Page 1

English (GB) Installation and operating instructions

Caution

Note

Note

Original installation and operating instructions.

CONTENTS

Page

1. Symbols used in this document

2. Applications

3. System sizing

4. Electrical connection

5. Ejector valve

5.1 Ejector valve setting

6. Start-up

6.1 Shaft seal run-in

7. Adjustment

7.1 Calculating the cut-in and cut-out

pressures

7.2 Adjusting the precharge pressure

7.3 Setting the pressure switch

8. Operation and maintenance

9. Frost protection

10. Technical data

11. Fault finding

12. Disposal

Warning

Prior to installation, read this document

and the quick guide. Installation and

operation must comply with local

regulations and accepted codes of

good practice.

Warning

The use of this product requires

experience with and knowledge of the

product.

Persons with reduced physical,

sensory or mental capabilities must not

use this product, unless they are under

supervision or have been instructed in

the use of the product by a person

responsible for their safety.

Children must not use or play with this

product.

1. Symbols used in this document

Warning

If these safety instructions are not

observed, it may result in personal

injury.

Warning

If these instructions are not observed,

it may lead to electric shock with

consequent risk of serious personal

injury or death.

If these safety instructions are not

observed, it may result in malfunction

or damage to the equipment.

9

9

9

2. Applications

9

The JP Booster PT is suitable for pressure boosting

of fresh water in domestic water supply systems.

10

10

3. System sizing

10

10

11

11

11

11

12

12

4. Electrical connection

12

13

13

Check that the supply voltage and frequency

correspond to the values stated on the nameplate.

Single-phase motors incorporate a thermal switch

and require no additional motor protection.

Three-phase motors must be connected to an

external mains switch and a motor-protective circuit

breaker.

Notes or instructions that make the job

easier and ensure safe operation.

Warning

The system in which the product is

incorporated must be designed for the

maximum pump pressure.

The default setting can be found in the

quick guide.

Warning

The electrical installation should be

carried out by an authorised person in

accordance with local regulations.

Warning

During electrical installation, make sure

that the power supply cannot be

accidentally switched on.

Warning

The unit must be connected to an

external mains switch with a minimum

contact gap of 3 mm in all poles.

As a precaution, the pump must be

connected to a socket with earth

connection.

We recommend to fit the permanent

installation with an earth leakage circuit

breaker (ELCB) with a tripping current

≤

30 mA.

English (GB)

