Grundfos DME series, DME 12 series, DME 19 series, DME 48 series, DME 8 series Installation And Operating Instructions Manual

...Page 1

DME

Installation and operating instructions

Montage- und Betriebsanleitung

Notice d’installation et d’entretien

Istruzioni di installazione e funzionamento

Instrucciones de instalación y funcionamiento

Instruções de instalação e funcionamento

√‰ЛБ›В˜ ВБО·Щ¿ЫЩ·ЫЛ˜ О·И ПВИЩФùÚÁ›·˜

Installatie- en bedieningsinstructies

Monterings- och driftsinstruktion

Asennus- ja käyttöohjeet

Monterings- og driftsinstruktion

GRUNDFOS INSTRUCTIONS

Page 2

Declaration of Conformity

We GRUNDFOS declare under our sole responsibility that the products DME, to which this declaration relates, are in conformity with

the Council Directives on the approximation of the laws of the EEC

Member States relating to

– Machinery (98/37/EEC).

Standard used: EN 292.

– Electromagnetic compatibility (89/336/EEC).

Standards used: EN 61 000-6-2 and EN 61 000-6-3.

– Electrical equipment designed for use within certain voltage lim-

its (73/23/EEC).

Standards used: EN 60 335-1 and EN 60 335-2-41.

Konformitätserklärung

Wir GRUNDFOS erklären in alleiniger Verantwortung, daß die Produkte DME, auf die sich diese Erklärung bezieht, mit den folgenden

Richtlinien des Rates zur Angleichung der Rechtsvorschriften der

EG-Mitgliedstaaten übereinstimmen:

– Maschinen (98/37/EWG).

Norm, die verwendet wurde: EN 292.

– Elektromagnetische Verträglichkeit (89/336/EWG).

Normen, die verwendet wurden: EN 61 000-6-2 und

EN 61 000-6-3.

– Elektrische Betriebsmittel zur V erwendung innerhalb b estimmter

Spannungsgrenzen (73/23/EWG).

Normen, die verwendet wurden: EN 60 335-1 und

EN 60 335-2-41.

Déclaration de Conformité

Nous GRUNDFOS déclarons sous notre seule responsabilité que

les produits DME auxquels se réfère cette déclaration sont conformes aux Directives du Conseil concernant le rapprochement des

législations des Etats membres CEE relatives à

– Machines (98/37/CEE).

Standard utilisé: EN 292.

– Compatibilité électromagnétique (89/336/CEE).

Standards utilisés: EN 61 000-6-2 et EN 61 000-6-3.

– Matériel électrique destiné à employer dans certaines limites de

tension (73/23/CEE).

Standards utilisés: EN 60 335-1 et EN 60 335-2-41.

Dichiarazione di Conformità

Noi GRUNDFOS dichia riamo sotto la nostra es clusiva respon sabilità

che i prodotti DME ai quali questa dichiarazione se riferisce sono

conformi alle Direttive del Consiglio concernente il ravvicinamento

delle legislazioni degli Stati membri CEE relative a

– Macchine (98/37/CEE).

Standard usato: EN 292.

– Compatibilità elettromagnetica (89/336/CEE).

Standard usati: EN 61 000-6-2 e EN 61 000-6-3.

– Materiale elettrico destinato ad essere utilizzato entro certi limiti

di tensione (73/23/CEE).

Standard usati: EN 60 335-1 e EN 60 335-2-41.

Declaración de Conformidad

Nosotros GRUNDFOS declaramos bajo nuestra única responsabilidad que los productos DME a los cuales se refiere esta declaración

son conformes con las Directivas del Consejo relativas a la aproximación de las legislaciones de los Estados Miembros de la CEE

sobre

– Máquinas (98/37/CEE).

Norma aplicada: EN 292.

– Compatibilidad electromagnética (89/336/CEE).

Normas aplicadas: EN 61 000-6-2 y EN 61 000-6-3.

– Material eléctrico destinado a utilizarse con determinadas lími-

tes de tensión (73/23/CEE).

Normas aplicadas: EN 60 335-1 y EN 60 335-2-41.

Declaração de Conformidade

Nós GRUNDFOS declaramos sob nossa única responsabilidade

que os produtos DME aos quais se refere esta declaração estão em

conformidade com as Directivas do Conselho das Comunidades

Europeias relativas à aproximação das legislações dos Estados

Membros respeitantes à

– Máquinas (98/37/CEE).

Norma utilizada: EN 292.

– Compatibilidade electromagnética (89/336/CEE).

Normas utilizadas: EN 61 000-6-2 e EN 61 000-6-3.

– Material eléctrico destinado a ser utilizado dentro de certos limi-

tes de tensão (73/23/CEE).

Normas utilizadas: EN 60 335-1 e EN 60 335-2-41.

¢‹ÏˆÛË ™щММЮЪКˆЫЛ˜

∂Ì›˜ Ë GRUNDF OS ‰ЛПТУФùМВ МВ ·рФОПВИЫЩИО¿ ‰ИО ‹ М·˜ Вùõ‡ÓË

ÞÙÈ Ù· ðÚÔÈÞÓÙ· DME ÛùММФЪКТУФУЩ·И МВ ЩЛУ √‰ËÁ›· ÙÔù

™ùÌ‚ÔùÏ›Ôù Вр› ЩЛ˜ Ы‡БОПИЫЛ˜ ЩˆУ УÞÌˆÓ ÙˆÓ ∫Ú·ÙÒÓ MÂÏÒÓ Ù˘

∂ùÚˆð·È΋˜ ∂ ÓˆÛ˘ Û ۯ¤ ÛË Ì ٷ

– ªË¯·Ó‹ Ì·Ù· (9 8/37/EE C).

¶ÚÞÙùðÔ ðÔù ¯ЪЛЫ ИМФрФИ‹õËÎÂ: EN 292.

– ∏ПВОЩЪФМ·БУЛЩИО‹ ЫùÌ‚·ÙÞÙË Ù· (89/336/EEC).

¶ÚÞÙùð· ðÔù ¯ЪЛЫИМФрФИ‹õËηÓ: EN 61 000-6-2 ηÈ

EN 61 000-6-3.

– ∏ПВОЩЪИО¤˜ ЫùÛÎÂù¤˜ ۯ‰ȷṲ̂Ó˜ ÁÈ¿ ¯Ú‹ÛË ÂÓÙÞ˜

ФЪИЫМ¤УˆУ ФЪ›ˆУ ЛПВОЩЪИО‹˜ Щ¿ЫЛ˜ (73/23/EEC).

¶ЪÞÙùð· ðÔù ¯ЪЛЫИМФрФИ‹õËηÓ: EN 60 335-1 ηÈ

EN 60 335-2-41.

Overeenkomstigheidsverklaring

Wij GRUNDFOS verklaren g eheel onder eige n verantwoordelijkheid

dat de produkten DME waarop deze verklaring betrekking heeft in

overeenstemming zijn met de Richtlijnen van de Raad inzake de

onderlinge aanpassing van de wetgevingen van de Lid-Staten

betreffende

– Machines (98/37/EEG).

Norm: EN 292.

– Elektromagnetische compatibiliteit (89/336/EEG).

Normen: EN 61 000-6-2 en EN 61 000-6-3.

– Elektrisch materiaal bestemd voor gebruik binnen bepaalde

spanningsgrenzen (73/23/EEG).

Normen: EN 60 335-1 en EN 60 335-2-41.

Försäkran om överensstämmelse

Vi GRUNDFOS försäkrar under ansvar, att produkterna DME, som

omfattas av denna försäkran, är i överensstämmelse med Rådets

Direktiv om inbördes närmande till EU-medlemsstaternas lagstiftning, avseende

– Maskinell utrustning (98/37/EC).

Använd standard: EN 292.

– Elektromagnetisk kompatibilitet (89/336/EC).

Använda standarder: EN 61 000-6-2 och EN 61 000-6-3.

– Elektrisk material avsedd för användning inom vissa spännings-

gränser (73/23/EC).

Använda standarder: EN 60 335-1 och EN 60 335-2-41.

Vastaavuusvakuutus

Me GRUNDFOS vakuutamme yksin vastuullisesti, että tuotteet

DME, jota tämä vakuutus koskee, noudattavat direktiivejä jotka

käsittelevät EY:n jäsenvaltioiden koneellisia laitteita koskevien

lakien yhdenmukaisuutta seur.:

– Koneet (98/37/EY).

Käytetty standardi: EN 292.

– Elektromagneettinen vastaavuus (89/336/EY).

Käytetyt standardit: EN 61 000-6-2 ja EN 61 000-6-3.

– Määrättyjen jänniterajoitusten puitteissa käytettävät sähköiset

laitteet (73/23/EY).

Käytetyt standardit: EN 60 335-1 ja EN 60 335-2-41.

Overensstemmelseserklæring

Vi GRUNDFOS erklærer under ansvar, at produkterne DME, som

denne erklæring omhandler, er i overensstemmelse med Rådets

direktiver om indbyrdes tilnærmelse til EF medlemsstaternes lovgivning om

– Maskiner (98/37/EØF).

Anvendt standard: EN 292.

– Elektromagnetisk kompatibilitet (89/336/EØF).

Anvendte standarder: EN 61 000-6-2 og EN 61 000-6-3.

– Elektrisk materiel bestemt til anvendelse inden for visse

spændingsgrænser (73/23/EØF).

Anvendte standarder: EN 60 335-1 og EN 60 335-2-41.

Bjerringbro, 1st January 2002

Jan Strandgaard

Technical Manager

Page 3

4

CONTENTS

Page

1. General descr ipti on 4

1.1 Applications 4

1.2 Type key 5

2. Technical data 6

2.1 Mechanical da ta 6

2.2 Electrical data 6

2.3 Input/output d at a 6

2.4 Dimensions 7

3. Installation 7

3.1 Safety instructions 7

3.2 Installation envi r on m en t 7

3.3 Installation of p um p 7

3.4 Installation example 8

3.5 Electrical connection 8

3.6 Connection overview 9

4. Functions 10

4.1 Control panel 10

4.2 Start/sto p of pump 11

4.3 Priming/ventin g of pum p 11

4.4 Level control 11

4.5 Indicator ligh ts and ala r m outp ut 11

4.6 Fieldbus communicat ion 12

4.7 Menu 13

4.8 Operating mod e s 14

4.9 Manual 14

4.10 Pulse 14

4.11 Analo g 14

4.12 Timer 16

4.13 Batch 17

4.14 Anti-c avita t io n 17

4.15 Capacit y l imi t at i on 18

4.16 Counte r s 18

4.17 Resett ing 19

4.18 Return 19

4.19 Language 19

4.20 Input se tu p 20

4.21 Measu rin g uni ts 21

4.22 Dosing monitoring 22

4.23 Control panel lock 23

5. Start-up 24

6. Calibration 25

6.1 Direct calibration 26

6.2 Indirect cali bra tio n 27

6.3 Check calibration 28

7. Maintenan ce 28

8. Service 28

9. Fault finding chart 29

10. Disposal 29

Before beginning in stallation proc ed ur es,

these installation an d opera ting instr uctions should be studie d caref ull y. The installation and opera tio n shou ld also be in

accordance with local regulations and accepted codes of go od p rac ti ce.

1. General description

The GRUNDFOS DME dosing pump is a self-priming

diaphragm pump.

The pump c on sis t s o f:

•a cabinet incorporating the drive unit and elec-

tronics,

•a dosing head with back plate, diaphr ag m,

valves, connections and vent valve and

•a control panel incorporating display and but tons.

The control panel can be fitted either to the end or

to the side of the cabinet.

Being equipped with a stepper motor, this dosing

pump is unique in its field. The stepper motor offers

the possibility of varying the capacity by changing

the duration of the dosing stroke.

Furthermore, the mot or is co nt rolled in s uch a wa y

that the dosing gets as even and constant as possible, irrespective of the capacity range in which the

pump is oper a ting.

