Page 1

GRUNDFOS INSTRUCTIONS

LFE, LCSE

End-suction, frame-mounted pumps with integrated VFD

End-suction, close-coupled, split-coupling pumps with integrated VFD

Installation and operating instructions

Page 2

LFE, LCSE

)UDQ©DLV&$

(VSD³RO0;

Table of contents

English (US)

Installation and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Notice d'installation et de fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Instrucciones de instalación y operación . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

2

Page 3

English (US) Installation and operating instructions

Original installation and operating instructions

These installation and operating instructions describe LFE,

LCSE.

Sections 1-5 give the information necessary to be able to unpack,

install and start up the product in a safe way.

Sections 6-30 give important information about the product, as

well as information on service, fault finding and disposal of the

product.

CONTENTS

Page

1. Limited warranty

2. General information

2.1 Symbols used in this document

2.2 Other important notes

3. Receiving the product

3.1 Unpacking the product

3.2 Inspecting the product

3.3 Temporary storage after delivery

4. Installing the product

4.1 Location

4.2 Horizontal pump foundation

4.3 Securing the base plate

4.4 Mechanical installation

4.5 Electrical connections

4.6 Motors

5. Starting up the product

5.1 Priming

5.2 Pre-start checklist

5.3 Motor direction of rotation

5.4 Starting the pump

5.5 Voltage and frequency variation

6. Storing and handling the product

7. Product introduction

7.1 Applications

7.2 Pumped liquids

7.3 Pump identification

8. Servicing the product

8.1 Maintaining the product

8.2 Lubricating the product

8.3 Disassembling the pump

8.4 Replacing the shaft seal (LCSE pumps)

8.5 Replacing the wear ring

8.6 Reassembling the pump

8.7 LFE, exploded view and parts list

8.8 LCSE, exploded view and parts list

9. Taking the product out of operation

9.1 General procedure

9.2 Short-term shutdown

9.3 Long-term shutdown

10. Fault finding

11. PACO MLE motors

11.1 Pumps without factory-fitted sensor

11.2 Pumps with pressure sensor

11.3 Settings

12. Installing the motor

12.1 Motor cooling

12.2 Outdoor installation

13. Electrical connection

13.1 Three-phase pumps, 3-10 hp

13.2 Three-phase pumps, 15-30 hp

13.3 Signal cables

10

10

10

10

10

10

10

11

11

11

11

11

11

11

13

14

14

14

15

16

17

17

17

17

18

20

20

20

20

20

20

20

21

21

23

26

13.4 E-pump electrical connections

13.5 Bus connection cable

14. Modes

14.1 Overview of modes

14.2 Operating mode

14.3 Control mode

15. Setting up the pump

15.1 Factory setting

16. Setting by means of control panel

16.1 Setting of operating mode

16.2 Setpoint setting

4

5

5

5

5

5

5

5

6

6

6

6

7

9

9

17. Setting by means of R100

17.1 Menu OPERATION

17.2 Menu STATUS

17.3 Menu INSTALLATION

17.4 Typical display settings for constant-pressure E-pumps

17.5 Typical display settings for analog-input E-pumps

17.6 Grundfos GO Remote

18. Setting by means of PC Tool E-products

19. Priority of settings

20. External forced-control signals

20.1 Start/stop input

20.2 Digital input

21. External setpoint signal

22. Bus signal

23. Other bus standards

24. Indicator lights and signal relay

25. Emergency operation (only 15-30 hp)

26. Insulation resistance

27. Maintaining and servicing the motor

27.1 Cleaning of the motor

27.2 Relubrication of motor bearings

27.3 Replacement of motor bearings

27.4 Replacement of varistor (only 15-30 hp)

27.5 Service parts and service kits

28. Technical data

28.1 Technical data - three-phase pumps, 3-10 hp

28.2 Technical data - three-phase pumps, 15-30 hp

28.3 Other technical data

29. Installing the product in the USA and Canada

29.1 Electrical connection

29.2 General considerations

30. Disposing of the product

26

28

28

28

28

29

29

29

29

29

30

30

32

33

35

42

43

44

45

45

45

45

46

46

47

47

47

49

50

50

50

50

50

51

51

51

51

52

53

54

54

54

54

English (US)

3

Page 4

English (US)

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

The use of this product requires experience with and

knowledge of the product. Persons with reduced

physical, sensory or mental capabilities must not use

this product, unless they are under supervision or

have been instructed in the use of the product by a

person responsible for their safety. Children must not

use or play with this product.

CAUTION

Successful operation depends on careful attention to

the procedures described in this manual. Keep this

manual for future use.

1. Limited warranty

New equipment manufactured by seller or service supplied by

seller is warranted to be free from defects in material and

workmanship under normal use and service for a minimum of

twelve (12) months from date of installation, eighteen (18) months

from date of shipment, unless otherwise stated in product warranty

guide (available upon request). In the case of spare or

replacement parts manufactured by seller, the warranty period

shall be for a period of twelve months from shipment. Seller's

obligation under this warranty is limited to repairing or replacing, at

its option, any part found to its satisfaction to be so defective,

provided that such part is, upon request, returned to seller's

factory from which it was shipped, transportation prepaid. Parts

replaced under warranty shall be warranted for twelve months

from the date of the repair, not to exceed the original warranty

period. This warranty does not cover parts damaged by

decomposition from chemical action or wear caused by abrasive

materials, nor does it cover damage resulting from misuse,

accident, neglect, or from improper operation, maintenance,

installation, modification or adjustment. This warranty does not

cover parts repaired outside seller's factory without prior written

approval. Seller makes no warranty as to starting equipment,

electrical apparatus or other material not of its manufacture. If

purchaser or others repair, replace, or adjust equipment or parts

without seller's prior written approval, seller is relieved of any

further obligation to purchaser under this paragraph with respect

to such equipment or parts, unless such repair, replacement, or

adjustment was made after seller failed to satisfy within a

reasonable time seller's obligations under this paragraph. Seller's

liability for breach of these warranties (or for breach of any other

warranties found by a court of competent jurisdiction to have been

given by seller) shall be limited to: (a) accepting return of such

equipment exw plant of manufacture, and (b) refunding any

amount paid thereon by purchaser (less depreciation at the rate of

15 % per year if purchaser has used equipment for more than

thirty [30] days), and canceling any balance still owing on the

equipment, or (c) in the case of service, at seller's option, redoing

the service, or refunding the purchase order amount of the

service or portion thereof upon which such liability is based.

These warranties are expressly in lieu of any other warranties,

express or implied, and seller specifically disclaims any implied

warranty of merchantability or fitness for a particular purpose, and

in lieu of any other obligation or liability on the part of the seller

whether a claim is based upon negligence, breach of warranty, or

any other theory or cause of action. In no event shall seller be

liable for any consequential, incidental, indirect, special or

punitive damages of any kind. For purposes of this paragraph, the

equipment warranted shall not include equipment, parts, and work

not manufactured or performed by seller. With respect to such

equipment, parts, or work, seller's only obligation shall be to

assign to purchaser the warranties provided to seller by the

manufacturer or supplier providing such equipment, parts or work.

No equipment furnished by seller shall be deemed to be defective

by reason of normal wear and tear, failure to resist erosive or

corrosive action of any fluid or gas, purchaser's failure to properly

store, install, operate, or maintain the equipment in accordance

with good industry practices or specific recommendations of

seller, including, but not limited to seller's installation and

operation manuals, or purchaser's failure to provide complete and

accurate information to seller concerning the operational

application of the equipment.

4

Page 5

2. General information

3. Receiving the product

2.1 Symbols used in this document

DANGER

Indicates a hazardous situation which, if not avoided,

will result in death or serious personal injury.

WARNING

Indicates a hazardous situation which, if not avoided,

could result in death or serious personal injury.

CAUTION

Indicates a hazardous situation which, if not avoided,

could result in minor or moderate personal injury.

The text accompanying the three hazard symbols DANGER,

WARNING and CAUTION will be structured in the following way:

SIGNAL WORD

Description of hazard

Consequence of ignoring the warning.

- Action to avoid the hazard.

Example

DANGER

Electric shock

Death or serious personal injury.

- Before starting any work on the product, make

sure that the power supply has been switched off

and that it cannot be accidentally switched on.

2.2 Other important notes

3.1 Unpacking the product

WARNING

Overhead load

Death or serious personal injury

- Do not lift the unit by the eye bolts on the motor.

Unload and handle the unit with a sling.

3.2 Inspecting the product

• Check that the product received is in accordance with the

order.

• Check that the voltage, phase and frequency of the product

match the voltage, phase and frequency of the installation site.

See section 7.3 Pump identification.

• Check the product for defects and damage immediately upon

arrival. Any accessories ordered will be packed in a separate

container and shipped with the product.

• If any equipment is damaged in transit, promptly report this to

the carrier's agent. Make complete notations on the freight bill.

3.3 Temporary storage after delivery

• If the product is not to be installed and operated immediately

after receiving it, store it in a clean, dry area at a moderate

ambient temperature.

• Rotate the shaft by hand periodically, at least weekly, to coat

the bearing with lubricant to retard oxidation and corrosion.

• Follow the motor manufacturer's storage recommendations

where applicable.

• During storage and transport maintain an ambient temperature

from -13 to +158 °F (-25 to +70 °C) for the E-motor. At

temperatures below the prescribed temperature, the E-motor

must be equipped with a anti-condensation heater. This could

be an external heating element or an incorporated functionality

of the E-motor.

English (US)

A blue or grey circle with a white graphical symbol

indicates that an action must be taken to avoid a

hazard.

A red or grey circle with a diagonal bar, possibly with

a black graphical symbol, indicates that an action

must not be taken or must be stopped.

If these instructions are not observed, it may result

in malfunction or damage to the equipment.

Notes or instructions that make the work easier and

ensure safe operation.

5

Page 6

English (US)

GroutBase plate

Finished grouting

0.75 - 1.25 in.

allowance

(20-32 mm)

for grout

Formwork

Pipe sleeve

Washer

Lug

Top foundation

Wedges or shims

left in place

0.25

in.

4. Installing the product

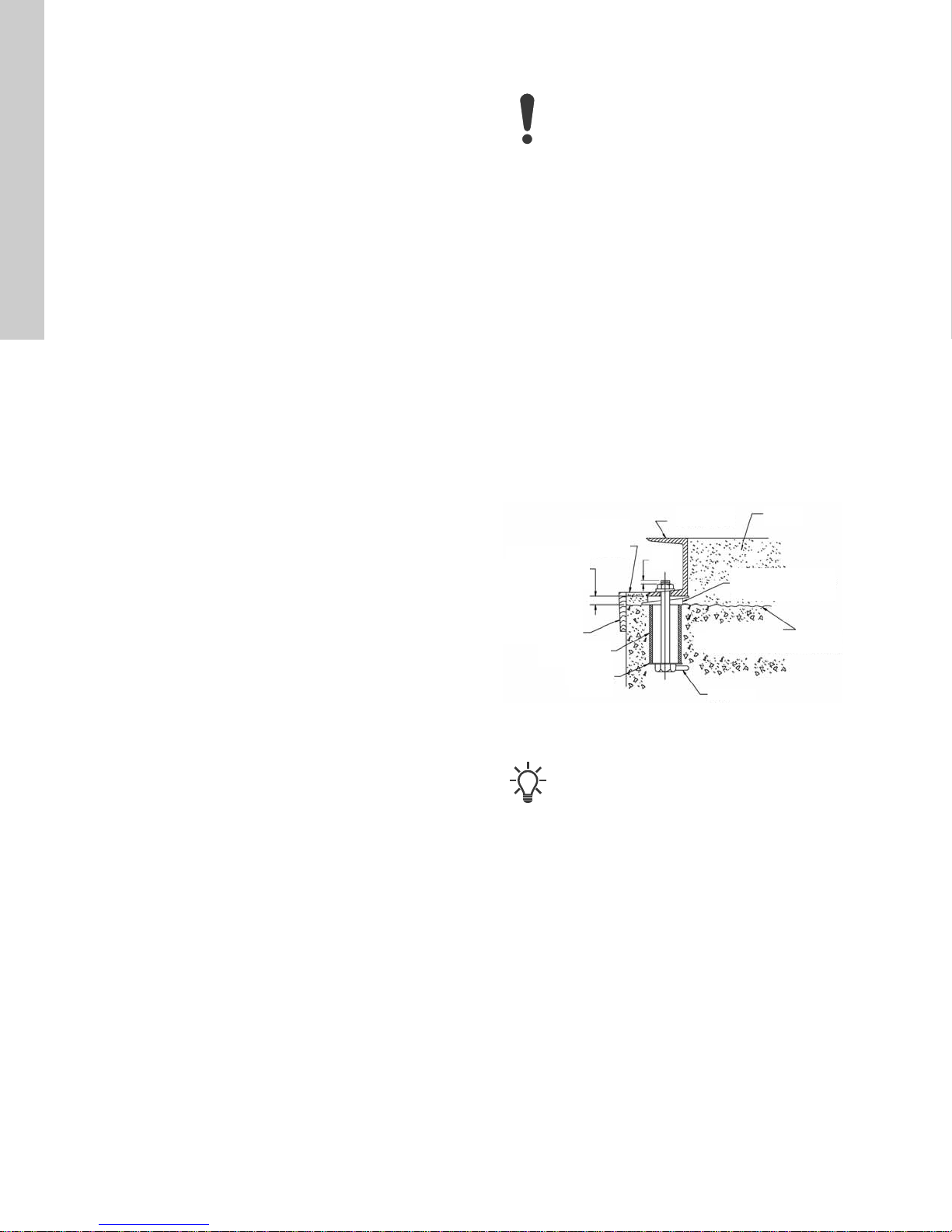

4.3 Securing the base plate

4.1 Location

• Locate the pump as close as possible to the liquid supply. Use

the shortest and most direct inlet pipe practical. Refer to

section 4.4.2 Inlet pi pe.

