Grundfos MAGNA 2000 Series, MAGNA 32-120, MAGNA 65-120, MAGNA 50-60, MAGNA 65-60 Installation And Operating Instructions Manual

...Page 1

GRUNDFOS INSTRUCTIONS

GRUNDFOS MAGNA

Series 2000

MAGNA 32-120, 40-120, 50-120, 65-120, 50-60, 65-60

Installation and operating instructions

Page 2

Declaration of Conformity

We Grundfos declare under our sole responsibility that the products

MAGNA Series 2000, to which this declaration relates, are in conformity

with the Council Directives on the approximation of the laws of the

EC Member States relating to

– Machinery (98/37/EC).

– Electrical equipment designed for use within certain voltage limits

(2006/95/EC).

Standards used: EN 60335-1: 2002 and EN 60335-2-51: 2003,

SAP96732176.

– Electromagnetic compatibility (2004/108/EC).

Standard used: EN 61800-3.

Déclaration de Conformité

Nous Grundfos déclarons sous notre seule responsabilité que les

produits MAGNA Série 2000 auxquels se réfère cette déclaration sont

conformes aux Directives du Conseil concernant le rapprochement des

législations des Etats membres CE relatives à

– Machines (98/37/CE).

– Matériel électrique destiné à employer dans certaines limites

de tension (2006/95/CE).

Standards utilisés: EN 60335-1: 2002 et EN 60335-2-51: 2003,

SAP96732176.

– Compatibilité électromagnétique (2004/108/CE).

Standard utilisé: EN 61800-3.

Declaración de Conformidad

Nosotros Grundfos declaramos bajo nuestra única responsabilidad que

los productos MAGNA Serie 2000 a los cuales se refiere esta declara-

ción son conformes con las Directivas del Consejo relativas a la

aproximación de las legislaciones de los Estados Miembros de la CE

sobre

– Máquinas (98/37/CE).

– Material eléctrico destinado a utilizarse con determinadas límites

de tensión (2006/95/CE).

Normas aplicadas: EN 60335-1: 2002 y EN 60335-2-51: 2003,

SAP96732176.

– Compatibilidad electromagnética (2004/108/CE).

Norma aplicada: EN 61800-3.

Δήλωση Συμμόρφωσης

Εμείς η Grundfos δηλώνουμε με αποκλειστικά δική μας ευθύνη ότι τα

προιόντα MAGNA Σειρά 2000 συμμορφώνονται με την Οδηγία το υ

Συμβουλίου επί της σύγκλισης των νόμων των Κρατών Mελών της

Ευρωπαικής Ενωσης σε σχέση με τα

– Μηχανήματα (98/37/EC).

– Ηλεκτρικές συσκευές σχεδιασμένες γιά χρήση εντός ορισμένων

ορίων ηλεκτρικής τάσης (2006/95/EC).

Πρότυπα που χρησιμοποιήθηκαν: EN 60335-1: 2002 και

EN 60335-2-51: 2003, SAP96732176.

– Ηλεκτρομαγνητική συμβατότητα (2004/108/EC).

Πρότυπο που χρησιμοποιήθηκε: EN 61800-3.

Försäkran om överensstämmelse

Vi Grundfos försäkrar under ansvar, att produkterna

MAGNA Serie 2000, som omfattas av denna försäkran, är i överens-

stämmelse med Rådets Direktiv om inbördes närmande till

EU-medlemsstaternas lagstiftning, avseende

– Maskinell utrustning (98/37/EC).

– Elektrisk material avsedd för användning inom vissa spännings-

gränser (2006/95/EC).

Använda standarder: EN 60335-1: 2002 och EN 60335-2-51: 2003,

SAP96732176.

– Elektromagnetisk kompatibilitet (2004/108/EC).

Använd standard: EN 61800-3.

Konformitätserklärung

Wir Grundfos erklären in alleiniger Verantwortung, dass die Produkte

MAGNA Serie 2000, auf die sich diese Erklärung bezieht, mit den fol-

genden Richtlinien des Rates zur Angleichung der Rechtsvorschriften

der EG-Mitgliedstaaten übereinstimmen

– Maschinen (98/37/EG).

– Elektrische Betriebsmittel zur Verwendung innerhalb bestimmter

Spannungsgrenzen (2006/95/EG).

Normen, die verwendet wurden: EN 60335-1: 2002 und

EN 60335-2-51: 2003, SAP96732176.

– Elektromagnetische Verträglichkeit (2004/108/EG).

Norm, die verwendet wurde: EN 61800-3.

Dichiarazione di Conformità

Noi Grundfos dichiariamo sotto la nostra esclusiva responsabilità che i

prodotti MAGNA Serie 2000 ai quali questa dichiarazione se riferisce

sono conformi alle Direttive del Consiglio concernente il ravvicinamento

delle legislazioni degli Stati membri CE relative a

– Macchine (98/37/CE).

– Materiale elettrico destinato ad essere utilizzato entro certi limiti

di tensione (2006/95/CE).

Standard usati: EN 60335-1: 2002 e EN 60335-2-51: 2003,

SAP96732176.

– Compatibilità elettromagnetica (2004/108/CE).

Standard usato: EN 61800-3.

Declaração de Conformidade

Nós Grundfos declaramos sob nossa única responsabilidade que os

produtos MAGNA Série 2000 aos quais se refere esta declaração estão

em conformidade com as Directivas do Conselho das Comunidades

Europeias relativas à aproximação das legislações dos Estados Membros respeitantes à

– Máquinas (98/37/CE).

– Material eléctrico destinado a ser utilizado dentro de certos limites

de tensão (2006/95/CE).

Normas utilizadas: EN 60335-1: 2002 e EN 60335-2-51: 2003,

SAP96732176.

– Compatibilidade electromagnética (2004/108/CE).

Norma utilizada: EN 61800-3.

Overeenkomstigheidsverklaring

Wij Grundfos verklaren geheel onder eigen verantwoordelijkheid dat de

produkten MAGNA Serie 2000 waarop deze verklaring betrekking heeft

in overeenstemming zijn met de Richtlijnen van de Raad inzake de

onderlinge aanpassing van de wetgevingen van de

Lid-Staten betreffende

– Machines (98/37/EG).

– Elektrisch materiaal bestemd voor gebruik binnen bepaalde

spanningsgrenzen (2006/95/EG).

Normen: EN 60335-1: 2002 en EN 60335-2-51: 2003,

SAP96732176.

– Elektromagnetische compatibiliteit (2004/108/EG).

Norm: EN 61800-3.

Vastaavuusvakuutus

Me Grundfos vakuutamme yksin vastuullisesti, että tuotteet

MAGNA Sarja 2000, jota tämä vakuutus koskee, noudattavat direktii-

vejä jotka käsittelevät EY:n jäsenvaltioiden koneellisia laitteita

koskevien lakien yhdenmukaisuutta seur.:

– Koneet (98/37/EY).

– Määrättyjen jänniterajoitusten puitteissa käytettävät sähköiset

laitteet (2006/95/EY).

Käytetyt standardit: EN 60335-1: 2002 ja EN 60335-2-51: 2003,

SAP96732176.

– Elektromagneettinen vastaavuus (2004/108/EY).

Käytetty standardi: EN 61800-3.

2

Page 3

Overensstemmelseserklæring

Vi Grundfos erklærer under ansvar, at produkterne

MAGNA Serie 2000, som denne erklæring omhandler, er i overens-

stemmelse med Rådets direktiver om indbyrdes tilnærmelse til EF

medlemsstaternes lovgivning om

– Maskiner (98/37/EF).