This is carried out as follows:

The speed of the suction stroke is kept constant and

the stroke relatively short, irrespective of the capacity. Contra ry to con v en tional pump s, whic h gener ate

the dosing st ro ke as a short pu l se, th e du ration of

the dosing stroke will be a s lo ng a s po ssible. Th us,

an even dosing without peak values is ensured. As

the pump is always dosing at full stroke length, it ensures the same high accuracy and suction capability,

irrespective of the capacity, which is infinitely variable in the ratio of 1:1000 .

The pump features an LCD display and a userfriendly control panel whi ch giv es acce ss to the

pump functions .

1.1 Applications

The DME dosin g pu m p is designed f or h an dl in g

chemicals within the following ranges of applications,

among others:

• Drinking water treatment.

• Wastewater treatment.

• Swimming pool water treatment.

• Boiler water treatment.

• Cooling wate r tr ea tm en t.

• Proc ess wate r tr ea tm en t.

• Washing sy ste ms.

Page 4

5

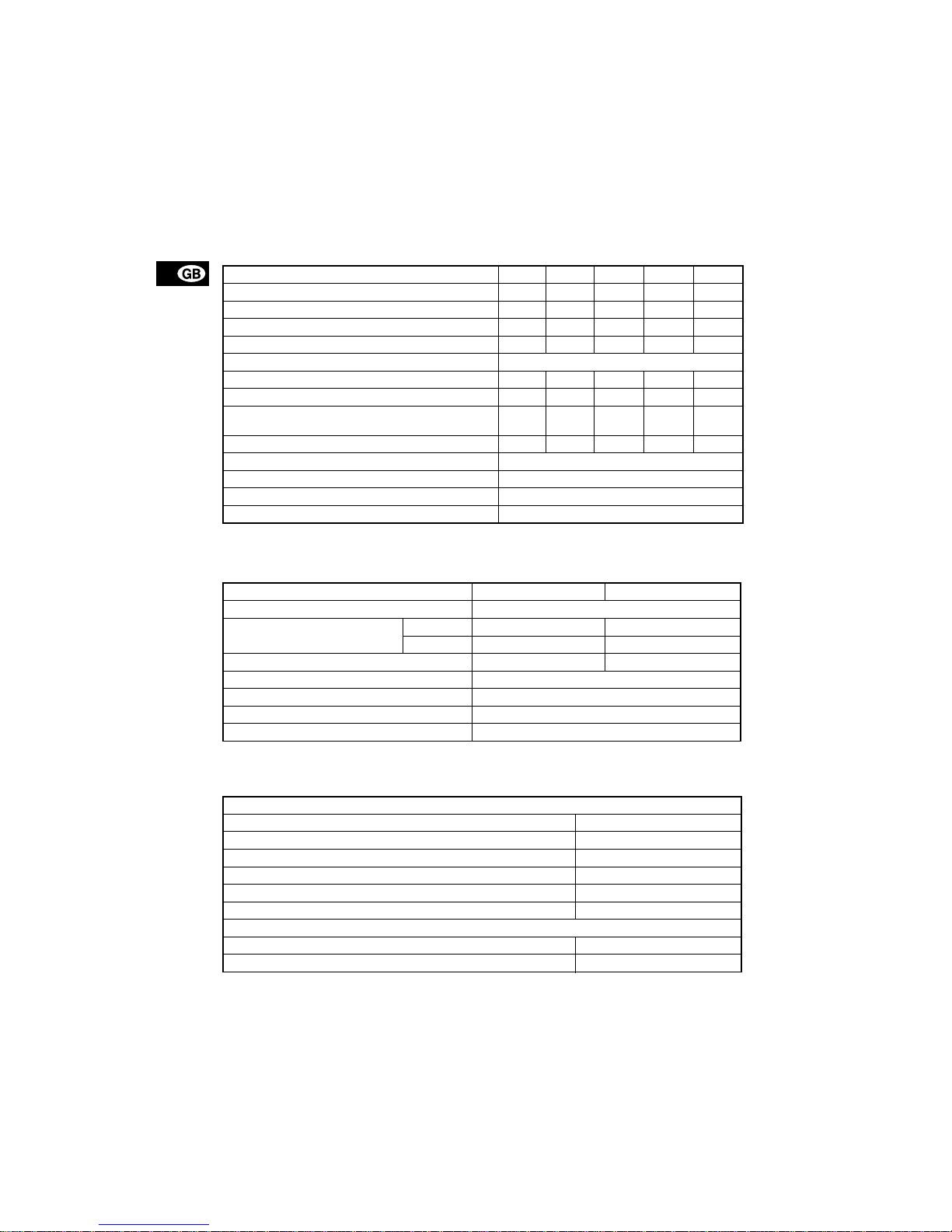

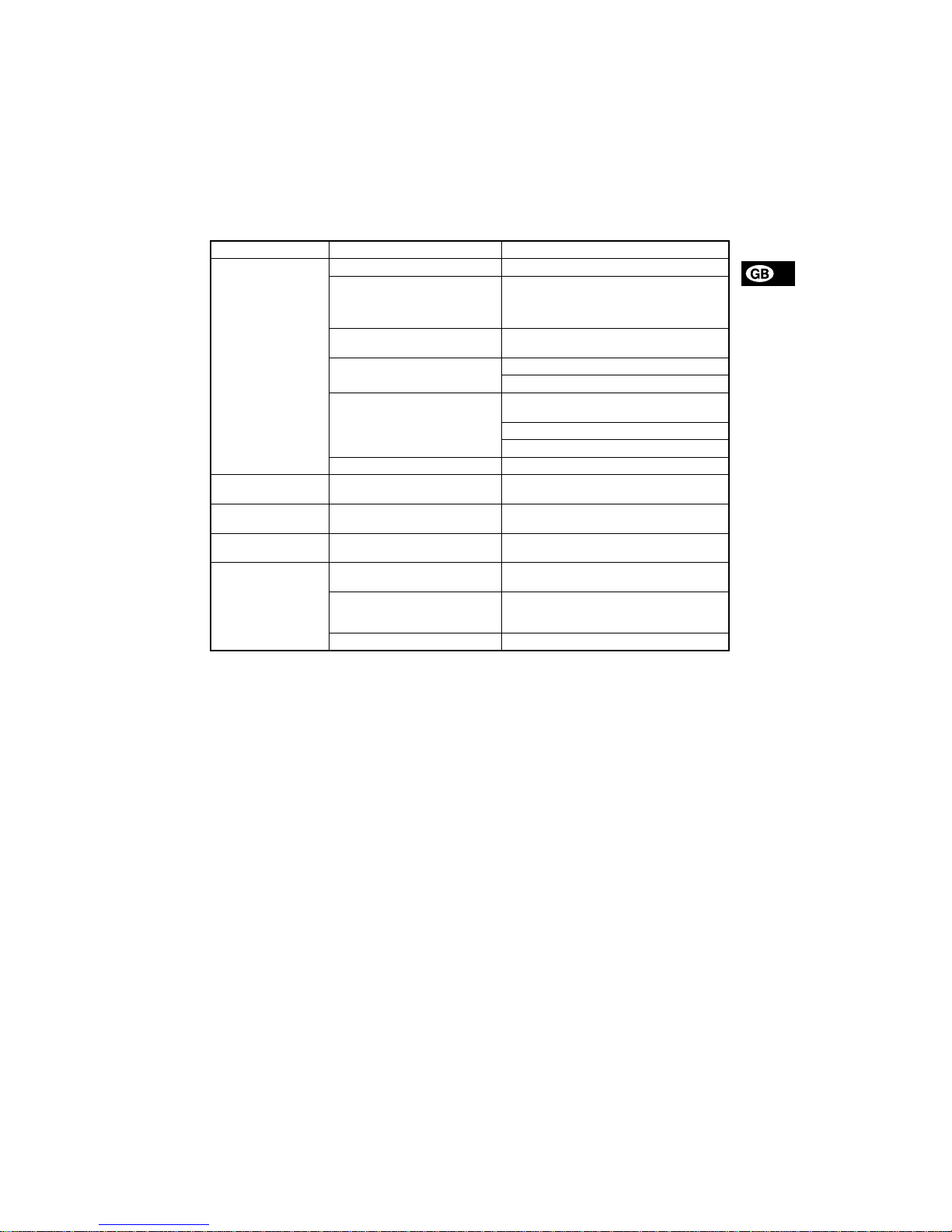

1.2 Type key

(Cannot be u sed f or p um p co nf i gu ra tio n. )

Example

:

Pump range DME ..

Control variant Code

Standard A

Standard + alarm relay AR

Standard + Profibus AP

Standard + GENIbus AG

Dosing head ma t eria l Code

Polypropylene PP

PVDF PV

Stainless steel 1.4401 SS

Code Mains plug

F EU (Schuko)

B USA, CAN

GUK

IAU

ECH

JJP

Code

Connection,

suction/disch arge

1 Tubing 6/9

Tubing 4/6

supplied with the pump

2 Tubing 6/9

Tubing 6/12+9/12

supplied with the pump

3 Tubing 4/6

4 Tubing 6/9

5 Tubing 6/12

6 Tubing 9/12

A Threaded Rp 1/4

B Threaded Rp 3/8

E Cementing d. 10

F Cemen ting d. 12

Code Valves

1 Standard valve

2 Spring-loaded valve

Valve ball material Code

Ceramics C

Stainless ste el 1. 44 01 SS

Gasket material Code

EPDM E

FKM V

PTFE T

Maximum pres sur e [b ar]

Control panel Code

Front-fitted F

Side-fitted S

Voltage Code

1 x 100-240 V, 50-60 Hz 3

DME 2-18 A-PP/E/C-F-3 1 1E F

Page 5

6

2. Technical data

2.1 Mechanical data

*1 Irrespective of counter pressure

*

2

Maximum suction lift 1 metre

2.2 Electrical data

2.3 Input/output data

The pump offers vario us in put a n d o u tput po ssib ilities, depending on contro l var iant.

DME 2 DME 8 DME 12 DME 19 DME 48

Maximum capa city without anti- cavi ta tio n *

1

[l/h] 2.5 7.5 12 18.5 4 8

Maximum capacity with anti-cavitation *

1

[l/h] 1.8 5.6 9 14.5 37

Maximum pressur e [bar ] 18 10 6 6.2 2.6

Maximum stroke rate per minute [stroke/min.] 180 180 180 151 151

Maximum suctio n l ift during operation [m] 6

Maximum suction lift wh en p r imin g w ith wet valves [m] 1.8 3 3 3 3

Maximum viscosity wi th spr in g -lo ad ed valves *

2

[mPas] 500 500 500 500 100

Maximum viscosity w ithou t spr ing- loade d valves *

2

[mPas]

200 200 200 200 100

Diaphragm diameter [mm] 28 38 42.5 55 77

Liquid tempe rat ur e [°C] 0 to 50

Ambient temperature [°C] 0 to 45

Accuracy of repeatability ±1%

Sound pressure level [dB(A)] <70

DME 2, 8, 12 DME 19, 48

Supply voltage [VAC] 1 x 100-240

Maximum current consumption [A]

at 100 V 0.30 0.36

at 230 V 0.16 0.26

Maximum power co ns um pt i on P

1

[W] 18 22

Frequency [Hz] 50-60

Enclosure class IP 65

Insulation class B

Supply cable 1.5 m H05RN-F with plug

Signal input

Voltage in level sensor input [VDC] 5

Voltage in pulse input [VDC] 5

Minimum pulse-repetition period [ms] 3.3

Impedance in analog 4-20 mA input [Ω]250

Maximum loop resistan ce in p uls e s ign a l cir cu it [ Ω ]350

Maximum loop resistan ce in level signal circuit [Ω]350

Signal ou tput

Maximum load of a larm relay output , a t oh m i c lo ad [ A ] 2

Maximum voltage, al arm relay output [V ] 250

Page 6

7

2.4 Dimensions

See dimensions at the end of these instructions.

All dimensions are in mm.

3. Installation

3.1 Safety in structions

• When wor kin g w ith ch emica ls, lo ca l sa fety r ules

and regulations must be observed (e.g. wear protective clothes).

