Grundfos DMX Series, DMX 1520-3, DMX 2000-3, DMX 860-5, DMX 1120-5 Installation And Operating Instructions Manual

...Page 1

Diaphragm Dosing Pump

DMX model 227

DMX 430-5 DMX 1120-5

DMX 770-3 DMX 1520-3

DMX 860-5 DMX 2000-3

Installation and operating instructions

15.720023-V3.0

Read this manual completely and keep it!

Subject to change.

Page 2

DMX model 227

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

Grundfos Alldos

Dosing & Disinfection

ALLDOS Oceania Pty. Ltd.

Unit 3 / 74 Murdoch Circuit

Acacia Ridge QLD 4100

Phone: +61 (0)7 3712 6888

Telefax: +61 (0)7 3272 5188

E-mail: alldos.au@alldos.com

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Canada Germany

GRUNDFOS Canada Inc. Grundfos Alldos

2941 Brighton Road Dosing & Disinfection

Oakville, Ontario ALLDOS Eichler GmbH

L6H 6C9 Reetzstraße 85

Phone: +1-905 829 9533 D-76327 Pfinztal (Söllingen)

Telefax: +1-905 829 9512 Tel.: +49 7240 61-0

China

Grundfos Alldos

Dosing & Disinfection

ALLDOS (Shanghai) Water Technology Co. GRUNDFOS GMBH

Ltd. Schlüterstr. 33

West Unit, 1 Floor, No. 2 Building (T 4-2) D-40699 Erkrath

278 Jinhu Road, Jin Qiao Export Process- Tel.: +49-(0) 211 929 69-0

ing Zone Telefax: +49-(0) 211 929 69-3799

Pudong New Area E-mail: infoservice@grundfos.de

Shanghai, 201206 Service in Deutschland:

Phone: +86 21 5055 1012 E-mail: kundendienst@grundfos.de

Telefax: +86 21 5032 0596

E-mail: alldos.cn@alldos.com

China

GRUNDFOS Pumps (Shanghai) Co. Ltd. P. O . Box 7 1

22 Floor, Xin Hua Lian Building GR-19002 Peania

755-775 Huai Hai Rd, (M) Phone: +0030-210-66 83 400

Shanghai 200020 Telefax: +0030-210-66 46 273

PRC

Phone: +86-512-67 61 11 80

Telefax: +86-512-67 61 81 67

Croatia

GRUNDFOS predstavništvo Zagreb

Cebini 37, Buzin

HR-10000 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

Czech Republic Hungary

GRUNDFOS s.r.o. GRUNDFOS Hungária Kft.

Čapkovského 21 Park u. 8

779 00 Olomouc H-2045 Törökbálint,

Phone: +420-585-716 111 Phone: +36-23 511 110

Telefax: +420-585-716 299 Telefax: +36-23 511 111

Telefax: +49 7240 61-177

E-mail: alldos.de@alldos.com

Germany

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

2

15.720023-V3.0

Page 3

DMX model 227

1

Belorussia

Представительство ГРУНДФОС в Минске

220090 Минск ул.Олешева 14

Телеф он: (8632) 62-40-49

Факс: (8632) 62-40-49

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Paromlinska br. 16,

BiH-71000 Sarajevo

Phone: +387 33 713290

Telefax: +387 33 231795

Brazil

GRUNDFOS do Brasil Ltda.

Rua Tomazina 106

CEP 83325 - 040

Pinhais - PR

Phone: +55-41 668 3555

Telefax: +55-41 668 3554

Bulgaria

GRUNDFOS Pumpen Vertrieb

Representative Office - Bulgaria

Bulgaria, 1421 Sofia

Lozenetz District

105-107 Arsenalski blvd.

Phone: +359 2963 3820, 2963 5653

Telefax: +359 2963 1305

Estonia India

GRUNDFOS Pumps Eesti OÜ GRUNDFOS Pumps India Private Limited

Peterburi tee 44 118 Old Mahabalipuram Road

11415 Tallinn Thoraipakkam

Tel: + 372 606 1690 Chamiers Road

Fax: + 372 606 1691 Chennai 600 096

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11 PT GRUNDFOS Pompa

FIN-01730 Vantaa Jl. Rawa Su mur I II, B lok I II / CC -1

Phone: +358-3066 5650 Kawasan Industri, Pulogadung

Telefax: +358-3066 56550 Jakarta 13930

France

Grundfos Alldos

Dosing & Disinfection

ALLDOS S.A.R.L. GRUNDFOS (Ireland) Ltd.

7, rue Gutenberg Unit A, Merrywell Business Park

F-67610 La Wantzenau Ballymount Road Lower

Tél.: +33-3 88 59 26 26 Dublin 12

Télécopie: +33-3 88 59 26 00 Phone: +353-1-4089 800

E-mail : alldos.fr@alldos.com Telefax: +353-1-4089 830

France Italy

Pompes GRUNDFOS Distribution S.A. GRUNDFOS Pompe Italia S.r.l.

Parc d’Activités de Chesnes Via Gran Sasso 4

57, rue de Malacombe I-20060 Truccazzano (Milano)

F-38290 St. Quentin Fallavier (Lyon) Tel.: +39-02-95838112

Tél.: +33-4 74 82 15 15 Telefax: +39-02-95309290 / 95838461

Télécopie: +33-4 74 94 10 51

Phone: +91-44 2496 6800

Indonesia

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

Japan

GRUNDFOS Pumps K.K.

1-2-3, Shin Miyakoda

Hamamatsu City

Shizuoka pref. 431-21

Phone: +81-53-428 4760

Telefax: +81-53-484 1014

3V3.0

Page 4

Korea Portugal Switzerland

GRUNDFOS Pumps Korea Ltd. Bombas GRUNDFOS Portugal, S.A. GRUNDFOS Pumpen AG

6th Floor, Aju Building 679-5 Rua Calvet de Magalhães, 241 Bruggacherstrasse 10

Yeoksam-dong, Kangnam-ku, 135-916 Apartado 1079 CH-8117 Fällanden/ZH

Seoul, Korea P-2770-153 Paço de Arcos Tel.: +41-1-806 8111

Phone: +82-2-5317 600 Tel.: +351-21-440 76 00 Telefax: +41-1-806 8115

Telefax: +82-2-5633 725 Telefax: +351-21-440 76 90

Latvia România

SIA GRUNDFOS Pumps Latvia GRUNDFOS Pompe România SRL 7 Floor, 219 Min-Chuan Road

Deglava biznesa centrs Bd. Biruintei, nr 103 Taichung, Taiwan, R.O.C.

