Grundfos DMX 37-5, DMX 52-8, DMX 152-6, DMX 315-3, DMX 321-4 Installation And Operating Instructions Manual

...Page 1

Diaphragm Dosing Pump

DMX model 226

DMX 24-8 DMX 142-8 DMX 280-8

DMX 37-5 DMX 152-6 DMX 315-3

DMX 52-8 DMX 160-5 DMX 321-4

DMX 60-3 DMX 190-8 DMX 321-6

DMX 67-10 DMX 190-10 DMX 380-3

DMX 82-5 DMX 199-8 DMX 460-3,5

DMX 95-8 DMX 224-5 DMX 460-6

DMX 100-8 DMX 249-3 DMX 525-3

DMX 130-3 DMX 255-3 DMX 765-3

DMX 132-10 DMX 280-6

Installation and Operating Instructions

EN

15.720017-V6.0

Read this manual completely and keep it!

Subject to change.

Page 2

DMX model 226

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

Grundfos Alldos

Dosing & Disinfection

ALLDOS Oceania Pty. Ltd.

Unit 3 / 74 Murdoch Circuit

Acacia Ridge QLD 4100

Phone: +61 (0)7 3712 6888

Telefax: +61 (0)7 3272 5188

E-mail: alldos.au@alldos.com

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belorussia

Представительство ГРУНДФОС в Минске

220090 Минск ул.Олешева 14

Телеф он: (8632) 62-40-49

Факс: (8632) 62-40-49

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Paromlinska br. 16,

BiH-71000 Sarajevo

Phone: +387 33 713290

Telefax: +387 33 231795

Brazil

GRUNDFOS do Brasil Ltda.

Rua Tomazina 106

CEP 83325 - 040

Pinhais - PR

Phone: +55-41 668 3555

Telefax: +55-41 668 3554

Bulgaria

GRUNDFOS Pumpen Vertrieb

Representative Office - Bulgaria

Bulgaria, 1421 Sofia

Lozenetz District

105-107 Arsenalski blvd.

Phone: +359 2963 3820, 2963 5653

Telefax: +359 2963 1305

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

Grundfos Alldos

Dosing & Disinfection

ALLDOS (Shanghai) Water Technology Co.

Ltd.

West Unit, 1 Floor, No. 2 Building (T 4-2)

278 Jinhu Road, Jin Qiao Export Processing Zone

Pudong New Area

Shanghai, 201206

Phone: +86 21 5055 1012

Telefax: +86 21 5032 0596

E-mail: alldos.cn@alldos.com

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

22 Floor, Xin Hua Lian Building

755-775 Huai Hai Rd, (M)

Shanghai 200020

PRC

Phone: +86-512-67 61 11 80

Telefax: +86-512-67 61 81 67

Croatia

GRUNDFOS predstavništvo Zagreb

Cebini 37, Buzin

HR-10000 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

Czech Republic

GRUNDFOS s.r.o.

Čapkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 44

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-3066 5650

Telefax: +358-3066 56550

France

Grundfos Alldos

Dosing & Disinfection

ALLDOS S.A.R.L.

7, rue Gutenberg

F-67610 La Wantzenau

Tél.: +33-3 88 59 26 26

Télécopie: +33-3 88 59 26 00

E-mail : alldos.fr@alldos.com

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

Grundfos Alldos

Dosing & Disinfection

ALLDOS Eichler GmbH

Reetzstraße 85

D-76327 Pfinztal (Söllingen)

Tel.: +49 7240 61-0

Telefax: +49 7240 61-177

E-mail: alldos.de@alldos.com

Germany

GRUNDFOS GMBH

Schlüterstr. 33

D-40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

E-mail: infoservice@grundfos.de

Service in Deutschland:

E-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P. O . Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chamiers Road

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / C C-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

1-2-3, Shin Miyakoda

Hamamatsu City

Shizuoka pref. 431-21

Phone: +81-53-428 4760

Telefax: +81-53-484 1014

2

15.720017-V6.0

Page 3

DMX model 226

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

México

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

Grundfos Alldos

Dosing & Disinfection

ALLDOS BV

Leerlooiersstraat 6

NL-8601 WK Sneek

Tel.: +31-51 54 25 789

Telefax: +31-51 54 30 550

E-mail: alldos.nl@alldos.com

Netherlands

GRUNDFOS Nederland B.V.

Postbus 104

NL-1380 AC Weesp

Tel.: +31-294-492 211

Telefax: +31-294-492244/492299

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Phone: (+48-61) 650 13 00

Telefax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

România

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундф ос

Росси я, 109544 Москва, Школьная 39

Тел. (+7) 095 737 30 00, 564 88 00

Факс (+7) 095 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47 496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS PUMPEN VERTRIEB

Ges.m.b.H.,

Podružnica Ljubljana

Blatnica 1, SI-1236 Trzin

Phone: +386 1 563 5338

Telefax: +386 1 563 2098

E-mail: slovenia@grundfos.si

South Africa

Grundfos Alldos

Dosing & Disinfection

ALLDOS (Pty) LTD

98 Matroosberg Road, Waterkloof Park

P.O. Box 36505, Menlo Park 0102

0181 ZA Pretoria

E-mail: alldos.za@alldos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Lunnagårdsgatan 6

431 90 Mölndal

Tel.: +46-0771-32 23 00

Telefax: +46-31 331 94 60

Switzerland

Grundfos Alldos

Dosing & Disinfection

ALLDOS International AG

Schönmattstraße 4

CH-4153 Reinach

Tel.: +41-61-717 5555

Telefax: +41-61-717 5500

E-mail: alldos.ch@alldos.com

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

947/168 Moo 12, Bangna-Trad Rd., K.M. 3,

Bangna, Phrakanong

Bangkok 10260

Phone: +66-2-744 1785 ... 91

Telefax: +66-2-744 1775 ... 6

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС Украина

ул. Владимирская, 71, оф. 45

г. Киев, 01033, Украи на,

Тел. +380 44 289 4050

Факс +380 44 289 4139

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

Grundfos Alldos

Dosing & Disinfection

ALLDOS Ltd.

39 Gravelly Industrial Park, Tyburn Road

Birmingham B24 8TG

Phone: +44-121-3283336

Telefax: +44-121-3284332

E-mail: alldos.uk@alldos.c om

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Usbekistan

Представительство ГРУНДФОС в

Ташкенте

700000 Ташке нт ул.Усма на Носира 1-й

тупик 5

Телефон: (3712) 55-68-15

Факс: (3712) 53-36-35

Addresses revised 15.01.2007

Adresses revised 7.04.2005

V6.0

3

Page 4

Contents

DMX model 226 en

Installation Data ............................................................................................. 48

Installation Diagram ...................................................................................... 48

Type key ......................................................................................................... 49

1 Of General Interest .............................................................................. 50

1.1 In General .................................................................................................50

1.2 Using this Paper ....................................................................................... 50

1.3 Warranty ...................................................................................................50

2 Safety Instructions .............................................................................. 51

2.1 Application of the Product ......................................................................... 51

2.2 Obligations of the Operating Authority ......................................................51

2.3 Averting Dangers ...................................................................................... 51

3 Technical Data ..................................................................................... 52

3.1 Pump Types .............................................................................................. 52

3.2 Pump Performance ...................................................................................52

3.2.1 Accuracy ..........................................................................................52

3.2.2 Performance ..................................................................................53

3.3 Suction heights .........................................................................................54

3.3.1 Media with a viscosity similar to water ..........................................54

3.3.2 Suction heights for media with maximum permissible viscosity ....54

3.4 Dosing Curves ..........................................................................................55

3.5 Materials ...................................................................................................55

3.6 Ambient and Operating Conditions ........................................................... 55

3.7 Weight.......................................................................................................56

3.8 Dimensional Drawing ................................................................................ 57

4 Installation............................................................................................ 59

4.1 Installation Information.............................................................................. 59

4.2 Transport and Storage ..............................................................................61

4.3 Mounting ...................................................................................................61

4.4 Connecting the Suction and Pressure Lines.............................................61

4.5 Electrical Connections ..............................................................................62

4.5.1 Versions with mains plug............................................................... 62

4.5.2 Versions without mains plug.......................................................... 62

5 Commissioning.................................................................................... 63

5.1 Inspections before Commissioning ........................................................... 63

5.2 Commissioning .........................................................................................63

4

15.720017-V6.0

Page 5

DMX model 226 en

6 Operation ............................................................................................. 64

6.1 Description of the Device..........................................................................64

6.2 Switching on / off ...................................................................................... 64

6.2.1 Switching on ..................................................................................64

6.2.2 Switching off ..................................................................................64

6.3 Adjusting the Dosing Flow by Means of the Stroke length........................65

6.4 Adjusting the Stroke Length Adjustment...................................................65

6.5 Possible Failures ....................................................................................... 66

7 Operation with Other Electronics....................................................... 67

7.1 Electronics Version Stroke sensor ............................................................67

7.2 Electronics Diaphragm Breakage Sensor ................................................. 67

7.2.1 Technical Data of the Electronics ..................................................67

7.2.2 Dimensional Drawing (Electronics Enclosure)...............................67

7.2.3 Function.........................................................................................68

7.2.4 Electrical Connections of the Electronics ......................................68

7.2.5 Relay Outputs ................................................................................ 69

7.2.6 Screwing the Sensor into the Dosing Head...................................69

7.2.7 Commissioning ..............................................................................70

7.2.8 Using the Contacts ........................................................................70

7.2.9 Description of the Device .............................................................. 70

7.2.10 Maintenance..................................................................................71

8 Integral Overflow Valve ....................................................................... 72

8.1 Function ....................................................................................................72

8.2 Permissible Media ....................................................................................72

8.3 Connections .............................................................................................. 72

8.4 Setting of Opening Pressure.....................................................................73

8.4.1 General .......................................................................................... 73

8.4.2 Setting Instructions for Opening Pressure.....................................73

8.5 Venting ......................................................................................................74

8.6 Possible Faults .......................................................................................... 74

8.7 Maintenance .............................................................................................74

8.7.1 Intervals for Cleaning and Maintenance ........................................ 74

8.7.2 Replacing the Diaphragm ..............................................................74

9 Maintenance ......................................................................................... 75

9.1 Replacing the Gear Grease ......................................................................75

9.2 Rates for cleaning and maintenance ........................................................75

9.3 Cleaning the Suction and Pressure Valves ............................................... 75

9.4 Exchanging the Diaphragm ...................................................................... 76

A. Appendix Dosing Curves .................................................................. 198

V6.0

5

Page 6

Installation Data

Grundfos customer No.:

Order No. of device:

Serial number of device:

Put into service on:

Location of device:

DMX model 226 en

NOTE Please fill in this form following commissioning. It will

help you and your Grundfos servicing partner to adjust

the device during subsequent corrections.

