Grundfos Multifit MD Series, Multifit MLD Series Installation And Operating Instructions Manual

Page 1

Multilift MD, MLD

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Other languages

http://net.grundfos.com/qr/i/98127059

Page 2

English (GB) Installation and operating instructions

Caution

Note

English (GB)

Original installation and operating instructions

TABLE OF CONTENTS

1. Symbols used in this document

2. Scope of delivery

2.1 MD

2.2 MLD

3. General description

3.1 Applications

4. Transportation and storage

5. Product description

5.1 Lifting station

5.2 LC 221 controller

6. Operating LC 221 controller

6.1 Description of display

6.2 Setup menu

6.3 Information menu

6.4 Description of fault indications

7. Installation of lifting station

7.1 General description

7.2 Guidelines for installation of lifting station

7.3 Procedure for installation of lifting station

8. Installation of LC 221 controller

8.1 Location

8.2 Mechanical installation

8.3 Electrical connection

8.4 Setting of LC 221

8.5 Wiring diagrams

9. Startup

10. Maintenance and service

10.1 Mechanical maintenance

10.2 Motor

10.3 Electrical maintenance

10.4 Cleaning the level sensor

10.5 Contaminated lifting station or components

11. Fault finding

12. Technical data

12.1 Lifting station

12.2 Collecting tank

12.3 Pump

12.4 LC 221 controller

13. Disposal

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

The use of this product requires experience with and

knowledge of the product.

Persons with reduced physical, sensory or mental

capabilities must not use this product, unless they

are under supervision or have been instructed in the

use of the product by a person responsible for their

safety.

Children must not use or play with this product.

Page

10

10

12

13

14

16

16

17

17

19

19

19

20

20

21

22

22

23

23

23

24

24

25

26

26

26

26

26

26

1. Symbols used in this document

Warning

If these safety instructions are not observed, it may

2

2

2

2

3

4

4

4

4

6

result in personal injury.

Warning

These instructions must be observed for

explosion-proof pumps.

If these safety instructions are not observed, it may

result in malfunction or damage to the equipment.

Notes or instructions that make the job easier and

ensure safe operation.

2. Scope of delivery

2.1 MD

Grundfos Multilift MD lifting stations are supplied complete with

collecting tank, butterfly-non-return valves, a sensor unit with

cable and two pumps with cable, both connected to the LC 221

controller. The controller includes a power supply cable with plug.

An accessories bag containing the following items is also

included:

• 1 x installation and operating instructions

• 1 x Quick guide for controller menu

• 1 x discharge adapter flange, DN 80, with connection piece,

DN 100 (outer diameter, 110 mm)

• 1 x flexible hose, DN 100, and two clamps to connect the

discharge pipe

• 1 x flexible hose, DN 70, and two clamps to connect the

venting pipe

• 2 x screw and expansion anchor for tank fixation

• 3 x screw and washer for fastening a pipe plug in the inlet disk,

if required

• 1 x socket seal, DN 100

• 1 x socket seal, DN 50, for diaphragm pump connection or

inlet, DN 50

• 1 x gasket kit, DN 80, 4 bolts M16, nuts and washers

(galvanised).

2.2 MLD

Grundfos Multilift MLD lifting stations are supplied complete with

collecting tank, butterfly-non-return valves, a sensor unit with

cable and two pumps with cable, both connected to the LC 221

controller. The controller includes a power supply cable with plug.

An accessories bag containing the following items is also

included:

• 1 x installation and operating instructions

• 1 x Quick guide for controller menu

• 1 x discharge adapter flange, DN 80, with connection piece,

DN 100 (outer diameter, 110 mm)

• 1 x flexible hose, DN 100, and two clamps to connect

discharge pipe

• 1 x flexible hose, DN 70, and two clamps to connect venting

pipe

• 4 x screw and expansion anchor for tank fixation

• 1 x socket seal, DN 150

• 1 x flexible hose connection with two clamps, DN 50, for

diaphragm pump connection or inlet, DN 50

• 1 x gasket kit, DN 80, 4 bolts M16, nuts and washers

(galvanized).

2

Page 3

3. General description

Grundfos Multilift MD and MLD lifting stations are supplied

complete with collecting tank, pumps, level sensor, LC 221

controller and connection accessories.

The following gives a description of the components.

English (GB)

Fig. 1 Multilift MD front and rear view

Pos. Description

1Pump

2 Lifting eye for pumps

3Nameplate

4 Venting port, DN 70 (outer diameter, 75 mm), open

5 Screw cap for pressure tube and tank inspection opening

6 Vertical inlet, DN 150 (seal is accessory)

7 Fixing point

Non-return butterfly valve, DN 80, with inspection cover

8

and drain screw to lift up the valve flap

Discharge adapter flange, DN 80, to pipe ∅110 w i th

9

flexible connection piece and 2 clamps

Side or top inlet, DN 50 (seals are accessory).

10

Socket for MD; connecting piece for MLD

Collecting tank with carrying handle moulded into tank

11

body

Port for manually operated diaphragm pump, 1 1/2".

12

Socket with seal for MD; connecting piece with flexible

connection hose and clamps for MLD

13 Horizontal inlet, DN 100 (seal is accessory)

Adjustable inlet disk, DN 100

14

(DN 150 optional as accessory)

15 Separate inspection cover

TM05 1521 2911

Fig. 2 Multilift MLD front and rear view

TM05 1522 2911

3

Page 4

3.1 Applications

Note

Typ

Prod.-Nr.

P. c.

fHz

Serial no.

Phases

UV

A

kW

Gkg

m

m

98127055

0197

I

1/1

P1

Qmax

Hmin

Hmax

T

Med

max

T

Amb

max

m /h

3

C

C

Made in Germany

96075419

DK - 8850 Bjerringbro, Denmark

1

2

3

4

5

6

10

11

12

13

14

15

16

17

18

20

19

7

8

9

English (GB)

Grundfos Multilift MD and MLD lifting stations are designed for

the collection and pumping of domestic wastewater with no free

flow to sewer level. Grundfos Multilift MD and MLD lifting stations

are designed for the collection and pumping of the following

liquids:

• domestic wastewater, including grey wastewater without

faeces, black wastewater with faeces (discharge from water

closets)

• sludge-containing water.

The lifting stations are capable of pumping liquids containing

fibres, textiles, faeces, etc., below sewer level from multi-family

houses, offices, schools, hotels, restaurants, public areas and

other commercial buildings and similar industrial applications.

Do not pump rainwater with the Multilift MD and MLD lifting

stations for these two reasons:

• The motors of the lifting stations are not designed for

continuous operation which may be necessary in case of

heavy rainfall.

• Rainwater must not be discharged into a lifting station inside a

building according to EN 12056-4.

If in doubt, please contact Grundfos for advice.

Do not discharge the following substances/types of wastewater

via a lifting station:

• solid matter, tar, high content of sand, cement, ash, cardboard,

debris, garbage etc.

• wastewater from sanitary installations situated above the flood

level (this must be drained away via a free-flow drainage

system according to EN 12056-1).

• wastewater containing hazardous substances such as greasy

wastewater from large-scale catering establishments.

For drainage of greasy wastewater, use a grease separator

according to EN 1825-2 between a canteen or commercial

kitchen and the Multilift MD or MLD.

5.1 Lifting station

The Grundfos Multilift MD and MLD lifting stations are supplied

complete with two single- or three-phase submersible pumps

connected to the LC 221 controller incorporating a level sensor.

Type key, lifting station

Example M L D .22 .3 .4

Multilift lifting station

L = large tank

D = 2 pumps

Output power, P

1 = single-phase motor

3 = three-phase motor

2 = 2-pole motor

4 = 4-pole motor

Nameplate, lifting station

/ 100 (W)

2

4. Transportation and storage

Warning

Fig. 3 Nameplate, lifting station

TM04 7639 2210

The motor lifting eye is only intended for lifting the

pump. Never lift or lower the lifting station by means

of the lifting eye.

Lift the lifting station by the collecting tank.

For long periods of storage, the LC 221 controller must be

protected against moisture and heat.

After a long period of storage, the pumps must be inspected

before they are started up again. Make sure that the impellers

can rotate freely.

5. Product description

The MD and MLD Multilift lifting stations are described in the

following sections:

• section 5.1 Lifting station describing the lifting station with

collecting tank, pumps, non-return valve and level sensor

• section 5.2 LC 221 controller describing the controller as well

as the functions and operation of the controller.

In section 7. Installation of lifting station and the following

sections, the above components are described as one unit.

Pos. Description

1 Type designation

2 Product number

3 Production code (year/week)

4 Frequency [Hz]

5 Number of phases + voltage [V]

6 Voltage [V]

7 Full-load current [A]

8 Motor input power P

[kW]

1

9 EAC and CE mark

10 Duty type

11 Serial number

3

12 Maximum flow rate [m

/h]

13 Minimum head [m]

14 Maximum head [m]

15 Maximum liquid temperature [°C]

16 Maximum ambient temperature [°C]

4

17 Weight [kg]

18 European norm identification code

19 Notified Body

20 Reference number for the Declaration of Performance

Page 5

5.1.1 Collecting tank

Note

The gas-, odour- and pressure-tight collecting tank is made of

wastewater resistant polyethylene (PE) and has all necessary

ports for the connection of inlet pipes, discharge pipe, venting

pipe and a manually operated diaphragm pump, which is

available as an accessory.

