Grundfos CRK 2, MTR 1s, MTR 3, CRK 4, MTR 5 Installation And Operating Instructions Manual

...Page 1

CRK, MTR

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

English (GB) Installation and operating instructions

Caution

Note

English (GB)

Original installation and operating instructions

1. Symbols used in this document

CONTENTS

Page

1. Symbols used in this document

2. Handling

3. Applications

3.1 Pumped liquids

4. Identification

4.1 Nameplate for CRK and MTR

4.2 Type key for CRK

4.3 Type key for MTR, MTRE

5. Technical data

5.1 Ambient temperature

5.2 Maximum permissible operating pressure

and liquid temperature for the shaft seal

5.3 Minimum flow rate

5.4 Electrical data

5.5 Maximum number of starts

6. Installation

6.1 Pump location

6.2 Suction conditions

7. Electrical connection

7.1 Frequency converter operation

7.2 Other motor makes

8. Start-up

8.1 Before starting the pump

8.2 Starting the pump

9. Maintenance

9.1 Filters

9.2 Periodic checks

10. Service

10.1 Service kits

10.2 Coupling adjustment

11. Sound pressure level

12. Fault finding

13. Disposal

2

2

3

3

3

3

4

5

6

6

6

7

7

7

7

7

2. Handling

8

When the entire pump is to be lifted, observe the

9

following:

9

• CRK and MTR pumps fitted with a Grundfos MG

9

10

• CRK and MTR pumps fitted with a Grundfos MG

10

10

10

• For other motor makes than those mentioned

11

11

11

11

11

11

12

13

Warning

If these safety instructions are not

observed, it may result in personal injury.

Warning

If these instructions are not observed, it

may lead to electric shock with consequent

risk of serious personal injury or death.

Warning

The surface of the product may be so hot

that it may cause burns or personal injury.

If these safety instructions are not

observed, it may result in malfunction or

damage to the equipment.

Notes or instructions that make the job

easier and ensure safe operation.

motor up to 0.75 kW should be lifted in the pump

head by means of straps or the like.

motor from 1.1 to 22 kW must be lifted by means

of the lifting eyes.

above, we recommend to lift the pump in the

pump head by means of straps.

Warning

Prior to installation, read these installation

and operating instructions. Installation and

operation must comply with local

regulations and accepted codes of good

practice.

2

Page 3

3. Applications

Type

MTR10-6/3 A-W-A-HUUV

Model A 96889995 P1 1019

f 50 Hz 1.1P2 kW

30.3 mmin H

max

2853n

Q10

m /h

H 22.7 m

CCWbar/ C25/90

Made in Hungary

p

max

/

t

max

Serial No. 0001

MEI 0.70

p

°

Ș

3

-1

DK-8850 Bjerringbro, Denmark

--.-

12 3 4 5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 20

The Grundfos pumps, types CRK and MTR, are tank

mounted multistage centrifugal pumps designed for

the following applications:

• liquid transfer in machine tools

• condensate transfer

• liquid transfer in industrial washing machines

• pressure boosting of cold or hot clean liquids

• similar applications.

Warning

Do not use the pump for flammable liquids,

such as diesel oil and petrol.

3.1 Pumped liquids

Thin, non-explosive liquids, not containing fibres.

The liquid must not attack the pump materials

chemically.

When pumping liquids with a density and/or viscosity

higher than that of water, use motors with

correspondingly higher outputs, if required.

MTR version A pumps have a cast iron pump head.

In MTR version I and CRK version I pumps all parts

in contact with the pumped liquid are of stainless

steel EN/DIN 1.4301 or better.

4. Identification

4.1 Nameplate for CRK and MTR

English (GB)

TM05 5279 3912

Fig. 1 Example of nameplate

Pos. Description

1 Type designation

2 Model

3 Product number

4 Place of production

5 Production year and week (YYWW)

6 P2, 50 Hz

7 Head against closed valve

8 Head at rated flow rate

Direction of rotation

9

CCW: Counter-clockwise

CW: Clockwise

10 Country of production

11 Approval marks

12 Frequency

13 Speed

14 Rated flow rate

15 Maximum pressure and temperature

The number of the copy of the technical

16

file kept at KEMA (stated if the pump is

ATEX classified)

The serial number of the pump (stated if

17

the pump is ATEX classified)

ATEX category (stated if the pump is

18

ATEX classified)

19 Minimum efficiency index

20 Hydraulic pump efficiency

3

Page 4

4.2 Type key for CRK

Number of

impellers

Number of

chambers

English (GB)

Example CRK E 4 - 160 / 2 -x -x -x -xxxx

Pump type

Pump with integrated

frequency control

Rated flow rate [m

Number of chambers

Number of impellers

3

/h]

*)

x 10

*)

Code for pump version

Code for pipework connection

Code for materials

Code for shaft seal and rubber pump parts

*)

See fig. 2.

