Page 1

G100

GRUNDFOS INSTRUCTIONS

Installation and operating instructions

Page 2

Declaration of Conformity

We Grundfos declare under our sole responsibility that the products

Profibus-DP and Radio/Modem/PLC version, to which this declaration

relates, are in conformity with the Council Directives on the approximation of the laws of the EC Member States relating to

– Electromagnetic compatibility (89/336/EEC).

Standards used: EN 61000-6-2 and EN 61000-6-3.

– Electrical equipment designed for use within certain voltage limits

(73/23/EEC) [95].

Standard used: EN 61010-1.

Konformitätserklärung

Wir Grundfos erklären in alleiniger Verantwortung, dass die Produkte

Profibus-DP und Radio/Modem/PLC-Ausführung, auf die sich diese

Erklärung bezieht, mit den folgenden Richtlinien des Rates zur Angleichung der Rechtsvorschriften der EG-Mitgliedstaaten übereinstimmen

– Elektromagnetische Verträglichkeit (89/336/EWG).

Normen, die verwendet wurden: EN 61000-6-2 und EN 61000-6-3.

– Elektrische Betriebsmittel zur Verwendung innerhalb bestimmter

Spannungsgrenzen (73/23/EWG) [95].

Norm, die verwendet wurde: EN 61010-1.

Déclaration de Conformité

Nous Grundfos déclarons sous notre seule responsabilité que les produits Profibus-DP et version Radio/Modem/PLC auxquels se réfère

cette déclaration sont conformes aux Directives du Conseil concernant

le rapprochement des législations des Etats membres CE relatives à

– Compatibilité électromagnétique (89/336/CEE).

Standards utilisés: EN 61000-6-2 et EN 61000-6-3.

– Matériel électrique destiné à employer dans certaines limites

de tension (73/23/CEE) [95].

Standard utilisé: EN 61010-1.

Försäkran om överensstämmelse

Vi Grundfos försäkrar under ansvar, att produkterna Profibus-DP och

version Radio/Modem/PLC, som omfattas av denna försäkran, är i

överensstämmelse med Rådets Direktiv om inbördes närmande till EUmedlemsstaternas lagstiftning, avseende

– Elektromagnetisk kompatibilitet (89/336/EC).

Använda standarder: EN 61000-6-2 och EN 61000-6-3.

– Elektrisk material avsedd för användning inom vissa spännings-

gränser (73/23/EC) [95].

Använd standard: EN 61010-1.

Overensstemmelseserklæring

Vi Grundfos erklærer under ansvar, at produkterne Profibus-DP og

Radio/Modem/PLC-udgave, som denne erklæring omhandler, er i

overensstemmelse med Rådets direktiver om indbyrdes tilnærmelse til

EF medlemsstaternes lovgivning om

– Elektromagnetisk kompatibilitet (89/336/EØF).

Anvendte standarder: EN 61000-6-2 og EN 61000-6-3.

– Elektrisk materiel bestemt til anvendelse inden for visse spændings-

grænser (73/23/EØF) [95].

Anvendt standard: EN 61010-1.

Свидетельство о соответствии

требованиям

Мы, фирма Grundfos, со всей ответственностью заявляем, что

изделия Profibus-DP и исполнение с функциями радиосвязи/

модема/программируемого процессора, к которым и относится

данное свидетел ьст во, отвеча ют требованиям следующих указаний

Совета ЕС об унификации законодательных предписаний странчленов ЕС:

– Электромагнитная совместимость (89/336/ЕЭС).

Применявшиеся стандарты: Евростандарт EN 61000-6-2 и

EN 61000-6-3.

– Электрические машины для эксплуатации в

пределах

определенного диапазона значений напряжения

(73/23/ЕЭС)[95].

Применявшиеся стандарты: Евростандарт EN 61010-1.

Bjerringbro, 1st April 2006

Svend Aage Kaae

Technical Director

2

Page 3

3

G100

Installation and operating instructions 4

Montage- und Betriebsanleitung 18

Notice d'installation et d'entretien 34

Monterings- och driftsinstruktion 49

Monterings- og driftsinstruktion 63

Руководство по монтажу и эксплуатации 77

Page 4

4

CONTENTS

Page

1. General description 4

2. Installation 5

2.1 Electrical connection 5

2.2 Installation requirements 5

2.3 Master programming 5

2.4 Start-up 5

3. Description of function 6

3.1 Data communication 6

3.2 Service port 6

3.3 Data logging 6

3.4 Digital inputs 6

3.5 Automatic call-back and SMS messages

(G100 Radio/Modem/PLC only) 7

3.6 Other functions 7

4. Profibus-DP 7

4.1 Profibus-DP settings 7

4.2 Profibus-DP front cover 8

4.3 Common connectors 9

4.4 Profibus-DP connector 9

5. Radio/Modem/PLC 10

5.1 Radio/Modem/PLC settings 10

5.2 Radio/Modem/PLC front cover 12

5.3 Common connectors 13

5.4 Radio/Modem/PLC connectors 13

6. Fault finding chart 14

7. Technical data 16

7.1 Data applying to all versions 16

7.2 Profibus-DP expansion board 17

7.3 Radio/Modem/PLC expansion board 17

7.4 Emission (applies to the USA) 17

8. Disposal 17

1. General description

Definition

The G100 is a gateway enabling communicatio n

between units connected to a Grundfos GENIbus

and a main network.