The MD collecting tank has a turnable, eccentric disk in the

back allowing adjustment of the inlet to any height between 180

and 315 mm above the floor. The most common heights are

marked beside the inlet. See section 7.3 Procedure for

installation of lifting station.

Furthermore, the MD collecting tank offers four horizontal inlets in

the sides (2 x DN 100 and 2 x DN 50) and three vertical inlets at

the top of the tank (2 x DN 150 and 1 x DN 50). The centres of the

horizontal inlets are 120 mm (DN 50) and 250 mm (DN 150)

above the floor.

The side and back inlets 180 and 250 mm above the floor are for

direct connection to wall-hung or floor-standing toilet according to

EN 33 and EN 37. Further sanitary appliances can be connected

to the other ports.

The MLD collecting tank offers one vertical inlet, DN 50, at the

top of the tank and one vertical inlet, DN 150, in the stepped part

of the tank.

The tank volume and effective volume (volume between start and

stop) for Multilift MD and MLD lifting stations appear from the

following table:

MD

Inlet level [mm] 180 250 315

Total tank volume [l] 130

Effective tank volume [l] 49 69 86

MLD

Inlet level [mm] 560

Total tank volume [l] 270

Effective tank volume [l] 190

Setting to the relevant start inlet level must be made during the

start-up phase via the setup menu. See section 6.2 Setup menu.

The first step after power supply connection is a start-up phase

with level setting.

To minimise sedimentation, the tank bottom is chamfered to lead

the wastewater to the pump.

5.1.2 Pumps

The pump impellers are designed as free-flow vortex impellers,

ensuring almost unchanged performance throughout the entire

life of the pump. The stator housing of the motor is made of cast

iron. The pump has a mechanical shaft seal.

See more technical data in section 12. Technical data.

Single-phase motors are protected by a thermal switch in the

windings and run via a capacitor inside the controller cabinet.

Three-phase motors are protected by a thermal switch in the

windings and an additional thermal circuit breaker in the cabinet

of Multilift MD/MLD22, 24, 32 and 38 to cut out the motor in case

of overload.

If the phase sequence for three-phase pumps is wrong, the

controller will indicate fault and prevent the pump(s) from starting.

For correction of phase sequence, see fig. 14. For direction of

rotation, see section 10.2 Motor.

If the motor is overloaded, it will stop automatically.

When it has cooled to normal temperature, it will

restart automatically.

Performance curves are available in the databooklet, which you

can download via the QR code or link below:

http://net.grundfos.com/qr/i/98288126

5.1.3 Shaft seal

The pumps have three shaft seals, the oil chambers in between are

filled for life and therefore require no maintenance.

For replacement in case of service, please see service

instructions.

5.1.4 Motor cable

The motor cable is fitted to the motor via a cable entry.

The enclosure class is IP68. The length of the cable is either 4 m

or 10 m.

Nameplate, motor

1

2

3

4

5

6

7

8

Prod.-Nr.

Phases

DK - 8850 Bjerringbro, Denmark

98189706 - A

P. c .

1217 001

f

50

Serial no.

Hz

3

400

U

1/1

I

P1

P2

5.3

2.8

2.2

V

A

kW

S3-40%-1min

0.77

1405

n

F

24

G

IP68

Made in Germany

min

kg

-1

98189706

9

10

11

12

13

14

15

Fig. 4 Nameplate, motor

Pos. Description

1 Product number and model

2 Production code (year/week)

3 Frequency

4 Number of phases

5 Rated voltage

6 Rated current

7 Input power

8 Shaft power

9 Serial number

10 Operating mode

11 Powe r factor

12 Rated speed

13 Insulation class

14 Weight

15 Production country

English (GB)

TM03 3618 0506

5

Page 6

5.1.5 Non-return valve

Note

English (GB)

The DN 80 non-return valve includes a drain screw to lift up the

internal flap in order to drain the discharge pipe in case of

maintenance or service. The valve is designed and tested

according to EN12050-4. See fig. 5.

Loosen the lock nut a little before turning the drain

screw.

Fig. 5 Butterfly (double) non-return valve, DN 80

5.2 LC 221 controller

The LC 221 is a level controller specially designed for controlling

and monitoring the Grundfos lifting stations, Multilift MD and

MLD. The basis for the control is the signal received continuously

from the piezoresistive, analogue level sensor.

The level controller switches the MD and MLD Multilift pumps on

and off according to the liquid level measured by the level sensor.

When the first start level is reached, the first pump will start, and

when the liquid level has been lowered to the stop level, the pump

will be stopped by the controller. If the liquid level rises up to the

second start level, the second pump will also start, and when the

liquid level has been lowered to the stop level, the pumps will be

stopped by the controller.

Starts alternate between the two pumps.

In case of pump failure in one pump, the other pump will take

over (automatic pump changeover).

An alarm will be indicated in case of high water-level in the tank,

pump failure, etc.

Furthermore, the level controller has many more functions as

described below.

TM051530 2911

5.1.6 Level sensor

The piezoresistive pressure sensor placed in the controller is

connected via a hose to a pressure tube in the tank. The screw

cap where the hose is connected includes a connection for a DN

100 tube. This tube, the pressure tube, extends down into the

tank. The rising liquid level compresses the air inside the

pressure tube and hose, and the piezoresistive sensor transforms

the changing pressure into an analogue signal. The control box

uses the analogue signal to start and stop the pump and to

indicate high water-level alarm. The pressure tube is fixed

underneath the screw cap and can be taken out for maintenance,

service and for cleaning the inside of the tube. An O-ring ensures

tightness.

The hose is supplied in lengths of 4 or 10 m. The hose must be

connected to the controller.

Fig. 6 Screw cap with hose, DN 100 tube

Fig. 7 LC 221 level controller for Multilift MD and MLD

The LC 221 controller has the following functions:

• on/off control of two wastewater pumps based on a continuous

signal from a piezoresistive level sensor with alternating

operation and automatic changeover in case of pump failure

• motor protection with motor-protective circuit breaker and/or

current measurement as well as connection of thermal

switches

• motor protection via operating-time limitation with subsequent

emergency operation. Normal operating times are max.

25 seconds (MD) and 55 seconds (MLD), and the operating

TM05 0332 1011

time is limited to three minutes (see section 6.4 Description of

fault indications, fault code F011).

• automatic test runs (2 seconds) during long periods of

inactivity (24 hours after last operation)

• re-starting delay up to 45 seconds after returning from power

cut-off to mains operation (in order to even out the mains load

when several appliances are started up at the same time)

TM05 1859 3811

6

Page 7

• setting of delay times:

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Type

Prod.-No.

P.c.

f

Phases U

G

Serial no.

P

max

TAmb max

IPump max

V

A

Hz

C

O

kg

98189707

LC 221.1.230.1.10.30/150 MPU

98189707

1221

1

10

250

16

0

V01

0012

220-240

3

2

5.2

40

50

Ucontact max

IFuse max

TAmb min

A

C

O

Icontact max

V

W

A

I

c < 10 kA

IP55

Made in Germany

• automatic current measurement for alarm indications

• setting of current values:

• operating indication of:

• alarm indication of:

• selection of automatic alarm resetting

• fault log of up to 20 alarms

• selection between different start levels

• selection of maintenance interval (0, 3, 6 or 12 months).

As standard, the LC 221 has four potential-free outputs for:

Furthermore, LC 221 has six digital inputs for the following

functions:

For updates and further adjustments, a PC Tool can be

connected. See service instructions.

To allow for the situation that the normal power supply should fail,

a battery (accessory) can be installed which activates an acoustic

alarm (buzzer). The buzzer is activated as long as the fault exists.

It cannot be reset.

In case of sectional power failure, the common alarm output

which is a potential-free changeover contact can be used to

forward the alarm signal to a control room by means of an

external power source.

– stopping delay (time from the stop level is reached till the

pump is stopped) - reduces water hammer if pipes are long

– starting delay (time from the start level is reached till the

pump is started)

– alarm delay (time from a fault appears till an alarm is

indicated). This prevents short-time high-level alarm in case

of temporary high inflow to the tank.

– overcurrent (preset)

– rated current (preset)

– dry running current (preset).

– operating mode (auto, manual)

– operating hours

– impulses (number of starts)

– highest measured motor current.

– pump status (running, fault)

– phase sequence failure and missing phase

– thermal-switch failure

– high-water alarm (5 seconds delay)

– time for service/maintenance (selectable).

– pump running

– pump failure

– high water-level alarm

– common fault.

– connecting an analogue sensor (4-20 mA or 0-5 V)

– connecting up to four level switches and pressure sensors

instead of analogue sensor. An additional float switch can

be connected to the alarm input as backup for the analogue

sensor.

– connecting a separate level switch to be used for flood

detection outside Multilift MD or MLD. Lifting stations are

often installed in a sump inside the basement - the lowest

point in the building. In case of e.g. groundwater inflow or

water pipe burst, an alarm will be indicated by the controller.

– connecting a piezoresistive pressure sensor PCB

(pre-assembled)

– connecting an external alarm reset

– connecting the thermal switch of the motor.

