates,

which are estimated based on conditions known at the time 16

A1d.1 606 supercedes 9/05 PACO PUMPS of quotation. Seller

shall not be liable for any nonperformance, loss, damage, or

delay due to war, riots, fire, flood, strikes or other labor difficulty,

governmental actions, acts of God, acts of the Buyer or its

customer, delays in transportation, inability to obtain necessary

labor or materials from usual sources, or other causes beyond the

reasonable control of Seller. In the event of delay in performance

due to any such cause, the date of delivery or time for completion

will be extended to reflect the length of time lost by reason of

such delay. Seller shall not be liable for any loss or damage to

Buyer resulting from any delay in delivery.

4

Page 5

2.10 Warranty

English (US)

3.2 Receiving

• Check pumping unit for shortage and damage immediately

upon arrival. Pump accessories when required are packaged

in a separate container and shipped with the unit.

• If equipment is damaged in transit, promptly report this to the

carrier's agent. Make complete notations on the freight bill to

speed satisfactory adjustment by the carrier.

• Unload and handle the unit with a sling. Do not lift unit by eye

bolts on the motor!

3.3 Temporary storage

• If pump is not to be installed and operated soon after arrival,

store it in a clean, dry area of moderate ambient temperature.

English (US)

2.14 law and arbitration

The Contract shall be governed by the law of the State of Texas.

Any disputes arising out of this Contract shall be resolved by

informal mediation in any manner that the parties may agree

within 45 days of written request for mediation by one party to the

other. Any dispute that cannot be resolved through mediation

shall be resolved by binding arbitration conducted in English in

Portland, Oregon under the Commercial Rules of the American

Arbitration Association except as otherwise provided in this

Section. The arbitration shall be conducted by three arbitrators

chosen in accordance with said Rules. The arbitrators are not

entitled to award damages in excess of compensatory damages.

Judgment upon the award may be entered in any court having

jurisdiction.

3.2 Receiving

• Check pumping unit for shortage and damage immediately

upon arrival. Pump accessories when required are packaged

in a separate container and shipped with the unit.

• If equipment is damaged in transit, promptly report this to the

carrier's agent. Make complete notations on the freight bill to

speed satisfactory adjustment by the carrier.

• Unload and handle the unit with a sling. Do not lift unit by eye

bolts on the motor!

3.3 Temporary storage

• If pump is not to be installed and operated soon after arrival,

store it in a clean, dry area of moderate ambient temperature.

• Rotate the shaft by hand periodically to coat bearing with

lubricant to retard oxidation and corrosion.

• Follow motor manufacturer's storage recommendations where

applicable.

3.4 Location

• Locate the pump as close to the suction supply as possible.

Use the shortest and most direct suction piping practical.

Refer to 3.9 Suction (inlet) piping.

• Locate the pump below system level wherever possible. This

will facilitate priming, assure a steady liquid flow, and provide

a positive suction head.

• Make sure sufficient NPSH (Net Positive Suction Head) is

provided at the suction end by considering the pump's location

in relation to the entire system. Available NPSH must always

equal or exceed required NPSH specified on the pump

performance curve.

Seller warrants that the equipment or services supplied will be

free from

24 months from the d

30 months from the date of shipment, whichever shall first

occur. In the case of spare or replacement parts manufactured

by Seller, the warranty period shall be for a period of six months

from shipment. Repairs shall be warranted for 24 months or, if

the repair is performed under this warranty, for the remainder of

the original warranty period, whichever is less. Buyer shall report

any claimed defect in writing to Seller immediately upon

discovery and in any event, within the warranty period. Seller

shall, at its sole option, repair the equipment or furnish

replacement equipment or parts thereof, at the original delivery

point. Seller shall not be liable for costs of removal,

reinstallation, or gaining access. If Buyer or others repair,

replace, or adjust equipment or parts without Seller's prior

written approv

Buyer under this section with respect to such equipment or

parts. The repair or replacement of the equipment or spare or

replacement parts by Seller under this section shall constitute

Seller's sole obligation and Buyer's sole and

for all claims of defects. SELLER MAKES NO OTHER

WARRANTY OR

RESPECT TO THE EQUIPMENT OR SERVICES OTHER THAN

AS SPECIFIED IN THIS SECTION 10. ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE HEREBY DISCLAIMED. For purposes of this

Section, the equipment warranted shall not include equipment,

parts, and work not manufactured or performed by Seller. With

respect to such equipment, parts, or work, Seller's only obligation

shall be to assign to Buyer any warranty provided to Seller by the

manufacturer or supplier providing such equipment, parts or

work. No equipment furnished by Seller shall be deemed to be

defective by reason of normal wear and tear, failure to resist

erosive or corrosive action of any fluid or gas, Buyer's failure to

properly store, install, operate or maintain the equipment in

accordance with good industry practices or specific

recommendations of Seller, or Buyer's failure to provide complete

and accurate information to Seller concerning the operational

application of the equipment.

defects in material, and workmanship for a period of

ate of initial operation of the equipment, or

al, Seller is relieved of any further obligation to

exclusive remedy

REPRESENTATION OF ANY KIND WITH

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

The use of this product requires experience with

and knowledge of the product. Persons with

reduced physical, sensory or mental

capabilities must not use this product, unless

they are under supervision or have been

instructed in the use of the product by a person

responsible for their safety. Children must not

use or play with this product.

2.11 Technical documents

Technical documents furnished by Seller to Buyer, such as

drawings, descriptions, designs and the like, shall be deemed

provided to Buyer on a confidential basis, shall remain Seller's

exclusive property, shall not be provided in any way to third

parties, and shall only be used by Buyer for purposes of

installation, operation and maintenance. Technical documents

submitted in connection with a Quotation that does not result in a

Purchase Order shall be returned to Seller upon request.

2.12 Limitation of liability

Seller shall in no event be liable for any consequential, incidental,

indirect, special or punitive damages arising out of the Contract,

or out of any breach of any of its obligations hereunder, or out of

any defect in, or failure of, or malfunction of the equipment,

including but not limited to, claims based upon loss of use, lost

profits or revenue, interest, lost goodwill, work stoppage,

impairment of other equipment, environmental damage, nuclear

incident, loss by reason of shutdown or nonoperation, increased

expenses of operation, cost of purchase of replacement power or

claims of Buyer or customers of Buyer for service interruption

whether or not such loss or damage is based on contract, tort

(including negligence and strict liability) or otherwise. Seller's

maximum liability under this Contract shall not exceed the

Purchase Order amount of the equipment or portion thereof upon

which such liability is based. All such liability shall terminate upon

the expiration of the warranty period, if not sooner terminated.