Communication

The G100 functions as a master to the GENIbus.

Only one G100 can be installed on a GENIbus net-

work, and a maximum of 32 units can be handled.

Data logging

Besides functioning as a gateway, the G100 basic

and Radio/Modem/PLC versions provide data logging facilities.

Data logging enables continual storage of measured

values in the G100 with a resolution down to 4 seconds.

Digital inputs

As standard, the G100 has four digital inputs to be

used as required. It is up to the user to determine the

function of the digital inputs.

Status of digital inputs can be reafd via the communication to the main network and can be used to trigger

SMS messages.

Automatic call-back and SMS messages

The G100 with a modem connection can be configured for automatic call-back to one or more phone

numbers (central management system) when one of

the connected GENIbus units goes into alarm condition, e.g. blocked pump.

The G100 can also be configured to send SMS m essages in case of an alarm condition or other selectable events.

Other functions

• Stop of all pumps in case of failing communication

with the building mangement system (optional).

• Acces s code for mode m communication

(optional).

• Logging of the last 10 alarms with address, time

stamp and cause.

Software

A software package is supplied with the G100.

The package includes two programs:

• PC Tool G100 and

• PC Tool G100 Data Log.

PC Tool G100

The program PC Tool G100 is a combined configuration/analysis tool to be used by the system integrator.

The program offers the following functions:

• Showing the unit hierarchy of the GENIbus network.

• Showing/managing the data points of the individual units.

• Showing the status of the G100.

• Configuring the G100.

PC Tool G100 Data Log

The program PC Tool G100 Data Log enables the user

• to configure the data logging facility in a G100.

• to retrieve the logged data values from the G100.

• to visualize the units connected to the G100.

• to retrieve a logging status of a connected G100

at any time.

Prior to installation, read these installation

and operating instructions. Installation and

operation must comply with local regulations and accepted codes of good practice.

Page 5

5

Help menu

The software for the G100 includes a help menu to

be used in connection with the installation and operation of the G100.

Software downloading

The software in the G100 can be updated by downloading new software via the service port directly or

by modem using the PC Tool G100.

2. Installation

2.1 Electrical connection

The electrical connection should be carried out in

accordance with local regulations.

The operating voltage and frequency are marked on

the nameplate. Please make sure that the G100 is

suitable for the electricity supply on which it will be

used.

Use the plug supplied for the electrical connection.

Supply voltage: 1 x 110-240 V, 45-65 Hz.

2.2 Installation requirements

The G100 must be positioned in a way ensuring that

electromagnetic noise from contactors, relays and

electric devices does not influence the functioning of

the G100.

Distance to power cables

G100: Place the G100 at a distance of minimum

15 cm from power cables.

Cables: Cables for the connection of

• Profibus,

• radio, modem, PLC and direct,

• GENIbus,

• DI (digital inputs) and

• Service

must also keep a distance of minimum 15 cm to

power cables.

G100 on control panel

When positioning the G100 on a control panel, it is

recommended that the G100 be located as close to

the bottom of the panel as possible due to temperature conditions.

G100 in control cabinet

The G100 is designed for mounting in a control cabinet, directly on a mounting plate.

Fig. 1

2.3 Master programming

Master programming on the main network must be

carried out by the system integrator according to the

instructions given on the "G100 Support Files" CDROM supplied with the G100.

Handling G100 from the management system

The management system on the main network must

be prepared for communication with the G100.

This involves adding some software

• handling the transfer of data,

• using data for monitoring and control purposes.

Reference: The "G100 Support Files" CD-ROM sup-

plied with the G100 contains the necessary documentation.

2.4 Start-up

Before powering on the G100,

• complete the GENIbus wiring and

• assign a unique address to each unit conn ected

(via the Grundfos remote control R100 or via the

control panel on the unit).

Switch on the electricity supply and make sure that

the light-emitting diodes on

• mother board

(see section 4.2 Profibus-DP front cover) and

• expansion board, if any,

(see the relevant section)

light up correctly.

As a precaution, the G100 must be

earthed. It is recommended to fit the installation with an earth leakage circuit breaker

(ELCB) with a tripping current < 30 mA.

Never dismantle the G100 unless the electricity supply has been switched off.

TM01 1712 1602

B

u

s In

Bus

O

u

t

M

a

in

N

etwo

rk

C

on

n

ec

tio

n

P

O

W

ER

P

OW

E

R M

NC

P

O

W

E

R G

E

N

I

GE

N

I T

xD

G

E

NI

Rx

D

F

A

UL

T

R

B

D

A

TR

B

A

R

C

GE

N

Ibu

s

S

e

rv

ice

D

I

Page 6

6

3. Description of function

3.1 Data communication

It is possible to connect up to 32 units to the

GENIbus. A unit may be a UPE pump with GENIbus

connection, a CU 3 control unit, etc.

The main network may be

• another fieldbus,

• radio,

• modem,

•PLC,

• direct RS-232 connection.

Information retrieval

Information such as

• measured values,

• operating status,

• fault status,

• configuration parameters and more

can be retrieved from each individual unit via the

G100.

