Page 1

GRUNDFOS INSTRUCTIONS

Rigid Suction Lances RSL

and Foot Valves FV

Installation and operating instructions

Page 2

2

Page 3

English (GB) Installation and operating instructions

Caution

Note

Original installation and operating instructions.

CONTENTS

1. Safety instructions

1.1 Symbols used in this document

1.2 Qualification and training of personnel

1.3 Safe operation

1.4 Safety instructions for the operating company/operator

2. Product introduction

2.1 Applications

2.2 Improper operating methods

2.3 Function

2.4 Warranty

2.5 Product description

2.6 Identification

3. Technical data

3.1 Dimensions

4. Installation

4.1 Hydraulic connection

4.2 Electrical connection of level indication

4.3 Container connection

5. Maintenance and service

5.1 Maintenance

5.2 Service

6. Fault finding

7. Disposal

Page

10

12

12

12

13

13

1.4 Safety instructions for the operating

company/operator

The owner of the system is responsible for training of operating

personnel.

3

3

3

3

3

3

3

3

3

4

4

5

6

7

8

8

9

Warnin g

When working with chemicals, the accident

prevention regulations applicable at the

installation site must be applied.

Observe the chemical manufacturer's safety data

sheets when handling chemicals.

Warnin g

When working on the product, or connections

and lines, always wear protective clothing (e.g.

safety goggles and gloves).

The system must be unpressurised.

Only operate the system if all lines are connected

correctly.

Warnin g

The chemical resistance of the parts that come

into contact with the dosing medium depends on

the medium, media temperature and operating

pressure.

Ensure that all parts in contact with the medium

are resistant to th e med ium un der opera tin g

conditions.

English (GB)

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

1. Safety instructions

1.1 Symbols used in this document

The safety instructions are identified by the following symbols:

Warning

If these safety instructions are not observed,

it may result in personal injury.

If these safety instructions are not observed,

it may result in malfunction or damage to the

equipment.

Notes or instructions that make the job easier

and ensure safe operation.

1.2 Qualification and training of per sonne l

The personnel responsible for the installation, operation and

service must be appropriately qualified for these tasks.

Areas of responsibility, levels of authority and the supervision of

the personnel must be precisely defined by the operator.

If necessary, the personnel must be trained appropriately.

1.3 Safe operation

If safe operation is no longer possible, the product must be taken

out of operation and secured against unintentional operation.

This is the case in the following situations:

• If the product is visibly damaged.

• If the product no longer seems operational.

• After long periods of storage under unfavourable conditions.

2. Product introduction

2.1 Applications

The foot valve and the rigid suction lance are suitable for the

following applications:

• Extraction of chemicals from unpressurised containers.

• Monitoring the liquid level in the chemical container (versions

with two-step level indication).

Special features:

• Protection of the suction assembly (suction lance).

• Easy handling when exchanging containers.

2.2 Improper operating methods

Warnin g

Improper use, foreseeable misuse or

misapplication can lead to personal injury and

damage to the equipment and is therefore not

permitted.

The operational safety of the product is only guaranteed, if it is

used in accordance with section 2.1 Applications.

The product may not be used for:

• operation in potentially explosive areas

• combustible media

• frozen media

• abrasive or crystallising media.

2.3 Function

• Extracting liquid from a container with a suction line.

• Filtering the liquid to protect the pump from soiling.

• Preventing backflow of liquid by means of a non-return valve.

• Keeping the foot valve upright at the container bottom.

• Indicating a low level of liquid or an empty tank by means of

two reed switches and floaters.

• Connecting an exchangeable container.

3

Page 4

2.4 Warranty

Note

1

1

2

3

4

5

6

7

8

9

10

11

7/9

7

10

1

English (GB)

A warranty claim in accordance with our general terms of sale

and delivery is only valid if these requirements are fulfilled:

• The product is used in accordance with the information within

this manual.

• The product is not dismantled or handled incorrectly.

• Maintenance is carried out by authorised and qualified

personnel.

• Only original spare parts are used for repairs during

maintenance.

Grundfos cannot be held liable for any damage

resulting from incorrect use.

