Grundfos DME AR Series, DME 60, DME 150, DME 375, DME 940 Installation And Operating Instructions Manual

Page 1

GRUNDFOS INSTRUCTIONS

DME, Variant AR (60-940 l/h)

Installation and operating instructions

Page 2

Page 3

DME, Variant AR (60-940 l/h)

Declaration of conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

English (GB)

Installation and operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Dansk (DK)

Monterings- og driftsinstruktion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Deutsch (DE)

Montage- und Betriebsanleitung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Ελληνικά (GR)

Οδηγίες εγκατάστασης και λειτουργίας . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Español (ES)

Instrucciones de instalación y funcionamiento . . . . . . . . . . . . . . . . . . . . . . . . 122

Français (FR)

Notice d'installation et de fonctionnement. . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Italiano (IT)

Istruzioni di installazione e funzionamento . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Nederlands (NL)

Installatie- en bedieningsinstructies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Português (PT)

Instruções de instalação e funcionamento . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Suomi (FI)

Asennus- ja käyttöohjeet. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Svenska (SE)

Monterings- och driftsinstruktion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 296

Appendix 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

Appendix 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Table of contents

3

Page 4

Declaration of conformity

Declaration of conformity

GB Declaration of Conformity

We, Grundfos, declare under our sole responsibility that the products

DME, to which this declaration relates, are in conformity with these

Council directives on the approximation of the laws of the EC member

states:

– Machinery Directive (2006/42/EC).

Standards used: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009

– Low Voltage Directive (2006/95/EC).

Standard used: EN 60204-1+A1: 2009.

– EMC Directive (2004/108/EC).

Standards used: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

DE Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung, dass die Produkte

DME, auf die sich diese Erklärung bezieht, mit den folgenden Richtlinien

des Rates zur Angleichung der Rechtsvorschriften der EUMitgliedsstaaten übereinstimmen:

– Maschinenrichtlinie (2006/42/EG).

Normen, die verwendet wurden: EN 809: 1998, EN ISO 12100-1+A1:

2009, EN ISO 12100-2+A1: 2009.

– Niederspannungsrichtlinie (2006/95/EG).

Norm, die verwendet wurde: EN 60204-1+A1: 2009.

– EMV-Richtlinie (2004/108/EG).

Normen, die verwendet wurden: EN 61000-6-2: 2005,

EN 61000-6-4: 2007.

ES Declaración de Conformidad

Nosotros, Grundfos, declaramos bajo nuestra entera responsabilidad

que los productos DME, a los cuales se refiere esta declaración, están

conformes con las Directivas del Consejo en la aproximación de las

leyes de las Estados Miembros del EM:

– Directiva de Maquinaria (2006/42/CE).

Normas aplicadas: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Directiva de Baja Tensión (2006/95/CE).

Norma aplicada: EN 60204-1+A1: 2009.

– Directiva EMC (2004/108/CE).

Normas aplicadas: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

IT Dichiarazione di Conformità

Grundfos dichiara sotto la sua esclusiva responsabilità che i prodotti

DME, ai quali si riferisce questa dichiarazione, sono conformi alle

seguenti direttive del Consiglio riguardanti il riavvicinamento delle

legislazioni degli Stati membri CE:

– Direttiva Macchine (2006/42/CE).

Norme applicate: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Direttiva Bassa Tensione (2006/95/CE).

Norma applicata: EN 60204-1+A1: 2009.

– Direttiva EMC (2004/108/CE).

Norme applicate: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

PT Declaração de Conformidade

A Grundfos declara sob sua única responsabilidade que os produtos

DME, aos quais diz respeito esta declaração, estão em conformidade

com as seguintes Directivas do Conselho sobre a aproximação das

legislações dos Estados Membros da CE:

– Directiva Máquinas (2006/42/CE).

Normas utilizadas: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Directiva Baixa Tensão (2006/95/CE).

Norma utilizada: EN 60204-1+A1: 2009.

– Directiva EMC (compatibilidade electromagnética) (2004/108/CE).

Normas utilizadas: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

SE Försäkran om överensstämmelse

Vi, Grundfos, försäkrar under ansvar att produkterna DME, som

omfattas av denna försäkran, är i överensstämmelse med rådets direktiv

om inbördes närmande till EU-medlemsstaternas lagstiftning,

avseende:

– Maskindirektivet (2006/42/EG).

Tillämpade standarder: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Lågspänningsdirektivet (2006/95/EG).

Tillämpad standard: EN 60204-1+A1: 2009.

– EMC-direktivet (2004/108/EG).

Tillämpade standarder: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

DK Overensstemmelseserklæring

Vi, Grundfos, erklærer under ansvar at produkterne DME som denne

erklæring omhandler, er i overensstemmelse med disse af Rådets

direktiver om indbyrdes tilnærmelse til EF-medlemsstaternes

lovgivning:

– Maskindirektivet (2006/42/EF).

Anvendt standarder: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

– Lavspændingsdirektivet (2006/95/EF).

Anvendt standard: EN 60204-1+A1: 2009.

– EMC-direktivet (2004/108/EF).

Anvendte standarder: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

GR ∆ήλωση Συμμόρφωσης

Εμείς, η Grundfos, δηλών ουμε με αποκλειστικά δική μας ευθύνη ότι τα

προϊόντα DME στα οποία αναφέρεται η παρούσ α δήλωση,

συμμορφώνονται με τις εξής Οδηγίες του Συμβουλίου περί προσέγγισης

των νομοθεσιών των κρατών μ ελών της ΕΕ:

– Οδηγία για μηχανήματα (2006/42/EC).

Πρότυπα που χρησιμοποιήθηκαν: EN 809: 1998,

EN ISO 12100-1+A1: 2009, EN ISO 12100-2+A1: 2009.

– Οδηγία χαμηλ ής τάση ς (2006/95/EC).

Πρότυπο που χρησιμοποιήθηκε: EN 60204-1+A1: 2009.

– Οδηγία Ηλεκτρομαγνητικής Συμβατότητας (EMC) (2004/108/EC).

FR Déclaration de Conformité

Nous, Grundfos, déclarons sous notre seule responsabilité, que les

produits DME, auxquels se réfère cette déclaration, sont conformes aux

Directives du Conseil concernant le rapprochement des législations des

Etats membres CE relatives aux normes énoncées ci-dessous :

– Directive Machines (2006/42/CE).

– Directive Basse Tension (2006/95/CE).

– Directive Compatibilité Electromagnétique CEM (2004/108/CE).

NL Overeenkomstigheidsverklaring

Wij, Grundfos, verklaren geheel onder eigen verantwoordelijkheid dat

de producten DME waarop deze verklaring betrekking heeft, in

overeenstemming zijn met de Richtlijnen van de Raad in zake de

onderlinge aanpassing van de wetgeving van de EG Lidstaten

betreffende:

– Machine Richtlijn (2006/42/EC).

– Laagspannings Richtlijn (2006/95/EC).

– EMC Richtlijn (2004/108/EC).

FI Vaatimustenmukaisuusvakuutus

Me, Grundfos, vakuutamme omalla vastuullamme, että tuotteet DME,

joita tämä vakuutus koskee, ovat EY:n jäsenvaltioiden lainsäädännön

yhdenmukaistamiseen tähtäävien Euroopan neuvoston direktiivien

vaatimusten mukaisia seuraavasti:

– Konedirektiivi (2006/42/EY).

– Pienjännitedirektiivi (2006/95/EY).

– EMC-direktiivi (2004/108/EY).

Pfinztal, 1st March 2011

που χρησιμοποιήθηκαν: EN 61000-6-2: 2005,

Πρότυπα

EN 61000-6-4: 2007.

