Page 1

SMART Digital S

DIGITAL DOSING up to 30 l/h

DDA, DDC, DDE

Pumps and accessories

GRUNDFOS DATA BOOKLET

Page 2

SMART Digital S

Table of contents

1. General data 3

Performance range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Features at a glance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2. Identification 6

Type key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Functions 7

Overview of functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Functional description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Control cube DDA and DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Wiring diagram, DDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Wiring diagram, DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Wiring diagram, DDE-PR, -P . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Construction 22

DDA and DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

DDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5. Dimensions 24

DDA and DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

DDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

6. Technical data 25

DDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

DDC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

DDE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

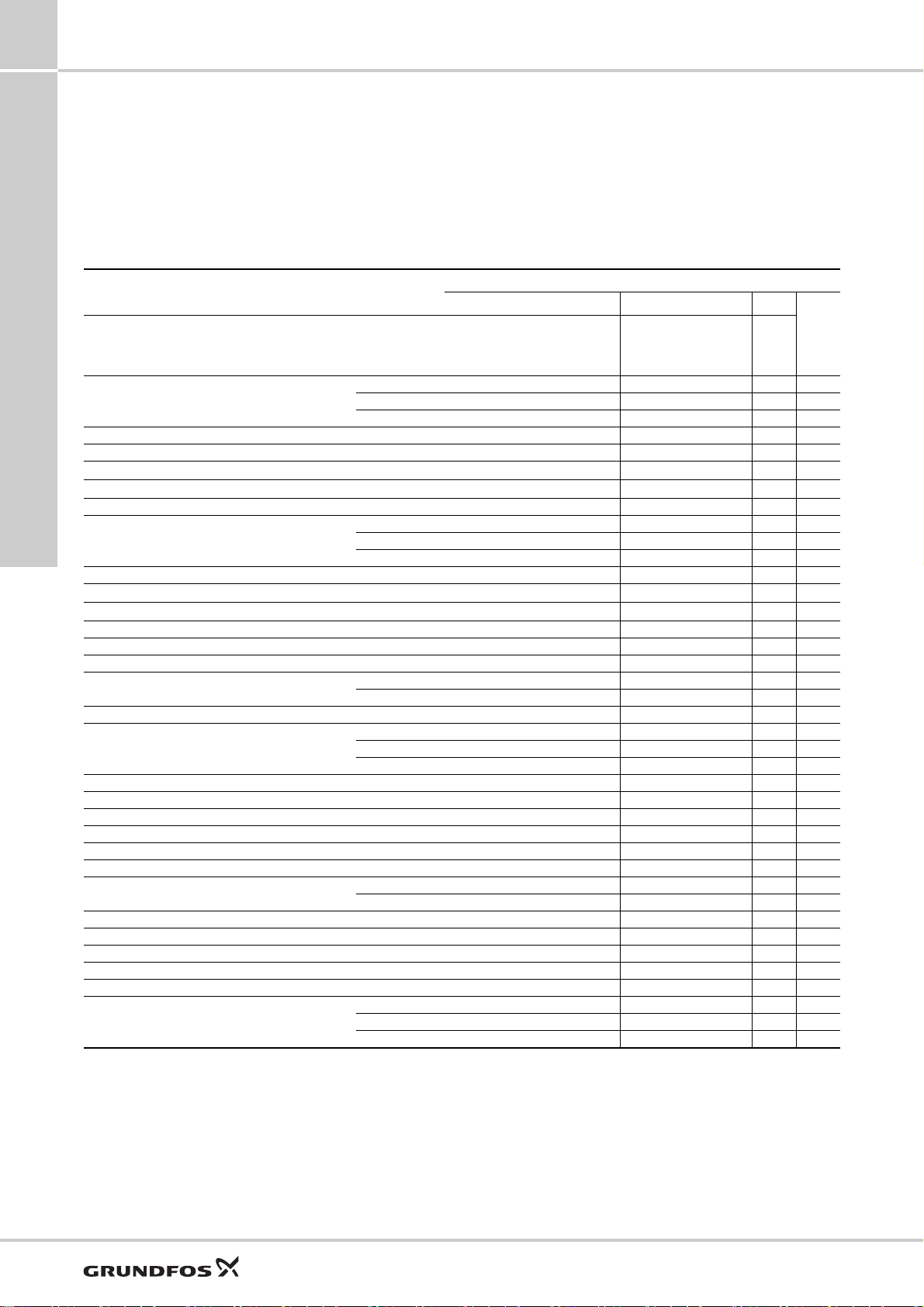

7. Pump selection 28

DDA, standard range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DDC, standard range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

DDE, standard range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

DDA, DDC, DDE, non-standard range. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

8. Accessories for small dosing pumps up to 60 l/h 33

Accessories overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Installation kits for dosing pumps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Cables and plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

E-box for SMART digital S DDA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

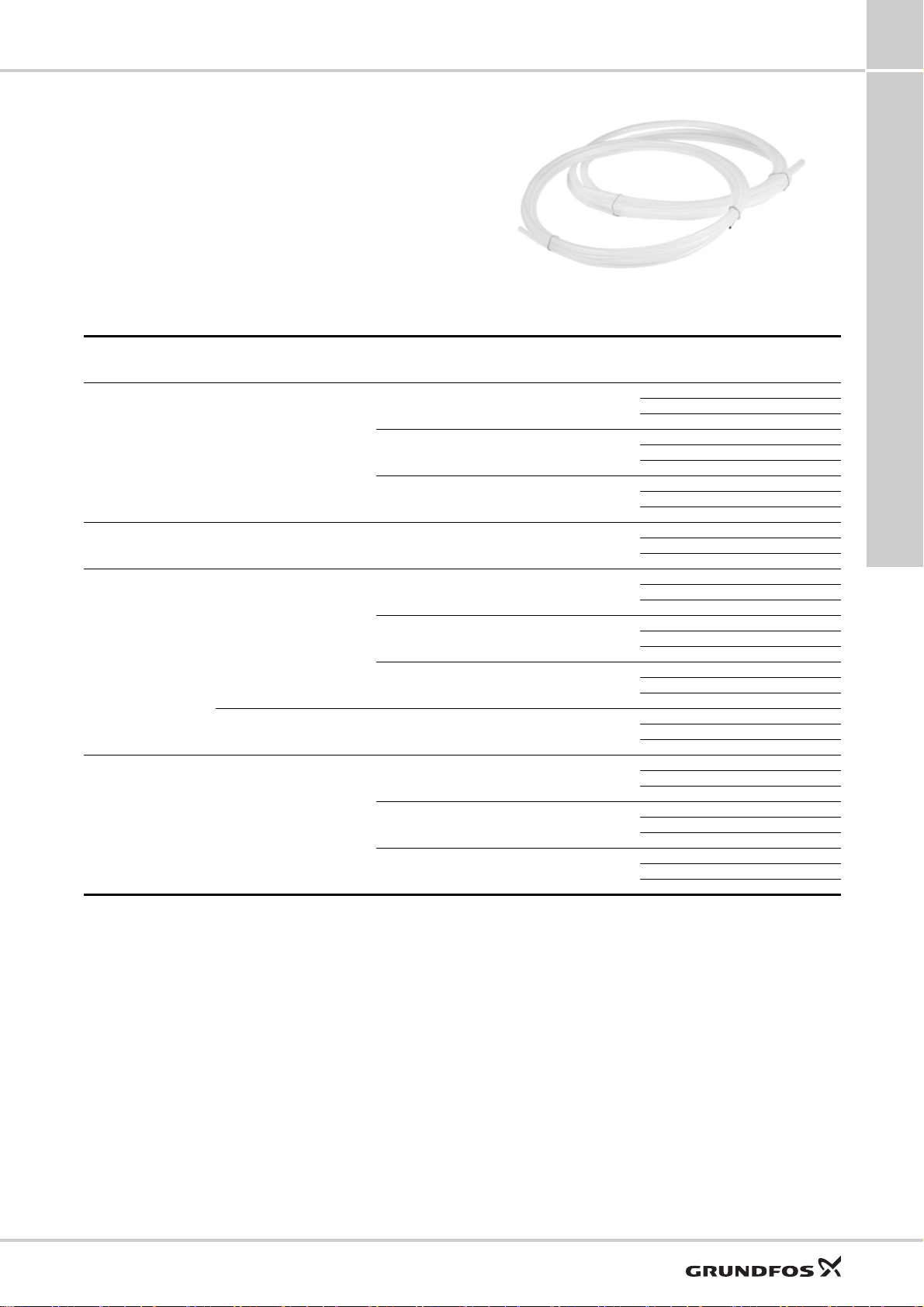

Hoses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Foot valves FV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Rigid suction lances RSL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

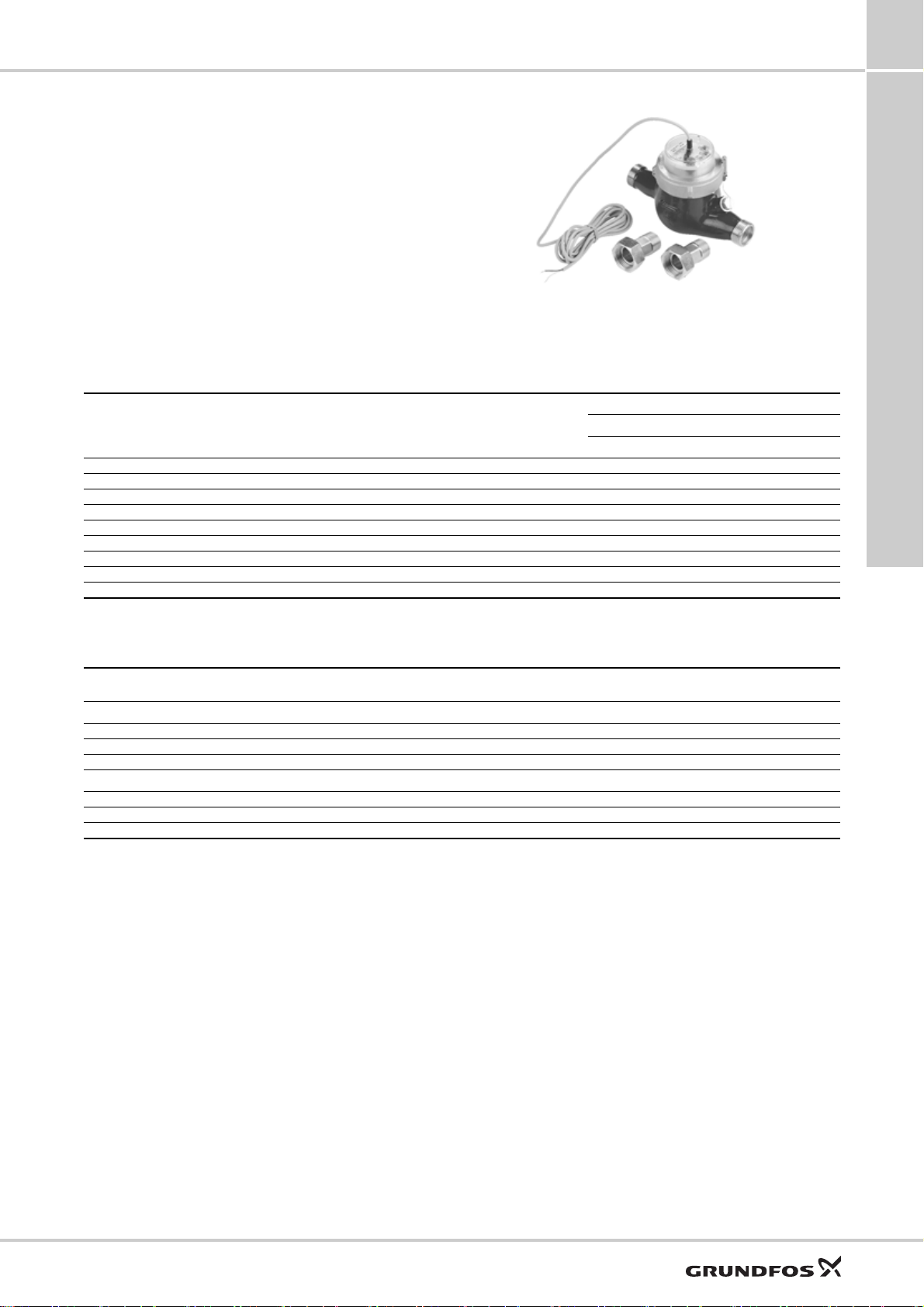

Injection units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Multi-function valves, pressure relief valves, pressure loading valves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Pump connection kits and inlay kits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Dosing tanks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Water meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9. Pumped liquids 56