Fig. 2 Number of chambers / impellers

TM01 4991 1299

4

Page 5

4.3 Type key for MTR, MTRE

Example MTR E 32 (s) -2 /1 -1 -A -F -A -H UU V

Pump type

Pump with integrated frequency control

Rated flow rate [m

All impellers with reduced diameter (applies only to MTR 1s)

Number of chambers, see fig. 2

Number of impellers, see fig. 2

Number of impellers with reduced diameter

Pump version

ABasic version

B Oversize motor

C Suction pipe

E Pump with certificate/approval

F 120 °C version

H Horizontal version

J Pump with different max. speed

P Undersize motor

T Double oversize

X Special version

Pipe connection

F DIN flange

G ANSI flange

J JIS flange

M Square flange with internal thread

W Internal thread

WB NPT internal thread

X Special version

Materials

ABasic version

I Wetted parts EN/DIN 1.4301 / AISI 304

X Special version

Shaft seal

H Balanced cartridge seal

Q Silicon carbide

U Tungsten carbide

B Carbon

E EPDM

FFXM

KFFKM

VFKM

3

/h]

English (GB)

5

Page 6

5. Technical data

20 25 30 35 40 45 50 55 60 65 70 75 80

50

60

70

80

90

100

[%]

P2

1

2

3

t[°C]

1000 2250 3500 4750 m

-20 -10 0 10 20 30 40 50 60 70 80 90 100 110

0

5

10

15

20

25

30

35

p [bar]

HUUE / HUUV

t [°C]

English (GB)

Pump type CRK MTR

Minimum liquid temperature [°C] -10 -10

Maximum liquid temperature [°C] +90

Maximum operating pressure [bar] 25 25

Enclosure class IP55 IP55

* Applies to pump version F

5.1 Ambient temperature

Motor power

[kW]

0.06 - 0.18 Siemens - +40 1000 1

0.25 - 0.55 MG - +40 1000 1

0.75 MG IE2 +60 3500 2

1.1 - 22 MG IE2 +60 3500 2

30-45 Siemens IE2 +55 2750 3

If the ambient temperature exceeds the above

temperature values or the pump is installed at an

altitude exceeding the above altitude values, the

motor must not be fully loaded due to the risk of

overheating. Overheating may result from excessive

ambient temperatures or the low density and

consequently low cooling effect of the air.

Motor make

Motor efficiency class

Max. ambient

temperature at full load

In such cases, it may be necessary to use a motor

with a higher rated output.

+90

(120*)

