Page 1

LLC 1000W

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

2

Page 3

LLC 1000W

English (GB)

Installation and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Dansk (DK)

Monterings- og driftsinstruktion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Deutsch (DE)

Montage- und Betriebsanleitung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table of contents

3

Page 4

English (GB) Installation and operating instructions

Caution

Note

English (GB)

Original installation and operating instructions.

CONTENTS

Page

1. Symbols used in this document

2. Applications

3. Product description

3.1 General construction

3.2 Description of function

3.3 Technical data

4. Transport and storage

5. Installation

5.1 Mechanical installation

5.2 Electrical installation

6. Startup

7. Operation

8. Taking the product out of operation

9. Maintenance

10. Fault finding

11. Service, spare parts, accessories

12. Disposal

Warning

Prior to installation, read these

installation and operating instructions.

Installation and operation must comply

with local regulations and accepted

codes of good practice.

Warning

This product can be used by children

of eight years and up and persons with

reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they are under

supervision or have been instructed in

the safe use of the product and

understand the hazards involved.

Children must not play with the

product. Cleaning and maintenance of

the product must not be made by

children without supervision.

1. Symbols used in this document

Warning

If these safety instructions are not

4

4

5

5

6

6

6

7

7

7

8

8

8

2. Applications

8

The level controller described in these installation

9

and operating instructions is used for

9

level-dependent on/off switching of grey wastewater

pumps. The level controller is primarily used where

9

the levels of conductive, non-flammable liquids in

tanks or pits must be strictly maintained, or where

these liquids require very shallow pumping.

observed, it may result in personal

injury.

Warning

If these instructions are not observed,

it may lead to electric shock with

consequent risk of serious personal

injury or death.

If these safety instructions are not

observed, it may result in malfunction

or damage to the equipment.

Notes or instructions that make the job

easier and ensure safe operation.

Warning

The level controller must only be used

for the applications mentioned in this

manual. Other applications are

considered as non-approved. No

liability is accepted for resulting

damages. The risk is borne solely by

the operator.

Warning

Use in explosion protection zones is

not permitted.

4

Page 5

3. Product description

1

5

4

3

6

2

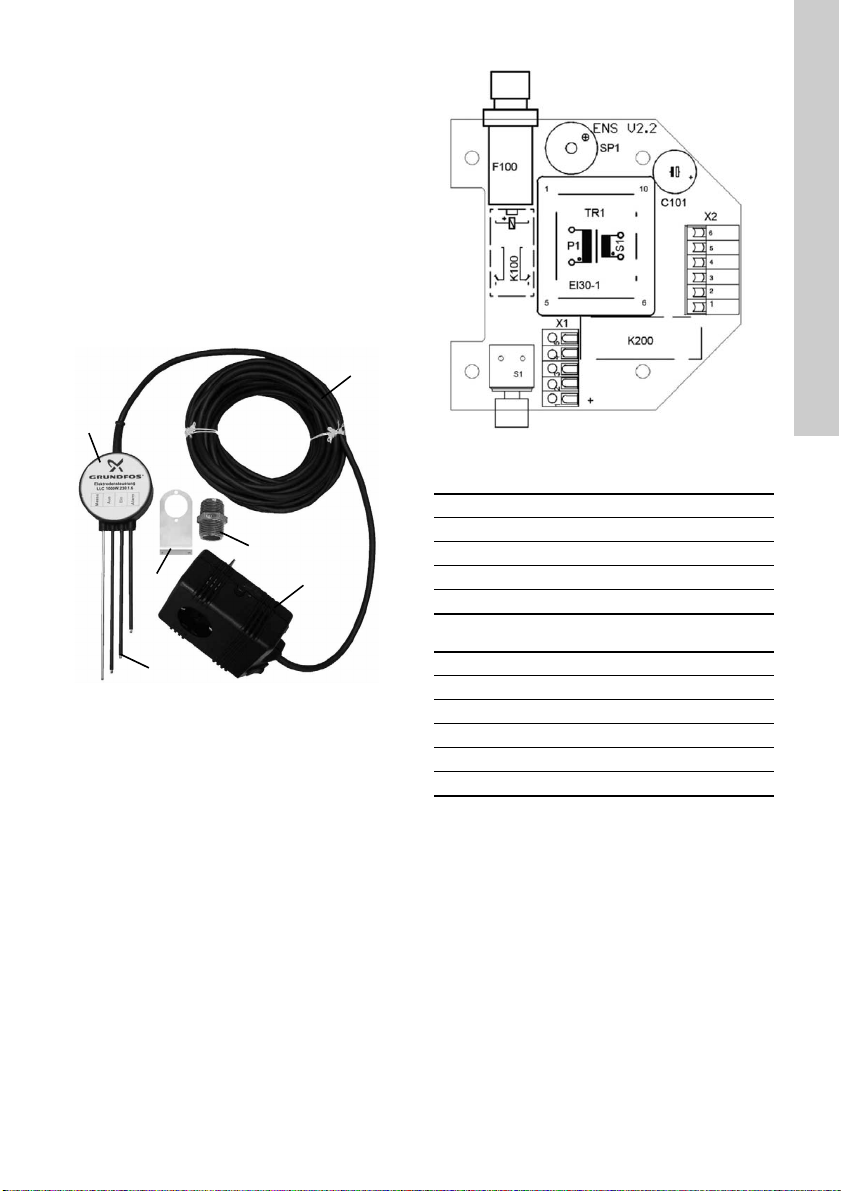

3.1 General construction

The level controller consists of four stainless steel

rod electrodes (pos. 1) (300, 600 or 1000 mm long)

in an electrode bracket (pos. 2), a mounting bracket

(pos. 3), 10 m cable (pos. 4), a plug-in control box

(pos. 5) and a 1 1/4" barrel nipple (pos. 6) for fixing

the sheet steel angle to the discharge port of

UNILIFT KP. See fig. 1.

The control box houses the evaluation electronics, a

safety plug and a Schuko outlet for connection to the

pump.

The control box houses the evaluation electronics, a

safety plug and a Schuko outlet for connection to the

pump.

Fig. 1 LLC 1000W level controller

Fig. 2 Terminal diagram

Contact assignment, terminal block X1

1 Emptying function (L)

2 Filling function (N)

3 Protective earth conductor

4 Plug (L)

5 Plug (N)

Contact assignment, terminal block X2

1 Long electrode (yellow/green)

TM05 3939 1812

2 Short electrode (blue)

3 Medium electrode (brown)

4 Alarm electrode (black)

5 Alarm contact, potential-free

6 Alarm contact, potential-free

English (GB)

TM05 3940 1812

5

Page 6

3.2 Description of function

English (GB)

The voltage between the electrodes is approximately

12 V DC, and the operating voltage for the pump

connection is 1 x 230 V. The four electrode rods

extend into the liquid to be pumped at differing

lengths. The longest electrode functions as a frame

electrode; the second-longest is the stop electrode,

followed by the start electrode, the shortest electrode

being the alarm electrode.