2.5 Product description

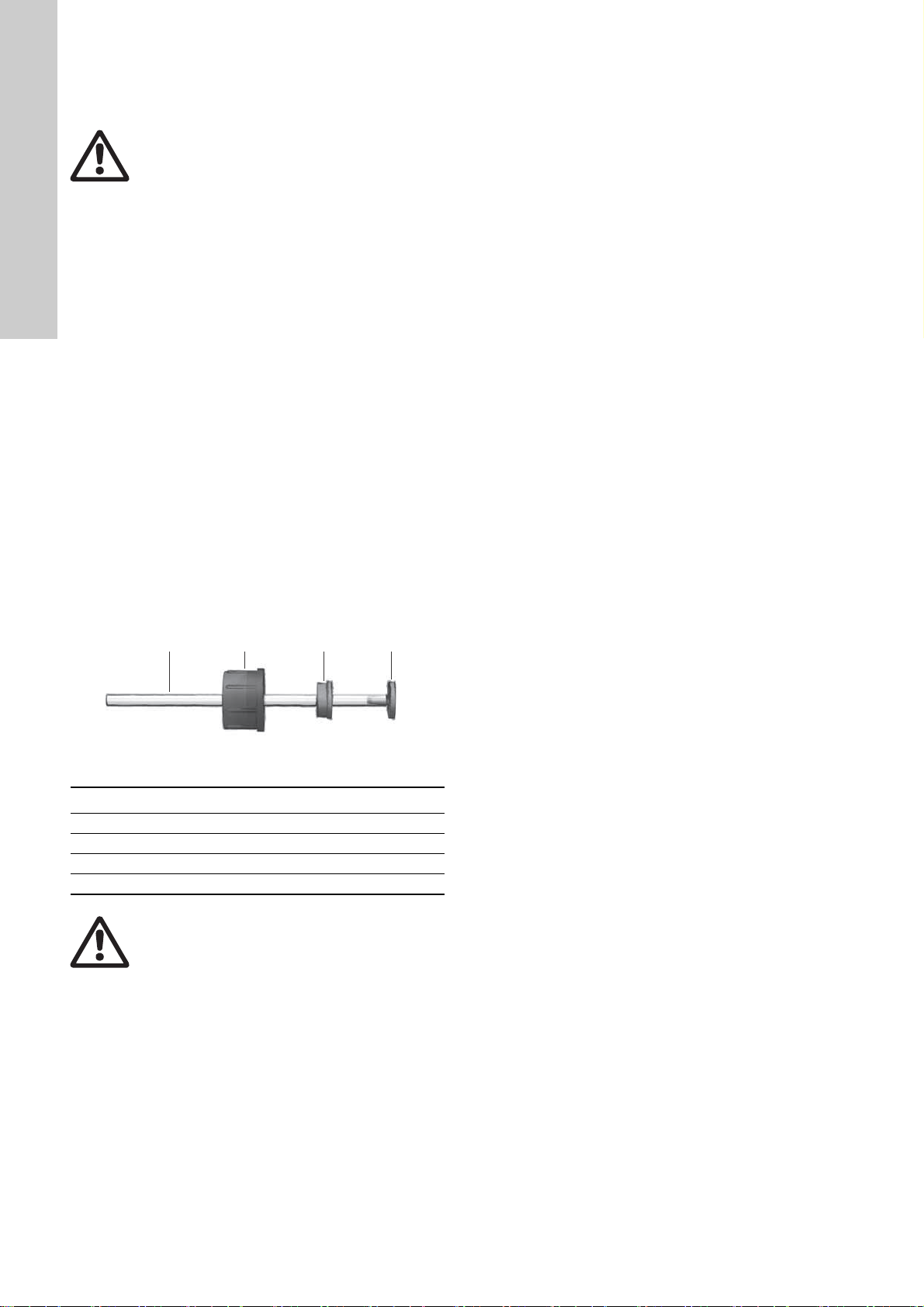

Fig. 1 From left to right: suction lance, foot valve with level indication, plastic and stainless-steel foot valve without level indication

