Page 1

GRUNDFOS INSTRUCTIONS

TPE, TPED, NKE, NKGE,

NBE, NBGE

Installation and operating instructions

Page 2

Declaration of conformity

Declaration of conformity

GB: EC declaration of conformity

We, Grundfos, declare under our sole responsibility that the products

TPE, TPED, NKE, NKGE, NBE and NBGE, to which this declaration

relates, are in conformity with these Council directives on the

approximation of the laws of the EC member states:

— Machinery Directive (2006/42/EC).

Standards used: EN 809:1998 and EN 60204-1:2006.

— Low Voltage Directive (2006/95/EC).

Standard used: EN 61800-5-1.

— EMC Directive (2004/108/EC).

Standard used: EN 61800-3:2004.

— Ecodesign Directive (2009/125/EC).

Water pumps:

Commission Regulation No 547/2012.

Applies only to water pumps marked with the minimum efficiency

index MEI. See pump nameplate.

This EC declaration of conformity is only valid when published as part of

the Grundfos installation and operating instructions (publication number

96782376 1112).

CZ: ES prohlášení o shodě

My firma Grundfos prohlašujeme na svou plnou odpovědnost, že výrobky

TPE, TPED, NKE, NKGE, NBE a NBGE, na něž se toto prohlášení

vztahuje, jsou v souladu s ustanoveními směrnice Rady pro sblížení

právních předpisů členských států Evropského společenství v oblastech:

—Směrnice pro strojní zařízení (2006/42/ES).

Použité normy: EN 809:1998 a EN 60204-1:2006.

—Směrnice pro nízkonapět’ové aplikace (2006/95/ES).

Použitá norma: EN 61800-5-1.

—Směrnice pro elektromagnetickou kompatibilitu (EMC)

(2004/108/ES).

Použitá norma: EN 61800-3:2004.

—Směrnice o ekodesignu (2009/125/ES).

Vodní čerpadla:

Nařízení Komise č. 547/2012.

Vztahuje se pouze na vodní čerpadla označená minimální účinností

index MEI. Viz typový štítek čerpadla.

Toto ES prohlášení o shodě je platné pouze tehdy, pokud je zveřejněno

jako součást instalačních a provozních návodů Grundfos (publikace číslo

96782376 1112).

DE: EG-Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung, dass die Produkte

TPE, TPED, NKE, NKGE, NBE und NBGE, auf die sich diese Erklärung

bezieht, mit den folgenden Richtlinien des Rates zur Angleichung der

Rechtsvorschriften der EU-Mitgliedsstaaten übereinstimmen:

— Maschinenrichtlinie (2006/42/EG).

Normen, die verwendet wurden: EN 809:1998 und

EN 60204-1:2006.

— Niederspannungsrichtlinie (2006/95/EG).

Norm, die verwendet wurde: EN 61800-5-1.

— EMV-Richtlinie (2004/108/EG).

Norm, die verwendet wurde: EN 61800-3:2004.

— ErP-Richtlinie (2009/125/EG).

Wasserpumpen:

Verordnung der Europäischen Kommission Nr. 547/2012.

Gilt nur für Pumpen, für die der Mindesteffizienzindex (MEI)

anzugeben ist. Siehe Typenschild der Pumpe.

Diese EG-Konformitätserklärung gilt nur, wenn sie in Verbindung mit der

Grundfos Montage- und Betriebsanleitung (Veröffentlichungsnummer

96782376 1112) veröffentlicht wird.

GR: ∆ήλωση συμμόρφωσης EC

Εμείς, η Grundfos, δηλώνουμε με αποκλειστικά δική μας ευθύνη ότι

τα προϊόντα TPE, TPED, NKE, NKGE, NBE και NBGE στα οποία

αναφέρεται η παρούσα δήλωση, συμμορφώνονται με τις εξής Οδηγίες

του Συμβουλίου περί προσέγγισης των νομοθεσιών των κρατών μελών

της ΕΕ:

— Οδηγία για μηχανήματα (2006/42/EC).

Πρότυπα που χρησιμοποιήθηκαν: EN 809:1998 και

EN 60204-1:2006.

— Οδηγία χαμηλής τάσης (2006/95/EC).

Πρότυπο που χρησιμοποιήθηκε: EN 61800-5-1.

— Οδηγία Ηλεκτρομαγνητικής Συμβατότητας

Πρότυπο που χρησιμοποιήθηκε: EN 61800-3:2004.

— Οδηγία Οικολογικού Σχεδιασμού (2009/125/EC).

Αντλίες νερού:

Ρύθμιση πρώτης εκκίνησης Νο 547/2012.

Ισχύει μόνο για αντλίες νερού που φέρουν τον ελάχιστο δείκτη

απόδοσης ΜΕΙ. Βλέπε πινακίδα αντλίας.

Αυτή η δήλωση συμμόρφωσης EC ισχύει μόνον όταν συνοδεύει τις

οδηγίες εγκατάστασης και λειτουργίας της Grundfos (κωδικός εντύπου

96782376 1112).

(EMC) (2004/108/EC).

BG: EC декларация за съответствие

Ние, фирма Grundfos, заявяваме с пълна отговорност, че продуктите

TPE, TPED, NKE, NKGE, NBE и NBGE, за които се отнася

настоящата декларация, отговарят на следните указания на Съвета

за уеднаквяване на правните разпоредби на държавите членки на

ЕС:

— Директива за машините (2006/42/EC).

Приложени стандарти: EN 809:1998 и EN 60204-1:2006.

— Директива за нисковолтови системи (2006/95/EC).

Приложен стандарт: EN 61800-5-1.

— Директива за електромагнитна съвместимост (2004/108/EC).

Приложен стандарт

— Директива за екодизайн (2009/125/EC).

Водни помпи:

Наредба No 547/2012 на Европейската комисия.

Отнася се само за водни помпи, маркирани с минималният

индекс за ефективност MEI. Вижте табелата с данни на помпата.

Тази ЕС декларация за съответствие е валидна само когато е

публикувана като част от инструкциите за монтаж и експлоатация на

Grundfos (номер на

: EN 61800-3:2004.

публикацията 96782376 1112).

DK: EF-overensstemmelseserklæring

Vi, Grundfos, erklærer under ansvar at produkterne TPE, TPED, NKE,

NKGE, NBE og NBGE som denne erklæring omhandler, er i

overensstemmelse med disse af Rådets direktiver om indbyrdes

tilnærmelse til EF-medlemsstaternes lovgivning:

— Maskindirektivet (2006/42/EF).

Anvendte standarder: EN 809:1998 og EN 60204-1:2006.

— Lavspændingsdirektivet (2006/95/EF).

Anvendt standard: EN 61800-5-1.

— EMC-direktivet (2004/108/EF).

Anvendt standard: EN 61800-3:2004.

— Ecodesigndirektivet (2009/125/EF).

Vandpumper:

Kommissionens forordning nr. 547/2012.

Gælder kun vandpumper der er mærket med

mindsteeffektivitetsindekset MEI. Se pumpens typeskilt.

Denne EF-overensstemmelseserklæring er kun gyldig når den publiceres

som en del af Grundfos-monterings- og driftsinstruktionen (publikationsnummer 96782376 1112).

EE: EL vastavusdeklaratsioon

Meie, Grundfos, deklareerime enda ainuvastutusel, et tooted TPE,

TPED, NKE, NKGE, NBE ja NBGE, mille kohta käesolev juhend käib,

on vastavuses EÜ Nõukogu direktiividega EMÜ liikmesriikide seaduste

ühitamise kohta, mis käsitlevad:

— Masinate ohutus (2006/42/EC).

Kasutatud standardid: EN 809:1998 ja EN 60204-1:2006.

— Madalpinge direktiiv (2006/95/EC).

Kasutatud standard: EN 61800-5-1.

— Elektromagnetiline ühilduvus (EMC direktiiv) (2004/108/EC).

Kasutatud standard: EN 61800-3:2004.

— Ökodisaini direktiiv (2009/125/EC).

Veepumbad:

Komisjoni regulatsioon nr 547/2012.

Kehtiv ainult veepumpadele, mis on märgitud miinimum kasuteguri

indeksiga MEI. Vaata pumba silti.

Käesolev EL-i vastavusdeklaratsioon kehtib ainult siis, kui see

avaldatakse Grundfosi paigaldus- ja kasutusjuhendi (avaldamisnumber

96782376 1112) osana.

ES: Declaración CE de conformidad

Nosotros, Grundfos, declaramos bajo nuestra entera responsabilidad

que los productos TPE, TPED, NKE, NKGE, NBE y NBGE, a los cuales

se refiere esta declaración, están conformes con las Directivas del

Consejo en la aproximación de las leyes de las Estados Miembros del

EM:

— Directiva de Maquinaria (2006/42/CE).

Normas aplicadas: EN 809:1998 y EN 60204-1:2006.

— Directiva de Baja Tensión (2006/95/CE).

Norma aplicada: EN 61800-5-1.

— Directiva EMC (2004/108/CE).

Norma aplicada: EN 61800-3:2004.

— Directiva sobre diseño ecológico (2009/125/CE).

Bombas de agua:

Reglamento de la Comisión Nº 547/2012.

Aplicable únicamente a las bombas de agua marcadas con el índice

de eficiencia mínima (IEM). Véase la placa de características de la

bomba.

Esta declaración CE de conformidad sólo es válida cuando se publique

como parte de las instrucciones de instalación y funcionamiento de

Grundfos (número de publicación 96782376 1112).

2

Page 3

FR: Déclaration de conformité CE

Nous, Grundfos, déclarons sous notre seule responsabilité, que les

produits TPE, TPED, NKE, NKGE, NBE et NBGE, auxquels se réfère

cette déclaration, sont conformes aux Directives du Conseil concernant

le rapprochement des législations des Etats membres CE relatives aux

normes énoncées ci-dessous:

— Directive Machines (2006/42/CE).

