Page 1

DMS, Variant B

GRUNDFOS INSTRUCTIONS

Installation and operating instructions

Page 2

GB Declaration of Conformity

We, Grundfos Alldos, declare under our sole responsibility that the

products DMS, to which this declaration relates, are in conformity with

these Council directives on the approximation of the laws of the EC

member states:

– Machinery Directive (2006/42/EC).

Standards used: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009

– Low Voltage Directive (2006/95/EC).

Standard used: EN 60204-1+A1: 2009.

– EMC Directive (2004/108/EC).

Standards used: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

DE Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung, dass die Produkte

DMS, auf die sich diese Erklärung bezieht, mit den folgenden Richtlinien

des Rates zur Angleichung der Rechtsvorschriften der EUMitgliedsstaaten übereinstimmen:

– Maschinenrichtlinie (2006/42/EG).

Normen, die verwendet wurden: EN 809: 1998, EN ISO 12100-1+A1:

2009, EN ISO 12100-2+A1: 2009.

– Niederspannungsrichtlinie (2006/95/EG).

Norm, die verwendet wurde: EN 60204-1+A1: 2009.

– EMV-Richtlinie (2004/108/EG).

Normen, die verwendet wurden: EN 61000-6-2: 2005,

EN 61000-6-4: 2007.

FR Déclaration de Conformité

Nous, Grundfos, déclarons sous notre seule responsabilité, que les

produits DMS, auxquels se réfère cette déclaration, sont conformes aux

Directives du Conseil concernant le rapprochement des législations des

Etats membres CE relatives aux normes énoncées ci-dessous :

– Directive Machines (2006/42/CE).

Normes utilisées : EN 809 : 1998, EN ISO 12100-1+A1 : 2009,

EN ISO 12100-2+A1 : 2009.

– Directive Basse Tension (2006/95/CE).

Norme utilisée : EN 60204-1+A1: 2009.

– Directive Compatibilité Electromagnétique CEM (2004/108/CE).

Normes utilisées : EN 61000-6-2: 2005, EN 61000-6-4: 2007.

IT Dichiarazione di Conformità

Grundfos dichiara sotto la sua esclusiva responsabilità che i prodotti

DMS, ai quali si riferisce questa dichiarazione, sono conformi alle

seguenti direttive del Consiglio riguardanti il riavvicinamento delle

legislazioni degli Stati membri CE:

– Direttiva Macchine (2006/42/CE).

Norme applicate: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Direttiva Bassa Tensione (2006/95/CE).

Norma applicata: EN 60204-1+A1: 2009.

– Direttiva EMC (2004/108/CE).

Norme applicate: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

ES Declaración de Conformidad

Nosotros, Grundfos, declaramos bajo nuestra entera responsabilidad

que los productos DMS, a los cuales se refiere esta declaración, están

conformes con las Directivas del Consejo en la aproximación de las

leyes de las Estados Miembros del EM:

– Directiva de Maquinaria (2006/42/CE).

Normas aplicadas: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Directiva de Baja Tensión (2006/95/CE).

Norma aplicada: EN 60204-1+A1: 2009.

– Directiva EMC (2004/108/CE).

Normas aplicadas: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

PT Declaração de Conformidade

A Grundfos declara sob sua única responsabilidade que os produtos

DMS, aos quais diz respeito esta declaração, estão em conformidade

com as seguintes Directivas do Conselho sobre a aproximação das

legislações dos Estados Membros da CE:

– Directiva Máquinas (2006/42/CE).

Normas utilizadas: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Directiva Baixa Tensão (2006/95/CE).

Norma utilizada: EN 60204-1+A1: 2009.

– Directiva EMC (compatibilidade electromagnética) (2004/108/CE).

Normas utilizadas: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

GR Δήλωση Συμμόρφωσης

Εμείς, η Grundfos, δηλώνουμε με αποκλειστικά δική μας ευθύνη ότι τα

προϊόντα DMS στα οποία αναφέρεται η παρούσα δήλωση,

συμμορφώνονται με τις εξής Οδηγίες του Συμβουλίου περί προσέγγισης

των νομοθεσιών των κρατών μελών της ΕΕ:

– Οδηγία για μηχανήματα (2006/42/EC).

Πρότυπα που χρησιμοποιήθηκαν: EN 809: 1998,

EN ISO 12100-1+A1: 2009, EN ISO 12100-2+A1: 2009.

– Οδηγία χαμηλής τάσης (2006/95/EC).

Πρότυπο που χρησιμοποιήθηκε: EN 60204-1+A1: 2009.

– Οδηγία Ηλεκτρομαγνητικής Συμβατότητας (EMC) (2004/108/EC).

Πρότυπα

που χρησιμοποιήθηκαν: EN 61000-6-2: 2005,

EN 61000-6-4: 2007.

NL Overeenkomstigheidsverklaring

Wij, Grundfos, verklaren geheel onder eigen verantwoordelijkheid dat

de producten DMS waarop deze verklaring betrekking heeft, in

overeenstemming zijn met de Richtlijnen van de Raad in zake de

onderlinge aanpassing van de wetgeving van de EG Lidstaten

betreffende:

– Machine Richtlijn (2006/42/EC).

Gebruikte normen: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Laagspannings Richtlijn (2006/95/EC).

Gebruikte norm: EN 60204-1+A1: 2009.

– EMC Richtlijn (2004/108/EC).

Gebruikte normen: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

SE Försäkran om överensstämmelse

Vi, Grundfos, försäkrar under ansvar att produkterna DMS, som

omfattas av denna försäkran, är i överensstämmelse med rådets direktiv

om inbördes närmande till EU-medlemsstaternas lagstiftning,

avseende:

– Maskindirektivet (2006/42/EG).