The level controller is factory-set to emptying

function. If the liquid level rises to the start electrode,

the controller switches on the pump. If the liquid level

falls below the stop electrode, the controller switches

the pump off. If the liquid reaches the alarm

electrode, a potential-free contact in the control box

closes, and the built-in buzzer will sound. The

additional potential-free changeover contact is

provided for special applications and can also be

used for an external alarm. The position of the

contacts (spring terminals) on the guide plate in the

control box is shown in fig. 2.

The function can be reversed by moving the cable

from connector X1-1 to connector X1-2, so that the

connected device turns on when the stop electrode

is reached, and turns off when the start electrode is

reached (filling function). The alarm is then triggered

when the tank to be filled is overfilled.

After installation, the level controller functions

automatically. Settings on the device must not be

adjusted.

3.3 Technical data

Designation LLC 1000W

Supply voltage: 1 x 230 V, 50 Hz, N, PE

Rated current Max. 6.0 A

Power 1000 W

Enclosure class, control

box

Enclosure class,

electrode bracket

Contact load, high-level

alarm, potential-free

Cable length 10 m

EMC noise emission

EMC noise immunity

Max. liquid temperature 55 °C

Ambient temperature 0-40 °C

Country of origin Germany

Materials

Component Material

Electrodes Stainless steel

Electrode bracket Plastic

Cable sheath Rubber

Plug housing Plastic

IP20

IP68

Max. 2 A, max. 230 V

According to EN

61000-6-3

According to EN

61000-6-2

4. Transport and storage

The level controller is delivered in appropriate

packaging and should remain packed until

installation.

The controller must be stored in a dry, cool, frost-free

space. The controller must not be exposed to direct

sunlight.

6

Page 7

5. Installation

Note

Rod electrodes

Caution

Warning

Installation and operation in a

potentially explosive environment are

not permissible.

Make sure that the power supply

cannot be accidentally switched on

during installation. We recommend that

you unplug the control box from the

socket.

The electronic connections on the

control box must not be exposed to

moisture.

5.1 Mechanical installation

5.1.1 Mounting bracket

Attach the bracket using the two screws on the

electrode bracket. See fig. 3.

The long side must face upwards.

Fig. 3 Place the mounting bracket on the

5.1.2 Electrode bracket

The electrode bracket can either be attached directly

to the pump or to a tank wall.

The level controller can be used for Grundfos pump

types Unilift CC and Unilift KP.

The length of the electrodes must be adjusted to the

length of the pump. The difference in length between

the start and stop electrodes corresponds to the

switching differential.

electrode bracket

The control electrodes must not come

into contact with the pump or the walls

of the pump pit. The frame electrode

must be the longest electrode and may

touch the bottom.

Make sure that the pump stop point as

specified by the electrode length is

safely reached.

Make sure that the pump stop point as

specified by the electrode length is

safely reached.

It may be necessary to shorten the stop electrode. If

the electrodes are to be trimmed to change the

switching points, cut the protective tube at the

bottom end of the electrodes by approximately 5 mm

after trimming. Tighten the rod electrodes gently with

pliers prior to startup in order to prevent them from

coming loose during pump operation.

Assembly on the pump

Push the electrode bracket onto the pump pressure

outlet using the mounting bracket, so that the

electrodes face down. Then connect the electrode

bracket to the discharge port of the UNILIFT KP

using the 3-stage pressure outlet of the UNILIFT CC

supplied with the pump or using the attached 1 1/4"

barrel nipple.

5.2 Electrical installation

Warning

Connection work must be carried out

by authorised staff.

The level controller is now ready for connection.

Electrical connection work on the device itself is not

necessary if the pump is equipped with a plug.

If electrical connection work is required in order to

use certain functions or to connect the power supply

for the pump and the mains directly to the control

box, and thus not use the sockets, detach the rear

wall of the control box.

TM05 3941 1812

If the potential-free alarm contact is to be used to

forward the alarm signal to a main controller, connect

the signal cable to terminal block X2, terminals 3 and

4.

If the filling function is to be used instead of the

emptying function, move the lead from terminal X1-1

to terminal X1-2.

Warning

Make sure that the power supply

cannot be accidentally switched on

during electrical installation. We

recommend that you unplug the control

box from the socket.

English (GB)

7

Page 8

6. Startup

Note

English (GB)

Trim the electrodes to the desired

length in advance, depending on the

pump. Take into account the

technically feasible switching levels of

the pump.

After installation, plug the control box into a socket

and plug the pump plug into the control box socket.

Carry out test runs. To do so, press and hold the

switch on the control box. The level controller will not

operate when the switch is actuated. The pump runs

for as long as the button is held.

If you encounter faults during test operation, verify

that the power supply is correct, that the connected

units function properly, and that the liquid has

sufficient conductivity. See section 10. Fault finding

for more details.

If the switch on the control box is not pressed, the

level controller operates automatically.

Change over from the emptying function (delivery

state) to the filling function is described in section

5.2 Electrical installati on.

7. Operation

Once the level controller has been installed and

started up, no further action is required.

The level controller operates automatically and

switches the connected wastewater pumps on and

off based on the liquid level.

For a trial run or to briefly switch the pump on and off

during commissioning or service work, the pump can

be manually operated by pushing the switch on the

control box. See also section 6. Startup.

9. Maintenance

The level controller is maintenance-free. However,

the electrode tips must be cleaned at regular

intervals to remove any deposits that could

otherwise lead to malfunctions. The maintenance

intervals to be observed depend on the operating

conditions and the liquid pumped.

Warning

Before starting work on the product,

switch off the power supply. Make sure

that the power supply cannot be

accidentally switched on. We

recommend that you unplug the control

box from the socket.

8. Taking the product out of operation

1. Disconnect the control box from the power

supply, for instance by unplugging the control box

from the socket.

2. Unplug the pump from the pump control box, or

remove the cables from the terminals in the event

of direct connection to the pump.

3. Remove the electrode bracket from the pump.

4. Carefully wash the electrodes with clean water.

8

Page 9

10. Fault finding

Note

Warning

Before starting work on the product, switch off the power supply. Make sure that the power

supply cannot be accidentally switched on. We recommend that you unplug the control box

from the socket.

Fault Possible cause Remedy

1. The pump does

not start.

2. The pump does

not stop.

3. Pump starts

and stops in

wrong order.

a) No power supply, or incorrect

power supply.

b) Incorrect electrical connection. Check the electrical connection and correct

c) Defective cable. Check the cable. Contact Grundfos Service

d) The motor protection of the pump

has tripped due to overheating,

blockage, voltage fault or other

pump fault.

e) Fuse in control box has blown. Replace fuse (fine-wire slow-blow fuse 8 A).

f) Controller fault or defective

electronics.

g) Electrodes contaminated. Clean the electrodes.

h) Pump defective. Replace the pump.

a) Button on the control box is stuck. Loosen the button.

b) Controller fault. Contact Grundfos Service.

c) Stop electrode too long. Trim the stop electrode. Note the minimum

a) Incorrect switching function

selected.

