Page 1

®

Oxiperm

OCD-164 (30-2000 g/h)

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Other languages

http://net.grundfos.com/qr/i/96709679

Page 2

English (GB) Installation and operating instructions

Caution

Note

English (GB)

Original installation and operating instructions

Contents

1. General safety instructions

1.1 Introduction

1.2 Purpose of this manual

1.3 Symbols used in this document

1.4 Users

1.5 Obligations of the operator

1.6 Maintenance and service personnel

1.7 Correct usage

1.8 Inappropriate usage

1.9 Safety and monitoring equipment

1.10 Chemicals

2. Technical data

2.1 General data

2.2 Electrical data

2.3 Delivery state

3. Fundamentals

3.1 Chlorine dioxide for water treatment

3.2 Functional sequence

4. Design and function

4.1 Design of the system

4.2 Components

4.3 Mode of operation of the system

5. Installation

5.1 Transport and storage

5.2 Unpacking

5.3 Installation location

5.4 Installation scheme

5.5 Wall mounting

5.6 Hydraulic connection

5.7 Electrical connection

5.8 Interfaces RS-232, -422 and -485

6. Operation of control electronics

6.1 Program structure

6.2 Control and display elements

6.3 Automatic mode

6.4 Manual operation

6.5 Logbook

6.6 System choice

6.7 Units

6.8 Setup

6.9 Local/remote

7. Commissioning

7.1 Directives

7.2 System choice

7.3 Selection of operation mode

7.4 Venting of the bypass line

7.5 Calibrating the dosing pumps

7.6 Adjusting the dosing controllers

8. Operation of the system

8.1 Automatic operation

8.2 Manual operation

8.3 Faults

8.4 Error messages of the controller

8.5 Fuses and LEDs of the controller

8.6 Possible faults when changing the tank

9. Maintenance

9.1 Maintenance of the dosing pumps

9.2 Maintenance of the suction lines

9.3 Maintenance of reactor

9.4 Maintenance of injector

10. Spare parts kits and spare parts

10.1 DMI dosing pumps with double-head system

10.2 DMI dosing pumps with single-head system

10.3 Dosing pumps DMX 221

10.4 Bypass, post mixer, and dosing controller

10.5 Enclosure exhaust device

Page

10

10

11

11

11

11

12

14

14

15

17

18

18

19

19

19

19

20

20

20

23

24

24

24

24

27

29

30

31

31

33

34

35

36

36

37

37

37

38

39

40

40

41

41

41

42

10.6 Bypass with solenoid valve and flow limiter (standard

version: solenoid valve)

10.7 Bypass, circulating pump 230 V - 50 Hz, 120 V - 60 Hz

10.8 Bypass (version solenoid valve/ball valve, batch mode)

2

2

2

2

3

3

3

3

3

3

3

5

5

7

7

8

8

8

9

9

10.9 Bypass for external booster pump

11. Accessories

11.1 External booster pump

11.2 Load unit for booster pump

11.3 Hose connections/hose

11.4 Gas sensor and gas warning device

12. Current setting data

13. Quick Guide

14. Disposal

1. General safety instructions

1.1 Introduction

The OCD-164 disinfection system is a state-of-the-art solution,

which complies with recognised safety regulations.

Conformity with applicable standards, directives and laws has

been verified. Nevertheless, certain risks which cannot be

prevented by the manufacturer are associated with the use of the

system.

1.2 Purpose of this manual

• Inform users of optimum use of the system.

• Warn users of possible residual risks when using the system

correctly, and identify measures that should be taken to avoid

damage.

• Caution users against obvious misuse or inappropriate use of

the system, and inform them of the necessary care that must

be taken when operating the system.

1.3 Symbols used in this document

Warning

If these safety instructions are not observed, it may

result in personal injury.

If these safety instructions are not observed, it may

result in malfunction or damage to the equipment.

Notes or instructions that make the job easier and

ensure safe operation.

Information about possible residual risks can be found:

• on warning signs located at the installation site, and

• immediately before steps associated with a residual risk.

43

44

45

47

48

48

50

50

50

51

52

52

2

Page 3

1.4 Users

Users are persons who are responsible for operating and

monitoring the disinfection system at the installation location.

The system must only be operated by trained and qualified

personnel. Personnel must have appropriate technical knowledge

and be familiar with the basic principles of measurement and

control technology.

1.4.1 Obligations of the users

• Read this manual before operating the disinfection system.

• Be trained by qualified personnel from Grundfos Water

Treatment in the operation of the system.

• Observe the recognised regulations governing safety in the

workplace and accident prevention.

• Wear appropriate protective clothing in accordance with

national regulations for the prevention of accidents when

operating the system and handling chemicals.

• Keep secret the user code for the operating software.

1.4.2 User workstation

The disinfection system is electronically controlled. Users and

service personnel operate the system via a display with control and

display elements. See section 6.2 Control and display elements.

1.5 Obligations of the operator

The owner of the building or the operator of the disinfection

system is responsible for the following:

• Keep this manual clearly accessible in the immediate vicinity

of the system.

• Meet the installation requirements specified by the

manufacturer (required water connections and fittings,

environmental conditions, electrical connection, protective

tube for dosing line (if necessary), audible or optical warning

device for alarm messages (if necessary)).

• Ensure that water lines and fixings are regularly checked,

serviced and maintained.

• Obtain official approval for storing chemicals, if necessary.

• Instruct users in the operation of the system.

• Provide the user code for the operating software only to users

who have received appropriate technical training.

• Ensure that the regulations for the prevention of accidents are

observed in the installation location.

• Provide all users and service personnel with protective

clothing (face mask, gloves, protective apron).

1.8 Inappropriate usage

Applications other than those listed in section 1.7 Correct usage

are not in accordance with the intended use and are not

permitted. The manufacturer, Grundfos Water Treatment,

accepts no liability for any damage resulting from incorrect use.

The system comprises state-of-the-art components and has

undergone safety-related testing.

Warning

Unauthorised structural modifications to the system

may result in serious damage to the equipment and

personal injury.

It is forbidden to dismantle, modify, change the

structure of, bridge, remove, bypass or disable

components, including safety equipment.

1.9 Safety and monitoring equipment

The disinfection system is fitted with the following safety and

monitoring equipment:

• two collecting trays for the two chemical containers

(accessories),

• alarm functions in the control system.

1.10 Chemicals

1.10.1 Chlorine dioxide concentration

In the reaction tank of the disinfection system, diluted sodium

chlorite and diluted hydrochloric acid are mixed to create a

chlorine dioxide concentration of approximately 20 g per litre of

water. The chlorine dioxide solution is diluted again, and dosed

into the main line to be disinfected, according to the

requirements. According to the German drinking water ordinance

(TrinkwV 2001), the chlorine dioxide concentration in drinking

water must not exceed a maximum of 0.4 mg per litre of water.

The following safety instructions must be observed:

Warning

Risk of explosion when using chemicals in too high a

concentration.

Only use sodium chlorite in a diluted concentration of

7.5 % by weight in accordance with DIN EN 938.

Only use hydrochloric acid in a diluted concentration

of 9.0 % by weight in accordance with DIN EN 939.

The safety data sheets from the supplier must be

observed.

English (GB)

1.6 Maintenance and service personnel

The system may only be maintained and serviced by authorised

service personnel from Grundfos Water Treatment.

1.7 Correct usage

The disinfection system is used to mix a diluted chlorine dioxide

solution from 7.5 % sodium chlorite and 9 % hydrochloric acid.

In accordance with the conditions described in this manual, it is

used to dose the chlorine dioxide solution produced continuously

or non-continuously into the (drinking) water line of a building or

to feed it into a swimming pool, process water, wastewater or

other industrial system for water disinfection.

Warning

Risk of explosion and serious damage to equipment

and personal injury as a result of operating faults due

to confusing the chemical containers or suction lines.

Do not confuse the containers.

Observe the red and blue markings on chemical

pumps, suction lines and chemical containers: Red =

HCl, blue = NaClO

Warning

Risk of burns when skin and clothing come into

contact with sodium chlorite and hydrochloric acid.

Affected skin and clothing must be washed

immediately in water.

Warning

Risk of irritation to eyes, respiratory system and skin,

if chlorine dioxide is inhaled.

When changing the chemical containers,

wear protective clothing in accordance with

regulations for the prevention of accidents.

.

2

3

Page 4

1.10.2 Storing chemicals

English (GB)

• Chemicals must be stored in the appropriately marked original

plastic containers.

• Do not store chemicals near grease, flammable substances,

oils, oxidising substances, acids or salts.

• Empty and full containers must be kept closed, and stored

exclusively in areas where national regulations for the

prevention of accidents apply to storage.

1.10.3 Procedure in case of an emergency

The general safety regulations and regulations for the procedure

in case of an emergency as specified in EN 12671 (D) apply.

Actions in case of an emergency:

• Ventilate the installation location immediately.

• Wear protective clothing (safety goggles, gloves, respirator

and/or self-contained breathing apparatus, protective apron).

• Implement initial help measures:

– In case of contact with the eyes, rinse immediately with

plenty of water for at least 15 minutes. Consult a doctor.

– In case of contact with the skin, wash immediately with

plenty of water. Remove all contaminated clothing.

– In case gas is inhaled, move the casualty to a source of

fresh air. Avoid taking deep breaths. Consult a doctor

(look out for a racing pulse, as vasodilating treatment may

be required).

• Spillages:

– In case of contact with clothing, remove the clothing

immediately and wash with plenty of water.

Chemical spillages in buildings must be washed away with

water.

• Firefighting:

– Aqueous solutions of chlorine dioxide are not directly

flammable. Extinguish the surrounding fire with water,

preferably using a fire sprinkler system to dilute the ambient

gas. Inform the fire brigade of the installed production

capacity and any harmful starting substances that are being

stored (precursor substances) so that precautions can be

taken regarding possible risks.

For emergency phone numbers, please see the acceptance

report.