Remote configuration

• Setpoints,

• commands and

• configuration parameters

can be sent to the GENIbus units via the G100.

Reference: The "G100 Support Files" CD-ROM sup-

plied with the G100 contains an overview of the data

which can be communicated between the main network and the different types of Grundfos products

having a GENIbus connection.

3.2 Service port

The service port enables the connection of a PC

directly or via radio modem to the G100.

By means of the PC Tool G100, the following can be

read:

• status of the units connected to the GENIbus,

• internal error codes i n the G100.

The PC Tool G100 can also be used:

• to display the individual data points with their

actual values,

• to change setpoints, change configuration parameters and send commands.

3.3 Data logging

Description

The G100 basic and Radio/Modem/PLC versions

include data logging facilities. Data logging means

that the G100 stores data point values sampled over

a given period.

The data logging facility is configured by means of

the program PC Tool G100 Data Log.

Purpose

The logged data can be used for various analyses of

e.g. flow, head, energy consumption, etc. enabling

optimum pump control.

Subsequently, stored data may be transmitted to a

PC. For example, the stored data can be analysed in

a spreadsheet.

Logging data points

By configuring the data logging of the individual data

points, each value may continually be monitored/registered, each logging being time-stamped to indicate

the date/time of the value.

G100 logging capacity

The number of log data points and the logging frequency determine for how long the G100 can perform data logging.

The 2 Mb memory installed makes it possible to log

up to 350,000 values. For example 20 data points for

• 120 days at 10-minute resolution or

• 2 days at 10-second resolution.

Maximum logging resolution is 4 seconds.

3.4 Digital inputs

The G100 features four digital inputs for optional

use.

The four digital inputs should be considered data

points, and they can thus be referenced from the

main network in the same way as the other da ta

points.

Purpose

An example could be the monitoring of an Uninterruptable Power Supply (UPS) or the registration of

status, e.g. alarms.

Page 7

7

3.5 Automatic call-back and SMS messages (G100 Radio/Modem/PLC only)

A G100 with a modem connection can be configured

for automatic call-back to one or more phone numbers (central management system) when one of the

connected GENIbus units goes into alarm condition,

e.g. blocked pump. The advantage of this function is

that regular dial-ups, or a fixed online connection, to

the system to be monitored are unnecessary.

The G100 can also be configured to send SMS messages via a GSM data modem (or via a UCP server

when a fixed-line modem is used) in case of an

alarm condition or other selectable events.

SMS messages can be combined with automatic

call-back so that both functions are carried out or

one is carried out only if the other fails. It is possible

to call back to five different phone numbers and the

call-backs can be controlled by other events than

faults:

• A GENIbus unit goes into alarm condition.

• A GENIbus unit comes out of alarm condition.

• A GENIbus unit goes into warning condition.

• A GENIbus unit comes out of warning condition.

• The G100 loses connection with a GENIbus unit

or gets into contact with a new GENIbus unit.

• Change of digital input.

These events can be selected or deselected as

desired. In addition, the "heartbeat" SMS function

can be set to send a message at fixed intervals, indicating that the telephone modem connection is operational.

3.6 Other functions

The G100 is capable of monitoring the communication via the service port as well as the communication port to the main network. If the communication is

disconnected within a given configurable period, the

G100 will stop all connected GENIbus units using

bus commands. This function can be enabled or disabled for each of the two communication ports.

In a given application, this function can be used to

stop all pumps in case of failing communication with

the central management system.

The G100 has an access code option for modem

communication. If the access code is not written correctly, the transmission of data to the G100 and the

GENIbus units will not be allowed. In this way, unauthorized persons are prevented from causing damage to the system.

The G100 will log the last 10 ala rms w ith addres s,

time stamp and cause. The alarm log can be useful

in connection with fault finding. The log can be

deleted by giving a command to the G100.

4. Profibus-DP

Description

The Profibus-DP builds upon a master-slave-principle, where the bus master (PC or PLC) also functions as the link to an overlying management system

(SCADA system).

The G100 functions as a slave on the Profibus-DP

network.

G100 Profibus-DP address

When installing the G100, the G100 Profibus-DP

address must be set manually by the use of DIP

switches on the Profibus-DP expansion board.

See section 4.1 Profibus-DP settings.

4.1 Profibus-DP settings

The physical Profibus-DP address must be set on

the Profibus-DP expansion board, fig. 2. This should

be done before connecting the G100 to the ProfibusDP.

Fig. 2

The G100 must be assigned a Profibus-DP address

which is not already being used on the Profibus-DP

network.

Example: The Profibus-DP address is set to No. 3

on the DIP switches in fig. 3.

Fig. 3

It is possible to set the address from No. 1 to 255.

The address No. 0 is reserved.

TM01 1706 5097

TM01 1707 5097

Connection

to mother

board

Address

1

2

3

4

5

6

7

8

Page 8

8

Master configuration

The Profibus-DP master (e.g. PLC) must be configured according to the specifications of the ProfibusDP master in question.

Data transmission and system demands

As the DP protocol does not transmit data via

objects. Consequently, the G100 uses a superimposed telegram format for the DP protocol. This telegram format must be implemented in the ProfibusDP master by the system integrator.