Owner:

Contract No.:

Used for:

Installation Diagram

6

15.720017-V6.0

Page 7

DMX model 226 en

Type key

(Cannot be used for pump configuration.)

Example: DME 2-18 A-PP/E/C-F-3 1 1E F

Pump range D ME...

Maximum pressure [bar]

Control variant Code

Standard A

Standard + alarm relay AR

Standard + ProfIbus AP

Standard + GENIbus AG

Dosing head material Code

Polypropylene PP

PVDF PV

Stainless steel 1.4401 SS

Gasket material Code

EPDM E

FKM V

Valve ball material Code

Ceramics C

Stainless steel 1.4401 SS

Control panel Code

Front-fitted F

Side-fitted S

Voltage Code

1 x 100-240 V, 50-60 Hz 3

Code Mains plug

F EU (Schuko)

B USA, CAN

GUK

IAU

ECH

JJP

Code Connection,

suction/ discharge

1 Tubing 6/9

Tubing 4/6

supplied with the pump

2 Tubing 6/9

Tubing 6/12+ 9/12

supplied with the pum

3 Tubing 4/6

4 Tubing 6/9

5 Tubing 6/12

6 Tubing 9/12

A Threaded Rp 1/4

B Threaded Rp 3/8

E Cementing d.10

F Cem enting d. 12

Code Valves

1 Standard valve

2 Spring- loaded valve

V6.0

7

Page 8

1 Of General Interest

1.1 In General

1.2 Using this Paper

DMX model 226 en

This operation manual contains all information for safe operation of the described

product.

If you require further information or if any problems arise which are not reflected in

detail in this manual, contact Grundfos directly for the information needed.

❏ Descriptions are written as plain text.

❏ Lists are indicated by squares (❏), sublists by dashes (-).

❏ Operation steps are indicated by bullets (●), substeps by small bullets (•).

❏ Cross-references are indicated by

❏ The headings

WARNING Danger of injuries and accidents!

WARNING, CAUTION

italic letters

and

NOTE

and an arrow (➜).

have the following meaning:

!

1.3 Warranty

CAUTION Danger of incorrect operation or damage to the product!

NOTE There is an exceptional feature.

Warranty in accordance with our general terms of sale and delivery shall only be

valid, if

❏ the product is used according to the information within this paper,

❏ the product is not being opened or used improperly,

❏ maintenance and repair is implemented exclusively by authorized and

qualified personnel,

❏ original spare parts are used for repairs.

8

15.720017-V6.0

Page 9

DMX model 226 en

2 Safety Instructions

2.1 Application of the Product

!

!

The dosing pump described here is suitable for dosing liquid, non-abrasive and noninflammable media strictly complying with the instructions of this manual.

WARNING Other applications are not intended and are not

permitted. Grundfos accept no responsibility for

damages caused by unintended use.

NOTE Explosion-proof pumps are indicated on the pump type

identification label as well as on the motor type

identification label. The enclosed declaration of

conformity with the 94/9/EC guideline will replace the

declaration of EC conformity incorporated in this

instructions manual.

WARNING For the use of a pump indicated as explosion-proof for

operation in potentially explosive operating places

according to guideline 94/9/EC, please follow the

enclosed instructions "Operating an explosion-proof

pump" in addition to this instructions manual.

2.2 Obligations of the Operating Authority

The operating authority of the plant is responsible for

❏ instructing the operation personnel

❏ arranging regular maintenance

2.3 Averting Dangers

WARNING When dosing dangerous media, observe the

!

CAUTION Adjust the stroke length only while the pump is

corresponding safety precautions!

Wear protective gloves and glasses when executing

work at the dosing head, connections or lines!

Only use the prescribed line types!

Do not open the pump!

Repair only by authorized personnel!

running!

Danger of damages.