Type key, LC 221 controller

Example LC 221 .2 .230 .1 .10 .30

LC 221 = controller type

1 = one-pump controller

2 = two-pump controller

Voltage [V]

1 = single-phase

3 = three-phase

Max. operating current [A]

Capacitors [μF]

Starting method:

[ ] = DOL

SD = Star-delta

Nameplate, LC 221 controller

The controller type, voltage variant, etc. are stated in the type

designation on the nameplate situated on the side of the

controller cabinet.

Fig. 8 Example of an LC 221 nameplate

Pos. Description

1 Type designation

2 Product number

3 Production code (year, week)

4 Number of phases

5 Maximum pump input current

6 Maximum voltage at potential-free contact

7 Maximum backup fuse

8 Minimum ambient temperature

9Version

10 Serial number

11 Rated voltage

12 Power consumption

13 Maximum current at potential-free contact

14 Weight

15 Maximum ambient temperature

16 Frequency

English (GB)

TM054782 3311

7

Page 8

5.2.1 Design

1

2

3

4

English (GB)

The LC 221 level controller incorporates the necessary

components to control and protect the pumps, such as relays and

capacitors for single-phase motors, contactors for three-phase

motors and additional motor-protective circuit breaker

(> Multilift MD22 or MLD22).

The control panel offers a user interface with operating buttons

and a display for indication of operating conditions and fault

indications.

Furthermore, it has an integrated piezoresistive pressure sensor

which is activated by compressed air directly via the pressure

tube inside the collecting tank. Finally, it has terminals for power

supply, connection to the pump and the inputs and outputs

mentioned in section 5.2 LC 221 controller.

The front cover is closed by four bayonet fastenings with quarter

turn locks. On the left side, the locks are extended and connected

to the cabinet bottom with hinge strings. The cabinet offers the

possibility of being mounted on a wall without opening it first.

A drilling template and six screws with rubber guides are

enclosed.

5.2.2 Control panel

Display (pos. 1)

The display shows all relevant operating data and fault indications.

The operation and fault indications are described in section

6.1 Description of display.

Operating buttons (pos. 2)

The level controller is operated by the operating buttons placed

under the display. The functions of the operating buttons are

described in the table below:

Operating

button

Status LEDs (pos. 3)

The upper LED (green) is on when the power supply is on.

The lower LED flashes (red) in case of fault to make the fault

visible from a long distance and is thus an addition to the display

symbols and fault codes.

Selector switch (pos. 4)

Description

• go left in the main menu.

• go up in the submenus.

• decrease values in the submenus.

• confirm a selection.

• activate the submenus.

• reset the buzzer.

• go right in the main menu.

• go down in the submenus.

• increase values in the submenus.

Fig. 9 Control panel

Pos. Description

1 Display

2 Operating buttons

3Status LEDs

4 ON-OFF-AUTO selector switch

Switch Description of function

The operating mode is selected by the

ON-OFF-AUTO selector switch which has three

different positions:

POS I:

Starts the pump manually. The operating time

protection is active and indicates alarm after three

minutes. Normal operating times are up to max.

25 seconds (MD) and 55 seconds (MLD).

TM05 1860 3811

POS O:

• Stops the pump when running and cuts off the

power supply to the pump. The three symbols

"Settings locked", "Information" and "Setup" will

be visible.

• Resets fault indications.

POS AUTO:

Automatic operation. The pump will start and stop

according to the signal from the level sensor.

8

Page 9

5.2.3 Internal layout of LC 221

Note: Cable connections for pos. 8-15:

Use a cable tie if leads protrude more than

20 mm from the cable sheath.

X5

Figure 10 shows the internal layout of LC 221.

English (GB)

7

20 7

>20

Fig. 10 Internal layout LC 221 (three-phase PCB as example)

Pos. Description Comments Terminal designation

1 Terminals for power supply PE, N, L3, L2, L1

2 Terminals for connecting pump 1 PE, N, W1, V1, U1

3 Terminals for connecting pump 2 PE, N, W2, V2, U2

4 Terminals for thermal switch, pump 1 T1, T2

5 Terminals for thermal switch, pump 2 T1, T2

6 Terminals for external reset 230 V 11, 12

7 Terminals for external alarm (outside the tank) 230 V 13, 14

8 Terminals for common fault

9 Terminals for high water-level alarm X10

10 Terminals for failure, pump 2 X9

11 Terminals for failure, pump 1 X8

12 Terminals for operation, pump 2 X7

Potential-free changeover NO/NC

contacts with max. 250 V / 2 A.

Attention: Connect these terminals

to supply network potential or low

voltage but do not mix the two.

X11

13 Terminals for operation, pump 1 X6

Terminals for level switches Digital 81-88

14

Terminals for additional high water-level alarm

(inside the tank)

Digital 81, 82

15 Terminals for analogue sensor 0-5 V or 4-20 mA 91 (GND), 92 (Signal), 93 (12 V)

16 Service connector to PC Tool 17 Connector for GENIbus interface module Not in use for this application -

18 Control circuit fuse

Fine-wire fuse:

100 mAT / 20 mm x ∅5

-

19 Piezoresistive pressure sensor module 0-5 V 20 DIP switches Not in use for this application -

Non-rechargeable batteries only.

21 Connector for battery, 9 V

The controller is not equipped with a

-

charging device.

TM05 3597 1612 - TM05 3719 1712

9

Page 10

6. Operating LC 221 controller

English (GB)

6.1 Description of display

The display of the LC 221 level controller is shown in fig. 11.

TM05 1861 3811

Fig. 11 LC 221 display

The table below describes the symbols shown in the display as well as the corresponding functions and indications.

Symbol Function Description

Settings locked

Automatic operating

mode

Information

Setup

Alarm

Impulse counter The symbol is visible when the number of starts in the information menu is shown in the display.

The symbol is visible when the setup menu is locked. This prevents unauthorised persons from

making changes to the settings. To unlock the buttons, enter the code 1234.

The symbol is visible when the level controller is in automatic mode, i.e. when the selector switch

is in position AUTO.

The symbol is visible when there is information about faults, operating hours, number of starts,

max. current of pump. The symbol will be visible if the level controller detects a fault and the fault

will be written into the fault log. After you have entered the fault log, the symbol will switch off.

See section 6.3 Information menu.

The setup menu holds information about setup for start level, rated current, the stop-, start- and alarm

delay, selection of maintenance interval, reset (automatic or manual) and reset back to factory

settings. For the procedure and a description of the settings, see section 6.2 Setup menu.

The symbol is visible if an alarm situation occurs. The type of alarm will appear from the

information menu. The symbol disappears when the fault has disappeared.

10

Settable times and fault

indication

The symbol is visible when the operating hours in the information menu and the delays set in the

setup menu are shown in the display. The symbol flashes when max. operating time has been

exceeded.

Page 11

Symbol Function Description

In automatic mode, faults are indicated by means of a code, and in normal operation these two

values are shown:

• the liquid level in the tank, if the pump is not running

• the current consumption, if the pump is running. If both pumps are running, the current

consumption shown is the value for both pumps.

In the information menu, the following information is indicated:

• fault codes

Values in the form of

digits

• operating hours

•impulses

• max. measured motor current.

In the setup menu, the following information is indicated:

•set start level

• set delays

•set currents

• sensor calibration (presettings for piezoresistive level sensor)

• service intervals

• total reset to factory settings.

English (GB)

Pump operation and

pump fault in pump 1

Pump operation and

pump fault in pump 2

Phase-sequence fault

Thermal-switch failure

High-water alarm The symbol is visible if the liquid level in the tank reaches max. level.

Liquid level The symbol is visible when the current liquid level is indicated in the middle of the display.

The symbol is visible when pump 1 is running and flashes when pump 1 has a fault. In case of

fault, it can be combined with other symbols or fault codes in the display.

The symbol is visible when pump 2 is running and flashes when pump 2 has a fault. In case of

fault, it can be combined with other symbols or fault codes in the display.

(Only three-phase pumps)

The symbol flashes in case of a phase-sequence fault and missing phase.

See section 6.4 Description of fault indications.

The symbol is visible if the motor temperature exceeds the permissible value and the thermal

switch cuts out the pump.

