Page 1

CU 241

Dual pump unit

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

Page 3

CU 241

English (GB)

Installation and operating instructions ..........................................................5

Български (BG)

Упътване за монтаж и експлоатация.........................................................29

Čeština (CZ)

Montážní a provozní návod .................................................................52

Deutsch (DE)

Montage- und Betriebsanleitung .............................................................74

Dansk (DK)

Monterings- og driftsinstruktion ..............................................................97

Eesti (EE)

Paigaldus- ja kasutusjuhend ...............................................................120

Español (ES)

Instrucciones de instalación y funcionamiento ..................................................143

Suomi (FI)

Asennus- ja käyttöohjeet ..................................................................166

Français (FR)

Notice d'installation et de fonctionnement .....................................................189

Table of contents

Ελληνικά (GR)

Οδηγίες εγκατάστασης και λειτουργίας........................................................212

Hrvatski (HR)

Montažne i pogonske upute ................................................................235

Magyar (HU)

Telepítési és üzemeltetési utasítás...........................................................257

Italiano (IT)

Istruzioni di installazione e funzionamento .....................................................280

Lietuviškai (LT)

Įrengimo ir naudojimo instrukcija ............................................................303

Latviešu (LV)

Uzstādīšanas un ekspluatācijas instrukcija ....................................................325

Nederlands (NL)

Installatie- en bedieningsinstructies ..........................................................347

Polski (PL)

Instrukcja montażu i eksploatacji ............................................................370

Português (PT)

Instruções de instalação e funcionamento .....................................................393

Română (RO)

Instrucţiuni de instalare şi utilizare ...........................................................416

Srpski (RS)

Uputstvo za instalaciju i rad ................................................................439

Русский (RU)

Паспорт, Руководство по монтажу и эксплуатации.............................................462

Svenska (SE)

Monterings- och driftsinstruktion.............................................................486

Slovensko (SI)

Navodila za montažo in obratovanje .........................................................508

Türkçe (TR)

3

Page 4

Table of contents

Montaj ve kullanım kılavuzu ................................................................530

Українська (UA)

Інструкції з монтажу та експлуатації ........................................................554

中文 (CN)

安装和使用说明书 .......................................................................577

(AR) ةيبرعلا

......................................................................599

4 CU 241

Page 5

English (GB) Installation and operating instructions

Original installation and operating instructions

Table of contents

1. General information ......................................................................6

1.1 Hazard statements........................................................................6

1.2 Notes ................................................................................6

2. Installing the product .....................................................................6

2.1 Location ..............................................................................6

2.2 Mechanical installation .....................................................................7

2.3 Electrical connection...................................................................... 11

3. Starting up the product ................................................................... 11

3.1 Connecting to Grundfos GO Remote............................................................ 11

3.2 Startup wizard on Grundfos GO Remote ......................................................... 11

3.3 Startup wizard on the operating panel ........................................................... 11

3.4 How to enable Bluetooth on the operating panel..................................................... 11

3.5 How to disable Bluetooth on the operating panel .................................................... 12

3.6 Testing the product.......................................................................12

4. Product introduction.....................................................................12

4.1 Product description ......................................................................12

4.2 Intended use ..........................................................................12

4.3 Features .............................................................................12

4.4 Application types ........................................................................12

4.5 Terminals ............................................................................14

4.6 Identification........................................................................... 14

4.7 Supported communication interface modules and protocols .............................................. 15

5. Control functions ....................................................................... 15

5.1 Operating panel ........................................................................ 15

6. Setting the product...................................................................... 16

6.1 Setting the application type with Grundfos GO Remote.................................................16

6.2 Setting the sensor type ....................................................................16

6.3 Setting the start level ..................................................................... 16

6.4 Setting the stop level .....................................................................17

6.5 Setting the high level .....................................................................17

6.6 Stop delay ............................................................................18

6.7 Power-on delay......................................................................... 18

6.8 Dry-running protection.....................................................................18

6.9 "Multipump settings" ...................................................................... 18

6.10 Using the same level switch for the start and stop level ................................................ 18

6.11 "Antiseizing"...........................................................................19

6.12 Signal-detection time ..................................................................... 19

6.13 Setting the maximum number of restarts with Grundfos GO Remote ........................................19

6.14 Setting the service interval with Grundfos GO Remote .................................................19

6.15 Motor protection ........................................................................ 19

6.16 Alarm reset ........................................................................... 20

6.17 Setting the buzzer with Grundfos GO Remote ......................................................20

6.18 Setting units for Grundfos GO Remote........................................................... 20

6.19 Setting units for the operating panel with Grundfos GO Remote ........................................... 21

6.20 GENIbus .............................................................................21

6.21 Security .............................................................................21

6.22 Starting the startup wizard with the operating panel ................................................... 22

7. Operating the product....................................................................22

7.1 Manual operation........................................................................ 22

8. Servicing the product .................................................................... 23

8.1 Updating the product software................................................................23

8.2 Replacing the control unit................................................................... 23

8.3 Replacing the CIM module ..................................................................23

8.4 Replacing the battery ..................................................................... 23

9. Fault finding the product ..................................................................24

9.1 Overview of alarm and warning codes ...........................................................24

9.2 Code 2 (Power phase missing) ............................................................... 24

9.3 Code 4 (Too many motor restarts) .............................................................24

9.4 Code 9 (Power phase sequence wrong)..........................................................24

9.5 Code 12 (Service needed) ..................................................................25

9.6 Code 22 (Moisture in motor of pump) ........................................................... 25

English (GB)

5

Page 6

English (GB)

9.7 Code 25 (Wrong configuration) ............................................................... 25

9.8 Code 48 (Motor is overloaded) ............................................................... 25

9.9 Code 57 (Missing water in the application) ........................................................25

9.10 Code 69 (Winding temperature too high) ......................................................... 25

9.11 Code 84 (Memory storage media faulty)..........................................................26

9.12 Code 117 (Door opened) ...................................................................26

9.13 Code 159 (Communication error CIMxxx) .........................................................26

9.14 Code 165 (Signal fault) ....................................................................26

9.15 Code 191 (High water level) .................................................................26

9.16 Code 205 (Level switch inconsistency) ..........................................................26

9.17 Code 225 (Communication error pump module) .....................................................27

9.18 Code 226 (Communication error IO module) ....................................................... 27

9.19 Code 229 (Water on floor) .................................................................. 27

10. Technical data......................................................................... 27

11. Disposing of the product ..................................................................28

1. General information

1.1 Hazard statements

The symbols and hazard statements below may appear in Grundfos installation and operating instructions, safety instructions and service

instructions.

Read this document before you install the product. Installation and operation must comply with local regulations and accepted codes

of good practice.

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious personal injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious personal injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate personal injury.

The hazard statements are structured in the following way:

SIGNAL WORD

Description of the hazard

Consequence of ignoring the warning

• Action to avoid the hazard.

1.2 Notes

The symbols and notes below may appear in Grundfos installation and operating instructions, safety instructions and service instructions.

Observe these instructions for explosion-proof products.

A blue or grey circle with a white graphical symbol indicates that an action must be taken.

A red or grey circle with a diagonal bar, possibly with a black graphical symbol, indicates that an action must not be taken or must be

stopped.

If these instructions are not observed, it may result in malfunction or damage to the equipment.

Tips and advice that make the work easier.