• Locate the pump below system level wherever possible. This

will facilitate priming, assure a steady liquid flow, and provide

a positive inlet pressure.

• The net positive suction head (NPSH) available must always

be equal to or exceed the required NPSH specified on the

pump performance curve. Make sure the required NPSH is

provided at the inlet.

• Always allow sufficient accessibility space for maintenance

and inspection. Provide a clearance of 24 in. (610 mm) with

ample head room for use of a hoist strong enough to lift the

product.

• Electrical characteristics must match those specified on the

motor nameplate, within the limits covered in section

5. Starting up the product.

• Do not expose the product to sub-zero temperatures to

prevent the pumped liquid from freezing and to prevent

damage to the e-motor. If there is frost during shutdown

periods, see sections 5. Starting up the product and 9.2 Short-

term shutdown.

4.2 Horizontal pump foundation

Install horizontal pumps permanently on a firm, raised concrete

foundation of sufficient size to dampen any vibration and prevent

any deflection or shaft misalignment. The foundation may float on

springs or be a raised part of the equipment room floor.

Proceed like this:

1. Pour the foundation without interruption to 0.75 - 1.5 in. (20-

35 mm) below the final pump level. Leave the top of the

foundation rough. Then clean and wet it down.

2. Score and groove the top surface of the foundation before the

concrete sets to provide a suitable bonding surface for the

grout.

3. Place anchor bolts in pipe sleeves for positioning allowance.

See fig. 1.

4. Allow enough bolt length for grout, lower base plate flange,

nuts, and washers.

5. Allow the foundation to cure several days before proceeding

to install the pump.

LFE pumps require grouting in order to ensure a

stable pump and motor shaft alignment.

LCSE pumps do not require alignment or grouting.

When the raised concrete foundation has been poured and

allowed to set, proceed as follows:

1. Lower the pump base plate over the anchor bolts and rest it

on loose adjustment wedges or shims placed near each

anchor bolt and at intervals not exceeding 24 in. (610 mm)

along each side.

2. Place the shims or wedges so that they raise the bottom of the

base 0.75 - 1.25 in. (20-32 mm) above the foundation,

allowing clearance for grout.

3. Level the pump shaft, flanges, and base plate using a spirit

level, adjusting the wedges or shims, as required.

4. Make sure that the pipes can be aligned to the pump flanges

without placing any strain on either flange.

5. For LFE, after pump alignment has been established, put nuts

on foundation bolts and tighten them just enough to keep the

base plate from moving.

6. Construct a formwork around the concrete foundation and

pour grout inside the base plate, as shown in fig. 1. The grout

will compensate for uneven foundation, distribute the weight

of the pump, and prevent shifting.

TM 05 4775 4713

Fig. 1 Anchor bolt installation

Use an approved, non-shrinking grout.

6

7. Allow at least 24 hours for this grout to set before proceeding

with pipe connections.

8. After the grout has thoroughly hardened, check the foundation

bolts and tighten them if necessary. Recheck the pump

alignment after tightening the foundation bolts.

Page 7

4.4 Mechanical installation

Eccentric

reducer

Concentric

reducer

Tapered side is down

Air pocket

Correct

Wrong

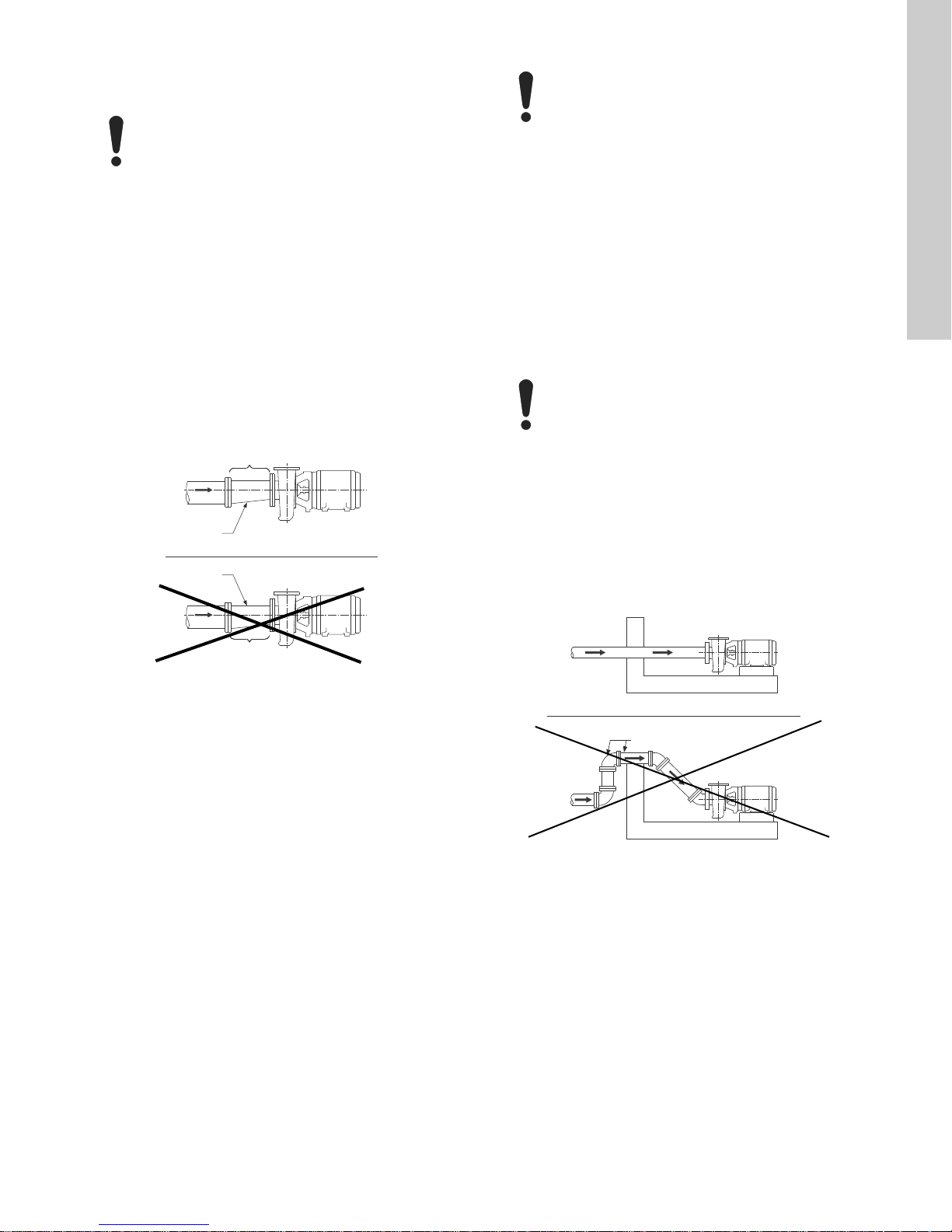

4.4.1 Piping

Do not let the pump support the pipes. Use pipe

hangers or other supports at proper intervals to

provide pipe support near the pump.

• Make sure that both the inlet and outlet pipes are

independently supported and properly aligned so that no strain

is transmitted to the pump when flange bolts are tightened.

• Make sure the pipes are as straight as possible, so as to avoid

unnecessary bends and fittings. Where necessary, use 45 ° or

long-sweep 90 ° pipe bends to decrease friction loss.

• Where flanged joints are used, make sure that inside

diameters match properly and that mounting holes are aligned.

• Do not apply force to pipes when making any connections!

4.4.2 Inlet pipe

The inlet pipe must be selected and installed in a manner that

minimizes pressure loss and permits sufficient liquid flow into the

pump during starting and operation.

Observe the following precautions when installing the inlet pipe:

At no point must the diameter of the inlet pipe be

smaller than that of the pump inlet port.

• If possible, run a horizontal inlet line along an even gradient.

We recommend a gradual upward slope to the pump under

suction lift conditions, and a gradual downward slope for

positive inlet pressure conditions.

• Avoid any high points, such as pipe loops (see fig. 3), as this

may create air pockets and throttle the system or cause erratic

pumping.

• Install a gate valve in the inlet line to be able to isolate the

pump during shutdown and maintenance, and to facilitate

pump removal. Where two or more pumps are connected to

the same inlet line, install two gate valves to be able to isolate

each pump from the line.

• Always install gate or butterfly valves in positions that prevent

air pockets.

Do not use globe valves, particularly when NPSH is

critical.

• During pumping operation, the valves on the inlet line must

always be fully open.

• Install properly sized pressure gauges in the tapped holes on

the pump inlet and outlet flanges.

Pressure gauges will enable the operator to monitor the pump

performance and determine whether the pump conforms to the

parameters of the performance curve. If cavitation, vapor

binding, or other unstable operating situations occur, pressure

gauges will indicate wide fluctuation in the inlet and outlet

pressures.

English (US)

Fig. 2 Inlet pipe

• Run the inlet pipe as direct as possible, and ideally, make sure

the length is at least ten times the pipe diameter. A short inlet

pipe can be the same diameter as the inlet port. A long inlet

pipe must be one or two sizes larger (depending on length)

than the inlet port, and with a reducer between the pipe and

the inlet port.

• Use an eccentric reducer, with the tapered side down. See fig.

2.

Correct

TM06 1087 1614

Air pockets

Wrong

TM06 1088 1614

Fig. 3 Air pocket prevention

7

Page 8

English (US)

4.4.3 Outlet pipe

• A short outlet pipe can be the same diameter as the pump

outlet port. A long outlet pipe must be one or two sizes larger

than the outlet port, depending on the length.

• An even gradient is best for long horizontal outlet pipes.

• Install a gate valve near the outlet port to be able to isolate the

pump during shutdown and maintenance, and to facilitate

pump removal.

• Any high points in the outlet pipe may entrap air or gas and

thus retard pump operation.

• If water hammer occurs (i.e. if check valves are used), close

the outlet gate valve before pump shutdown.

Shaft seals

The pumps are available with stuffing boxes with packing rings or

mechanical shaft seals.

Stuffing boxes

The stuffing boxes are normally packed before shipment.

If the pump is installed within 60 days after shipment, the packing

material will be in good condition for operation with a sufficient

supply of lubricating liquid.

If the pump is stored for more than 60 days, it may be necessary

to repack the stuffing boxes.

The stuffing box must be supplied at all times with a source of

clean, clear liquid to flush and lubricate the packing rings.

Packing gland adjustment

With the pump running, adjust the packing gland to permit 40 to

60 drops per minute for shaft lubrication. After initial start up,

additional packing and adjustment may be required.

Mechanical shaft seals

Mechanical shaft seals require no maintenance or adjustment.

End suction pumps equipped with mechanical shaft seals are

matched to the operating conditions for which the pump was sold.

Observe the following precautions to avoid shaft seal damage

and obtain maximum shaft seal life.

4.4.4 Coupling alignment of LCSE pumps

No alignment of the pump and motor is required.

4.4.5 Coupling alignment of LFE pumps

The pump and motor were accurately aligned from factory, but

handling during shipment could alter this pre-alignment.

1. If the pump and motor were shipped mounted on a common

base frame as an assembly, remove the coupling guard.

