Grundfos LME Series, LMDE Series, LPE Series, LPDE Series, TPE Series Installation And Operating Instructions Manual

...Page 1

LM(D)E, LP(D)E, TPE(D), NKE,

GRUNDFOS INSTRUCTIONS

NBE, CLME, 1~ and

Installation and operating instructions

Montage- und Betriebsanleitung

Notice d’installation et d’entretien

Istruzioni di installazione e funzionamento

Instrucciones de instalación y funcionamiento

Instruções de instalação e funcionamento

√‰ЛБ›В˜ ВБО·Щ¿ЫЩ·ЫЛ˜ О·И ПВИЩФ˘ÚÁ›·˜

Installatie- en bedieningsinstructies

Monterings- och driftsinstruktion

Asennus- ja käyttöohjeet

Monterings- og driftsinstruktion

3

~

Page 2

Declaration of Conformity

We GRUNDFOS declare under our sole responsibility that the products

LM(D)E, LP(D)E, TPE(D), NKE, NBE and CLME, to which this declaration

relates, are in conformity with the Council Directives on the approximation

of the laws of the EEC Member States relating to:

– Machinery (98/37/EEC).

Standard used: EN 292.

– Electromagnetic compatibility (89/336/EEC).

Standard used: EN 61 800-3.

– Electrical equipment designed for use within certain voltage limits

(73/23/EEC).

Standards used: EN 60 335-1 and EN 60 335-2-51.

Konformitätserklärung

Wir GRUNDFOS erklären in alleiniger Verantwortung, daß die Produkte

LM(D)E, LP(D)E, TPE(D), NKE, NBE und CLME, auf die sich diese Er-

klärung bezieht, mit den folgenden Richtlinien des Rates zur Angleichung

der Rechtsvorschriften der EG-Mitgliedstaaten übereinstimmen:

– Maschinen (98/37/EWG).

Norm, die verwendet wurde: EN 292.

– Elektromagnetische Verträglichkeit (89/336/EWG).

Norm, die verwendet wurde: EN 61 800-3.

– Elektrische Betriebsmittel zur Verwendung innerhalb bestimmter

Spannungsgrenzen (73/23/EWG).

Normen, die verwendet wurden: EN 60 335-1 und EN 60 335-2-51.

Déclaration de Conformité

Nous GRUNDFOS déclarons sous notre seule responsabilité que les produits LM(D)E, LP(D)E, TPE(D), NKE, NBE et CLME auxquels se réfère

cette déclaration sont conformes aux Directives du Conseil concernant le

rapprochement des législations des Etats membres CEE relatives à

– Machines (98/37/CEE).

Standard utilisé: EN 292.

– Compatibilité électromagnétique (89/336/CEE).

Standard utilisé: EN 61 800-3.

– Matériel électrique destiné à employer dans certaines limites de ten-

sion (73/23/CEE).

Standards utilisés: EN 60 335-1 et EN 60 335-2-51.

Declaración de Conformidad

Nosotros GRUNDFOS declaramos bajo nuestra única responsabilidad

que los productos LM(D)E, LP(D)E, TPE(D), NKE, NBE y CLME a los

cuales se refiere esta declaración son conformes con las Directivas del

Consejo relativas a la aproximación de las legislaciones de los Estados

Miembros de la CEE sobre

– Máquinas (98/37/CEE).

Norma aplicada: EN 292.

– Compatibilidad electromagnética (89/336/CEE).

Norma aplicada: EN 61 800-3.

– Material eléctrico destinado a utilizarse con determinados límites de

tensión (73/23/CEE).

Normas aplicadas: EN 60 335-1 y EN 60 335-2-51.

¢‹ÏˆÛË ™˘ÌÌfiÚʈÛ˘

∂Ì›˜ Ë GRUNDFOS ‰ЛПТУФ˘МВ МВ ·рФОПВИЫЩИО¿ ‰ИО‹ М·˜ В˘ı‡ÓË fiÙÈ

Ù· ðÚÔÈfiÓÙ· LM(D)E, LP(D)E, TPE(D), NKE, NBE Î·È CLME Û˘Ì-

МФЪКТУФУЩ·И МВ ЩЛУ √‰ËÁ›· ÙÔ˘ ™˘Ì‚Ô˘Ï›Ô˘ Вр› ЩЛ˜ Ы‡БОПИЫЛ˜ ЩˆУ

УfiÌˆÓ ÙˆÓ ∫Ú·ÙÒÓ MÂÏÒÓ Ù˘ ∂˘Úˆð·È΋˜ ∂ÓˆÛ˘ Û ۯ¤ÛË Ì ٷ:

– ªË¯·Ó‹Ì·Ù· (98/37/EEC).

¶ÚfiÙ˘ðÔ ðÔ˘ ¯ЪЛЫИМФрФИ‹ıËÎÂ: EN 292.

– ∏ПВОЩЪФМ·БУЛЩИО‹ Ы˘Ì‚·ÙfiÙËÙ· (89/336/EEC).

¶ÚfiÙ˘ðÔ ðÔ˘ ¯ЪЛЫИМФрФИ‹ıËÎÂ: EN 61 800-3.

– ∏ПВОЩЪИО¤˜ Ы˘Û΢¤˜ ۯ‰ȷṲ̂Ó˜ ÁÈ¿ ¯Ú‹ÛË ÂÓÙfi˜ ФЪИЫМ¤УˆУ

ФЪ›ˆУ ЛПВОЩЪИО‹˜ Щ¿ЫЛ˜ (73/23/EEC).

¶ЪfiÙ˘ð· ðÔ˘ ¯ЪЛЫИМФрФИ‹ıËηÓ: EN 60 335-1 Î·È EN 60 335-2-51.

Dichiarazione di Conformità

Noi GRUNDFOS dichiariamo sotto la nostra esclusiva responsabilità che

i prodotti LM(D)E, LP(D)E, TPE(D), NKE, NBE e CLME, ai quali questa

dichiarazione si riferisce, sono conformi alle direttive del Consiglio, concernenti il ravvicinamento delle legislazioni degli Stati membri CEE relativi

a

– Macchine (98/37/CEE).

Standard usato: EN 292.

– Compatibilità elettromagnetica (89/336/CEE).

Standard usato: EN 61 800-3.

– Materiale elettrico destinato ad essere utilizzato entro certi limiti di

tensione (73/23/CEE).

Standard usati: EN 60 335-1 e EN 60 335-2-51.

Declaração de conformidade

Nós GRUNDFOS declaramos sob nossa responsabilidade que os produtos LM(D)E, LP(D)E, TPE(D), NKE, NBE e CLME, aos quais esta declaração se refere, estão em conformidade com as Directivas Comunitárias

com aproximação das leis dos estados membros da CEE para:

– Máquinas (98/37/CEE).

Norma usada: EN 292.

– Compatibilidades Electromagnéticas (89/336/CEE).

Norma usada: EN 61 800-3.

– Equipamento Eléctrico desenhado para uso de certos limites de tensão

(73/23/CEE).

Norma usada: EN 60 335-1 e EN 60 335-2-51.

Overeenkomstigheidsverklaring

Wij GRUNDFOS verklaren geheel onder eigen verantwoordelijkheid dat

de produkten LM(D)E, LP(D)E, TPE(D), NKE, NBE en CLME waarop

deze verklaring betrekking heeft in overeenstemming zijn met de Richtlijnen van de Raad inzake de onderlinge aanpassing van de wetge vingen

van de Lid-Staten betreffende

– Machines (98/37/EEG).

Norm: EN 292.

– Elektromagnetische compatibiliteit (89/336/EEG).

Norm: EN 61 800-3.

– Elektrisch materiaal bestemd voor gebruik binnen bepaalde spannings-

grenzen (73/23/EEG).

Normen: EN 60 335-1 en EN 60 335-2-51.

