Page 1

LC, LCD 115

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

English (GB) Installation and operating instructions

Caution

Note

English (GB)

Original installation and operating instructions.

CONTENTS

1. Symbols used in this document

2. Introduction

2.1 Product description

2.2 Features

2.3 Identification

2.4 Requirements

3. Product overview

3.1 Controller cabinet

3.2 Terminal block

4. Installation

4.1 Location

4.2 Mounting the cabinet

4.3 Connecting the cabinet

5. Choosing the mode

5.1 Starting unit

5.2 Starting unit with alternation (LCD only)

5.3 Level converter

6. Reading the display

7. Configuring the controller

8. Maintenance

9. Technical data

10. Fault finding

11. Disposal

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

1. Symbols used in this document

Warning

If these safety instructions are not observed,

it may result in personal injury.

Warning

If these instructions are not observed, it may lead

to electric shock with consequent risk of serious

personal injury or death.

Warning

These instructions must be observed for

explosion-proof pumps. We recommend that you

also follow these instructions for standard

pumps.

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment.

Notes or instructions that make the job easier

and ensure safe operation.

Page

2. Introduction

You can find these instructions in other languages by using the

QR code or link below.

2

2

2

2

2

2

grundfos.com/LCLCD115-manual

3

2.1 Product description

3

3

The LC, LCD 115 controller is designed for the control of one or

two pumps in wastewater and drainage systems.

4

4

It automatically starts/stops pumps and generates alarms based

4

on signals from an analog level sensor in the pump pit.

4

The controller can be set to three modes:

6

• starting unit

6

• starting unit with alternation

6

• level converter.

6

6

2.2 Features

6

• Control of one or two pumps based on analog level

8

8

9

9

measurement

• indication of liquid level

• alarm indications:

– high liquid level via level sensor

– high liquid level via float switch (optional)

– overload (via motor protection relay)

– overtemperature (via PTC resistance or thermal switch in

motor)

• buzzer alarm (optional)

• automatic alarm resetting

• automatic restarting after stop due to overtemperature.

2.3 Identification

Example LC 115. 230. 1. 12. DOL

LC:

LCD:

115: type designation

Phase voltage [V]

1:

3:

Maximum operating current per pump [A]

DOL:

SS:

40:

40/150:

The controller type, voltage variant, etc. are stated on the

nameplate on the side of the controller cabinet.

one-pump controller

two-pump controller

single-phase

three-phase

direct on line

soft starter

run capacitor

run and starting capacitor

2.4 Requirements

Level sensor

Type: 2-wire screened cable.

Output signal: 4-20 mA.

Sensor supply: 24 VDC (+ 5/- 15 %).

Maximum cable length: 30 m.

Pit

The liquid level of the pit must not exceed 10 m, which is the

maximum capacity of the sensor.