2. Installing the product

2.1 Location

Install the product in a location that meets the following requirements:

6

Page 7

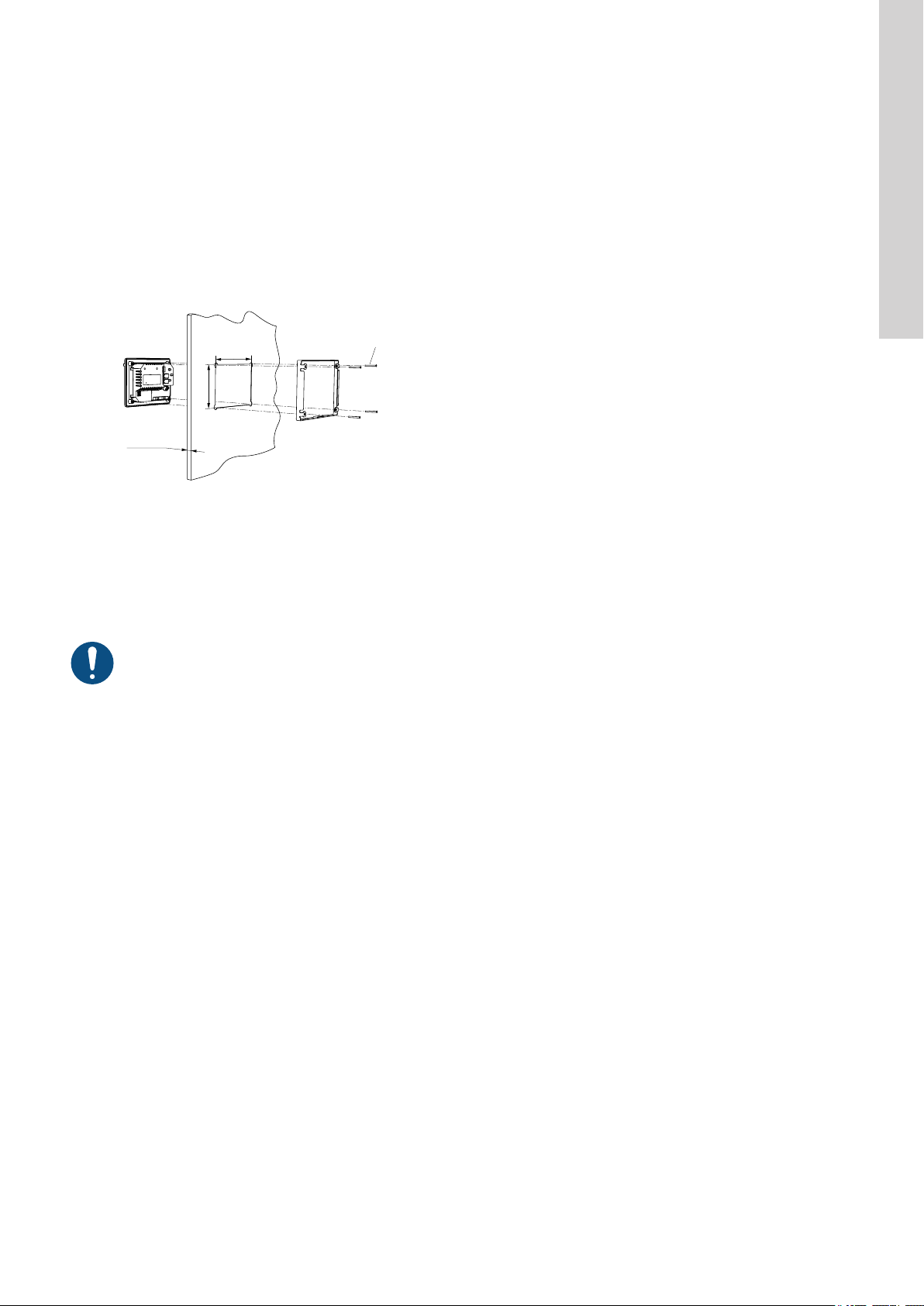

• Place the product in a flood-safe place.

1

160.5 (6.3")

110.5 (4.35")

Min. 1 (0.04")

Max. 5 (0.2")

• Make sure that the ambient temperature is within the limits.

• Install the product as close as possible to the connected pumps, sensors, and accessories.

• The product must be protected from direct sunlight.

• The product must be easily accessible.

• Outdoor installation: the product must be installed in a protective shed or enclosure, class IP 54.

• Indoor installation:The product must be installed in a well-ventilated room to ensure cooling of its components.

2.2 Mechanical installation

2.2.1 Mounting the control unit

1. Fasten the control unit with the four screws (1), M4 x 12, supplied with the unit. Torque value: 0.5 Nm.

Fig. Mounting the control unit

Related information

8.2 Replacing the control unit

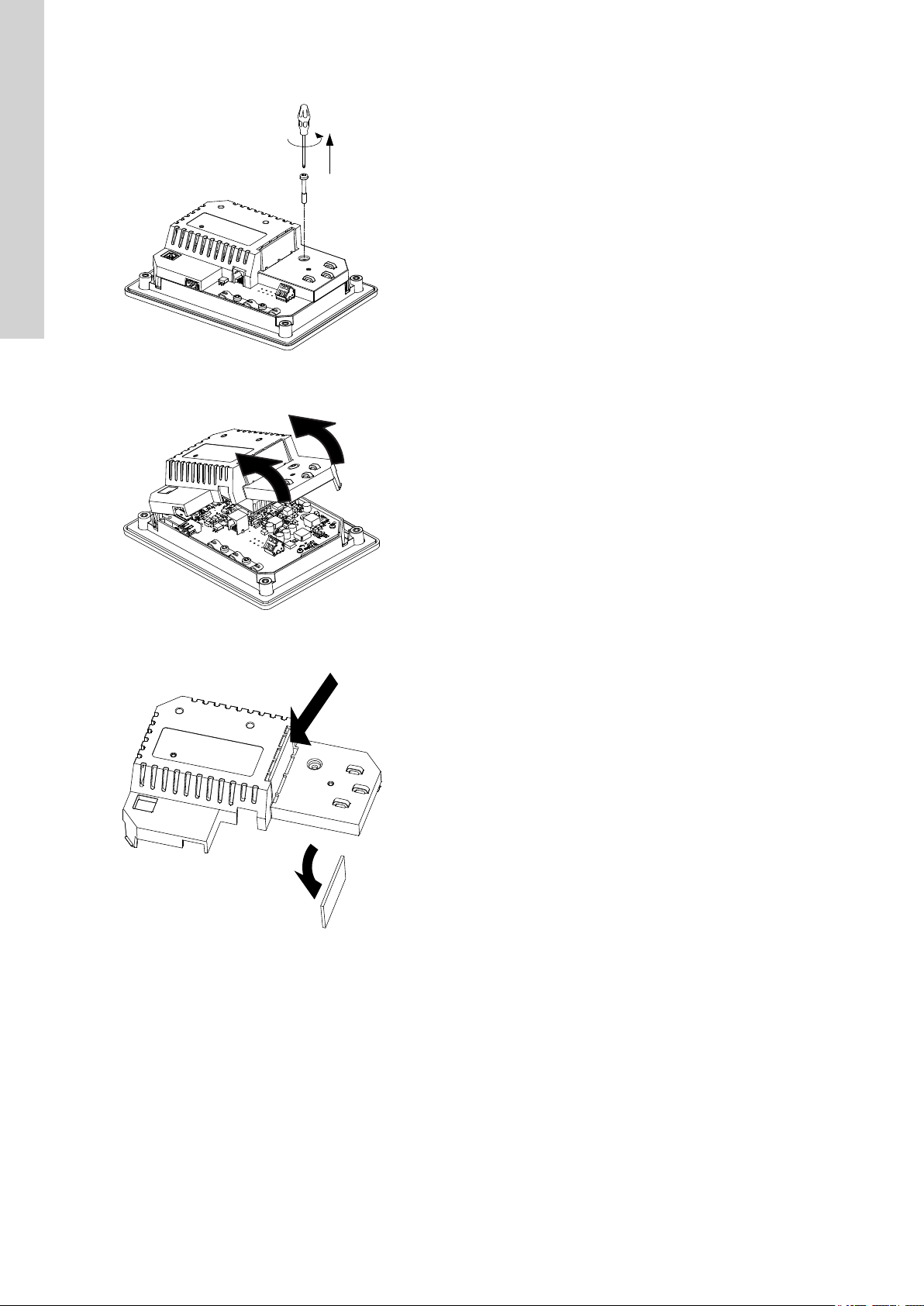

2.2.2 Installing a communication interface module

You can fit a communication interface module (CIM) in the control unit to enable communication with external systems. The module is optional

and is not delivered with the product. See the installation and operating instruction for the module regarding electrical connections.

English (GB)

TM072345

Use an antistatic service kit when handling electronic components. This prevents static electricity from damaging the components.

7

Page 8

English (GB)

1. Remove the screw in the back cover of the CU product.

2. Remove the back cover.

TM071905

3. Break off the tap.

TM071906

TM071977

8

Page 9

4. Fit the CIM module.

English (GB)

TM071907

9

Page 10

Type:

Kit Funct. module - Geni/RS485Op

0538

9854

CIM XXX

CIM XXX

96824795

V01

Prod. No.