9

Page 2

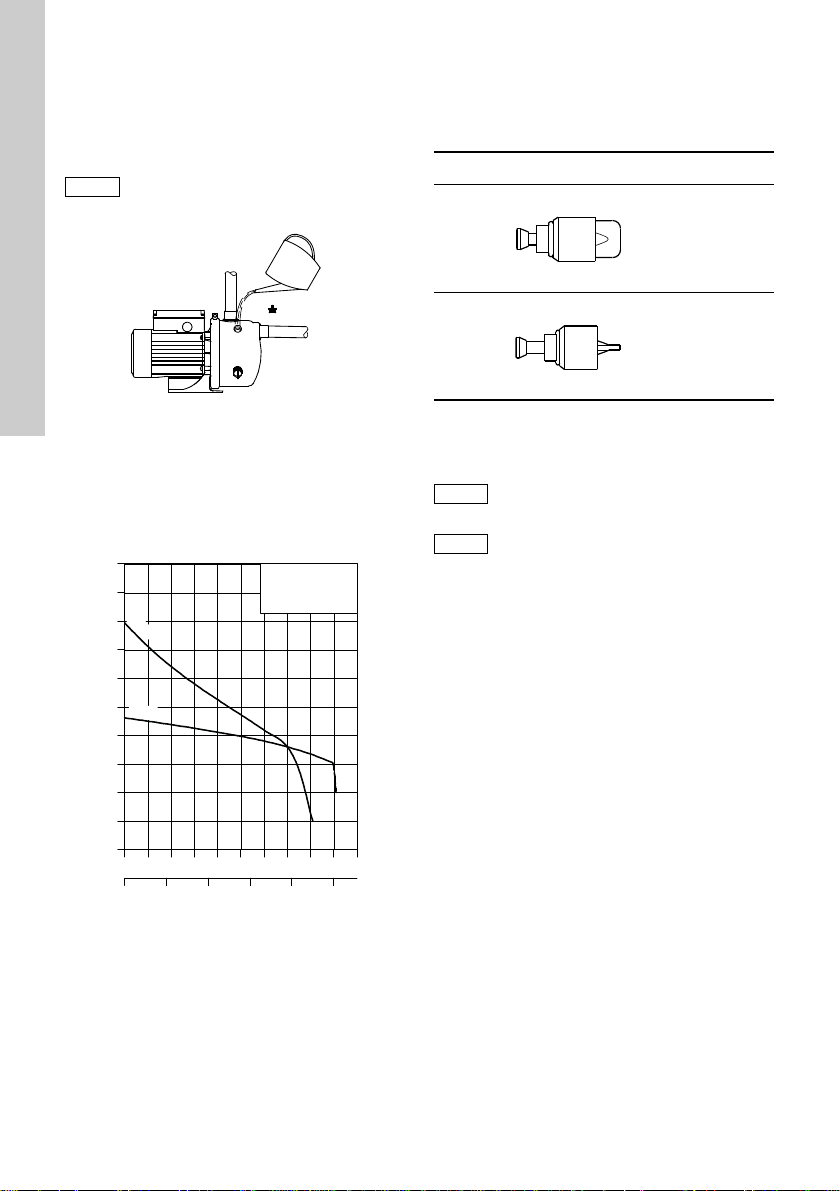

5. Ejector valve

Note

V

S

P

T

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 Q [m³/h]

0

5

10

15

20

25

30

35

40

45

H

[m]

0.00 0. 25 0.50 0.75 1.00 Q [l/s]

JP 5

IS O 9906 Annex A

P

o

s

.

1

P

o

s

.

2

Caution

Note

English (GB)

The ejector valve is supplied separate with the

pump.

Remove the plug (V), see fig. 1, and fit the ejector

valve into the hole.

The O-ring must be fitted to the ejector

valve.

Tighten the valve using fingers only.

Pos. 2

Turn the valve to the right (in).

Select pos. 2 when the pump has been primed, and

a large quantity of water and a low pressure are

required.

Pos. Ejector valve Direction

1

Left

(out)

TM04 2299 2308

Fig. 1 Ejector valve

5.1 Ejector valve setting

The ejector valve in the plug hole (V) can be turned

to two positions. See fig. 3.

Figure 2 shows an example of how the ejector valve

position may affect the QH curve.

Fig. 2 QH curve and ejector valve positions

Pos. 1

Turn the valve to the left (out).

Select pos. 1 when the suction pipe is empty and the

pump is to be primed.

Select also pos. 1 when a small quantity of water and

a high pressure are required.

10

2

TM00 5495 4995TM00 7474 1396

Right

(in)

Fig. 3 Ejector valve positions

6. Start-up

Do not start the pump until it has been

filled with liquid. See the quick guide.

We recommend to fit a non-return valve

on the suction side of the pump.

6.1 Shaft seal run-in

The seal faces are lubricated by the pumped liquid,

meaning that there may be a certain amount of

leakage from the shaft seal.

When the pump is started up for the first time, or

when a new shaft seal is installed, a certain run-in

period is required before the leakage is reduced to

an acceptable level. The time required for this

depends on the operating conditions, i.e. every time

the operating conditions change, a new run-in period

will be started.

Under normal conditions, the leaking liquid will

evaporate. As a result, no leakage will be detected.

TM04 2300 2308

Page 3

7. Adjustment

Note

Caution

Note

The JP Booster PT comes with the following factory

settings in bar:

Pump

JP 5 & 6 1.9 2.2 3.3

Tank

precharge

pressure

7.1 Calculating the cut-in and cut-out pressures

The cut-in pressure is the sum of these variables:

• required minimum pressure at the highest

tapping point

from the pump to the highest tapping point

• head

• pressure loss in pipes.