Tillämpade standarder: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Lågspänningsdirektivet (2006/95/EG).

Tillämpad standard: EN 60204-1+A1: 2009.

– EMC-direktivet (2004/108/EG).

Tillämpade standarder: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

FI Vaatimustenmukaisuusvakuutus

Me, Grundfos, vakuutamme omalla vastuullamme, että tuotteet DMS,

joita tämä vakuutus koskee, ovat EY:n jäsenvaltioiden lainsäädännön

yhdenmukaistamiseen tähtäävien Euroopan neuvoston direktiivien

vaatimusten mukaisia seuraavasti:

– Konedirektiivi (2006/42/EY).

Sovellettavat standardit: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Pienjännitedirektiivi (2006/95/EY).

Sovellettu standardi: EN 60204-1+A1: 2009.

– EMC-direktiivi (2004/108/EY).

Sovellettavat standardit: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

DK Overensstemmelseserklæring

Vi, Grundfos, erklærer under ansvar at produkterne DMS som denne

erklæring omhandler, er i overensstemmelse med disse af Rådets

direktiver om indbyrdes tilnærmelse til EF-medlemsstaternes

lovgivning:

– Maskindirektivet (2006/42/EF).

Anvendt standarder: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Lavspændingsdirektivet (2006/95/EF).

Anvendt standard: EN 60204-1+A1: 2009.

– EMC-direktivet (2004/108/EF).

Anvendte standarder: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

Pfinztal, 15th July 2010

Ulrich Stemick

Technical Director

ALLDOS Eichler GmbH

Reetzstr. 85, D-76327 Pfinztal, Germany

Person authorised to compile technical file and

empowered to sign the EC declaration of conformity.

2

Page 3

3

DMS, Variant B

Installation and operating instructions 4

Montage- und Betriebsanleitung 22

Notice d'installation et d'entretien 41

Istruzioni di installazione e funzionamento 59

Instrucciones de instalación y funcionamiento 77

Instruções de instalação e funcionamento 95

Οδηγίες εγκατάστασης και λειτουργίας 113

Installatie- en bedieningsinstructies 131

Monterings- och driftsinstruktion 149

Asennus- ja käyttöohjeet 167

Monterings- og driftsinstruktion 185

Page 4

4

Original inst alla ti on and ope rat ing ins truct ion s.

CONTENTS

Page

1. General de scr ipti on 4

1.1 Applicat ion s 4

1.2 Type key 5

2. Technical data 6

2.1 Mechanic al da ta 6

2.2 Electrical data 6

2.3 Dimensi on s 6

3. Installati on 7

3.1 Safety instructions 7

3.2 Installati on e nv i ro nm en t 7

3.3 Installation o f p um p 7

3.4 Installation example 8

3.5 Electrical conne ct ion 8

4. Functions 9

4.1 Control panel 9

4.2 Start/stop of pum p 10

4.3 Priming/ve nting of pu mp 10

4.4 Indicator lights 10

4.5 Menu 11

4.6 Counters 12

4.7 Resetti ng 13

4.8 Return 13

4.9 Language 14

4.10 Measuring units 15

4.11 Co n tro l pa nel lock 16

5. Start-up 17

6. Calibra ti on 17

6.1 Direct cali brat ion 18

6.2 Indirect ca libr a tion 19

6.3 Check calib r ati on 20

7. Mainte na nce 20

8. Service 20

9. Fault finding chart 21

10. Disposa l 21

1. General descripti on

The GRUNDFOS DMS dosing pump is a self-priming

diaphragm pump.

The pump c on s ists o f:

•a cabinet incorporating the drive unit an d

electroni cs,

•a dosing head with back plate, dia ph r ag m ,

valves, connections and vent valve and

•a control panel incorporating dis play and

buttons.

The pump is fi t te d wi th a sy nch r on ou s m o to r, w h ich

is started an d stopped by mean s of the i nteg rated

electronics. The capacity is varied by changing the

stroke frequency. The pump always generates a

complete stroke with full stroke length and the speed

of the suction and dosing strokes is constant, irrespective of the ca pa ci t y se tt ing . T h e mo t or d ri v e als o

eliminates undesired peak values during the suction

and dosing strokes. As the pump is always dosin g at

full stroke len gth , i t e nsur es the sa m e hig h a ccu racy

and suction c apab ilit y, irrespective o f th e capa city,

which is infinitely variable in the ratio of 1:100.

The pump features an LCD display and a userfriendly co ntr o l pan el w h ich gi ves access to th e

pump func tio ns .

1.1 Applications

The DMS do sin g pu m p is designed f or h an dl in g

chemicals within the following ranges of applications:

• Drinking water treatment.

• Wastewater treatment.

• Swi mm in g po ol water tre atm ent .

• B o iler water treatm e nt .

• Co o ling wa te r tr ea tm en t.

• P r oc ess wa te r tr ea tm en t.

• Washing systems.

Before be gi nn i ng in stall a tio n pr o c ed ur e s,

these installation and operating instructions should be s tu die d ca re fu lly. The

install ation and o pera tion s houl d als o be in

accordance wi t h loca l r e gu lat ion s a n d

accepted co de s o f go od p ra ct i ce .

