Page 1

Service instructions

Oxiperm® Pro

OCD-162

1 / 152

1. General safety regulations.............................................................................................................. 3

1.1 Purpose of this manual........................................................................................................................................3

1.2 Layout of this manual...........................................................................................................................................3

1.3 Authorised service personnel ..............................................................................................................................4

1.4 Obligations of the operator ..................................................................................................................................4

1.5 Correct usage ......................................................................................................................................................4

1.6 Inappropriate usage............................................................................................................................................. 5

1.7 Safety and monitoring equipment........................................................................................................................ 5

1.8 Chemicals............................................................................................................................................................ 5

2. Product description......................................................................................................................... 7

2.1 Application examples...........................................................................................................................................7

2.2 Functional principle.............................................................................................................................................. 8

2.3 Components of the Oxiperm Pro ....................................................................................................................... 12

2.4 System peripheral devices and accessories......................................................................................................14

2.5 Power supply connections and electronic connections ..................................................................................... 16

2.6 Control and display elements ............................................................................................................................ 16

2.7 Operating modes ...............................................................................................................................................19

2.8 Access codes..................................................................................................................................................... 19

2.9 User menu structure .......................................................................................................................................... 20

3. Transport and packaging.............................................................................................................. 25

3.1 Unpacking..........................................................................................................................................................25

3.2 Transport damages............................................................................................................................................25

4. Installation...................................................................................................................................... 26

4.1 Installation location ............................................................................................................................................ 26

4.2 Mounting the unit on the wall (OCD-162-5/-10).................................................................................................28

4.3 Mounting the unit on the floor (OCD-162-30/-60) ..............................................................................................29

4.4 Additional modules ............................................................................................................................................32

4.5 Installing the chemical containers and attaching the suction lances .................................................................32

4.6 Hydraulic connections........................................................................................................................................33

4.7 Connecting the electronic components..............................................................................................................36

4.8 Connecting the power supply cable...................................................................................................................38

5. Commissioning.............................................................................................................................. 39

5.1 System configuration ......................................................................................................................................... 39

5.2 Operating software settings...............................................................................................................................40

5.3 Commissioning procedure................................................................................................................................. 44

5.4 Switching on the system – initial start-up...........................................................................................................45

5.5 Basic setup ........................................................................................................................................................46

5.6 Setting the water flow meter (if applicable)........................................................................................................48

5.7 Selecting the measuring cell type and measured variables (if applicable) ........................................................50

5.8 Assigning measuring range(s) (if applicable).....................................................................................................52

5.9 Setting the output current to an external device (if applicable) ..........................................................................55

5.10 Setting the ClO

2

controller (not applicable for group 3 applications) .................................................................56

5.11 Setting the output current to an external dosing pump (if continuous controller is selected).............................60

5.12 Setting the warning and alarm relay ..................................................................................................................61

5.13 Manual ventilation..............................................................................................................................................66

15.710373 V1.0

GB

95719551 1109

Page 2

2 / 152

5.14 Setting the operating mode ............................................................................................................................... 68

5.15 Starting operation .............................................................................................................................................. 69

5.16 Interrupting operation ........................................................................................................................................ 71

5.17 Continuing operation after an interruption ......................................................................................................... 72

5.18 Monitoring the production and dosing process.................................................................................................. 73

5.19 Flushing............................................................................................................................................................. 81

5.20 Calibration ......................................................................................................................................................... 84

5.21 Responding to error messages ......................................................................................................................... 90

5.22 Testing the system ............................................................................................................................................ 90

5.23 Setting the user display language (if applicable)............................................................................................... 98

5.24 Saving the settings after commissioning ........................................................................................................... 98

5.25 Switching off the system.................................................................................................................................... 98

5.26 Completing the acceptance record.................................................................................................................... 98

6. Maintenance................................................................................................................................... 99

6.1 Viewing the maintenance interval.................................................................................................................... 100

6.2 Planning maintenance – obtaining maintenance kits ...................................................................................... 101

6.3 Maintaining the pumps .................................................................................................................................... 102

6.4 Maintaining the solenoid valve ........................................................................................................................ 105

6.5 Maintaining the multi-function valve ................................................................................................................ 107

6.6 Maintaining the reaction tank .......................................................................................................................... 111

6.7 Maintaining the volume compensation bag and activated carbon filter (OCD-162-5, -10).............................. 116

6.8 Maintaining the volume compensation bag and absorption filter (OCD-162-30, -60)...................................... 118

6.9 Confirming the Maintenance Release ............................................................................................................. 120

7. Servicing....................................................................................................................................... 121

7.1 Preparing for servicing .................................................................................................................................... 121

8. Fault finding ................................................................................................................................. 125

8.1 Faults with error message ............................................................................................................................... 125

8.2 Faults without error message at the OCD-162................................................................................................ 130

9. Dismantling and decommissioning the system........................................................................ 131

9.1 Planning and preparing for dismantling ........................................................................................................... 131

9.2 Dismantling the hydraulic components............................................................................................................ 132

9.3 Dismantling the electrical components............................................................................................................ 133

9.4 Dismantling the system frame......................................................................................................................... 133

9.5 Packing the system for transport..................................................................................................................... 133

9.6 Final dismantling steps.................................................................................................................................... 133

9.7 Temporary storage of the dismantled system ................................................................................................. 133

9.8 Recommissioning after dismantling................................................................................................................. 134

10. Disposal........................................................................................................................................ 135

11. Technical data.............................................................................................................................. 135

11.1 Terminal connection plan ................................................................................................................................ 143

12. Spare parts list............................................................................................................................. 145

13. Applicable standards and directives ......................................................................................... 147

14. Operator’s accessories list......................................................................................................... 148

15. Photos........................................................................................................................................... 149

Page 3

3 / 152

1. General safety regulations

1.1 Purpose of this manual

The Oxiperm Pro disinfection system from Grundfos Alldos reflects the best available technology and complies with

recognised safety regulations.

Compliance with applicable standards, guidelines and laws has been confirmed (declaration of conformity and list of

applicable standards and guidelines directives can be found in section 13. Applicable standards and directives).

Nevertheless, risks which are beyond the manufacturer's control may arise from the use of the system.

This manual is aimed at specialist personnel responsible for installation, commissioning, maintenance, servicing,

dismantling and (temporary) storage.

The purpose of this manual is as follows:

• to provide guidance on safe and correct installation.

• to provide guidance on safe and correct commissioning.

• to provide information about safe and correct maintenance and the correct installation of spare parts.

• to provide information about safe and correct fault finding and the correct replacement of components.

• to provide information about safe and correct dismantling, (temporary) storage and recommissioning.

• to warn against potential residual risks associated with the correct usage of the system and to identify means of

avoiding damage.

• to warn against obvious misuse or inappropriate usage of the system and to identify the need for due care when

using the system.

See the separate Installation and operating instructions for the Oxiperm Pro.

1.2 Layout of this manual

This manual contains the following standard risk and safety warnings relating to potential residual risks:

Information about potential residual risks can be found:

• on warning signs located at the installation site

• at the beginning of each section in this manual

• immediately before steps associated with a residual risk.

Warning

If these safety instructions are not observed, it may result in personal injury!

Caution

If these safety instructions are not observed, it may result in malfunction or damage to the

equipment!

Note

Notes or instructions that make the job easier and ensure safe operation.

Page 4

4 / 152

1.3 Authorised service personnel

Only authorised service personnel trained by Grundfos Alldos are permitted to undertake installation, commissioning,

maintenance, servicing, dismantling and (temporary) storage of the system. Appropriate technical expertise and

familiarity with the principles of measurement and control technology are assumed.

1.3.1 Obligations of the service personnel

Service personnel are required to do the following:

• Read this manual thoroughly before commencing installation, commissioning, maintenance, service, dismantling or

(temporary) storage of the Oxiperm Pro disinfection system.

• Obtain instruction from specialist personnel of Grundfos Alldos on all service work relating to the system.

• Observe the recognised health and safety and accident prevention regulations.

See section 1.4 Obligations of the operator.

• Wear protective clothing when working with the system and with chemicals.

See section 1.3.3 Protective clothing.

• Keep secret the user and service codes for the operating software.

1.3.2 Work station for service personnel

The Oxiperm Pro disinfection system is electronically controlled. Users and service personnel operate the system via a

display with control and display elements. See fig. 17.

1.3.3 Protective clothing

Service personnel are obliged to wear protective clothing in accordance with national safety regulations

(Germany: GUV-V D5 Accident prevention regulations, "Chlorination of water", January 1997) when working with the

system and with the chemicals. The protective clothing is supplied by the operator and stored in a dry place in the

installation room.

1.4 Obligations of the operator

Owners of the building and/or operators of the Oxiperm Pro disinfection system are required to:

• Consider this manual to be part of the product and ensure that it is kept clearly accessible in the immediate vicinity

of the system for the entire service life of the system.