Check the power supply.

as needed.

in the event of a defective cable.

For actions to take when motor protection on

the pump has tripped, see the installation

and operating instructions for the pump.

If the fuse blows again immediately, identify

and remedy the cause.

Contact Grundfos Service.

possible stop point of the pump.

Move cable on terminal block X1 from

terminal 1 to terminal 2 or vice versa.

English (GB)

11. Service, spare parts, accessories

Spare parts and accessories not

supplied by Grundfos will not be

inspected or approved by Grundfos.

The use of non-authorised spare parts and

accessories voids any Grundfos warranty liability for

consequential damage.

Any malfunctions which cannot be repaired must

only be corrected by Grundfos or authorised

specialist companies.

Please provide an exact description in the event of a

malfunction to allow our service technician to

prepare and provide the appropriate spare parts.

12. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

Subject to alterations.

9

Page 10

Dansk (DK) Monterings- og driftsinstruktion

Forsigtig

Bemærk

Dansk (DK)

Oversættelse af den originale engelske udgave.

INDHOLDSFORTEGNELSE

Side

1. Symboler brugt i dette dokument

2. Anvendelse

3. Produktbeskrivelse

3.1 Generel konstruktion

3.2 Funktionsbeskrivelse

3.3 Tekniske data

4. Transport og opbevaring

5. Installation

5.1 Mekanisk installation

5.2 Elektrisk installation

6. Idriftsætning

7. Drift

8. Sådan tages produktet ud af drift

9. Vedligeholdelse

10. Fejlfinding

11. Servicering, reservedele og tilbehør

12. Bortskaffelse

Advarsel

Læs denne monterings- og drifts-

instruktion før installation. Følg lokale

forskrifter og gængs praksis ved installation og drift.

Advarsel

Dette produkt må anvendes af børn fra

8 år og personer med begrænsede fysiske, sansemæssige eller mentale evner

samt personer med manglende erfaring

med og kendskab til produktet forudsat

at de er under opsyn eller har fået klare

instrukser vedrørende sikker brug af

produktet og forstår den dermed forbundne risiko.

Børn må ikke lege med dette produkt.

Rengøring og vedligeholdelse af produktet må ikke foretages af børn uden

opsyn.

1. Symboler brugt i dette dokument

Advarsel

Hvis disse sikkerhedsanvisninger ikke

10

10

11

11

12

12

12

13

13

13

14

14

14

2. Anvendelse

14

Niveaustyringen der er beskrevet i denne monte-

15

rings- og driftsinstruktion, er beregnet til niveauaf-

15

hængig start/stop af pumper til gråt spildevand.

Niveaustyringen anvendes primært til applikationer

15

hvor niveauet af ledende, ikke-brandbare væsker i

beholdere eller brønde kræver regulering, eller hvor

sådanne væsker kræver en meget lav pumpehøjde.

overholdes, kan det medføre personskade.

Advarsel

Hvis disse anvisninger ikke overhol-

des, kan det medføre elektrisk stød

med deraf følgende risiko for alvorlig

personskade eller død.

Hvis disse sikkerhedsanvisninger ikke

overholdes, kan det medføre funktionsfejl eller skade på materiellet.

Råd og anvisninger som letter arbejdet

og sikrer pålidelig drift.

Advarsel

Niveaustyringen må kun anvendes til

de formål der er nævnt i denne manual.

Andre anvendelsesformål betragtes

som ikke godkendte. Grundfos kan ikke

holdes ansvarlig for resulterende skader. Risikoen påhviler alene operatøren.

Advarsel

Anvendelse i eksplosionsbeskyttelses-

zoner er ikke tilladt.

10

Page 11

3. Produktbeskrivelse

1

5

4

3

6

2

3.1 Generel konstruktion

Niveaustyringen består af fire stavelektroder i rustfrit

stål (pos. 1) (300, 600 eller 1000 mm længde) i en

elektrodekonsol (pos. 2), en monteringskonsol (pos.

3), 10 m kabel (pos. 4), en indstikskontrolboks (pos.

5) og et 1 1/4" nippelrør (pos. 6) til fastgørelse af pladestålvinklen til afgangsstudsen på UNILIFT KP. Se

fig. 1.

Kontrolboksen indeholder evalueringselektronik, et

sikkerhedsstik og en Schuko-udgang for tilslutning til

pumpen.

Fig. 1 LLC 1000W-niveaustyring

Fig. 2 Klemrækkediagram

Kontaktildeling, klemrække X1

1 Tømmefunktion (L)

2 Påfyldningsfunktion (N)

3 Beskyttelsesjordleder

4Stik (L)

5Stik (N)

TM05 3939 1812

Kontaktildeling, klemrække X2

1 Lang elektrode (gul/grøn)

2 Kort elektrode (blå)

3 Mellemlang elektrode (brun)

4 Alarmelektrode (sort)

5 Alarmkontakt, potentialfri

6 Alarmkontakt, potentialfri

Dansk (DK)

TM05 3940 1812

11

Page 12

3.2 Funktionsbeskrivelse

Dansk (DK)

Spændingen mellem elektroderne er ca. 12 VDC, og

pumpetilslutningen har en driftsspænding på 1 x 230

V. De fire stavelektroder nedsænkes i mediet til

pumpning i forskellige længder. Den længste elektrode fungerer som rammeelektrode, den næstlængste er stopelektroden, efterfulgt af startelektroden,

og den korteste elektrode er alarmelektroden.

Niveaustyringen er fabriksindstillet til tømmefunktion.

Hvis væskeniveauet stiger til startelektroden, tændes pumpen af styringen. Hvis væskeniveauet falder

under stopelektroden, afbrydes pumpen af styringen.

Hvis væskeniveauet når alarmelektroden, slutter en

potentialfri kontakt i kontrolboksen, og den indbyggede summer udløses. Den ekstra potentialfrie skiftekontakt er monteret til særlige formål og kan også

anvendes til en ekstern alarm. Kontakternes placering (fjederterminaler) på ledepladen i kontrolboksen

er vist i fig. 2.

Funktionen kan vendes om ved at flytte kablet fra

konnektor X1-1 til konnektor X1-2, så den tilsluttede

enhed tændes når stopelektroden nås, og slukkes

når startelektroden nås (påfyldningsfunktion). Herefter udløses alarmen når beholderen er overfyldt.

Efter installationen fungerer niveaustyringen automatisk. Enhedens indstillinger bør ikke justeres.

