Page 1

GRUNDFOS INSTRUCTIONS

CRE, CRIE, CRNE, SPKE, CRKE,

MTRE, CME

Grundfos E-pumps with MLE frequency-controlled, asynchronous

motors

Installation and operating instructions

Page 2

English (US)

English (US) Installation and operating instructions

Original installation and operating instructions.

CONTENTS

1. Limited warranty

2. Symbols used in this document

3. General information

4. General description

4.1 Pumps without factory-fitted sensor

4.2 Pumps with pressure sensor

4.3 Settings

5. Mechanical installation

5.1 Motor cooling

5.2 Outdoor installation

6. Electrical connection

6.1 Single-phase pumps

6.2 Three-phase pumps, 1.5 - 10 hp

6.3 Three-phase pumps, 15-30 hp

6.4 Signal cables

6.5 E-pump electrical connections

6.6 Bus connection cable

7. Modes

7.1 Overview of modes

7.2 Operating mode

7.3 Control mode

8. Setting up the pump

8.1 Factory setting

9. Setting by means of control panel

9.1 Setting of operating mode

9.2 Setpoint setting

10. Setting by means of R100

10.1 Menu OPERATION

10.2 Menu STATUS

10.3 Menu INSTALLATION

10.4 Typical display settings for constant-pressure E-pumps

10.5 Typical display settings for analog-input E-pumps

10.6 Grundfos GO Remote

11. Setting by means of PC Tool E-products

12. Priority of settings

13. External forced-control signals

13.1 Start/stop input

13.2 Digital input

14. External setpoint signal

15. Bus signal

16. Other bus standards

17. Indicator lights and signal relay

18. Emergency operation (only 15-30 hp)

19. Insulation resistance

20. Maintenance and service

20.1 Cleaning of the motor

20.2 Relubrication of motor bearings

20.3 Replacement of motor bearings

20.4 Replacement of varistor (only 15-30 hp)

20.5 Service parts and service kits

21. Technical data - three-phase pumps, 1.5 - 10 hp

21.1 Supply voltage

21.2 Overload protection

21.3 Leakage current

21.4 Inputs/output

Page

10

10

10

10

10

11

11

11

12

12

12

14

15

16

23

24

25

26

26

26

26

27

27

28

28

28

30

31

31

31

31

31

31

31

31

31

31

31

31

22. Technical data - three-phase pumps, 15-30 hp

22.1 Supply voltage

22.2 Overload protection

22.3 Leakage current

2

3

3

3

3

3

3

3

3

3

4

4

4

6

9

9

22.4 Inputs/output

22.5 Other technical data

23. Disposal

1. Limited warranty

Products manufactured by GRUNDFOS PUMPS CORPORATION

(Grundfos) are warranted to the original user only to be free of

defects in material and workmanship for a period of 24 months

from date of installation, but not more than 30 months from date

of manufacture. Grundfos' liability under this warranty shall be

limited to repairing or replacing at Grundfos' option, without

charge, F.O.B. Grundfos' factory or authorized service station,

any product of Grundfos' manufacture. Grundfos will not be liable

for any costs of removal, installation, transportation, or any other

charges which may arise in connection with a warranty claim.

Products which are sold but not manufactured by Grundfos are

subject to the warranty provided by the manufacturer of said

products and not by Grundfos' warranty. Grundfos will not be

liable for damage or wear to products caused by abnormal

operating conditions, accident, abuse, misuse, unauthorized

alteration or repair, or if the product was not installed in

accordance with Grundfos' printed installation and operating

instructions.

To obtain service under this warranty, the defective product must

be returned to the distributor or dealer of Grun dfos' products from

which it was purchased together with proof of purchase and

installation date, failure date, and supporting installation data.

Unless otherwise provided, the distributor or dealer will contact

Grundfos or an authorized service station for instructions. Any

defective product to be returned to Grundfos or a service station

must be sent freight prepaid; documentation supporting the

warranty claim and/or a Return Material Authorization must be

included if so instructed.

GRUNDFOS WILL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES, LOSSES, OR EXPENSES

ARISING FROM INSTALLATION, USE, OR ANY OTHER

CAUSES. THERE ARE NO EXPRESS OR IMPLIED

WARRANTIES, INCLUDING MERCHANTABILITY OR FITNESS

FOR A PARTICULAR PURPOSE, WHICH EXTEND BEYOND

THOSE WARRANTIES DESCRIBED OR REFERRED TO

ABOVE.

Some jurisdictions do not allow the exclusion or limitation of

incidental or consequential damages and some jurisdictions do

not allow limit actions on how long implied warranties may last.

Therefore, the above limitations or exclusions may not apply to

you. This warranty gives you specific legal rights and you may

also have other rights which vary from jurisdiction to jurisdiction.

Warnin g

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

32

32

32

32

32

33

33

2

Page 3

2. Symbols used in this document

Caution

Note

Note

Note

Note

Warnin g

If these safety instructions are not observed, it

may result in personal injury!

Warnin g

The surface of the product may be so hot that

it may cause burns or personal injury.

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment.

4.3 Settings

The description of settings apply both to pumps without factoryfitted sensor and to pumps with a factory-fitted pressure sensor.

Setpoint

The desired setpoint can be set in three different ways:

• directly on the pump control panel

• via an input for external setpoint signal

• by means of Grundfos wireless remote control R100.

Other settings

All other settings can only be made by means of the R100.

Important parameters such as actual value of control parameter,

power consumption, etc. can be read via the R100.

If special or customized settings are required, use Grundfos PC

Tool E-products. Contact your local Grundfos company for more

information.

English (US)

Notes or instructions that make the job easier

and ensure safe operation.

3. General information

These installation and operating instructions are a supplement to

installation and operating instructions for the corresponding

standard pumps CR, CRI, CRN, CRK, SPK, MTR, CHI and CM.

For instructions not mentioned specifically here, please see

installation and operating instructions for the standard pump.

4. General description

Grundfos E-pumps have standard motors with integrated

frequency converter. The pumps are for single-phase or threephase power supply connection.

4.1 Pumps without factory-fitted sensor

The pumps have a built-in PI controller and can be set up for an

external sensor enabling control of the following parameters:

• pressure

• differential pressure

• temperature

• differential temperature

•flow rate

• liquid level in a tank.

From factory, the pumps have been set to control mode

uncontrolled. The PI controller can be activated by means of

R100.

4.2 Pumps with pressure sensor

The pumps have a built-in PI controller and are set up with a

pressure sensor enabling control of the pump discharge

pressure.

The pumps are set to control mode controlled. The pumps are

typically used to hold a constant pressure in variable-demand

systems.

5. Mechanical installation

The pump must be secured to a solid foundation by means of

bolts through the holes in the flange or baseplate.

In order to retain the UL/cUL approval, follow the

additional installation procedures on page 35.

5.1 Motor cooling

To ensure sufficient cooling of motor and electronics, observe the

following requirements:

• Make sure that sufficient cooling air is available.

• Keep the temperature of the cooling air below 104 °F (40 °C).

• Keep cooling fins and fan blades clean.

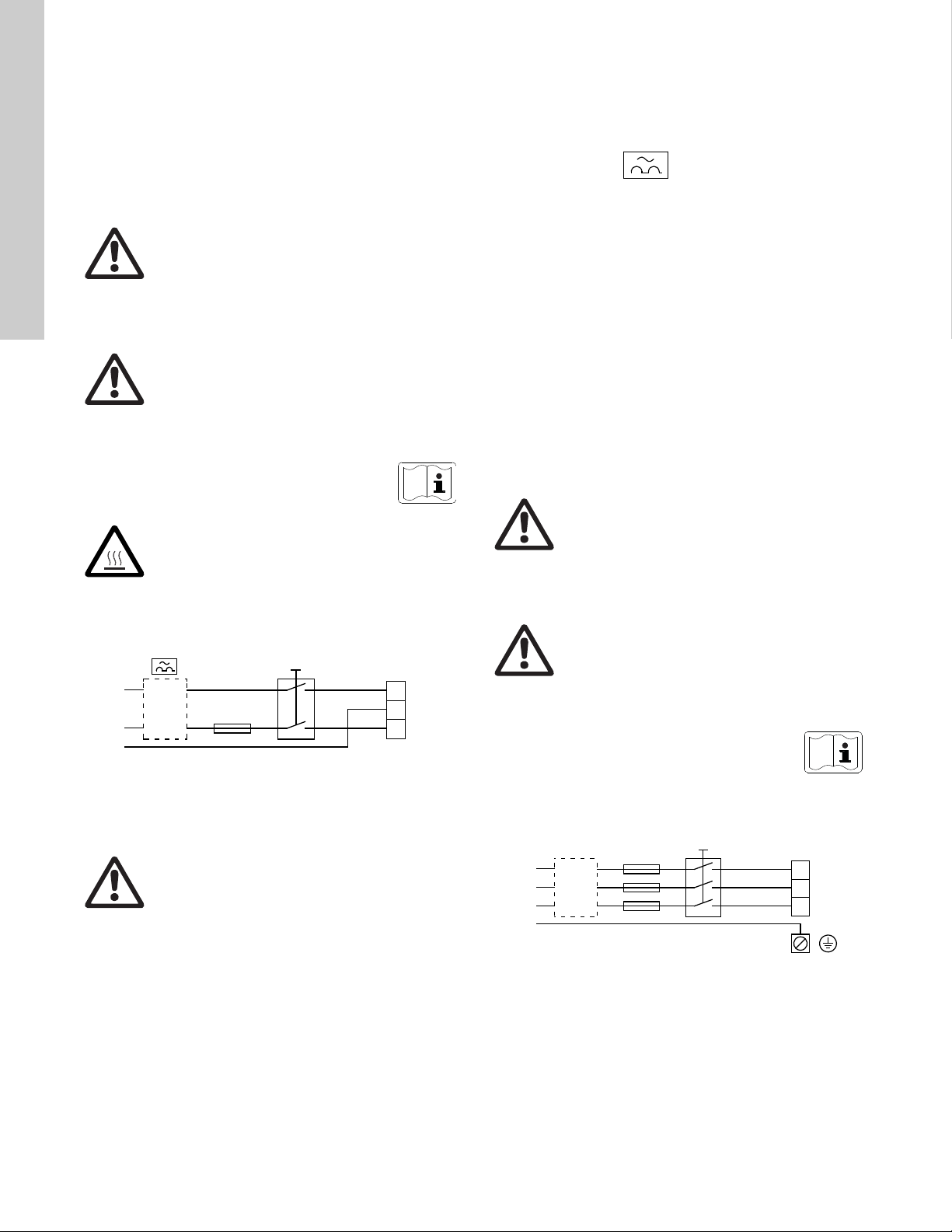

5.2 Outdoor installation

When installed outdoors, the pump must be provided with a

suitable cover to avoid condensation on the electronic

components. See fig. 1.