• Provide the installation requirements specified by the manufacturer (necessary water connections and fittings,

environmental conditions, electrical connections, protective pipe for dosing line, audible or visual warning system

for alarms. See section 4.1 Installation location.

• Have water lines and fittings inspected, maintained and serviced on a regular basis.

• Obtain official approval, if necessary, to store the chemicals.

• Instruct users in the operation of the system.

• Attach the labels supplied by the manufacturer at the installation site so that they are clearly visible.

• Disclose the user code for the operating software only to appropriately trained users.

• Ensure compliance with accident prevention regulations at the installation site (Germany: GUV-V D5 Accident

prevention regulations, "Chlorination of water", January 1997).

• Provide all users and service personnel with protective clothing in accordance with accident prevention regulations

(German GUV-V D5) (face mask, gloves, protective apron, breathing mask, if necessary).

• If the system is supplied without a dosing pump, provide an external dosing pump prior to installation, and allow

only authorised specialist personnel from Grundfos Alldos to connect it to the Oxiperm Pro disinfection system.

1.5 Correct usage

The purpose of the Oxiperm Pro disinfection system is to mix a diluted chlorine dioxide solution from 7.5 % sodium

chlorite and 9 % hydrochloric acid. In accordance with the conditions described in this manual, the chlorine dioxide

solution may be dosed continuously or discontinuously into the (drinking) water supply of a building, or it may be

introduced into a swimming pool, service water plant, wastewater plant or other industrial plant for the purposes of water

disinfection.

Page 5

5 / 152

1.6 Inappropriate usage

Applications other than those listed in section 1.5 Correct usage are considered not to be in accordance with the

intended use and are not permitted. The manufacturer, Grundfos Alldos, accepts no liability for any damage resulting

from incorrect use.

The system comprises state-of-the-art components and has undergone safety-related testing.

1.7 Safety and monitoring equipment

The Oxiperm Pro disinfection system is fitted with the following safety and monitoring equipment:

• cover on the system frame

• two collecting trays for the two chemical containers (accessories)

• safety/multi-function valve at the dosing pump (optional)

• solenoid valve at the dilution water inlet

• volume compensation bag and activated carbon filter for ClO

2

gas that escapes from the reaction tank

• alarm functions in the control system.

1.8 Chemicals

1.8.1 Chlorine dioxide concentration

In the reaction tank of the Oxiperm Pro disinfection system, diluted sodium chlorite and diluted hydrochloric acid are

mixed to create a chlorine dioxide concentration of 2 g per litre of water. The system doses the diluted chlorine dioxide

solution according to the disinfection requirement into the main line to be disinfected. According to the German drinking

water ordinance (TrinkwV 2001), the chlorine dioxide concentration in drinking water must not exceed a maximum of

0.4 mg per litre of water.

The following safety instructions must be observed:

1.8.2 Storing chemicals

– Chemicals must be stored in the appropriately marked original plastic containers.

– Do not store chemicals near grease, flammable substances, oils, oxidising substances, acids or salts.

– Empty and full containers must be kept closed, especially in areas where national regulations for the prevention

of accidents apply to storage (German GUV-V D5).

Warning

Unauthorised structural modifications to the system may result in serious damage to

equipment and personal injury. It is forbidden to dismantle, modify, change the structure of,

bridge, remove, bypass or disable components, in cluding sa fety equipment.

Warning

Risk of explosion when using chemicals in too high a concentration.

Only use sodium chlorite in a diluted concentration of 7.5 % by weight in accord ance with

EN 938.

Only use hydrochloric acid in a diluted concentration of 9.0 % by weight in accordance with

EN 938.

The safety data sheets from the chemicals supplier must be observed.

Warning

Risk of explosion and serious damage to equipment and personal injury as a result of

operating faults due to confusing the chemical containers or suction lances.

Do not confuse the containers.

Observe the red and blue markings on chemical pumps, suction lances an d chemical

containers: Red = HCl, blue = NaClO

2

.

Warning

Risk of burns when skin and clothing come into contact with sodium chlorite and hydrochloric

acid.

Affected skin and clothing must be washed in water immediately.

Warning

Risk of irritation to eyes, respiratory system and skin if chlorine dioxide is inha led.

When changing the chemical containers, wear protective clothing in accordance with

regulations for the prevention of accidents (Germany: GUV-V D5 Accident prevention

regulations, "Chlorination of water", January 1997).

Page 6

6 / 152

1.8.3 Procedure in case of an emergency

The general safety regulations and regulations for the procedure in case of an emergency as specified in

EN 12671: 2007 (D) apply.

Actions in case of an emergency:

• Ventilate the installation location immediately.

• Wear protective clothing (safety goggles, gloves, respirator and/or self-contained breathing apparatus, protective

apron).

• Implement initial help measures:

– In case of contact with the eyes, rinse immediately with plenty of water for at least 15 minutes. Consult a doctor.

– In case of contact with the skin, wash immediately with plenty of water. Remove all contaminated clothing.

– In case gas is inhaled, move the casualty to a source of fresh air. Avoid taking deep breaths. Consult a doctor

(look out for a racing pulse, as vasodilating treatment may be required).

• Spillages:

– In case of contact with clothing, remove the clothing immediately and wash with plenty of water.

Chemical spillages in buildings must be washed away with water.

• Firefighting:

– Aqueous solutions of chlorine dioxide are not directly flammable. Extinguish the surrounding fire with water,

preferably using a fire sprinkler system to dilute the ambient gas. Inform the fire brigade of the installed

production capacity and any harmful starting substances that are being stored (precursor substances) so that

precautions can be taken regarding possible risks.

For emergency phone numbers, see the acceptance report.

Page 7

7 / 152

2. Product description

Fig. 1 Oxiperm Pro – without cover and peripheral devices

The Grundfos Alldos Oxiperm Pro disinfection system is used to produce and dose chlorine dioxide for the disinfection

of drinking water, process water, cooling water and wastewater.

The device itself consists of a plastic system frame, on which the internal components are mounted. It is prepared for

wall- or floor-mounting and covered by a plastic cover.

The chemicals are supplied from two original chemical containers, which are located in two collecting trays directly

under the system (Oxiperm Pro systems up to 10 g/h) or in a separate tray for each container next to the unit

(Oxiperm Pro systems with more than 10 g/h). A suction lance is inserted in each container and is permanently

connected to the corresponding chemical pump in the device. The suction lance cables are used to send "pre-empty"

and "empty" signals to the control system.

The device is connected to two water lines:

• The drinking water line for supplying dilution water and flushing water.

• The main water line to be disinfected, into which the final ClO

2

solution is dosed.

2.1 Application examples

The Oxiperm Pro disinfection system can be used for three different types of application:

Group 1: Disinfection of drinking water lines

• The flow rate of the water in the lines can fluctuate greatly (peak times when water is used for bathing and

cooking).

• Examples: Drinking water lines in:

– hotels, multi-storey buildings

– schools, hospitals, nursing homes

– showers in sports facilities

– food and beverage plants

– waterworks

Group 2: Disinfection of industrial systems

• The water quantity in these systems is relatively constant.

• Examples:

– bottle cleaning plants in breweries

– industrial process water or wastewater systems

– cooling water systems.

Group 3: Shock disinfection

• Applications requiring large quantities of disinfectant in a short time

TM03 6914 4506

OCD-162-5, -10 OCD-162-30 OCD-162-60

Page 8

8 / 152

• Example:

– cleaning of whirlpool baths

2.2 Functional principle

2.2.1 Production of chlorine dioxide

Chlorine dioxide is prepared in the reaction tank as follows (see. figs. 2 and 4):

1. When a finished batch of ClO

2

solution flows out of the reaction tank and into the reservoir tank, the float drops

with the liquid level in the reaction tank. 60 seconds (OCD-162-5) or 70 seconds (OCD-162-10, -30, -60) after

the float dropped below the lowest switching point (K1), the reaction tank is empty.

2. The control unit starts a new production process by opening the solenoid valve. The level in the reaction tank

rises.

3. When the water level in the reaction tank reaches the lowest level (K1), the solenoid valve closes, and the

water supply is interrupted.

4. The control unit starts up pump 1. HCl flows into the reaction tank.

5. When the float reaches level K2, the control unit stops pump 1.

6. The control unit starts up pump 2. NaClO

2

flows into the reaction tank.

7. When the float reaches level K3, the control unit stops pump 2.

8. The reaction process begins. Reaction time: 15 minutes.

9. When the reaction time has elapsed (timer), the control unit opens the solenoid valve again. The reaction tank

is filled up with water to level K4.

10.The reaction tank now contains the ready-to-use ClO

2

solution in a concentration of approximately 2 g per litre

of water. Provided that the reservoir tank is still full, the ready-to-use ClO

2

solution remains in the reaction

tank, and the water supply is shut off.