Reference: The telegram format is described in the

"G100 Support Files" CD-ROM supplied with the

G100. The necessary GSD file for the DP master is

also available on the CD-ROM.

4.2 Profibus-DP front cover

Front cover

Light-emitting diodes:

Operating/fault indications

Colour

Normal

condition

POWER:

The G100 is powered.

Green

Permanently on

POWER MNC:

The network communication chip to the

main network is powered.

Green

Permanently on

POWER GENI:

The GENIbus RS-485 communication

chips are powered.

Green

Permanently on

GENI TxD:

Data is sent via GENIbus RS-485.

Yellow Flashing

GENI RxD:

Data is received from GENIbus

RS-485.

Yellow Flashing

FAULT:

Data memory fau lt.

Red Off

DES:

Data Exchange State.

Connection to DP network is OK.

Green

Permanently on

G100 connectors

• GENIbus

• DI

• Service

See section 4.3 G100 common connectors.

• Main Network Connection: See section 4.4 Profibus-DP

connector.

Power

Power MNC

Power Geni

Geni T xD

Geni RxD

Fault

DES

Genibus DI Service

Main

Network

Connection

G100 Gateway

Profibus

TM01 1705 1602

Page 9

9

4.3 Common connectors

This section describes G100 connectors (male) for

• GENIbus,

• DI (digital inputs) and

• Service.

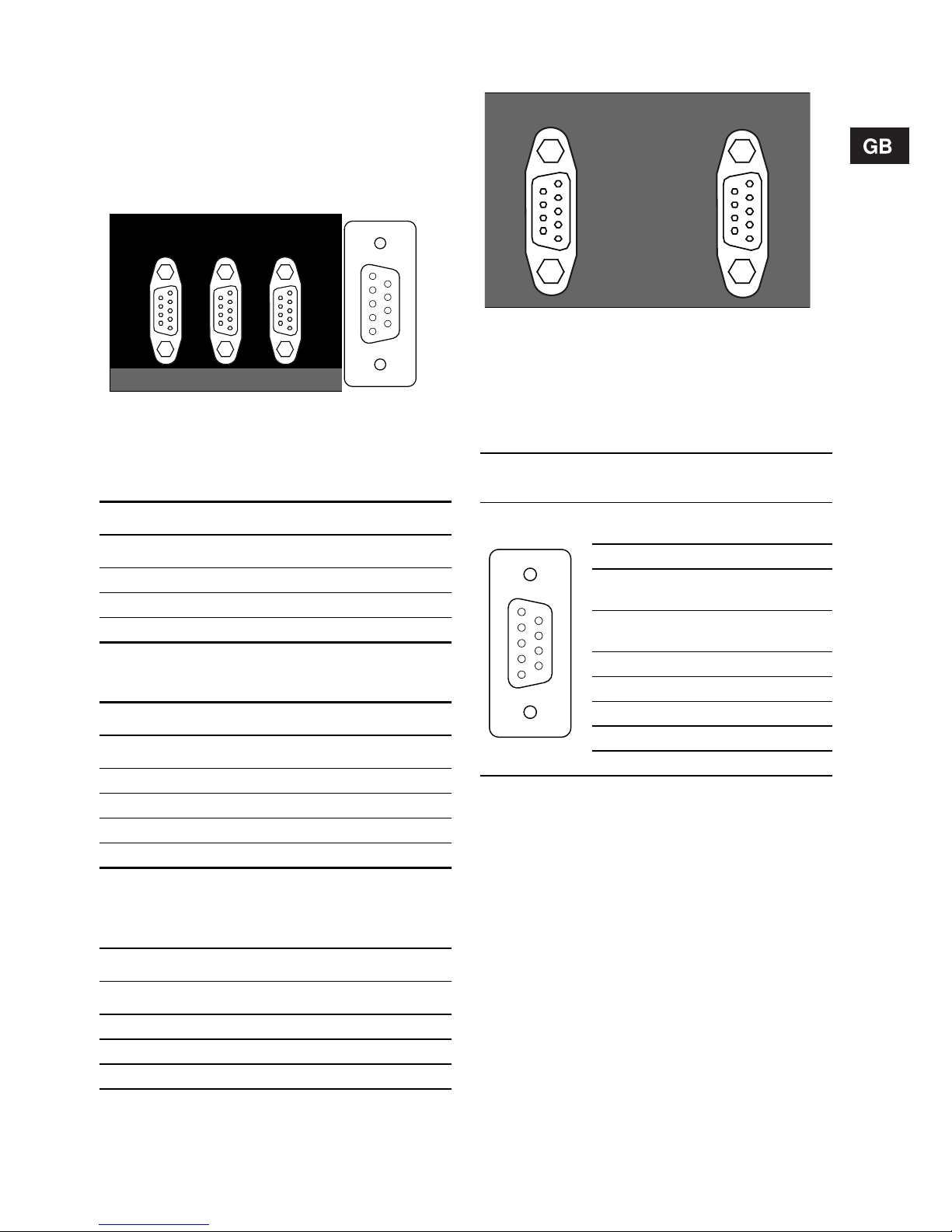

Figure 4 shows the three G100 male connectors and

a 9-pin D-sub female connector with pin numbers.