TM00 8622 0101 - TM02 8514 0304

Fig. 1 Examples of covers

Remove the drain plug pointing downwards in order to avoid

moisture and water build-up inside the motor.

Vertically mounted pumps are IP55 after removal of the drain

plug. Horizontally mounted pumps change enclosure class to

IP54.

3

Page 4

English (US)

N

PE

L

N

L

PE

ELCB

ELCB

L1

L2

L3

L2

L1

L3

PE

ELCB

6. Electrical connection

For description of how to connect E-pumps electrically, see the

following pages:

6.1 Single-phase pumps, page 4

6.2 Three-phase pumps, 1.5 - 10 hp, page 4

6.3 Three-phase pumps, 15-30 hp, page 6.

6.1.4 Additional protection

If the pump is connected to an electric installation where an

ground leakage circuit breaker (ELCB) is used as additional

protection, the circuit breaker must be of a type marked with the

following symbol:

6.1 Single-phase pumps

Warnin g

The user or the installer is responsible for the

installation of correct grounding and protection

according to current national and local

standards. All operations must be carried out by

qualified personnel.

Warnin g

Never make any connections in the pump

terminal box unless all electric supply circuits

have been switched off for at least 5 minutes.

Note for instance that the signal relay may be

connected to an external supply which is still

connected when the power supply is

disconnected.

The above warning is indicated on the motor terminal

box by this yellow label:

Warnin g

The surface of the terminal box may be above

158 °F (70 °C) when the pump is operating.

6.1.1 Preparation

Before connecting the E-pump to the power supply, take the

issues illustrated in the figure below into consideration.

The total leakage current of all the electrical equipment in the

installation must be taken into account.

The leakage current of the motor in normal operation can be seen

in section 22.3 Leakage current on page 32.

During start and at asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

6.1.5 Motor protection

The pump requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking (IEC 34-11, TP 211).

6.1.6 Protection against voltage transients

The pump is protected against voltage transients by built-in

varistors between phase-neutral and phase-ground.

6.2 Three-phase pumps, 1.5 - 10 hp

Warnin g

The user or the installer is responsible for the

installation of correct grounding and protection

according to current national and local

standards. All operations must be carried out by

qualified personnel.

Warnin g

Never make any connections in the pump

terminal box unless all electric supply circuits

have been switched off for at least 5 minutes.

Note for instance th at th e sign al rel ay may be

connected to an external supply which is still

connected when the power supply is

disconnected.

Fig. 2 Power supply-connected pump with power switch,

backup fuse, additional protection and protective

grounding

6.1.2 Protection against electric shock - indirect contact

Warnin g

The pump must be grounded and protected

against indirect contact in accordance with

national regulations.

Protective ground leads must always have a yellow/green (PE) o r

yellow/green/blue (PEN) color marking.

6.1.3 Backup fuses

For recommended fuse sizes, see section 22.1 Supply voltage on

page 32.

4

The above warning is indicated on the motor terminal

TM02 0792 0101

box by this yellow label:

6.2.1 Preparation

Before connecting the E-pump to the power supply, take the

issues illustrated in the figure below into consideration.

Fig. 3 Power supply-connected pump with power switch,

backup fuses, additional protection and protective

grounding

TM00 9270 4696

Page 5

6.2.2 Protection against electric shock - indirect contact

ELCB

Caution

Note

Note

L1

L2

L3

L1

L2

L3

Warnin g

The pump must be grounded in accordance with

national regulations.

As the leakage current of 5-10 hp (4 - 7.5 kW)

motors is > 3.5 mA, take extra precautions when

grounding these motors.

EN 50178 and BS 7671 specify the following precautions when

leakage current > 3.5 mA:

• The pump must be stationary and installed permanently.

• The pump must be permanently connected to the power

supply.

• The grounding connection must be carried out as duplicate

leads.

Protective ground leads must always have a yellow/green (PE) o r

yellow/green/blue (PEN) color marking.

6.2.3 Backup fuses

For recommended fuse sizes, see section 21.1 Supply voltage on

page 32.

6.2.4 Additional protection

If the pump is connected to an electric installation where an

ground leakage circuit breaker (ELCB) is used as additional

protection, the circuit breaker must be of a type marked with the

following symbols:

English (US)

TM03 8600 2007

Fig. 4 Power connection

Cable glands

Cable glands comply with EN 50626.

• 2 x M16 cable gland

• 1 x M20 cable gland

• 2 x M16 knock-out cable entries.

This circuit breaker is type B.

The total leakage current of all the electrical equipment in the

installation must be taken into account.

The leakage current of the motor in normal operation can be seen

in section 21.3 Leakage current on page 31.

During start and at asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

6.2.5 Motor protection

The pump requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking (IEC 34-11, TP 211).

6.2.6 Protection against voltage transients

The pump is protected against voltage transients by built-in

varistors between the phases and between phases and ground.

6.2.7 Supply voltage and power supply

3 x 460-480 V - 10 %/+ 10 %, 50/60 Hz, PE.

3 x 208-230 V - 10 %/+ 10 %, 50/60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Make sure that the pump is suitable for the power

supply of the installation site.

The wires in the terminal box must be as short as possible.

Excepted from this is the protective ground lead which must be so

long that it is the last one to be disconnected in case the cable is

inadvertently pulled out of the cable entry.

Warnin g

If the supply cable is damaged, it must be

replaced by qualified personnel.

Grid types

Three-phase E-pumps can be connected to all grid types.

Warnin g

Do not connect three-phase E-pumps to a power

supply with a voltage between phase and ground

of more than 440 V.

6.2.8 Start/stop of pump

The number of starts and stops via the power

supply must not exceed 4 times per hour.

When the pump is switched on via the power supply, it will start

after approx. 5 seconds.

If a higher number of starts and stops is desired, use the input for

external start/stop when starting/stopping the pump.

When the pump is switched on via an external on/off switch, it will

start immediately.

Automatic restart

If a pump set up for automatic restart is stopped

due to a fault, it will restart automatically when

the fault has disappeared.

However, automatic restart only applies to fault types set up to

automatic restart. These faults could typically be one of these

faults:

• temporary overload

• fault in the power supply.

5

Page 6

English (US)

Note

Note

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 1

Group 2

Group 3

13: GND (frame)