4

Page 5

2. Technical data

Caution

2.1 General data

2.1.1 Performance and consumption data

System

OCD-164

ClO

preparation capacity

2

at 6 bar

counterpressure

Max. system

pressure

50 Hz 60 Hz

Consumption of

components

1)

HCl NaClO

Dilution water requirement for bypass system

Solenoid valve

2

(standard)

2)

Bypass pump

internal/external

3)

In batch mode

4)

Min.

g/h l/h bar bar l/h l/h l/h l/h l/h l/h

-30 30 421 10 10 0.7 0.7 420 420 7.7 14

-120 120 426 9 6 2.9 2.9 420 420 31 55

-220 220 430 7 7 5.2 5.2 420 420 56 100

-350 350 437 9 9 8.3 8.3 420 420 89 160

-700 700 933 9 9 16.5 16.5 900 900 179 320

-1000 1000 948 9 9 24 24 900 900 258 450

-1500 1500 970 9 9 35 35 900 900 383 680

-2000 2000 996 9 6 48 48 900 900 517 900

General concentration range for all systems: 0.5 - 3.3 g/l

1) With max. preparation capacity, shortened reaction time

2) With admission pressure 2 bar higher compared with the pressure at the injection unit

3) Depends on flow losses of solution line up to injection unit

4) Concentration of ClO

5) Concentration of ClO

solution approx. 3.3 g/l. Inlet pressure for bypass water: 3-8 bar

2

solution approx. 2 g/l. Inlet pressure for bypass water: 3-8 bar

2

2.1.2 Temperatures and concentrations 2.1.3 Materials

Permissible concentration of NaClO2 solution 7.5 % by weight

Permissible concentration of the HCl solution 9.0 % by weight

Permissible ambient temperature 5 °C to 40 °C

Permissible process water temperature

(bypass water)

Permissible component temperature

(chemicals)

2 °C to 40 °C

5 °C to 40 °C

Storage temperature of system -5 °C to 50 °C

Storage temperature of chemicals 5 °C to 40 °C

Permissible relative humidity

max. 80 %,

non-condensing

Components Materials

Supporting frame PP

Screws, washers and nuts 1.4301

Reactor

Grey PVC, 1.4571 painted

RAL 6017

Post-mixer Grey PVC

Piping Grey PVC

Gaskets FPM/PTFE

2.1.4 Connections and weights

Max.

English (GB)

5)

Enclosure exhaust device

optional

2

Motive water

pressure

Motive water

requirements

Connection,

exhaust

device

Weight of system

164-OCD

Connection for bypass

(water inlet)

Connection for ClO

solution line

DN DN bar l/h DN kg

-30

800

-120 800 34

-220 800 34

-350 1300 57

-700 1300 62

20 20 5

20

-1000 1300 66

-1500 1300 76

-2000 1300 82

The solution line must be provided with a pressure

relief valve set to 10 bar.

This is a safety measure for the case that a pressure

of more than 10 bar occurs in the dilution water line

while the chlorine solution line at the outlet side of

the system is shut.

33

5

Page 6

2.1.5 Dimensions

$

$

%

*

/

+

.

)

(

0

&

&&

&

English (GB)

Fig. 1 Dimensioning of the system with drillholes

OCD-164 A A1 B C E F G H K L M C1 C2

-30 700 740 650 40 800 760 230 148 148 410 9 DN 20 DN 20

-120 700 740 650 40 800 760 230 148 148 410 9 DN 20 DN 20

-220 700 800 650 40 800 760 230 148 148 410 9 DN 20 DN 20

-350 760 800 650 70 1010 970 268 135 181 470 11 DN 20 DN 20

-700 760 800 650 70 1010 970 268 135 181 470 11 DN 20 DN 20

-1000 760 800 650 70 1010 970 268 135 181 470 11 DN 20 DN 20

-1500 760 800 650 70 1300 1260 268 135 181 470 11 DN 20 DN 20

-2000 760 800 650 70 1300 1260 268 135 181 470 11 DN 20 DN 20

TM04 8193 4510

6

Page 7

2.2 Electrical data

Max. permissible load of

potential-free output contacts

Analog input 0/4-20 mA, load: 50 Ω

Analog output 0/4-20 mA, load: max. 500 Ω

Contact input max. 50 contacts/second

Max. permissible mains

impedance with 90 Watt

bypass

Max. permissible mains

impedance with 340 Watt

bypass

2.2.1 Power consumption

OCD-164 Power consumption [VA]

-30 to -220 300

-350 to -2000 650

2.2.2 IP codes

Component IP code

Electronics, dosing pumps, solenoid valve,

flowmeter

Bypass pump IP44

Dosing controller IP67

250 V, 6 A, max. 550 VA

0.168 + j 0.168) Ω, (testing

according to EN 61000-3-11)

0.059 + j 0.059) Ω, (testing

according to EN 61000-3-11)

IP65

English (GB)

2.3 Delivery state

The compact chlorine dioxide system comprises:

• The preparation system, completely assembled and wired up,

on a PP supporting frame, including dosing pumps and suction

lines.

• Dosing controller for flow monitoring of hydrochloric acid and

sodium chlorite.

• Tank-level monitor and empty indication for hydrochloric acid

and sodium chlorite.

• Chlorine dioxide reactor.

• Bypass system with flowmeter and solenoid valve,

or optionally

– circulating pump and flowmeter,

– solenoid valve, dosing ball valve and flowmeter.

• Static mixer.

• Control electronics, directly mounted on the supporting frame,

and wired up.

• Optional exhaust device: Injector with solenoid valve,

electrically connected to the control electronics,

supporting frame with side parts.

7

Page 8

3. Fundamentals

Reactor

Bypass water

NaClO

2

HCl

ClO

2

solution

English (GB)

3.1 Chlorine dioxide for water treatment

Properties of chlorine dioxide

• Strong and fast oxidation and disinfection agent.

• Applications in the treatment of drinking, service, cooling, and

waste water.

• Chemically unstable compound

– Can explosively decompose into chlorine and oxygen when

heated.

– Must be generated on site as required, since storage in

cylinders is not possible.

Advantages of chlorine dioxide compared to chlorine

• Largely good to very good bactericidal, virucidal and sporicidal

effects in the complete pH range of drinking water (pH 6.5 - 9).

The disinfecting effect of chlorine decreases with increasing

pH value.

• No or reduced forming of trihalogen methanes.

• No generation of chloramines with ammonium or amino

compounds.

• Highly reduced potential for generation of organic halogen

compounds of high molecular weight.

• Good stability in water. Long bactericidal and bacteriostatic

protection in the water network.

3.1.1 Preparation of chlorine dioxide

The chlorine dioxide preparation system was specially developed

for the continuous or discontinuous preparation of a chlorine

dioxide solution for water disinfection. The chlorine dioxide is

generated according to the hydrochloric acid/sodium chlorite

procedure in line with the following stoichiometric equation:

5 NaClO

Sodium chlorite + Hydrochloric acid <=> Chlorine dioxide +

Sodium chlorite + Water

This system uses a 7.5 % NaClO

solution in a volume ratio 1:1 for chemical reaction.

The reaction time is approx. 10 minutes. This application uses a

multiple stoichiometric excess of hydrochloric acid for the

following reasons:

• A non-critical chlorine dioxide concentration of 20 g ClO

generated in the reactor.

+ 4 HCl <=> 4 ClO2 + 5 NaCl + 2 H2O

2

Warning

The system must only be operated using a 9 %

hydrochloric acid solution and a 7.5 % sodium

chlorite solution.

Commercially available solutions such as 24.5 %

sodium chlorite or 32 % hydrochloric acid would

generate an explosive concentration, and must

therefore never be used undiluted in the system.