Normes utilisées: EN 809:1998 et EN 60204-1:2006.

— Directive Basse Tension (2006/95/CE).

Norme utilisée: EN 61800-5-1.

— Directive Compatibilité Electromagnétique CEM (2004/108/CE).

Norme utilisée : EN 61800-3:2004.

— Directive sur l'éco-conception (2009/125/CE).

Pompes à eau:

Règlement de la Commission Nº 547/2012.

S'applique uniquement aux pompes à eau marquées de l'indice de

performance minimum IEM. Voir plaque signalétique de la pompe.

Cette déclaration de conformité CE est uniquement valide lors de sa

publication dans la notice d'installation et de fonctionnement Grundfos

(numéro de publication 96782376 1112).

IT: Dichiarazione di conformità CE

Grundfos dichiara sotto la sua esclusiva responsabilità che i prodotti

TPE, TPED, NKE, NKGE, NBE e NBGE, ai quali si riferisce questa

dichiarazione, sono conformi alle seguenti direttive del Consiglio

riguardanti il riavvicinamento delle legislazioni degli Stati membri CE:

— Direttiva Macchine (2006/42/CE).

Norme applicate: EN 809:1998 e EN 60204-1:2006.

— Direttiva Bassa Tensione (2006/95/CE).

Norma applicata: EN 61800-5-1.

— Direttiva EMC (2004/108/CE).

Norma applicata: EN 61800-3:2004.

— Direttiva Ecodesign (2009/125/CE).

Pompe per acqua:

Regolamento CE n. 547/2012.

Applicabile solo a pompe per acqua con l'indice di efficienza minimo

MEI. Vedere la targhetta di identificazione della pompa.

Questa dichiarazione di conformità CE è valida solo quando pubblicata

come parte delle istruzioni di installazione e funzionamento Grundfos

(pubblicazione numero 96782376 1112).

LT: EB atitikties deklaracija

Mes, Grundfos, su visa atsakomybe pareiškiame, kad gaminiai TPE,

TPED, NKE, NKGE, NBE ir NBGE, kuriems skirta ši deklaracija, atitinka

šias Tarybos Direktyvas dėl Europos Ekonominės Bendrijos šalių narių

įstatymų suderinimo:

—Mašinų direktyva (2006/42/EB).

Taikomi standartai: EN 809:1998 ir EN 60204-1:2006.

—Žemų įtampų direktyva (2006/95/EB).

Taikomas standartas: EN 61800-5-1.

— EMS direktyva (2004/108/EB).

Taikomas standartas: EN 61800-3:2004.

— Ekologinio projektavimo direktyva (2009/125/EB).

Vandens siurbliai:

Komisijos reglamentas Nr. 547/2012.

Galioja tik vandens siurbliams, ant kurių nurodytas minimalus

efektyvumo koeficientas MEI. Žr. siurblio vardinę plokštelę.

Ši EB atitikties deklaracija galioja tik tuo atveju, kai yra pateikta kaip

"Grundfos" įrengimo ir naudojimo instrukcijos (leidinio numeris 96782376

1112) dalis.

NL: EC overeenkomstigheidsverklaring

Wij, Grundfos, verklaren geheel onder eigen verantwoordelijkheid dat

de producten TPE, TPED, NKE, NKGE, NBE en NBGE waarop deze

verklaring betrekking heeft, in overeenstemming zijn met de Richtlijnen

van de Raad in zake de onderlinge aanpassing van de wetgeving van de

EG Lidstaten betreffende:

— Machine Richtlijn (2006/42/EC).

Gebruikte normen: EN 809:1998 en EN 60204-1:2006.

— Laagspannings Richtlijn (2006/95/EC).

Gebruikte norm: EN 61800-5-1.

— EMC Richtlijn (2004/108/EC).

Gebruikte norm: EN 61800-3:2004.

— Ecodesign Richtlijn (2009/125/EC).

Waterpompen:

Verordening (EG) Nr. 547/2012 van de Commissie.

Is alleen van toepassing op waterpompen die gekenmerkt worden

door de minimale efficiëntie index MEI. Zie het typeplaatje van de

pomp.

Deze EC overeenkomstigheidsverklaring is alleen geldig wanneer deze

gepubliceerd is als onderdeel van de Grundfos installatie- en

bedieningsinstructies (publicatienummer 96782376 1112).

HR: EZ izjava o usklađenosti

Mi, Grundfos, izjavljujemo pod vlastitom odgovornošću da je proizvod

TPE, TPED, NKE, NKGE, NBE i NBGE, na koji se ova izjava odnosi,

u skladu s direktivama ovog Vijeća o usklađivanju zakona država članica

EU:

— Direktiva za strojeve (2006/42/EZ).

Korištene norme: EN 809:1998 i EN 60204-1:2006.

— Direktiva za niski napon (2006/95/EZ).

Korištena norma: EN 61800-5-1.

— Direktiva za elektromagnetsku kompatibilnost (2004/108/EZ).

Korištena norma: EN 61800-3:2004.

— Direktiva o ekološkoj izvedbi (2009/125/EZ).

Crpke za vodu:

Uredba Komisije No 547/2012.

Odnosi se samo na crpke za vodu označene s indeksom minimalne

učinkovitosti MEI. Pogledajte natpisnu pločicu crpke.

Ova EZ izjava o suklađnosti važeća je jedino kada je izdana kao dio

Grundfos montažnih i pogonskih uputa (broj izdanja 96782376 1112).

LV: EK atbilstības deklarācija

Sabiedrība GRUNDFOS ar pilnu atbildību dara zināmu, ka produkti TPE,

TPED, NKE, NKGE, NBE un NBGE, uz kuriem attiecas šis paziņojums,

atbilst šādām Padomes direktīvām par tuvināšanos EK dalībvalstu

likumdošanas normām:

—Mašīnbūves direktīva (2006/42/EK).

Piemērotie standarti: EN 809:1998 un EN 60204-1:2006.

— Zema sprieguma direktīva (2006/95/EK).

Piemērotais standarts: EN 61800-5-1.

— Elektromagnētiskās saderības direktīva (2004/108/EK).

Piemērotais standarts: EN 61800-3:2004.

— Ekodizaina direktīva (2009/125/EK).

Ūdens sūkņi:

Komisijas regula Nr. 547/2012.

Attiecas tikai uz ūdens sūkņiem, kuriem ir minimālais efektivitātes

indekss MEI. Sk. sūkņa pases datu plāksnītē.

Šī EK atbilstības deklarācija ir derīga vienīgi tad, ja ir publicēta kā

no GRUNDFOS uzstādīšanas un ekspluatācijas instrukcijām

(publikācijas numurs 96782376 1112).

daļa

HU: EK megfelelőségi nyilatkozat

Mi, a Grundfos, egyedüli felelősséggel kijelentjük, hogy a TPE, TPED,

NKE, NKGE, NBE és NBGE termékek, amelyekre jelen nyilatkozik

vonatkozik, megfelelnek az Európai Unió tagállamainak jogi irányelveit

összehangoló tanács alábbi előírásainak:

— Gépek (2006/42/EK).

Alkalmazott szabványok: EN 809:1998 és EN 60204-1:2006.

— Kisfeszültségű Direktíva (2006/95/EK).

Alkalmazott szabvány: EN 61800-5-1.

— EMC Direktíva (2004/108/EK).

Alkalmazott szabvány: EN 61800-3:2004.

— Környezetbarát tervezésre vonatkozó irányelv (2009/125/EK).

Víz szivattyúk:

Az Európai Bizottság 547/2012. számú rendelete.

Csak a MEI minimum hatásfok index-el jelölt víz szivattyúkra

vonatkozik. Lásd a szivattyú adattábláján.

Ez az EK megfelelőségi nyilatkozat kizárólag akkor érvényes, ha

Grundfos telepítési és üzemeltetési utasítás (kiadvány szám 96782376

1112) részeként kerül kiadásra.

UA: Декларація відповідності ЄС

Компанія Grundfos заявляє про свою виключну відповідальність

за те, що продукти TPE, TPED, NKE, NKGE, NBE та NBGE, на які

поширюється дана декларація, відповідають таким рекомендаціям

Ради з уніфікації правових норм країн - членів ЕС:

— Механічні прилади (2006/42/ЄС).

Стандарти, що застосовувалися: EN 809:1998 та

EN 60204-1:2006.

— Низька напруга (2006/95/ЄС).

Стандарти, що застосовувалися: EN 61800-5-1.

— Електромагнітна сумісність (2004/108/ЄС).

Стандарти, що застосовувалися: EN 61800-3:2004.

— Директива з екодизайну (2009/125/

Насоси для води:

Регламент Комісії № 547/2012.

Стосується тільки насосів для води, що відзначені мінімальним

показником ефективності МЕІ. Дивіться паспортну табличку на

насосі.

Ця декларація відповідності ЄС дійсна тільки в тому випадку, якщо

публікується як частина інструкцій Grundfos з монтажу та

експлуатації (номер публікації 96782376 1112).

ЄС).

Declaration of conformity

3

Page 4

Declaration of conformity

PL: Deklaracja zgodności WE

My, Grundfos, oświadczamy z pełną odpowiedzialnością, że nasze

wyroby TPE, TPED, NKE, NKGE, NBE oraz NBGE, których deklaracja

niniejsza dotyczy, są zgodne z następującymi wytycznymi Rady d/s

ujednolicenia przepisów prawnych krajów członkowskich WE:

— Dyrektywa Maszynowa (2006/42/WE).

Zastosowane normy: EN 809:1998 oraz EN 60204-1:2006.

— Dyrektywa Niskonapięciowa (LVD) (2006/95/WE).

Zastosowana norma: EN 61800-5-1.