12: Analog output

11: Digital input 4

10: Digital input 3

1: Digital input 2

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

L1

L2

L3

L2

L1

L3

PE

ELCB

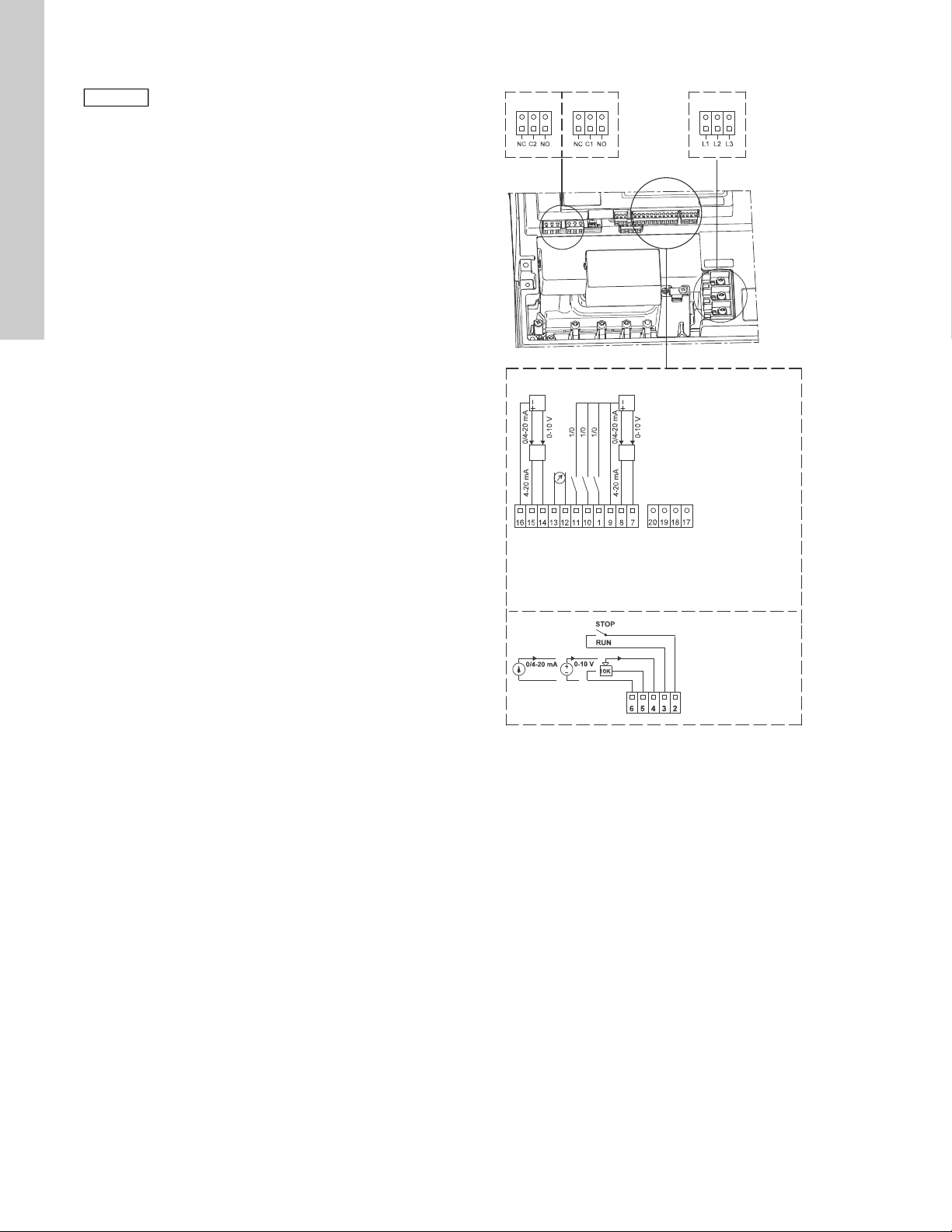

6.2.9 Connections

6.3 Three-phase pumps, 15-30 hp

If no external on/off switch is connected,

connect terminals 2 and 3 using a short wire.

As a precaution, the wires to be connected to the following

connection groups must be separated from each other by

reinforced insulation in their entire lengths:

Group 1: Inputs

• start/stop terminals 2 and 3

• digital input terminals 1 and 9

• setpoint input terminals 4, 5 and 6

• sensor input terminals 7 and 8

• GENIbus terminals B, Y and A

All inputs (group 1) are internally separated from the powerconducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied with protective extra-low voltage

(PELV), thus ensuring protection against electric shock.

Group 2: Output (relay signal, terminals NC, C, NO)

The output (group 2) is galvanically separated from other circuits.

Therefore, the supply voltage or protective extra-low voltage can

be connected to the output as desired.

6.2.10 Three-phase pumps, 1.5 - 10 hp

Group 3: Power supply (terminals L1, L2, L3)

Warnin g

The user or the installer is responsible for the

installation of correct grounding and protection

according to current national and local

standards. All operations must be carried out by

qualified personnel.

Warnin g

Never make any connections in the pump

terminal box unless all electric supply circuits

have been switched off for at least 5 minutes.

Note for instance th at th e sign al rel ay may be

connected to an external supply which is still

connected when the power supply is

disconnected.

Warnin g

The surface of the terminal box may be above

158 °F (70 °C) when the pump is operating.

6.3.1 Preparation

Before connecting the E-pump to the power supply, take the

issues illustrated in the figure below into consideration.

Fig. 5 Connection terminals

A galvanic separation must fulfill the requirements for reinforced

insulation including creepage distances and clearances specified

in EN 60335.

6

TM00 9270 4696

Fig. 6 Power supply-connected pump with power switch,

backup fuses, additional protection and protective

grounding

6.3.2 Protection against electric shock - indirect contact

Warnin g

The pump must be grounded in accordance with

national regulations.

As the leakage current of 15-30 hp motors is

> 10 mA, take extra precautions when grounding

these motors.

EN 61800-5-1 specifies that the pump must be stationary and

installed permanently when the leakage current is > 10 mA.

One of the following requirements must be fulfilled:

• A single protective ground lead (7 AWG m i n i m u m copper)

TM05 2985 0812

TM04 3021 3508

Fig. 7 Connection of a single protective ground lead using

one of the leads of a 4-core power cable

(7 AWG minimum)

Page 7

• Two protective ground leads of the same cross-sectional area

ELCB

Caution

Torques, terminals L1-L3:

Min. torque: 1.6 ft-lbs

Max. torque: 1.8 ft-lbs

as the power supply leads, with one lead connected to an

additional ground terminal in the terminal box.

Fig. 8 Connection of two protective ground leads using two of

the leads of a 5-core power supply cable

Protective ground leads must always have a yellow/green (PE) o r

yellow/green/blue (PEN) color marking.

6.3.3 Backup fuses

For recommended fuse sizes, see section 22.1 Supply voltage on

page 32.

6.3.4 Additional protection

If the pump is connected to an electric installation where an

ground leakage circuit breaker (ELCB) is used as additional

protection, the circuit breaker must be of a type marked with the

following symbols:

This circuit breaker is type B.

The total leakage current of all the electrical equipment in the

installation must be taken into account.

The leakage current of the motor in normal operation can be seen

in section 22.3 Leakage current.

During start and at asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

6.3.5 Motor protection

The pump requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking (IEC 34-11, TP 211).

6.3.6 Protection against voltage transients

The pump is protected against voltage transients in accordance

with EN 61800-3 and is capable of withstanding a VDE 0160

pulse.

The pump has a replaceable varistor which is part of the transie nt

protection.

Over time this varistor will be worn and need to be replaced.

When the time for replacement has come, R100 and PC Tool

E-products will indicate this as a warning. See section

20. Maintenance and service on page 31.

6.3.7 Supply voltage

3 x 460-480 V - 10 %/+ 10 %, 50/60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Make sure that the motor is suitable for the power

supply of the installation site.

The wires in the terminal box must be as short as possible.

Excepted from this is the protective ground lead which must be so

long that it is the last one to be disconnected in case the cable is

inadvertently pulled out of the cable entry.

TM03 8606 2007

Fig. 9 Power connection

Cable glands

Cable glands comply with EN 50626.

• 1 x M40 cable gland

• 1 x M20 cable gland

• 2 x M16 cable gland

• 2 x M16 knock-out cable entries.

Warnin g

If the supply cable is damaged, it must be

replaced by qualified personnel.

Grid types

Three-phase E-pumps can be connected to all grid types.

Warnin g

Do not connect three-phase E-pumps to a power

supply with a voltage between phase and ground

of more than 440 V.

6.3.8 Start/stop of pump

The number of starts and stops via the power

supply must not exceed 4 times per hour.

When the pump is switched on via the power supply, it will start

after approx. 5 seconds.

If a higher number of starts and stops is desired, use the input for

external start/stop when starting/stopping the pump.

When the pump is switched on via an external on/off switch, it will

start immediately.

English (US)

TM03 8605 2007 - TM04 3048 3508

7

Page 8

English (US)

Note

Note

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 2

Group 3

20: PT 100 B

19: PT 100 B

18: PT 100 A

17: PT 100 A

16: GND (frame)

15: +24 V

14: Sensor input 2

13: GND

12: Analog output

11: Digital input 4

10: Digital input 3

1: Digital input 2

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

Group 1

6.3.9 Connections

If no external on/off switch is connected, connect

terminals 2 and 3 using a short wire.

As a precaution, the wires to be connected to the following

connection groups must be separated from each other by

reinforced insulation in their entire lengths:

Group 1: Inputs

• start/stop terminals 2 and 3

• digital input terminals 1 and 9

• setpoint input terminals 4, 5 and 6

• sensor input terminals 7 and 8

• GENIbus terminals B, Y and A

All inputs (group 1) are internally separated from the powerconducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied with protective extra-low voltage

(PELV), thus ensuring protection against electric shock.

Group 2: Output (relay signal, terminals NC, C, NO)

The output (group 2) is galvanically separated from other circuits.

Therefore, the supply voltage or protective extra-low voltage can

be connected to the output as desired.

Group 3: Power supply (terminals L1, L2, L3)

TM05 2986 0812

Fig. 10 Connection terminals

A galvanic separation must fulfill the requirements for reinforced

insulation including creepage distances and clearances specified

in EN 61800-5-1.

8

Page 9

6.4 Signal cables

Dry-running sensor

Set to automatic resetting

Connection terminals on E-pump:

2 (Start/Stop) and 3 (GND)

3

2

1 x 200-240 VAC

or

1 X 80-130 VAC

Brown

Black

Blue

White

Jumper cable

• Use screened cables with a conductor cross-section of min.

28 AWG and max. 16 AWG for external on/off switch, digital

input, setpoint and sensor signals.

• Connect the screens of the cables to frame at both ends with

good frame connection. The screens must be as close as

possible to the terminals. See fig. 11.

Fig. 11 Stripped cable with screen and wire connection

• Always tighten screws for frame connections whether a cable

is fitted or not.

• Make the wires in the pum p ter m inal box as short as possible.

6.5.2 Connection of E-pump to LiqTec®

6.5 E-pump electrical connections

6.5.1 Connection of E-pump to Danfoss pressure sensor MBS3000

The blue wire of the pressure sensor is connected to the #7

terminal of the E-pump. The brown wire of the pressure sensor is

connected to the #8 terminal of the E-pump.

See section 6.4 Signal cables on page 9 for additional details.

TM02 1325 0901

Fig. 12 Danfoss pressure sensor

English (US)

TM05 1533 2911

TM03 0437 5104

Fig. 13 Connection of E-pump to LiqTec

9

Page 10

English (US)

A

Y

B

A

Y

B

1

2

3

1

2

3

Pump

A

Y

B

A

Y

B

1

2

1

2

Pump

Q

H

Max.

Min.