Augusta Deglava ielā 60, LV-1035, Rīga, Pantelimon county Ilfov Phone: +886-4-2305 0868

Tālr.: + 371 714 9640, 7 149 641 Phone: +40 21 200 4100 Telefax: +886-4-2305 0878

Fakss: + 371 914 9646 Telefax: +40 21 200 4101

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6 ООО Грундфо с Bangna, Phrakanong

LT-03201 Vilnius Россия, 109544 Москва, Школьная 39 Bangkok 10260

Tel: + 370 52 395 430 Тел. (+7) 095 737 30 00, 564 88 00 Phone: +66-2-744 1785 ... 91

Fax: + 370 52 395 431 Факс (+7) 095 737 75 36, 564 88 11 Telefax: +66-2-744 1775 ... 6

Malaysia Turkey

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25 GRUNDFOS Predstavništvo Beograd Gebze Organize Sanayi Bölgesi

Glenmarie Industrial Park Dr. Milutina Ivkovića 2a/29 Ihsan dede Caddesi,

40150 Shah Alam YU-11000 Beograd 2. yol 200. Sokak No. 204

Selangor Phone: +381 11 26 47 877 / 11 26 47 496 41490 Gebze/ Kocaeli

Phone: +60-3-5569 2922 Telefax: +381 11 26 48 340 Phone: +90 - 262-679 7979

Telefax: +60-3-5569 2866 Telefax: +90 - 262-679 7905

México

Bombas GRUNDFOS de México S.A. de 24 Tuas West Roa d

C.V. Jurong Town ТОВ ГРУНДФОС Укра ина

Boulevard TLC No. 15 Singapore 638381 ул. Владимирская, 71, оф. 45

Parque Industrial Stiva Aeropuerto Phone: +65-6865 1222 г. Киев, 01033, Украи на,

Apodaca, N.L. 66600 Telefax: +65-6861 8402 Тел. +380 44 289 4050

Phone: +52-81-8144 4000 Факс +380 44 289 4139

Telefax: +52-81-8144 4010

E-mail: romania@grundfos.ro

Russia

E-mail grundfos.moscow@grundfos.com

Serbia

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

Thailand

GRUNDFOS (Thailand) Ltd.

947/168 Moo 12, Bangna-Trad Rd., K.M. 3,

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

E-mail: satis@grundfos.com

Ukraine

DMX model 227

4

15.720023-V3.0

Page 5

DMX model

0

Netherlands

Grundfos Alldos Podružnica Ljubljana P.O. Box 16768

Dosing & Disinfection Blatnica 1, SI-1236 Trzin Jebel Ali Free Zone

ALLDOS BV Phone: +386 1 563 5338 Dubai

Leerlooiersstraat 6 Telefax: +386 1 563 2098 Phone: +971-4- 8815 166

NL-8601 WK Sneek E-mail: slovenia@grundfos.si Telefax: +971-4-8815 136

Tel.: +31-51 54 25 789

Telefax: +31-51 54 30 550

E-mail: alldos.nl@alldos.com

Netherlands

GRUNDFOS Nederland B.V.

Postbus 104

NL-1380 AC Weesp

Tel.: +31-294-492 211

Telefax: +31-294-492244/492299

New Zealand

GRUNDFOS Pumps NZ Ltd. Camino de la Fuentecilla, s/n GRUNDFOS Pumps Ltd.

17 Beatrice Tinsley Crescent E-28110 Algete (Madrid) Grovebury Road

North Harbour Industrial Estate Tel.: +34-91-848 8800 Leighton Buzzard/Beds. LU7 8TL

Albany, Auckland Telefax: +34-91-628 0465 Phone: +44-1525-850000

Phone: +64-9-415 3240 Telefax: +44-1525-850011

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S 431 90 Mölndal 17100 West 118th Terrace

Strømsveien 344 Tel.: +46-0771-32 23 00 Olathe, Kansas 66061

Postboks 235, Leirdal Telefax: +46-31 331 94 60 Phone: +1-913-227-3400

N-1011 Oslo Telefax: +1-913-227-3500

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

ne: (+48-61) 650 13 00

Pho

elefax: (+48-61) 650 13 50

T

Addresses revised 15.01.2007

Slovenia

GRUNDFOS PUMPEN VERTRIEB

Ges.m.b.H., GRUNDFOS Gulf Distribution

South Africa United Kingdom

Grundfos Alldos Grundfos Alldos

Dosing & Disinfection Dosing & Disinfection

ALLDOS (Pty) LTD ALLDOS Ltd.

98 Matroosberg Road, Waterkloof Park 39 Gravelly Industrial Park, Tyburn Road

P.O. Box 36505, Menlo Park 0102 Birmingham B24 8TG

0181 ZA Pretoria Phone: +44-121-3283336

E-mail: alldos.za@alldos.com Telefax: +44-121-3284332

Spain

Bombas GRUNDFOS España S.A.

Sweden

GRUNDFOS AB

Lunnagårdsgatan 6 GRUNDFOS Pumps Corporation

Switzerland

Grundfos Alldos

Dosing & Disinfection Представит ельство ГРУНДФОС в

ALLDOS International AG Ташкенте

Schönmattstraße 4 700000 Ташке нт ул.Ус ман а Носира 1-й

CH-4153 Reinach тупик 5

Tel.: +41-61-717 5555 Телефон: (3712) 55-68-15

Telefax: +41-61-717 5500

E-mail: alldos.ch@alldos.com

United Arab Emirates

E-mail: alldos.uk@alldos.c om

United Kingdom

U.S.A.

Usbekistan

Факс: (3712) 53-36-35

5V3.0

Page 6

Type key

(Cannot be used for pump configuration.)

DMX model 227

6

15.720023-V3.0

Page 7

DMX model 227

Example: DMX 2000 -3 D -PP /E /PP -X -J 2 TT X E0

Type range DMX...

Maximum flow [l/h]

Maximum pres sur e [bar]

Control variant Code

without D

Dosing head variant Code

Polypropylene PP

Polyv inyl chloride PV C

Stainless steel SS

PP + integrated diaphragm PP-L

leakage detection

PVC + integrated dia- PVC-L

phragm leakage dete ct ion

SS + integrated diaphragm SS-L

leakage detection

Gasket materi al Code

EPDM (ethylene propylene E

diene monomer )

FKM (fluorocarbon) V

Code Moto r vari ant

E0 3-phase PTC 400 V

for frequency cont ro l

E6 3-phase PTC 400 V

with frequency control

Code Mains plug

X No plug

Code Connection,

suction/discharge

R Flange, DN 65, with

connecto r fo r PV C pi pe ,

65/75 mm

T Flang e, DN 65 , with

connector for PP pipe,

65/75 mm

U Flange, DN 65, with

connector for SS pipe,

65/75 mm

Y Flange, DN 65

Z Flange, ANSI, 2 1/2"

Code Valve type

2 Spring-loaded

0,1 bar suction,

0,1 bar discharge

Valve ball material Code

Polypropylene PP

Polyv inyl chlorid e PVC

Stainless steel SS

Contro l pa n e l po s iti o n Code

no control panel X

Code Supply voltage

0 Without motor (flange for

single head: IEC BG90 B14

duplex head:

IEC BG100 B14)

F Without motor,

NEMA flange 145 C (US )

J 220-240 V / 380- 420 V,

50/60Hz

7V3.0

Page 8

Content

DMX model 227

Installationdata ................................................................................................10

Installation diagram ........................................................................................10

