Page 1

LCD 108

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

Declaration of Conformity

We, Grundfos, declare under our sole responsibility that the product

LC/LCD 108, to which this declaration relates, is in conformity with these

Council directives on the approximation of the laws of the EC member

states:

— Machinery Directive (98/37/EC).

Standard used: EN 809: 2000.

— Low Voltage Directive (2006/95/EC).

Standards used: EN 60335-1: 2002 and EN 60335-2-51: 2003.

— EMC Directive (2004/108/EC).

Standards used: EN 61000-6-2 and EN 61000-6-3.

Bjerringbro, 15th December 2008

Niels Vinther

Technical Manager

2

Page 3

CONTENTS

Page

1. General 3

1.1 Applications 3

1.2 Variants 3

2. Location and mounting 3

2.1 Location 4

2.2 Mounting of LCD 108 for direct-on-line starting 4

3. Systems for parallel operation with 3 float switches 4

3.1 Electrical connection 4

3.2 Setting 5

3.3 Control panel 7

3.4 Battery back-up functions 7

3.5 Reset button and ON-OFF-AUTO selector switch 8

4. Systems for parallel operation with 4 float switches 8

4.1 Electrical connection 8

4.2 Setting 9

4.3 Control panel 10

4.4 Battery back-up functions 11

4.5 Reset button and ON-OFF-AUTO selector switch 12

5. Systems for 100 % standby operation 13

5.1 Electrical connection 13

5.2 Setting 13

5.3 Control panel 15

5.4 Battery back-up functions 15

5.5 Reset button and ON-OFF-AUTO selector switch 16

6. System for full-control operation 17

6.1 Electrical connection 17

6.2 Setting 17

6.3 Control panel 19

6.4 Battery back-up functions 19

6.5 Reset button and ON-OFF-AUTO selector switch 20

7. Start-up 21

8. Maintenance 21

9. Technical data 21

10. Fault finding chart 22

11. Disposal 22

Before beginning installation procedures, these

installation and operating instructions should be

studied carefully. The installation and operation

should also be in accordance with local regulations

and accepted codes of good practice.

1. General

The LCD 108 controller is designed for the control of pumps in

wastewater systems.

Type key:

1.1 Applications

The LCD 108 enables:

• control of two pumps based on signals from float switches,

• automatic pump changeover (even distribution of operating

hours on both pumps),

• selection of automatic test run during long periods of inactivity

(every 24 hours),

• battery back-up in case of mains supply failure (accessory for

certain variants),

• starting delay within the range from 0 to 255 sec. (random)

after returning from battery operation to mains operation

(resulting in an even mains load when several pumping

stations are started up at the same time),

• selection of automatic alarm resetting,

• selection of automatic restarting,

• setting of stop delays matching the actual operating

conditions,

• indication of liquid level,

• alarm indication of:

- inadmissibly high liquid level,

- overload (via motor protection relay),

- overtemperature (via PTC resistance or thermal switch in

motor),

- wrong phase sequence (only certain variants),

- mains supply failure (only certain variants),

- defective float switch.

As standard, the LCD 108 has one alarm output for common

alarm. Certain variants have an additional alarm output for

separate high-level alarm.

Furthermore, the controller incorporates a buzzer (only certain

variants).

1.2 Variants

The actual controller type, voltage variant, etc. are stated in the

type key on the nameplate situated on the side of the controller

cabinet.

The LCD 108 is available for direct-on-line starting.

The LCD 108 can be connected and set to operation/control in 4

different ways, see sections 3. to 6.:

• Section 3. Systems for parallel operation with 3 float switches.

(Electrodes can also be used.)

• Section 4. Systems for parallel operation with 4 float switches.

(Electrodes can also be used.)

• Section 5. Systems for 100 % standby operation.

• Section 6. System for full-control operation.

2. Location and mounting

Example LCD 108 400 3 23 SMS

LCD = two-pump controller

108 = type designation

Phase voltage [V]

1 = single-phase

3 = three-phase

Maximum operating current per pump [A]

SMS = with SMS unit

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting of

pumps, pits, etc. must be carried out according to

local regulations.

Before making any connections in the LCD 108 or

work on pumps, pits, etc., it must be ensured that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

The installation must be carried out by authorized personnel in

accordance with local regulations.

3

Page 4

2.1 Location

22

12

T21

T11

T22

T12

H-NOH-COM

H-NC

G-NO

G-COM

G-NC

21

11

32

42

31

41

The LCD 108 controller and an EEx barrier, if

required, must not be installed in explosion hazard

areas.

Only float switches approved for use in explosion

hazard areas may be used. The float switches must

be connected via an EEx barrier, e.g. Grundfos

number 96440300.

The LCD 108 can be mounted at ambient temperatures ranging

from –30 °C to +50 °C.

Enclosure class: IP 65.

When installed outdoors, the LCD 108 must be placed in a

protective shed or cupboard.

The LCD 108 must not be exposed to direct sunlight.

2.2 Mounting of LCD 108 for direct-on-line starting

Before mounting, remove the transport protectors, if any, from

inside the cabinet.

Mount the LCD 108:

• on a plane wall surface,

• with the Pg cable entries pointing downwards

(additional Pg cable entries, if required, must be fitted in the

bottom plate of the cabinet),

• with four screws through the mounting holes in the back plate

of the cabinet. The mounting holes must be bored with a 4 mm

bore. Fit the screws into the mounting holes and tighten

securely. Fit the plastic caps supplied with the controller on the

screws (IP 65).

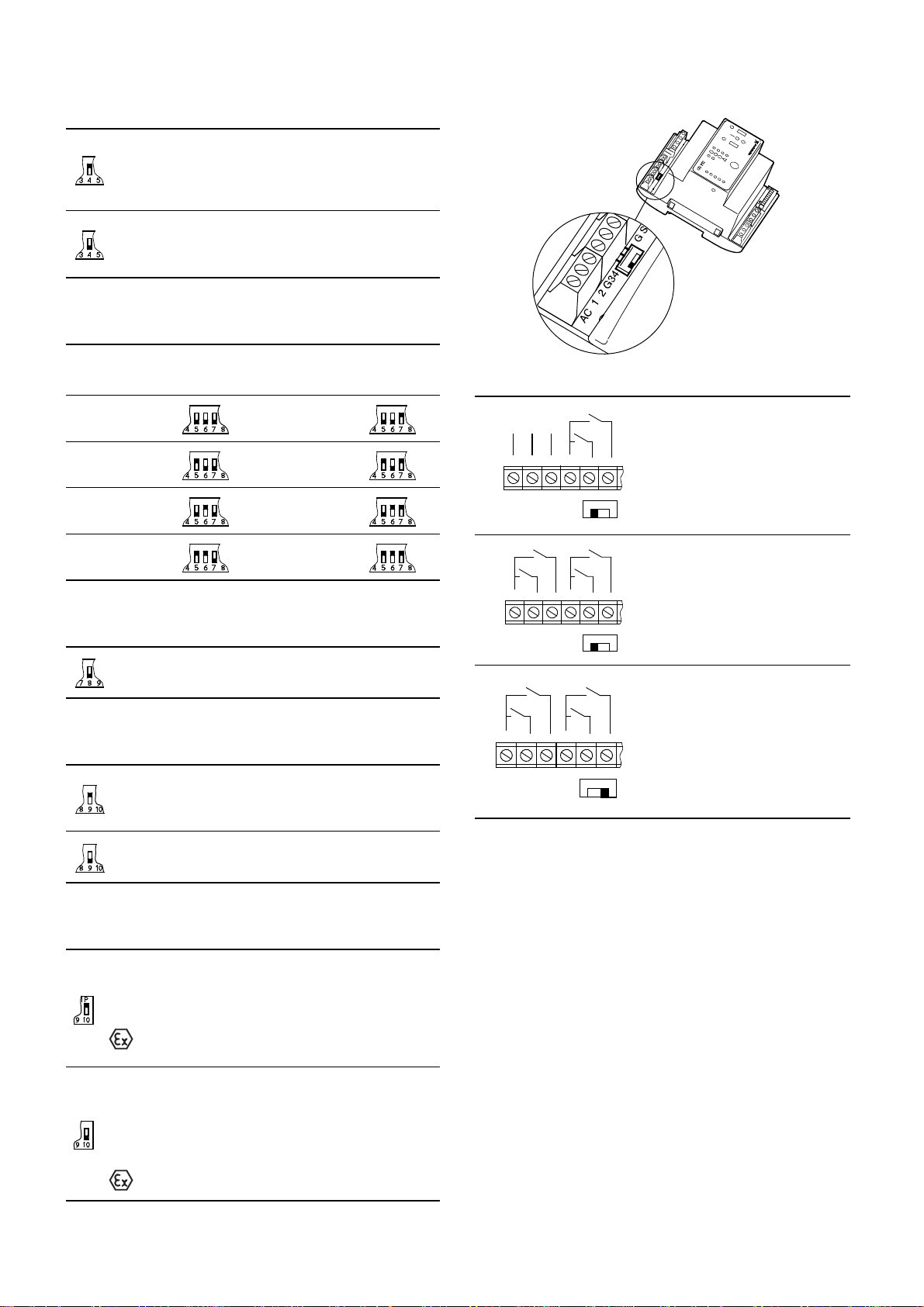

Figure 1 shows the terminals listed under positions 2 and 3.