TM04 4914 2209

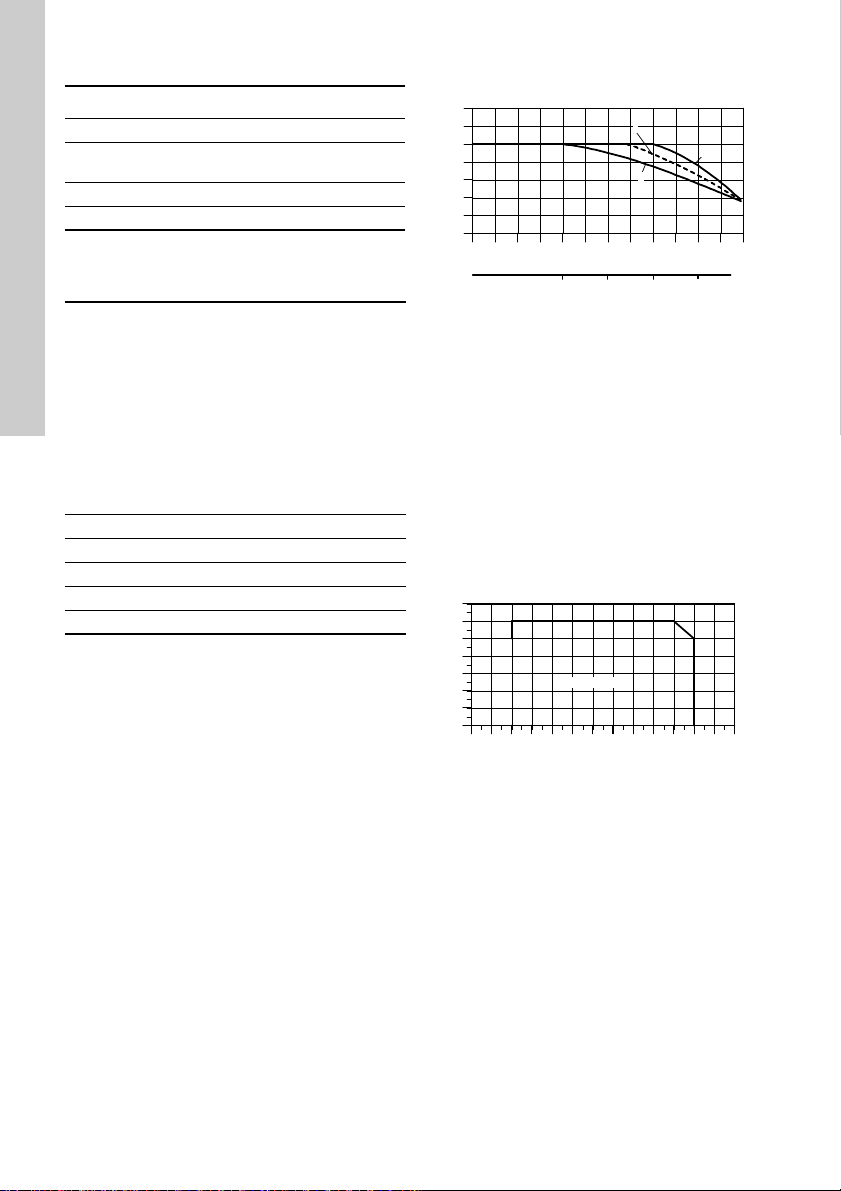

Fig. 3 Relationship between motor output (P2)

and ambient temperature/altitude

Example: A pump with a 1.1 kW IE2 MG motor: If

this pump is installed 4750 m above sea level, the

motor must not be loaded more than 88 % of rated

output. At an ambient temperature of 75 °C, the

motor must not be loaded more that 78 % of rated

output. If the pump is installed 4750 m above sea

level at an ambient temperature of 75 °C, the motor

must not be loaded more than 88 % x 78 % = 68.6 %

of rated output.

[°C]

Max. altitude above sea level

[m]

Pos. in output curve in fig. 3

5.2 Maximum permissible operating pressure and liquid temperature for the shaft seal

TM02 7854 4303

Fig. 4 MTR 1s to 64

6

Page 7

5.3 Minimum flow rate

40 50 60 70 80 90 100 110 120

t [°C]

0

10

20

30

Qmin

[%]

Caution

Caution

Caution

Vertical Horizontal

Due to the risk of overheating, the pump should not

be used at flows below the minimum flow rate.

The curve below shows the minimum flow rate as a

percentage of the nominal flow rate in relation to the

liquid temperature.

Fig. 5 Minimum flow rate in relation to

temperature

Note: The pump must never operate against a

closed discharge valve.

5.4 Electrical data

See motor nameplate.

5.5 Maximum number of starts

Motor size

[kW]

0.06 - 0.18 100

0.25 - 2.2 250

3-4 100

5.5 - 11 50

15-22 40

30-45 8

Recommended maximum

number of starts per hour

6. Installation

Warning

The pump must be installed so that

persons cannot accidentally come into

contact with the hot surface of the motor.

6.1 Pump location

The pump is designed for tank mounting in vertical

and horizontal position. However, only MTR version

H and MTRE version H are suitable for horizontal

mounting.

The pump is positioned in a hole cut into the tank

and is secured to the tank by four hexagon head

screws through the holes in the mounting flange.

TM04 5693 3809

Fig. 6 Vertical and horizontal installation

On horizontally installed MTR, MTRE pumps with

motors from 5.5 kW and up the motors have feet and

must be supported.