Fig. 4

GENIbus connector

The GENIbus is a serial RS-485 connection.

A, B and Y are placed as follows:

DI connector

The digital inputs are paired as follows:

Service connector

The service port is a serial RS-232 connection.

RxD, TxD and GND are placed as follows:

:

4.4 Profibus-DP connector

Fig. 5

The connection of the G100 to the Profibus-DP is

made by connecting the Profibus-DP cable to the

Profibus-DP connector shown in fig. 5.

The network topology on Profibus-DP is multidrop.

Pin configuration

The pin configuration of the connector is made

according to the Profibus-DP standard.

* The assignment of pin Nos. 1, 2, 7 and 9 corre-

sponds to that of the connected unit.

When connecting to Profibus-DP, a standard connector from Siemens should be used.

Example: 6ES7 972-OBA10-OXAO.

TM01 1700 1602 / 6904 3699

Connections

GENIbus Pin number

A2

B3

Y (screen) 5

Connections

DI Pin number

DI 1 1 + 6

DI 2 2 + 7

DI 3 3 + 8

DI 4 4 + 9

Connections

Service Pin number

RxD 2

TxD 3

GND 5

1

2

3

4

5

6

7

8

9

Genibus DI Service

TM01 1705 1602

Illustration

Pin

No.

Signal Description

1* – –

2* – –

3 RxD/TxD-P Data line B

4RTS

Request to

send

5M5V2

Data reference potential (from

station)

6P5V2

Supply plus

(from station)

7* – –

8 RxD/TxD-N Data line A

9* – –

Main

Network

Connection

Profibus

1

2

3

4

5

6

7

8

9

TM01 6904 3699

Page 10

10

5. Radio/Modem/PLC

Description

In addition to the GENIbus protocol, the G100 Radio/

Modem/PLC can communicate via the standard PLC

protocols COMLI and Modbus.

For all three protocols, direct connection (RS-232) or

connection via telephone modem or radio modem

can be used. The G100 usually functions as a slave

on the network.

When using direct connection or modem connection,

it is possible to multiplex the connection to the G100

(port 1, RS-232). This means that several G100 units

with different addresses can be connected to a single serial port of a PC, when the appropriate equipment is used, e.g. modem data splitter or radio

modems.

G100 address

When installing the G100, the physical bus address

must be set manually by the use of DIP switches on

the expansion board.

See section 5.1 Radio/Modem/PLC settings.

5.1 Radio/Modem/PLC settings

When the G100 is incorporated in a network together

with other G100 units, an address must be allocated

to each unit. Note that the address 0 is the "broadcast" address (default). All units will reply to this

address when asked.

The physical bus address must be set on the Radio/

Modem/PLC expansion board.

This should be done before start-up.

Fig. 6

The G100 must be assigned a bus address which is

not already being used on the network.

Example: The bus address is set to No. 3 on the DIP

switches in fig. 7.

Fig. 7

It is possible to set the address from No. 1 to 255.

The address 0 is reserved.

In Port 1, the switches 1 to 8 have the following purposes:

TM01 1711 5097

Address

Port 2

Port 2

Port 1

TM01 1707 5097

DIP switch Purpose

1 - 2 IO type

3 - 5 Protocol

6 - 8 Communication speed

1

2

3

4

5

6

7

8

Page 11

11

The following table shows how the DIP switches in

Port 1 should be set.

.

Data transmission

The data transmission itself is made via objects

(identified by means of an index No.).

Reference: The "G100 Support Files" CD-ROM

supplied with the G100 contains a description of the

objects available.

Note: The G100 is not supplied with a radio, modem

or PLC. They must all be acquired separately.

Port 1

Function

DIP switch setting

12345678

IO type

Direct 00––––––

Modem 1 0––––––

Radio 01––––––

PLC 11––––––

Protocol

Auto

detect

––000–––

G100 ––100–––

Satt Control

COMLI

––010–––

Communication speed

1200 baud –––––000

2400 baud –––––100

4800 baud –––––010

9600 baud –––––110

19200 baud – ––––001

Reserved –––––101

Reserved –––––011

Reserved –––––111

Page 12

12

5.2 Radio/Modem/PLC front cover

*) For explanation to Power, Power MNC, Power Geni, Geni TxD, Geni RxD, Fault, see section 4.2 Profibus-

DP front cover.

Front cover

Light-emitting diodes:

Operating/fault indications *)

Colour

Normal

condition

DCD:

Data Carrier Detect

DCD pin is active. Light diode indication according to the IO type selected:

Radio

DCD is on

when a unit in the radio system has asked for and received permission to send data.

Modem (G100 with modem (dial-up)

connection to main system. G100 can

make alarm dial-up).

DCD is on

when G100 is connected to

main system.

PLC

DCD is permanently on

when G100 is

powered.

Direct (G100 permanently connected to

main system).

DCD is permanently on

when G100 is

powered.

Direct (G100 with modem (dial-up) connection to main system. G100 cannot

make alarm dial-up).

DCD is on

when G100 is connected to

the main system.

Green

RTS:

Request To Send

RTS pin on line is active. Light diode indication according to the IO type selected:

Radio

RTS is o n

when G100 desires to send

data or data is actually being sent.