Försäkran om överensstämmelse

Vi GRUNDFOS försäkrar under ansvar, att produkterna LM(D)E, LP(D)E,

TPE(D), NKE, NBE och CLME, som omfattas av denna försäkran, är i

överensstämmelse med Rådets Direktiv om inbördes närmande till EUmedlemsstaternas lagstiftning, avseende

– Maskinell utrustning (98/37/EC).

Använd standard: EN 292.

– Elektromagnetisk kompatibilitet (89/336/EC).

Använd standard: EN 61 800-3.

– Elektrisk material avsedd för användning inom vissa spänningsgränser

(73/23/EC).

Använda standarder: EN 60 335-1 och EN 60 335-2-51.

Overensstemmelseserklæring

Vi GRUNDFOS erklærer under ansvar, at produkterne LM(D)E, LP(D)E,

TPE(D), NKE, NBE og CLME, som denne erklæring omhandler, er i over-

ensstemmelse med Rådets direktiver om indbyrdes tilnærmelse til EF

medlemsstaternes lovgivning om:

– Maskiner (98/37/EEC).

Anvendt standard: EN 292.

– Elektromagnetisk kompatibilitet (89/336/EEC).

Anvendt standard: EN 61 800-3.

– Elektrisk materiel bestemt til anvendelse inden for visse

spændingsgrænser (73/23/EEC).

Anvendte standarder: EN 60 335-1 og EN 60 335-2-51.

2

Vastaavuusvakuutus

Me GRUNDFOS vakuutamme yksin vastuullisesti, että tuotteet LM(D)E,

LP(D)E, TPE(D), NKE, NBE ja CLME, jota tämä vakuutus koskee, nou-

dattavat direktiivejä jotka käsittelevät EY:n jäsen valtioiden koneellisia laitteita koskevien lakien yhdenmukaisuutta seur.:

– Koneet (98/37/EY).

Käytetty standardi: EN 292.

– Elektromagneettinen vastaavuus (89/336/EY).

Käytetty standardi: EN 61 800-3.

– Määrättyjen jänniterajoitusten puitteissa käytettävät sähköiset laitteet

(73/23/EY).

Käytetyt standardit: EN 60 335-1 ja EN 60 335-2-51.

Bjerringbro, 1st January 2002

Jan Strandgaard

Technical Manager

Page 3

LM(D)E, LP(D)E, TPE(D), NKE,

NBE, CLME, 1~ and

Installation and

operating instructions

Montage- und

Betriebsanleitung

Notice d’installation

et d’entretien

Istruzioni di installazione

e funzionamento

3

~

Page 4

Seite 21

Page 39

Pag. 56

Instrucciones de instalación

y funcionamiento

Instruções de instalação

e funcionamento

√‰ЛБ›В˜ ВБО·Щ¿ЫЩ·ЫЛ˜

О·И ПВИЩФ˘ÚÁ›·˜

Installatie- en

bedieningsinstructies

Monterings- och

driftsinstruktion

Pág. 73

Pág. 90

™ÂÏ›‰· 107

Pag. 124

Sida 141

Asennus- ja

käyttöohjeet

Monterings- og

driftsinstruktion

Sivu 158

Side 175

3

Page 4

CONTENTS

Page

1. General 4

1.1 Twin-head pumps 4

2. Installation 4

2.1 Electrical connection – single-phase pumps 5

2.1.1 Mains switch 5

2.1.2 Protection against electric shock – indirect contact 5

2.1.3 Additional protection 5

2.1.4 Motor protection 5

2.1.5 Overvoltage protection 5

2.1.6 Supply voltage 5

2.1.7 Start/stop of pump 5

2.2 Electrical connection – three-phase pumps 6

2.2.1 Mains switch 6

2.2.2 Protection against electric shock – indirect contact 6

2.2.3 Additional protection 6

2.2.4 Motor protection 6

2.2.5 Overvoltage protection 6

2.2.6 Supply voltage 6

2.2.7 Start/stop of pump 6

2.3 Other connections – single-phase pumps 7

2.4 Other connections – single-phase TPED pumps 7

2.5 Other connections – three-phase pumps 8

2.6 Signal cables 8

3. Setting the pump 9

3.1 Control modes 9

3.2 Operating modes 9

3.2.1 Additional operating modes – single-phase TPED

pumps 9

3.3 Factory setting 10

3.4 Factory setting – single-phase TPED pumps 10

4. Setting by means of control panel 10

4.1 Setpoint setting 10

4.2 Setting to max. curve duty 11

4.3 Setting to min. curve duty 11

4.4 Start/stop of pump 11

5. Setting by means of R100 12

5.1 Menu OPERATION 13

5.1.1 Setpoint setting 13

5.1.2 Setting of operating mode 13

5.1.3 Fault indications 13

5.1.4 Alarm log 13

5.2 Menu STATUS 13

5.2.1 Display of actual setpoint 13

5.2.2 Display of operating mode 13

5.2.3 Display of actual value 13

5.2.4 Display of actual speed 14

5.2.5 Display of input power and power consumption 14

5.2.6 Display of operating hours 14

5.3 Menu INSTALLATION 14

5.3.1 Selection of control mode 14

5.3.2 Setting of controller 14

5.3.3 Selection of external setpoint signal 15

5.3.4 Selection of fault, operating or ready signal relay 15

5.3.5 Blocking of the buttons on the pump 15

5.3.6 Allocation of pump number 15

5.3.7 Selection of function for digital input 15

5.3.8 Setting of sensor 15

5.3.9 Setting of min. and max. curves 15

6. External forced-control signals 16

6.1 Start/stop input 16

6.2 Digital input 16

7. External setpoint signal 16

8. Bus signal 16

9. Priority of settings 17

10. Indicator lights and signal relay 18

11. Megging 18

12. Technical data – single-phase pumps 19

12.1 Supply voltage 19

12.2 Leakage current 19

12.3 Inputs/output 19

13. Technical data – three-phase pumps 19

13.1 Supply voltage 19

13.2 Leakage current 19

13.3 Inputs/output 19

13.4 Other technical data 20

14. Disposal 20

Before beginning installation procedures, these installation and operating instructions should be studied carefully. Furthermore, the enclosed installa-

tion and operating instructions for the standard

pump should be studied carefully. The installation

and operation should also be in accordance with local regulations and accepted codes of good practice.

1. General

GRUNDFOS E-pumps are pumps fitted with frequency-controlled

standard motors for single-phase or three-phase mains connection.

The pumps have a built-in PI controller and can be connected to

an external sensor enabling control of for instance pressure, differential pressure, temperature, differential temperature or flow in

the system in which the pumps are installed. The pumps can be

set to uncontrolled operation, i.e. the pump performance can be

set according to the demand.

The pumps are typically used as circulator pumps in large heating

or cooling water systems with variable demands.

The desired value (setpoint), e.g. the desired differential pressure

if a differential pressure sensor has been installed, can be set directly on the pump control panel, via an input for external setpoint

signal or by means of the GRUNDFOS wireless remote control

R100.

All other settings are made by means of the R100.

Important parameters such as actual value of control parameter,

power consumption, etc. can be read via the R100.

The pump incorporates inputs for external potential-free contacts

for start/stop and digital function. The digital function enables external setting of max. curve or min. curve.

The pump incorporates an output for a potential-free fault, operating or ready signal.

Furthermore, the pump has an input for bus communication. Via

the bus communication input, the pump can be controlled and

monitored by a building management system or another external

control system.

1.1 Twin-head pumps

Single-phase twin-head pumps do not require any external controller.

Three-phase twin-head pumps usually require an external controller. The GRUNDFOS Delta Control 2000 ME has been developed for this application.

For further details about the setting and connection of threephase twin-head pumps, see installation and operating instructions for the Delta Control 2000 ME.

2. Installation

To ensure cooling of motor and electronics, the following must be

observed:

• Place the pump in such a way that sufficient cooling is ensured.

• The temperature of the cooling air must not exceed 40°C.

• Motor cooling fins and fan bl ades must be kept clean.

When installed outdoors, the motor must be provided with a suitable cover to avoid condensation on the electronic components,

fig. 1.