Pos. Description

1 Hose connection thread

2 Signal cable with plug

3 Tank connection, slidable

4 Tank cap, slidable

5 Protective tube with hose

6 Floater low-level

7 Valve body with switch unit

8 Floater empty

9 Inlet with strainer

10 Inlet with strainer and weight

11 Connection for hose or pipe

TM04 8524 1212

4

Page 5

2.6 Identification

2.6.1 Type key of suction lances

Code Example RSL - 0500 - 2L - G5/8 PE / V,E / C U2

RSL Rigid Suction Lance

Maximum immersion depth

0400 up to 400 mm

0500 up to 500 mm

0570 up to 570 mm

0690 up to 690 mm

0820 up to 820 mm

0980 up to 980 mm

1100 up to 1100 mm

1200 up to 1200 mm

Level indication

NL Without level indication

2L Two-step level indication (low-level signal, tank-empty signal)

Connection size

G5/8 Male thread G 5/8 with groove for O-Ring on top

Material of enclosure, connection, floater

PE High density polyethylene (HDPE)

PV Polyvinylidenfluoride (PVDF)

Material of O-ring

V,E Fluorocarbon elastomer (FKM) and ethylene propylene diene rubber (EPDM)

T Polytetrafluorethylene (PTFE)

Material of ball

CCeramic

Connections for hose

U2 Hose connection set: 4/6 mm, 6/9 mm, 6/12 mm, 9/12 mm

U7 Hose connection set: 0.17" x 1/4", 1/4" x 3/8", 3/8" x 1/2"

X Without connections

English (GB)

2.6.2 Type key of foot valves

Code Example FV - 2L - G5/8 PE / V,E / C U2

FV Foot valve

Level indication

NL Without level indication

2L Two-step level indication (low-level signal, tank-empty signal)

Connection size

G5/8 Male thread G 5/8 with groove for O-Ring on top

Material of enclosure, connection, floater

PE High density polyethylene (HDPE)

PV Polyvinylidenfluoride (PVDF)

SS Stainless steel 1.4571

Material of O-ring

V,E Fluorocarbon elastomer (FKM) and ethylene propylene diene rubber (EPDM)

T Polytetrafluorethylene (PTFE)

Material of ball

C Ceramic

SS Stainless steel 1.4401

Connections for hose or pipe

U2 Hose connection set: 4/6 mm, 6/9 mm, 6/12 mm, 9/12 mm

U7 Hose connection set: 0.17" x 1/4", 1/4" x 3/8", 3/8" x 1/2"

A Threaded pipe connection Rp 1/4" (G 1/4" female)

V Threaded pipe connection 1/4" (NPT female)

X Without connections

5

Page 6

3. Technical data

English (GB)

Data

Mechanical data

Max. flow rate

Max. pressure

1)

2)

[l/h] 60

[gph] 15.85

[bar] 2

[psi] 29

Max. liquid temperature [°C] 45 60 80

Min. liquid temperature [°C] 0 0 -10

Foot valve and

suction lance (PE)

Max. ambient temperature [°C] 45

Min. ambient temperature [°C] 0 0 -10

Max. storage temperature [°C] 45

Min. storage temperature [°C] 0 0 -10

3)

[m] 5 5 -

Electrical data

(for versions with

two-step level

indication)

Length of included signal cable

Type of included signal cable LIY2Y LIY2Y -

Max. voltage of reed switches [V] 48 48 -

Max. current of reed switches [A] 0.5 0.5 -

Max. load of reed switches [VA] 10 10 -

Suction lance [kg] 0.28 - 0.4 0.43 - 0.62 -

Weight

4)

Foot valve without level

indication

[kg] 0.11 0.13 0.18

Foot valve with level indication [kg] 0.26 0.28 -

1)

Liquids with viscosity similar to water

2)

Applies to the inside of the suction installation. The container must be unpressurised!

3)

Also for suction lances, the indicated cable length is measured starting from the valve body

4)

When installed, without packaging

Foot valve and

suction lance

(PVDF)

Foot valve

(stainless steel)

6

Page 7

3.1 Dimensions

/

/

/

/

/

/

*

'

*

'

/

/

/

*

'

'

/

'

'

'

$

$

/

/

'

*

/

/

'

*

English (GB)

TM04 8445 4511, TM04 8447 4511

Fig. 2 Left: rigid suction lance with / without level indication, right: foot valve with level indication

Dimensions [mm]