2.13 This company is an equal opportunity employer

This agreement incorporates by reference applicable provisions

and requirements of Executive Order 11246 and FAR Section

52.222-26 (covering race, color, religion, sex and national origin);

the Vietnam Era Veterans Readjustment Assistance Act of 1974

and FAR Section 52.222-35 (covering special disabled and

Vietnam era veterans); and the Rehabilitation Act of 1973 and

FAR Section 52.222-36 (covering handicapped individuals). By

acceptance of this agreement Buyer certifies that it does not and

will not maintain any facilities in a segregated manner, or permit

its employees to perform their services at any location under its

control where segregated facilities are maintained, and further

that appropriate physical facilities are maintained for both sexes.

Buyer agrees that it will obtain a similar certificate prior to award

of any nonexempt lower-tier subcontracts.

2.14 law and arbitration

The Contract shall be governed by the law of the State of Texas.

Any disputes arising out of this Contract shall be resolved by

informal mediation in any manner that the parties may agree

within 45 days of written request for mediation by one party to the

other. Any dispute that cannot be resolved through mediation

shall be resolved by binding arbitration conducted in English in

Portland, Oregon under the Commercial Rules of the American

Arbitration Association except as otherwise provided in this

Section. The arbitration shall be conducted by three arbitrators

chosen in accordance with said Rules. The arbitrators are not

entitled to award damages in excess of compensatory damages.

Judgment upon the award may be entered in any court having

jurisdiction.

Terms and Conditions

5

Page 6

PACOpaQ System Installation

Installation instructions

Assembly of packaged sections (if applicable):

1. Refer to specic installation documents or

drawings for the package system.

2. Familiarity with the parts requirements and

any referenced documents or drawings will

aid in the piping assembly. All hardware and

gaskets required for re-assembly are supplied.

Final package system connections hardware by

others.

3. Check pipe/pump/ttings/valves end

connections. Any loose scale, paint or dirt must

be removed.

4. Ensure alignment of end connections

between pump/pipe/ttings/valves

Connections must be square.

5. Package piping must be supported

independent of the pump. If package pipe

support is not part of the original package

others should supply it. Package steel base

is designed to provide a structural support

beginning.

6. Use proper gasket (if required) and install

the individual pump suction & discharge pipe/

ttings/valves with the nuts & bolts provided

(at & lock washers also provided). Install

the required bolts for the tting connections

(elbow, wye strainer,and buttery valve)-to-pipe

connection and tighten bolts to a snug t.

7. Tighten and torque all pipe connection bolts

as required.

8. Install and/or tighten loose pipe support

brackets as required. Remove any temporary

supports.

9. Refer to specic installation documents or

drawings for the package system.

10. Familiarity with the parts requirements and

any referenced documents or drawings will

aid in the piping assembly. All hardware and

gaskets required for re-assembly are supplied.

Final package system connections hardware by

others.

11. Ensure alignment of pipe end connections

between sections. Connections must be square.

Install the required bolts for each of the tting

connections- (elbow, separator, valve, etc.) -to

pipe connections and tighten bolts to a snug t.

Gasket may be required.

12. Working from the middle of base sections

to the outside. Snug all base connection bolts

making sure the base channel anges are ush

top, bottom and side. Torque base connection

bolts to approx. 75 ft/lb

13. Ensure pipe connections are aligned.

Tighten and torque all the pipe connection bolts

as required.

14. Install and/or tighten loose pipe support

brackets and bolts as required.

Other packaged system requirements:

1. Required electrical wiring can now be

connected. A qualied electrician should do

the electrical wiring. Power/control/sensing

runs may be disconnected for package splits or

remote/future use, and tagged with color-coded

tape or with a numbering system.

2. Mount the gauge & switch wing panel.

Required sensing lines can now be connected.

Sensing lines may be disconnected for package

splits or for remote/future use, and tagged with

color-coded tape or with a numbering system.

3. Complete the package system installation

per individual parts provider or manufacturer,

customer, or maintenance instructions

requirements.

Installation

5

3. PACOpaQ Installation

3.1 General instructions

Important notice:

Carefully inspect this equipment for damage,

and missing pieces. If the shipment has

been damaged or there are missing pieces,

have the carrier note the condition on the

receipt. Also, check as soon as possible for

any concealed damage. It is the customer’s

responsibility to le a claim for damage or

missing pieces with the carrier. Failure to follow

this procedure may result in refusal by the

carrier to honor any claims with a consequent

loss to the customer.

3.2 Lifting and rigging instructions:

Avoid twisting or uneven lifting of unit. Lifting

lugs are provided on the sides, or as part of

the internal structure of the system base.

Lifting with a single hook will require cables.

Cables are to be connected to the lugs by use

of shackles. Required cable lengths may vary

due to lifting lugs not being symmetrical to the

center of gravity of system, or to avoid system

internals.

Fig. 1 Side view of lifting points

Fig. 2 Plan view of lifting points

3.3 Storage:

Unit should be stored in a dry and dust free

and temperature controlled environment.

It is not recommended the unit be stored

outside. If the unit must be stored outside it is

required that the entire unit must be covered

with a watertight seal. Electronic equipment

is delicate and will not withstand variations in

humidity and temperature.

3.4 Bolt check instructions:

System bolts may become loose during

shipment due to vibration. Bolts must be

checked for tightness and for required torque.

This must be done before system is pressurized.

3.5 Field connections:

Piping isolation is recommended on all package

system eld connections. It is the installer’s

responsibility to suppor

piping.

Request for assistance:

If there are questions concerning the

installation of this package system contact:

Service Department

Grundfos Commercial Building Services

902 Koomey Road

Brookshire, TX. 77423

t and anchor eld

6

1-800-955-5847

Page 7

3.6 Assembly of packaged sections

Installation

5

(if applicable):

gaskets required for re-assembly are supplied.

Final package system connections hardware by

others.

1. Refer to specic installation documents or

drawings for the package system.

2. Familiarity with the parts requirements and

any referenced documents or drawings will

aid in the piping assembly. All hardware and

gaskets required for re-assembly are supplied.

Final package system connections hardware by

others.

3. Check pipe/pump/ttings/valves end

connections. Any loose scale, paint or dirt must

be removed.

4. Ensure alignment of end connections

between pump/pipe/ttings/valves

Connections must be square.

5. Package piping must be supported

independent of the pump. If package pipe

support is not part of the original package

others should supply it. Package steel base

is designed to provide a structural support

beginning.

6. Use proper gasket (if required) and install

the individual pump suction & discharge pipe/

ttings/valves with the nuts & bolts provided

(at & lock washers also provided). Install

the required bolts for the tting connections

(elbow, wye strainer,and buttery valve)-to-pipe

connection and tighten bolts to a snug t.

7. Tighten and torque all pipe connection bolts

as required.

8. Install and/or tighten loose pipe support

brackets as required. Remove any temporary

supports.

11. Ensure alignment of pipe end connections

between sections. Connections must be square.

Install the required bolts for each of the tting

connections- (elbow, separator, valve, etc.) -to

pipe connections and tighten bolts to a snug t.

Gasket may be required.