Page 5

5

1.2 Type key

(Cannot be u s ed f or p um p co nf i gu rat io n. )

Code Example DMS 2 - 11 B - PP/ E/ C - F - 2 1 1E F

Grundfos do si n g pu m p

Pump range DMS

Maximum pres sur e [bar]

B

Control variant:

Standard

PP

PV

SS

Dosing head mater ia l:

Polypropyle ne

PVDF

Stainless steel 1.4401

E

V

T

Gasket ma te r ia l:

EPDM

FKM

PTFE

C

SS

Valve ball material:

Ceramics

Stainless steel 1.4401

F

Control panel:

Front-fitted

1

Voltage:

1 x 230 V, 50 Hz

1

2

Valves:

Standard valve

Spring-loaded valve

1

2

3

4

5

6

A

B

E

F

Connection, suction/discharge:

Tubing 6/9

Tubing 4/6

supplied with th e pump

Tubing 6/9

Tubing 6/12+9 /1 2

supplied with th e pump

Tubing 4/6

Tubing 6/9

Tubing 6/12

Tubing 9/12

Threaded Rp 1/4

Threaded Rp 3/8

Cementing d.10

Cementing d.12

F

B

G

I

E

J

Mains plug:

EU (Schuko)

USA, CAN

UK

AU

CH

JP

Page 6

6

2. Tec hnical data

2.1 Mechanic al data

*1 Irrespective of counter pressure

*

2

Maximum suction lift 1 metre

2.2 Electrical data

2.3 Dimensions

See dimensions at the end of these instructions.

All dimensions are in mm.

DMS 2 DMS 4 DMS 8 DMS 12

Maximum capacity *

1

[l/h] 2.5 4 7.5 12

Maximum pressure [bar] 11 7 5.4 3.4

Maximum strok e rate per minute [stroke/min.] 180

Maximum suction lift during operation [m] 6

Maximum suction lift whe n pr imin g wit h w et va lves [ m] 1.8 2 3 3

Maximum viscosity with spring -loade d valves *

2

[mPas] 500

Maximum viscosity without spring-loaded valves *

2

[mPas] 200

Diaphragm diameter [mm] 28 30 38 42.5

Liquid temp erat ure [° C] 0 to 50

Ambient temperature [°C] 0 to 45

Accuracy of repea tability ±1%

Sound pressure level [dB(A)] <70

DMS 2, 4, 8, 12

Voltage [VAC], frequency [Hz] 1 x 230, 50

Maximum current consumption [A] 0.1

Power cons um p tio n, P

1

[W] 16

Enclosure cl ass IP 65

Insulation cl ass F

Supply cable 1.5 m H05RN-F with plug

Page 7

7

3. Installation

3.1 Safety instructions

• Wh en working with chem icals, local safet y rules

and regulations must be observed (e.g. wear protective clothes).

• B efor e startin g work on the dosin g pum p and system, disc on ne ct t he elec t ri c ity s up ply to th e p um p,

ensuring th at it cannot b e acc ide ntally switche d

on. Before reconnecting the electri city supply,

make sure that the dosing hose is positioned in

such a way t hat a ny ch em ic al left in the dosing

head is not ejected, thereby exposing persons to

danger.

• If th e ve nt valve in th e do sin g he ad is used, it

must be connected to a hose which is led back to

the tank.

• When changing a chemical, make sure that the

materials of t he d osin g pu m p an d syst em a r e

resistant to the new chemical. If there is any risk

of chemical reaction between the two types of

chemicals, clean the pump and system thoroughly

before adding the new chemical.

Proceed as follows:

Place the sucti on ho se in water and pr ess the

button unt i l r es i du al ch em ic a l h as be e n r e mo ve d.

Note: When th e bu tt on s and ar e p r ess ed

simultaneously, the pump can be set to run for a

specific num be r of sec on ds a t ma xim um capa city.

The remaining number o f sec on ds will ap p ear in

the display. The maximum valu e is 30 0 secon ds.

• The liquid is under pressure and may be hazardous.

3.2 Installation environment

• E xpos ure to dir ect sun lig ht shou ld be avo ided.

This applies espe cially to pu m ps with pla sti c d osing heads, as this material can be damaged by

sunlight.

• If th e pump is in stalle d outside, an e ncl osu r e o r

similar pr ot ect i on is required t o protect the pump

against r ain a nd similar we at he rs.

3.3 Installation of pump

• Se e also th e instal lation examp le in se ction 3.4.

• Note: The do sing head may co ntain water from

the factory test. If a liquid which must not come

into contact with w ate r is to be d os ed, it is recommended to let the pump r un w i th an other liquid to

remove the wat er fro m the dosi ng head befor e

installation .

• Alw ays install the pu mp on the sup po rt i ng f oo t

with vertical suction and discharge ports.

• Always use suitable tools fo r the mounting of plastic parts. Never a pp ly un ne ce ssa ry fo r ce.

• Make sure that the dosing pump and system are

designed i n su ch a wa y t ha t n ei t he r s yst em e qu i pment nor buil ding s are da mage d in ca se of leak age from the pump or rupture of hoses/pi pes. The

installation o f le akage hoses a nd c oll e ct ing tan ks

is recommended.

• Ma ke sure that the drain ho le in th e dosin g head

points downwards, see fig. 1.

Note: It is important that the drain pipe/hole is not

inserted di rect in to the tank cont en ts, a s g a sse s

may penetrate into the pump.

Fig. 1

100%

100%

TM01 8420 5099

Drain hole

Page 8

8

3.4 Installation ex amp le

The drawing in fig. 2 shows an installation example.

Fig. 2

3.5 Electrical connection

• Th e el ectrical conn ect ion o f the pump sh ou ld b e

carried out by qualified persons in accordance

with local regulati on s.

• For electrical data of the pump, see section 2.2.

The DMS pump can be ins talled in ma ny di fferent wa ys. Th e tank is a G RUND FOS c hemic al tank.