10. Grundfos Product Center 57

2

Page 3

SMART Digital S

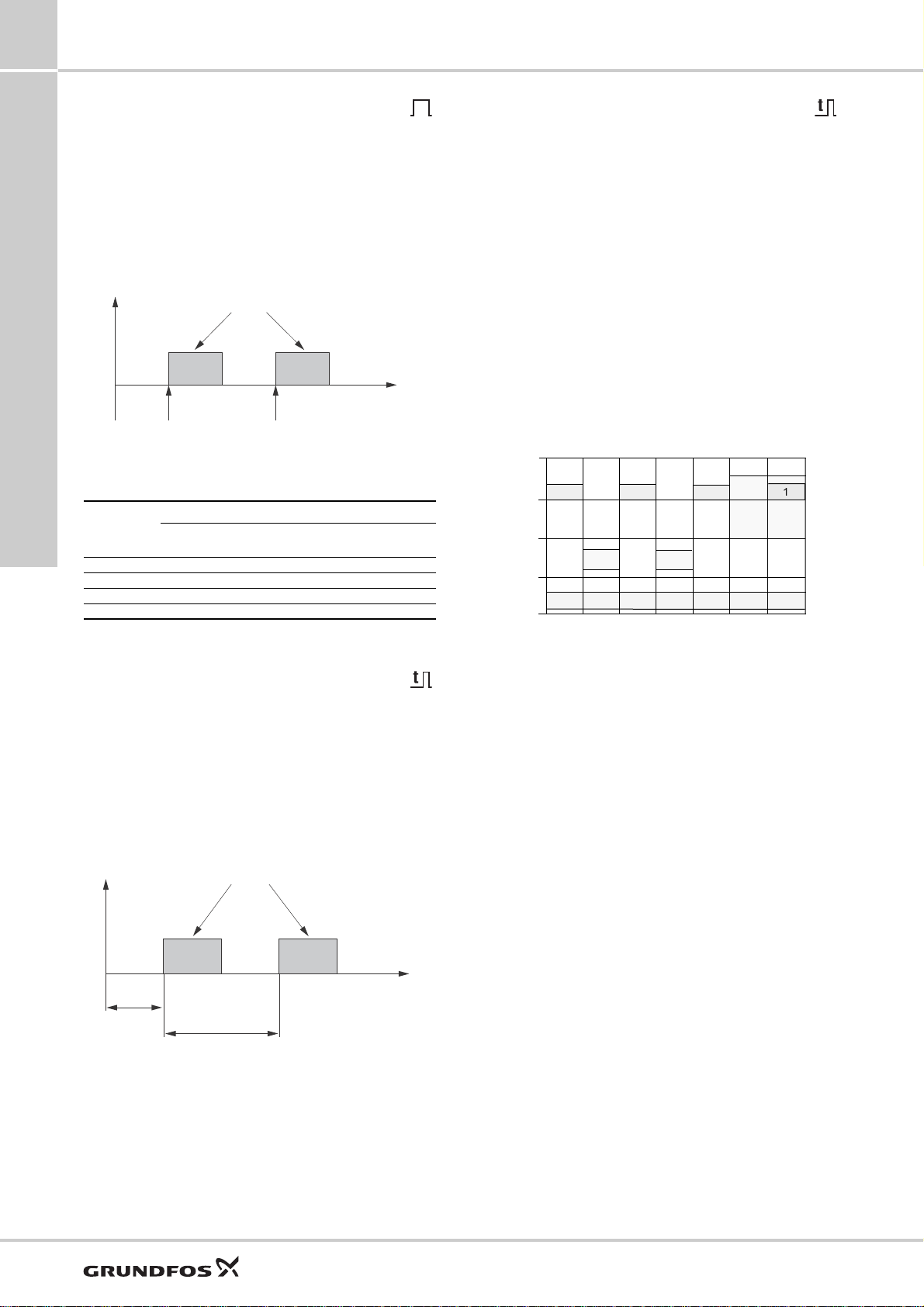

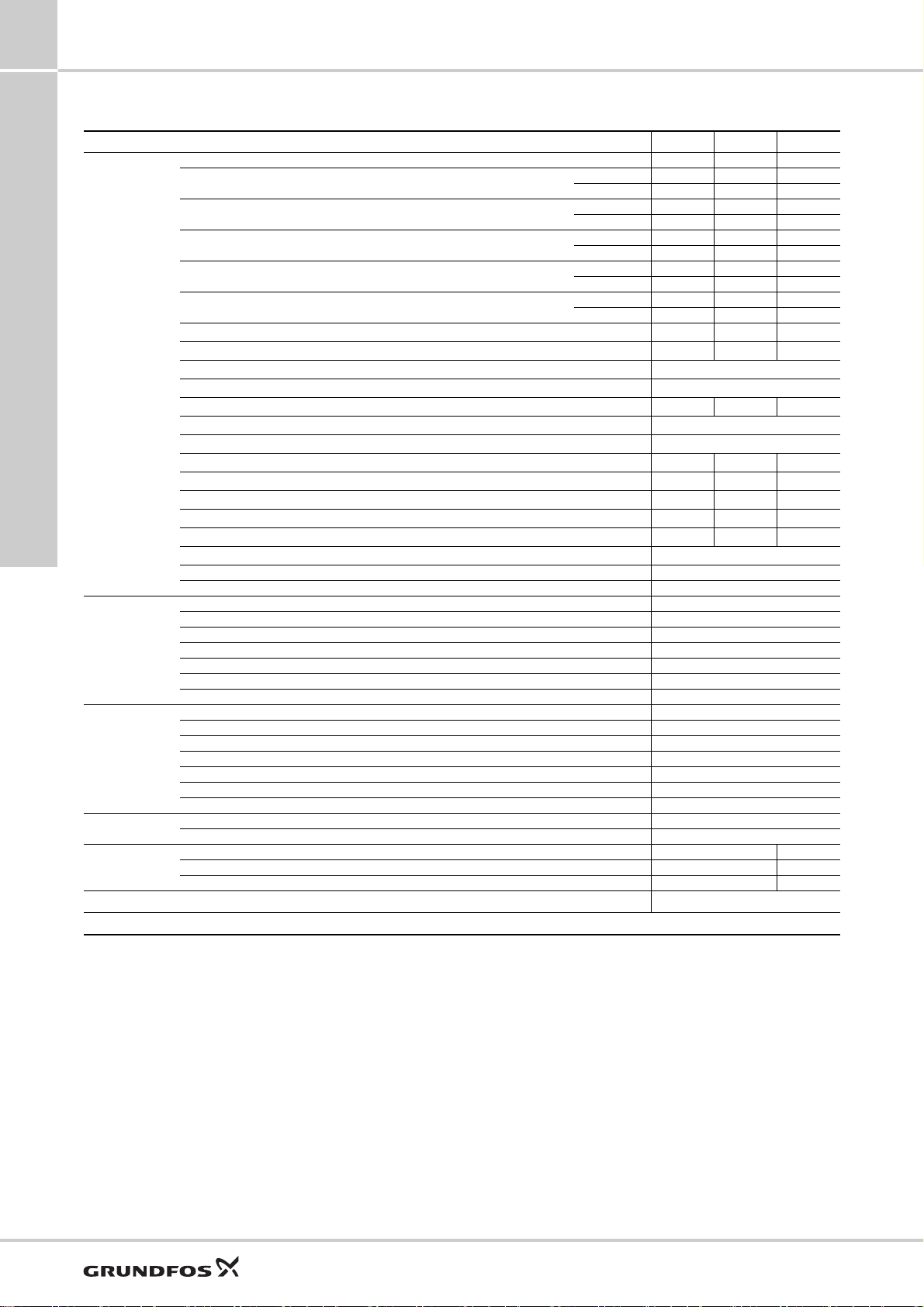

Q [l/h]

10

7

6

12

15

17

30

4

0

p

[bar]

16

9

7.5

DDA 7.5-16

DDA 12-10

DDA 17-7

DDA 30-4

DDC 15-4

DDE 15-4

DDC 9-7

DDC 6-10

DDE 6-10

1. General data

Performance range

1

General data

Fig. 1 Performance range

TM04 1480 0410

3

Page 4

1

SMART Digital S

General data

Features at a glance

TM06 8988 2417TM04 1662 2610

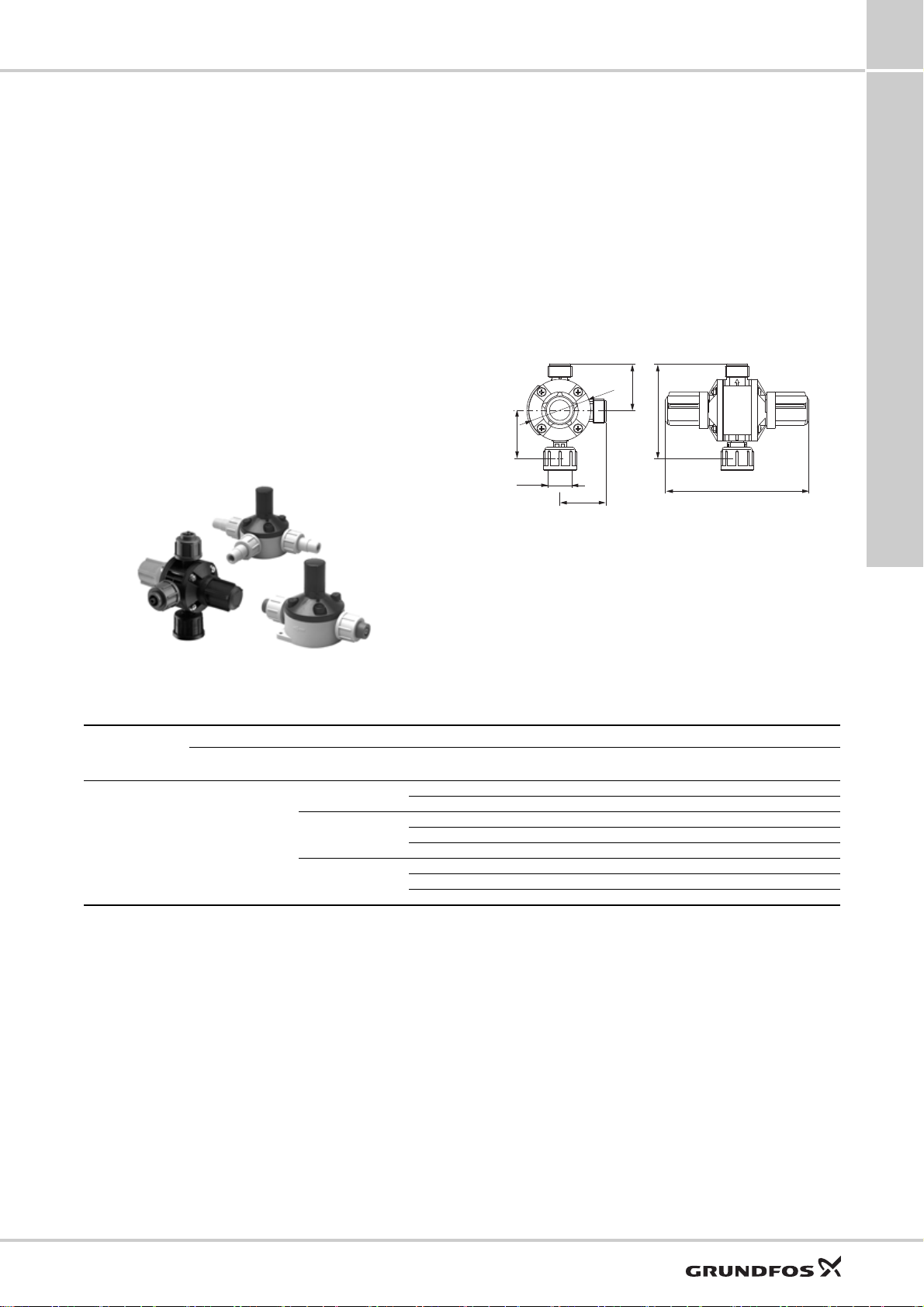

Fig. 2 DDA, DDC, DDE

Digital Dosing

The SMART Digital S generation DDA, DDC and DDE

with powerful variable-speed stepper motor brings

state-of-the-art technology to perfection.

Combined expert knowledge and the patented

solutions set future standards. Traditional technologies

such as stroke length or stroke frequency adjustment

with synchronous motor or solenoid drive become a

thing of the past.

Unique flexibility with only a few variants

The included click-stop mounting plate makes the

pump more flexible. Three different positions are

possible without using any additional accessories,

such as wall brackets. Service and pump exchange

can now be done easily and fast just by clicking the

pump in and out of the mounting plate.

The control cube on the DDA and DDC pump can be

lifted and turned easily into three different positions:

front, left or right.

Fig. 3 Modularity of the control cube

A turn-down ratio of up to 1:3000, a wide supply

voltage range (100-240 V; 50/60 Hz), combined

connection sets and other features reduce the models

and variants to a minimum.

TM

Precise and easy setting / usability and interaction

The operator can easily install the pump and set it to

discharge exactly the quantity of dosing liquid required

for the application. In the display, the setting of the

pump is read out directly, the flow is shown in ml/h, l/h,

or gph.

The click wheel (turn-and-push knob) and the

graphical LC display with plain-text menu in more than

25 languages make commissioning and operation

intuitive. As the LCD is backlit in different colours, the

pump status can be seen from a distance (traffic-light

concept).

TM04 1661 2610

Fig. 4 Display DDA, DDC

Thanks to a variety of operation modes, signal inputs

and outputs, the pump can easily be integrated into

every process.

Advanced process reliability

An intelligent drive and microprocessor control

ensures that dosing is performed precisely and with

low pulsation, even if the pump is dosing high-viscosity

or degassing liquids. Malfunctions, caused e.g. by air

bubbles, are detected quickly by the maintenance-free

FlowControl system and then displayed in the alarm

menu.

The AutoFlowAdapt function automatically adjusts the

pump according to the process conditions, e.g. varying

backpressure. The integrated flow measurement

makes additional monitoring and control equipment

redundant.

Designed to save costs

In general, the investment for a dosing pump

installation is low compared to its life cycle costs

including the cost of the chemicals. The following

features make the SMART Digital S DDA, DDC and

DDE pumps contribute to low life cycle costs:

• No underdosing or overdosing due to high dosing

accuracy and FlowControl

• Longer maintenance intervals thanks to the

universal chemical resistance of the full-PTFE

diaphragm

• Reduced energy consumption thanks to

state-of-the-art drive technology.

4

Page 5

SMART Digital S

Three application-oriented type ranges

DDA: High-end pump range for extended flow and

pressure ranges with sensor-based FlowControl and

measurement functions for challenging industrial

applications, e.g.

• Process water

• Food and beverage

• Ultrafiltration and reverse osmosis

• Pulp and paper

• Boiler feed water

• CIP (Cleaning-In-Place).

DDC: User-friendly pump range with standard inputs

and outputs for common applications, e.g.

• Drinking water

• Waste water

• Swimming pool water

• Cooling tower

• Chemical industry.

DDE: Low-budget pump range with basic functions

including manual operation or control via PLC for OEM

applications, e.g.