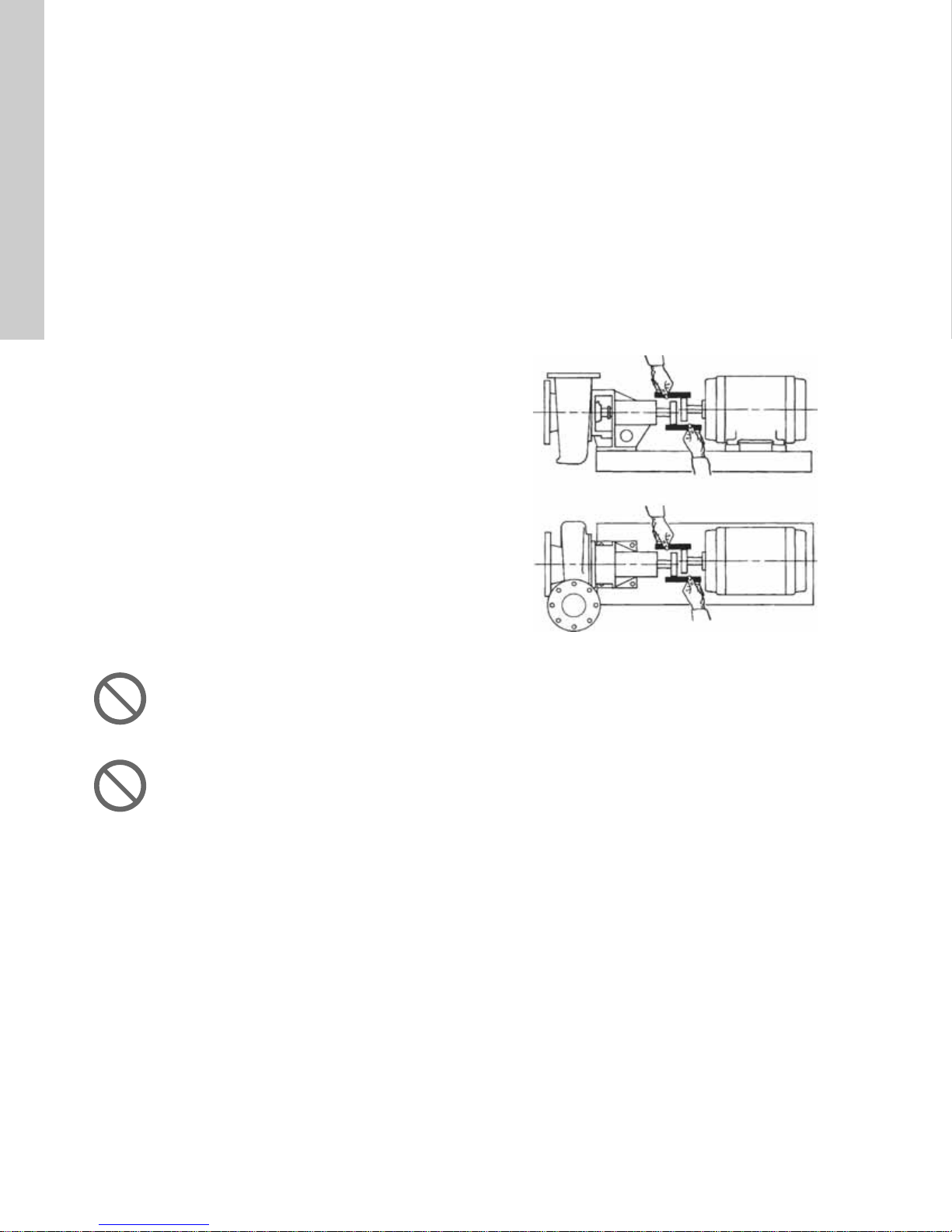

2. Checking parallel alignment

Place a straight edge across both coupling rims at the top, the

bottom, and both sides. See fig. 4. After each adjustment,

recheck all features of alignment. Parallel alignment is correct

when the measurements show that all points of the coupling

faces are within ± 0.005 in. (0.127 mm) of each other. If

misalignment is detected, loosen the motor and shift or shim

as necessary to re-align. Then re-tighten the bolts. Always

align the motor to the pump as pipe strain will occur if the

pump is shifted. Never reposition the pump on the base frame.

TM05 4794 2613

Fig. 4 Checking parallel alignment

Do not run the pump dry or against a closed valve!

Dry running will cause seal failure within minutes.

Do not exceed the temperature or pressure

limitations for the mechanical shaft seal used.

Clean and purge the inlet pipe in new installations before

installing and operating pump. Pipe scale, welding slag and other

abrasives can cause rapid shaft seal failure.

8

Page 9

3. Checking angular alignment

Insert a pair of inside callipers or a taper gauge at four points

at 90 ° intervals around the coupling. See fig. 5. Angular

alignment is correct when the measurements show that all

points of the coupling faces are within ± 0.005 in. (0.127 mm)

of each other.

– If misalignment is detected, loosen the motor and shift or

shim as necessary to re-align. Then re-tighten the bolts.

Always align the motor to the pump as pipe strain will occur

if the pump is shifted. Never reposition the pump on the

base frame.

Fig. 5 Checking angular alignment

• Check shaft seal alignment once again after final pipe

connections to the pump have been made, motor wiring has

been checked, correct direction of rotation has been

established, and pipes have been filled with liquid.

• Leave the coupling guards off until the pump priming

procedure has been completed.

• Install the coupling guards after installation has been

completed to protect personnel from rotating machinery.

4.5 Electrical connections

DANGER

Electric shock

Death or serious personal injury

- The electrical installation must be carried out by a

qualified electrician in accordance with local

regulations and the manuals provided with the

electrical accessories.

4.6 Motors

See also section 11. PACO MLE m otors.

The motor control circuit must include the following components

in order to comply with the National Electrical Code:

Motor disconnecting device

• Install a motor disconnecting device that is capable of

disconnecting both the controller (motor starter) and the motor

from their source of power.

• Locate the disconnecting device in such a way that the

controller (motor starter) can be seen from the disconnecting

device. In all cases, the distance from the disconnecting

device to the controller must be less than 50 ft (15.24 m).

• In most installations the disconnecting device will be a circuit

breaker or fusible disconnect switch.

Motor short circuit and ground fault circuit interrupter

• A short circuit and ground fault circuit interrupter is usually a

circuit breaker or fusible disconnect switch.

• Select the circuit breaker or fuse in accordance with applicable

local and state electrical codes in addition to the National

Electrical Code.

Motor controller with current protection (magnetic starter)

• Install these components in accordance with applicable local

and state electrical codes in addition to the National Electrical

Code.

DANGER

TM05 4795 2613

4.6.1 Wiring

• Mount the control panel or the motor starter(s) close to the

pump to provide convenient control and easy installation.

• Wire panel or starter(s) to motor(s) and pilot device(s).

Wires to the motor(s) must be sized for at least 125 % of the

motor nameplate full load amps. We recommend AWG #16

Type THW stranded wire for wiring of pilot devices, such as

float switches.

• Check that the voltage, phase and frequency of the incoming

power source correspond to the voltage, phase and frequency

of the motor(s).

• Make sure that the starters are suitable for operating the pump

motors on the voltage, phase and frequency available.

Explosive environment

Death or serious personal injury

- Observe the rules and regulations generally or

specifically imposed by the relevant responsible

authorities or trade organizations in relation to

running powered equipment in an explosive

environment.

English (US)

DANGER

Electric shock

Death or serious personal injury

- Before starting any work on the product, be sure

the power supply has been switched off and that it

cannot be accidentally switched on.

9

Page 10

English (US)

5. Starting up the product

5.3 Motor direction of rotation

5.1 Priming

• End suction pumps are non-self-priming, and must be

completely primed, i.e. filled with liquid, before starting.

• If the pump will be operated with a positive inlet pressure,

prime it by opening the inlet valve and allowing liquid to enter

the pump housing. Open the air vents at this time, and make

sure all air is forced out of pump by the liquid before closing

the air vents.

• Rotate the shaft by hand to free entrapped air from the

impeller passageways.

• If the pump will be operating with a suction lift, priming must

be accomplished by other methods. Use foot valves or

ejectors, or fill the pump housing and the inlet line manually

with liquid.

Never run the pump dry in the hope that it will prime

itself. The result will be serious damage to the shaft

seals, pump wear rings and shaft sleeves.

5.2 Pre-start checklist

WARNING

Product failure

Death or serious personal injury

- Do not operate the product above the nameplate

conditions.

Make the following inspections before starting your end suction

pump:

1. Make sure the inlet and outlet pipes have been cleaned and

flushed to remove dirt and debris.

2. Double check the direction of rotation is clockwise. Operating

in reverse will destroy the impeller and shaft.

3. Make sure all wiring connections to the motor and starting

device are in accordance with the wiring diagram.

4. If the motor has been in storage for a long time, either before

or after installation, refer to the motor instructions before

starting.

5. Check the voltage, phases, and frequency with the motor

nameplate. Turn the impeller by hand to make sure it rotates

freely.

6. Tighten the plugs in the gauge and drain holes. If the pump is

fitted with pressure gauges, keep the gauge cocks closed

when they are not in use.

7. Check the inlet and outlet pipes for leaks, and make sure all

flange bolts are securely tightened.

Never check the motor direction of rotation unless

the pump and motor couplings have been

disconnected and physically separated. Failure to

follow this instruction can result in serious damage

to the pump and the motor if the direction of rotation

is wrong.

5.4 Starting the pump

DANGER

Moving machine parts

Death or serious personal injury

- Mount an approved coupling guard before

operating the product.

1. Install the factory-provided coupling guard on coupled

products.

2. Fully open the gate valve (if any) in the inlet line, and close

the gate valve in the outlet line.

3. Fill the inlet line with liquid and completely prime the pump.

4. Start the pump.

5. Immediately make a visual check of the pump and inlet pipe

for pressure leaks.

6. Immediately after the pump has reached full operating speed,

slowly open the outlet gate valve until complete system flow is

achieved.

7. Check the outlet pipe for pressure leaks.

8. If the pump is fitted with pressure gauges, open gauge cocks

and record pressure readings for future reference. Verify that

the pump is performing in accordance with the parameters

specified in the performance curves.

9. Check and record voltage, amperage per phase, and

kilowatts, if a wattmeter is available.

5.5 Voltage a nd frequency variation

The motor will operate satisfactorily under the following voltage

and frequency variations, but not necessarily in accordance with

the standards established for operation under rated conditions:

• The voltage variation may not exceed 10 % above or below

the rating specified on the motor nameplate.

• The frequency variation may not exceed 5 % above or below

the motor rating.

• The sum of the voltage and frequency variations may not

exceed 10 % above or below the motor rating, provided the

frequency variation does not exceed 5 %.

6. Storing and handling the product

See sections 3.3 T emporary storage af ter delivery, 9.2 Short-term

shutdown and 9.3 Long-term shutdown.

10

Page 11

7. Product introduction

CAT#: 21-20709-133L01-25E1MS1

STOCK#: 91893522

SER#: 1971001000

GPM: 234

TDH: 88

MFD BY GRUNDFOS CBS INC 34014412

IMP

DIA

5.11

:

This data booklet describes:

• LFE end-suction, frame-mounted pumps with integrated VFD

• LCSE end-suction, close-coupled, split-coupling pumps with

integrated VFD.

7.1 Applications

We recommend the integrated VFD end suction pumps for these

applications:

• commercial and industrial cooling systems

– pumping both primary and secondary cooling water

• condenser water systems

• district cooling systems

• water distribution systems

• irrigation systems.

7.2 Pumped liquids

Clean, thin, non-aggressive liquids, not containing solid particles

or fibers. Do not pump liquids that will attack the pump materials

chemically.

7.3 Pump identification

Pumps are identified by catalog and serial numbers (LFE

nameplate shown in fig. 6). These numbers are stamped on the

pump nameplate as shown in fig. 6, affixed to each pump volute

casing, and should be referred to in all correspondence with

Grundfos.

Fig. 6 Nameplate

8. Servicing the product

8.1 Maintaining the product

WARNING

Moving machine parts

Death or serious personal injury

- Before any inspection, maintenance, service or

repair of the product, make sure the motor controls

are in the "OFF" position, locked and tagged.

8.2 Lubricating the product

8.2.1 Lubricating the motor

Always follow the motor manufacturer's lubricating instructions, if

they are available, and periodically check grease fittings and

drain plugs for leaks. Use the standard lubrication interval. See

the installation and operating instructions or the lubrication plate

on the E-motor. If the lubricating instructions are not available,

refer to the table below for recommended lubricating intervals.

Recommended lubricating intervals

Motor rpm Motor hp Operating conditions

Standard Severe Extreme

1750

and below

above 1750 all hp 6 mo 3 mo 3 mo

Standard conditi ons:

Operating 8 hours per day operation, normal or light load, clean

air, 100 °F (37 °C), maximum ambient temperature.

Severe conditions:

Operating continuously 24 hours, shock loads or vibrations,

poor ventilation, 100-150 °F (37-65 °C), ambient temperature.

Extreme conditions:

Continuous operation, heavy shocks or vibrations, dirt or dust in

the air, extremely high ambient temperature.

TM 06 1036 1414

3.00-7.50 3 yrs 1 yr 6 mo

10-30 1-3 yrs 6 mo-1 yr 3 mo

English (US)

11

Page 12

English (US)

8.2.2 Lubricating the pump

Grease lubrication

In the standard configuration, LFE pumps with horizontal bearing

frames have sealed-for-life bearings (requiring no lubrication).