3. Systems for parallel operation with 3 float

switches

Description (see also page 23 or 24):

The pumps are controlled by the liquid level in the pit.

• When the float switch, pos. 1, registers liquid, the first pump is

started.

• When the float switch, pos. 2, registers liquid, the next pump is

started.

• When the float switch, pos. 1, does not register any liquid, the

"stop delay" is initiated (can be set). After expiration of the

stop delay, both pumps are stopped.

• The pumps operate alternately.

The top float switch, pos. 3, activates the high-level alarm.

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting of

pumps, pits, etc. must be carried out according to

local regulations.

Before making any connections in the LCD 108 or

work on pumps, pits, etc., it must be ensured that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

3.1 Electrical connection

Parallel operation with 3 float switches, pages 23 or 24.

Before starting work on the system, switch off the

supply voltage and lock the mains switch in

position 0.

Any external voltage connected to the system must

be switched off before work is started.

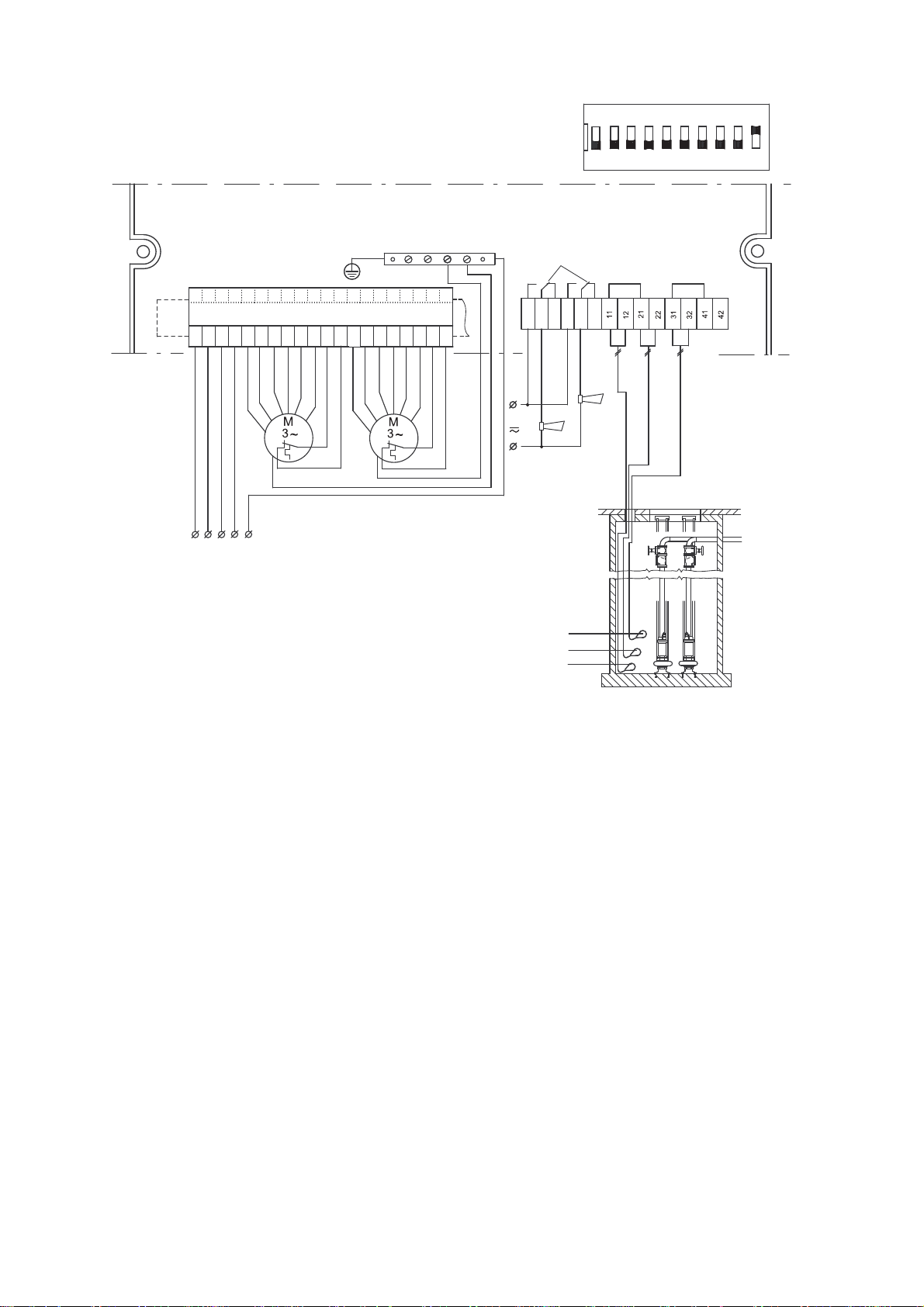

Fig. A1 on page 23.

The figures show all electrical connections required to connect

the LCD 108 for direct-on-line starting, parallel operation with

3 float switches.

Fig. A2 on page 24.

The figure shows all electrical connections required to connect

the LCD 108 for star-delta starting, parallel operation with 3 float

switches.

Fig. 1

Key to the symbols in figs. 1 and 1:

Pos. Description

Terminal block for level inputs

1

(11-12, 21-22, 31-32, 41-42).

Terminal block with:

• input for the PTC resistance/thermal switch of the

motor (T11-T21, T12-T22),

2

• output for external alarm device for high-level alarm

(H-NC, H-COM, H-NO) (only certain variants),

• output for external alarm device for common alarm

(G-NC, G-COM, G-NO).

Note: If the distance between the controller and pit exceeds

20 metres, it is not advisable to use electrodes as problems with

the signal values sent back to the controller may arise.

In such cases, it is recommended to use float switches.

Note: Cables of up to 100 metres can be connected between the

controller and the float switches.

4

TM01 4833 2308

The LCD 108 must be connected in accordance with

the rules and standards in force for the application in

question.

The operating voltage and frequency are marked on the controller

nameplate. Make sure that the controller is suitable for the

electricity supply on which it will be used.

All cables/wires must be fitted through the Pg cable entries and

gaskets (IP 65).

Maximum back-up fuse is stated on the controller nameplate.

If required according to local regulations, an external mains

switch must be installed.

Note: If the PTC resistance/thermal switch of the motor is

connected, the factory-fitted short-circuit jumper must be

removed (terminals T11-T21, T12-T22). For correct installation of

PTC resistor/thermal switch, see the installation and operating

instructions of the pump.

Single-phase motors must be connected to an external operating

capacitor and in certain cases also to a starting capacitor. Further

details can be found in the installation and operating instructions

for the pump in question.

Float switches placed in an explosion hazard area

must be connected via an EEx barrier, e.g. Grundfos

number 96440300.

The EEx barrier must not be installed in the explosion

hazard area.

Equipment used in explosion hazard areas must in

each individual case have been approved for this

particular application. Furthermore, the cables into

the explosion hazard area must be laid in accordance

with local regulations.

Page 5

Note: Float switches of the same type as Grundfos product

number 96003332 or 96003695, i.e. float switches with

gold-plated contacts suitable for low voltages and currents (40 V/

100 mA), must be used. All EEx-approved float switches are also

suitable.

The float switches must be connected as NO contacts, i.e. brown

and black leads, when float switches, Grundfos product number

96003332 or 96003695, are used.

Key to the symbols in fig. A1 on page 23 and fig. A2 on

page 24:

Pos. Description

Float switch for start of the first pump/

1

common stop.

2 Float switch for start of the next pump. 21-22

3 Float switch for high-level alarm. 31-32

Terminal

number

11- 12

3.2 Setting

Parallel operation with 3 float switches, pages 23 and 24.