•Car wash

• Irrigation.

1

General data

5

Page 6

2

Identification

SMART Digital S

2. Identification

Type key

Example: DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

Type range

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

DDA

DDC

DDE

Max. flow [l/h]

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

Maximum pressure [bar]

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

Control variant

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

BBasic (DDE)

P B with pulse mode (DDE)

PR P with relay output (DDE)

A Standard (DDC)

AR A with alarm relay and analog input (DDA, DDC)

FC AR with FlowControl (DDA)

FCM FC with flow measurement (DDA)

Dosing head variant

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

PP Polypropylene

PVC Polyvinyl chloride**

PV PVDF (polyvinylidene fluoride)

SS Stainless steel 1.4401

Gasket material

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

E EPDM

VFKM

TPTFE

Valve ball material

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

C Ceramic

SS Stainless steel 1.4401

Connection, suction/discharge

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

Union nut G 5/8" with parts for hose connection

U2U2

4/6 mm, 6/9 mm, 6/12 mm, 9/12 mm

Union nut G 5/8" with parts for hose connection

U7U7

0.17" x 1/4"; 1/4" x 3/8"; 3/8" x 1/2"

Union nut G 5/8" with threaded connection Rp 1/4",

AA

internal thread

Union nut G 5/8" with threaded connection 1/4" NPT,

VV

internal thread

XX No connections included

*

Hose 4/6 mm (up to 7.5 l/h, 13 bar)

I001

*

Hose 9/12 mm (up to 60 l/h, 9 bar)

I002

*

Hose 0.17" x 1/4" (up to 7.5 l/h, 13 bar)

I003

*

I004

Hose 3/8" x 1/2" (up to 60 l/h, 10 bar)

Mains plug

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

FEU

B USA, Canada

GUK

I Australia, New Zealand

E Switzerland

J Japan

L Argentina

Design/approval

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

G Grundfos red

A Grundfos green

B Grundfos black

X Neutral/black

C China approval

Special variant

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F GC3

C3 Inspection Certificate 3.1 (EN 10204)

* Installation set: Including 2 pump connections, foot valve, injection

unit, 6 m PE discharge hose, 2 m PVC suction hose, 2 m PVC

deaeration hose (4/6 mm)

** PVC dosing heads only up to 10 bar

Control cube position

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

F Front-mounted (change to left and right possible)

X No control cube (DDE)

Supply voltage

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

3 1 x 100-240 V, 50/60 Hz

Valve type

DDA 7.5-16 AR-PP/V/C-F-3 1 U2U2 F G

1 Standard

2 Spring-loaded

0.1 bar suction opening pressure

0.1 bar discharge opening pressure

6

Page 7

SMART Digital S

3. Functions

3

Overview of functions

DDA DDC DDE

Control variant: FCM FC AR AR A PR P B

General

Digital Dosing: Internal stroke speed and frequency control ●●●● ●●●●

Mounting plate (basic/wall mounting) ●●●● ●●●●

Control panel, see page 9

Control cube mountable in three positions: front, left, right ●●● ● ●

Control panel position: front-fitted ●●●

Transparent protective cover for control elements ●●● ● ●

Capacity setting in millilitres, litres or US-gallons ●●● ● ●

Graphical display with background light in four colours for status

indication: white, green, yellow, red

Plain-text menu in different languages ●●● ● ●

Turn-and-push knob (click wheel) for easy navigation ●●● ● ●

Capacity adjustment knob (0.1 - 100 %) ●●●

Start/Stop key ●●● ● ●

100 % key (deaearation) ●●●● ●●●

Operation mode switch (manual/pulse) ●●

Operation modes, see page 11

Manual speed control ●●●● ●●●●

Pulse control in ml/pulse ●●● ● ●

Pulse control (1:n) ●●

Analog control 0/4-20 mA ●●● ●

Batch control (pulse-based) ●●●

Dosing timer cycle ●●●

Dosing timer week ●●●

Fieldbus control ●●●

Functions, see page 13

Auto deaeration also during pump standby ●●●

FlowControl system with selective fault diagnosis ●●

Pressure monitoring (min/max) ●●

Flow measurement ●

AutoFlowAdapt ●

SlowMode (anti-cavitation) ●●● ● ●

Calibration mode ●●● ● ●

Scaling of analog input ●●●

Service information display ●●● ● ●

Relay setting: alarm, warning, stroke signal, pump dosing, pulse input* ●●● ● ●

Relay setting (additionally): timer cycle, timer week ●●●

Inputs/outputs, see page 14

Input for external stop ●●●● ●●●

Input for pulse control ●●●● ●●●

Input for analog 0/4-20 mA control ●●● ●

Input for low-level signal ●●●● ●●●

Input for empty tank signal ●●●● ●●●

Output relay (2 relays) ●●● ● ●

Output analog 0/4-20 mA ●●●

Input/Output for GENIbus ●●●

Input/Output for E-box (e.g. E-box 150 with Profibus DP) ●●●

* DDE-PR: relay 1: alarm; relay 2: low-level signal, stroke signal, pulse input

●●● ● ●

Functions

7

Page 8

3

100 %

50 %

10 %

Discharge

Discharge

Discharge

Duration

Duration

Duration

Suction

Suction

Suction

Capacity

setting

Duration

10 %

Discharge

Suction

SlowMode

50 %

Extended suction stroke (SlowMode)

-

-

-

SMART Digital S

Functions

Functional description

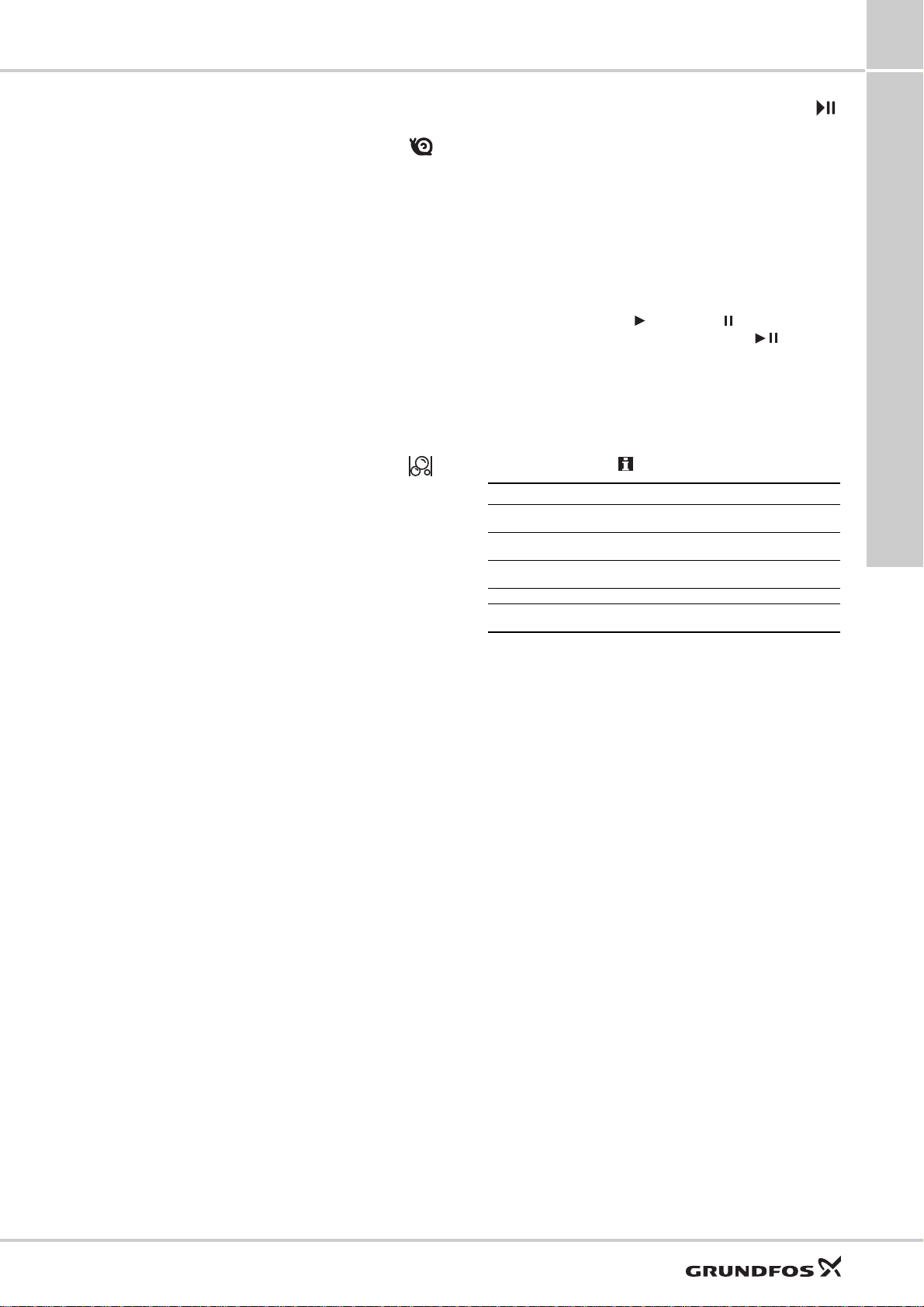

The electronically controlled variable-speed motor

(stepper motor) of the DDA, DDC and DDE pumps

provides optimum control of the stroke speed.

The duration of each discharge stroke varies

according to the capacity set, resulting in optimum

discharge flow in any operating situation, while the

duration of each suction stroke is constant (see figure

below).

The advantages are as follows:

• The pump always operates at full stroke length,

• A capacity range of up to 1:3000 (turn-down ratio)

• Smooth and continuous dosing ensuring an

• Significant reduction of pressure peaks, preventing

• The installation is less affected by long suction and

• Easier dosing of high-viscosity and degassing

The optimum dosing control shown below takes place

in any operation mode.

irrespective of the capacity set; this ensures

optimum accuracy, priming and suction.

reduces variants and spare parts.

optimum mixing ratio at the injection point without

needing static mixers.

mechanical stress on wearing parts such as

diaphragm, tubes, connections, resulting in

extended maintenance intervals.

discharge lines.

liquids (SlowMode).

8

Fig. 5 Relation between stroke-frequency adjustment and capacity

TM04 1481 0410

Page 9

SMART Digital S

7.49 l/h

Manual

7.5

l/h

Operation

1

2

3

4

100%

0%

0.15

0.2

0.3

0.4

0.5

0.6

0.8

1.5

2

3

4

5

6

8

15

20

30

40

50

60

80

10

1

1

3

2

4

5

6

7

100 %

3

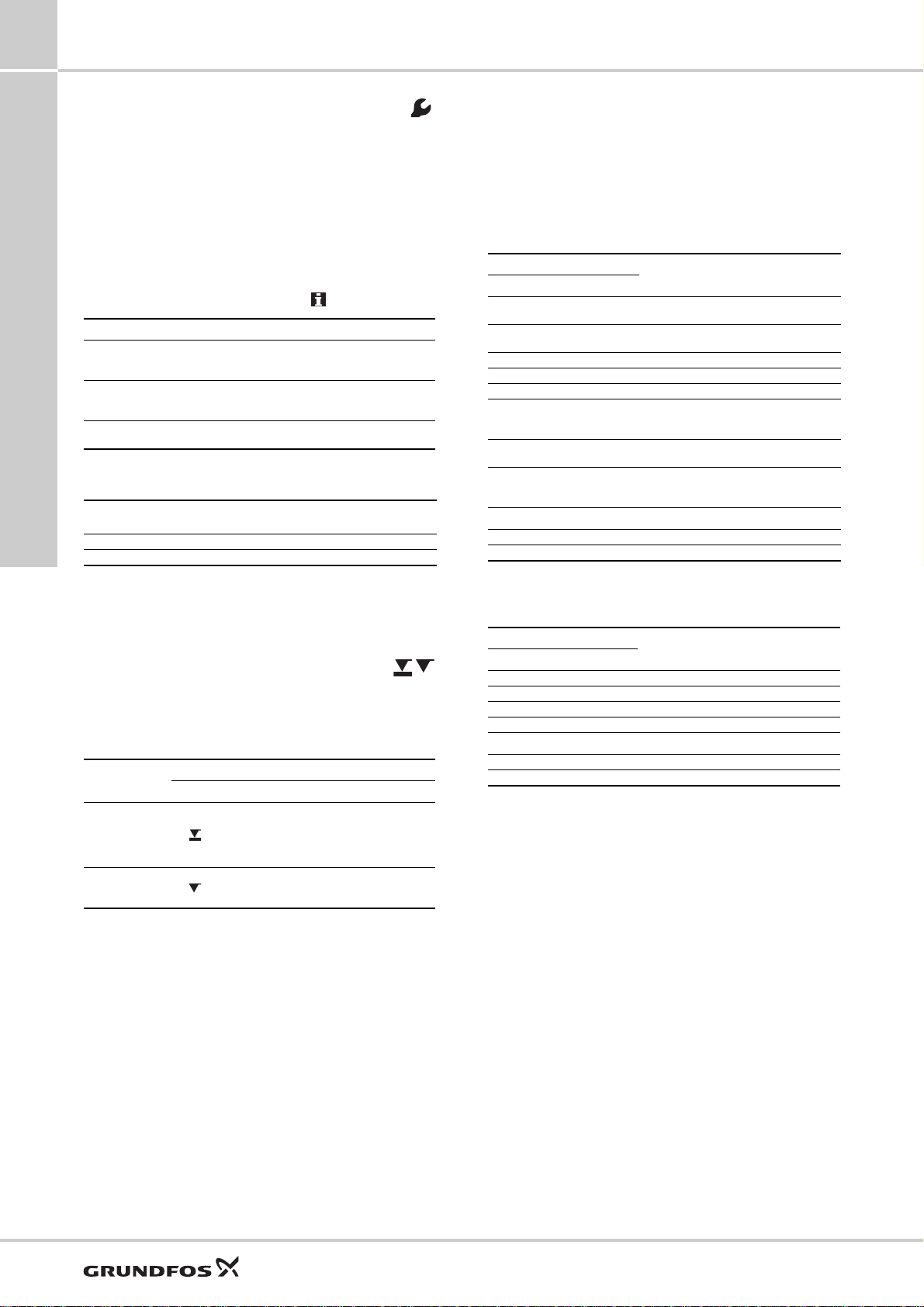

Control cube DDA and DDC

DDA and DDC pumps are supplied with front-mounted

control cube. The position of the control cube can

easily be changed by unfastening 2 screws, lifting the

cube, turning it to the left or to the right and fastening

both screws again.