For customized pumps with regreasable bearings, use an

approved grease and proceed as described below.

Approved grease lubricants

Manufacturer Lubricant

Shell Dolium

Exxon Polyrex

Chevron

SRI GreaseNLGI 2

Black Pearl - NLGI 2

p

R

p

Philips Polytacറ

Texaco Polystar RB

• Remove the drain plug, if any, and the filler plug. Add clean

lubricant until grease appears at the drain hole or along the

pump shaft. On pumps with drain hole, all old grease can be

purged. In such cases, the drain hole must be left unplugged

for several minutes during pump operation to allow excess

grease to be forced out.

• Lubricate the pump bearings at 1-3 month intervals,

depending on the severity of the environment. Pumps in a

clean, dry, moderate temperature (100 °F (37 °C) maximum)

environment must be regreased at 3-month intervals.

Do not over-grease! Too much grease can cause

overheating and premature bearing failure.

Oil lubrication

LFE pumps with oil lubricated bearings are fitted with a

transparent reservoir, a constant-level oiler, that maintains the oil

level about the centerline of the bearing. See fig. 7.

• Follow a regular maintenance program. When necessary,

renew the oil supply in the reservoir of the constant-level oiler.

• Change the oil after the first 200 hours of operation. To change

the oil, remove the drain plug at the bottom of the bearing

cover and the filler plug, that also acts as a vent plug, at the

top of the bearing frame. After draining the oil, replace the

fittings and refill the reservoir with an acceptable oil from the

table List of acceptable oil lubricants on page 12. After the first

oil change, the oil must be changed again at 2000 hours and

then at intervals of 8000 hours or once a year, thereafter.

Oil level

Fig. 7 Oil lubrication

List of acceptable oil lubricants

Lubricant manufacturer Bearing oil brand name

Aral Refining Co.

British Petroleum Co.

Calypsol Oil Co.

Aral Oil CMU

Aral Oil TU 518

BP Energol

TH 100-HB

Calypsol Bison Oil

SR 25 or SR 36

Chevron

Standard Oil Co.

Hydraulic Oil 11

Circulating oil 45

Esso-Mar 25

Esso Corp

Teresso 47

Esstic 50

Fina Oil Co.

Gulf Refining Co.

Socony Mobil Oil Co.

Fina hydran 34

Fina Cirkan 32

Gulf Harmony 47

Gulf Paramount 45

Vac hlp 25

Mobulix D.T.E. 25

Shell Oil Co. Shell Tellus oil 29

Sundco Oil Co. Sunvis 821

The Texas Co.

Texaco ursa oil P 20

Dea viscobil sera 4

TM06 1089 1614

12

Page 13

8.3 Disassembling the pump

8.3.1 Preparations before disassembling the pump

DANGER

Electric shock

Death or serious personal injury

- Before starting any work on the product, be sure

the power supply has been switched off and that it

cannot be accidentally switched on.

CAUTION

Toxic material

Minor or moderate personal injury.

- Wash down the pump before doing any work on it.

DANGER

Hot, caustic, flammable or toxic materials,

including vapors

Death or serious personal injury

- Be extremely cautious when venting and/or

draining hazardous liquids.

- Wear protective clothing when there are caustic,

corrosive, volatile, flammable, or hot liquids.

- DO NOT breathe toxic vapors.

- DO NOT allow sparks, open fire, or hot surfaces

near the equipment.

Complete disassembly instructions are outlined below. Proceed

only as far as required to perform the maintenance work needed.

1. Switch off the power supply.

2. Drain the system.

3. Flush the system, if necessary.

4. For closed coupled units: Remove the motor fixation bolts.

8.3.2 Disassembling the liquid end

1. Remove the pump housing screws (8B).

2. Remove the back pull-out bearing frame (20Y) from the pump

housing (1A).

3. Remove the impeller screw (8A).If necessary, use a strap

wrench around the impeller or shaft to prevent rotation.

8.3.3 Disassembling the bearing frame (LFE)

1. Remove the slinger (13G).

2. Remove the lip seal(s) (14S), if any.

3. Remove the bearing housing locking ring (61K).

4. Press or tap on the pump end of the bearing-shaft assembly

until one bearing is out.

5. When one bearing is out, remove the second locking ring

(61F), then remove the complete bearing-shaft assembly from

the bearing housing.

6. Remove the shaft locking ring (61C) and press off the

bearings.

7. Press new bearings onto the shaft; remember to press only on

the inner race of the bearings while pressing them on.

8. Assemble the bearing frame in the reverse procedure used for

disassembling.

9. Observe the following when reassembling the bearing frame.

– Replace the lip seals (14S) if they are worn or damaged.

– Replace the bearings (18A) and (18B) if they are loose,

rough or noisy when rotated.

– Check the shaft (6A) for shaft runout at the sleeve (5A) area.

Maximum permissible runout is 0.002 in. (0.0508 mm) total

indicator runout.

English (US)

WARNING

Moving machine parts

Death or serious personal injury

- Do not insert a screwdriver between the impeller

vanes to prevent rotation.

4. Use an appropriately sized puller aligned behind the impeller

vanes to remove the impeller (3A) from the shaft (6A).

5. Remove the impeller key (12A).

6. Remove the back plate screws (8D). Remove the back plate

(2K) and the seal housing (26P).

7. Place the seal housing on a flat surface and press out the

shaft seal (14A).

8. If the shaft sleeve (5A) requires replacement, heat it evenly to

approximately 350 °F (176 °C) to loosen the thread-locking

fluid. Twist the sleeve off the shaft (6A).

13

Page 14

English (US)

8.4 Replacing the shaft seal (LCSE pumps)

1. Complete preparations listed in section 8.3 Disassembling the

pump.

2. Remove the coupling guard screws (8E).

3. Remove the coupling guard (34F).

4. Remove the nut (35E) and the bolt (8E) that hold the coupling

halves together.

5. Pry apart the coupling halves (23D), remove the coupling key

(12B).

Mark or measure the original position of the pump

coupling on the motor side.

6. For pumps with lubrication lines, unscrew the tubing

connector from the pipe tee of the air vent assembly. Thread

sealing compound was applied to the threads during factory

assembly, and the resulting bond may retard but will not

prevent manual disassembling.

7. Remove the seal housing cap screws and slide the seal

housing (2N) up the shaft to remove it.

8. Remove the shaft seal (14A) manually from the shaft (6A).

Apply water-soluble lubricant to the shaft, if necessary, to

ease the removal of the shaft seal. Pull the seal head

assembly manually from the shaft, using a slight twisting

motion (as necessary) to loosen bellows from shaft.

9. Remove and discard the shaft seal spring and the shaft seal

retainer.

10. Remove and discard the shaft seal seat from the seal housing

(2N) and thoroughly clean the inside cavity of the seal

housing.

11. The interior surface of the bellows on a new shaft seal is

coated with a bonding agent that adheres to the motor shaft.

When the old shaft seal is removed, the bonding agent no

longer exists and the bellows may crack or split during

removal. We always recommend that you install a new

mechanical shaft seal if it becomes necessary to remove the

existing shaft seal from the shaft.

12. Clean and lubricate the shaft (6A) with a water-soluble

lubricant and make sure no sharp edges can cut or scratch

the bellows of the new shaft seal.

13. Press the new shaft seal seat firmly into the seal housing.

Avoid direct contact between the seal face and metallic or

abrasive objects, and wipe the seal face clean after

installation to ensure an abrasive-free sealing surface.

14. Slide the new shaft seal (14A) onto the shaft by applying even

pressure to the shaft seal.

15. Install the shaft seal housing (2N) on the shaft.

16. See the reassembly instructions in section 8.6 Reassembling

the pump.

8.5 Replacing the wear ring

1. Complete preparations in sections 8.3.1 Preparations before

disassembling the pump and 8.3.2 Disassembling the liquid

end.

2. Remove the rotating assembly.

3. Remove the pump housing (1A) from the pipes, if necessary,

to facilitate easy access to the interior of the pump housing. If

necessary, remove the flange bolts at the pipes.

4. Remove a worn wear ring (4A) by drilling two holes slightly

smaller than the width of the wear ring into the exposed edge

of the wear ring. Insert a chisel into the holes to completely

sever the wear ring at the holes and break the wear ring into

two halves for easy removal.

5. Clean the wear ring cavity in the pump housing prior to

installing a new wear ring to ensure a properly aligned fit.

6. To reassemble, press fit the new wear ring squarely into the

pump housing cavity. Tap the wear ring into place to make

sure it is pressed home into the cavity.

Do not use metal tools on the wear ring surfaces.

Use only rubber, rawhide, wood or other soft

material to prevent damage to the wear ring.

8.6 Reassembling the pump

WARNING

Moving machine parts

Death or serious personal injury

- Reinstall approved coupling guards and make sure

they are in place prior to operation.

1. Clean all parts before reassembly.

2. Refer to the parts list to identify required replacement items.

3. Specify the pump serial or catalog number when ordering

parts.

4. Reassemble the pump in the reverse procedure used for

disassembling.

5. Observe the following when reassembling the pump:

– All mechanical seal components must be in good condition

or leakage may result. We recommend that you replace the

complete shaft seal.

– Install new shaft sleeves by bonding them to the shaft with a

thread-locking fluid.

6. Re-install the coupling guards on coupled pumps.

14

Page 15

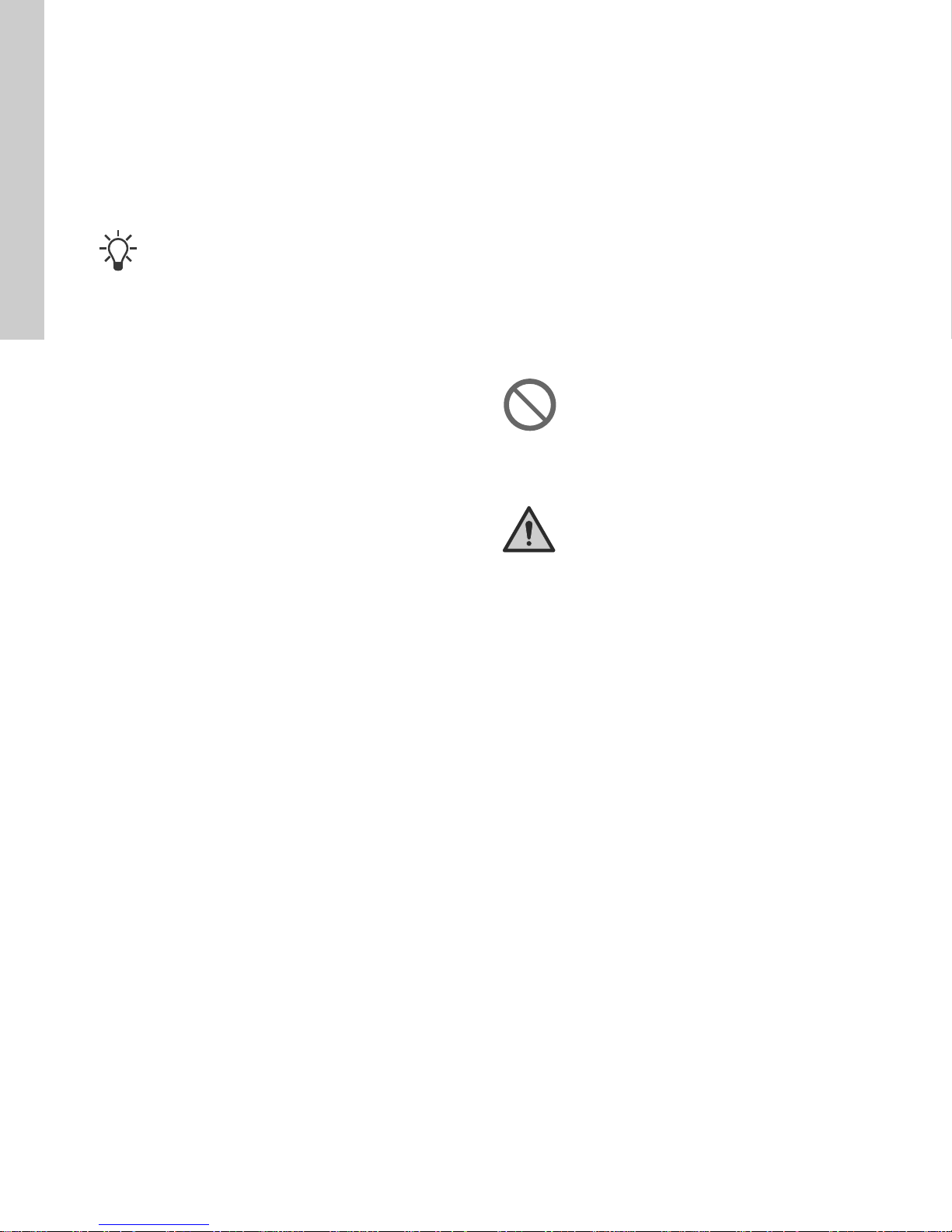

8.7 LFE, exploded view and parts list

English (US)