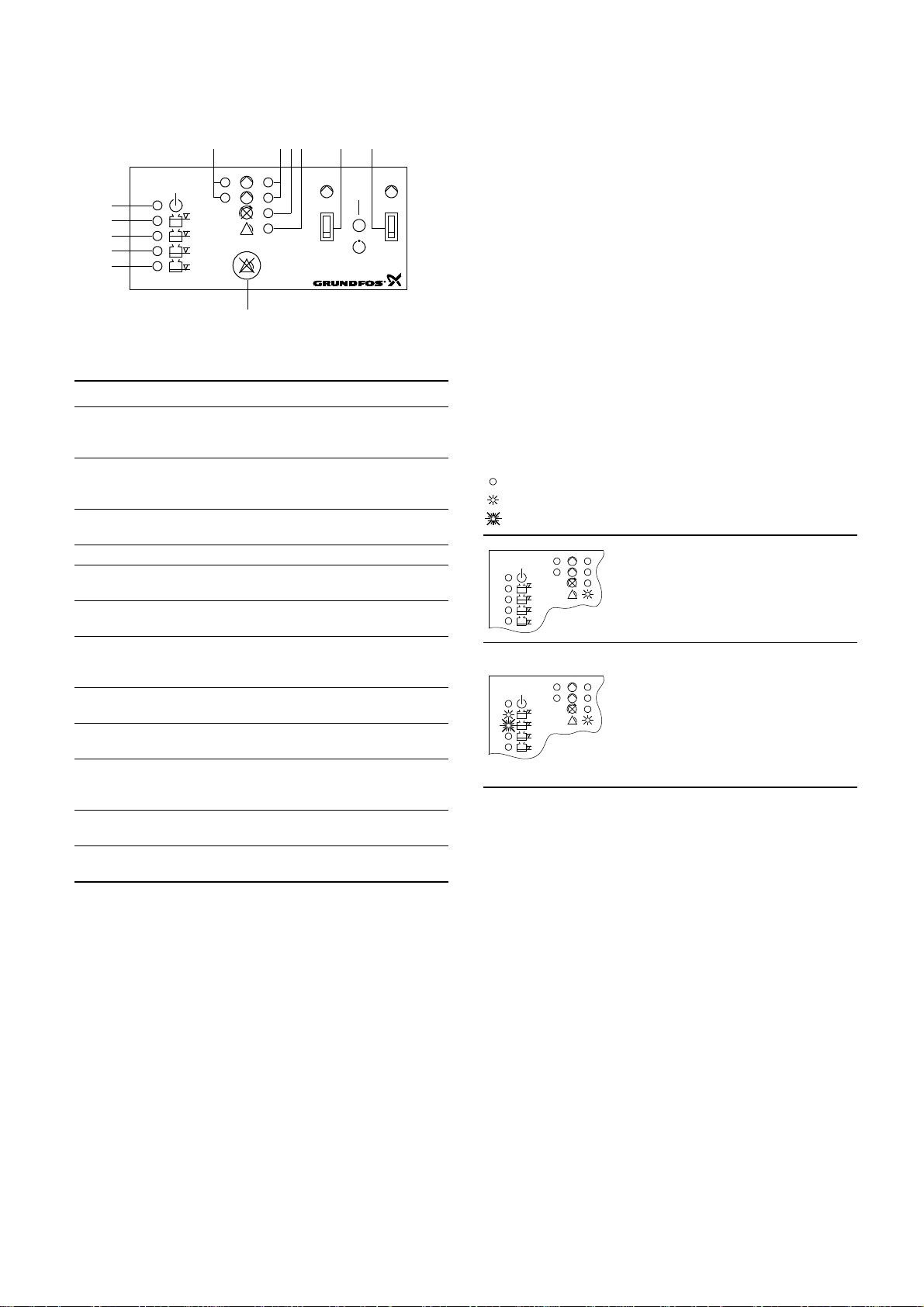

The module CU 212 has a 10-pole DIP switch in the bottom right

corner, see fig. 2.

Note: During the setting of the DIP switch, the controller must

always be dead for at least 1 minute to achieve the correct

configuration during start-up after change of the DIP switch

setting.

The DIP switch setting offers the following possibilities:

• selection of starting delay and automatic test run (switch 4),

• setting of stop delay (switches 5, 6 and 7),

• selection of automatic alarm resetting (switch 9),

• selection of automatic restarting (switch 10).

At this setting, the start-up is delayed within the range

from 0 to 255 sec. (random) after the electricity supply

has been switched on when the liquid level is

sufficiently high.

Automatic test run carried out every 24 hours.

After the electricity has been switched on, the pump will

start immediately when the liquid level is sufficiently

high.

No automatic test run.

• Switches 5, 6 and 7, stop delay:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

The stop delay is the time from the stop signal is given until the

pump is stopped.

It must be ensured that the pump is not running dry.

0 sec. 60 sec.

15 sec. 90 sec.

30 sec. 120 sec.

45 sec. 180 sec.

•Switch 8:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

Switch 8 has no function in connection with the actual

application (parallel operation with 3 float switches,

pages 23 and 24), but this setting must be maintained!

•Switch 9, automatic alarm resetting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

Fig. 2

Set the DIP switch as shown in fig. 2.

Each individual switch (1 to 10) of the DIP switch can be set to

position OFF or ON.

During the setting of the DIP switch, the controller must always

be dead for at least 1 minute to achieve the correct configuration

during start-up after change of the DIP switch setting.

Set the switches 1 to 10 as follows:

•Switches 1, 2 and 3, application type:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting determines the actual application type

(parallel operation with 3 float switches, pages 23

and 24).

•Switch 4, starting delay and automatic test run

(only in the case of battery back-up):

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting ensures automatic resetting of alarm

signals to external alarm devices and the built-in

buzzer. However, an alarm signal will only be reset if

the cause of the fault no longer exists.

At this setting, the alarm signal must be reset manually

by means of the reset button (the reset button is

described in section 3.5).

•Switch 10, automatic restarting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

TM01 6870 2308

This setting enables automatic restarting after the PTC

resistance/thermal switch of the motor has cut out the

pump. Restarting will not be carried out until the motor

has cooled to normal temperature.

When the pumps connected are used in explosion

hazard areas, switch 10 must not be in this

position!

At this setting, the pump must be restarted manually after

the PTC resistance/thermal switch of the motor has cut

out the pump. To restart the pump, push the ON-OFFAUTO selector switch into position OFF for a short period

(the ON-OFF-AUTO selector switch is described in

section 3.5).

When the pumps connected are used in explosion

hazard areas, switch 10 must be in this position!

5

Page 6

AC/DC selector:

AC 1 2

13-18 VAC

0 V

AC

DC

G3 4

AC 1 2

13-18 VAC

0 V

AC

DC

G3 4

AC 1 2

12 VDC

0 V

AC

DC

G3 4

The AC/DC selector switch for electrodes and/or float switches is

placed as shown in fig. 3.

Fig. 3

Operation with electrodes and

float switches:

Selector switch in position AC:

It is possible to connect 3

electrodes (1 as reference

electrode) and 2 float switches.

The controller transmits a 13 to

18 VAC signal.

Operation with float switches:

Selector switch in position AC:

It is possible to connect 4 float

switches.

The controller transmits a 13 to

18 VAC signal.

TM02 5747 3902

Operation with float switches:

Selector switch in position DC:

It is possible to connect 4 float

switches.

Cables of up to 100 metres can be

connected between the controller

and the float switches.

The controller transmits a 12 VDC

signal.

If the distance between the controller and pit exceeds 20 metres,

it is not advisable to use electrodes as problems with the signal

values sent back to the controller may arise. In such cases, it is

recommended to use float switches.

6

Page 7

3.3 Control panel

CU 212

21

1

2

1234756

12

11

9

8

10

1

CU 212

2

CU 212

2

1

Parallel operation with 3 float switches, pages 23 and 24.

Figure 4 shows the control panel of the CU 212 module.

Fig. 4

Key to the symbols in fig. 4:

Pos. Description

Green indicator light for pump 1 and 2, indicating

1

starting delay (flashing) and pump operation

(permanently on).

Red indicator light for pump 1 and 2.

2

Flashing: Fault in PTC resistor/thermal switch

On: Fault in motor-protective circuit breaker.

Red indicator light, indicating wrong phase sequence

3

(only certain variants and three-phase pumps only).

4 Red indicator light, indicating common alarm.

ON-OFF-AUTO selector switch for pump 1, three

5

positions, see section 3.5.

ON-OFF-AUTO selector switch for pump 2, three

6

positions, see section 3.5.

Reset button, push-button for manual resetting of alarm

7

signals to external alarm devices and the built-in buzzer

(only certain variants), see section 3.5.

Orange indicator light, which is activated by the float

8

switch for start of the first pump/common stop.

Orange indicator light, which is activated by the float

9

switch for start of the next pump.

Two orange indicator lights, which are activated by the

10

float switch for high-level alarm. In case of high-level

and

alarm, the top indicator light is flashing and the other is

11

permanently on.

Green indicator light, indicating that the electricity

12

supply has been switched on.

The table below shows the situations which may occur if the

normal electricity supply to the LCD 108 fails and a back-up

battery is connected:

= the indicator light is off.

= the indicator light is on.

= the indicator light is flashing.