Normes utilisées : EN 809 : 1998, EN ISO 12100-1+A1 : 2009,

EN ISO 12100-2+A1 : 2009.

Norme utilisée : EN 60204-1+A1: 2009.

Normes utilisées : EN 61000-6-2: 2005, EN 61000-6-4: 2007.

Gebruikte normen: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

Gebruikte norm: EN 60204-1+A1: 2009.

Gebruikte normen: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

Sovellettavat standardit: EN 809: 1998, EN ISO 12100-1+A1: 2009,

EN ISO 12100-2+A1: 2009.

Sovellettu standardi: EN 60204-1+A1: 2009.

Sovellettavat standardit: EN 61000-6-2: 2005, EN 61000-6-4: 2007.

Ulrich Stemick

Technical Director

Grundfos Water Treatment GmbH

Reetzstr. 85, D-76327 Pfinztal, Germany

Person authorised to compile technical file and

empowered to sign the EC declaration of conformity.

4

Page 5

English (GB) Installation and operating instructions

Caution

Note

Original installation and operating instructions.

CONTENTS

Page

1. Safety instructions

1.1 Identification of safety instructions in

these instructions

1.2 Qualification and training of personnel

1.3 Safety instructions for the operator/user

1.4 Safety of the system in the event of a

failure in the dosing pump

1.5 Dosing chemicals

2. General description

2.1 Applications

2.2 Type key

3. Technical data

3.1 Mechanical data

3.2 Electrical data

3.3 Input/output data

3.4 Dimensions

4. Installation

4.1 Safety instructions

4.2 Installation environment

4.3 Installation of pump

4.4 Installation example

4.5 Electrical connection

4.6 Connection overview

5. Functions

5.1 Control panel

5.2 Start/stop of pump

5.3 Priming/venting of pump

5.4 Level control

5.5 Diaphragm leakage sensor

5.6 Alarm output and indicator lights

5.7 Fieldbus communication

5.8 Menu

5.9 Operating modes

5.10 Manual

5.11 Pulse

5.12 Analog

5.13 Timer

5.14 Batch

5.15 Anti-cavitation

5.16 Capacity limitation

5.17 Counters

5.18 Resetting

5.19 Return

5.20 Language

5.21 Input setup

5.22 Empty tank (alarm)

5.23 Measuring units

5.24 Dosing monitoring

5.25 Control panel lock

6. Start-up

7. Calibration

7.1 Direct calibration

7.2 Check calibration

5

8. Maintenance

9. Service

5

10. Fault finding chart

5

11. Disposal

6

6

6

7

7

8

9

9

1. Safety instructions

9

These installation and operating instructions contain

9

general instructions that must be observed during

10

installation, operation and maintenance of the pump.

10

It must therefore be read by the installation engineer

10

and the relevant qualified operator prior to

installation and start-up, and must be available at the

10

installation location at all times.

10

11

1.1 Identification of safety instructions in

11

12

The safety instructions are identified by the following

14

symbols:

14

15

15

15

15

16

17

18

19

19

19

20

21

1.2 Qualification and training of personnel

22

The personnel responsible for the installation,

22

operation and service must be appropriately

qualified for these tasks. Areas of responsibility,

23

levels of authority and the supervision of the

23

personnel must be precisely defined by the operator.

24

If necessary, the personnel must be trained

24

appropriately.

24

Risks of not observing the safety instructions

25

Non-observance of the safety instructions may have

26

dangerous consequences for the personnel, the

26

environment and the pump and may result in the loss

27

of any claims for damages.

28

It may lead to the following hazards:

• Personal injury from exposure to electrical,

Warning

Prior to installation, read these

installation and operating instructions.

Installation and operation must comply

with local regulations and accepted

codes of good practice.

these instructions

Warning

If these safety instructions are not

observed, it may result in personal

injury!

If these safety instructions are not

observed, it may result in malfunction

or damage to the equipment!

Notes or instructions that make the job

easier and ensure safe operation.

29

30

31

32

32

32

33

33

English (GB)

5

Page 6

English (GB)

Caution

Note

Caution

Caution

Caution

Caution

mechanical and chemical influences.

• Damage to the environment and personal injury

from leakage of harmful substances.

1.3 Safety instructions for the operator/

user

The safety instructions described in these

instructions, existing national regulations on health

protection, environmental protection and for accident

prevention and any internal working, operating and

safety regulations of the operator must be observed.

Information attached to the pump must be observed.

Leakages of dangerous substances must be

disposed of in a way that is not harmful to the

personnel or the environment.

Damage caused by electrical energy must be

prevented, see the regulations of the local electricity

supply company.

Before starting work on the pump, the

pump must be disconnected from the

mains. The system must be

pressureless!

The mains plug is the separator

separating the pump from the mains.

Only orginal accessories and original spare parts

should be used. Using other parts can result in

exemption from liability for any resulting

consequences.

1.4 Safety of the system in the event of a

failure in the dosing pump

The dosing pump was designed according to the

latest technologies and is carefully manufactured

and tested.

If it fails regardless of this, the safety of the overall

system must be ensured. Use the relevant

monitoring and control functions for this.

Make sure that any chemicals that are

released from the pump or any

damaged lines do not cause damage to

system parts and buildings.

The installation of leak monitoring

solutions and drip trays is

recommended.

1.5 Dosing chemicals

Warning

Before switching the supply voltage

back on, the dosing lines must be

connected in such a way that any

chemicals in the dosing head cannot

spray out and put people at risk.

The dosing medium is pressurised and

can be harmful to health and the

environment.

Warning

When working with chemicals, the

accident prevention regulations

applicable at the installation site

should be applied (e.g. wearing

protective clothing).

Observe the chemical manufacturer's

safety data sheets and safety

instructions when handling chemicals!

A deaeration hose, which is routed into

a container, e.g. a drip tray, must be

connected to the deaeration valve.

The dosing medium must be in liquid

aggregate state!

Observe the freezing and boiling points

of the dosing medium!

The resistance of the parts that come

into contact with the dosing medium,

such as the dosing head, valve ball,

gaskets and lines, depends on the

medium, media temperature and

operating pressure.

Ensure that parts in contact with the

dosing medium are resistant to the

dosing medium under operating

conditions, see data booklet!

Should you have any questions

regarding the material resistance and

suitability of the pump for specific

dosing media, please contact

Grundfos.

6

Page 7

2. General description

The Grundfos DME dosing pump is a self-priming

diaphragm pump.

The pump consists of:

•a cabinet incorporating the drive unit and

electronics,

•a dosing head with back plate, diaphragm,

valves, connections and vent valve,

•a control panel incorporating display and

buttons. The control panel is fitted either to the

front or to the side of the cabinet.

The motor is controlled in such a way that the dosing

gets as even and constant as possible, irrespective

of the capacity range in which the pump is operating.

This is carried out as follows:

The speed of the suction stroke is kept constant and

the stroke relatively short, irrespective of the

capacity. Contrary to conventional pumps, which

generate the dosing stroke as a short pulse, the

duration of the dosing stroke will be as long as

possible. Thus, an even dosing without peak values

is ensured. As the pump is always dosing at full

stroke length, it ensures the same high accuracy and

suction capability, irrespective of the capacity, which

is infinitely variable in the ratio of 1:800.

The pump features an LCD display and a userfriendly control panel which gives access to the

pump functions.

2.1 Applications

The DME dosing pump is designed for handling

chemicals within the following ranges of applications,

among others:

• drinking water treatment

• wastewater treatment

• cooling water treatment

• washing systems

• process water treatment

• chemical industry.

English (GB)

7

Page 8

2.2 Type key

English (GB)

(Cannot be used for pump configuration.)