V6.0

9

Page 10

3 Technical Data

p

p

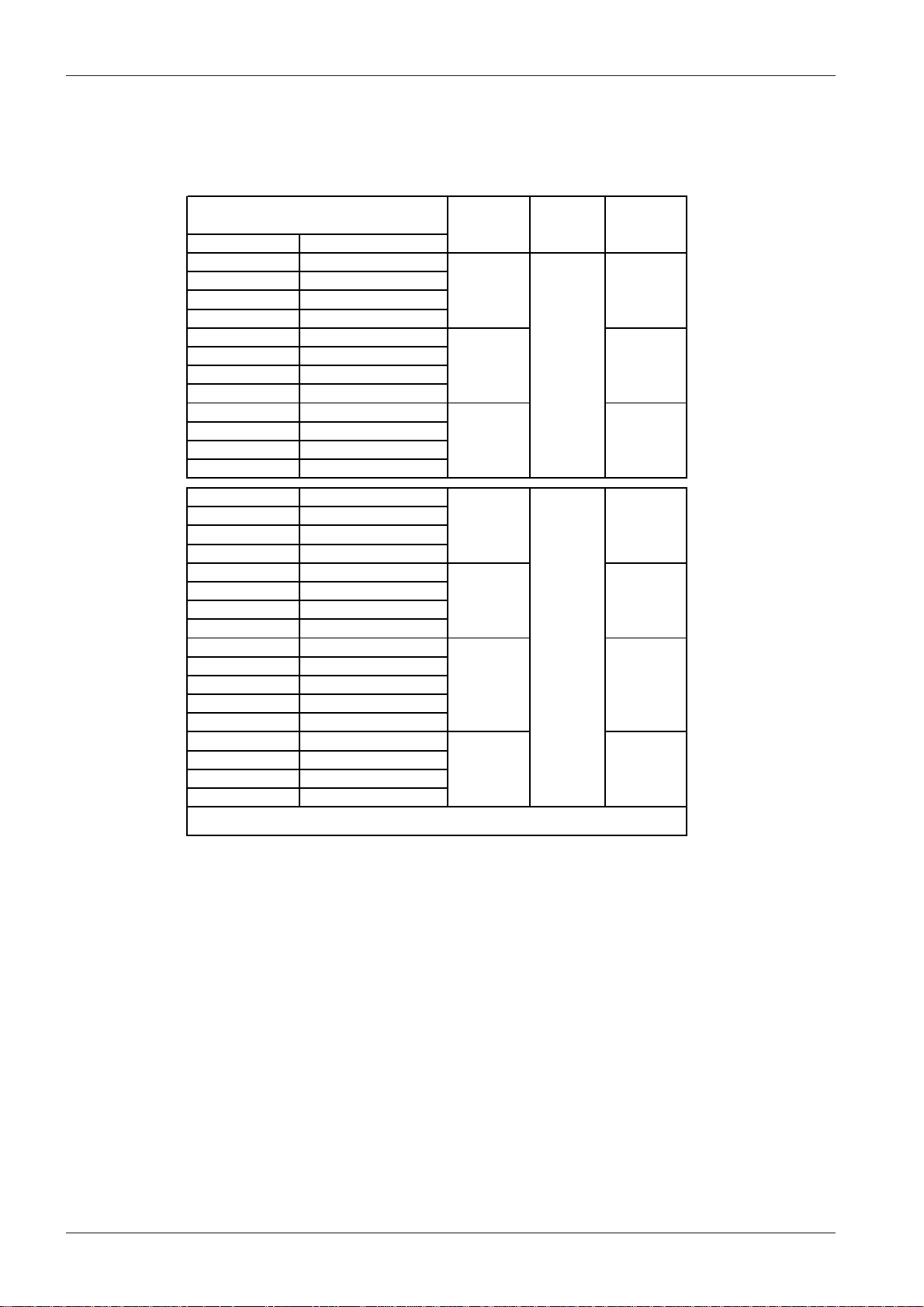

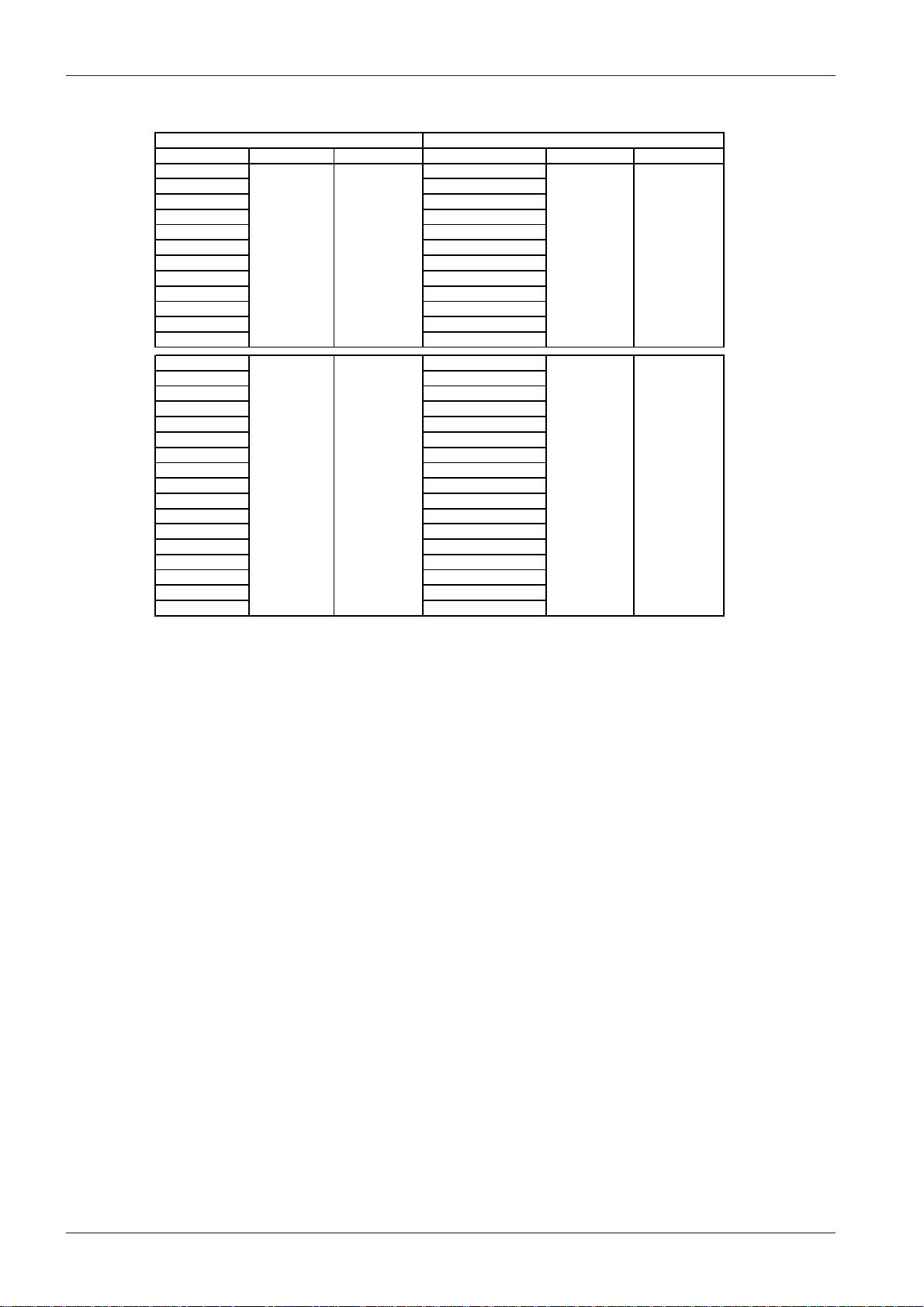

3.1 Pump Types

DMX model 226 en

Order No.

Simple pum

Double pum

DMX 24-8 DMX 24-8/24-8

DMX 52-8 DMX 52-8/25-8

DMX 100-8 DMX 100-8/ 100-8

DMX 142-8 DMX 142-8/ 142-8

DMX 37-5 DMX 37-5/37-5

DMX 82-5 DMX 82-5/82-5

DMX 160-5 DMX 160-5/ 160-5

DMX 224-5 DMX 224-5/ 224-5

DMX 60-3 DMX 60-3/60-3

DMX 130-3 DMX 130-3/ 130-3

DMX 255-3 DMX 255-3/ 255-3

DMX 380-3 DMX 380-3/ 380-3

DMX 67-10 DMX 67-10/67-10

DMX 132-10 DMX 132-10/132-10

DMX 190-10 DMX 190-10/190-10

DMX 190-8 DMX 190-8/ 190-8

DMX 95-8 DMX 95-8/95-8

DMX 199-8 DMX 199-8/ 199-8

DMX 280-8 DMX 280-8/ 280-8

DMX 280-6 DMX 280-6/ 260-6

DMX 152-6 DMX 152-6/ 152-6

DMX 321-6 DMX 321-6/ 321-6

DMX 321-4 DMX 321-4/ 321-4

DMX 460-6 DMX 460-6/ 460-6

DMX 460-3,5 D M X 460 -3 , 5 / 46 0-3,5

DMX 249-3 DMX 249-3/ 249-3

DMX 315-3 DMX 315-3/ 315-3

DMX 525-3 DMX 525-3/ 525-3

DMX 765-3 DMX 765-3/ 765-3

Dosing

head size

Motor

1

222

0,18kW

Stroke

volume

[ml]

13,8

336

1

18,5

227,8

0,37kW *

344,6

473

* with PTC thermistor: 0,55 kW

3.2 Pump Performance

3.2.1 Accuracy

Dosing flow fluctuation

Linearity deviation

10

< ± 1.5 % within the control range 1:10

± 4 % of full-scale value within control range 1:5,

direction of adjustment from maximum to minimum stroke length

These data refer to:

- dosing medium water

- fully deaerated dosing head

- measurement according to ALLDOS factory standard No. 0010/0011

- standard version of pump

15.720017-V6.0

Page 11

DMX model 226 en

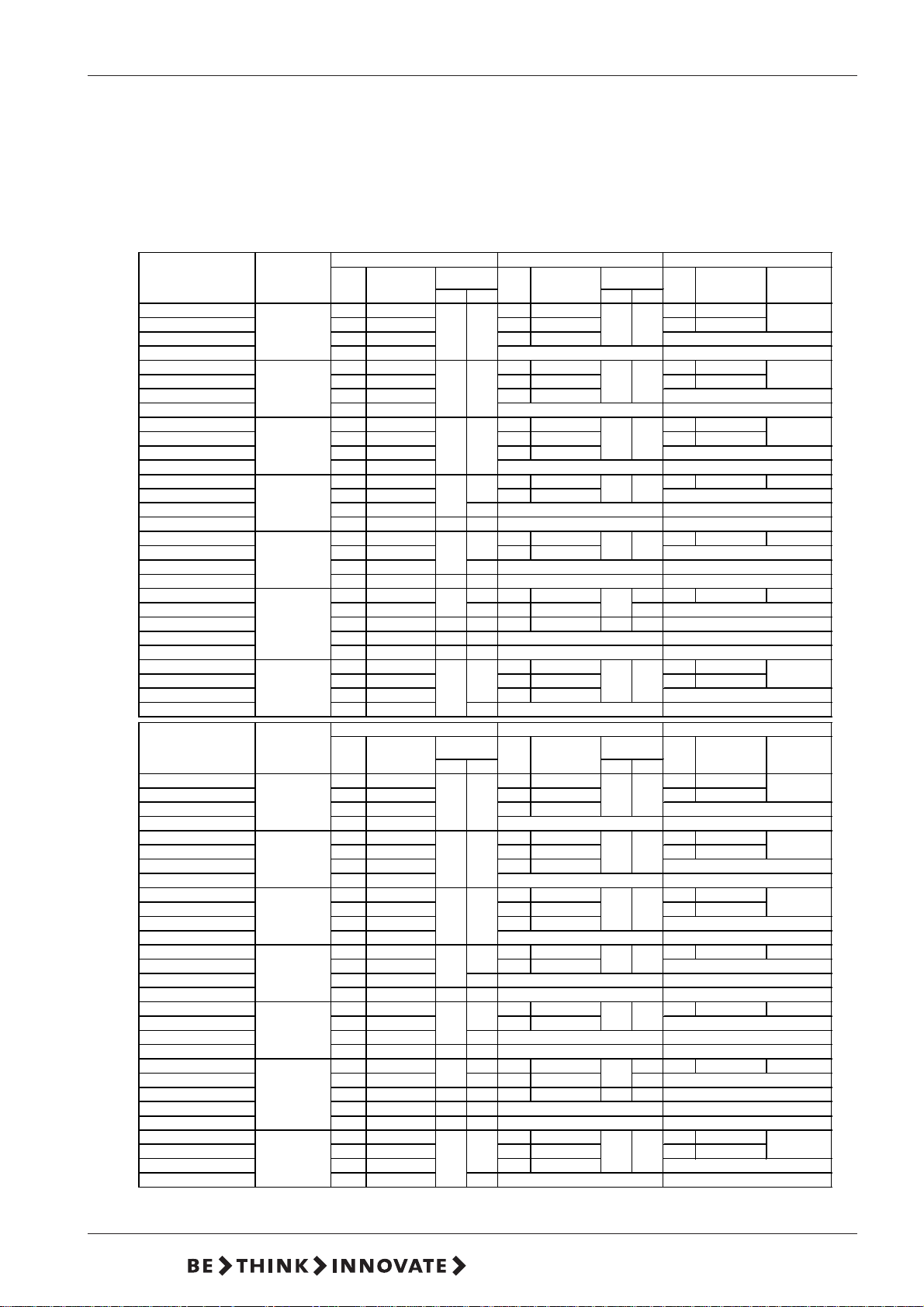

3.2.2 Performance

The data in the following table refer to:

- maximum counterpressure

- dosing medium water

- flooded suction 0.5 m w. c.