11.When the float switch in the reservoir tank sends an "empty" (K5) signal to the control unit, it opens the

solenoid valve again, and water flows into the reaction tank. The reaction tank overflows, and the hydraulic

effect causes the entire batch to flow through a pipe in the middle of the reaction tank into the reservoir tank.

When the level in the reservoir tank rises above K5, the water supply is shut off.

12. If the system is set to "once" mode, the production stops. In "continuous" mode, the production starts again.

See step 1.

13.The dosing pump doses the ClO

2

solution with the adjusted dosing capacity from the reservoir tank to the

injection unit.

2.2.2 Flow-rate-proportional dosing

Suitable for group 1 applications – drinking water:

1. The control system is set to proportional controller.

2. A water meter measures the water flow rate in the main water line and continuously sends measured values to

the Oxiperm Pro control system.

3. The proportional controller calculates the required ClO

2

dosing volume in proportion to the water flow rate in

the main line.

4. The proportional controller sends the corresponding output signals to the dosing pump.

5. The dosing pump doses the corresponding quantity of the ClO

2

solution from the reservoir tank into the main

water line.

6. An optional measuring cell monitors the ClO

2

concentration in the main line.

2.2.3 Setpoint-controlled dosing

Suitable for group 2 applications – industrial water:

1. The control system is set to setpoint controller. A setpoint for the desired ClO

2

concentration in the main line is

specified for the setpoint controller.

2. A measuring cell monitors the ClO

2

concentration in the main line.

Page 9

9 / 152

3. The measuring cell continuously sends actual values for the ClO2 concentration to the control system of the

disinfection system.

4. The setpoint controller compares the incoming actual values with the setpoint and based on the deviation

calculates the quantity of the ClO

2

solution that is required to achieve the desired concentration.

5. The setpoint controller sends output signals to the dosing pump.

6. The dosing pump doses the corresponding quantity of the ClO

2

solution from the reservoir tank into the main

water line.

A combined controller is also available for applications with setpoint controller and flow meter.

See section 5.10.1 Selecting the controller type and switching on the controller.

Fig. 2 Longitudinal cross section through the reaction tank and reservoir tank of OCD-162-5, -10

TM03 6915 4506

Pos. Description

A Manual drain

B From overflow line of multi-function valve

C To dosing pump

D To volume compensation bag

E HCl, NaClO

2

, H2O

FClO

2

solution

G Deaeration reservoir tank

Page 10

10 / 152

Fig. 3 Longitudinal cross section through the reaction tank and reservoir tank of OCD-162-30 and through the reaction

tank of OCD-162-60

For information on controls and operating software settings, see sections 5.2 Operating software settings and

5.10 Setting the ClO

2

controller (not applicable for group 3 applications).

TM04 0950 1709

Pos. Description

A Manual drain

B From the overflow line of the multi-function valve

C To dosing pump

D To volume compensation bag

E HCl, NaClO

2

, H2O

FClO

2

solution

G Deaeration reservoir tank

K1

K2

K3

K4

F

G

D

E

E

E

OCD-162-60

K1

K2

K3

K4

K5

K6

A

B

C

D

F

F

E

E

OCD-162-30

E

Page 11

11 / 152

Fig. 4 Diagram of process cycle for ClO2 production

TM03 6916 4506

Process stop

"Start ClO

2

production" menu command

Solenoid valve opens

H

2

O supply 1

Level K1 reached/solenoid valve closes,

HCl pump starts

Level K2 reached/HCl pump stops,

NaClO

2

pump starts

Level K3 reached/NaClO

2

pump stops,

reaction time timer starts

Reaction

Timer times out, solenoid valve opens

H

2

O supply 2

Level K4 reached

Yes

HCI supply

NaClO

2

supply

No

"Continuous" production?

Level K1 reached/waiting time starts

ClO

2

dosing

Level in reservoir tank rises above K5 /

solenoid valve closes

Waiting time has elapsed

Stop H

2

O

Wait until reservoir tank is empty

Reservoir tank still full?

Level in reservoir tank drops under

level K5 / solenoid valve opens

H

2

O supply 3, reaction tank overflows

No

Yes

Reservoir tank still full?

Page 12

12 / 152

2.3 Components of the Oxiperm Pro

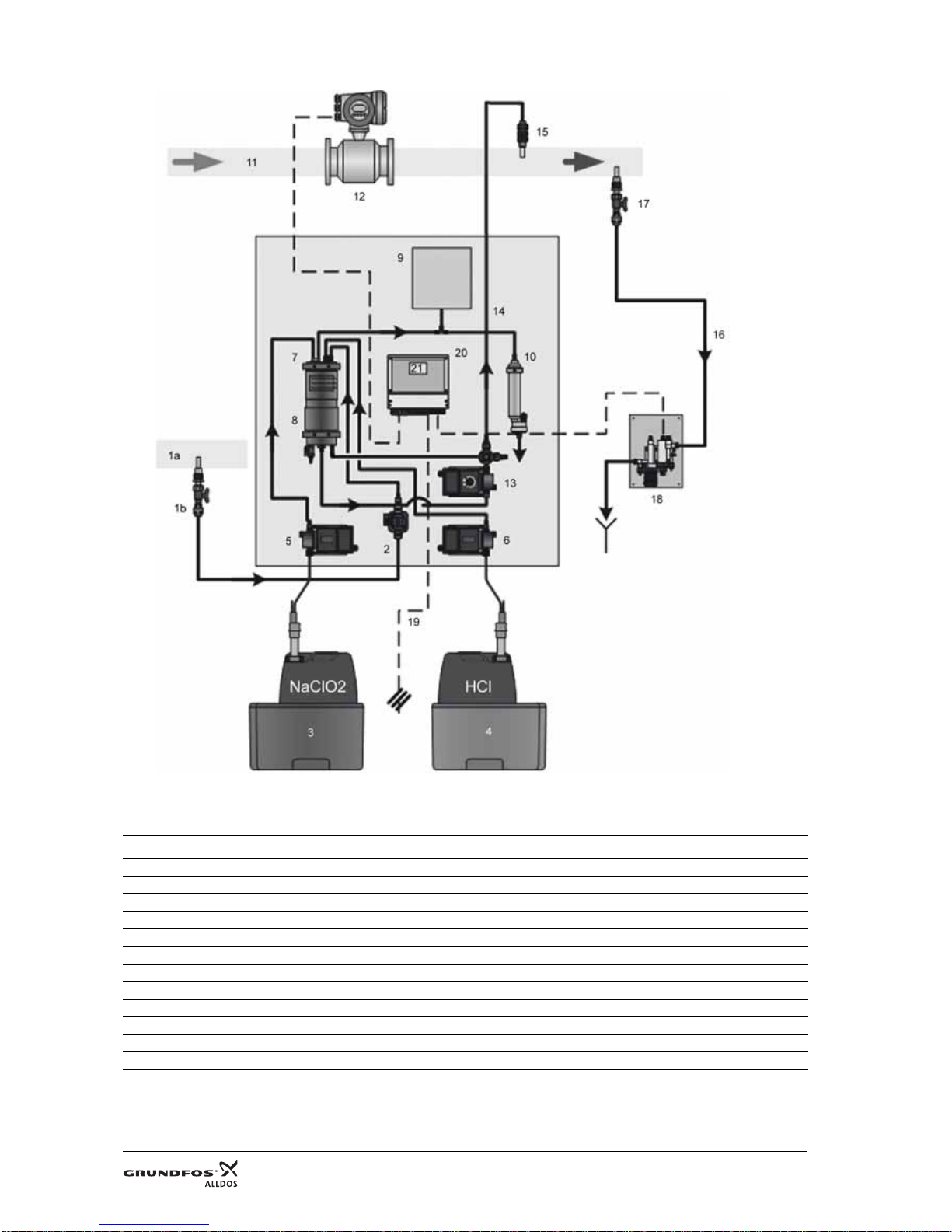

Fig. 5 Components of Oxiperm Pro (here: OCD-162-5, -10)

2.3.1 External parts

See also the photos in section 15. Photos.