Version

Serial No.

P. C.

English (GB)

5. If supplied, place the labels on the back cover.

6. Refit the back cover to the CU product and secure it with the mounting screw. Secure cables using the cable tie holders.

TM071908

10

TM071909

Page 11

2.3 Electrical connection

2.3.1 Connecting the power supply

1. Check that the supply voltage corresponds with the needed 24 VDC and ensure that the polarity is connected correctly according to the

label on the product itself.

2. Connect the power cables and pump cables according to the relevant electrical diagram.

Connecting a wire to a terminal with spring clamps

3. Starting up the product

3.1 Connecting to Grundfos GO Remote

1. Open Grundfos GO Remote on your device. Make sure that Bluetooth is enabled.

Your device must be within reach of the product to establish Bluetooth connection.

2. Press the Bluetooth CONNECT button on Grundfos GO Remote.

3. Press the connect button on the operating panel. The blue LED above the connect button is flashing blue until your device is connected.

Grundfos GO Remote is now loading the data for the product.

Related information

3.4 How to enable Bluetooth on the operating panel

3.5 How to disable Bluetooth on the operating panel

English (GB)

TM070570

3.2 Startup wizard on Grundfos GO Remote

The product is designed for Bluetooth communication with Grundfos GO Remote.

Once you have connected your product to Grundfos GO Remote, a startup wizard appears. Follow the instructions to make your settings.

Grundfos GO Remote enables you to set functions and gives you access to status overviews, technical product information and current

operating parameters.

Related information

8.2 Replacing the control unit

3.3 Startup wizard on the operating panel

The first time the control unit is switched on, a startup wizard will guide you through the basic settings. You can select the sensor type and

sensor levels. For some products, you can also set the nominal pump current and number of phases.

If you have an analog sensor, select S-1 and set the height of the different levels, from dry running to high level.

If you have a digital sensor, select S-2 and enable or disable the dry-running level, the start level for pump 2, if available and the high level.

To change settings, use the Up and Down buttons on the operating panel.

Use the OK button to confirm each setting and navigate to the next setting.

For filling applications, you must use Grundfos GO Remote.

Units can only be changed with Grundfos GO Remote.

Designation

S-1 Analog sensor

S-2 Digital sensor

Related information

6.22 Starting the startup wizard with the operating panel

Description

3.4 How to enable Bluetooth on the operating panel

If the Bluetooth signal on the operating panel has been disabled for some reason, you are not able to connect with Grundfos GO Remote. You

must enable Bluetooth first.

1. Press and hold the connect button on the operating panel for 15 seconds. Wait for the blue LED to light up.

2. Press the Bluetooth CONNECT button on Grundfos GO Remote.

3. Press the connect button on the operating panel. The blue LED above the connect button is flashing blue until your device is connected

Grundfos GO Remote is now loading the data for the product.

11

Page 12

English (GB)

Related information

3.1 Connecting to Grundfos GO Remote

3.5 How to disable Bluetooth on the operating panel

In some installation areas it is not allowed to have a Bluetooth signal enabled during operation. After installation, the Bluetooth signal must be

disabled manually.

1. Press and hold the connect button on the operating panel for 15 seconds. Wait for the blue LED to switch off.

Grundfos GO Remote is not connected to the product anymore.

Related information

3.1 Connecting to Grundfos GO Remote

3.6 Testing the product

When you have made all the electrical installations and completed the startup wizard, you can test the system.

For emptying applications:

• Fill the pit with water and check that the pump starts automatically at the defined level.

• Test the dry-running function by starting the pump manually and wait while the pit with the pump is emptied. Check that the control unit

indicates an alarm and stops the pump when the defined level is reached.

• Test the high-level function by stopping the pump manually and continue to fill the pit with water. Check that the control unit indicates an

alarm when the defined level is reached. Set the pump to Auto and observe that the pump starts and stops when the stop level has been

reached.

For filling applications:

• Start by draining the tank to be filled. When the tank is empty and the start level is reached, the pump must start. When the tank is full and

the stop level is reached, the pump must stop.

• Test the high-level function by stopping the pump manually and continue to fill the tank without the pump with water. Check that the control

unit indicates an alarm when the defined level is reached.

• Test the dry-running function by starting the pump manually and wait while the tank with the pump is emptied. Check that the control unit

indicates an alarm and stops the pump when the defined level is reached. If the pump is placed in a well, this test may not be possible

since the pump cannot empty the well. Alternatively, pull the dry-run level switch up to simulate a dry-run situation. The same can be done

with a pressure level sensor.

4. Product introduction

4.1 Product description

The level-control unit switches the pump on and off according to the liquid level measured by float switches or a pressure sensor. When the

start level is reached, the pump starts, and when the liquid level has been lowered to the stop level, the pump is stopped by the control unit.

An alarm is indicated in case of for example high-water level in the tank or sensor failure.

Basic settings are configured via the operating panel and advanced settings are configured with Grundfos GO Remote. Furthermore, you can

read important operating parameters with Grundfos GO Remote.

4.2 Intended use

The control unit is designed to control two pumps.

The product can be configured for two purposes: emptying a wastewater pit or filling a pit or tank. The product can be used for network

pumping stations, main pumping stations, commercial buildings and municipal systems.

The control unit is only intended for use in control panels.

4.3 Features

The control unit features among others the following functions:

• support of up to two pumps

• manual and automatic control of the pump

• Bluetooth pairing with Grundfos GO Remote

• operating indication, such as power on and pump running

• alarm and warning indication, such as power phase missing and high-water level

• motor and phase failure protection

• setting of stop delays matching the actual operating conditions.

• automatic alternation of pumps.

4.4 Application types

You can choose between two application types:

• Empty

• Fill

You can set the application type with Grundfos GO Remote.

12

Page 13

Empty

1

2

3

4

5

1

2

3

4

5

Pos. Description

1 High level

2 Start level P2: start level for pump 2

3 Start level P1: start level for pump 1

4 Stop level

5 Dry-running level

The pump will start to empty the tank or pit when Start level P1 is reached.

A second pump will start if the liquid level reaches Start level P2.

The pump stops when the liquid level is lowered to Stop level.

If the inflow of liquid exceeds the capacity of the installed pump, the level in the tank or pit will rise. Eventually, the High level sensor will

register a high liquid level in the tank or pit. If set, the signal from the High level sensor can be used to activate an output relay which can then

be used to indicate a visual or acoustic alarm or send a signal to a SCADA system.

If the pump is running and the liquid level in the tank or pit falls below the dry-running level, the dry-running protection will stop the pump to

ensure that it is not damaged mechanically.

Fill

English (GB)

TM0713341

Designation

Description

1 High level

2 Stop level

3 Start level P1: start level for pump 1

4 Start level P2: start level for pump 2

5 Dry-running level

In the filling application, the pump is installed in a tank or well from where it pumps the liquid. The liquid is pumped into a second tank where

the level sensors are installed.

The pump will start to fill the second tank when Start level P1 is reached.

A second pump will start if the liquid level reaches Start level P2.

The pump stops when the liquid level reaches Stop level.

If the pump for some reason does not stop at Stop level and the liquid level keeps rising, the High level sensor will eventually register this. If

set, the signal from the High level sensor can be used to activate a relay output which can then be used to indicate a visual or acoustic alarm

or send a signal to a SCADA system via a communication interface.

If the pump is running and the liquid level in the tank falls below the dry-running level, the dry-running protection will stop the pump to ensure

that it is not damaged.

Related information

7.1.2 Automatic operation

TM0713351

13

Page 14

7

1

4

5

6

3

2

Type

P.N.

UN

Pmax

IP

99350754

S.N.

P.C.

°C

P1

Tamb max

DK - 8850 Bjerringbro Denmark

Made in Denmark

1

2

3

4

567

9

10

11

8

English (GB)

4.5 Terminals

Pos. Description

1 Terminal for a CIM module, optional

2 Cable tie holders

3 Terminal for the power supply

4 GENIbus, for internal use between modules.

5 USB port

6 Service connection

7 Nameplate

4.6 Identification

4.6.1 Nameplate

TM072351

Pos.

Description

1 Production code, year and week

2 Serial number

3 Enclosure class

4 Max. ambient temperature

5 Max. power consumption

6 Factory code

7 Markings and approvals

8 Production site

9 Supply voltage

10 Version number

11 Product name

4.6.2 Type key

Example

CU 241 1

Pos. 1 2

TM072129

Pos.