H

Q

6.6 Bus connection cable

6.6.1 New installations

For the bus connection, use a screened 3-core cable with a

conductor cross-section of 28-16 AWG.

• If the pump is connected to a unit with a cable clamp which is

identical to the one on the pump, connect the screen to this

cable clamp.

• If the unit has no cable clamp as shown in fig. 14, leave the

screen unconnected at this end.

7.2 Operating mode

When the operating mode is set to Normal, the control mode can

be set to controlled or uncontrolled. See section 7.3Control mode

on page 10.

The other operating modes that can be selected are S t op, Min. or

Max.

• Stop: the pump has been stopped

• Min.: the pump is operating at its minimum speed

• Max.: the pump is operating at its maximum speed.

Figure 16 is a schematic illustration of min. and max. curves.

Fig. 14 Connection with screened 3-core cable

6.6.2 Replacing an existing pump

• If a screened 2-core cable is used in the existing installation,

connect it as shown in fig. 15.

Fig. 15 Connection with screened 2-core cable

• If a screened 3-core cable is used in the existing installation,

follow the instructions in section 6.6.1 New installations on

page 10.

7. Modes

Grundfos E-pumps are set and controlled according to operating

and control modes.

7.1 Overview of modes

TM02 8841 0904TM02 8842 0904

TM00 5547 0995TM00 7746 1304

Fig. 16 Min. and max. curves

The max. curve can for instance be used in connection with the

venting procedure during installation.

The min. curve can be used in periods in which a minimum flow is

required.

If the power supply to the pump is disconnected, the mode sett ing

will be stored.

The remote control R100 offers additional possibilities of setting

and status displays. See section 10. Setting by means of R100 on

page 12.

7.3 Control mode

7.3.1 Pumps without factory-fitted sensor

The pumps are factory-set to control mode uncontrolled.

In control mode uncontrolled, the pump will operate according to

the constant curve set, fig. 17.

Operating modes Normal Stop Min. Max.

Control modes Uncontrolled Controlled

Fig. 17 Pump in control mode uncontrolled (constant curve)

Constant

curve

1) For this control mode the pump is equipped with a pressure

Constant

pressure

1)

sensor. The pump may also be equipped with a temperature

sensor in which case the description would be constant

temperature in control mode controlled.

10

Page 11

7.3.2 Pumps with pressure sensor

Q

H

set

H

Q

H

UncontrolledControlled

Light fields Buttons

Indicator lights

Buttons

Indicator lights

Light fields

The pump can be set to one of two control modes, i.e. controlled

and uncontrolled, fig. 18.

In control mode controlled, the pump will adjust its performance,

i.e. pump discharge pressure, to the desired setpoint for the

control parameter.

In control mode uncontrolled, the pump will operate according to

the constant curve set.

Fig. 18 Pump in control mode controlled (constant pressure)

or uncontrolled (constant curve)

8. Setting up the pump

8.1 Factory setting

Pumps without factory-fitted sensor

The pumps have been factory-set to control mode uncontrolled.

The setpoint value corresponds to 100 % of the maximum pump

performance (see data sheet for the pump).

Pumps with pressure sensor

The pumps have been factory-set to control mode controlled.

The setpoint value corresponds to 50 % of the sensor measuring

range (see sensor nameplate).

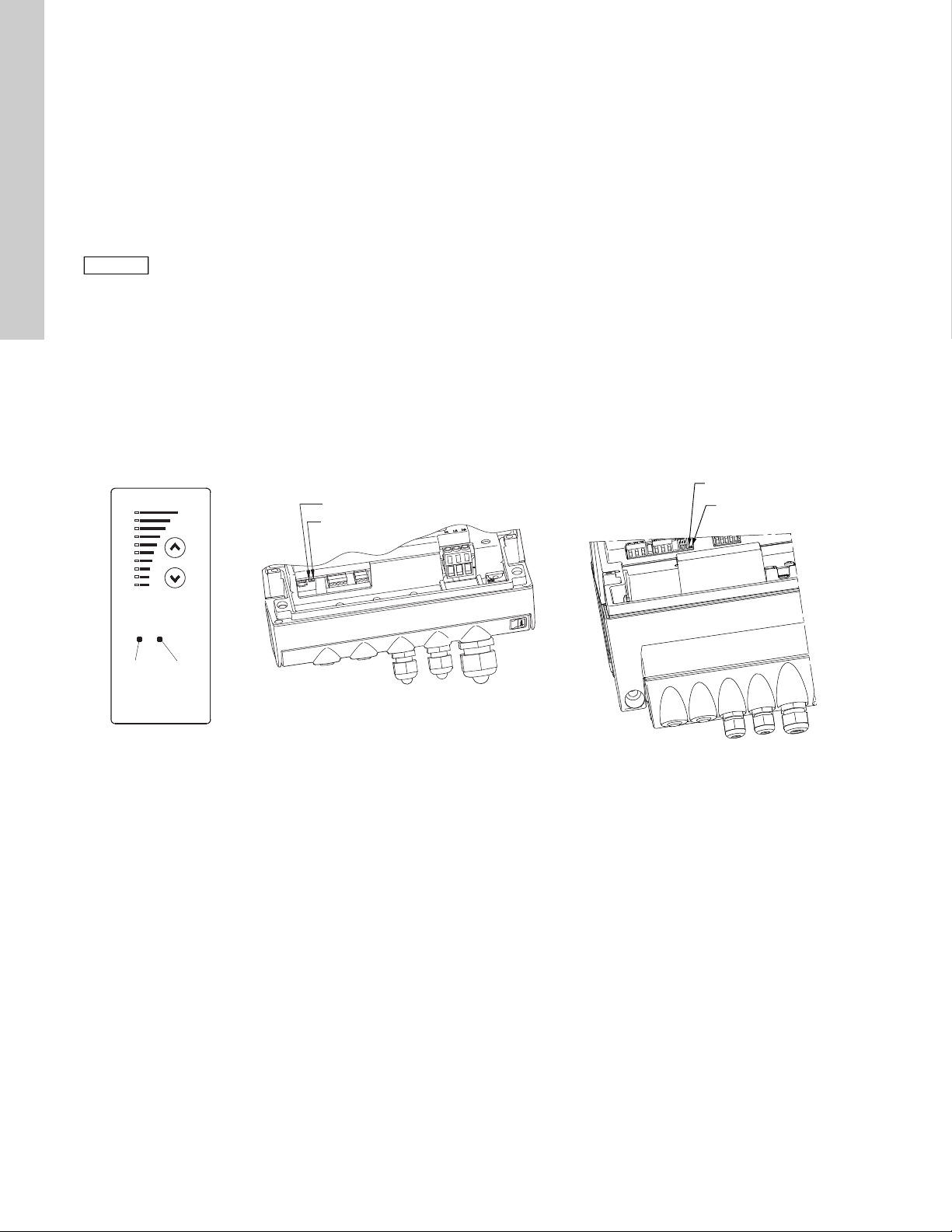

9. Setting by means of control panel

The pump control panel, see fig. 19 or 20, incorporates the

following buttons and indicator lights:

• Buttons, and , for setpoint setting.

• Light fields, yellow, for indication of setpoint.

• Indicator lights, green (operation) and red (fault).

TM00 7668 0404

Fig. 19 Control panel, single-phase pumps, 0.5 - 1.5 hp

English (US)

TM00 7600 0304TM02 8513 0304

Fig. 20 Control panel, three-phase pumps, 1-30 hp

11

Page 12

English (US)

H

Q

H

Q

0

6

3

[bar]

H

Q

9.1 Setting of operating mode

Settings available:

•Normal

•Stop

•Min.

•Max.

Start/stop of pump

Start the pump by continuously pressing until the desired

setpoint is indicated. This is operating mode Normal.

Stop the pump by continuously pressing until none of the light

fields are activated and the green indicator light flashes.

Setting to Min.

Press

(bottom light field flashes). When the bottom light field is on,

press for 3 seconds until the light field starts flashing.

To return to uncontrolled or controlled operation, press

continuously until the desired setpoint is indicated.

continuously to change to the min. curve of the pump

TM00 7743 0904TM00 7746 1304TM02 0936 0501

Fig. 23 Setpoint set to 3 bar, pressure control

9.2.2 Pump in control mode uncontrolled Example

In control mode uncontrolled, the pump performance is set within

the range from min. to max. curve. See fig. 24.

TM00 7346 1304TM00 7345 1304

Fig. 21 Min. curve duty

Setting to Max.

Press continuously to change to the max. curve of the pump

(top light field flashes). When the top light field is on, press for

3 seconds until the light field starts flashing.

To return to uncontrolled or controlled operation, press

continuously until the desired setpoint is indicated.

Fig. 22 Max. curve duty

9.2 Setpoint setting

Set the desired setpoint by pressing the button or .

The light fields on the control panel will indicate the setpoint set.

See examples in sections 9.2.1 on page 12 and 9.2.2 on page 12.

9.2.1 Pump in control mode controlled (pressure control)

Example

Figure 23 shows that the light fields 5 and 6 are activated,

indicating a desired setpoint of 3 bar. The setting range is equal

to the sensor measuring range (see sensor nameplate).