— Dyrektywa EMC (2004/108/WE).

Zastosowana norma: EN 61800-3:2004.

— Dyrektywa Ekoprojektowa (2009/125/WE).

Pompy do wody:

Rozporządzenie komisji nr 547/2012.

Dotyczy tylko pomp do tłoczenia wody z minimalnym indeksem

sprawności MEI. Patrz tabliczka znamionowa pompy.

Deklaracja zgodności WE jest ważna tylko i wyłącznie wtedy kiedy jest

opublikowana przez firmę Grundfos i umieszczona w instrukcji montażu

i eksploatacji (numer publikacji 96782376 1112).

RU: Декларация о соответствии ЕС

Мы, компания Grundfos, со всей ответственностью заявляем, что

изделия TPE, TPED, NKE, NKGE, NBE и NBGE, к которым относится

настоящая декларация, соответствуют следующим Директивам

Совета Евросоюза об унификации законодательных предписаний

стран-членов ЕС:

— Механические устройства (2006/42/ЕС).

Применявшиеся стандарты: EN 809:1998 и EN 60204-1:2006.

— Низковольтное оборудование (2006/95/EC).

Применявшийся стандарт: EN 61800-5-1.

— Электромагнитная совместимость (2004/108/EC).

Применявшийся стандарт: EN 61800-3:2004.

— Директива по экологическому проектированию

энергопотребляющей продукции (2009/125/EC).

Насосы для перекачивания

Регламент Комиссии ЕС № 547/2012.

Применимо только к насосам для перекачивания воды,

промаркированным показателем минимальной эффективности

MEI. См. фирменную табличку насоса.

Данная декларация о соответствии ЕС имеет силу только в случае

публикации в составе инструкции по монтажу и эксплуатации на

продукцию производства компании Grundfos (номер публикации

96782376 1112).

воды:

SK: Prehlásenie o konformite ES

My firma Grundfos prehlasujeme na svoju plnú zodpovednost’, že výrobky

TPE, TPED, NKE, NKGE, NBE a NBGE, na ktoré sa toto prehlásenie

vzt’ahuje, sú v súlade s ustanovením smernice Rady pre zblíženie

právnych predpisov členských štátov Európskeho spoločenstva

v oblastiach:

— Smernica pre strojové zariadenie (2006/42/ES).

Použité normy: EN 809:1998 a EN 60204-1:2006.

— Smernica pre nízkonapät’ové aplikácie (2006/95/ES).

Použitá norma: EN 61800-5-1.

— Smernica pre elektromagnetickú kompatibilitu (2004/108/ES).

Použitá norma: EN 61800-3:2004.

— Smernica o ekodizajne (2009/125/ES).

Čerpadlá na vodu:

Nariadenie Komisie č. 547/2012.

Vzťahuje sa iba na čerpadlá pre vodu označené minimálnym

indexom energetickej účinnosti MEI. Viď typový štítok čerpadla.

Toto prehlásenie o konformite ES je platné iba vtedy, ak je zverejnené

ako súčasť montážnych a prevádzkových pokynov Grundfos (publikácia

číslo 96782376 1112).

RS: EC deklaracija o usaglašenosti

Mi, Grundfos, izjavljujemo pod vlastitom odgovornošću da je proizvod

TPE, TPED, NKE, NKGE, NBE i NBGE, na koji se ova izjava odnosi,

u skladu sa direktivama Saveta za usklađivanje zakona država članica

EU:

— Direktiva za mašine (2006/42/EC).

Korišćeni standardi: EN 809:1998 i EN 60204-1:2006.

— Direktiva niskog napona (2006/95/EC).

Korišćen standard: EN 61800-5-1.

— EMC direktiva (2004/108/EC).

Korišćen standard: EN 61800-3:2004.

— Direktiva o ekološkom projektovanju (2009/125/EC).

Pumpe za vodu:

Uredba Komisije br. 547/2012.

Odnosi se samo na pumpe za vodu označene sa indeksom

minimalne efikasnosti MEI. Pogledajte natpisnu pločicu pumpe.

Ova EC deklaracija o usaglašenosti važeća je jedino kada je izdata kao

deo Grundfos uputstava za instalaciju i rad (broj izdanja 96782376 1112).

PT: Declaração de conformidade CE

A Grundfos declara sob sua única responsabilidade que os produtos

TPE, TPED, NKE, NKGE, NBE e NBGE, aos quais diz respeito esta

declaração, estão em conformidade com as seguintes Directivas do

Conselho sobre a aproximação das legislações dos Estados Membros

da CE:

— Directiva Máquinas (2006/42/CE).

Normas utilizadas: EN 809:1998 e EN 60204-1:2006.

— Directiva Baixa Tensão (2006/95/CE).

Norma utilizada: EN 61800-5-1.

— Directiva EMC (compatibilidade electromagnética) (2004/108/CE).

Norma utilizada: EN 61800-3:2004.

— Directiva de Concepção Ecológica (2009/125/CE).

Bombas de água:

Regulamento da Comissão No 547/2012.

Aplica-se apenas a bombas de água registadas com o índice de

eficiência mínimo MEI. Ver a chapa de características da bomba.

Esta declaração de conformidade CE é apenas válida quando publicada

como parte das instruções de instalação e funcionamento Grundfos

(número de publicação 96782376 1112).

RO: Declaraţie de conformitate CE

Noi, Grundfos, declarăm pe propria răspundere că produsele TPE,

TPED, NKE, NKGE, NBE şi NBGE, la care se referă această declaraţie,

sunt în conformitate cu aceste Directive de Consiliu asupra armonizării

legilor Statelor Membre CE:

— Directiva Utilaje (2006/42/CE).

Standarde utilizate: EN 809:1998 şi EN 60204-1:2006.

— Directiva Tensiune Joasă (2006/95/CE).

Standard utilizat: EN 61800-5-1.

— Directiva EMC (2004/108/CE).

Standard utilizat: EN 61800-3:2004.

— Directiva Ecodesign (2009/125/CE).

Pompe de apa:

Regulamentul Comisiei nr. 547/2012.

Se aplica numai pompelor de apa cu marca de eficienta minima

index MEI. Vezi plăcuţa de identificare a pompei.

Această declarație de conformitate CE este valabilă numai când este

publicată ca parte a instrucțiunilor Grundfos de instalare şi utilizare

(număr publicație 96782376 1112).

SI: ES izjava o skladnosti

V Grundfosu s polno odgovornostjo izjavljamo, da so naši izdelki

TPE, TPED, NKE, NKGE, NBE in NBGE, na katere se ta izjava nanaša,

v skladu z naslednjimi direktivami Sveta o približevanju zakonodaje za

izenačevanje pravnih predpisov držav članic ES:

— Direktiva o strojih (2006/42/ES).

Uporabljeni normi: EN 809:1998 in EN 60204-1:2006.

— Direktiva o nizki napetosti (2006/95/ES).

Uporabljena norma: EN 61800-5-1.

— Direktiva o elektromagnetni združljivosti (EMC) (2004/108/ES).

Uporabljena norma: EN 61800-3:2004.

— Eco-design direktiva (2009/125/ES).

Vodne črpalke:

Uredba Komisije št. 547/2012.

Velja le za vodne črpalke označene z indeksom minimalne

učinkovitosti MEI. Glejte tipsko ploščico črpalke.

ES izjava o skladnosti velja samo kadar je izdana kot del Grundfos

instalacije in navodil delovanja (publikacija številka 96782376 1112).

FI: EY-vaatimustenmukaisuusvakuutus

Me, Grundfos, vakuutamme omalla vastuullamme, että tuotteet TPE,

TPED, NKE, NKGE, NBE ja NBGE, joita tämä vakuutus koskee, ovat

EY:n jäsenvaltioiden lainsäädännön yhdenmukaistamiseen tähtäävien

Euroopan neuvoston direktiivien vaatimusten mukaisia seuraavasti:

— Konedirektiivi (2006/42/EY).

Sovellettavat standardit: EN 809:1998 ja EN 60204-1:2006.

— Pienjännitedirektiivi (2006/95/EY).

Sovellettu standardi: EN 61800-5-1.

— EMC-direktiivi (2004/108/EY).

Sovellettu standardi: EN 61800-3:2004.

— Ekologista suunnittelua koskeva direktiivi (2009/125/EY).

Vesipumput:

Komission asetus nro 547/2012.

Koskee vain vesipumppuja, jotka on merkitty

minimihyötysuhdeindeksillä MEI. Katso pumpun tyyppikilvestä.

Tämä EY-vaatimustenmukaisuusvakuutus on voimassa vain, kun se

julkaistaan osana Grundfosin asennus- ja käyttöohjeita (julkaisun numero

96782376 1112).

4

Page 5

SE: EG-försäkran om överensstämmelse

Vi, Grundfos, försäkrar under ansvar att produkterna TPE, TPED, NKE,

NKGE, NBE och NBGE, som omfattas av denna försäkran, är i

överensstämmelse med rådets direktiv om inbördes närmande till EUmedlemsstaternas lagstiftning, avseende:

— Maskindirektivet (2006/42/EG).

Tillämpade standarder: EN 809:1998 och EN 60204-1:2006.

— Lågspänningsdirektivet (2006/95/EG).

Tillämpad standard: EN 61800-5-1.

— EMC-direktivet (2004/108/EG).

Tillämpad standard: EN 61800-3:2004.

— Ekodesigndirektivet (2009/125/EG).

Vattenpumpar:

Kommissionens förordning nr. 547/2012.

Avser endast vattenpumpar markerade med min. effektivitetsindex

(MEI). Se pumpens typskylt.

Denna EG-försäkran om överensstämmelse är endast giltig när den

publiceras som en del av Grundfos monterings- och driftsinstruktion

(publikation nummer 96782376 1112).