Code Example DME 60 - 10 AR - PP/ E/ C - F - 3 1 1 F

Pump range

Maximum capacity [l/h]:

60

150

375

940

Maximum pressure [bar]:

4

10

Control variant:

AR

Standard

AP

Standard + Profibus

Dosing head material:

PP

Polypropylene

PV

PVDF

SS

Stainless steel 1.4401

Gasket material:

EPDM

E

PTFE

T

FKM

V

Valve ball material:

C

Ceramics

Glass

G

Stainless steel 1.4401

SS

PTFE

T

Control panel:

F

Front-fitted

Side-fitted

S

Voltage:

3

1 x 100-240 V, 50-60 Hz

Valves:

1

Standard valve

2

Spring-loaded valve

Connection, suction/discharge:

A1

Threaded Rp 3/4

A2

Threaded Rp 1 1/4

Q

Tubing 19/27 mm + 25/34 mm

Mains plug:

F

EU (Schuko)

G

UK

I

AU

B

USA

J

JP

E

CH

L

Argentina

8

Page 9

3. Technical data

3.1 Mechanical data

DME 60 DME 150 DME 375 DME 940

Maximum capacity*

Maximum capacity with anti-cavitation 75 %*

Maximum capacity with anti-cavitation 50 %*

Maximum capacity with anti-cavitation 25 %*

Maximum pressure [bar] 10 4 10 4

Maximum stroke rate per minute [strokes/min.] 160

Maximum suction lift during operation [m] 4

Maximum suction lift when priming with wet valves [m] 1.5

Maximum viscosity with spring-loaded valves*

Maximum viscosity without spring-loaded valves*

Diaphragm diameter [mm] 79 106 124 173

Liquid temperature [°C] 0 to 50

Ambient temperature [°C] 0 to 45

Accuracy of repeatability ±1 %

Sound pressure level [dB(A)] <70

*1 Irrespective of counter pressure

2

*

Maximum suction lift 1 metre

3.2 Electrical data

Supply voltage [VAC] 1 x 100-240 V

Maximum current consumption [A]

Maximum power consumption P

Frequency [Hz] 50-60

Enclosure class IP 65

Insulation class B

Supply cable 1.5 m H05RN-F with plug

1

[l/h] 60 150 376 940

1

[l/h] 45 112 282 705

1

[l/h] 33.4 83.5 210 525

1

[l/h] 16.1 40.4 101 252

2

[mPa s] 3000 [mPa s] at 50 % capacity

2

[mPa s] 200

DME 60 DME 150 DME 375 DME 940

at 100 V 1.25 2.4

at 230 V 0.67 1.0

[W] 67.1 240

1

English (GB)

3.3 Input/output data

The pump offers various input and output options, depending on control variant.

Signal input

Voltage in level sensor input [VDC] 5

Voltage in pulse input [VDC] 5

Minimum pulse-repetition period [ms] 3.3

Impedance in analog 0/4-20 mA input []

The analog input requires a signal which is isolated from frame.

Min. resistance to frame: 50 k

Maximum loop resistance in pulse signal circuit [] 250

Maximum loop resistance in level signal circuit [] 250

Signal output

Maximum load of alarm relay output, at ohmic load [A] 2

Maximum voltage, alarm relay output [V] 42

250

9

Page 10

3.4 Dimensions

100%

100%

Drain hole

English (GB)

See dimensions at the end of these instructions.

All dimensions are in mm.

4. Installation

4.1 Safety instructions

• Liquid is under pressure and may be hazardous.

• When working with chemicals, local safety rules

and regulations must be observed (e.g. wear

protective clothes).

• Before starting work on the dosing pump and

system, disconnect the electricity supply to the

pump, ensuring that it cannot be accidentally

switched on. Before reconnecting the electricity

supply, make sure that the dosing hose is

positioned in such a way that any chemical left in

the dosing head is not ejected, thereby exposing

persons to danger.

• If the vent valve in the dosing head is used, it

must be connected to a hose which is led back to

the tank.

• When changing a chemical, make sure that the

materials of the dosing pump and system are

resistant to the new chemical. If there is any risk

of chemical reaction between the two types of

chemicals, clean the pump and system

thoroughly before adding the new chemical.

Proceed as follows:

Place the suction tube in water and press the

button until residual chemical has been removed.

Note: When the buttons and are pressed

simultaneously, the pump can be set to run for a

specific number of seconds at maximum

capacity. The remaining number of seconds will

appear in the display. The maximum value is

300 seconds.

4.2 Installation environment

• Exposure to direct sunlight should be avoided.

This applies especially to pumps with plastic

dosing heads, as this material can be damaged

by sunlight.

• If the pump is installed outside, an enclosure or

similar protection is required to protect the pump

against rain and similar weathers.

4.3 Installation of pump

• See also the installation example in section 4.4.

• Note: The dosing head may contain water from

the factory test. If a liquid which must not come

into contact with water is to be dosed, it is

recommended to let the pump run with another

liquid to remove the water from the dosing head

before installation.

• Always install the pump on the supporting foot

with vertical suction and discharge ports.

• Always use suitable tools for the mounting of

plastic parts. Never apply unnecessary force.

• Tighten the dosing head after 2 to 5 operating

hours (torque 5.5 Nm).

• Make sure that the dosing pump and system are

designed in such a way that neither system

equipment nor buildings are damaged in case of

leakage from the pump or rupture of hoses/pipes.

The installation of leakage hoses and collecting

tanks is recommended.

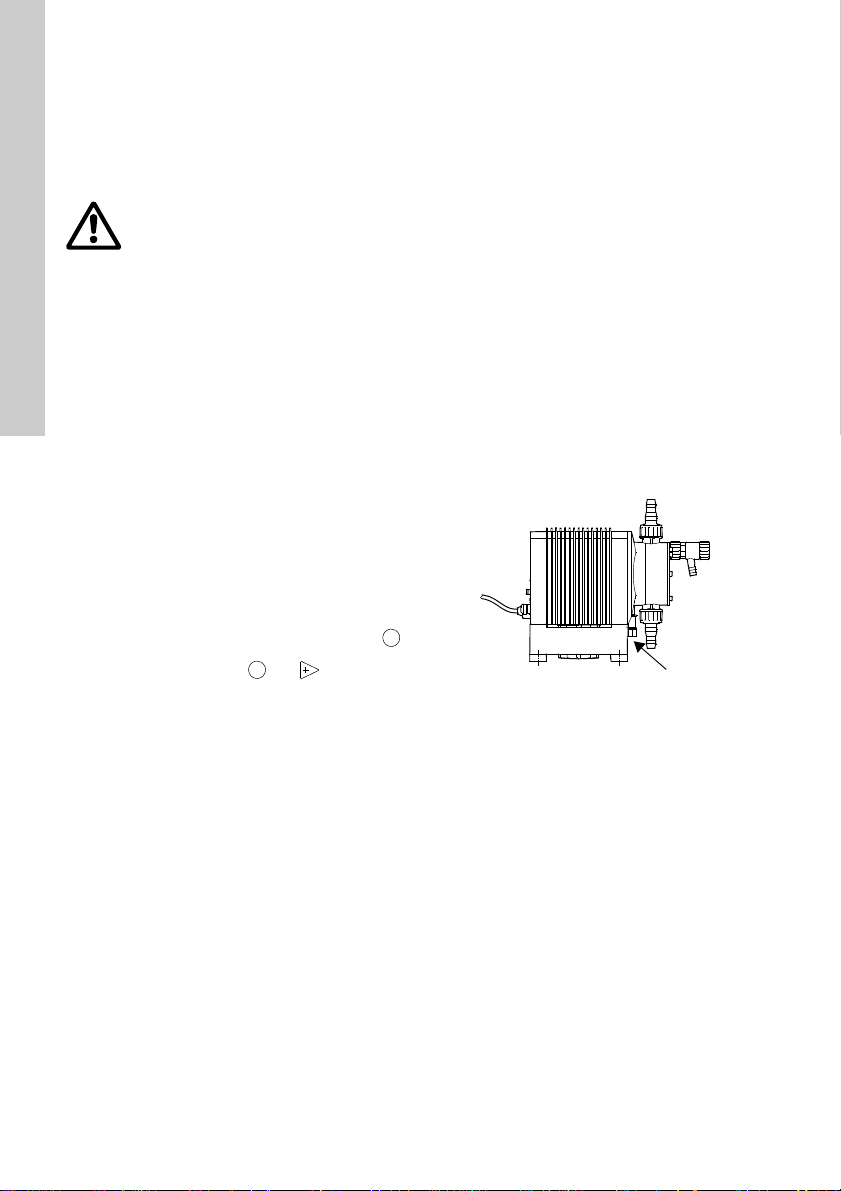

• Make sure that the drain hole in the dosing head

points downwards, see fig. 1.