Recommended cut-out pressure:

cut-in pressure + 1.0 - 1.5 bar.

The cut-out pressure must not exceed

the maximum discharge pressure of the

pump.

7.2 Adjusting the precharge pressure

When the pump cut-in pressure has been

determined, the required precharge pressure of the

diaphragm tank can be calculated. The precharge

pressure must be adjusted to 90 % of the cut-in

pressure.

When adjusting/reading the precharge

pressure, make that there is no water

pressure on the diaphragm tank from

the pipework.

If the pressure switch setting is

changed, the precharge pressure must

be adjusted too.

See the installation and operating instructions for the

diaphragm tank.

Cut-in

pressure

Cut-out

pressure

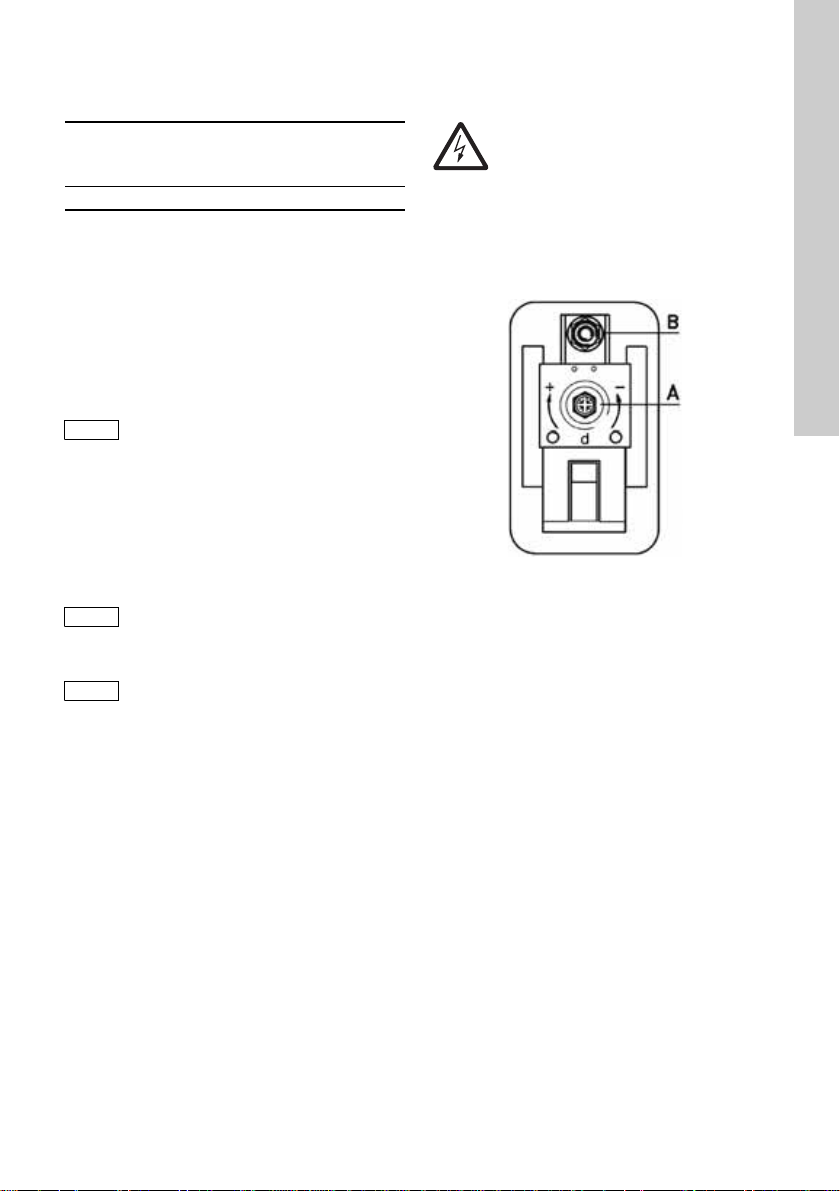

7.3 Setting the pressure switch

Warning

Switch off the power supply before

adjusting the pressure switch.