TM06 6570 1816

Pos. Description Pos. Description Pos. Description

1A Pump housing 11F Gasket 20A Base plate

2K Backplate 12A Key 20Y Bearing frame

3A Impeller 12B Key 23A Coupling hub

4A Wear ring 13G Slinger 26P Seal housing

4F* Balance wear ring 14A Shaft seal 34A Coupling guard

5A Shaft sleeve 14S Lip seal 61C Locking ring

6A Shaft 16A Drain plug 61F Locking ring

8D Cap screw 18A Bearing, inboard 61K Locking ring

10A Washer 18B Bearing, outboard 65A Motor

11A Ga ske t

* If applicable

15

Page 16

English (US)

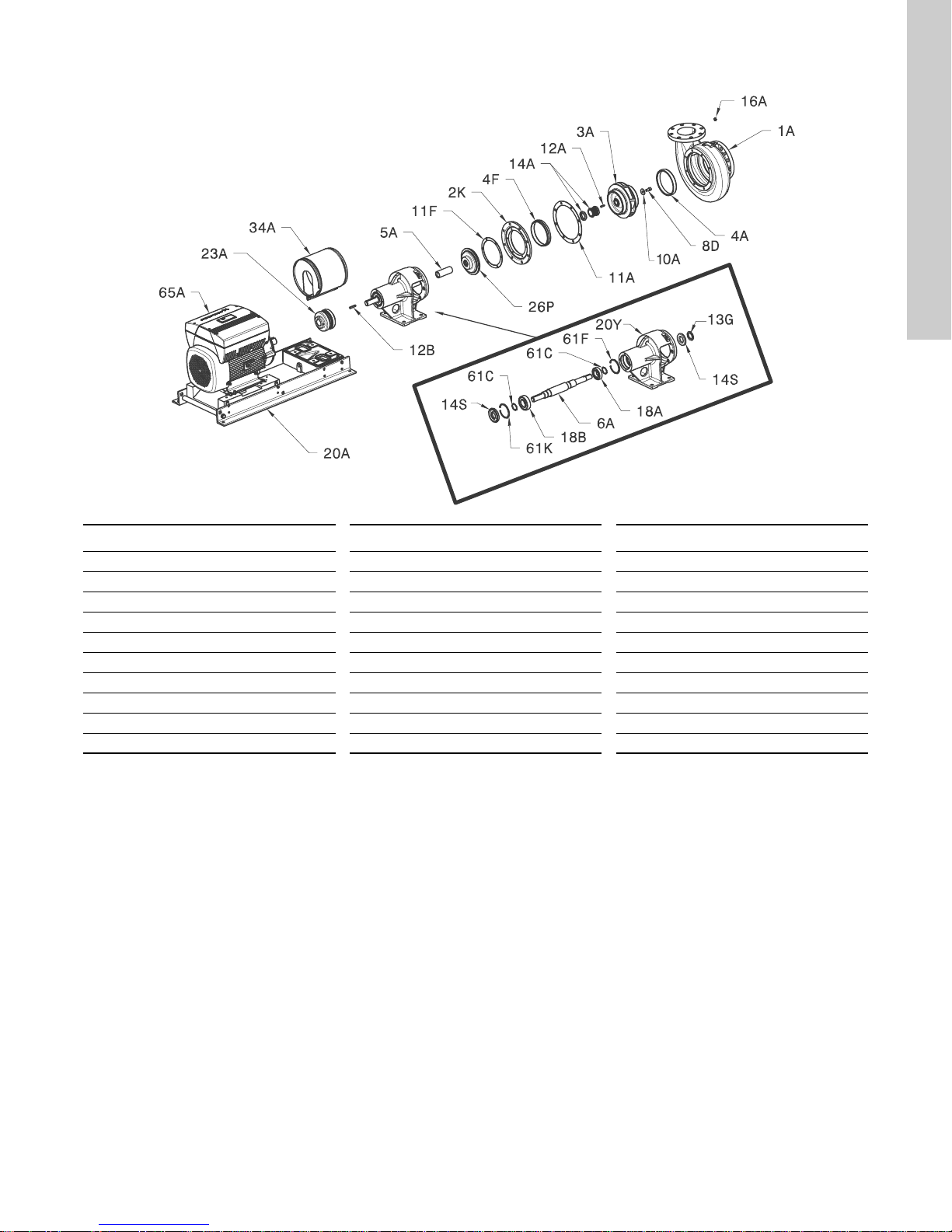

8.8 LCSE, exploded view and parts list

Pos. Description Pos. Description

1A Pump housing 15A Locating ring

2N Shaft seal housing 16A Drain plug

3A Impeller 17E O-ring

4A Wear ring 20A+20B Base plate rails

4F Balance wear ring 20C Base plate

6A Pump shaft 20D Pump support

8B Cap screw 21A Motor stool

8C Screw 22A Stud

8D Screw 23D Coupling halves

8E Bolt 24H Bushing

8F Screw 34A Washer

8G Screw 34B Washer

8H Cap screw 34C Washer

8I Cap screw 34D Washer

8J Screw 34E Washer

8N Screw 34F Coupling guard

11A Ga ske t 35 E Nu t

12A Key 35F Nut

12B Key 65A Motor

14A Shaft seal

TM06 4401 2215

16

Page 17

9. Taking the product out of operation

The following shutdown procedures will apply for the L pumps in

most normal shutdown situations. If the pump will be inoperative

for a long time, follow the storage procedures in section 9.3 Long-

term shutdown.

9.1 General procedure

• Always close the outlet gate valve before stopping the pump.

Close the valve slowly to prevent hydraulic shock.

• Disconnect and lock off the power to the motor.

9.2 Short-term shutdown

• For overnight or temporary shutdown periods under nonfreezing conditions, the pump may remain filled with liquid.

Make sure the pump is fully primed before restarting.

• For short or frequent shutdown periods under freezing

conditions, keep the liquid moving within the pump housing

and insulate or heat the pump exterior to prevent freezing.

9.3 Long-term shutdown

• For long shutdown periods, or to isolate the pump for

maintenance, close the inlet gate valve. If no inlet valve is

used and the pump has positive inlet pressure, drain all liquid

from the inlet line to stop the liquid flow into the pump inlet.

Remove the plugs in the pump drain and vent holes, as

required, and drain all liquid from the pump housing.

• If there will be freezing conditions during long shutdown

periods, completely drain the pump and blow out all liquid

passages and pockets with compressed air. Freezing of the

pumped liquid can also be prevented by filling the pump with

antifreeze solution.

English (US)

17

Page 18

English (US)

10. Fault finding

DANGER

Electric shock

Death or serious personal injury

- Before starting any work on the product, be sure

the power supply has been switched off and that it

cannot be accidentally switched on.

CAUTION

Toxic material

Minor or moderate personal injury.

- Wash down the pump before doing any work on it.

Fault Cause Remedy

1. Outlet pressure is too low. a) The speed of rotation is too low. Reestablish correct speed and direction of

b) The system pressure is lower than

anticipated.

c) There is air or gas in the pumped liquid. Remove the air from the pumped liquid.

d) The wear rings are worn. Replace the wear rings.

e) The impeller is damaged. Repair or replace the impeller.

f) The impeller diameter is too small. Replace the impeller with one of the correct

g) Wrong direction of rotation. Interchange two wires in the power supply.

h) The pump has lost its prime. Re-prime the pump.

i) There is insufficient NPSH. Restore required NPSH.

j) Passages are restricted. Clean the impeller and pump housing

k) Joints or the stuffing box are leaking. • Tighten the joints or the stuffing box gland.

2. Insufficient inlet pressure. a) The inlet line is drawing air. Tighten the connections.

b) The suction lift is too high or there is

insufficient NPSH.

c) Air or gas is trapped in the pumped liquid. Remove the trapped air/gas from liquid.

d) The strainer is clogged. Clean the strainer.

3. Noise level has increased. a) Poor alignment of the pump.

Inlet and outlet pipe clamps are loose.

b) Cracked foundation. Repair the foundation.

c) Worn ball bearings. • Replace the worn bearings.

d) The motor is unbalanced. • Disconnect the motor and operate it alone.

e) Hydraulic resonance. • Alter the resonant pipes.

DANGER

Hot, caustic, flammable or toxic materials,

including vapors

Death or serious personal injury

- Be extremely cautious when venting and/or

draining hazardous liquids.

- Wear protective clothing when there are caustic,

corrosive, volatile, flammable, or hot liquids.

- DO NOT breathe toxic vapors.

- DO NOT allow sparks, open fire, or hot surfaces

near the equipment.

rotation.

Check the system curve.

diameter.

passages.

• Replace the shaft sleeve.

• Replace the gaskets.

Reduce the suction lift or restore required

NPSH.

• Ensure proper alignment of the pump and

the motor.

• Support the inlet and outlet pipes.

• Make sure the vibration dampers, flexible

pipes, and conduit connectors are installed

correctly.

• Renew the lubrication.

• Remove large pieces of debris, such as

wood or rags from the pump.

• Clean out the pump, if necessary.

• Change the pump speed.

• Insert a pulsation damper on the pump or the

pipes.

• Insert a flow straightener.

18

Page 19

Fault Cause Remedy

4. Insufficient flow. a) The pump is not primed. Prime the pump.

b) The system pressure exceeds the shut off

pressure.

c) The rotation speed is too low. Reestablish the correct speed of rotation.

d) The suction lift is too high or there is

insufficient NPSH.

e) The strainer or impeller is clogged. Clean the strainer and impeller passages.

f) Wrong direction of rotation. Reestablish the correct direction of rotation.

g) Leaking joints. Tighten the joints.

h) Broken shafting or coupling. Repair or replace damaged parts.

i) Closed inlet valve. If the inlet valve is closed, open it slowly.

j) There is not enough inlet pressure for hot

or volatile liquids.

k) Foot valve is too small. Replace the foot valve.

l) Worn or damaged hydraulic parts. Repair or replace the worn parts.

m) Excessive clearance between the wear

surfaces.

5. Pump loses its prime after

starting.

6. Excessive power required. a) The speed of rotation is too high. Reduce the speed of rotation.

a) Joints or the stuffing box are leaking. • Tighten the joints or the stuffing box gland.

b) The suction lift is too high or there is

insufficient NPSH.

b) The pump is operating beyond its

recommended performance range.

c) The specific gravity or the viscosity of the

pumped liquid is too high.

d) The shaft is bent. Replace the shaft.

e) Stuffing-boxes too tight. Retighten the stuffing box if possible.

f) Impeller clearances are too small causing

rubbing or worn wear surfaces.

g) There is an electrical or mechanical defect

in the motor.

h) The pump is restricted in its rotation. Remove any obstacles or replace any worn

i) Incorrect lubrication of the motor. Reestablish correct lubrication of the motor.

• Increase the liquid level on the inlet side.

• Open the isolating valve in the inlet pipe.

Reduce the suction lift or restore required

NPSH.

Reestablish required inlet pressure.

See section 8.5 Replacing the wear ring.

• Replace the shaft sleeve.

• Replace the gaskets.

Reduce the suction lift or restore required

NPSH.

Set the duty point in accordance with the

recommended performance range.

If less flow is sufficient, reduce the flow on the

outlet side, or fit the pump with a more powerful

motor.

Alternatively, repair or replace the stuffing box.

Adjust the impeller clearance, if possible, or

replace the wear ring.

Contact your local service center for

diagnostics.

parts.

English (US)

19

Page 20

English (US)

11. PACO MLE motors

Grundfos E-pumps have standard motors with integrated variable

frequency drive. The pumps are for a single-phase or three-phase

power supply connection.

12. Installing the motor

The pump must be secured to a firm, raised concrete foundation

by means of bolts through the holes in the flange or baseplate.

11.1 Pumps without factory-fitted sensor

The pumps have a built-in PI controller and can be set up for an

external sensor enabling control of the following parameters:

• pressure

• differential pressure

• temperature

• differential temperature

•flow rate

• liquid level in a tank.

From the factory, the pumps have been set to control mode

uncontrolled. The PI controller can be activated by means of the

Grundfos GO Remote or R100.

11.2 Pumps with pressure sensor

The pumps have a built-in PI controller and are set up with a

pressure sensor enabling control of the pump outlet pressure.

The pumps are set to control mode controlled. The pumps are

typically used to hold a constant pressure in variable-demand

systems or differential pressure in closed-loop applications.

11.3 Settings

The description of settings apply both to pumps without factoryfitted sensor and to pumps with a factory-fitted pressure sensor.

Setpoint

The desired setpoint can be set in three different ways:

• directly on the pump control panel

• via an input for external setpoint signal

• by means of the Grundfos GO remote or wireless remote

control.

Other settings

All other settings can only be made by means of the Grundfos GO

Remote or R100.