Fig. 6 Two of three possible control cube positions

Operating elements DDA and DDC

Fig. 7 Operating elements DDA and DDC

Pos. Description

1 Graphical LC display

2 [Start/Stop] key

3 Click wheel

4 [100%] key

The click wheel guides the user quickly and easily

through the plain-text menu.

If the maximum capacity is required over a short period

of time, for example during start-up, press the 100 %

key. To set the pump to run for a specific number of

seconds at maximum capacity, press the 100 % key

and turn the click wheel clockwise simultaneously.

Operating elements DDE

Functions

TM04 1596 1817

Fig. 8 Operating elements DDE

TM06 9584 2517TM06 8989 1517

Pos. Description

1 Status LED pulse (DDE-PR and DDE-P)

2 Operation mode switch (DDE-PR and DDE-P)

3 Status LED manual

4 Capacity adjustment knob

5 Logarithmic scale

6 100 % key (DDE-PR and DDE-P)

7 Mechanical lock

With the capacity adjustment knob the capacity of the

pump can easily be adjusted in % of the maximum

flow.

Applies to DDE-PR, DDE-P

When holding down the operation mode switch, the

pump changes from manual operation to pulse mode

or vice versa.

If the maximum capacity is required over a short period

of time, for example during start-up, press the 100 %

key.

Depending on the selected operation mode, the

respective status LED (pulse or manual) is activated

according to the following table:

LED colour Pump status

Green (flashing) Stopped

Green Running

Red-green (flashing) External stop

Yellow Low level (warning)

Red Empty tank (alarm)

Red (flashing) Motor blocked (alarm)

9

Page 10

3

Alarm

1 12.12.2009 13:34

Low level

2

Empty

11.12.2009 14:34

Setup

Language

Operation mode

Analog output

SlowMode

.............................

English >

Manual >

Input >

Off >

Info

Fr 12.12.2009

Counter

Service

Service kit

.............................

12:34

>

-

7.49 l/h

Manual

l/h

Operation

7.50

SMART Digital S

Functions

Menu

The DDA and DDC dosing pumps feature a user-friendly plain-text menu. The menu consists of 4 tabs: Operation;

set to display other languages.

This example applies to DDA pumps:

Info; Alarm; Setup. During initial start-up, all menu text appears in the English language. The menu can be

Fig. 9 Menu overview (example of main menus)

The menu text appears in more than 25 languages on a big graphical display, backlit in four different colours according

to the traffic light concept.

Display Fault Pump status

White - Stop Standby

Green - Running

Yellow Warning Stop Standby Running

Red Alarm Stop Standby

TM04 1553 1210

10

Page 11

SMART Digital S

0

Q [%]

0 - 20 mA

4 - 20 mA

[mA]

4

2081216

100

80

0

60

40

20

Dosing capacity

Input signal

0

Q [%]

[mA]

4 2081216

100

80

0

60

40

20

I / Q

1 1

I / Q

2 2

I ' / Q '

1 1

I ' / Q '

2 2

Dosing capacity

Input signal

3

Operation modes

Manual control

The pump ensures constant dosing according to

the quantity set in l/h or ml/h or gph by means of the

click wheel. The pump automatically changes between

the measuring units.

Setting range

Pump type

DDA 7.5-16 0.0025 7.5

DDA 12-10 0.0120 12.0

DDA 17-7 0.0170 17.0

DDA 30-4 0.0300 30.0

DDC 6-10 0.0060 6.0

DDC 9-7 0.0090 9.0

DDC 15-4 0.0150 15.0

DDE 6-10 0.0060 6.0

DDE 15-4 0.0150 15.0

* When the SlowMode function is enabled the max. flow is reduced

(see page 13)

From [l/h] To [l/h]

Pulse control

The pump doses in proportion to an external

potential-free pulse signal, for example from a water

meter. There is no direct relation between pulses and

dosing strokes. The pump automatically calculates its

optimal speed to ensure that the required quantity is

dosed for each incoming pulse.

Applies to DDA and DDC

The quantity to be dosed is set in ml/pulse. The pump

adjusts its speed according to two factors:

• the frequency of external pulses

• the set quantity per pulse.

Setting range

Pump type Setting range [ml/pulse]

DDA 7.5-16 0.0015 - 14.9

DDA 12-10 0.0029 - 29.0

DDA 17-7 0.0031 - 31.0

DDA 30-4 0.0062 - 62.0

DDC 6-10 0.0016 - 16.2

DDC 9-7 0.0017 - 16.8

DDC 15-4 0.0032 - 31.6

The frequency of external pulses is multiplied by the

set quantity. If the product exceeds the maximum flow

of the pump, a maximum of 65,000 pulses can be

stored for later processing with the Memory pulse

function, when activated.

Setting range*

Applies to DDE-PR, DDE-P control variant

The dosing quantity per pulse is adjusted with the

adjustment knob according to the scale from 0.1 to

100 % of the stroke volume. The pump adjusts its

speed according to two factors:

• the frequency of external pulses

• the set percentage of stroke volume.

Setting range, DDE-PR, DDE-P

Pump type Setting range [ml/pulse]

DDE 6-10 0.0008 - 0.81

DDE 15-4 0.0016 - 1.58

Analog 0/4-20 mA control

Applies to DDA and DDC-AR control variant

The pump ensures dosing according to an external

analog signal. The dosed capacity is proportional to

the input value in mA.

Operation mode Input signal Dosing capacity

4-20

0-20

Fig. 10 0/4-20 mA control

Applies to DDA

With the analog scaling function, the curve can be

individually drawn between two arbitrary points: l

2/Q2

.

and l

≤ 4.1 mA 0 %

≥ 19.8 mA 100 %

≤ 0.1 mA 0 %

≥ 19.8 mA 100 %

1/Q1

Functions

TM04 1574 1410TM04 1575 1410

Fig. 11 Analog scaling

11

Page 12

3

Batch volume

Pulse Pulse

t

1

t

1

Batch volume

t

1

t

1

t

3

t

2

0:00

6:00

12:00

18:00

0:00

33333

3

3

22

1

4

4

11 1

Mo Tu We Th Fr Sa Su

SMART Digital S

Functions

Pulse-based batch control

Applies to DDA

The set quantity is dosed in batches within the set

dosing time (t

receives an external pulse. If the pump receives new

pulses before a batch is completed, these pulses will

be ignored. In the event of interrupts such as external

stop or alarm, incoming pulses will also be ignored.

After ending of the interrupts, a new batch will be

dosed with the next incoming pulse.

Setting range

Pump type

DDA 7.5-16 0.74 999 0.09

DDA 12-10 1.45 999 0.18

DDA 17-7 1.55 999 0.19

DDA 30-4 3.10 999 0.39

* Due to the digital motor control, down to 1/8 of the dosing volume

Dosing timer cycle

Applies to DDA

After a start delay (t

repeatedly dosed in the set cycle time (t3). The dosing

time (t

during any interrupt, e.g. power supply failure or

external stop while the time continues running in the

background (real-time clock). After ending of the

interrupt, batch dosing proceeds according to the

current status in the timeline.

). A batch is dosed every time the pump

1

Fig. 12 Pulse-based batch control

Setting range

From

[ml/batch]

can be dosed.

) can be adjusted. Batch dosing is stopped

1

To [l/batch] Resolution [ml]*

) the set batch volume is

2

Dosing timer week

Applies to DDA

The integrated real-time clock features also batch

dosing based on a weekly period. There is a maximum

of 16 procedures per week. Each dosing procedure

consists of:

• Batch volume

• Dosing time

• Start time

• 1 to 7 weekdays (Monday to Sunday).

In case several procedures are overlapping, the

procedure with the highest flow rate has the highest

priority. Batch dosing is stopped during any interrupt,

e.g. power supply failure or external stop, while the

time continues running in the background (real-time

clock). After ending of the interrupt, batch dosing

proceeds according to the current status in the

timeline.

TM04 1578 2010

TM04 1576 1410

Fig. 14 Dosing timer week (example with 4 procedures)

Setting range

The batch volume setting range corresponds to the

pulse-based batch control setting range.

12

Fig. 13 Dosing timer cycle

Setting range

The batch volume setting range corresponds to the

pulse-based batch control setting range.

TM04 1577 1410

Page 13

SMART Digital S

3

Functions

SlowMode

Applies to DDA, DDC

When the SlowMode function (anti-cavitation) is

selected, the pump extends and smooths its suction

stroke. This results in a softer suction stroke.

The SlowMode function is used in these situations:

• when pumping high-viscosity liquids

• when pumping degassing liquids

• when the suction line is long

• when the suction lift is high.

Depending on the application, the motor speed during

the suction stroke can be reduced individually to

approximately 50 % or 25 % of the normal motor

speed.

The maximum pump capacity is reduced accordingly.

See pages 25 and 26 for further details.

Auto deaeration

Applies to DDA

The auto deaeration function avoids breakdown of the

dosing process due to air-locking, when dosing

degassing liquids such as sodium hypochlorite.

During long dosing breaks, e.g. at the weekend or

overnight, air-bubbles can form in the suction line and

get into the dosing head. If too much air is in the

dosing head, and the dosing process is started again,

no liquid will be dosed (air-lock). Software-controlled

diaphragm movements at regular intervals encourage

the air bubbles to rise and finally to be displaced out of

the dosing head.

These movements are executed

• when the pump is not stopped and

• during dosing breaks (e.g. external stop or no

incoming pulses).

External stop

Applies to DDA, DDC, DDE-PR, DDE-P

With the external stop function, the pump can be

stopped from a remote place via an external contact. It

is not recommended to switch on and off the power

supply as it was usual when working with a

conventional dosing pump. When working with

microprocessor-controlled digital dosing pumps, the

external stop signal has to be used, in order to keep

the optimal dosing precision and to prevent damages

to the electronics.

When activating the external stop signal, the pump

changes from running

to standby . The operation

display shows an activated external stop .

The signal input can be set to normally open (default)

or normally closed contact.

Counters

Applies to DDA and DDC

The pump displays resettable and non-resettable

counters in the info menu tab.

Counter Description Resettable

Volume

Operating

hours

Motor

runtime

Strokes Accumulated number of dosing strokes No

Power on/off

Accumulated dosed quantity in litres or

US gallons

Accumulated number of operating hours

(power-on)

Accumulated number of motor runtime

hours

Accumulated number of times the mains

supply has been switched on

Yes

No

No

No

Functions

Calibration

Applies to DDA and DDC

The pump is calibrated in the factory at the nominal

pressure of the respective pump type (see maximum

pressure Technical data page 25, 26). After start-up,

the dosing pump can be calibrated for the actual

installation to ensure that the displayed value (ml, l or

gph) is correct. A calibration program in the setup

menu facilitates this process. The AutoFlowAdapt

function keeps the dosing precision (DDA-FCM control

variant), even if the backpressure changes.

For the description of the AutoFlowAdapt function, see

page 18.

13

Page 14

3

SMART Digital S

Functions

Service display

Applies to DDA, DDC

Due to the optimised construction and the smooth

digital dosing principle, the service periods are more

than twice as long, if compared to conventional pumps.

However, the wear parts have to be exchanged in

regular intervals in order to keep the dosing precision

and the process reliability at a high level. The service

display in the pump shows when service of the wear

parts is required. The displayed service kit product

number makes service more convenient. The following

information is displayed in the Info display:

Display Description

Service

Service kit

Reset service system

The following service messages appear, depending on

what happens first:

Display

Service soon 7,500 23

Service now 8,000 24

* Applies to DDA only

Soon

Now

8-digit Grundfos

product number

Motor runtime

[h]

No service required

Order parts for service soon

Service must be performed now

The service kit contains all parts

needed for standard maintenance:

diaphragm + valves

After performing the service, reset

the system

Regular intervals

[months]*

Relay output

Applies to DDA, DDC-AR and DDE-PR

The pump can activate 2 external signals by means of

built-in relays switched via internal potential-free

contacts. Depending on the process control

requirements, the following relay output settings can

be chosen:

Applies to DDA and DDC-AR

Signal

Relay 1 Relay 2

Alarm* Alarm

Warning * Warning

Stroke signal Stroke signal Every completed stroke

Pump dosing Pump dosing* Pump is running and dosing

Pulse input Pulse input Every pulse coming in from pulse input

Bus control Bus control

Timer cycle

Timer week

Contact type

NO* NO* Normally Open Contact

NC NC Normally Closed Contact

* default setting

Description

Display red, pump stopped

(e.g. empty tank signal, etc.)

Display yellow, pump running

(low level signal, etc.)

Set by a command in the Bus

communication function (page 15)

(only DDA)

Timer can be set in menu: on-time,

cycle-time, start delay (only DDA)

Timer can be set in menu: procedure,

on-time, start time and weekdays (only

DDA)

In case of difficult liquids the service intervals can be

shorter and service has to be performed earlier.