1

2 Number of pumps supported

14

Description

Type

• CU 241

Page 15

4.7 Supported communication interface modules and protocols

7

6

8

8

9

11

10

13

14

15

12

5

4

3

2

1

ft

m

The following Grundfos communication interface modules can be added to the product.

Communication interface module Protocol

CIM 050 GENIbus

CIM 150 PROFIBUS DP

CIM 200 Modbus RTU

CIM 260 3G/4G

CIM 270 GRM

CIM 280 Grundfos iSolution Cloud (GiC)

Modbus TCP

CIM 500

PROFINET IO

GRM IP

5. Control functions

5.1 Operating panel

English (GB)

TM070082

Pos. Symbol Description

1 Display

2

3 High level

Units

4 Start level, pump 2

5 Start level, pump 1

6 Stop level, pump 1 and 2

7 Dry-running level

8

9

10

Up/Down buttons:

• Press these buttons to navigate between submenus or change the value settings.

OK button:

• Press this button to save changed values.

Connect button:

• Press this button to connect the control unit to Grundfos GO Remote via Bluetooth.

15

Page 16

On

Off

Auto

Setpoint

5.00 bar

Control mode

Const. pressure

Status Settings Assist

1 2 3

English (GB)

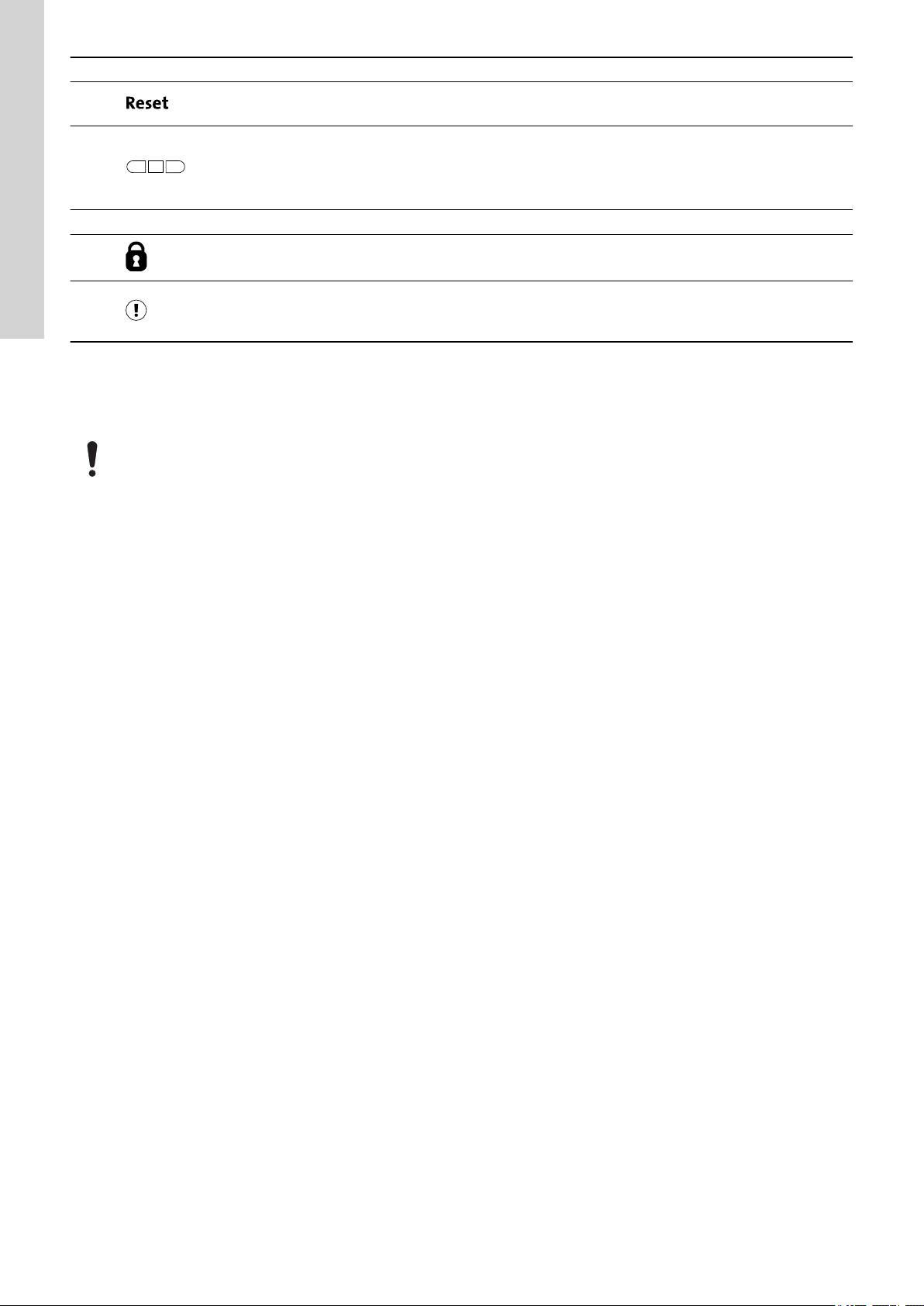

Pos. Symbol Description

11

12

13 Display The display shows the pump status.

Reset button:

• Press this button during startup to reset settings and start over or to reset an alarm or warning.

Operating mode for the pump:

• On: The pump has been switched on manually.

• Off: The pump has been switched off manually.

• Auto: The pump is running automatically based on settings.

14

15

The control unit enables manual setting and monitoring of the system.

Lock symbol:

If the symbol is lit, the control unit is locked from making changes.

Alarm and warning symbol:

Red: Alarm

Yellow: Warning

6. Setting the product

Make sure that all settings are entered according to the pump and system requirements to avoid malfunction.

6.1 Setting the application type with Grundfos GO Remote

1. Go to Settings > Level control > Application type.

2. Select the type.

• Empty

• Fill

6.2 Setting the sensor type

6.2.1 Setting the sensor type with Grundfos GO Remote

1. Go to Settings > Level control > Sensor type.

2. Select the type.

• Analog sensors

• Digital sensors

6.2.2 Setting the sensor type with the operating panel

1. Press and hold OK until S-1 or S-2 starts flashing.

2. Select the sensor type using the Up and Down buttons.

• S-1: Analog sensors

• S-2: Digital sensors.

3. Press OK to confirm the setting.

4. Continuously press OK to confirm all other settings and to exit the setup.

6.3 Setting the start level

6.3.1 Setting the start level with Grundfos GO Remote

The settings apply to analog sensors. For digital sensors, the setting is automatically activated.

1. Go to Settings > Level Control > Start level P1.

2. Set the start level for pump 1.

3. Go to Settings > Level Control > Start level P2.

4. Set the start level for pump 2.

6.3.2 Setting the start level with the operating panel

The settings apply to analog sensors. For digital sensors, the setting is automatically activated.

16

Page 17

1. Press and hold OK until the display and dry running start flashing.

2. Continuously press OK until the indicator light for the start level for pump 1 starts flashing.

3. Set the start level for pump 1 by using the Up and Down buttons.

4. Press OK.

The indicator light for the start level for pump 2 starts flashing.

English (GB)

TM071336

5. Set the start level for pump 2 by using the Up and Down buttons.

6. Continuously press OK until the display stops flashing.

The settings have now been stored.

6.4 Setting the stop level

6.4.1 Setting the stop level with Grundfos GO Remote

The settings apply to analog sensors. For digital sensors, the setting is automatically activated.

The stop level is the same for pump 1 and pump 2.

1. Go to Settings > Level control > Stop level

2. Set the stop level.

If you are using the same level for start and stop, remember to set a stop delay. This will prevent the pump from starting and

stopping too frequently.

6.4.2 Setting the stop level with the operating panel

The settings apply to analog sensors. For digital sensors, the setting is automatically activated.

The stop level is the same for pump 1 and pump 2.

1. Press and hold OK until the display starts flashing.

2. Press OK once.

The current stop level is indicated on the display.

3. Set the stop level using the Up and Down buttons.

4. Continuously press OK to confirm all other settings and to exit the setup.

TM071337

If you are using the same level for the start and stop level, remember to set a stop delay. This will prevent the pump from starting

and stopping too frequently.