• Before starting work on the dosing pump and system, disconnect the electricity supply to the pump,

ensuring that i t ca nn ot be a ccidentally switche d

on. Before reconnecting the ele ctr icity sup ply,

make sure that the dosing hose is positioned in

such a way that any chemical left in the dosing

head is not ej ect ed , the r eby expos ing persons to

danger.

• If the vent valv e in the do sin g head i s used, i t must

be connected to a hose which is led back to the

tank.

• When changing a chemical, make sure that the

materials of the dosing pump and system are resistant to the new c he mic al. If th e re is any r isk of

chemical reaction between the two types of chemicals, clean the pump and system thoroughly before adding the new chemical.

Proceed as follows:

Place the suction tub e in wate r and pr ess the

button until residual chemical has been removed.

Note: When the buttons and are pressed

simultaneously, the pump can be set to run for a

specific number of seconds at maximu m ca pa cit y.

The remaining number of se cond s w ill a ppea r in

the display. The maximum value is 3 00 s eco n ds.

3.2 Installation environment

• Expos ure to dir ect sun lig ht shou ld be avoided.

This applies especially to pu m ps with p la stic d osing heads, as this material can be damaged by

sunlight.

• If the pump is instal le d ou tsi d e, a n en clo su re o r

similar protection is requir ed t o pr otect the pump

against rain and simil ar weath ers.

3.3 Installation of pump

• See also the installation example in section

3.4

.

• Note: The dosing head may contain water from

the factory test. If a liquid which must not come

into contact with wate r is to be d os ed , i t is r eco m mended to le t th e pu mp run with an ot he r l iqu id to

remove the water from the dosing head before installation.

• Always install the pump on the supporting foot

with vertical suction and discharge ports.

• Always use suitable tools for the mounting of plastic parts. Never apply un ne ce ssa ry force.

• Make sure that the dosing pump and system are

designed in such a way that neither system equipment nor buildings are dama ged in ca se of leakage from the pump or rupture of hoses/pipes. The

installation of l e ak ag e ho ses and collectin g ta nk s

is recommended.

• Make sure th at the drain hol e in th e dosing head

points downwards, see fig. 1.

Note: It is important that the drain pipe/ho le is not

inserted dir ec t in to the tank conten ts, as ga sse s

may penetrate into the pump.

Fig. 1

100%

100%

TM01 8420 5099

hole

Drain

Page 7

8

3.4 Installation exam ple

The drawing in fig. 2 shows an installation example.

Fig. 2

3.5 Electrical connection

• The electrical connection of the pump should be

carried out by qualified pers ons in a cco r dance

with local regulations.

• For electrical data of the pump, see section

2.2

.

• Do not lay signal cabl es, if any, together with

power cables.

TM01 8421 1600

The DME pump ca n be installed in ma ny different ways. The sketch below s ho ws an example w ith sidefitted control panel. Th e ta nk is a G RUN DF OS c hemi cal ta nk wit h a G RUN DF OS leve l c on trol un it.

Page 8

9

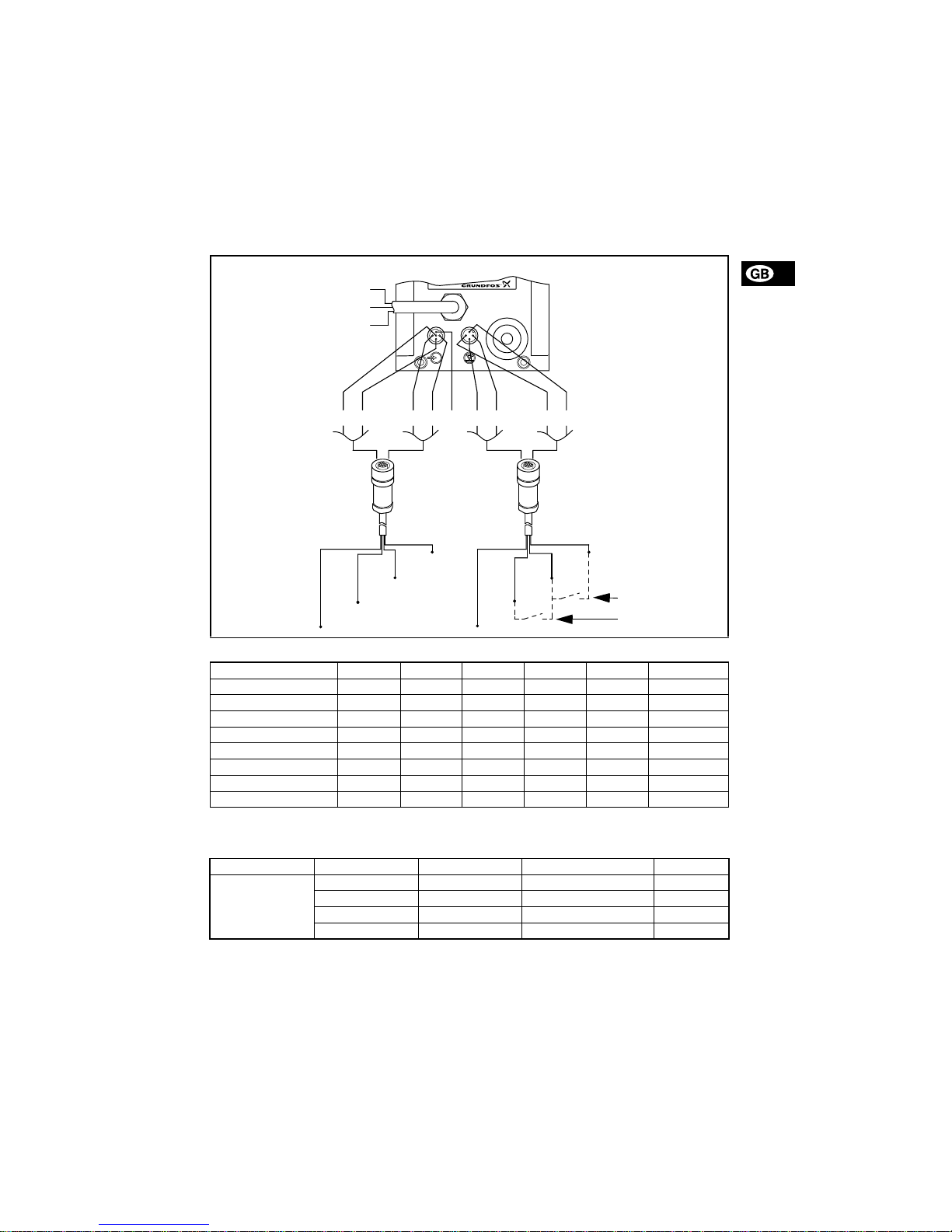

3.6 Connection overview

Fig. 3

Control input:

1 = Contact for pulse signal

2 = Contact for external on/off

Level input:

TM01 8422 0603

2

3

1

4

1

3

4

5

1

3

4

5

3

1

4

2

2

Alarm relay (control variant “AR” only)

Control cable,

see table below

Level cable,

see table below

“NO” black

“NC” blue

“Com” brown

Empty tank

Low level

Number / colour 1 / brown 2 / white 3 / blue 4 / black 5 / grey Description

Function

Manual 2 2

Pulse 1 1

Pulse + external on/o ff 1 1 + 2 2

Analog – + mA signal

Analog + external on/off 2 2 – + mA signal

Timer + external on /off 2 2

Batch 1 1

Number / colour 1 / brown 2 / white 3 / blue 4 / black

Function

Low level Low level

Empty tank Empty tank

Low level Empty ta nk Low level + empty tank

Dosing monitoring Dosing monitoring

Page 9

10

4. Functions

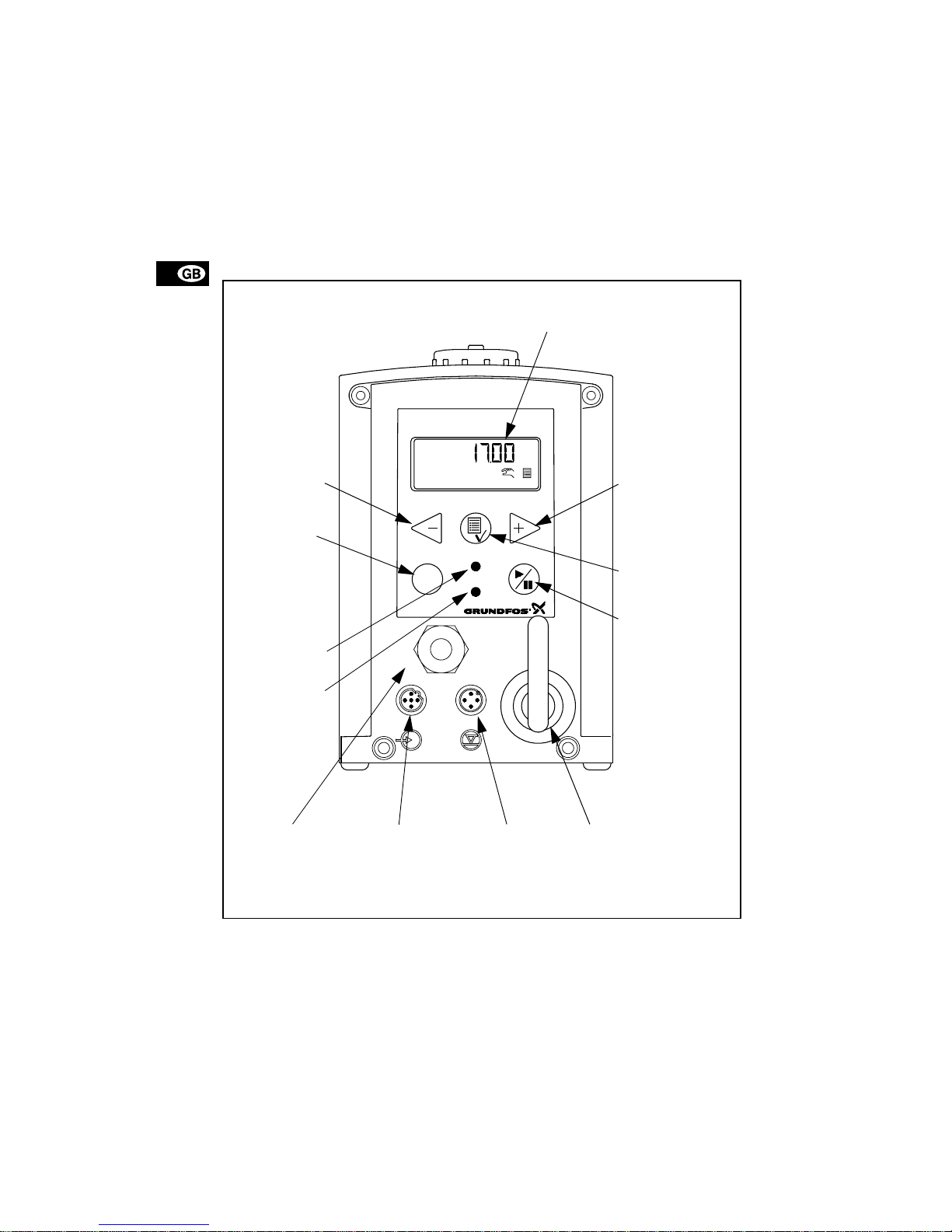

4.1 Control panel

Fig. 4

TM01 8423 0100

ml/h

100%

LCD display,

see section

4.7

Navigation/

settings,

see section

4.7

Menu,

see section

4.7

On/off button,

see section

4.7

Mains connectionM12 connection

level control,

see section

4.4

M12 connection

pulse/analog input,

see section

4.4

Connection

alarm relay/bus.

Control variants

“AR”, “AP” and “ A G” ,

see sections

4.5

and

4.6

Red

indicator light,

see section

4.5

Green

indicator light,

see section

4.5

Maximum capacity

(priming),

see section

4.3

Navigation/

settings,

see section

4.7

Page 10

11

4.2 Start/stop of pump

The pump can be started/stopped in three different

ways:

• Locally on the pump control panel.