TM03 6897 4506

Pos. Components

1a Water line for supplying dilution water and flushing water (via solenoid valve in the device)

1b Extraction point for dilution water with stopcock

3 Chemical container for NaClO

2

(diluted concentration of 7.5 % by volume) with suction lance and collecting tray

4 Chemical container for HCl (diluted concentration of 9 % by volume) with suction lance and collecting tray

11 Main water line to be disinfected

12 Flow meter (or contact water meter)

14 Dosing line

15 Injection unit for dosing the ClO

2

16 Measuring water pipe

17 Measuring water extraction point

18 Measuring cell for checking the chlorine dioxide concentration in the main line (optional)

19 Power supply connection

Blue Red

Page 13

13 / 152

2.3.2 Internal components

Pos. Components

2 Solenoid valve for supplying dilution water and flushing water

5 Chemical pump for sodium chlorite (pump 2)

6 Chemical pump for hydrochloric acid (pump 1)

7 Reaction tank with float switch

8 Chlorine dioxide reservoir tank with float switch and drain cock (bottom left)

9 Volume compensation bag for ClO

2

gas

10 Activated carbon filter for ClO

2

gas

13 Dosing pump with multi-function valve

20 Electronic control system with measured-value sensor for check measurements

21 Display with control and display elements

Page 14

14 / 152

2.4 System peripheral devices and accessories

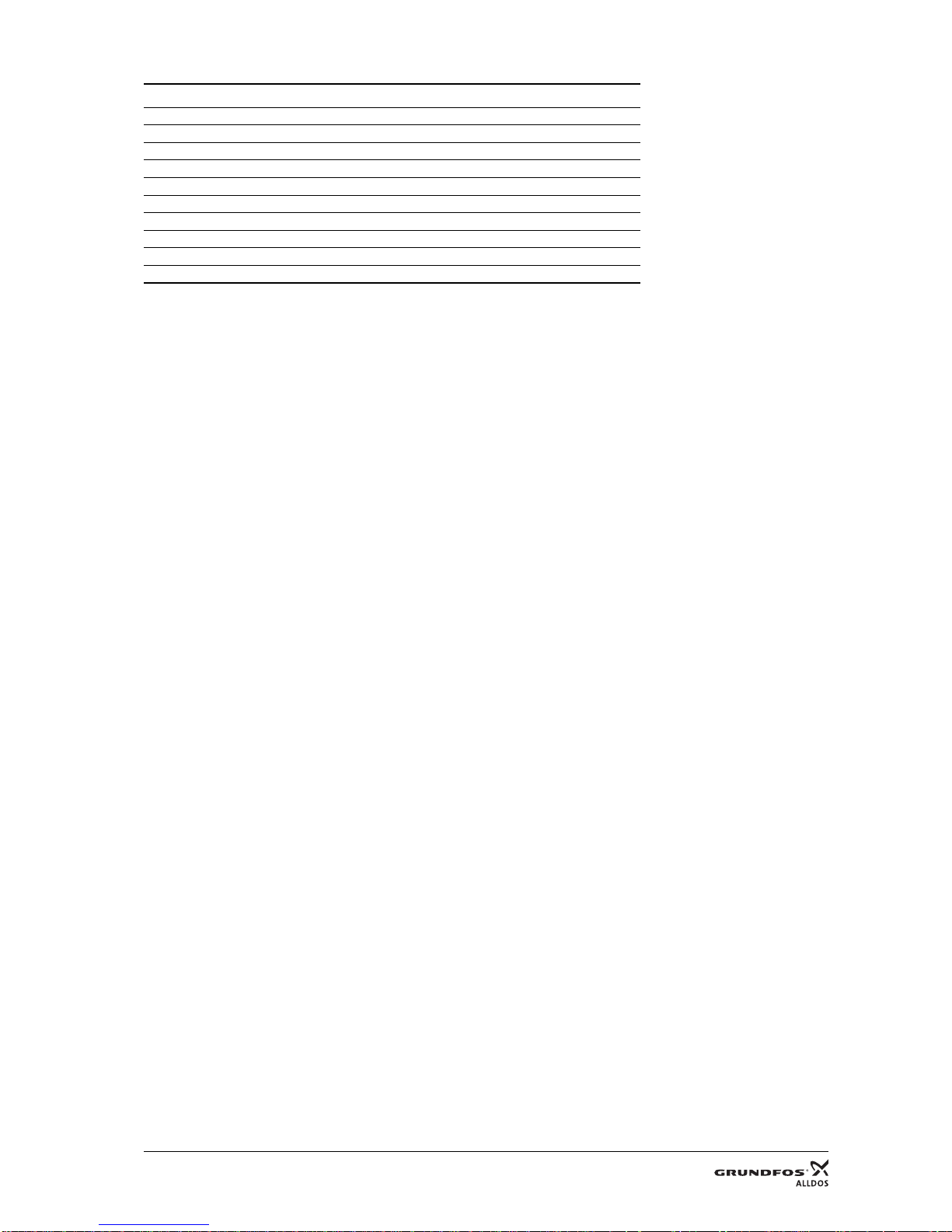

Fig. 6 Complete OCD-162-5, -10 system with measuring cell and without extension module

Fig. 7 Complete OCD-162-30, -60 system with measuring cell and without extension module

TM03 6918 4506TM03 0875 1509

Red

Blue

17

1a

14

1b

19

15

23

26

12

24

25

16

18

17

11

Page 15

15 / 152

2.4.1 Accessories for the dilution water line (not included)

• Stopcock (ball valve)

• Tapping sleeve for dilution water extraction (optional) (if necessary, with double nipple and connection piece for

hose) (optional).

• Hose with connection to solenoid valve.

Stopcock and tapping sleeve are not required, if the bypass mixing module with dilution water connection has been

selected.

2.4.2 Accessories for the main water line (not included)

• Contact water meter or fitted flow meter (in case of a new water line, water flow meter that provides signals or

ultrasonic flow meter).

• Tapping sleeve for the injection unit (optional).

• Protective pipe for the dosing line, installed from the dosing pump to the injection unit (optional).

• Grundfos Alldos DIT photometer (measures ClO

2

concentration after dosing) (optional).

2.4.3 Measuring cell (optional)

• Measuring cell

• Tapping sleeve for sample-water extraction at the main line (not included).

• Hose from the sample-water extraction point to the measuring cell.

• Hose from the measuring cell to the sample-water drain.

2.4.4 Extension modules (optional)

The standard system can be extended using modules:

• measuring cell for cold and hot water (main water up to 50 °C, pressure 4 bar) for connection to the Oxiperm Pro

• measuring module for cold and hot water (main water up to 70 °C, pressure 8 bar) for connection to the

Oxiperm Pro

• bypass mixing module for cold and hot water for connection to the Oxiperm Pro (separate installation and operating

instructions).

Pos. Components

1a

Water line for supplying dilution water and flushing water (via solenoid

valve in the device)

1b Extraction point for dilution water with stopcock

3

Chemical container for NaClO

2

(diluted concentration of 7.5 % by volume)

with suction lance and collecting tray

4

Chemical container for HCl (diluted concentration of 9 % by volume) with

suction lance and collecting tray

11 Main water line to be disinfected

12 Flow meter (or contact water meter)

14 Dosing line

15 Injection unit for dosing the ClO

2

16 Hose for sample-water extraction

17 Sample-water extraction point

18 Measuring cell

19 Power supply connection/main switch

23 Connection cable for measuring cell

24 Sample-water drain

25 Connection cable for cleaning motor

26 Hose for dilution water

Note

In case of fluctuating flow rates in the main water flow, the use of a bypass mixing module is

recommended in order to optimise mixing and red uce the risk of corrosion . See the separate

installation and operating instructions for the bypass mixing module .

Page 16

16 / 152

2.5 Power supply connections and electronic connections

The Oxiperm Pro disinfection system is equipped with an electronic control system. See fig. 8.

The control system has connections for the following:

• power supply cable to the main switch

• cable from the water flow meter or flow meter

• cable from external batch tank to level control, if necessary

• cables for measuring cell AQC-D1 or AQC-D6, if necessary:

– measuring electrode and counter-electrode

– sample-water deficiency sensor

– Pt100 sensor

– pH electrode, if necessary (for pH or ORP) (AQC-D1 only)

– cleaning motor (AQC-D1 only)

• or the cables from the measuring module, if necessary:

– measuring electrode and counter-electrode

– water sensor

– Pt100 sensor

• or the cable from the mixing module, if necessary:

– flow controller.

For additional connections, see section 4.7 Connecting the electronic components.

2.6 Control and display elements

Fig. 8 The display and control panel

2.6.1 Using the control panel

TM03 6920 4506

Buttons and LEDs Functions

[Esc] button Cancels command, exits menu

[Up] button Selects the previous menu item or sets a higher numerical value

[Down] button Selects the next menu item or sets a lower numerical value

[OK] button Confirms the menu selection

[Cal] button Calibration

[Man] button Manual operation

"Alarm" LED Alarm (red)

"Caution" LED Warning (yellow)

"Cal" LED Calibration (yellow)

"Man" LED Manual operation (yellow)

Page 17

17 / 152

2.6.2 Using the display

After switching on the system (not initial start-up), the following display appears:

Fig. 9 Display level after starting the system

The header indicates the status (here: no process started). For symbols and numbers for relays, see the table below.

Press [OK] to access the MAIN MENU:

During operation, press [Esc] to access the display level:

Fig. 10 PROCESS RUNNING display level

Messages in the display level

TM03 6921 4506

MAIN MENU

PROCESS

CONTROLLER

ClO

2

ALARM

SERVICE

SETUP

MAINTENANCE

TM03 6922 4506

Number or

symbol

Message in the

display level

Meaning of the message

1

Headers

PROCESS

RUNNING

ClO

2

production is active.