3.3 Tekniske data

Betegnelse LLC 1000W

Forsyningsspænding 1 x 230 V, 50 Hz, N, PE

Nominel strøm Maks. 6,0 A

Effekt 1000 W

Kapslingsklasse,

kontrolboks

Kapslingsklasse,

elektrodekonsol

Kontaktbelastning,

højvandsalarm,

potentialfri

Kabellængde 10 m

EMC-støjemission

EMC-støjimmunitet

Maks. medietemperatur 55 °C

Omgivelsestemperatur 0-40 °C

Oprindelsesland Tyskland

Materialer

Komponent Materiale

Elektroder Rustfrit stål

Elektrodekonsol Plast

Kabelkappe Gummi

Stikhus Plast

IP20

IP68

Maks. 2 A, maks. 230 V

I henhold til EN

61000-6-3

I henhold til EN

61000-6-2

12

4. Transport og opbevaring

Niveaustyringen leveres i passende emballage og

skal først pakkes ud ved installationen.

Styringen skal opbevares tørt, køligt og frostfrit. Styringen må ikke udsættes for direkte sollys.

Page 13

5. Installation

Bemærk

Stavelektroder

Forsigtig

Advarsel

Installation og drift i eksplosionsfarlige

driftsmiljøer er ikke tilladt.

Sørg for at strømforsyningen ikke ufor-

varende kan genindkobles under installationen. Vi anbefaler at kontrolboksen

fjernes fra stikkontakten.

Kontrolboksens elektroniske forbindelser må ikke udsættes for fugt.

5.1 Mekanisk installation

5.1.1 Monteringsbeslag

Fastgør beslaget med de to skruer på elektrodekonsollen. Se fig. 3.

Den lange side skal vende opad.

Fig. 3 Placér monteringsbeslaget på elektrode-

5.1.2 Elektrodekonsol

Elektrodekonsollen kan fastgøres enten direkte på

pumpen eller på en beholdervæg.

Niveaustyringen kan anvendes til Grundfos-pumpetyperne Unilift CC og Unilift KP.

Elektrodernes længde skal tilpasses efter pumpens

længde. Aktiveringsdifferencen mellem start- og stopelektroderne svarer til skiftedifferensen.

konsollen

Kontrolelektroderne må ikke komme i

kontakt med pumpen eller pumpebrøndens vægge. Rammeelektroden skal

være den længste elektrode og må

godt berøre bunden.

Sørg for at pumpens stoppunkt som

specificeret af elektrodelængden nås

sikkert.

Det kan være nødvendigt at afkorte stopelektroden.

Hvis det er nødvendigt at afkorte elektroderne for at

ændre aktiveringspunkterne, skal beskyttelsesrøret

beskæres ca. 5 mm ved bunden af elektroderne efter

afkortning. Spænd forsigtigt stavelektroderne med

tang inden opstart for at forhindre at de løsnes under

pumpedrift.

Samling på pumpen

Skub elektrodekonsollen fast på pumpens trykafgang med monteringsbeslaget så elektroderne vender nedad. Slut derefter elektrodekonsollen til

afgangsstudsen på UNILIFT KP med 3-trins trykafgangen på UNILIFT CC der følger med pumpen,

eller ved hjælp af det tilsluttede 1 1/4" nippelrør.

5.2 Elektrisk installation

Advarsel

Tilslutningen skal udføres af autorise-

ret personale.

Nu er niveaustyringen klar til tilslutning. Det er ikke

nødvendigt at foretage eltilslutning på selve enheden

hvis pumpen er forsynet med et stik.

Hvis eltilslutning er nødvendig for at bruge bestemte

funktioner eller tilslutte spændingsforsyningen til

pumpen og nettet direkte til kontrolboksen for derved

at undgå at bruge stikkene, skal kontrolboksens bagvæg afmonteres.

TM05 3941 1812

Hvis den potentialfrie alarmkontakt skal bruges til at

viderestille alarmsignalet til en hovedstyring, skal

signalkablet sluttes til klemrække X2, klemme 3 og 4.

Hvis påfyldningsfunktionen skal bruges i stedet for

tømmefunktionen, skal lederen flyttes fra klemme

X1-1 til klemme X1-2.

Advarsel

Sørg for at strømforsyningen ikke ufor-

varende kan genindkobles under den

elektriske installation. Vi a nbefaler at

kontrolboksen fjernes fra stikkontakten.

Dansk (DK)

13

Page 14

6. Idriftsætning

Bemærk

Dansk (DK)

Afkort på forhånd elektroderne til den

ønskede længde, afhængig af pumpen.

Tag højde for pumpens teknisk mulige

aktiveringsniveauer.

Forbind kontrolboksen med en stikkontakt efter

installationen, og sæt pumpens stik i kontakten på

kontrolboksen.

Udfør testkørsler. Dette gøres ved at holde kontakten på kontrolboksen nede. Niveaustyringen fungerer kun når kontakten aktiveres. Pumpen kører så

længe knappen holdes nede.

Hvis der opstår fejl under testkørslen, kontrollér at

spændingsforsyningen er korrekt, at de tilsluttede

enheder fungerer korrekt og at mediets ledningsevne

er tilstrækkelig. Se yderligere oplysninger i afsnit

10. Fejlfinding.

Hvis kontakten på kontrolboksen ikke er trykket ned,

kører niveaustyringen automatisk.

Skift fra tømmefunktionen (leveringstilstand) til

påfyldningsfunktion er beskrevet i afsnit 5.2 Elektrisk

installation.

7. Drift

Når niveaustyringen er installeret og startet op, er

det ikke nødvendigt at foretage sig yderligere.

Niveaustyringen fungerer automatisk og slutter de tilsluttede spildevandspumper til og fra, afhængigt af

væskeniveauet.

Pumpen kan betjenes manuelt ved at trykke på kontakten på kontrolboksen til brug ved prøvekørsel

eller for at slå pumpen kortvarigt til eller fra under

idriftsætning eller servicearbejde. Se også afsnit

6. Idriftsætning.

9. Vedligeholdelse

Niveaustyringen er vedligeholdelsesfri. Elektrodespidserne skal dog rengøres regelmæssigt for at

fjerne eventuelle aflejringer der kan medføre funktionsfejl. Hvilke vedligeholdelsesintervaller der skal

overholdes, afhænger af driftsforholdene og pumpemediet.

Advarsel

Afbryd strømforsyningen før du f oreta-

ger arbejde på produktet. Sørg for at

strømforsyningen ikke uforvarende kan

genindkobles. Vi anbefaler at kontrolboksen fjernes fra stikkontakten.

8. Sådan tages produktet ud af drift

Fortsæt på følgende måde for at tage LLC

1000W-niveaustyringen ud af drift:

1. Afbryd spændingsforsyningen til kontrolboksen

f.eks. ved at tage kontrolboksens stik ud af kontakten.

2. Afbryd forbindelsen fra pumpens kontrolboks til

pumpen, eller fjern kablerne fra klemmerne i tilfælde af direkte forbindelse til pumpen.