4

Page 5

Fig. 1

Figure 2 shows an example of a mains-connected pump with

mains switch, back-up fuses and additional protection.

Fig. 2

MGE 71 and MGE 80

For further installation, see installation and operating instructions

for the standard pump.

2.1 Electrical connection – single-phase pumps

Note: The user or the installer is responsible for the installation of

the correct earthing and protection according to valid national and

local standards. All operations must be carried out by a qualified

electrician.

Never make any connections in the pump terminal

box unless the electricity supply has been switched

off for at least 5 minutes.

2.1.1 Mains switch

The pump must be connected to an external all-pole mains switch

with a contact separation of at least 3 mm in each pole according

to IEC 364.

2.1.2 Protection against electric shock – indirect contact

The pump must be earthed and protected against

indirect contact in accordance with national regulations.

Protective earth conductors must always have a yellow/green

(PE) or yellow/green/blue (PEN) colour marking.

2.1.3 Additional protection

If the pump is connected to an electric installation where an earth

leakage circuit breaker is used as additional protection, this circuit breaker must be marked with the following symbol:

N

ELCB

L

TM02 0789 0101

PE

Actual mains connection is shown in figs. 3 and 4.

Max. 10 A

Fig. 3

MGE 71 and MGE 80

I

Fig. 4

TPED - MGE 71 and MGE 80

I

N

PE

L

TM02 0792 0101TM02 0827 4702TM02 5990 4702

L

PE

N

ELCB

Note: When an earth leakage circuit breaker is selected, the total

leakage current of all the electrical equipment in the installation

must be taken into account.

The leakage current of the pump can be found in section

12.2 Leakage current.

2.1.4 Motor protection

The pump requires no external motor protection. The motor incorporates thermal protection against slow overloading and blocking

(IEC 34-11: TP 211).

2.1.5 Overvoltage protection

The pump is overvoltage-protected through built-in varistors between phase-neutral and phase-earth.

2.1.6 Supply voltage

1 x 200-240 V ±10%, 50/60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Please make sure that the motor is suitable for the

electricity supply on which it will be used.

The wires in the pump terminal box must be as short as possible.

Excepted from this is the protective earth conductor which must

be so long that it is the last one to be disconnected in case the

cable is inadvertently pulled out of the cable entry.

L

PE

N

2.1.7 Start/stop of pump

The number of starts and stops via the mains voltage must not

exceed 4 times per hour.

When the pump is switched on via the mains, it will start after approx. 5 seconds.

If a higher number of starts and stops is desired, the input for external start/stop must be used when starting/stopping the pump.

When the pump is started/stopped via an external on/off switch, it

will start immediately.

5

Page 6

2.2 Electrical connection – three-phase pumps

Note: The user or the installer is responsible for the installation of

the correct earthing and protection according to valid nation al and

local standards. All operations must be carried out by a qualified

electrician.

Never make any connections in the pump terminal

box unless the electricity supply has been switched

off for at least 5 minutes.

2.2.1 Mains switch

The pump must be connected to an external all-pole main s switch

with a contact separation of at least 3 mm in each pole according

to IEC 364.

2.2.2 Protection against electric shock – indirect contact

The pump must be earthed and protected against

indirect contact in accordance with national regulations.

Protective earth conductors must always have a yellow/green

(PE) or yellow/green/blue (PEN) colour marking.

Note: As the leakage current of 4 kW to 7.5 kW motors is

> 3.5 mA, these motors must be connected to especially

reliable/sturdy earth connections.

The leakage current of the individual motor size can be found in

section 13.2 Leakage current.

EN 50 178 and BS 7671 specify the following:

Leakage current > 3.5 mA:

The pump must be stationary and installed permanently. Furthermore, the pump must be connected permanently to the electricity

supply or may be connected via an industrial type of plug (CEE).

The plug must comply with EN 60 309 or IEC 309.

• The earth connection must be carried out as duplicate conductors.

2.2.3 Additional protection

If the pump is connected to an electric installation where an earth

leakage circuit breaker is used as additional protection, this circuit breaker must be of the type:

• which is suitable for handling leakage currents and cutting-in

with short pulse-shaped leakage.

• which trips out when alternating fault currents and fault currents with DC content, i.e. pulsating DC and smooth DC fault

currents, occur.

For these pumps an earth leakage circuit breaker type B m ust be

used.

This circuit breaker must be marked with the following symbols:

ELCB

2.2.6 Supply voltage

3 x 380-415 V ±10%, 50/60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Please make sure that the motor is suitable for the

electricity supply on which it will be used.

The wires in the pump terminal box must be as short as possible.

Excepted from this is the protective earth conductor which must

be so long that it is the last one to be disconnected in case the

cable is inadvertently pulled out of the cable entry.

Figure 5 shows an example of a mains-connected pump with

mains switch, back-up fuses and additional protection.

Fig. 5

MGE 90 to MGE 132

L1

ELCB

L2

L3

PE

Max. 16/32 A

L1

L2

L3

Actual mains connection is shown in figs. 6 and 7.

Fig. 6

MGE 90 and MGE 100

L1

L2

L3

L1

L2

L3

Fig. 7

MGE 112 and MGE 132

L1

L2

L3

L1

L2

L3

TM00 9270 4696

TM00 7631 1596

TM00 7665 1696

Note: When an earth leakage circuit breaker is selected, the tota l

leakage current of all the electrical equipment in the installation

must be taken into account.

The leakage current of the pump can be found in section

13.2 Leakage current.

2.2.4 Motor protection

The pump requires no external motor protection. The motor incorporates thermal protection against slow overloading and blocking

(IEC 34-11: TP 211).

2.2.5 Overvoltage protection

The pump is overvoltage-protected through built-in varistors between the phases and between phases and earth.

6

2.2.7 Start/stop of pump

The number of starts and stops via the mains voltage must not

exceed 4 times per hour.

When the pump is switched on via the mains, it will start after approx. 5 seconds.

If a higher number of starts and stops is desired, the input for external start/stop must be used when starting/stopping the pump.

When the pump is started/stopped via an external on/off switch , it

will start immediately.

Page 7

2.3 Other connections – single-phase pumps

Note: For single-phase TPED pumps, see section 2.4 Other con-

nections – single-phase TPED pumps.

The connection terminals of external potential-free contacts for

start/stop and digital function, external setpoint signal, sensor signal, GENIbus and relay signal are shown in fig. 8.

Note: If no external on/off switch is connected, short-circuit terminals 2 and 3 using a short wire.

Note: As a precaution, the wires to be connected to the following

connection groups must be separated from each other by reinforced insulation in their entire lengths:

1. Inputs (external start/stop, digital function, setpoint and sensor signals, terminals 1-9, and bus connection, B, Y, A).

All inputs (group 1) are internally separated from the mainsconducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied by protective extra-low voltage (PELV), thus ensuring protection against electric shock.

2. Output (relay signal, terminals NC, C, NO).

The output (group 2) is galvanically separated from other cir-

cuits. Therefore, the supply voltage or protective extra-low

voltage can be connected to the output as desired.

3. Supply voltage (terminals N, PE, L).

A galvanically safe separation must fulfil the requirements for reinforced insulation including creepage distances and clearances

specified in EN 50 178.

Fig. 8

MGE 71 and MGE 80

Group

NC C NO N PE L

2

Group 3

2.4 Other connections – single-phase TPED pumps

The connection terminals of external potential-free contacts for

start/stop and digital function, external setpoint signal, sensor signal, GENIbus, relay signal and communication cable are shown in

fig. 9.

Note: If no external on/off switch is connected, short-circuit terminals 2 and 3 using a short wire.

Note: As a precaution, the wires to be connected to the following

connection groups must be separated from each other by reinforced insulation in their entire lengths:

1. Inputs (external start/stop, digital function, setpoint and sensor signals, terminals 1-9, and bus connection, B, Y, A).

All inputs (group 1) are internally separated from the mainsconducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied by protective extra-low voltage (PELV), thus ensuring protection against electric shock.