12. Working from the middle of base sections

to the outside. Snug all base connection bolts

making sure the base channel anges are ush

top, bottom and side. Torque base connection

bolts to approx. 75 ft/lb

13. Ensure pipe connections are aligned.

Tighten and torque all the pipe connection bolts

as required.

14. Install and/or tighten loose pipe support

brackets and bolts as required.

3.7 Other packaged system requirements:

1. Required electrical wiring can now be

connected. A qualied electrician should do

the electrical wiring. Power/control/sensing

runs may be disconnected for package splits or

remote/future use, and tagged with color-coded

tape or with a numbering system.

2. Mount the gauge & switch wing panel.

Required sensing lines can now be connected.

Sensing lines may be disconnected for package

splits or for remote/future use, and tagged with

color-coded tape or with a numbering system.

3. Complete the package system installation

per individual parts provider or manufacturer,

customer, or maintenance instructions

requirements.

PACOpaQ System Installation

9. Refer to specic installation documents or

drawings for the package system.

10. Familiarity with the parts requirements and

any referenced documents or drawings will

aid in the piping assembly. All hardware and

7

Page 8

English (US)

5

English (US)

2.14 law and arbitration

The Contract shall be governed by the law of the State of Texas.

Any disputes arising out of this Contract shall be resolved by

informal mediation in any manner that the parties may agree

within 45 days of written request for mediation by one party to the

other. Any dispute that cannot be resolved through mediation

shall be resolved by binding arbitration conducted in English in

Portland, Oregon under the Commercial Rules of the American

Arbitration Association except as otherwise provided in this

Section. The arbitration shall be conducted by three arbitrators

chosen in accordance with said Rules. The arbitrators are not

entitled to award damages in excess of compensatory damages.

Judgment upon the award may be entered in any court having

jurisdiction.

3.2 Receiving

• Check pumping unit for shortage and damage immediately

upon arrival. Pump accessories when required are packaged

in a separate container and shipped with the unit.

• If equipment is damaged in transit, promptly report this to the

carrier's agent. Make complete notations on the freight bill to

speed satisfactory adjustment by the carrier.

• Unload and handle the unit with a sling. Do not lift unit by eye

bolts on the motor!

3.3 Temporary storage

• If pump is not to be installed and operated soon after arrival,

store it in a clean, dry area of moderate ambient temperature.

• Rotate the shaft by hand periodically to coat bearing with

lubricant to retard oxidation and corrosion.

• Follow motor manufacturer's storage recommendations where

applicable.

3.4 Location

• Locate the pump as close to the suction supply as possible.

Use the shortest and most direct suction piping practical.

Refer to 3.9 Suction (inlet) piping.

• Locate the pump below system level wherever possible. This

will facilitate priming, assure a steady liquid flow, and provide

a positive suction head.

• Make sure sufficient NPSH (Net Positive Suction Head) is

provided at the suction end by considering the pump's location

in relation to the entire system. Available NPSH must always

equal or exceed required NPSH specified on the pump

performance curve.

• Always allow sufficient accessibility for maintenance and

inspection. Provide a clear space with ample head room for

use of a hoist strong enough to lift the unit.

• Make sure a suitable power source is available for the pump

motor. Electrical characteristics should match those specified

on the motor data plate, within the limits covered in

4. Installation-electrical and 5. Operation.

• Avoid pump exposure to sub-zero temperatures to prevent

pump liquid from freezing. If freezing conditions exist during

shutdown periods, see Sections 5.6 Pump shutdownand

5.7 Short duration shutdown for specific recommendations.

3.5 Horizontal pump foundation

Horizontal pumps should be permanently installed on a firm,

concrete foundation mounting pad of sufficient size to dampen

any vibration and prevent any deflection or misalignment. The

pad may float on springs or be a raised part of the equipment

room floor. The foundation should be poured without interruption

to 3/4 to 1 - 1/2 inches below the final pump elevation. The top

surface should be well scored or grooved before the concrete

sets to provide a suitable bonding surface for the grout. Anchor

bolts should be set in pipe sleeves for positioning allowance, as

shown in Fig. 2. Allow enough bolt length for grout, lower base

plate flange, nuts and washers. Allow the foundation to cure

several days before proceeding with pump installation.

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

The use of this product requires experience with

and knowledge of the product. Persons with

reduced physical, sensory or mental

capabilities must not use this product, unless

they are under supervision or have been

instructed in the use of the product by a person

responsible for their safety. Children must not

use or play with this product.

PACO Pumps

Paco Pumps

Installation and Opereating Procedures

3.4 Installation - Mechanical

Read these instructions thoroughly before installing and

operating your PACO Type L Centrifugal Pump. Successful

operation depends on careful attention to the procedures

described in Sections 1, 2, 3 and 4 of this manual. Keep this

instruction manual handy for future use.

4.1 Pump identification

All PACO Pumps are identified by Catalog and Serial Numbers.

These numbers are stamped on the pump nameplate (Fig. 1)

affixed to each pump volute casing, and should be referred to in

all correspondence with the Company.

Fig. 1 Nameplate

4.2 Receiving

• Check pumping unit for shortage and damage immediately

upon arrival. Pump accessories when required are packaged

in a separate container and shipped with the unit.

• If equipment is damaged in transit, promptly report this to the

carrier's agent. Make complete notations on the freight bill to

speed satisfactory adjustment by the carrier.

• Unload and handle the unit with a sling. Do not lift unit by eye

bolts on the motor!

4.3 Temporary storage

• If pump is not to be installed and operated soon after arrival,

store it in a clean, dry area of moderate ambient temperature.

• Rotate the shaft by hand periodically to coat bearing with

lubricant to retard oxidation and corrosion.

• Follow motor manufacturer's storage recommendations where

applicable.

4.4 Location

• Locate the pump as close to the suction supply as possible.

TM 05 8912 3712

Use the shortest and most direct suction piping practical.

Refer to 3.9 Suction (inlet) piping.

• Locate the pump below system level wherever possible. This

will facilitate priming, assure a steady liquid flow, and provide

a positive suction head.

• Make sure sufficient NPSH (Net Positive Suction Head) is

provided at the suction end by considering the pump's location

in relation to the entire system. Available NPSH must always

equal or exceed required NPSH specified on the pump

performance curve.

• Always allow sufficient accessibility for maintenance and

inspection. Provide a clear space with ample head room for

use of a hoist strong enough to lift the unit.

• Make sure a suitable power source is available for the pump

motor. Electrical characteristics should match those specified

on the motor data plate, within the limits covered in

4. Installation-electrical and 5. Operation.

• Avoid pump exposure to sub-zero temperatures to prevent

pump liquid from freezing. If freezing conditions exist during

shutdown periods, see Sections 5.6 Pump shutdownand

5.7 Short duration shutdown for specific recommendations.

8

4.5 Horizontal pump foundation

Horizontal pumps should be permanently installed on a firm,

concrete foundation mounting pad of sufficient size to dampen

any vibration and prevent any deflection or misalignment. The

pad may float on springs or be a raised part of the equipment

room floor. The foundation should be poured without interruption

to 3/4 to 1 - 1/2 inches below the final pump elevation. The top

surface should be well scored or grooved before the concrete

sets to provide a suitable bonding surface for the grout. Anchor

bolts should be set in pipe sleeves for positioning allowance, as

shown in Fig. 2. Allow enough bolt length for grout, lower base

plate flange, nuts and washers. Allow the foundation to cure

several days before proceeding with pump installation.