11

Page 12

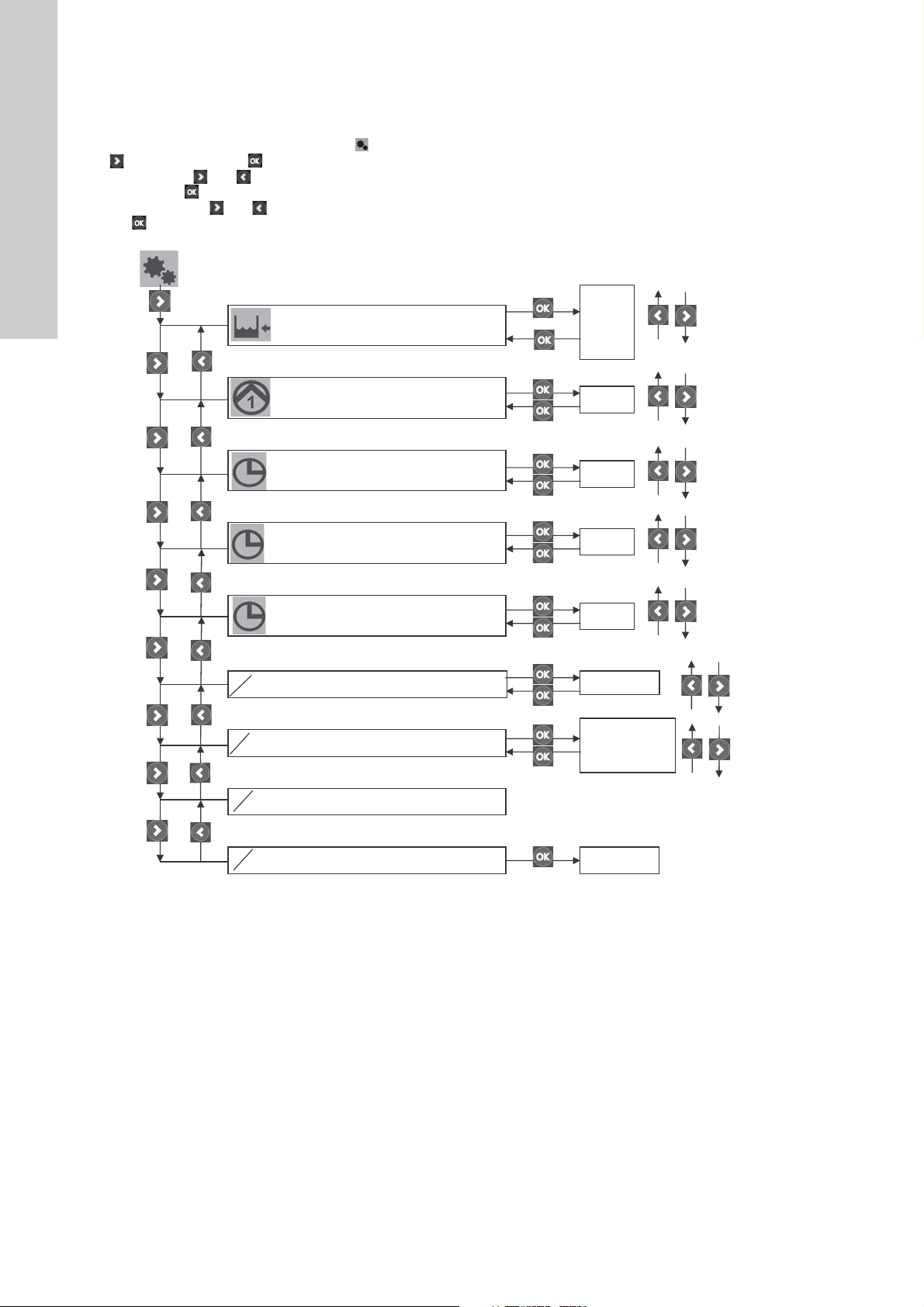

6.2 Setup menu

L_01 Start level [mm]

Setup menu

3.8

I_02 Rated current [A]

T_01 Stop delay [sec.]

T_02 Start delay [sec.]

2

0

T_03 Alarm delay [sec.]

5

Manual/

Automatic

0, 3, 6, 12

EXIT

EXIT Back to main menu

G_01 Reset to factory settings

A_01 Reset alarm

M_01 Maintenance interval [month]

180

250

315

English (GB)

All settings are preset except for the start level. The start level

depends on the inlet height and must be set during the start-up

phase. See section 8.4 Setting of LC 221. However, in case

adjustments are required, settings can be made via the setup

menu. To open the setup menu, mark the symbol using the

button and press the button . Navigate through the menu by

means of the buttons and . Select the desired menu item by

pressing the button . Enter values or select settings from a list

by means of the buttons and . Save the settings by pressing

the button . See also fig. 12.

The following settings can be made:

•start level

• rated current

• stop delay

•start delay

• alarm delay

• time for maintenance

• alarm reset (manually or automatically)

• reset to factory settings.

Fig. 12 Menu structure for setup menu

TM06 6676 2016

12

Page 13

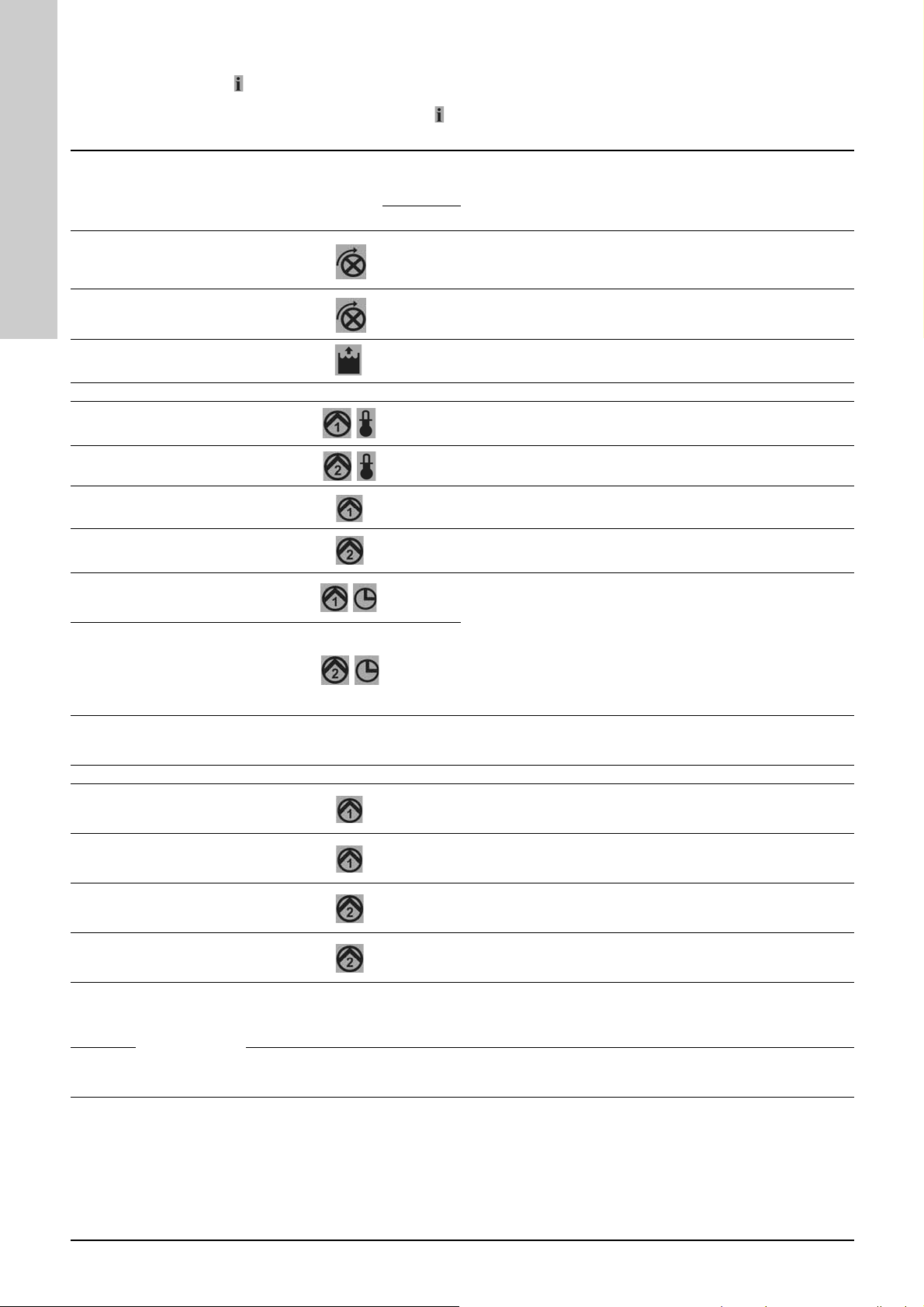

6.3 Information menu

EXIT

EXIT Back to main menu

R_03 Measured max. motor current [A]

3.9

007200

000020

20 faults from 01 to 20

20 F006 …

01 F002

R_02 Impulse counter

R_01 Hour counter

F_01 Fault LOG

Information menu

All status data and fault indications can be seen in the information

menu. The information menu can be seen in all operating modes

(ON-OFF-AUTO). To open the information menu, mark the

symbol using the button and press the button .

Navigate through the menu by means of the buttons and .

Select the desired menu item by pressing the button .

See also fig. 13.

In the information menu the following data can be read:

• fault indications

• operating hours

• number of starts

• max. measured motor current.

English (GB)

Fig. 13 Menu structure for information menu

TM05 1809 3811

13

Page 14

6.4 Description of fault indications

English (GB)

If a fault occurs, the symbol will be visible, an audible alarm will be given by the buzzer and the fault code will be written by means of

the 14-segment characters in the display. To see the kind of fault, if it is automatically reset and the code is not longer visible, open the

fault log (see fig. 13). When you leave the fault log, the symbol will disappear.

The last 20 faults are stored in the fault log as fault codes. The meaning of the fault codes are described in the table below:

Reset of

Fault

code

F001

Meaning

Phase sequence

failure

Displayed

text

F001 ●

Flashing

symbols

fault

indications

Auto Man

Description

(Only three-phase pumps)

The phase sequence between control board and power supply is

wrong. See fig. 14.

F002

F003 High liquid level F003 ●●The liquid level is high in relation to preset value.

F004 Sensor failure SENSOR - ●●Sensor signal out of range or lost.