TM06 3679 0815

2

Page 3

3. Product overview

PE

254

354

4

2

7

6

8

9

5

10

11

6

1

3

T11 T21

T22T12

Ub

5

Io

4

4241

3

2

1

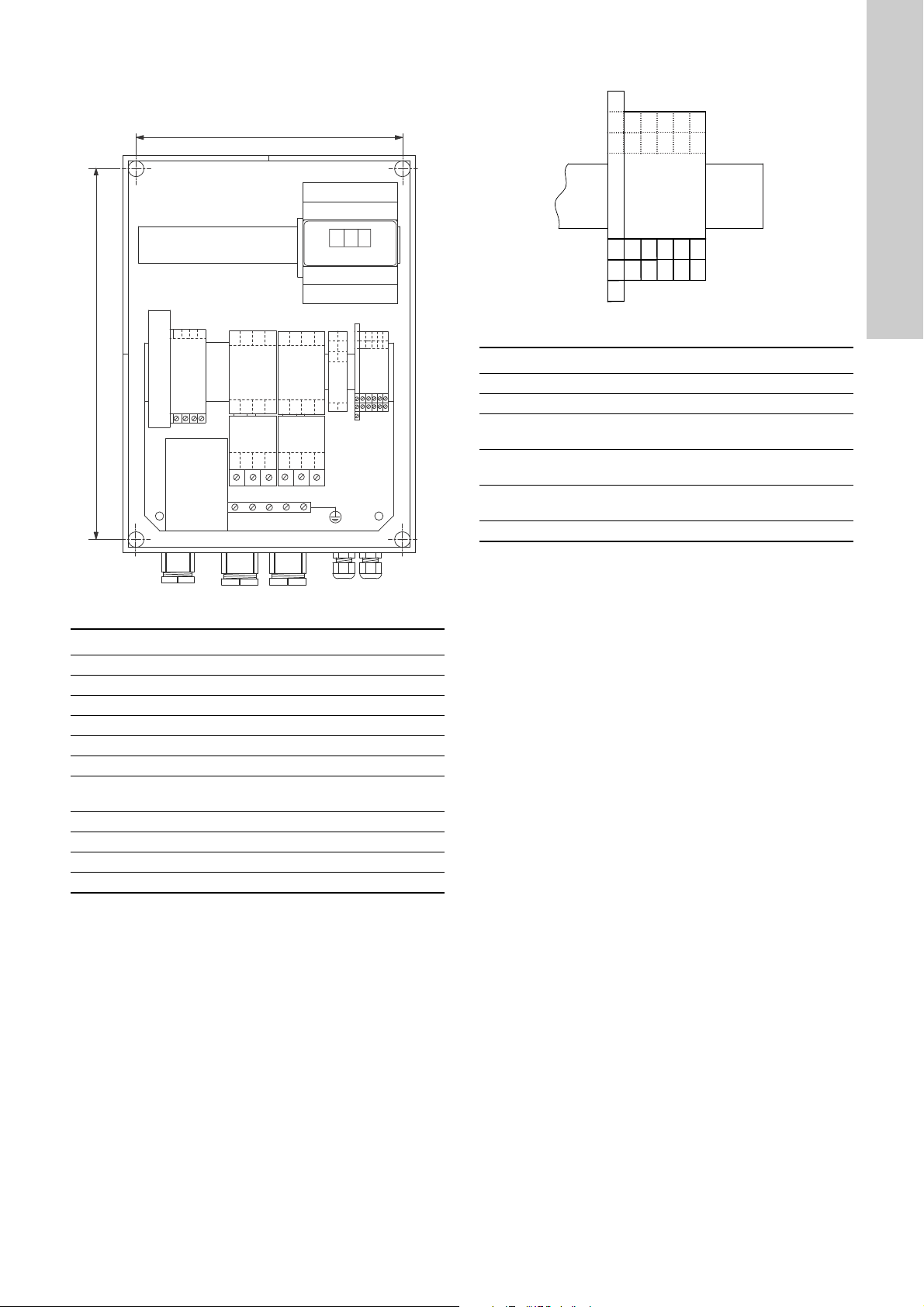

3.1 Controller cabinet

3.2 Terminal block

Fig. 2 Terminal block for sensor and alarm devices (LCD)

Pos. Description

1-2-3 Output for external high-level alarm device (NO-NC)

T11-T21 Input for motor PTC resistance/thermal switch

T12-T22

lo-Ub

41-42 Input for high-level float switch (optional)

Input for second motor PTC resistance/thermal

switch. Only LCD.

Input for analog level sensor. Ub delivers a 24 VDC

voltage to the CU 215.

Output for external overtemperature alarm device

4-5

(NO)

English (GB)

TM06 1921 3314

Fig. 1 Internal construction of the LCD 115, 12-23A, DOL

Pos. Description

1 CU 215 module

2 Terminal block for sensor and alarm devices. See fig. 2.

3 High-level relay

4 Contactor

5 Overload relay. Only DOL.

6 Terminal block for power supply

Fuse holders for control circuit fuses (1 to 3 depending

7

on current/voltage variant)

8 Isolation transformer

9 Earth bar

10 Cable glands

11 Holes for mounting screws

TM06 2742 4614

3

Page 4

4. Installation

Note

Caution

Note

M1 M2

3 - NC T21

2 - NO T11

T22

T12

5

4

Ub

Io

42

41

1 - COM

4-20

mA

PE

LNLN

English (GB)

Warning

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting

of pumps, pits, etc. must be carried out

according to local regulations.