Note: It is important that the drain pipe/hole is

not inserted direct into the tank contents, as

gasses may penetrate into the pump.

Fig. 1

TM02 7066 2503

10

Page 11

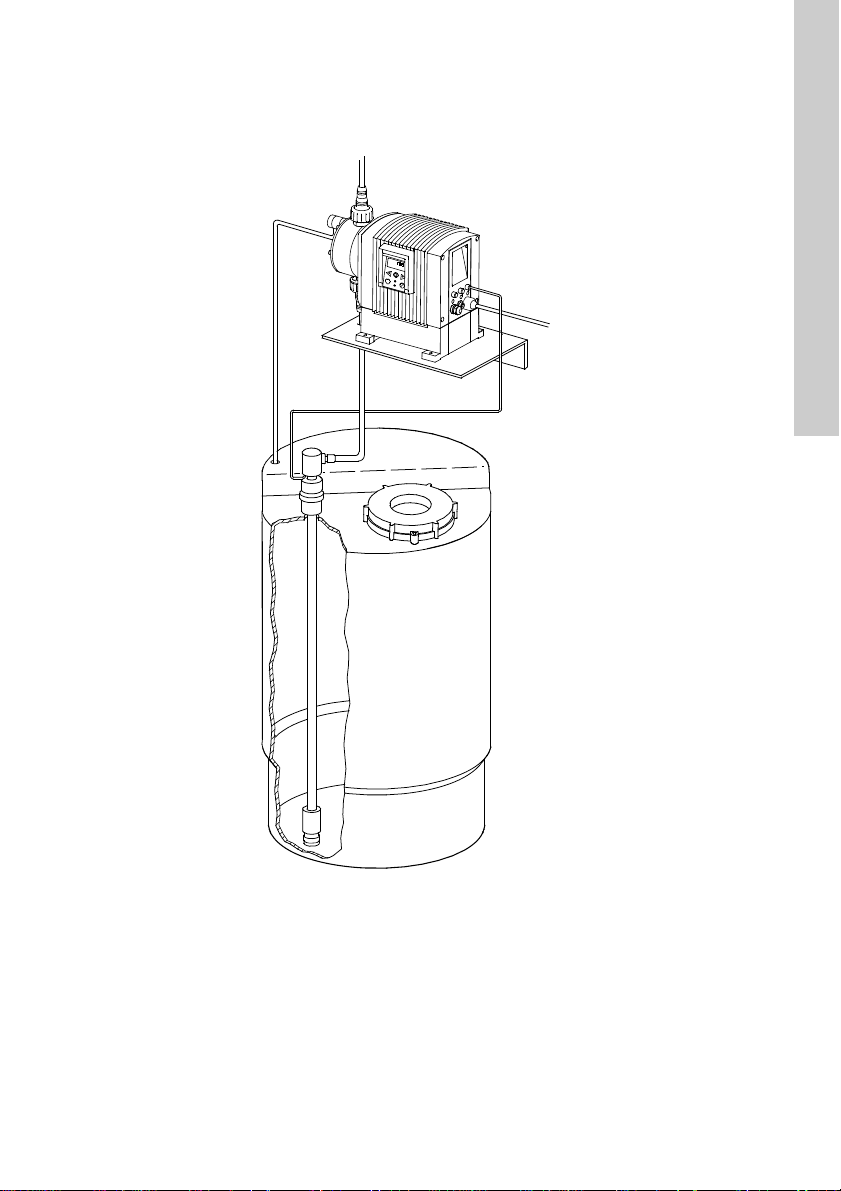

4.4 Installation example

The drawing in fig. 2 shows an installation example.

The DME pump can be installed in many different ways. The sketch below shows an example with sidefitted control panel. The tank is a Grundfos chemical tank with a Grundfos level control unit.

English (GB)

Fig. 2

4.5 Electrical connection

• The electrical connection of the pump should be

carried out by qualified persons in accordance

with local regulations.

• For electrical data of the pump, see section 3.2.

• Do not lay signal cables, if any, together with

power cables.

TM02 7065 0604

11

Page 12

4.6 Connection overview

Cable 1.

See table below

Cable 2.

See table below

Cable 3.

See table below

Cable 4.

See table below

2

1

3

4

5

3

1

4

2

3

1

2

3

1

5

2

5

2

2

3 1

1

3

4

5

2

1

3

4

2

1

3

4

English (GB)

Fig. 3

Cable 1: Input for analog signal, pulse signal and diaphragm leakage

Number / colour 1 / brown 2 / white 3 / blue 4 / black 5 / grey

Function

Analog

Pulse Potential-free Potential-free

Pulse 5 V Ground

Number / colour 2 / black 3 / brown 4 / blue

Diaphragm leakage* 5 V PNP Ground

* Grundfos diaphragm leakage sensor, product number 96534443

Cable 2: Alarm relay output

Number / colour 1 / brown 2 / white 3 / blue

Function

Alarm relay Common Normally open Normally closed

12

TM02 7069 0307

(–) 4-20 mA

input

(+) 4-20 mA

input

Page 13

Cable 3: Input for dosing stop and dosing moni toring or dosing o utput

Relay

Lamp

Power

Lamp

24 VDC

Number / colour 1 / brown 2 / white 3 / blue 4 / black 5 / grey

Function

Dosing stop (input) 5 V Ground

Dosing stop (input) Potential-free Potential-free

Dosing monitoring Potential-free Potential-free

Dosing monitoring Ground 5 V

Dosing output

(pump running)

* Open collector (NPN) can be used for a relay or a lamp.

Open collector

(NPN)*

Ground

English (GB)

1. Using the intern al 5 VDC power supply:

Max. current: 100 mA

Fig. 4

Cable 4: Level input

Number / colour 1 / brown 2 / white 3 / blue 4 / black

Function

Empty tank Potential-free* Potential-free*

Empty tank 5 V Ground

Low level Potential-free* Potential-free*

Low level 5 V Ground

* The function of the potential-free contact sets can

be selected via the control panel (NO = normally

open and NC = normally closed), see

section 5.21.

2. Using an externa l power supply:

Max. 24 VDC - 100 mA

TM03 7868 5006

TM03 7869 5006

13

Page 14

5. Functions

100%

LCD display.

See section 5.8

Navigation/

settings.

See section 5.8

Green indicator

light.

See section 5.6

Maximum capacity

(priming).

See section 5.3

Red indicator light.

See section 5.6

M12 connection

analog/pulse /

leakage input.

See sections

5.11, 5.12, 5.5

Cable for

Profibus control.

See section 5.7

Connection alarm

relay.

See section 5.6

Power supply

M12 connection

level control.