Page 9

Finished

Wedges or shims

grouting

.75 to 1.25

allowance for grout

Base plate

Grout

left in place

4.9 Suction (inlet) piping

The sizing and installation of suction piping is particularly

important. It must be selected and installed in a manner that

minimizes pressure loss and permits sufficient liquid flow into the

pump during starting and operation. Many NPSH problems can

be traced directly to improper design of suction piping systems.

Observe the following precautions when installing suction piping:

PACO Pumps

Dam

Pipe sleeve

Washer

Fig. 2 Anchor bolt installation

ecuring base plate

4.6 S

• After the concrete pad has been poured and set, lower the

pump base plate over the anchor bolts and rest it on loose

adjustment wedges or shims placed near each anchor bolt and

at intervals not to exceed 24" along each side. Shims or

wedges must be placed to raise the bottom of the base 3/4" to

1 - 1/4" above the pad, allowing clearance for grout. Level the

pump shaft, flanges, and base plate using a spirit level,

adjusting the wedges or shims, as required.

• Check to make sure that the piping can be aligned to the pump

flanges without placing any strain on either flange.

• After pump alignment has been established (LF), put nuts on

foundation bolts and tighten them just enough to keep the unit

base plate from moving. Construct a form or dam around the

concrete pad and pour grout in and around the pump base, as

shown in Fig. 2. Grout compensates for uneven foundation,

distributes the weight of the unit, and prevents shifting. Use an

approved, non shrinking grout (such as Embeco 636 by

Master Builders, Cleveland, Ohio or equivalent). Allow at least

24 hours for this grout to set before proceeding with piping

connections.

• After the grout has thoroughly hardened, check the foundation

bolts and tighten if necessary. Recheck the pump alignment

after the foundation bolts are secured.

• No alignment or grouting required for LCS pump.

4.7 Vertical mount

The PACO LCV Vertical Close Coupled pump need not be

grouted to its foundation, but should be anchored with 4 anchor

bolts set in concrete similar to the horizontal anchoring

arrangement Fig. 2.

4.8 P

iping-general

• Do not use pump as a support for piping! Use pipe hangers or

other supports at proper intervals to provide complete piping

support near the pump.

• Both suction and discharge piping should be independently

supported and properly aligned so that no strain is transmitted

to the pump when flange bolts are tightened.

• Make sure piping is as straight as possible, avoiding

unnecessary bends and fittings. Where necessary, use 45 ° or

long-sweep 90 ° pipe fittings to decrease friction loss.

• Where flanged joints are used, make sure that inside

diameters properly match and mounting holes are aligned.

• Do not spring or force piping when making any connections!

ing instructions

Top foundation

leave rough clean

& wet down

LUG

TM 05 4775 2512

TM05 4791 2613

Fig. 3 Inlet piping

• Suction piping should be as direct as possible, and ideally the

length should be at least ten times the pipe diameter. Short

suction piping can be the same diameter as the suction

opening. Longer piping should be one or two sizes larger

(depending on length), reducing to the diameter of the pump

suction opening.

• Use an eccentric reducer, with the eccentric side down Fig. 3

when reducing the pipe diameter to the diameter of suction

opening.

• At no point should suction piping be smaller in diameter than

the pump suction opening.

• Horizontal suction lines should follow an even gradient, if

possible. A gradual upward slope to the pump is

recommended for suction lift conditions, and a gradual

downward slope for positive suction head.

• Avoid any high points, such as pipe loops Fig. 4, that may

create air pockets and throttle the system or produce erratic

pumping.

• Install a valve in the suction line to isolate the pump during

shutdown and maintenance, and facilitate pump removal.

Where two or more pumps are connected to the same suction

line, install duplicate gate valves to isolate each pump from

the line.

• Gate valves should always be installed in positions that avoid

air pockets. Globe valves should not be used, particularly

when NPSH is critical.

• During pumping operation, valves on suction line must always

be at FULL OPEN.

• Properly sized pressure gauges can be installed in gauge taps

on pump suction and discharge nozzles. Gauges enable the

operator to monitor pump performance and determine that the

pump conforms to the parameters of the performance curve. If

cavitation, vapor binding, or other unstable operation occurs,

pressure gauges will indicate wide fluctuation in suction and

discharge pressures.

9

Page 10

English (US)

PACO Pumps

Fig. 4 Air pocket prevention

4.10 Discharge (outlet) piping

• Short discharge piping can be the same diameter as the pump

discharge opening. Longer piping should be one or two sizes

larger depending on length.

• An even gradient is best for long horizontal runs of discharge

piping.

• Install a valve near the discharge opening to prime and start

the pump. The discharge gate valve is also used to isolate the

pump during shutdown, maintenance, and facilitate pump

removal.

• Any high points in discharge piping may entrap air or gas and

thus retard pump operation.

• If the possibility of liquid hammer exists, (i.e. check valves are

used) close the discharge gate valve before pump shutdown.

4.11 Shaft sealing-general comments

• PACO offers both mechanical seals and packed stuffing boxes

as a means to seal the shaft. Pumps with stuffing boxes are

normally packed before shipment. If the pump is installed

within 60 days after shipment, the packing material will be in

good condition for operation with a sufficient supply of

lubrication. If the pump is stored for a longer period, it may be

necessary to repack the stuffing boxes.

• The stuffing box must be supplied at all times with a source of

clean, clear liquid to flush and lubricate the packing. When

pumps are equipped with mechanical seals, no maintenance

or adjustment is required. Mechanical seals are preferred to

packing on most applications because they require less

maintenance.

4.13 Mechanical seals

All PACO Type L pumps that are equipped with mechanical seals

are matched to conditions for which the pump was sold. Observe

the following precautions to avoid seal damage and obtain

maximum seal life:

• Do not exceed temperature or pressure limitations for the

mechanical seal used.

• DO NOT RUN THE PUMP DRY OR AGAINST A CLOSED

VALVE! Dry operation will cause seal failure within minutes.

• Clean and purge suction piping in new installations before

installing and operating pump. Pipe scale, welding slag and

TM05 4792 2613

other abrasives can cause rapid seal failure.

Fig. 5 Checking parallel alignment

TM05 4795 2613TM05 4794 2613

4.12 Packing gland adjustment

With the pump running, the packing gland should be adjusted to

permit 40 to 60 drops per minute leakage. This is required for

shaft lubrication. After initial start up, additional packing and

adjustment may be required. Pumps with mechanical seals

require no adjustment.