Modem, PLC or Direct

RTS is permanently on

when G100 is

powered.

Green

TxD1:

Data transmission on line 1.

Yellow Flashing

RxD1:

Data reception from line 1.

Yellow Flashing

TxD2:

Data transmission on line 2.

Reserved for future use.

––

RxD2:

Data reception from line 2.

Reserved for future use.

––

G100 connectors

• GENIbus

• DI

• Service

See section 4.3 G100 common connectors.

• Main Network Connection: See section 5.4 Radio/Modem/

PLC connectors.

TM01 1710 1602

Power

Power MNC

Power Geni

Geni T xD

Geni RxD

Fault

DCD

RTS

TxD1

RxD1

TxD2

RxD2

Genibus DI Service

Port 1 Port 2

Main

Network

Connection

G100 Gateway

Page 13

13

5.3 Common connectors

This section describes G100 connectors (male) for

• GENIbus,

• DI (digital inputs) and

• Service.

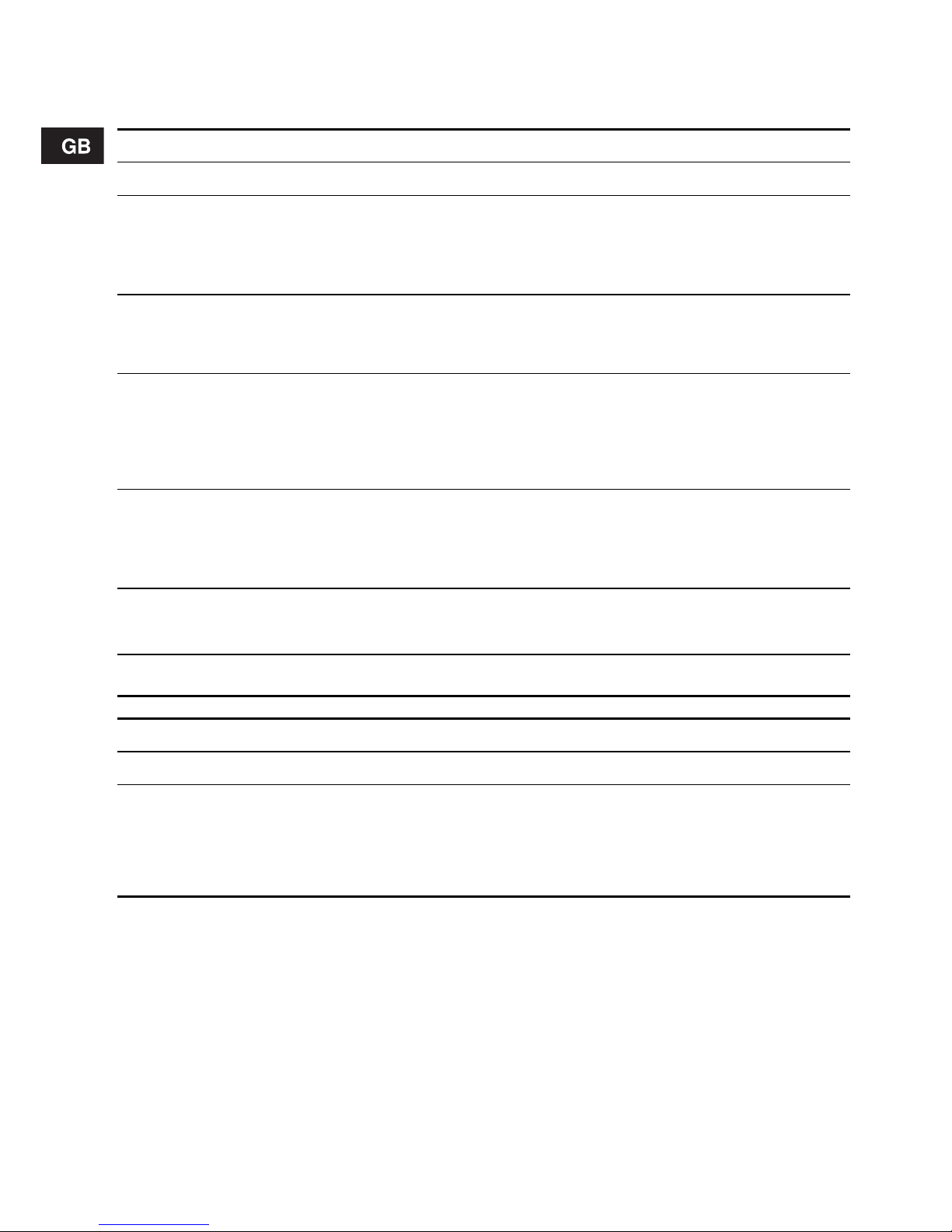

Figure 8 shows the three G100 male connectors and

a 9-pin D-sub female connector with pin numbers.

Fig. 8

GENIbus connector

The GENIbus is a serial RS-485 connection.

A, B and Y are placed as follows:

DI connector

The digital inputs are paired as follows:

Service connector

The service port is a serial RS-232 connection.

RxD, TxD and GND are placed as follows:

:

5.4 Radio/Modem/PLC connectors

Fig. 9

The connection of the G100 to radio, modem or PLC

is made by connecting the cable to the Port 1 connector shown in fig. 9.