PROCESS STOP ClO

2

production has been stopped.

PROCESS

ABORT

ClO

2

production has been aborted by a menu command or alarm.

FLUSHING Flushing is started automatically or manually.

2

Relays

1

Relay for solenoid valve.

Display:

White number on a black background: relay active.

Black number on a white background: relay not active.

2

Relay for HCl pump:

display as for 1.

3

Relay for NaClO

2

pump:

display as for 1.

4

Alarm relay:

display as for 1.

5

Warning relay:

display as for 1.

54321

.........

24

,

5

°C

pH

7

,

35

5

4

3

2

1

0,23 mg

/

l

1

2

6

7

4/3

5

8

PROCESS RUNNING

Page 18

18 / 152

3

Symbol

Symbol for relay for the pulse pause controller.

Symbol for controller stop for the pulse pause controller.

4

Symbol

Symbol for continuous controller.

Box with plotted line.

The height of the line is proportional to the actuating variable (ClO

2

dosing volume).

Line not visible:

actuating variable = 0 %

Line fills the entire box:

actuating variable = 100 %

Symbol for stop of continuous controller.

White box with a diagonal line through it.

5

Symbol

Symbol for external disturbance value input (water flow as pulse or current signal).

Box with plotted triangle.

The black fill is proportional to the flow (the greater the fill, the greater the flow, 0-100 %).

(Only visible if proportional or combined controller is configured.)

6

Val ue

e.g. 24.5 °C Water temperature, display value is only available with connected measuring cell.

7

Val ue

e.g. 0.23 mg/l ClO

2

concentration, display value is only available with connected measuring cell.

8

Val ue

e.g. 7.35 pH value in the sample water, display value is only available with connected measuring cell.

Number or

symbol

Message in the

display level

Meaning of the message

6

6

Page 19

19 / 152

2.7 Operating modes

During the commissioning process, you set up the disinfection system in accordance with the application.

After switching on and starting up ClO2 production via menu commands, the system runs fully automatically.

Two operating modes are available for the production of ClO

2

(see section 5.14 Setting the operating mode):

• continuous operation ("continuous" mode)

• single operation ("once" mode).

• external batch tank ("ext. batch" mode)

The appropriate dosing for the application is set at the dosing pump and via the controller parameter settings.

Dosing takes place automatically.

Manual operation is used for shutting down the controller (see section 5.14 Setting the operating mode) and for

temporary manual control if required (pulse dosing).

2.8 Access codes

When the system is ready for operation, the MAIN MENU cannot be accessed without a code.

Two different access authorisations/security levels are assigned for all submenus. Each code automatically enables the

levels below it too.

• User code: By default, all user menus can initially be accessed without a code request.

(When the menu selection has been confirmed using [OK], a code request is not displayed.)

Once the user has entered his/her own user code (MAIN MENU – SETUP – CHANGE CODE), the code request

appears before any user submenu can be accessed. The modified user code must only allow access for trained

users with appropriate technical training and experience. Access is enabled for 60 minutes after entry of the code.

• Service code: This code is reserved for trained Grundfos Alldos service engineers. Access is enabled for

30 minutes after entry. The service code is necessary for commissioning. See section 5.4 Switching on the system

– initial start-up.

• Super-user code: Some menus in the maintenance section are only accessible with a super-user code.

They are not described in these instructions.

For details of how to change the user code, see section Modifying setup in the separate installation and operating

instructions. This is only needed for basic factory settings.

Page 20

20 / 152

2.9 User menu structure

Users can view certain submenus in the display and can also modify certain values.

2.9.1 Finding user menus

In the following tables, the first column indicates whether users can access a submenu:

• without a code (0)

• with the user code (A).

Users can access the following submenus from the MAIN MENU (without a code or with the user code):

User menus,

Note

All software menus can be selected from the MAIN MENU using the [Up] and [Down] buttons

and accessed using [OK].

Press [Esc] to return to the menu level above.

For operating instructions for each menu, see se ction 5. Commissioning.

Code Main menu Submenu 1 Submenu 2 Submenu 3 Submenu 4 Submenu 5

A

Main menu

Process

Start

Star t

Start ClO

2

production?

ABack

A

Abortion

Abortion

Abort ClO

2

production?

ABack

A

Operation

continuous

A once

A ext. batch

0

Service

Process

Status

Display:

Process Status

0 List of events

0

ClO

2

production

Cycles

0

Chemicals

HCl/NaClO

2

since 14.09.2006

HCl (l)

NaClO

2

(l)

reset

0 Age of ClO

2

(mm:ss)

0 Maintenance

A

Flushing

Start

A Abortion

0

Measurement

ClO

2

Measured value

0 CalData/logbook

0 Temperature

°C or °F

Measured value

0

pH or ORP

Measured value

0 CalData/logbook

0ClO

2

controller

Display:

Controller setting

0

Water flow meter

1.00 - 100.00 pulses/

sec.

(Note 5*)

50 pulses/sec., 50 %*

(or: 5 mA, 25 %)

0 Test display

Program version

Page 21

21 / 152

Notes to table:

Note 4*:

• The ALARM settings are only available when MEASUREMENT has been enabled (using the service code).

• The alarm relay is activated if previously set alarm values for chlorine dioxide are exceeded or not reached, if the

maximum dosing time is exceeded, and in case of a fault.

Note 5*:

The WATER FLOW METER submenu only appears if a WATER FLOW METER is enabled (using the service code).

Menus for service engineers

Initial start-up is carried out using a special service code.

After initial start-up, the service engineer can access the service menus using this service code. The following

submenus can be opened from the main menu using the service code:

A

Main menu

Setup

Language

Deutsch

A English

A (all listed)

A

Date/time

Date

ATime

A Daylight sav. t.

Begin, end, time shift

(± x hours), off

A

Code function

Change

A Delete

A Display Contrast 50 %

0

A

Alarm

(Note 4*)

ClO

2

alarm values

Alarm off

A

Alarm on

Alarm value 1

0.15 mg/l

Upward

violation or

downward viol.

A

Alarm value 2

0.70 mg/l

Upward

violation or

downward viol.

A

Hysteresis

0.01

A

Alarm delay

0 sec.

A Dos. time monit. Off/On

A

Calibration

Chlorine dioxide

Cal. meas. value

A Cal. result Slope µA, mg/l

A Cal. cycle On/Off

A

pH

Cal. meas. value

Grundfos, DIN/Nist,

other

ACal. result

Slope µA, mg/l

asym. mV

A Cal. cycle On/Off

A

ORP

Cal. meas. value

A Cal. result Asym. mV

A Cal. cycle On/Off

HB

Manual

operation

ClO

2

controller On/Off

Code Main menu Submenu 1 Submenu 2 Submenu 3 Submenu 4 Submenu 5

Page 22

22 / 152

2.9.2 Menus for service engineers, table 1

Notes to menus for service engineers, table 1:

(* 1) PROPORT. and COMBINED CONTRL only appear if a water flow meter has been defined under SETUP > WATER FLOW METER.

Otherwise, only SETPOINT CONTRL appears.

Code Main menu Submenu 1 Submenu 2 Submenu 3 Submenu 4 Submenu 5

0

Main menu

S

Setup

Measurement

Measuring cell

AQC-D1

AQC-D6

off

S

ClO

2

ClO2 + pH

ClO

2

+ ORP

S

Measuring

range

ClO

2

0.00 - 1.00

S

Temperature

0-100 °C

S pH 0.00 - 14.00

S ORP 0-1000

S

Water flow

meter

Off

S Pulse x l/pulses

S

Current

0-20 mA

4-20 mA

others

x m

3

/h

S

Relay

Warning relay

Fail safe

On (N.C.)

Off (N.O.)

SAlarm relay

Fail safe

On (N.C.)

Off (N.O.)

S

Current output

Control

0-20 mA

4-20 mA

others

S Measurement ClO

2

0-20 mA

4-20 mA

others

S

Factory setting

Setup

Save

S Activate

S Reset (Factory code)

S

ClO

2

controller

Proport. contrl

(Note * 1)

Interpulse ctrl.

S

Cont. controller

0-20 mA

S

Setpoint contrl

Interpulse ctrl. P, PI, PID

S

Cont. controller

0-20 mA

P, PI, PID

S

Combined contrl

(Note * 1)

Interpulse ctrl. P, PI, PID

S

Cont. controller

0-20 mA

P, PI, PID

SOFF

Page 23

23 / 152

Menus for service engineers, table 2

Code Main menu Submenu 1 Submenu 2

Factory

setting

Submenu 3 Factory setting

S

Main Menu

Controller ClO

2

(Note * 1 b)

(for

proportional

controller –

continuous

controller)

Added quantity 0.4 mg/l ClO

2

S Min. switch-on 1.0 s

S Max. dosing flow 100 %

S Controller stop N.O.