1 Of General Interest ................................................................................11

1.1 In General ................................................................................................ 11

1.2 Using this Paper ...................................................................................... 11

1.3 Warranty .................................................................................................. 11

2 Safety Instructions ................................................................................12

2.1 Application of the Product ....................................................................... 12

2.2 Obligations of the Operating Authority .................................................... 12

2.3 Averting Dangers .................................................................................... 12

3 Technical Data .......................................................................................13

3.1 Pump Types ............................................................................................. 13

3.2 Ambient and Operating Conditions ........................................................ 13

3.3 Dosing medium ....................................................................................... 13

3.3.1 Admissible temperature of dosing liquids ................................... 13

3.3.2 Maximum permissible viscosity ................................................... 14

3.4 Pump Performance.................................................................................. 14

3.4.1 Accuracy ......................................................................................... 14

3.4.2 Performance ................................................................................. 14

3.5 Suction heights........................................................................................ 15

3.5.1 Media with a viscosity similar to water ........................................ 15

3.5.2 Suction heights for media with maximum permissible viscosity . 15

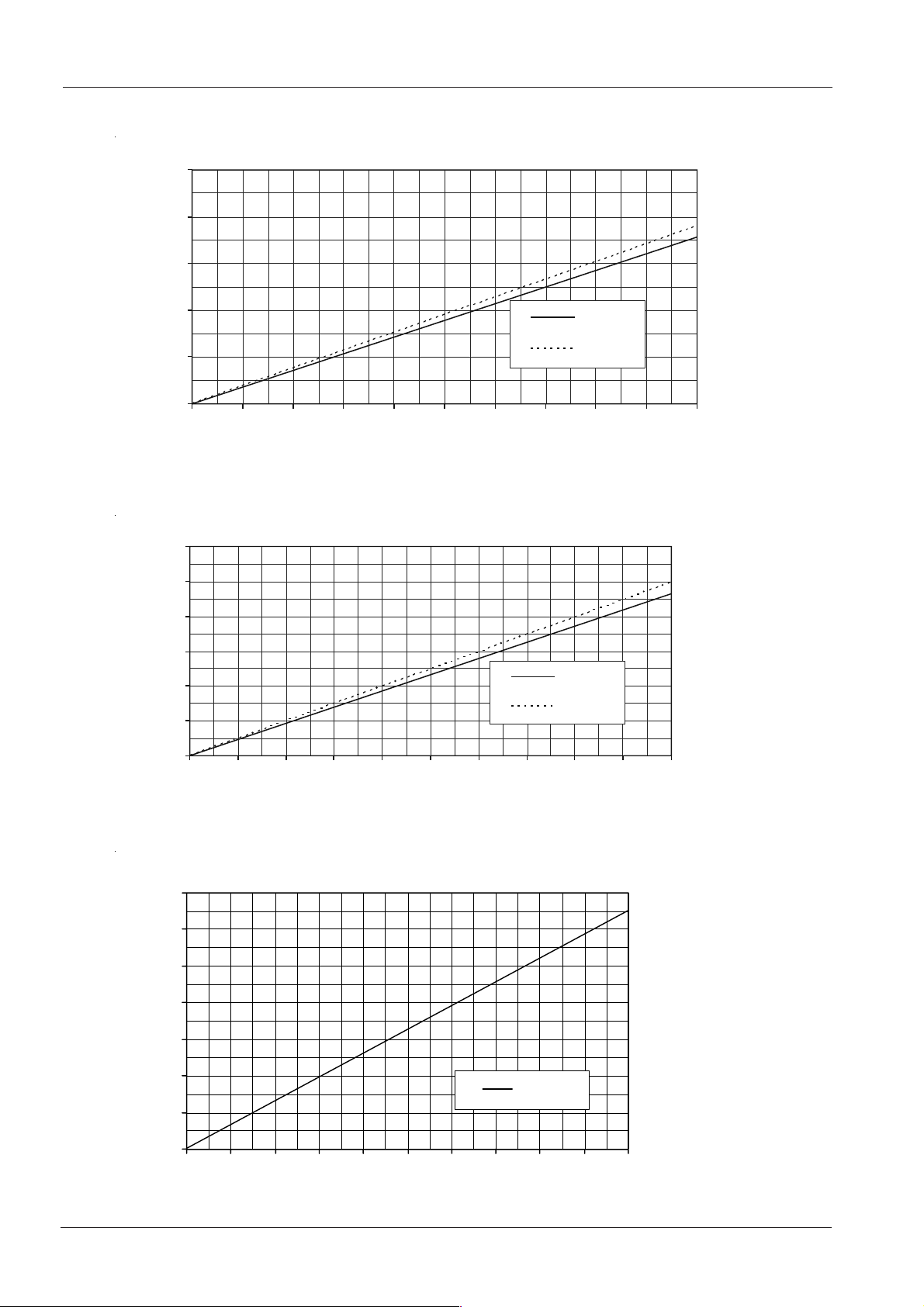

3.6 Dosing Curves ........................................................................................ 15

3.7 Weight ..................................................................................................... 15

3.8 Materials.................................................................................................. 15

3.9 Dimensional Drawing ............................................................................. 16

4 Installation .............................................................................................17

4.1 Installation Information ............................................................................ 17

4.2 Transport and Storage ............................................................................ 19

4.3 Mounting ................................................................................................. 19

4.4 Connecting the Suction and Pressure Lines .......................................... 19

4.5 Electrical Connections ............................................................................ 20

4.5.1 Connect the motor ....................................................................... 20

5 Commissioning .....................................................................................21

5.1 Inspections before Commissioning ........................................................ 21

5.2 Commissioning ....................................................................................... 21

6 Operation ...............................................................................................22

6.1 Description of the Device ........................................................................ 22

8

15.720023-V3.0

Page 9

DMX model 227

6.2 Principle of function ................................................................................. 23

6.3 Switching on / off ..................................................................................... 23

6.3.1 Switching on ................................................................................ 23

6.3.2 Switching off................................................................................. 23

6.4 Adjustment of dosing rate using frequency converter ............................ 23

23

6.5 Possible Failures ..................................................................................... 24

7 Electronics Diaphragm Breakage Sensor ............................................ 25

7.1 Technical Data of the Electronics............................................................ 25

7.2 Dimensional Drawing (Electronics Enclosure)....................................... 25