Warning

Before making any connections in the controller

or work on pumps, pits, etc., switch off the power

supply. Make sure that it cannot be accidentally

switched on.

The installation must be carried out by authorised staff in

accordance with local regulations.

4.1 Location

Warning

In potentially explosive areas, the float switch, if

any, must be connected via an Ex-barrier, e.g.

Grundfos LC-Ex4 Zener barrier (No. 96440300).

Use only float switches approved for use in

potentially explosive areas.

Install the controller and the Ex-barrier outside

the potentially explosive area.

The controller can be installed at ambient temperatures from

-20 to 50 °C.

When installed outdoors, the controller must be placed in a

protective shed or cupboard. It must not be exposed to direct

sunlight.

The maximum length of the sensor cable is 30 m.

4.2 Mounting the cabinet

1. Remove the transport protectors, if any, from inside the

cabinet.

2. Mount the cabinet on a plane wall with screws through the

mounting holes. See fig. 1.

The cable glands must point downwards.

Fit additional cable glands to the base of the

cabinet, if necessary.

4.3 Connecting the cabinet

Make sure that a 250 mA backup fuse is installed

in the fuse holder. See pos. 6 in fig. 1.

Connect the following devices to the controller:

• Level sensor. See fig. 3.

• Power supply. See fig. 4.

• Pump(s). See fig. 4.

Optional:

• Overtemperature protection. See fig. 3.

• High-level float switch. See fig. 3.

• External high-level alarm device. See fig. 3.

• External overtemperature alarm device. See fig. 3.

See also the wiring diagram delivered with the product.

Connect the screen of the conductor from the

level sensor via a metal bracket to the earthed

metal backplate of the cabinet.

Fig. 3 Connecting sensor and alarm devices

4

TM06 2108 3714

Page 5

The following diagrams show how to connect motors and power

PE

1U2 1N2 2U2 2N2

U1

N1

LNPE

T12 T22

T11 T21

1~

NL3L1 L2

T12 T22T11 T21

3~

PE

PE

W1

V1

U1

N1

1U2 1V2 1W2 2U2 2V2 2W2

PE

T12 T22

T11 T21

1~

LNPE

1U2 1N2 2U2 2N2

U1

N1

1U2 1V2 1W2 2U2 2V2 2W2

W1V1U1

N1

L3 NL1 L2

T12 T22T11 T21

3~

PE

PE

supply to the DOL and SS versions. For other versions, please

refer to the wiring diagram delivered with the product.

DOL, single-phase DOL, three-phase

English (GB)

TM06 2126 3714

TM06 2127 3714

SS, single-phase SS, three-phase

TM06 2651 4514

Fig. 4 Connecting motor and power supply for DOL and SS versions

TM06 2652 4514

5

Page 6

5. Choosing the mode

English (GB)

The controller can be set to three modes:

– starting unit

– starting unit with alternation

– level converter.

In an application with pumps, we recommend that you use a

starting unit or starting unit with alternation.

5.1 Starting unit

The controller converts the analog signal from the level sensor

into digital signals. This enables start/stop of the pump at two

setpoints and activation of high-level alarm.

This is the usual setting for a pit with heavy and random flow

intake.

5.2 Starting unit with alternation (LCD only)

The controller enables start/stop of the two pumps alternately.

This mode is ideal for a pit with slow water intake.

5.3 Level converter

The same setpoint is used for start and stop. We do not

recommend this mode in an application with pumps.