- fully deaerated dosing head

- three-phase 400 V motor

50 Hz 60 Hz 100 Hz

Stroke

value [H/min]

3 AC 1 AC 3 AC 1 AC

Q [l/h]

Stroke

value [H/min]

p max * [bar]p max * [bar]

Q [l/h]

Stroke

value [H/min]

p max * [bar]

Simple pump

Dosing head

size

Q [l/h]

DMX 24-8 24 29 28 34,8 48 58

-

88

-

-

DMX 52-8

DMX 100-8

DMX 142-8

188

52 63 62 75,6 104 126

100 120 120 144

142 168

DMX 37-5 37 29 45 34,8 75 58

5

DMX 82-5

DMX 160-5

255

DMX 224-5 224 168

DMX 60-3

DMX 130-3

DMX 255-3

333

DMX 380-3 380 168

DMX 67-10

DMX 132-10

DMX 190-10 190 175 -

1

DMX 190-8

DMX 95-8

DMX 199-8 199 120 239 144

DMX 280-8

2

DMX 280-6

DMX 152-6

DMX 321-6 321 120 - 385 144 -

DMX 321-4

3

DMX 460-6

DMX 460-3,5 460 175 - 3,5

DMX 249-3

DMX 315-3

DMX 525-3

43

DMX 765-3 765 175 -

Double pump

Dosing head

size

DMX 24-8/24-8

DMX 52-8/25-8

DMX 100-8/100-8 200 120 240 144

188

DMX 142-8/142-8 284 168

DMX 37-5/37-5

DMX 82-5/82-5

DMX 160-5/160-5 320 120 384 144

255

DMX 224-5/224-5

DMX 60-3/60-3

DMX 130-3/130-3 260 63 312 75,6 520 126

DMX 255-3/255-3 510 120 612 144

333

DMX 380-3/380-3

DMX 67-10/67-10 134 57 161 68,4 268 114 10

DMX 132-10/132-10 264 120 317 144

DMX 190-10/190-10

1

DMX 190-8/190-8

DMX 95-8/95-8 190 57 228 68,4 380 114 8

DMX 199-8/199-8

DMX 280-8/280-8

2

DMX 280-6/260-6 560 175 - 6

DMX 152-6/152-6 304 57 6 365 68,4 6 608 114 6

DMX 321-6/321-6

DMX 321-4/321-4

3

DMX 460-6/460-6 920 175 6 -

DMX 460-3,5/460-3,5

DMX 249-3/249-3

DMX 315-3/315-3 630 72 756 86,4 1260 144

DMX 525-3/525-3 1050 120 1260 144

4

DMX 765-3/765-3

82 63 98 75,6 164 126

160 120 192 144

--

60 29 72 34,8 120 58

130 63 156 75,6 260 126

255 120 306 144

--

67 57 80 68,4 134 114 10

132 120 158 144

10 10 10

10

--

190 175 - 8

95 57 114 68,4 190 114 8

888

8

280 175 280 175 - 6

152 57 6 182 68,4 6 304 114 6

66

-

-

-

321 120 - 4 385 144 - 4

460 175 6 -

--

-

249 57 299 68,4 498 114

315 72 378 86,4 630 144

333

525 120 630 144

--

60 Hz

Stroke

value [H/min]

Q [l/h]

50 Hz

Stroke

value [H/min]

p max * [bar]

3 AC 1 AC 3 AC 1 AC

Q [l/h]

48 29 56 34,8 96 58

104 63 125 75,6 208 126

--

74 29 90 34,8 148 58

164 63 197 75,6 328 126

448 168

-

120 29 144 34,8 240 58

760 168

10 10 10

10

380 175 380 175 - 8

88

398 120 478 144

8

560 175 -

--

--

-

--

-

304 120 - 365 144 -

6

642 120 - 4 770 144 - 4

--

920 175 - 3,5

--

498 57 598 68,4 996 114

333

3

1530 175 -

--

5

33

p max * [bar]

88

55

33

8

6

Q [l/h]

100 Hz

Stroke

value [H/min]

-

-

-

-

-

-

-

-

-

-

-

p max * [bar]

-

-

-

-

-

-

-

-

-

-

-

8

5

3

3

8

5

3

3

*) maximum counterpressure

V6.0

11

Page 12

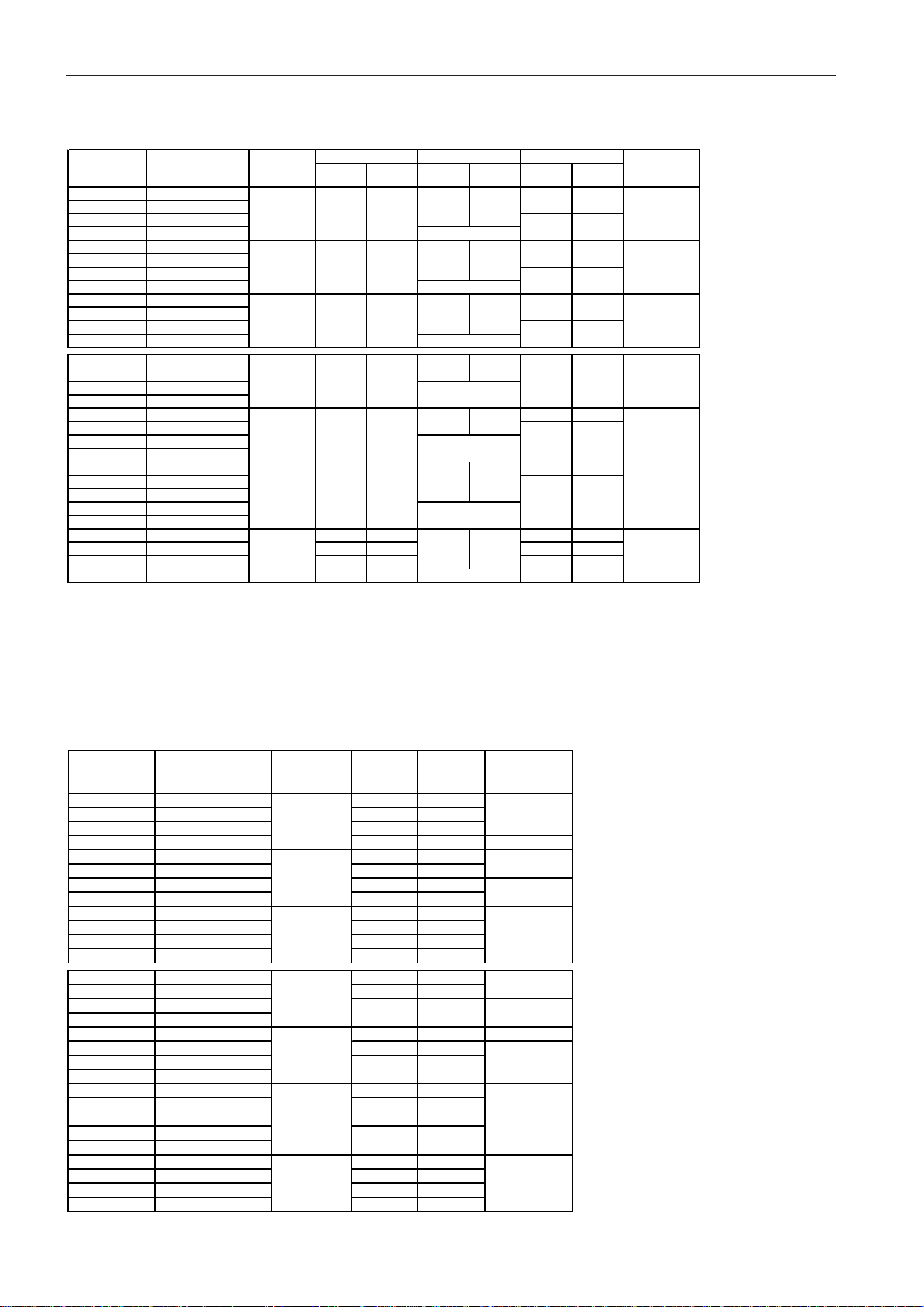

3.3 Suction heights

5

5

3.3.1 Media with a viscosity similar to water

Simple

pump

DMX 24-8 DMX 24-8/24-8

DMX 52-8 DMX 52-8/25-8

DMX 100-8 DMX 100-8/100-8

DMX 142-8 DMX 142-8/142-8

DMX 37-5 DMX 37-5/37-

DMX 82-5 DMX 82-5/82DMX 160-5 DMX 160-5/160-5

DMX 224-5 DMX 224-5/224-5

DMX 60-3 DMX 60-3/60-3

DMX 130-3 DMX 130-3/130-3

DMX 255-3 DMX 255-3/255-3

DMX 380-3 DMX 380-3/380-3

DMX 67-10 DMX 67-10/67-10

DMX 132-10 DMX 132-10/132-10

DMX 190-10 DMX 190-10/190-10

DMX 190-8 DMX 190-8/190-8

DMX 95-8 DMX 95-8/95-8

DMX 199-8 DMX 199-8/199-8

DMX 280-8 DMX 280-8/280-8

DMX 280-6 DMX 280-6/260-6

DMX 152-6 DMX 152-6/152-6

DMX 321-6 DMX 321-6/321-6

DMX 321-4 DMX 321-4/321-4

DMX 460-6 DMX 460-6/460-6

DMX 460-3,5 DMX 460-3,5/460-3,5

DMX 249-3 DMX 249-3/249-3

DMX 315-3 DMX 315-3/315-3

DMX 525-3 DMX 525-3/525-3

DMX 765-3 DMX 765-3/765-3

Data in m w. c.

these data refer to:

- counterpressure 1.5 to 3 bar

- not degassing and not abrasive media

- temperature of 20 °C

- stroke length 100%

- standard version

Double

pump

Dosing head

Suction

size

height *

1 3 m 1 m 4 m

23 m1 m

13 m1 m

23 m1 m

32 m1 m

1,5 m 1 m 1 m 0,5 m

4

1,5 m 1 m

1 m 0,5 m

0 m 0 m

DMX model 226 en

50 Hz

suction

lift **

60 Hz

Suction

height *

2,5 m

-

2,5 m 1 m

-

2 m 1 m

-

2,5 m 1 m

-

2,5 m 1 m

-

2 m 1 m

-

1 m 0,5 m

-

suction

lift **

1 m

100 Hz

Suction

height *

suction

lift **

2,5 m 1 m

--

2 m

1,5 m

2,5 m 1 m

2 m 1 m

1,5 m 1 m

1 m

--

1 m

--

-

--

--

--

-

Max. suction

line le ng th

3 m

3 m32 m1 m

4 m

3 m

3 m

2 m

*) suction line and dosing head filled (continuous operation)

With version S 01 (stronger restoring spring), the values for dosing head

size 1 are increased by 2 m, and for dosing head sizes 2 and 3 by 1 m.