TM01 8452 3600

Page 9

9

4. Functions

4.1 Control panel

Fig. 3

TM01 8453 0100

ml/h

100%

LCD display,

see section 4.5

Navigation/

settings,

see section 4.5

Max. capacity

(priming),

see section 4.3

Green

indicator light,

see section 4.4

Red

indicator light,

see section 4.4

Mains connec tion

On/off button,

see section 4.5

Menu,

see section 4.5

Navigation/

settings,

see section 4.5

Page 10

10

4.2 Start/stop of pum p

The pump can be started/stopped in two different

ways:

• Locally on the pump control panel.

• By switc hing on/o ff the electricity sup ply.

4.3 Priming/venting of pump

The pump control panel incorporates a button.

Press this bu tto n if th e m a xim um p ump ca pa cit y is

required over a short period, e.g. during start-up.

When the button is released, the pump automatically

returns to th e pr evious operat i ng m ode.

During priming/ventin g, it is recommende d to let the

pump run w ith out a c ou nter p res s ur e or to l o os en t he

vent valve by giving it a 1/8 to 1/4 turn.

Note: When th e bu tt on s and ar e p r essed

simultaneously, th e pump can be set to run for a specific number of seconds at maximum capacity. The

remaining number o f s ec onds will appe ar in t he d isplay. The maximum value is 300 seconds.

4.4 Indicator lights

The green and red indicator lights on the pump are

used for o pe ra ti n g an d fa ult indication .

The functions of the indicator lights appear from the

table below :

Condition

Green

LED

Red

LED

Display

Pump running On Off

Normal

indicati on

Set to stop Flashing Off

Normal

indicati on

Pump fault Off On EEPROM

Supply failure Off Off Off

Overheati ng O ff On

MAX.

TEMP.

100%

100%

Page 11

11

4.5 Menu

The pump features a user-friendly menu which is

activat ed by p re ssi ng the button . Duri n g start-up,

all texts will appear in Englis h l angu age. To select

language, see secti on 4.9.

All menu items are described in the following sections. When appears at a menu item, it means

that this item is a ctiv ated . By selec tin g “RET UR N”

anywhere in the menu structure, you will return to the

operating d isp l ay wi t ho ut ch an ge s.

Fig. 4

See section 6. See section 4.8

See section 4.6 See section 4.9

See section 4.11 Se e sectio n 4.10

See section 4.7

Page 12

12

4.6 Counters

The pump can display “non-resettable” counters for:

•“QUANTITY”

Accumulated value of dosed quantity in litres or

US gallons.

•“STROKES”

Accumulated nu mber of do sing str okes.

•“HOURS”

Accumulate d numb er of op erat ing hou rs

(Power on).

•“POWER ON”

Accumulate d numb er of tim es the ele ctrici ty sup ply has be en s wi tc he d on .

Fig. 5

Total dosed

quantity

To tal number

of strokes

To tal number

of operating

hours

To tal number

of starts

Operating display

Page 13

13

4.7 Resetting

When “DEFAULT” is activated, the pump will return

to the factory settings.

Note: The calibr at ion is a lso se t b ac k to the defau lt

setting. This means that a new calibration is required

when the “ D EFAULT” function ha s b ee n us ed .

Fig. 6

4.8 Return

Fig. 7

The “RETURN” fun ction m ake s it p ossib le to r etur n

from any level in the menu to the operating display

without chan g es afte r th e me nu fun ctions have been

used.