See section 5.4

M12 connection

stop dosing.

See section 5.2

On/off button.

See section 5.8

Navigation/

settings.

See section 5.8

Menu.

See section 5.8

English (GB)

5.1 Control panel

Fig. 5

TM02 7068 2503

14

Page 15

5.2 Start/stop of pump

100%

100%

The pump can be started/stopped in two different

ways:

• Locally on the pump control panel.

• By means of an external on/off switch.

See connection overview in section 4.6.

5.3 Priming/venting of pump

The pump control panel incorporates a button.

Press this button if the maximum pump capacity is

required over a short period, e.g. during start-up.

When the button is released, the pump automatically

returns to the previous operating mode.

During priming/venting, it is recommended to let the

pump run without a counter pressure or to open the

vent valve.

Note: When the buttons and are pressed

simultaneously, the pump can be set to run for a

specific number of seconds at maximum capacity.

The remaining number of seconds will appear in the

display. The maximum value is 300 seconds.

5.4 Level control

The pump can be fitted with a level control unit for

monitoring of the chemical level in the tank.

The pump can react to two level signals. The pump

will react differently, depending on the influence on

the individual level sensors.

Level sensors Pump reaction

Upper sensor

activated

(closed contact)

Lower sensor

activated

(closed contact)

• Red indicator light is on.

• Pump running.

• Alarm relay activated.

• Red indicator light is on.

• Pump stopped.

• Alarm relay activated.

For connection of the level control unit and alarm

output, see section 4.6.

5.5 Diaphragm leakage sensor

The pump can be fitted with a diaphragm leakage

sensor, which detects diaphragm leakage.

The sensor should be connected to the drain hole in

the dosing head.

In case of diaphragm leakage, the signal from the

sensor generates an alarm and the alarm relay will

be activated. See also section 5.6.

For connection of the diaphragm leakage sensor,

see section 4.6.

English (GB)

15

Page 16

5.6 Alarm output and indicator lights

Note

1 32

NC NO C

1 32

NC NO C

1

2 3

NC NO C

1 32

NC NO C

1

2 3

NC NO C

1

2 3

NC NO C

1

2 3

NC NO C

1

2 3

NC NO C

1

2 3

NC NO C

1

2 3

NC NO C

1

2 3

NC NO C

1

2 3

NC NO C

English (GB)

The green and red indicator lights on the pump are

used for operating and fault indication.

In control variant "AR", the pump can activate an

external alarm signal by means of a built-in alarm

relay which must only be connected to a safety extra

low voltage (SELV) connection.

The alarm signal is activated by means of an internal

potential-free contact.

The functions of the indicator lights and the built-in

alarm relay appear from the table below.

Connect the alarm relay only to

voltages which comply with the SELV

requirements in EN/IEC 60 335-1.

Condition Green LED Red LED Display Alarm output

Pump running On Off Normal indication

Set to stop Flashing Off Normal indication

Pump fault Off On EEPROM

Supply failure Off Off Off

Pump running, low

chemical level

Empty tank

Analog signal

< 2 mA

1

1

On On LOW

Off On EMPTY

Off On NO mA

The pump is

running, but the

dosed quantity is

too small according

to the signal from

the dosing

2

monitor

On On NO FLOW

Overheating Off On MAX. TEMP.

Internal

communication fault

Internal Hall fault

Diaphragm

leakage

3

4

Off On INT. COM.

Off On HALL

Off On LEAKAGE

16

Page 17

Condition Green LED Red LED Display Alarm output

1

2 3

NC NO C

1

2 3

NC NO C

1

2 3

NC NO C

Maximum pressure

exceeded

4

More pulses than

capacity

No motor rotation

3

detected

1

Requires connection to level sensors.

5

Off

On On MAX. FLOW

Off On ORIGO

See section 5.22 Empty tank (alarm).

2

Requires activation of the dosing monitoring

function and connection to a dosing monitor.

3

Please contact a Grundfos service centre.

4

Alarms can be reset when the faults have

been corrected.

5

The pump will make 10 attempts to restart

before going into permanent OFF mode.

5.7 Fieldbus communication

The pump can be configured for fieldbus applications

(Profibus). Apart from the usual installation and

operating instructions, Profibus pumps are supplied

with a special Profibus installation and operating

instructions.

On OVERLOAD

English (GB)

17

Page 18

5.8 Menu

Applies only to versions with Profibus

English (GB)

The pump features a user-friendly menu which is

activated by pressing the button. During start-up,

all texts will appear in English language. To select

language, see section 5.20.

Fig. 6

See section 5.10 See section 5.25

All menu items are described in the following

sections. When appears at a menu item, it

means that this item is activated. By selecting

"RETURN" anywhere in the menu structure, you will

return to the operating display without changes.

18

See section 5.11 See section 5.18

See section 5.12 See section 5.19

See section 5.13 See section 5.20

See section 5.14 See section 5.16

See section 5.15 See section 5.21

See section 7. See section 5.22

See section 5.17 See section 5.23

Page 19

5.9 Operating modes

Set value

Set quantity in

ml/pulse

Actual capacity in

ml/h or l/h

Note: The displayed l and ml values are only reliable

if the pump has been calibrated to the actual

installation, see section 7.

The pump can run in five different operating modes:

•Manual

•Pulse

•Analog

• Timer (internal batch control)

• Batch (external batch control)

See description in the following sections.

5.10 Manual

The pump is dosing as constantly and evenly as

possible, without any external signals.

Set the quantity to be dosed in l/h or ml/h. The pump

automatically changes between the measuring units.

Setting range:

DME 60: 75 ml/h - 60 l/h

DME 150: 200 ml/h - 150 l/h

DME 375: 500 ml/h - 375 l/h

DME 940: 1200 ml/h - 940 l/h

Fig. 7

5.11 Pulse

The pump is dosing according to an external pulse

signal, i.e. a water meter with pulse output or a

controller.

Set the quantity to be dosed per pulse in ml/pulse.

The pump adjusts its capacity according to two

factors:

• Frequency of external pulses.

• The set quantity per pulse.

The pump measures the time between two pulses

and then calculates the speed giving the capacity

required (set quantity per pulse multiplied by the

pulse frequency).

The pump does not start until it has received the

second pulse, and thus it delivers a constant flow as

in the case of "manual" control. The pump calculates

a speed for each pulse received.

The pump stops

• when the time between two pulses is three times

longer than the time between the two previous

pulses, or

• if the time between two pulses exceeds

2 minutes.

The pump will operate at the latest calculated speed

until one of the two cases occurs.

The pump stops at the point reached in its duty cycle

and starts at this point again having received two

new pulses.

Setting range:

DME 60: 0.000625 ml/pulse - 120 ml/pulse

DME 150: 0.00156 ml/pulse - 300 ml/pulse

DME 375: 0.00392 ml/pulse - 750 ml/pulse

DME 940: 0.00980 ml/pulse - 1880 ml/pulse

Fig. 8

If the set quantity per pulse multiplied by the pulse

frequency exceeds the pump capacity, the pump will

run at maximum capacity. Excess pulses will be

ignored and "MAX. FLOW" will appear in the display.

19

English (GB)

Page 20

5.12 Analog

0 4 8 12 16 20

0

20

40

60

80

100

[%]

0-20 mA

[mA]

4-20 mA

Value according to

analog signal

Use the buttons

for navigation

English (GB)

The pump is dosing according to an external analog

signal. The dosed quantity is proportional to the input

value in mA.

4-20 (default): 4 mA = 0 %.

20-4: 4 mA = 100 %.

0-20: 0 mA = 0 %.

20-0: 0 mA = 100 %.

20 mA = 100 %.

20 mA = 0 %.

20 mA = 100 %.

20 mA = 0 %.