**) suction line and dosing head not filled, but dosing head and

valves moistened (commissioning)

3.3.2 Suction heights for media with maximum permissible viscosity

Simple

pump

Double

pump

Dosing head

size

Stroke

value

[1/min]

Viscosity

[mPas]

DMX 24-8 DMX 24-8/24-8 29 1000

DMX 52-8 DMX 52-8/25-8 63

DMX 100-8 DMX 100-8/100-8 120

1

DMX 142-8 DMX 142-8/142-8 168

DMX 37-5 DMX 37-5/37-5 29

DMX 82-5 DMX 82-5/82-5 63

DMX 160-5 DMX 160-5/160-5 120

2

DMX 224-5 DMX 224-5/224-5 168

DMX 60-3 DMX 60-3/60-3

DMX 130-3 DMX 130-3/130-3

DMX 255-3 DMX 255-3/255-3

3

DMX 380-3 DMX 380-3/380-3

DMX 67-10 DMX 67-10/67-10

DMX 132-10 DMX 132-10/132-10 120

DMX 190-10 DMX 190-10/190-10

1

DMX 190-8 DMX 190-8/190-8

DMX 95-8 DMX 95-8/95-8

DMX 199-8 DMX 199-8/199-8

DMX 280-8 DMX 280-8/280-8

2

DMX 280-6 DMX 280-6/260-6

29 500

63 400

120 100

168 50

57 700

175

57 500 1

120 200

175 150

DMX 152-6 DMX 152-6/152-6 57

DMX 321-6 DMX 321-6/321-6

DMX 321-4 DMX 321-4/321-4

DMX 460-6 DMX 460-6/460-6

DMX 460-3,5 DMX 460-3,5/460-3,5

30

120 100

175 50

DMX 249-3 DMX 249-3/249-3 57

DMX 315-3 DMX 315-3/315-3 72

DMX 525-3 DMX 525-3/525-3 120

4

DMX 765-3 DMX 765-3/765-3 175

700

400

200 0

600

500

200

150

400

200 0

400

100

100

Suction height

50

10

[m water

gauge]

1

1

0

0

1

0

0

These data refer to:

- Newtonian liquids

- not degassing and

not abrasive media

- temperature of 20 °C

- standard version

12

15.720017-V6.0

Page 13

DMX model 226 en

3.4 Dosing Curves

The dosing curves shown here are trend curves according to the ALLDOS factory

standard No. 0010/0011

They refer to:

❏ Performance of single pump

(the flow rate is doubled for the double pump)

❏ Water as the dosing medium

❏ Zero point of pump Q

❏ Standard version of pump

3.5 Materials

Pump

Pump housing

Diaphragm flanges

Adjustment knob, front panel

Al 226

GG 25

ABS

3.6 Ambient and Operating Conditions

for specified pressure - see diagram.

0

Admissible ambient temperature

Admissible storage temperature

Admissible humidity

!

Noise level

Minimum counterpressure

Admissible temperature of dosing liquids

0 °C to +40 °C

-20 °C to + 70 °C

rel. humidity: 70% at 40 °C, 90% at 35 °C

CAUTION Danger of malfunctioning or damage!

Do not install outdoors!

WARNING Risk of hot surfaces! Pumps with A.C. motors can

become hot. Allow a minimum spacing of 100 mm to

the ventilator cowl!

± 55 dB (A), testing following DIN 45635-01-KL3

1 bar

These data refer to the pressure valve of the pump. Pressure losses along the way

to the injection point inclusively are not taken into account.

Materials up to 10 bar

PVC

1.4571

PP

PVDF

1)

0 °C - 40 °C

-10 °C - 70 °C

0 °C - 40 °C

-10 °C - 60 °C

(70 °C at 9 bar)

V6.0

1)

For SIP/CIP applications 145 °C are admissible for a short time

(approx. 15 min) at < 2 bar .

CAUTION Observe freezing and boiling point of the medium!

13

Page 14

p

p

V4A

p

V

3.7 Weight

DMX model 226 en

le pum

Sim

DMX 24-8 DMX 24-8/24-8

DMX 52-8 DMX 52-8/25-8

DMX 100- 8 DMX 100- 8 /100-8

DMX 142- 8 DMX 142- 8 /142-8

DMX 37-5 DMX 37-5/37-5

DMX 82-5 DMX 82-5/82-5

DMX 160- 5 DMX 160- 5 /160-5

DMX 224- 5 DMX 224- 5 /224-5

DMX 60-3 DMX 60-3/60-3

DMX 130- 3 DMX 130- 3 /130-3

DMX 255- 3 DMX 255- 3 /255-3

DMX 380- 3 DMX 380- 3 /380-3

DMX 67-1 0 DMX 67- 10 /67-10

DMX 132-10 DMX 132-10/132-10

DMX 190-10 DMX 190-10/190-10

DMX 190- 8 DMX 190- 8 /190-8

DMX 95-8 DMX 95-8/95-8

DMX 199- 8 DMX 199- 8 /199-8

DMX 280- 8 DMX 280- 8 /280-8

DMX 280- 6 DMX 280- 6 /260-6

DMX 152- 6 DMX 152- 6 /152-6

DMX 321- 6 DMX 321- 6 /321-6

DMX 321- 4 DMX 321- 4 /321-4

DMX 460- 6 DMX 460- 6 /460-6

DMX 460- 3,5 DMX 460- 3,5 / 460 -3, 5

DMX 249- 3 DMX 249- 3 /249-3

DMX 315- 3 DMX 315- 3 /315-3

DMX 525- 3 DMX 525- 3 /525-3

DMX 765- 3 DMX 765- 3 /765-3

Weight Weight

PVC

Approx. 15 kg Approx. 21 kg Approx. 24 kg Approx. 36 kg

Approx. 21 kg Approx. 30 kg Approx. 30 kg Approx. 48 kg

Double pum

PVC

4A

14

15.720017-V6.0

Page 15

DMX model 226 en

3.8 Dimensional Drawing

DM X 24-8

DM X 52-8

DM X 100-8

DM X 142-8

DM X 37-5

DM X 82-5

DM X 160-5

DM X 224-5

DM X 60-3

DM X 130-3

DM X 255-3

DM X 380-3

abcdefghik l m n prrxs

302 178 152

310

302 310

302

97,5

310

Values in brackets with Ex motor

V6.0

85,597,5

190 118 180 180

190 188 152 85,5 425 208

425 208 104,5

85,5 425 208 106,5 250 (315) 4 G 11/4" 118 180 180 19897,5 190 208 152

250 (315) 4 198

104,5

250 (315) 4 G 11/4" 118 180 180 198

G 11/4"

15

Page 16

DMX model 226 en

DM X 67-10

DMX 132-10

DMX 190-10

DM X 190-8

DM X 95-8

DM X 199-8

DM X 280-8

DM X 280-6

DM X 152-6

DM X 321-6

DM X 321-4

DM X 460-6

DM X 460-3,5

DM X 249-3

DM X 315-3

DM X 525-3

DM X 765-3

16

abcde fghik l m n prrxs

380 136 222 178 140 123 440 208 80 233 (352) 34 G 11/4" 160 190 258 223

372

136 222 188 140 123 444 208 80 233 (352) 29 G 11/4" 160 190 258 223

372

380

136 222 208 140 123 453 208 83 258 223233 (352) 19 G 11/4" 160 190

372

380

136 222 240 140 258 -233 (352) 3 G 2" 160 190123 498 208 92

390

389

15.720017-V6.0

Page 17

DMX model 226 en

4 Installation

4.1 Installation Information

Picture of optimal installation:

8

1 Dosing tank

2

9

7

2 Electric agitator

3 Extraction device

10

6

4 Suction pulsation damper

5 Dosing pump

6 Overflow valve

1

4

3

5

7 Pressure retention valve

8 Pulsation damper

9 Measuring glass

10 Injection unit

11

12

For easy deaeration of the pump:

● Install a ball valve (11) with bypass line (back to the dosing tank)

immediately behind the pressure valve

In case of long pressure lines:

● Install a check-back valve (12) into the dosing line.

V6.0

● Keep the suction line as short as possible, avoid a tangled suction

line

• If necessary, use swept bends instead of elbows.

● Always lay the suction line rising to the suction valve of the dosing

pump.

• Avoid loops which cause air bubbles.

p

10

6

● For non-degassing media with viscosity similar to water, the pump can

be mounted onto the tank (observe the admissible suction height).

Preferably flooded suction.

For dosing media which tend to sedimentation:

● Install a suction line with filter (13) in a way ensuring that the suction

13

valve remains several centimetres a bove the botton of the tank.

6 Overflow valve

10 Injection unit

17

Page 18

DMX model 226 en

4

● In dosing systems that require a long suction line:

Provide a properly dimensioned pulsation damper (4) directly in front of the

suction valve of the dosing pump.

8

● Note for pressure side installation:

to protect the piping use pulsations damper (8) for rigid piping longer than

3m and tubing longer than 5m.

p

6

10

● For outgassing and viscous media: flooded suction

● To protect the dosing pump and the pressure line agains: excessive

development of pressure: Install an overflow valve (6) in the pressure line.

10 Injection unit

7

p≥ 2 bar

● With open outflow of the dosing medium or a counterpressure below 1 bar:

Install a pressure retention valve (7) directly in front of the outlet or the

injection unit.