Fit the cover on the pressure switch

before you switch on the power supply

to check the cut-in and cut-out

pressure.

The cut-out pressure must be lower than the

maximum operating pressure of the pump and tank.

Remove the cover from the pressure switch to

access the adjusting screws. See fig. 4.

Fig. 4 Pressure switch

Setting the cut-out pressure

1. Turn screw (pos. A) clockwise to increase the

cut-out pressure.

Turn it counter-clockwise to reduce the cut-out

pressure.

The differential pressure range remains

unchanged.

2. Start the pump and check by reading the

pressure gauge whether the desired cut-out and

cut-in pressures have been obtained.

Setting the cut-in pressure

1. Turn screw (pos. B) clockwise to reduce the

cut-in pressure.

Turn it counter-clockwise to increase the cut-in

pressure.

The differential pressure range is widened and

narrowed respectively.

2. Start the pump and check by reading the

pressure gauge whether the desired cut-out and

cut-in pressures have been obtained.

Repeat the procedure until the right cut-in and

cut-out pressures have been obtained.

English (GB)

TM01 6914 3799

11

Page 4

8. Operation and maintenance

Caution

English (GB)

Warning

Prior to start-up, the system should be

flushed through with clean water and

drained to remove possible impurities.

Do not cover the motor of the booster

system as an adequate supply of cool

air must reach the motor cooling fan.

9. Frost protection

If there is a risk of frost, the tank and pump must be

drained.

10. Technical data

Ambient temperature

Maximum +40 °C.

Storage temperature

Minimum -20 °C.

Maximum +70 °C.

Liquid temperature

+40 °C.

System pressure

Maximum 6 bar.

Inlet pressure

At inlet pressures above 1.5 bar the discharge

pressure must be at least 2.5 bar.

Supply voltage

1 x 220-240 V, 50 Hz.

3 x 220-240/380-415 V, 50 Hz.

Insulation class

F.

Enclosure class

IP44.

Relative air humidity

Maximum 95 %.

Sound power level

The sound power level of the pump is lower than

72 dB(A).

Start/stop frequency

Maximum 100 per hour.

12

Page 5

11. Fault finding

Warning

Before starting fault finding, switch off

the power supply. Make sure that the

power supply cannot be accidentally

switched on.

Fault Cause Remedy

1. The pump does

not start.

2. There is power on

the pressure

switch but not the

pump.

3. The pump does

not start when

water is

consumed.

4. Frequent

starts/stops.

5. The pump does

not stop.

6. The motor cuts

out during

operation.

* Or contact the nearest Grundfos company or

service workshop.

a) The fuses in the electric

installation have burnt.

b) The earth leakage circuit

breaker or the

voltage-operated circuit

breaker has tripped.

a) The power supply to the pump

is disconnected after the

pressure switch unit.

b) The pressure switch unit is

defective.

a) Too big difference in height

between the pressure switch

unit and the tapping point.

b) The pressure switch unit is

defective.

a) Leakage in the pipework. Check and repair the pipework.

b) The pressure tank has no

precharge pressure, or the

tank size is insufficient.

a) The pressure switch unit is

defective.

a) The thermal switch in the

motor has tripped due to

overheating.

Replace the fuses. If the new fuses also burn,

check the electric installation.

Cut in the circuit breaker and check the electric

installation.

Check the cable connections.

Repair or replace the pressure switch unit. *

Adjust the cut-in pressure.

Repair or replace the pressure switch unit. *

Check the tank precharge pressure, and

recharge the tank, if necessary. See section 7.

Repair or replace the pressure switch unit. *

The thermal switch will cut in automatically

when the motor has cooled sufficiently.

If the problem still persists, check these two

possible causes:

• Impeller stuck.

Clean the pump.

• Motor defective.

Repair or replace the motor. *

English (GB)

12. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

Subject to alterations.

13

Loading...

Loading...