– Elektrisk materiel bestemt til anvendelse inden for visse spændings-

grænser (2006/95/EF).

Anvendte standarder: EN 60335-1: 2002 og EN 60335-2-51: 2003,

SAP96732176.

– Elektromagnetisk kompatibilitet (2004/108/EF).

Anvendt standard: EN 61800-3.

Декларация о соответствии

Мы, фирма Grundfos, со всей ответственностью заявляем, что

изделия MAGNA серии 2000, к которым и относ ится данное

свид етельст во, отвечают требованиям следующих указаний Совета

ЕС об унификации законодательных предписаний стран-членов ЕС:

– Машиностроение (98/37/ЕС).

– Элек трич еские машины для эк сплуатации в пределах

определенного диапазона значений напряжения

(2006/95/ЕС).

Применявшиеся стандарты: Евростандарт EN 60335-1: 2002 и

EN 60335-2-51: 2003, SAP96732176.

– Электромагнитная

Применявшиеся стандарты: Евростандарт EN 61800-3.

совместимость (2004/108/ЕС).

Deklaracja zgodności

My, Grundfos, oświadczamy z pełną odpowiedzialnością, ż e nasze

wyroby MAGNA seria 2000 których deklaracja niniejsza dotyczy, są

zgodne z następującymi wytycznymi Rady d/s ujednolicenia przepisów

prawnych krajów członkowskich EG:

– maszyny (98/37/EG).

– wyposażenie elektryczne do stosowania w określonym zakresie

napięć (2006/95/EG),

zastosowane normy: EN 60335-1: 2002 i EN 60335-2-51: 2003,

SAP96732176.

– zgodność elektromagnetyczna (2004/108/EG),

zastosowana norma: EN 61800-3.

Bjerringbro, 1st August 2007

Svend Aage Kaae

Technical Director

3

Page 4

4

Page 5

GRUNDFOS MAGNA

Series 2000

MAGNA 32-120, 40-120, 50-120, 65-120, 50-60, 65-60

Installation and operating instructions 6

Montage- und Betriebsanleitung 30

Notice d'installation et d'entretien 56

Istruzioni di installazione e funzionamento 81

Instrucciones de instalación y funcionamiento 106

Instruções de instalação e funcionamento 130

Οδηγίες εγκατάστασης και λειτουργίας 156

Installatie- en bedieningsinstructies 182

Monterings- och driftsinstruktion 206

Asennus- ja käyttöohjeet 231

Monterings- og driftsinstruktion 255

Instrukcja montażu i eksploatacji 279

Руководство по монтажу и эксплуатации 305

5

Page 6

CONTENTS

1. Symbols used in this document 6

2. General description 6

3. Applications 6

3.1 Pumped liquids 6

4. Installation 7

4.1 Changing the control box position 7

4.2 Twin-head pumps 7

4.3 Non-return valve 7

4.4 Frost protection 8

5. Electrical connection 8

5.1 Supply voltage 8

5.2 Connection diagram 9

6. Start-up 10

7. Functions 11

7.1 Control modes 12

7.2 Selection of control mode 13

7.3 Automatic night-time duty 14

7.4 Constant-curve duty 14

7.5 Max. or min. curve duty 14

7.6 Temperature influence 14

7.7 External start/stop 15

7.8 Signal relay 15

7.9 Indicator lights 15

7.10 Expansion modules 16

7.11 Wiring diagrams for expansion modules 17

7.12 GENI module 18

7.13 LON module 18

8. Setting the pump 19

8.1 Factory setting 19

8.2 Control panel 19

8.3 R100 remote control 21

8.4 R100 display overview 22

8.5 Menu OPERATION 23

8.6 Menu STATUS 24

8.7 Menu INSTALLATION 25

8.8 Priority of settings 26

9. Fault finding chart 27

10. Megging 28

11. Technical data 29

12. Disposal 29

Warning

Prior to installation, read these

installation and operating instructions.

Installation and operation must comply

with local regulations and accepted

codes of good practice.

Page

1. Symbols used in this document

Warning

If these safety instructions are not

observed, it may result in personal

injury!

If these safety instructions are not

Caution

observed, it may result in malfunction

or damage to the equipment!

Notes or instructions that make the job

Note

easier and ensure safe operation.

2. General description

The GRUNDFOS MAGNA Series 2000 is a complete

range of circulator pumps with integrated differential

pressure control enabling adjustment of pump

performance to the actual system requirements.

In many systems, this will reduce the power

consumption considerably, reduce noise from

thermostatic valves and similar fittings, and improve

the control of the system.

The desired head can be set on the pump control

panel.

3. Applications

The GRUNDFOS MAGNA is designed for circulating

liquids in heating and air-conditioning systems. The

pump can also be used in domestic hot-water

systems.

The pump range is primarily used in

• systems with a variable flow.

The pump range can also be used in

• systems with a constant flow where it is

desirable to optimise the setting of the pump duty

point,

• systems with variable flow-pipe temperature.

3.1 Pumped liquids

Thin, clean, non-aggressive and non -explosive liquids,

not containing solid particles, fibres or mineral oil.

In heating systems, the water should meet the

requirements of accepted standards on water quality

in heating systems, e.g. the German standard

VDI 2035.

In domestic hot-water systems, it is advisable to

use GRUNDFOS MAGNA pumps only for water with

a degree of hardness lower than approx. 14 °dH.

Warning

The pump must not be used for the

transfer of inflammable liquids such as

diesel oil, petrol or similar liquids.

6

Page 7

4. Installation

Arrows on the pump housing indicate the liquid flow

direction through the pump.

4.1 Changing the control box position

Warning

Before any dismantling of the pump,

the system must be drained or the

isolating valves on either side of the

pump must be closed as the pumped

liquid may be scalding hot and under

high pressure.

Change the control box position as follows:

1. Remove the inspection screw (1) and the four

screws (2) in the stator housing, see fig. 1.

2. Lift off the stator housing (3). Keep the rotor (4) in

place using a suitable tool, e.g. a T-key (M8) (5),

see fig. 2.

3. Check that the O-ring (6) is intact.

A defective O-ring must be replaced.

4. Hold the stator housing/control box (3) in the

desired position.

5. Lower the stator housing over the rotor.

Keep the rotor in place as described in point 2.

6. Fit and tighten the four screws and the inspection

screw.

1

3

2

Fig. 1 Rem oving the control box

Pos. Description

1 Inspection screw

2Screw

3 Stator housing/control box

4 Rotor

5T-key

6 O-ring

4.2 Twin-head pumps

Twin-head pumps are supplied fitted with a GENI

module on each control box. The modules are

connected via a cable. The modules determine the

operating mode of the pump, see section

7.12.1 Control of twin-head pumps.

Twin-head pumps mounted in

horizontal pipes must be fitted with an

Caution

automatic air vent (Rp 1/4) in the upper

part of the pump housing, see fig. 3.

The automatic air vent is not supplied with the pump.

Fig. 3 Automatic ai r vent

4.3 Non-return valve

If a non-return valve is fitted in the pipe system, see

fig. 4, it must be ensured that the set minimum

discharge pressure of the pump is always higher

TM02 5506 3402TM02 5507 3402

than the closing pressure of the valve. This is

especially important in proportional-pressure control

mode (reduced head at low flows).

TM03 8831 2607TM02 0640 0301

5

4

6

Fig. 2 Chan ging the control box position

Fig. 4 Non- return v alve

7

Page 8

4.4 Frost protection

If the pump is not used during periods of frost,

necessary steps must be taken to prevent frost

bursts.