6.5 Setting the high level

6.5.1 Setting the high level with Grundfos GO Remote

For analog sensors:

17

Page 18

English (GB)

1. Go to Settings > Level control > High level.

2. Set the high level.

For digital sensors:

1. Go to Settings > LC 231 IO terminals

2. Select which terminal to configure.

6.5.2 Setting the high level with the operating panel

The settings apply to analog sensors

1. Press and hold OK until the display starts flashing.

2. Press OK four times. The current high level is indicated on the display.

3. Set the high level using the Up and Down button.

For digital sensors, enable or disable the setting.

1. Press OK once to complete the setting.

6.6 Stop delay

The stop delay is the time from when the stop level is reached until the pump stops. The stop delay prevents the pump from starting and

stopping too frequently and reduces water hammer in long pipes.

6.6.1 Setting the stop delay with Grundfos GO Remote

1. Select Settings > Level control > Stop delay > State

2. Select Stop delay time.

3. Set the Stop delay time.

6.7 Power-on delay

With this function it is possible to delay the startup of the pump after the power supply has been switched on. The purpose is to avoid

disturbing the main power network which could happen if several pumps start up immediately when the power supply is switched on.

6.7.1 Setting the power-on delay with Grundfos GO Remote

1. Go to Settings > Power-on delay.

2. Set the function to Enabled.

3. Set the time delay.

6.8 Dry-running protection

If the pump is running and the liquid level in the tank or pit becomes lower than the dry-running level, the dry-running protection will stop the

pump to ensure that it is not damaged.

Dry-running protection is dependent on a feedback signal from a level sensor installed in the tank or pit.

6.8.1 Setting the dry-running level with Grundfos GO Remote

1. Go to Settings > Level control > Dry-running level.

2. Set the dry-running level.

The dry-running level must be set to a value which ensures that the pump is not damaged due to dry-running. The specific level

depends on the installed pump type. See the installation and operating instructions for the product.

6.8.2 Setting the dry-running level with the operating panel

1. Press and hold OK until the display starts flashing.

2. Set the dry-running level using the Up or Down button.

3. Continuously press OK to confirm all other settings and to exit the setup.

6.9 "Multipump settings"

The control unit enables start and stop of the two pumps alternately. The pump with the lowest number of running hours is always started first.

The function ensures that the running hours of the pumps are the same.

It is possible to set a time delay before the next pump is started.

6.9.1 Setting "multipump settings" with Grundfos GO Remote

1. Go to Settings > Multi pump settings

2. Set Inter pump delay.

This is the starting delay between the pumps ensuring that they do not start at the same time.

3. Set Max number of running pumps.

This is the maximum number of pumps which are allowed to run at the same time.

6.10 Using the same level switch for the start and stop level

1. Set one digital input to Start pump 1 or Stop. All other digital inputs must be disabled.

2. Set a stop delay.

This will prevent the pump from starting and stopping too frequently.

18

Page 19

6.11 "Antiseizing"

The Antiseizing function prevents a pump from choking or seizing up as a result of deposits buildup. Antiseizing is used in pits that have had

no inlet flow for a long period. The Antiseizing function ensures that the pump starts as often as set in Antiseizing > interval. The pump will

operate for the number of seconds indicated by the user.

6.11.1 Setting the "Anti-seizing" function with Grundfos GO Remote

1. Go to Settings > Anti-seizing.

2. Set the function to Enabled.

3. Set the time interval.

4. Set the operating time.

6.12 Signal-detection time

The signal-detection time is the minimum time a level has to be active before the control unit initiates an action, such as starting or stopping a

pump.

6.12.1 Setting the signal-detection time with Grundfos GO Remote

1. Go to Settings > Level control > Signal detection time.

2. Set the signal-detection time.

6.13 Setting the maximum number of restarts with Grundfos GO Remote

If the pump is seized up as a result of deposits buildup, it will be stopped automatically due to overheating, provided that the motor protection

has been set. When the motor has cooled down, the control unit will unsuccessfully try to restart the pump and this scenario will be repeated.

In order to prevent this, it is possible to set a maximum number of restart attempts within a set interval.

1. Go to Settings > Max number of restarts.

2. Enable the function.

3. Set the interval within which the allowed number of restarts are to be counted.

4. Set the maximum number of pump restarts which are allowed during the set interval.

Related information

6.15.4 Setting the motor protection with Grundfos GO Remote

9.3 Code 4 (Too many motor restarts)

English (GB)

6.14 Setting the service interval with Grundfos GO Remote

You can set a time in Grundfos GO Remote in order to get a reminder that the pump needs service when the time comes.

1. Go to Settings > Service > State

2. Select Enable and press OK.

3. Select the pump.

4. Enter the number of hours until next service and press OK.

6.15 Motor protection

6.15.1 Overheat protection

The control unit offers thermal protection for the connected motors. Two types of thermal-protection sensor can be connected to the control

unit: a PTC sensor (analog) and a thermal switch (digital).

Under normal running conditions, the sensor will act as a short circuit, but when its temperature limit is reached, it will open and tell the control

unit that the temperature is too high, and the pump is stopped. When the temperature has dropped to the sensor-trigger level, the pump will

return to normal running conditions. It will not be possible to start the pump manually as long as the temperature is too high.

Related information

9.10 Code 69 (Winding temperature too high)

6.15.2 Overload protection

The pump is protected by a motor-protection relay. The nominal current draw must be set manually on the motor-protection relay. See the

specific documentation for the relay on how to set the trigger level. If the current exceeds the trigger level, the relay will switch off the pump

and the controller will give an alarm. The alarm has to be manually reset directly on the motor protection relay.

Related information

9.8 Code 48 (Motor is overloaded)

6.15.3 Moisture protection

When a moisture sensor is installed in series with the temperature sensor, the control unit needs to know how to determine whether there is a

high temperature or moisture in the pump. If the temperature is too high, normally the temperature sensor will go back to its normal stage

when the temperature has dropped to its trigger level. If there is moisture in the pump, then the moisture sensor will keep the series

connection open until the pump is opened and serviced.

To determine which sensor has been active, a cool down time must be entered. This is the time that will normally pass until the temperature

has dropped enough for the temperature sensor to return to its normal stage. If the cool down time is exceeded, the control unit will assume

that there is moisture in the pump, and it will send a moisture alarm.

19

Page 20

English (GB)

Related information

6.15.4 Setting the motor protection with Grundfos GO Remote

6.15.4 Setting the motor protection with Grundfos GO Remote

You can set the current, temperature and moisture protection via a setup wizard.

1. Go to Settings > Motor protection pump 1 or Motor protection pump 2.

2. Follow the on-screen wizard to set the following:

• Nominal pump current

• Trip IEC class

• Pump connection

• Overheat protection.

Related information

6.13 Setting the maximum number of restarts with Grundfos GO Remote

6.15.3 Moisture protection

6.16 Alarm reset

6.16.1 Resetting alarms and warnings manually with Grundfos GO Remote

1. Go to Alarms and warnings.

2. Press Reset alarm.

All current alarms and warnings have been reset. However, if the fault causing the alarm or warning has not been removed, the alarm or

warning will appear again.

3. If you want to delete all alarms and warnings from the history log, press Show log > Reset alarm and warning logs.

6.16.2 Setting the automatic alarm reset with Grundfos GO Remote

1. Go to Settings > Automatic alarm reset.

2. Select one of the following:

No automatic reset

All except pump critical

All alarms

6.16.3 Resetting alarms and warnings on the operating panel

You can manually reset alarms and warnings on the operating panel. However, if the fault causing the alarm or warning has not been removed,

the alarm or warning will appear again.

1. Press Reset on the operating panel to reset the alarm or warning.

The control unit does not reset any alarm or warning. You must do

it manually.

The control unit resets alarms and warnings unless the related fault

can damage the pump.

The control unit resets alarms and warnings, regardless of the

fault.

6.17 Setting the buzzer with Grundfos GO Remote

The internal buzzer is used to give an acoustic sound if there is a warning or an alarm.

1. Go to Settings > Buzzer settings.

2. Select when the buzzer is to be activated:

• All alarms

• All alarms and warnings.

6.18 Setting units for Grundfos GO Remote

Changing units as described here will only change the units shown in Grundfos GO Remote. It will not affect the units shown on the operating

panel of products connected to Grundfos GO Remote.