10

Fig. 6 Checking alignment

Page 11

4.14 Coupling alignment (LF)

• The following anchoring and alignment procedure is typical

and, if performed with care, should result in a smooth running,

trouble-free installation.

• If the pump and motor were shipped mounted on the pump

base as an assembly, remove the coupling guard.

• The pump and motor were accurately aligned at the factory,

but handling during shipment usually alters this pre-alignment.

Using a small straight edge and feeler gauges or a dial

indicator, check for horizontal, vertical, and angular

misalignment of the coupling hubs Fig. 5 and Fig. 6.

• Coupling alignment is correct when the dial indicator reads no

more than .005" run out in any direction (or when the straight

edge contacts both hubs evenly in both horizontal and vertical

positions). If misalignment is detected, loosen the motor and

shift or shim as necessary to re-align, then re-tighten bolts.

Always align the motor to the pump as piping strain will occur

if the pump is shifted. Never reposition pump on base!

• After final piping connections to the pump have been made,

motor wiring compared, correct rotation has been established,

and piping filled with liquid, check shaft alignment once again.

• Leave the coupling guards off until the pump priming

procedure is completed for a final shaft alignment check.

• To protect personnel from rotating machinery, Always install

coupling guards after installation is complete; before starting

pump!

4.15 Coupling alignment (LCS)

• No alignment of the pump and motor is required.

Installation-electrical

5.

Warning

Use only qualified electricians for electrical

installation and maintenance.

Refer to manuals provided with electrical

accessory components and disconnect power

supply as recommended for servicing.

Warning

Never do maintenance work when the unit is

connected to power.

5.1 Motors general

the motor control circuit must have the following components in

order to comply with the National Electrical Code.

• Motor Disconnecting Device: A motor disconnecting device

must be installed that is capable of disconnecting both the

controller (motor starter) and the motor from their source of

power.

• The disconnecting device must be located so that the

controller (motor starter) can be seen from the disconnecting

means. In all cases, the distance from the disconnecting

device to the controller must be less than 50'.

• In most installations the disconnecting device will be a circuit

breaker or fusible disconnect switch.

Motor short circuit and ground fault protection:

• Short circuit and ground fault protection are usually provided

by means of a circuit breaker or fusible disconnect switch.

• The selection of the size of the circuit breaker or fuse must be

in accordance with Section 430-52 and Table 430-152 of the

National Electrical Code.

Motor controller with running over current protection (magnetic

starter):

• These components must be installed in accordance with

applicable local and state electrical codes in addition to the

National Electrical Code.

PACO Pumps

Warning

Whenever powered equipment is being used in

explosive surroundings, the rules and

regulations generally or specifically imposed by

the relevant responsible authorities or trade

organizations must be observed.

5.2 Installation wiring

• Mount the control panel or motor starter(s) in close proximity

to the pump to provide convenient control and ease of

installation.

• Wire panel or starter(s) to motor(s) and pilot device(s): Wires

to each motor must be sized for at least 125 % of the motor

nameplate full load amps. AWG #16 Type THW stranded wire

is recommended for wiring of pilot devices (float switches).

• Check incoming power source to ensure that it is the same as

the voltage and phase of the motors.

• Verify that the starters are suitable to operate the pump motors

on voltage and phase that is available.

11

Page 12

English (US)

Caution

Caution

PACO Pumps

Operation

6.

5.1 Priming

• The PACO Type L pump is not self-priming, and must be

completely primed (filled with liquid) before starting.

• If the pump will operate with a positive suction head, prime by

opening the suction valve and allowing liquid to enter pump

casing. Open air vents at this time, and make sure all air is

forced from pump by liquid before closing.

• Rotate the shaft by hand to free entrapped air from impeller

passageways.

• If pump has a suction lift, priming must be accomplished by

other methods. The use of foot valves or ejectors, or manual

filling of the pump casing and suction line with liquid are

possible methods suggested for this purpose.

• CAUTION: Never run the pump dry in the hope that it will

prime itself! Serious damage to the mechanical seal will result.

Never run the pump dry in the hope that it will

prime itself! Serious damage to the shaft seals,

pump wear rings and shaft sleeves will result.

6.2 Pre-start checklist

Warning

In the interest of operator safety, the unit must

not be operated above the nameplate conditions.

Such operation could result in unit failure

causing injury to operating personnel. Consult

instruction book for proper operation and

maintenance of the pump and its supporting

components.

Make the following inspections before starting your PACO Type L

pump:

1. Make sure the suction and discharge piping has been cleaned

and flushed to remove dirt and debris before operating pump.

2. Double check rotation must be clockwise operating in reverse

will destroy the impeller and shaft.

3. Make sure all wiring connections to the motor (and starting

device) match the wiring diagram and produce clockwise

rotation as viewed from the back of the motor.

4. If the motor has been in storage for an extended length of

time, either before or after installation, refer to motor

instructions before starting.

5. Check the voltage, phase, and line circuit frequency with the

motor nameplate. Turn rotating element by hand to make sure

it rotates freely.

6. Tighten plugs in gauge and drain taps. If the pump is fitted

with pressure gauges, keep gauge clocks closed when not in

use.

7. Check suction and discharge piping for leaks, and make sure

all flange bolts are securely tightened.

6.3 Motor rotation

Never check driver rotation unless pump and

driver couplings are disconnected and physically

separated. Failure to follow this instruction can

result in serious damage to pump and driver if

rotation is wrong.

After the unit has been wired and checked to insure that all

components in the system (disconnect device, magnetic starters,

pilot devices and motors) are properly connected, check motor

rotation as follows:

• For 3 phase units only—momentarily energize the motors to

ensure that the rotation is correct as indicated by the arrow

cast into the pump volute. If rotation is incorrect, interchange

two wires at the motor starter terminals T1 and T2.

• IMPORTANT: The pumps must not be operated while dry. Use

extreme caution that motors are energized only momentarily to

determine proper rotation.

6.4 Starting the pump

Warning

The pump must not be operated without an

approved coupling guard in place. Failure to

observe this warning could result in injury to

operating personnel.

1. Install coupling guard on coupled units.

2. Fully open gate valve (if any) in suction line, and close gate

valve in discharge line.

3. Fill suction line with liquid and completely prime pump.

4. Start the motor (pump).

5. Immediately make a visual check of pump and suction piping

for pressure leaks.

6. Immediately after pump reaches full operating speed, slowly

open the discharge gate valve until complete system flow is

achieved.

7. Check discharge piping for pressure leaks.

8. If pump is fitted with pressure gauges, open gauge cocks and

record pressure reading for future reference. Verify that the

pump is performing in accordance with parameters specified

on performance curve.

9. Check and record voltage, amperage per phase, and

kilowatts, if a wattmeter is available.

12

Page 13

6.5 Voltage regulation

The motor will operate satisfactorily under the following

conditions for voltage and frequency variation, but not necessarily

in accordance with the standards established for operation under

rated conditions:

• The voltage variation may not exceed 10 % above or below

rating specified on the motor data plate.