2. Output (relay signal, terminals NC, C, NO).

The output (group 2) is galvanically separated from other cir-

cuits. Therefore, the supply voltage or protective extra-low

voltage can be connected to the output as desired.

3. Supply voltage (terminals N, PE, L).

4. Communication cable (8-pin male socket).

The communication cable is connected to the socket in group

4. The cable ensures communication between the two pumps,

whether one or two pressure sensors are connected, see section 2.6 Signal cables.

The selector switch in group 4 enables changeover between

the operating modes “alternating operation” and “standby operation”. See description in section 3.2.1 Additional operating

modes – single-phase TPED pumps.

A galvanically safe separation must fulfil the requirements for reinforced insulation including creepage distances and clearances

specified in EN 50 178.

Fig. 9

0-10 V

0/4-20 mA

0/1

0/4-20 mA 0-10 V

4-20 mA

STOP

RUN

10K

1987

65432

BYA

1: Digital input

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Scree n

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

TM02 0795 4702

Group

4

0-10 V

0/4-20 mA

0/4-20 mA 0-10 V

4-20 mA

0/1

BYA

MGE 71 and MGE 80

NC C NO

1987

STOP

RUN

10K

65432

Group

2

1: Digital input

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Scree n

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 3

NPEL

Group 1

TM02 6009 0703

7

Page 8

2.5 Other connections – three-phase pumps

The connection terminals of external potential-free contacts for

start/stop and digital function, external setpoint si gn al, sensor sig nal, GENIbus and relay signal are shown in figs. 10 and 11.

Note: If no external on/off switch is connected, short-circuit terminals 2 and 3 using a short wire.

Note: As a precaution, the wires to be connected to the following

connection groups must be separated from each other by reinforced insulation in their entire lengths:

1. Inputs (external start/stop, digital function, setpoint and sensor signals, terminals 1-8, and bus connection, A, Y, B).

All inputs (group 1) are internally separated from the mainsconducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied by protective extra-low voltage (PELV), thus ensuring protection against electric shock.

2. Output (relay signal, terminals NC, NO, C).

The output (group 2) is galvanically separated from other cir-

cuits. Therefore, the supply voltage or protective extra-low

voltage can be connected to the output as desired.

3. Supply voltage (terminals L1, L2, L3).

A galvanically safe separation must fulfil the requirements for reinforced insulation including creepage distances and clearances

specified in EN 50 178.

Fig. 10

MGE 90 and MGE 100

0/4-20 mA

0-5/10 V

0/4-20 mA

0-5/10 V

CNONC

4-20 mA

10 k

Signal relay

8: +24 V

7: Sensor input

6: GND (frame)

5: +5 V

4: Setpoint input

3: GND (frame)

2: Start/stop

1: Digital input

A: RS-485A

Y: Screen

B: RS-485B

Group 1

Group 2

Fig. 11

MGE 112 and MGE 132

0/4-20 mA

0-5/10 V

0/4-20 mA

0-5/10 V

4-20 mA

10 k

8: +24 V

7: Sensor input

6: GND (frame)

5: +5 V

4: Setpoint input

3: GND (frame)

2: Start/stop

1: Digital input

A: RS-485A

Y: Screen

B: RS-485B

Group 1

Group 2

NC

NO

C

L1

L2

Signal relay

Group 3

Mains

connection

L3

2.6 Signal cables

• Use screened cables having a cross-sectional area of min.

0.5 mm² and max. 1.5 mm² for external on/off switch, digital input, setpoint and sensor signals.

• The screens of the cables must be connected to frame at both

ends with good frame connection. They must be as close as

possible to the terminals, fig. 12.

Fig. 12

TM00 7666 1002

L1

L2

L3

Mains

connection

Group 3

TM00 6788 0101

TM00 7667 1696

• Screws for frame connections must always be tightened

whether a cable is fitted or not.

• The wires in the pump terminal box must be as short as possible.

For the bus connection a screened 2-core cable must be used.

Connect the screen to terminal Y at both ends, fig. 13.

Fig. 13

Y

TM00 7601 0101

8

Page 9

Communication cable for single-phase TPED pumps only:

Connect the communication cable between the two pump heads.

A good frame connection near the cable clamp must be made.

See also the above description.

Fig. 14

When connecting the communication cable, the following m ust be

observed:

If one sensor is connected , insert the communication ca ble plugs

into the sockets in the terminal boxes as shown in fig. 15.

Fig. 15

3. Setting the pump

3.1 Control modes

E-pumps can be set to two control modes, i.e:

• controlled-operation or

• uncontrolled-operation.

In controlled-operation mode, the pump will adjust its perform-

ance to the desired setpoint for the control parameter (pressure,

differential pressure, temperature, differential temperature or

flow). Figure 18 shows a differential-pressure controlled pump as

an example of controlled operation.

In uncontrolled-operation mode, the pump will operate according to the constant curve set.

TM02 5991 4702

Fig. 18

Controlled operation

H

H

set

Uncontrolled operation

H

If two sensors are connected, cut the red wire, see fig. 16.

Fig. 16

If one sensor is connected, it is connected to t he master pu mp to

the left of the flow direction.

If two sensors are connected, one sensor is connected to the

master pump (to the left of the flow direction) and the other to the

slave pump, see fig. 17.

Fig. 17

Master

Master

Q

The pumps have been factory-set to uncontrolled operation, see

section 3.3 Factory setting.

3.2 Operating modes

The following operating modes can be selected:

•Stop,

•Min.,

TM02 6012 4702TM02 6013 4702TM02 6014 4702

• Normal (controlled or uncontrolled operation),

•Max.

The operating modes can all be set on the pump control panel.

Fig. 19

The min. curve can be used in periods in which a minimum flow is

required.

The max. curve can for instance be used in connection with the

venting procedure during installation.

If the electricity supply to the pump is disconnected, the pump

setting will be stored.

The remote control R100 offers additional possibilities of setting

and status displays, see section 5. Setting by means of R100.

3.2.1 Additional operating modes – single-phase TPED

pumps

The single-phase TPED pumps offer the following additional operating modes:

• Alternating operation. Pump operation alternates every

24 hours. If the duty pump stops due to a fault, the other pump

will start.

• Standby operation. One pump is operating continuously. In

order to prevent seizing-up, the other pump is started 10 sec.

every 24 hours. If the duty pump st ops due to a fault, the other

pump will start.

The operating mode is selected by means of a selector switch in

each terminal box, see fig. 9.

H

Max.

Min.

Q

Q

TM00 7668 1696TM00 5547 0995

9

Page 10

The selector switches enable changeover between the operating

modes “alternating operation” (left position) and “standby oper-

ation” (right position).

The switches in the two terminal boxes must be set to the same

position. If the switches are positioned differently, “standby operation” is selected.

Twin-head pumps can be set and operated in the same way as

single-head pumps. The duty pump uses its setpoint setting,

whether it is made by means of the control panel, via the R100 or

via bus.

Note: Both pumps should be set to the same setpoint and control

mode. Different settings will result in different operation when

changing between the two pumps.

If the electricity supply to the pump is disconnected, the pump

setting will be stored.

The remote control R100 offers additional possibilities of setting

and status displays, see section 5. Setting by means of R100.

3.3 Factory setting

Note: For single-phase TPED pumps, see section 3.4 Factory

setting – single-phase TPED pumps.

The pumps have been factory-set to uncontrolled operation. The

setpoint value corresponds to 100% of the maximum pump performance (see data sheet for the pump).

Other pump settings are marked with bold-faced type under each

individual display in sections 5.1 Menu OPERATION and

5.3 Menu INSTALLATION.

3.4 Factory setting – single-phase TPED pumps

The pumps have been factory-set to uncontrolled operation and

the additional operating mode “alternating operation”.

The setpoint value corresponds to 100% of the maximum pump

performance (see data sheet for the pump).