20

Page 21

1. Press the Menu button in the upper left corner of Grundfos GO Remote.

2. Go to General > Settings > Products > Units.

3. Select US or Grundfos default units.

6.19 Setting units for the operating panel with Grundfos GO Remote

Changing units as described below changes the units shown in the operating panel of the product connected to Grundfos GO Remote. It does

not affect the units shown in Grundfos GO Remote.

1. Go to Settings > Display units.

2. Select the units to be used on the operating panel.

• SI Units

• US Units.

English (GB)

TM070084

6.20 GENIbus

GENIbus, the Grundfos Electronics Network Intercommunications bus, is a fieldbus developed by Grundfos to meet the need for data transfer

in all typical Grundfos motor or pump applications. Grundfos devices with GENIbus can be wired together in networks and integrated in

automation systems. Each device on the network must have a unique GENIbus address. GENIbus is based on the RS485 hardware standard

and typically operates at a baud rate of 9600 bits/s.

6.20.1 Setting the GENIbus address with Grundfos GO Remote

If CU 241 is used in a GENIbus network, a CIM 050 must be installed to add a GENIbus connection.

1. Go to Settings > GENI bus address.

2. Set the GENIbus address.

The GENIbus address is a unique identifier for the product on the network.

6.21 Security

6.21.1 Locking the operating panel

The operating panel can only be locked with Grundfos GO Remote.

1. Go to Settings > Security > Lock display.

2. Enable the setting and press Done.

3. Select if you want to restrict access to Settings only or Settings and operation.

4. Press Done.

The lock symbol on the operating panel is now lit.

6.21.2 Unlocking the operating panel

The operating panel can only be unlocked with Grundfos GO Remote.

1. Go to Settings > Security > Lock display.

2. Disable the setting and press Done.

The lock symbol on the operating panel is switched off.

6.21.3 Locking Grundfos GO Remote

1. Go to Settings > Security > Lock GO Remote.

2. Enable the setting and press Done.

3. Enter a four digit PIN code and press CONFIRM.

A lock symbol indicates which menus are locked. To view or change settings, you must enter the PIN code.

6.21.4 Unlocking Grundfos GO Remote

1. Go to Settings > Security.

2. Enter the four digit PIN code.

21

Page 22

English (GB)

3. Select Lock GO Remote.

4. Disable the setting and press Done.

All menus in Grundfos GO Remote are unlocked.

6.22 Starting the startup wizard with the operating panel

• Press and hold the OK button for 8 seconds until S-1 or S-2 starts flashing.

Related information

3.3 Startup wizard on the operating panel

7. Operating the product

7.1 Manual operation

7.1.1 Starting and stopping the pump manually with Grundfos GO Remote

1. Go to Settings > Control, pump 1 or Control, pump 2.

2. Start the pump by selecting On and pressing OK.

3. Stop the pump by selecting Off and pressing OK.

Related information

7.1.4 Choosing what the pump must do after manual start

7.1.2 Automatic operation

In automatic operating mode, the control unit starts and stops the pump based on the signals it receives from the connected level sensors and

the corresponding level settings within the control unit.

Related information

4.4 Application types

7.1.3 Starting and stopping the pump manually with the operating panel

1. To start a pump manually, press and hold the Pump button until the pump starts.

The On indicator light is lit when the pump is operating in manual mode.

2. Stop the pump by pressing the Pump button.

The Off indicator light is lit when the pump is stopped.

Related information

7.1.4 Choosing what the pump must do after manual start

7.1.4 Choosing what the pump must do after manual start

The following can be configured:

• Automatic return

Here you select if the pump must automatically return to a defined operating mode when the manual start ends.

• Return to

Here you select whether the pump must return to automatic operating mode or stop when the manual start ends and Automatic return

has been enabled.

• Forced start time

Here you set the time period in which the pump must run in manual operating mode.

1. Go to Settings > Manual start.

2. Select Automatic return and choose one of the following options:

• Disabled

• Enabled.

3. Go one step back in the menu and select Return to.

4. Choose one of the following options:

• Auto

• Off.

5. Go one step back in the menu and select Forced start time.

6. Set the time period in which the pump must run in manual operating mode.

Related information

7.1.1 Starting and stopping the pump manually with Grundfos GO Remote

7.1.3 Starting and stopping the pump manually with the operating panel

22

Page 23

8. Servicing the product

WARNING

Electric shock

Death or serious personal injury

‐ Switch off the incoming power supply before you start any work on the product or connected pumps.

‐ Make sure that the power supply cannot be switched on accidentally.

8.1 Updating the product software

New features and functions can be made available during the product's life cycle.

1. Contact Grundfos to get your product software updated.

8.2 Replacing the control unit

WARNING

Electric shock

Death or serious personal injury

‐ Switch off the power supply before making any electrical connections.

‐ Make sure that the power supply cannot be switched on accidentally.

Remember to save the controller's settings in Grundfos GO Remote under Settings. The settings can then be transferred to the new control

unit when installed.

1. Switch off the power supply to the product and other components with external supply.

2. Write down the terminal connection of each wire to ensure correct re-connection.

3. Disconnect all wires.

4. Remove the control unit from the panel or cabinet.

5. Fit the new unit.

6. Connect all wires.

7. Configure the new control unit using Grundfos GO Remote.

Related information

2.2.1 Mounting the control unit

3.2 Startup wizard on Grundfos GO Remote

English (GB)

8.3 Replacing the CIM module

WARNING

Electric shock

Death or serious personal injury

‐ Switch off the power supply before making any electrical connections.

‐ Make sure that the power supply cannot be switched on accidentally.

1. Switch off the power supply to the product and other components with external supply.

2. Write down the terminal connection of each wire to ensure correct re-connection.

3. Disconnect all wires connected to the CIM module.

4. Remove the screws that holds the module.

5. Remove the module from the control unit.

6. Fit the new module.

7. Connect all wires.

8.4 Replacing the battery

CAUTION

Fire and chemical leakage

Minor or moderate personal injury

‐ Risk of explosion if the battery is replaced by an incorrect type.

To replace the battery, do the following:

1. Remove the back cover.

2. Gently grab around the battery without touching it too much.

3. Pull the battery up.

4. Insert a new battery of the correct type.

Related information

10. Technical data

23

Page 24

English (GB)

9. Fault finding the product

Fault finding and fault correction must be carried out by qualified persons.