solution and a 9 % HCl

2

2

/l is

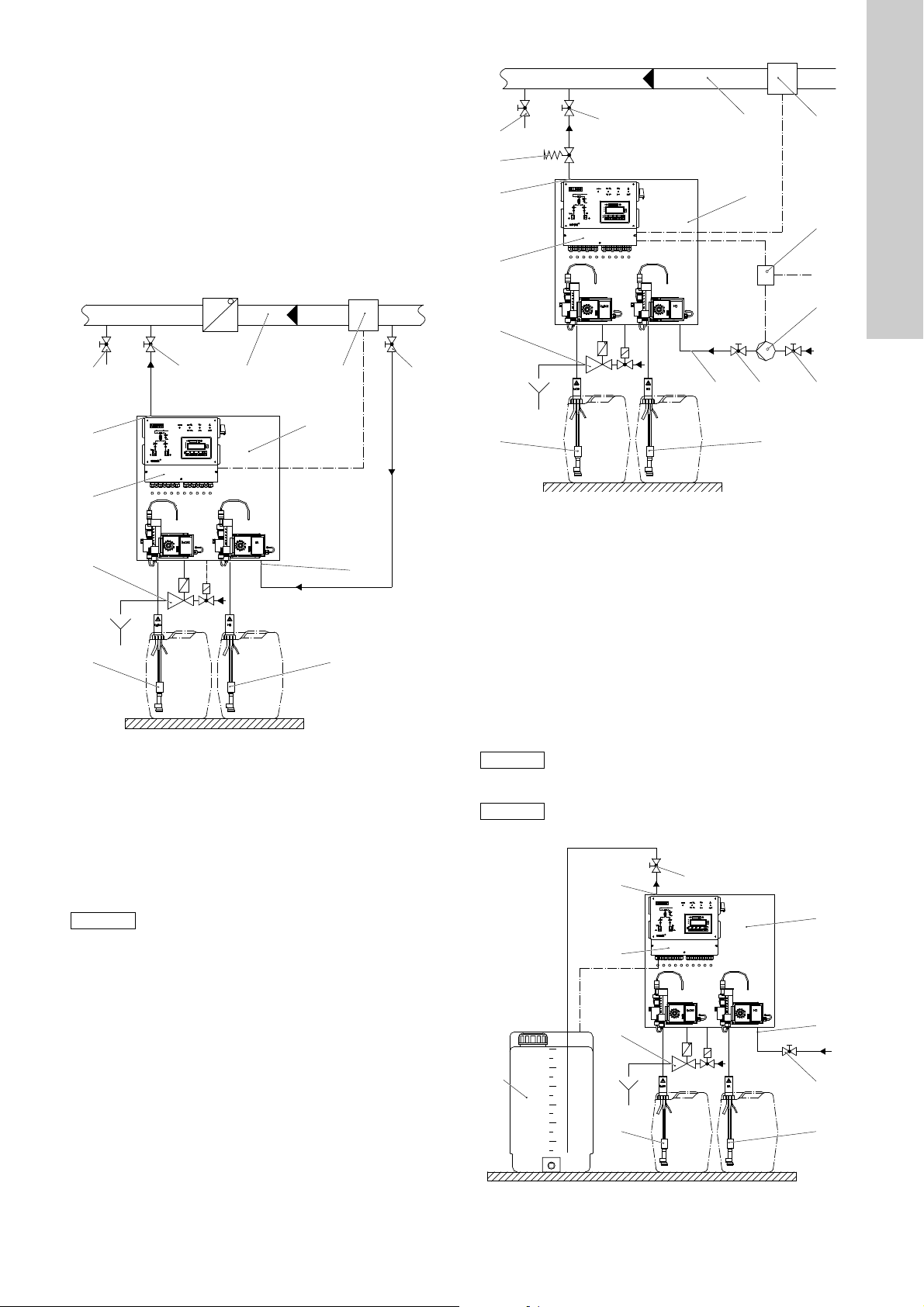

3.2 Functional sequence

• Three components are required to generate a chlorine dioxide

solution:

– Hydrochloric acid (HCl)

– Sodium chlorite (NaClO

– Dilution water (bypass).

The added quantities of these components are defined by the

process, and must not be changed. The flows of the individual

components are therefore monitored by flowmeters and flow

controllers.

Hydrochloric acid (9 % solution) and sodium chlorite (7.5 %

solution) are dosed into the reactor with a volume ratio 1:1. There

they react together, and generate an uncritical chlorine dioxide

concentration of 20 g/l.

Following the reactor, the chlorine dioxide solution is diluted by

the bypass water into a solution ready for use.

Fig. 2 Preparation of chlorine dioxide solution

)

2

TM04 8194 4510

Warning

Gaseous chlorine dioxide is explosive above a

concentration of 300 g/m

3

.

• A good yield of chlorine dioxide is achieved with excess acid

of 250-300 %. A further increase in the excess acid only

results in a small improvement in the efficiency.

• Excess acid shifts the equilibrium of the disproportionation

reaction between hydrochloric acid and sodium chlorite to the

right, resulting in an optimum yield.

8

Page 9

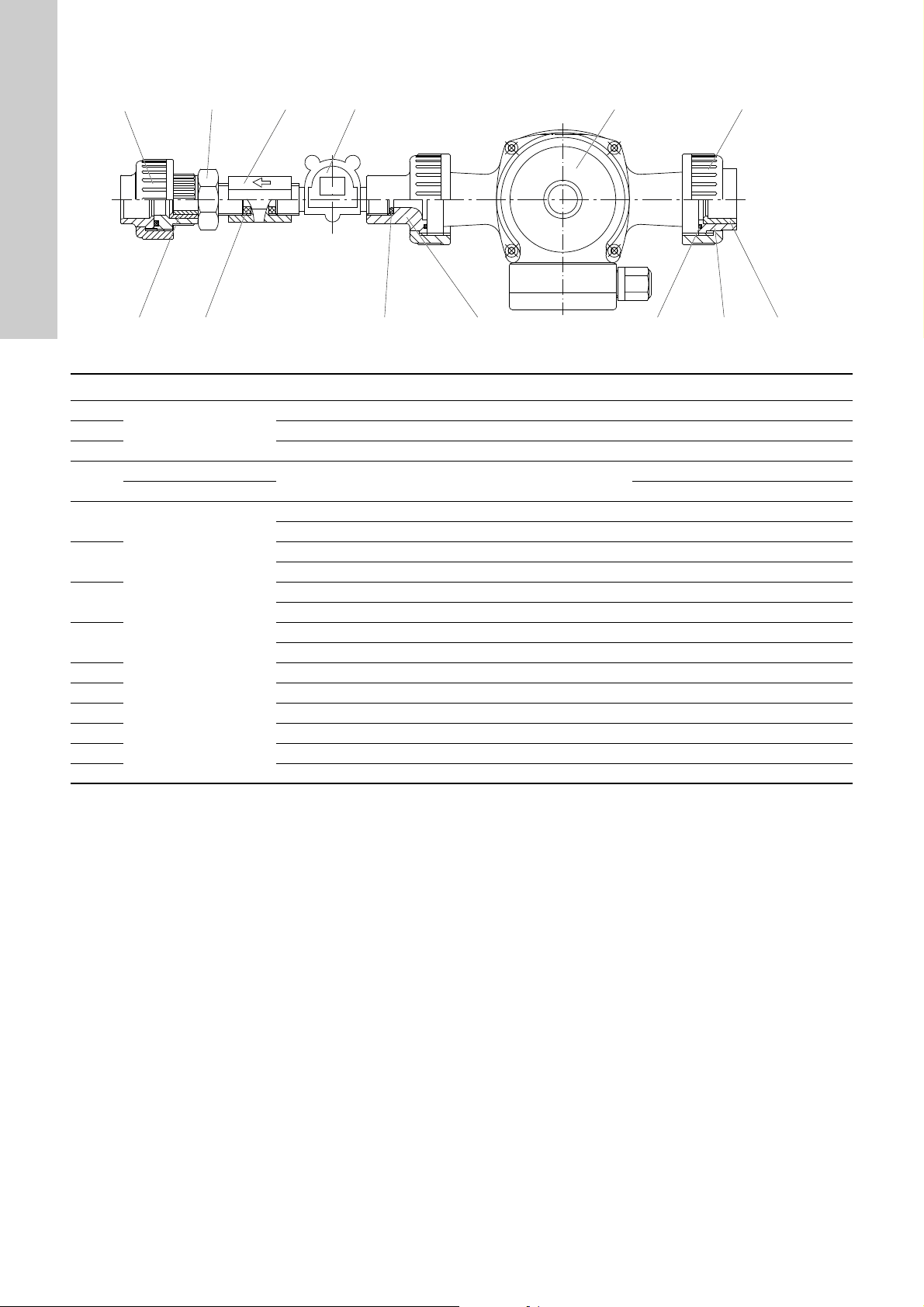

4. Design and function

PAPA

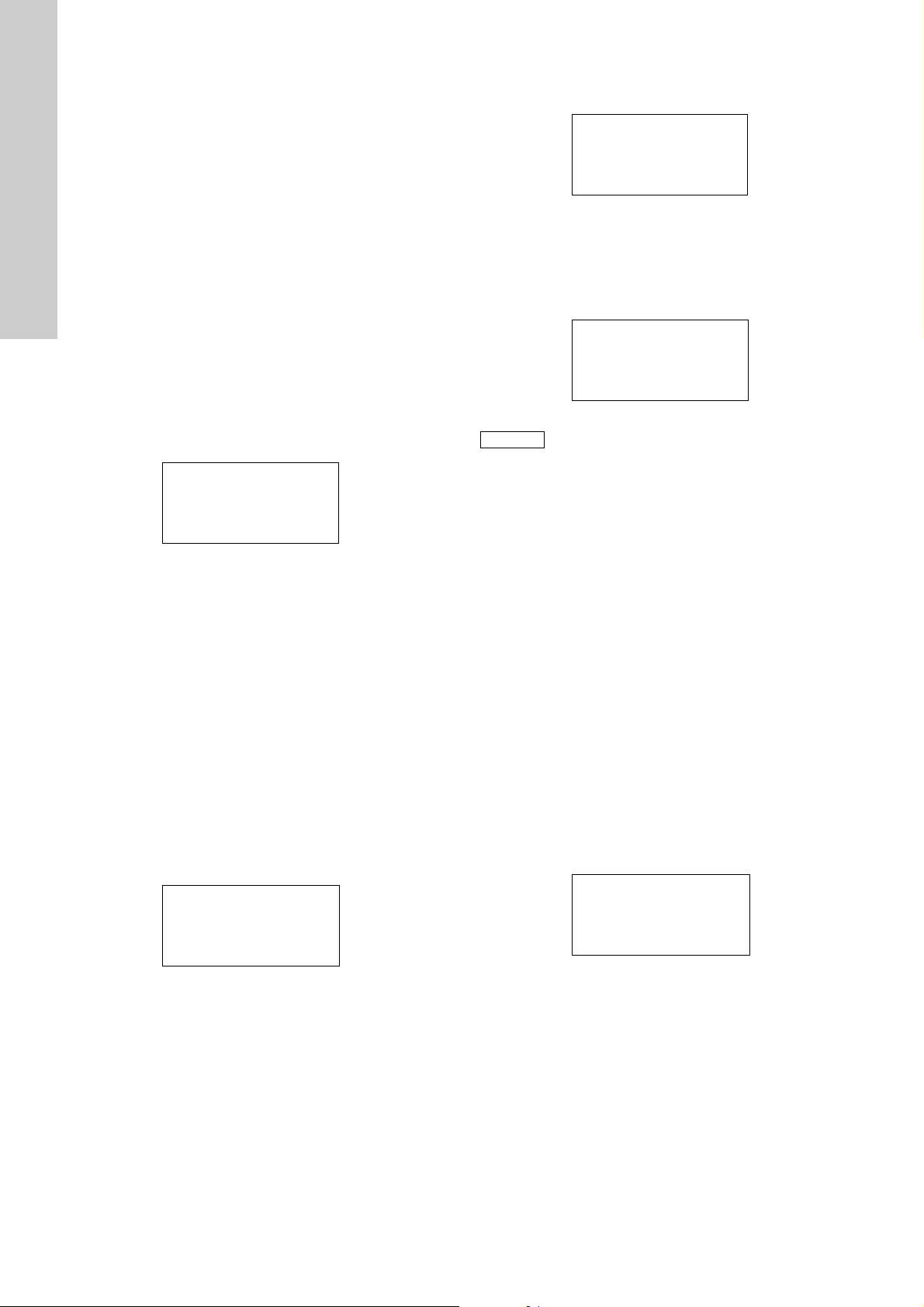

4.1 Design of the system

English (GB)