A positive pressure difference of at least 1 bar has to exist between the

counterpressure at the injection point and the pressure of the dosing medium

at the suction valve of the dosing pump. If this cannot be guaranteed:

• Install a pressure retention valve (7) in the pressure line

p

1

p2 - p

1

1 bar

_

>

To avoid the siphon effect:

p

● Install a pressure retention valve in the dosing line and, if

2

necessary, a solenoid valve (14) in the suction line.

14

18

WARNING Risk of hot surfaces! Pumps with A.C. motors can

!

become hot. Allow a minimum spacing of 100 mm to

the ventilator cowl!

15.720017-V6.0

Page 19

DMX model 226 en

4.2 Transport and Storage

● Handle with care, do not throw!

❏ Dry and cool storage place.

❏ Take heed of upright position of the dosing pump when storing it, so that

gear grease can not leak out.

CAUTION Observe permissible storing temperature!

4.3 Mounting

● Mount the pump horizontally with 4 screws M8 on the tank or on a console.

● Replace the screw plugs by the attached venting screws.

4.4 Connecting the Suction and Pressure Lines

WARNING All lines must be stress-free!

!

Only use the prescribed line types!

B

A

C

A: Suction valve C: Pipe connection

B: Discharge valve D: Tube connection (only DN20)

● Connect the suction line to the suction valve (A).

• The foot valve must keep a distance of ca. 10 cm to the bottom of the

container.

● Connect the pressure line to the pressure valve (B).

D

V6.0

19

Page 20

4.5 Electrical Connections

4.5.1 Versions with mains plug

4.5.2 Versions without mains plug

DMX model 226 en

WARNING Prior to the mains connection check if the voltage

!

NOTE The pump is being switched by switching the mains

● Connect the mains plug to a mains socket.

● Connect the motor according to the terminal connection diagram (stamped in

the clamp box).

CAUTION Observe the sense of rotation!

indicated on the type plate corresponds with the local

voltage!

Switch off mains before connecting!

No changes at the mains cable and the mains plug may

be done!

voltage.

Do not switch on the mains until the pump should be

started.

A motor protector, adjusted to nominal motor current,

must be installed by the customer.

For use with a frequency converter the jumpers in the

clamp box have to be set according to the converter

voltage.

In the state of delivery, the jumpers of 3-phase motors

are set for star connection.

20

15.720017-V6.0

Page 21

DMX model 226 en

5 Commissioning

5.1 Inspections before Commissioning

● Check the tightness of all connections. If necessary, retighten.

● Check the correctness of all electrical connections.

● Check if the voltage indicated on the type plate corresponds with the local

voltage!

5.2 Commissioning

CAUTION After initial start-up and after each diaphragm

● Open the shut-off valves (15, 16, if installed) both at the suction and

pressure side.

● Open the deaeration valve (17, if installed) of the dosing line, or remove

pressure on the pressure side so that the medium is able to issue without

counterpressure.

● Switch on mains voltage.

● Set the stroke length adjustment knob to 100%.

Keep the dosing pump in operation until bubble-free medium comes out of the

deaeration valve or the dosing line.

● Close the deaeration valve (17, if installed).

The pump is now ready for operation.

exchange, tighten the fixing screws of the dosing

head:

After approx. 6 to 10 working hours or two

days, tighten the dosing head screws crosswise using

a torque wrench, torque 6 Nm.

15

1617

V6.0

21

Page 22

6 Operation

6.1 Description of the Device

DMX model 226 en

1

2

47

3

9

5

6

1 Motor

2 Gears

3 Eccentric

4 Dosing diaphragm

5 Dosing head

6 Suction valve

7 Pressure valve

8 Stroke length adjustment knob

9 Hall sensor

Principle of function

❏ Reciprocating displacement pump with electric motor and mechanical

diaphragm guide

.

❏ The rotation of the motor is transformed into the reciprocating movement of

the dosing diaphragm by the eccentric and the tappet.

❏ Adjustment of the dosing flow is possible by adjusting the stroke length of

the tappet.

8

6.2 Switching on / off

6.2.1 Switching on

6.2.2 Switching off

22

● Switch on the mains power.

● Switch off the mains power.

15.720017-V6.0

Page 23

DMX model 226 en

6.3 Adjusting the Dosing Flow by Means of the Stroke length

CAUTION Adjust the stroke length only while the pump is

running!

Danger of damages.

5

6

0

7

0

8

0

9

0

100

%

4

0

0

3

0

2

0

1

0

0

● Loosen the locking screw (A) on the stroke length adjustment knob (8) a little

using a screwdriver.

● Increasing the dosing flow: Turn the stroke adjustment knob slowly to the left

until the desired dosing flow is reached.

● Decreasing the dosing flow: Turn the stroke adjustment knob slowly to the

right until the desired dosing flow is reached.

● Gently tighten the locking screw (A) again using a screwdriver.

8

A

6.4 Adjusting the Stroke Length Adjustment

WARNING Wear protective gloves and glasses when executing

!

CAUTION Adjust the stroke length only while the pump is

work at the dosing head, connections or lines!

running!

Danger of damages.

The zero point (no dosing) of the dosing pump is adjusted in the works at a

counterpressure of 3 bar (see dosing curves).

If the operational counterpressure at the injection point is considerably above or

below this value, it is advisable to readjust the zero point to obtain more precise

values of the dosing output.

● Install a graduated tube at the suction valve.

If this is not present:

• insert the suction line into a graduated measuring jug.

● Start the dosing pump and adjust the dosing flow to 15%.

For pumps with tank empty indication:

• Remove the plug of the tank empty indication.

● Completely unscrew the locking screw (A) on the stroke length adjustment

knob (1) using a screwdriver.

● Turn the adjustment knob slowly clockwise until the dosage stops in the

measuring jug or tube.

● Remove the plug with a small screw driver without changing the position of

the adjustment knob and unscrew the cheese head screw together with the

flat spiral spring.

● Fit the adjustment knob on the adjusting spindle so that the zero line on the

scale and the mark on the adjustment knob coincide.

● Screw in the cheese head screw and the spiral spring until the spring is

preloaded but does not block. Even when adjusted to 100% the spring of the

adjustment knob must still remain preloaded.

● Screw in the locking screw (A) again using a screwdriver, and tighten gently.

V6.0

23

Page 24

6.5 Possible Failures

g

p

play

y

g

gg

y

g

y

A

j

y

y

quip

g

g

p

p

p

g

p

)

y

p

g

p

y)

g

Failure Cause Correction

Not connected to mains Connect the mains line

Wron

mains voltage Replace the dosing pum

Electrical failure Return the dosing pump to the works for repair

DMX model 226 en

Dosing pump does not run

Dosing pump does not suck in

Dosing pump does not dose

Dosing output of the pump

inaccurate

The empty indication has responded. The

empty indication symbol blinks in the display

The diaphragm breakage indication has

responded. ERROR and MBS are blinking in

the dis

Leak

Cross-section of the suction line too narrow or

or suction line too lon

Clo

Foot valve covered b

Buckled suction line Lay the suction line correctly, check for

Cr

Diaphragm broken or diaphragm tappet torn

out

ir in the suction line and dosing head Wait, until the pump has deaerated

Stroke ad

Medium too viscous or densit

Cr

Valves not correctly assembled Assemble the valve inside parts in the right

Injection point blocked Check and possibly correct the flow direction,

Inexpert installation of lines and peripheral

e

Dosin

De

Valves

Zero-point misadjusted Adjust the zero-point to the actual back

Fluctuations of back pressure Application of a pressure retention valve and a

Fluctuations of suction hei

Siphon effect (admission pressure higher than

back

Leak

Parts in contact with media not resistant Re

Dosing diaphragm worn out (incipient tears) Replace the diaphragm, also observe

Fluctuations of mains volta

Variation of the dosing medium (density,

viscosit

.

suction line Exchange or seal the suction line

ed suction line Rinse or replace the suction line

sediment Suspend the suction line at a higher position

stalline deposits in the valves Clean the valves

ustment set to zero Turn the adjustment knob in the "+" direction

too high Check the installation

stalline deposits in the valves Clean the valves

ment

head not fully deaerated Repeat deaeration

assing medium Check the installation

artially soiled or incrusted Clean the valves

ht Keep the suction level constant

ressure

or porous suction line or pressure line Replace the suction line or pressure line

e Decrease the back pressure of the pum

Remove the cause

Replace the diaphragm.

Check with specification of Grundfos

e

dama

Exchange the diaphragm

order and check or possibly correct the flow

direction

or remove the occlusion

Check for perviousness and correct installation

ressure

ulsation damper

Install a pressure retention valve

lace with resistant materials

maintenance instructions

Examine the concentration, possibly employ an

itator

a

24

15.720017-V6.0

Page 25

DMX model 226 en

7 Operation with Other Electronics

CAUTION First refer to the general Section 6 "Operation". This

7.1 Electronics Version Stroke sensor

Pump type with inductive proximity switch of two-wire design according to NAMUR

DIN 19 234for signalling the strokes.

The sensor can be installed in potentially explosive atmospheres if PTB-approved

isolating switching amplifiers with an intrinsically-safe control circuit [EExia] or

[EExib] are connected. The sensor can be used up to zone 1 depending on the

isolating amplifier. The specifications on the conformity certificate for the isolating

amplifier must be observed.

Supply voltage U

B

7.2 Electronics Diaphragm Breakage Sensor

7.2.1 Technical Data of the Electronics

7.7 ... 10 V

Section 7 "Operation with Other Electronics" only

describes the additional functions.

Contact load

Power consumption

Degree of protection

Permissible temperature range

250 V / 6 A, max. 550VA

1.15 VA

IP 65

0 - 40 °C

7.2.2 Dimensional Drawing (Electronics Enclosure)

80

63.5

Description

Model 230 V (+10% /-10%)

Model 115 V (+10% /-10%)

130

113.5

V6.0

25

Page 26

7.2.3 Function

Pumps prepared for a diaphragm breakage indication:

❏ Special dosing head flange for inserting the optoelectronic sensor

❏ Optoelectronic sensor, contains

- infrared sender

- infrared receiver

In case of a leaking diaphragm:

❏ Dosing liquid penetrates the dosing head flange.