F005

F006

F007

F008

F011

F012

F013 External fault EXT - ●

F014 Battery failure BAT - ●●The battery is empty and must be replaced.

F015

F016

F017

F018

F019

F117 F117 ●

F020

One phase

missing

Overtemperature,

pump 1

Overtemperature,

pump 2

Overcurrent,

pump 1

Overcurrent,

pump 2

Operating time

exceeded, pump 1F011 ●●

Operating time

exceeded, pump 2F012 ●●

Relay or

contactor does

not open, pump 1

Relay or

contactor does

not close, pump 1

Relay or

contactor does

not open, pump 2

Relay or

contactor does

not close, pump 2

Display

communication

failure

High level alarm

in tank

F002 ●●

TEMP ●●

TEMP ●●

F007 ●

F008 ●

RELAY ●

RELAY

RELAY ●

RELAY

Display is

off.

F020 ●

(Only three-phase pumps)

One phase is missing.

Motor thermal switches connected to the controller will stop pump 1

in case of overheating.

Motor thermal switches connected to the controller will stop pump 2

in case of overheating.

Pump 1 is stopped if an overcurrent is measured for a certain period

of time (blockage protection).

Pump 2 is stopped if an overcurrent is measured for a certain period

of time (blockage protection).

The pump has run for more than the allowed operating time and the

controller has stopped the pump for a defined cool-down period in

order to prevent overheating. The operating time and cool down

period depends on the pump. See duty type on nameplate.

Check that the outlet isolating valve is open.

Check that the non-return valve is functioning. A leaky non-return

valve can allow liquid in the outlet pipe to flow back in to the

collecting tank.

Remove any blockage from the venting system, see fig. 33.

An external level switch can be connected to the controller to give

an alarm when basement outside the lifting station is flooded by

groundwater or water from burst water pipe.

Pump 1 receives a signal to stop, but does not react. This situation

is detected by current measurement.

Pump 1 receives a signal to start, but does not react. This situation

is detected by current measurement.

Pump 2 receives a signal to stop, but does not react. This situation

is detected by current measurement.

Pump 2 receives a signal to start, but does not react. This situation

is detected by current measurement.

Communication failure between the main board and the display. As

the display is off, the fault code can be found via PC tool only.

●

Check the patch cable RJ45 between the main board and the

display.

Communication failure between the main board and the display.

The display is still on and is displaying the fault code F117. Check

the patch cable RJ45 between the main board and the display.

Alarm triggered by the additional float switch inside the tank. The

piezoresistive sensor has failed to detect the start level. The float

switch is triggered and starts a pump for 20 seconds (preset value,

changeable via PC tool).

Check the tank, the level sensor hose and the hose connections for

any air leakage.

The level sensor hose is connected correctly to the pneumatic

coupling underneath the controller when you cannot pull it out

without pressing the locking mechanism.

14

Page 15

If a fault occurs, the red LED will flash, the symbol will be

visible and the fault will be added to the fault log.

Furthermore,Hthe buzzer will be activated, the symbol will be

visible, the corresponding symbols will flash and the fault code

will be displayed. When the fault has disappeared or has been

removed, the controller will automatically switch to normal

operation again. However, the controller enables resetting of the

fault indication (visible and acoustic alarms) either manually

(Man) or automatically (Auto).

If manual resetting was selected in setup menu, the acoustic

alarm and red LED can be reset by pressing the button .

The fault indication will be reset when the fault has disappeared,

has been removed or the ON-OFF-AUTO switch has been set to

OFF position.

You can get an overview of faults in the fault log in information

menu.

The symbol will be visible as long as the fault log is open.

If automatic resetting was selected in menu setup, the red LED

and the symbol will disappear, and the buzzer will be

deactivated again after the fault has disappeared, has been

removed or the ON-OFF-AUTO switch has been set to OFF

position. However, even if automatic resetting was selected,

some of the fault indications have to be reset manually.

See the table above.

Every 30 minutes the fault indication will be written from the

short-term memory into the long-term memory.

English (GB)

Fig. 14 Changing phases of a three-phase controller with

phase inverter

TM05 3455 0616

15

Page 16

7. Installation of lifting station

472165

3

3

4

65

English (GB)

7.1 General description

When installing the Multilift MD or MLD lifting station, make sure

that all local regulations covering venting, access to the stations,

etc. are observed.

7.1.1 Installation sketches

Fig. 15 Installation sketch, Multilift MD

Fig. 16 Installation sketch, Multilift MLD

TM05 1864 3811

TM05 1865 3811

Pos. Accessories Product number

1 Socket seal, DN 100 97726942

2 Socket seal, DN 50 98079669

3 Diaphragm pump, 1 1/2" 96003721

4 PVC isolating valve, DN 100 96615831

5 Cast iron isolating valve, DN 80 96002011

6 Gasket kit, DN 80, with bolts, nuts and washers 96001999

7 Inlet disk with socket seal, DN 150, for replacement 98079681

16

Page 17

7.2 Guidelines for installation of lifting station

Note

Caution

Note

The guidelines for correct mechanical installation of lifting station

are according to EN 12056-4.

See section 7.1.1 Installation sketches.

• Install the lifting station in a properly lit and vented room with

60 cm free space around all parts to be serviced and operated.

• Provide a pump sump below the floor level. If a lifting station is

installed in a basement with the risk of penetrating

groundwater, it is advisable (in certain countries required) to

install a drainage pump in a separate pump sump below floor

level in order to drain the room. See figures 15 and 16.

The collecting tank, pump and cables may be flooded

(max. 2 m for 7 days).

The controller must be installed in a dry and well

ventilated place.

• All pipe connections must be flexible to reduce resonance.

• Lifting stations must be secured against uplift and twist.

• All discharge pipes from lifting station, diaphragm pump and

drainage pump must have a bend above the local backwater

level. The highest point of the bend/reversed water seal must

be above street level. See figures 15 and 16.

• For discharge pipes, DN 80 and upwards, install an isolating

valve in the discharge pipe. Also provide an isolating valve in

the inlet line.

• Surface water must not be discharged into the lifting station

inside the building. It must have its own pumping station

outside the building.

• Lifting stations must be provided with an approved non-return

valve according to EN 12050-4.

• The volume of the discharge pipe above the non-return-valve

up to the backwater level must be smaller than the effective

tank volume.

• In general, a lifting station for black wastewater must be

vented above roof level. However, it is permitted to lead the

ventilation, as a secondary ventilation, into the main building

ventilation system. Special venting valves (accessory) must be

placed outside the building.

• If the wastewater is discharged into a collecting line, this

collecting line must have a filling ratio of at least h/d = 0.7.

The collecting line must be at least one nominal diameter

bigger after the discharge pipe connection.

• The controller must be placed in a flood safe place and be

equipped with an alarm.

• Use a diaphragm pump for simple, manual draining of the

collecting tank in case of pump failure (not obligatory).

7.3 Procedure for installation of lifting station

7.3.1 Inlet pipe connections, Multilift MD

1. Check the scope of delivery.

For scope of delivery see section 2. Scope of delivery.

2. Prepare the adjustable inlet on the back of Multilift MD.

The turnable inlet disk has a DN 100 inlet and allows the inlet

height to be adjusted to any height between 180 and 315 mm

above floor level. The most common heights, 180, 250 and

315 mm, are marked beside the inlet. See fig. 17. An inlet disk

with a DN 150 inlet is available as an accessory. See fig. 18.

The screws around the outer ring of the inlet disk are not fully

tightened allowing the inlet disk to be turned. This will allow

the inlet to be adjusted to the desired inlet height. When the

desired inlet height has been set, tighten all screws.

All screws must be tightened to max. 9 Nm.

Before connecting Multilift MD, consider that when

turning the inlet disk to fit to the height of the inlet

pipe, the lifting station and the discharge will move

sideways accordingly (max. 72.5 mm). See fig. 17.

Fig. 17 DN 100 inlet disk, adjustable from 180 to 315 mm

above the floor to the middle of the inlet pipe

English (GB)

TM05 0351 1011

TM051669 3411

Fig. 18 Optional DN 150 inlet disk, adjustable from 207 to

279 mm above the floor to the middle of the inlet pipe

17

Page 18

English (GB)

Caution

Note

Caution

DN 50 - ∅43

DN 100 - ∅100

DN 150 - ∅150

Fig. 19 Untightened screw in outer ring

Multilift MD lifting stations are supplied with loose

screws in the outer ring of the turnable inlet disk. See

fig. 19. Check and tighten all screws to max.

tightening torque of 9 Nm before connecting the inlet

pipe.

If the main inlet is not to be used it can easily be

plugged using a standard DN 100 pipe plug fastened

with three screws and washers.

See fig. 20.

4. Prepare the connection for diaphragm pump (optional).

Use cup drill, ∅43, for DN 50 connection socket. To avoid

sharp cutting edges, the hole must be deburred.

TM05 0336 1011

TM05 1242 2511

Fig. 21 Cutting or drilling of optional connection holes

5. Connect the inlet pipe to the tank.

Install an isolating valve between inlet pipe and lifting station

to avoid inflow during maintenance and service.

We recommend an easy-to-handle PVC isolating valve.