• The frequency variation may not exceed 5 % above or below

motor rating.

• The sum of the voltage and frequency variations may not

exceed 10 % above or below motor rating, provided the

frequency variation does not exceed 5 %.

6.6 Pump shutdown

The following shutdown procedures will apply in most normal

shutdowns for the PACO Type L pumps. If the pump will be

inoperative for an extended length of time, follow storage

procedures in Extended Period Shutdown.

• Always close the discharge valve before stopping the pump.

Close the valve slowly to prevent hydraulic shock.

• Cut and lock off power to the motor.

6.7 Short duration shutdown

• For overnight or temporary shutdown periods under nonfreezing conditions, the pump may remain filled with liquid.

Make sure the pump is fully primed before restarting.

• For short or frequent shutdown periods under freezing

conditions, keep fluid moving within the pump casing and

insulate or heat the pump exterior to pre vent freezing.

6.8 Extended period shutdown

• For long shutdown periods, or to isolate the pump for

maintenance, close suction gate valve. If no suction valve is

used and the pump has positive suction head, drain all liquid

from suction line to terminate liquid flow into pump suction

nozzle. Remove plugs in pump drain and vent taps, as

required, and drain all liquid from the pump volute casing.

• If freezing conditions will exist during long shutdown periods,

completely drain the pump and blow out all liquid passages

and pockets with compressed air. Freezing of pump liquid can

also be prevented by filling the pump with antifreeze solution.

7. Maintenance

Warning

Do not attempt any maintenance, inspection,

repair or cleaning in the vicinity of rotating

equipment. Such action could result in personal

injury to operating personnel.

Before attempting any inspection or repair on the pump, the driver

controls must be in the "OFF" position, locked and tagged to

prevent injury to personnel performing service on the pump.

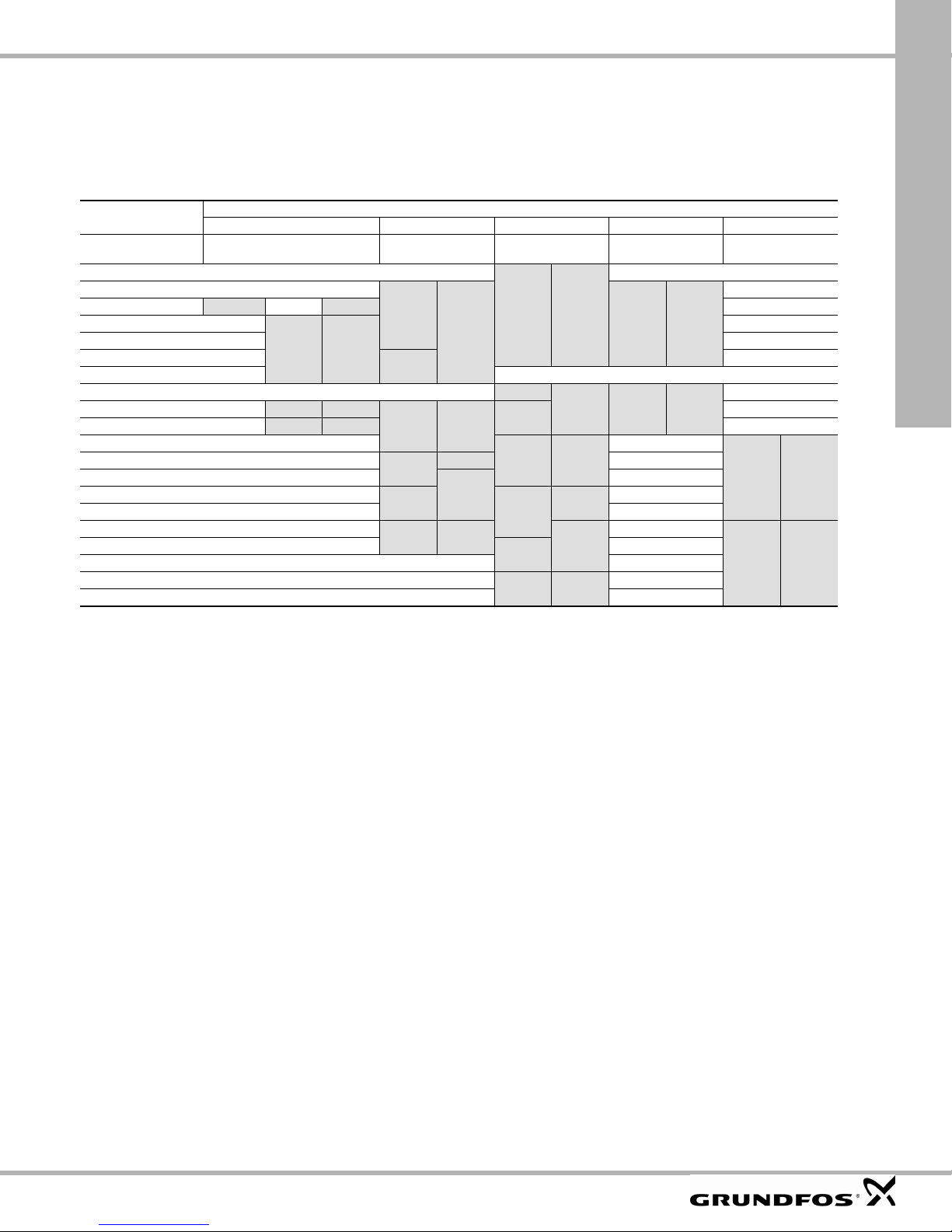

7.1 Motor lubrication

Always follow motor manufacturer's lubrication instructions if

available, and periodically check grease fittings and drain plugs

for leaks. If lubricating instructions do not accompany motor, refer

to for recommended lubrication periods.

• To lubricate the motor while running or at rest, remove grease

drain plug (if any) and filler plug on grease fitting. Grease with

clean lubricant until grease appears at drain hole or along

motor shaft.

Recommended Lubrication Periods

Motor RPM Motor HP Operating conditions

Standard Severe Extreme

0.33 - 7.50p 3 yrs 1 yr 6 mo

1750 and

below

above 1750 all hp 6 mo 3 mo 3 mo

Standard conditions:

8 Hours per day operation, normal or light loading, clean air,

100 °F, maximum ambient temperature.

Severe conditions:

Continuous 24-hour operation, shock loading or vibration, poor

ventilation, 100-150 °F, ambient temperature.

Extreme conditions:

Continuous operation, heavy shock or vibration, dirt or dust in

air, extreme ambient temperature.

• One-half to one cubic inch of grease is sufficient for motors 5

HP and under, with proportionately more grease for greater

HP motors.

• Most fractional and some integral frame motors have "sealedfor-life" bearings, and do not require further lubrication

throughout motor life.

• Always follow motor manufacturer's lubrication instructions,

and periodically check grease fittings and drain plugs for

leaks.