Operating display Operating display

without ch an ge s

Page 14

14

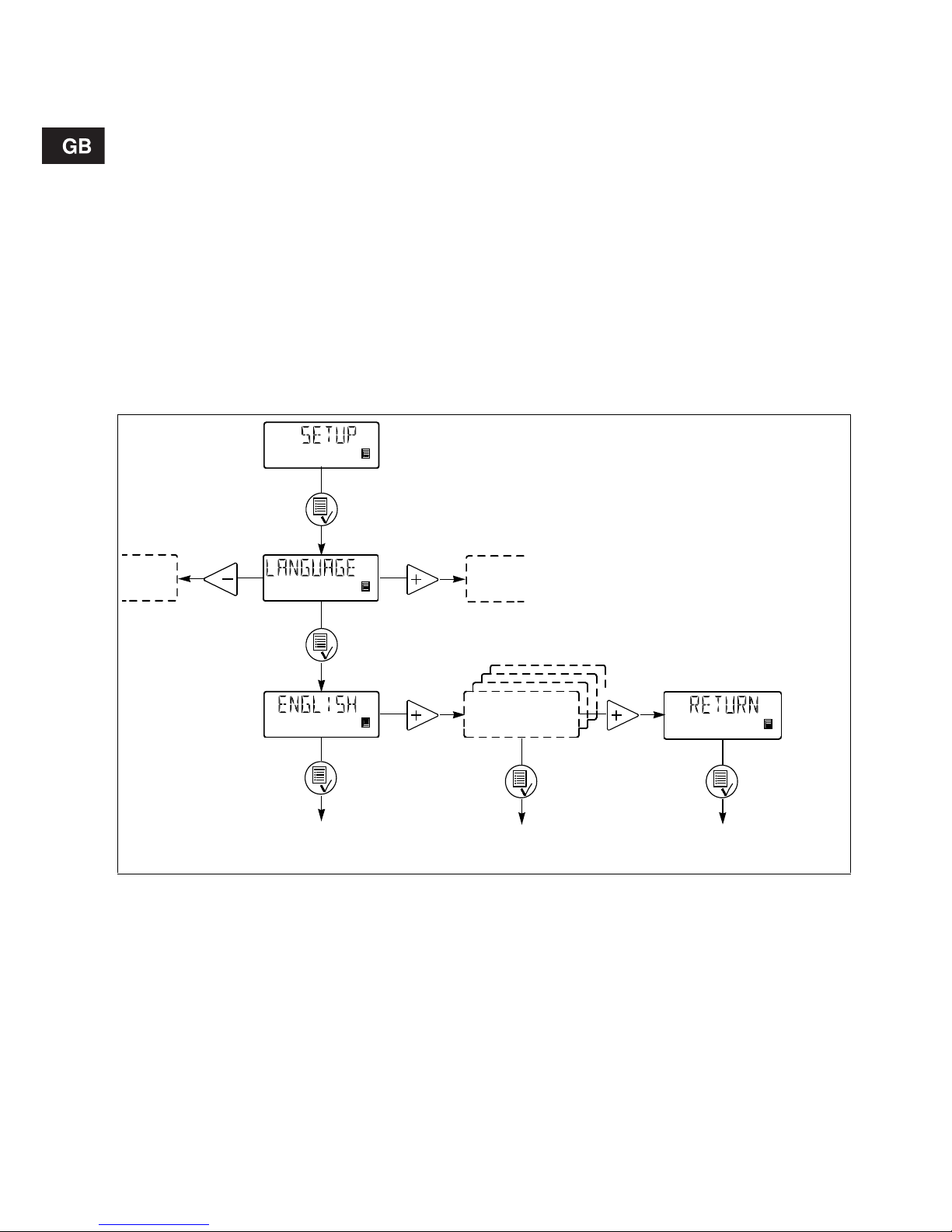

4.9 Language

The display text can be displaye d in one of the

following languag es:

• Eng lish

•German

•French

• Italia n

• Spanish

• P or tu gu ese

•Dutch

•Swedish

•Finnish

•Danish

• Cze ch

•Slovak

• Polis h

•Russian

Fig. 8

Operating di splay Operatin g displa y Operating dis pla y

without changes

Page 15

15

4.10 Measuring units

It is possible to s ele ct m etric un its (litr e/ mil lilitr e) o r

US units (gallons/millilitre).

Metric measuring units:

• In manual and analog mode s, set the quantity to

be dosed in litres p e r h our (l /h) o r millilit re s per

hour (ml/h ).

• In pulse mode, set the quantity to be dose d i n

ml/pulse. The actu al capacit y is indica ted in l itres

per hour (l/h) or m illil itr es pe r ho ur (m l/h ).

• For calibration, set the qu a nti ty to be d os ed in

ml per 100 stroke s.

• In timer and batch modes, set the quantity to be

dosed in litres (l) or millilitres (ml).

• Un de r th e “ QU A NT IT Y” me nu it em i n t he

“COUNTERS” menu, the dosed quantity is indicated in li tr es.

US measuring units:

• In manual and analog modes, set the quantity to

be dosed in ga llons pe r ho ur (gph) .

• In pulse mode, set the quantity to be dosed in

ml/pulse. The actual capac ity is indicated in

gallons per hour (gph).

• For calibration, set the q u an tity to b e do se d in

ml per 100 strokes.

• In timer and batch modes, set the quantity to be

dosed in gallons (gal).

• Under the “QUANTITY” menu item in the

“COUNTER S” m en u, th e dosed quantity is indicated in US gallons (gal).

Fig. 9

Operating d i sp lay

3 x

Operating d isplay

Page 16

16

4.11 Control panel lock

It is possible to lo ck th e b u tto ns o n t he co n tro l pa nel

to prevent malfunction of the pump. The locking

function can be set to “ON” or “OFF”. The default

setting is “O FF” .

A PIN code must be en tere d to cha nge fr om “OFF” to

“ON”. When “ON” is sele cted for the firs t time,

“_ _ _ _” will ap pe ar in th e di splay. If a code h as

already been entered, it will appear when an attempt

to change to “ON” is made . This co de can eit he r be

re-entered or changed.

If no code has been entered, a code must be set.

If a code has already been entered, active digits are

flashing.

If attempts are made to operate the pump in locked

condition, “LOCKED” will appear in the disp la y f or

2 seconds, followed by “_ _ _ _”. A code must be

entered. If the entering of a code has not been

started within 10 seconds, the operating display without changes w ill app ear.

If a wrong code is e nt ered, “ L OCKED ” w ill app ear in

the display for 2 seconds, followed by “_ _ _ _”. A

new code must be entered. If the entering of a code

has not been started within 10 seconds, the operating display without ch an ges will a pp ear. This display

will also appea r if t he e nt erin g o f th e c orre ct code

exceeds 2 minutes.

If the locki ng fu nction has bee n ac tiva te d bu t th e

control panel is unlock ed , t he co n trol pane l wi ll b e

locked a uto m at ica ll y if i t is no t op er at ed fo r 2 minutes.

The locking function can also be reactivated by

selecting “ON” in the “LOCK” menu. The previously

entered code will then appear and must be reentered by pressing the button four times. The

code can also be changed.

The control pan el can be unlocke d eit her by mea ns

of the selected code or th e facto ry code 2583.

The following buttons and inputs are still active when

the panel is locked:

• P r im i ng ( -button).

• On/off butto n.

• All ex ternal inputs.

Fig. 10

Activati ng t h e lo ck in g f un c ti on a n d locking t h e

control panel:

1. Select “LOCK” in t he menu.

2. Sel e ct “O N” by means of th e bu tt on s and

and confirm with .

3. Enter or re-enter a code by means of the buttons

, and .

The locking fu nc t ion ha s no w been acti v ated and th e

control panel is locked .

Unlocking the cont rol panel (wit hout de activa ting

the locking function):

1. Press once. “LOCK ED” appea rs in the displ ay

for 2 seco nd s, fo ll ow ed b y “ _ _ _ _” .

2. Enter the code by means of the buttons ,

and *.