- The light refraction will be changed.

❏ The sensor produces a signal.

- The electronics switches two contacts which can be used e. g. for

7.2.4 Electrical Connections of the Electronics

WARNING Electrical connections only by qualified personnel!

!

DMX model 226 en

triggering an alarm device or switching off the pump.

Switch off mains before connecting!

Observe the local safety regulations!

Protect the cable connections and plugs from

corrosion and moisture.

CAUTION Before connecting the power supply cable:

Check that the supply voltage specified on the rating

plate agrees with the local voltage. An incorrect power

supply could destroy the unit!

To guarantee electromagnetic compatibility (EMC):

The input cables and current output cables must be

shielded.

•

Connect shield at one end to PE.

➜

Refer to the connection diagram!

Route input cables, current output cables and power

supply cables in separate ducts.

● Connect the device to the mains according to the connection chart.

● Connect the electronics with the sensor according to the connection chart.

WARNING The potential-loaded contact 1, terminals 6 and 7, is

!

loaded with mains voltage.

Switch off mains before connecting contact 1!

26

CAUTION The contacts have no protective circuits. Only pure

ohmic loads may be switched. For switching the pump

motor, a contactor has to be connected inbetween.

● Connect contacts 1 and 2 according to individual needs.

➜

Refer to Section "Electrical connections"

15.720017-V6.0

Page 27

DMX model 226 en

7.2.5 Relay Outputs

NOTE The relay output connection depends on the

application and the connected actuators.

Interference suppression is required for inductive loads (also relays and contactors).

If this is not possible, protect the relay contacts using a suppressor circuit as

described below.

R

❏ With AC voltage:

Current up to Capacitor C Resistor R

C

60 mA 10 nF 260 V 390 Ω 2 W

70 mA 47 nF 260 V 22 Ω 2 W

150 mA 100 nF 260 V 47 Ω 2 W

1.0 A 220 nF 260 V 47 Ω 2 W

+

❏ With DC voltage: connect freewheeling diode parallel to relay or contactor.

CAUTION Provide relay outputs on site with an appropriate

backup fuse!

NOTE These connections depend on the type of actuator

used, and should only be understood as guidelines.

➜

Refer to actuator documentation.

-

S1

S2

K1LK2NK3PEK4PEK5NK6 K7 K8 K9 K10

230 V AC /

115 V AC

contakt 1

(non-floating

230 V AC / 115 V AC)

contakt 2 (floating) sensor

7.2.6 Screwing the Sensor into the Dosing Head

● Screw in the sensor from the lower side into the hole of the dosing head

flange (M14 x 1.5).

❏ Now the diaphragm breakage indication is ready for start-up.

1

111111111111

green yellow white

V6.0

27

Page 28

7.2.7 Commissioning

CAUTION Carry out a functional check before commissioning!

Functional Check

● Dip the sensor into water

- Green LED and red LED are lighting:

Sensor and electronics are ready for operation!

- One or more LED do not light:

Sensor or electronics are defective!

• Call Grundfos service.

● Carefully dry the senor.

- Only the green LED still lights:

Sensor and electronics are ready for operation!

- the red LED still lights:

Sensor or electronics are defective!

• Call Grundfos service.

WARNING Do not open electronics or sensor!

!

Repair only by authorized qualified personnel.

DMX model 226 en

7.2.8 Using the Contacts

7.2.9 Description of the Device

❏ Terminals 6 and 7 (potential-loaded):

- e. g. for switching off the dosing pump in case of a diaphragm breakage

➜

Observe Technical Information of the dosing pump!

❏ Terminals 8, 9 and 10 (potential-free):

- e. g. for triggering an alarm device

There are two light-emitting diodes (LED) at the electronics.

❏ Green LED:

- Shows the readiness for operation of the system.

- It only lights when the sensor is connected to the electronics. If it does

not light in this case, either the sensor or the cable is defective or wrongly

connected.

❏ Red LED:

- Lights in case of a diaphragm breakage being detected.

- The green LED continues lighting.

28

15.720017-V6.0

Page 29

DMX model 226 en

7.2.10Maintenance

WARNING Do not open electronics or sensor!

!

❏ Sensor

• Clean it in case of malfunction.

• If it still does not operate correctly:

Replace sensor.

Description

Optosensor with 3 m cable

❏ Electronics

- No maintenance possible by the user.

• If it does not operate correctly:

Call Grundfos service.

WARNING Repair only by authorized qualified personnel.

Repair only by authorized qualified personnel.

!

V6.0

29

Page 30

8 Integral Overflow Valve

8.1 Function

8.2 Permissible Media

!

8.3 Connections

DMX model 226 en

The integral overflow valve (option) protects the complete pressure side of the

dosing line system from an impermissibly high buildup of pressure.

The valve opens if the pressure rises above its set opening pressure, and the dosing

medium can return to the solution tank.

In contrast to series-connected overflow valves, the integral valve also provides

pump protection if the pressure valve is contaminated or blocked.

WARNING Dosing heads with integral overflow valve must not be

used for abrasive or crystallizing media.

B

C

A

● Connect suction line to suction valve (A).

● Connect pressure line to pressure valve (B).

● Connect overflow line to overflow valve (C) and allow to flow by gravity into

the tank or to an appropriate overflow.

WARNING Danger of injury! Never use the pump if the line is not

!

correctly connected to the overflow valve.

30

15.720017-V6.0

Page 31

DMX model 226 en

8.4 Setting of Opening Pressure

8.4.1 General

!

!

!

The opening pressure can only be set if a manometer is installed in the system

between the pump and the next shut-off valve or pressure retention valve.

WARNING Settings on the overflow valve must only be carried out

by authorized specialists!

The opening pressure of the overflow valve is set in the factory to the maximum

pump back-pressure specified in the technical data. The opening pressure during

operation depends on various factors, e.g. the flow, the stroke frequency of the

pump, or the back-pressure. If an exact setting is required, the overflow valve must

be adapted to the local conditions.

The opening pressure must only be set to values below the maximum permissible

operating pressure.

WARNING Danger of injury! Never set the opening pressure

higher than the maximum permissible operating

pressure of the dosing system and dosing pump.

WARNING When dosing dangerous media, always refer to the

corresponding safety data sheets!

Wear protective clothing (goggles, gloves) when

working on the connections and lines!

8.4.2 Setting Instructions for Opening Pressure

Proceed as follows if the factory-set pressure is to be changed:

With the pump running

● Remove the cap from the top part of the overflow valve.

● Close the shut-off valve downstream of the manometer.

● When overflowing of the dosing medium is heard, read the current opening

pressure on the manometer.

● Using pointed pliers, rotate

- in the clockwise direction to increase the pressure or

- in the counterclockwise direction to reduce the pressure

until the desired opening pressure is set.

● Open the shut-off valve downstream of the manometer.

● Attach the cap again.

V6.0

31

Page 32

8.5 Venting

(

)

g

g

(

)

g

A

8.6 Possible Faults

Fault Cause Elimination

Permanent output from

overflow valve

No output from overflow valve

DMX model 226 en

The overflow valve can also be opened manually, thus serving as a venting valve

at the same time.

If manual venting is required (e.g. when commissioning or when the tank has been

replaced):

● Rotate the knob such that the smaller cut-out rests on the nub of the dosing

head (the rotary knob is then further away from the dosing head, the valve

B

spring is unloaded (position B).

● Once the pump has been completely vented, rotate the knob back into the

position "Operation" (position A).

A Operation

B Venting

Overflow valve set incorrectly

too low

Diaphra

m faulty Replace diaphragm

Set overflow valve to a higher

openin

pressure

Contamination Clean overflow valve

Overflow valve set incorrectly

too high

Set overflow valve to a lower

openin

pressure

8.7 Maintenance

WARNING When dosing dangerous media, always refer to the

!

8.7.1 Intervals for Cleaning and Maintenance

Clean the overflow valve, and replace the diaphragm if necessary

❏ at least every 12 months or after 8000 operating hours or

❏ should faults occur.

8.7.2 Replacing the Diaphragm

● Shut down the dosing system.

● Make it impossible for a return flow or overpressure to occur.

● Loosen the 4 screws on the top part of the overflow valve.

● Remove top part of overflow valve.

● Remove the diaphragm.

● Insert new diaphragm.

● Return top part of overflow valve and tighten screws diagonally.

Max. torque 6 Nm.

● Start up the dosing system again.

● Tighten the screws on the top part of the overflow valve again after 48 hours

of operation. Max. torque 6 Nm.

corresponding safety data sheets!

Wear protective clothing (goggles, gloves) when

working on the connections and lines!

Maintenance must only be carried out by authorized

specialists!

32

15.720017-V6.0

Page 33

DMX model 226 en

9 Maintenance

!

9.1 Replacing the Gear Grease

!

WARNING When dosing dangerous media, observe the

corresponding safety precautions!

Wear protective gloves and glasses when executing

work at the dosing head, connections or lines!

Do not open the pump!

Repair only by authorized personnel!

Switch off the pump and disconnect from mains before

doing maintenance and repair!

WARNING The gear grease may only be changed by authorized,

qualified personnel. For this purpose send the pump to

the factory.

To guarantee fault-free operation, it is recommended to have the gear grease

exchanged after 5 years or after 20000 operation hours.

9.2 Rates for cleaning and maintenance

❏ Regularly every 12 months or after 4000 operation hours, or

❏ in case of malfunction

Clean the diaphragm and valves, or replace if necessary (with stainless steel

valves: internal components). -> see spare parts

9.3 Cleaning the Suction and Pressure Valves

DN 20

optionaloptional

WARNING Wear protective gloves and glasses when executing

!