7.2 Function................................................................................................... 25

7.2.1 Pumps prepared for a diaphragm breakage indication .............. 25

7.2.2 Using the Contacts ...................................................................... 26

7.2.3 Description of the Device............................................................. 26

7.3 Electrical Connections of the Electronics ............................................... 26

7.3.1 Relay Outputs .............................................................................. 27

7.4 Screwing the Sensor into the Dosing Head ........................................... 28

7.5 Commissioning ....................................................................................... 28

7.6 Maintenance ........................................................................................... 29

8 Maintenance ..........................................................................................30

8.1 Rates for cleaning and maintenance...................................................... 30

8.2 Gear oil change....................................................................................... 30

8.3 Cleaning the Suction and Pressure Valves ............................................ 31

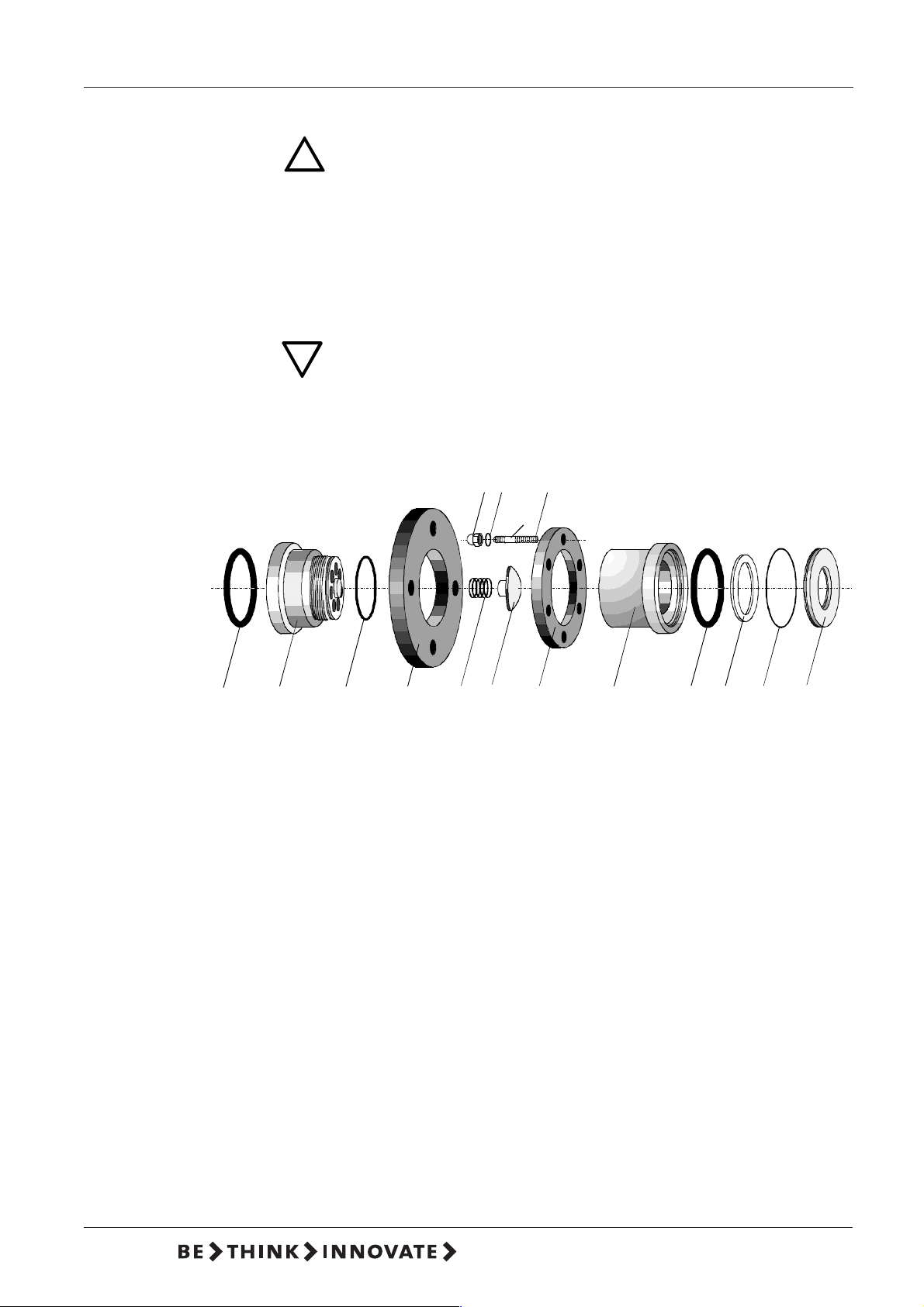

8.4 Exchanging the Diaphragm .................................................................... 32

A. Appendix: Dosing Curves for DMX model 227 .....................................33

9V3.0

Page 10

Installationdata

GRUNDFOS customer No.:

Order No. of unit:

Serial No. of unit:

Put into service on:

DMX model 227

NOTE Please fill in this form following commissioning. It will

help you and your GRUNDFOS servicing partner to

adjust the unit during subsequent corrections.

Owner:

Contract No.:

Location of unit:

Used for:

Installation diagram

10 15.720023-V3.0

Page 11

DMX model 227

1 Of General Interest

1. 1 In General

1.2 Using this Paper

This operation manual contains all information for safe operation of the described

product.

If you require further information or if any problems arise which are not reflected

in detail in this manual, contact Grundfos directly for the information needed.

❏ Descriptions are written as plain text.

❏ Lists are indicated by squares (❏), sublists by dashes (-).

❏ Operation steps are indicated by bullets (●), substeps by small bullets (•).

❏ Cross-references are indicated by

❏ The headings

meaning:

WARNING Danger of injuries and accidents!

WARNING, CAUTION

italic letters

and

NOTE

and an arrow (➜).

have the following

!

1.3 Warranty

CAUTION Danger of incorrect operation or damage to the product!

NOTE There is an exceptional feature.

Warranty in accordance with our general terms of sale and delivery shall only be

valid, if

❏ the product is used according to the information within this paper,

❏ the product is not being opened or used improperly,

❏ maintenance and repair is implemented exclusively by authorized and

qualified personnel,

❏ original spare parts are used for repairs.

11V3.0

Page 12

2 Safety Instructions

2.1 Application of the Product

The dosing pump described here is suitable for dosing liquid, non-abrasive and

non-inflammable media strictly complying with the instructions of this manual.

The dosing pumps model 227 are not certified according to the guideline

94/9/EC. The application of these pumps in explosive operational facilities according

to the guideline 94/9/EC is therefore not permitted.

WARNING Other applications are not intended and are not

!

2.2 Obligations of the Operating Authority

The operating authority of the plant is responsible for

❏ instructing the operation personnel

❏ arranging regular maintenance

2.3 Averting Dangers

DMX model 227

permitted. Grundfos accept no responsibility for

damages caused by unintended use.

WARNING When dosing dangerous media, observe the

!

corresponding safety precautions!

Wear protective gloves and glasses when executing

work at the dosing head, connections or lines!

Only use the prescribed line types!

Do not open the pump!

Repair only by authorized personnel!

12 15.720023-V3.0

Page 13

DMX model 227

3 Technical Data

3.1 Pump Types

Order No.

Simple pump Double pump Simple pump Double pump

DMX 430-5 DMX 430-5/430-5

DMX 860-5 DMX 860-5/860-5

DMX 1120-5 DMX 1120-5/1120-5

DMX 770-3 DMX 770-3/770-3

DMX 1520-3 DMX 1520-3/1520-3

DMX 2000-3 DMX 2000-3/2000-3

3.2 Ambient and Operating Conditions

Admissible ambient temperature

Admissible storage temperature

Admissible humidity

Noise level

Minimum counterpressure

Maximum pressure suction side

0 °C to +40 °C

-20 °C to + 70 °C

rel. humidity: 95% (not condensing)

CAUTION Danger of malfunctioning or damage!