Fig. 24 Pump performance setting, control mode uncontrolled

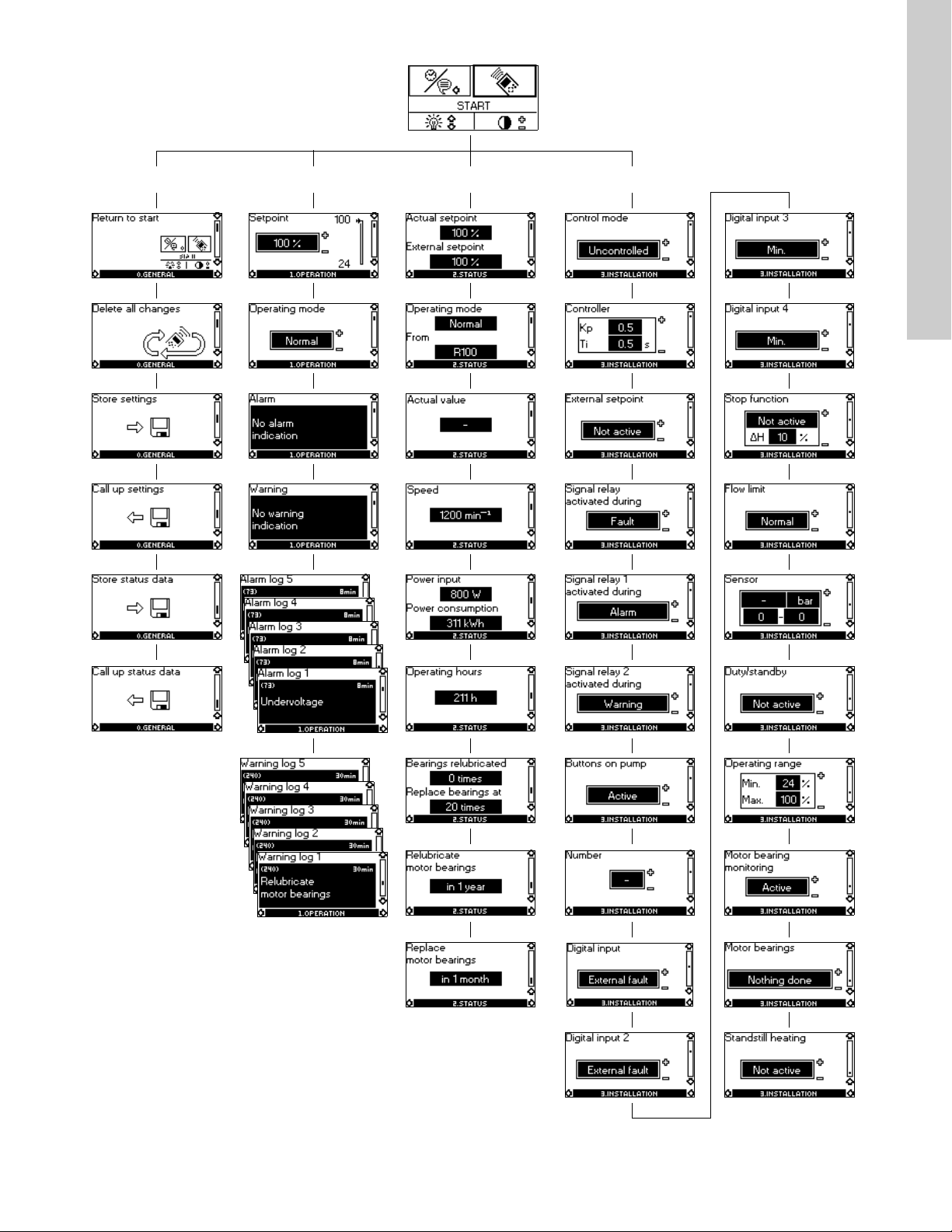

10. Setting by means of R100

The pump is designed for wireless communication with

Grundfos remote control R100.

Fig. 25 R100 communicating with the pump via infra-red light

During communication, the R100 must be pointed at the control

panel. When the R100 communicates with the pump, the red

indicator light will flash rapidly. Keep pointing the R100 at the

control panel until the red LED diode stops flashing.

The R100 offers setting and status displays for the pump.

The displays are divided into four parallel menus (see fig. 34):

0. GENERAL (see operating instructions for the R100)

1. OPERATION

2. STATUS

3. INSTALLATION

The figure above each individual display in fig. 34 refers to the

section in which the display is described.

12

Page 13

0. GENERAL 1. OPERATION 2. STATUS 3. INSTALLATION

10.1.1 10.2.1 10.3.1 10.3.7

10.1.2 10.2.2 10.3.2 10.3.7

10.1.3 10.2.3 10.3.3 10.3.8

10.1.3 (1) 10.2.4 10.3.4 (3) 10.3.9 (1)

10.1.4 10.2.5 10.3.4 - 1 (2) 10.3.10

English (US)

10.2.6 10.3.4 - 2 (2) 10.3.11 (1)

10.1.4 (1) 10.2.7 (2) 10.3.5 10.3.12

10.2.8 (2) 10.3.6 10.3.13 (1)

10.2.9 (1) 10.3.7 10.3.14 (1)

(1) This display only appears for three-phase pumps, 1.5 - 30 hp.

(2) This display only appears for three-phase pumps, 15 - 30 hp.

(3) This display only appears for three-phase pumps, 1.5 - 10 hp.

10.3.7 10.3.15 (1)

Fig. 26 Menu overview

13

Page 14

English (US)

Note

Note

Displays in general

In the following explanation of the functions, one or two displays

are shown.

One display

Pumps without or with factory-fitted sensor have the same

function.

Two displays

Pumps without or with factory-fitted pressure sensor have

different functions and factory settings.

10.1 Menu OPERATION

The first display in this menu is this:

10.1.1 Setpoint

Without sensor

(uncontrolled)

Setpoint set

Actual setpoint

Actual value

Set the setpoint in %.

In control mode uncontrolled, the setpoint is set in % of the

maximum performance. The setting range will lie between the

min. and max. curves.

In control mode controlled, the setting range is equal to the

sensor measuring range.

If the pump is connected to an external setpoint signal, the value

in this display will be the maximum value of the external setpoint

signal. See section 14. External setpoint signal on page 27.

Setpoint and external signal

The setpoint cannot be set if the pump is controlled via external

signals (Stop, Min. curve or Max. curve). R100 will give this

warning: External control!

Check if the pump is stopped via terminals 2-3 (open circuit) or

set to min. or max. via terminals 1-3 (closed circuit).

See Fig. 35 Menu overview on page 24.

Setpoint and bus communication

The setpoint cannot be set either if the pump is co ntrolled from a n

external control system via bus communication. R100 will give

this warning: Bus control!

To override bus communication, disconnect the bus connection.

See Fig. 35 Menu overview on page 24.

10.1.2 Operating mode

Set one of the following operating modes:

• Normal (duty)

•Stop

•Min.

•Max.

With pressure sensor

(controlled)

Setpoint set

Actual setpoint

Actual value

Set the desired pressure in

bar.

The operating modes can be set without changing the setpoint

setting.

10.1.3 Fault indications

In E-pumps, faults may result in two types of indication: alarm or

warning.

An "alarm" fault will activate an alarm indication in R100 and

cause the pump to change operating mode, typically to stop.

However, for some faults resulting in alarm, the pump is set to

continue operating even if there is an alarm.

A "warning" fault will activate a warning indication in R100, but

the pump will not change operating or control mode.

The indication, Warning, only applies to threephase pumps.

Alarm

In case of alarm, the cause will appear in this display.

Possible causes:

• No alarm indication

• Too high motor temperature

• Undervoltage

• Mains voltage asymmetr y (15-30 hp)

•Overvoltage

• Too many restarts (after faults)

• Overload

• Underload

• Sensor signal outside signal range

• Setpoint signal outside signal range

• External fault

• Duty/standby, Communication fault

• Dry running

• Other fault.

If the pump has been set up to manual restar t, an alarm indication

can be reset in this display if the cause of the fault has

disappeared.

Warning (only three-phase pumps)

In case of warning, the cause will appear in this display.

Possible causes:

• No warning indication.

• Sensor signal outside signal range.

• Relubricate motor bearings, see section 20.2 on page 31.

• Replace motor bearings, see section 20.3 on page 31.

• Replace varistor, see section 20.4 on page 31.

A warning indication will disappear automatically once the fault

has been remedied.

14

Page 15

10.1.4 Fault log

For both fault types, alarm and warning, the R100 has a log

function.

Alarm log

In case of "alarm" faults, the last five alarm indications will appear

in the alarm log. "Alarm log 1" shows the latest fault, "Alarm log 2 "

shows the latest fault but one, etc.

The example above gives this information:

• the alarm indication Undervoltage

• the fault code (73)

• the number of minutes the pump has been connected to the

power supply after the fault occurred, 8 min.

Warning log

In case of "warning" faults, the last five warning indications will

appear in the warning log. "Warning log 1" show s the la test fa ult,

"Warning log 2" shows the latest fault but one, etc.

The example above gives this information:

• the warning indication Relubricate motor bearings

• the fault code (240)

• the number of minutes the pump has been connected to the

power supply since the fault occurred, 30 min.

10.2 Menu STATUS

The displays appearing in this menu are status displays only. It is

not possible to change or set values.

The displayed values are the values that applied when the last

communication between the pump and the R100 took place. If a

status value is to be updated, point the R100 at the control panel

and press "OK". If a parameter, e.g. speed, should be called up

continuously, press "OK" const antly during the period in wh ich the

parameter in question should be monitored.

The tolerance of the displayed value is stated under e ach display.

The tolerances are stated as a guide in % of the maximu m va lues

of the parameters.

10.2.1 Actual setpoint

Without sensor

(uncontrolled)

With pressure sensor

(controlled)

10.2.2 Operating mode

This display shows the actual operating mode (Normal (duty),

Stop, Min., or Max.). Furthermore, it shows where this operating

mode was selected (R100, Pump, Bus, External or Stop func.).

For further details about the stop function (Stop func.), see

section 10.3.8 Stop function on page 19.