• By mean s of an extern al on /off switch con necte d

to the pulse input. See connection overview in

section

3.6

.

• By switching on/ off t he e lectr ic ity su pp ly.

4.3 Priming/venting of pump

The pump control panel incorporates a button.

Press this button if the maximum pump capacity is

required ove r a s ho rt p er iod , e.g. during st ar t- up .

When the button i s rel ea se d, th e pu mp au t oma tic a lly

returns to the previou s oper at ing mod e.

During priming/venting, it is recommended to let the

pump run without a counter pressure or to loosen the

vent valve by giving it a 1/8 to 1/4 turn.

Note: When the butt on s and are pr ess ed si-

multaneously, the pump can be set to run for a specific number of seco nd s a t ma ximu m ca pacity. The

remaining number of seco nds will appear in the dis play. The maximum value is 300 seconds.

4.4 Level control

The pump can be fitted with a level control unit for

monitoring of the chemical level in the tank.

The pump can react to two level signals. The pump

will react differently, depending on the influenc e on

the individual level sensors.

* Control variant “AR” o nl y.

See section

3.6

for connectio n of th e level control

unit and alar m output.

4.5 Indicator lights and alarm output

The green and red indicator lights on the pump are

used for ope rat in g an d fault indicati on .

In control varia nt “A R ”, th e pump can activ at e an external alarm s ign al by mea ns of a b ui lt -i n al arm r el ay.

The alarm signal i s act i vat ed by m eans of an in te rn al

potential-free contact.

The functions of the i ndica tor li ghts and the bu ilt-in

alarm relay appear from th e table belo w:

!1

Control variant AR only.

!2

Requires connection to level sensors.

!3

Requires activation of the dosing monitoring

function and connection to a dosing monitor.

Level sensors Pump reaction

Upper sensor

activated

(closed contact )

• Red indicat or lig h t is o n.

• Pump running.

• Alar m r elay activated.*

Lower sensor

activated

(closed contact )

• Red indicat or lig h t is o n.

• Pump stopped.

• Alar m r elay activated.*

100%

100%

Condition

Green

LED

Red

LED

Display

Alarm

output

!1

Pump

running

On Off

Normal

indication

Set to stop

Flash-

ing

Off

Normal

indication

Pump fault Off On EEPROM

Supply

failure

Off Off Off

Pump running, low

chemical

level

!2

On On

Normal

indication

Empty

tank

!2

Off On

Normal

indication

Analog

signal

< 2 mA

Off On

Normal

indication

The dosed

quantity is

too small

according

to the signal from the

dosing

monitor

!3

On On

Normal

indication

Overheating

Off On

MAX.

TEMP.

132

NC NO C

132

NC NO C

1

23

NC NO C

132

NC NO C

1

23

NC NO C

1

23

NC NO C

1

23

NC NO C

1

23

NC NO C

1

23

NC NO C

Page 11

12

4.6 Fieldbus communication

The pump can be configured for fieldbus applications.

The following b u s t ype s ar e ava i la ble:

Separate instructions are supplied with each bus

type.