S Max. dosing flow 100 %

S Controller stop N.O.

S

Dosing pump

Stroke adjustm. 100 %

S

Dosing capacity

DMI 3.0-10 with OCD-162-5: 3.0 l/h

S DDI 5.5-10 with OCD-162-5: 2.3 l/h

S DMI 6.0-8 with OCD-162-10: 6.0 l/h

S DDI 5.5-10 with OCD-162-10: 5.0 l/h

S DMX 16-10 with OCD-162-30: 16 l/h

S DDI 60-10 with OCD-162-30: 16 l/h

S DMI 35-10 with OCD-162-60: 35 l/h

S DDI 60-10 with OCD-162-60: 35 l/h

S

Controller

(Note * 2 a)

(for setpoint

controller –

interpulse

controller)

Min. switch-on 1.0 s

S Max. dosing flow 100 %

S Controller stop N.O.

S Set point 0.40 mg/l ClO

2

S Prop.range XP 30 %

S Reset time TN 60 s

S Deriv. action TV 0 s

S

Controller

(Note * 2 b)

(for setpoint

controller –

continuous

controller)

Max. dosing flow 100 %

S Controller stop N.O.

S Set point 0.40 mg/l ClO

2

S Prop.range XP 30 %

S Reset time TN 60 s

S Deriv. action TV 0 s

S

Controller

(Note * 3 a)

Combined

controller –

interpulse

controller

Min. switch-on 1.0 s

S Max. dosing flow 100 %

S Controller stop N.O.

S Set point 0.40 mg/l ClO

2

S Prop.range XP 30 %

S Reset time TN 60 s

S Deriv. action TV 0 s

S

Dosing pump

Stroke adjustm. 100 %

S

Dosing capacity

DMI 3.0-10 with OCD-162-5: 3.0 l/h

S DDI 5.5-10 with OCD-162-5: 2.3 l/h

S DMI 6.0-8 with OCD-162-10: 6.0 l/h

S DDI 5.5-10 with OCD-162-10: 5.0 l/h

S DMX 16-10 with OCD-162-30: 16 l/h

S DDI 60-10 with OCD-162-30: 16 l/h

S DMI 35-10 with OCD-162-60: 35 l/h

S DDI 60-10 with OCD-162-60: 35 l/h

Page 24

24 / 152

* 1 a, 1 b, 2 a, 2 b, 3 a, 3 b: Only appears if the controller has been defined under the service code in MAIN MENU > SETUP > ClO2 CONTROLLER

and parameterised in the ClO

2

CONTROLLER menu.

(* 1 a) If proportional controller – interpulse controller has been selected.

(* 1 b) If proportional controller – continuous controller has been selected.

(* 2 a) If setpoint controller – interpulse controller has been selected.

(* 2 b) If setpoint controller – continuous controller has been selected.

(* 3 a) If combined controller – interpulse controller has been selected.

(* 3 b) If combined controller – continuous controller has been selected.

Menus for service engineers, table 3

Notes to menus for service engineers, tables 2 and 3:

(* 4) Temperature correction is active if ON is selected in SETUP – MEASUREMENT. The resistance of the Pt100 resistance thermometer is higher

on long lines. The additional line resistance is offset with this menu function (for unit, see SETUP – MEASURING RANGE).

S

Main Menu

Controller

(Note * 3 b)

Combined

controller –

continuous

controller

Max. dosing flow 100 %

S Controller stop N.O.

S Set point 0.40 mg/l ClO

2

S Prop.range XP 30 %

S Reset time TN 60 s

S Deriv. action TV 0 s

S

Dosing pump

Stroke adjustm. 100 %

S

Dosing capacity

DMI 3.0-10 with OCD-162-5: 3.0 l/h

S DDI 5.5-10 with OCD-162-5: 2.3 l/h

S DMI 6.0-8 with OCD-162-10: 6.0 l/h

S DDI 5.5-10 with OCD-162-10: 5.0 l/h

S DMX 16-10 with OCD-162-30: 16 l/h

S DDI 60-10 with OCD-162-30: 16 l/h

S DMI 35-10 with OCD-162-60: 35 l/h

S DDI 60-10 with OCD-162-60: 35 l/h

Code Main menu Submenu 1 Submenu 2 Submenu 3 Submenu 4 Submenu 5

S

Main menu

Service

Test current

Control

measurement ClO

2

0/4 mA on/off

10/12 mA off/on

20 mA off/on

STest relay

Test relay off/on

SV H

2

O off

Pump HCl off

Pump NaCl

2

off

Pump ClO

2

off

Alarm relay off

Warning relay off

S

Test level

Reaction tank

S Reservoir tank

S Ext. batch tank

S suction line

S

Maintenance

Maintenance rel.

S

Temp. correction

(Note * 4)

S

Manual

operation

Dosing flow

Cont. controller or

Interpulse

controller

xx % dosing flow

Code Main menu Submenu 1 Submenu 2

Factory

setting

Submenu 3 Factory setting

Page 25

25 / 152

3. Transport and packaging

3.1 Unpacking

Number of packing units: 1 box.

Procedure:

1. Unpack the device.

2. Unpack the cover.

3. Unpack the measuring cell, if supplied.

4. Unpack the extension modules, supplied.

5. Retain the original packaging in order to return the device for servicing.

6. Check the device(s) for transport damage (especially hoses and lines).

3.2 Transport damages

In case of transport damage:

1. Pack the device in its original packaging.

2. Inform the forwarder of the transport damage.

3. Return the device to the supplier.

Warning

Increased risk of damage to equipment and personal injury as a result of operatin g faults due

to transport damage.

Do not shake, crush or drop the box. Open th e packag ing ca refully.

Do not use a sharp or pointed blade.

Carefully remove the device from the box. Do not bend the hoses and cables.

Note

Do not adjust the stroke-length adjustment knob on the pump. It must no t be adjuste d until the

pump is running.

Box

Dimensions

L x W x H

[mm]

Contents Weight gross / net

1 900 x 900 x 518

Device with cover, hoses, screws, accessories

OCD-162-5: 30 kg / 26 kg

OCD-162-10: 32 kg / 28 kg

1 766 x 558 x 1813

OCD-162-30-D: 80 kg / 70 kg

OCD-162-30-P: 79 kg / 69 kg

1 766 x 558 x 1813

OCD-162-60-D: 100 kg / 85 kg

OCD-162-60-P: 99 kg / 84 kg

Page 26

26 / 152

4. Installation

Installation faults may give rise to a number of risks:

4.1 Installation location

The operator must ensure that all the conditions listed below for structurally and technically safe and optimum operation

of the system are met prior to commencing installation.

An installation location must be provided that fulfils the following:

• It is protected from the sun, frost-proof, well-ventilated and has sufficient lighting (the system must not be installed

outdoors).

• It meets the conditions specified in section 11. Technical data regarding air temperature, humidity, permissible

component operating temperature and dilution water quality.

• It has steel or concrete walls, which enable the OCD-162-5, -10 system to be wall-mounted (minimum wall

thickness of 10 cm for the mounting screws) or the OCD-162-30, -60 floor-mounted system to be fixed.

• It has a power supply connection (see section 11. Technical data).

• It has access to the main water line.

• It has a connection for dilution water of drinking water quality in accordance with TrinkwV 2001.

• It has a floor drain for washing away chemicals and a drain (tank) for sample water.

• It has a separate storage room for empty and full chemical containers.

• It is isolated from other areas with regard to fire protection.

• It is secured against unauthorised access and meets the regulations for the prevention of accidents.

• It is not in permanent use by personnel (maximum stay: two hours).

Warnin g

Incorrect installation may result in serious personal in jury and damag e to property.

Only authorised and qualified personnel may install the system.

Warnin g

Risk of corrosion damage to electro nic circu its a nd gas poisoning d ue to th e escape of

gaseous ClO

2

from a damaged volume compensation bag.

• Do not reach into the void behind the contro l unit.

Risk of severe burns resulting from the spray of chemicals from damaged seals, valves, h ose

connections or hoses or from handling chemicals.

• Do not bend the hoses. Route them directly down from the unit where possible, and connect

with care. Tighten nuts by hand only.

• Wear protective clothing (safety goggles, gloves, protective apron, breathing mask, if

necessary).

• Do not mix up containers. Always check the label. Do not use cleaning agents.

Warnin g

Risk of fire and corrosion due to incorrect storage of chemicals. Do not store hydrochloric acid

and sodium chlorite near grease, flammable or oxidising substances, oils, acids or salts.

Obtain approval for storing chemicals.

Page 27

27 / 152

4.1.1 Operator’s checklist

4.1.2 Preparing the installation site

4.1.3 Preparing tools and protective clothing

• Hand drill with masonry bit, diameter 10 mm.