Level control

Applies to DDA, DDC, DDE-PR and DDE-P

The pump can be connected to a dual level control unit

for monitoring of the chemical level in the tank. The

pump can react to two level signals:

Level sensors

Low-level signal

Empty tank

signal

* Depending on the pump model and settings, the relay outputs can

be activated (see Relay output, page 14)

DDA, DDC DDE-PR, DDE-P

• Display is yellow

(Warning)

• is flashing

• Pump continues

running

• Display is red (Alarm)

• is flashing

• Pump stops

Pump reaction*

• LED lights up in

yellow

• Pump continues

running

• LED lights up in red

• Pump stops

Applies to DDE-PR control variant

Signal

Relay 1 Relay 2

Alarm* Empty tank, motor blocked

Low level* Low level tank

Stroke signal Every completed stroke

Pulse input Every pulse coming in from pulse input

Contact type

NO* NO* Normally Open Contact

NC NC Normally Closed Contact

* default setting

Description

14

Page 15

SMART Digital S

100%

100%

3

Analog output

Applies to DDA

In addition to the analog input (operation mode: analog

0/4-20 mA) the pump is also equipped with an analog

0/4-20 mA output signal. Depending on the process

control requirements, the following analog output

settings are available:

Setting

Output = Input

Actual flow

Backpressure

Bus control

* Output signal is calculated based on motor speed and pump status

(target flow rate).

Description of analog

output signal

Analog feedback signal (not

for master-slave application).

The analog input signal is

mapped 1:1 to the analog

output.

Flow measured in the dosing

head

(Flow Measurement page 18)

Backpressure measured in

the dosing head

(Pressure monitoring page 18)

Set by a command in the bus

communication (see below)

Control variant

FCM FC AR

XXX

XX*X*

XX

XXX

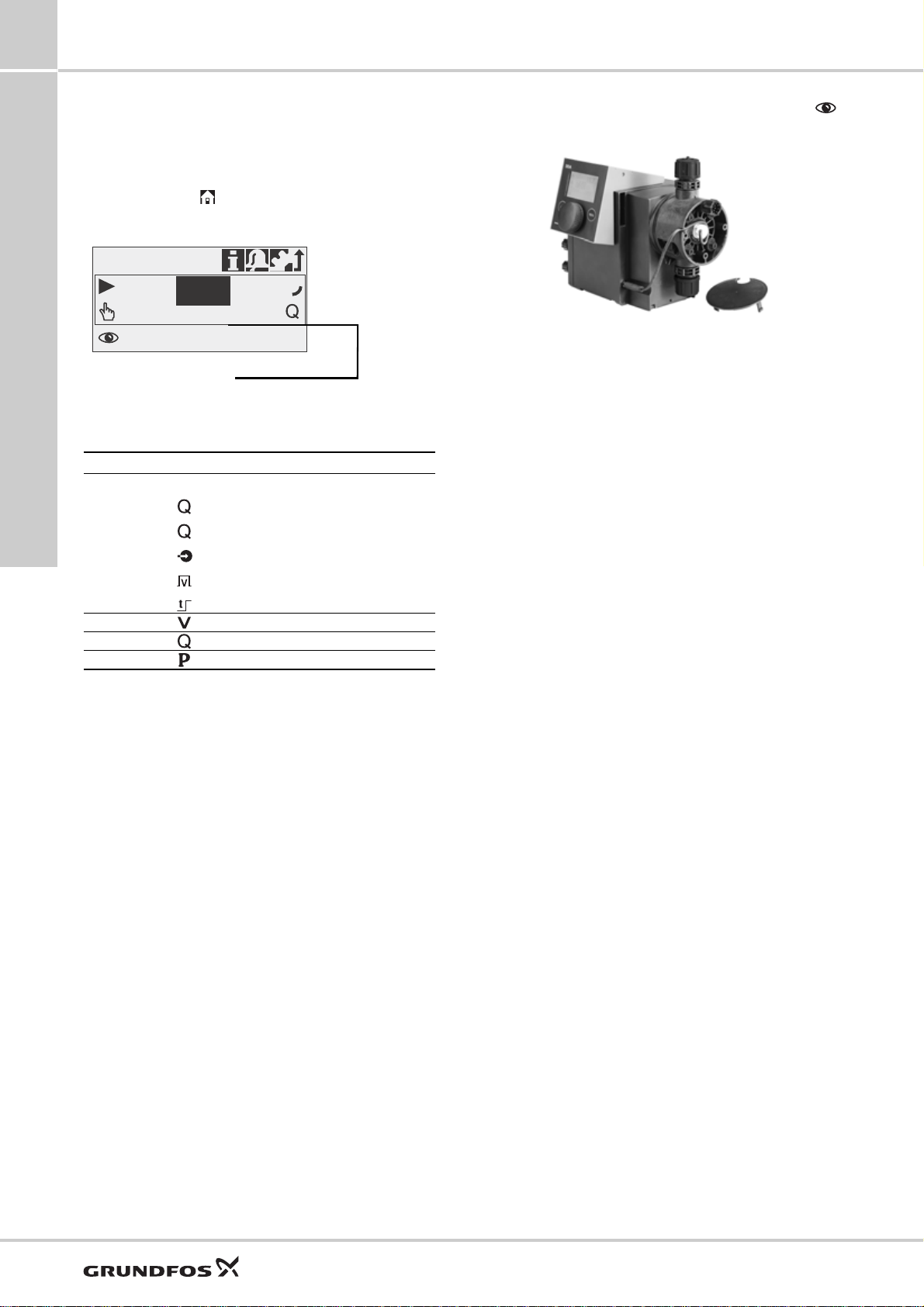

Bus communication

Applies to DDA

The pump is equipped with a built-in module for

GENIbus communication. With the additional E-Box

module (please see page 36) the pump can be

integrated into a fieldbus network.

The bus communication possibilities enable remote

monitoring and setting via the fieldbus system.

Key lock and mechanical lock

Applies to DDA, DDC

To protect the pump from maloperation, a key lock can

be set by entering a 4-digit PIN-code. When the pump

is locked, it is still possible to navigate through the

menus Alarm and Info and to acknowledge

alarms. Two levels of protection are available:

• Settings: the keys and are still available.

• Settings + keys: the keys and are also

locked.

For temporary (2 minutes) or final deactivation the

preset 4-digit pin-code has to be entered again.

Applies to DDE

The adjustment knob can be locked with a locking

screw to fix the current setting.

Basic settings

Applies to DDA, DDC

With load factory settings, the pump can be reset to

the default settings. In addition, with save customer

settings, the current configuration of the pump is

stored and can be activated later by load customer

settings. The latest saved configuration is stored in the

memory.

Units

Applies to DDA, DDC

It is possible to select metric units (litre/millilitre/bar) or

US units (US gallons/psi). Depending on the operation

mode and menu, the following units are displayed:

Functions

Fig. 15 DDA with E-box

Operation mode/Function M etric units US units

Manual control ml/h or l/h gph

Pulse control ml/ ml/

Analog 0/4-20 mA control ml/h or l/h gph

Batch control

(pulse- or timer-based)

Calibration ml ml

Volume counter l gal

Pressure monitoring bar psi

TM04 1640 2617

ml or l gal

15

Page 16

3

7.49 l/h

Manual

7.50

l/h

Operation

Additional display

SMART Digital S

Functions

Additional display

Applies to DDA, DDC

The additional display function provides further useful

status information, e.g. the target flow rate as well as

the actual flow rate. The value is shown in the

operation display together with the corresponding

symbol.

The following additional information can be selected:

Settings Description

Default display

Dosed volume

Actual flow

Backpressure

1) Only DDA-FCM control variant

2) Only DDA-FCM/FC control variant

3) Only DDA pumps

4) Only DDA pumps and DDC-AR control variant

Fig. 16 Additional display

Depending on the operation mode:

Actual flow (manual, pulse)

Target flow (pulse)

Input current (analog)

Remaining batch volume (batch, timer)

Time until next batch (timer)

Total dosed volume (Counters see page 13)

Actually measured flow

Current backpressure in the dosing head

FlowControl

Applies to DDA-FC/FCM

TM04 1641 2617

Fig. 17 DDA FlowControl

The pump monitors the dosing process of liquids when

TM04 1633 1810

1)

4)

3)

3)

1)

2)

the FlowControl function is activated. Although the

pump is still operating, some influences such as air

bubbles may cause reduced flow rates or even stop

the dosing process. For optimal process safety and

reliability, the activated FlowControl function

immediately detects and displays the following

malfunctions:

• Overpressure

• Discharge line burst

• Air bubbles in the dosing head

• Cavitation at the suction side

• Suction valve leakage

• Discharge valve leakage.

The unique FlowControl is based on an intelligent and

maintenance-free sensor integrated in the dosing

head. During the dosing process, the sensor measures

the actual pressure and sends the measured value to

the microprocessor in the pump. An internal indicator

diagram is generated combining the actual pressure

value with the diaphragm position (stroke length).

With it, the dosing process is monitored, as the

different malfunctions can immediately be detected

due to their specific deviations in the curve.

Compressible air bubbles, for instance, will reduce the

discharge phase and the stroke volume (see fig. 18).

The sensitivity and the delay of the FlowControl

function can be adjusted individually.

FlowControl requires a minimum backpressure of

2 bar. Grundfos recommend an additional

spring-loaded valve (approx. 3 bar) on the discharge

side for dosing low capacities (< 1 l/h) (please see

page 46).

16

Page 17

SMART Digital S

1

2

3

4

Pressure

Stroke length

Trouble-free dosing stroke

Air bubbles disturbing

the dosing stroke

3

Functions

TM04 1610 1710

Fig. 18 Indicator diagram

1 Compression phase

2 Discharge phase

3 Expansion phase

4 Suction phase

17

Page 18

3

SMART Digital S

Functions

Pressure monitoring

Applies to DDA-FC/FCM

The integrated pressure sensor measures the actual

pressure of the system, which is shown in the display.

A maximum pressure can be set. If the pressure in the

system exceeds the set maximum (e.g. caused by a

closed valve), the pressure monitoring function stops

the dosing process immediately. As soon as the

backpressure falls below the set maximum, the dosing

process is continued. In case the pressure drops below

the minimum limit (e.g. caused by a burst discharge

line) the pump stops and major chemical spills are

prevented.

Pressure setting range

Pump type

DDA 7.5-16 < 2 3 ... 17 (default)

DDA 12-10 < 2 3 ... 11 (default)

DDA 17-7 < 2 3 ... 8 (default)

DDA 30-4 < 2 3 ... 5 (default)

* Can be either set as a warning (pump keeps running) or as an

** The adjustable max. pressure is equivalent to the max. operating

Flow measurement

Applies to DDA-FCM

The pump can precisely measure and display the

actual dosing flow. Via the analog 0/4-20 mA output,

the actual flow signal can easily be integrated in any

process control system, without needing any additional

measurement equipment.

The Flow measurement function is based on an

indicator diagram as described in FlowControl

(page 16). Accumulating the length of each discharge

stroke phase and multiplying it with the stroke

frequency results in the displayed actual flow.

Any malfunctions, such as air bubbles or lower

backpressure, will result in a reduced or increased

actual flow rate. When the AutoFlowAdapt function

(page 18) is activated, the pump compensates these

influences by correcting the stroke speed.

Fixed min. pressure

alarm (pump stops)

pressure plus 1 bar

[bar]*

Adjustable max. pressure

[bar]**

AutoFlowAdapt

Applies to DDA-FCM

When activating the AutoFlowAdapt function even

environmental changes will be compensated, so that

the required target flow rate will be achieved.

The integrated AutoFlowAdapt makes additional

monitoring and control devices redundant.

The AutoFlowAdapt function is based on:

• FlowControl: malfunctions are detected

• Pressure monitoring: system pressure changes are

detected

• Flow measurement: deviations in the target flow are

detected.

Examples:

• FlowControl detects air bubbles in the system.

Due to a special motor drive strategy and a certain

speed increase, the pump will try to keep the flow

rate constant. This is especially important when

dosing degassing liquids.

• In general, increasing system pressure reduces the

stroke volume whereas falling system pressure

increases the stroke volume. The AutoFlowAdapt

function compensates this by automatically and

continuously adapting the motor speed.

Despite fluctuating system pressure, dosing

accuracy is maintained.

18

Page 19

SMART Digital S

2

1

3

4

2

1

3

4

5

2

3

4

1

2

1

3

►

2

1

GND

GND

BUS

BUS

GND

12

34

12

34

12

5

34

34

12

Cable 1

Analog/external stop/pulse

Product No.

2 m cable: 96609014

5 m cable: 96609016

Cable 2

Level input

see page 39, suction

lances

Cable 3

GENIbus, analog output

Product No.

2 m cable: 96632921

5 m cable: 96632922

Cable 4

Relay output

Product No.

2 m cable: 96609017

5 m cable: 96609019

FlowControl input

Sensor

Wiring diagram, DDA

3

Functions

Cable 1: Analog, external stop and pulse input

Function

Analog GND/ (-) mA (+) mA mA signal

External stop GND X Contact

Pulse GND X Contact

1/brown 2/white 3/blue 4/black

Cable 2: Level input

Function

Low level X GND Contact

Empty tank X GND Contact

1234

Cable 3: GENIbus, analog output

Function

GENIbus +30 V GENI bus A GENI bus B GND Bus

Analog output (+) mA GND/ (-) mA mA signal

1/brown 2/white 3/blue 4/black 5/yellow-green

Cable 4: Relay output

Function

Relay 1 X X Contact

Relay 2 X X Contact

1/brown 2/white 3/blue 4/black

Pin holes

Pin holes

Pin holes

Pin holes

TM04 1121 0110 - TM06 8987 1517

Plug type

Plug type

Plug type

Plug type

19

Page 20

3

2

1

3

4

►

GND

12

34

34

12

2

3

4

1

1

2

12

34

2

1

3

GND

Cable 1

Analog/external stop/pulse

Product No.

2 m cable: 96609014

5 m cable: 96609016

Cable 2

Level input

see page 39, suction

lances

Cable 4

Relay output

Product No.