Port 2 is not used.

Pin configuration

TM01 1700 1602 / 6904 3699

Connections

GENIbus Pin number

A2

B3

Y (screen) 5

Connections

DI Pin number

DI 1 1 + 6

DI 2 2 + 7

DI 3 3 + 8

DI 4 4 + 9

Connections

Service Pin number

RxD 2

TxD 3

GND 5

1

2

3

4

5

6

7

8

9

Genibus DI Service

TM01 1710 1602

Illustration

Pin

No.

Signal Description

1DCD

Data carrier

detect

2 RxD Received data

3TxD

Transmitted

data

4DTR

Data terminal

ready

5 GND Ground

6 DSR Data set ready

7 RTS Request to send

8 CTS Clear to send

9 RI Ring indicator

Port 1 Port 2

Main

Network

Connection

1

2

3

4

5

6

7

8

9

TM01 6904 3699

Page 14

14

6. Fault finding chart

Additional instructions for fault finding in the communication with the G100 can be found on the "G100 Support

Files" CD-ROM supplied with the G100.

G100 mother board

Indication Cause Remedy

1. POWER

off.

a) No electricity supply. • Check the electricity supply.

• Check that the G100 is OK by removing

connection to main network and to

GENIbus.

• Contact the system supplier.

b) Fault in components/fatal component

fault.

2. POWER MNC

faint or off.

a) Fault in main network or in the G100. • Check that the G100 is OK by removing

connection to main network. POWER

MNC must now be on.

• Check MNC cables for faults.

b) Cable fault, possibly short-circuit.

3. POWER GENI

faint or off.

a) GENIbus is overloading the G100. • Check that the G100 is OK by removing

connection to GENIbus. All POWER diodes must now be permanently on.

• Check the GENIbus connection and cabling.

• Contact the system supplier.

4. GENI TxD

not flashing.

a) The G100 is not communicating. • Disconnect/connect the electricity sup-

ply.

• Check the bus.

If this does not help, then replace the

G100.

b) GENIbus connection or cable may be

short-circuited.

5. GENI RxD

not flashing.

a) GENIbus connection or cable may be

short-circuited.

Check the GENIbus connection and

cabling.

b) No units are connected to GENIbus.

6. FAULT

permanently on.

a) RAM memory fault. Replace the G100.

Profibus-DP expansion board

Indication Cause Remedy

1. DES

off.

a) Cable fault. • Check the cable.

• Check that the master applies the correct maker’s ID No., address and ID

size.

- Maker’s ID No.

- Address: As set on DIP switch.

b) Configuration fault on master.

Page 15

15

Radio/Modem/PLC expansion board

Indication Cause Remedy

1. DCD

- Modem

off.

a) Wrong modem type. • Check that the modem initialization

commands are compatible.

• Make a redial.

b) Poor telephone line.

2. DCD

- Radio

permanently on.

a) Fault in a radio network unit. Reset or disconnect/connect the unit in

case of fault.

If this does not help, then replace the unit

in case of fault.

3. RTS

- Radio

permanently on.

a) The G100 is constantly attempting to

send.

• Disconnect/connect the electricity supply or

• reset the G100 using the PC Tool

G100.

4. RTS

- Direct/modem

not permanently on.

a) Fault in the G100. • Disconnect/connect the electricity sup-

ply or

• reset the G100 using the PC Tool

G100.

If this does not help, then replace the

G100.

5. TxD1

not flashing.

a) No communication with the G100. • Connect the G100.

• Check the cable.

• Check that the cable is connected correctly according to IO type (radio, modem, PLC or direct).

6. RxD1

not on

as expected.

a) Cable is connected incorrectly. Check that the cable is connected cor-

rectly according to IO type (radio, modem,

PLC or direct).

Page 16

16

7. Technical data

7.1 Data applying to all versions

Mains supply

Rated voltage 110-240 V AC.

Voltage tolerance –25%/+15% of rated voltage.

Mains frequency 45-65 Hz.

Power consumption 6 W.

Construction

• Number of slots

• Dimensi ons (W x H x D) in mm

• Weight (incl. expansion board)

• 2 (1 for the mother board and 1 for one expansion board).

• 73 x 227 x 165.

• 1800 g.

Operating range

• Ambient tempera ture during operation

• Transportation and storage temperature

• Relative air humidity

• –20°C to +60°C.

• –20°C to +60°C.

• Maximum 95% (without condensation).

Materials, housing Steel.

Enclosure class IP 20.

Approvals The G100 has been CE marked.

CPU

• Proce ssor

• Instruction size

• Proce ssor speed

• Intel 80251.

• 16-bit.

• 20 MHz.

Data logging

FLASH memory size 2 Mb ~ up to 350,000 time-stamped values.

Note: This feature applies to the G100 basic and Radio/

Modem/PLC versions.

GENIbus connection

•Bus

• Connection

• Electri cally separated

• Cable

• RS-485 up to 32 units.

• 9-pin D-sub male connector.

•Yes.

• 0.25 - 1 mm

2

screened 2-core cable.

Maximum cable length: 1200 m.

Connection for service/analysis

•Serial

• Connection

• Electri cally separated

• RS-232.