Other pump settings are marked with bold-faced type under each

individual display in sections 5.1 Menu OPERATION and

5.3 Menu INSTALLATION.

4. Setting by means of control panel

At high system temperatures, the pump may be so

hot that only the buttons should be touched to avoid

burns.

The pump control panel, fig. 20, incorporates the following:

• Buttons, “+” and “–”, for setpoint setting.

• Light fields, yellow, for indication of setpoint.

• Indicator lights, green (operation) and red (fault).

Fig. 20

Light fields

Indicator lights

4.1 Setpoint setting

The desired setpoint is set by pressing the button “+” or “–”.

The light fields on the control panel will indicate the setpoint set.

See the following examples, figs. 21 and 22.

Example: Pump in controlled-operation mode (differential pres-

sure control):

Figure 21 shows that the light fields 5 and 6 are activated, indicat-

ing a desired setpoint of 4 m with a sensor measuring range from

0 to 8 m. The setting range is equal to the sensor measuring

range (see sensor nameplate).

Fig. 21

H m

8

7

6

5

4

3

2

1

0

Example: Pump in uncontrolled-operation mode:

In uncontrolled-operation mode, the pump performance is set

within the range from min. to max. curve, fig. 22.

Fig. 22

H

Q

Q

Buttons

TM00 7600 1196

TM00 7749 1896

10

Q

TM00 7746 1896

Page 11

4.2 Setting to max. curve duty

Press “+” continuously to change over to the max. curve of the

pump (top light field flashes). When the top light field is on, “+”

must be pressed for 3 seconds before the light field starts flashing.

To change back, press “–” continuously until the desired setpoint

is indicated.

Fig. 23

H

QQ

Max. curve

4.3 Setting to min. curve duty

Press “–” continuously to change over to the min. curve of the

pump (bottom light field flashes). When the bottom light field is

on, “–” must be pressed for 3 seconds before the light field starts

flashing.

To change back, press “+” continuously until the desired setpoint

is indicated.

Fig. 24

H

TM00 7345 1196

Min. curve

QQ

4.4 Start/stop of pump

Stop the pump by continuously pressing “–” until none of the light

fields are activated and the green indicator light flashes.

Start the pump by continuously pressing “+” until the desired setpoint is indicated.

TM00 7346 1196

11

Page 12

5. Setting by means of R100

The pump is designed for wireless communication with the

GRUNDFOS remote control R100.

Fig. 25

Fig. 26

The R100 communicates with the pump via infra-red light. The

transmitter and the receiver are incorporated in the pump control

panel, fig. 25.

During communication, the R100 must be pointed at the control

panel.

When the R100 communicates with the pump, the red indicator

light will flash rapidly.

The R100 offers additional possibilities of setting and status displays for the pump.

The displays are divided into four parallel menus, fig. 26:

0. GENERAL (see operating instructions for the R100)

1. OPERATION

2. STATUS

3. INSTALLATION

The number stated at each individual display in fig. 26 refers to

TM02 0791 0101

the section in which the display is described.

0. GENERAL

1. OPERATION 2. STATUS 3. INSTALLATION

5.1.1

5.1.2

5.1.3

5.2.1

5.2.2

5.2.3

5.2.4

5.3.1

5.3.2

5.3.3

5.3.4

5.1.4

5.2.5

5.3.5

12

5.2.6

5.3.6

5.3.7

5.3.8

5.3.9

Page 13

5.1 Menu

When communication between the R100 and the pump has been

established, the first display in this menu will appear.

5.1.1 Setpoint setting

In this display, the setpoint is set.

In controlled-operation mode, the setting range is equal to the

sensor measuring range, e.g. 0 to 25 m.

In uncontrolled-operation mode, the setpoint is set in % of the

maximum performance. The setting range will lie between the

min. and max. curves.

Select one of the following operating modes:

• Stop,

• Min. (min. curve),

• Max. (max. curve).

If the pump is connected to an external setpoint signal, the set-

point in this display will be the maximum value of the external setpoint signal, see section 7. External setpoint signal.

If the pump is controlled via external signals (Stop, Min. curve or

Max. curve) or a bus, this will be indicated in the display if setpoint setting is attempted.

In this case, the number of possible settings will be reduced, see

section 9. Priority of settings.

5.1.2 Setting of operating mode

OPERATION

Setpoint set

Actual setpoint

Actual value

• Setpoint signal outside signal range (only 4-20 mA)

• Dry running

• Other fault

A fault indication can be reset in this display if the cause of the

fault has disappeared.

5.1.4 Alarm log

If faults have been indicated, the last five fault indications will appear in the alarm log. “Alarm log 1” shows the newest/latest fault.

The example shows the fault indication “Undervoltage”, the fault

code and the number of minutes the pump has been connected to

the electricity supply after the fault occurred.

The time cannot be displayed for three-phase pumps as the software does not support this function.

5.2 Menu STATUS

The displays appearing in this menu are status displays only. It is

not possible to change or set values.

The displayed values are the values that applied when the last

communication between the pump and the R100 took place. If a

status value is to be updated, point the R100 at the control panel

and press “OK”.

If a parameter, e.g. speed, should be called up continuously,

press “OK” constantly during the period in which the parameter in

question should be monitored.

The tolerance of the displayed value is stated under each display.

The tolerances are stated as a guide in % of the maximum values

of the parameters.

5.2.1 Display of actual setpoint

Select one of the following operating modes:

• Stop,

• Min.,

• Normal (duty),

• Max.

The operating modes can be selected without changing the set-

point setting.

5.1.3 Fault indications

If the pump is faulty, the cause will appear in this display.

Possible causes:

• Too high motor temperature

• Undervolta ge

• Overvoltage

• Phase failure (three-phase pumps only)

• Mains supply failure (three-phase pumps only)

• Too many restarts (after faults)

• Overload

• Sensor signal outside signal range (only 4-20 mA)

Tolerance: ±2%

This display shows the actual setpoint and the external setpoint in

% of the range from minimum value to the setpoint set, see section 7. External setpoint signal.

5.2.2 Display of operating mode

This display shows the actual operating mode (Stop, Min., Normal

(duty) or Max.). Furthermore, it shows where this operating mode

was selected (R100, Pump, BUS or External).

5.2.3 Display of actual value

The actually measured value of a connected sensor will appea r in

this display, e.g. 12 metres.

If no sensor is connected to the pump, “–” will appear in the display.

13

Page 14

5.2.4 Display of actual speed

Tolerance: ±5%

The actual pump speed will appear in this display.

5.2.5 Display of input power and power consumption

Tolerance: ±10%

This display shows the actual pump input power from the mains

supply. The power is displayed in W or kW.

The pump power consumption can also be read from this display.

The value of power consumption is an accumulated value calculated from the pump’s birth and it cannot be reset.

5.2.6 Display of operating hours

Furthermore, it is possible to set the controller to inverse control

(if the setpoint is increased, the speed will be reduced). In the

case of inverse control, the gain (K

) must be set within the range

p

from –0.1 to –20.

Setting the PI controller:

For most applications, the factory setting of the controller constants K

and Ti will ensure optimum pump operation. In the fol-

p

lowing cases, a change of the setting can be useful or necessary.

A change of the T

setting can be useful:

i

• in a differential-pressure control system if the sensor is placed

far away from the pump.

A change of the T

be necessary:

setting, and in some cases the Kp setting, may

i

• if the pump is controlled on the basis of temperature or differential temperature.

The table below shows the recommended controller settings:

K

1)

p

Cooling

system

T

i

2)

System/

application

Heating

system

0.5 0.5

∆p

Tolerance: ±2%

The value of operating hours is an accumulated value and cannot

be reset.

5.3 Menu INSTALLATION

5.3.1 Selection of control mode

Select one of the following control modes (see fig. 18):

• Controlled,

• Uncontrolled.

The desired performance is set in section 5.1.1 Setpoint sett ing.

Note: If the pump is connected to a bus (see section 8. Bus sig-

nal), it is not possible to select the control mode via the R100.