TM04 8196 4510

Fig. 4 Reactor with components, assembled on the back of

the supporting frame

Pos. Description

1 Dosing system for hydrochloric acid (HCl)

1.1 Dosing pump for hydrochloric acid

Suction line with pre-empty and empty signal for HCl

1.2

(red)

1.3 Dosing controller for HCl flow monitoring

2 Dosing system for sodium chlorite (NaClO

2.1 Dosing pump NaClO

Suction line with pre-empty and empty signal for NaClO

2.2

(blue)

2.3 Dosing controller for NaClO

2

flow monitoring

2

)

2

2

3 Bypass water feed pipe

TM04 8195 4510

Fig. 3 Complete system with components, assembled on a

supporting frame

3.1 Solenoid valve (optional circulating pump)

3.2 Impeller counter (flowmeter for bypass water)

3.3 Non-return valve

3.4 Flow limiter

4 Reactor

4.1 Reactor housing

4.2 Reactor valves

5 Post-mixer

6 Connection for ClO

solution line to the injection unit

2

7 Connection for bypass water

8 Controller with display

9 Injector for exhaust device (option)

9

Page 10

4.2 Components

Note

English (GB)

4.2.1 Suction lines

The suction lines must be matched to the tank size and the

system performance (diameter of suction line). They have a dual

level-control unit.

If the level of the components (HCl/NaClO

) drops to the first

2

stage ("Min" contact/pre-empty signal), the alarm "HCl- MIN" or

"NaClO

the controller display. The system remains in operation, the relay

"pre-empty signal NaClO

MIN" is output. This is indicated by flashing of a LED on

2

/HCl" is activated.

2

The system is switched off when the second stage is reached

("Min"-"Min"contact/empty signal), and the alarm "HCl empty

signal" or "NaClO

empty signal" is displayed, the "Alarm" is

2

activated and the alarm LED lights up red permanently.

If a buzzer is connected to the potential-free output relay,

an audible signal is output.

4.2.2 Dosing pumps

The dosing pumps are mounted at the supporting frame.

They operate according to the pulse/pause procedure. The stroke

length is adjusted with a rotary knob. The stroke length is preset,

but may have to be corrected following gauging of the pumps

since the local pressure conditions depend on the application.

The dosing pumps for the systems OCD-164-30 to OCD-164-220

are delivered with an integral gauging system. Gauging of the

dosing pumps for the systems OCD-164-350 to OCD-164-2000 is

carried out using calibration cylinders on the suction side.

Refer to the table 2.1.1 Performance and consumption data for

the dosing rate to be set for the pumps.

The dosing rates of the pumps should be set approximately the

same (± 10-15 %) to guarantee uniform consumption of the

chemicals.

The stroke length must not be adjusted any further following

gauging.

4.2.3 Dosing controller

The dosing controllers guarantee that both chemicals flow into

the system during operation. If the volume flow of one of the

chemicals drops by more than 25-30 %, the dosing controller

outputs an alarm and switches off the system.

The working point must be correctly set to guarantee safe

functioning of the dosing controller, see section 7. Commissioning.

A correctly set working point is indicated by the flashing LEDs on

the controller flowchart, see section 6.2 Control and display

elements.

4.2.4 Reactor

The reactor is installed at the rear of the supporting frame.

The non-return valves on the reactor inlet and outlet must be

selected depending on the system pressure. Standard valves are

suitable for a system pressure of less than 3 bar.

4.2.5 Bypass

The bypass water line dilutes the chlorine dioxide solution

generated in the reactor (approx. 20 g/l) and routes it to the main

water flow. Several versions of the bypass line are available:

• Bypass with solenoid valve and flow limiter

• Bypass with circulation pump

• Bypass with solenoid valve and dosing ball valve (batch mode)

• Bypass for external booster pump (and load unit), see section

10.9 Bypass for external booster pump.

The water in the bypass is monitored by a flowmeter.

The flowmeter switches the system off, if the bypass water falls

below a minimum flow; the LED on the flowchart flashes.

The LED lights up permanently, if the water flow is above the

minimum quantity, see section 6.2 Control and display elements.

Fit a particle filter upstream, if the bypass water is not

free of solids.

4.2.6 Post-mixer

The chlorine dioxide solution is mixed with the bypass water in

the post-mixer (standard).

4.2.7 Options

Power Supply

• 230 V, 50/60 Hz

• 115 V, 50/60 Hz.

Bypass

• Bypass with pump 230 V, 50/60 Hz

• Bypass with pump 115 V, 60 Hz

• Bypass with solenoid valve 230 V, 50/60 Hz and flow limiter

(standard)

• Bypass with solenoid valve 115 V, 50/60 Hz and flow limiter

• Bypass for external booster pump, see section 10.9 Bypass for

external booster pump.

Suction lines

• Suction line 1.3 m for 30/60-litre tank (standard)

• Suction line 2.5 m for 30/60-litre tank

• Suction line 2.5 m for 200-litre tank.

Exhaust device

• Exhaust device, DN 20, 230 V 50/60 Hz (standard)

• Exhaust device, DN 20, 115 V 50/60 Hz

• Without exhaust device.

Reactor non-return valves

• System pressure less than 3 bar (standard)

• System pressure more than 3 bar.

Bus systems

• Profibus DP module

• Ethernet TCP/IP module.

Interface

• RS-232 interface

• RS-422 and RS-485 interface.

4.3 Mode of operation of the system

Positions in brackets, see fig. 4.

When the system is started in normal mode, the solenoid valve

(3.1) opens. Dilution water flows to the post-mixer (5), the flow is

controlled via the impeller counter (3.2).

The two dosing pumps simultaneously pass 9 % hydrochloric acid

and 7.5 % sodium chlorite solution with a ratio of 1:1 into the

reactor (4). The flow quantities of the chemicals are monitored by

the dosing controllers (1.3 and 2.3).

The reaction between sodium chlorite and hydrochloric acid results

in a chlorine dioxide solution with a concentration of 20 g/l in the

reactor (4). The dwell time in the reactor is approx. 10 minutes.

In the subsequent mixer, this solution is diluted down to a

concentration of max. 3.3 g ClO

and performance setting, and passed on to the injection unit.

The system is switched off immediately, if one of the dosing

controllers or the impeller counters detects a low flow.

Warning

Chlorine dioxide is a toxic gas, hydrochloric acid and

sodium chlorite are highly corrosive chemicals which

must be handled properly.

Installation and operating personnel must therefore

be acquainted with the regulations concerning the

handling of chlorine dioxide, hydrochloric acid and

sodium chlorite.

In Germany, the accident prevention regulations UVV

are applicable.

/l, depending on the system size

2

10

Page 11

Note

A set of warning signs for the chlorine dioxide system

Bypass water

Reactor

ClO

2

solution

ClO

2

HCl

NaClO

2

Note

Note

Caution

in accordance with the specifications is available

under Order No 96727022 (515-662).

Please find further general information for operation

of a chlorine dioxide system in:

– Accident prevention regulations "Chlorination of

water" (VGB 65 or GUV 8.15)

– Directive on dangerous working materials

– DIN 938 "Sodium chlorite solution for water

treatment; technical conditions of delivery"

– DIN 939 "Hydrochloric acid for water treatment"

– "Chlorine dioxide for water treatment" DVGW

directive, worksheet W 224 (German)

4.3.1 How the system operates in batch mode

In batch mode, a defined ClO

(batch container), and transported to the injection units by means

solution is added to a holding tank

2

of dosing pumps.

The ClO

3.3 g/l.

concentration can be adjusted within a range of 0.5 to

2

Fig. 5 Preparation of chlorine dioxide solution

For a concentration between 2 and 3.3 g/l, the quantity of bypass

water is set via a dosing ball valve. In the case of concentrations

below 2 g/l, the required quantity of bypass water for a 2 g/l

solution is set. The desired concentration inside the solution

container is then achieved by regulating the two dosing pumps.

The limits for the bypass water quantity are -50 % and +20 % of

the target value. If the target value is undershot (up to -50 %), the

system will automatically regulate the dosing flow of the chemical

pumps for the current water quantity. This is achieved by means

of a pulse-pause control on the dosing pumps. When the water

quantity target value is undershot, the overall performance of the

system is reduced by up to -50 %.

This control makes it possible to compensate pressure

fluctuations in the bypass pipe.

Warning

Protection units should be provided in addition, such

as separate collecting trays for the hydrochloric acid

and sodium chlorite tanks.

Protective clothing for operators has to be provided.

Furthermore, the specified warning signs, danger

information and first aid information must be

positioned at the specified points.

5. Installation

5.1 Transport and storage

Warning

Only transport the system, when it's empty, observe

the weight.

Only use suitable lifting and transport equipment.

• Transport system carefully.

• Dry, cool storage location.

• Protect from direct sunlight.

5.2 Unpacking

• The system is tested at the factory and ready for connection.

• Check for damage, do not install or connect a damaged

system!

• When unpacking, look for loosely packed components.

• Install as soon a spossible following unpacking.

Retain packaging material, of dispose of according to

local regulations.

5.3 Installation location

The applicable local or country-specific regulations

must be observed when selecting and designing the

installation location for the chlorine dioxide system.

In Germany, the accident prevention regulations UVV

are applicable.

The installation location for the system must fulfil the following

requirements:

• The permissible ambient temperature of +5 to +40 °C must be

guaranteed.

• The installation location must be vibration-free and isolated

TM04 8197 4510

fireproof from other rooms.

Reference to the dangers when using the chlorine

dioxide system and to the relevant precautionary

measures must be provided using appropriate signs

at access points to the system rooms and to the

associated chemical storage rooms.