10.2.3 Actual value Without sensor

(uncontrolled)

This display shows the value actually measured by a connected

sensor.

If no sensor is connected to the pump, "-" will appear in the

display.

10.2.4 Speed

Tolerance: ± 5 %

The actual pump speed will appear in this display.

10.2.5 Power input and power consumption

Tolerance: ± 10 %

This display shows the actual pump input power from the power

supply. The power is displayed in W or kW.

The pump power consumption can also be read from this display.

The value of power consumption is an accumulated value

calculated from the pump’s birth and it cannot be reset.

10.2.6 Operating hours

With pressure sensor

(controlled)

English (US)

Tolerance: ± 2 %. Tolerance: ± 2 %.

This display shows the actual setpoint and the external se tpoint in

% of the range from minimum value to the setpoint set. See

section 14. External setpoint signal on page 27.

Tolerance: ± 2 %

The value of operating hours is an accumulated value and cannot

be reset.

15

Page 16

English (US)

Note

Note

10.2.7 Lubrication status of motor bearings (only 15-30 hp)

10.3 Menu INSTALLATION

10.3.1 Control mode

This display shows how many times the motor bearings have

been relubricated and when to replace the motor bearings.

When the motor bearings have been relubricated, confirm this

action in the INSTALLATION menu.

See section 10.3.14 Confirming relubrication/replacement of

motor bearings (only three-phase pumps) on page 22. When

relubrication is confirmed, the figure in the above display will be

increased by one.

10.2.8 Time till relubrication of motor bearings

This display shows when to relubricate the motor bearings. The

controller monitors the operating pattern of the pump and

calculates the period between bearing relubrications. If the

operating pattern changes, the calculated time till relubrication

may change as well.

The displayable values are these:

• in 2 years

• in 1 year

• in 6 months

• in 3 months

• in 1 month

• in 1 week

•Now!

10.2.9 Time till replacement of motor bearings

When the motor bearings have been relubricated a prescribed

number of times stored in the controller, the display in section

10.2.8 Time till relubrication of motor bearings on page 16 will be

replaced by the display below.

Without sensor

(uncontrolled)

Select one of the following

control modes (see fig. 18):

• Controlled

• Uncontrolled.

With pressure sensor

(controlled)

Select one of the following

control modes (see fig. 18):

• Controlled

• Uncontrolled.

If the pump is connected to a bus, the control

mode cannot be selected via the R100. See

section 15. Bus signal.

10.3.2 Controller

E-pumps have a factory default setting of gain (K

time (T

). However, if the factory setting is not the optimum

i

setting, the gain and the integral time can be changed in the

) and integral

p

display below.

• The gain (K

) can be set within the range from 0.1 to 20.

p

• The integral time (Ti) can be set within the range from 0.1 to

3600 s. If 3600 s is selected, the controller will function as a P

controller.

• Furthermore, it is possible to set the controller to inverse

control, meaning that if the setpoint is increased, the speed

will be reduced. In the case of inverse control, the gain (Kp)

must be set within the range from -0.1 to -20.

This display shows when to replace the motor bearings. The

controller monitors the operating pattern of the pump and

calculates the period between bearing replacements.

The displayable values are these:

• in 2 years

• in 1 year

• in 6 months

• in 3 months

• in 1 month

• in 1 week

•Now!

16

Page 17

The table below shows the suggested controller settings: How to set the PI controller

p

p

L1 [ft]

p

Q

t

L L2 [ft]

t

L2 [ft]

t

L2 [ft]

For most applications, the factory setting of the controller

constants K

However, in some applications an adjustment of the controller

and Ti will ensure optimum pump operation.

p

may be needed.

Proceed as follows:

1. Increase the gain (K

) until the motor becomes uns table.

p

System/application

Heating

systems

K

p

Cooling

system

T

i

Instability can be seen by observing if the measured value

0.5 0.5

starts to fluctuate. Furthermore, instability is audible as the

motor starts hunting up and down.

Some systems, such as temperature controls, are slowreacting, meaning that it may be several minutes before the

motor becomes unstable.

0.5

L

< 16.4 ft: 0.5

1)

L > 16.4 ft: 3

L > 32.8 ft: 5

2. Set the gain (K

unstable. This is the correct setting of the gain.

3. Reduce the integral time (T

unstable.

4. Set the integral time (T

motor unstable. This is the correct setting of the integral time.

) to half of the value which made the motor

p

) to twice the value which made the

i

General rules of thumb:

0.5 0.5

• If the controller is too slow-reacting, increase K

• If the controller is hunting or unstable, dampen the system by

reducing K

or increasing Ti.

p

10.3.3 External setpoint

0.5 0.5

) until the motor becomes

i

.

p

English (US)

0.5 -0.5 10 + 1.52L

0.5 10 + 1.52L

0.5 -0.5 30 + 1.52L

+2.5 100

Heating systems are systems in which an increase in pump

performance will result in a rise in temperature at the

sensor.

Cooling systems are systems in which an increase in pump

performance will result in a drop in temperature at the

sensor.

(L1) Distance in [ft] between pump and sensor

(L2) Distance in [ft] between heat exchanger and sensor

The input for external setpoint signal can be set to dif fere nt signal

types.

Select one of the following types:

•0-10 V

•0-20 mA

•4-20 mA

• Not active.

If Not active is selected, the setpoint set by means of the R100 or

on the control panel will apply.

If one of the signal types is selected, the actual setpoint is

influenced by the signal connected to the external setpoint input.

See section 14. External setpoint signal on page 27.

17

Page 18

English (US)

Note

Note

10.3.4 Signal relay

Pumps of 1.5 - 10 hp have one signal relay. The factory setting of

the relay will be Fault.

Pumps of 15-30 hp have two signal relays. Signal relay 1 is

factory set to Alarm and signal relay 2 to Warning.

In one of the displays below, select in which one of three or six

operating situations the signal relay should be activated.

1.5 - 10 hp

• Ready

• Fault

• Operation

• Pump running (only three-phase pumps, 1.5 - 10 hp)

• Warning (only three-phase pumps, 1-10 hp).

15-30 hp 15-30 hp

10.3.5 Buttons on pump

The operating buttons and on the control panel can be set

to these values:

•Active

• Not active.

When set to Not active (locked), the buttons do not function. Set

the buttons to Not active if the pump should be controlled via an

external control system.

10.3.6 Pump number

A number between 1 and 64 can be allocated to the pump. In the

case of bus communication, a number must be allocated to each

pump.

10.3.7 Digital inputs

• Ready

•Alarm

• Operation

• Pump running

• Warning

• Relubricate.

Fault and Alarm cover faults resulting in Alarm.

Warning covers faults resulting in Warning.

Relubricate covers only that one individual event.

For distinction between alarm and warning, see

section 10.1.3 Fault indications on page 14 .

For further information, see section 17. Indicator lights and signal

relay on page 28.

• Ready

•Alarm

• Operation

• Pump running

• Warning

• Relubricate.

The digital inputs of the pump can be set to different functions.

Select one of the following functions:

• Min. (min. curve)

• Max. (max. curve)

• External fault

• Flow switch

• Dry running (from external sensor) (only three-phase pumps).

The selected function is activated by closing the contact between

terminals 1 and 9, 1 and 10 or 1 and 11.

See also section 13.2 Digital input on page 27.

Min.:

When the input is activated, the pump will operate according to

the min. curve.

Max.:

When the input is activated, the pump will operate according to

the max. curve.

External fault:

When the input is activated, a timer will be started. If the input is

activated for more than 5 seconds, the pump will be stopped and

a fault will be indicated. If the input is deactivated for more than 5

seconds, the fault condition will cease and the pump can only be

restarted manually by resetting the fault indication.

Flow switch:

When this function is selected, the pump will be stopped when a

connected flow switch detects low flow.

It is only possible to use this function if the pump is connected to

a pressure sensor.

If the input is activated for more than 5 seconds, the stop function

incorporated in the pump will take over. See section 10. 3.8 Stop

function on page 19.

18

Page 19

Dry running

Stop pressure

ΔH

Start pressure

H

Q

Caution

Pressure sensor

Diaphragm tank

Non-return

valve

Pump

Diaphragm tank

Pressure sensor

Pump Non-return valve

When this function is selected, lack of inlet pressure or water

shortage can be detected. This requires the use of an accessory,

such as these:

®

• a Grundfos Liqtec

dry-running sensor

• a pressure switch installed on the suction side of a pump

• a float switch installed on the suction side of a pump.

When lack of inlet pressure or water shortage (Dry running) is

detected, the pump will be stopped. The pump cannot restart as

long as the input is activated.

10.3.8 Stop function

The stop function can be set to these values:

•Active

• Not active.

When the stop function is active, the pump will be stopped at very

low flows. The controller will stop the pump to protect the pump

as follows:

• avoid unnecessary heating of the pumped liquid

• reduce wear of the shaft seals

• reduce noise from operation.

Three-phase pumps

1. If the flow is higher than the low-flow limit, the pump will return

to continuous operation at constant pressure.

2. If the flow is still lower than the low-flow limit, the pump will

continue in start/stop operation. It will continue in start/stop

operation until the flow is higher than the low-flow limit; when

the flow is higher than the low-flow limit, the pump will return

to continuous operation.

2. Flow switch

When the digital input is activated for more than 5 seconds

because there is low flow, the speed will be increased until the

stop pressure (actual setpoint + 0.5 x ΔH) is reached, and the

pump will stop. When the pressure has fallen to start pressure,

the pump will start again. If there is still no flow, the pump will

quickly reach stop pressure and stop. If there is flow, the pump

will continue operating according to the setpoint.