TR: EC uygunluk bildirgesi

Grundfos olarak bu beyannameye konu olan TPE, TPED, NKE, NKGE,

NBE ve NBGE ürünlerinin, AB Üyesi Ülkelerin kanunlarını birbirine

yaklaştırma üzerine Konsey Direktifleriyle uyumlu olduğunun yalnızca

bizim sorumluluğumuz altında olduğunu beyan ederiz:

— Makineler Yönetmeliği (2006/42/EC).

Kullanılan standartlar: EN 809:1998 ve EN 60204-1:2006.

—Düşük Voltaj Yönetmeliği (2006/95/EC).

Kullanılan standart: EN 61800-5-1.

— EMC Diretifi (2004/108/EC).

Kullanılan standart: EN 61800-3:2004.

— Çevreye duyarlı tasarım (Ecodesign) Direktifi (2009/125/EC).

Devirdaim su pompaları:

547/2012 sayılı Komisyon Yönetmeliği.

Yal nızca Minimum Enerji Verimlilik Endeksine (MEI) dahil olan olan

devirdaim su pompaları için geçerlidir. Pompanın bilgi etiketine

bakın.

İşbu EC uygunluk bildirgesi, yalnızca Grundfos kurulum ve çalıştırma

talimatlarının (basım numarası 96782376 1112) bir parçası olarak

basıldığı takdirde geçerlilik kazanmaktadır.

Bjerringbro, 15th November 2012

Svend Aage Kaae

Technical Director

Grundfos Holding A/S

Poul Due Jensens Vej 7

8850 Bjerringbro, Denmark

Person authorised to compile technical file and

empowered to sign the EC declaration of conformity.

Declaration of conformity

Декларация о соответствии на территории РФ

Насосы центробежные TPE, TPED, NKE, NKGE, NBE, NBGE

сертифицированы на соответствие требованиям Технического

регламента о безопасности машин и оборудования (Постановление

правительства РФ от 15.09.2009 № 53).

Сертификат соответствия:

№ C-RU.АЯ56.В.04430, срок действия до 13.09.2017 г.

№ C-RU.AЯ56.B.01938, срок действия до 15.06.2016 г.

№ C-RU.АЯ56.B.03301, срок действия до 13.03.2017 г.

№ C-DK.АЯ56.B.03740, срок действия до 27.05.2017 г.

Изделия, произведенные в России, изготавливаются в

с

ТУ 3631-008-59379130-2006

ТУ 3631-009-59379130-2007

ТУ 3631-011-59379130-2007.

Истра, 15 ноября 2012 г.

Касаткина В. В.

Руководитель отдела качества,

экологии и охраны труда

ООО Грундфос Истра, Россия

143581, Московская область,

Истринский район,

дер. Лешково, д.188

соответствии

5

Page 6

English (GB) Installation and operating instructions

Caution

Note

English (GB)

Original installation and operating instructions.

CONTENTS

1. Symbols used in this document

2. General information

3. General description

3.1 Settings

3.2 Twin-head pumps

4. Mechanical installation

4.1 Motor cooling

4.2 Outdoor installation

5. Electrical connection

5.1 Electrical connection - single-phase pumps

5.2 Electrical connection - three-phase pumps up to

7.5 kW

5.3 Electrical connection - three-phase pumps, 11-22 kW

5.4 Signal cables

5.5 Bus connection cable

5.6 Communication cable for TPED pumps

6. Modes

6.1 Overview of modes

6.2 Operating mode

6.3 Control mode

6.4 Factory setting

7. Setting by means of control panel

7.1 Setpoint setting

7.2 Setting to max. curve duty

7.3 Setting to min. curve duty

7.4 Start/stop of pump

8. Setting by means of R100

8.1 Menu OPERATION

8.2 Menu STATUS

8.3 Menu INSTALLATION

9. Setting by means of PC Tool E-products

10. Priority of settings

11. External forced-control signals

11.1 Start/stop input

11.2 Digital input

12. External setpoint signal

13. Bus signal

14. Other bus standards

15. Indicator lights and signal relay

16. Insulation resistance

17. Emergency operation (only 11-22 kW)

18. Maintenance and service

18.1 Cleaning of the motor

18.2 Relubrication of motor bearings

18.3 Replacement of motor bearings

18.4 Replacement of varistor (only 11-22 kW)

18.5 Service parts and service kits

19. Technical data - single-phase pumps

19.1 Supply voltage

19.2 Overload protection

19.3 Leakage current

19.4 Inputs/outputs

20. Technical data - three-phase pumps up to 7.5 kW

20.1 Supply voltage

20.2 Overload protection

20.3 Leakage current

20.4 Inputs/output

21. Technical data - three-phase pumps, 11-22 kW

21.1 Supply voltage

21.2 Overload protection

21.3 Leakage current

21.4 Inputs/output

22. Other technical data

23. Disposal

Page

11

14

14

14

15

15

15

16

16

16

17

17

17

17

17

19

20

21

24

24

25

25

25

25

26

26

26

27

28

29

29

29

29

29

29

29

29

29

29

29

30

30

30

30

30

30

30

30

30

31

31

33

Warnin g

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

6

6

1. Symbols used in this document

6

6

6

7

7

7

7

7

9

codes of good practice.

Warnin g

If these safety instructions are not observed,

it may r esult in pe rson al in jury !

Warnin g

The surface of the product may cause burns or

personal injury!

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment!

Notes or instructions that make the job easier

and ensure safe operation.

2. General information

These installation and operating instructions are a supplement to

installation and operating instructions for the corresponding

standard pumps TP, TPD, NK, NKG and NB, NBG.

For instructions not mentioned specifically here, please see

installation and operating instructions for the standard pump.

3. General description

Grundfos E-pumps have standard motors with integrated

frequency converter. The pumps are for single-phase or

three-phase mains connection.

The pumps have a built-in PI controller and can be set up for an

external sensor enabling control of the following parameters:

•pressure

• differential pressure

•temperature

• differential temperature

•flow.

From factory, the pumps have been set to control mode

uncontrolled. The PI controller can be activated by means of

R100.

The pumps are typically used as circulator pumps in large heating

or cooling water systems with variable demands.

3.1 Settings

The desired setpoint, can be set in three different ways:

• directly on the pump control panel

• via an input for external setpoint signal

• by means of the Grundfos wireless remote control R100.

All other settings are made by means of the R100.

Important parameters such as actual value of control parameter,

power consumption, etc. can be read via the R100.

3.2 Twin-head pumps

Twin-head pumps do not require any external controller.

6

Page 7

4. Mechanical installation

Note

N

PE

L

N

L

PE

ELCB

ELCB

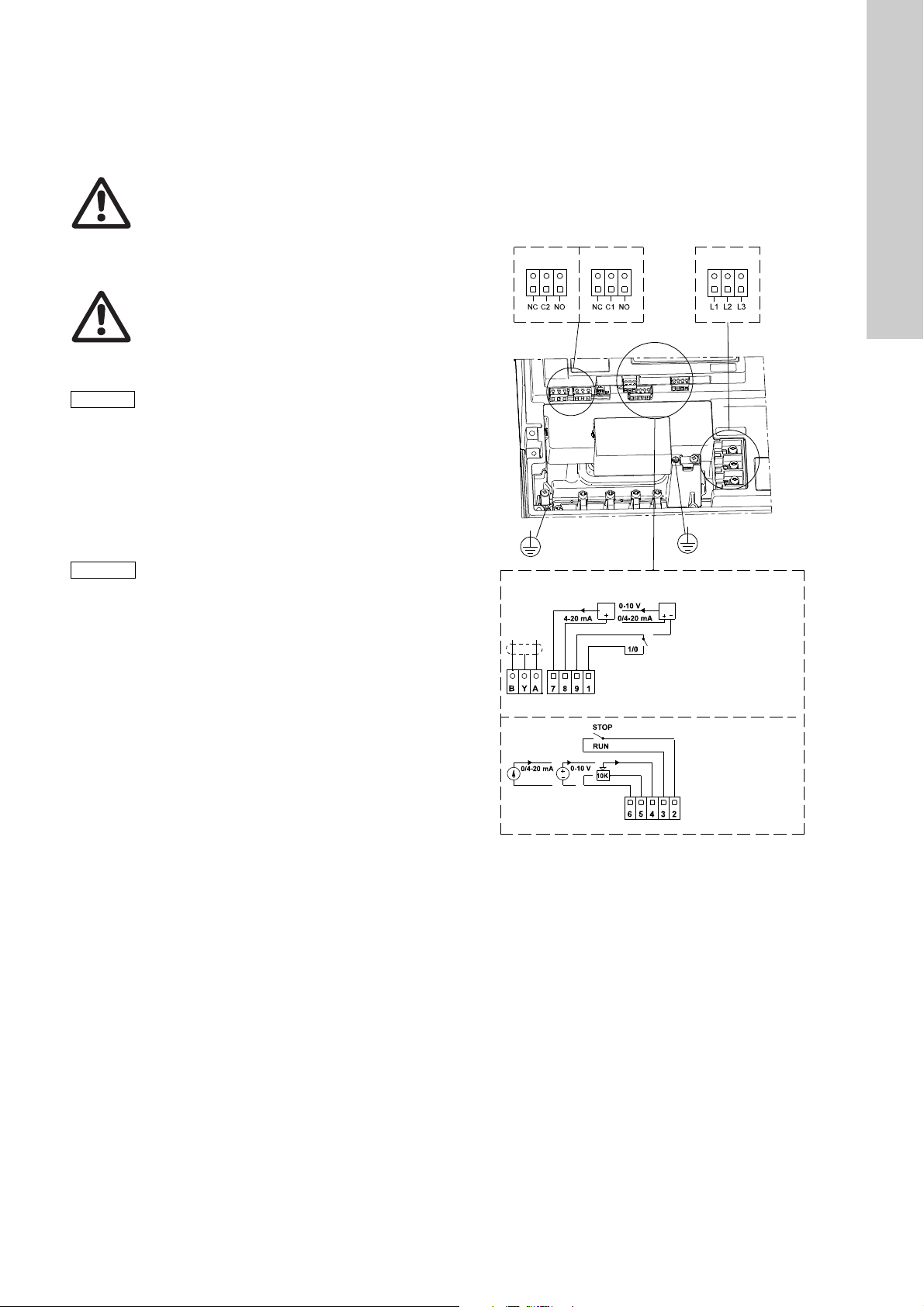

5.1 Electrical connection - single-phase pumps

In order to retain the UL/cURus approval, follow

the additional installation procedures on

page 747.