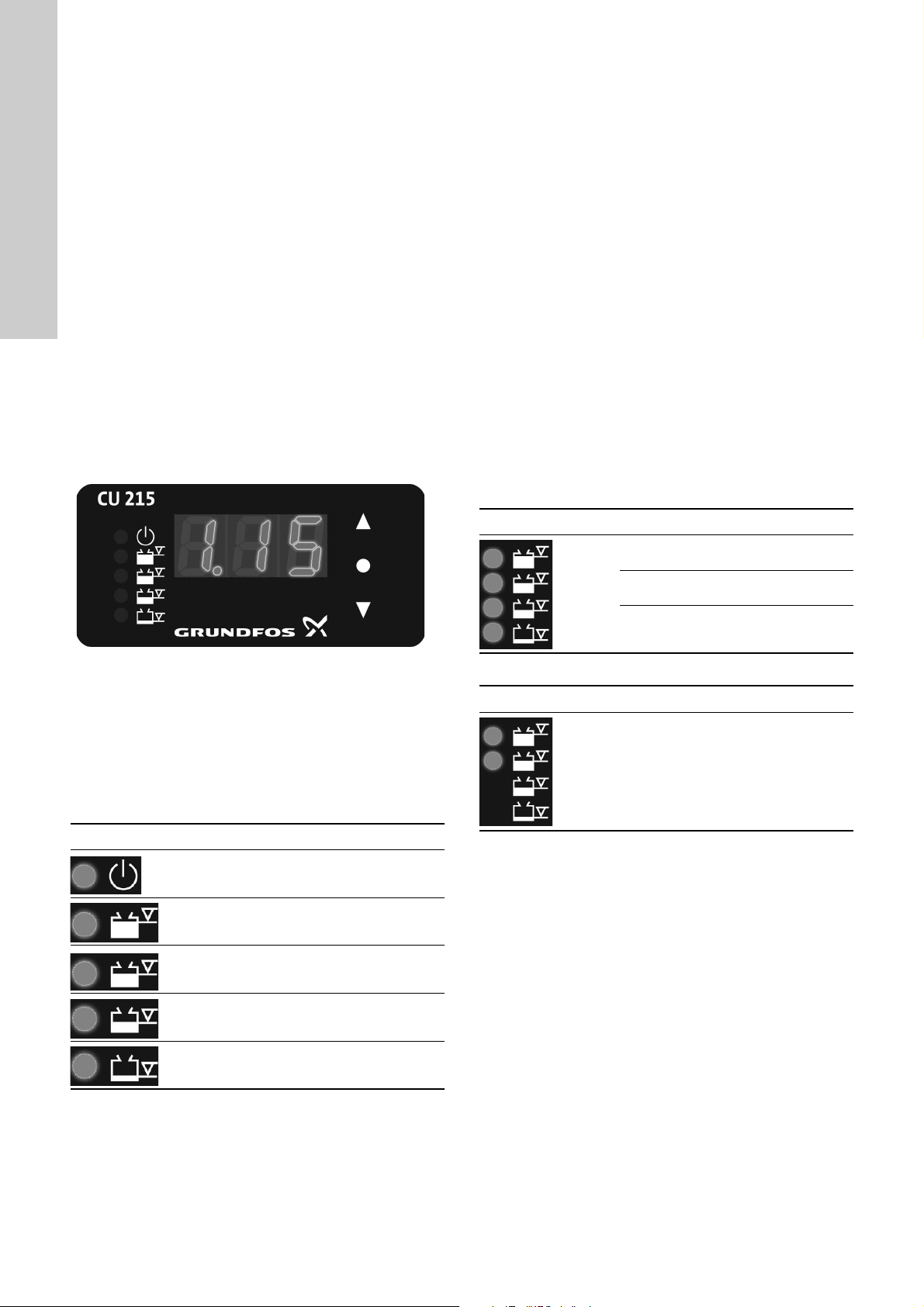

6. Reading the display

7. Configuring the controller

The following parameters can be set:

• Mode:

– starting unit

– starting unit with alternation

– level converter.

• Range of the level sensor (liquid level in metres corresponding

to 20 mA).

• Setpoints S1, S2, S3 and S4.