Fig. 20 Plugging the main inlet

3. Prepare optional inlets by cutting out the desired one.

Use cup drills ∅150 for DN 150, ∅100 for DN 100 and ∅43 for

DN 50 inlets. The cutting line is recessed. To avoid sharp

cutting edges, the holes must be deburred. The socket seals

are provided with collars.

18

TM05 0329 1011 - TM05 0352 1011

TM05 1503 2811

Fig. 22 Installation of isolating valve

Make sure that weight from inlet, discharge and vent

pipes does not rest on the tank. Long pipe sections,

valves, etc. must be supported.

Warning

Never step on the lifting station.

Page 19

7.3.2 Inlet pipe connections, Multilift MLD

Note

1. Check the scope of delivery.

For scope of delivery, see section 2. Scope of delivery.

2. Prepare the ∅150 inlet.

Use a cup drill ∅150 to drill out the hole along the recessed

line. See fig. 21. The tank minimum inlet level for MLD is

approximately 560 mm. See fig. 23.

3. Prepare the additional ∅50 inlet.

Cut along the stepped line of the ∅50 inlet port on top of the

tank.

Fig. 23 Minimum inlet level for MLD

7.3.3 Further connections for Multilift MD and MLD

1. Connect the discharge pipe.

Install an isolating valve between the non-return valve and the

supplied flexible connection hose, DN 100 (internal diameter

110 mm). A flexible connection can be ensured if a distance of

approx. 3 cm is left between the pipe ends of the connection

piece and the discharge pipes.

4. Fix the tank to the floor.

Fig. 25 Fixing point for fixation of tank to the floor

8. Installation of LC 221 controller

Warning

Before making any connections in LC 221 or working

on pump, pit, etc., make sure that the power supply

has been switched off and that it cannot be

accidentally switched on.

The installation must be carried out by authorised personnel in

accordance with local regulations.

8.1 Location

TM03 3613 0406TM05 1866 3811

Warning

Do not install the LC 221 controller in explosion

hazard areas.

LC 221 can be installed at ambient temperatures ranging from

0 °C to +40 °C.

Enclosure class: IP55.

Install the controller as close as possible to the lifting station.

When installed outdoors, LC 221 must be placed in a protective

shed or enclosure. LC 221 must not be exposed to direct sunlight.

English (GB)

TM05 0334 1011

Fig. 24 Isolating valve on top of non-return valve

2. Connect the venting pipe.

The DN 70 venting port on top of the tank is open.

Connect the venting pipe to the venting port via a flexible

connection piece. The venting pipe must be led out above the

roof into the open air in accordance with local regulations.

Check the use of venting valves (accessory) according to

local regulations if venting above the roof is impossible.

A flexible connection can be ensured if a distance of

approx. 3 cm is left between the venting pipe end and the

venting port.

3. Connect the diaphragm pump (optional).

Fit the diaphragm pump on the discharge side. To facilitate

servicing of the diaphragm pump, we recommend fitting a

1 1/2" isolating valve to the tank port.

8.2 Mechanical installation

Warning

When drilling the holes, take care not to damage any

cables or water and gas pipes. Ensure a safe

installation.

LC 221 can be mounted without removing the front

cover.

Proceed as follows:

• Mount LC 221 on a plane wall surface.

• Mount LC 221 with the cable entries pointing downwards

(additional cable entries, if required, must be fitted in the

bottom plate of the cabinet).

• Mount LC 221 with four screws through the mounting holes in

the back plate of the cabinet. Drill the mounting holes with a

6 mm drill using the drilling template supplied with the

controller. Fit the screws into the mounting holes and tighten

securely. Fit the plastic caps.

19

Page 20

English (GB)

Fig. 26 Mounting of controller to the wall

8.3 Electrical connection

Warning

The protective earth (PE) of the power outlet must be

connected to the protective earth of the product. The

plug must have the same PE connection system as

the power outlet.

Warning

The installation must be fitted with a residual current

device (RCD) with a tripping current less than 30 mA.

Warning

The product must be connected to an external main

switch with a minimum contact gap of 3 mm (0.12

inch) in all poles.

Warning

LC 221 must be connected in accordance with the

rules and standards in force for the application in

question.

Warning

Before opening the cabinet, switch off the power

supply.

The operating voltage and frequency are marked on the controller

nameplate. Make sure that the controller is suitable for the power

supply on which it will be used.

All cables/wires must be fitted through the cable entries and

gaskets.

The power outlet must be placed near the cabinet as the

controller is supplied with a 1.5 m cable.

Maximum back-up fuse is stated on the controller nameplate.

8.4 Setting of LC 221

Only the start level corresponding to the inlet level to the

collecting tank needs to be set. All other values are preset but

can be adjusted if required.

Select the height of the inlet pipe, 180, 250 or 315 mm above

floor level, using the buttons and , and press the button

to save the desired value. If the height of the inlet pipe is between

two values, e.g. 220 mm above the floor, choose the nearest

lower value (180 mm). Now the controller is ready for automatic

mode.

The following values can be changed, if necessary:

Start level

The start level must be set according to the inlet pipe height

above floor level (180, 250 and 315 mm). Stop and alarm levels

are preset.

Rated current

Preset value from factory according to the rated current of the

motor. The protection against pump blockage is a preset value for

overcurrent.

Stop delay

The stop delay increases the effective volume and reduces the

quantity of residual water in the tank. It also prevents water

hammer. The non-return valve closes more softly. The preset

value is 0.

Start delay

TM05 1940 4011

Normally there is no need to make adjustments for lifting stations

except on a houseboat or pontoon boat. The preset value is 0.

Alarm delay

High temporary inflow can cause short-time high-level alarm.

This situation may arise when a backwash filter of a swimming

pool is connected to Multilift MD. Preset value is 5 seconds.

Maintenance interval

The maintenance/service interval can be set to 0, 3, 6 or

12 months and is indicated in the "SERVICE" display (no acoustic

signal).

Reset alarm

It is possible to set the controller to reset some alarms

automatically when the fault disappears; however, most alarms

must be reset manually. See section 6.4 Description of fault

indications. Preset value is AUTO.

Reset to factory settings

The controller will reboot, and start-up settings will have to be

made again. See section 6.2 Setup menu.

8.4.1 External alarm

Lifting stations are often installed in sumps below the basement

of buildings. That is the deepest point in the building, and an

additional alarm level switch can be placed outside the lifting

station to detect flooding caused by leakages, pipe bursts or

groundwater inflow.

The external alarm can be connected to a level switch (230 V /

2 A) at terminals 13, 14.

20

Page 21

8.5 Wiring diagrams

Fig. 27 Wiring diagram, single-phase Multilift MD/MLD.12.1.4

and MD/MLD.15.1.4

English (GB)

TM05 3595 1612TM05 3596 1612

Fig. 29 Wiring diagram, three-phase Multilift MD/MLD.22.3.4

with contactors

TM05 3593 1612TM05 3594 1612

Fig. 28 Wiring diagram, three-phase Multilift MD/MLD.12.3.4

and MD/MLD.15.3.4

Fig. 30 Wiring diagram, three-phase Multilift MD/MLD.24.3.2,

MD/MLD.32.3.2 and MD/MLD.38.3.2 with

motor-protective circuit breaker

21

Page 22

9. Startup

Note

English (GB)

Warning

Before starting any work on a pump used for

pumping liquids which could be hazardous to health,

clean and vent the pump, pit, etc., thoroughly

according to local regulations.

Warning

Before making any connections in LC 221 or working

on pump, pit, etc., make sure that the power supply

has been switched off and that it cannot be

accidentally switched on.

Prior to start-up, the connection and settings must have been

carried out according to sections 8.3 Electrical connection and

8.4 Setting of LC 221.

Start-up must be carried out by authorised personnel.

Proceed as follows:

1. Check all connections.

2. Connect the plug to the power supply and follow the controller

start-up sequence.

Note: It will take up to 45 seconds to boot the controller.

This time can be reduced to 5 seconds by pressing the OK

button. When the power supply is connected for the first time,

three values for the start level can be chosen (180, 250 or

315 mm above floor level) according to the inlet height to the

collecting tank. If the inlet height is between two levels,

choose the lower level for start in the display. All other

settings are preset. Some settings can be changed.

See section 8.4 Setting of LC 221. Now the controller is ready

for automatic mode (selector switch in pos. AUTO).

3. Open the isolating valves in discharge and inlet lines.

4. Activate a sanitary appliance connected to the inflow of the

Multilift MD or MLD and monitor the increasing liquid level in

the tank up to the start level. Check the starts and stops at

least twice.

If the pump cable was disconnected from the

controller, for instance to lead the cable through an

empty cable conduit, check the direction of rotation

of the pump. See section 10.2 Motor.

10. Maintenance and service

The Multilift MD and MLD require a minimum of maintenance.

Warning

Before carrying out maintenance and service on

lifting stations used for pumping liquids which might

be hazardous to health, make sure that the lifting

station has been thoroughly flushed with clean water

and that the discharge pipe has been drained. Rinse

the parts in water after dismantling. Make sure that

the isolating valves have been closed. The work

must be carried out in accordance with local

regulations.

Warning

Before making any connections in LC 221 or working

on lifting stations, make sure that the power supply

has been switched off and that it cannot be

accidentally switched on.