4.1 Motor cooling

To ensure sufficient cooling of motor and electronics, observe the

following requirements:

• Make sure that sufficient cooling air is available.

• Keep the temperature of the cooling air below 40 °C.

• Keep cooling fins and fan blades clean.

4.2 Outdoor installation

When installed outdoors, the pump must be provided with a

suitable cover to avoid condensation on the electronic

components. See fig. 1.

Fig. 1 Examples of covers

TM00 8622 0101 - TM02 8514 0304

The above

warning is

indicated

on the

motor

terminal

box by this

yellow

label:

Warnin g

The user or the installer is responsible for the

installation of correct earthing and protection

according to current national and local

standards. All operations must be carried out by

qualified personnel.

Warnin g

Never make any connections in the pump

terminal box unless all electric supply circuits

have been switched off for at least 5 minutes.

Note for instance that the signal relay may be

connected to an external supply which is still

connected when the mains supply is

disconnected.

Warning

The surface of the terminal box may be above

70 °C when the pump is operating.

English (GB)

Remove the drain plug pointing downwards in order to avoid

moisture and water build-up inside the motor.

Vertically mounted pumps are IP55 after removal of the drain

plug. Horizontally mounted pumps change enclosure class to

IP54.

5. Electrical connection

For description of how to connect E-pumps electrically, see the

following pages:

5.1 Electrical connection - single-phase pumps, page 7

5.2 Electrical connection - three-phase pumps up to 7.5 kW,

page 9

5.3 Electrical connection - three-phase pumps, 11-22 kW,

page 11.

5.1.1 Preparation

Before connecting the E-pump to the mains, take the issues

illustrated in the figure below into consideration.

TM02 0792 0101

Fig. 2 Mains-connected pump with mains switch, backup

fuse, additional protection and protective earthing

5.1.2 Protection against electric shock - indirect contact

Warnin g

The pump must be earthed and protected against

indirect contact in accordance with national

regulations.

Protective earth conductors must always have a yellow/green

(PE) or yellow/green/blue (PEN) colour marking.

5.1.3 Backup fuses

For recommended fuse sizes, see section 19.1 Supply voltage.

5.1.4 Additional protection

If the pump is connected to an electric installation where an earth

leakage circuit breaker (ELCB) is used as additional protection,

the circuit breaker must be of a type marked with the following

symbol:

The total leakage current of all the electrical equipment in the

installation must be taken into account.

The leakage current of the motor in normal operation can be seen

in section 19.3 Leakage current.

During start and at asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

7

Page 8

5.1.5 Motor protection

Caution

Note

0/1

10K

RUN

STOP

NC C NO N PE L

1987

65432

BYA

0-10 V

0/4-20 mA

4-20 mA

0/4-20 mA

0-10 V

1: Digital input

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

Group 3

Group 2

English (GB)

The pump requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking (IEC 34-11, TP 211).

5.1.6 Protection against mains voltage transients

The pump is protected against voltage transients by built-in

varistors between phase-neutral and phase-earth.

5.1.7 Supply voltage and mains

1 x 200-240 V - 10 %/+ 10 %, 50/60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Make sure that the motor is suitable for the power

supply of the installation site.

The wires in the terminal box must be as short as possible.

Excepted from this is the protective earth conductor which must

be so long that it is the last one to be disconnected in case the

cable is inadvertently pulled out of the cable entry.

Fig. 3 Mains connection

N

PE

L

5.1.9 Connections

If no external on/off switch is connected, connect

terminals 2 and 3 using a short wire.

As a precaution, the wires to be connected to the following

connection groups must be separated from each other by

reinforced insulation in their entire lengths:

Group 1: Inputs

• start/stop, terminals 2 and 3

• digital input, terminals 1 and 9

• setpoint input, terminals 4, 5 and 6

• sensor input, terminals 7 and 8

• GENIbus, terminals B, Y and A

All inputs (group 1) are internally separated from the mains-

conducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied with protective extra-low

voltage (PELV), thus ensuring protection against electric

shock.

Group 2: Output (relay signal, terminals NC, C, NO)

The output (group 2) is galvanically separated from other

circuits. Therefore, the supply voltage or protective extra-low

voltage can be connected to the output as desired.

Group 3: Mains supply (terminals N, PE, L)

Group 4: Communication cable (8-pin male socket) -

only TPED

The communication cable is connected to the socket in

group 4. The cable ensures communication between the two

pumps, whether one or two pressure sensors are connected.

See section 5.6 Communication cable for TPED pumps.

The selector switch in group 4 enables changeover between

the operating modes "alternating operation" and "standby

operation". See description in section 6.2.1 Additional

operating modes - TPED pumps.

TM02 0827 2107

Cable glands

Cable glands comply with EN 50626.

• 2 x M16 cable gland, cable diameter ∅4-∅10

• 1 x M20 cable gland, cable diameter ∅10-∅14

• 1 knock-out cable entry for M16 cable gland.

Warning

If the supply cable is damaged, it must be

replaced by qualified personnel.

Grid types

Single-phase E-pumps can be connected to all grid types.

Warning

Do not connect single-phase E-pumps to a mains

supply with a voltage between phase and earth of

more than 250 V.

5.1.8 Start/stop of pump

The number of starts and stops via the mains

voltage must not exceed 4 times per hour.

When the pump is switched on via the mains, it will start after

approx. 5 seconds.

If a higher number of starts and stops is desired, use the input for

external start/stop when starting/stopping the pump.

When the pump is switched on via an external on/off switch, it will

start immediately.

TM02 0795 0904

Fig. 4 Connection terminals - TPE, NKE, NKGE and NBE,

NBGE

8

Page 9

NC

Group 4

Group 2

Group 3

1: Digital input

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

L1

L2

L3

L2

L1

L3

PE

ELCB

ELCB

0-10 V

0/4-20 mA

0/4-20 mA

4-20 mA

0/1

BYA

0-10 V

CNO

1987

STOP

RUN

10K

65432

NP

EL

Fig. 5 Connection terminals - TPED

A galvanic separation must fulfil the requirements for reinforced

insulation including creepage distances and clearances specified

in EN 60335.

5.2 Electrical connection - three-phase pumps up to

7.5 kW

5.2.1 Preparation

Before connecting the E-pump to the mains, take the issues

illustrated in the figure below into consideration.

Fig. 6 Mains-connected pump with mains switch, backup

fuses, additional protection and protective earthing

5.2.2 Protection against electric shock - indirect contact

Warnin g

The pump must be earthed in accordance with

national regulations.

As the leakage current of 4 - 7.5 kW motors is

> 3.5 mA, take extra precautions when earthing

these motors.

EN 50178 and BS 7671 specify the following precautions when

leakage current > 3.5 mA:

• The pump must be stationary and installed permanently.

• The pump must be permanently connected to the power

supply.

• The earth connection must be carried out as duplicate

conductors.

Protective earth conductors must always have a yellow/green

(PE) or yellow/green/blue (PEN) colour marking.

TM02 6009 0703

5.2.3 Backup fuses

For recommended fuse sizes, see section 20.1 Supply voltage.

5.2.4 Additional protection

If the pump is connected to an electric installation where an earth

leakage circuit breaker (ELCB) is used as additional protection,

the circuit breaker must be of a type marked with the following

symbols:

English (GB)

TM00 9270 4696

The above

warning is

indicated

on the

motor

terminal

box by this

yellow

label:

Warning

The user or the installer is responsible for the

installation of correct earthing and protection

according to current national and local

standards. All operations must be carried out by

qualified personnel.

Warning

Never make any connections in the pump

terminal box unless all electric supply circuits

have been switched off for at least 5 minutes.

Note for instance that the signal relay may be

connected to an external supply which is still

connected when the mains supply is

disconnected.

This circuit breaker is type B.

The total leakage current of all the electrical equipment in the

installation must be taken into account.

The leakage current of the motor in normal operation can be seen

in section 20.3 Leakage current.

During start and at asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

9

Page 10

5.2.5 Motor protection

Caution

Note

Note

English (GB)

The pump requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking (IEC 34-11, TP 211).

5.2.6 Protection against mains voltage transients

The pump is protected against voltage transients by built-in

varistors between the phases and between phases and earth.

5.2.7 Supply voltage and mains

3 x 380-480 V - 10 %/+ 10 %, 50/60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Make sure that the pump is suitable for the power

supply of the installation site.

The wires in the terminal box must be as short as possible.

Excepted from this is the protective earth conductor which must

be so long that it is the last one to be disconnected in case the

cable is inadvertently pulled out of the cable entry.

Fig. 7 Mains connection

Cable glands

Cable glands comply with EN 50626.

• 2 x M16 cable gland, cable diameter ∅4-∅10

• 1 x M20 cable gland, cable diameter ∅9-∅17

• 2 x M16 knock-out cable entries.

Warning

If the supply cable is damaged, it must be

replaced by qualified personnel.

Grid types

Three-phase E-pumps can be connected to all grid types.

Warning

Do not connect three-phase E-pumps to a mains

supply with a voltage between phase and earth of

more than 440 V.