Fig. 7 Horizontally installed MTR with foot

English (GB)

TM01 4990 1399TM04 5755 3809

For horizontally mounted pumps ensure a

sufficient sealing between pump flange

and tank. A sealing gasket will usually

suffice.

Before changing shaft seals for

horizontally mounted pumps, drain the

tank.

MTR 32, 45 and 64 pumps can only be

installed in vertical position.

7

Page 8

English (GB)

D1

D2

D3

4 x X

C

L

B

A

25 mm

B

A

25 mm

A

25 mm

Fig. 8 Vertical installation

Mounting flange dimensions:

Pump type D1 D2 D3 L C X

CRK 2, 4 140 160 180 100

MTR 1s, 1,

3, 5

MTR 10,

15, 20

140 160 180 100

200 225 250 125

MTR 32 190 220 250 150 DN 65 ∅12

MTR 45,

64

240 265 290 165 DN 80 ∅12

6.2 Suction conditions

The bottom of the pump strainer must be at least 25

mm above the bottom of the tank.

The pumps are designed to provide full performance

down to a level of A mm above the bottom of the

strainer.

At a liquid level between A and B mm above the

bottom of the strainer, the built-in priming screw will

protect the pump against dry running.

Note: MTR 32, 45 and 64 pumps have no priming

screw.

Rp 1 1/4

G 1 1/4

Rp 1 1/4

G 1 1/4

Rp 2

G 2

∅7.5

∅9.5

∅9

TM05 7223 0813TM05 7224 0813TM05 7225 0813

Fig. 9 CRK 2, 4 and MTR 1s, 1, 3, 5

TM02 8042 4503

Fig. 10 MTR 10, 15, 20

Fig. 11 MTR 32, 45, 64

Pump type A [mm] B [mm]

CRK 2, 4 and MTR 1s, 1, 3, 5 41 28

MTR 10, 15, 20 50 25

MTR 32, 45, 64 70 -

8

Page 9

7. Electrical connection

0˚

90˚

180˚

270˚

Caution

The electrical connection should be carried out by an

authorized electrician in accordance with local

regulations.

The electrical connection should be carried out as

shown in the wiring diagram inside the terminal box

cover.

Warning

Before removing the terminal box cover

and before any removal/dismantling of the

pump, make sure that the power supply

has been switched off.

The pump must be connected to an

external mains switch with a minimum

contact gap of 3 mm in all poles.

The operating voltage and frequency are marked on

the pump nameplate. Please make sure that the

motor is suitable for the power supply on which it will

be used.

Single-phase Grundfos motors incorporate a

thermal switch and require no additional motor

protection.

Three-phase motors must be connected to a motorprotective circuit breaker.

The terminal box can be turned to four positions, in

90 ° steps. See fig. 12.

1. If necessary, remove the coupling guards. Do not

remove the coupling.

2. Remove the bolts securing the motor to the

pump.

3. Turn the motor to the required position.

4. Replace and tighten the bolts.

5. Replace the coupling guards.

7.1 Frequency converter operation

7.1.1 Motors supplied by Grundfos

All three-phase motors supplied by Grundfos can be

connected to a frequency converter.

Depending on the frequency converter type, this may

cause increased acoustic noise from the motor.

Furthermore, it may cause the motor to be exposed

to detrimental voltage peaks.

Grundfos motors, types MG 71 and MG 80

as well as MG 90 (1.5 kW, 2-pole), for

supply voltages up to and including 440 V

(see motor nameplate), must be protected

against voltage peaks higher than 650 V

(peak value) between the supply terminals.

We recommend to protect all other motors against

voltage peaks higher than 850 V.

The above disturbances, i.e. both increased acoustic

noise and detrimental voltage peaks, can be

eliminated by fitting an LC filter between the

frequency converter and the motor.

For further information, please contact the frequency

converter or motor supplier.

7.2 Other motor makes

If other motors makes than those supplied by

Grundfos are used, contact Grundfos or the motor

manufacturer.

English (GB)

TM00 4257 2294

Fig. 12 Terminal box positions

9

Page 10

8. Start-up

Caution

Air vent valve

English (GB)

Warning

Pay attention to the direction of the vent

hole and take care to ensure that the

escaping water does not cause injury to

persons or damage to the motor or other

components.