Control variant Bus type

AP Profibus

AG GENIbus

Page 12

13

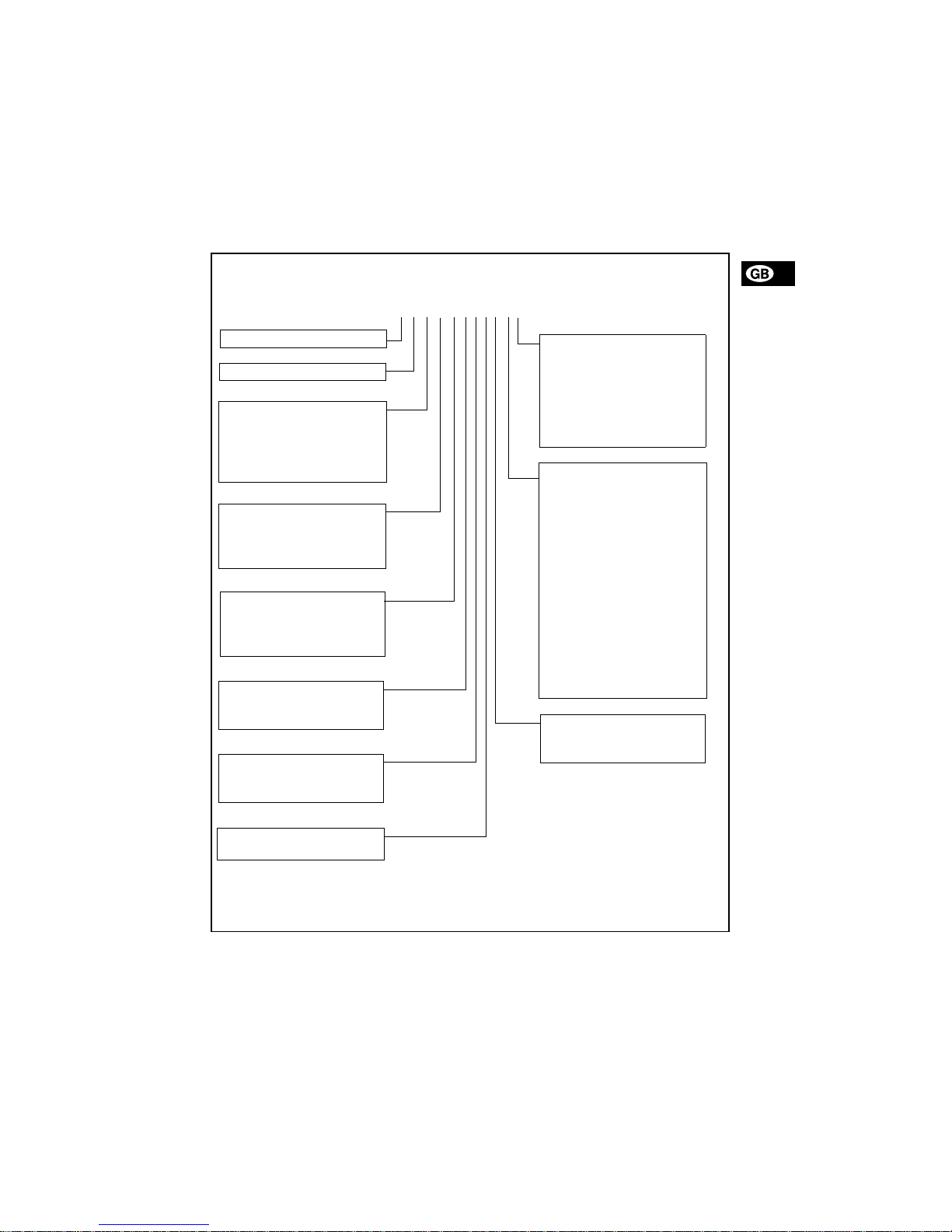

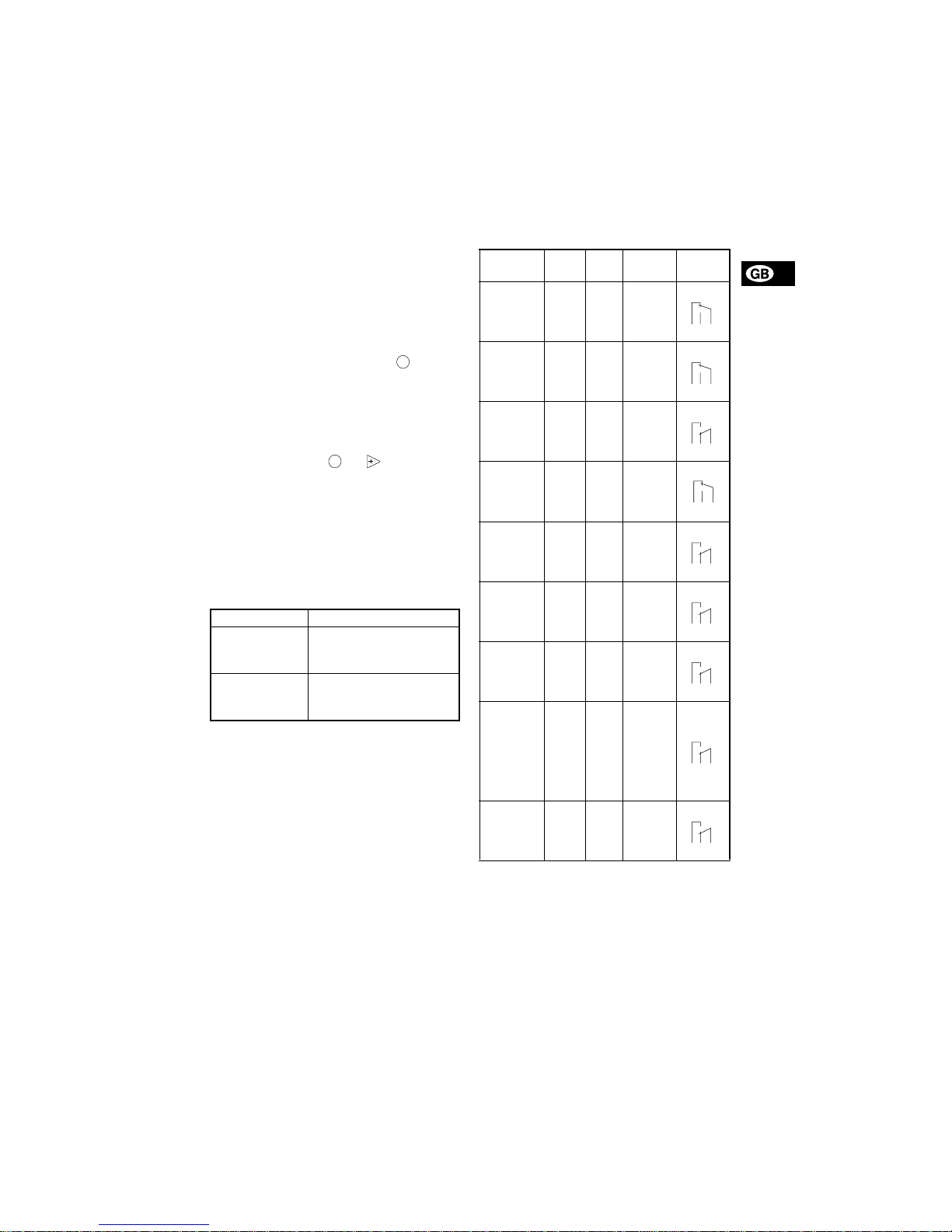

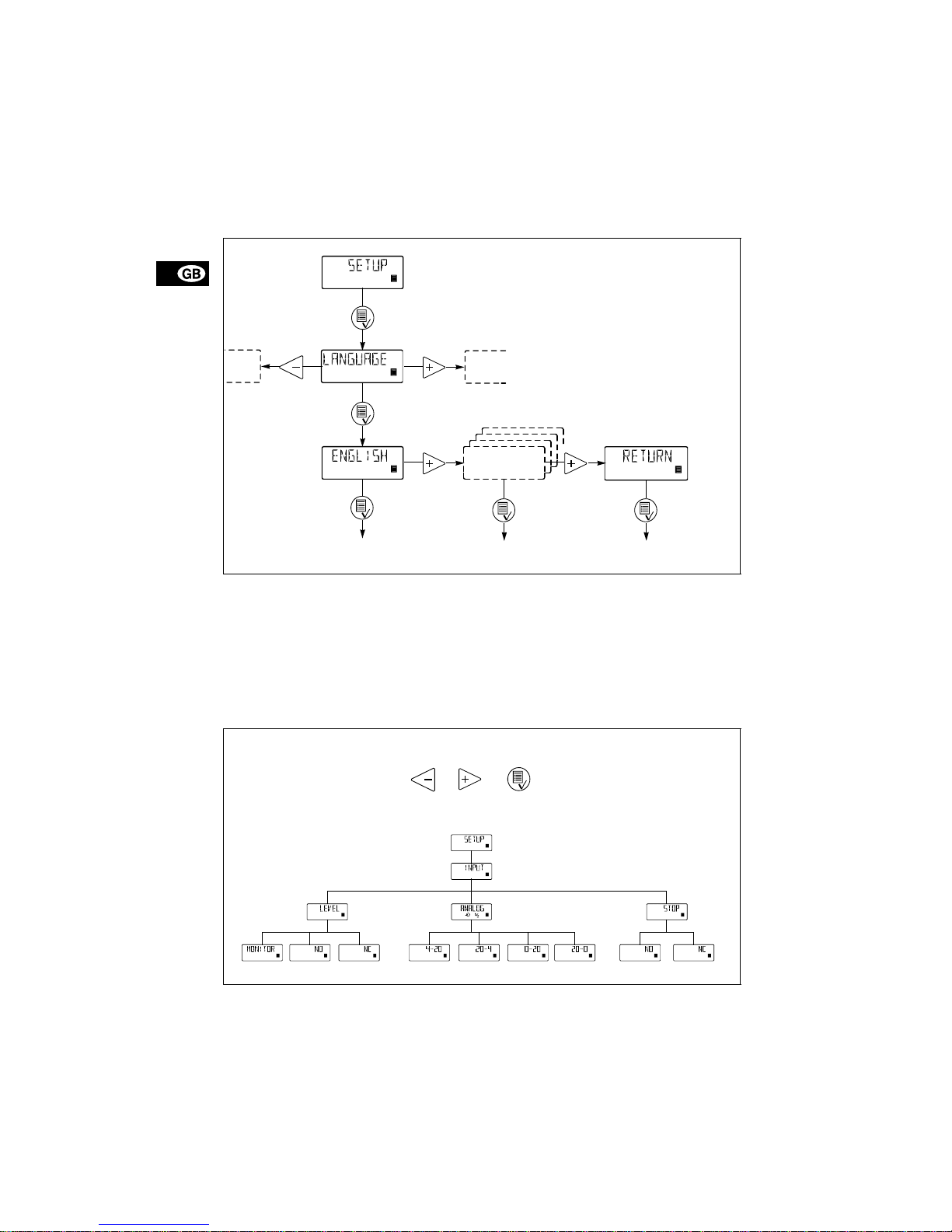

4.7 Menu

The pump features a user-friendly menu which is activated by pressing the button. During start-up, all

texts will appear in English la ngua g e. T o s elect la nguage, see section

4.19

.

All menu items are described in the following sections. When appears at a menu item, it means

that this item is activated. By sele ct ing “ RETURN”

anywhere in the menu structure, you will return to the

operating display without changes.

Fig. 5

See section

4.9

See section

4.23

See section

4.10

See section

4.17

See section

4.11

See section

4.18

See section

4.12

See section

4.19

See section

4.13

See section

4.15

See section

4.14

See section

4.20

See section

6

See section

4.21

See section

4.16

Page 13

14

4.8 Operating modes

Note: The displayed l and ml v alu es ar e on ly re l iab l e

if the pump has been calibrated to the actual installation, see section

6

.

The pump can run in five different operating modes:

•Manual

•Pulse

•Analog

•Timer (internal batch control)

• Batch (external batch control)

See description in the following sections.

4.9 Manual

The pump is dosi ng as constantl y and evenly as possible, without a ny ex te rn al sig na l s.

Set the quanti ty to be dosed in l/h or ml/h. The pump

automatically ch a ng es over betwee n th e me as ur i ng

units.

Setting range:

DME 2: 2.5 ml/h - 2.5 (1.8*) l/h

DME 8: 7.5 ml/h - 7.5 (5.6*) l/h

DME 12: 12 ml/h - 12 (9*) l/h

DME 19: 18.5 ml/h - 18.5 (14.5*) l/h

DME 48: 48 ml/h - 48 (37*) l/h

* The figures in brac kets ind icat e the ma ximum ca-

pacity when the anti-ca vitation fu nction is activated.

Fig. 6

4.10 Pulse

The pump is dosing according to an external pulse

signal, i.e. a water meter with pulse output or a controller.

Set the quantity to be dosed per pulse in ml/pulse.

The pump adjusts its capacity acco rding to two factors:

• Frequency of external pulses.

• The set quantity per pulse.

Setting range:

DME 2: 0.000018 m l/pulse - 5 ml/pulse

DME 8: 0.000069 m l/pulse - 15 ml/pulse

DME 12: 0.000111 ml/puls e - 24 ml/pulse

DME 19: 0.000204 ml/puls e - 37 ml/pulse

DME 48: 0.0053 0 ml/pulse - 96 ml/pulse

Fig. 7

If the set qu an tit y p e r p u lse mu l ti pl ie d by the pulse

frequency exceeds the pump capacity, the pump will

run at maximum capacity. Exc es s p uls es will be ig nored and the “actual capacity” display will flash.

4.11 Analog

The pump is d osin g according to a n ex te rn al an alog

signal. The dosed quantity is proportional to the input

value in mA.

4-20 (default): 4 mA = 0%.

20 mA = 100%.

20-4: 4 mA = 100%.

20 mA = 0%.

0-20: 0 mA = 0%.

20 mA = 100%.

20-0: 0 mA = 100%.

20 mA = 0%.

See fig. 8.

The capacity limitatio n will i nfl uenc e t he capacity.

100% corresponds to the maximum capacity of the

pump or the set m aximu m ca pa city , s ee se ct ion

4.15

.

Fig. 8

Set valu e

TM02 4498 1102

Set quantity in

ml/pulse

Actual capacity

in ml/h or l/h

0 4 8 12 16 20

0

20

40

60

80

100

4-20 mA

0-20 mA

[mA]

[%]

Page 14

15

Fig. 9

If 4-20 mA or 20-4 mA is selected and the signal falls

below 2 mA, the pump will indicate a fault. This situation occurs if the connection is interrupted, for instance if the wire is damaged.

Change the analog mo de as illu st ra te d in fig . 1 0:

Fig. 10

Value

according to

analog signal

Use the buttons

for navigation

Page 15

16

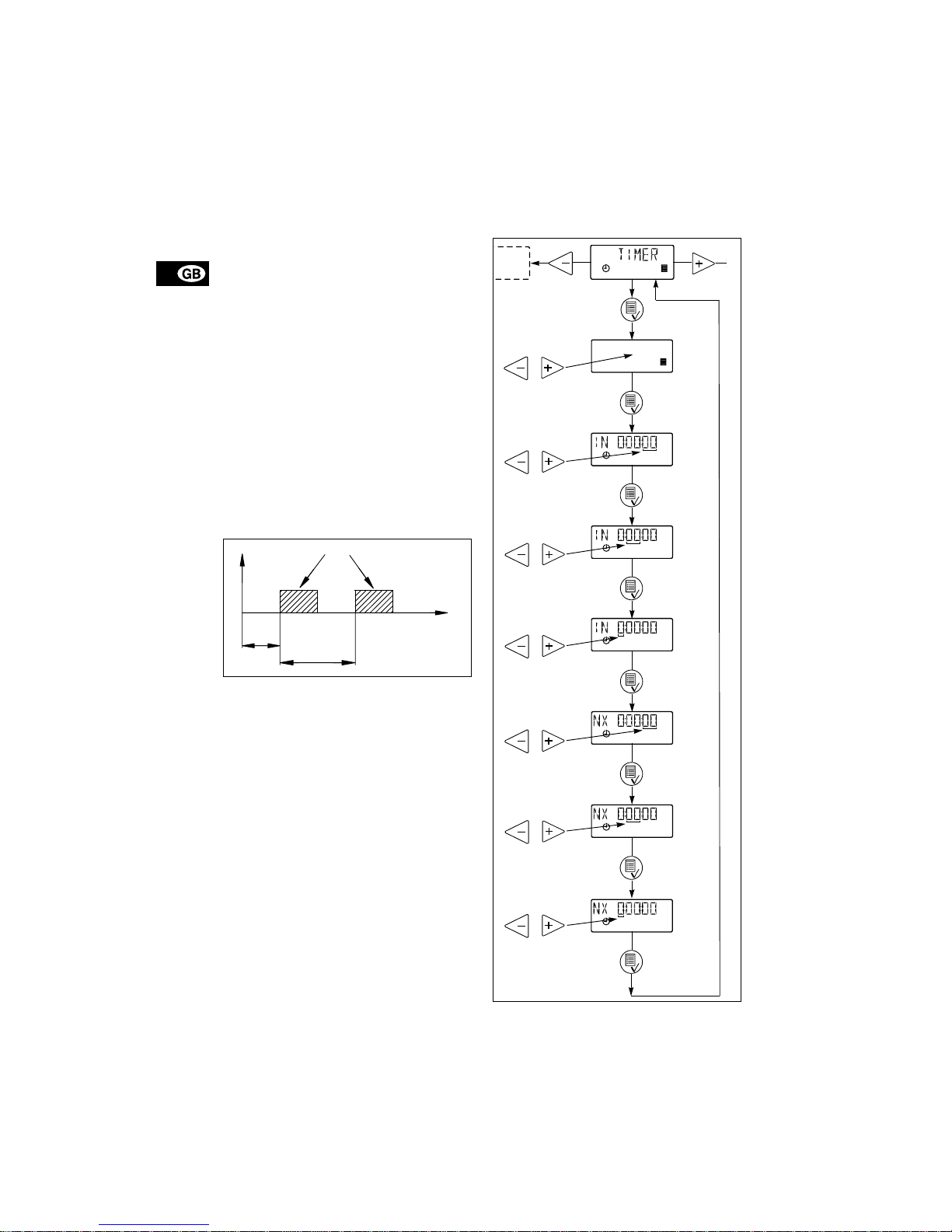

4.12 Timer

The pump is dosing th e s et quan ti t y in bat che s a t t he

maximum capacity or the set maximum capacity, see

section

4.15

.

The time until the first dosing “NX” and the following

sequences “IN” c an b e set in m i nu te s, ho u rs an d

days. The maxim um t i me li mi t is 9 days, 23 ho ur s

and 59 minut es (9 :2 3: 59 ). T he l o we st acceptable

value is 1 minute.

The interna l time r cont inues even

if the pump is stopped by means of the on/off button,

empty tank or stop signal , see fig . 11.

During operation, “NX” will alwa ys cou n t dow n fro m

“IN” to zero. In th is way, the remaining tim e un til th e

next batch can a l wa ys be r ea d.

“IN” must be higher than the time required to perform

one batch. If “IN” is low er, t he n ext b at ch will be ig nored.

In case of supply fa ilu re , the s et qu a nti ty to be

dosed, the “IN” time and the remaining “NX” time are

stored. When the sup ply is re conn ecte d, the pu mp

will start up with the “NX” time at the time of the supply failure. In this way , t he ti me r cyc le will c ontin ue ,

but it has been delayed by the duration of the supply

failure.

Fig. 11

Setting range:

DME 2: 0.23 ml/batch - 5 l/batch

DME 8: 0.69 ml/batch - 15 l/batch

DME 12: 1.11 ml/batch - 24 l/batch

DME 19: 2.04 ml/batch - 37 l/batch

DME 48: 5.3 ml/batch - 96 l/batch

Only values corresponding to complete dosing

strokes (accordi ng to t he ca lib ra tio n fa ctor) ca n be

selected.

Example: If the calibration factor is 23.3 (= 0.233 ml/

stroke), the minim um se tta bl e val ue in time r or batch

mode will be 0.233 ml -> the n ext will be 0 .4 66 ml ->

the next will be 0.699 ml, etc.

These steps wi ll continue up to a value correspond ing to 100 dosing strokes. Abov e this val ue, the set ting range has standard steps as in other operating

modes.

If the calibration f ac tor is changed after se ttin g of

timer or batch mode , the p ump will automatically recalculate a new amount of dosing strokes per batch

and change the dis pl a y val ue to t he ne ar est pos s ibl e

value compared to the first one set.

Fig. 12

TM01 8942 0900

NX

IN

Quantity per bat ch

Set quantity

per batch

Set IN value

in minutes

Set IN value

in hours

Set IN value

in days

Set NX value

in hours

Set NX value

in minutes

Set NX value

in days

Page 16

17

4.13 Batch

The pump is dosi ng th e s et qua nt it y in bat c he s a t the

maximum capacity or the set maximum capacity, see

section

4.15

.