• If lubricating instructions do not accompany motor, refer to

Table , “Recommended Lubrication Periods,” on page 10 for

recommended lubrication periods.

• Table , “Approved lubricants,” on page 11 lists recommended

types of grease for both pump and motor lubrication. These

types have all been thoroughly tested and should be used

whenever possible.

10-40 1-3 yrs 6 mo - 1 yr 3 mo

50-150 1 yr 6 mo 3 mo

200 and up 1 yr 6 mo 3 mo

PACO Pumps

13

Page 14

English (US)

PACO Pumps

7.2 Pump lubrication

• PACO Type LF pumps on horizontal bearing frames have

bearing that may be sealed for life (requiring no lubrication),

regreasable or oil lubricated.

.

Approved lubricants

MANUFACTURER LUBRICANT

®

SHELL DOLIUM

EXXON POLYREX

CHEVRON

PHILIPS POLYTAC™

TEXACO POLYSTAR RB

• To lubricate regreasable bearings, remove grease drain plug

(if any) and filler plug. Add clean ball bearing lubricant until

grease appears at drain hole or along shaft. On units with

drain hole, all old grease can be purged out ahead of new. In

such cases, the drain should be left unplugged for several

minutes during pump operation to allow excess grease to be

forced out.

• Lubricate bearing frame bearings at intervals of one to three

months, depending on severity of environment. Pumps in a

clean, dry, moderate temperature (100 °F maximum)

environment should be regreased at three month intervals.

Too much grease can cause premature bearing failure-do not

overgrease.

On those PACO Type LF Centrifugal End Suction pumps

•

ordered with oil lubricated bearings, Fig. 7. A regular oil

maintenance program must be enforced.

After the first 200 hours of operation the oil should be

•

changed. To change the oil, remove the drain plug at the

bottom of the bearing cover and the filler plug (that also acts

as a vent plug) at the top of the housing. After draining oil,

replace the fittings and refill with an acceptable oil selected

from Table , “List of acceptable Lube oils,” on page 11. After

the first oil change, the oil should be changed again at 2000

hours and then at intervals of 8000 hours or once yearly,

thereafter.

SRI GREASE NLGI 2

BLACK PEARL - NLGI 2

R

®

List of acceptable Lube oils

Lubricant Manufacturer Bearing oil brand name

Aral Refining Co.

British Petroleum Co.

Calypsol Oil Co.

Standard Oil Co.

Esso Corp

Fina Oil Co.

Gulf Refining Co.

Socony Mobil Oil Co.

Shell Oil Co. Shell Tellus oil 29

Sundco Oil Co. Sunvis 821

The Texas Co.

Wisura Refining Co.

Aral Oil CMU

Aral Oil TU 518

BP Energol

TH 100-HB

Calypsol Bison Oil

SR 25 or SR 36

Chevron

Hydraulic Oil 11

Circulating oil 45

Esso-Mar 25

Teresso 47

Esstic 50

Fina hydran 34

Fina Cirkan 32

Gulf Harmony 47

Gulf Paramount 45

Vac hlp 25

Mobulix D.T.E. 25

Texaco ursa oil P 20

Dea viscobil sera 4

Wisura norma 25 (36)

Wisura tempo 25 (36)

14

Page 15

7.3 Disassembly of pumps

Caution

Note

Note

Caution

Warning

Depending on the product being pumped, the

pump should be washed down before any work is

done on it.

Warning

Observe extreme caution when venting and/or

draining hazardous liquids. Wear protective

clothing in the presence of caustic, corrosive,

volatile, flammable, or hot liquids. DO NOT

breathe toxic vapors. DO NOT allow sparking,

flames, or hot surfaces in vicinity of the

equipment.

1. Complete disassembly instructions are outlined below.

Proceed only as far as required to perform the maintenance

work needed.

2. Turn of power.

3. Drain System. Flush, if necessary.

4. Closed coupled units. Remove motor hold down bolts.

7.3.1 Disassembly of liquid end

1. Remove casing bolts (8B).

2. Remove back pull-out bearing frame assembly (20Y) from

casing (1A).

3. Unscrew impeller nut (8A).

Do not screwdriver between impeller vanes to

prevent rotation. It may be necessary to use a

strap wrench around the impeller or shaft to

prevent rotation.

4. Use appropriate size gear puller aligned behind impeller

vanes to remove impeller (3A) from shaft (6A).

5. Remove impeller key (12A).

6. Remove back plate bolts (8D). Remove back plate (2K) and

seal housing (26P).

7. Place seal housing on flat surface and press out seal seat

(14A).

8. If shaft sleeve (5A) requires replacement, it must be evenly

heated to approximately 350 °F to loosen locktite. Twist

sleeve off shaft (6A).

7.3.2 Disassembly of bearing frame (LF)

1. Remove slinger (13G).

2. Remove grease seal(s), (14S) if any.

3. Remove bearing house retaining ring (61K).

4. Press or tap on the pump end of the bearing-shaft assembly

until one bearing is out.

5. When one bearing is out, remove second retaining ring (61F),

then remove complete assembly from bearing housing.

6. Remove shaft retaining ring (61C) and press off bearings.

7. press on new bearings, remember to press only on inner race

of bearing while pressing them on.

8. Assemble frame in the reverse procedure used for

disassembly.

9. Observe the following when reassembling the bearing frame.

10. Replace lip seals (14S) if worn or damaged.

11. Replace bearings (18A), (18B) if loose, rough or noisy when

rotated.

12. Check shaft (6A) for runout at the sleeve (5A) area. Maximum

permissible is .002" T.I.R.

7.4 Seal replacement (LCS)

1. Complete preparations noted.

2. Remove coupling guard (34F).

3. Remove coupling bolts (8E). Pry apart the coupling halves

(23D), remove keys (12B) and set aside.

Mark or measure the original position of the

pump coupling on the motor side.

4. Unscrew tubing connector from pipe tee of air vent assembly.

Pipe dope is applied to threads during factory assembly, and

resulting bond may retard but will not prevent manual

disassembly.

5. Remove seal cap bolts and slide seal cap (2N) up shaft to

remove.

6. Remove seal head assembly manually from shaft (6A).

Water-soluble lubricant may be applied to shaft to ease

removal of shaft seal (14A). Pull seal head assembly

manually from shaft, using slight twisting motion (as

necessary) to loosen bellows from shaft.

7. Remove and discard seal spring and retainer.

8. remove and discard seal seat from seal cap (2N) and

thoroughly clean the inside cavity of seal cap.

9. Interior surface of bellows on new seal head is coated with

bonding agent that adheres to motor shaft. When old seal

head is removed, bonding agent no longer exists and bellows

may crack or split during removal. Installation of new

mechanical seal is always recommended if it becomes

necessary to remove existing seal from shaft.

10. Clean and lubricate shaft (6A) with water-soluble lubricant

and make sure no sharp edges exist to cut or scratch bellows

of new seal.

11. Press new seal seat firmly into seal cap. Avoid direct contact

of seal face with metallic or abrasive objects and wipe clean

after installation to ensure abrasive free sealing surface.