The control panel has now been u nlocke d and will

automatically be locked a ga in i f th e con tr ol pan el is

not operat ed for 2 minute s.

Deactivating the l ocking function:

1. Un l oc k t he control pa ne l a s d es cr i be d ab ov e.

2. Select “LOCK” in the menu.

3. Select “OFF” by mean s of the bu tton s and

and confirm wi th .

The locking function has now been deactivated and

the control panel is unlo cke d.

* The panel can al w ay s be un l o cke d wit h co de 2583.

100%

Operating display Operating display

Page 17

17

5. Start-up

If the pump is not operating satisfactorily, see section 9. Fault finding chart.

6. Calibration

It is importan t tha t th e pu mp is ca lib ra te d a fter in stallation to ensure that the correct value (ml/h or l/h)

appears in the display.

The calibration can be carried out in three different

ways:

• Direct cal ib r at io n (recommended).

The dosed quantity of 100 strokes is measured

directly. See sectio n 6.1.

• Indirect calibration.

A calibration factor selected from a table is used

for the specific ins ta llat ion. Th is meth od c an b e

used if it is n ot po ssi ble to c ar ry o ut a dir ec t c alibration. Indirect ca libr atio n w ill n ev er b e as ac cu rate as direct cal ibr ation . See section 6.2.

• Check calibration. See section 6.3.

Step Action

1

Connect the hoses/pipes:

• Connect the suction and dosing hoses/pipes to the pump.

• Co n ne ct a hose to the ve nt va lve , if required, an d le ad th e ho se to t he

tank.

2

Switch on t h e e le ct r ic it y su p ply:

• T he d isp la y is on .

• The green indicator light is flashing (the pump has stopped).

• Select language, if required, see section 4.9.

3

Start the pump:

• Start th e pu mp b y p r essing the on/o ff b ut ton .

• The green indicator light is permanently on.

4

Priming/venting:

• Press the button on the pump control panel and let the pump run

without a counter pressure. Loosen the vent valve by giving it a 1/8 to

1/4 turn, if required.

When the b ut to ns and ar e pr es se d simultaneous l y d u rin g pr i m ing, the pump can be set to run for a specific number of seconds at

maximum capacity.

5

Calibration:

• When the pump has been primed and is running at the right counter

pressure, calibr ate the pu mp, see section 6.

100%

100%

100%

100%

100%

Page 18

18

6.1 Direct calib ratio n

Before calibration , make sure:

• th at the pump is installe d with foo t va lve, inje cti on

valve, etc. in th e ex isti ng sy ste m.

• that the pump is running at the counter pressure it

is supposed to operate at (adjust the counter

pressure valve, if required).

• that the pump is operating with the correct suction

lift.

To car ry out a direct cal ibr ation , proce ed as fo llow s:

Action Pump disp lay

1. Vent the do sin g he ad a nd t he su ct i on h ose.

2. Stop the p um p. T h e g r ee n LE D is flashin g.

3. Fill a gr aduate d glass wit h do sing liquid, Q

1

.

DMS 2: approx. 40 ml DMS 8: approx. 150 ml

DMS 4: approx. 150 ml DMS 12: approx. 250 ml

4. Rea d and no te the qu antit y Q

1

.

5. Place the sucti on hose in the graduated glass

6. Go to th e ca libr at ion m e nu , see section 4.5.

7. Pres s the bu tton tw ice.

8. The pump is performing 100 dosing strokes.

9. The factory-calibration value appears in the display.

10.Remove the suction hose from the graduated glass

and read Q

2

.

11. Set the display value to Q

d

= Q1 – Q2.

12.Confirm with the button.

13.The pump is now calibrated and returns to the

operating display.

Set value

to Q

d

Operating display

Q

1

Q

2

Q

d

Page 19

19

6.2 Indir ect cal i bration

A value from the following table is to be added to the

default fac tor y calibration v alu e in the disp la y. To

reset the p u mp to the factory c alibration valu e, activate the “DEFAULT” function, see section 4.7.

To us e th e va lue s, th e following must be fu lfille d:

• The viscosity and density of the liquid to be dosed

must not differ considerably from w ater at 20°C.

• A G RUND FO S installa tion kit or c or resp onding

foot valv e, inj e ct ion va l ve an d ho se dia met er mus t

be used.

• The length of the dosing hose must not exceed

6 metres.

• The suction lift must lie between 0.1 and 1.5 metres.

Adding the val ue:

Fig. 11

Pump type

Values to be added to the calibration value at various counter pressures [bar]

0-1 1-2 2-3 3-4 4-5 5-6 6-8 8-10 10-12

DMS 2 1.4 1.1 0 .8 0. 5 0.2 -0.2 -0.6 -1.2 -1.8

DMS 4 2.2 1.6 1 .0 0.3 -0.3 -1 .0 -1.9 -3 .2 DMS 8 2.0 1.2 0.4 -0.4 -1.2 -2.0 - - DMS 12 1.3 0.4 -0. 4 -1.3 - - - - -

Operating display

without c ha ng es

Operating d i sp lay

Set value

to table value

+ display value

Page 20

20

6.3 Check calibr atio n

In check calibr ati on, t he ca libra tio n va lue is ca lcu lated by reading the consumption of chemical in a

specific pe ri o d an d co mpa rin g th i s w i th th e nu m be r

of dosing strokes performed in the same period.

This calibratio n m e th od is ve ry ac cur a te an d es pe cially suitable for check calibration after long periods

of operation or if direct calibration is impossibl e. The

calibratio n c an f or in stan ce be ca r rie d ou t w he n th e

chemical tank is replaced or filled.