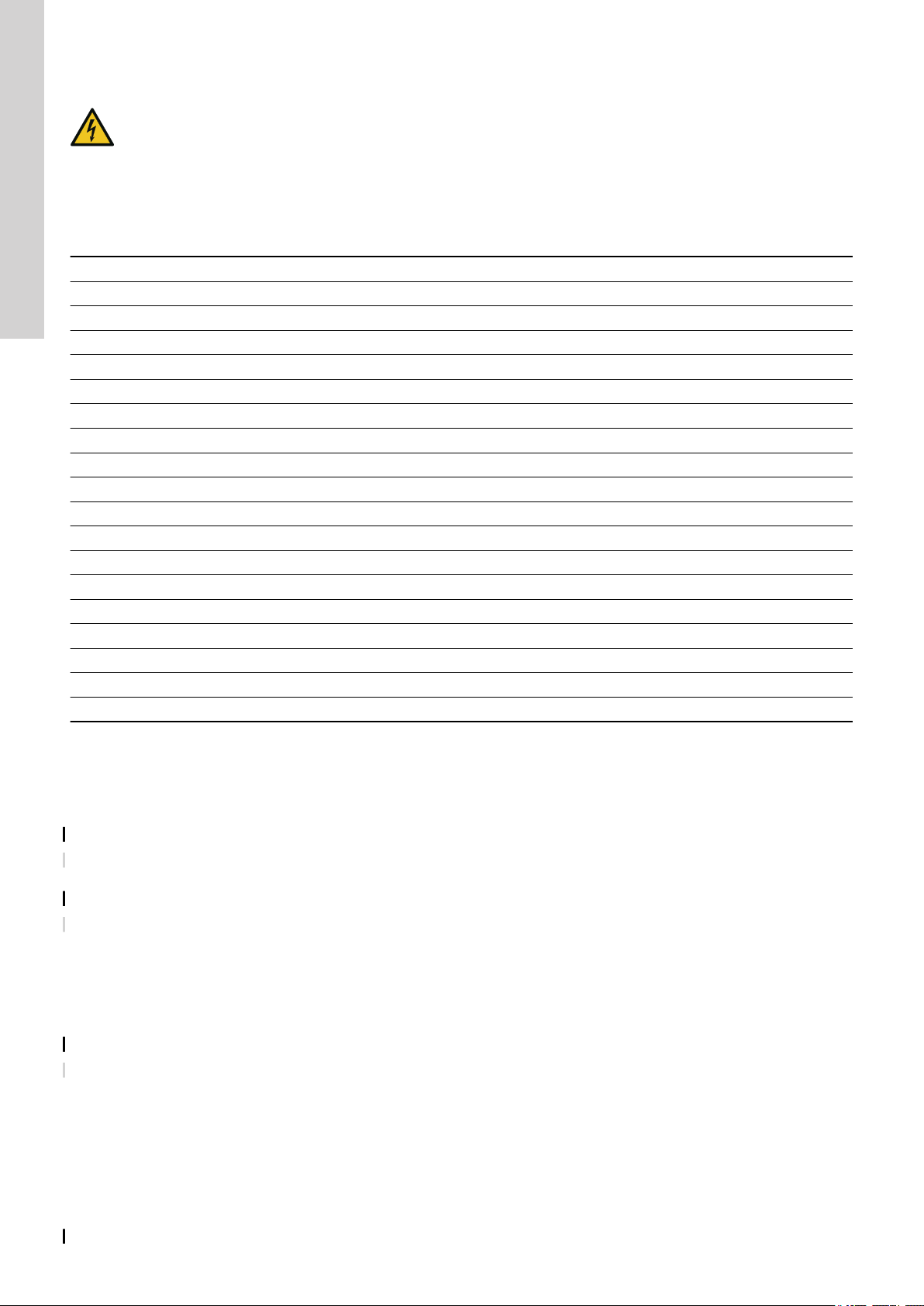

9.1 Overview of alarm and warning codes

Code number Description

Code 2 The power phase is missing.

Code 4 Too many motor restarts.

Code 9 The power-phase sequence is wrong.

Code 12 Service is needed.

Code 22 Moisture in motor of pump.

Code 25 Wrong configuration.

Code 48 The motor is overloaded.

Code 57 Missing water in the application.

Code 69 The winding temperature is too high.

Code 84 The memory-storage media is faulty.

Code 117 The door is opened.

Code 159 Communication error CIMxxx.

Code 165 Signal fault.

Code 191 High water level.

Code 205 Level-switch inconsistency.

Code 225 Communication error pump module.

Code 226 Communication error IO module.

Code 229 Water on the floor.

WARNING

Electric shock

Death or serious personal injury

‐ Switch off the power supply before you start any work on the product.

‐ Make sure that the power supply cannot be switched on accidentally.

9.2 Code 2 (Power phase missing)

• Alarm code 2 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Power phase missing is displayed in Grundfos GO Remote.

Cause

Remedy • Connect the phase.

Cause The fuse is blown somewhere on the incoming power line.

Remedy • Replace the fuse.

One of the power supply phases is not connected.

9.3 Code 4 (Too many motor restarts)

• Alarm code 4 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Too many motor restarts is displayed in Grundfos GO Remote.

Cause

Remedy • Remove the blockage from the pump.

Related information

6.13 Setting the maximum number of restarts with Grundfos GO Remote

The pump has been blocked or partly blocked causing overload in the motor.

9.4 Code 9 (Power phase sequence wrong)

• Alarm code 9 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Power phase sequence wrong is displayed in Grundfos GO Remote.

Cause

The power supply phase is set incorrectly.

24

Page 25

Remedy • Interchange two phases.

9.5 Code 12 (Service needed)

• Warning code 12 is shown on the display if you press the Up or Down button.

• The warning symbol on the display turns yellow and the pump's operating mode is unchanged.

• Warning code Service needed is displayed in Grundfos GO Remote.

Cause The pump requires service based on time to next service countdown.

Remedy • Contact Grundfos or an authorised service workshop.

• In order for the product to determine the service time, you must have enabled the service countdown with Grundfos GO

Remote: Settings > Service

9.6 Code 22 (Moisture in motor of pump)

• Alarm code 22 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Moisture in motor of pump is displayed in Grundfos GO Remote.

Cause Moisture is detected in the motor of the pump.

Remedy • Service is needed on the pump. Contact Grundfos.

9.7 Code 25 (Wrong configuration)

• Alarm code 25 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Wrong configuration is displayed in Grundfos GO Remote.

Cause

Remedy • Check and adjust the level control configuration with Grundfos GO Remote.

The level control is not configured correctly.

English (GB)

Cause The IO terminal is not configured correctly.

Remedy • Select which IO terminal to change in Grundfos GO Remote and adjust the configuration.

9.8 Code 48 (Motor is overloaded)

• Alarm code 48 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Motor is overloaded is displayed in Grundfos GO Remote.

Cause

Remedy • Remove the blockage.

Related information

6.15.2 Overload protection

The pump is clogged.

The blockage causes the motor current to rise, which could damage the pump.

• Check the pit conditions to ensure blockage is not possible again.

9.9 Code 57 (Missing water in the application)

• Alarm code 57 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Dry Run is displayed in Grundfos GO Remote.

Cause

Remedy • Check and configure the sensor for stop level.

Low water level in the pit and the pump stops due to the dry-running function.

9.10 Code 69 (Winding temperature too high)

• Alarm code 69 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Winding temperature too high is displayed in Grundfos GO Remote.

Cause

Remedy • Remove the blockage.

Cause The pump has run for too long.

Remedy • Allow the pump to cool down.

The pump is clogged, causing the pump to use more current and thereby overheat.

• Adjust the distance between start and stop levels.

25

Page 26

English (GB)

Related information

6.15.1 Overheat protection

9.11 Code 84 (Memory storage media faulty)

• Warning code 84 is shown on the display if you press the Up or Down button.

• The warning symbol on the display turns yellow and the pump's operating mode is unchanged.

• Warning code Memory storage media faulty is displayed in Grundfos GO Remote.

Cause An error in the internal memory has been detected.

Remedy • Replace the control unit.

9.12 Code 117 (Door opened)

• Warning code 117 is shown on the display if you press the Up or Down button.

• The warning symbol on the display turns yellow and the pump's operating mode is unchanged.

• Warning code Door opened is displayed in Grundfos GO Remote.

Cause The door to the control-unit room has been opened.

Remedy • Check the room with the control unit.

9.13 Code 159 (Communication error CIMxxx)

• Warning code 159 is shown on the display if you press the Up or Down button.

• The warning symbol on the display turns yellow and the pump's operating mode is unchanged.

• Warning code Communication error CIMxxx is displayed in Grundfos GO Remote.

• The CIM module is unable to communicate with the product.

Cause

Remedy • Ensure that the module, including cables, is fitted correctly.

• Contact Grundfos or an authorised service workshop.

The CIM module is installed incorrectly.

Cause The CIM module is defective.

Remedy • Contact Grundfos.

9.14 Code 165 (Signal fault)

• Alarm code 165 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Signal fault is displayed in Grundfos GO Remote.

Cause

Remedy • Go to Settings > Level Control in Grundfos GO Remote and ensure that the configured range corresponds to the

The signal from the sensor is out of the configured range.

physical application type.

• Change the sensor, if needed.

9.15 Code 191 (High water level)

• Alarm code 191 is shown on the display.

• The alarm symbol on the display turns red, but the pump's operating mode is unchanged.

• Alarm code High water level is displayed in Grundfos GO Remote.

Cause

Remedy • Check and configure the sensor for start level.

Cause The pump is not big enough to remove the water.

Remedy • Contact Grundfos or an authorised service workshop.

The defined start level did not start the pump.

Cause The level sensor is defective and not reacting on level changes.

Remedy • Check the functionality of the level sensor.

9.16 Code 205 (Level switch inconsistency)

• Alarm code 205 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Level switch inconsistency is displayed in Grundfos GO Remote.

Cause

Remedy • Check the functionality of each float switch.

A float switch could be defective or stuck.

26

Page 27

9.17 Code 225 (Communication error pump module)

187 (7.36")

137 (5.4")

52 (2")

• Alarm code 225 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Communication error is displayed in Grundfos GO Remote.