English (GB)

11

Page 12

5.4 Installation scheme

Note

Note

Note

Caution

L

1D&O2

+&O

English (GB)

Select or set a contact water meter in such a way

that, at max. installation output, the control pulses

are not < 5 pulses/sec. Calculation of the contacts

see section 7.3.3 Contact input.

The control for the system can process a max. rate of

50 pulses/sec. If a value greater than 50 pulses/sec.

is calculated, use a different contact water meter.

If the pressure at the injection unit is < 1 bar,

a pressure loading valve must be installed.

A pressure loading valve may not be used in

installations with an internal centrifugal pump, as this

pump only generates an increase in pressure of

approx. 5 mWC.

For the dosing pumps DMI with Plus3 system, ensure

that the container is always underneath the dosing

pump, and the suction line is positioned in a

downwards direction, so that the chemicals can

easily flow back via the return pipe into the container.

Recommended L = min. 200 mm, see fig. 6.

TM04 8199 4510

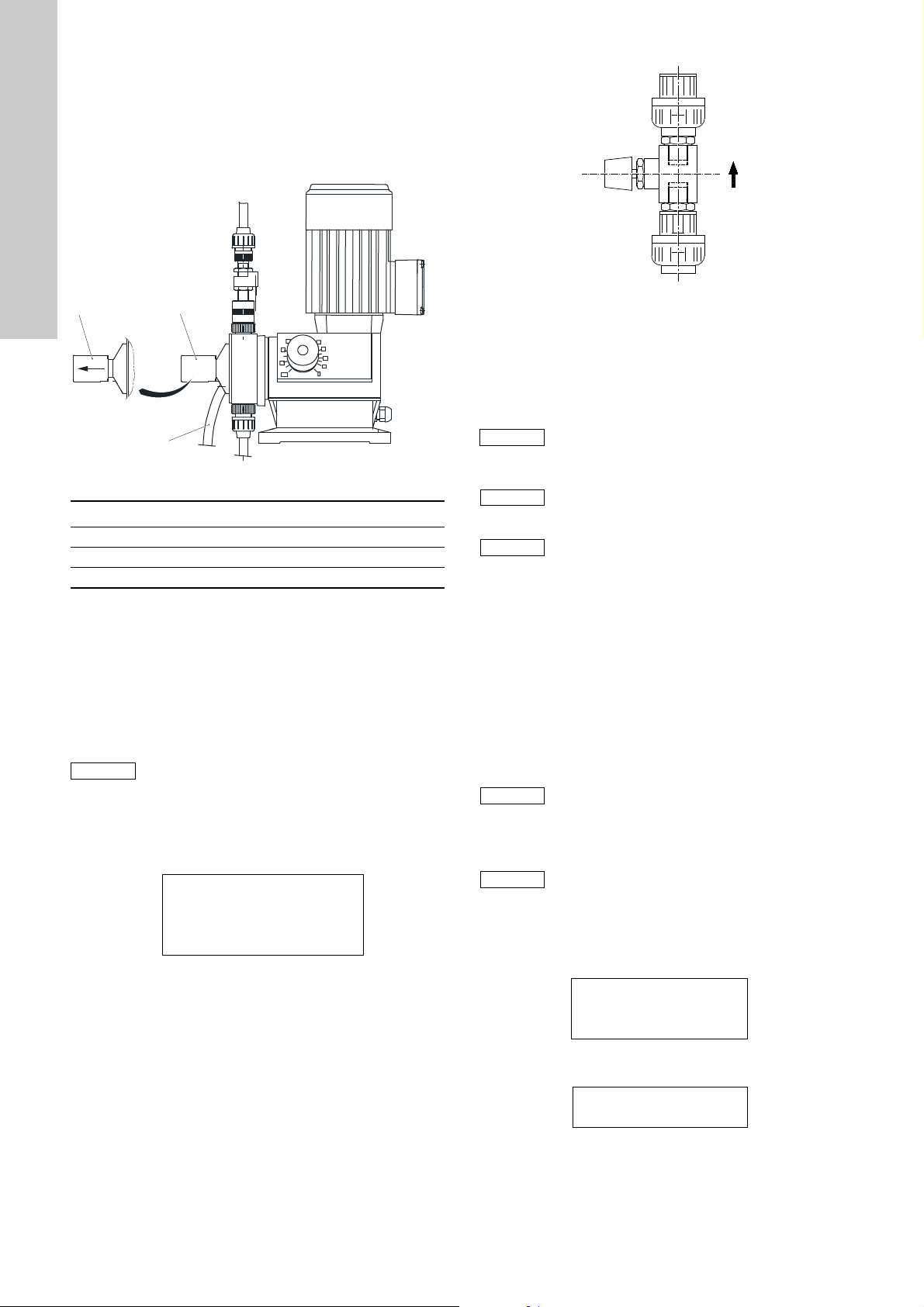

Fig. 7 System with solenoid valve, installation scheme

Pos. Description

1 Supporting frame

2 Electronics

3 Connection for dilution water

4 Connection for solution line to the injection unit

5 Suction line for HCl dosing pump

TM04 8198 4510

Fig. 6 Installation scheme with suction line length

5.4.1 System with solenoid valve

The systemis delivered as a standard with a solenoid valve in the

dilution water line. In this version, the supply of dilution water and

the addition of chlorine dioxide solution are not carried out in the

same water circuit.

Requirements

• 10 bar > water pressure > 1 bar.

• The counterpressure at the connection of the solution line

should be at least 0.5 bar less than the inlet pressure of the

dilution water.

With the chlorine dioxide solution line shut off (at the

outlet) and an input pressure of more than 10 bar in

the dilution water line (at the inlet), there is a danger

that the system will be damaged.

The solution line must therefore be provided with an

excess pressure valve set to 10 bar.

7 Main water pipe (supplied by the customer)

Isolating valve for the injection unit (supplied by the

8

customer)

9 Sample extraction (supplied by the customer)

10 Non-return valve (supplied by the customer)

Isolating valve for dilution water extraction (supplied by

11

the customer)

Supporting frame exhaust device, with solenoid valve

12

(option)

13 Solution tank with level control (option)

14 External booster pump (option)

15 Load unit for the external booster pump

Pressure loading valve (supplied by the customer), if the

16

system pressure is < 1 bar

Inductive flowmeter (4-20 mA) or contact water meter for

17

proportional control of the system (observe the contacts

from the contact water meter).

6 Suction line for NaClO

dosing pump

2

12

Page 13

5.4.2 System with internal bypass pump

Note

1D&O2

+&O

Note

Note

1D&O2

+&O

1D&O2

+&O

As an option, the system can be delivered with an internal bypass

pump instead of the solenoid valve. This version is required for

treating closed water circuits, i.e. the sampling of dilution water

and the addition of chlorine dioxide solution are present in the

same water circuit.

The bypass pump is only designed for compensation of the

internal friction losses of the system, and for counteracting the

pressure losses of approx. 0.1 bar in the solution line to the

injection unit.

The solution line to the injector should therefore be kept as short

as possible. The geodetic difference in height between the

connection of the solution line and the injection unit must not

exceed 1 m.

English (GB)

TM04 8201 4510

Fig. 9 System with booster pump, installation scheme

Fig. 8 System with bypass pump, installation scheme

5.4.3 System with external booster pump and load unit

An external booster pump can be connected to the dilution water

line as a further option. This version is required, if sampling of the

dilution water and addition of the chlorine dioxide solution are not

in the same water circuit, and the system pressure at the injector

is higher than the pressure of the dilution water supply line. In this

version, a load unit is required in addition, and is controlled

directly by the system electronics, see fig. 42.

Booster pump and load unit must be selected

separately (see section 11. Accessories).

5.4.4 System with solenoid valve/ball valve (batch tank)

As a further option, the dilution water line can also be selected

with a solenoid valve and dosing ball valve.

This version is required if batch mode is present, i. e. a certain

concentration of ClO

is prepared in a tank. Dosing of the ClO2

2

solution to the injection unit is carried out using dosing pumps.

The concentration of the ClO

adjusted from 2 to 3.3 g/l.

solution in the tank can be

2

The set pressure must be adjusted to the local conditions during

startup. The pressure retention valve must be set such that

siphoning does not take place through emptying of the solution

line when the system is switched off.

TM04 8200 4510

If the pressure set on the loading valve is too high, it

may occur that the required quantity of bypass water

cannot be correctly set.

If the bypass water is not free from solids, a dirt filter

should be installed upstream.

TM04 8202 4510

Fig. 10 System with solenoid valve and ball valve

13

Page 14

5.5 Wall mounting

Caution

Note

Caution

%$

English (GB)

• The mounting material includes screws, wall plugs, washers

and nuts.

• Mount the supporting frame on the wall using the enclosed

mounting material. Select the mounting height such that the

containers with chemicals can be located underneath, and that

the controller display is easy to read. Drilling scheme see

section 2.1.5 Dimensions.

• The liquid level of the containers when full with chemicals

should always be below the dosing pumps.

The system must be freely accessible on the left and

right for maintenance work (approx. 50-60 cm

space).

The mounting material also contains a M6x20

countersunk screw for fixing a gas sensor, see

section 11. Accessories, underneath the reactor.

5.6 Hydraulic connection

Warning

Before hydraulic connection, disconnect the system

from the mains.

It must be possible to insert the suction lines (items 5 and 6) for

hydrochloric acid and sodium chlorite into the tanks without

tension.

• Install the suction hose, return hose and the two empty alarm

cables of the suction line in the tank such that the bottom end

of the suction line is approx. 1 cm above the base of the tank.

5.6.1 Bypass

• In the case of the version with solenoid valve, provide the

dilution water supply line with an isolating valve, and route the

remaining part of the line up to the inlet connection in PVC

tube, and connect.

• In the case of the version with internal bypass pump, route the

dilution water line in a PVC tube as directly as possible from

the main water line up to the inlet connection. Provide a

sampling shut-off valve on the main water line.

Warning

If the sampling line and the solution line are

connected to the same water circuit, a non-return

valve must be fitted in the main line between the

dilution water sampling point and the injector in order

to prevent circulation of the solution with dangerous

building up of chlorine dioxide.