To carr y out a che ck calibr ati on, proc ee d as follow s:

1. Stop the pump by pressing the button.

2. Rea d t he co u nte r an d note the nu mb er o f dosing

strokes, se e sec tio n 4. 6.

3. Rea d an d no te the quantit y in the chemic al tank .

4. Star t the pu mp by pre ssin g the button and let

it run for at leas t 1 hour. The longer the pump is

operating, the more accurate the calibration will

be.

5. Stop the pump by pressing the button.

6. Rea d t he co u nte r an d note the nu mb er o f dosing

strokes, se e sec tio n 4. 6.

7. Rea d an d no te the quantit y in the chemic al tank .

8. Calc u la te th e do se d quantity in m l a nd t he

number o f d osing stroke s pe rf or me d du ring the

operating period.

9. Calcula te th e ca librat ion v alue as fo llows:

(dosed quantity in ml/dosing strokes) x 100.

10.Set the calculated value in the calibration menu

like for indirect calib ration, see sectio n 6.2.

7. Maintenance

The pump is maintenance-free. However, it is recommended to k ee p th e p u mp clean.

The dosing pump is produced according to the highest quality standards and has long life. The pump

incorporates wear parts such as diaphragm, valve

seat and valve balls.

To en sur e long life an d t o re du ce th e risk of distu rbance of operation, visual checks should be carried

out regularly.

It is possibl e to order dosing heads, valves and diaphragms i n m a te ria l s w hich are suita ble fo r th e sp ecific liquid to be pumped. See the product numbers

at the end of these instructions.

8. Service

Before ret ur nin g th e pu m p t o GRU NDF OS fo r service, the s afety declaration at the end of these instructions must be f illed in b y a u thor ize d pe rso nne l a nd

attached to th e pu mp in a v i sib le po siti on .

Note: If a pump has been used for a liquid which is

injurious to h ealth o r to xic, the pu mp will b e cla ssified as contaminated.

If GRUNDFOS is requested to service the pump, it

must be ensured that the pump is free from substance s that can be injurious to he alth or toxic. If the

pump has been used for such subs tances, the pump

must be cleaned before it is returned.

If proper cleanin g is n ot p ossib le, all r eleva nt infor mation about the chemical must be provided.

If the above is not fulfilled, G RUNDFO S ca n re fu se

to accept the pump for service. Possible costs of

returning the pum p are paid by the custo mer.

The safety declaration can be found at the end of these

instructions (only in English).

Note: The replacement of the supply cable must be

carried out by an authorised GRUNDFOS ser vice

workshop.

Page 21

21

9. Fault finding chart

10. Disposal

Disposal of this product or parts of it must be carried

out according to the f ollowin g guide lin es:

1. Use the local public or private wa ste collectio n

service.

2. In ca se such wa ste collectio n serv ice does not

exist or cannot handle the materials used in the

product, please deliver the product or any hazardous m ate r ial s fr om it to your ne ar e s t

GRUNDFOS company or service work shop .

Fault Cause Remedy

The dosing has

stopped or t he o utp u t

is too low.

Valves leaking or blocked. Check and cle an valve s.

Valves incorrectly installed . Remove and fit valves. C heck th at the arro w

on the valve casing is pointing in the liquid

flow direction. Check that all O-rings have

been fitted correctly.

Suction valve or suct i on pipe /h os e

leaking or blocked.

Clean and se al the s uctio n pip e/ho se.

Suction lift too high. Install the pump in a low er p osition .

Install a priming tank.

Viscosity too high. Install a pipe/hose with larger cross-section.

Fit spring-loaded valves.

Pump out of calibration. Calibrate the pump, see section 6.

Pump dosing too little

or too much.

Pump out of calibration. Calibrate the pump, see section 6.

Pump dos i ng ir re gu larly.

Valves leaking or blocked. Check and cle an the valv es.

Leakage from drain

hole.

Diaphragm defective. Install a new diaphragm.

Frequent diaphragm

failures.

Diaphragm not fastened properly. Install a new diaphragm and ensure that the

diaphragm is fastened properly.

Counter-pr essure too high (meas ured at the pump discha rge po rt ).

Check the system. Check the injection valve, if

required. R edu c e th e do sin g st ro k e by fitt i ng a

pulsation d am p en er.

Sediment in do sing he ad. C lea n/flu sh the do sing he ad.

Subject to al te ra tio ns .