2 m cable: 96609017

5 m cable: 96609019

SMART Digital S

Functions

Wiring diagram, DDC

Cable 1: Analog, external stop and pulse input

Function

Analog* GND/ (-) mA (+) mA mA signal

External stop GND X Contact

Pulse GND X Contact

Cable 2: Level input

Function

Low level X GND Contact

Empty tank X GND Contact

Cable 4: Relay output*

Function

Relay 1 X X Contact

* applies to DDC-AR

Relay 2 X X Contact

Pin holes

1/brown 2/white 3/blue 4/black

Pin holes

1234

Pin holes

1/brown 2/white 3/blue 4/black

TM04 1531 1010

Plug type

Plug type

Plug type

20

Page 21

SMART Digital S

1

3

4

2

3

4

1

2

1

3

Ź

2

1

GND

GND

12

34

34

12

12

34

Cable 2

Level input

see page 39, suction

lances

Cable 1

External stop/pulse

Product No.

2 m cable: 96609014

5 m cable: 96609016

Cable 4

Relay output

Product No.

2 m cable: 96609017

5 m cable: 96609019

Wiring diagram, DDE-PR, -P

3

Functions

Cable 1: External stop and pulse input

Function

External stop GND X Contact

Pulse GND X Contact

1/brown 2/white 3/blue 4/black

Cable 2: Level input

Function

Low level X GND Contact

Empty tank X GND Contact

Cable 4: Relay output*

Function

Relay 1 (Alarm) X X Contact

Relay 2 (see page 14) X X Contact

* applies to DDE-PR

1/brown 2/white 3/blue 4/black

Pin holes

Pin holes

1234

Pin holes

TM04 1597 0312

Plug type

Plug type

Plug type

21

Page 22

4

1

2

3

4

5

6

7

8

9

13

14

15 16

17

23

24

25

26

27

28

29

18 19

20

21

22

10

11

12

Construction

SMART Digital S

4. Construction

DDA and DDC

TM04 1533 1010

Fig. 19 Sectional drawing, DDA

Construction

The DDA and DDC pumps are motor-driven diaphragm

dosing pumps consisting of the following main parts:

Dosing head: Patented design with a minimum of

clearance space optimised for degassing liquids.

With integrated deaeration valve for priming and

venting complete with connection for a 4/6 mm or 0.17"

x 1/4" tubing. DDA-FCM/FC pumps have an integrated

pressure sensor in the dosing head.

Valves: Double-ball discharge and suction valve*

design for less clearance space - optimised for

degassing liquids. Spring-loaded valves for higher

viscosities are available as an option.

Connections: Robust and easy-to-use connection

packages for various sizes of tubing or pipes.

Diaphragm: Full PTFE diaphragm designed for long

life and universal chemical resistance.

Flange: With separation chamber, safety diaphragm

and drain hole.

Drive unit: Positive return crank with patented

noiseless spur gear drive, energy recovery spring for

high efficiency (only DDA), stepper motor, all mounted

in a robust gear housing.

Control cube: Containing operation electronics with

display, keys, click-wheel and protective cover.

Housing: Containing drive unit and power electronics

with robust signal sockets. The housing can be clicked

on the mounting plate.

22

Material specification

Pos. Description Material options

1 Stepper motor 2 Cooling element** Aluminium

3 Suction valve, complete *** -

4 Valve ball, DN 4*

5 Dosing head PP, PVC, PVDF, SS 1.4435

6 Safety diaphragm EPDM

7 Dosing head screw SS 1.4301

8 Diaphragm full PTFE

9 Pressure sensor 10 Dosing head cover PP, SS 1.4301

11 Deaeration valve PP, PVC, PVDF

12 Deaeration valve O-ring EPDM/FKM

13 Discharge valve, complete*** 14 Discharge valve O-ring EPDM, FKM, PTFE

15 Discharge valve ball, DN 8

16 Discharge valve seat EPDM, FKM, PTFE

17 Discharge valve ball cage PP, PVC, PVDF, SS 1.4435

18 Flange PPO/PS 20 % gf

19 Energy recovery spring** EN 10270-2/VD SiCr

20 Connecting rod PA 6.6 30 % gf

21 Gear box PPO/PS 20 % gf

22 Housing PPO/PS 20 % gf

23 Control cube PPO/PS 20 % gf

24 Display cover PC

25 Operation PCB 26 Click wheel PPO/PS 20 % gf

27 Hall sensor 28 Power PCB 29 Mounting plate PPO/PS 20 % gf

* Only for pumps up to 7.5 l/h with standard valves

** Only for DDA

*** Pump can be supplied with spring-loaded valves (Material: Tantal)

Ceramic Al

SS 1.4401

Ceramic Al

SS 1.4401

2O3

2O3

99.5 %,

99.5 %,

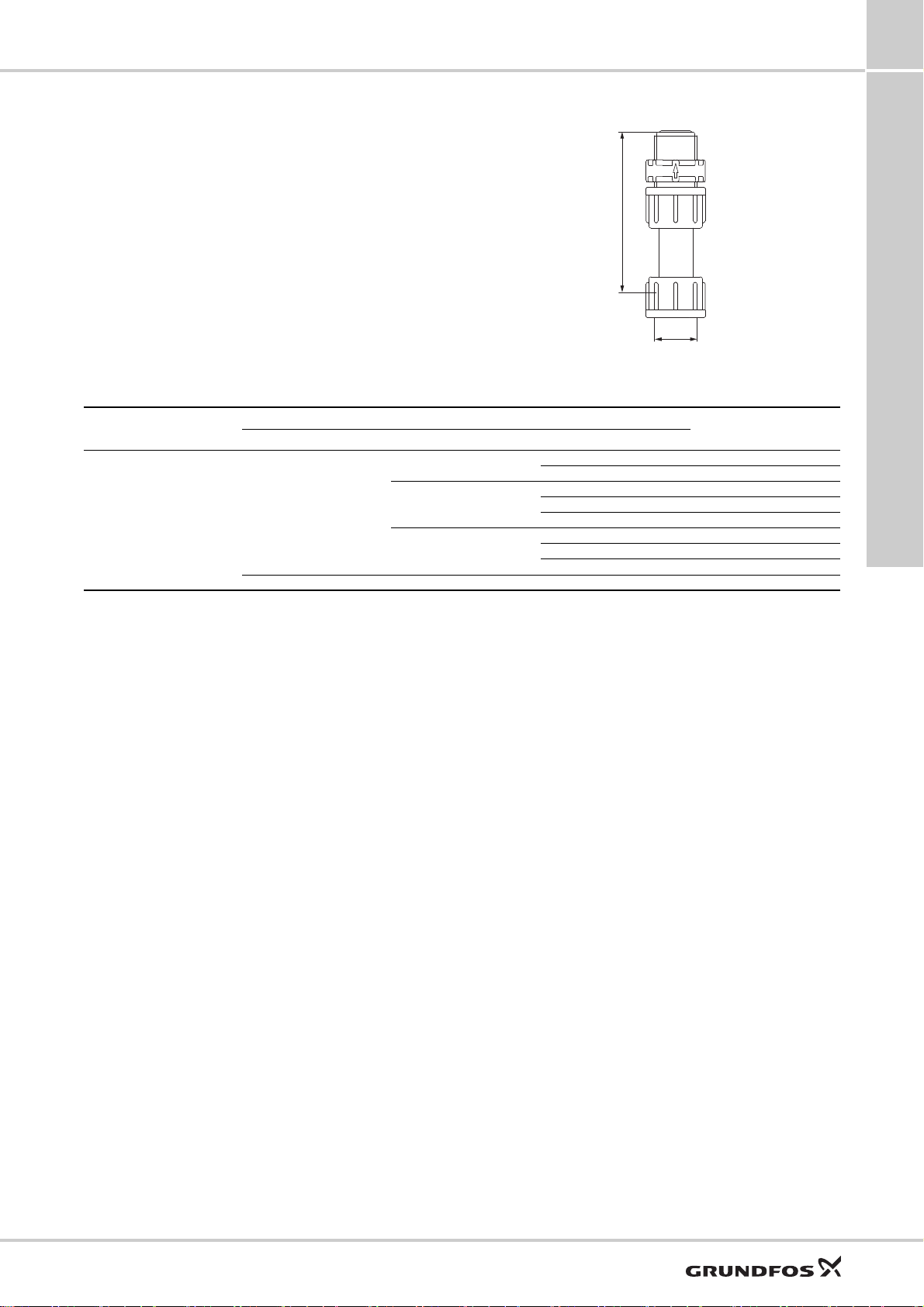

Page 23

SMART Digital S

DDE

4

11

10

9

8

7

6

5

4

3

2

1

12

13 15

14

16

Fig. 20 Sectional drawing, DDE

Construction

The DDE pump is a motor-driven diaphragm dosing

pump consisting of the following main parts:

Dosing head: Patented design with a minimum of

clearance space optimised for degassing liquids.

With integrated deaeration valve for priming and

venting complete with connection for a 4/6 mm or 0.17"

x 1/4" tubing.

Valves: Double-ball discharge and suction valve*

design for less clearance space - optimised for

degassing liquids. Spring-loaded valves for higher

viscosities are available as an option.

Connections: Robust and easy-to-use connection

packages for various sizes of tubing or pipes.

Diaphragm: Full PTFE diaphragm designed for long

life and universal chemical resistance.

Flange: With separation chamber, safety diaphragm

and drain hole.

Drive unit: Positive return crank with patented

noiseless spur gear drive, stepper motor, all mounted

in a robust gear housing.

Housing: Containing drive unit, control panel and

electronics with robust signal sockets. The housing

can be clicked on the mounting plate.

18

17

19

20

Construction

21

22

23

TM04 1609 1710

Material specification

Pos. Description Material options

1 Stepper motor -

2 Suction valve, complete ** -

3 Valve ball, DN 4*

4 Dosing head PP, PVC, PVDF, SS 1.4435

5 Safety diaphragm EPDM

6 Dosing head screw SS 1.4301

7 Diaphragm full PTFE

8 Dosing head cover PP, SS 1.4301

9 Deaeration valve PP, PVC, PVDF

10 Deaeration valve O-ring EPDM/FKM

11 Discharge valve, complete** 12 Discharge valve O-ring EPDM, FKM, PTFE

13 Discharge valve ball, DN 8

14 Discharge valve ball cage PP, PVC, PVDF, SS 1.4435

15 Discharge valve seat EPDM, FKM, PTFE

16 Flange PPO/PS 20 % gf

17 Connecting rod PA 6.6 30 % gf

18 Gear box PPO/PS 20 % gf

19 Housing PPO/PS 20 % gf

20 Hall sensor 21 Capacity adjustment knob PPO/PS 20 % gf

22 Power PCB 23 Mounting plate PPO/PS 20 % gf

* Only for pumps up to 6 l/h with standard valves

** Pump can be supplied with spring-loaded valves (Material: Tantal)

Ceramic Al

SS 1.4401

Ceramic Al

SS 1.4401

2O3

2O3

99.5 %,

99.5 %,

23

Page 24

5

100%

110

17.5

168

161

D

B

C

A1

G 5/8

A

200.8

17

161 17D

A1

B

C

161.5

G 5/8

4 x Ø6

110

105

120

17.5

Dimensions

SMART Digital S

5. Dimensions

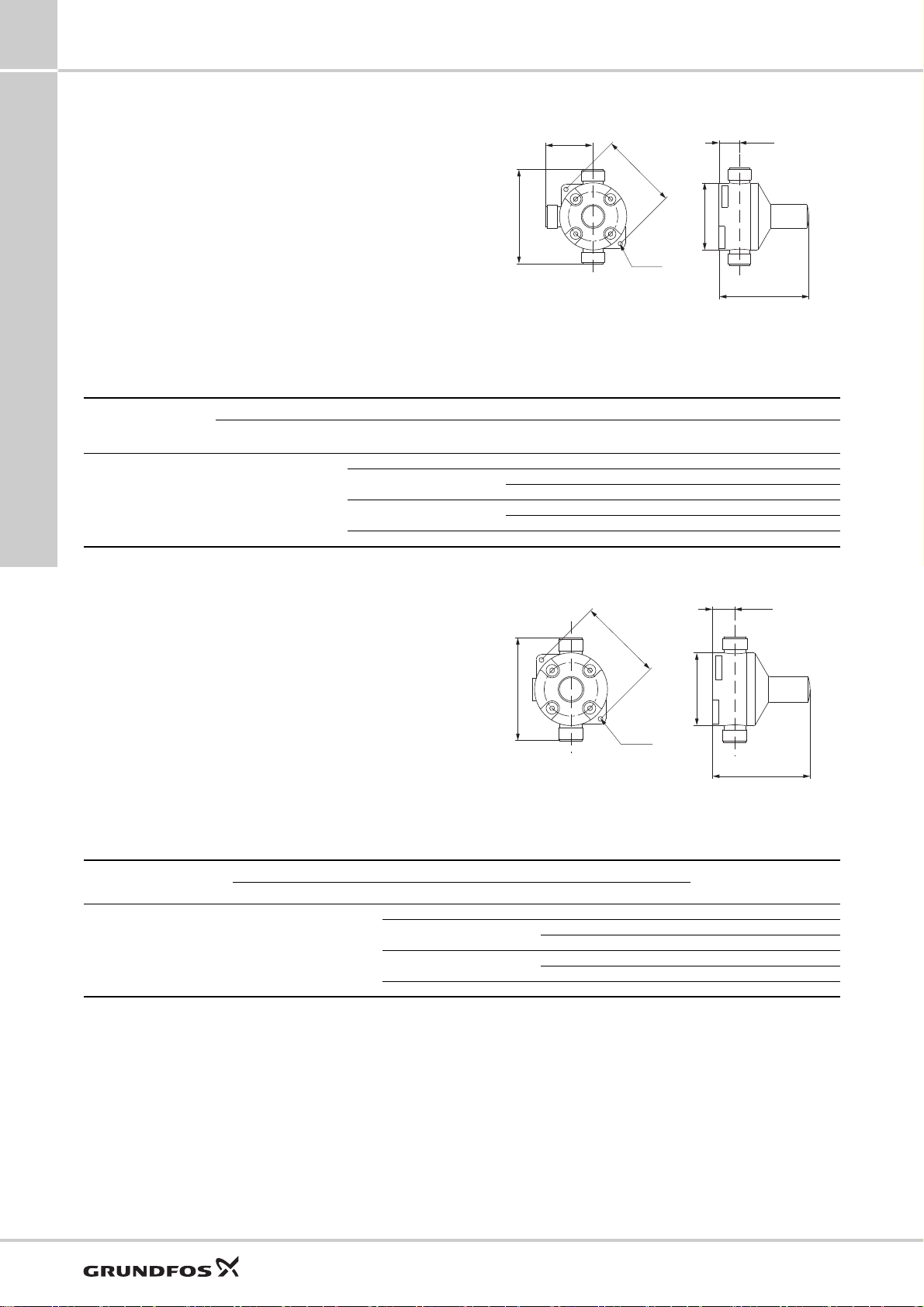

DDA and DDC

4 x Ø6

105

120

Fig. 21 DDA and DDC with front-fitted or side-fitted control cube

DDE

TM04 1487 0710

24

Fig. 22 DDE-PR with front-fitted control elements

Pump type A [mm] A1 [mm] B [mm] C [mm] D [mm]