See fig. 9.

The capacity limitation will influence the capacity.

100 % corresponds to the maximum capacity of the

pump or the set maximum capacity, see section 5.16.

The analog input requires a signal which is isolated

from frame. Min. resistance to frame: 50 k

Fig. 9

Change the analog mode as illustrated in fig. 11:

Fig. 11

TM02 4498 1102

Fig. 10

If 4-20 mA or 20-4 mA is selected and the signal falls

below 2 mA, the pump will indicate a fault. This

situation occurs if the connection is interrupted, for

instance if the wire is damaged.

20

Page 21

5.13 Timer

NX

IN

Quantity per batch

Set quantity

per batch

Set IN value

in days

Set IN value

in hours

Set IN value

in minutes

Set NX value

in days

Set NX value

in hours

Set NX value

in minutes

The pump is dosing the set quantity in batches at the

maximum capacity or the set maximum capacity, see

section 5.16.

The time until the first dosing "NX" and the following

sequences "IN" can be set in minutes, hours and

days. The maximum time limit is 9 days, 23 hours

and 59 minutes (9:23:59). The lowest acceptable

value is 1 minute.

if the pump is stopped by means of the on/off button,

empty tank or stop signal, see fig. 12.

During operation, "NX" will always count down from

"IN" to zero. In this way, the remaining time until the

next batch can always be read.

"IN" must be higher than the time required to perform

one batch. If "IN" is lower, the next batch will be

ignored.

In case of supply failure, the set quantity to be

dosed, the "IN" time and the remaining "NX" time are

stored. When the supply is reconnected, the pump

will start up with the "NX" time at the time of the

supply failure. In this way, the timer cycle will

continue, but it has been delayed by the duration of

the supply failure.

The internal timer continues even

English (GB)

Fig. 12

Setting range:

DME 60: 6.25 ml/batch - 120 l/batch

DME 150: 15.6 ml/batch - 300 l/batch

DME 375: 39.1 ml/batch - 750 l/batch

DME 940: 97.9 ml/batch - 1880 l/batch

Only values corresponding to complete dosing

strokes (according to the calibration factor) can be

selected. The minimum setting depends on the

calibration factor. The minimum setting shown above

corresponds to the default calibration value.

Example:

If the calibration factor is 625 (= 6.25 ml/stroke), the

minimum settable value in timer or batch mode will

be 6.25 ml (= 1 stroke) -> the next will be 12.5 ml

(= 2 strokes), etc.

These steps will continue up to a value

corresponding to 100 dosing strokes. Above this

value, the setting range has standard steps as in

other operating modes.

If the calibration factor is changed after the setting of

timer or batch mode, the pump will automatically

recalculate a new number of dosing strokes per

batch and change the display value to the nearest

possible value compared to the first one set.

TM01 8942 0900

Fig. 13

21

Page 22

5.14 Batch

Quantity per batch

Pulse Pulse

Set value per batch

Operating display

English (GB)

The pump is dosing the set quantity in batches at the

maximum capacity or the set maximum capacity, see

section 5.16.

The quantity is dosed every time the pump receives

an external pulse.

If the pump receives new pulses before the previous

batch is performed, these pulses will be ignored.

Fig. 14

The setting range is the same as for Timer, see

section 5.13.

Fig. 15

5.15 Anti-cavitation

The pump features an anti-cavitation function. When

this function is selected, the pump extends its

suction stroke, resulting in optimized priming.

The anti-cavitation function is used:

• when pumping liquids of high viscosity

TM01 8947 0900

• in the case of a long suction tube

• in the case of a high suction lift.

Depending on the circumstances, the motor speed

during the suction stroke can be reduced by 75 %,

50 % or 25 % compared to the normal motor speed

during the suction stroke.

The maximum pump capacity is reduced when the

anti-cavitation function is selected. See section

3.1 Mechanical data.

Fig. 16

22

Page 23

5.16 Capacity limitation

100%

Operating display

Set maximum capacity

Total dosed

quantity

Total number

of strokes

Total number of

operating hours

Total number

of starts

Operating display

This function offers the possibility of reducing the

maximum pump capacity (MAX. CAP.). It influences

the functions in which the pump is normally operating

at maximum capacity.

Under normal operating conditions, the pump cannot

operate at a capacity which is higher than the one

stated in the display. This does not apply to the

maximum capacity button , see section 5.3.

English (GB)

Fig. 17

5.17 Counters

The pump can display "non-resettable" counters for:

•"QUANTITY"

Accumulated value of dosed quantity in litres or

US gallons.

•"STROKES"

Accumulated number of dosing strokes.

•"HOURS"

Accumulated number of operating hours.

•"POWER ON"

Accumulated number of times the electricity

supply has been switched on.

Fig. 18

23

Page 24

5.18 Resetting

Operating display

Operating display

without changes

English (GB)

When "DEFAULT" is activated, the pump will return

to the factory settings.

Note: The calibration is also set back to the default

setting. This means that a new calibration is required

when the "DEFAULT" function has been used.

Default settings are the factory settings of standard

pumps. Select "DEFAULT" in the "SETUP" menu.

Default settings:

Operating mode: Manual

Capacity: Maximum capacity

Control panel lock: Unlocked

Default lock code: 2583

Anti-cavitation: Not active

Analog signal: 4-20 mA

Digital inputs: NO (normally open)

Capacity limitation: Maximum capacity

Alarm reset required to restart the pump

Dosing monitoring: Off

Language: English

Units: Metric

Fig. 19

5.19 Return

Fig. 20

The "RETURN" function makes it possible to return

from any level in the menu to the operating display

without changes after the menu functions have been

used.

24

5.20 Language

The display text can be displayed in one of the

following languages:

• English

•German

• French

• Italian

• Spanish

• Portuguese

•Dutch

• Swedish

• Finnish

• Danish

• Czech

•Slovak

•Polish

•Russian

Page 25

Fig. 21

Operating display Operating display Operating display

without changes

Use the buttons

for navigation

5.21 Input setup

Fig. 22 shows all possible settings.

The inputs for level, stop dosing and diaphragm

leakage can be changed from NO (normally open) to

NC (normally closed) function. If changed, the inputs

must be short-circuited in normal operation. The

dosing monitoring input can be changed from "OFF"

to "ON".

For the analog input, one of the following signal

types can be selected:

• 4-20 mA (default)

• 20-4 mA

• 0-20 mA

• 20-0 mA.

See also section 5.12 Analog.

English (GB)

Fig. 22

25

Page 26

5.22 Empty tank (alarm)

Operating display O perating display

3 x

English (GB)

The alarm function can be set to "AUT. RES." or

"MAN. RES.". This function is used when the level

sensor indicates "EMPTY".

The alarm can be reset automatically (AUT. RES.) or

manually (MAN. RES.).

For more information about other alarm functions,

see section 5.6 Alarm output and indicator lights.

5.23 Measuring units

It is possible to select metric units (litre/millilitre) or

US units (gallons).

Metric measuring units:

• In manual and analog modes, set the quantity

to be dosed in litres per hour (l/h) or millilitres per

hour (ml/h).

• In pulse mode, set the quantity to be dosed in

ml/pulse. The actual capacity is indicated in litres

per hour (l/h) or millilitres per hour (ml/h).

• For calibration, set the quantity to be dosed in

ml per 100 strokes.

• In timer and batch modes, set the quantity to be

dosed in litres (l) or millilitres (ml).

• Under the "QUANTITY" menu item in the

"COUNTERS" menu, the dosed quantity is

indicated in litres.

US measuring units:

• In manual and analog modes, set the quantity

to be dosed in gallons per hour (gph).

• In pulse mode, set the quantity to be dosed in

ml/pulse. The actual capacity is indicated in

gallons per hour (gph).