Additives with a density and/or

kinematic viscosity higher than those/

Note

that of water will reduce the hydraulic

performance.

5. Electrical connection

The electrical connection and protection should be

carried out in accordance with local regulations.

Warning

Never make any connections in the

pump control box unless the electricity

supply has been switched off for at

least 5 minutes.

The earth terminal of the pump must be

earthed.

The pump must be connected to an

external mains switch with a contact

separation of at least 3 mm in each

pole.

Earthing or neutralisation can be used

for protection against indirect contact.

Megging must be carried out as

described in section 10. Megging.

If the pump is connected to an electric

installation where an earth leakage

circuit breaker (ELCB) is used as

additional protection, this circuit

breaker must trip out when earth fault

currents with DC content (pulsating

DC) occur.

The earth leakage circuit breaker must

be marked with the symbol shown:

Open the control box cover as shown in fig. 5.

Step Action

1

2

Fig. 5 Opening the control box

If the control box cover cannot be lifted sufficiently, it

can be removed as shown in fig. 6.

Step Action

1

TM02 0456 3503

TM02 0457 3503

• The pump requires no external motor protection.

• The operating voltage and frequency are marked

on the pump nameplate. Please make sure that

the motor is suitable for the electricity supply on

which it will be used.

8

TM02 7441 3503

2

TM02 7442 3503

Fig. 6 Removing the con trol box cover

5.1 Supply voltage

1 x 230-240 V – 10 %/+ 6 %, 50/60 Hz.

Page 9

5.2 Connection diagram

Supply connection Signal output Start/stop input

78

L

N

Fig. 7 Conn ection diagram

Warning

• Wires connected to

– supply terminals,

– outputs NC, NO, C and

– start/stop input

must be separated from each other

and from the supply by reinforced

insulation.

• All wires connected to a terminal

block must be tied up at the

terminals.

Concerning demands on signal wires and signal

transmitters, see section 11. Technical data.

A connection example can be found on page 337.

213

NC NO C

NC NO C

Note:

• If no external on/off switch is connected, the

connection across terminals STOP and should

be maintained.

• All cables used must be heat-resistant up to

+85 °C.

• All cables used must be installed in accordance

with EN 60204-1 and EN 50174-2: 2000.

• If a GENI module is fitted, the screen must be

connected to . See page 339.

S

T

O

P

TM02 0235 1007

9

Page 10

6. Start-up

Do not start the pump until the system has been filled

with liquid and vented. Furthermore, the required

minimum inlet pressure must be available at the

pump inlet, see section 11. Technical data.

The system cannot be vented through the pump.

The pump can be vented by slackening the

inspection screw.

Warning

If the inspection screw is to be

slackened, see fig. 8, care should be

taken to ensure that the escaping,

scalding hot liquid does not cause

personal injury or damage to

components.

Inspection screw

Fig. 8 Venting the pump

TM02 5508 3402

10

Page 11

7. Functions

Most functions can be selected on the pump control panel. However, some functions can only be selected with

the R100 or via expansion modules.

On the pump control panel, see fig. 19, page 19:

• AUTO

ADAPT (factory setting)

Recommended for most heating installations.

During operation, the pump automatically makes the necessary adjustment to the actual system

characteristic. This setting ensures minimum energy consumption and noise level which reduces operating

costs and increases comfort.

• Proportional-pressure control

The pump head is changed continuously in accordance with the water demand in the system. The desired

setpoint can be set on the pump control panel.

• Constant-pressure control

A constant head is maintained, irrespective of water demand. The desired setpoint can be set on the pump

control panel.

• Automatic night-time duty

The pump changes automatically between normal duty and night-time duty depending on the flow-pipe

temperature. Automatic night-time duty can be combined with the above-mentioned control modes.

Further functions:

Via the digital input:

• External start/stop

The pump can be started or stopped via the digital input.

With the R100 remote control:

• Constant-curve duty

The pump runs at a constant speed, on or between the max. and min. curves.

• Temperature influence

The head varies depending on the liquid temperature.

• External fault and operating signal

The pump controls an external fault or operating signal device via a potential-free output.

Via expansion modules:

GENI module

• External analog control of head or speed via a signal from an external 0-10 V signal transmitter.

• External forced control via inputs for:

- Max. curve,

- Min. curve.

• Bus communication via GENIbus

The pump can be controlled and monitored by a GRUNDFOS Pump Management System 2000,

a building management system or another type of external control system.

• Control of twin-head pumps

The control of twin-head pumps is described in section 7.12.1.

LON module

• Bus communication via LON

This module enables connection to a network based on LonWorks

are based on this communication standard.

®

technology and to other units which

11

Page 12

7.1 Control modes

A GRUNDFOS MAGNA pump can be set to the

control mode which is most suitable for the individual

system.

Possible control modes:

ADAPT (factory setting)

•AUTO

• Proportional pressure

• Constant pressure.

Each of the control modes can be combined with

automatic night-time duty, see section 7.3 Automatic

night-time duty.

ADAPT

AUTO

To be set on the control panel or with the R100, see

section 8. Setting the pump.

The control mode AUTO

the pump performance.

The setpoint of the pump has been factory-set as

follows and cannot be changed manually:

• MAGNA 32-120, 40-120, 50-120, 65-120 to

6.5 metres.

• MAGNA 50-60, 65-60 to 3.5 metres.

When the pump registers a lower pressure on the

max. curve, A

automatically selects a correspondingly lower control

curve, H

2

, thus reducing the energy consumption.

set2

H

H

max.

ADAPT continuously adapts

, the AUTOADAPT function

Proportional-pressure control

To be set on the control panel or with the R100, see

section 8. Setting the pump.

The pump head is reduced at decreasing water

demand and increased at rising water demand, see

fig. 10.

Constant-pressure control

To be set on the control panel or with the R100, see

section 8. Setting the pump.

The pump maintains a constant pressure,

irrespective of water demand, see fig. 10.

Q

H

H

set

Constant

pressure

Q

H

H

set

H

set

2

2

Proportional

pressure

Fig. 10 Pressure control

TM00 5546 4596

H

fac.

Fig. 9 AUTO

A

1

ADAPT

H

set1

H

set2

A

2

A

3

Q

A1: Original duty point.

A

: Lower registered pressure on the max. curve.

2

: New duty point after AUTOADAPT control.

A

3

: Original setpoint.

H

set1

H

: New setpoint after AUTOADAPT control.

set2

: Factory-set setpoint.

H

fac.

The AUTO

the button for approx. 10 seconds until the control

mode is back to the starting point (AUTO

AUTO

ADAPT function can be reset by pressing

ADAPT with automatic night-time duty).

ADAPT or

12

TM02 0251 4800

Page 13

7.2 Selection of control mode

System type Description

Typical heating

systems

Relatively great

head losses in

the distribution

pipes and airconditioning

systems

Relatively small

head losses in

the distribution

pipes

Grundfos recommends to let the pump remain in AUTO

This ensures optimum performance at the lowest possible energy

consumption.

1. Two-pipe

heating

systems with

thermostatic

valves and:

• with a dimensioned pump head higher than

4metres,

• very long distribution pipes,

• strongly throttled pipe balancing valves,

• differential pressure regulators,

• great head losses in those parts of the system

through which the total quantity of water flows

(e.g. boiler, heat exchanger and distribution pipe up

to the first branching).

2. Primary circuit pumps in systems with great head losses in the primary

circuit.

3. Airconditioning

systems with

1. Two-pipe

heating

systems with

thermostatic

valves and:

• he at exchangers (fan coils),

• c ooling ceilings,

• cooli ng surfaces.