8.1 Before starting the pump

• Make sure that all pipe connections are tight.

• Make sure that the pump is partly filled with liquid

(partly submerged).

• Make sure that the strainer is not blocked by

impurities.

8.2 Starting the pump

1. Close the isolating valve on the discharge side of

the pump.

2. If the pump is fitted with an air vent valve, this

valve must be opened. See fig. 13.

9. Maintenance

Warning

Before starting work on the pump, make

sure that all power supplies to the pump

have been switched off and that they

cannot be accidentally switched on.

Pump bearings and shaft seal are maintenance-free.

Motor bearings

Motors not fitted with grease nipples are

maintenance-free.

Motors fitted with grease nipples should be

lubricated with a high-temperature, lithium-based

grease. See the instructions on the fan cover.

In the case of seasonal operation (motor is idle for

more than 6 months of the year), we recommend to

grease the motor when the pump is taken out of

operation.

Depending on the ambient temperature, the motor

bearings must be replaced or lubricated according to

the table below. The table applies to 2-pole motors.

The number of operating hours stated for bearing

replacement are guidelines only.

Fig. 13 Position of the air vent valve

3. See the correct direction of rotation of the pump

on the motor fan cover or on the coupling guard.

When seen from the top, the pump should rotate

counter-clockwise.

4. Start the pump and check the direction of

rotation.

5. Open the discharge pipe isolating valve a little.

6. If the pump is fitted with an air vent valve, this

valve must be closed when a steady flow of liquid

runs out of it.

7. Completely open the discharge pipe isolating

valve.

The pump has now been vented and is ready for

operation.

Do not run the pump against closed

discharge valve for more than approx. 5

minutes as this will cause an increase in

temperature/formation of steam in the

pump which may cause damage to the

pump.

Motor

size

[kW]

0.37 - 0.75 18000 - - - -

1.1 - 7.5 20000 15500 12500 10000 7500

TM01 6428 2399

Motor

size

[kW]

11 - 18.5 4500 3400 2500 1700 1100

22 4000 3100 2300 1500 1000

30-55 4000 3000 2000 1500 -

75 2000 1500 1000 500 -

Intervals for 4-pole motors are twice as long as those

for 2-pole motors.

If the ambient temperature is lower than 40 °C,

bearings must be replaced/lubricated at the intervals

mentioned under 40 °C.

Bearing replacement interval

[operating hours]

40 °C 45 °C 50 °C 55 °C 60 °C

Lubrication interval

[operating hours]

40 °C 45 °C 50 °C 55 °C 60 °C

10

Page 11

9.1 Filters

LpA [dB(A)]

Chip trays, filters, etc. should be cleaned at regular

intervals to ensure a correct flow of liquid.

9.2 Periodic checks

At regular intervals, depending on the conditions and

time of operation, the following checks should be

made:

• Check the quantity of liquid and operating

pressure.

• Check that there are no leaks.

• Check that the motor is not overheating.

• Check the tripping function of the motorprotective circuit breaker.

• Check that all controls are operating

satisfactorily.

If the above checks do not reveal any abnormal

operating details, no further checks are necessary.

Should any faults be found, check the symptoms

according to section 12. Fault finding.

10. Service

Warning

If a pump has been used for a liquid which

is injurious to health or toxic, the pump will

be classified as contaminated.

If Grundfos is requested to service the pump,

Grundfos must be contacted with details about the

pumped liquid, etc. before the pump is returned for

service. Otherwise Grundfos can refuse to accept

the pump for service.

Possible costs of returning the pump are paid by the

customer.

However, any application for service (no matter to

whom it may be made) must include details about

the pumped liquid if the pump has been used for

liquids which are injurious to health or toxic.

10.1 Service kits

Service kits for CRK and MTR, see https://productselection.grundfos.com/ or Service Kit Catalogue.

10.2 Coupling adjustment

For adjustment of coupling in CRK and MTR 1s to

20, see page 14.

For adjustment of coupling in MTR 32, 45, 64, see

page 15.

11. Sound pressure level

The table below shows airborne noise emitted by

CRK and MTR pumps with motors fitted by

Grundfos.