L1

L2

L3

5.2.8 Start/stop of pump

The number of starts and stops via the mains

voltage must not exceed 4 times per hour.

When the pump is switched on via the mains, it will start after

approx. 5 seconds.

If a higher number of starts and stops is desired, use the input for

external start/stop when starting/stopping the pump.

When the pump is switched on via an external on/off switch, it will

start immediately.

Automatic restart

If a pump set up for automatic restart is stopped

due to a fault, it will restart automatically when

the fault has disappeared.

However, automatic restart only applies to fault types set up to

automatic restart. These faults could typically be one of these

faults:

• temporary overload

• fault in the power supply.

5.2.9 Connections

If no external on/off switch is connected,

connect terminals 2 and 3 using a short wire.

As a precaution, the wires to be connected to the following

connection groups must be separated from each other by

reinforced insulation in their entire lengths:

Group 1: Inputs

• start/stop, terminals 2 and 3

• digital input, terminals 1 and 9

• setpoint input, terminals 4, 5 and 6

• sensor input, terminals 7 and 8

• GENIbus, terminals B, Y and A

All inputs (group 1) are internally separated from the mains-

conducting parts by reinforced insulation and galvanically

separated from other circuits.

TM03 8600 2007

All control terminals are supplied with protective extra-low

voltage (PELV), thus ensuring protection against electric

shock.

Group 2: Output (relay signal, terminals NC, C, NO)

The output (group 2) is galvanically separated from other

circuits. Therefore, the supply voltage or protective extra-low

voltage can be connected to the output as desired.

Group 3: Mains supply (terminals L1, L2, L3)

Group 4: Communication cable (8-pin male socket) -

only TPED

The communication cable is connected to the socket in

group 4. The cable ensures communication between the two

pumps, whether one or two pressure sensors are connected.

See section 5.6 Communication cable for TPED pumps.

The selector switch in group 4 enables changeover between

the operating modes "alternating operation" and "standby

operation". See description in section 6.2.1 Additional

operating modes - TPED pumps.

10

Page 11

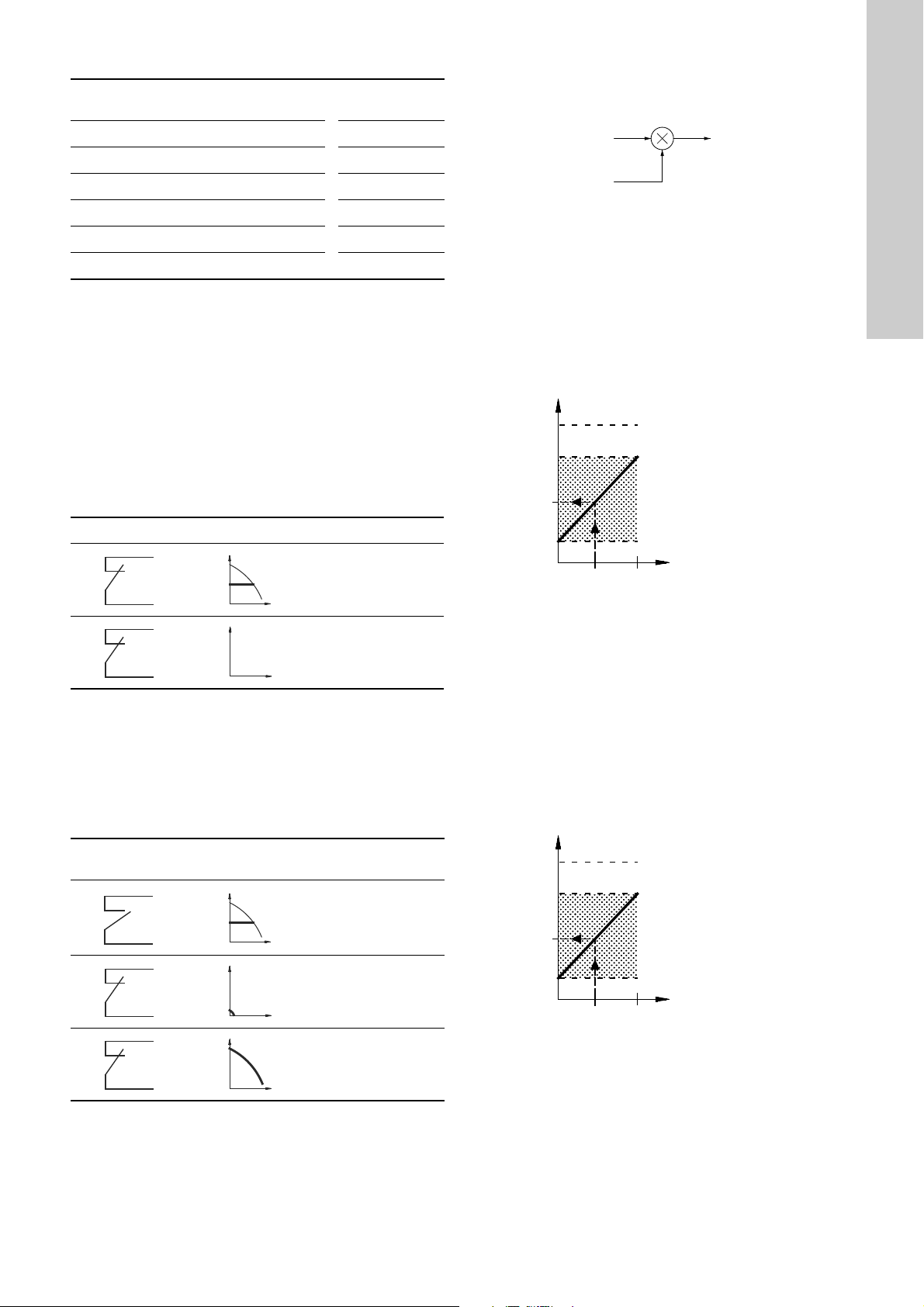

1987

BYA

0-10 V

0/4-20 mA

4-20 mA

1/0

NC

CNO

L1 L2 L3

10K

RUN

STOP

65432

0/4-20 mA

0-10 V

1: Digital input

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

Group 3

Group 2

0-10 V

Group 4

Group 2

Group 3

1: Digital input

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

0/4-20 mA

0/1

BYA

0/4-20 mA 0-10 V

4-20 mA

STOP

RUN

10K

1987

NOCNC

L3L2L1

English (GB)

Fig. 8 Connection terminals - TPE, NKE, NKGE and NBE,

NBGE

TM02 8414 5103

65432

Fig. 9 Connection terminals - TPED

A galvanic separation must fulfil the requirements for reinforced

insulation including creepage distances and clearances specified

in EN 60335.

5.3 Electrical connection - three-phase pumps,

11-22 kW

Warnin g

The user or the installer is responsible for the

installation of correct earthing and protection

according to current national and local

standards. All operations must be carried out by

qualified personnel.

Warnin g

Never make any connections in the pump

terminal box unless all electric supply circuits

have been switched off for at least 5 minutes.

Note for instance that the signal relay may be

connected to an external supply which is still

connected when the mains supply is

disconnected.

Warning

The surface of the terminal box may be above

70 °C when the pump is operating.

TM03 0125 4104

11

Page 12

5.3.1 Preparation

L1

L2

L3

L2

L1

L3

PE

ELCB

ELCB

Torques, terminals L1-L3:

Min. torque: 2.2 Nm

Max. torque: 2.8 Nm

English (GB)

Before connecting the E-pump to the mains, take the issues

illustrated in the figure below into consideration.

Fig. 10 Mains-connected pump with mains switch, backup

fuses, additional protection and protective earthing

5.3.2 Protection against electric shock - indirect contact

Warning

The pump must be earthed in accordance with

national regulations.

As the leakage current of 11-22 kW motors is

> 10 mA, take extra precautions when earthing

these motors.

EN 61800-5-1 specifies that the pump must be stationary and

installed permanently when the leakage current is > 10 mA.

One of the following requirements must be fulfilled:

• A single protective earth conductor having a cross-sectional

area of min. 10 mm

2

copper.

5.3.3 Backup fuses

For recommended fuse sizes, see section 21.1 Supply voltage.

5.3.4 Additional protection

If the pump is connected to an electric installation where an earth

leakage circuit breaker (ELCB) is used as additional protection,

the circuit breaker must be of a type marked with the following

symbols:

TM00 9270 4696

This circuit breaker is type B.

The total leakage current of all the electrical equipment in the

installation must be taken into account.

The leakage current of the motor in normal operation can be seen

in section 21.3 Leakage current.

During start and at asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

5.3.5 Motor protection

The pump requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking (IEC 34-11, TP 211).

5.3.6 Protection against mains voltage transients

The pump is protected against mains voltage transients in

accordance with EN 61800-3 and is capable of withstanding a

VDE 0160 pulse.

The pump has a replaceable varistor which is part of the transient

protection.

Over time this varistor will be worn and need to be replaced.

When the time for replacement has come, R100 and PC Tool

E-products will indicate this as a warning. See section

18. Maintenance and service.

5.3.7 Supply voltage and mains

3 x 380-480 V - 10 %/+ 10 %, 50/60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Make sure that the motor is suitable for the power

supply of the installation site.

The wires in the terminal box must be as short as possible.

Excepted from this is the protective earth conductor which must

be so long that it is the last one to be disconnected in case the

cable is inadvertently pulled out of the cable entry.

Fig. 11 Connection of a single protective earth conductor

using one of the conductors of a 4-core mains cable

(with cross-sectional area of min. 10 mm

2

)

• Two protective earth conductors of the same cross-sectional

area as the mains conductors, with one conductor connected

to an additional earth terminal in the terminal box.

Fig. 12 Connection of two protective earth conductors using

two of the conductors of a 5-core mains cable

Protective earth conductors must always have a yellow/green

(PE) or yellow/green/blue (PEN) colour marking.