3. Afmontér elektrodekonsollen fra pumpen.

4. Skyl forsigtigt elektroderne med rent vand.

14

Page 15

10. Fejlfinding

Bemærk

Advarsel

Afbryd strømforsyningen før du foretager arbejde på produktet. Sørg for at strømforsyningen

ikke uforvarende kan genindkobles. Vi anbefaler at kontrolboksen fjernes fra stikkontakten.

Fejl Mulig årsag Afhjælpning

1. Pumpen starter

ikke.

2. Pumpen stopper ikke.

3. Pumpen starter

og stopper i den

forkerte rækkefølge.

a) Ingen forsyningsspænding eller for-

kert forsyningsspænding.

b) Forkert eltilslutning. Kontrollér eltilslutningen, og ret eventuelle

c) Kablet er defekt. Kontrollér kablet. Kontakt Grundfos Service

d) Motorbeskyttelsen på pumpen er

udløst på grund af overophedning,

blokering, spændingsfejl eller

anden pumpefejl.

e) Sikringen i kontrolboksen er

brændt.

f) Fejl i styring eller defekt elektronik. Kontakt Grundfos Service.

g) Elektroderne er snavsede. Rens elektroderne.

h) Pumpen er defekt. Udskift pumpen.

a) Knappen på kontrolboksen sidder

fast.

b) Fejl i styring. Kontakt Grundfos Service.

c) Stopelektroden er for lang. Afkort stopelektroden. Bemærk pumpens

a) Forkert skiftefunktion valgt.

Kontrollér forsyningsspændingen.

fejl.

i tilfælde af et defekt kabel.

For handlinger i tilfælde af udløsning af

motorbeskyttelsen på pumpen henvises til

pumpens monterings- og driftsinstruktion.

Udskift sikringen (træg finsikring 8 A). Hvis

sikringen brænder igen med det samme,

skal årsagen identificeres og afhjælpes.

Frigør knappen.

mulige minimumsstoppunkt.

Flyt kablet på klemrække X1 fra klemme 1

til klemme 2 eller omvendt.

Dansk (DK)

11. Servicering, reservedele og tilbehør

Reservedele og tilbehør som ikke er

leveret af Grundfos, vil ikke blive efterset eller godkendt af Grundfos.

Ved brug af ikke-godkendte reservedele og tilbehør

bortfalder enhver Grundfos-garantidækning af følgeskader.

Fejlfunktioner som ikke kan repareres, må kun

udbedres af Grundfos eller autoriserede specialistfirmaer.

Giv en nøjagtig beskrivelse i tilfælde af fejlfunktion

så vores servicetekniker kan forberede sig og skaffe

de korrekte reservedele.

12. Bortskaffelse

Dette produkt eller dele deraf skal bortskaffes på

en miljørigtig måde:

1. Brug de offentlige eller godkendte, private

renovationsordninger.

2. Hvis det ikke er muligt, kontakt nærmeste

Grundfos-selskab eller -serviceværksted.

Ret til ændringer forbeholdes.

15

Page 16

Deutsch (DE) Montage- und Betriebsanleitung

Achtung

Hinweis

Deutsch (DE)

Übersetzung des englischen Originaldokuments.

INHALTSVERZEICHNIS

Seite

1. Verwendete Symbole

2. Verwendungszweck

3. Produktbeschreibung

3.1 Allgemeiner Aufbau

3.2 Funktionsbeschreibung

3.3 Technische Daten

4. Transport und Lagerung

5. Installation

5.1 Montage

5.2 Elektrischer Anschluss

6. Inbetriebnahme

7. Betrieb

8. Außerbetriebnahme

9. Wartung

10. Störungsübersicht

11. Service, Ersatzteile, Zubehör

12. Gewährleistung

13. Entsorgung

Warnung

Lesen Sie diese Montage- und

Betriebsanleitung vor der Montage.

Montage und Betrieb müssen nach den

örtlichen Vorschriften und den anerkannten Regeln der Technik erfolgen.

Warnung

Dieses Produkt kann von Kindern ab

acht Jahren und Personen mit eingeschränkten körperlichen, sensorischen oder geistigen Fähigkeiten

sowie von Personen mit mangelnden

Erfahrungen und Kenntnissen verwendet werden, wenn sie dabei beaufsichtigt werden oder in die sichere Nutzung

des Produktes eingewiesen wurden

und die damit verbundenen Gefahren

verstehen.

Kinder dürfen dieses Produkt nicht als

Spielzeug verwenden. Kinder dürfen

dieses Produkt nicht unbeaufsichtigt

reinigen oder warten.

16

16

17

17

18

18

18

19

19

19

20

20

20

20

21

21

21

21

1. Verwendete Symbole

Warnung

Die Nichtbeachtung dieser Sicherheits-

hinweise kann zu Personenschäden

führen.

Warnung

Die Nichtbeachtung dieser Sicherheits-

hinweise kann zum elektrischen Schlag

führen, der schwere Personenschäden

oder den Tod zur Folge haben kann.

Die Nichtbeachtung dieser Sicherheitshinweise kann Fehlfunktionen oder

Sachschäden zur Folge haben.

Hinweise oder Anweisungen, die das

Arbeiten erleichtern und einen sicheren

Betrieb gewährleisten.

2. Verwendungszweck

Die in der vorliegenden Betriebsanleitung beschriebene elektronische Niveausteuerung dient zum

niveauabhängigen Ein- und Ausschalten von

Schmutzwasserpumpen für Grauwasser. Sie wird vor

allem dort eingesetzt, wo Füllstände leitfähiger,

nichtbrennbarer Medien in Behältern oder Gruben

entweder sehr genau eingehalten werden müssen

oder diese Flüssigkeiten sehr flach abgepumpt werden sollen.

Warnung

Die Niveausteuerungen dürfen nur für

den hier angegebenen Verwendungszweck eingesetzt werden. Jeder darüber hinaus gehende Gebrauch gilt als

nicht bestimmungsgemäß. Für daraus

entstehende Schäden wird keine Haftung übernommen. Das Risiko hierfür

trägt allein der Betreiber.

Warnung

Die Verwendung in Ex-S chutz-Zonen ist

nicht zulässig.

16

Page 17

3. Produktbeschreibung

1

5

4

3

6

2

3.1 Allgemeiner Aufbau

Die elektronische Niveausteuerung besteht aus 4

(im Auslieferzustand durchgehend 300 mm langen)

Edelstahlelektroden (Pos. 1) im Elektrodenhalter

(Pos. 2), Befestigungswinkel (Pos. 3), 10 m Kabel

(Pos. 4), Steckerschaltgerät (Pos. 5), siehe Abb. 1,

sowie 1 1/4" Doppelnippel (Pos. 6) zur Fixierung des

Blechwinkels am Druckstutzen der UNILIFT KP.

Im Steckerschaltgerät befinden sich die Auswerteelektronik ein Schutzkontaktstecker und eine Schutzkontaktsteckdose zum Anschluss der Pumpe.