1. Scroll through the parameters using the up and down buttons

on the display.

2. To change a parameter, press [ ● ] for eight seconds. The first

digit flashes and can be changed.

3. Press the button again to select the next digit.

4. When you have selected the last digit, press the button again.

The display will cease to flash, and the parameter has been

changed.

Reactions if none of the buttons are pressed for eight seconds:

• When scrolling through the parameters:

The display reverts to its original state, and the diodes revert

to the normal displaying of the liquid level.

• When changing a parameter:

The parameter is set to the actual value shown in the display,

and the display ceases to flash.

Setting the mode

Fig. 5 Display of the CU 215

When the controller is connected to the power supply and

properly connected to the level sensor, the CU 215 module shows

the liquid level.

If the level sensor is not properly connected, the display will show

"---".

The four orange light diodes correspond to four configurable relay

outputs: S1, S2, S3 and S4. Each of them corresponds to a liquid

level. See table below.

LED Colour Description

Green

Orange

Orange

The CU 215 is functioning

normally.

Output S4 is activated. The level

is higher than setpoint S4.

Output S3 is activated. The level

is higher than setpoint S3.

LED Indicator Description

All LEDs

on.

TM06 2104 3714

Setting the range

LED Description

LED 1

and 2 on.

LvL: Level converter.

StA: Starting unit.

S.t.A.: Starting unit with alternation of

pump 1 and 2. Only LCD.

Range of the level sensor (liquid level

in metres corresponding to 20 mA).

Max. 10 m.

Orange

Orange

Output S2 is activated. The level

is higher than setpoint S2.

Output S1 is activated. The level

is higher than setpoint S1.

6

Page 7

Setting the setpoints

Note

Note

Starting unit

LED Indicator Description

LED 1 on.

LED 1

flashing.

LED 2 on.

LED 2

flashing.

S1: Start level of pump 1.

Must be ≤ S2.

S1: Stop level of pump 1.

Must be ≤ S1.

S2: Start level of pump 2.

Must be ≤ S3.

Only LCD.

S2: Stop level of pump 2.

Must be ≤ S2.

Only LCD.

Level converter

LED Indicator Description

LED 1 on.

LED 2 on.

LED 3 on.

LED 4 on. S4: High-level alarm 2.

S1: Start and stop level of pump 1.

Must be ≤ S2.

S2: Start and stop level of pump 2.

Must be ≤ S3.

Only LCD.

S3: High-level alarm 1.

Must be ≤ S4.

English (GB)

LED 3 on.

LED 4 on. S4: High-level alarm 2.

In starting unit mode, we recommend that you set

the stop level below the start level. It will prevent

frequent starts/stops of the pump.

If you attempt to change a parameter to an invalid

value, for example 99.0 in the level sensor range,

the parameter reverts to its original value when

the display ceases to flash.

S3: High-level alarm 1.

Must be ≤ S4.

7

Page 8

8. Maintenance

Note

English (GB)

Warning

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting

of pumps, pits, etc. must be carried out

according to local regulations.

Warning

Before making any connections in the controller

or work on pumps, pits, etc., switch off the power

supply. Make sure that it cannot be accidentally

switched on.

We recommend that you carry out minor checks of the controller,

pump pits, tanks, pumps, etc. at regular intervals.

These checks must be carried out by authorised staff.

• Check the gaskets of the cable glands and on the front of the

cabinet.

• Check for possible deposits/sludge build-up in the pump pit/

tank. Sludge may settle in areas with almost stagnant liquid.

• Check for possible blockage on the inlet side of the pump.

A blockage will typically be a large solid object.

• If the controller has been installed in a particularly aggressive

environment, we recommend that you check the motor

protection contacts in order to identify possible chemical

attack resulting in corrosion. In typical installations, the motor

protection contacts will work for several years and do not

require any inspection.

The above list is not complete. The controller

may be installed in systems, installations and/or

environments which require thorough and

regular maintenance.

9. Technical data

Voltage variants, rated voltages

• 1 x 230 V.