12

TM04 3021 3508TM03 8606 2007

TM03 8605 2007 - TM04 3048 3508

Fig. 13 Mains connection

Page 13

Cable glands

Caution

Note

1: Digital input

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Scree n

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

Group 2

Group 3

Cable glands comply with EN 50626.

• 1 x M40 cable gland, cable diameter ∅16-∅28

• 1 x M20 cable gland, cable diameter ∅9-∅17

• 2 x M16 cable gland, cable diameter ∅4-∅10

• 2 x M16 knock-out cable entries.

Warning

If the supply cable is damaged, it must be

replaced by qualified personnel.

Grid types

Three-phase E-pumps can be connected to all grid types.

Warning

Do not connect three-phase E-pumps to a mains

supply with a voltage between phase and earth of

more than 440 V.

5.3.8 Start/stop of pump

The number of starts and stops via the mains

voltage must not exceed 4 times per hour.

When the pump is switched on via the mains, it will start after

approx. 5 seconds.

If a higher number of starts and stops is desired, use the input for

external start/stop when starting/stopping the pump.

When the pump is switched on via an external on/off switch, it will

start immediately.

5.3.9 Connections

Group 4: Communication cable (8-pin male socket) -

only TPED

The communication cable is connected to the socket in

group 4. The cable ensures communication between the two

pumps, whether one or two pressure sensors are connected.

See section 5.6 Communication cable for TPED pumps.

The selector switch in group 4 enables changeover between

the operating modes "alternating operation" and "standby

operation". See description in section 6.2.1 Additional

operating modes - TPED pumps.

English (GB)

If no external on/off switch is connected,

connect terminals 2 and 3 using a short wire.

As a precaution, the wires to be connected to the following

connection groups must be separated from each other by

reinforced insulation in their entire lengths:

Group 1: Inputs

• start/stop, terminals 2 and 3

• digital input, terminals 1 and 9

• setpoint input, terminals 4, 5 and 6

• sensor input, terminals 7 and 8

• GENIbus, terminals B, Y and A

All inputs (group 1) are internally separated from the mains-

conducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied with protective extra-low

voltage (PELV), thus ensuring protection against electric

shock.

Group 2: Output (relay signal, terminals NC, C, NO)

The output (group 2) is galvanically separated from other

circuits. Therefore, the supply voltage or protective extra-low

voltage can be connected to the output as desired.

Group 3: Mains supply (terminals L1, L2, L3)

TM03 8608 2007

Fig. 14 Connection terminals - TPE, NKE, NKGE and NBE,

NBGE

13

Page 14

English (GB)

Group 4Group 2 Group 3

1: Digital input

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

A

Y

B

A

Y

B

1

2

3

1

2

3

Pump

A

Y

B

A

Y

B

1

2

1

2

Pump

Jumper

White label

Master end

Slave end

5.5 Bus connection cable

5.5.1 New installations

For the bus connection, use a screened 3-core cable with a

conductor cross-section of min. 0.2 mm

• If the pump is connected to a unit with a cable clamp which is

identical to the one on the pump, connect the screen to this

cable clamp.

• If the unit has no cable clamp as shown in fig. 17, leave the

screen unconnected at this end.

Fig. 17 Connection with screened 3-core cable

5.5.2 Replacing an existing pump

• If a screened 2-core cable is used in the existing installation,

connect it as shown in fig. 18.

2

and max. 1.5 mm2.

TM02 8841 0904TM02 8842 0904TM02 5991 4702TM04 5497 3309

Fig. 15 Connection terminals - TPED

A galvanic separation must fulfil the requirements for reinforced

insulation including creepage distances and clearances specified

in EN 61800-5-1.

5.4 Signal cables

• Use screened cables with a conductor cross-section of

min. 0.5 mm

digital input, setpoint and sensor signals.

• Connect the screens of the cables to frame at both ends with

good frame connection. The screens must be as close as

possible to the terminals. See fig. 16.

Fig. 16 Stripped cable with screen and wire connection

• Always tighten screws for frame connections whether a cable

is fitted or not.

• Make the wires in the pump terminal box as short as possible.

14

2

and max. 1.5 mm2 for external on/off switch,

Fig. 18 Connection with screened 2-core cable

• If a screened 3-core cable is used in the existing installation,

follow the instructions in section 5.5.1 New installations.

TM03 9134 3407TM02 1325 0901

5.6 Communication cable for TPED pumps

The communication cable is connected between the two terminal

boxes. The screen of the cable is connected to the frame at both

ends with a good frame connection.

Fig. 19 Communication cable

The communication cable has a master end and a slave end as

shown in fig. 20.

Fig. 20 Master end and slave end

On pumps with factory-fitted sensor, the master end and the

sensor are connected to the same terminal box.

When the power supply to the two pumps has been switched off

for 40 seconds and switched on again, the pump connected to the

master end will start up first.

Page 15

5.6.1 Connection of two sensors

Jumper

White label

Master end

Slave end

Jumper

White label

Master end

Slave end

Q

H

Max.

Min.

The sensor signal is copied to the other pump through the red

wire of the communication cable.

If, optionally, two sensors are connected (one sensor to each

terminal box), cut the red wire. See fig. 21.

6. Modes

Grundfos E-pumps are set and controlled according to operating

and control modes.

6.1 Overview of modes

Fig. 21 Elimination of copied sensor signal

5.6.2 Elimination of "alternating operation" and

"standby operation"

If "alternating operation" and "standby operation" are not desired,

but the copied sensor signal (one sensor signal to two pumps) is

desired, cut the green wire. See fig. 22.

Operating modes Normal Stop Min. Max.

Control modes Uncontrolled Controlled

Constant

TM04 5495 3309TM04 5496 3309

1) In this example the pump is equipped with a differential

curve

Constant

pressure

pressure sensor. The pump may also be equipped with e.g.

a temperature sensor in which case the description would be

constant temperature in control mode controlled.

6.2 Operating mode

When the operating mode is set to Normal, the control mode can

be set to controlled or uncontrolled. See section 6.3 Control

mode.

The other operating modes that can be selected are Stop, Min. or

Max.

• Stop: The pump has been stopped.

• Min.: The pump is operating at its minimum speed.

• Max.: The pump is operating at its maximum speed.

Figure 23 is a schematic illustration of min. and max. curves.

English (GB)

1)

Fig. 22 Elimination of "alternating operation" and

"standby operation"

5.6.3 Elimination of TPED function

If "alternating operation" and "standby operation" as well as the

copied sensor signal are not desired, remove the communication

cable completely.

TM00 5547 0995

Fig. 23 Min. and max. curves

The max. curve can for instance be used in connection with the

venting procedure during installation.

The min. curve can be used in periods in which a minimum flow is

required.

If the power supply to the pump is disconnected, the mode setting

will be stored.

The remote control R100 offers additional possibilities of setting

and status displays. See section 8. Setting by means of R100.

15

Page 16

6.2.1 Additional operating modes - TPED pumps

Note

Q

H

set

H

Q

H

Controlled

Uncontrolled

Buttons

Indicator lights

Light fields

Light fields

Buttons

Indicator

lights

English (GB)

The TPED pumps offer the following additional operating modes:

• Alternating operation. Pump operation alternates every

24 hours. If the duty pump stops due to a fault, the other pump

will start.

• Standby operation. One pump is operating continuously.

In order to prevent seizing-up, the other pump is started

10 sec. every 24 hours. If the duty pump stops due to a fault,

the other pump will start.

Select the operating mode by means of the selector switch in the

terminal box. See figs 5, 9 and 15.

The selector switch enables changeover between the operating

modes "alternating operation" (left position) and "standby

operation" (right position).

The switches in the two terminal boxes must be set to the same

position. If the switches are positioned differently, the pump will

be in "standby operation".

Twin-head pumps can be set and operated in the same way as

single-head pumps. The duty pump uses its setpoint setting,

whether it is made by means of the control panel, via the R100 or

via bus.

Both pumps should be set to the same setpoint

and control mode. Di ffer en t se t tin g s wi ll r e su l t in

different operation when changing between the

two pumps.

If the power supply to the pump is disconnected, the pump setting

will be stored.

The remote control R100 offers additional possibilities of setting

and status displays. See section 8. Setting by means of R100.

6.4 Factory setting

TPE, NKE, NKGE and NBE, NBGE pumps

The pumps have been factory-set to uncontrolled operation.

The setpoint value corresponds to 100 % of the maximum pump

performance (see data sheet for the pump).

In sections 8.1 Menu OPERATION and 8.3 Menu

INSTALLATION, the factory-setting is marked with bold-faced

type under each individual display.

TPED pumps

The pumps have been factory-set to uncontrolled operation and

the additional operating mode "alternating operation".

The setpoint value corresponds to 100 % of the maximum pump

performance (see data sheet for the pump).

In sections 8.1 Menu OPERATION and 8.3 Menu

INSTALLATION, the factory-setting is marked with bold-faced

type under each individual display.

7. Setting by means of control panel

Warning

At high system temperatures, the pump may be

so hot that only the buttons should be touched to

avoid burns.

The pump control panel, see fig. 25 or 26, incorporates the

following buttons and indicator lights:

• Buttons, and , for setpoint setting.

• Light fields, yellow, for indication of setpoint.

• Indicator lights, green (operation) and red (fault).

6.3 Control mode

The pump can be set to two control modes, i.e.

• controlled

• uncontrolled.

In control mode controlled, the pump will adjust its performance

to the desired setpoint for the control parameter (pressure,

differential pressure, temperature, differential temperature or

flow).

In control mode uncontrolled, the pump will operate according to

the constant curve set.

Fig. 24 Pump in control mode controlled (differential pressure

control) and in control mode uncontrolled

The pumps have been factory-set to control mode uncontrolled.