5.3.2 Setting of controller

L [m]

∆t

∆p

p

t

Q

L [m]

L [m]

L [m]

L < 5 m: 0.5

0.5

L > 5 m: 3

L > 10 m: 5

0.5 0.5

0.5 0.5

0.5 -0.5 10 + 5L

0.5 10 + 5L

t

0.5 -0.5 30 + 5L

In this display, the gain (K

) and the integral-action time (Ti) of the

p

built-in PI controller can be set if the factory setting is not the optimum setting:

•The gain (K

• The integral-action time (T

) is set within the range from 0.1 to 20.

p

) is set within the range from 0.1 to

i

3600 s. If 3600 s is selected, the controller will function as a

P controller.

14

1) Heating systems are systems in which an increase in pump

performance will result in a rise in temperature at the sensor.

2) Cooling systems are systems in which an increase in pump

performance will result in a drop in temperature at the sensor.

Page 15

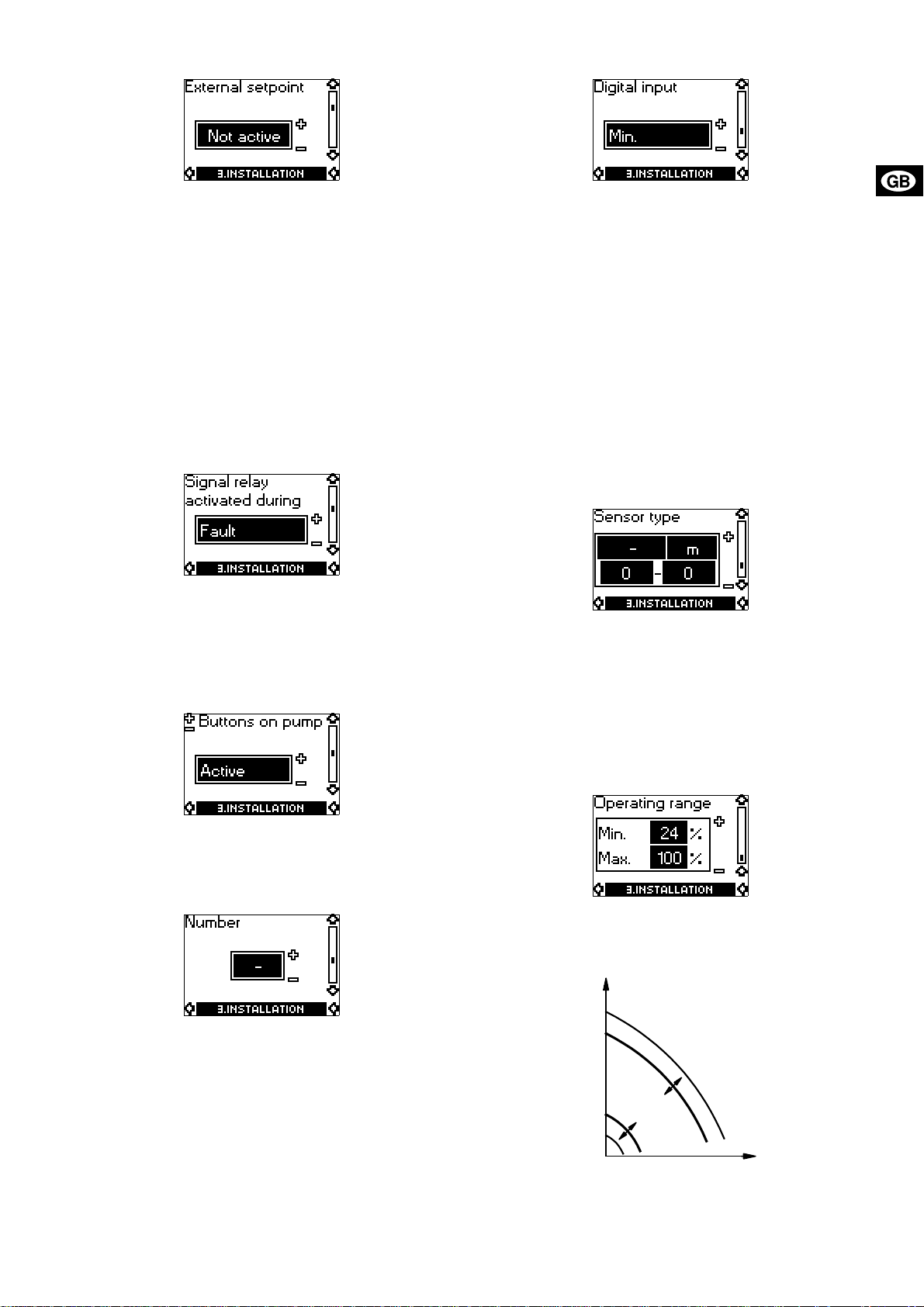

5.3.3 Selection of external setpoint signal

5.3.7 Selection of function for digital input

The input for external setpoint signal can be set to different signal

types.

Select one of the following types:

• 0-5 V (three-phase pumps only),

• 0-10 V,

• 0-20 mA,

• 4-20 mA,

• Not active.

If Not active is selected, the setpoint set by means of the R100 or

on the control panel will apply.

The setpoint set is the maximum value of the external setpoint

signal, section 7. External setpoint signal. The actual value of the

external setpoint can be read from section 5.2.1 Display of actual

setpoint.

5.3.4 Selection of fault, operating or ready signal relay

It can be selected in which situation the relay should be activated:

• Fault (fault indication),

• Operation (operating indication),

• Ready (ready indication).

See section 10. Indicator lights and signal relay.

5.3.5 Blocking of the buttons on the pump

The digital input of the pump (terminal 1, fig. 8, 9,10 or 11) can be

set to different functions.

Select one of the following functions:

• Min. (min. curve),

• Max. (max. curve).

The selected function is activated by closing the contact between

the following terminals:

• 1 and 9 of single-phase pumps (fig. 8 or 9) and

• 1 and 3 of three-phase pumps (fig. 10 or 11).

See also section 6.2 Digital input.

Min.:

When the input is activated, the pump is operating according to

the min. curve.

Max.:

When the input is activated, the pump is operating according to

the max. curve.

5.3.8 Setting of sensor

The setting of the sensor is only carried out in the case of controlled operation.

Select the following:

• Sensor output signal (0-5 V (three-phase pumps only), 0-10 V,

0-20 mA or 4-20 mA),

• sensor measuring unit (bar, mbar, m, kPa, psi, ft, m³/h, m³/s,

l/s, gpm, °C, °F or %) and

• sensor measuring range.

5.3.9 Setting of min. and max. curves

The buttons “+” and “–” on the pump can be set to:

• Active,

• Not active.

5.3.6 Allocation of pump number

A number between 1 and 64 can be allocated to the pump. In the

case of bus communication, a number must be allocated to each

pump.

Set the min. and max. curves in % of maximum performance if

the operating range must be reduced, fig. 27.

Fig. 27

H

100%

Max. curve

Op

er

a

ti

n

Min. curve

12%

g r

a

nge

Q

TM00 7747 1896

15

Page 16

• The max. curve can be adjusted within the range from maxi-

Q

Q

Q

mum performance (100%) to min. curve.

• The min. curve can be adjusted within the range from max.

curve to 12% of maximum performance. The pump has been

factory-set to 24% of maximum performance.

• The operating range lies between the min. and max. curves.

6. External forced-control signals

The pump has inputs for external signals for the forced-control

functions:

• Start/stop of pump.

• Digital function.

6.1 Start/stop input

Functional diagram: Start/stop input:

Start/stop (terminals 2 and 3)

H

Normal duty

Q

H

Stop

6.2 Digital input

By means of the R100, one of the following functions can be selected for the digital input:

•Min. curve.

•Max. curve.

Functional diagram: Input for digital function:

In controlled-operation mode, the setpoint can be set externally

within the range from the lower value of the sensor measuring

range to the setpoint set on the pump or by means of the R100,

fig. 28.