According to EN 12056-4 lifting stations must be checked at the

following regular intervals:

• every 12 months in single-family houses

• every 6 months in multi-family dwellings

• every 3 months in commercial and industrial applications.

During the check, local regulations must be observed.

The periodic checks of the lifting station must be carried out by

authorised personnel and must comprise electrical and

mechanical maintenance.

Check the following points:

• Discharge and inlet connections

Check all connections to the lifting station for tightness and

leakages. Make sure that weight from the inlet, discharge and

venting pipes does not rest on the tank. Long pipe sections,

valves, etc. must be supported.

• Power consumption

See nameplate.

• Cable entry

Make sure that the cable entry is watertight and that the

cables are not bent sharply and/or pinched.

• Pump parts

Remove eight screws and dismantle the pump from the tank

and check that the vent hole of the pump housing is clear.

When the pumps is mounted again, we recommend to replace

the O-ring between pump and tank. Make a test run with clean

water. In case of noise, vibration or abnormal running, contact

Grundfos.

• Ball bearings

Check the shaft for noisy or heavy operation. Replace defective

ball bearings. A general overhaul of the pump is usually

required in case of defective ball bearings or poor motor

function. This work must be carried out by the manufacturer or

an authorised service workshop.

Cleaning the non-return valve (if required)

Proceed as follows:

1. Close the isolating valves in the discharge pipe and in the

inlet pipe (if fitted) or drain the discharge pipe by tightening

the drain screw on the side of the non-return valve. See fig. 5.

2. Clean the non-return valve via its inspection cover.

Replace the gasket of the inspection cover when

reassembling the non-return valve.

22

Page 23

10.1 Mechanical maintenance

Caution

Note

• Remove possible deposits and/or sludge build-up in the

collecting tank.

• Remove any blockages on the inlet side of the lifting station.

A blockage will typically be a large solid object.

• Check and replace the gaskets of connections at valves, etc.,

if necessary.

• Check the tank for cracks and deformations. These may occur

in case of faulty assembly and therefore excessive stress on

the tank.

Note: The above list is not complete. The lifting station may be

installed in environments which require thorough and frequent

maintenance.

10.2 Motor

Check the direction of rotation of the pump in the following way:

• Turn off the power.

• Unscrew the lifting eye on top of motor. See fig. 31.

• The top of the motor shaft is now visible. See fig. 32.

Check that rotor and impeller can be turned freely by turning

the shaft with a large slotted screwdriver.

English (GB)

TM05 0344 1011TM05 0330 1011

Fig. 33 Vent holes in pump housing and collecting tank

Fig. 31 Lifting eye

Fig. 32 Top of slotted motor shaft

If the pump has been disassembled, remember to

align the vent hole in the pump with the vent hole in

the tank when remounting the pump to the tank. See

figures 33 and 34.

TM05 0338 1011TM05 0339 1011

Fig. 34 Alignment marks on tank and pump flange

10.3 Electrical maintenance

• Check the gasket of the LC 221 cabinet front cover and of the

cable entries.

• Check the cable connections.

• Check the controller functions.

• Check and clean the level sensor. See section 10.4 Cleaning

the level sensor.

• If LC 221 is installed in a particularly moist environment in a

basement, we recommend checking the terminals on the PCB

in order to identify possible corrosion. In typical installations,

the contacts will work for several years and do not require any

inspection.

• Replace the 9 V battery, if fitted, in connection with annual

service.

The above list is not complete. LC 221 may be

installed in environments which require thorough and

frequent maintenance.

23

Page 24

10.4 Cleaning the level sensor

English (GB)

1. Push the ON-OFF-AUTO selector switch to position OFF ( ).

See section 5.2.2 Control panel.

2. Loosen the screw cap by turning it counterclockwise.

See fig. 35.

3. Lift the pressure tube carefully out of the collecting tank.

Do not lift it by means of the hose.

4. Check for possible deposits on or in the pressure tube. See

section 5.1.6 Level sensor.

5. Scrape off any deposits. If necessary, remove the hose from

the controller, and rinse the tube and hose with clean water at

low pressure. Make sure no water remains in the hose.

6. Refit the pressure tube by screwing the screw cap on to the

tank. Reconnect the hose to the controller.

7. Check the sensor by test running Multilift MD, MLD.

Fig. 35 Removing the level sensor

10.5 Contaminated lifting station or components

Warning

If a Multilift lifting station has been used for a liquid

which is injurious to health or toxic, it will be

classified as contaminated.

If Grundfos is requested to service the lifting station, Grundfos

must be contacted with details about the pumped liquid, etc. before

the lifting station is returned for service. Otherwise Grundfos can

refuse to accept the lifting station for service.

Lifting stations which have been in contact with the pumped liquid

must be thoroughly cleaned before they are returned to Grundfos.

Any costs of returning the lifting station are to be paid by the

customer.

However, any application for service (no matter to whom it may

be made) must include details about the pumped liquid if the

lifting station has been used for liquids which are injurious to

health or toxic.

TM05 0545 1011

24

Page 25

11. Fault finding

Warning

Before carrying out any work on lifting stations used for pumping liquids which might be hazardous to health, make sure that

the lifting station has been thoroughly flushed with clean water and that the discharge pipe has been drained. Rinse the parts

in water after dismantling. Make sure that the isolating valves have been closed. The work must be carried out in accordance

with local regulations.

Before making any connections in the LC 221 or work on lifting stations, etc., it must be ensured that the power supply has

been switched off and that it cannot be accidentally switched on.

Fault Cause Remedy

1. The pump(s)

does/do not run.

2. The sensor signal is

out of range.

All pumps are

started and high

level alarm is on.

3. The pump(s) is/are

starting/stopping

too frequently and

even if there is no

inflow.

4. One pump starts

sometimes without

visible reason.

a) No power supply.

None of the indicator lights are on.

With battery back-up:

See section 5.2 LC 221 controller.

b) The ON-OFF-AUTO selector switch is in position

OFF ( ), see section 6. Operating LC 221

controller.

c) Control circuit fuses are blown. Check and eliminate the cause. Replace the control

d) The motor-protective circuit breaker has cut out

the pump (only relevant if a motor-protective

circuit breaker has been installed). The pump

symbol in the display is flashing and the red

indicator light for fault is flashing. The fault

indication in the display is RELAY and the fault

code is F018.

e) Motor/supply cable is defective or the connections

have become loose.

f) The fault indication in the display is SENSOR and

in the fault code is F005 and/or F006.

g) The module power circuit board or the LCD board

is defective.

a) Discharge valves are not all opened. Open all discharge isolating valves.

b) There is a blockage in the tank or pump. Remove blockage.

c) The pump venting is not working, which means

that the pump cannot built pressure.

d) The lifting station is undersized. Recalculate the inflow parameters and compare with

a) The level sensor fails. The sensor gives wrong

signal.

b) The operating time protection is activated, the

pump and time symbols are flashing, the red LED

is flashing and the display indicates fault code

F011 and/or F012. If the pump runs longer than 3

minutes, a protection program of the controller will

stop the pump for 3 minutes and the other pump

will take over. At the next start impulse, the first

pump will be activated again. If the venting

problem persists, the pump will be stopped after 3

minutes and so on.

Note: Normal operating times are up to

60 seconds depending on duty point and effective

tank volume.

c) The thermal switch has cut out the pump. The

pump and thermal switch symbols on the display

are flashing, and the red indicator light for fault is

permanently on. The fault indication in the display

is TEMP and in the fault code is F005 and/or

F006.

a) Test run 24 hours after last operation. No action necessary. It is a safety function that

Switch on the power supply or wait until the power cut

is over. During the power cut, drain the collecting tank

with diaphragm pump.

Push the ON-OFF-AUTO selector switch into position

ON ( ) or AUTO ( ).

circuit fuses.

Check the pump and tank as well as the setting of the

motor-protective circuit breaker. If the pump is

blocked, remove the blockage. If the setting of the

motor-protective circuit breaker is wrong, readjust it

(compare the setting with the nameplate).

Check motor and supply cable. Replace cable or

retighten connections if necessary.

Clean the level sensor (see section 10.4 Cleaning the

level sensor), and start up again. Check the cable and

the connection on the controller board. If the signal is

still wrong, please call Grundfos service.

Replace the PCB or LCD board.

Remove blockage from the pump venting hole,

located above the impeller.

the size and pumping volume of the lifting station.

Contact the nearest Grundfos sales company for

ordering a new product if needed.

Clean the level sensor

(see section 10.4 Cleaning the level sensor).

Check that the discharge valve is open. Check the

venting of the pump housing. If blocked clean the vent

hole. See fig. 33.

Allow the pump to cool. After cooling, the pump will

restart automatically unless the LC 221 has been set

to manual restarting. See section 8.4 Setting of LC

221. If so, the ON-OFF-AUTO selector switch must be

pushed into position OFF ( ) for a short period.

Check the inflow parameters and the non-return valve.

The risk is low, but if the non-return valve flap is leaky,

liquid in the discharge pipe can flow back.

A high number of starts without cooling time in

between over a longer period can cause thermal

cut-out. Consider S3 duty. See section 12. Technical

data.

See also section 10.4 Cleaning the level sensor.

prevents the shaft sealing from seizing up.

English (GB)

25

Page 26

12. Technical data

English (GB)

12.4 LC 221 controller

12.1 Lifting station

Weight:

Temperature range:

Flood conditions: Max. 2 m for 7 days

Sound pressure level:

Depending on variant.