See section 6.4 Factory setting.

TM00 7600 0304TM02 8513 0304

Fig. 25 Control panel, single-phase pumps

TM00 7668 0404

Fig. 26 Control panel, three-phase pumps

16

Page 17

7.1 Setpoint setting

Note

H

Q

H

Q

H

Q

The setpoint can only be set when the operating

mode is Normal.

Set the desired setpoint by pressing the button or .

The light fields on the control panel will indicate the setpoint set.

See examples in sections 7.1.1 and 7.1.2.

7.1.1 Pump in control mode controlled (differential pressure

control)

Example

Figure 27 shows that the light fields 5 and 6 are activated,

indicating a desired setpoint of 3.4 m. The sensor measuring

range is 0 to 6 m. The setting range is equal to the sensor

measuring range (see sensor nameplate).

Fig. 27 Setpoint set to 3.4 m (differential pressure control)

7.1.2 Pump in control mode uncontrolled

Example

In control mode uncontrolled, the pump performance is set within

the range from min. to max. curve, fig. 28.

7.3 Setting to min. curve duty

Press continuously to change to the min. curve of the pump

(bottom light field flashes).

To change back, press continuously until the desired setpoint

is indicated.

Fig. 30 Min. curve duty

7.4 Start/stop of pump

Start the pump by continuously pressing until the desired

setpoint is indicated.

Stop the pump by continuously pressing until none of the light

fields are activated and the green indicator light flashes.

8. Setting by means of R100

TM03 5845 4006TM00 7746 1304TM00 7345 1304

The pump is designed for wireless communication with the

Grundfos remote control R100.

English (GB)

TM00 7346 1304TM02 0936 0501

Fig. 31 R100 communicating with the pump via infra-red light

During communication, the R100 must be pointed at the control

panel. When the R100 communicates with the pump, the red

indicator light will flash rapidly. Keep pointing the R100 at the

control panel until the red LED diode stops flashing.

Fig. 28 Pump performance setting, control mode uncontrolled

7.2 Setting to max. curve duty

Press continuously to change to the max. curve of the pump

(top light field flashes).

To change back, press continuously until the desired setpoint

is indicated.

Fig. 29 Max. curve duty

The R100 offers setting and status displays for the pump.

The displays are divided into four parallel menus, fig. 32:

0. GENERAL (see operating instructions for the R100)

1. OPERATION

2. STATUS

3. INSTALLATION

The figure above each individual display in fig. 32 refers to the

section in which the display is described.

17

Page 18

English (GB)

0. GENERAL 1. OPERATION 2. STATUS 3. INSTALLATION

8.1.1 8.2.1 8.3.1 8.3.9

8.1.2 8.2.2 8.3.2 8.3.10 (3)

8.1.3 8.2.3 8.3.3 8.3.11 (3)

8.1.3 (3) 8.2.4 8.3.4 (1) 8.3.12 (3)

8.1.4 8.2.5 8.3.4 - 1 (2)

8.2.6 8.3.4 - 2 (2)

8.1.4 (3) 8.2.7 (2) 8.3 .5

8.2.8 (2) 8.3.6

8.2.9 (3) 8.3.7

(1)This display only appears for pumps up to 7.5 kW.

(2)This display only appears for three-phase pumps, 11-22 kW.

(3)This display only appears for three-phase pumps.

Fig. 32 Menu overview

18

8.3.8

Page 19

8.1 Menu

Note

The first display in the menu is this.

8.1.1 Setpoint

Set the desired setpoint in this display.

In control mode controlled, the setting range is equal to the

sensor measuring range, e.g. 0 to 25 m.

In control mode uncontrolled, the setpoint is set in % of the

maximum performance. The setting range will lie between the

min. and max. curves.

If the pump is connected to an external setpoint signal, the value

in this display will be the maximum value of the external setpoint

signal. See section 12. External setpoint signal.

Setpoint and external signal

The setpoint cannot be set if the pump is controlled via external

signals (Stop, Min. curve or Max. curve). The R100 will give this

warning: External control!

Check if the pump is stopped via terminals 2-3 (open circuit) or

set to min. or max. via terminals 1-3 (closed circuit).

See section 10. Priority of settings.

Setpoint and bus communication

The setpoint cannot be set either if the pump is controlled from an

external control system via bus communication. The R100 will

give this warning: Bus control!

To override bus communication, disconnect the bus connection.

See section 10. Priority of settings.

OPERATION

Setpoint set

Actual setpoint

Actual value

8.1.2 Operating mode

Set one of the following operating modes:

• Max.

• Normal (duty)

•Min.

•Stop.

The operating modes can be set without changing the setpoint

setting.

8.1.3 Fault indications

In E-pumps, faults may result in two types of indication: alarm or

warning.

An "alarm" fault will activate an alarm indication in the R100 and

cause the pump to change operating mode, typically to stop.

However, for some faults resulting in alarm, the pump is set to

continue operating even if there is an alarm.

A "warning" fault will activate a warning indication in the R100,

but the pump will not change operating or control mode.

The indication "Warning" only applies to threephase pumps.

Alarm

In case of alarm, the cause will appear in this display.

Possible causes:

• No alarm indication

• Too high motor temperature

• Undervoltage

• Mains voltage asymmetry (11-22 kW)

• Overvoltage

• Too many restarts (after faults)

• Overload

• Underload (11-22 kW)

• Sensor signal outside signal range

• Setpoint signal outside signal range

• External fault

• Other fault.

If the pump has been set up to manual restart, an alarm indication

can be reset in this display if the cause of the fault has

disappeared.

English (GB)

19

Page 20

Warning (only three-phase pumps)

English (GB)

In case of warning, the cause will appear in this display.

Possible causes:

• No warning indication

• Sensor signal outside signal range

• Relubricate motor bearings (only 11-22 kW), see section 18.2

• Replace motor bearings. See section 18.3

• Replace varistor (only 11-22 kW), see section 18.4.

A warning indication will disappear automatically once the fault

has been remedied.

8.1.4 Fault log

For both fault types, alarm and warning, the R100 has a log

function.

Alarm log

8.2 Menu STATUS

The displays appearing in this menu are status displays only. It is

not possible to change or set values.

The displayed values are the values that applied when the last

communication between the pump and the R100 took place. If a

status value is to be updated, point the R100 at the control panel

and press "OK".

If a parameter, e.g. speed, should be called up continuously,

press "OK" constantly during the period in which the parameter in

question should be monitored.

The tolerance of the displayed value is stated under each display.

The tolerances are stated as a guide in % of the maximum values

of the parameters.

8.2.1 Actual setpoint

Tolerance: ± 2 %

This display shows the actual setpoint and the external setpoint in

% of the range from minimum value to the setpoint set.

See section 12. External setpoint signal.

8.2.2 Operating mode

In case of "alarm" faults, the last five alarm indications will appear

in the alarm log. "Alarm log 1" shows the latest fault, "Alarm log 2"

shows the latest fault but one, etc.

The example above gives this information:

• the alarm indication Undervoltage

• the fault code (73)

• the number of minutes the pump has been connected to the

power supply after the fault occurred, 8 min.

Warning log (only three-phase pumps)

In case of "warning" faults, the last five warning indications will

appear in the warning log. "Warning log 1" shows the latest fault,

"Warning log 2" shows the latest fault but one, etc.

The example above gives this information:

• the warning indication Relubricate motor bearings

• the fault code (240)

• the number of minutes the pump has been connected to the

power supply since the fault occurred, 30 min.

This display shows the actual operating mode (Stop, Min.,

Normal (duty) or Max.). Furthermore, it shows where this

operating mode was selected (R100, Pump, Bus or External).

8.2.3 Actual value

This display shows the value actually measured by a connected

sensor.

If no sensor is connected to the pump, "-" will appear in the

display.

8.2.4 Speed

Tolerance: ± 5 %

The actual pump speed will appear in this display.

20

Page 21

8.2.5 Power input and power consumption

Note

Tolerance: ± 10 %

This display shows the actual pump input power from the mains

supply. The power is displayed in W or kW.

The pump power consumption can also be read from this display.

The value of power consumption is an accumulated value

calculated from the pump’s birth and it cannot be reset.

8.2.6 Operating hours

Tolerance: ± 2 %

The value of operating hours is an accumulated value and cannot

be reset.

8.2.7 Lubrication status of motor bearings (only 11-22 kW)

8.2.9 Time till replacement of motor bearings (only three-phase pumps)

When the motor bearings have been relubricated, a prescribed

number of times stored in the controller, the display in section 8.2.8

will be replaced by the display below.

English (GB)

This display shows when to replace the motor bearings.

The controller monitors the operating pattern of the pump and

calculates the period between bearing replacements.

The displayable values are these:

• in 2 years

• in 1 year

• in 6 months

• in 3 months

• in 1 month

• in 1 week

• Now!

8.3 Menu INSTALLATION

8.3.1 Control mode

This display shows how many times the motor bearings have

been relubricated and when to replace the motor bearings.

When the motor bearings have been relubricated, confirm this

action in the INSTALLATION menu. See section 8.3.11 Confirming

relubrication/replacement of motor bearings (only three-phase

pumps). When relubrication is confirmed, the figure in the above

display will be increased by one.

8.2.8 Time till relubrication of motor bearings (only 11-22 kW)

This display shows when to relubricate the motor bearings.

The controller monitors the operating pattern of the pump and

calculates the period between bearing relubrications. If the

operating pattern changes, the calculated time till relubrication

may change as well.

The displayable values are these:

• in 2 years

• in 1 year

• in 6 months

• in 3 months

• in 1 month

• in 1 week

• Now!

Select one of the following control modes (see fig. 24):

• Controlled

• Uncontrolled.

How to set the desired performance, see section 8.1.1 Setpoint.

If the pump is connected to a bus, the control