• Protective clothing in accordance with the German GUV-V D5. See section 1.4 Obligations of the operator.

Operator’s checklist – preparing for installation

Done

1. Read the installation and operating instructions for Oxiperm Pro and for the dosing pumps

DMI 208, DDI 209, DMX 221 or DDI 222, if applicable, as well as for the multi-function valve, the

measuring cell and the extension module, if used. Store the manuals in a dry place in the

installation location.

2. Measure the pressure and temperature in the dilution water line and in the main water line.

3. Measure the room temperature and the humidity.

4. Obtain official approval for storing chemicals, if necessary.

5. Purchase accessories. See section 14. Operator’s accessories list.

6. Fit a tapping sleeve for the dilution water supply in the drinking water line.

7. Fit a tapping clamp for the injection unit in the main line.

8. Install a protective pipe for the dosing line, if necessary.

At the main line:

9. Fit a tapping sleeve for sample-water extraction, if necessary.

10.Fit tapping sleeves for the measuring or mixing module, if used.

11.Provide protective clothing in the room in accordance with the regulations for the prevention of

accidents (German GUV-V D5).

12.Display a "No fires, naked flames or smoking" warning sign. Display all warning signs provided.

Checklist for service engineers – carry out installation tasks

Done

• Check that all connections to the main line are installed.

• Check that all necessary parts have been supplied (chemical containers, hoses, cables).

• Fix the unit on the wall or on the floor. See the mounting diagram (fig. 11) and the dimensional

sketch (fig. 12).

• Mount the measuring cell (if applicable) (see the mounting diagram in the installation and operating

instructions for the measuring cell).

• Mount the measuring or mixing module (if applicable).

• Connect the hydraulic components:

- dilution water hose to solenoid valve

- dosing line to injection unit

- dosing line from supply bottle to external dosing pump (if applicable).

• Install the chemical containers, and attach the suction lances.

• Connect the hydraulic components to the measuring cell (if applicable).

• Connect the hydraulic components to the measuring or mixing module (if applicable).

•Route the cables through the glands into the control unit.

• Connect the electronic components:

- contact water meter/flow meter

- measuring cell AQC-D1 or AQC-D6 (if applicable)

- measuring or mixing module (if applicable)

- higher-level control system (if applicable)

- warning lamp or audible warning system (if applicable)

- gas detector (if applicable)

- external non-switching device (if applicable).

• Connect the power supply cable.

• Fit the cover.

Page 28

28 / 152

4.2 Mounting the unit on the wall (OCD-162-5/-10)

See the mounting diagram, fig. 11, and the dimensional sketch, fig. 12.

Minimum wall thickness (brick or concrete): 100 mm.

1. Mark the below centre drill hole of the system frame (maximum 1400 mm above the ground).

2. From the below centre drill hole, mark the left drill hole 430 mm above and 250 mm to the left.

3. From the below centre drill hole, mark the right drill hole 430 mm above and 250 mm to the right.

4. Allow a minimum distance from the top of the system frame to the ceiling of 190 mm.

5. The drill holes (∅10 mm) must have a minimum depth of 70 mm.

Insert SX dowel pins (dowel pin length: 50 mm), and screw in hanger bolts to a depth of 55 to 60 mm.

6. Get two people to lift up the system frame and position it on the hanger bolts.

7. Secure with a nut and washer on each bolt, and fit protective caps on top.

Page 29

29 / 152

4.3 Mounting the unit on the floor (OCD-162-30/-60)

See the mounting diagram, fig. 11 (identical with the unit OCD-162-5) and the dimensional sketch, fig. 13.

1. Get two people to carry the unit to the place where it will be commissioned. The ground has to be even.

The ceiling height must be at least 2.20 m.

2. Mark the four drill holes, e.g. with a punch, and put the unit aside.

3. Drill the holes (∅10.5 mm) with a minimum depth of 70 mm and insert SX dowel pins (length: 50 mm).

4. Place the unit at the desired position and screw in the screws with washers.

4.3.1 Checking the mounting diagram

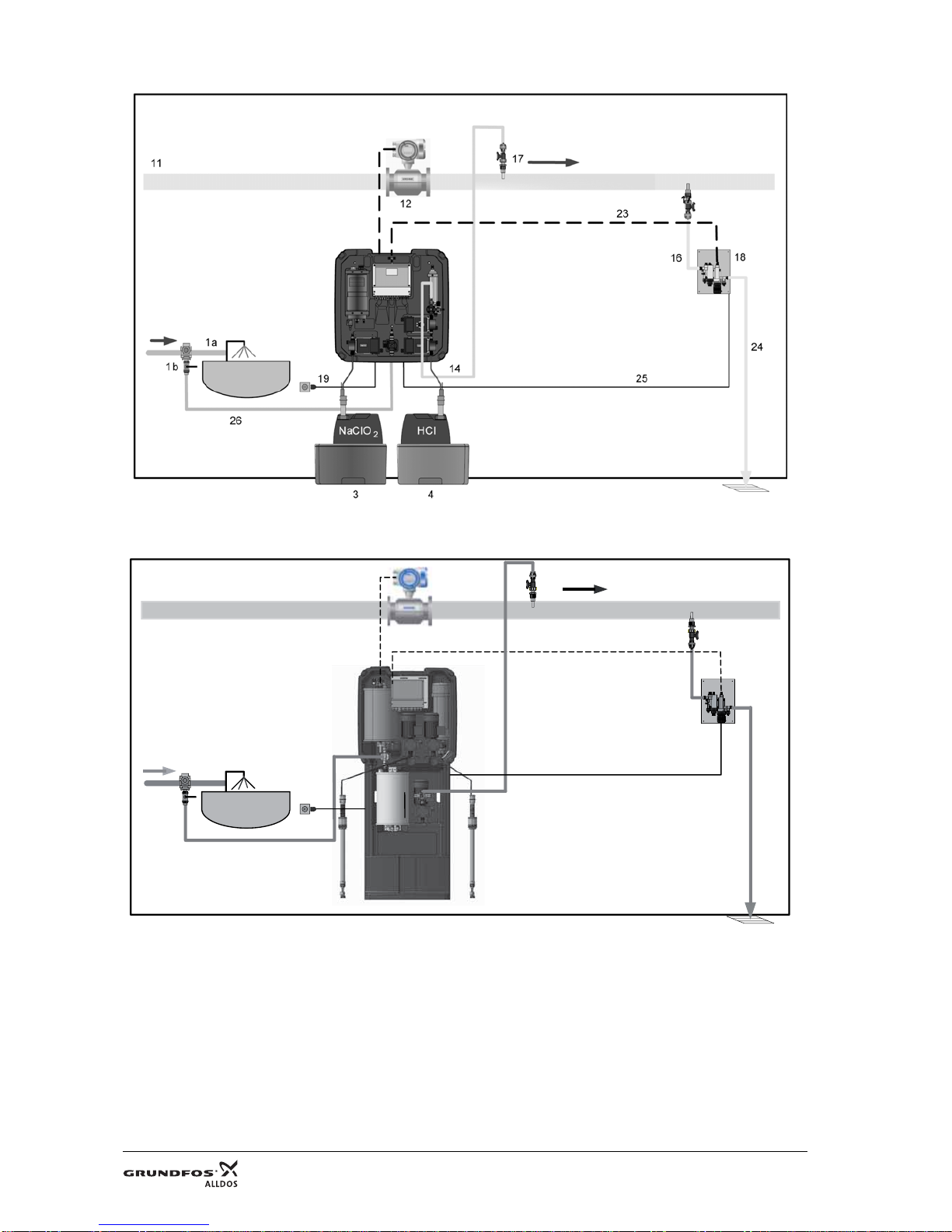

Fig. 11 Mounting diagram for the Oxiperm Pro (here: OCD-162-5) with measuring cell and mixing module (22)

Minimum distance between injection unit and measuring point = 3 metres.

TM03 6923 4506

Pos. Components

1a Water line for supplying dilution water and flushing water (via solenoid valve in the device)

1b Extraction point for dilution water with stopcock

3 Chemical container for NaClO

2

(diluted concentration of 7.5 % by volume) with suction lance and collecting tray

4 Chemical container for HCl (diluted concentration of 9 % by volume) with suction lance and collecting tray

11 Main water line to be disinfected

12 Flow meter (or contact water meter)

14 Dosing line

16 Hose for sample-water extraction

17 Sample-water extraction point

18 Measuring cell

19 Power supply connection/main switch

23 Connection cable for measuring cell

24 Sample-water drain

25 Connection cable for cleaning motor

26 Hose for dilution water

Blue

Red

Page 30

30 / 152

4.3.2 Dimensional sketch OCD-162-5, -10

Fig. 12 Dimensional sketch of unit with drill holes (OCD-162-5, -10)

Mounting height: display at eye level.

Distance from ground to lower edge of system frame: maximum 1.145 m.

Length of suction hoses: maximum 1.30 m.