See nameplates

0-40 °C

For short periods up to 60 °C

(max. 5 minutes per hour)

< 70 dB(A) according to

EN 12050-1 and the Machinery

Directive

12.2 Collecting tank

Material: PE (polyethylene)

12.3 Pump

Motor

Mains frequency: 50 Hz

Isolation class: F (155 °C)

Impeller type: Vortex

Enclosure class: IP68

pH-range: 4-10

Starts per hour: Max. 60

Max density of liquid: 1100 kg/m

3

Controller

Voltage variants,

rated voltages:

Voltage tolerances for LC 221: - 10 %/+ 6 % of rated voltage

Mains frequency for LC 221: 50/60 Hz

Supply system earthing: For TN systems

Controller power consumption: 6 W

Control circuit fuse:

Ambient temperature:

During operation:

In stock:

Enclosure class: IP55

Potential-free contacts: NO/NC, max. 250 VAC / 2 A

Input external reset: 230 V

Cabinet of LC 221

External dimensions:

Material:

Weight:

1 x 230 V, 3 x 230 V,

3 x 400 V

Fine-wire fuse:

100 mAT / 250 V / 20 mm x ∅5

0 to +40 °C (must not be

exposed to direct sunlight)

-30 to +60 °C

Height = 390 mm

Width = 262 mm

Depth = 142 mm

ABS

(acrylonitrile butadiene styrene)

Depending on variant.

See nameplate

Component Material

Pump housing Cast iron

Impeller PPE+PS

Pump shaft

Motor cable Polychloroprene

O-rings NBR rubber

Multilift MD

Multilift MLD

MD/MLD.12.1.4

MD/MLD.12.3.4 3 x 400 V 1.8 / 1.5 3.7 / 19 CEE 3P+N+E, 16 A

MD/MLD.15.1.4 1 x 230 V 2.3 / 1.7 10.1 / 39

MD/MLD.15.3.4 3 x 400 V 2.3 / 1.8 4 / 19 CEE 3P+N+E, 16 A

MD/MLD.22.3.4

MD/MLD.22.3.4 3 x 400 V 5.5 / 29.7 CEE 3P+N+E, 16 A

MD/MLD.24.3.2 3 x 230 V

MD/MLD.24.3.2 3 x 400 V 5.5 / 39 CEE 3P+N+E, 16 A

MD/MLD.32.3.2 3 x 230 V

MD/MLD.32.3.2 3 x 400 V 6.7 / 39 CEE 3P+N+E, 16 A

MD/MLD.38.3.2

MD/MLD.38.3.2 3 x 400 V 7.5 / 39 CEE 3P+N+E, 16 A

S3 -50 %, 1 min.

S3 -50 %, 1 min.

S3 -40 %, 1 min.

Stainless steel,

DIN W.-Nr. 1.4301

Duty Voltage [V]

1 x 230 V 1.9 / 1.4 9 / 39

3 x 230 V

3 x 230 V

Power P1 / P2

[kW]

2.8 / 2.3

3.1 / 2.6

4.0 / 3.4

4.6 / 3.9

I

/ I

1/1

start

10.2 / 51.5

9.7 / 88.7

88.7

13 / 88.7

[A] RPM [min-1]

1430 4

1410 4

1430 4

2920 2

2920 2

2880 2

Number of

poles

Plug type

E/F, I

-

E/F, I

-

CEE 3P+E 16 A

CEE 3P+E 16 A

CEE 3P+E 16 A

CEE 3P+E 16 A

13. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest Grundfos company

or service workshop.

26

The crossed-out wheelie bin symbol on a product

means that it must be disposed of separately from

household waste. When a product marked with this

symbol reaches its end of life, take it to a collection

point designated by the local waste disposal

authorities. The separate collection and recycling of such

products will help protect the environment and human health.

Page 27

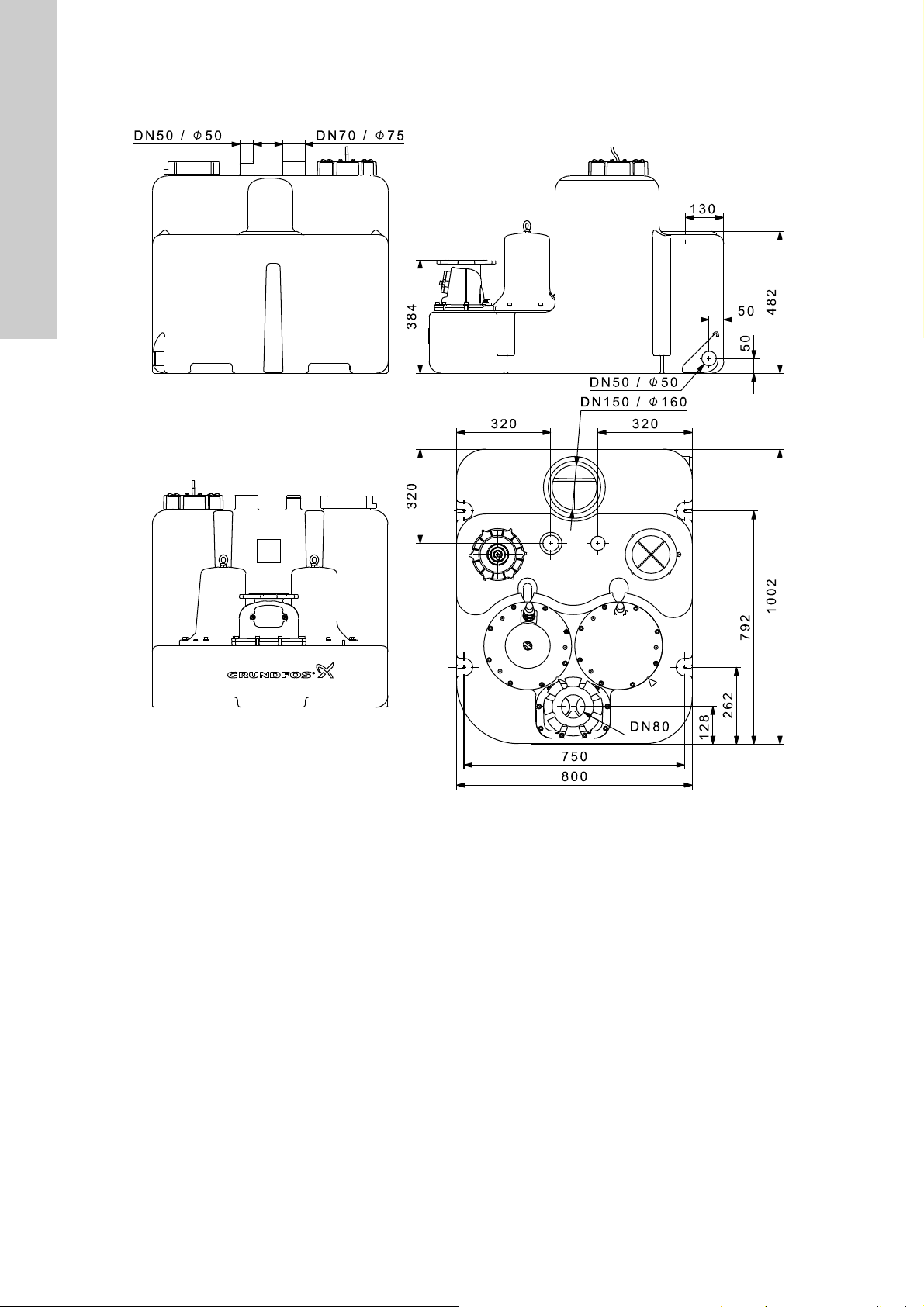

Appendix 1

Fig. A - Dimensional sketches - MD

Appendix

27

TM05 0441 1011

Page 28

Appendix

Fig. B - Dimensional sketches - MLD

TM05 0442 1011

28

Page 29

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Centro

Industrial Garin

1619 Garín Pcia. de B.A.

Phone: +54-3327 414 444

Telefax: +54-3327 45 3190

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belarus

Представительство ГРУНДФОС в

Минске

220125, Минск

ул. Шафарнянская, 11, оф. 56, БЦ

«Порт»

Тел.: +7 (375 17) 286 39 72/73

Факс: +7 (375 17) 286 39 71

E-mail: minsk@grundfos.com

Bosnia and Herzegovina

GRUNDFOS Sarajevo

Zmaja od Bosne 7-7A,

BH-71000 Sarajevo

Phone: +387 33 592 480

Telefax: +387 33 590 465

www.ba.grundfos.com

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

10F The Hub, No. 33 Suhong Road

Minhang District

Shanghai 201106

PRC

Phone: +86 21 612 252 22

Telefax: +86 21 612 253 33

COLOMBIA

GRUNDFOS Colombia S.A.S.

Km 1.5 vía Siberia-Cota Conj. Potrero

Chico,

Parque Empresarial Arcos de Cota Bod.

1A.

Cota, Cundinamarca

Phone: +57(1)-2913444

Telefax: +57(1)-8764586

Croatia

GRUNDFOS CROATIA d.o.o.

Buzinski prilaz 38, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.hr.grundfos.com

GRUNDFOS Sales Czechia and

Slovakia s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com