The quantity is dosed every time the pump receives

an external pulse.

If the pump receives new pulses before the previous

batch is performed, these pulses will be ignored.

Fig. 13

The setting range is the same as for Timer, see section

4.12

.

Fig. 14

4.14 Anti-cavitation

The pump features an anti-cavitation function. When

this function is selected, the pump extends and

smooths its suct ion stroke, resulting i n s of te r pr iming.

The anti-cavitation function is used:

• when pu mp in g liquids of high viscosity,

• in the case of a long suction tube and

• in the case of a high suction lift.

The maximum pump capacity is reduced when this

function is selected. See section

2.1 Mechanical

data

.

Fig. 15

TM01 8947 0900

Pulse Pulse

Quantity per bat ch

Set value

per batch

Operating display

Page 17

18

4.15 Capacity limitat ion

This function offers the p ossib ility of r ed uci ng t he

maximum pump capac ity (MAX CAP). It influen ces

the function s in whic h the pu mp is nor mally oper ating

at maximum capacity.

Under normal operating conditions, the pump cannot

operate at a capacity which is higher than the one

stated in the display. This does not apply to the maximum capacity button , see section

4.3

.

Fig. 16

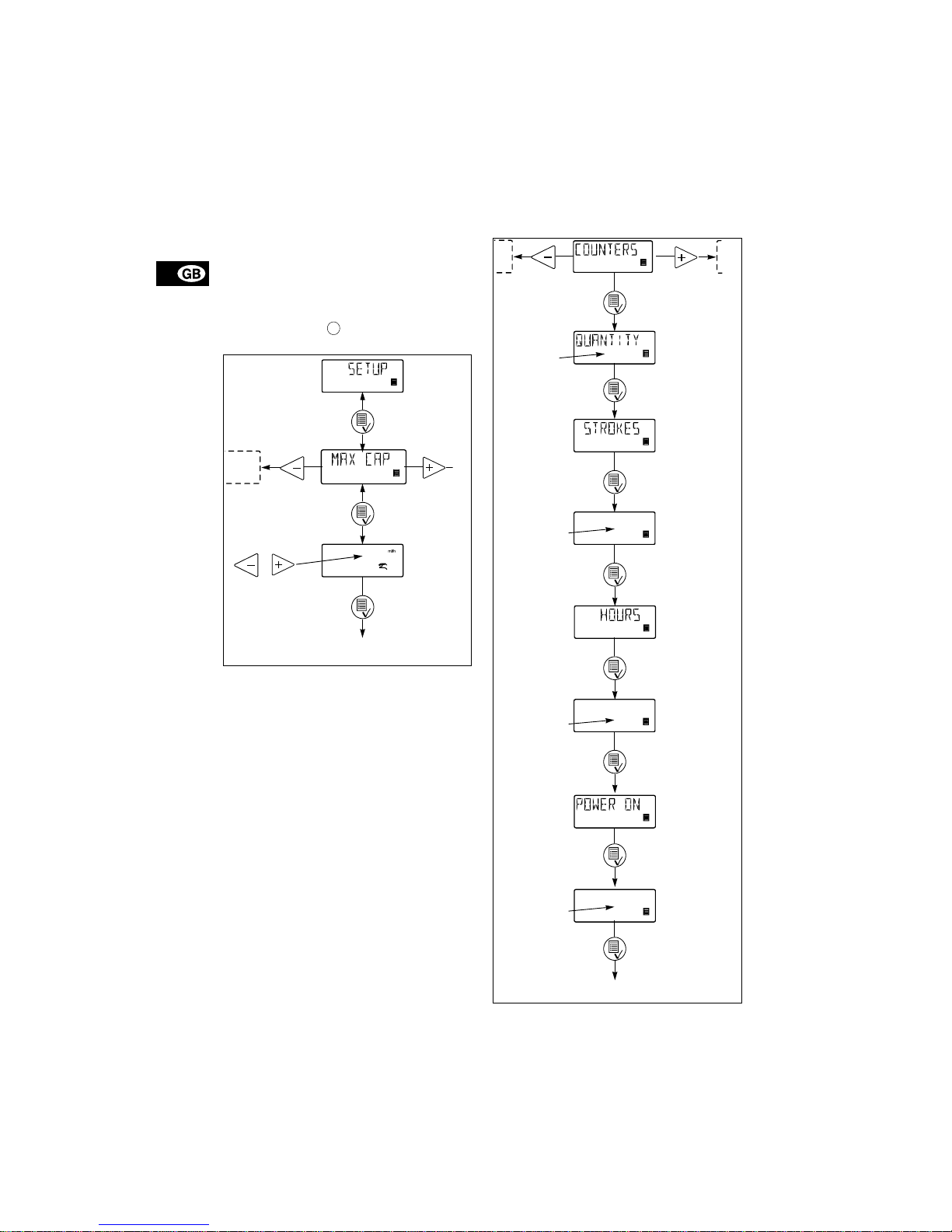

4.16 Counters

The pump can display “non-resettable” counters for:

•“QUANTITY”

Accumulated value of dosed quantity in litres or

US gallons.

•“STROKES”

Accumulated number of dosing strokes.

•“HOURS”

Accumulated number of operating hours

(Power on).

•“POWER ON”

Accumulated number of times the electricity supply has been switc he d on .

Fig. 17

100%

Set maximum

capacity

Operating display

Operating display

Total number

of strokes

Total number

of operating

hours

Total number

of starts

Total dosed

quantity

Page 18

19

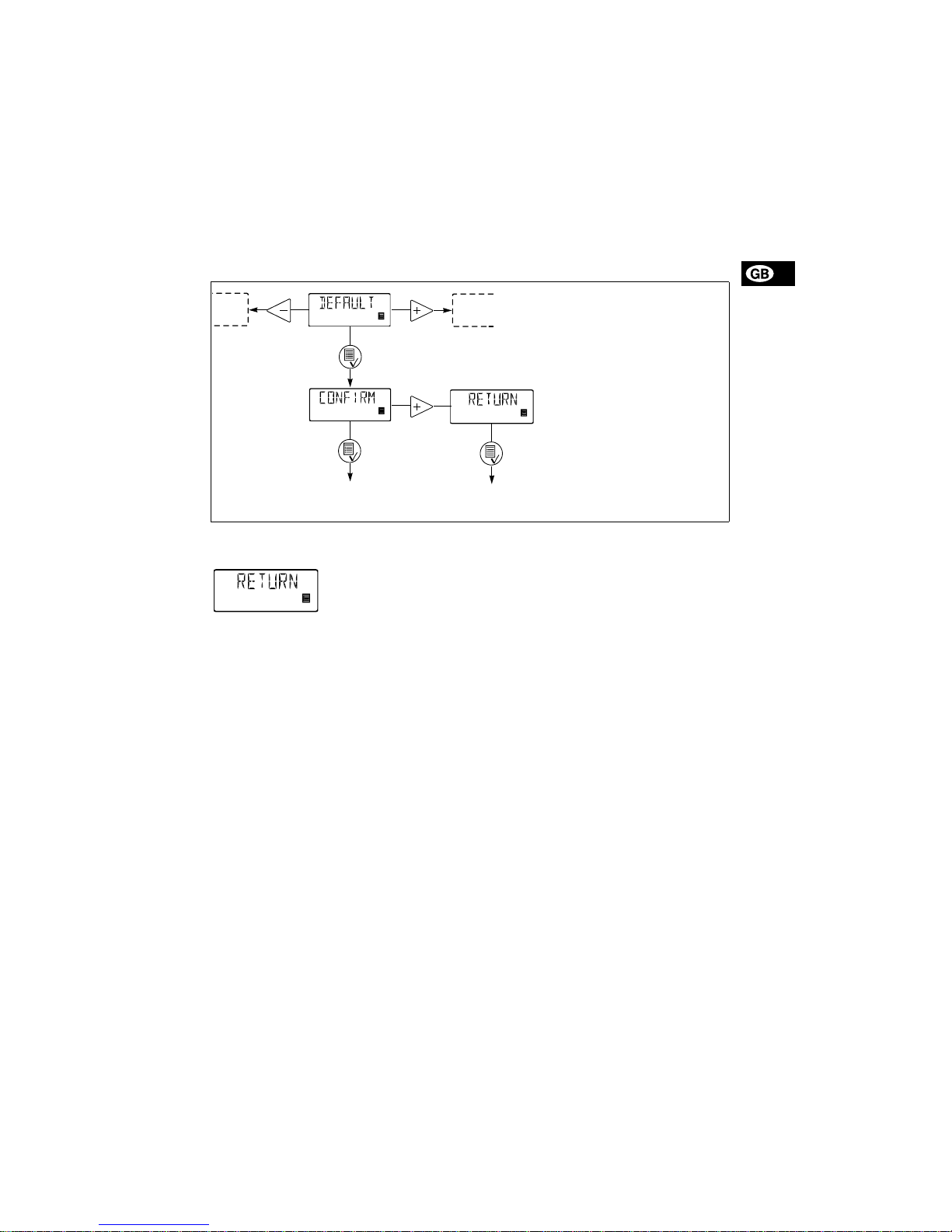

4.17 Resetting

When “DEFAULT” is activate d, th e pum p will r etur n

to the factory settings.

Note: The calibration is also set b ac k t o th e d e fau lt

setting. This means that a new calibration is required

when the “DEFAULT” function has been used.

Fig. 18

4.18 Return

Fig. 19

The “RETURN” function m ake s it p o ssible to r etur n

from any level in the menu to the operating display

without changes after the menu functions have been

used.

4.19 Language

The display text can be displayed in one of the following languages:

•English

•German

•French

• Italian

• Spanish

• Portugu es e

•Dutch

•Swedish

•Finnish

•Danish

•Czech

• Slovak

• Polish

• Russian

Operating display Operating display

without changes

Page 19

20

Fig. 20

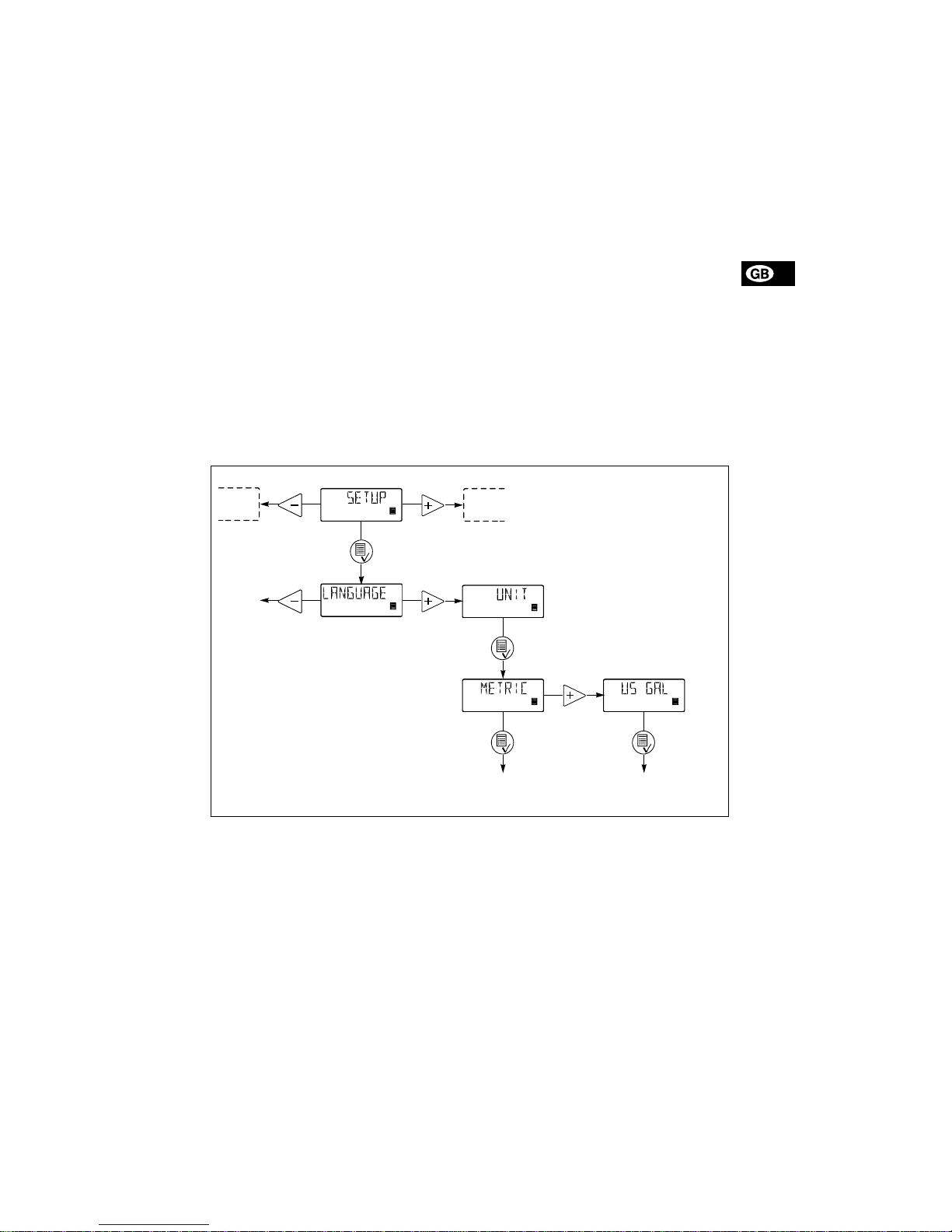

4.20 Input setup

Fig. 21 shows all possible settings.