Code

Suction lance Foot valve

L1 see type key 2.6.1 196

L2 ≥ 114 ~ 103.5

L3 ≥ 103 ~ 43.5

L4 ~ 85 18.5

L5 ~ 25 L6 4.5 D1 68.5 35

D2 32 58

D3 - 12

D4 - 9

D5 - 6

Fig. 3 Foot valve without level indication. Left: PE and PVDF

version, right: stainless-steel version

Dimensions [mm]

Code

Foot valve PE, PVDF Foot valve stainless steel

TM04 8446 4511, TM04 8494 0612

L1 67.5 30

L2 19 4

D1 35 30

7

Page 8

4. Installation

1

2

3

4

English (GB)

4.1 Hydraulic connection

Warning

Danger of chemical burn!

Avoid direct contact with chemicals.

Wear protective clothing when handling

chemicals.

4.1.1 Conditions for installation

• Proper functioning can only be guaranteed when using

Grundfos accessories.

• For suction height and line diameter, please see the technical

data of the pump.

4.1.2 Notes for installa tion

• Shorten the hoses at right angles.

• Make sure there are no loops or kinks in the hoses.

• Keep the suction line as short as possible.

• Install the suction line upwards to the suction valve of the

pump.

4.1.3 Connecting the hose (fig. 4)

1. Slide union nut (2) and tensioning ring (3) onto the hose (1).

2. Insert the cone part (4) fully into the hose.

3. Put the cone part with hose onto the corresponding threaded

connection of foot valve / suction lance or suction valve of the

pump.

4. Tighten union nut manually. Do not use any tools!

– Tighten up union nut after 2-5 operating hours if using

PTFE gaskets!

5. If existing, insert the deaeration line of the pump and the relief

line of the multi-function or pressure relief valve via the

corresponding connection of the foot valve or suction lance

into the container.

Fig. 4 Hydraulic connection

Pos. Description

1Hose

2 Union nut

3 Tensioning ring

4 Cone part

Warning

Do not immerse the return lines into the liquid.

TM04 8559 2212

8

Page 9

4.2 Electrical connection of level indication

Note

2

1

3

GND

34

12

Note

1

2

In order to monitor the filling level of the container, a two-step

level indication (low-level signal, tank-empty signal) can be connected to the pump or other downstream devices.

Observe the manuals of the downstream devices.

4.2.1 Signal connection with round plug

All SMART Digital pumps and the digital dosing pump DDI 222

are connected with round plugs.

4.2.3 Changing the contact type

Suction lances and foot valves with two-step level indication have

two signal outputs. Both are factory-set to NO contact type.

The symbol is on the floater top (see fig. 7).

• The symbol that is visible from above shows the switch mode

"floater above".

• The symbol that is visible from below shows the switch mode

"floater below".

The contact type can be changed from NO to NC by turning the

floater horizontally by 180 °. A cable break will provoke a

tank-empty signal.

Reversing the floater:

1. Remove the floater sidewards

2. Turn the floater horizontally by 180 ° and attach it. Make sure

that the NC symbol at the floater points upwards.

3. Adjust the signal inputs of the downstream devices (pump)

accordingly

Observe the manuals of the downstream devices

(pump).

English (GB)

Fig. 5 Signal connection with round plug

Level signal: low-level and tank-empty

Function

Low level X GND

Tank empty X GND

1/white 2/green 3/brown

Pins

4.2.2 Signal connection with flat plug

The foot valves and suction lances are supplied with round plugs.

An adapter is required for connection to the dosing pumps

DMX 221 and DMH with AR control.

Product number: 96635010

Fig. 6 Flat plug

TM04 8448 4511

TM04 8451 1112

Fig. 7 Changing the contact type

Pos. Description Symbol

1 Floater NO (normally open) contact

2 Floater NC (normally closed) contact

TM04 8449 4511

9

Page 10

4.3 Container connection

English (GB)

4.3.1 Connecting to a Grundfos tank

1. Remove the screw cap from the tank.

2. Insert suction lance / foot valve into the threaded hole of the

tank. Tighten the adapter screw manually.

3. Adapt the immersion depth of suction lance / foot valve to the

tank height.