Important parameters such as actual value of control parameter,

power consumption, etc. can be read via the Grundfos GO

remote or R100.

If special or customized settings are required, use Grundfos PC

Tool E-products. Contact Grundfos for more information.

In order to retain the UL/cUL approval, follow the

additional installation procedures on page 54.

12.1 Motor cooling

To ensure sufficient cooling of motor and electronics, observe the

following requirements:

• Make sure that sufficient cooling air is available.

• Keep the temperature of the cooling air below 104 °F (40 °C).

• Keep cooling fins and fan blades clean.

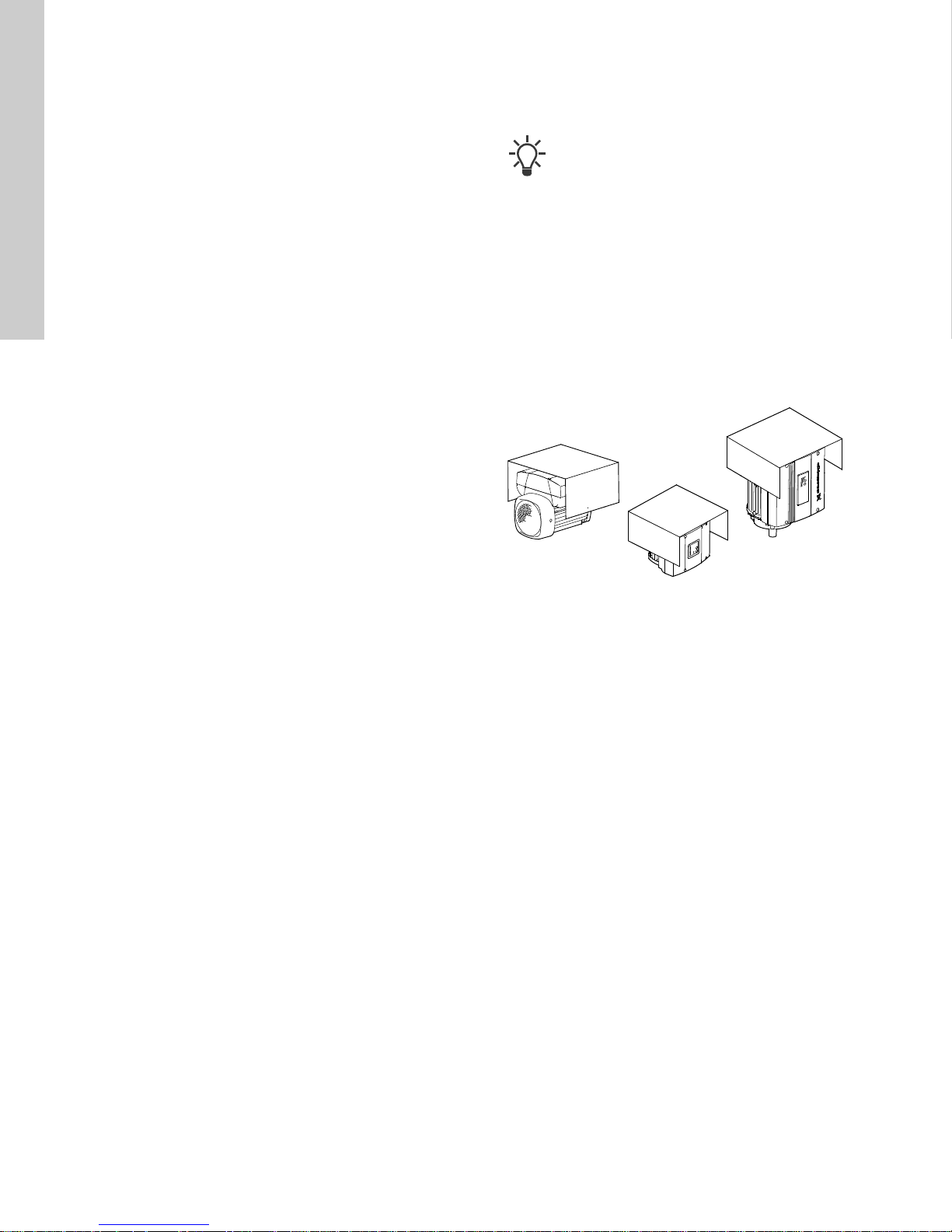

12.2 Outdoor installation

When installed outdoors, the pump must be provided with a

suitable cover to avoid condensation on the electronic

components. See fig. 8.

TM00 8622 0101 - TM02 8514 0304

Fig. 8 Examples of covers

Remove the drain plug pointing downwards in order to avoid

moisture and water build-up inside the motor.

Vertically mounted pumps are IP55 after removal of the drain

plug. Horizontally mounted pumps change enclosure class to

IP54.

20

Page 21

13. Electrical connection

L1

L2

L3

L2

L1

L3

PE

For description of how to connect E-pumps electrically, see the

following sections:

13.1 Three-phase pumps, 3-10 hp.

13.2 Three-phase pumps, 15-30 hp.

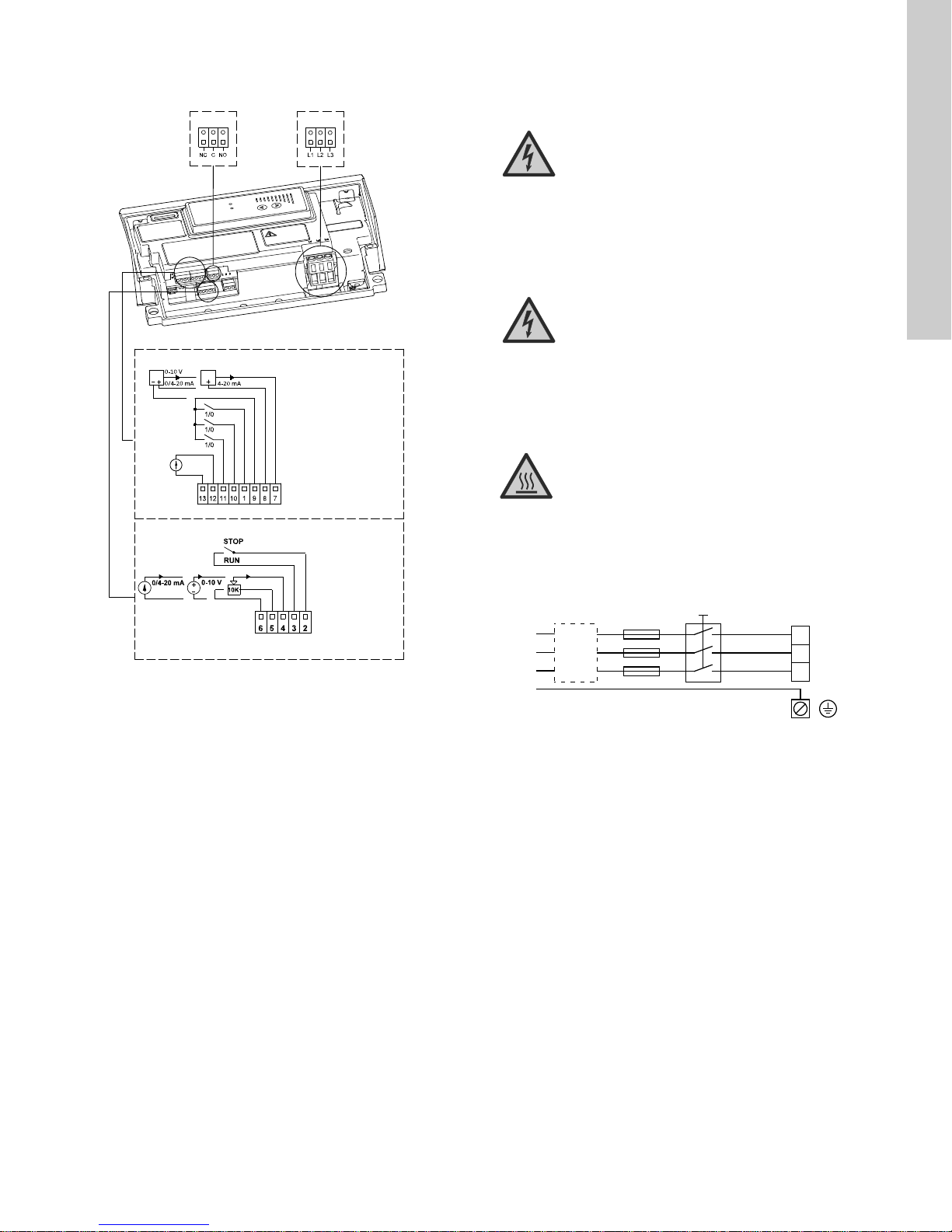

13.1 Three-phase pumps, 3-10 hp

DANGER

Electric shock

Death or serious personal injury

- The user or the installer is responsible for the

installation of correct grounding and protection

according to current national and local standards.

- All operations must be carried out by qualified

personnel.

DANGER

Electric shock

Death or serious personal injury

- Disconnect all electric supply circuits and ensure

these have been switched off for at least 5 minutes

before making any connections in the pump

terminal box. For instance, the signal relay may be

connected to an external supply which is still

connected when the power supply is

disconnected.

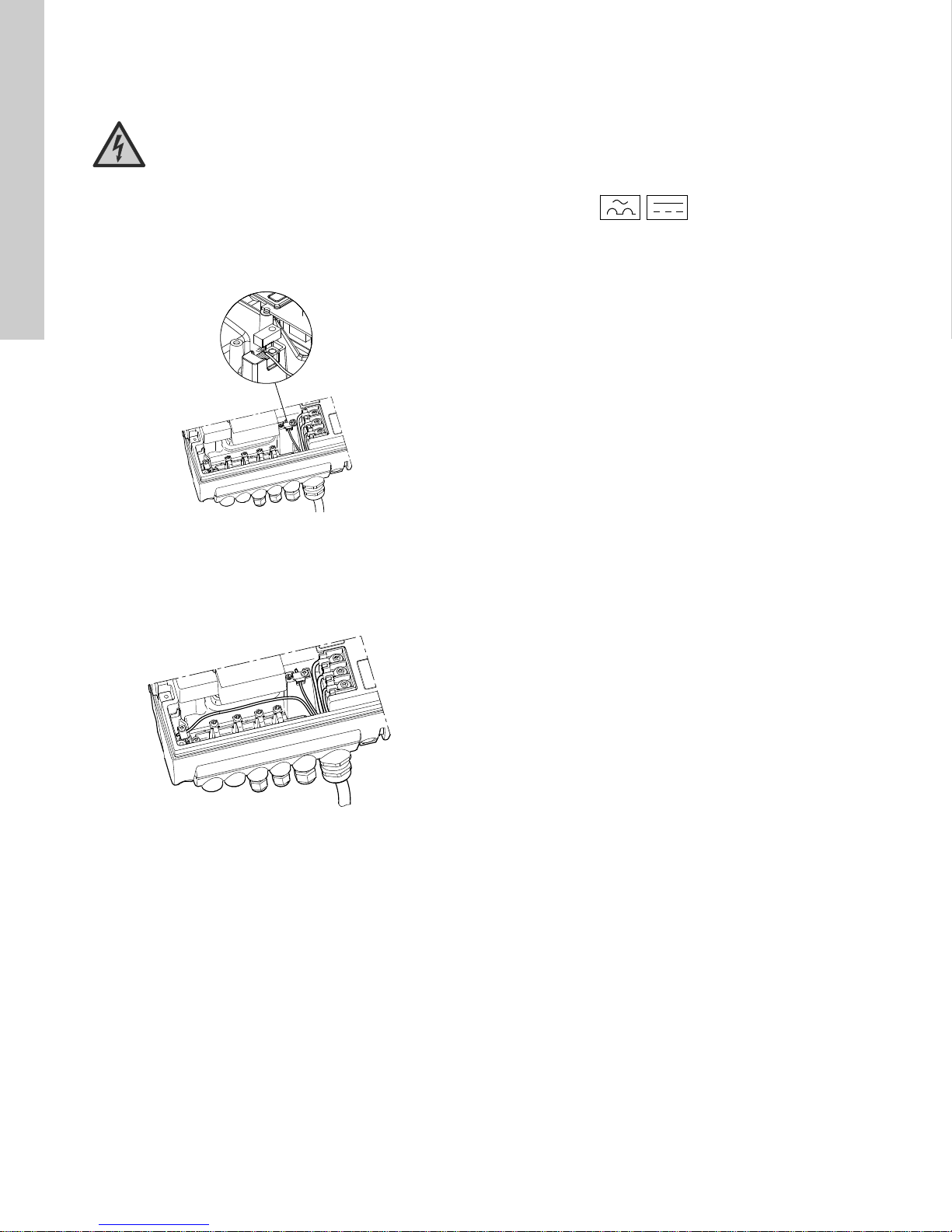

The above warning is indicated on the motor

terminal box by this yellow label:

13.1.1 Preparation

Before connecting the E-pump to the power supply, take the

issues illustrated in the figure below into consideration.