Mains supply failure:

• The common alarm is active.

The red indicator light is on.

• The green indicator light (electricity

supply switched on) is off.

Mains supply failure and high-level alarm:

TM01 6397 3902

• The common alarm is active.

The red indicator light is on.

• The top orange indicator light is

flashing.

• The second orange indicator light from

the top is on.

• The green indicator light (electricity

supply switched on) is off.

3.4 Battery back-up functions

Parallel operation with 3 float switches, pages 23 and 24.

If a back-up battery for CU 212 (accessory for certain variants) is

installed, the following functions will be carried out if the normal

electricity supply to the LCD 108 fails (see also the illustrations

below):

• The common alarm is active, the red indicator light is on –

cannot be reset!

• If the external alarm device for common alarm is supplied from

an external power source, this device will be active – cannot

be reset by means of the reset button!

• The built-in buzzer (only certain variants) is activated – can be

reset by means of the reset button!

• If the liquid level in the pit rises above the level for high-level

alarm, the top orange indicator light will be flashing and the

second orange indicator light from the top will be permanently

on.

• If the starting delay function and automatic test run were

selected (switch 4 of the DIP switch), the start-up will be

delayed after the electricity supply has been switched on when

the liquid level is sufficiently high, see section 3.2.

7

Page 8

3.5 Reset button and ON-OFF-AUTO selector switch

21

Parallel operation with 3 float switches, pages 23 and 24.

The reset button is a push-button for manual resetting of alarm signals to external alarm devices and the built-in

buzzer (i.e. not for resetting of the alarm memory as this is reset by means of the ON-OFF-AUTO selector switch,

see position OFF ( )).

Even if the fault condition still exists, the external alarm devices and the built-in buzzer will be reset when the reset

button is pressed.

The ON-OFF-AUTO selector switch for each pump has three different positions:

ON ( ), top position:

• The pump will start when the selector switch is pushed into this position (unless the motor protection relay has cut

out the pump).

• If the PTC resistance/thermal switch of the motor registers overtemperature, the pump will not be switched off.

Note: It is the user’s responsibility to decide how long the pump is to run with this fault indication. Over a long

period, the pump will be damaged!

In explosion hazard areas, switch 10 of the DIP switch must be set as stated in section 3.2. Consequently,

the pump cannot be started when the PTC resistance/thermal switch of the motor registers overtemperature.

OFF ( ), middle position:

• The pump cannot start when the selector switch has been set to this position.

• The alarm memory is reset by pushing the selector switch into position OFF ( ). The alarm memory is the light

indication of a fault condition which has disappeared. If a fault condition still exists when the selector switch is

pushed into position ON ( ) or AUTO ( ), the alarm indication will be repeated immediately.

AUTO ( ), bottom position:

• The pump is controlled by the input signals from the float switches and the pump according to the selected

DIP switch setting.

• Alarm signals will automatically be reset. Switch 9 of the DIP switch can, however, be set to manual resetting

which is carried out by means of the reset button, see section 3.2.

• The pump will restart automatically when a given fault condition disappears. However, this is dependent on the

setting of switch 10 of the DIP switch, see section 3.2.

• When the pump starts automatically after a fault condition which has disappeared, the indicator light will continue

to show the fault condition (alarm memory) and the indication can only be removed by resetting the alarm memory,

see position OFF ().

4. Systems for parallel operation with 4 float

switches

Description (see also page 25 or 26):

The pumps are controlled by the liquid level in the pit.

• The float switch, pos. 2, starts the first pump.

• The float switch, pos. 3, starts the next pump.

• The float switch, pos. 1, stops both pumps after expiration of

the "stop delay" (can be set).

• The pumps operate alternately.

• The top float switch, pos. 4, activates the high-level alarm.

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting of

pumps, pits, etc. must be carried out according to

local regulations.

Before making any connections in the LCD 108 or

work on pumps, pits, etc., it must be ensured that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

4.1 Electrical connection

Parallel operation with 4 float switches, pages 25 and 26.

Before starting work on the system, switch off the

supply voltage and lock the mains switch in

position 0.

Any external voltage connected to the system must

be switched off before work is started.

Fig. B1 on page 25.

The figures show all electrical connections required to connect

the LCD 108 for direct-on-line starting, parallel operation with

4 float switches.

Fig. B2 on page 26.

The figure shows all electrical connections required to connect

the LCD 108 for star-delta starting, parallel operation with 4 float

switches.

The LCD 108 must be connected in accordance with

the rules and standards in force for the application in

question.

The operating voltage and frequency are marked on the controller

nameplate. Make sure that the controller is suitable for the

electricity supply on which it will be used.

All cables/wires must be fitted through the Pg cable entries and

gaskets (IP 65).

Maximum back-up fuse is stated on the controller nameplate.

If required according to local regulations, an external mains

switch must be installed.

Note: If the PTC resistance/thermal switch of the motor is

connected, the factory-fitted short-circuit jumper must be

removed (terminals T11-T21, T12-T22). For correct installation of

PTC resistor/thermal switch, see the installation and operating

instructions of the pump.

Single-phase motors must be connected to an external operating

capacitor and in certain cases also to a starting capacitor. Further

details can be found in the installation and operating instructions

for the pump in question.

Float switches placed in an explosion hazard area

must be connected via an EEx barrier, e.g. Grundfos

number 96440300.

The EEx barrier must not be installed in the explosion

hazard area.

Equipment used in explosion hazard areas must in

each individual case have been approved for this

particular application. Furthermore, the cables into

the explosion hazard area must be laid in accordance

with local regulations.

8

Page 9

Note: Float switches of the same type as Grundfos product

number 96003332 or 96003695, i.e. float switches with

gold-plated contacts suitable for low voltages and currents (40 V/

100 mA), must be used. All EEx-approved float switches are also

suitable.

The float switches must be connected as NO contacts, i.e. brown

and black leads, when float switches, Grundfos product number

96003332 or 96003695, are used.

Key to the symbols in fig. B1 on page 25 and fig. B2 on

page 26:

Pos. Description

1 Float switch for common stop. 11-12

2 Float switch for start of the first pump. 21-22

3 Float switch for start of the next pump. 31-32

4 Float switch for high-level alarm. 41-42

Terminal

number

4.2 Setting

Parallel operation with 4 float switches, pages 25 and 26.

The module CU 212 has a 10-pole DIP switch in the bottom right

corner, see fig. 5.

Note: The controller must be off circuit to ensure the correct

configuration during start-up after change of the DIP switch

setting.

The DIP switch setting offers the following possibilities:

• selection of starting delay and automatic test run (switch 4),

• setting of stop delay (switches 5, 6 and 7),

• selection of automatic alarm resetting (switch 9),

• selection of automatic restarting (switch 10).

•Switch 4, starting delay and automatic test run

(only in the case of battery back-up):

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

At this setting, the start-up is delayed within the range

from 0 to 255 sec. (random) after the electricity supply

has been switched on when the liquid level is

sufficiently high.

Automatic test run carried out every 24 hours.

After the electricity has been switched on, the pump will

start immediately when the liquid level is sufficiently

high.

No automatic test run.

• Switches 5, 6 and 7, stop delay:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

The stop delay is the time from the stop signal is given until the

pump is stopped.

It must be ensured that the pump is not running dry.

0 sec. 60 sec.

15 sec. 90 sec.

30 sec. 120 sec.

45 sec. 180 sec.

Fig. 5

Set the DIP switch as shown in fig. 5. Each individual switch (1 to

10) of the DIP switch can be set to position OFF or ON.

Note: The DIP switch must not be set to other switch

combinations than those described in this section.

Set the switches 1 to 10 as follows:

•Switches 1, 2 and 3, application type:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting determines the actual application type

(parallel operation with 4 float switches, pages 25 and

26).

•Switch 8:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

Switch 8 has no function in connection with the actual

application (parallel operation with 4 float switches,

pages 25 and 26), but this setting must be maintained!

•Switch 9, automatic alarm resetting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting ensures automatic resetting of alarm

signals to external alarm devices and the built-in

buzzer. However, an alarm signal will only be reset if

the cause of the fault no longer exists.

At this setting, the alarm signal must be reset manually

by means of the reset button (the reset button is

TM04 2341 2308

•Switch 10, automatic restarting:

described in section 4.5).

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting enables automatic restarting after the PTC

resistance/thermal switch of the motor has cut out the

pump. Restarting will not be carried out until the motor

has cooled to normal temperature.

When the pumps connected are used in explosion

hazard areas, switch 10 must not be in this

position!

At this setting, the pump must be restarted manually after

the PTC resistance/thermal switch of the motor has cut

out the pump. To restart the pump, push the ON-OFFAUTO selector switch into position OFF for a short period

(the ON-OFF-AUTO selector switch is described in

section 4.5).