Motor

[kW]

0.37 50 55

0.55 50 53

0.75 50 54

1.1 52 57

1.5 54 59

2.2 54 59

3.0 55 60

4.0 62 66

5.5 60 65

7.5 60 65

11 60 65

15 60 65

18.5 60 65

22 66 70

30 71 75

37 71 75

45 71 75

50 Hz 60 Hz

English (GB)

11

Page 12

12. Fault finding

English (GB)

Warning

Before starting work on the pump, make

sure that all power supplies to the pump

have been switched off and that they

cannot be accidentally switched on.

Fault Cause Remedy

1. Motor does not run

when started.

2. Motor-protective

circuit breaker trips

out immediately

when power supply

is switched on.

3. Motor-protectivecircuit breaker trips

out occasionally.

4. Motor-protectivecircuit breaker has

not tripped out but

the pump does not

run.

5. Pump runs but

gives no liquid or

pump performance

is not constant.

6. Leakage in shaft

seal.

7. Noise. a) Cavitation. Check the suction conditions.

a) Power supply failure. Connect the power supply.

b) Fuses are blown. Replace fuses.

c) Motor-protective circuit breaker has

tripped out.

d) Thermal protection has tripped out. Reactivate the thermal protection.

e) Main contacts in motor-protective

circuit breaker are not making contact

or the coil is faulty.

f) Control circuit is defective. Repair the control circuit.

g) Motor is defective. Replace the motor.

a) One fuse blown/automatic circuit

breaker has tripped out.

b) Contacts in motor-protective circuit

breaker are faulty.

c) Cable connection is loose or faulty. Fasten or replace the cable

d) Motor winding is defective. Replace the motor.

e) Pump mechanically blocked. Remove the mechanical blocking of

f) Motor-protective circuit breaker

overload setting is too low.

a) Motor-protective circuit breaker

overload setting is too low.

b) Low voltage at peak times. Reestablish constant power supply.

a) Check 1 a), b), d), e) and f).

a) Pump strainer partly blocked by

impurities.

b) Liquid level in tank too low. Increase the liquid level.

c) Pump draws in air. Check the suction conditions.

a) Shaft seal is defective.

b) Pump does not rotate freely (frictional

resistance) because of incorrect

pump shaft position.

c) Frequency converter operation. See section 7.1 Frequency converter

Reactivate the motor-protective

circuit breaker.

Replace contacts or magnetic coil.

Replace fuse/cut in the circuit

breaker.

Replace motor-protective circuit

breaker contacts.

connection.

the pump.

Set the motor-protective circuit

breaker correctly.

Set the motor-protective circuit

breaker correctly.

Clean the strainer.

Replace the shaft seal.

Adjust the pump shaft.

operation.

12

Page 13

13. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

Subject to alterations.

English (GB)

13

Page 14

Appendix 1

M6: 13 Nm

M8: 31 Nm

M10: 62 Nm

M5: 2.5 Nm

Appendix

CRK and MTR 1s to 20

TM02 8050 4503

TM02 8052 4503

TM02 8051 4503

TM02 7420 3403

14

Page 15

MTR 32, 45, 64

1.7 mm

M10 x 2.5: 62 Nm

MTR32

MTR45

MTR64

Appendix

TM01 9785 3100

TM01 9788 3100

TM01 9786 3100

15

Page 16

Declaration of conformity

Declaration of conformity 2

GB: EC/EU declaration of conformity

We, Grundfos, declare under our sole responsibility that the products

CRK, MTR, to which the declaration below relates, are in conformity

with the Council Directives listed below on the approximation of the

laws of the EC/EU member states.

Note: There are two sets of Council Directives and standards listed

below. One set applies until and including 19th April 2016. The other

set applies from 20th April 2016 and onwards.

DE: EG-/EU-Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung, dass die

Produkte CRK, MTR, auf die sich diese Erklärung beziehen, mit den

folgenden Richtlinien des Rates zur Angleichung der

Rechtsvorschriften der EG-/EU-Mitgliedsstaaten übereinstimmen.

Hinweis: Nachfolgend sind zwei Gruppen aus Richtlinien des Rates

und Standards aufgeführt. Eine Gruppe gilt bis einschließlich 19. April

2016. Die andere Gruppe gilt ab dem 20. April 2016.

FR: Déclaration de conformité CE/UE

Nous, Grundfos, déclarons sous notre seule responsabilité, que les

produits CRK, MTR, auxquels se réfère cette déclaration, sont

conformes aux Directives du Conseil concernant le rapprochement

des législations des États membres CE/UE relatives aux normes

énoncées ci-dessous.