• 9-pin D-sub male connector.

•No.

Real time clock

• Accuracy

•Battery

• Battery durability

• ±5 min./year.

• DC 3 V, lithium battery for preservation of real time clock

during power off.

• When in use > 5 years, when stored > 10 years.

Dig i ta l i npu ts

• Number of inputs

• Input

• Logic "0"

• Logic "1"

• Connection

•4.

• External potential- free NO contact.

• Open (U > 3.2 V).

• Closed (U < 0.9 V).

• 9-pin D-sub male connector, screened cable.

Visual indication

Operating status 6 light-emitting diodes.

Page 17

17

7.2 Profibus-DP expansion board

7.3 Radio/Modem/PLC expansion board

7.4 Emission (applies to the USA)

8. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

Profibus-DP connection

• Communi cation chip

• Communication speed

• Connection

• SPC3.

• 9.6 kbaud to 12 Mbaud.

• RS-485, 9-pin D-sub male connector.

Visual indication

Operating status 1 light-emitting diode.

Radio/modem/PLC connectio n

•Port 1

• Connection

• Communication speed

• Modem type

• Radio type

• RS-232.

• 9-pin D-sub male connector.

• 1.2 to 19.2 kbaud.

• Zyxel or others.

• Radio modem or protocol -based Niros 2001.

Visual indication

Operating status 6 light-emitting diodes.

Radio/Modem/PLC

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation.

This equipment generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with these instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and recei ver.

• Connect the equipme nt into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/T V technician for help.

Profibus-DP

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with these instructions, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Subject to alterations.

Page 18

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote

34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb

Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belorussia

Представительство ГРУНДФОС в

Минске

220090 Минск ул.Олешева 14

Телефо н: (8632) 62-40-49

Факс: (8632) 62-40-49

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Paromlinska br. 16,

BiH-71000 Sarajevo

Phone: +387 33 713290

Telefax: +387 33 231795

Brazil

GRUNDFOS do Brasil Ltda.

Rua Tomazina 106

CEP 83325 - 040

Pinhais - PR

Phone: +55-41 668 3555

Telefax: +55-41 668 3554

Bulgaria

GRUNDFOS Pumpen Vertrieb

Representative Office - Bulgaria

Bulgaria, 1421 Sofia

Lozenetz District

105-107 Arsenalski blvd.

Phone: +359 2963 3820, 2963 5653

Telefax: +359 2963 1305

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

GRUNDFOS Pumps (Shanghai) Co.

Ltd.

22 Floor, Xin Hua Lian Building

755-775 Huai Hai Rd, (M)

Shanghai 200020

PRC

Phone: +86-512-67 61 11 80

Telefax: +86-512-67 61 81 67

Croatia

GRUNDFOS predstavništvo Zagreb

Cebini 37, Buzin

HR-10000 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-438 906

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 44

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

Piispankylä

FIN-01730 Vantaa (Helsinki)

Phone: +358-9 878 9150

Telefax: +358-9 878 91550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706/27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

Flat A, Ground Floor

61/62 Chamiers Aptmt

Chamiers Road

Chennai 600 028

Phone: +91-44 432 3487

Telefax: +91-44 432 3489

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910/460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290/95838461

Japan

GRUNDFOS Pumps K.K.

1-2-3, Shin Miyakoda

Hamamatsu City

Shizuoka pref. 431-21

Phone: +81-53-428 4760

Telefax: +81-53-484 1014

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Mexico

Bombas GRUNDFOS de Mexico S.A.

de C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Mexico

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Nederland B.V.

Postbus 104

NL-1380 AC Weesp

Tel.: +31-294-492 211

Telefax: +31-294-492244/492299

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Phone: (+48-61) 650 13 00

Telefax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

România

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундфос

Росс ия, 109544 Москва, Школьная 39

Тел. (+7) 095 737 30 00, 564 88 00

Факс (+7) 095 737 75 36, 564 88 11

E-mail

grundfos.moscow@grundfos.com

Serbia and Montenegro

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877, 11 26 47

496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS PUMPEN VERTRIEB

Ges.m.b.H.,

Podružnica Ljubljana

Blatnica 1, SI-1236 Trzin

Phone: +386 1 563 5338

Telefax: +386 1 563 2098

E-mail: slovenia@grundfos.si

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Lunnagårdsgatan 6

431 90 Mölndal

Tel.: +46-0771-32 23 00

Telefax: +46-31 331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

947/168 Moo 12, Bangna-Trad Rd.,

K.M. 3,

Bangna, Phrakanong

Bangkok 10260

Phone: +66-2-744 1785 ... 91

Telefax: +66-2-744 1775 ... 6

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd.

Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС Укра ин а

ул. Владимирская, 71, оф. 45

г. Киев, 01033,

Украина,

Тел. +380 44 289 4050

Факс +380 44 289 4139

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Usbekistan

Представительство ГРУНДФОС в

Ташк енте

700000 Ташк ент ул.Усм ан а Носира 1й

тупик 5

Телефо н: (3712) 55-68-15

Факс: (3712) 53-36-35

Addresses revised 18.04.2006

Page 19

www.grundfos.com

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

96417298 0406

169

Repl. 96417298 0504

Loading...

Loading...