When the pumps connected are used in explosion

hazard areas, switch 10 must be in this position!

9

Page 10

AC/DC selector:

AC 1 2

13-18 VAC

0 V

AC

DC

G3 4

AC 1 2

13-18 VAC

0 V

AC

DC

G3 4

AC 1 2

12 VDC

0 V

AC

DC

G3 4

CU 212

21

1

2

1234756

12

11

9

8

10

The AC/DC selector switch for electrodes and/or float switches is

placed as shown in fig. 6.

Fig. 6

Operation with electrodes and

float switches:

Selector switch in position AC:

It is possible to connect 3

electrodes (1 as reference

electrode) and 2 float switches.

The controller transmits a 13 to

18 VAC signal.

Operation with float switches:

Selector switch in position AC:

It is possible to connect 4 float

switches.

The controller transmits a 13 to

18 VAC signal.

Operation with float switches:

Selector switch in position DC:

It is possible to connect 4 float

switches.

Cables of up to 100 metres can be

connected between the controller

and the float switches.

The controller transmits a 12 VDC

signal.

If the distance between the controller and pit exceeds 20 metres,

it is not advisable to use electrodes as problems with the signal

values sent back to the controller may arise. In such cases, it is

recommended to use float switches.

4.3 Control panel

Parallel operation with 4 float switches, pages 25 and 26.

Figure 7 shows the control panel of the CU 212 module.

Fig. 7

TM02 5747 3902

Key to the symbols in fig. 7:

Pos. Description

Green indicator light for pump 1 and 2, indicating

1

starting delay (flashing) and pump operation

(permanently on).

Red indicator light for pump 1 and 2.

2

Flashing: Fault in PTC resistor/thermal switch

On: Fault in motor-protective circuit breaker.

Red indicator light, indicating wrong phase sequence

3

(only certain variants and three-phase pumps only).

4 Red indicator light, indicating common alarm.

ON-OFF-AUTO selector switch for pump 1, three

5

positions, see section 4.5.

ON-OFF-AUTO selector switch for pump 2, three

6

positions, see section 4.5.

Reset button, push-button for manual resetting of alarm

7

signals to external alarm devices and the built-in buzzer

(only certain variants), see section 4.5.

Orange indicator light, which is activated by the float

8

switch for common stop.

Orange indicator light, which is activated by the float

9

switch for start of the first pump.

Orange indicator light, which is activated by the float

10

switch for start of the next pump.

Orange indicator light, which is activated by the float

11

switch for high-level alarm. In case of high-level alarm,

the indicator light is flashing.

Green indicator light, indicating that the electricity

12

supply has been switched on.

TM01 6397 3902

10

Page 11

4.4 Battery back-up functions

1

CU 212

2

CU 212

2

1

Parallel operation with 4 float switches, pages 25 and 26.

If a back-up battery for CU 212 (accessory for certain variants) is

installed, the following functions will be carried out if the normal

electricity supply to the LCD 108 fails (see also the illustrations

below):

• The common alarm is active, the red indicator light is on –

cannot be reset!

• If the external alarm device for common alarm is supplied from

an external power source, this device will be active – cannot

be reset by means of the reset button!

• The built-in buzzer (only certain variants) is activated – can be

reset by means of the reset button!

• If the liquid level in the pit rises above the level for high-level

alarm, the top orange indicator light will be flashing and the

second orange indicator light from the top will be permanently

on.

• If the starting delay function and automatic test run were

selected (switch 4 of the DIP switch), the start-up will be

delayed after the electricity supply has been switched on when

the liquid level is sufficiently high, see section 4.2.

The table below shows the situations which may occur if the

normal electricity supply to the LCD 108 fails and a back-up

battery is connected:

= the indicator light is off.

= the indicator light is on.

= the indicator light is flashing.

Mains supply failure:

• The common alarm is active.

The red indicator light is on.

• The green indicator light (electricity

supply switched on) is off.

Mains supply failure and high-level alarm:

• The common alarm is active.

The red indicator light is on.

• The top orange indicator light is

flashing.

• The second orange indicator light from

the top is on.

• The green indicator light (electricity

supply switched on) is off.

11

Page 12

4.5 Reset button and ON-OFF-AUTO selector switch

21

Parallel operation with 4 float switches, pages 25 and 26.

The reset button is a push-button for manual resetting of alarm signals to external alarm devices and the built-in

buzzer (i.e. not for resetting of the alarm memory as this is reset by means of the ON-OFF-AUTO selector switch,

see position OFF ( )).

Even if the fault condition still exists, the external alarm devices and the built-in buzzer will be reset when the reset

button is pressed.

The ON-OFF-AUTO selector switch for each pump has three different positions:

ON ( ), top position:

• The pump will start when the selector switch is pushed into this position (unless the motor protection relay has cut

out the pump).

• If the PTC resistance/thermal switch of the motor registers overtemperature, the pump will not be switched off.

Note: It is the user’s responsibility to decide how long the pump is to run with this fault indication. Over a long

period, the pump will be damaged!

In explosion hazard areas, switch 10 of the DIP switch must be set as stated in section 4.2. Consequently,

the pump cannot be started when the PTC resistance/thermal switch of the motor registers overtemperature.

OFF ( ), middle position:

• The pump cannot start when the selector switch has been set to this position.

• The alarm memory is reset by pushing the selector switch into position OFF ( ). The alarm memory is the light

indication of a fault condition which has disappeared. If a fault condition still exists when the selector switch is

pushed into position ON ( ) or AUTO ( ), the alarm indication will be repeated immediately.

AUTO ( ), bottom position:

• The pump is controlled by the input signals from the float switches and the pump according to the selected DIP

switch setting.

• Alarm signals will automatically be reset. Switch 9 of the DIP switch can, however, be set to manual resetting

which is carried out by means of the reset button, see section 4.2.

• The pump will restart automatically when a given fault condition disappears. However, this is dependent on the

setting of switch 10 of the DIP switch, see section 4.2.

• When the pump starts automatically after a fault condition which has disappeared, the indicator light will continue

to show the fault condition (alarm memory) and the indication can only be removed by resetting the alarm memory,

see position OFF ().

12

Page 13

5. Systems for 100 % standby operation

Description (see also page 27 or 28):

The pumps are controlled by the liquid level in the pit.

• The float switch, pos. 2, starts the first pump.

• The float switch, pos. 4, starts the next pump.

• The float switch, pos. 1, stops both pumps after expiration of

the "stop delay" (can be set).

• The pumps operate alternately.

• The float switch, pos. 3, activates the high-level alarm.

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting of

pumps, pits, etc. must be carried out according to

local regulations.

Before making any connections in the LCD 108 or

work on pumps, pits, etc., it must be ensured that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

5.1 Electrical connection

100 % standby operation, pages 27 and 28.

Before starting work on the system, switch off the

supply voltage and lock the mains switch in

position 0.

Any external voltage connected to the system must

be switched off before work is started.

Fig. C1 on page 27.

The figures show all electrical connections required to connect

the LCD 108 for direct-on-line starting, 100 % standby operation.

Fig. C2 on page 28.

The figure shows all electrical connections required to connect

the LCD 108 for star-delta starting, 100 % standby operation.

The float switches must be connected as NO contacts, i.e. brown

and black leads, when float switches, Grundfos product number

96003332 or 96003695, are used.

Key to the symbols in fig. C1 on page 27 and fig. C2 on

page 28:

Pos. Description

1 Float switch for common stop. 11-12

2 Float switch for start of the first pump. 21-22

3 Float switch for high-level alarm. 31-32

4 Float switch for start of the next pump. 41-42

Terminal

number

5.2 Setting

100 % standby operation, pages 27 and 28.

The module CU 212 has a 10-pole DIP switch in the bottom right

corner, see fig. 8.

Note: During setting, the controller must be off circuit for at least

1 minute to ensure the correct configuration during start-up after

change of the DIP switch setting.

The DIP switch setting offers the following possibilities:

• selection of starting delay and automatic test run (switch 4),

• setting of stop delay (switches 5, 6 and 7),

• selection of automatic alarm resetting (switch 9),

• selection of automatic restarting (switch 10).

The LCD 108 must be connected in accordance with

the rules and standards in force for the application in

question.

The operating voltage and frequency are marked on the controller

nameplate. Make sure that the controller is suitable for the

electricity supply on which it will be used.

All cables/wires must be fitted through the Pg cable entries and

gaskets (IP 65).

Maximum back-up fuse is stated on the controller nameplate.

If required according to local regulations, an external mains

switch must be installed.

Note: If the PTC resistance/thermal switch of the motor is

connected, the factory-fitted short-circuit jumper must be

removed (terminals T11-T21, T12-T22). For correct installation of

PTC resistor/thermal switch, see the installation and operating

instructions of the pump.