Abb. 1 Elektronische Niveausteuerung

LLC 1000W

Der Klemmenbelegungsplan ist in Abb. 2 dargestellt.

Abb. 2 Klemmenbelegungsplan

Kontaktbelegung Klemmenleiste X1

1 Pumpe Funktion Leeren (L)

2 Pumpe Funktion Füllen (N)

3 Erde Schutzleiter

4Stecker (L)

TM05 3939 1812

5Stecker (N)

Kontaktbelegung Klemmenleiste X2

1 Elektrode lang (gelb/grün)

2 Elektrode kurz (blau)

3 Elektrode mittel (braun)

4 Elektrode Alarm (schwarz)

5 Alarmkontakt, potentialfrei

6 Alarmkontakt, potentialfrei

Deutsch (DE)

TM05 3940 1812

17

Page 18

3.2 Funktionsbeschreibung

Deutsch (DE)

Die Elektrodenspannung zwischen den Elektroden

beträgt ca. 12 V Gleichspannung und die Arbeitsspannung für den Pumpenanschluss 1 x 230 V.

Die vier Elektrodenstäbe ragen unterschiedlich lang

in die leitende Flüssigkeit. Die längste Elektrode fungiert als Masseelektrode, die nächste (in der Länge

abnehmend) ist die Ausschaltelektrode dann kommt

die Einschaltelektrode und die kürzeste ist die Alarmelektrode.

Die elektronische Niveausteuerung ist werkseitig auf

die Funktion "Leeren" eingestellt. Steigt der Flüssigkeitsspiegel bis zur Einschaltelektrode an, schaltet

die Steuerung die angeschlossene Pumpe ein.

Unterschreitet der Flüssigkeitsstand die Ausschaltelektrode, so schaltet die Steuerung die Pumpe ab.

Wird die Alarmelektrode von der Flüssigkeit erreicht,

so schließt im Schaltgerät ein potentialfreier Kontakt

und der eingebaute Summer ertönt. Der zusätzliche

potentialfreie Wechselkontakt ist für Sonderanwendungen vorgesehen und kann auch für eine externe

Alarmierung genutzt werden. Die Lage der Kontakte

(Federklemmen) auf der Leiterplatte im Schaltgerät

ist in Abb. 2 dargestellt.

Durch einen Wechsel des Kabels vom Anschluss

X1-1 auf den Anschluss X1-2 kann die Funktion

umgekehrt werden, so dass das angeschlossene

Gerät bei Erreichen der AUS-Elektrode einschaltet

und bei Erreichen der EIN-Elektrode abschaltet

(Funktion "Füllen"). Der Alarm wird dann ausgelöst,

wenn das zu füllende Gefäß überfüllt wird.

Nach der Installation arbeitet die elektronische

Niveausteuerung automatisch. Einstellarbeiten am

Gerät sind nicht vorzunehmen.

3.3 Technische Daten

Bezeichnung LLC 1000W

Versorgungsspannung 1 x 230 V, 50 Hz, N, PE

Nennstrom Max. 6,0 A

Leistung 1000 W

Schutzart

Steckerschaltgerät

Schutzart

Elektrodenhalter

Max. Kontaktbelastung

Hochwasseralarm

potentialfrei

Kabellänge 10 m

EMV-Störemmission gemäß EN 61000-6-3

EMV-Störfestigkeit gemäß EN 61000-6-2

Max. Medientemperatur 55 °C

Umgebungstemperatur 0-40 °C

Ursprungsland Deutschland

Werkstoffe

Komponente Werkstoff

Elektroden Edelstahl

Elektrodenhalter Kunststoff

Kabelmantel Gummi

Steckergehäuse Kunststoff

IP20

IP68

Max. 2 A, max. 230 V

18

4. Transport und Lagerung

Die elektronische Niveausteuerung wird in einer

zweckmäßigen Verpackung geliefert, in der sie bis

zur Installation auch verbleiben sollte.

Die Lagerung der Steuerung darf nur an einem trockenen, kühlen aber frostfreien Raum erfolgen.

Die Steuerung darf keinem direkten Sonnenlicht ausgesetzt werden.

Page 19

5. Installation

Hinweis

Stabelektroden

Achtung

Warnung

Die Montage und der Betrieb in einer

explosionsgefährdeten Umgebung sind

nicht zulässig.

Die Steuerung muss in Übereinstimmung mit den örtlichen Vorschriften

montiert und angeschlossen werden.

Vor sämtlichen Montagearbeiten ist die

Spannungsversorgung zur Niveausteuerung zu unterbrechen und gegen versehentliches Wiedereinschalten zu

sichern.

Die elektrischen Anschlüsse des Steckerschaltgerätes dürfen keiner Feuchtigkeit ausgesetzt werden.

5.1 Montage

5.1.1 Befestigungswinkel montieren

Den beiliegenden Winkel mit den zwei am Elektrodenhalter befindlichen Schrauben befestigen.

Siehe Abb. 3.

Der lange Schenkel muss nach oben

zeigen.

Abb. 3 Anbringen des Befestigungswinkels an

5.1.2 Elektrodenhalter montieren

Der Elektrodenhalter kann entweder direkt an der

Pumpe oder an einer Behälterwand befestigt werden.

Die Niveausteuerung ist einsetzbar für die Grundfos

Pumpenbaureihen Unilift CC und Unilift KP.

Die Länge der Elektroden beträgt standardmäßig

jeweils 300 mm. Sie sind auf die Länge der jeweiligen Pumpen anzupassen. Die Längendifferenz von

Ein- und Ausschaltelektrode entspricht der Schaltdifferenz.

den Elektrodenhalter

Die Steuerelektroden dürfen weder die

Pumpe noch die Wände des Pumpensumpfes berühren. Die Masseelektrode muss die längste Elektrode sein

und kann auf dem Boden aufstehen.

Es ist darauf zu achten, dass der durch

die Elektrodenlänge vorgegebene Ausschaltpunkt von der Pumpe auch

sicher erreicht wird.

Ggf. ist die Ausschaltelektrode zu kürzen. Sollen die

Elektroden zur Veränderung der Schaltpunkte

gekürzt werden, so ist der Schutzschlauch am unteren Ende der Elektroden nach dem Kürzen ca. 5 mm

abzuschneiden. Die Stabelektroden sind vor der

Inbetriebnahme mit einer Zange leicht festzuziehen

um ein Lösen beim Pumpbetrieb zu vermeiden.

Montage an der Pumpe

Der Elektrodenhalter wird mit Hilfe des Befestigungswinkels direkt auf den Druckabgang der Pumpe aufgeschoben, so dass die Elektroden nach unten zeigen, und anschließend mit dem 3-stufigen

Druckabgang der UNILIFT CC (im Lieferumfang der

Pumpe) oder mittels beigefügtem 1 1/4" Doppelnippel am Druckstutzen der UNILIFT KP befestigt.