• with a dimensioned pump head lower than

2metres,

• dimensioned for natural circulation,

• with small head losses in those parts of the system

through which the total quantity of water flows

(e.g. boiler, heat exchanger and distribution pipe up

to the first branching) or

• modified to a high differential temperature between

flow pipe and return pipe (e.g. district heating).

2. Underfloor heating systems with thermostatic valves.

3. One-pipe heating systems with thermostatic valves or pipe balancing

valves.

4. Primary circuit pumps in systems with small head losses in the primary

circuit.

7.2.1 Setpoint setting

If AUTO

ADAPT is selected, the setpoint cannot be set.

The setpoint can be set by pressing or when

the pump is in control mode:

• proportional pressure

• constant pressure

• constant-curve duty.

Set the setpoint so that it matches the system.

A too high setting may result in noise in the system

whereas a too low setting may result in insufficient

heating or cooling in the system.

ADAPT mode.

Select this

control mode

ADAPT

AUTO

Proportional

pressure

Constant

pressure

13

Page 14

7.3 Automatic night-time duty

To be set on the control panel or with the R100, see

section 8. Setting the pump.

Once automatic night-time duty has been activated,

the pump automatically changes between normal

duty and night-time duty (duty at low performance).

Changeover between normal duty and night-time

duty is dependent on the flow-pipe temperature.

The pump automatically changes over to night-time

duty when the built-in sensor registers a flow-pipe

temperature drop of more than 10-15 °C within

approx. 2 hours. The temperature drop must be at

least 0.1 °C/min.

Changeover to normal duty takes place without a

time lag when the temperature has increased by

approx. 10 °C.

Automatic night-time duty cannot be

Note

used in air-conditioning systems.

7.4 Constant-curve duty

To be set with the R100, see section 8. Setting the

pump.

The pump can be set to operate according to a

constant curve, like an uncontrolled pump, see

fig. 11.

MAGNA 32-120, 40-120, 50-120, 65-120

Select one of 91 curves between the max. and min.

curves.

MAGNA 50-60, 65-60

Select one of 41 curves between the max. and min.

curves.

H

H

Max.

Min.

Q

Fig. 12 Max. and min. curves

The max. curve mode can be selected if an

uncontrolled pump is required.

The min. curve mode can be used in periods in

which a minimum flow is required. This operating

mode is for instance suitable for manual night-time

duty if automatic night-time duty is not desired.

7.6 Temperature influence

To be set with the R100, see section 8. Setting the

pump.

When this function is activated in proportional- or

constant-pressure control mode, the setpoint for

head will be reduced according to the liquid

temperature.

It is possible to set temperature influence to function

at liquid temperatures below 80 °C or below 50 °C.

These temperature limits are called T

setpoint is reduced in relation to the head set

(= 100 %) according to the characteristics below.

H

H

H

100%

actual

max.

. The

TM00 5547 4596TM01 0626 1797

Max.

Min.

Q

Fig. 11 Operating curves

7.5 Max. or min. curve duty

To be set on the control panel, with the R100 or via

GENI module, see section 8. Setting the pump.

The pump can be set to operate according to the

max. or min. curve, like an uncontrolled pump, see

fig. 12.

This operating mode is available, irrespective of the

control mode.

14

30%

50

T

actual

80

t [°C]

20

Fig. 13 Temperature influence

TM02 0245 0904

In the above example, T

selected. The actual liquid temperature T

causes the setpoint for head to be reduced from

100 % to H

actual

.

= 80 °C has been

max.

The temperature influence function requires:

• Proportional- or constant-pressure control mode.

• The pump must be installed in the flow pipe.

• System with flow-pipe temperature control.

actual

Q

Page 15

Temperature influence is suitable in:

• systems with variable flows (e.g. two-pipe heating

systems), in which the activation of the

temperature influence function will ensure a

further reduction of the pump performance in

periods with small heating demands and

consequently a reduced flow-pipe temperature.

• systems with almost constant flows (e.g. one-pipe

heating systems and underfloor heating systems),

in which variable heating demands cannot be

registered as changes in the head as is the case

with two-pipe heating systems. In such systems,

the pump performance can only be adjusted by

activating the temperature influence function.

Selection of T

In systems with a dimensioned flow-pipe

temperature of:

• up to and including 55 °C, select T

• above 55 °C, select T

Note

max.

= 50 °C,

max.

= 80 °C.

max.

The temperature influence function

cannot be used in air-conditioning

systems.

7.7 External start/stop

The pump can be started or stopped via an external

potential-free contact or a relay connected to

terminals 7 and 8, see section 5.2 Connection

diagram.

Functional diagram: Start/stop input

Start/stop input

H

Q

H

Q

Normal duty

Stop

7.8 Signal relay

The pump incorporates a signal relay, terminals

1, 2 and 3, for a potential-free fault and operating

signal. The function of the signal relay, fault signal

(factory setting) or operating signal, is set with the

R100.

The output, terminals 1, 2 and 3, is electrically

separated from the rest of the controller.

The signal relay is activated as follows:

• Fault signal

The signal relay is activated together with the red

indicator light on the pump, see section

8.2 Control panel.

• Operating signal

The signal relay is activated together with the

green indicator light on the pump, see section

8.2 Control panel.

Functions of signal relay

Signal relay Fault signal

Not activated:

• T he electricity supply has been

132

NC NO C

switched off.

• The p ump has not registered

a fault.

Activated:

12 3

NC NO C

• T he pump has registered a fault.

Signal relay Operating signal

Not activated:

• The p ump has bee n set to stop.

132

NC NO C

• T he pump has registered a fault

and is unable to run.

Activated:

• T he pump is running.

12 3

NC NO C

• T he pump has registered a fault,

but is able to run.

Resetting of fault indications

A fault indication can be reset in one of the following

ways:

• Briefly press , or on the pump. This will

not influence the pump performance set.

• Briefly switch off the electricity supply to the

pump.

• With the R100, see section 8.4 R100 display

overview.

Before the pump can revert to normal duty, the fault

cause must be eliminated.

If the fault disappears by itself, the fault indication

will automatically be reset.

The fault cause will be stored in the pump alarm log.

The latest five faults can be called up with the R100.

7.9 Indicator lights

For position on pump, see fig. 19, section 8.2 Control

panel.

The indicator lights, pos. 2, are used for operating

and fault indication. Furthermore, they indicate

whether the pump is externally controlled.

When the R100 remote control

Note

communicates with the pump, the red

indicator light will flash rapidly.

The function of the operating and fault indicator

lights can be found in section 9. Fault finding chart.

The indicator light for external control is on

• if the pump control panel is inactive,

• if the pump is in constant-curve operating mode,

• if the temperature influence is active or

• if the pump is controlled by an external unit.

15

Page 16

7.10 Expansion modules

The pump can be fitted with an expansion module

enabling communication with external signals

(signal transmitters).

Two types of expansion module are available:

• GENI module.

• LON module.

The fitting of a module is illustrated in fig. 14.

Open the control box cover and fit the module as

shown in fig. 14.

Warning

Before removing the control box cover,

make sure that the electricity supply

has been switched off for at least

5minutes.

Step Action

1

TM02 0241 0904

2

3

Fig. 14 Fitting an expansion module

16

TM02 0242 0904

TM02 0805 0904

Page 17

7.11 Wiring diagrams for expansion modules

Min. curve

Max. curve

Analog 0-10 V input

MIN

Twin-head

MAX

10 V

pump

XQZBYA

DC 0-10 V

Bus signal

4

5 6 7 9 10 11 12 2122 23

Bus signal

BA

TM02 0237 0904

Screen

Min.

Max.