Single-phase motors must be connected to an external operating

capacitor and in certain cases also to a starting capacitor. Further

details can be found in the installation and operating instructions

for the pump in question.

Float switches placed in an explosion hazard area

must be connected via an EEx barrier, e.g. Grundfos

number 96440300.

The EEx barrier must not be installed in the explosion

hazard area.

Equipment used in explosion hazard areas must in

each individual case have been approved for this

particular application. Furthermore, the cables into

the explosion hazard area must be laid in accordance

with local regulations.

Note: Float switches of the same type as Grundfos product

number 96003332 or 96003695, i.e. float switches with

gold-plated contacts suitable for low voltages and currents

(40 V/100 mA), must be used. All EEx-approved float switches

are also suitable.

TM04 2340 2308

Fig. 8

Set the DIP switch as shown in fig. 8.

Each individual switch (1 to 10) of the DIP switch can be set to

position OFF or ON.

Note: The DIP switch must not be set to other switch

combinations than those described in this section.

Set the switches 1 to 10 as follows:

• Switches 1, 2 and 3, application type:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting determines the actual application type

(100 % standby operation, pages 27 and 28).

13

Page 14

•Switch 4, starting delay and automatic test run

AC 1 2

13-18 VAC

0 V

AC

DC

G3 4

AC 1 2

13-18 VAC

0 V

AC

DC

G3 4

AC 1 2

12 VDC

0 V

AC

DC

G3 4

(only in the case of battery back-up):

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

At this setting, the start-up is delayed within the range

from 0 to 255 sec. (random) after the electricity supply

has been switched on when the liquid level is

sufficiently high.

Automatic test run carried out every 24 hours.

After the electricity has been switched on, the pump will

start immediately when the liquid level is sufficiently

high.

No automatic test run.

• Switches 5, 6 and 7, stop delay:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

The stop delay is the time from the stop signal is given until the

pump is stopped.

It must be ensured that the pump is not running dry.

0 sec. 60 sec.

15 sec. 90 sec.

30 sec. 120 sec.

45 sec. 180 sec.

•Switch 8:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

Switch 8 has no function in connection with the actual

application (100 % standby operation, pages 27 and

28), but this setting must be maintained!

•Switch 9, automatic alarm resetting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting ensures automatic resetting of alarm

signals to external alarm devices and the built-in

buzzer. However, an alarm signal will only be reset if

the cause of the fault no longer exists.

At this setting, the alarm signal must be reset manually

by means of the reset button (the reset button is

described in section 5.5).

•Switch 10, automatic restarting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

AC/DC selector:

The AC/DC selector switch for electrodes and/or float switches is

placed as shown in fig. 9.

TM02 5747 3902

Fig. 9

Operation with electrodes and

float switches:

Selector switch in position AC:

It is possible to connect 3

electrodes (1 as reference

electrode) and 2 float switches.

The controller transmits a 13 to

18 VAC signal.

Operation with float switches:

Selector switch in position AC:

It is possible to connect 4 float

switches.

The controller transmits a 13 to

18 VAC signal.

Operation with float switches:

Selector switch in position DC:

It is possible to connect 4 float

switches.

Cables of up to 100 metres can be

connected between the controller

and the float switches.

The controller transmits a 12 VDC

signal.

If the distance between the controller and pit exceeds 20 metres,

it is not advisable to use electrodes as problems with the signal

values sent back to the controller may arise. In such cases, it is

recommended to use float switches.

This setting enables automatic restarting after the PTC

resistance/thermal switch of the motor has cut out the

pump. Restarting will not be carried out until the motor

has cooled to normal temperature.

When the pumps connected are used in explosion

hazard areas, switch 10 must not be in this

position!

At this setting, the pump must be restarted manually after

the PTC resistance/thermal switch of the motor has cut

out the pump. To restart the pump, push the ON-OFFAUTO selector switch into position OFF for a short period

(the ON-OFF-AUTO selector switch is described in

section 5.5).

When the pumps connected are used in explosion

hazard areas, switch 10 must be in this position!

14

Page 15

5.3 Control panel

CU 212

21

1

2

1234756

12

11

9

8

10

1

CU 212

2

CU 212

2

1

100 % standby operation, pages 25 and 26.

Figure 10 shows the control panel of the CU 212 module.

Fig. 10

Key to the symbols in fig. 10:

Pos. Description

Green indicator light for pump 1 and 2, indicating

1

starting delay (flashing) and pump operation

(permanently on).

Red indicator light for pump 1 and 2.

2

Flashing: Fault in PTC resistor/thermal switch

On: Fault in motor-protective circuit breaker.

Red indicator light, indicating wrong phase sequence

3

(only certain variants and three-phase pumps only).

4 Red indicator light, indicating common alarm.

ON-OFF-AUTO selector switch for pump 1, three

5

positions, see section 5.5.

ON-OFF-AUTO selector switch for pump 2, three

6

positions, see section 5.5.

Reset button, push-button for manual resetting of alarm

7

signals to external alarm devices and the built-in buzzer

(only certain variants), see section 5.5.

Orange indicator light, which is activated by the float

8

switch for common stop.

Orange indicator light, which is activated by the float

9

switch for start of the first pump.

Orange indicator light, which is activated by the float

10

switch for high-level alarm. In case of high-level alarm,

the indicator light is flashing.

Orange indicator light, which is activated by the float

11

switch for start of the next pump.

Green indicator light, indicating that the electricity

12

supply has been switched on.

5.4 Battery back-up functions

100 % standby operation, pages 25 and 26.

If a back-up battery for CU 212 (accessory for certain variants) is

installed, the following functions will be carried out if the normal

electricity supply to the LCD 108 fails (see also the illustrations

below):

• The common alarm is active, the red indicator light is on –

cannot be reset!

• If the external alarm device for common alarm is supplied from

an external power source, this device will be active – cannot

be reset by means of the reset button!

• The built-in buzzer (only certain variants) is activated – can be

reset by means of the reset button!

• If the liquid level in the pit rises above the level for high-level

TM01 6397 3902

alarm, the second orange indicator light from the top will be

flashing. If the liquid level is higher than the level for start of

the next pump, the top orange indicator light will be

permanently on.

• If the starting delay function and automatic test run were

selected (switch 4 of the DIP switch), the start-up will be

delayed after the electricity supply has been switched on when

the liquid level is sufficiently high, see section 5.2.

The table below shows the situations which may occur if the

normal electricity supply to the LCD 108 fails and a back-up

battery is connected:

= the indicator light is off.

= the indicator light is on.

= the indicator light is flashing.

Mains supply failure:

• The common alarm is active.

The red indicator light is on.

• The green indicator light (electricity

supply switched on) is off.

Mains supply failure and high-level alarm:

• The common alarm is active.

The red indicator light is on.

• The top orange indicator light is on.

• The second orange indicator light from

the top is flashing.

• The green indicator light (electricity

supply switched on) is off.

15

Page 16

5.5 Reset button and ON-OFF-AUTO selector switch

21

100 % standby operation, pages 25 and 26.

The reset button is a push-button for manual resetting of alarm signals to external alarm devices and the built-in

buzzer (i.e. not for resetting of the alarm memory as this is reset by means of the ON-OFF-AUTO selector switch,

see position OFF ( )).

Even if the fault condition still exists, the external alarm devices and the built-in buzzer will be reset when the reset

button is pressed.

The ON-OFF-AUTO selector switch for each pump has three different positions:

ON ( ), top position:

• The pump will start when the selector switch is pushed into this position (unless the motor protection relay has cut

out the pump).

• If the PTC resistance/thermal switch of the motor registers overtemperature, the pump will not be switched off.

Note: It is the user’s responsibility to decide how long the pump is to run with this fault indication. Over a long

period, the pump will be damaged!

In explosion hazard areas, switch 10 of the DIP switch must be set as stated in section 5.2. Consequently,

the pump cannot be started when the PTC resistance/thermal switch of the motor registers overtemperature.

OFF ( ), middle position:

• The pump cannot start when the selector switch has been set to this position.

• The alarm memory is reset by pushing the selector switch into position OFF ( ). The alarm memory is the light

indication of a fault condition which has disappeared. If a fault condition still exists when the selector switch is

pushed into position ON ( ) or AUTO ( ), the alarm indication will be repeated immediately.

AUTO ( ), bottom position:

• The pump is controlled by the input signals from the float switches and the pump according to the selected

DIP switch setting.

• Alarm signals will automatically be reset. Switch 9 of the DIP switch can, however, be set to manual resetting

which is carried out by means of the reset button, see section 5.2.

• The pump will restart automatically when a given fault condition disappears. However, this is dependent on the

setting of switch 10 of the DIP switch, see section 5.2.