72 ± 5 dB (A), testing following DIN 45635-01-KL3

1 bar

These data refer to the pressure valve of the pump. Pressure losses along the way

to the injection point inclusively are not taken into account.

1 bar

Dosing

Motor

head size

1 256

2 457

Pumps with electronics are only suitable for indoor use!

Do not install outdoors!

1,5 kW 2, 2 kW

1,5 kW

2,2 kW

Stroke

volume [ml]

3.3 Dosing medium

The dosing medium must have the following basic characteristics:

- Liquid

- Non-abrasive

3.3.1 Admissible temperature of dosing liquids

Materials up to 10 bar

PVC

1.4571

PP

1)

CAUTION Observe freezing and boiling point of the medium!

1)

-10 °C - 70 °C

0 °C - 40 °C

For SIP/CIP applications 145 °C are admissible for a short time

(approx. 15 min) at < 2 bar .

0 °C - 40 °C

13V3.0

Page 14

3.3.2 Maximum permissible viscosity

DMX model 227

3.4 Pump Performance

3.4.1 Accuracy

Dosing flow fluctuation

3.4.2 Performance

Simple

pump

Double

pump

DMX 430-5 DMX 430-5/430-5

DMX 860-5 DMX 860-5/860-5

DMX 1120-5 DMX 1120-5/1120-5

DMX 770-3 DMX 770-3/770-3

DMX 1520-3 DMX 1520-3/1520-3

DMX 2000-3 DMX 2000-3/2000-3

< ± 2 % within the control range 1:10

These data refer to:

- dosing medium water

- fully deaerated dosing head

- standard version of pump

The data in the following table refer to:

- maximum counterpressure

- dosing medium water

- flooded suction 0.5 m w. c.

- fully deaerated dosing head

- three-phase 400 V motor

Dosing

head

size

1

2

Viscosity

[mPas]

50 Hz 60 Hz

1000 800

800 400

400 200

800 400

400 200

200 100

Simple pump

DMX 430-5

DMX 860-5

DMX 1120-5

DMX 770-3

DMX 1520-3

DMX 2000-3

Double pump

DM X 430 -5/ 43 0- 5

DM X 860 -5/ 86 0- 5

DMX 1120-5/1 120-5

DM X 770 -3/ 77 0- 3

DMX 1520-3/1520-3

DMX 2000-3/2000-3

*) maximum counterpressure

Dosing

head size

p max *

[bar] [psi] [l/h] [H/min] [l/h] [gal/h ] [H /m in ] [l/h] [g a l/h] [H/min]

50 Hz 60 Hz

Q Strokes Strokes Strokes

430 28 516 136 34 860 227 56

1

573

860 56 1032 273 67 1720 454 112

1120 73 1344 355 88 2240 592 146

770 28 924 244 34 1540 407 56

2

344

1520 56 1824 482 67 3040 803 1 12

2000 73 2400 634 88 4000 1057 146

Dosing

head size

p max *

[bar] [psi] [l/h] [H/min] [l/h] [gal/h ] [H /m in ] [l/h] [gal/h] [H/m in ]

50 Hz

Q Strokes Strokes Strokes

860 63 1032 273 76 1720 454 126

1

573

1720 120 2064 545 144 3440 909 240

2240 168 2688 710 202 4480 1184 336

1540 63 1848 488 76 3080 814 126

2

344

3040 120 3648 964 144 6080 1606 240

4000 168 4800 1268 202 8000 2114 336

1) Operation with frequency converter

100 Hz

QQ

60 Hz

100 Hz

QQ

1)

1)

14 15.720023-V3.0

Page 15

DMX model 227

3.5 Suction heights

Data in m w. c.

these data refer to:

- not degassing and not abrasive media

- Newtonian liquids

- temperature of 20 °C

- standard version

3.5.1 Media with a viscosity similar to water

maximum suction height: 3 m w. c.

3.5.2 Suction heights for media with maximum permissible viscosity

Flooded suction 1-3 m

3.6 Dosing Curves

see "Appendix Dosing Curves"

The dosing curves shown in "'Appendix Dosing Curves" are trend curves

They refer to:

❏ Performance of single pump

(the flow rate is doubled for the double pump)

❏ Water as the dosing medium

❏ Zero point of the dosing pump at a counterpressure of 3 bar

❏ Standard version of pump

Q = flow rate

f = drive frequency

3.7 Weight

3.8 Materials

Pump housing

diaphragm flange

Housing

Simple pump Weight Double pump Weight

DMX 430-5 DMX 2000-3

Pump

Al 226

GG 25

Opto-electronic diaphragm monitoring

ABS

Approx. 50 kg

DMX 4 30-5/430-5 -

DMX 2000-3/2000-3

Approx. 90 kg

15V3.0

Page 16

3.9 Dimensional Drawing

ø185

ø140

DN65

C

d

DMX model 227

DMX model 227

57

555 (605*)

øe

f

b

ø17

ø9.5

ca. a

241

333

g

290

*) dimension with double pump

25

b

170

194.5

16 15.720023-V3.0

Page 17

DMX model 227

4 Installation

4. 1 Installation Information

Picture of optimal installation:

8

1 Dosing tank 502

2

9

7

2 Electric agitator 509

3 Extraction device 521

10

6

4 Suction pulsation damper 516

5 Dosing pump

6 Overflow valve 525

1

4

3

5

7 Pressure retention valve 525

8 Pulsation damper 517

9 Measuring glass

10 Injection unit 522

11

12

For easy deaeration of the pump:

● Install a ball valve (11) with bypass line (back to the dosing tank)

immediately behind the pressure valve

In case of long pressure lines:

● Install a check-back valve (12) into the dosing line.

● Keep the suction line as short as possible, avoid a tangled suction

line

• If necessary, use swept bends instead of elbows.

● Always lay the suction line rising to the suction valve of the dosing

pump.

• Avoid loops which cause air bubbles.

p

10

6

● For non-degassing media with viscosity similar to water, the pump

can be mounted onto the tank (observe the admissible suction

height). Preferably flooded suction.

For dosing media which tend to sedimentation:

● Install a suction line with filter (13) in a way ensuring that the suction

13

valve remains several centimetres a bove the botton of the tank.

6 Overflow valve

10 Injection unit

17V3.0

Page 18

DMX model 227

4

● In dosing systems that require a long suction line:

Provide a properly dimensioned pulsation damper (4) directly in front of the

suction valve of the dosing pump.

8

● Note for pressure side installation:

to protect the piping use pulsations damper (8) for rigid piping longer than

3m and tubing longer than 5m.

p

6

10

● For outgassing and viscous media: flooded suction

● To protect the dosing pump and the pressure line agains: excessive

development of pressure: Install an overflow valve (6) in the pressure line.

10 Injection unit

7

p≥ 2 bar

● With open outflow of the dosing medium or a counterpressure below 1 bar:

Install a pressure retention valve (7) directly in front of the outlet or the

injection unit.