• Route chlorine dioxide solution line to the injection unit in PVC

tube. An isolating valve should also be fitted in this line directly

upstream of the injection unit.

5.6.2 Safety exhaust device (option)

1. Mount the safety exhaust device underneath the system

cabinet.

2. Cut the supplied PE hose to length, and connect to the

diaphragm check valve of the suction injector and to the

associated screwed gland of the supporting frame (in the

centre of the base).

3. Route the injector motive water line in PVC tube of DN 20,

and connect to the solenoid valve. Route the disposal line in

PVC tube of DN 20, and connect to the outlet connection of

the suction injector.

4. Insert the plug of the control voltage cable into the solenoid

valve socket and tighten the plug screw.

The motive water of the suction injector must be free

from sand and suspended matter. It is therefore

recommendable to install a dirt trap upstream of the

solenoid valve.

TM04 8203 4510

Fig. 11 Safety exhaust device, installation scheme

Pos. Description

1 Disposal pipe (waste water/untreated water) DN 20

2 Suction injector

3 Solenoid valve

4 Pressure reducer

5 Water supply line

6 Booster pump

Connection - version A

This connection option is used if the pressure in the water line is

> 4 bar, and there is an adequate total quantity of water (bypass

water and motive water for the suction injector).

If the pressure is > 5 bar, there should be a pressure reducer (4)

installed, so that the pressure upstream of the suction injection is

between 4 and 5 bar.

Connection - version B

This connection option is used if the pressure in the water line is

> 4 bar, i.e. the prescribed pressure upstream of the suction

injection must be generated via a booster pump (6). If there is an

adequate volume of water in the supply line (5) (sufficient water

for the bypass and suction injector), the booster pump (6) can be

connected to the water supply line (5).

The water supply to the booster pump (6) can be conducted via a

separate water supply line at any time.

14

Page 15

5.7 Electrical connection

Caution

Note

A direct connection of the system to the power supply is made

using the terminals 1 (L1), 2 (N) and 3 (PE). Depending on the

Warning

The electrical connection must only be carried out by

qualified personnel.

Observe the local safety regulations!

Switch off the power supply before connecting the

mains cable.

version, the power supply can be 230 V (AC) or 115 V (AC).

Connection to an incorrect power supply may destroy

the system.

Make the electrical connection according to the

enclosed connection diagram.

5.7.1 Terminal connection diagram

Fig. 12 Terminal connection diagram

5.7.2 Power supply

L N PE Description L N PE Description

1 2 3 Power input 16 17 18

4 5 6 Power output 19 20 21

-------------------------------------------

7 8 9 ------------------- 22 23 24 Solenoid valve/pump/bypass water

10 11 12 HCl dosing pump 25 26 27

13 14 15 NaClO

dosing pump 28 29 30

2

Solenoid valve: enclosure exhaust

device

Solenoid valve: exhaust device for

batch tank

English (GB)

TM04 8204 4510

5.7.3 Potential-free outputs

Root NO Description Function

31 33 Fault 31/33 open in case of fault

32 34 Pre-empty signal HCl/NaClO

2

32/34 open in case of pre-empty signal

37 39 Automatic 37/39 closed in case of "system active"

38 40 Tank run dry 38/40 open in case of dry run

5.7.4 Inputs +8 V

+8 V GND IN Description

59 (brown) 60 61 (blue) Dosing controller NaClO

63 (brown) 64 62 (blue) Dosing controller HCl

65 66 67 ------------------------------

69 (brown) 70 (white) 68 (green) Bypass water impeller counter

2

15

Page 16

5.7.5 Inputs +12 V

English (GB)

+12 V GND IN Description Function

43 ------- 44 Batch tank ClO

45 ------- 46 Batch tank ClO

47 ------- 48 Batch tank ClO

49 ------- 50 Batch tank ClO

51 (brown) ------- 52 (white) Pre-empty signal NaClO

------- ------- 53 (green) Empty signal NaClO

------- ------- 54 (green) Empty signal HCl

55 (brown) ------- 56 (white) Pre-empty signal HCl

57 ------- 58 ----------------------------------71 (white) 72 (brown) 73 (green) Hall sensor NaClO

75 (white) 76 (brown) 74 (green) Hall sensor HCl pump

77 (white) 78 (brown) 79 (green)

83 - 84 Contact input water meter

85 - 86 Remote on/off Contact open: "Remote off"

87 - 88 Fault gas warning device Contact open: fault

89 - 90 Contact main water min. Contact open: min. contact main water

-8180

-----------------------------------

overflow

2

max.

2

min.

2

dry run

2

pump

2

NC

Contact open in case of overflow

level above contact

ClO

2

NO contact

Contact closed in case of "Max"

level above contact

ClO

2

NO contact

Contact open in case of "Min"

level below contact

ClO

2

NO contact

Contact open in case of dry run

level below contact

ClO

2

NC

2

Contact open in case of pre-empty signal

level below contact

NaClO

2

NC

2

Contact open in case of empty signal

level below contact

NaClO

2

NC

Contact open in case of empty signal

HCl level below contact

NC

Contact open in case of pre-empty signal

HCl level below contact

-----------------------------------------

5.7.6 Analog signals

Shield IN/OUT Description

95 93 IN + Analog IN

96 97 OUT + Analog OUT

16

Page 17

5.7.7 Profibus/Ethernet (option)

'39

'3*1'

5['7['3

5['7['1

3*1'

576

The controller can be optionally equipped with Profibus or

Ethernet.

Profibus-DP module

The Profibus-DP connection is made via a 6-pin plug.

5.8 Interfaces RS-232, -422 and -485

The controller can optionally be equipped with interfaces.

5.8.1 Connection of RS-232 interface

English (GB)

Fig. 13 Profibus connection diagram

Plug Signal Description

0 RTS (CNTR-P/RTS) Control signal for repeater

1 PGND Shield/protective earth

2 RxD/TxD-N

3 RxD/TxD-P

4 DP GND Ground to DP 5 V

5DP 5 V

CNTR-N Control signal for repeater

Ethernet TCP/IP

• Ethernet 10 Base-T/100 Base-TX (10/100 MBit/s).

• Transport protocol TCP or UDP connection.

• The connection is made using an RJ 45 plug of category 5.

Received data/transmitted data

Negative

Received data/transmitted data

Positive

5 V supply for terminating

resistors

TM04 8205 4510

Fig. 14 Connection diagram of RS-232 interface

5.8.2 Connection of RS-422 and -485 interfaces

Fig. 15 Connection diagram of RS-422 and-485 interfaces

TM04 8206 4510TM04 8207 4510

17

Page 18

6. Operation of control electronics

Automatic

Manual

operation

Logbook

Main menu

System choice Setup Service mode

Type 1, Type 2,

etc.

System type Language Venting

Batch mode Operation mode

Min. contact

water

Startup mode

Current input Units System choice Test mode

Contact input Current output

Manual control Code function

Target value

external

Reset function

Date/time

Exhaust

enclosure

Program

version

Bypass MIN

time

Auto start

English (GB)

6.1 Program structure

Fig. 16 Program structure

18

TM04 8208 4510

Page 19

6.2 Control and display elements

11

10

15 14 13

12

4

3

5

2

1

678

9

17

18

16

Note

Note

Fig. 17 Controller

Pos. Description

LED for dosing controller NaClO

1

• LED flashes: dosing controller set correctly

LED for NaClO

• LED off: correct level

2

• LED flashes: pre-empty alarm active

• LED on: empty alarm active

LED for bypass water

3

• LED on: bypass water is correct

• LED flashes: bypass water outside tolerance

LED for dosing controller HCl

4

• LED flashes: dosing controller set correctly

LED for HCl tank

• LED off: correct level

5

• LED flashes: pre-empty alarm

• LED on: empty alarm

6 Arrow keys for moving in the menus

Function keys

7

• [F1], [F2], and [F3]: select menu items

• [F4]: [Reset] key

[Enter] key

8

• Confirm inputs

[Escape] key

9

• Cancel or switch over to submenu

10 Display, 4-line

11 Master switch with [Emergency stop] function

LED for alarms

12

• LED on or flashing: present alarm

LED display of operation mode "automatic/manual"

13

• LED flashes: automatic control

LED for remote on/off mode

• LED flashes: remote on/off by min. contact for main

14

water

• LED on: remote on/off by external contact

LED for service mode

15

16

17

18

• LED flashes: system in [Service] menu

LED for alarms on the display

• LED on or flashing: present alarm

LED for connection of display to PLC

• LED on: connection correct

LED display

• LED on: display in operation

tank

2

2

The selection possibilities shown on the display are identified by

the numbers 1, 2, and 3, e. g.:

Main menu

1 Automatic

2 Manual operation

3 Logbook

Menu selection is made using the keys [F1], [F2], [F3], e. g. the

function key [F1] is used to select the menu item list under "1",

etc.

Example

• Press the [F1] key to switch to the menu "Automatic".

• Press the [F2] key to switch to the submenu "Manual

operation".

• Press the [F3] key to select the menu "Logbook".

• Press the [Escape] key to return to the main menu (9).

• Press the [Enter] key to confirm an input (8).

6.3 Automatic mode

TM04 8209 4510

In this operation mode the capacity of the system can be

controlled automatically by incoming signals such as contact

input, current input or Bus control.

In order to operate the system in "Automatic" mode,

it is first necessary to select the system type and the

operation mode, see section 6.6.2 Operation modes.

In "Manual control" mode there is no "Automatic" operation.

"Automatic" operation is activated in the main menu using the

[F1] key, and indicated by flashing on the display.

6.4 Manual operation

This operation mode facilitates the manual input of the dosing

capacity by the display in the modes current input, contact input,

manual control, or Bus control.

In order to operate the system in "Manual" mode, it is

first necessary to select the system type and the

operation mode.

"Manual" operation is activated in the main menu using the [F2]

key, and indicated by flashing on the display.

6.5 Logbook

In the "Logbook" menu, all activated and acknowledged alarm

messages are recorded. The operating hours can also be called

in this menu.