• When the pump starts automatically after a fault condition which has disappeared, the indicator light will continue

to show the fault condition (alarm memory) and the indication can only be removed by resetting the alarm memory,

see position OFF ().

16

Page 17

6. System for full-control operation

Description (see also page 29 or 30):

The pumps are controlled by the liquid level in the pit.

• The float switch, pos. 3, starts the first pump.

• The float switch, pos. 4, starts the next pump.

• The float switch, pos. 2, stops the last pump but one and the

float switch, pos. 1, stops the last pump. It is possible to set a

"stop delay" which delays the stop of the pumps.

• The pumps operate alternately.

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting of

pumps, pits, etc. must be carried out according to

local regulations.

Before making any connections in the LCD 108 or

work on pumps, pits, etc., it must be ensured that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

6.1 Electrical connection

Full-control operation, pages 29 and 30.

Before starting work on the system, switch off the

supply voltage and lock the mains switch in

position 0.

Any external voltage connected to the system must

be switched off before work is started.

Fig. D2 on page 29.

The figures show all electrical connections required to connect

the LCD 108 for direct-on-line starting, full-control operation.

Fig. D2 on page 30.

The figure shows all electrical connections required to connect

the LCD 108 for star-delta starting, full-control operation.

The float switches must be connected as NO contacts, i.e. brown

and black leads, when float switches, Grundfos product number

96003332 or 96003695, are used.

Key to the symbols in fig. D1 on page 30 and fig. D2 on

page 30:

Pos. Description

1 Float switch for stop of the last pump. 11-12

Float switch for stop of the last pump but

2

one.

3 Float switch for start of the first pump. 31-32

4 Float switch for start of the next pump. 41-42

Terminal

number

21-22

6.2 Setting

Full-control operation, pages 29 and 30.

The module CU 212 has a 10-pole DIP switch in the bottom right

corner, see fig. 11.

Note: The controller must be off circuit to ensure the correct

configuration during start-up after change of the DIP switch

setting.

The DIP switch setting offers the following possibilities:

• selection of starting delay and automatic test run (switch 4),

• setting of stop delay (switches 5, 6 and 7),

• selection of automatic alarm resetting (switch 9),

• selection of automatic restarting (switch 10).

The LCD 108 must be connected in accordance with

the rules and standards in force for the application in

question.

The operating voltage and frequency are marked on the controller

nameplate. Make sure that the controller is suitable for the

electricity supply on which it will be used.

All cables/wires must be fitted through the Pg cable entries and

gaskets (IP 65).

Maximum back-up fuse is stated on the controller nameplate.

If required according to local regulations, an external mains

switch must be installed.

Note: If the PTC resistance/thermal switch of the motor is

connected, the factory-fitted short-circuit jumper must be

removed (terminals T11-T21, T12-T22). For correct installation of

PTC resistor/thermal switch, see the installation and operating

instructions of the pump

Single-phase motors must be connected to an external operating

capacitor and in certain cases also to a starting capacitor. Further

details can be found in the installation and operating instructions

for the pump in question.

Float switches placed in an explosion hazard area

must be connected via an EEx barrier, e.g. Grundfos

number 96440300.

The EEx barrier must not be installed in the explosion

hazard area.

Equipment used in explosion hazard areas must in

each individual case have been approved for this

particular application. Furthermore, the cables into

the explosion hazard area must be laid in accordance

with local regulations.

Note: Float switches of the same type as Grundfos product

number 96003332 or 96003695, i.e. float switches with

gold-plated contacts suitable for low voltages and currents

(40 V/100 mA), must be used. All EEx-approved float switches

are also suitable.

TM04 2342 2308

Fig. 11

Set the DIP switch as shown in fig. 11.

Each individual switch (1 to 10) of the DIP switch can be set to

position OFF or ON.

Note: The DIP switch must not be set to other switch

combinations than those described in this section.

Set the switches 1 to 10 as follows:

• Switches 1, 2 and 3, application type:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting determines the actual application type

(full-control operation, pages 29 and 30).

17

Page 18

•Switch 4, starting delay and automatic test run

AC 1 2

13-18 VAC

0 V

AC

DC

G3 4

AC 1 2

13-18 VAC

0 V

AC

DC

G3 4

AC 1 2

12 VDC

0 V

AC

DC

G3 4

(only in the case of battery back-up):

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

At this setting, the start-up is delayed within the range

from 0 to 255 sec. (random) after the electricity supply

has been switched on when the liquid level is

sufficiently high.

Automatic test run carried out every 24 hours.

After the electricity has been switched on, the pump will

start immediately when the liquid level is sufficiently

high.

No automatic test run.

• Switches 5, 6 and 7, stop delay:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

The stop delay is the time from the stop signal is given until the

pump is stopped.*

It must be ensured that the pump is not running dry.

0 sec. 60 sec.

15 sec. 90 sec.

30 sec. 120 sec.

•Switch 10, automatic restarting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting enables automatic restarting after the PTC

resistance/thermal switch of the motor has cut out the

pump. Restarting will not be carried out until the motor

has cooled to normal temperature.

When the pumps connected are used in explosion

hazard areas, switch 10 must not be in this

position!

At this setting, the pump must be restarted manually after

the PTC resistance/thermal switch of the motor has cut

out the pump. To restart the pump, push the ON-OFFAUTO selector switch into position OFF for a short period

(the ON-OFF-AUTO selector switch is described in

section 6.5).

When the pumps connected are used in explosion

hazard areas, switch 10 must be in this position!

AC/DC selector:

The AC/DC selector switch for electrodes and/or float switches is

placed as shown in fig. 12.

45 sec. 180 sec.

* The stop delay applies to both stop float switches, pos. 1 and 2,

on pages 29 and 30. If the two stop float switches are placed

so close to each other that the stop delay for the upper stop

float switch has not expired before the liquid level reached the

lower stop float switch, then both pumps will not be stopped

until the stop delay for the lower float switch has expired.

•Switch 8:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

Switch 8 has no function in connection with the actual

application (full-control operation, pages 29 and 30),

but this setting must be maintained!

•Switch 9, automatic alarm resetting:

When the DIP switch setting is changed, the controller must

be switched off for at least 1 minute!

This setting ensures automatic resetting of alarm

signals to external alarm devices and the built-in

buzzer. However, an alarm signal will only be reset if

the cause of the fault no longer exists.

At this setting, the alarm signal must be reset manually

by means of the reset button (the reset button is

described in section 6.5).

TM02 5747 3902

Fig. 12

Operation with electrodes and

float switches:

Selector switch in position AC:

It is possible to connect 3

electrodes (1 as reference

electrode) and 2 float switches.

The controller transmits a 13 to

18 VAC signal.

Operation with float switches:

Selector switch in position AC:

It is possible to connect 4 float

switches.

The controller transmits a 13 to

18 VAC signal.

Operation with float switches:

Selector switch in position DC:

It is possible to connect 4 float

switches.

Cables of up to 100 metres can be

connected between the controller

and the float switches.

The controller transmits a 12 VDC

signal.

If the distance between the controller and pit exceeds 20 metres,

it is not advisable to use electrodes as problems with the signal

values sent back to the controller may arise. In such cases, it is

recommended to use float switches.

18

Page 19

6.3 Control panel

CU 212

21

1

2

1234756

12

11

9

8

10

1

CU 212

2

Full-control operation, pages 29 and 30.

Figure 13 shows the control panel of the CU 212 module.

Fig. 13

Key to the symbols in fig. 13:

Pos. Description

Green indicator light for pump 1 and 2, indicating

1

starting delay (flashing) and pump operation

(permanently on).

Red indicator light for pump 1 and 2.

2

Flashing: Fault in PTC resistor/thermal switch

On: Fault in motor-protective circuit breaker.

Red indicator light, indicating wrong phase sequence

3

(only certain variants and three-phase pumps only).

4 Red indicator light, indicating common alarm.

ON-OFF-AUTO selector switch for pump 1, three

5

positions, see section 6.5.

ON-OFF-AUTO selector switch for pump 2, three

6

positions, see section 6.5.

Reset button, push-button for manual resetting of alarm

7

signals to external alarm devices and the built-in buzzer

(only certain variants), see section 6.5.

Orange indicator light, which is activated by the float

8

switch for stop of the last pump.

Orange indicator light, which is activated by the float

9

switch for stop of the last pump but one.

Orange indicator light, which is activated by the float

10

switch for start of the first pump.

Orange indicator light, which is activated by the float

11

switch for start of the next pump.

Green indicator light, indicating that the electricity

12

supply has been switched on.

6.4 Battery back-up functions

Full-control operation, pages 29 and 30.

If a back-up battery for CU 212 (accessory for certain variants) is

installed, the following functions will be carried out if the normal

electricity supply to the LCD 108 fails (see also the illustrations

below):

• The common alarm is active, the red indicator light is on –

cannot be reset!