Remarque : Deux groupes de Directives du Conseil et normes sont

énoncés ci-dessous. Un groupe s'applique jusqu'au 19 avril 2016

inclus. L'autre groupe entrera en vigueur le 20 avril 2016.

PL: Deklaracja zgodności WE/UE

My, Grundfos, oświadczamy z pełną odpowiedzialnością, że nasze

produkty CRK, MTR, których deklaracja niniejsza dotyczy, są zgodne

z następującymi dyrektywami Rady w sprawie zbliżenia przepisów

prawnych państw członkowskich.

Uwaga: Poniżej podano dwa zestawy dyrektyw i norm. Pierwszy

zestaw obowiązuje do 19 kwietna 2016 r. włącznie. Drugi zacznie

obowiązywać 20 kwietnia 2016 r.

These Directives and standards apply until and including 19th April

2016:

– Machinery Directive (2006/42/EC).

Standard used:

EN 809:1998 + A1:2009.

– EMC Directive (2004/108/EC).

– Ecodesign Directive (2009/125/EC).

Electric motors:

Commission Regulation No 640/2009.

Applies only to three-phase Grundfos motors marked IE2 or IE3.

See motor nameplate.

Standard used EN 60034-30:2009.

– Ecodesign Directive (2009/125/EC).

Water pumps:

Commission Regulation No 547/2012.

Applies only to water pumps marked with the minimum efficiency

index MEI. See pump nameplate.

CZ: Prohlášení o shodě EU

My firma Grundfos prohlašujeme na svou plnou odpovědnost, že

výrobky CRK, MTR, na které se toto prohlášení vztahuje, jsou

v souladu s níže uvedenými ustanoveními směrnice Rady pro

sblížení právních předpisů členských států Evropského společenství.

Poznámka: Níže jsou uvedeny dvě sady směrnic Rady a standardů.

První sada je platná do 19. dubna 2016 (včetně). Druhá sada platí od

20. dubna 2016.

ES: Declaración de conformidad de la CE/UE

Grundfos declara, bajo su exclusiva responsabilidad, que los

productos CRK, MTR a los que hace referencia la siguiente

declaración cumplen lo establecido por las siguientes Directivas del

Consejo sobre la aproximación de las legislaciones de los Estados

miembros de la CE/UE.

Nota: A continuación se recogen dos conjuntos de normas y

Directivas del Consejo. Uno de ellos es válido hasta el 19 de abril de

2016. El otro es válido a partir del 20 de abril de 2016.

IT: Dichiarazione di conformità CE/UE

Grundfos dichiara sotto la sua esclusiva responsabilità che i prodotti

CRK, MTR, ai quale si riferisce questa dichiarazione, sono conformi

alle seguenti direttive del Consiglio riguardanti il riavvicinamento delle

legislazioni degli Stati membri CE/UE.

Nota: Di seguito sono elencate due serie di direttive del Consiglio e

norme. Una serie si applca fino al19 aprile 2016 (incluso). La seconda

serie si applica a partire dal 20 aprile 2016.

RU: Декларация о соответствии нормам

ЕЭС/ЕС

Мы, компания Grundfos, со всей ответственностью заявляем, что

изделия CRK, MTR, к которым относится нижеприведённая

декларация, соответствуют нижеприведённым Директивам

Совета Евросоюза о тождественности законов стран-членов

ЕЭС/ЕС.

Примечание: Существует два комплекта Директив Совета

Евросоюза и стандартов, перечисленных ниже. Один комплект

применяется до 19 апреля 2016 г. включительно. Второй комплект

применяется начиная с 20 апреля 2016 г.

These Directives and standards apply from 20th April 2016 and

onwards:

– Machinery Directive (2006/42/EC).

Standard used:

EN 809:1998 + A1:2009

– EMC Directive (2014/30/EU).

– Ecodesign Directive (2009/125/EC).

Electric motors:

Commission Regulation No 640/2009.

Applies only to three-phase Grundfos motors marked IE2 or IE3.

See motor nameplate.

Standard used EN 60034-30:2009.