A positive pressure difference of at least 1 bar has to exist between the

counterpressure at the injection point and the pressure of the dosing medium at the suction valve of the dosing pump. If this cannot be guaranteed:

• Install a pressure retention valve (7) in the pressure line

p

p2 - p

1

14

1 bar

1

_

>

To avoid the siphon effect:

p

2

● Install a pressure retention valve in the dosing line and, if necessary, a

solenoid valve (14) in the suction line.

18 15.720023-V3.0

Page 19

DMX model 227

4.2 Transport and Storage

● Handle with care, do not throw!

❏ Dry and cool storage place.

❏ Take heed of upright position of the dosing pump when storing it, so that

gear grease can not leak out.

CAUTION Observe permissible storing temperature!

4.3 Mounting

● Mount the pump horizontally on the tank or on a console.

4.4 Connecting the Suction and Pressure Lines

WARNING All lines must be stress-free!

!

● Depending on the material of the connection flanges (1) (mating flanges)

• Pipe and flange made of 1.4571 steel:

Weld the pipe in the blanking flange

• Pipe and flange made of PP:

Weld the pipe in the flange sleeve

• Pipe and flange made of PVC:

Adhere the pipe in the flange sleeve

Only use the prescribed line types!

❏ The internal diameter of the lines, adapters and connectors should not be

smaller than DN 65; if necessary, use bends instead of elbows.

❏ The suction lines must be designed such that cavitation is avoided.

IMPORTANT:

● Pulsation dampers should be fitted on both the suction and pressure

sides.

NOTE A positive pressure difference of 10 m water gauge is

required for correct operation of the dosing pump. If the

total of the back-pressure and the static difference in

height between the suction valve and the dosing point is

less than 10 m water gauge, a pressure maintenance

valve must be installed directly upstream of the dosing

point.

19V3.0

Page 20

DMX model 227

● Connect suction line to suction valve (A).

• Install the suction line in the solution tank such that the foot valve

remains approx. 10 cm above the bottom of the tank.

● Connect pressure line to pressure valve (B).

IMPORTANT:

● To protect the pump from excessively high pressures:

fit an appropriate overflow valve in the pressure line.

● Make sure that the valves are seated correctly

– position of valve disk (C)!

4. 5 Electrical Connections

4.5.1 Connect the motor

WARNING Prior to the mains connection check if the voltage

!

NOTE The pump is being switched by switching the mains

● Connect the motor according to the terminal connection diagram (stamped

in the clamp box).

CAUTION Observe the sense of rotation!

indicated on the type plate corresponds with the local

voltage!

Switch off mains before connecting!

No changes at the mains cable and the mains plug may

be done!

voltage.

Do not switch on the mains until the pump should be

started.

A motor protector, adjusted to nominal motor current,

must be installed by the customer.

For use with a frequency converter the jumpers in the

clamp box have to be set according to the converter

voltage.

In the state of delivery, the jumpers of 3-phase motors

are set for star connection.

20 15.720023-V3.0

Page 21

DMX model 227

5 Commissioning

5.1 Inspections before Commissioning

● Check the tightness of all connections. If necessary, retighten.

● Check the correctness of all electrical connections.

● Check if the voltage indicated on the type plate corresponds with the local

voltage!

5.2 Commissioning

CAUTION After initial start-up and after each diaphragm

Fill with gear oil

The pump has been tested in the factory, and the oil drained prior to shipping.

Before using, fill with the supplied special oil as follows:

● Switch off the pump.

● Unscrew the venting screw with oil dipstick.

● Slowly pour the supplied gear oil into the opening of the venting screw until

it reaches the mark on the dipstick.

- Gear oil for single pumps: 5.0 l

- Gear oil for dual pumps: 7.5 l

● Switch of the pump after approx. 10 minutes, check the oil level, and add

more if necessary.

● Refit the oil dipstick.

exchange, tighten the fixing screws of the dosing head:

After approx. 6 to 10 working hours or two days, tighten

the dosing head screws crosswise using a torque

wrench, torque 70-80 Nm.

Start the pump

● Switch on the power supply.

● Pumps with frequency converter: set dosing rate to 100%.

➜

See Operation Manual of frequency converter! See also chapter

Adjustment of dosing rate using frequency converter

● The pump is now ready for use.

21V3.0

Page 22

6 Operation

6.1 Description of the Device

DMX model 227

1 Motor

2 Frequency converter

3 Worm wheel

4 Eccentric

5 Tappet

6 Support disk

7 Dosing diaphragm

8 Dosing head

9 Suction valve

10 Pressure valve

22 15.720023-V3.0

Page 23

DMX model 227

6.2 Principle of function

❏ Oscillating positive displacement pump with electric drive, mechanical

diaphragm deflection, and constant stroke length.

❏ Following reduction of the motor speed by a worm gear, the rotation of the

drive is converted into the suction and compression movement of the

diaphragm by means of an eccentric and tappet. A defined volume (stroke

volume) of the dosed medium is thus sucked into the dosing head via the

suction valve, and displaced into the dosing line by the pressure valve.

❏ The dosing rate can be adjusted in the range 1:10 if a frequency converter

is fitted.

6.3 Switching on / off

6.3.1 Switching on

● Switch on the mains power.

6.3.2 Switching off

● Switch off the mains power.

6.4 Adjustment of dosing rate using frequency converter

❏❏

❏ The dosing rate can only be adjusted in the range 1:10 if the frequency

❏❏

converter is fitted.Diaphragm Dosing Pump

➜

Refer to Operation Manual of the frequency converter!

WARNING Observe operating instructions of the manufacturer!

!

Settings in conjunction with GRUNDFOS dosing pumps

Please observe especially the following parameters of the frequency converter:

❏ P013 (maximum motor frequency):

Set to maximum 100 Hz.

Due to this setting, the maximum stroke frequency of the pump cannot be

exceeded.

❏ P086 (motor current limit):

Do not change the default setting (150%).

The motor is protected by a PTC resistor. Therefore, this parameter is not

necessary.

❏ P081 - P 085 (motor data)

Please set this parameters to the values indicated on the type plate of the

motor.

(➜

Observe operating instructions of the manufacturer.

Establish connections as being described there.

)

23V3.0

Page 24

6. 5 Possible Failures

Failure Cause Correction

Not connected to mains Connec t the mains line

Wrong mains voltage Replace the dosing pump

Dos ing pump does not run

Dos ing pu mp does not suck in

Dos ing pu mp does not dose

Dosing output of the pump

inaccurate

Electrical failure Return the dosing pump to the works for

repair

The diaphragm breakag e indicat ion has

responded.