• If the external alarm device for common alarm is supplied from

an external power source, this device will be active – cannot

be reset by means of the reset button!

• The built-in buzzer (only certain variants) is activated – can be

reset by means of the reset button!

• If the starting delay function and automatic test run were

TM01 6397 3902

selected (switch 4 of the DIP switch), the start-up will be

delayed after the electricity supply has been switched on when

the liquid level is sufficiently high, see section 6.2.

The table below shows the situation which may occur if the

normal electricity supply to the LCD 108 fails and a back-up

battery is connected:

= the indicator light is off.

= the indicator light is on.

= the indicator light is flashing.

Mains supply failure:

• The common alarm is active.

The red indicator light is on.

• The green indicator light (electricity

supply switched on) is off.

19

Page 20

6.5 Reset button and ON-OFF-AUTO selector switch

21

Full-control operation, pages 29 and 30.

The reset button is a push-button for manual resetting of alarm signals to external alarm devices and the built-in

buzzer (i.e. not for resetting of the alarm memory as this is reset by means of the ON-OFF-AUTO selector switch,

see position OFF ( )).

Even if the fault condition still exists, the external alarm devices and the built-in buzzer will be reset when the reset

button is pressed.

The ON-OFF-AUTO selector switch for each pump has three different positions:

ON ( ), top position:

• The pump will start when the selector switch is pushed into this position (unless the motor protection relay has cut

out the pump).

• If the PTC resistance/thermal switch of the motor registers overtemperature, the pump will not be switched off.

Note: It is the user’s responsibility to decide how long the pump is to run with this fault indication. Over a long

period, the pump will be damaged!

In explosion hazard areas, switch 10 of the DIP switch must be set as stated in section 6.2. Consequently,

the pump cannot be started when the PTC resistance/thermal switch of the motor registers overtemperature.

OFF ( ), middle position:

• The pump cannot start when the selector switch has been set to this position.

• The alarm memory is reset by pushing the selector switch into position OFF ( ). The alarm memory is the light

indication of a fault condition which has disappeared. If a fault condition still exists when the selector switch is

pushed into position ON ( ) or AUTO ( ), the alarm indication will be repeated immediately.

AUTO ( ), bottom position:

• The pump is controlled by the input signals from the float switches and the pump according to the selected

DIP switch setting.

• Alarm signals will automatically be reset. Switch 9 of the DIP switch can, however, be set to manual resetting

which is carried out by means of the reset button, see section 6.2.

• The pump will restart automatically when a given fault condition disappears. However, this is dependent on the

setting of switch 10 of the DIP switch, see section 6.2.

• When the pump starts automatically after a fault condition which has disappeared, the indicator light will continue

to show the fault condition (alarm memory) and the indication can only be removed by resetting the alarm

memory, see position OFF ().

20

Page 21

7. Start-up

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting of

pumps, pits, etc. must be carried out according to

local regulations.

Before making any connections in the LCD 108 or

work on pumps, pits, etc., it must be ensured that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

Prior to start-up, the connection and DIP switch setting must have

been carried out according to sections 3. to 6.

Start-up must be carried out by authorized personnel.

Proceed as follows:

1. Check whether the float switches have been connected

according to the wiring diagram for the actual application.

2. Check that the pump inlets are submerged in the liquid to be

pumped.

3. Set the motor protection relays to the rated current stated on

the nameplates.

4. Warning:

Ensure that the short-circuit protection is suitable for

the installation.

5. Switch on the electricity supply.

Three-phase pumps only: Check for wrong phase sequence,

(the pump cannot be started if the phase sequence is wrong!).

6. Start the pumps, see section 3.5, 4.5, 5.5 or 6.5.

7. Check that the pumps are not running dry. The risk of dry

running can be eliminated by a renewed time setting by means

of the DIP switch according to section 3.2, 4.2, 5.2 or 6.2 and/

or by moving the float switches.

8. Three-phase pumps only: Check whether the direction of

rotation of the pumps is correct according to the installation

and operating instructions for the pump in question.

9. Select the required operating mode by means of the ON-OFFAUTO selector switch, see section 3.5, 4.5, 5.5 or 6.5.

8. Maintenance

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting of

pumps, pits, etc. must be carried out according to

local regulations.

Before making any connections in the LCD 108 or

work on pumps, pits, etc., it must be ensured that the

electricity supply has been switched off and that it

cannot be accidentally switched on.

During normal application and operation, the controller LCD 108

is maintenance-free.

However, it is advisable to carry out minor checks of the LCD 108

controller, pump pits, tanks, pumps, etc. at suitable intervals.

These checks should be carried out by authorized personnel.

• Check the gaskets of the LCD 108 cabinet front and those of

the Pg cable entries.

• Check the cable entries for the explosion hazard area.

• Check for possible deposits/sludge build-up in the pump pit/

tank. Sludge may settle in areas with almost stagnant liquid.

• Check for beginning sludge build-up around the float switches.

• Check for possible blockage on the suction side of the pump.

A blockage will typically be a large solid object.

• If the LCD 108 has been installed in a particularly aggressive

environment, it is advisable to check the motor protection contacts in order to identify possible chemical attack resulting in

corrosion. In typical installations, the motor protection contacts

will work for several years and do not require any inspection.

Note: The list above is not complete. The LCD 108 may be

installed in systems, installations and/or environments which

require thorough and regular maintenance.

9. Technical data

Voltage variants, nominal voltages

• 1 x 230 V.

• 3 x 415 V.

Voltage tolerances for LCD 108

–15 %/+10 % of nominal voltage.

See also installation and operating instructions for the pump in

question.

Mains frequency for LCD 108

50/60 Hz. See also installation and operating instructions for the

pump in question.

Supply system earthing

For TN systems and TT systems.

Rated insulation voltage, U

4 kV.

Rated impulse withstand voltage, U

4 kV.

Short-circuit protection of supply

Depending on variant, see nameplate.

Control circuit fuse

Fine-wire fuse: 250 mA / F / 32 mm x ∅6 mm.

Ambient temperat ur e

• During operation: –30 to +50 °C

(must not be exposed to direct sunlight).

• In stock: –30 to +60 °C.

Enclosure class

IP 65.

EMC (electromagnetic compatibility)

According to EN 61 000-6-2 and EN 61 000-6-3.

Cabinet LCD 108 for direct-on-line starting

• External dimensions (including glands):

Height = 590 mm, width = 380 mm, depth = 220 mm.

• Material: ABS (Acrylonitrile butadiene styrene).

• Weight: Approx. 5 kg, depending on variant, see nameplate.

Outputs for alarm devices

Max. 230 VAC / max. 2 A / min. 10 mA / AC1.

i

imp

21

Page 22

10. Fault finding chart

Subject to alterations.

Before starting any work on pumps used to pump liquids which could be constituted as being hazardous to health, thorough

cleaning/venting of pumps, pits, etc. must be carried out according to local regulations.

Before making any connections in the LCD 108 or work on pumps, pits, etc., it must be ensured that the electricity supply has

been switched off and that it cannot be accidentally switched on.

Fault Cause Remedy

1. The pumps do not run. a) No electricity supply.

Without battery back-up:

None of the indicator lights are on.

With battery back-up

(accessory for certain variants):

See section 3.4, 4.4, 5.4 or 6.4.

b) The ON-OFF-AUTO selector switch is in

position OFF, see section 3.5, 4.5, 5.5 or

6.5.

c) Control circuit fuses are blown. Check and eliminate the cause. Replace the control

d) The motor protection relays have cut out the

pumps (the red indicator light for pump fault

is permanently on).

e) The PTC resistance/thermal switch has cut

out the pump (the red indicator light for

pump fault is flashing).

f) The control circuit for the motor protection

relays has been broken or fails (the green

indicator light indicating pump operation is

permanently on, see section 3.3, 4.3, 5.3 or

6.3).

g) Motor/supply cable is defective. Check motor and cable.

h) The float switches are defective. Check cables and float switches.

i) The CU 212 module is defective. Replace the CU 212 module.

j) The new DIP switch setting does not work

correctly.

2. The pumps are starting/

stopping too frequently.

See also installation and operating instructions for the pump in question.

a) The float switches are defective. Check cables and float switches.

Switch on the electricity supply.

Push the ON-OFF-AUTO selector switch into position

ON or AUTO.

circuit fuses (see pos. 6 in fig. 1 or fig. 3).

Check the pump/pit.

Allow the pump to cool. After cooling, the pump will

restart automatically unless the LCD 108 has been set

to manual restarting, see section 3.2, 4.2, 5.2 or 6.2.

If so, the ON-OFF-AUTO selector switch must be

pushed into position OFF for a short period.

If the pump cutout was caused by choked-up float

switches, these must be cleaned or replaced.

Check the control circuit.