ELCB

Fig. 9 Power supply-connected pump with power switch,

backup fuses, additional protection and protective

grounding

13.1.2 Protection against electric shock - indirect contact

DANGER

Electric shock

Death or serious personal injury

- Ensure the pump is grounded in accordance with

national regulations. As the leakage current of 510 hp (4-7.5 kW) motors is > 3.5 mA, take extra

precautions when grounding these motors.

EN 50178 and BS 7671 specify the following precautions when

leakage current > 3.5 mA:

• Install the pump in a stationary, permanent position.

• Connect the pump permanently to the power supply.

• Carry out the grounding connection as duplicate leads.

Mark the protective ground leads with a yellow/green (PE) or

yellow/green/blue (PEN) color marking.

13.1.3 Backup fuses

For recommended fuse sizes, see section 28.1.1 Supply voltage.

13.1.4 Additional protection

If the pump is connected to an electric installation where an

ground leakage circuit breaker (ELCB) is used as additional

protection, use a circuit breaker of a type marked with the

following symbols:

ELCB

This circuit breaker is type B.

Take into account the total leakage current of all the electrical

equipment in the installation.

Check the leakage current of the motor in normal operation; see

section 28.1.3 Leakage current.

During start and at asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

13.1.5 Motor protection

The pump requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking (IEC 34-11, TP 211).

13.1.6 Protection against voltage transients

TM00 9270 4696

The pump is protected against voltage transients by built-in

varistors between the phases and between phases and ground.

English (US)

21

Page 22

English (US)

L1

L2

L3

L1

L2

L3

13.1.7 Supply voltage and power supply

3 x 440-480 V - 10 %/+ 10 %, 60 Hz, PE.

3 x 208-230 V - 10 %/+ 10 %, 60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Make sure that the pump is suitable for the power

supply of the installation site.

The wires in the terminal box must be as short as possible.

Excepted from this is the protective ground lead which must be

long enough that it is the last one to be disconnected in case the

cable is inadvertently pulled out of the cable entry.

Fig. 10 Power connection

Cable glands

Cable glands comply with EN 50626.

• 2 x M16 cable gland

• 1 x M20 cable gland

• 2 x M16 knock-out cable entries.

DANGER

Electric shock, malfunction or damage

Death or serious personal injury; product damage or

failure

- Replace power supply cable immediately if

damaged. Only qualified personnel must replace

it.

Grid types

Three-phase E-pumps can be connected to all grid types.

DANGER

Electric shock

Death or serious personal injury; product damage or

failure

- Do not connect three-phase E-pumps to a power

supply with a voltage between phase and ground

of more than 440 V.

13.1.8 Start/stop of pump

The number of starts and stops via the power supply

must not exceed 4 times per hour.

When the pump is switched on via the power supply, it will start

after approximately 5 seconds.

If a higher number of starts and stops is desired, use the input for

external start/stop when starting/stopping the pump.

When the pump is switched on via an external On/Off switch, it

will start immediately.

Automatic restart

If a pump set up for automatic restart is stopped due

to a fault, it will restart automatically when the fault

has disappeared.

However, automatic restart only applies to fault types set up to

automatic restart. These faults could typically be one of these

faults:

• temporary overload

• fault in the power supply.

13.1.9 Connections

If no external On/Off switch is connected, connect

terminals 2 and 3 using a short wire.

TM03 8600 2007

As a precaution, the wires to be connected to the following

connection groups must be separated from each other by

reinforced insulation in their entire lengths:

Group 1: Inputs

• start/stop terminals 2 and 3

• digital input terminals 1 and 9

• setpoint input terminals 4, 5 and 6

• sensor input terminals 7 and 8

• GENIbus terminals B, Y and A

All inputs (group 1) are internally separated from the power-

conducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied with protective extra-low voltage

(PELV), thus ensuring protection against electric shock.

Group 2: Output (relay signal, terminals NC, C, NO)

The output (group 2) is galvanically separated from other circuits.

Therefore, the supply voltage or protective extra-low voltage can

be connected to the output as desired.

22

Page 23

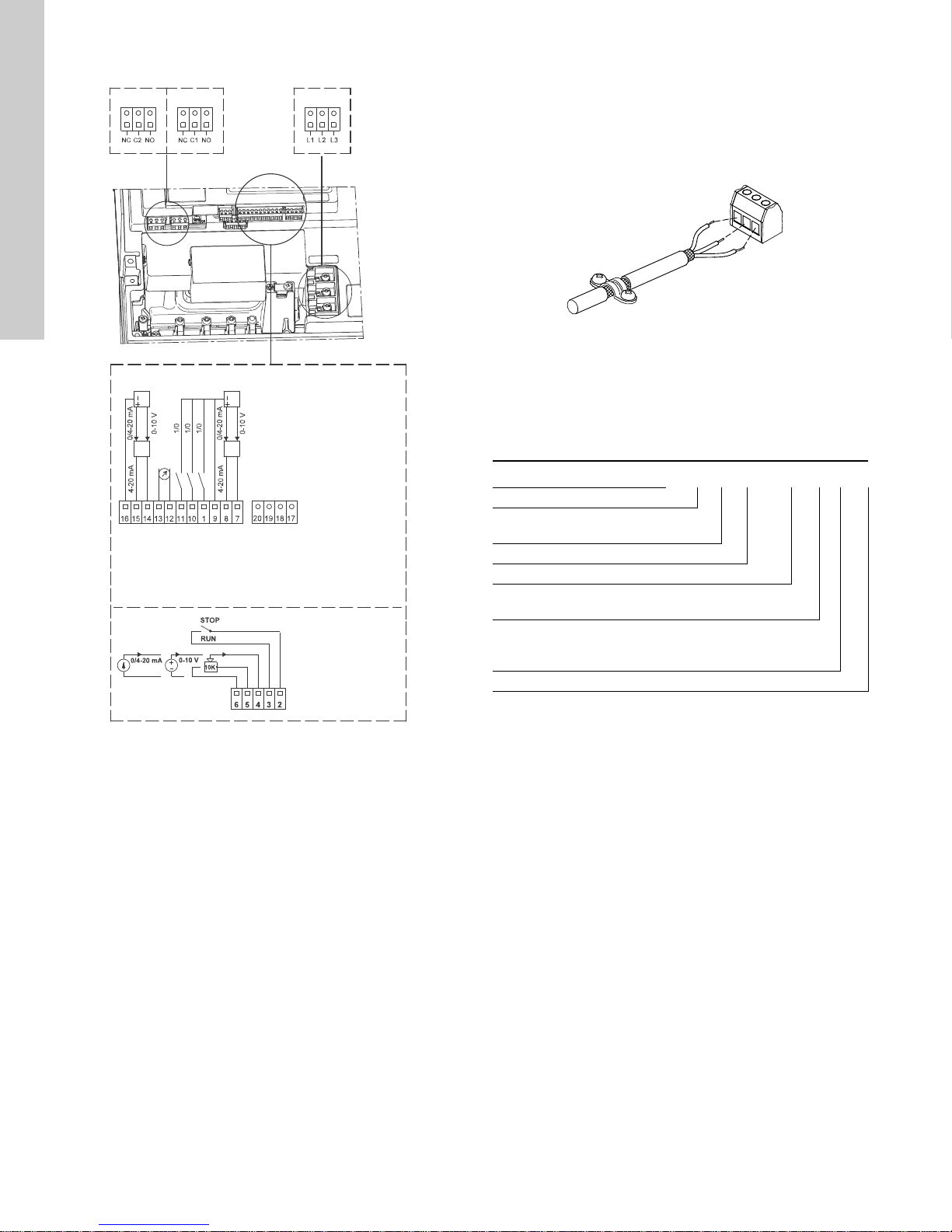

13.1.10 Three-phase pumps, 3-10 hp

L1

L2

L3

L2

L1

L3

PE

Group 3: Power supply (terminals L1, L2, L3)

Group 2

13: GND (frame)

12: Analog output

11: Digital input 4

10: Digital input 3

1: Digital input 2

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

13.2 Three-phase pumps, 15-30 hp

DANGER

Group 3

Electric shock

Death or serious personal injury

- The user or the installer is responsible for the

installation of correct grounding and protection

according to current national and local standards.

- All operations must be carried out by qualified

personnel.

English (US)

DANGER

Electric shock

Death or serious personal injury

- Disconnect all electric supply circuits and ensure

these have been switched off for at least 5 minutes

before making any connections in the pump

terminal box. For instance, the signal relay may be

connected to an external supply which is still

connected when the power supply is

disconnected.

CAUTION

Hot surface

Group 1

13.2.1 Preparation

Before connecting the E-pump to the power supply, take the

issues illustrated in the figure below into consideration.

Minor or moderate personal injury

- Wear hand protection and use care when handling

terminal box when product is operating. The

surface of the terminal box may be above 158 °F

(70 °C) when the pump is operating.

Fig. 11 Connection terminals

A galvanic separation must fulfill the requirements for reinforced

insulation including creepage distances and clearances specified

in EN 60335.

TM05 2985 0812

ELCB

TM00 9270 4696

Fig. 12 Power supply-connected pump with power switch,

backup fuses, additional protection and protective

grounding

23

Page 24

English (US)

13.2.2 Protection against electric shock - indirect contact

DANGER

Electric shock

Death or serious personal injury

- Ensure the pump is grounded in accordance with

national regulations. As the leakage current of 510 hp (4-7.5 kW) motors is > 3.5 mA, take extra

precautions when grounding these motors.

EN 61800-5-1 specifies that the pump must be stationary and

installed permanently when the leakage current is > 10 mA.

One of the following requirements must be fulfilled:

• A single protective ground lead (7 AWG minimum copper)

Fig. 13 Connection of a single protective ground lead using

one of the leads of a 4-core power cable (7 AWG

minimum)

• Two protective ground leads of the same cross-sectional area

as the power supply leads, with one lead connected to an

additional ground terminal in the terminal box.

13.2.3 Backup fuses

For recommended fuse sizes, see section 28.2.1 Supply voltage.

13.2.4 Additional protection

If the pump is connected to an electric installation where an

ground leakage circuit breaker (ELCB) is used as additional

protection, use a circuit breaker of a type marked with the

following symbols:

ELCB

This circuit breaker is type B.

Take into account the total leakage current of all the electrical

equipment in the installation.

Check the leakage current of the motor in normal operation. See

section 28.2.3 Leakage current.

During start and at asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

13.2.5 Motor protection

The pump requires no external motor protection. The motor

incorporates thermal protection against slow overloading and

blocking (IEC 34-11, TP 211).

13.2.6 Protection against voltage transients

The pump is protected against voltage transients in accordance

with EN 61800-3 and is capable of withstanding a VDE 0160

pulse.

TM04 3021 3508TM03 8606 2007

The pump has a replaceable varistor which is part of the transient

protection.

Over time this varistor will become worn and will need to be

replaced. When the time comes for replacement, Grundfos GO,

R100 and PC Tool E-products will indicate this as a warning. See

section 27. Maintaining and servicing the motor.

Fig. 14 Connection of two protective ground leads using two of

the leads of a 5-core power supply cable

Protective ground leads must always have a yellow/green (PE) or

yellow/green/blue (PEN) color marking.

24

Page 25

13.2.7 Supply voltage

3 x 440-480 V - 10 %/+ 10 %, 60 Hz, PE.

The supply voltage and frequency are marked on the pump

nameplate. Make sure that the motor is suitable for the power

supply of the installation site.

The wires in the terminal box must be as short as possible.

Excepted from this is the protective ground lead which must be so

long that it is the last one to be disconnected in case the cable is

inadvertently pulled out of the cable entry.

Torques, terminals L1-L3:

Min. torque: 1.6 ft-lbs (2.2 Nm)

Max. torque: 1.8 ft-lbs (2.4 Nm)

Fig. 15 Power connection

Cable glands

Cable glands comply with EN 50626.

• 1 x M40 cable gland

• 1 x M20 cable gland

• 2 x M16 cable gland

• 2 x M16 knock-out cable entries.

DANGER

Electric shock, malfunction or damage

Death or serious personal injury; product damage or

failure

- Replace power supply cable immediately if

damaged.

- Only qualified personnel must replace it.

Grid types

Three-phase E-pumps can be connected to all grid types.

13.2.8 Start/stop of pump

The number of starts and stops via the power supply

must not exceed 4 times per hour.

When the pump is switched on via the power supply, it will start

after approx. 5 seconds.

If a higher number of starts and stops is desired, use the input for

external start/stop when starting/stopping the pump.

When the pump is switched on via an external On/Off switch, it

will start immediately.

13.2.9 Connections

If no external On/Off switch is connected, connect

terminals 2 and 3 using a short wire.