Operating conditions for the stop function

It is only possible to use the stop function if the system

incorporates a pressure sensor, a non-return valve and a

diaphragm tank.

The non-return valve must always be installed

before the pressure sensor. See fig. 28 and

fig. 29.

English (US)

Fig. 27 Difference between start and stop pressures (H)

ΔH is factory-set to 10 % of actual setpoint.

ΔH can be set within the range from 5 % to 30 % of actual

setpoint.

Low flow can be detected in two different ways:

1. A built-in "low-flow detection function" which functions if the

digital input is not set up for flow switch.

2. A flow switch connected to the digital input.

1. Low-flow detection function

The pump will check the flow regularly by reducing the speed for

a short time. If there is no or only a small change in pressure, this

means that there is low flow. The sp eed will be increased until the

stop pressure (actual setpoint + 0.5 x ΔH) is reached and the

pump will stop. When the pressure has fallen to the start pressure

(actual setpoint - 0.5 x ΔH), the pump will restart.

When restarting, the pumps will react differently according to

pump type:

TM03 8582 1907TM03 8583 1907

Fig. 28 Position of the non-return valve and pressure sensor in

system with suction lift operation

TM00 7744 1896

Fig. 29 Position of the non-return valve and pressure sensor in

system with positive inlet pressure

19

Page 20

English (US)

Note

Note

ΔH

Low

High

Normal

Diaphragm tank

The stop function requires a diaphragm tank of a certain minimum

size. The tank must be installed immediately after the pump and

the precharge pressure must be 0.7 x actual setpoint.

Recommended diaphragm tank size:

Rated flow of

pump

3

[gpm (m

h)]

0-26

(0 - 5.9)

27-105

(6.1 - 23.8)

106-176

(24.2 - 40)

177-308

(40.2 - 70.0)

309-440

(70.2 - 99.9)

441-750

(100-170)

CRE pump

1s, 1, 3 2 (7.6)

5, 10, 15 4.4 (16.7)

20, 32 14 (53.0)

45 34 (128.7)

64, 90 62 (234.7)

120, 150 86 (325.5)

Typical diaphragm

tank size

[gal (liter)]

If a diaphragm tank of the above size is installed in the system,

the factory setting of ΔH is the correct setting.

If the tank installed is too small, the pump will start and stop too

often. This can be remedied by increasing ΔH.

10.3.9 Flow limit for the stop function

Flow limit for the stop function only works if the

system is not set up for flow switch.

In order to set at which flow rate the system is to go from

continuous operation at constant pressure to start/stop operation,

select among these four values of which three are preconfigured

flow limits:

•Low

•Normal

•High

•Custom.

The default setting of the pump is Normal, representing approx.

10 % of the rated flow rate of the pump.

If a lower flow limit than normal is desired or the tank size is

smaller than recommended, select Low.

If a higher flow than normal is wanted or a large tank is used, set

the limit to High.

The value Custom can be seen in R100 but it can only be set by

means of the PC Tool E-products. Custom is for customized setup and optimizing to the process.

Fig. 30 Three preconfigured flow limits, Low, Normal and High

10.3.10 Sensor Without sensor

(uncontrolled)

With pressure sensor

(controlled)

The setting of the sensor is only relevant in the case of controlled

operation.

Select among the following values:

• Sensor output signal

0-10 V

0-20 mA

4-20 mA,

• Unit of measurement of sensor:

bar, mbar, m, kPa, psi, ft, m³/h, m³/s, l/s, gpm, °C, °F, %,

• Sensor measuring range.

10.3.11 Duty/standby

The duty/standby function applies to two pumps connected in

parallel and controlled via GENIbus.

The duty/standby function can be set to these values:

•Active

• Not active.

When the function is set to Active, the following applies:

• Only one pump is running at a time.

• The stopped pump (standby) will automatically be cut in if the

running pump (duty) has a fault. A fault will be indicated.

• Changeover between the duty pump and the standby pump

will take place every 24 hours.

Activate the duty/standby function as follows:

1. Install and prime the two pumps according to the installation

and operating instructions supplied with the pumps.

2. Check that the power supply is connected to the first pump

according to the installation and operating instructions.

3. Use Grundfos R100 to set the duty/standby to Not active in

the installation menu.

TM03 9060 3307

20

Page 21

4. Use Grundfos R100 to set the Operating mode to Stop in the

PE

L3

L2

L1

Cable gland

Plug

H

100 %

Max. curve

12 %

Min. curve

Op

e

rat

i

n

g

ra

ng

e

operation menu.

5. Use Grundfos R100 to set the other displays as required for

the pump application (such as setpoint).

6. Disconnect the power supply to both pumps.

7. Installation of the AYB cable (91125604):

a. Remove the plug from ea ch M LE term inal bo x with a flat

head screw driver. See fig. 31.

b. Screw a new cable gland into each MLE terminal box with a

crescent wrench. See fig. 31.

c. Loosen the new cable gland caps and push the cable ends

through the cable glands and into MLE motors.

d. Remove the AYB connector plug from the first MLE motor.

See fig. 32.

e. Connect the black wire to the A terminal of the AYB

connector plug.

f. Connect the orange wire to the Y terminal of the AYB

connector plug.

g. Connect the red wire to the B terminal of the AYB connector

plug.

h. Reconnect the AYB connector plug to the first MLE motor.

i. Tighten the cable gland cap to secure the cable. See fig. 31.

j. Repeat steps d to i for the second MLE motor.

8. Connect the power supply to the two pumps according to the

installation and operation instructions.

9. Use Grundfos R100 to check that the Operating mode is set to

Normal in the operation menu of the second pump.

10.Use Grundfos R100 to set the other displays as required for

the pump application (such as Setpoint).

11.Use Grundfos R100 to set the duty/standby to Active in the

installation menu of the second pump. Please note the second

pump will search for the first pump and automatically set the

duty/standby to Active in the installation menu.

12.The second pump will operate for the first 24 hours. The two

pumps will then alternate operation every 24 hours.

English (US)

TM05 2985 0812TM00 7747 1896

Fig. 32 AYB connector plug

10.3.12 Operating range

How to set the operating range:

• Set the min. curve within the range from max. curve to 12 % of

maximum performance. The pump is factory-set to 24 % of

maximum performance.

• Set the max. curve within the range from maximum

performance (100 %) to min. curve.

The area between the min. and max. curves is the operating

range.

TM05 1626 3311

Fig. 31 Removing the plug and connecting cable gland to the

terminal box

Fig. 33 Setting of the min. and max. curves in % of maximum

performance

21

Page 22

English (US)

Note

Note

Note

Note

10.3.13 Motor bearing monitoring (only three-phase pumps)

The motor bearing monitoring function can be set to these values:

•Active

• Not active.

When the function is set to Active, a counter in the controller will

start counting the mileage of the bearings. See section

10.2.7 Lubrication status of motor bearings (only 15-30 hp) on

page 16.

The counter will continue counting even if the

function is switched to Not active, but a warning

will not be given when it is time for relubrication.

When the function is switched to Active again,

the accumulated mileage will again be used to

calculate the relubrication time.

10.3.14 Confirming relubrication/replacement of motor bearings (only three-phase pumps)

This function can be set to these values:

• Relubricated (only 15-30 hp)

•Replaced

• Nothing done.

When the bearing monitoring function is Active, the controller will

give a warning indication when the motor bearings are due to be

relubricated or replaced. See section 10.1.3 Fault indications on

page 14.

When the motor bearings have been relubricated or replaced,

confirm this action in the above display by pressing OK.

Relubricated cannot be selected for a period of

time after confirming relubrication.

10.3.15 Standstill heating (only three-phase pumps)

The standstill heating function can be set to these values:

•Active

• Not active.

When the function is set to Active, an AC voltage will be applied

to the motor windings. The applied voltage will ensure that

sufficient heat is generated to avoid condensation in the motor.

22

Page 23

10.4 Typical display settings for constant-pressure E-pumps

1. OPERATION 2. STATUS 3. INSTALLATION

10.1.1 10.2.1 10.3.1 10.3.7

10.1.2 10.2.2 10.3.2 10.3.7

10.1.3 10.2.3 10.3.3 10.3.8

10.1.3 (1) 10.2.4 10.3.4 - 1 (2) 10.3.9 (1)

English (US)

10.2.5 10.3.4 - 2 (2) 10.3.10

10.2.6 10.3.5 10.3.11 (1)

10.2.7 (2) 10.3.6 10.3.12

10.2.8 (2) 10.3.7 10.3.13 (1)

(1) This display only appears for three-phase pumps, 1.5 - 30 hp.

(2) This display only appears for three-phase pumps, 15 - 30 hp.

(3) This display only appears for three-phase pumps, 1.5 - 10 hp.

10.3.14 (1)

10.3.15 (1)

Fig. 34 Menu overview

23

Page 24

English (US)

10.5 Typical display settings for analog-input E-pumps

1. OPERATION 2. STATUS 3. INSTALLATION

10.1.1 10.2.1 10.3.1 10.3.7

10.1.2 10.2.2 10.3.2 10.3.7

10.1.3 10.2.3 10.3.3 10.3.8

10.1.3 (1) 10.2.4 10.3.4 - 1 (2) 10.3.9 (1)

10.2.5 10.3.4 - 2 (2) 10.3.10

10.2.6 10.3.5 10.3.11 (1)

10.2.7 (2) 10.3.6 10.3.12

10.2.8 (2) 10.3.7 10.3.13 (1)

(1) This display only appears for three-phase pumps, 1.5 - 30 hp.

(2) This display only appears for three-phase pumps, 15 - 30 hp.

(3) This display only appears for three-phase pumps, 1.5 - 10 hp.