4. Fasten suction lance at hose connection.

TM04 8513 1012TM04 8514 1012TM04 8515 1012

Fig. 10 Fastening the suction lance

5. Fasten return lines, if existing.

Fig. 8 Inserting the suction lance

Fig. 11 Foot valve: insert lines into PE cap

TM04 8511 1012TM04 8512 1012

Fig. 12 Suction lance: insert lines into tank connection

Warnin g

Do not immerse the return lines into the liquid.

Fig. 9 Inserting the foot valve

10

Page 11

4.3.2 Connecting to an exchangeable container

/

'

'

/

'

'

/

'

'

1. Select adapter type and immersion depth from the tables

below.

2. Mount adapter on foot valve or suction lance.

3. Adapt immersion depth of foot valve or suction lance (see

table).

Immersion depth of suction lances

English (GB)

Container type Volume [l]

L-ring drum (blue)

120 820

220 980

Immersion

depth [mm]

Steel drum (standard) 216 980

12, 33

Standard jerrican according

to EN 12712/12713

(large opening)

25, 30, 33 500

60 690

IBC

(intermediate bulk container)

all 1200

Adaptors for exchangeable containers

Dimensions

Dimensioned drawing

D1 D2 L1

G 2 2 NPT 31 mm

G 2 S 70 x 6 28 mm

G 2 S 56 x 4 28 mm

TM04 8490 0612

G 2 CCS 46 x 4 28 mm

G 2 CCS 60 x 6 28 mm

G 2 CCS 70 x 6 31 mm

G 2 ASTM 63 28 mm

TM04 8491 0612

400

Adaptor type

Adaptor for containers with 2"

NPT threaded opening

Adaptor for drums with S 70 x 6

coarse thread (MAUSER 2")

Adaptor for drums with S 56 x 4

coarse thread (TriSure

®

)

Adaptor for jerricans with

opening of approx. 36 mm,

according to EN 12713

Adaptor for jerricans with

opening of approx. 45 mm,

according to EN 12713

Adaptor for jerricans with

opening of approx. 57 mm,

according to EN 12713

Adaptor for US containers with

bung hole of 63 mm (ASTM

International)

Material,

colour

Product No.

PVC, grey 98156690

PE, blue 98071171

PE, orange 98071172

PE, green 98071173

PE, yellow 98071174

PE, brown 98071175

PE, white 98071176

Adaptor for IBC (Intermediate

G 2 S 160 x 7 12.8 mm

Bulk Container) with opening of

PE, black 98071177

150 mm

TM04 8493 0612

11

Page 12

4.3.3 Connecting a suction lance to a container without

/

'

Caution

English (GB)

opening provided

4. Cut a hole (∅60) into the container top surface and insert the

suction lance.

5. Fix the suction lance with the counter nut.

6. Adapt the immersion depth of the suction lance

(see section 4.3.1).

Immersion depth of suction lances

Container type Volume [l]

Grundfos cylindrical tank

40 400

1000 1200

Immersion

depth [mm]

Grundfos square tank 100 470

When using other containers, the required immersion depth must

be determined by measurement.

Counter nut

Dimensions

Dimensioned drawing

D1 L1

G 2 21 mm

TM04 8492 0612

5. Maintenance and service

5.1 Maintenance

Clean the strainer,

• if it is soiled

• if the suction performance drops.

5.1.1 Cleaning the stra iner

1. Shut down the dosing system.

2. Suction lances or foot valves with level indication: disconnect

signal line from the pump or downstream device.

3. Remove suction line from the dosing head. If existing, remove

deaeration line from the dosing head.

4. Take suction lance or foot valve out of the container.

5. Empty the suction lance.

6. Suction lance: Unscrew inlet with strainer unit from the bottom

of the suction lance and clean it.

Foot valve: Unscrew inlet with weight and strainer from the

valve, remove the strainer and clean it.

Clean the strainer of the foot valve or suction

lance regularly, depending on the degree of

pollution.

Adaptor type

Counter nut for drums with opening of

60 mm (without thread), e.g. 100-litre

square tank or 1000-litre cylindrical tank

Fig. 13 Foot valve (left), suction lance (right): removing the

strainer

Material,

colour

Product No.

PVC, grey 98071170

TM04 8522 1112

5.2 Service

Foot valves and suction lances cannot be repaired.