• In the main menu, switch to the "Logbook" submenu using the

[F3] key (Logbook).

Logbook

1 active alarms

2 event list

3 operating hours

• Use the [F1] key to display the alarm messages (if present).

• Use the [F2] key to call all events.

• The alarm messages can be deleted, if necessary.

Switching to page 2 is possible using the [ARROW RIGHT]

key, the buffer can be deleted using the [F1] key. Switching to

page 1 is possible using the [ARROW LEFT] key.

• Use the [F3] key to display the operating hours.

Scroll in the respective menu using the [UP] and [DOWN] arrow

keys.

English (GB)

19

Page 20

6.6 System choice

Note

Note

Note

Note

Note

Note

English (GB)

Define the system size and the operation mode in the "System

choice" menu.

The input can be cancelled at any time using the [Escape] key.

The activated system type or the activated mode is displayed

flashing on the display.

6.6.1 System type

• Scroll in the main menu using the [ARROW RIGHT] key on

page 2.

• Use the [F1] key to switch to the "System choice" menu.

• In the "System choice" menu, switch to the "System type"

menu using the [F1] key.

• Select the system size using the [F1], [F2] or [F3] keys, scroll if

necessary using the [ARROW RIGHT] or [ARROW LEFT] key.

After selection of the system type, the following message is

displayed:

System type

164-XXXXD

activated

• Use the [Enter] or [Escape] key to return to the "System

choice" menu.

The system is preset in the factory. The selected type

of system is displayed flashing in the "System

choice" menu.

Check this setting for correctness prior to starting up,

or select a new system type.

6.6.2 Operation modes

5 different operation modes can be selected:

• Batch mode

The performance of the system (100 %) is controlled by the

use of a buffer tank.

• Current input

The system performance (2.5 - 100 %) is controlled via an

external current input signal, e. g. 4-20 mA.

• Contact input

The system performance (2.5 - 100 %) is controlled via an

external contact input signal, e. g. from a contact water meter.

Set the contact water meter in such a way that, at

max. performance the control contacts are not < 1

contact/sec.

If, in exceptional cases, this value is < 1, min. 0.25

contacts/sec., the bypass "Min" time must be

increased.

The controller can process a maximum of

47 contacts/sec. If a value greater than

47 contacts/sec. is calculated, use a different contact

water meter.

• Target value external

The system performance (2.5 - 100 %) is controlled via a Bus

system (can only be selected, if a bus system has been

selected in the "Basic settings > Bus" menu).

The mode is factory-set, i.e. the selected mode is

displayed flashing in the "Operation mode" menu.

Check that this mode is correct before

commissioning; if necessary, select a new mode.

The entry of the parameters for current input and

contact input is described in the Section on

"Commissioning".

6.7 Units

Either metric or US units of measurement can be selected on the

system:

Metric units US units

Bypass water [m

3

/h] Bypass water [gal/h]

System capacity [g/h] System capacity [lb/day]

Contact water meter

[contacts/litre]

Contact water meter

[contacts/gal]

6.8 Setup

In the main menu, switch to the "Basic setting" menu using the

[F2] key (scroll if necessary).

6.8.1 Language

• In the "Basic setting" menu, switch to the "Language" menu

using the [F1] key.

• Select language using [ARROW RIGHT] or [ARROW LEFT]

key.

• Confirm using [Enter].

• Use the [Enter] or [Escape] key to return to the "Basic setting"

menu.

6.8.2 Min. contact water

The min. contact in the main water line (on site) switches the

system to standby, if the set minimum main water flow is fallen

below.

• In the "Basic setting" menu, select the "Min. contact water"

menu using the [F2] key.

• Activate or deactivate the function using the [F1] or [F2] key.

Min. contact main water

activated

Use the [Enter] or [Escape] key to return to the "Basic setting"

menu. The selected function is displayed flashing in the "Min.

contact water" menu.

6.8.3 Current output

• In the "Basic setting" menu, select the "Current output" menu

using the [F3] key.

Example

Default quantity of ClO

Main water quantity 30 m

2

0.3 ppm

3

/h

Contact water meter 1 contact/litre

3

Max. system capacity 0.3 ppm x 30 m

Contacts from water

meter

1 contact/litre x 30 m

1000/3600 = 8.33 contact/sec.

/h = 9 g/h

3

/h x

• Manual control

The system performance (0-100 %) is controlled by manual

input.

When "Manual control" is selected, the installation

can only be started in "Manual mode". If the

installation is started in "Automatic mode", an alarm

message is displayed, and the system stops.

20

Current output

ClO

capacity

2

0 % = XX mA

100 % = YY mA

• Press the [F1] key to select the variable input fields.

Switching between the values (0 %; XX mA; 100 %; YY mA) is

also carried out using the [F1] key.

• Enter individual values using the [UP] and [DOWN] keys

(modify numerical values) and the [ARROW LEFT] and

[ARROW RIGHT] keys (change input position).

• Confirm the set values using the [Enter] key. The selected

current output is activated by pressing the [Enter] key again.

Current output

XX - YY mA

activated

• Use the [Enter] or [Escape] key to return to the "Basic setting"

menu.

Page 21

6.8.4 Code function

Note

Note

2 different code functions can be selected:

• Level 1: Operators

Authorisation for the menus "Automatic, "Manual operation",

"Logbook" and "local/remote".

• Level 2: Parameters

unlimited privileges

Level 1 and 2 are set to "0" each. This means

unlimited privileges without password scanning.

The entered codes are reset by entering the number

"1998". Then both levels are reset to "0".

• In the "Basic setting" menu, scroll to page 2 using the

[ARROW RIGHT] key.

• Switch to "Code function" menu using the [F1] key.

Code function

1 Level 1

2 Level 2

Switch to operator selection using [F1] key.

Level 1 operator

Code: 0

• Activate the input field using [F1] key.

• Enter code (max. 4 digits) using the arrow keys [RIGHT],

[LEFT], (UP], and [DOWN].

• Confirm using [Enter] key.

• Use the [Enter] or [Escape] key to return to the "Code

function" menu.

Switch to "Level 2 Parameters" using [F2] key.

• Activate the input field using [F1] key.

• Enter code as described for "Level 1".

• Use the [Enter] or [Escape] key to return to the "Code

function" menu.

• Use [Escape] key again to return to "Basic setting" menu.

6.8.5 Reset function

In the "Basic setting" menu, select the reset function using the

[F2] key, or scroll in the "Basic setting" menu.

Reset function

Code: xxxx

Input password

• Switch to the input field using the [F1] key, enter new code

using the arrow keys [RIGHT], [LEFT], [UP], and [DOWN],

enter code.

Reset code: 6742

• Confirm using [Enter] key.

• Use the [Enter] or [Escape] key to return to the "Basic setting"

menu.

6.8.6 Date/time

In the "Basic setting" menu, select the "Date/time" menu using

the [F3] key.

Time setting

1 Time

2 Date

3 Daylight sav.

Time

• Switch to the "Time" menu using the [F1] key.

Time setting

New Current

XX:YY:ZZ 17.07.02

2 Accept

Use the [F1] key to activate the input fields for hours (XX),

minutes (YY) and seconds (ZZ) (input field flashing). Switch from

hours to minutes or seconds by pressing the [F1] key again.

• Use the [Escape] key to deactivate the input field.

Setting the time

Following activation of the respective input field using the [F1]

key, set the new value using the arrow keys [RIGHT], [LEFT],

[UP], and [DOWN].

• Confirm the new value in each case using the [Enter] key

(input field no longer flashes).

Once all values have been set and confirmed using the [Enter]

key, press the [F2] key (accept) to update the new time.

• Return to the "time setting" menu with the [escape] key,

by pressing the [escape] key once again return to the "setup"

menu.

Setting the date/day of week

• Switch to the "Date setting" menu using the [F2] key.

Date setting

New Current

XX.YY.ZZ 15.05.02

2 Accept

• Switch to the "Day of week" menu using the arrow [RIGHT]

key, and back to the "Date setting" menu using the arrow

[LEFT] key.

Day of week

New Current

XX.YY.ZZ 15.05.02

XX Monday

2 Accept

The setting is made analogous to the time setting, i.e. activate

input fields using the [F1] key, set new value using the arrow keys

[RIGHT], [LEFT], (UP], and [DOWN], and confirm with [Enter].

The new value is updated by pressing the [F2] key (accept).

• Use the [Escape] key to return to the "Time setting" menu.

Daylight saving time

• Switch to the "Daylight saving time" menu using the [F3] key.

Daylight saving time off

Switch <off>

>

• Activate the input field using the [F1] key (input field flashing).

Various settings can be selected using the [UP] and [DOWN]

arrow keys.

Settings

ON Direct switching to daylight saving time

MANUAL Manual entering of daylight saving time

EU Pre-setting of daylight saving time for EU countries

• Confirm the settings using the [Enter] key.

• Use the [Escape] key to return to the "Time setting" menu.

English (GB)

21

Page 22

MANUAL (manual daylight saving time)

Note

English (GB)

• In the "Daylight saving time" menu, switch to the "Manual

daylight saving time" menu using the [RIGHT] arrow key.

In this menu you can redefine the daylight saving time.

• Activate the input field using the [F1] key (input field flashing).

Enter the new values using the arrow keys [RIGHT], [LEFT],

[UP], and [DOWN], and confirm using the [Enter] key.

• Activate the respective input fields by pressing the [F1] key as

often as required.

Following manual setting of the daylight saving time, return to the

"Daylight saving time" menu using the [LEFT] arrow key.

• Activate the input field using the [F1] key, and select "Manual"

setting using the [UP] and [DOWN] keys.

• Confirm new setting using the [Enter] key.

• Use the [Escape] key to return to the "Time setting" menu,

and press again to return to the "Basic setting" menu.

6.8.7 Enclosure exhaust device

The enclosure exhaust device is used to regularly exchange the

air within the supporting frame. The exhaust device is

time-controlled, defined by switch-on and switch-off times.