Leaky su ction line Exchang e or seal the suction line

Cross-se ct ion of th e sucti on line too nar row

or or suction line too long

Clogged suction line Rinse or replace the suction lin e

Foot valve covered by sediment Suspend the suction line at a higher position

Crystal line depo sits in the valves Clean the valv es

Diaph ragm broken or di aphragm tappe t t orn

out

Dosing tank is empty Change the tank

Air in the suction line and dosing head Wait, until the pump has deaerated

Medi um too vi s c ous or density to o hig h Check t he installation

Crystal line depo sits in the valves Clean the valv es

Valves not correctly assembled A ss e mb le t he valve i nsi de parts in the rig ht

Injection point blocked Check a nd possibly corre ct the flow direction,

Inexpert installati on of line s and peripheral

equipment

Dosing head not fully deaerated Repeat deaeration

Degassing medium Check the installation

Valves p artially soile d or incr usted Clean the valves

Fluctuations o f back pressure Application of a pressure retention valve and a

Fluctuations o f suctio n height Keep the sucti on level c onstant

Siphon effect (admission pressure higher

than ba ck pr e ssu re)

Leaky or porous suction line or pressure line Replace the suction line or pressure line

Parts in contact with medi a not resistant Replace with resis tant mat erials

Dos ing diaphragm w orn ou t (incipient tear s) Replace the diaphragm , al so ob ser v e

Variation of the dosing medium (density,

viscosity)

Replace the diaphragm.

Check with speci fication of Grund fos

Exchange the diaphragm

order and check or possibly correct the flow

direction

or remove the occlusion

Check for perviousness and correct

installation

pulsati on damper

Install a pressure retention valve

main te nance instructi o ns

Exami n e th e co ncentration, possibly em pl oy

an agitator

DMX model 227

24 15.720023-V3.0

Page 25

DMX model 227

7 Electronics Diaphragm Breakage Sensor

7.1 Technical Data of the Electronics

Description

Model 230 V (+10% /-10%)

Model 115 V (+10% /-10%)

Contact load

Power consumption

Degree of protection

Permissible temperature range

250 V / 6 A, max. 550VA

1.15 VA

IP 65

0 - 40 °C

7.2 Dimensional Drawing (Electronics Enclosure)

80

63.5

130

113.5

7.2 Function

7.2.1 Pumps prepared for a diaphragm breakage indication

❏ Special dosing head flange for inserting the optoelectronic sensor

❏ Optoelectronic sensor, contains

- infrared sender

- infrared receiver

In case of a leaking diaphragm:

❏ Dosing liquid penetrates the dosing head flange.

- The light refraction will be changed.

❏ The sensor produces a signal.

- The electronics switches two contacts which can be used e. g. for

triggering an alarm device or switching off the pump.

25V3.0

Page 26

7.2.2 Using the Contacts

❏ Terminals 6 and 7 (potential-loaded):

- e. g. for switching off the dosing pump in case of a diaphragm breakage

➜

Observe Technical Information of the dosing pump!

❏ Terminals 8, 9 and 10 (potential-free):

- e. g. for triggering an alarm device

7.2.3 Description of the Device

There are two light-emitting diodes (LED) at the electronics.

❏ Green LED:

- Shows the readiness for operation of the system.

- It only lights when the sensor is connected to the electronics. If it does

not light in this case, either the sensor or the cable is defective or

wrongly connected.

❏ Red LED:

- Lights in case of a diaphragm breakage being detected.

- The green LED continues lighting.

7.3 Electrical Connections of the Electronics

DMX model 227

WARNING Electrical connections only by qualified personnel!

!

CAUTION Before connecting the power supply cable:

● Connect the device to the mains according to the connection chart.

● Connect the electronics with the sensor according to the connection chart.

Switch off mains before connecting!

Observe the local safety regulations!

Protect the cable connections and plugs from corrosion

and moisture.

Check that the supply voltage specified on the rating

plate agrees with the local voltage. An incorrect power

supply could destroy the unit!

To guarantee electromagnetic compatibility (EMC):

The input cables and current output cables must be

shielded.

•

Connect shield at one end to PE.

➜

Refer to the connection diagram!

Route input cables, current output cables and power

supply cables in separate ducts.

WARNING The potential-loaded contact 1, terminals 6 and 7, is

!

CAUTION The contacts have no protective circuits. Only pure

● Connect contacts 1 and 2 according to individual needs.

Refer to Section "Electrical connections"

➜

26 15.720023-V3.0

loaded with mains voltage.

Switch off mains before connecting contact 1!

ohmic loads may be switched. For switching the pump

motor, a contactor has to be connected inbetween.

Page 27

DMX model 227

7.3.1 Relay Outputs

R

C

+

NOTE The relay output connection depends on the application

and the connected actuators.

Interference suppression is required for inductive loads (also relays and contactors).

If this is not possible, protect the relay contacts using a suppressor circuit as

described below.

❏ With AC voltage:

Current up to Capacitor C Resistor R

60 mA 10 nF 275 V 390 Ω 2 W

70 mA 47 nF 275 V 22 Ω 2 W

150 mA 100 nF 275 V 47 Ω 2 W

1.0 A 220 nF 275 V 47 Ω 2 W

❏ With DC voltage: connect freewheeling diode parallel to relay or contactor.

CAUTION Provide relay outputs on site with an appropriate

backup fuse!

-

1

K1

L

230 V AC /

115 V AC

NOTE These connections depend on the type of actuator

used, and should only be understood as guidelines.

➜

Refer to actuator documentation.

S1

1

1

1

1

1

1

K2

K3

K4

K5

K6

N

PE

PE

N

K7 K8 K9 K10

contakt 1

1

contakt 2 (float ing) sensor

(non-floating

230 V AC / 115 V AC)

S2

11

1

1 1

green yellow white

27V3.0

Page 28

7.4 Screwing the Sensor into the Dosing Head

● Screw in the sensor from the lower side into the hole of the dosing head

flange (M14 x 1.5).

❏ Now the diaphragm breakage indication is ready for start-up.

DMX model 227

7.5 Commissioning

CAUTION Carry out a functional check before commissioning!

Functional Check

● Dip the sensor into water

- Green LED and red LED are lighting:

Sensor and electronics are ready for operation!

- One or more LED do not light:

Sensor or electronics are defective!

• Call GRUNDFOS service.

● Carefully dry the senor.

- Only the green LED still lights:

Sensor and electronics are ready for operation!

- the red LED still lights:

Sensor or electronics are defective!

• Call GRUNDFOS service.

WARNING Do not open electronics or sensor!

!

Repair only by authorized qualified personnel.

28 15.720023-V3.0

Page 29

DMX model 227

7.6 Maintenance

WARNING Do not open electronics or sensor!

!

❏ Sensor

• Clean it in case of malfunction.

• If it still does not operate correctly:

Replace sensor.

❏ Electronics

- No maintenance possible by the user.

• If it does not operate correctly:

Call GRUNDFOS service.

Repair only by authorized qualified personnel.

29V3.0

Page 30

8 Maintenance

WARNING When dosing dangerous media, observe the

!

8.1 Rates for cleaning and maintenance

❏ Clean the diaphragm and valves, or replace if necessary:

❏ Regularly every 12 months or after 3000 operation hours, or

❏ in case of malfunction

Gear oil change:

❏ Regularly every 12 months

If the place of installation is dusty:

❏ Regularly every 3000 hours

DMX model 227

corresponding safety precautions!

Wear protective gloves and glasses when executing

work at the dosing head, connections or lines!

Do not open the pump!

Repair only by authorized personnel!

Switch off the pump and disconnect from mains before

doing maintenance and repair!