The level and st op i n pu ts ca n be ch an ge d fr om N O

(normally open) t o N C (no rm a lly clos ed ) fu nction. If

changed, the i n pu ts mu st be s ho rt -circuited in no r mal operation.

For the analog input, one of the following signal

types can be selected:

• 4-2 0 mA (defa ult),

• 20- 4 mA,

• 0-2 0 mA,

• 20- 0 mA.

See also section

4.11 Analog

.

Change the level input to an input for dosing monitoring as illustrated i n fig. 2 1.

Fig. 21

Operating display Operating display Operating display

without changes

Use the buttons

for navigation

Page 20

21

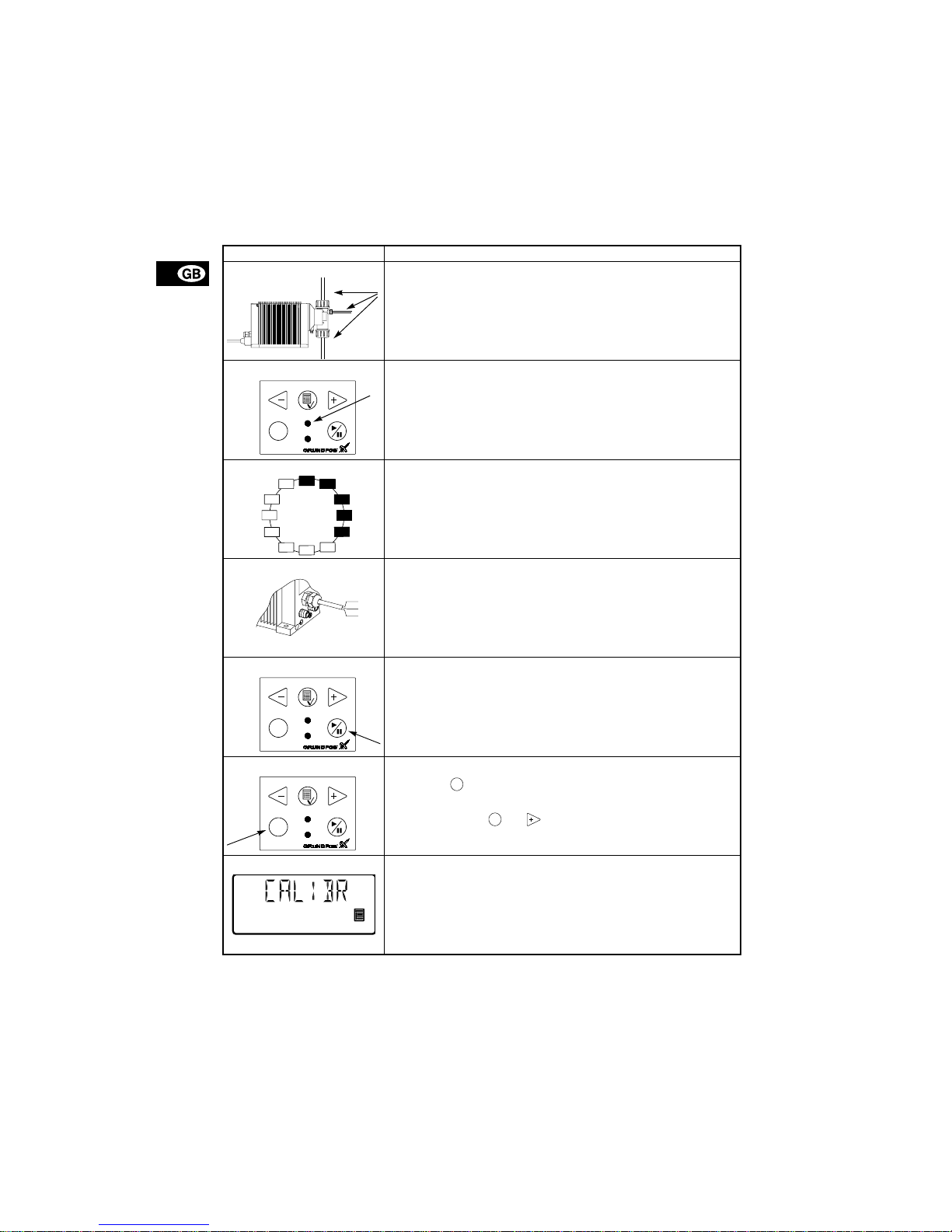

4.21 Measuring units

It is possible to s elect m etr ic units (l itr e/m illi litr e) o r

US units (gallons/millilitre).

Metric measuring units:

• In manual and analog modes, set the quantity to

be dosed in litres per h our ( l/h ) or millilit re s p er

hour (ml/h).

• In pulse mode, set the qu an ti t y t o be dosed in

ml/pulse. The actual capacity is indicate d in litres

per hour (l/h) or millilitres per hour (ml /h).

• For calibration, set the quantity to be dosed in

ml per 100 strokes.

• In timer and batch modes, set the quantity to be

dosed in litres (l) or millilitres (ml).

• Under th e “ QUANTITY ” me nu ite m in th e

“COUNTERS” me nu, the dosed qu an ti t y i s in di cated in litres.

US measuring units:

• In manual and analog modes, set the quantity to

be dosed in gallons per ho ur (gp h).

• In pulse mode, set the quantity to be do se d in

ml/pulse. The actual capacity is indicated in

gallons per hour (gph).

• For calibration, set the quan tity to b e do se d in

ml per 100 strokes.

• In timer and batch modes, set the quantity to be

dosed in gallons (gal).

• Under th e “QUANTI TY” m e nu item in the

“COUNTERS” menu, the dosed quantity is indicated in US gallons (gal).

Fig. 22

Operating display Operating display

3 x

Page 21

22

4.22 Dosing monitoring

A dosing monitor is available as an accessory . Separate instructions are su pp lie d with t he m oni tor.

Fig. 23

The dosing moni tor is desig ned t o moni tor the dos ing

of liquids whi c h ma y cau se g as accumulation in the

dosing head, thus stopping the dosing process even

if the pump is still ope ratin g.

For every meas ur ed d osing stroke, t he d os ing m on i tor gives a pulse signal to the level input so that the

pump can compare performed dosing strokes (from

internal stroke sensor) with externally measured

physical strokes (from the dosing monitor). If an external dosing str o ke is n o t m e asu re d to ge th er wi th

the internal dos ing stroke, this is co ns ide re d a fa ult

that may have been provoked by empty tank or gas

in the dosing head.

TM02 2029 3201

Monitor mounted on the suction side of the pump

Dosing stroke measu re d

Page 22

23

4.23 Control panel lock

It is possible to l o ck t he b ut ton s on th e con tr ol pa ne l

to prevent malfunction of the pump. The locking

function can be set to “ON” or “OFF”. The default

setting is “OFF”.

A PIN code must be entered to change from “OFF” to

“ON”. When “ON” is selected for the first tim e,

“_ _ _ _” will appear in t he d isp lay. I f a co d e ha s a lready been entered, it will a ppe ar wh en a n atte mp t

to change to “O N” is ma d e. T his co de ca n ei the r be

re-entered or changed.

If no code has been entered, a code must be set in

the same way as the “NX” and “IN” values desc rib ed

in section

4.12

.

If a code has already been entered, active digits are

flashing.

If attempts are made to operate the pump in locked

condition, “LOCKED” will app ear in the disp la y for

2 seconds, followed by “_ _ _ _”. A code must be entered. If the entering of a code has not been started

within 10 seconds, the operating display without

changes will appear.

If a wrong code is entered, “L OCKED ” will a p pear in

the display for 2 seconds, followed by “_ _ _ _”. A

new code must be entered. If the entering of a code

has not been started within 10 seconds, the operating display without changes will appear. This display

will also appear if the entering of the correct code exceeds 2 minutes.

If the locking function has been activated but the

control panel is unlocke d , the co ntro l pan e l will be

locked autom at ica ll y i f i t is no t op er at ed f or 2 m i nutes.

The locking f un c t ion ca n al s o be r ea cti v at ed b y s electing “ON” in the “LOCK” menu. The previously entered code will then appear and must be re-entere d

by pressing the button four times. The code can

also be change d.

The control panel can be unlocked either by means

of the selected co de o r th e fa cto ry co de 2 58 3.

The following buttons and inputs are still active when

the panel is locked:

• Prim i ng ( -button).

• On/of f but to n.

• All externa l i np ut s.

Fig. 24

Activating the locking function and locking the

control panel:

1. Select “LOCK” in the menu.

2. Select “ON” by means of the buttons and

and confirm with .

3. Enter or re-ent er a co d e by me an s o f th e buttons

, and .

The locking functi o n ha s no w been act iv at ed and th e

control panel is locked.

Unlocking the co ntrol panel ( with out deac tiva ting

the locking function):

1. Press once. “LOCKED” appears in the display

for 2 seconds, followed by “_ _ _ _”.

2. Enter the code by means of the buttons ,

and *.

The control panel has now been unlocked and will

automatically be locked again if the control panel is

not operated f or 2 m i nu te s.

Deactivating the locking function:

1. Unlock the control panel as described above.

2. S e lect “ LO CK ” in th e me nu.

3. Select “OFF” by mean s of t he b u tton s and

and confirm with .

The locking function has now been deactivated and

the control panel is unlo cke d.

* The panel can always be unlocked with code 2583.

100%

Operating disp lay

Operating display

Page 23

24

5. Start-up

If the pump is n ot operating sat isf act or i ly, se e se cti o n

9. Fault finding char t

.

Step Action

1

Connect the hoses/pipes:

• Connect the suction and dosing tubes/pipes to the pump.

• Connect a tube to the vent valve, if required, and lead the hose to the

tank.

2

Switch on the electricity supply:

• The di splay is o n.

• The gree n indi cato r light i s flashi ng (t he pum p has sto pped ).

• Select language, if required, see section

4.19

.

3

Select the operating mode (see section

4.8

):

• Manual .

•Pulse.

•Analog.

•Timer.

•Batch.

4

Connect the cables:

• Connect the control/level cables, if any, to the pump, see section

3.6

.

5

Start the pump:

• Start the pump by p re ssin g th e on /o ff butto n.

• The gree n indi cato r ligh t is per ma nent ly on .

6

Priming/venting:

• Press the button on the pump control panel and let the pump run

without a counter pr essu re. Loose n the vent valve by giving it a 1/ 8 to

1/4 turn, if required.