• The pump module is unable to communicate with the product.

Cause The connection to GENIbus is missing.

Remedy • Check the GENIbus connection cable between CU 241 and IO 242.

Cause The pump module is defective.

Remedy • Contact Grundfos.

9.18 Code 226 (Communication error IO module)

• Alarm code 226 is shown on the display.

• The alarm symbol on the display turns red and the pump stops.

• Alarm code Communication error is displayed in Grundfos GO Remote.

• The pump module is unable to communicate with the product.

Cause The connection to GENIbus is missing.

Remedy • Check the GENIbus connection cable between CU 241 and IO 242.

Cause The IO module is defective.

Remedy • Contact Grundfos.

English (GB)

9.19 Code 229 (Water on floor)

• Warning code 229 is shown on the display if you press the Up or Down button.

• The warning symbol on the display turns yellow and the pump's operating mode is unchanged.

• Warning code Water on floor is displayed in Grundfos GO Remote.

Cause

The sensor detects water on the floor.

Remedy • Check for water leakage.

10. Technical data

Supply voltage

24 VDC, - 10 %/+ 10 %.

Power supply is required to be class 2.

Check that the supply voltage corresponds to the values stated on the nameplate.

Maximum power dissipation

Object

99347488 3.4 W

Enclosure class

IP54, 3R for CU 241 built into panel of similar or higher enclosure class.

GENIbus terminal

- 7 VDC to + 12 VDC.

Nominal current condition: 4 mADC.

Short-circuit current condition: 328 mA.

Dimensions

Maximum power dissipation

TM072339

Related information

8.4 Replacing the battery

27

Page 28

English (GB)

11. Disposing of the product

This product or parts of it must be disposed of in an environmentally sound way.

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest Grundfos company or service workshop.

3. Dispose of the waste battery through the national collective schemes. If in doubt, contact your local Grundfos company.

See also end-of-life information at www.grundfos.com/product-recycling.

28

Page 29

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Centro

Industrial Garin

1619 - Garín Pcia. de B.A.

Tel.: +54-3327 414 444

Fax: +54-3327 45 3190

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Tel.: +61-8-8461-4611

Fax: +61-8-8340-0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Fax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tel.: +32-3-870 7300

Fax: +32-3-870 7301

Belarus

Представительство ГРУНДФОС в Минске

220125, Минск

ул. Шафарнянская, 11, оф. 56, БЦ «Порт»

Тел.: +7 (375 17) 286 39 72/73

Факс: +7 (375 17) 286 39 71

E-mail: minsk@grundfos.com

Bosnia and Herzegovina

GRUNDFOS Sarajevo

Zmaja od Bosne 7-7A

BiH-71000 Sarajevo

Tel.: +387 33 592 480

Fax: +387 33 590 465

www.ba.grundfos.com

E-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Campo - SP

Tel.: +55-11 4393 5533

Fax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel.: +359 2 49 22 200

Fax: +359 2 49 22 201

E-mail: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Tel.: +1-905 829 9533

Fax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

10F The Hub, No. 33 Suhong Road

Minhang District

Shanghai 201106 PRC

Tel.: +86 21 612 252 22

Fax: +86 21 612 253 33

Columbia

GRUNDFOS Colombia S.A.S.

Km 1.5 vía Siberia-Cota Conj. Potrero

Chico,

Parque Empresarial Arcos de Cota Bod. 1A.

Cota, Cundinamarca

Tel.: +57(1)-2913444

Fax: +57(1)-8764586

Croatia

GRUNDFOS CROATIA d.o.o.

Buzinski prilaz 38, Buzin

HR-10010 Zagreb

Tel.: +385 1 6595 400

Fax: +385 1 6595 499

www.hr.grundfos.com

Czech Republic

GRUNDFOS Sales Czechia and Slovakia

s.r.o.

Čajkovského 21

779 00 Olomouc

Tel.: +420-585-716 111

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tel.: +45-87 50 50 50

Fax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel.: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Trukkikuja 1

FI-01360 Vantaa

Tel.: +358-(0) 207 889 500

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tel.: +33-4 74 82 15 15

Fax: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Fax: +49-(0) 211 929 69-3799

E-mail: infoservice@grundfos.de

Service in Deutschland:

kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Tel.: +0030-210-66 83 400

Fax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor, Siu Wai Industrial

Centre

29-33 Wing Hong Street & 68 King Lam

Street, Cheung Sha Wan

Kowloon

Tel.: +852-27861706 / 27861741

Fax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Tópark u. 8

H-2045 Törökbálint

Tel.: +36-23 511 110

Fax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 097

Tel.: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Graha Intirub Lt. 2 & 3

Jln. Cililitan Besar No.454. Makasar,

Jakarta Timur

ID-Jakarta 13650

Tel.: +62 21-469-51900

Fax: +62 21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Tel.: +353-1-4089 800

Fax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Fax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

1-2-3, Shin-Miyakoda, Kita-ku

Hamamatsu

431-2103 Japan

Tel.: +81 53 428 4760

Fax: +81 53 428 5005

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Tel.: +82-2-5317 600

Fax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60

LV-1035, Rīga,

Tel.: + 371 714 9640, 7 149 641

Fax: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel.: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam, Selangor

Tel.: +60-3-5569 2922

Fax: +60-3-5569 2866

Mexico

Bombas GRUNDFOS de México

S.A. de C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Tel.: +52-81-8144 4000

Fax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Fax: +31-88-478 6332

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Tel.: +64-9-415 3240

Fax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tel.: +47-22 90 47 00

Fax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel.: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Fax: +351-21-440 76 90

Romania

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Tel.: +40 21 200 4100

Fax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундфос Россия

ул. Школьная, 39-41

Москва, RU-109544, Russia

Тел. (+7) 495 564-88-00 (495) 737-30-00

Факс (+7) 495 564 8811

E-mail grundfos.moscow@grundfos.com

Serbia

Grundfos Srbija d.o.o.

Omladinskih brigada 90b

11070 Novi Beograd

Tel.: +381 11 2258 740

Fax: +381 11 2281 769

www.rs.grundfos.com

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

25 Jalan Tukang

Singapore 619264

Tel.: +65-6681 9688

Faxax: +65-6681 9689

Slovakia

GRUNDFOS s.r.o.

Prievozská 4D 821 09 BRATISLAVA

Tel.: +421 2 5020 1426

sk.grundfos.com

Slovenia

GRUNDFOS LJUBLJANA, d.o.o.

Leskoškova 9e, 1122 Ljubljana

Tel.: +386 (0) 1 568 06 10

Fax: +386 (0)1 568 06 19

E-mail: tehnika-si@grundfos.com

South Africa

GRUNDFOS (PTY) LTD

16 Lascelles Drive, Meadowbrook Estate

1609 Germiston, Johannesburg

Tel.: (+27) 10 248 6000

Fax: (+27) 10 248 6002

E-mail: lgradidge@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Fax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölndal

Tel.: +46 31 332 23 000

Fax: +46 31 331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-44-806 8111

Fax: +41-44-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Tel.: +886-4-2305 0868

Fax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road

Dokmai, Pravej, Bangkok 10250

Tel.: +66-2-725 8999

Fax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Tel.: +90 - 262-679 7979

Fax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

Бізнес Центр Європа

Столичне шосе, 103

м. Київ, 03131, Україна

Tel.: (+38 044) 237 04 00

Fax: (+38 044) 237 04 01

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone, Dubai

Tel.: +971 4 8815 166

Fax: +971 4 8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 4TL

Tel.: +44-1525-850000

Fax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

9300 Loiret Boulevard

Lenexa, Kansas 66219 USA

Tel.: +1 913 227 3400

Fax: +1 913 227 3500

Uzbekistan

Grundfos Tashkent, Uzbekistan

The Representative Office of Grundfos

Kazakhstan in Uzbekistan

38a, Oybek street, Tashkent

Tel.: (+998) 71 150 3290 / 71 150 3291

Fax: (+998) 71 150 3292

Revision Info

Last revised on 14-01-2019

Grundfos companies

Page 30

99506145 0119

ECM: 1239476

Trademarks displayed in this material, including but not limited to Grundfos, the Grundfos logo and “be think innovate” are registered trademarks owned by The Grundfos Group. All rights reserved. © 2019 Grundfos Holding A/S, all rights reserved.

Loading...

Loading...