8.2 Gear oil change

WARNING The gear oil may only be changed by authorized,

!

To guarantee fault-free operation, it is recommendable to regularly renew the gear

oil.

CAUTION Use exclusively original gear oil.

qualified personnel.

When renewing the gear oil, check the dosing

diaphragm and replace if necessary, for safety

reasons.

30 15.720023-V3.0

Page 31

DMX model 227

8.3 Cleaning the Suction and Pressure Valves

WARNING Wear protective gloves and glasses when executing

!

● Loosen the cap nuts (8) on the flange (1).

● Remove the valve housing (2/9) and other parts of the valve.

● Remove the other internal parts (see assembly diagram) and clean, or

replace if necessary.

● Fit the valvetogether again according to the assembly diagram.

● Screw in the valve.

CAUTION Take heed that the O-ring is fitted exactly into the

work at the dosing head, connections or lines!

provided groove.

Observe the flow direction (indicated by an arrow)!

11

8

7

6 x

913101441

1 Flange

2 Valve housing

3 Valve seat

4 Valve disk

6 Double-end stud

7 Washer

8 Cap nut

9 Valve housing

10 Supporting ring

11 O-ring

12 O-ring

13 O-ring

14 Spring

15 Valve disk

6

211

15 12

3

31V3.0

Page 32

8.4 Exchanging the Diaphragm

!

DMX model 227

WARNING Wear protective gloves and glasses when carrying out

work on the dosing head, connections or lines!

● Loosen the 6 screws (2) on the dosing head (3).

● Remove the dosing head (3).

● Unscrew the diaphragm (1) to the left.

● Refit the retaining ring (4), shim ring (5), lip seal (7) and supporting ring (6),

replacing if necessary.

● Screw in the new diaphragm (1).

● Remove the ventilation hood of the motor, and rotate the fan blades until

the diaphragm reaches the rear dead point.

● Attach the dosing head (3), and tighten the screws (2) diagonally.

Max. torque 70-80 Nm.

● Vent the pump, and restart.

CAUTION After initial start-up and after each diaphragm

exchange, tighten the fixing screws of the dosing head:

After approx. 6 to 10 working hours or two days, tighten

the dosing head screws crosswise using a torque

wrench, torque 70-80 Nm.

7

2

3

5

6

1

4

32 15.720023-V3.0

Page 33

DMX model 227

A. Appendix: Dosing Curves for DMX model 227

The dosing curves shown here are trend curves

They refer to:

❏ Performance of single pump

(the flow rate is doubled for the double pump)

❏ Water as the dosing medium

❏ Zero point of the dosing pump at a counterpressure of 3 bar

❏ Standard version of pump

Q = flow rate

f = drive frequency

100

0

Q [l/h]

80

60

40

20

2.000

Q [l/h]

DMX 430-5

0

0

0

p = 5bar

0

p = 2bar

0

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

0

9

0

f [Hz]

10

0

DMX 77 0-3

1.500

1.000

500

0

0 102030405060708090100

p = 3bar

f [Hz]

33V3.0

Page 34

Q [l/h]

5

DMX model 227

DMX 860-5

2500

2000

1500

Q [l/h]

1000

500

0

0 102030405060708090100

p = 5bar

p = 2bar

DMX 1120 -

3000

2500

2000

1500

1000

500

0

0 102030405060708090100

p = 5bar

p = 2bar

f [Hz]

f [Hz]

DMX 1520-3

3.500

Q [l/h]

3.000

2.500

2.000

1.500

1.000

500

0

0 102030405060708090100

p = 3bar

f [Hz]

15.720023-V3.0

34

Page 35

DMX model 227

4.500

Q [l/h]

4.000

3.500

3.000

2.500

2.000

1.500

1.000

500

DMX 20 00-3

p = 3bar

0

0 102030405060708090100

f [Hz]

35V3.0

Page 36

DMX model 227

Declaration of Conformity

We Grundfos declare under our sole responsibility that the

products DMX model 227, to which this declaration relates, are in

conformity with the Council Directives on the approximation of the

laws of the EC Member States relating to

⎯ Machinery (98/37/EC).

Standards used: EN ISO 12100 and EN 809: 1998.

⎯ Electromagnetic compatibility (89/336/EEC).

Standards used:

EN 61000-3-11: 2000,

EN 61000-6-2: 2001 and

EN 61000-6-4: 2001.

⎯ Electrical equipment designed for use within certain voltage limits

(73/23/EEC) [95].

Standard used: EN 61010-1: 2002.

Konformitätserklärung

Wir Grundfos erklären in alleiniger Verantwortung, dass die

Produkte DMX Modell 227, auf die sich diese Erklärung

bezieht, mit den folgenden Richtlinien des Rates zur

Angleichung der Rechtsvorschriften der EG-Mitgliedstaaten

übereinstimmen:

⎯ Maschinen (98/37/EG).

Normen, die verwendet wurden: EN ISO 12100 und EN

809: 1998.

⎯ Elektromagnetische Verträglichkeit (89/336/EWG).

Normen, die verwendet wurden: EN 61000-3-11: 2000, EN

61000-6-2: 2001 und EN 61000-6-4: 2001.

⎯ Elektrische Betriebsmittel zur Verwendung innerhalb

bestimmter Spannungsgrenzen (73/23/EWG) [95].

Norm, die verwendet wurde: EN 61010-1: 2002.

Déclaration de Conformité

Nous Grundfos déclarons sous notre seule responsabilité que les

produits DMX modèle 227 auxquels se réfère cette déclaration sont

conformes aux Directives du Conseil concernant le rapprochement

des législations des Etats membres CE relatives à

⎯ Machines (98/37/CE).

Standards utilisés: EN ISO 12100 et EN 809: 1998.

⎯ Compatibilité électromagnétique (89/336/CEE).

Standards utilisés:

EN 61000-3-11: 2000,

EN 61000-6-2: 2001 et

EN 61000-6-4: 2001.

⎯ Matériel électrique destiné à employer dans certaines limites

de tension (73/23/CEE) [95].

Standard utilisé: EN 61010-1: 2002.

Dichiarazi on e di Conf ormità

Noi Grundfos dichiariamo sotto la nostra esclusiva

responsabilità che i prodotti DMX modello 227 ai quali questa

dichiarazione se riferisce sono conformi alle Direttive del

Consiglio concernente il ravvicinamento delle legislazioni degli

Stati membri CE relative a

⎯ Macchine (98/37/CE).

Standard usati: EN ISO 12100 e EN 809: 1998.

⎯ Compatibilità elettromagnetica (89/336/CEE).

Standard usati:

EN 61000-3-11: 2000,

EN 61000-6-2: 2001 e

EN 61000-6-4: 2001.

⎯ Materiale elettrico destinato ad essere utilizzato entro certi

limiti di tensione (73/23/CEE) [95].

Standard usato: EN 61010-1: 2002.

Bjerringbro, 15th May 2006

Jan Strandgaard

Technical Director

36

15.720023-V3.0

Page 37

Page 38

Page 39

Page 40

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

96681390 1107

Repl.

www.grundfos.com

en

Loading...

Loading...