• In the "Basic setting" menu, scroll using the [RIGHT] and

[LEFT] arrow keys.

• Switch to the "Exhaust enclosure" menu using the [F1] key.

Exhaust enclosure

1 ON/OFF <off>

2 Switch-on time

3 Switch-off time

• Activate or deactivate the injector using the [F1] key.

Switch-on time

• Switch to the "Switch-on time" menu using the [F2] key.

The switch-on time is specified in minutes (0 to 30 minutes).

• Activate the input field using the [F1] key (flashing), enter

numerical value using the [UP] and [DOWN] keys, change the

input point using the arrow [LEFT] and [RIGHT] keys.

• Confirm using [Enter] key.

• Use the [Enter] or [Escape] key to return to the "Exhaust

enclosure" menu.

Switch-off time

• Switch to the "Switch-off time" menu using the [F3] key,

the switch-off time is specified in hours (0 to 24 hours).

The input is made analogous to the input for the "switch-on time".

6.8.8 Bus options

• In the "Basic setting" menu, scroll using the [RIGHT] and

[LEFT] arrow keys.

• Use the [F2] key to switch to the "Bus options" menu.

Bus options

1 Profibus DP

2 Modbus

3 no bus >

For Ethernet, switch to display page 2.

• Select bus system using the [F2] or [F3] key.

• Use the [Enter] and [Escape] key to return to the "Basic

setting" menu.

6.8.9 Program version

• In the "Basic setting" menu, switch to the "Program version"

menu using the [F2] key.

Hardware C16 x_01

Software

SPS: ......

OP: ......

• Use the [Enter] or [Escape] key to return to the "Basic setting"

menu.

• Use the [Escape] key to return to the main menu.

6.8.10 Bypass MIN time

• In the "Basic setting" menu, switch to the "Bypass MIN time"

menu using the [F1] key.

Bypass MIN time

new XXX s

current XXX s

2 Accept

The bypass MIN time is factory-set to 60 seconds.

This time can be adjusted between 20 and

210 seconds.

Changing the bypass MIN time

• Activate the input field using the [F1] key (flashing), enter

numerical value using the [UP] and [DOWN] keys, change the

input point using the arrow [LEFT] and [RIGHT] keys.

• Confirm using [Enter] key.

• Accept the new setting using the [F2] key. The "New" and

"Current" values are now identical.

6.8.11 Auto start

This function is used to perform an automatic system restart.

This is required, if the system’s bypass water supply becomes

compromised as a result of pressure fluctuations (bypass water

undershoots the MIN limit) or if the bypass water overshoots the

MAX limit.

The system will restart automatically following a set pause time.

The number of start attempts (cycles) is configurable.

No. of cycles: 0-10

Pause time: 1-10 minutes

"Automatic start" function is not activated, when the number of

cycles is set to 0.

If the bypass water supply remains compromised after the set

number of cycles has elapsed, an alarm message will be output

("bypass water MIN" or "bypass water MAX").

In the "Basic setting" menu, switch to the "Automatic start" menu.

Auto start

Cycles xxx

Pause time xxx min

2 Accept

22

Page 23

6.8.12 Startup mode

Note

Note

Note

The startup mode is used to fill the reactor with water. The dosing

pumps can be gauged, and the dosing controllers can be

readjusted at the same time.

• In the "Service mode" menu, switch to the "Startup mode"

menu using the [F2] key.

Startup mode

1 Batch concentration

2 Bypass water

3 Start

• Use the [F2] key to switch to the "Bypass water" menu.

2 Bypass water <off>

setpt.: 420 l/h

actual: 0 l/h

1 Limit -xx %/+xxx % >

• Activate or deactivate the bypass using the [F1] key.

The "setpt." value shows what quantity of water is required

(depending on system size). The "actual" value shows the current

water flow, "Limit" defines the minimum and maximum bypass

water quantities.

• Switch to the impeller counter contacts display using the arrow

[RIGHT] key.

Bypass water

Pulses XX.X lmp./s

Water YYY l/h

2 Accept <

Warning

Enter a new quantity of water using the [F1] key only

in case of batch concentration error, see section

9. Maintenance!

If this input is used incorrectly, the factory settings

can be restored using the reset function.

• Use the arrow [LEFT] key to return to the "Bypass water

ON/OFF" menu.

• Use the [Escape] key to return to the "Startup mode" menu.

• Use the [F3] key to switch to the "Startup mode/Start?" menu.

Startup mode

Start?

Use the [Enter] key to start the startup mode (startup time approx.

13 minutes).

Startup mode can be cancelled at any time using the

[Escape] key.

The remaining time during which the system is in startup mode is

output on the display. The system switches off automatically at

the end of the startup time.

Startup mode

finished

6.8.13 Test mode

The Test mode permits checking of current output, relay, display

and LEDs.

Current output

In the "Service mode" menu, switch to the "Test mode" menu

using the [F3] key.

• In the "Test mode" menu, switch to "Test current output" using

the [F1] key.

Check the individual current outputs using the [F1] to [F3] keys.

• Activate the current outputs using the [F1], [F2] and [F3] keys.

• Deactivate using the [Escape] key, returning to the "Test

mode" menu.

Relay

Checking of relays for: NaClO

exhaust system, automatic/manual, error message, pre-empty

pump, HCl pump, bypass,

2

and dry-run.

• Activate using the [F1] to [F3] keys, scrolling if necessary;

Deactivate by pressing the [F1] to [F3] keys again.

• Use the [Escape] key to return to the "Test mode" menu.

Display

• In the "Test mode" menu, switch to the display test using the

[F3] key.

• Set the contrast using the [UP] and [DOWN] keys.

• Activate using the [Enter] key.

• Deactivate using the [Enter] key (press 2x), or the [Escape]

key.

• Use the [Escape] key to return to the "Test mode" menu.

LED

• In the "Test mode" menu, scroll using the arrow [RIGHT] and

[LEFT] keys, and switch over to the LED test using the [F1]

key.

• Activate using the [Enter] key.

• Deactivate using the [Enter] or the [Escape] key.

• Use the [Escape] key to return to the "Service mode" menu or

to the main menu.

6.9 Local/remote

The "local/remote" menu is only displayed, if a bus

system was selected in the "setup/Bus" menu.

• Scroll with the arrow [RIGHT] key in the main menu.

• Use the [F1] key to switch to the "local/remote" menu.

Local/remote

1 local control

2 remote control

Select control mode using the [F1] or [F2] key.

local control/remote control

activated

Use the [Enter] or [Escape] key to return to the main menu.

• Local control: operation and control of the system on site

• Remote control: control of the system via a bus system.

English (GB)

If the Startup mode is cancelled prematurely and

then restarted, the startup time commences again at

approx. 20 minutes.

• Use the [Escape] key to return to the "Service mode" menu.

23

Page 24

7. Commissioning

Note

Note

Note

Note

Note

Note

English (GB)

The system should always be commissioned with

water. To do this, immerse both suction lines into a

tank filled with water.

Commissioning must only be carried out by

authorized specialists.

7.1 Directives

As a result of the applicable accident prevention regulations,

chlorine dioxide systems may only be commissioned when their

correct condition has been checked by a specialist.

The chlorine dioxide systems must be checked by a specialist

each time they are restarted. This test must be repeated every 6

to 12 months according to the regulations.

Only persons who have been appropriately trained may be

commissioned with operation and maintenance of the chlorine

dioxide systems and the handling of chemicals.

Commissioning must only be carried out by trained specialists

using appropriate instructions.

7.2 System choice

Define the system size and the operation mode in the "System

choice" menu.

• The input can be cancelled at any time using the [Escape] key.

• Use the arrow [right] key in the main menu to switch to page 2

in the display.

Main menu <

1 System choice

2 Basic settings

3 Service mode >

• Use the [F1] key to switch to the "System choice" menu.

System choice

1 System type

2 Operation mode

• In the "System choice" menu, switch to the "System type"

menu using the [F1] key.

• Press [F1], [F2] or [F3] to select the system size. If necessary,

scroll to the left or right using the arrow keys.

The preset system size is displayed flashing;

if necessary select a new size.

Once the system type has been selected, the following message

appears on the display:

System type

OCD-164-XXXD

activated

• Use the [Enter] or [Escape] key to return to the "System

choice" menu.

7.3 Selection of operation mode

The chlorine dioxide system can be operated in four different

modes:

• Batch mode

• Current input

• Contact input

• Manual control

• Target value external

The preset mode is displayed flashing; if necessary

select a new mode.

When "Manual control" is selected, the installation

can only be started in "Manual mode". If the

installation is started in "Automatic mode", an alarm

message is displayed, and the system stops.

Main menu

Main menu

1 Automatic

2 Manual operation

3 Logbook >

• Switching to page 2 is possible using the arrow [RIGHT] key.

Display page 2

Main menu <

1 System choice

2 Basic settings

3 Service mode >

• Use the [F1] key to switch to the "System choice" menu.

System choice

1 System type

2 Operation mode

• Use the [F2] key to switch to the "Operation mode" menu.

Display page 1

Operation mode

1 Batch mode

2 Current input

3 Contact input >

If necessary, use the arrow key to scroll to page 2.

Display page 2

Operation mode

1 Manual control

2 Target value ext.

The "Target value ext." menu option is only visible if a

bus system has been selected in the "Basic

settings/bus options" menu.

24

Page 25

7.3.1 Batch mode

Note

Note

Note

Note

Note

Activating the operation mode "Others"

• In the "Operation mode" menu, switch to the "Others" menu

using the [F1] key.

Batch mode

activated

• Use the [Enter] and [Escape] key to return to the "System

choice" menu.

Ensure that the level contacts of the batch containers

are connected and correctly set up. Faulty settings

may result in error messages in the batch mode.

Setting the concentration

• Use the [Escape] key to switch to the "Main menu", display

page 2.

Main menu <

1 System choice

2 Basic settings

3 Service mode >

• Use the [F3] key to switch to the "Service mode" menu.

Service mode

1 Venting

2 Startup mode

3 Test mode