– Ecodesign Directive (2009/125/EC).

Water pumps:

Commission Regulation No 547/2012.

Applies only to water pumps marked with the minimum efficiency

index MEI. See pump nameplate.

This EC/EU declaration of conformity is only valid when published as

part of the Grundfos installation and operating instructions

(publication number 96496966 0316).

Székesfehérvár, 3 February 2016

16

Róbert Kis

Engineering Manager

GRUNDFOS Holding A/S

Poul Due Jensens Vej 7

8850 Bjerringbro, Denmark

Person authorised to compile the technical file and

empowered to sign the EC/EU declaration of conformity.

Page 17

17

Page 18

Grundfos companies

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Centro

Industrial Garin

1619 Garín Pcia. de B.A.

Phone: +54-3327 414 444

Telefax: +54-3327 45 3190

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb

Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belarus

Представительство ГРУНДФОС в

Минске

220125, Минск

ул. Шафарнянская, 11, оф. 56, БЦ

«Порт»

Тел.: +7 (375 17) 286 39 72/73

Факс: +7 (375 17) 286 39 71

E-mail: minsk@grundfos.com

Bosna and Herzegovina

GRUNDFOS Sarajevo

Zmaja od Bosne 7-7A,

BH-71000 Sarajevo

Phone: +387 33 592 480

Telefax: +387 33 590 465

www.ba.grundfos.com

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo

Branco, 630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

10F The Hub, No. 33 Suhong Road

Minhang District

Shanghai 201106

PRC

Phone: +86 21 612 252 22

Telefax: +86 21 612 253 33

Croatia

GRUNDFOS CROATIA d.o.o.

Buzinski prilaz 38, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.hr.grundfos.com

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Trukkikuja 1

FI-01360 Vantaa

Phone: +358-(0) 207 889 500

Telefax: +358-(0) 207 889 550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private

Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT. GRUNDFOS POMPA

Graha Intirub Lt. 2 & 3

Jln. Cililitan Besar No.454. Makasar,

Jakarta Timur

ID-Jakarta 13650

Phone: +62 21-469-51900

Telefax: +62 21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg., 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Page 19

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Mexico

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

Romania

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундф ос Россия

109544, г. Москва, ул. Школьная, 39-

41, стр. 1

Тел. (+7) 495 564-88-00 (495) 737-3000

Факс (+7) 495 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

Grundfos Srbija d.o.o.

Omladinskih brigada 90b

11070 Novi Beograd

Phone: +381 11 2258 740

Telefax: +381 11 2281 769

www.rs.grundfos.com

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

25 Jalan Tukang

Singapore 619264

Phone: +65-6681 9688

Telefax: +65-6681 9689

Slovakia

GRUNDFOS s.r.o.

Prievozská 4D

821 09 BRATISLAVA

Phona: +421 2 5020 1426

sk.grundfos.com

Slovenia

GRUNDFOS LJUBLJANA, d.o.o.

Leskoškova 9e, 1122 Ljubljana

Phone: +386 (0) 1 568 06 10

Telefax: +386 (0)1 568 06 19

E-mail: tehnika-si@grundfos.com

South Africa

GRUNDFOS (PTY) LTD

Corner Mountjoy and George Allen

Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölndal

Tel.: +46 31 332 23 000

Telefax: +46 31 331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-44-806 8111

Telefax: +41-44-806 8115

Tai wan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd.

Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

Бізнес Центр Європа

Столичне шосе, 103

м. Київ, 03131, Україна

Телефон : (+38 044) 237 04 00

Факс.: (+38 044) 237 04 01

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971 4 8815 166

Telefax: +971 4 8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 4TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Uzbekistan

Grundfos Tashkent, Uzbekistan The

Representative Office of Grundfos

Kazakhstan in Uzbekistan

38a, Oybek street, Tashkent

Телефон: (+998) 71 150 3290 / 71 150

3291

Факс: (+998) 71 150 3292

Addresses Revised 25.01.2016

Grundfos companies

Page 20

96496966 0316

ECM: 1181099

www.grundfos.com

© Copyright Grundfos Holding A/S

owned by Grundfos Holding A/S or Grundfos A/ S, Denmark. All rights reserved worldwide.

The name Grundfos, the Grundfos logo, and be think innovate are registered trademarks

Loading...

Loading...