• For calibration, set the quantity to be dosed in

ml per 100 strokes.

• In timer and batch modes, set the quantity to be

dosed in gallons (gal).

• Under the "QUANTITY" menu item in the

"COUNTERS" menu, the dosed quantity is

indicated in US gallons (gal).

26

Fig. 23

Page 27

5.24 Dosing monitoring

2 x

3 x

The pump incorporates a dosing monitoring input (see connection overview in fig. 3).

Fig. 24

The dosing monitoring input is designed to receive a

potential-free pulse signal from a dosing monitor.

The dosing monitoring input feature enables the

pump to react on gas accumulation in the suction

line.

A dosing monitor must always be connected to the

suction side of the pump.

English (GB)

27

Page 28

5.25 Control panel lock

100%

Operating display

Operating display

English (GB)

It is possible to lock the buttons on the control panel

to prevent malfunction of the pump. The locking

function can be set to "ON" or "OFF". The default

setting is "OFF".

A PIN code must be entered to change from "OFF" to

"ON". When "ON" is selected for the first time,

"0000" will appear in the display. If a code has

already been entered, it will appear when an attempt

to change to "ON" is made. This code can either be

re-entered or changed.

If no code has been entered, a code must be set in

the same way as the "NX" and "IN" values described

in section 5.13.

If a code has already been entered, active digits are

flashing.

If attempts are made to operate the pump in locked

condition, "LOCKED" will appear in the display for

2 seconds, followed by "0000". A code must be

entered. If the entering of a code has not been

started within 10 seconds, the operating display

without changes will appear.

If a wrong code is entered, "LOCKED" will appear in

the display for 2 seconds, followed by "0000". A new

code must be entered. If the entering of a code has

not been started within 10 seconds, the operating

display without changes will appear. This display will

also appear if the entering of the correct code

exceeds 2 minutes.

If the locking function has been activated but the

control panel is unlocked, the control panel will be

locked automatically if it is not operated for 2

minutes.

The locking function can also be reactivated by

selecting "ON" in the "LOCK" menu. The previously

entered code will then appear and must be reentered by pressing the button four times. The

code can also be changed.

The control panel can be unlocked either by means

of the selected code or the factory code 2583.

The following buttons and inputs are still active when

the panel is locked:

• Priming ( -button).

• On/off button.

• All external inputs.

Fig. 25

Activating the locking function and locking the

control panel:

1. Select "LOCK" in the menu.

2. Select "ON" by means of the buttons and

and confirm with .

3. Enter or re-enter a code by means of the buttons

, and .

The locking function has now been activated and the

control panel is locked.

Unlocking the control panel (without deactivating

the locking function):

1. Press once. "LOCKED" appears in the

display for 2 seconds, followed by "0000".

2. Enter the code by means of the buttons ,

and *.

28

The control panel has now been unlocked and will

automatically be locked again if the control panel is

not operated for 2 minutes.

Deactivating the locking function:

1. Unlock the control panel as described above.

2. Select "LOCK" in the menu.

3. Select "OFF" by means of the buttons and

and confirm with .

The locking function has now been deactivated and

the control panel is unlocked.

* The panel can always be unlocked with

code 2583.

Page 29

6. Start-up

100%

100%

100%

100%

100%

Step Action

1

Prior to start-up, retighten the dosing head screws:

• Cross-tighten the screws to 5.5 Nm (+ 0.5/– 0 Nm).

English (GB)

Connect the hoses/pipes:

2

• Connect the suction and dosing tubes/pipes to the pump.

• Connect a tube to the vent valve, if required, and lead the hose to

the tank.

Connect the cables:

3

• Connect the control/level cables, if any, to the pump, see

section 4.6.

Switch on the electricity supply:

4

• The display is on.

• The green indicator light is flashing (the pump has stopped).

• Select language, if required, see section 5.20.

Select the operating mode (see section 5.9):

• Manual.

5

•Pulse.

• Analog.

•Timer.

•Batch.

6

• Start the pump by pressing the on/off button.

• The green indicator li ght is perman ently on.

Priming/venting:

• Press the button on the pump control panel and let the pump

Start the pump:

7

run without a counter pressure. Open the vent valve, if required.

When the buttons and are pressed simultaneously during

priming, the pump can be set to run for a specific number of

seconds at maximum capacity.

Calibration:

8

• When the pump has been primed and is running at the right

counter pressure, calibrate the pump, see section 7.

If the pump is not operating satisfactorily, see section 10. Fault finding chart.

29

Page 30

7. Calibration

Operating display

without changes

Set value.

See section 7.2

Operating display Operating display

The pump

performs 100

dosing strokes

English (GB)

It is important that the pump is calibrated after

installation to ensure that the correct value (ml/h or

l/h) appears in the display.

The calibration can be carried out in two different

ways:

• Direct calibration.

The dosed quantity of 100 strokes is measured

directly. See section 7.1.

• Check calibration. See section 7.2.

Fig. 26

30

Page 31

7.1 Direct calibration

Set value

to Q

d

Operating display

Q

1

Q

2

Q

d

Before calibration, make sure:

• that the pump is installed with foot valve, injection

valve, etc. in the existing system.

• that the pump is running at the counter pressure

it is supposed to operate at (adjust the counter

pressure valve, if required).

• that the pump is operating with the correct

suction lift.

To carry out a direct calibration, proceed as follows:

Action Pump display

1. Prime the dosing head and the suction tubing.

2. Stop the pump. The green LED is flashing.

3. Fill a graduated glass with dosing liquid, Q

.

1

DME 60: approx. 1.5 l

DME 150: approx. 2.5 l

DME 375: approx. 6 l

DME 940: approx. 14 l

4. Read and note the quantity Q

.

1

5. Place the suction tubing in the graduated glass.

TM02 7067 2503

6. Go to the calibration menu, see section 5.8.

English (GB)

7. Press the button twice.

8. The pump is performing 100 dosing strokes.

9. The factory-calibration value appears in the display.

10.Remove the suction tubing from the graduated

glass and read Q

11.Set the display value to Q

.

2

= Q1 – Q2.

d

12.Confirm with the button.

13.The pump is now calibrated and returns to the

operating display.

31

Page 32

7.2 Check calibration

English (GB)

In check calibration, the calibration value is

calculated by reading the consumption of chemical in

a specific period and comparing this with the number

of dosing strokes performed in the same period.

This calibration method is very accurate and

especially suitable for check calibration after long

periods of operation or if direct calibration is

impossible. The calibration can for instance be

carried out when the chemical tank is replaced or

filled.

To carry out a check calibration, proceed as follows:

1. Stop the pump by pressing the button.

2. Read the counter and note the number of dosing

strokes, see section 5.17.

3. Read and note the quantity in the chemical tank.

4. St art the pump by pressing the button and let

it run for at least 1 hour. The longer the pump is

operating, the more accurate the calibration will

be.

5. Stop the pump by pressing the button.

6. Read the counter and note the number of dosing

strokes, see section 5.17.

7. Read and note the quantity in the chemical tank.

8. Calculate the dosed quantity in ml and the

number of dosing strokes performed during the

operating period.

9. Calculate the calibration value as follows:

(dosed quantity in ml/dosing strokes) x 100.

10.Set the calculated value in the calibration menu.

8. Maintenance

The pump is maintenance-free. However, it is

recommended to keep the pump clean.

The dosing pump is produced according to the

highest quality standards and has long life. The

pump incorporates wear parts such as diaphragm,

valve seat and valve balls.

To ensure long life and to reduce the risk o f

disturbance of operation, visual checks should be

carried out regularly.

It is possible to order dosing heads, valves and

diaphragms in materials which are suitable for the

specific liquid to be pumped. See the product

numbers at the end of these instructions.