12. Slide new seal head assembly onto shaft by applying even

pressure to base of assembly.

13. Install seal cap (2N) down shaft.

14. See reassembly instructions.

7.5 Wear ring replacement

1. Complete preparations.

2. Back-pull rotating assembly.

3. It may be necessary to remove volute (1A) from piping, to

facilitate easy access to interior of volute. If necessary,

remove flange bolts at piping.

4. To remove worn Case Wear Ring (4A), drill two holes slightly

smaller than width of ring into exposed edge of ring. Once

holes are drilled, a chisel may be used to completely sever

ring at holes and break ring into two halves for easy removal.

5. Clean the ring cavity in the volute prior to installing wear ring

to ensure a properly aligned fit.

6. To reassemble, press fit new wear ring squarely into volute

casing cavity. Ring may be tapped into place to make sure it

is completely impressed into cavity.

Do not use metal tooling against wear ring

surfaces. Use only rubber, rawhide, wood or

other soft material to prevent damage to ring.

PACO Pumps

15

Page 16

English (US)

PACO Pumps

7.6 Reassembly of pumps

1. All parts should be cleaned before reassembly.

2. Refer to parts list to identify required replacement items

Specify pump serial or catalog number when ordering parts.

3. Reassembly is the reverse of disassembly.

4. Observe the following when reassembling the liquid end:

• All mechanical seal components must be in good condition or

leakage may result. Replacement of complete seal assembly

is recommended.

• New shaft sleeves are installed by bonding to shaft with

hydraulic setting locktite.

5. Re-install coupling guards on coupled pumps.

7.7 Ordering parts

Grundfos Pumps has over 90 years of experience in the design,

manufacture, and application of centrifugal pumps and pumping

systems. Grundfos's commitment to state-of-the-art pump design

and quality manufacturing assures maximum user benefits with

optimum equipment life at lower cost.

Grundfos's commitment to their customers continues through an

extensive service organization. Highly trained technicians can

assist customers with initial startup, troubleshooting, repair, and

system analysis.

PACO maintains an extensive stock of replacement parts and

parts kits for our most popular model pumps. Shipment of these

parts is normally made within three days after receipt of an order.

On larger pumps, where it is impractical for our factory to

inventory low usage parts, replacement parts are normally

manufactured and shipped within 15 working days of receipt of an

order. In order to reduce pump repair time and shorten

inconvenient pump service interruptions, it is suggested that the

pump user stock spare parts. For suggested spare parts see

Replacement Parts Guide A1b.2, attached, and contact your local

PACO Sales Representative (see back cover for the number of

your nearest PACO Sales office). Since spare parts requirements

and quantities vary for specific pump constructions, allow your

PACO Representative to help in defining your spare part

requirements. To ensure that the proper replacement parts are

ordered for your particular pump model, when you call:

• Identify all pertinent data from the pump name plate (see

Pump Identification ). This should always include the pump

Catalog or Model Number, and the pump Serial Number.

• For replacement impellers, also include from the nameplate

the operating conditions (GPM and TDH) and the impeller

diameter.

• Identify all parts by item number and description as indicated

by the appropriate assembly drawing in this manual, for your

particular pump model.

Warning

Coupling guard must be reinstalled and in place

prior to operation.

16

Page 17

7.8 Type LF, cross section and parts list

PACO Pumps

ITEM NO PART NAME ITEM NO PART NAME ITEM NO PART NAME

1A Casing *10A Washer, Packing 16L Plug, Seal Chamber

2K Backplate 10A Washer, Impeller 18A Bearing, Inboard

3A Enclosed Impeller 11A Gasket, Casing 18B Bearing, Outboard

4A Case Wear Ring 11F Gasket, Backplate 20Y Bearing Frame

**4F Balance Ring 12A Key, Impeller *22A

5A Shaft Sleeve 12B Key, Coupling 26P Seal Housing

*5L Lantern Ring *13A Packing *26U Packing Box

6A Shaft 13G Slinger *35F Nut, Packing Gland

*7A Packing Gland 14A Shaft Seal 61C Snap Ring

8A Cap Screw, Impeller 14S Lip Seal *61J Snap Ring

8B Cap Screw, Casing 16A Plug, Drain

8D Cap Screw, Brg. Frame 16D Plug, Grease/Oil Filter

* Packed Pumps Only

** If Applicable

Stud, Packing

Gland

TM05 4796 3712

17

Page 18

English (US)

PACO Pumps

7.9 Type LC, cross section and parts list

ITEM NO PART NAME ITEM NO PART NAME

*1A Casing 11F Gasket, backplate

2K Backplate 12A Key

3A Impeller *13A Packing

4A Front case wear ring 13G Slinger

4F Rear case wear ring 14A Mechanical seal

5A Shaft sleeve 16A Plug, drain

*5L Lantern ring 16J Plug, stuffing box

*7A Packing gland 21A Bracket

8A Impeller capscrew *22A Stud, packing gland

8B Capscrew, casing 34B Nameplate

8D Capscrew, bracket *35F Nut, packing gland

8N Capscrew, motor 61B Snap ring

10A Washer, impeller *61L Retaining ring

*10K Washer, packing 65A Motor

11A Gasket, casing 84R Set screws

* Packed pumps only

TM05 8911 2913

18

Page 19

7.10 Type LCV, cross section and parts list

PACO Pumps

ITEM NO PART NAME ITEM NO PART NAME

1A Volute 10A Impeller washer

2H Hand hole cover (not shown) 12A Key

2K Backplate 13G Slinger

3A Impeller 14A Single mechanical seal assembly

4Q Suction cover wear ring 20H Stand

4S Impeller wear ring 21F Pedestal bracket

5A Sleeve 32C Elbow with clean out port

8A Impeller screw

TM05 8910 2913

19

Page 20

English (US)

PACO Pumps

7.11 Type LCS, cross section and parts

ITEM NO PART NAME ITEM NO PART NAME

1A VOLUTE 17E SEAL CAP O-RING

2N SEAL CAP 20B BASE RAIL

3A IMPELLER 20C MOTOR DECK

4A CASE WEAR RING 20J CAST IRON STAND

4F BALANCE RING 20D PUMP SUPPORT

6A PUMP SHAFT 21A MOTOR BRACKET

8B VOLUTE SCREW 22A SEAL CAP STUDS

8C PUMP SHAFT SCREW 23D COUPLING HALVES

8E COUPLING SCREW 24H BUSHING

8F COUPLING GUARD SCREW 34B IMPELLER WASHER

8G LOCATING RING SCREW 34C PUMP SHAFT WASHER

8N MOTOR SCREW 34D COUPLING WASHER

11A VOLUTE GASKET 35E COUPLING NUT

12B COUPLING KEY 34F COUPLING GUARD

14A SEAL ASSEMBLY 35F SEAL CAP NUT

15A LOCATING RING 65A MOTOR