As a precaution, the wires to be connected to the following

connection groups must be separated from each other by

reinforced insulation in their entire lengths:

Group 1: Inputs

• start/stop terminals 2 and 3

• digital input terminals 1 and 9

• setpoint input terminals 4, 5 and 6

TM03 8605 2007 - TM04 3048 3508

• sensor input terminals 7 and 8

• GENIbus terminals B, Y and A

All inputs (group 1) are internally separated from the power-

conducting parts by reinforced insulation and galvanically

separated from other circuits.

All control terminals are supplied with protective extra-low voltage

(PELV), thus ensuring protection against electric shock.

Group 2: Output (relay signal, terminals NC, C, NO)

The output (group 2) is galvanically separated from other circuits.

Therefore, the supply voltage or protective extra-low voltage can

be connected to the output as desired.

English (US)

DANGER

Electric shock

Death or serious personal injury; product damage or

failure

- Do not connect three-phase E-pumps to a power

supply with a voltage between phase and ground

of more than 440 V.

25

Page 26

English (US)

6: GND (frame)

5: +10 V

4: Setpoint input

3: GND (frame)

2: Start/stop

Group 2

Group 3

20: PT 100 B

19: PT 100 B

18: PT 100 A

17: PT 100 A

16: GND (frame)

15: +24 V

14: Sensor input 2

13: GND

12: Analog output

11: Digital input 4

10: Digital input 3

1: Digital input 2

9: GND (frame)

8: +24 V

7: Sensor input

B: RS-485B

Y: Screen

A: RS-485A

Group 1

Group 3: Power supply (terminals L1, L2, L3)

13.3 Signal cables

• Use screened cables with a conductor cross-section of min. 28

AWG and maximum 16 AWG for external On/Off switch, digital

input, setpoint and sensor signals.

• Connect the screens of the cables to frame at both ends with

good frame connection. The screens must be as close as

possible to the terminals. See fig. 17.

Fig. 17 Stripped cable with screen and wire connection

• Always tighten screws for frame connections whether a cable

is fitted or not.

• Make the wires in the pump terminal box as short as possible.

13.4 E-pump electrical connections

13.4.1 Type key

DPI +T 0-6 G 1/2" 020 E, Set

Type

Temperature sensor:

+T = with temperature Sensor

Flow range [m

Thread size

Output signal:

020 = 4-20 mA

O-ring material:

E = EPDM

F = FKM

Set = Complete pressure transmitter

3

/h]

TM02 1325 0901

Fig. 16 Connection terminals

A galvanic separation must fulfill the requirements for reinforced

insulation including creepage distances and clearances specified

in EN 61800-5-1.

26

TM05 2986 0812

Page 27

13.4.2 Electrical connections

p

Dry-running sensor

Set to automatic resetting

Connection terminals on E-pump:

2 (Start/Stop) and 3 (GND)

3

2

1 x 200-240 VAC or

1 x 80-130 VAC

Jumper cable

Brown

Black

Blue

White

PIN 123 4

Fig. 18 Electrical connections

13.4.3 Connection of E-pump to LiqTec

2

1

4

Wire color Brown Grey Blue Black

Output

4-20 mA

Output

2 x 0-10 V

+ Not used - Not used

Pressure

+

signal

-*

Temperature

signal

English (US)

* Common ground for both pressure and temperature signal.

3

* Power supply (screened cable): SELV or PELV.

* Grundfos will not be liable for damage or wear to products

TM04 7156 1610

caused by abnormal operating conditions, accident abuse,

misuse unauthorized alteration or repair, or if the product was

not installed in accordance with Grundfos' printed installation

and operating instructions. Splicing of the supplied cable

would void any warranty.

Fig. 19 Connection of E-pump to LiqTec

TM03 0437 5104

27

Page 28

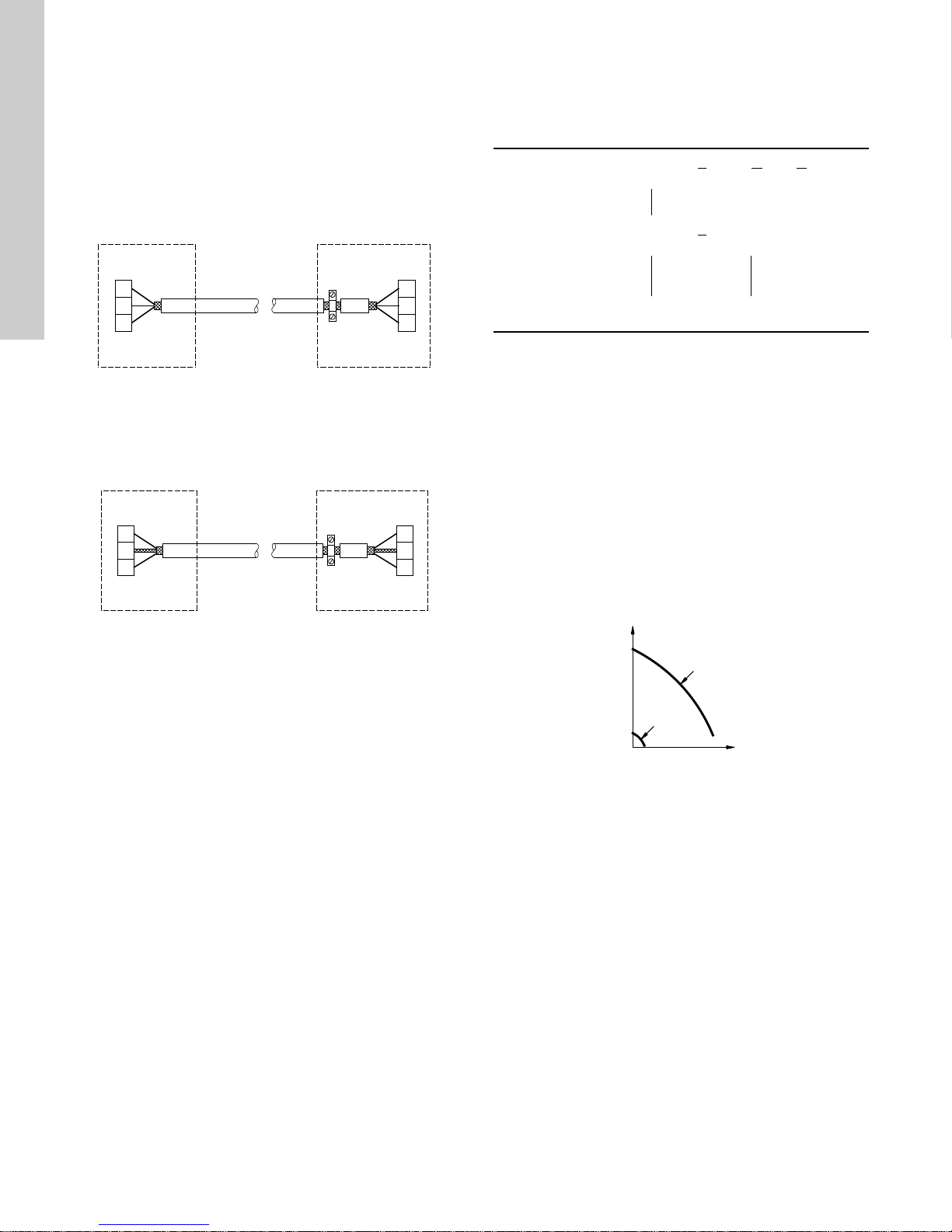

English (US)

Pump

Pump

Q

H

13.5 Bus connection cable

13.5.1 New installations

For the bus connection, use a screened 3-core cable with a

conductor cross-section of 28-16 AWG.

• If the pump is connected to a unit with a cable clamp which is

identical to the one on the pump, connect the screen to this

cable clamp.

• If the unit has no cable clamp as shown in fig. 20, leave the

screen unconnected at this end.

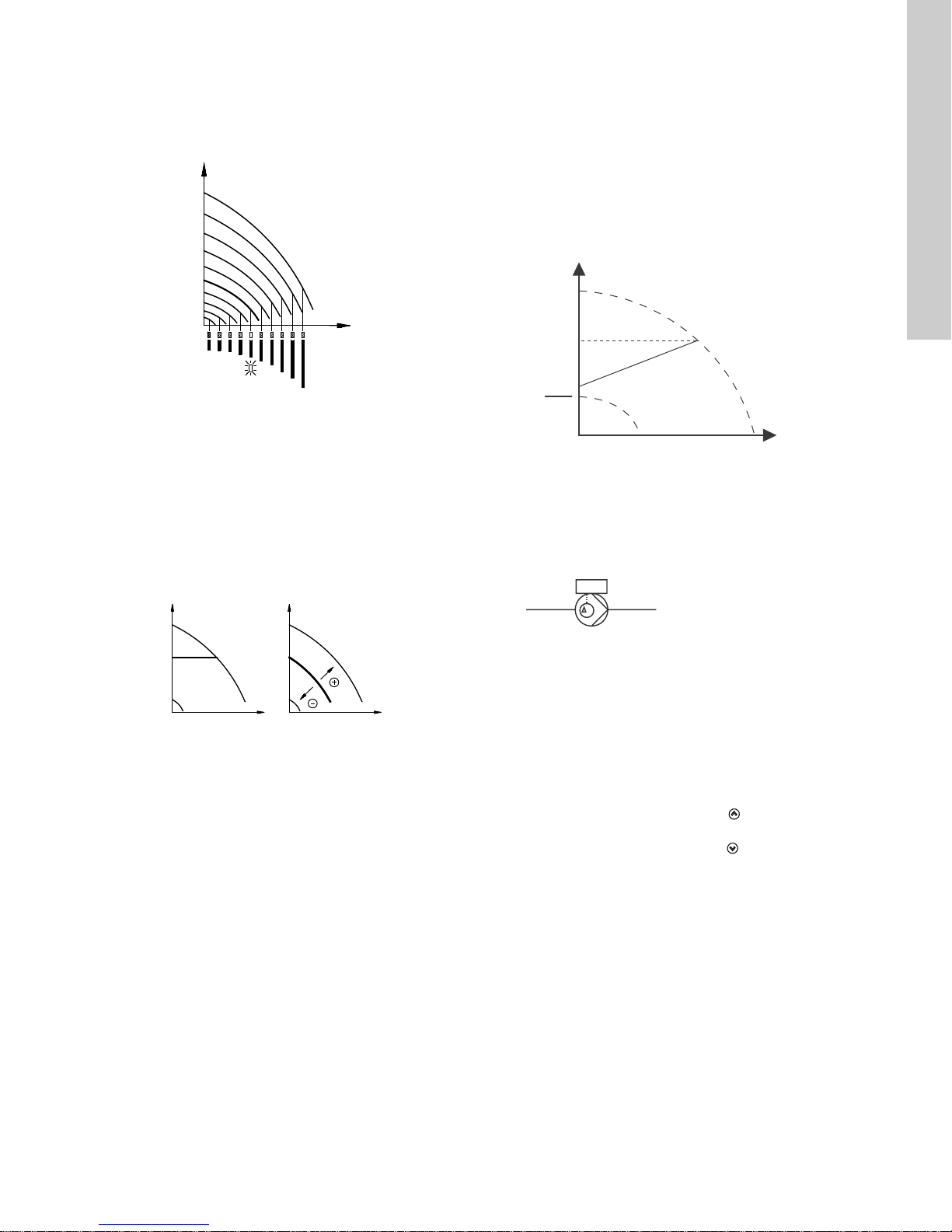

14. Modes

Grundfos E-pumps are set and controlled according to operating

and control modes.

14.1 Overview of modes

Operating modes Normal Stop Min. Max.

Control modes Uncontrolled Controlled

A

1

2

Y

3

B

A

1

2

Y

3

B

Fig. 20 Connection with screened 3-core cable

13.5.2 Replacing an existing pump

• If a screened 2-core cable is used in the existing installation,

connect it as shown in fig. 21.

A

1

Y

2

B

A

1

Y

2

B

Fig. 21 Connection with screened 2-core cable

• If a screened 3-core cable is used in the existing installation,

follow the instructions in section 13.5.1 New installations.

Constant

curve

1)

For this control mode the pump is equipped with a pressure

TM02 8841 0904TM02 8842 0904

sensor. The pump may also be equipped with a temperature

sensor in which case the description would be constant

Constant

pressure

1)

temperature in control mode controlled.

14.2 Operating mode

When the operating mode is set to Normal, the control mode can

be set to controlled or uncontrolled. See section 14.3 Control

mode.

The other operating modes that can be selected are Stop, Min. or

Max.

• Stop: the pump has been stopped

• Min.: the pump is operating at its minimum speed

• Max.: the pump is operating at its maximum speed.

Figure 22 is a schematic illustration of minimum and maximum

curves.

Max.

Min.

TM00 5547 0995

Fig. 22 Minimum and maximum curves

The maximum curve can for instance be used in connection with

the venting procedure during installation.