12

Page 13

6. Fault finding

Fault Possible cause Possible remedy

Strainer is soiled. Clean the strainer.

Pump is switched off. Switch on the pump.

Too low flow or no flow

Low-level or empty indication does not work

Suction line is installed incorrectly. Check the suction line and connection.

Internal diameter of suction line is too small.

Suction line is not tight. Check the line and connections.

Signal line is not connected to the pump. Connect the signal line to the pump.

Contact type is set incorrectly.

Reed switch is defective. Replace the foot valve or suction lance.

Use suction line with larger internal

diameter.

Adapt setting of contact type

(see section 4.2.3).

7. Disposal

This product or parts of it must be disposed of in an

environmentally sound way. Use appropriate waste collection

services. If this is not possible, contact the nearest Grundfos

company or service workshop.

Subject to alterations.

English (GB)

13

Page 14

14

Page 15

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belarus

Представительство ГРУНДФОС в

Минске

220123, Минск,

ул. В. Хоружей, 22, оф. 1105

Тел.: +(375) 17 233 97 65

Факс: (375) 17 233 97 69

E-mail: grundfos_minsk@mail.ru

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Trg Heroja 16,

BiH-71000 Sarajevo

Phone: +387 33 713 290

Telefax: +387 33 659 079

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

Grundfos Alldos

Dosing & Disinfection

ALLDOS (Shanghai) Water Technology

Co. Ltd.

West Unit, 1 Floor, No. 2 Building (T 4-2)

278 Jinhu Road, Jin Qiao Export Processing Zone

Pudong New Area

Shanghai, 201206

Phone: +86 21 5055 1012

Telefax: +86 21 5032 0596

E-mail: grundfosalldos-C N@grundfos.com

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

50/F Maxdo Centre No. 8 Xing Yi Rd.

Hongqiao Development Zone

Shanghai 200336

PRC

Phone: +86-21 6122 5222

Telefax: +86-21 6122 5333

Croatia

GRUNDFOS CROATIA d.o.o.

Cebini 37, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.grundfos.hr

Czech Republic

GRUNDFOS s.r.o.

Čapkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-3066 5650

Telefax: +358-3066 56550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS Water Treatment GmbH

Reetzstraße 85

D-76327 Pfinztal (Söllingen)

Tel.: +49 7240 61-0

Telefax: +49 7240 61-177

E-mail: gwt@grundfos.com

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

E-mail: infoservice@grundfos.de

Service in Deutschland:

E-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. B ox 7 1

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 097

Phone: +91-44 4596 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg. 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo,

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Mexico

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Velu we zoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

Romania

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундф ос

Россия, 109544 Москва, ул. Школьная

39

Тел. (+7) 495 737 30 00, 564 88 00

Факс (+7) 495 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47 496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS d.o.o.

Šlandrova 8b, SI-1231 Ljubljana-Črnuče

Phone: +386 1 568 0610

Telefax: +386 1 568 0619

E-mail: slovenia@grundfos.si

South Africa

Grundfos (PTY) Ltd.

Corner Mountjoy and George Allen Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

(Box 333) Lunnagårdsgatan 6

431 24 Mölndal

Tel.: +46 31 332 23 000

Telefax: +46 31-331 94 60

Switzerland

GRUNDFOS ALLDOS International AG

Schönmattstraße 4

CH-4153 Reinach

Tel.: +41-61-717 5555

Telefax: +41-61-717 5500

E-mail: grundfosalldos-CH@grundfos.com

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС УКРАЇНА

01010 Київ, Вул. Московська 8б,

Тел.:(+38 044) 390 40 50

Фах.: (+38 044) 390 40 59

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Uzbekistan

Представительство ГРУНДФОС в

Ташкенте

700000 Ташк ент ул.Ус ма на Носира 1-й

тупик 5

Телефон : (3712) 55-68-15

Факс: (3712) 53-36-35

Addresses revised 27.04.2012

Grundfos companies

Page 16

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

98131771 0712

ECM: 1085307

www.grundfos.com

The name Grundfos, the Grundfos logo, and the payoff Be–Think–Innovate are registrated trademarks

owned by Grundfos Management A/S or Grundfos A/S, Denmark. All rights reserved worldwide.

Loading...

Loading...