DDA 7.5-16

DDC 6-10

DDC 9-7

DDE 6-10

DDA 12-10

DDA 17-7

DDC 15-4

DDE 15-4

DDA 30-4 295 267 204.5 35.5 38.5

280 251 196 46.5 24

280 251 200.5 39.5 24

TM04 1598 0312

Page 25

SMART Digital S

6. Technical data

DDA

6

DDA 7.5-16 12-10 17-7 30-4

Turn-down ratio (setting range) [1:X] 3000 1000 1000 1000

Max. dosing capacity

Max. dosing capacity with SlowMode 50 %

Max. dosing capacity with SlowMode 25 %

Min. dosing capacity

Max. operating pressure

Max. stroke frequency

Stroke volume

Mechanical data

Electrical data

Signal input

Signal output

Weight/size

Sound pressure Max. sound pressure level [dB(A)] 60

Approvals CE, CB, CSA-US, NSF61, EAC, ACS, C-Tick

1) The maximum stroke frequency varies depending on calibration

2) Data is based on measurements with water

3) Maximum suction lift: 1 m, dosing capacity reduced (approx. 30 %)

4) Length of suction line: 1.5 m, length of discharge line: 10 m (at max. viscosity)

5) With E-box

Accuracy of repeatability

Max. suction lift during operation

Max. suction lift when priming with wet valves

Min. pressure difference between suction and discharge side

Max. inlet pressure, suction side

Max. viscosity in SlowMode 25 % with spring-loaded valves

Max. viscosity in SlowMode 50 % with spring-loaded valves

Max. viscosity without SlowMode with spring-loaded valves

Max. viscosity without spring-loaded valves

Min. internal hose/pipe diameter suction/discharge side

Min. internal hose/pipe diameter suction/discharge side (high viscosity)

Min./Max. liquid temperature [°C] -10/45

Min./Max. ambient temperature [°C] 0/45

Voltage [V] 100-240 V, 50/60 Hz

Length of mains cable [m] 1.5

Max. inrush current for 2 ms at 100 V [A] 8

Max. inrush current for 2 ms at 230 V [A] 25

Max. power consumption P

Enclosure class IP65, Nema 4X

Electrical safety class II

Max. load low-level / empty tank / pulse / external stop input 12 V, 5 mA

Min. pulse length [ms] 5

Max. pulse frequency [Hz] 100

Impedance at analog 0/4-20 mA input [Ω]15

Accuracy of analog input (full-scale value) [%] ± 1.5

Min. resolution of analog input [mA] 0.05

Max. resistance in level/pulse circuit [Ω] 1000

Max. ohmic load on relay output [A] 0.5

Max. voltage on relay/analog output [V] 30 VDC/30 VAC

Impedance at 0/4-20 mA analog output [Ω]500

Accuracy of analog output (full-scale value) [%] ± 1.5

Min. resolution of analog output [mA] 0.02

Weight (PVC, PP, PVDF) [kg] 2.4 2.4 2.6

Weight (stainless steel) [kg] 3.2 3.2 4.0

Diaphragm diameter [mm] 44 50 74

1)

2)

2)

3)

3)

3)

3)

4), 2)

4)

1

[l/h] 7.5 12.0 17.0 30.0

[gph] 2.0 3.1 4.5 8.0

[l/h] 3.75 6.00 8.50 15.00

[gph] 1.00 1.55 2.25 4.00

[l/h] 1.88 3.00 4.25 7.50

[gph] 0.50 0.78 1.13 2.00

[l/h] 0.0025 0.0120 0.0170 0.0300

[gph] 0.0007 0.0031 0.0045 0.0080

[bar] 16 ★ 10 7 4

[psi] 230 150 100 60

[strokes/min] 190 155 205 180

[ml] 0.74 1.45 1.55 3.10

[%] ± 1

[m] 6

[m] 2332

[bar] 1 (FC and FCM: 2)

[bar] 2

[mPas] (= cP) 2500 2500 2000 1500

[mPas] (= cP) 1800 1300 1300 600

[mPas] (= cP) 600 500 500 200

[mPas] (= cP) 50 300 300 150

[mm] 4 6 6 9

[mm] 9

[W]

★ Max. pressure for PVC version: 10 bar

24

5)

Technical data

25

Page 26

6

SMART Digital S

Technical data

DDC

DDC 6-10 9-7 15-4

Turn-down ratio (setting range) [1:X] 1000 1000 1000

Max. dosing capacity

Max. dosing capacity with SlowMode 50 %

Max. dosing capacity with SlowMode 25 %

Min. dosing capacity

Max. operating pressure

Max. stroke frequency

Stroke volume

Mechanical data

Electrical data

Signal input

Signal output

Weight/size

Sound pressure Max. sound pressure level [dB(A)] 60

Approvals CE, CB, CSA-US, NSF61, EAC, C-Tick

1) The maximum stroke frequency varies depending on calibration

2) Data is based on measurements with water

3) Maximum suction lift: 1 m, dosing capacity reduced (approx. 30 %)

4) Length of suction line: 1.5 m, length of discharge line: 10 m (at max. viscosity)

Accuracy of repeatability

Max. suction lift during operation

Max. suction lift when priming with wet valves

Min. pressure difference between suction and discharge side

Max. inlet pressure, suction side

Max. viscosity in SlowMode 25 % with spring-loaded valves

Max. viscosity in SlowMode 50 % with spring-loaded valves

Max. viscosity without SlowMode with spring-loaded valves

Max. viscosity without spring-loaded valves

Min. internal hose/pipe diameter suction/discharge side

Min. internal hose/pipe diameter suction/discharge side (high viscosity)

Min./Max. liquid temperature [°C] -10/45

Min./Max. ambient temperature [°C] 0/45

Voltage AC [V] 100-240 V, 50/60 Hz

Length of mains cable [m] 1.5

Max. inrush current for 2 ms at 100 V [A] 8

Max. inrush current for 2 ms at 230 V [A] 25

Max. power consumption P

Enclosure class IP65, Nema 4X

Electrical safety class II

Max. load low-level / empty tank / pulse / external stop input 12 V, 5 mA

Min. pulse length [ms] 5

Max. pulse frequency [Hz] 100

Impedance at analog 0/4-20 mA input [Ω]15

Accuracy of analog input (full-scale value) [%] ± 1.5

Min. resolution of analog input [mA] 0.05

Max. resistance in level/pulse circuit [Ω] 1000

Max. ohmic load on relay output [A] 0.5

Max. voltage on relay output [V] 30 VDC/30 VAC

Weight (PVC, PP, PVDF) [kg] 2.4 2.4

Weight (stainless steel) [kg] 3.2 3.2

Diaphragm diameter [mm] 44 50

1)

2)

2)

3)

3)

3)

3)

4), 2)

4)

1

[l/h] 6.0 9.0 15.0

[gph] 1.5 2.4 4.0

[l/h] 3.00 4.50 7.50

[gph] 0.75 1.20 2.00

[l/h] 1.50 2.25 3.75

[gph] 0.38 0.60 1.00

[l/h] 0.0060 0.0090 0.0150

[gph] 0.0015 0.0024 0.0040

[bar] 10 7 4

[psi] 150 100 60

[strokes/min] 140 200 180

[ml] 0.81 0.84 1.58

[%] ± 1

[m] 6

[m] 2 2 3

[bar] 1

[bar] 2

[mPas] (= cP) 2500 2000 2000

[mPas] (= cP) 1800 1300 1300

[mPas] (= cP) 600 500 500

[mPas] (= cP) 50 50 300

[mm] 4 6 6

[mm] 9

[W] 22

26

Page 27

SMART Digital S

DDE

DDE 6-10 15-4

Turn-down ratio (setting range) [1:X] 1000 1000

Max. dosing capacity

Min. dosing capacity

Max. pressure

Max. stroke frequency

Stroke volume [ml] 0.81 1.58

Accuracy of repeatability [%] ± 5

Mechanical data

Electrical data

Signal input

Signal output

Weight/size

Sound pressure Max. sound pressure level [dB(A)] 60

Approvals CE, CB, CSA-US, NSF61, EAC, C-Tick

1) Data is based on measurements with water

2) Maximum suction lift: 1 m, dosing capacity reduced (approx. 30 %)

3) Length of suction line: 1.5 m, length of discharge line: 10 m (at max. viscosity)

Max. suction lift during operation

Max. suction lift when priming with wet valves

Min. pressure difference between suction and discharge side

Max. inlet pressure, suction side

Max. viscosity with spring-loaded valves

Max. viscosity without spring-loaded valves

Min. internal hose/pipe diameter suction/discharge side

Min. internal hose/pipe diameter suction/discharge side (HV)

Min./Max. liquid temperature [°C] -10/45

Min./Max. ambient temperature [°C] 0/45

Voltage [V] 100-240 V, 50/60 Hz

Length of mains cable [m] 1.5

Max. inrush current for 2 ms at 100 V [A] 8

Max. inrush current for 2 ms at 230 V [A] 25

Max. power consumption P

Enclosure class IP65, Nema 4X

Electrical safety class II

Max. load low-level / empty tank / pulse / external stop input 12 V, 5 mA

Min. pulse length [ms] 5

Max. pulse frequency [Hz] 100

Max. resistance in level/pulse circuit [Ω] 1000

Max. ohmic load on relay output [A] 0.5

Max. voltage on relay output [V] 30 VDC/30 VAC

Weight (PVC, PP, PVDF) [kg] 2.4 2.4

Weight (stainless steel) [kg] 3.2 3.2

Diaphragm diameter [mm] 44 50

1)

1)

2)

2)

1), 3)

3)

1

[l/h] 6.0 15.0

[gph] 1.5 4.0

[l/h] 0.0060 0.0150

[gph] 0.0015 0.0040

[bar] 10 4

[psi] 150 60

[strokes/min] 140 180

[m] 6

[m] 2 3

[bar] 1

[bar] 2

[mPas] (= cP) 600 500

[mPas] (= cP) 50 50

[mm] 4 6

[mm] 9

[W] 19

6

Technical data

27

Page 28

7

Pump selection

7. Pump selection

DDA, standard range

Power supply: 1 x 100-240 V, 50/60 Hz (switch mode)

Mains plug: EU

Valves: Standard

Connection set: U2U2 / I001 / AA (see Type key on page 6)

SMART Digital S

Max.

flow

[l/h]

7.5 16

12 10

17 7

30 4

* Installation set includes: 2 pump connections, foot valve, injection unit, 6 m PE discharge hose, 2 m PVC suction hose, 2 m PVC deaeration hose

** Also available in FC- and FCM-control version

*** PVC dosing heads only up to 10 bar

(4/6 mm)

Max.

pressure

[bar]