Distance from top edge of unit to ceiling: minimum 19 cm.

Allowance on either side: minimum 20 cm.

TM03 6924 4506

1910 mm

765 mm

765 mm

328 mm

1145 mm

500 mm

10,5 mm

430 mm

1400 mm

250 mm

190 mm

NaClO2

HCL

250 mm

430 mm

max.1400 mm

765 mm

max. 1910 mm

max. 1145 mm

min.

190 mm

328 mm

∅10.5 mm

765 mm

500 mm

250 mm

250 mm

NaClO

2

HCl

Page 31

31 / 152

4.3.3 Dimensional sketch OCD-162-30, -60

Fig. 13 Dimensional sketch of unit with drill holes (OCD-162-30, -60)

Length of suction hoses: maximum 6.00 m.

Ceiling height: minimum 2.20 m.

Allowance on either side: minimum 20 cm.

TM04 0952 1709

1800

766

568

50

660

580

A-A

320

10,5

o

A

A

500

Page 32

32 / 152

4.4 Additional modules

Additional modules such as a measuring cell or a measuring/mixing module (if applicable) must be fixed onto the wall.

See the installation and operating instructions for the respective additional modules.

4.5 Installing the chemical containers and attaching the suction lances

1. Screw the intake-side hose connection on the HCl suction lance (red mark) onto the hose connection on the

HCl pump (red mark) (see fig. 15, pos. 6b).

Fig. 14 Correct orientation of the float

2. Position the HCl container in the red collecting tray on the right under the unit (for containers up to 30 g/h for

OCD-162-5, -10) or next to the unit (OCD-162-30, -60).

3. Unscrew the cover. Immerse the suction lance with the red mark in the container. Screw the cover of the

red marked suction lance onto the container.

4. Keep the original cover for storing the empty container.

5. Screw the hose connection of the NaClO

2

suction lance (blue mark) onto the hose connection on the NaClO2

pump (blue mark) (see fig. 15, pos. 5b).

6. Position the NaClO

2

container in the blue collecting tray on the left under the unit (for containers up to 30 g/h

for OCD-162-5, -10) or next to the unit (OCD-162-30, -60) .

7. Unscrew the cover. Immerse the suction lance with the blue mark in the container. Screw the cover of the

suction lance onto the container. Keep the original cover for storing the empty container.

Warnin g

Kinked hoses and lines may result in personal injury a nd damag e to p roper ty. Route the hoses

directly down from the unit where possible, do not lay in loops. Do not kink the suction lines

and cables.

Warnin g

Malfunctions due to the mix-up of chemical containers or suction lances may result in serious

personal injury, damage to property and risk of explosion. Always check the re d and blue

labels on chemical containers, suction lances and pumps.

Note

Check the correct orientation of the float at the suction lances. See fig. 14.

The symbol "normally opened" must be visible on top!

TM04 0854 0908

Page 33

33 / 152

4.6 Hydraulic connections

4.6.1 Hydraulic connections Oxiperm Pro (OCD-162-5, -10)

Fig. 15 Hydraulic connections Oxiperm Pro OCD-162-5, -10

TM03 6899 4506

Position Device connections of the Oxiperm Pro

5b, 6b Hoses for both suction lances on the suction side of the chemical pumps

8b Hose at the drain cock of the reservoir tank (only installed for flushing and ventilation)

14

Dosing line from the dosing pump to the injection unit at the main line or to the injection unit at the mixing module or to

the external batch tank

26 Dilution water hose at the solenoid valve

8b

6b

14

26

5b

Page 34

34 / 152

4.6.2 Hydraulic connections Oxiperm Pro (OCD-162-30, -60)

Fig. 16 Hydraulic connections Oxiperm Pro OCD-162-30, -60

For nominal width of the hose connections, see section 11. Technical data.

4.6.3 Connecting the system frame

For nominal diameters of the hose connections, see section 11. Technical data.

1. Close the dilution water stopcock (fig. 4, pos. 1b).

2. Connect the dilution water hose to the stopcock (fig. 5, pos. 1b).

3. Route the hose to the system frame.

4. Connect the hose to the solenoid valve (fig. 15, pos. 26).

Dosing line to injection unit

1. Route the hose from the multi-function valve on the dosing pump (fig. 15, pos. 14) to the injection unit

(in the protective pipe laid by the customer).

2. Connect the hose to the injection unit.

Connect the hose to the drain cock of the reservoir tank (fig. 15, pos. 8b) for flushing and ventilation only.

See section 5.19 Flushing.

TM04 0953 1509

Position Device connections of the Oxiperm Pro

5b, 6b Hoses for both suction lances on the suction side of the chemical pumps

8b Hose at the drain cock of the reservoir tank (only installed for flushing and ventilation)

14

Dosing line from the dosing pump to the injection unit at the main line or to the injection unit at the mixing module or to

the external batch tank

26 Dilution water hose at the solenoid valve

8b

6b

14

26

5b

6b

14

OCD-162-30

OCD-162-60

8b

5b

Page 35

35 / 152

4.6.4 Connecting the dosing line for the external dosing pump (if applicable)

1. Remove the cap from the connector on the reservoir tank.

2. Route the dosing line from the reservoir tank to the external dosing pump, and connect it to the suction valve

on the external dosing pump.

3. Route the overflow line from the external dosing pump back to the reservoir tank, and connect it.

4. Route the dosing line from the external dosing pump to the injection unit, and connect it to the injection unit.

4.6.5 Connecting the hydraulic components to the measuring cell (if applicable)

1. Connect the sample-water hose (fig. 11, pos. 16) to the extraction point in the main line, route it to the

measuring cell, and connect it.

2. Connect the sample-water hose (fig. 11, pos. 24) to the measuring cell, and route it into the drain.

After dosing, the ClO

2

concentration, temperature and pH/ORP value of the sample water are measured in the

measuring cell.

The measuring cell has connections for the following:

• hose from the sample-water extraction point to the measuring cell

• hose from the measuring cell to the drain.

See the installation and operating instructions for the measuring cell.

4.6.6 Measuring module connections

The measuring module is hydraulically connected to the main line.

The measuring module has connections for the following:

• hose from tapping sleeve 1 to the measuring module and hose from the measuring module to tapping sleeve 2 at

the main line.

See the installation and operating instructions for the measuring module.

4.6.7 Mixing module connections

The mixing module is hydraulically connected to the main line and the Oxiperm Pro.

The mixing module has connections for the following:

• dosing line from the Oxiperm Pro dosing pump to the injection unit in the mixing module.

• hose from tapping sleeve 1 to the mixing module and hose from the mixing module to tapping sleeve 2 at the main

line.

See the installation and operating instructions for the mixing module.

Warning

Incorrect installation may result in personal inju ry and damag e to property. Only authorised,

trained service personnel may connect an external dosing pump mo dule to the Oxiperm Pro .

Page 36

36 / 152

4.7 Connecting the electronic components

Fig. 17 Control unit with controls, display elements and cable glands

Most cables are already connected to the control unit on delivery. The following cables need to be connected at the

commissioning stage. See also the terminal connection plan in fig. 53:

4.7.1 Passing the cables through glands into the control unit

1. Unfasten the two screws on the rectangular cover underneath the control unit, and remove the cover.

2. Screw on the corresponding cable gland, and push through the cable.

3. Connect the cable as shown in the terminal connection plan in fig. 53.

4. Close the cable gland by hand.

4.7.2 Connecting the contact water meter/flow meter

1. Route the control cable from the contact water meter/flow meter to the control unit.

2. Connect the control cable to the control unit.

Warnin g

Risk of shock from damaged electronic compone nts (transport damage or installation faults).

Only authorised and qualified personnel may connect the electronic compon ents.

Do not reach into the void behind the control unit. Do not kink cables.

TM03 6926 4506

Connection for

Warning lamp or audible warning system

Contact water meter

Flow meter (current input signal)

Measuring electrode (measuring cell)

Reference electrode (measuring cell)

Counter-electrode (measuring cell)

GND_Cl (measuring cell)

Cleaning motor (measuring cell)

Pt100 temperature sensor

Sample-water deficiency sensor on main line

Fault input, for example gas detector

Flow monitor on mixing module or higher-level control system

Level control external batch tank

Page 37

37 / 152

4.7.3 Connecting the measuring cell (if applicable)

• Connect measuring cell AQC-D1 or AQC-D6 (if applicable):

– measuring and counter-electrode (for measuring ClO

2

)

– sample-water deficiency sensor

– Pt100 sensor

– pH electrode, if applicable (for pH or ORP) (AQC-D1 only)

– cleaning motor (AQC-D1 only).

4.7.4 Connecting the measuring module (if applicable)

• Connect the measuring module to measuring cell AQC-D1 or AQC-D6 (if applicable):

– measuring and counter-electrode for measuring ClO

2

– sample-water deficiency sensor