• 3 x 230/400 V.

Voltage tolerances

- 15 %/+ 10 % of rated voltage.

See also installation and operating instructions for the pump in

question.

Mains frequency

50/60 Hz.

See also installation and operating instructions for the pump in

question.

Supply system earthing

For TN systems and TT systems.

Short-circuit protection of power supply

Depending on variant. See nameplate.

Ambient temperature

• During operation: -20 - 50 °C (must not be exposed to direct

sunlight).

• In stock: -30 - 60 °C.

Enclosure class

IP65.

EMC (electromagnetic compatibility)

According to EN 61 000-6-2 and EN 61 000-6-3.

Material

ABS (acrylonitrile butadiene styrene).

Weight

Depending on variant. See nameplate.

Dimensions including cable glands

• LC, LCD 115 1-23A DOL: 410 x 280 x 150 mm.

• LC, LCD 115 9.2-25A SS: 410 x 280 x 150 mm.

• LC 115 14-43A SS: 600 x 280 x 195 mm.

• LCD 115 14-43A SS: 600 x 500 x 210 mm.

• LC, LCD 115 12A 40: 600 x 280 x 150 mm.

• LC, LCD 115 12A 40/150: 600 x 280 x 150 mm.

Outputs for alarm devices

Max. 230 VAC / max. 2 A / min. 10 mA / AC1.

Accuracy of sensor/controller

• ± 0.3 % of range, ± 1 digit.

8

Page 9

10. Fault finding

Warning

Before starting any work on pumps used to pump

liquids which could be constituted as being

hazardous to health, thorough cleaning/venting

of pumps, pits, etc. must be carried out according

to local regulations.

Warning

Before making any connections in the controller

or work on pumps, pits, etc., switch off the power

supply. Make sure that it cannot be accidentally

switched on.

Fault Cause Remedy

1. The pump does not run

even though the liquid level

is higher than the start level

of the pump.

2. The pump is starting/

stopping too frequently.

See also installation and operating instructions for the pump in

question.

a) No power supply. None of the indicator lights

are on.

b) Control circuit fuses are blown. Check and eliminate the cause. Replace the

c) The motor protection relay has cut out the

pump.

d) The PTC resistance/thermal switch has cut

out the pump.

e) An external alarm device, if any, is activated.

f) The control circuit for the motor protection

relay has been broken or fails.

g) Motor/supply cable is defective. Check motor and cable.

h) The level sensor is defective. Check level sensor and cable.

i) The CU 215 module is defective. Replace the module.

a) The level sensor is defective. Check level sensor and cable.

Switch on the power supply.

control circuit fuses. See pos. 6 in fig. 1.

Check the pump/pit.

Allow the pump to cool. The pump will restart

automatically according the signal from the level

sensor.

Check the control circuit.

English (GB)

11. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest Grundfos company

or service workshop.

Subject to alterations.

9

Page 10

Declaration of conformity

Declaration of conformity 1

GB: EC declaration of conformity

We, Grundfos, declare under our sole responsibility

that the product LC, LCD 115, to which this

declaration relates, is in conformity with these

Council directives on the approximation of the laws

of the EC member states:

DE: EG-Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung,

dass das Produkt LC, LCD 115, auf das sich diese

Erklärung bezieht, mit den folgenden Richtlinien

des Rates zur Angleichung der Rechtsvorschriften

der EU-Mitgliedsstaaten übereinstimmt:

ES: Declaración CE de

conformidad

Nosotros, Grundfos, declaramos bajo nuestra

propia responsabilidad que el producto LC, LCD

115, al cual se refiere esta declaración, está

conforme con las Directivas del Consejo en la

aproximación de las leyes de los Estados

Miembros del EM:

DK: EF-

overensstemmelseserklæring

Vi, Grundfos, erklærer under ansvar at produktet

LC, LCD 115 som denne erklæring omhandler, er i

overensstemmelse med disse af Rådets direktiver

om indbyrdes tilnærmelse til EF-medlemsstaternes

lovgivning:

GR: ∆ήλωση συμμόρφωσης EC

Εμείς, η Grundfos, δηλώνουμε με αποκλειστικά

δική μας ευθύνη ότι τα προϊόντα LC, LCD 115, στα

οποία αναφέρεται η παρούσα δήλωση,

συμμορφώνονται με τις εξής Οδηγίες του

Συμβουλίου περί προσέγγισης των νομοθεσιών

των κρατών μελών της ΕΕ:

IT: Dichiarazione di conformità CE

Grundfos dichiara sotto la sua esclusiva

responsabilità che il prodotto LC, LCD 115, al quale

si riferisce questa dichiarazione, è conforme alle

seguenti direttive del Consiglio riguardanti il

riavvicinamento delle legislazioni degli Stati membri

CE:

HU: EK megfelelőségi nyilatkozat

Mi, a Grundfos, egyedüli felelősséggel kijelentjük,

hogy a LC, LCD 115 termék, amelyre jelen

nyilatkozik vonatkozik, megfelel az Európai Unió

tagállamainak jogi irányelveit összehangoló tanács

alábbi előírásainak:

PL: Deklaracja zgodności WE

My, Grundfos, oświadczamy z pełną

odpowiedzialnością, że nasze wyroby LC, LCD

115, których deklaracja niniejsza dotyczy, są

zgodne z następującymi wytycznymi Rady d/s

ujednolicenia przepisów prawnych krajów

członkowskich WE:

FI: EY-

vaatimustenmukaisuusvakuut

us

Me, Grundfos, vakuutamme omalla vastuullamme,

että tuote

LC, LCD 115, jota tämä vakuutus koskee, on EY:n

jäsenvaltioiden lainsäädännön

yhdenmukaistamiseen tähtäävien Euroopan

neuvoston direktiivien vaatimusten mukainen

seuraavasti:

NL: EC

overeenkomstigheidsverklarin

g

Wij, Grundfos, verklaren geheel onder eigen

verantwoordelijkheid dat het product LC, LCD 115

waarop deze verklaring betrekking heeft, in

overeenstemming is met de Richtlijnen van de

Raad in zake de onderlinge aanpassing van de

wetgeving van de EG lidstaten betreffende:

RU: Декларация о соответствии

ЕС

Мы, компания Grundfos, со всей

ответственностью заявляем, что изделия LC,

LCD 115, к которым относится настоящая

декларация, соответствуют следующим

Директивам Совета Евросоюза об унификации

законодательных предписаний стран-членов ЕС:

SE: EG-försäkran om

överensstämmelse

Vi, Grundfos, försäkrar under ansvar att produkten

LC, LCD 115, som omfattas av denna försäkran, är

i överensstämmelse med rådets direktiv om

inbördes närmande till EU-medlemsstaternas

lagstiftning, avseende:

10

Page 11

— Machinery Directive (2006/42/EC).

Standard used: EN 60204-1:2006.

— Low Voltage Directive (2006/95/EC).

Standard used: EN 60439-1:2004.

— EMC Directive (2004/108/EC).

Standards used: EN 61 000-6-2:2005 and

EN 61000-6-3:2007.

Bjerringbro, 12 January 2015

Jan Strandgaard

Technical Director

Grundfos Holding A/S

Poul Due Jensens Vej 7

8850 Bjerringbro, Denmark

Person authorised to compile the technical file and

empowered to sign the EC declaration of conformity.

Declaration of conformity

11

Page 12

Declaration of conformity RU

Declaration of conformity RU 2

Электрические блоки управления насосами серии LC, LCD с

комплектующими и запасными частями к ним и Низковольтные

комплектные устройства серии «Control» сертифицированы на

соответствие требованиям Технических регламентов Таможенного

союза ТР ТС 020/2011 «Электромагнитная совместимость

технических средств»; TP TC 004/2011 «О безопасности

низковольтного оборудования».

Сертификат соответствия:

№ ТС RU C-DK.АИ30.В.01166, срок действия до 07.12.2019г.