When the buttons and are pressed simultaneously during priming, the pump can be set to run for a specific number of seconds at

maximum capacity.

7

Calibration:

• When the pump has been primed and is running at the right counter

pressure, calibrate th e pu m p, see se ctio n

6

.

100%

100%

100%

100%

100%

Page 24

25

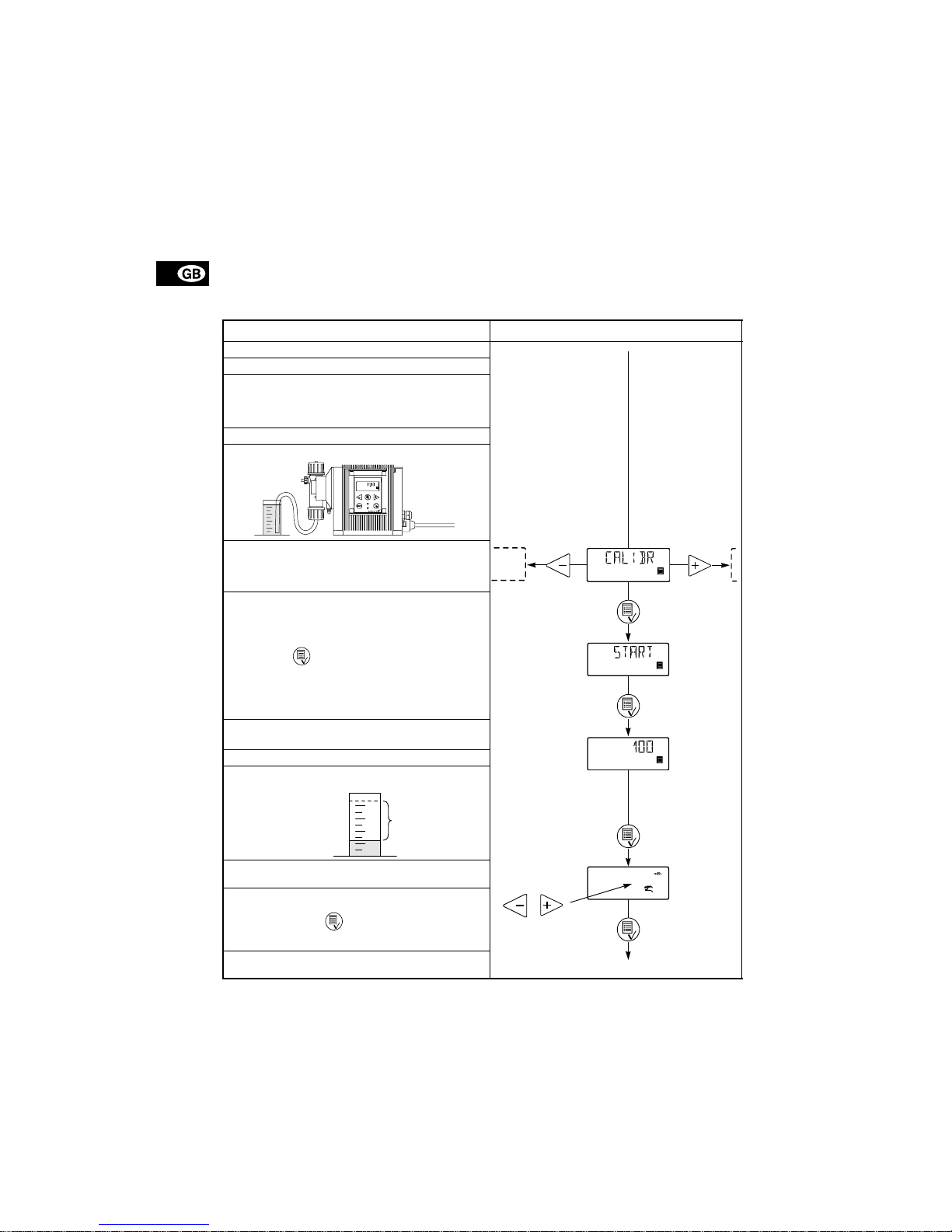

6. Calibration

It is important that th e p um p is ca lib rate d a ft er in sta llation to ensure that the correct value (ml/h or l/h)

appears in the display.

The calibration can be carried out in three different

ways:

• Dire ct c alibration (recommended).

The dosed quan tity of 100 strokes i s me as ur ed directly. See section

6.1

.

• Ind irec t ca libration.

A calibration factor selected from a table is used

for the specific installa tio n. Thi s m et hod ca n be

used if it is not pos sible to ca rry o u t a d irect ca libration. Indirect calib rati on will ne ve r be a s a ccu rate as direct ca lib ra tio n. Se e sec tio n

6.2

.

• Check ca libr atio n. See section

6.3

.

Page 25

26

6.1 Direct calibratio n

Before calibration, ma ke sur e :

• that the pum p is in sta lle d with foot valve, injection

valve, etc. in the existing system.

• that the pump is running at the coun te r pre s su re it

is supposed to operate at (adjust the counter pressure valve, if required).

• that the pump is operating with the correct suction

lift.

To carry out a direct calibration, proceed as follows:

Action Pump display

1. Prime the dosing hea d and th e suctio n tubi ng.

2. Stop the pump. The gr ee n LE D i s fl a shin g.

3. F ill a graduated glass with dos ing liquid, Q

1

.

DME 2: approx. 40 ml DME 19: approx. 500 ml

DME 8: approx. 150 ml DME 48: approx. 1000 ml

DME 12: approx. 250 ml

4. Read and note the quantit y Q

1

.

5. Place the suction tu bi ng i n th e grad ua te d gl a ss .

6. Go to the calibration menu, see secti on

4.7

.

7. Press the button twice.

8. The pump is performing 100 dosing strokes.

9. The factory-calibrat i on value a pp ea rs in the display.

10.Remove the suction tubing from the graduated

glass and read Q

2

.

11.Set the display value to Q

d

= Q1 – Q2.

12.C on firm with th e button.

13.Th e pump is now cali bra te d an d re tu rns to the op erating display.

Set value

to Q

d

Operating display

Q

1

Q

2

Q

d

Page 26

27

6.2 Indirect cal i bration

A value from th e following table is to be added to the

default factory cal ibrat ion value in th e displ ay. To reset the pump to the factory calibration value, activate

the “DEFAULT” fu nctio n, see sec tio n

4.17

.

To use the values, the fo llo wing m u st be fu lfi lled :

• The viscosity and density of th e liquid to be dosed

must not differ considerably from water at 20°C.

• A GRUNDFOS installat ion k it o r co rres pond ing

foot valve, in jection valve and hose diameter must

be used.

• The length of the dosing hose must not exceed

6 metres.

• The suction lift must lie between 0.1 and 1.5 metres.

Adding the value:

Fig. 25

Pump type

Values to be added to the calibration value at various counter pressures [bar]

0-1 1-2 2-3 3-4 4-5 5-6 6-8 8-10 10- 12 12-14 14-16 16-18

DME 2 1.4 1.1 0.8 0.5 0.2 -0.2 -0.6 -1.2 -1.8 -2 .4 - 3. 0 -3 .6

DME 8 3.5 2.7 2.0 1.2 0.4 -0.4 -1.6 -3.1 - - - DME 12 2.1 1.3 0.4 -0.4 -1.3 -2.1 -3.4 - - - - DME 19 18.3 12.2 6.1 0 -6 .1 -12.2 -21.4 - - - - DME 48 24.38.3-8.3---------

Operating display

without changes

Operating display

Set value

to table value

+ display value

Page 27

28

6.3 Check calibration

In check calibration, the c alibra tio n value is ca lculated by reading the consumption of chemical in a

specific perio d and co mpar ing this with the number

of dosing strokes performed in the same period.

This calibration method is very accurate and especially suitable for check calibration after long periods

of operation or if d i re ct c ali b rat i on is i m po ssible. Th e

calibration can for instance be carried out when the

chemical tank is replac ed o r fille d.

To carry out a check calibration, proceed as follows:

1. Stop the pump by pr es sin g the button.

2. Read the counter and note the number of dosing

strokes, see s e ction

4.16

.

3. Read and note the quantity in t he ch e mical tank.

4. Start the pump by pressing the button and let

it run for at least 1 hour. The longer the pump is

operating, the more accurate the calibration will

be.

5. Stop the pump by pr es sin g the button.

6. Read the counter and note the number of dosing

strokes, see s e ction

4.16

.

7. Read and note the quantity in t he ch e mical tank.

8. Calculate the dose d quantity in m l a nd t he

number of dosing strokes pe rfor med du rin g the

operating period.

9. C alcula te the calibration value as follows:

(dosed quantity in ml/dosin g s t rokes) x 100.

10.Se t the cal cul ate d value in the calib ration menu

like for indirect calibration, see se ct ion

6.2

.

7. Maintenance

The pump is maintenance-free. However, it is recommended to kee p th e p ump clean.

The dosing pump is produced according to the highest quality standards and has long life. The pump incorporates wear part s such as di aphra gm, v alve s eat

and valve balls.

To ensure long life and to reduce the risk of disturbance of operation, visual checks should be carried

out regularly.

It is possible to order dosing heads, valves and diaphragms in ma te ri a ls which are suit ab le fo r the specific liquid to be pumped. See the product numbers

at the end of these instructions.

8. Service

Before returnin g th e pu m p t o GRU NDF OS fo r s er vice, the safety declaration at the end of these instructions must be filled in b y a u thor ize d pe rso nne l a nd

attached to the pump in a visible position.

Note: If a pump has been used for a liquid which is

injurious to health o r to xic, th e pu m p will be cla ssified as contaminated.

If GRUNDFOS is requested to service the pump, it

must be ensured that the pump is free from substances that can be injurious to health or toxic. If the

pump has been used for such substances, the pump

must be cleaned before it is returned.

If proper cleaning is not p ossib le, all r ele vant infor mation about the chemical must be provided.

If the above is not fu lfille d, G RUNDFO S ca n re fu se

to accept the pump for service. Possible costs of returning the pump are paid by the customer.

The safety declaration can be found at the end of these

instructions (only in English).

Note: The replacement of the supply cable must be

carried out by an authorised GRUNDFOS service

workshop.

Page 28

29

9. Fault finding chart

10. Disposal

Disposal of this product or parts of it must be carried

out according to the f ollowin g guide lin es:

1. Use the local pu blic or p r i vate wast e col l ect i on

service.

2. In case such waste collection ser vice do es not

exist or cannot handle the materials used in the

product, please deliver the product or any hazardous materi als fr om it to you r near es t G RUNDFOS company or service workshop.

Fault Cause Reme dy

The dosing has

stopped or the output

is too low.

Valves leaking or blocked. Check and clean valves.

Valves incorrectly installed. Remove and fit valves. Check that the arrow

on the valve casing is point ing in t he liq uid

flow direction. Check that all O-rings have

been fitted co rr ec tly.

Suction valve or suction pipe/hose

leaking or blocked.

Clean and seal th e su ctio n pipe/hose.

Suction lift too high. Install the pump in a lower position.

Install a priming tank.

Viscosity too high. Select the anti-cavitation function, see sec-

tion

4.14

.

Install a pipe/hose with larger cross-section.

Fit spring-loa ded valves.

Pump out of calibration. Ca librate the pu mp, see sec tio n

6

.

Pump dosing too little

or too much.

Pump out of calibration. Ca librate the pu mp, see sec tio n

6

.

Pump dosing irregularly.

Valves leaking or blocked. Check and clean the valves.

Leakage from drain

hole.

Diaphragm defective. Install a new diaphragm.

Frequent diaphragm

failures.

Diaphragm not fastened properly. Install a new diaphragm and ensure that the

diaphragm is fastened properly.

Counter-pressure too high (measured at the pump discharge port).

Check the system. Check the injection valve,

if required. Redu ce t he dosi ng s trok e b y f itti ng

a pulsation damp ene r.

Sediment in dosing head. Clean/flush the dosing head.

Subject to alteratio ns.

Loading...

Loading...