9. Service

Before returning the pump to Grundfos for service,

the safety declaration at the end of these

instructions must be filled in by authorized personnel

and attached to the pump in a visible position.

Note: If a pump has been used for a liquid which is

injurious to health or toxic, the pump will be

classified as contaminated.

If Grundfos is requested to service the pump, it must

be ensured that the pump is free from substances

that can be injurious to health or toxic. If the pump

has been used for such substances, the pump must

be cleaned before it is returned.

If proper cleaning is not possible, all relevant

information about the chemical must be provided.

If the above is not fulfilled, Grundfos can refuse to

accept the pump for service. Possible costs of

returning the pump are paid by the customer.

The safety declaration can be found at the end of these

instructions (only in English).

Note: The replacement of the supply cable must be

carried out by an authorised Grundfos service

workshop.

32

Page 33

10. Fault finding chart

Subject to alterations.

Fault Cause Remedy

Valves leaking or blocked. Ch eck and clean valves.

Remove and fit valves. Check that the arrow

on the valve casing is pointing in the liquid

flow direction. Check that all O-rings have

been fitted correctly.

Clean and seal the suction pipe/hose.

Install the pump in a lower position.

Install a priming tank.

Select the anti-cavitation function, see

section 5.15.

Install a pipe/hose with larger cross-section.

Fit spring-loaded valves.

Install a new diaphragm and ensure that the

diaphragm is fastened properly.

Check the system. Check the injection valve.

The dosing has

stopped or the output

is too low.

Pump dosing too little

or too much.

Pump dosing

irregularly.

Leakage from drain

hole.

Frequent diaphragm

failures.

Valves incorrectly installed.

Suction valve or suction pipe/hose

leaking or blocked.

Suction lift too high.

Viscosity too high.

Pump out of calibration. Calibrate the pump, see section 7.

Pump out of calibration. Calibrate the pump, see section 7.

Valves leaking or blocked. Ch eck and clean the valves.

Diaphragm defective. Install a new diaphragm.

Diaphragm not fastened properly.

Counter-pressure too high

(measured at the pump discharge

port).

Sediment in dosing head. Clean/flush the dosi ng head.

English (GB)

11. Disposal

This product and all its associated parts must

be disposed of in an environmentally friendly

manner. Use appropriate waste collection

services. If there is no such facility or the facility

refuses to accept the materials used in the product,

the product can be sent to the nearest Grundfos

company or Grundfos service centre.

33

Page 34

Appendix 1

Dimensions

DME 60 DME 150 DME 375 DME 940

A = [mm] 176 176 238 238

B = [mm] 198 198 218 218

C = [mm] 331 345 471 496

D = [mm] 284 284 364 364

E = [mm] 180 180 230 230

F = [mm] 444 444 5 40 539

G = [mm] 41 28 31 6

H = [mm] 74 74 95 95

I = [mm] 187 187 246 246

Appendix

TM02 7062 2503

325

Page 35

Appendix 1

Appendix

Safety declaration

Please copy, fill in and sign this sheet and attach it to the pump returned for service.

We hereby declare that this product:

Product type:____________________________

Model number:_________________________

No media or water:_________________________

A chemical solution, name:_____________________

(see pump nameplate)

is free from hazardous chemicals, biological and radioactive substances.

Fault description

Please make a circle around the damaged part.

In the case of an electrical or functional fault, please mark the cabinet.

Please give a short description of the fault:

_________________ _________________

Date and signature Company stamp

326

TM02 8955 1104

Page 36

Argentina

Grundfos companies

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Lote 34A

1619 - Garin

Pcia. de Buenos Aires

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belorussia

Представительство ГРУНДФОС в Минске

220123, Минск,

ул. В. Хоружей, 22, оф. 1105

Тел.: +(37517) 233 97 65

Факс: (37517) 233 9769

E-mail: grundfos_minsk@mail.ru

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Trg Heroja 16 ,

BiH-71000 Sarajevo

Phone: +387 33 713 290

Telefax: +387 33 659 079

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo Branco,

630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

Grundfos Alldos

Dosing & Disinfection

ALLDOS (Shanghai) Water Technology Co.

Ltd.

West Unit, 1 Floor, No. 2 Building (T 4-2)

278 Jinhu Road, Jin Qiao Export

Processing Zone

Pudong New Area

Shanghai, 201206

Phone: +86 21 5055 1012

Telefax: +86 21 5032 0596

E-mail: grundfosalldos-CN@grundfos.com

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

22 Floor, Xin Hua Lian Building

755-775 Huai Hai Rd, (M)

Shanghai 200020

PRC

Phone: +86-512-67 61 11 80

Telefax: +86-512-67 61 81 67

Croatia

GRUNDFOS CROATIA d.o.o.

Cebini 37, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.grundfos.hr

Czech Republic

GRUNDFOS s.r.o.

Čapkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Mestarintie 11

FIN-01730 Vantaa

Phone: +358-3066 5650

Telefax: +358-3066 56550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS Water Treatment GmbH

Reetzstraße 85

D-76327 Pfinztal (Söllingen)

Tel.: +49 7240 61-0

Telefax: +49 7240 61-177

E-mail: gwt@grundfos.com

Germany

GRUNDFOS GMBH

Schlüterstr. 33

D-40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

E-mail: infoservice@grundfos.de

Service in Deutschland:

E-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 096

Phone: +91-44 2496 6800

Indonesia

PT GRUNDFOS Pompa

Jl. Rawa Sumur III, Blok III / CC-1

Kawasan Industri, Pulogadung

Jakarta 13930

Phone: +62-21-460 6909

Telefax: +62-21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg. 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo,

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Page 37

México

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

România

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундфос

Россия, 109544 Москва, ул. Школьная 39

Тел. (+7) 495 737 30 00, 564 88 00

Факс (+7) 495 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47 496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

24 Tuas West Road

Jurong Town

Singapore 638381

Phone: +65-6865 1222

Telefax: +65-6861 8402

Slovenia

GRUNDFOS d.o.o.

Šlandrova 8b, SI-1231 Ljubljana-Črnuče

Phone: +386 1 568 0610

Telefax: +386 1 568 0619

E-mail: slovenia@grundfos.si

South Africa

Grundfos (PTY) Ltd.

Corner Mountjoy and George Allen Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

(Box 333) Lunnagårdsgatan 6

431 24 Mölndal

Tel.: +46(0)771-32 23 00

Telefax: +46(0)31-331 94 60

Switzerland

GRUNDFOS ALLDOS International AG

Schönmattstraße 4

CH-4153 Reinach

Tel.: +41-61-717 5555

Telefax: +41-61-717 5500

E-mail: grundfosalldos-CH@grundfos.com

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-1-806 8111

Telefax: +41-1-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd. Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

ТОВ ГРУНДФОС УКРАЇНА

01010 Київ, Вул. Московська 8б,

Тел.:(+38 044) 390 40 50

Фах.: (+38 044) 390 40 59

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 8TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Usbekistan

Представительство ГРУНДФОС в

Ташкенте

700000 Ташке нт ул.Усмана Носира 1-й

тупик 5

Телефон : (3712) 55-68-15

Факс: (3712) 53-36-35

Grundfos companies

Addresses revised 03.11.2010

Page 38

Being responsible is our foundation

Thinking ahead makes it possible

Innovation is the essence

96527377 0311

Repl. 96527377 0111

ECM: 1065172

The name Grundfos, the Grundfos logo, and the payoff Be–Think–Innovate are registrated trademarks

owned by Grundfos Management A/S or Grundfos A/S, Denmark. All rights reserved worldwide.

www.grundfosalldos.com

Loading...

Loading...