5.2 Elektrischer Anschluss

Warnung

Elektrische Anschlussarbeiten dürfen

nur durch autorisiertes Fachpersonal

vorgenommen werden.

Die elektronische Niveausteuerung ist anschlussfertig montiert. Elektrische Anschlussarbeiten am Gerät

selbst müssen nicht durchgeführt werden, wenn die

Pumpe mit einem Stecker ausgestattet ist.

Sind dennoch elektrische Anschlussarbeiten erforderlich, um bestimmte Funktionen zu nutzen oder die

Spannungsversorgung für die Pumpe und den Netzanschluss direkt im Gerät unter Umgehung der

Steckdosen vorzunehmen, ist die Rückwand des

Steckerschaltgeräts abzuschrauben.

Warnung

Vor elektrischen Anschlussarbeiten ist

unbedingt das Schaltgerät von der

TM05 3941 1812

Soll der potentialfreie Alarmkontakt zur Weiterleitung

der Alarmmeldung an eine übergeordnete Steuerung

genutzt werden, ist das Signalkabel an die Klemmenleiste X2, Klemmen 3 und 4 anzuschließen.

Soll statt der Funktion "Leeren" die Funktion "Füllen"

genutzt werden, ist der Leiter von Klemme X1-1 auf

die Klemme X1-2 aufzulegen.

Spannungsversorgung zu trennen und

gegen versehentliches Einschalten zu

sichern, z.B. durch Herausziehen des

Schaltgeräts aus der Steckdose.

Deutsch (DE)

19

Page 20

6. Inbetriebnahme

Hinweis

Deutsch (DE)

Abgestimmt auf die jeweilige Pumpe

sind im Vorfeld die Elektroden auf die

richtige Länge zu kürzen. Bitte hierzu

vorher die technisch möglichen Schaltniveaus der Pumpen beachten.

Nach der ordnungsgemäßen Installation zunächst

das Schaltgerät in eine geeignete Steckdose stecken

und dann den Stecker der Pumpe in die Steckdose

des Schaltgeräts stecken.

Probeläufe durchführen. Dazu den Schalter am

Schaltgerät drücken und gedrückt halten.

Die Niveausteuerung ist bei Betätigung des

Schalters nicht wirksam. Die Pumpe läuft, solange

der Taster betätigt wird.

Sollten während des Probebetriebs Störungen auftreten, ist zu prüfen, ob die Spannungsversorgung

korrekt bzw. die angeschlossenen Geräte einwandfrei funktionieren und die Flüssigkeit eine ausreichende Leitfähigkeit besitzt. Weitere Hinweise finden

Sie im Abschnitt 10. Störungsübersicht.

Wird der Schalter am Schaltgerät nicht gedrückt,

befindet sich die elektronische Niveausteuerung im

Automatikbetrieb.

Das Umschalten von der Funktion Leeren (Auslieferungszustand) in die Funktion Füllen ist unter

Abschnitt 5.2 Elektrischer Anschluss beschrieben.

7. Betrieb

Nachdem die elektronische Niveausteuerung ordnungsgemäß installiert und in Betrieb genommen

worden ist, ist keine weitere Bedienung erforderlich.

Die elektronische Niveausteuerung arbeitet automatisch und schaltet die angeschlossene Abwasserpumpe niveauabhängig ein und aus.

Für einen Probelauf oder kurzzeitiges Ein- oder Ausschalten der Pumpe während der Inbetriebnahme

oder Servicearbeiten kann die Pumpe durch Drücken

des Schalters am Schaltgerät manuell betrieben

werden. Siehe auch Abschnitt 6. Inbetriebnahme.

9. Wartung

Die elektronische Niveausteuerung ist wartungsfrei.

In regelmäßigen Zeitabständen sollten jedoch die

Elektrodenspitzen von möglichen Ablagerungen

gereinigt werden, da hierdurch Fehlfunktionen verursacht werden könnten. Die Intervalle sind von den

Betriebsbedingungen und dem Fördermedium

abhängig.

Warnung

Vor Wartungsarbeiten ist unbedingt

das Schaltgerät von der Spannungsversorgung zu trennen und gegen versehentliches Einschalten zu sichern

(z.B. durch Herausziehen des Schaltgeräts aus der Steckdose).

8. Außerbetriebnahme

Warnung

Elektrische Arbeiten dürfen nur durch

autorisiertes Fachpersonal vorgenommen werden.

Zur Außerbetriebnahme der elektronischen Niveauerfassung LLC 1000W ist wie folgt vorzugehen:

1. Steckerschaltgerät von der Spannungsversorgung trennen (z.B. durch Herausziehen des

Schaltgeräts aus der Steckdose).

2. Pumpenstecker aus dem Pumpenschaltgerät ziehen oder bei direktem Pumpenanschluss die

Kabel an den Klemmen entfernen.

3. Elektrodenhalter von der Pumpe demontieren.

4. Elektroden sorgfältig mit klarem Wasser reinigen.

20

Page 21

10. Störungsübersicht

Hinweis

Warnung

Vor Arbeiten an der elektronischen Niveausteuerung ist unbedingt das Schaltgerät von der

Spannungsversorgung zu trennen und gegen versehentliches Einschalten zu sichern

(z.B. durch Herausziehe n des Schaltgeräts aus der Steckdose).

Störung Mögliche Ursache Abhilfe

1. Pumpe schaltet

nicht ein.

2. Pumpe schaltet

nicht aus.

3. Pumpe schaltet in

falscher Reihenfolge ein und aus.

a) Keine oder falsche Spannungsver-

sorgung.

b) Fehlerhafter elektrischer Anschluss. Elektrischen Anschluss überprüfen und

c) Defektes Kabel. Kabel überprüfen. Bei einem defekten

d) Motorschutz an der Pumpe hat aus-

gelöst (Überhitzung, Blockierung,

Spannungsfehler oder sonstiger

Defekt an der Pumpe).

e) Sicherung im Schaltgerät durchge-

brannt.

f) Steuerungsfehler/Elektronik defekt. Bitte an den Grundfos Service wenden.

g) Elektroden verschmutzt. Elektroden reinigen.

h) Pumpe defekt. Pumpe austauschen.

a) Taster am Schaltgerät verhakt. Taster lösen.

b) Steuerungsfehler. Bitte an den Grundfos Service wenden.

c) Ausschaltelektrode zu lang. Ausschaltelektrode kürzen

a) Falsche Schaltfunktion gewählt. Kabel an der Klemmenleiste X1 von

Spannungsversorgung überprüfen.

ordnungsgemäß ausführen.

Kabel bitte an den Grundfos Service

wenden.

Maßnahmen bei Auslösen des Motorschutzes der Pumpe, siehe Montageund Betriebsanleitung der Pumpe.

Sicherung ersetzen (Feinsicherung 8 A,

träge). Bei sofortigem, erneutem Durchbrennen der Sicherung Ursache suchen

und beheben.