Fig. 28

Control

Parameter

Upper value of sensor measuring range

Setpoint set on pump or with the R100

Lower value of sensor measuring range

0

0

0

4

Example: At a lower differential-pressure sensor value of 0 m, a

setpoint set of 20 m and an external setpoint of 80%, the actual

setpoint will be as follows:

H

= (H

actual

In uncontrolled-operation mode, the setpoint can be set externally within the range from the min. curve to the setpoint set on

the pump or by means of the R100, fig. 29.

Fig. 29

set

= (20 - 0) x 80% + 0

= 16 m

5 V (three-phase pumps only)

10 V

20 mA

20 mA

- H

) x %

lower

external setpoint

+ H

lower

%

TM00 7669 1696

Digital function

(terminals 1 and 9 – single-phase pumps)

(terminals 1 and 3 – three-phase pumps)

H

Normal duty

Q

H

Min. curve

H

Max. curve

7. External setpoint signal

By connecting an analog signal transmitter to the input for the

setpoint signal (terminal 4), it is possible to remote-set the setpoint.

The actual external signal (0-5 V (three-phase pumps only),

0-10 V, 0-20 mA, 4-20 mA) must be selected via the R100, see

section 5.3.3 Selection of external setpoint signal.

If uncontrolled operation is selected by means of the R100, the

pump can be controlled by any controller.

Max. curve

Setpoint set on pump or with the R100

Min. curve

0

0

0

4

5 V (three-phase pumps only)

10 V

20 mA

20 mA

8. Bus signal

The pump enables serial communication via an RS-485 input.

The communication is carried out according to the GRUNDFOS

bus protocol, GENIbus protocol, and enables connection to a

building management system or another external control system.

Via the bus signal, it is possible to remote-set pump operating parameters, like setpoint, operating mode, etc. At the same time,

the pump can provide status information about impo rtant parameters, like actual value of control parameter, input power, fault indications, etc.

Contact GRUNDFOS for further details.

Note: If a bus signal is used, the number of settings available via

the R100 will be reduced.

TM00 7669 1696

16

Page 17

9. Priority of settings

The start/stop and digital inputs will influence the number of possible settings.

By means of the R100, the pump can always be se t to ma x. curve

duty or to stop.

If two or more functions are activated at the same time, the pump

will operate according to the function with the highest priority.

The priority of the settings is as shown in the following tables:

Without bus signal

Possible settings

Priority

1 Stop

2 Max. curve

3 Stop

4 Max. curve

5 Min. curve Min. curve

6 Setpoint setting Setpoint setting

Example: If, via the digital input, the pump has been forced to op-

erate according to the max. curve, the pump control panel and

the R100 can only set the pump to stop.

Control panel on

pump or R100

External

signals

With bus signal

Possible settings

Priority

1 Stop

2 Max. curve

3 Stop Stop

4 Max. curve

5 Min. curve

6

Example: If, via the digital input, the pump has been forced to op-

erate according to the max. curve, the pump control panel, the

R100 and the bus signal can only set the pump to stop.

Control

panel on

pump or

R100

External

signals

Bus signal

Setpoint

setting

17

Page 18

10. Indicator lights and signal relay

The operating condition of the pump is indicated by the green and

red indicator lights on the pump control panel, fig. 30.

Fig. 30

The pump incorporates an output for a potential-free signal via an

internal relay.

The signal output can be set to fault, operating or ready indication

by means of the R100, see section 5.3.4 Selection of fault, oper-

ating or ready signal relay.

The functions of the two indicator lights and the signal relay are

as shown in the following table:

Green

Red

Indicator lights Signal relay activated during:

Fault

(red)

Opera-

tion

(green)

Fault Operation Ready

Off Off

Off

Perman-

ently on

NCNO

C

NCNO

C

NCNO

C

NONC

C

Off Flashing

Perman-

ently on

Perman-

ently on

Perman-

ently on

Off

Perman-

ently on

Flashing

NCNO

C

NONC

C

NONC

C

NONC

C

NCNO

C

NCNO

C

NONC

C

NCNO

C

TM00 7600 1196

Description

The electricity supply has been switched off.

NCNO

C

The pump is operating.

NONC

C

The pump has been set to stop.

NONC

C

The pump has stopped because of a fault. Restarting will be

attempted (it may be necessary to restart the pump by resetting the fault indication).

NCNO

C

The pump is operating, but it has been stopped because of a

fault.

If the cause is “sensor signal outside signal range”, the pump

will continue operating according to the max. curve and the

fault indication cannot be reset until the signal is inside the

C

NONC

signal range.

If the cause is “setpoint signal outside signal range”, the

pump will continue operating according to the min. curve and

the fault indication cannot be reset until the signal is inside

the signal range.

The pump has been set to stop, but it has been stopped because of a fault.

NONC

C

A fault indication can be reset in one of the following ways:

• By briefly pressing the button “+” or “–” on the pump. This will

not change the setting of the pump.

A fault indication cannot be reset by means of “+” or “–” if the

buttons have been locked.

• By switching off the electricity supply until the indicator lights

are off.

• By means of the R100, see section 5.1.3 Fault indications.

When the R100 communicates with the pump, the red indicator

light will flash rapidly.

18

11. Megging

Note: Megging of an installation incorporating E-pumps is not al-

lowed, as the built-in electronics may be damaged.

Page 19

12. Technical data – single-phase pumps

13. Technical data – three-phase pumps

12.1 Supply voltage

1 x 200-240 V ±10%, 50/60 Hz, PE.

See nameplate.

Back-up fuse

Motor sizes from 0.37 to 1.1 kW: Max. 10 A.

Standard as well as quick-blow or slow-blow fuses may be used.

12.2 Leakage current

Earth leakage current < 3.5 mA.

The leakage currents are measured in accordance with

EN 60 355-1.

12.3 Inputs/output

Start/stop

External potential-free switch.

Voltage: 5 VDC.

Current: < 5 mA.

Screened cable.

Digital

External potential-free switch.

Voltage: 5 VDC.

Current: < 5 mA.

Screened cable.

Setpoint signals

• Potentiometer

0-10 VDC, 10 kΩ (via internal voltage supply).

Screened cable.

Maximum cable length: 100 m.

• Voltage signal

0-10 VDC, R

Tolerance: +0%/–3% at maximum voltage signal.

Screened cable.

Maximum cable length: 500 m.

• Current signal

DC 0-20 mA/4-20 mA, R

Tolerance: +0%/–3% at maximum current signal.

Screened cable.

Maximum cable length: 500 m.

Sensor signals

• Voltage signal

0-10 VDC, R

Tolerance: +0%/–3% at maximum voltage signal.

Screened cable.

Maximum cable length: 500 m.

• Current signal

DC 0-20 mA/4-20 mA, R

Tolerance: +0%/–3% at maximum current signal.

Screened cable.

Maximum cable length: 500 m.

• Electricity supply to sensor:

+24 VDC, max. 40 mA.

Signal output

Potential-free changeover contact.

Maximum contact load: 250 VAC, 2 A.

Minimum contact load: 5 VDC, 1 mA.

Screened cable: 0.5 - 2.5 mm².

Maximum cable length: 500 m.

Bus input

GRUNDFOS bus protocol, GENIbus protocol, RS-485.

0.5 - 1.5 mm²

Maximum cable length: 500 m.

*

*

*

> 50 kΩ.

i

*

= 175 Ω.

i

*

> 50 kΩ (via inter nal voltage supply).

i

*

= 175 Ω.

i

*

screened 2-core cable.

* Cross section min. 0.5 mm² and max. 1.5 mm².

13.1 Supply voltage

3 x 380-415 V ±10%, 50/60 Hz, PE.

See nameplate.

Back-up fuse

Motor sizes from 1.1 to 5.5 kW: Max. 16 A.

Motor size 7.5 kW: Max. 32 A.

Standard as well as quick-blow or slow-blow fuses may be used.

13.2 Leakage current

Motor size

[kW]

1.1 to 3.0 < 3.5

4.0 to 5.5

5.5 kW, 1400-1800 min

7.5 < 10

The leakage currents are measured in accordance with

EN 60 355-1.