Dosing

head

PVC***

PVDF PTFE Ceramic

PVDF PTFE Ceramic

PVDF PTFE Ceramic

PVDF PTFE Ceramic

Materials

Gaskets

EPDM Ceramic

PP

FKM Ceramic

EPDM Ceramic

FKM Ceramic

SS PTFE SS 1.4401 No DDA 7.5-16 AR-SS/T/SS-F-31AAFG 97721970 97722004 97722038

EPDM Ceramic

PP

FKM Ceramic

EPDM Ceramic

PVC

FKM Ceramic

SS PTFE SS 1.4401 No DDA 12-10 AR-SS/T/SS-F-31AAFG 97722072 97722106 97722140

EPDM Ceramic

PP

FKM Ceramic

EPDM Ceramic

PVC

FKM Ceramic

SS PTFE SS 1.4401 No DDA 17-7 AR-SS/T/SS-F-31AAFG 97722174 97722208 97722242

EPDM Ceramic

PP

FKM Ceramic

EPDM Ceramic

PVC

FKM Ceramic

SS PTFE SS 1.4401 No DDA 30-4 AR-SS/T/SS-F-31AAFG 97722276 97722311 97722355

Valve

balls

Installation

set*

Type designation**

No DDA 7.5-16 AR-PP/E/C-F-31U2U2FG 97721938 97721972 97722006

Yes DDA 7.5-16 AR-PP/E/C-F-31I001FG 97721939 97721973 97722007

No DDA 7.5-16 AR-PP/V/C-F-31U2U2FG 97721942 97721976 97722010

Yes DDA 7.5-16 AR-PP/V/C-F-31I001FG 97721943 97721977 97722011

No DDA 7.5-16 AR-PVC/E/C-F-31U2U2FG 97721946 97721980 97722014

Yes DDA 7.5-16 AR-PVC/E/C-F-31I001FG 97721947 97721981 97722015

No DDA 7.5-16 AR-PVC/V/C-F-31U2U2FG 97721950 97721984 97722018

Yes DDA 7.5-16 AR-PVC/V/C-F-31I001FG 97721951 97721985 97722019

No DDA 7.5-16 AR-PV/T/C-F-31U2U2FG 97721966 97722000 97722034

Yes DDA 7.5-16 AR-PV/T/C-F-31I001FG 97721967 97722001 97722035

No DDA 12-10 AR-PP/E/C-F-31U2U2FG 97722040 97722074 97722108

Yes DDA 12-10 AR-PP/E/C-F-31I002FG 97722041 97722075 97722109

No DDA 12-10 AR-PP/V/C-F-31U2U2FG 97722044 97722078 97722112

Yes DDA 12-10 AR-PP/V/C-F-31I002FG 97722045 97722079 97722113

No DDA 12-10 AR-PVC/E/C-F-31U2U2FG 97722048 97722082 97722116

Yes DDA 12-10 AR-PVC/E/C-F-31I002FG 97722049 97722083 97722117

No DDA 12-10 AR-PVC/V/C-F-31U2U2FG 97722052 97722086 97722120

Yes DDA 12-10 AR-PVC/V/C-F-31I002FG 97722053 97722087 97722121

No DDA 12-10 AR-PV/T/C-F-31U2U2FG 97722068 97722102 97722136

Yes DDA 12-10 AR-PV/T/C-F-31I002FG 97722069 97722103 97722137

No DDA 17-7 AR-PP/E/C-F-31U2U2FG 97722142 97722176 97722210

Yes DDA 17-7 AR-PP/E/C-F-31I002FG 97722143 97722177 97722211

No DDA 17-7 AR-PP/V/C-F-31U2U2FG 97722146 97722180 97722214

Yes DDA 17-7 AR-PP/V/C-F-31I002FG 97722147 97722181 97722215

No DDA 17-7 AR-PVC/E/C-F-31U2U2FG 97722150 97722184 97722218

Yes DDA 17-7 AR-PVC/E/C-F-31I002FG 97722151 97722185 97722219

No DDA 17-7 AR-PVC/V/C-F-31U2U2FG 97722154 97722188 97722222

Yes DDA 17-7 AR-PVC/V/C-F-31I002FG 97722155 97722189 97722223

No DDA 17-7 AR-PV/T/C-F-31U2U2FG 97722170 97722204 97722238

Yes DDA 17-7 AR-PV/T/C-F-31I002FG 97722171 97722205 97722239

No DDA 30-4 AR-PP/E/C-F-31U2U2FG 97722244 97722278 97722313

Yes DDA 30-4 AR-PP/E/C-F-31I002FG 97722245 97722279 97722314

No DDA 30-4 AR-PP/V/C-F-31U2U2FG 97722248 97722282 97722317

Yes DDA 30-4 AR-PP/V/C-F-31I002FG 97722249 97722283 97722318

No DDA 30-4 AR-PVC/E/C-F-31U2U2FG 97722252 97722286 97722331

Yes DDA 30-4 AR-PVC/E/C-F-31I002FG 97722253 97722288 97722332

No DDA 30-4 AR-PVC/V/C-F-31U2U2FG 97722256 97722291 97722335

Yes DDA 30-4 AR-PVC/V/C-F-31I002FG 97722257 97722292 97722336

No DDA 30-4 AR-PV/T/C-F-31U2U2FG 97722272 97722307 97722351

Yes DDA 30-4 AR-PV/T/C-F-31I002FG 97722273 97722308 97722352

Product number

AR FC FCM

28

Page 29

SMART Digital S

DDC, standard range

Power supply: 1 x 100-240 V, 50/60 Hz (switch mode)

Mains plug: EU

Valves: Standard

Connection set: U2U2 / I001 / AA (see Type key on page 6)

Max. flow

[l/h]

610

97

15 4

* Installation set includes: 2 pump connections, foot valve, injection unit, 6 m PE discharge hose, 2 m PVC suction hose, 2 m PVC deaeration hose

(4/6 mm)

** Also available in AR-control version

Max.

pressure

[bar]

Dosing

head

PP

PVC

PVDF PTFE Ceramic

SS PTFE SS 1.4401 No DDC 6-10 A-SS/T/SS-F-31AAFG 97721356 97721391

PP

PVC

PVDF PTFE Ceramic

SS PTFE SS 1.4401 No DDC 9-7

PP

PVC

PVDF PTFE Ceramic

SS PTFE SS 1.4401 No DDC 15-4 A-SS/T/SS-F-31AAFG 97721493 97721527

Materials

Gaskets Valve balls A AR

EPDM Ceramic

FKM Ceramic

EPDM Ceramic

FKM Ceramic

EPDM Ceramic

FKM Ceramic

EPDM Ceramic

FKM Ceramic

EPDM Ceramic

FKM Ceramic

EPDM Ceramic

FKM Ceramic

Installation

set*

No DDC 6-10 A-PP/E/C-F-31U2U2FG 97721324 97721358

Yes DDC 6-10 A-PP/E/C-F-31I001FG 97721325 97721359

No DDC 6-10 A-PP/V/C-F-31U2U2FG 97721328 97721362

Yes DDC 6-10 A-PP/V/C-F-31I001FG 97721329 97721363

No DDC 6-10 A-PVC/E/C-F-31U2U2FG 97721332 97721366

Yes DDC 6-10 A-PVC/E/C-F-31I001FG 97721333 97721367

No DDC 6-10 A-PVC/V/C-F-31U2U2FG 97721336 97721370

Yes DDC 6-10 A-PVC/V/C-F-31I001FG 97721337 97721371

No DDC 6-10 A-PV/T/C-F-31U2U2FG 97721352 97721387

Yes DDC 6-10 A-PV/T/C-F-31I001FG 97721353 97721388

No DDC 9-7 A-PP/E/C-F-31U2U2FG 97721393 97721427

Yes DDC 9-7 A-PP/E/C-F-31I002FG 97721394 97721428

No DDC 9-7 A-PP/V/C-F-31U2U2FG 97721397 97721431

Yes DDC 9-7 A-PP/V/C-F-31I002FG 97721398 97721432

No DDC 9-7 A-PVC/E/C-F-31U2U2FG 97721401 97721435

Yes DDC 9-7 A-PVC/E/C-F-31I002FG 97721402 97721436

No DDC 9-7 A-PVC/V/C-F-31U2U2FG 97721405 97721439

Yes DDC 9-7 A-PVC/V/C-F-31I002FG 97721406 97721440

No DDC 9-7 A-PV/T/C-F-31U2U2FG 97721421 97721455

Yes DDC 9-7 A-PV/T/C-F-31I002FG 97721422 97721456

No DDC 15-4 A-PP/E/C-F-31U2U2FG 97721461 97721495

Yes DDC 15-4 A-PP/E/C-F-31I002FG 97721462 97721496

No DDC 15-4 A-PP/V/C-F-31U2U2FG 97721465 97721499

Yes DDC 15-4 A-PP/V/C-F-31I002FG 97721466 97721500

No DDC 15-4 A-PVC/E/C-F-31U2U2FG 97721469 97721503

Yes DDC 15-4 A-PVC/E/C-F-31I002FG 97721470 97721504

No DDC 15-4 A-PVC/V/C-F-31U2U2FG 97721473 97721507

Yes DDC 15-4 A-PVC/V/C-F-31I002FG 97721474 97721508

No DDC 15-4 A-PV/T/C-F-31U2U2FG 97721489 97721523

Yes DDC 15-4 A-PV/T/C-F-31I002FG 97721490 97721524

Type designation**

A-SS/T/SS-F-31AAFG 97721425 97721459

Product number

7

Pump selection

29

Page 30

7

SMART Digital S

Pump selection

DDE, standard range

Power supply: 1 x 100-240 V, 50/60 Hz (switch mode)

Mains plug: EU

Valves: Standard

Connection set: U2U2 / I001 / AA (see Type key on page 6)

Max. flow

[l/h]

610

15 4

* Installation set includes: 2 pump connections, foot valve, injection unit, 6 m PE discharge hose, 2 m PVC suction hose, 2 m PVC deaeration hose

(4/6 mm)

** Also available in P- and PR-control version

Max.

pressure

[bar]

Materials

Dosing

head

PVC

PVDF PTFE Ceramic

PVC

PVDF PTFE Ceramic

Gaskets Valve balls B P PR

EPDM Ceramic

PP

FKM Ceramic

EPDM Ceramic

FKM Ceramic

SS PTFE SS 1.4401 No DDE 6-10 B-SS/T/SS-X-31AAFG 97720947 97720981 98147292

EPDM Ceramic

PP

FKM Ceramic

EPDM Ceramic

FKM Ceramic

SS PTFE SS 1.4401 No DDE 15-4 B-SS/T/SS-X-31AAFG 97721015 97721049 98147326

Installation

Type designation**

set*

No DDE 6-10 B-PP/E/C-X-31U2U2FG 97720905 97720949 98147240

Yes DDE 6-10 B-PP/E/C-X-31I001FG 97720906 97720950 98147261

No DDE 6-10 B-PP/V/C-X-31U2U2FG 97720909 97720953 98147264

Yes DDE 6-10 B-PP/V/C-X-31I001FG 97720910 97720954 98147265

No DDE 6-10 B-PVC/E/C-X-31U2U2FG 97720923 97720957 98147268

Yes DDE 6-10 B-PVC/E/C-X-31I001FG 97720924 97720958 98147269

No DDE 6-10 B-PVC/V/C-X-31U2U2FG 97720927 97720961 98147272

Yes DDE 6-10 B-PVC/V/C-X-31I001FG 97720928 97720962 98147273

No DDE 6-10 B-PV/T/C-X-31U2U2FG 97720943 97720977 98147288

Yes DDE 6-10 B-PV/T/C-X-31I001FG 97720944 97720978 98147289

No DDE 15-4 B-PP/E/C-X-31U2U2FG 97720983 97721017 98147294

Yes DDE 15-4 B-PP/E/C-X-31I002FG 97720984 97721018 98147295

No DDE 15-4 B-PP/V/C-X-31U2U2FG 97720987 97721021 98147298

Yes DDE 15-4 B-PP/V/C-X-31I002FG 97720988 97721022 98147299

No DDE 15-4 B-PVC/E/C-X-31U2U2FG 97720991 97721025 98147302

Yes DDE 15-4 B-PVC/E/C-X-31I002FG 97720992 97721026 98147303

No DDE 15-4 B-PVC/V/C-X-31U2U2FG 97720995 97721029 98147306

Yes DDE 15-4 B-PVC/V/C-X-31I002FG 97720996 97721030 98147307

No DDE 15-4 B-PV/T/C-X-31U2U2FG 97721011 97721045 98147322

Yes DDE 15-4 B

-PV/T/C-X-31I002FG 97721012 97721046 98147323

Product number

30

Page 31

SMART Digital S

DDA, DDC, DDE, non-standard range

Key to the three following tables:

Maximum flow - pressure [l/h] - [bar]

B: Basic (DDE)

P: B with pulse mode (DDE)

PR: P with relay output (DDE)

Control variant

Materials

Control cube position

Supply voltage 3: 1 x 100-240 V, 50/60 Hz

Valve type

Connection / Installation set

Mains plug

Design

Special variant C3: Inspection Certificate 3.1 (EN 10204)

* Installation set includes 2 pump connections, foot valve, injection unit, 6 m PE discharge hose, 2 m PVC suction hose, 2 m PVC deaeration hose

(4/6 mm)

A: Standard (DDC)

AR: A with alarm relay and analog input (DDA, DDC)

FC: AR with FlowControl (DDA)

FCM: FC with flow measurement (DDA)

Dosing head

PP: PP

PVC: PVC (PVC dosing heads only up to 10 bar)

PV: PVDF

SS: Stainless steel 1.4401

Gaskets

E: EPDM

V: FKM

T: PT F E

Valve balls

C: Ceramic

SS: Stainless steel 1.4401

F: Front-mounted (change to left and right possible)

X: No control cube (DDE)

1: Standard

2: Spring-loaded (HV version)

Suction / discharge connection

U2U2: Union nut G 5/8" with parts for hose connection 4/6 mm, 6/9 mm, 6/12 mm, 9/12 mm

U7U7: Union nut G 5/8" with parts for hose connection 0.17" x 1/4"; 1/4" x 3/8"; 3/8" x 1/2"

AA: Union nut G 5/8" with threaded connection Rp 1/4", internal thread

VV: Union nut G 5/8" with threaded connection 1/4" NPT, internal thread

XX: No connections included

Installation set*

I001: 4/6 mm (up to 7.5 l/h, 13 bar)

I002: 9/12 mm (up to 60 l/h, 9 bar)

I003: 0.17" x 1/4" (up to 7.5 l/h, 13 bar)

I004: 3/8" x 1/2" (up to 60 l/h, 10 bar)

F: EU

B: USA, Canada

G: UK

I: Australia, New Zealand

E: Switzerland

J: Japan

L: Argentina

G: Grundfos red

A: Grundfos green

B: Grundfos black

X: Neutral/black

C: China approval

7

Pump selection

31

Page 32

7

SMART Digital S

Pump selection

DDA

Max.

flow -

press.

7.5-16ARFC

12-10

17-7

30-4

DDC

Max.

flow -

press.

6-10

9-7

15-4

DDE

Control

variant

FCM

AR

FC

FCM

Control

variant

A

AR

A

AR

Materials Control

Head Gaskets Balls

PP

PVC E

PV

SS T SS F 3

PP

PVC E

PV

SS T SS F 3

Head Gaskets Balls

PP

PVC E

PV

SS T SS F 3

PP

PVC E

PV

SS T SS F 3

E

V

V

T

E

V

V

T

Materials Control

E

V

V

T

E

V

V

T

C

C

C

C

C

C

C

C

cube

position

F3

F3

cube

position

F3

F3

Supply

voltage

Supply

voltage

Valve type

1

2

1

2

1

2

1

2

Valve type

1

2

1

2

1

2

1

2