TM02 0236 1007

Warning

• Wires connected to

– supply terminals,

– outputs NC, NO, C and

– start/stop inputs, A, Y, B, MIN,

MAX, 10 V

must be separated from each other

and from the supply by reinforced

insulation.

• All wires connected to a terminal

block must be tied up at the

terminals.

Warning

• Twisted-pair cable.

• Wires connected to

– supply terminals,

– outputs NC, NO, C and

– start/stop inputs, A, B

must be separated from each other

and from the supply by reinforced

insulation.

• All wires connected to a terminal

block must be tied up at the

terminals.

Fig. 15 GENI module Fig. 16 LON module

Note:

• If the 0-10 V input is used, there must be a connection across terminals MIN and (input for min. curve

must be closed).

• All cables used must be heat-resistant up to +85 °C.

• All cables used must be installed in accordance with EN 60204-1 and EN 50174-2: 2000.

Concerning demands on signal wires and signal transmitters, see section 11. Technical data.

Connection examples (GENI module) can be found on pages 338 to 341.

17

Page 18

7.12 GENI module

The GENI module offers the following functions:

• External analog 0-10 V control

• External forced control

• Bus communication via GENIbus

• Control of twin-head pumps.

7.12.1 Control of twin-head pumps

Twin-head pumps have a GENI module incorporated

in each control box. The modules are internally

connected via a wire.

MasterSlave

7.12.2 Selection of operating mode

Select the operating mode by means of the

mechanical contact in each module.

Operating

mode

Left pump

head

Right pump

head

Alternating Alternating Alternating

Standby Alternating Standby

Standby Standby Alternating

Standby Standby Standby

Alternating

operation

Flow direction

Fig. 17 Master/slave pumps

For connection of the communication cable between

the GENI modules, see pages 340 and 341.

Twin-head pumps are factory-set to the control mode

ADAPT and the operating mode "alternating

AUTO

operation", which is described below.

Operating modes:

• Alternating operation

Pump operation alternates every 24 hours. If the

duty pump stops due to a fault, the other pump

will start.

• Standby operation

One pump is operating continuously. In order to

prevent seizing-up, the other pump will start at a

fixed frequency and run for a short period. If the

duty pump stops due to a fault, the other pump

will start.

In air-conditioning systems, standby

Note

operation is recommended to minimise

condensation inside the pump.

Standby operation

Fig. 18 Mechanical contact

TM03 4635 2406

Operating the pump

Twin-head pumps can be set and operated in the

same way as single-head pumps. The duty pump

uses its setpoint setting, whether it is made on the

control panel, with the R100 or via bus.

Both pumps should be set to the same

setpoint and control mode. Different

Note

settings will result in different

operation when changing between the

two pumps.

7.13 LON module

The LON module offers the possibility of connecting

the pump to a LonWorks network. The module is

used for data transmission between a network and

pumps of the type MAGNA 32-120, 40-120, 50-120,

65-120, 50-60 and 65-60.

For further information, see the documentation files

on the floppy disk supplied with the LON module.

TM02 0243 0904

18

Page 19

8. Setting the pump

EXT

Q

100%

MAX

STOP

5

4

1

2

3

AUTO

ADAPT

H

For the setting of the pump, use:

• control panel

• R100 remote control

• bus communication (not described in detail in

these instructions, contact Grundfos).

The table shows the application of the individual

operating units and in which section the function has

been described.

Possible settings

AUTOADAPT 8.2.1 8.7.1

Automatic night-time duty 8.2.1 8.7.2

Proportional-pressure

control

Constant-pressure control 8.2.1 8.7.1

Setpoint setting 8.2.2 8.5.1

Max. curve duty 8.2.3 8.5.2

Min. curve duty 8.2.4 8.5.2

Constant-curve duty – 8.5.2

Temperature influence – 8.7.3

Activation/deactivation of

pump buttons

Allocation of pump number – 8.7.6

Start/stop 8.2.5 8.5.2

Resetting of fault

indications

Reading of various data –

"–" = not available with this operating unit.

8.1 Factory setting

The pump is factory-set to AUTOADAPT without

automatic night-time duty.

Control

panel

8.2.1 8.7.1

– 8.7.4

8.2.6 8.5.3

R100

8.6.1 -

8.6.7

8.2 Control panel

Warning

At high liquid temperatures, the pump

may be so hot that only the buttons

should be touched to avoid burns.

The control panel, fig. 19, incorporates:

Pos. Description

1 Buttons for setting

• Indica tor lights for operating and fault

indication and

2

• symbol for in dication of external control

3 Button for change of control mode

Light symbols for indication of control

4

mode and night-time duty

Light fields for indication of head, flow and

5

operating mode

For further information, see section 9. Fault finding

chart.

Fig. 19 Control panel

TM03 8798 2507

19

Page 20

8.2.1 Control mode setting

H

H

Description of function, see section 7.1 Control

modes.

To change the control mode, press , pos. 3,

according to this cycle:

AUTO

ADAPT

AUTO

+

ADAPT

+

8.2.2 Setpoint setting

Set the setpoint of the pump by pressing or

when the pump has been set to proportionalpressure control, constant-pressure control or

constant-curve duty.

The light fields, pos. 5, on the control panel indicate

the setpoint set.

MAGNA 32-120, 40-120, 50-120, 65-120

The light fields can indicate a maximum setpoint of

10 metres.

+

Fig. 20 Cycle of control modes

Automatic night-time duty can be activated together

with each of the control modes.

The light symbols in pos. 4, see fig. 19, indicate the

pump settings:

Light in Control mode

AUTO

ADAPT AUTOADAPT NO

Proportional

pressure

Automatic

night-time

duty

NO

Constant pressure NO

– Constant curve NO

AUTO

ADAPT

AUTOADAPT YES

Proportional

pressure

YES

Constant pressure YES

– Constant curve YES

"–" = no light.

TM03 1288 1505

Fig. 21 Light fields MAGNA xx-120

MAGNA 50-60, 65-60

The light fields can indicate a maximum setpoint of

5metres.

Fig. 22 Light fields MAGNA xx-60

8.2.3 Setting to max. curve duty

Description of function, see section 7.5 Max. or min.

curve duty.

To change over to the max. curve, press

continuously until "MAX" illuminates, see fig. 23. To

change back, press continuously until the desired

setpoint is indicated.

MAX

TM02 0482 2507TM02 0483 2507TM02 0246 2507

H

Fig. 23 Max. curve

20

Page 21

8.2.4 Setting to min. curve duty

Description of function, see section 7.5 Max. or min.

curve duty.

To change over to the min. curve, press

continuously until "MIN" illuminates, see fig. 24. To

change back, press continuously until the desired

setpoint is indicated.

8.3 R100 remote control

The pump is designed for wireless communication

with the Grundfos R100 remote control. The R100

communicates with the pump via infra-red light.

During communication, the R100 must be pointed at

the pump control panel. When the R100 is

communicating with the pump, the red indicator light

will flash rapidly.

The R100 offers additional possibilities of setting and

status displays for the pump.

H MIN

Fig. 24 Min. curve

8.2.5 Start/stop of pump

To stop the pump, press continuously until

"STOP" illuminates. When the pump is stopped, the

green indicator light will be flashing.

To start the pump, press continuously.

If the pump is to be stopped, it is

recommended to use the start/stop

input, the R100 or to switch off the

Note

electricity supply. In this way, the

setpoint will remain unchanged when

the pump is started again.

8.2.6 Resetting of fault indications

The fault indications are reset by briefly pressing

any button. The settings remain unchanged. If the

fault has not disappeared, the fault indication will

reappear. The time until the fault reappears may vary

from 0 to 255 seconds.