If the pump loses capacity, clean the suction and pressure valves as follows:

● Unscrew the valve

● Unscrew the screw part or the

● Clean all parts, replace faulty parts by new ones.

● Re-assemble the valve.

● Replace the O-rings by new ones, and place the valve. Observe the direction

arrow.

CAUTION Take heed that the O-ring is fitted exactly into the

work at the dosing head, connections or lines!

valve seat with round pliers.

provided groove.

V6.0

CAUTION Observe the flow direction (indicated by an arrow)!

Tighten the valves only by hand. Danger of damage!

33

Page 34

9.4 Exchanging the Diaphragm

!

DMX model 226 en

WARNING Wear protective gloves and glasses when carrying out

work on the dosing head, connections or lines!

CAUTION Adjust the stroke length only while the pump is

running!

Danger of damage.

● While pump is running set the stroke length adjustment knob to 100%.

● Switch off pump and disconnect from power supply.

● Loosen the 6 dosing head screws.

● Remove the dosing head.

● Turn the fan blades until the diaphragm reaches the front dead center

(diaphragm detaches itself from diaphragm flange).

● Unscrew the diaphragm by manually turning it to the left.

● If necessary, place the O-ring, intermediate ring and support disk.

● Screw in the new diaphragm completely, then rotate back until the holes in

the diaphragm and flange coincide.

● Turn the fan blades until the diaphragm reaches the bottom dead center

(diaphragm is pulled onto the diaphragm flange).

● Place the dosing head carefully and tighten the screws crosswise.

Max. torque: 6 Nm.

● Deaerate the dosing pump and commission it.

CAUTION After initial start-up and after each diaphragm

exchange, tighten the fixing screws of the dosing

head:

After approx. 6 to 10 working hours or two

days, tighten the dosing head screws crosswise using

a torque wrench, torque 6 Nm.

34

15.720017-V6.0

Page 35

DMX model 226

A. Appendix Dosing Curves

en:

Q = flow rate

h = stroke length

V6.0

35

Page 36

DMX model 226

DMX 24-8 (50Hz) Q0 = 3bar

30

Q [l/h]

25

20

15

10

5

0

0 102030405060708090100

DMX 52-8 (50Hz) Q0 = 3bar

70

Q [l/h]

60

50

40

30

20

10

0

0 102030405060708090100

8bar

3bar

8bar

3bar

h [%]

h [%]

DMX 24-8 (60Hz) Q0 = 3bar

30

Q [l/h]

25

20

15

10

5

0

0 102030405060708090100

DMX 52-8 (60Hz) Q0 = 3bar

70

Q [l/h]

60

50

40

30

20

10

0

0 102030405060708090100

8bar

3bar

h [%]

8bar

3bar

h [%]

Q [l/h]

Q [l/h]

DMX 100-8 (50Hz) Q0 = 3bar

140

120

100

80

60

40

20

8bar

3bar

0

0 102030405060708090100

DMX 142-8 (50Hz) Q0 = 3bar

180

160

140

120

100

80

60

40

20

0

3bar

8bar

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 100-8 (60Hz) Q0 = 3bar

140

120

100

80

60

40

20

8bar

3bar

0

0 102030405060708090100

DMX 37-5 (50Hz) Q0 = 3bar

50

45

40

35

30

25

20

15

10

5

0

1,5bar

4bar

0 102030405060708090100

h [%]

h [%]

36

15.720017-V6.0

Page 37

DMX model 226

Q [l/h]

Q [l/h]

DMX 37-5 (60Hz) Q0 = 3bar

50

45

40

35

30

25

20

15

10

5

1,5bar

4bar

0

0 102030405060708090100

DMX 82-5 (60Hz) Q0 = 3bar

120

100

80

60

40

20

1,5bar

4bar

0

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 82-5 (50Hz) Q0 = 3bar

120

100

80

60

40

20

1,5bar

4bar

0

0 102030405060708090100

DMX 160-5 (50Hz) Q0 = 3bar

200

160

120

80

40

0

1,5bar

4bar

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 160-5 (60Hz) Q0 = 3bar

200

160

120

80

40

1,5b ar

4bar

0

0 102030405060708090100

DMX 60-3 (50Hz) Q0 = 3bar

100

90

80

70

60

50

40

30

20

10

1,5bar

3bar

0

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 224-5 (50Hz) Q0 = 3bar

300

200

100

1,5bar

4bar

0

0 102030405060708090100

DMX 60-3 (50Hz) Q0 = 3bar

100

90

80

70

60

50

40

30

20

10

1,5b ar

3bar

0

0 102030405060708090100

h [%]

h [%]

V6.0

37

Page 38

DMX model 226

Q [l/h]

Q [l/h]

DMX 130-3 (50Hz) Q0 = 3bar

180

160

140

120

100

80

60

40

20

1,5b ar

3bar

0

0 102030405060708090100

DMX 255-3 (50Hz) Q0 = 3bar

350

300

250

200

150

100

50

1,5bar

3bar

0

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 130-3 (60Hz) Q0 = 3bar

180

160

140

120

100

80

60

40

20

p = 1,5bar

p = 3bar

0

0 102030405060708090100

DMX 255-3 (60Hz) Q0 = 3bar

350

300

250

200

150

100

50

1,5b ar

3bar

0

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 380-3 (50Hz) Q0 = 3bar

400

300

200

100

1,5bar

3bar

0

0 102030405060708090100

DMX 67-10 (60Hz) Q0 = 3bar

100

80

60

40

20

1,5bar

4bar

0

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 67-10 (50Hz) Q0 = 3bar

100

80

60

40

20

3bar

10bar

0

0 102030405060708090100

DMX 132-10 (50Hz) Q0 = 3bar

180

160

140

120

100

80

60

40

20

3bar

10bar

0

0 102030405060708090100

h [%]

h [%]

38

15.720017-V6.0

Page 39

DMX model 226

180

Q [l/h]

160

140

120

100

80

60

40

20

0

0 102030405060708090100

280

Q [l/h]

240

200

160

120

80

40

0

0 102030405060708090100

DMX 132-10 (60Hz) Q0 = 3bar

DMX 199-8 (50Hz) Q0 = 3bar

10bar

3bar

3bar

6bar

8bar

h [%]

h [%]

Q [l/h]

Q [l/h]

Q [l/h]

Q [l/h]

Q [l/h]

DMX 280-8 (50Hz) Q0 = 3bar

DMX 95-8 (50Hz) Q0 = 3bar

DMX 199-8 (60Hz) Q0 = 3bar

DMX 190-10 (50Hz) Q0 = 3bar

DMX 199-8 (50Hz) Q0 = 3bar

220

360

140

280

280

200

320

120

180

240

240

280

160

100

200

240

200

140

80

200

120

160

160

100

160

60

120

120

80

120

40

60

80

80

80

40

20

40

40

40

20

0

0

0

0

0

0 102030405060708090100

0 102030405060708090100

0 102030405060708090100

0 102030405060708090100

0 102030405060708090100

Q [l/h]

140

120

100

80

60

40

20

0

DMX 95-8 (60Hz) Q0 = 3bar

6bar

6bar

3bar

3bar

6bar

3bar

3bar

10bar

6bar

3bar

8bar

8bar

8bar

8bar

1,5bar

0 102030405060708090100

h [%]

h [%]

h [%]

h [%]

h [%]

3bar

6bar

8bar

h [%]

V6.0

39

Page 40

DMX model 226

Q [l/h]

Q [l/h]

DMX 280-6 (50Hz) Q0 = 3bar

360

320

280

240

200

160

120

80

40

6bar

3bar

0

0 102030405060708090100

DMX 152-6 (60Hz) Q0 = 3bar

220

200

180

160

140

120

100

80

60

40

20

0

3bar

1,5bar

6bar

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 152-6 (50Hz) Q0 = 3bar

180

160

140

120

100

80

60

40

20

3bar

6bar

1,5bar

0

0 102030405060708090100

DMX 321-6 (50Hz) Q0 = 3bar

500

400

300

200

100

3bar

6bar

0

0 102030405060708090100

h [%]

h [%]

Q [l/h]

DMX 321-6 (60Hz) Q0 = 3bar

500

400

300

200

100

3bar

6bar

0

0 102030405060708090100

h [%]

DMX 321-4 (50Hz) Q0 = 3bar

500

Q [l/h]

400

300

200

100

0

0 102030405060708090100

DMX 460-6 (50Hz) Q0 = 3bar

600

Q [l/h]

500

400

300

200

100

0

0 102030405060708090100

3bar

h [%]

6bar

3bar

h [%]

40

15.720017-V6.0

Page 41

DMX model 226

600

Q [l/h]

500

400

300

200

100

Q [l/h]

DMX 460-3,5 (50Hz) Q0 = 3bar

3bar

0

0 102030405060708090100

h [%]

DMX 249-3 (60Hz) Q0 = 3bar

320

280

240

200

160

120

80

40

3bar

1,5bar

0

0 102030405060708090100

h [%]

Q [l/h]

Q [l/h]

DMX 249-3 (50Hz) Q0 = 3bar

320

280

240

200

160

120

80

40

3bar

1,5bar

0

0 102030405060708090100

DMX 315-3 (50Hz) Q0 = 3bar

500

400

300

200

100

3bar

1,5bar

0

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 315-3 (60Hz) Q0 = 3bar

500

400

300

200

100

3bar

1,5bar

0

0 102030405060708090100

DMX 525-3 (60Hz) Q0 = 3bar

800

600

400

200

3bar

1,5bar

0

0 102030405060708090100

h [%]

h [%]

Q [l/h]

Q [l/h]

DMX 525-3 (50Hz) Q0 = 3bar

800

600

400

200