№ TC RU C-RU.АИ30.В.01231, срок действия

до 23.12.2019г.

Низковольтные комплектные устройства серии «Control»,

произведенные в России, изготовлены в соответствии с ТУ 3432-021-

59379130-2014

Истра, 1 февраля 2015 г.

Руководитель отдела качества,

экологии и охраны труда

ООО Грундфос Истра, Россия

143581, Московская область,

Касаткина В. В.

Истринский район,

дер. Лешково, д.188

12

Page 13

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Centro

Industrial Garin

1619 Garín Pcia. de B.A.

Phone: +54-3327 414 444

Telefax: +54-3327 45 3190

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belarus

Представительство ГРУНДФОС в

Минске

220125, Минск

ул. Шафарнянская, 11, оф. 56, БЦ

«Порт»

Тел.: +7 (375 17) 286 39 72/73

Факс: +7 (375 17) 286 39 71

E-mail: minsk@grundfos.com

Bosna and Herzegovina

GRUNDFOS Sarajevo

Zmaja od Bosne 7-7A,

BH-71000 Sarajevo

Phone: +387 33 592 480

Telefax: +387 33 590 465

www.ba.grundfos.com

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

10F The Hub, No. 33 Suhong Road

Minhang District

Shanghai 201106

PRC

Phone: +86 21 612 252 22

Telefax: +86 21 612 253 33

Croatia

GRUNDFOS CROATIA d.o.o.

Buzinski prilaz 38, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.hr.grundfos.com

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-(0)207 889 900

Telefax: +358-(0)207 889 550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

HILGE GmbH & Co. KG

Hilgestrasse 37-47

55292 Bodenheim/Rhein

Germany

Tel.: +49 6135 75-0

Telefax: +49 6135 1737

e-mail: hilge@hilge.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg., 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Mexico

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Velu we zoom 3 5

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

Romania

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундф ос Россия

109544, г. Москва, ул. Школьная, 39-41,

стр. 1

Тел. (+7) 495 564-88-00 (495) 737-30-00

Факс (+7) 495 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

Grundfos Srbija d.o.o.

Omladinskih brigada 90b

11070 Novi Beograd

Phone: +381 11 2258 740

Telefax: +381 11 2281 769

www.rs.grundfos.com

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

25 Jalan Tukang

Singapore 619264

Phone: +65-6681 9688

Telefax: +65-6681 9689

Slovakia

GRUNDFOS s.r.o.

Prievozská 4D

821 09 BRATISLAVA

Phona: +421 2 5020 1426

sk.grundfos.com

Slovenia

GRUNDFOS d.o.o.

Šlandrova 8b, SI-1231 Ljubljana-Črnuče

Phone: +386 31 718 808

Telefax: +386 (0)1 5680 619

E-mail: slovenia@grundfos.si

South Africa

GRUNDFOS (PTY) LTD

Corner Mountjoy and George Allen Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölndal

Tel.: +46 31 332 23 000

Telefax: +46 31 331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-44-806 8111

Telefax: +41-44-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

Бізнес Центр Європа

Столичне шосе, 103

м. Київ, 03131, Україна

Телефон: (+38 044) 237 04 00

Факс.: (+38 044) 237 04 01

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971 4 8815 166

Telefax: +971 4 8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 4TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Uzbekistan

Grundfos Tashkent, Uzbekistan The Representative Office of Grundfos Kazakhstan in

Uzbekistan

38a, Oybek street, Tashkent

Телефон: (+998) 71 150 3290 / 71 150

3291

Факс: (+998) 71 150 3292

Addresses Revised 10.03.2015

Grundfos companies

Page 14

98770282 0215

ECM: 1152933

www.grundfos.com

The name Grundfos, the Grundfos logo, and be think innovate are registered trademarks owned by Grundfos Holding A/S or Grundfos A/S, Denmark. All rights reserved worldwide. © Copyright Grundfos Holding A/S

Loading...

Loading...