TM02 0247 2507

21

Page 22

8.4 R100 display overview

The R100 displays are divided into four parallel

menus, see fig. 25:

0. GENERAL, see operating instructions for R100

1. OPERATION

2. STATUS

3. INSTALLATION

This display appears only once, i.e. when the R100

gets contact with the pump.

8.5.1

The number stated at each individual display in

fig. 25 refers to the section in which the display is

described.

3. INSTALLATION2. STAT US0. GENERAL 1. OPERATION

8.6.1

8.7.1

8.5.2

8.5.3

8.5.4

Fig. 25 Menu overview

8.6.2

8.6.3

8.6.4

8.6.5

8.6.6

8.6.7

8.7.2

8.7.3

8.7.4

8.7.5

8.7.6

22

Page 23

8.5 Menu OPERATION

When the communication between the R100 and the

pump has been established, "Contact with" appears

in the display. When the "arrow down" on the R100 is

pressed, menu OPERATION appears.

The display "Contact with" appears

Note

only once, i.e. when the R100 gets

contact with the pump.

8.5.1 Setpoint

This display depends on the control mode selected

in the display "Control mode" in menu

INSTALLATION.

If the pump is forced-controlled via external signals,

the number of possible settings will be reduced, see

section 8.8 Priority of settings. Attempts to change

the settings will result in an indication in the display

saying that the pump is forced-controlled and

changes therefore cannot be made.

This display will appear when the pump is in

ADAPT mode.

AUTO

Set the desired setpoint by pressing the buttons

"+" and "–" on the R100 (not possible when the pump

is in AUTO

Furthermore, it is possible to select one of the these

operating modes:

• Stop

• Min. (min. curve)

• Max. (max. curve).

The display is different if proportional pressure,

constant pressure or constant curve has been

selected.

The actual duty point of the pump is indicated by a

square in the Q/H field. No indication at low flow.

8.5.2 Operating mode

ADAPT mode).

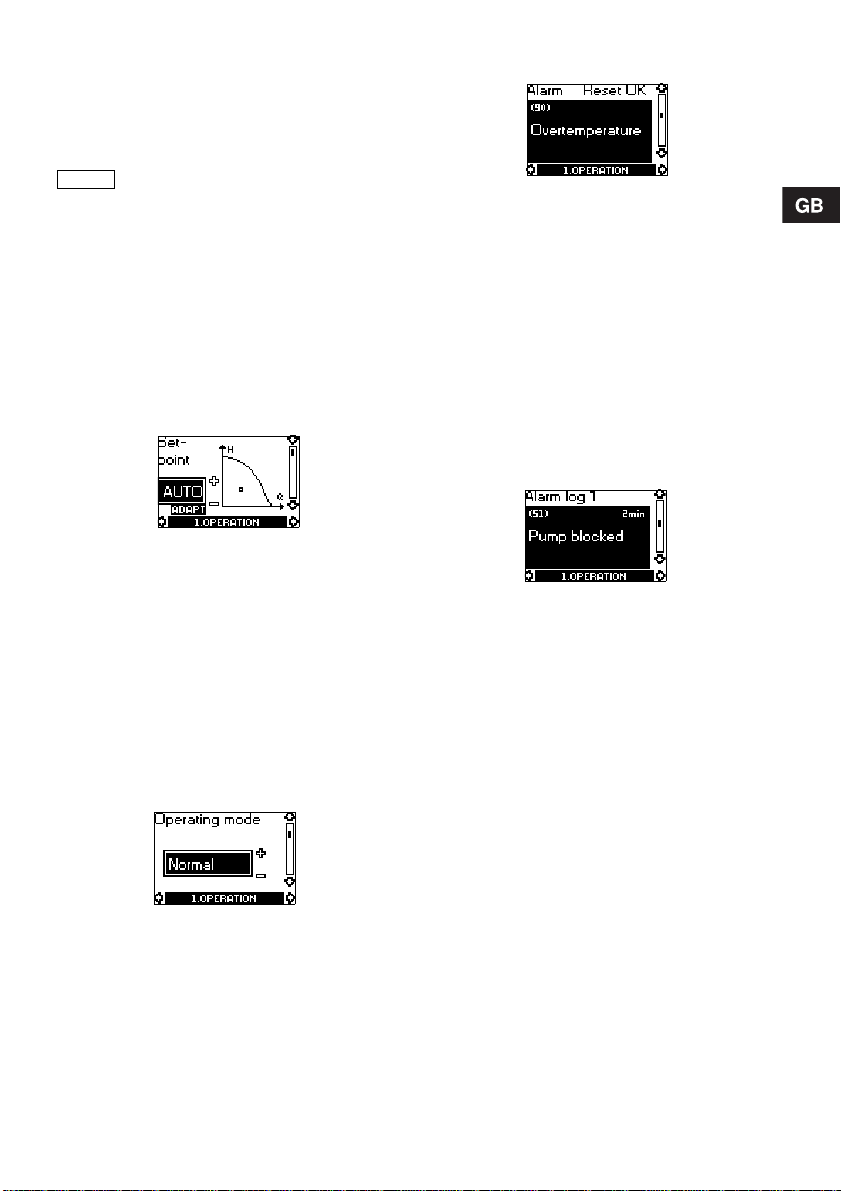

8.5.3 Fault indications

If the pump is faulty, the cause will appear in this

display.

Possible causes:

• Pump blocked

• Internal fault

• Overvoltage

• Undervoltage

• Overtemperature

• Module fault

• Fault in module communication.

The fault indication can be reset in this display.

If the fault has not disappeared when resetting is

attempted, the fault indication will reappear in the

display when communicating with the pump.

8.5.4 Alarm log

The alarm code with text appears in this display.

The display also shows the number of minutes the

pump has been connected to the electricity supply

after the fault occurred.

The last five fault indications will appear in the alarm

log.

Select an operating mode:

• Stop

• Min. (min. curve)

• Normal (AUTO

ADAPT, proportional pressure,

constant pressure or constant curve)

• Max. (max. curve).

23

Page 24

8.6 Menu STATUS

The displays appearing in this menu are status

displays only. It is not possible to change or set

values.

The actual values in the display are indicative and

based on estimation.

8.6.1 Actual setpoint

Field "Actual setpoint":

Actual setpoint of pump.

Field "corresponding to":

Actual setpoint in % of the setpoint set if the pump is

connected to an external analog 0-10 V signal

transmitter or if temperature influence or

proportional-pressure control is activated.

8.6.2 Operating mode

8.6.5 Liquid temperature

The actual temperature of the pumped liquid.

8.6.6 Power input and power consumption

Actual power input and power consumption of the

pump.

The value of power consumption is an accumulated

value and cannot be set to zero.

8.6.7 Operating hours

This display shows the actual operating mode (Stop,

Min., Normal or Max.) and where it was selected

(Pump, R100, BUS or External).

8.6.3 Head and flow

The actual head and flow of the pump.

If "<" is indicated in front of the flow, the flow is less

than the displayed value.

8.6.4 Speed

The actual pump speed.

24

Operating hours of the pump.

The value of operating hours is an accumulated

value and cannot be set to zero.

Page 25

8.7 Menu INSTALLATION

This menu shows the settings that should be

considered when installing the pump.

8.7.1 Control mode

Description of function, see section 7.1 Control

modes or section 7.4 Constant-curve duty.

Select one of the control modes:

•AUTO

• Prop. pressure (proportional pressure)

• Const. pressure (constant pressure)

• Const. curve (constant curve).