(minimal möglichen Ausschaltpunkt der

Pumpe beachten).

Klemme 1 auf Klemme 2 legen

(bzw. umgekehrt).

Deutsch (DE)

11. Service, Ersatzteile, Zubehör

Wir machen ausdrücklich darauf aufmerksam, dass nicht von uns gelieferte

Ersatzteile und Zubehör auch nicht von

uns geprüft und freigegeben sind.

Für Schäden, die durch die Verwendung von nicht

Original-Ersatzteilen und Zubehör entstehen ist jede

Haftung und Gewährleistung ausgeschlossen.

Störungen, die nicht selbst behoben werden können,

sollten nur vom Grundfos Service oder autorisierten

Fachfirmen beseitigt werden.

Bitte geben Sie eine genaue Schilderung im Fall

einer Störung, damit sich unser Service-Techniker

vorbereiten und mit den entsprechenden Ersatzteilen

ausrüsten kann.

12. Gewährleistung

Die Gewährleistung erfolgt im Rahmen unserer allgemeinen Lieferbedingungen. Von der Haftung ausgenommen sind Schäden, die auf Fehler beim Einbau, dem elektrischen Anschluss oder auf falsche

Verwendung zurückzuführen sind. Für Folgeschäden

wird nicht gehaftet. Der Gewährleistungsbeginn ist

nachzuweisen.

13. Entsorgung

Dieses Produkt sowie Teile davon müssen umweltgerecht entsorgt werden:

1. Nutzen Sie die öffentlichen oder privaten

Entsorgungsgesellschaften.

2. Ist das nicht möglich, wenden Sie sich bitte an

die nächste Grundfos Gesellschaft oder Werkstatt.

Technische Änderungen vorbehalten.

21

Page 22

Declaration of conformity

Declaration of conformity 1

GB: EC declaration of conformity

We, Grundfos, declare under our sole responsibility that the product LLC

1000W, to which this declaration relates, is in conformity with these

Council directives on the approximation of the laws of the EC member

states:

DE: EG-Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung, dass das Produkt

LLC 1000W, auf das sich diese Erklärung bezieht, mit den folgenden

Richtlinien des Rates zur Angleichung der Rechtsvorschriften der

EU-Mitgliedsstaaten übereinstimmt:

– Low Voltage Directive (2006/95/EC)*.

Standard used: EN 60335-1:2002 and EN 60204-1:2006.

– EMC Directive (2004/108/EC).

Standards used: EN 61000-6-2:2005 and EN 61000-6-3:2007.

* Only for products with operating voltage > 50 VAC or > 75 VDC.

This EC declaration of conformity is only valid when published as part of

the Grundfos installation and operating instructions (publication number

98335640 0315).

DK: EF-overensstemmelseserklæring

Vi, Grundfos, erklærer under ansvar at produktet LLC 1000W som denne

erklæring omhandler, er i overensstemmelse med disse af Rådets

direktiver om indbyrdes tilnærmelse til EF-medlemsstaternes lovgivning:

Székesfehérvár, 17 April 2013

Jannek Uldal Christesen

D&E Central Europe

Site Manager

Grundfos Hungary Ltd.

Ipari Park

Búzavirág u. 14

2890 Tatabánya, Hungary

Person authorised to compile technical file and

empowered to sign the EC declaration of conformity.

22

Page 23

232425

Page 24

Page 25

Page 26

Argentina

Grundfos companies

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Centro

Industrial Garin

1619 Garín Pcia. de B.A.

Phone: +54-3327 414 444

Telefax: +54-3327 45 3190

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb

Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belarus

Представительство ГРУНДФОС в

Минске

220125, Минск

ул. Шафарнянская, 11, оф. 56, БЦ

«Порт»

Тел.: +7 (375 17) 286 39 72/73

Факс: +7 (375 17) 286 39 71

E-mail: minsk@grundfos.com

Bosna and Herzegovina

GRUNDFOS Sarajevo

Zmaja od Bosne 7-7A,

BH-71000 Sarajevo

Phone: +387 33 592 480

Telefax: +387 33 590 465

www.ba.grundfos.com

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo

Branco, 630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

10F The Hub, No. 33 Suhong Road

Minhang District

Shanghai 201106

PRC

Phone: +86 21 612 252 22

Telefax: +86 21 612 253 33

Croatia

GRUNDFOS CROATIA d.o.o.

Buzinski prilaz 38, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.hr.grundfos.com

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-(0)207 889 900

Telefax: +358-(0)207 889 550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

HILGE GmbH & Co. KG

Hilgestrasse 37-47

55292 Bodenheim/Rhein

Germany

Tel.: +49 6135 75-0

Telefax: +49 6135 1737

e-mail: hilge@hilge.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private

Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg., 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Page 27

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Mexico

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

Romania

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундф ос Россия

109544, г. Москва, ул. Школьная,

39-41, стр. 1

Тел. (+7) 495 564-88-00 (495)

737-30-00

Факс (+7) 495 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

Grundfos Srbija d.o.o.

Omladinskih brigada 90b

11070 Novi Beograd

Phone: +381 11 2258 740

Telefax: +381 11 2281 769

www.rs.grundfos.com

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

25 Jalan Tukang

Singapore 619264

Phone: +65-6681 9688

Telefax: +65-6681 9689

Slovakia

GRUNDFOS s.r.o.

Prievozská 4D

821 09 BRATISLAVA

Phona: +421 2 5020 1426

sk.grundfos.com

Slovenia

GRUNDFOS d.o.o.

Šlandrova 8b, SI-1231 Ljubljana-Črnuče

Phone: +386 31 718 808

Telefax: +386 (0)1 5680 619

E-mail: slovenia@grundfos.si

South Africa

GRUNDFOS (PTY) LTD

Corner Mountjoy and George Allen

Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölndal

Tel.: +46 31 332 23 000

Telefax: +46 31 331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-44-806 8111

Telefax: +41-44-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd.

Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

Бізнес Центр Європа

Столичне шосе, 103

м. Київ, 03131, Україна

Телефон : (+38 044) 237 04 00

Факс.: (+38 044) 237 04 01

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971 4 8815 166

Telefax: +971 4 8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 4TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Uzbekistan

Grundfos Tashkent, Uzbekistan The Representative Office of Grundfos Kazakhstan

in Uzbekistan

38a, Oybek street, Tashkent

Телефон: (+998) 71 150 3290 / 71 150

3291

Факс: (+998) 71 150 3292

Addresses Revised 10.03.2015

Grundfos companies

Page 28

98335640 0315

ECM: 1113736

www.grundfos.com

© Copyright Grundfos Holding A/S

owned by Grundfos Holding A/S or Grundfos A/ S, Denmark. All rights reserved worldwide.

The name Grundfos, the Grundfos logo, and be think innovate are registered trademarks

Loading...

Loading...