10.3.14 (1)

10.3.15 (1)

Fig. 35 Menu overview

24

Page 25

10.6 Grundfos GO Remote

+

1

2

3

+

+

1

2

3

5

7

9

10

13

15 16 17 18

14

12

11

8

6

4

Dashboard

The motor is designed for wireless radio or infrared

communication with Grundfos GO Remote.

Grundfos GO Remote enables setting of functions and gives

access to status overviews, technical product information and

actual operating parameters.

English (US)

Grundfos GO Remote offers three different mobile interfaces

(MI). See fig. 36.

TM05 5609 3912

Fig. 37 Example of dashboard

Pos. Description Action

This text appears when Grundfos

GO Remote app has connected

to an MI 201, MI 202 or MI 301.

If the hardware is not connected,

it will not be possible to

communicate with a Grundfos

product.

Fig. 36 Grundfos GO Remote communicating with the motor

via radio or infrared light

Connection

1

TM05 5383 3612

indicator

2 Back button Returns to the previous display.

Pos. Description

3

Product

information

Grundfos MI 201:

1

Consists of an Apple iPod touch 4G and a Grundfos

cover.

Grundfos MI 202:

2

Add-on module which can be used in conjunction

with Apple iPod touch 4, iPhone 4G or later.

Grundfos MI 301:

Separate module enabling radio or infrared

communication. The module can be used in

3

conjunction with an Android or iOS-based

Smartphone with Bluetooth connection.

10.6.1 Communication

When Grundfos GO Remote communicates with the pump, the

indicator light in the middle of the Grundfos Eye will flash green.

Communication must be established using one of these

communication types:

• radio communication

• infrared communication.

Radio communication

Radio communication can take place at distances up to 30

meters. It is necessary to enable communication by pressing

4 Product name

Alarms and

5

warnings

6 Grundfos Eye

Primary status

7

value

Secondary status

8

value

9 Control source

10 Control mode

Actual setpoint

11

value

12 Operating mode Shows the operating mode.

13 Show menu Gives access to other menus.

14 Stop Stops the product.

Tool bar

or on the pump control panel.

Infrared communication

15 Help

When communicating via infrared light, Grundfos GO Remote

must be pointed at the pump control panel.

10.6.2 Navigation

Navigation can be done from the dashboard. See fig. 37.

16 Documentation

17 Report

18 Update

Provides technical information

about the product.

Name of the product

communicating with Grundfos GO

Remote.

Shows alarms and warnings.

Shows the operating condition of

the product.

Shows the primary status value.

Shows the secondary status

value.

Shows by which interface the

product is controlled.

Shows the control mode of the

product.

Shows the actual setpoint value.

The help function describes the

menus making it easy for the user

to change settings, etc.

Gives access to installation and

operating instructions and quick

guides.

Enables the creation of userdefined reports.

Enables update of Grundfos GO

Remote app.

25

Page 26

English (US)

Note

Note

Q

H

Q

H

11. Setting by means of PC Tool E-products

Special setup requirements differing from the settings available

via the R100 require the use of Grundfos PC Tool E-products.

This again requires the assistance of a Grundfos service

technician or engineer. Contact your local Grundfos company for

more information.

12. Priority of settings

The priority of settings depends on two factors:

1. control source

2. settings.

1. Control source

Control panel

R100

External signals

(external setpoint signal, digital inputs, etc.).

Communication from another control system via

bus

2. Settings

• Operating mode Stop

• Operating mode Max. (Max. curve)

• Operating mode Min. (Min. curve)

• Setpoint setting.

An E-pump can be controlled by different control sources at the

same time, and each of these sources can be set differently.

Consequently, it is necessary to set an order of priority of the

control sources and the settings.

If two or more settings are activated at the same

time, the pump will operate according to the

function with the highest priority.

Priority of settings without bus communication

Priority of settings with bus communication

Priority

Example: If the E-pump is operating according to a setpoint set

via bus communication, the control panel or R100 can set the

E-pump to operating mode Stop or Max., and the external signal

can only set the E-pump to operating mode Stop.

Control panel

or R100

1 Stop

2 Max.

3 Stop Stop

4 Max.

5 Min.

6 Setpoint setting

External

signals

Bus

communication

13. External forced-control signals

The pump has inputs for external signals for these forced-control

functions:

• Start/stop of pump

• Digital function.

13.1 Start/stop input

Functional diagram: Start/stop input:

Start/stop (term inals 2 and 3)

Normal duty

Stop

Priority Control panel or R100 External signals

1 Stop

2 Max.

3 Stop

4 Max.

5 Min. Min.

6 Setpoint setting Setpoint setting

Example: If the E-pump has been set to operating mode Max.

(Max. frequency) via an external signal, such as digital input, the

control panel or R100 can only set th e E -pump to ope rating mode

Stop.

26

Page 27

13.2 Digital input

Q

H

Q

H

Q

H

Q

H

5 s

delay

Q

H

5 s

5 s

delay

Q

H

Setpoint

External setpoint

Actual setpoint

0 10 V

0 20 mA

4 20 mA

Actual setpoint

Sensor

max

Setpoint set by means of

control panel, R100 or PC Tool

E-products

Sensor

min

External setpoint signal

Actual

setpoint

0 10 V

0 20 mA

4 20 mA

Actual setpoint

Max

curve

Setpoint set by means of

control panel, R100 or PC Tool

E-products

Min

curve

External setpoint signal

Actual

setpoint

By means of the R100, one of the following functions can be

selected for the digital input:

• Normal duty

•Min. curve

•Max. curve

• External fault

• Flow switch

• Dry running.

Functional diagram: Input for digital function

Digital function

(terminals 1 and 9) (terminals 9 and 10) (terminals 9 and 11)

Normal duty

English (US)

TM02 8988 1304

Fig. 39 Relation between the actual setpoint and the external

setpoint signal in control mode controlled

Min. curve

Max. curve

External fault

Flow switch

Dry running

14. External setpoint signal

The setpoint can be remote-set by connecting an analogue signal

transmitter to the input for the setpoint signal (terminal 4).

Example: At a sensor

and an external setpoint of 80 % (an 8V analog signal to Terminal

value of 0 psi, a setpoint set of 50 psi

min

4 if using an analog signal of 0-10 V), the actual setpoint will be

as follows:

Actual

setpoint

= (se tpoi nt - se nsor

min

) x %

external setpoint

+ sensor

min

= (50 - 0) x 80 % + 0

=40 psi

In control mode uncontrolled, the setpoint can be set externally

within the range from the min. curve to the setpoint set on the

pump or by means of the R100. Typically the setpoint is set to

100 % when the control mode is uncontrolled

(see section 10.5 Typical display settings for analog-input E-

pumps on page 24).

Select the actual external signal, 0-10 V, 0-20 mA, 4-20 mA, via

the R100. See section 10.3.3 External setpoint on page 17.

If control mode uncontrolled is selected by means of the R100,

the pump can be controlled by any controller.

In control mode controlled, the setpoint can be set externally

within the range from the lower value of the sensor measuring

range to the setpoint set on the pump or by means of the R100.

Fig. 38 Actual setpoint as a product (multiplied value) of

setpoint and external setpoint

TM02 8988 1304

TM03 8601 2007

Fig. 40 Relation between the actual setpoint and the external

setpoint signal in control mode uncontrolled

27

Page 28

English (US)

Note

Note

Green Red

Green

Red

Green

Red

15. Bus signal

The pump supports serial communication via an RS-485 input.

The communication is carried out according to Grundfos bus

protocol, GENIbus protocol, and enables connection to a building

management system or another external control system.

Operating parameters, such as setpoint, operating mode, et c. can

be remote-set via the bus signal. At the same time, the pump can

provide status information about important parameters, such as

actual value of control parameter, input power, fault indications,

etc.

Contact Grundfos for further details.

If a bus signal is used, the number of settings

available via the R100 will be reduced.

16. Other bus standards

Grundfos offers various bus solutions with communication

according to other standards.

Contact Grundfos for further details.

17. Indicator lights and signal relay

The operating condition of the pump is indicated by the green an d

red indicator lights fitted on the pump control panel and inside the

terminal box. See fig. 41.

Besides, the pump incorporates an output for a potential-free

signal via an internal relay.

For signal relay output values, see section 10.3.4 Signal relay on

page 18.

28

TM02 8513 0304

Fig. 41 Position of indicator lights

TM02 9036 4404

TM03 9063 3307

Page 29

The functions of the two indicator lights and the signal relay are as shown in the following table:

NCNOCNCNOCNCNOCNCNO

C

NCNO

C

C

NO NCCNO NCCNO NC

NCNO

C

C

NO NCCNO NC

NCNO

C

NCNOCNCNO

C

C

NO NC

NCNO

C

C

NO NC

NCNOCNCNOCNCNO

C

C

NO NCCNO NCCNO NCCNO NC

C

NO NC

NCNO

C

C

NO NC

NCNO

C

Indicator lights Signal relay activated during:

Fault

(red)

Operation

(green)

Fault/Alarm,

Warning

and

Operating Ready

Pump

running

Description

Relubricate

Off Off The power supply has been switched off.

Off

Off

Permanently

on

Permanently

on

The pump is operating.

The pump is stopped by the stop

function.

Off Flashing The pump has been set to stop.

The pump has stopped because of a

Fault/Alarm or is running with a Warning

or Relubricate indication.

If the pump was stopped, restarting will

Permanently

on

Off

be attempted (it may be nece ssar y to

restart the pump by resetting the Fault

indication).

If the cause is "external fault", the pump

must be restarted manually by resetting

the Fault indication.

The pump is operating, but it has or has

had a Fault/Alarm allowing the pump to