-1

Leakage current

[mA]

< 5

< 10

13.3 Inputs/output

Start/stop

External potential-free switch.

Voltage: 5 VDC.

Current: < 5 mA.

Screened cable.

Digital

External potential-free switch.

Voltage: 5 VDC.

Current: < 5 mA.

Screened cable.

Setpoint signals

• Potentiometer

0-5 VDC, 10 kΩ (via internal voltage supply).

Screened cable.

Maximum cable length: 100 m.

• Voltage signal

0-5 VDC/0-10 VDC, R

Tolerance: +0%/–3% at maximum voltage signal.

Screened cable.

Maximum cable length: 500 m.

• Current signal

DC 0-20 mA/4-20 mA, R

Tolerance: +0%/–3% at maximum current signal.

Screened cable.

Maximum cable length: 500 m.

Sensor signals

• Voltage signal

0-5 VDC/0-10 VDC, R

Tolerance: +0%/–3% at maximum voltage signal.

Screened cable.

Maximum cable length: 500 m.

• Current signal

DC 0-20 mA/4-20 mA, R

Tolerance: +0%/–3% at maximum current signal.

Screened cable.

Maximum cable length: 500 m.

• Electricity supply to sensor:

+24 VDC, max. 40 mA.

Signal output

Potential-free changeover contact.

Maximum contact load: 250 VAC, 2 A.

Minimum contact load: 5 V DC, 1 mA.

Screened cable: 0.5 - 2.5 mm².

Maximum cable length: 500 m.

Bus input

GRUNDFOS bus protocol, GENIbus protocol, RS-485.

0.5 - 1.5 mm²

Maximum cable length: 500 m.

*

*

*

> 50 kΩ.

i

*

= 250 Ω.

i

*

> 50 kΩ (via internal voltage supply).

i

*

= 250 Ω.

i

*

screened 2-core cable.

* Cross section min. 0.5 mm² and max. 1.5 mm².

19

Page 20

13.4 Other technical data

EMC (electromagnetic compatibility)

EN 61 800-3.

Motors of 0.37 to 5.5 kW, except for 5.5 kW, 1400-1800 min

Residential areas - unlimited distribution,

corresponding to CISPR 11, class B, group 1.

Motors of 7.5 kW and 5.5 kW, 1400-1800 min

Residential areas - limited distribution.

Industrial areas - unlimited distribution,

corresponding to CISPR 11, class A, group 1.

When pumps fitted with motors of 7.5 kW and 5.5 kW,

1400-1800 min

-1

, are installed in residential areas, an additional

EMC filter is required to obtain class B, group 1 status.

The motor fulfils EN 50 178.

Contact GRUNDFOS for further information.

Enclosure class

Standard: IP 55 (IEC 34-5).

Insulation class

F (IEC 85).

Ambient temperature

During operation: –20°C to +40°C.

During storage/transport: –40°C to +60°C.

Relative air humidity

Maximum 95%.

-1

:

Sound pressure level

Single-phase pumps:

<70 dB(A).

-1

:

Three-phase pumps:

Motor

[kW]

1.1

Speed stated

Sound pressure

on nameplate

-1

[min

]

1400-1500 52

1700-1800 55

level

[dB(A)]

1400-1500 53

1.5

1700-1800 56

2800-3000 63

3400-3600 68

1400-1500 52

2.2

1700-1800 54

2800-3000 64

1400-1500 57

3.0

1700-1800 59

2800-3000 64

3400-3600 68

1400-1500 59

4.0

2800-3000 68

3400-3600 73

5.5

7.5

2800-3000 68

3400-3600 73

2800-3000 74

3400-3600 79

14. Disposal

Disposal of this product or parts of it must be carried out according to the following guidelines:

1. Use the local public or private waste collection service.

2. In case such waste collection service does not exist or cannot

handle the materials used in the product, please deliver the

product or any hazardous materials from it to your nearest

GRUNDFOS company or service workshop.

20

Subject to alterations.

Page 21

Denmark

GRUNDFOS DK A/S

Poul Due Jensens Vej 7A

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 5 0 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +4 3-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Brazil

GRUNDFOS do Brasil Ltda.

Rua Tomazi na 106

CEP 83325 - 040

Pinhais - PR

Phone: +55-41 668 3555

Telefax: +55-41 6 68 3554

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 8 29 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

22 Floor, Xin Hua Lian Building

755-775 Huai Hai Rd, (M)

Shanghai 200020

PRC

Phone: +86-512-67 61 11 80

Telefax: +86-512-67 61 8 1 67

Czech Republic

GRUNDFOS s.r.o.

Cajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-5 85-43 8 906

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

Piispankylä

FIN-01730 Vantaa (Helsinki)

Phone: +358-9 878 9150

Telefax: +358 -9 878 91 550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +4 9-(0) 211 929 69-0

Telefax: +49-(0) 211 9 29 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Bo x 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706/27861741

Telefax: +852-2785866 4

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbalint,

Phone: +36-34 520 100

Telefax: +36-34 520 200

India

GRUNDFOS Pumps India Private Limited

Flat A, Ground Floor

61/62 Chamiers Aptmt

Chamiers Road

Chennai 600 028

Phone: +91-44 432 3487

Telefax: +91-44 432 3489

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910/ 460 690 1

Ireland

GRUNDFOS (Ireland) Ltd.

Unit 34, Stillorgan Industrial Park

Blackrock

County Dublin

Phone: +353-1-2954926

Telefax: +353-1-2954739

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel. : +39-02-95838 112

Telefax: +39-02-9530929 0/9583846 1

Japan

GRUNDFOS Pumps K.K.

1-2-3, Shin Miyakoda

Hamamatsu City

Shizuoka pref. 431-21

Phone: +81-53-428 4760

Telefax: +81-53-484 1014

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kang nam-ku, 135-91 6

Seoul Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industria l Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Mexico

Bombas GRUNDFOS de Mexico S.A. de C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Mexico

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Nederland B.V.

Postbus 104

NL-1380 AC Weesp

Tel. : +31-294-492 21 1

Telefax: +31-294-49 2244/4922 99

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industr ial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 32 50

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przezmierowo

Phone: +48-61-650 13 00

Telefax: +48-61-650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel. : + 351 -2 1-440 7 6 00

Telefax: +351-21-440 76 90

Russia

OOO GRUNDFOS

Shkolnaya 39

RUS-109544 Moscow

Phone: +7-095 564 88 00, +7-095 7 37 30 00

Telefax: +7-095 564 88 11, +7-095 737 75 36

e-mail: grundfos.moscow@grundfos.com

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel. : + 34-91 -848 88 00

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 63, Angeredsvinkeln 9

S-424 22 Angered

Tel. : + 46-771-32 23 00

Telefax: +46-31 331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel. : + 41-1-806 811 1

Telefax: +41-1-806 81 15

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

14, Min-Yu Road

Tu nglo Indus tr ial Park

Tunglo, Miao-Li County

Tai wan, R.O.C .

Phone: +886-37-98 05 57

Telefax: +886-37-98 05 70

Thailand

GRUNDFOS (Thailand) Ltd.

947/168 Moo 12, Bangna-Trad Rd., K.M. 3,

Bangna, Phrakanong

Bangkok 10260

Phone: +66-2-744 1785 ... 91

Telefax: +66-2-744 17 75 ... 6

Turkey

GRUNDFOS POMPA SAN. ve TIC. LTD. STI

Bulgurlu Caddesi no. 32

TR-81190 Üsküdar Istanbul

Phone: +90 - 216-4280 306

Telefax: +90 - 216-3279 988

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525 -8500 11

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Addresses revised 06.11.2003

Page 22

Being responsible is our foundation

Being responsible is our foundation

Thinking ahead makes it possible

Thinking ahead makes it possible

Innovation is the essence

Innovation is the essence

96 40 57 42 0203

Repl. 96 40 57 42 1002

www.grundfos.com

134

Loading...

Loading...