Setting of setpoint and curve is carried out in display

8.5.1 Setpoint in menu OPERATION (not possible

when the pump is in AUTO

8.7.2 Automatic night-time duty

In this display, automatic night-time duty can be

activated or deactivated.

Automatic night-time duty can be set to:

• Active

• Not active,

irrespective of the control mode selected.

8.7.3 Temperature influence

Description of function, see section 7.6 Temperature

influence.

ADAPT

ADAPT mode).

In the case of temperature influence, the pump must

be installed in the flow pipe. It is possible to choose

between maximum temperatures of 50 °C and 80 °C.

When the temperature influence is active, a small

thermometer is shown in the display "Setpoint" in

menu OPERATION, see section 8.5.1 Setpoint.

8.7.4 Buttons on pump

To prevent unauthorised persons from operating the

pump, the function of the buttons , and can

be deactivated in this display. The buttons can be

reactivated only with the R100.

The buttons can be set to:

• Active

• Not active.

8.7.5 Signal relay

In this display, the function of the internal signal relay

can be set:

• Fault (functions as a fault signal relay)

• Operation (functions as an operating signal

relay).

8.7.6 Pump number

If the pump is in control mode

AUTO

Note

ADAPT or constant curve, the

temperature influence cannot be set

with the R100.

The temperature influence function can be activated

in this display when the control mode is proportional

pressure or constant pressure, see section

8.7.1 Control mode.

A number from 1 up to and including 64 can be

allocated to a pump or can be changed so that the

R100, Pump Management System 2000 or other

systems can distinguish between two or more

pumps.

25

Page 26

8.8 Priority of settings

The external forced-control signals will influence the

settings available on the pump control panel and with

the R100. However, the pump can always be set to

max. curve duty or to stop on the pump control panel

or with the R100.

If two or more functions are activated at the same

time, the pump will operate according to the setting

with the highest priority.

The priority of the settings is as shown in the table.

Without expansion module

Possible settings

Priority

1 Stop

2Max. curve

3Stop

4Min. curve

5 Setpoint setting

Example: If the pump has been forced to stop via an

external signal, the pump control panel or the R100

can only set the pump to max. curve.

Pump control

panel or R100

External signals

With expansion module

Priority

1 Stop

2 Max. curve

3Stop

4

5

6

As illustrated in the table, the pump does not react to

external signals (max. curve and min. curve) when

the pump is controlled via bus.

If the pump is to react to external signals (max. curve

and min. curve), the system must be configured for

that function.

For further details, please contact Grundfos.

Possible settings

Pump

control

panel

or R100

Min. curve Min. curve Min. curve

Setpoint

setting

Not active when the pump is controlled

via bus.

Only active when the pump is

controlled via bus.

External

signals

Max.curve Max.curve

Bus

signal

Stop

Setpoint

setting

26

Page 27

9. Fault finding chart

Warning

Before removing the control box cover, make sure that the electricity supply has been

switched off for at least 5 minutes.

The pumped liquid may be scalding hot and under high pressure. Before any removal or

dismantling of the pump, the system must therefore be drained or the isolating valves on

either side of the pump must be closed.

Indicator light is off.

Indicator light is on.

Indicator light is flashing.

Indicator

lights

Green Red

Fault Cause Remedy

The pump is not

running.

The pump is not

running.

The pump has

stopped due to a

fault.

The pump is

running but is

faulty.

The pump has

been set to stop

and is faulty.

One fuse in the installation is

blown/tripped out.

The current-operated or voltageoperated circuit breaker has tripped

out.

The pump may be defective. Replace the pump or call

The pump has been stopped in one

of the following ways:

1. With the button .

2. With the R100.

3. External on/off switch in position

off.

4. Via bus signal.

Electricity supply failure. Check that the electricity supply falls

Pump blocked and/or impurities in

the pump.

The pump may be defective. Use the R100 for fault finding, see

The pump is faulty, but is able to

operate.

The pump is faulty, but is able to

operate (has been set to STOP).

Replace/cut in the fuse.

Check that the electricity supply falls

within the specified range.

Cut in the circuit breaker.

Check that the electricity supply falls

within the specified range.

GRUNDFOS SERVICE for

assistance.

1. Start the pump by pressing .

2. Start the pump with the R100 or

by pressing .

3. Switch on the on/off switch.

4. Start the pump via bus signal.

within the specified range.

Dismantle and clean the pump.

section 8.5.3 Fault indications.

Replace the pump or call

GRUNDFOS SERVICE for

assistance.

The pump is able to operate.

Try to reset the fault indication by

briefly switching off the electricity

supply or by pressing the button ,

or .

Use the R100 for fault finding, see

section 8.5.3 Fault indications.

In the case of repeated faults,

contact GRUNDFOS SERVICE.

27

Page 28

Indicator

lights

Fault Cause Remedy

Green Red

Noise in the

system.

Air in the system. Vent the system.

The flow is too high. Reduce the setpoint and possibly

The pressure is too high. Reduce the setpoint and possibly

Noise in the

pump.

Note

The R100 can also be used for fault finding.

Air in the pump. Vent the pump.

The inlet pressure is too low. Increase the inlet pressure and/or

10. Megging

Megging of an installation incorporating a

GRUNDFOS MAGNA pump is not allowed, as the

built-in electronics may be damaged. If megging of

the pump is necessary, the pump should be

electrically separated from the installation.

Megging of the pump can be carried out as

described below.

Megging of pumps

change over to AUTO

constant pressure.

change over to AUTO

ADAPT or

ADAPT or

proportional pressure.

check air volume in the expansion

tank (if installed).

1. Switch off the electricity supply.

2. Remove the wires from terminals L and N and the earth

conductor.

3. Short-circuit terminals L and N using a short wire

(see B).

4. Remove the screw for electronics frame connection

(see A).

5. Test between terminals L/N and earth (see C).

Maximum test voltage: 1000 VAC/1500 VDC.

Note: Never test between supply terminals (L and N).

Maximum permissible leakage current: < 35 mA.

6. Fit the screw for electronics frame connection (see A).

7. Remove the short wire between terminals L and N

(see B).

8. Fit the supply wires to terminals L and N and the earth

conductor.

9. Switch on the electricity supply.

28

A

B

C

TM02 0238 0904

Page 29

11. Techn ical data

Supply voltage

1 x 230-240 V – 10 %/+ 6 %, 50/60 Hz.

Motor protection

The pump requires no external motor protection.

Enclosure class

IP 44.

Insulation class

F.

Relative air humidity

Maximum 95 %.

Ambient temperature

0 °C to +40 °C.

Temperature class

TF110 to EN 60335-2-51.

Liquid temperature

Maximum +110 °C.

Continuously: +2 °C to +95 °C.

Pumps in domestic hot-water systems:

Continuously: +2 °C to +60 °C.

Ambient

temperature

[°C]

0 2 95/110

30 2 95/110

35 2 90/90

40 2 70/70

Maximum system pressure

The maximum system pressure is indicated on the

pump flanges: PN 6 / PN 10: 10 bar/1.0 MPa.

Number of bolt holes in the pump flange: 4.

Inlet pressure

Recommended inlet pressures:

• Min. 0.15 bar at +75 °C.

• Min. 0.45 bar at +95 °C.

EMC (electromagnetic compatibility)

EN 61800-3.

Sound pressure level

The sound pressure level of the pump is lower than

54 dB(A).

Leakage current

The pump mains filter will cause a discharge current

to earth during operation. I

Standby loss

Lower than 3 W.

Liquid temperature

Min. [°C] Max. [°C]

< 3.5 mA.

leakage

Pump inputs and outputs

Internal potential-free changeover contact.