Page 22

203

Service kits

Pump

size

Valves

Materials

dosing head/

gaskets/

valve balls

Product nu mb ers

Complete dosing head

Pos. 3+9+13+14+15+18

Valves +

diaphragm

Pos. 2+3 x

pos. 3

Diaphragm

Pos. 2

Valves

3 x pos. 3

DMS 2

Standard

PP/EPDM/ceramics 96440665 96441131 96440740 96440705

PP/FKM/ceramics 96446814 96446774 96440740 96446834

PVDF/FKM/ceramics 96440667 96441133 96440740 96440707

Stainless steel/FKM/stainless steel 96440669 96441135 96440740 96440709

Springloaded

PP/EPDM/ceramics 96440666 96441132 96440740 96440706

PP/FKM/ceramics 96446815 96446775 96440740 96446835

PVDF/FKM/ceramics 96440668 96441134 96440740 96440708

Stainless steel/FKM/stainless steel 96440670 96441136 96440740 96440710

DMS 4

Standard

PP/EPDM/ceramics 96440699 96441177 96440750 96440705

PP/FKM/ceramics 96446818 96446782 96440750 96446834

PVDF/FKM/ceramics 96440701 96441179 96440750 96440707

Stainless steel/FKM/stainless steel 96440703 96441181 96440750 96440709

Springloaded

PP/EPDM/ceramics 96440700 96441178 96440750 96440706

PP/FKM/ceramics 96446819 96446783 96440750 96446835

PVDF/FKM/ceramics 96440702 96441180 96440750 96440708

Stainless steel/FKM/stainless steel 96440704 96441182 96440750 96440710

DMS 8

Standard

PP/EPDM/ceramics 96440671 96441149 96440743 96440705

PP/FKM/ceramics 96446816 96446780 96440743 96446834

PVDF/FKM/ceramics 96440673 96441151 96440743 96440707

Stainless steel/FKM/stainless steel 96440675 96441153 96440743 96440709

Springloaded

PP/EPDM/ceramics 96440672 96441150 96440743 96440706

PP/FKM/ceramics 96446817 96446781 96440743 96446835

PVDF/FKM/ceramics 96440674 96441152 96440743 96440708

Stainless steel/FKM/stainless steel 96440676 96441154 96440743 96440710

DMS 12

Standard

PP/EPDM/ceramics 96440659 96441125 96440739 96440705

PP/FKM/ceramics 96446812 96446772 96440739 96446834

PVDF/FKM/ceramics 96440661 96441127 96440739 96440707

Stainless steel/FKM/stainless steel 96440663 96441129 96440739 96440709

Springloaded

PP/EPDM/ceramics 96440660 96441126 96440739 96440706

PP/FKM/ceramics 96446813 96446773 96440739 96446835

PVDF/FKM/ceramics 96440662 96441128 96440739 96440708

Stainless steel/FKM/stainless steel 96440664 96441130 96440739 96440710

Page 23

204

TM01 9976 3500

14

13

2

4

5

6

7

8

10

11

12

3

9

15

18

Page 24

205

Dimensions

TM01 8636 3600

259

137

160

110

98

168

36

50

ml/h

100%

Page 25

206

Safety declaration

Please copy, fill in and sign this sheet and attach it to the pu mp re turn ed for s ervice.

We hereby declare th at th is pro duct:

Product type:_ _____ _____ ___ _____ ___ _____ _

Model numbe r: _ ________________________

(see pump nameplate)

is free from hazardous chemicals, biological and radioactive substances.

Fault description

Please make a circ le arou nd th e dama ged part.

In the case of an ele ctrica l or fu nction al faul t, pleas e ma rk th e cabi net.

Please give a shor t descr iptio n of the fault:

___________ ___ __ _ ____________ __ ___

Date and signature Company stamp

TM02 8953 1104

ml/h

100%

Page 26

Argentina

Bombas GRUNDFO S de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 01 55

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Gröd ig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenw eg 81-83

B-2630 Aartselaar

Tél.: +32-3- 870 7300

Télécopie: +32-3-870 7301

Belorussia

Пред став итель ство ГРУНДФОС в

Минске

220123, Минск,

ул. В. Хоружей, 22 , оф. 1105

Тел.: +(37517) 233 97 65,

Факс: +(37517) 233 97 69

E-mail: grundfos_minsk@mail.ru

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Trg Heroja 16,

BiH-71000 S arajevo

Phone: +387 33 713 290

Telefax: +387 33 659 079

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Cam po - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 95 12

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

50/F Maxdo Center No. 8 XingYi Rd.

Hongqiao development Zone

Shanghai 200336

PRC

Phone: +86-021-612 252 22

Telefax: +86-021-612 2 53 33

Croatia

GRUNDFOS CROATIA d.o.o.

Cebini 37, Buzin

HR-10010 Zagre b

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.grundfos.hr

Czech Republic

GRUNDFOS s.r.o.

Čajkovského 21

779 00 Olomouc

Phone: +420 -585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GD K@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358 -3066 5650

Telefax: +358-3066 56550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

e-mail: infoservice@grundfos.de

Service in Deutschland:

e-mail: kundendienst@grundfos .de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. A thinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +003 0-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floo r

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852 -27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Ind ustri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353 -1-4089 800

Telefax: +353-1-4089 8 30

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg., 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangna m-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 72 5

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 3 71 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 28 66

México

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No . 15

Parque Industrial Stiva Aeropue rto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4 010

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 63 32

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Es tate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 325 0

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 23 5, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Pozn ania

PL-62-081 P rzeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFO S Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 0 0

Telefax: +351-21-440 7 6 90

România

GRUNDFOS Pompe România SRL

Bd. Bir uintei, n r 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грунд фо с

Россия, 109544 Москва, ул. Школьная 39

Тел. (+7) 495 737 30 00, 564 88 00

Факс (+7) 495 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47 496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS d.o .o.

Šlandrova 8b, SI-1231 Ljubljana-Črnuče

Phone: +386 1 568 0610

Telefax: +386 1 568 0619

E-mail: slovenia@grundfos.si

South Africa

Corner Mountjoy and George Allen Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

Box 333 (Lunnagårdsgatan 6)

431 24 Mölnda l

Tel.: +46(0)771-32 23 00

Telefax: +46(0)31-331 94 60

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrass e 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Ca ddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7 905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС УКРАЇНА

01010 Київ, Вул. Московська 8б,

Тел.:(+38 044) 390 40 50

Фах.: (+38 044) 390 40 59

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P. O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8 TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Usbekistan

Представительство ГРУНДФОС в

Таш ке нте

700000 Ташк ент ул.Усм ана Носира 1-й

тупик 5

Теле фо н: (3712) 55-68-15

Факс: (3712) 53-36-35

Addresses revised 29.09.2010

Page 27

www.grundfos.com

Being respon sib le is our founda tion

Thinking ahead makes it possible

Innovation is the essence

ECM: 1065056

96441962 0710

Repl. V7157380 0203

Loading...

Loading...