Signal output

Maximum load:

250 V, 2 A, AC1.

Minimum load: 5 V, 100 mA.

Screened cable depending on

signal level.

External potential-free switch.

Input for external

start/stop

Contact load: 5 V, 10 mA.

Screened cable.

Loop resistance:

Maximum 130 Ω.

Inputs of pump with GENI module

External potential-free switch.

Inputs for max.

and min. curves

Input for analog

0-10 V signal

Bus input

Contact load: 5 V, 1 mA.

Screened cable.

Loop resistance:

Maximum 130 Ω.

External signal: 0-10 VDC.

Maximum load: 1 mA.

Screened cable.

Grundfos bus protocol,

GENIbus protocol, RS-485.

Screened cable.

Wire cross section:

0.25 - 1 mm

Cable length:

2

.

Maximum 1200 m.

Input of pump with LON module

®

protocol, FTT 10.

LonTalk

Bus input

Twisted-pair cable.

Wire cross section:

0.25 - 1 mm

2

.

12. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

Subject to alterations.

29

Page 30

Rp 1/4

H3

B2

H4

H2H1

B1

M

B5

L1

L3

B4 B3

B6 B7

D4

D2

D1

D5

D3

D3

TM02 0239 2601

MAGNA

32-120

MAGNA

40-120

MAGNA

50-120

MAGNA

65-120

MAGNA

50-60

MAGNA

65-60

PN 6 / PN 10 PN 6 / PN 10 PN 6 / PN 10 PN 6 / PN 10 PN 6 / PN 10 PN 6 / PN 10

L1 220 250 280 340 280 340

L3 110 125 140 170 140 170

B1 77 77 77 77 77 77

B2 115 115 125 125 115 115

B3 75 75 84 88 84 88

B4 76 80 98 104 98 104

B5 96 96 96 96 96 96

B6 110 115 130 145 130 145

B7 110 115 130 145 130 145

H1 66 68 79 82 79 82

H2 244 242 245 252 245 252

H3 310 310 324 334 324 334

H4 86 102 128 128 128 128

D1 32 40 50 65 50 65

D2 76 84 1 02 119 102 119

D3 90/100 100/110 110/125 130/145 110/125 130/145

D4 140 150 165 185 165 185

D5 14/19 14/19 14/19 14/19 14/19 14/19

335

Page 31

B3

B1

H3

H1 H2

B7

B6B6

D4

D2

D1

D5

L1

M

MAGNA

Rp1/4

MAGNA

Twin

32-120

MAGNA

Twin

40-120

MAGNA

Twin

50-120

L2

L3

B5B4

MAGNA

Twin

65-120

MAGNA

Twin

50-60

PN 6 / PN 10 PN 6 / PN 10 PN 6 / PN 10 PN 6 / PN 10 PN 6 / PN 10 PN 6 / PN 10

L1 220 250 280 340 280 340

L2 103 125 126 126 126 126

L3 52 45 60 60 60 60

B1 115 115 125 125 115 115

B3 465 465 490 490 485 480

B4 260 260 275 275 270 270

B5 190 187 215 215 215 215

B6 100 100 120 120 120 120

B7 200 200 240 240 240 240

H1 85 87 88 88 88 88

H2 240 234 234 242 234 242

H3 325 321 322 330 322 330

D1 32 40 50 65 50 65

D2 76 84 102 119 102 119

D3 90/100 100/110 110/125 130/145 110/125 130/145

D4 140 150 165 185 165 185

D5 14/19 14/19 14/19 14/19 14/19 14/19

D3

D3

Twin

65-60

TM02 0790 2601

336

Page 32

MAGNA 32-120, 40-120, 50-120, 65-120, 50-60, 65-60

S

T

O

NL

C

P

NONC

78321

337

TM02 0477 1004

Page 33

MAGNA 32-120, 40-120, 50-120, 65-120, 50-60, 65-60, GENI module

S

T

O

CNONCNL

P

AY B XQZ

MIN

MAX

10 V

2322211211109765478321

338

Max. ø7

TM02 0478 1004

Page 34

MAGNA 32-120, 40-120, 50-120, 65-120, 50-60, 65-60, GENI module

S

T

O

CNONCNL

P

AY B X QZ

MIN

MAX

10 V

2322211211109765478321

Max. ø7

TM02 0479 1004

339

Page 35

MAGNA, Twin, 32-120, 40-120, 50-120, 65-120, 50-60, 65-60 GENI module,

Master

S

T

O

CNONCNL

P

AY B XQ Z

MIN

MAX

10 V

2322211211109765478321

Master definition

340

Max. ø7

TM02 0480 1004

Page 36

MAGNA, Twin, 32-120, 40-120, 50-120, 65-120, 50-60, 65-60, GENI module,

Slave

S

T

O

P

CNONCNL

AY B XQZ

MIN

MAX

10 V

2322211211109765478321

Max. ø7

TM02 0481 1004

341

Page 37

342

Page 38

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belorussia

Представ ительство ГРУНДФОС в

Минске

220090 Минск ул.Олешева 14

Телеф он: (8632) 62-40-49

Факс: (8632) 62-40-49

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Paromlinska br. 16,

BiH-71000 Sarajevo

Phone: +387 33 713290

Telefax: +387 33 231795

Brazil

Mark GRUNDFOS Ltda.

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

GRUNDFOS Pumpen Vertrieb

Representative Office - Bulgaria

Bulgaria, 1421 Sofia

Lozenetz District

105-107 Arsenalski blvd.

Phone: +359 2963 3820, 2963 5653

Telefax: +359 2963 1305

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

51 Floor, Raffles City

No. 268 Xi Zang Road. (M)

Shanghai 200001

PRC

Phone: +86-021-612 252 22

Telefax: +86-021-612 253 33

Croatia

GRUNDFOS predstavništvo Zagreb

Cebini 37, Buzin

HR-10000 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 44

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-3066 5650

Telefax: +358-3066 56550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chamiers Road

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg., 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

México

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Nederland B.V.

Postbus 104

NL-1380 AC Weesp

Tel.: +31-294-492 211

Telefax: +31-294-492244/492299

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Phone: (+48-61) 650 13 00

Telefax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

România

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грун дф ос

Россия, 109544 Москва, Школьная 39

Тел. (+7) 095 737 30 00, 564 88 00

Факс (+7) 095 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47 496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS PUMPEN VERTRIEB

Ges.m.b.H.,

Podružnica Ljubljana

Blatnica 1, SI-1236 Trzin

Phone: +386 1 563 5338

Telefax: +386 1 563 2098

E-mail: slovenia@grundfos.si

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Lunnagårdsgatan 6

431 90 Mölndal

Tel.: +46-0771-32 23 00

Telefax: +46-31 331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiw an, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

947/168 Moo 12, Bangna-Trad Rd., K.M. 3,

Bangna, Phrakanong

Bangkok 10260

Phone: +66-2-744 1785 ... 91

Telefax: +66-2-744 1775 ... 6

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС Ук раи на

ул. Владимирская, 71, оф. 45

г. Киев, 01033, Украина,

Тел. +380 44 289 4050

Факс +380 44 289 4139

United Arab Emirate s

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Usbekistan

Представ ительство ГРУНДФОС в

Ташкен те

700000 Ташке нт ул .Усма на Носира 1-й

тупик 5

Телеф он: (3712) 55-68-15

Факс: (3712) 53-36-35

Addresses revised 26.06.2007

Page 39

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

96549346 0807

Repl. 96549346 0205

www.grundfos.com

139

Loading...

Loading...