Page 1

CUE, 110-250 kW

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

English (GB)

2

English (GB) Installation and operating instructions

Original installation and operating instructions

CONTENTS

Page

1. Symbols used in this document

2. Introduction

This manual introduces all aspects of your Grundfos CUE

frequency converter in the power range of 110 to 250 kW.

Always keep this manual close to the CUE.

2.1 General description

CUE is a series of external frequency converters especially

designed for pumps.

Thanks to the startup guide in the CUE, the installer can quickly

set central parameters and put the CUE into operation.

Connected to a sensor or an external control signal, the CUE will

quickly adapt the pump speed to the actual demand.

2.2 Applications

The CUE series and Grundfos standard pumps are a supplement

to the Grundfos E-pumps range with integrated frequency

converter.

A CUE solution offers the same E-pump functionality in these

cases:

• in mains voltage or power ranges not covered by the E-pump

range

• in applications where an integrated frequency converter is not

desirable or permissible.

1. Symbols used in this document

2

2. Introduction

2

2.1 General description

2

2.2 Applications

2

2.3 References

3

3. Safety and warnings

3

3.1 Warning

3

3.2 Safety regulations

3

3.3 Installation requirements

3

3.4 Reduced performance under certain conditions

3

4. Identification

4

4.1 Nameplate

4

4.2 Packaging label

4

5. Mechanical installation

4

5.1 Receipt and storage

4

5.2 Transportation and unpacking

4

5.3 Space requirements and air circulation

5

5.4 Mounting

5

6. Electrical connection

7

6.1 Electrical protection

7

6.2 Mains and motor connection

7

6.3 Connecting the signal terminals

8

6.4 Connecting the signal relays

11

6.5 Connecting the MCB 114 sensor input module

11

6.6 EMC-correct installation

12

6.7 RFI filters

12

6.8 Output filters

13

7. Operating modes

14

8. Control modes

14

8.1 Uncontrolled operation (open loop)

14

8.2 Controlled operation (closed loop)

14

9. Menu overview

15

10. Setting by means of the control panel

17

10.1 Control panel

17

10.2 Back to factory settings

18

10.3 CUE settings

18

10.4 Startup guide

18

10.5 GENERAL

23

10.6 OPERATION

24

10.7 STATUS

25

10.8 INSTALLATION

27

11. Setting by means of PC Tool E-products

35

12. Priority of settings

35

12.1 Control without bus signal, local operating mode

35

12.2 Control with bus signal, remote-controlled operating

mode

35

13. External contro l sig nals

36

13.1 Digital inputs

36

13.2 External setpoint

36

13.3 GENIbus signal

37

13.4 Other bus standards

37

14. Maintenance and service

37

14.1 Cleaning the CUE

37

14.2 Service parts and service kits

37

15. Fault finding

37

15.1 Warning and alarm list

37

15.2 Resetting of alarms

38

15.3 Indicator lights

38

15.4 Signal relays

38

16. Technical data

39

16.1 Enclosure

39

16.2 Main dimensions and weights

39

16.3 Surroundings

40

16.4 Terminal torques

40

16.5 Cable length

40

16.6 Fuses and cable cross-section

40

16.7 Inputs and outputs

41

16.8 Sound pressure level

41

17. Disposal

41

Warning

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

Warning

If these safety instructions are not observed, it may

result in personal injury.

Caution

If these safety instructions are not observed, it may

result in malfunction or damage to the equipment.

Note

Notes or instructions that make the job easier and

ensure safe operation.

Caution

If the pump speed exceeds the rated speed, the

pump will be overloaded.

Page 3

English (GB)

3

2.3 References

Technical documentation for Grundfos CUE:

• The manual contains all information required for putting the

CUE into operation.

• The data booklet contains all technical information about the

construction and applications of the CUE.

• The service instructions contain all required instructions for

dismantling and repairing the frequency converter.

Technical documentation is available on www.grundfos.com >

Grundfos Product Center.

If you have any questions, please contact the nearest Grundfos

company or service workshop.

3. Safety and warnings

3.1 Warning

Wait only for shorter time if stated so on the nameplate of the

CUE in question.

3.2 Safety regulations

• The on/off button of the control panel does not disconnect the

CUE from the power supply and must therefore not be used as

a safety switch.

• The CUE must be earthed correctly and protected against

indirect contact according to local regulations.

• The leakage current to earth exceeds 3.5 mA.

• Enclosure class IP20/21 must not be installed freely

accessible, but only in a panel.

• Enclosure class IP54/55 must not be installed outdoors

without additional protection against weather conditions and

the sun.

• Always observe local regulations as to cable cross-section,

short-circuit protection and overcurrent protection.

3.3 Installation requirements

The general safety necessitates special considerations as to

these aspects:

• fuses and switches for overcurrent and short-circuit protection

• selection of cables (mains current, motor, load distribution and

relay)

• net configuration (IT, TN, earthing)

• safety on connecting inputs and outputs (PELV).

3.3.1 IT mains

In connection with IT mains and earthed delta mains, the mains

voltage may exceed 440 V between phase and earth.

3.3.2 Aggressive en viro nmen t

The CUE contains a large number of mechanical and electronic

components. They are all vulnerable to environmental impact.

3.4 Reduced performance under certain conditions

The CUE will reduce its performance under these conditions:

• low air pressure (at high altitude)

• long motor cables.

The required measures are described in the next two sections.

3.4.1 Reduction at low air pressure

PELV = Protective Extra Low Voltage.

At low air pressure, the cooling capacity of air is reduced, and the

CUE automatically reduces the performance to prevent overload.

It may be necessary to select a CUE with a higher performance.

3.4.2 Reduction in connection with long motor cables

The maximum cable length for the CUE is 300 m for unscreened

and 80 m for screened cables. In case of longer cables, contact

Grundfos.

The CUE is designed for a motor cable with a maximum crosssection as stated in section 16.6 Fuses and cable cross-section.

Warning

Any installation, maintenance and inspection must be

carried out by trained personnel.

Warning

Touching the electrical parts may be fatal, even after

the CUE has been switched off.

Before performing any work on the CUE, the mains

supply and other input voltages must be switched off

for a minimum time of 20 minutes.

Warning

Do not connect 380-500 V CUE frequency converters

to mains supplies with a voltage between phase and

earth of more than 440 V.

Caution

The CUE should not be installed in an environment

where the air contains liquids, particles or gases

which may affect and damage the electronic

components.

Warning

At altitudes above 2000 m, the PELV requirements

cannot be met.

Page 4

English (GB)

4

4. Identification

4.1 Nameplate

The CUE can be identified by means of the nameplate. An

example is shown below.

Fig. 1 Example of nameplate

4.2 Packaging label

The CUE can also be identified by means of the label on the

packaging.

5. Mechanical installation

The individual CUE cabinet sizes are characterised by their

enclosures. The table in section 16.1 Enclosure shows the

relationship between enclosure class and enclosure type.

5.1 Receipt and storage

Check on receipt that the packaging is intact, and the unit is

complete. In case of damage during transport, contact the

transport company to complain.

Note that the CUE is delivered in packaging which is not suitable

for outdoor storage.

5.2 Transportation and unpacking

To prevent damage during the transport to the site, the CUE must

only be unpacked at the installation site.

Remove the cardboard box, and keep the CUE on the pallet for

as long as possible.

The packaging contains accessory bag(s), documentation and

the unit itself.

5.2.1 Lifting the CUE

Always lift the CUE using the lifting holes. Use a bar to avoid

bending the lifting holes. See fig. 2.

Fig. 2 Recommended lifting method

TM04 3272 4808

Text Description

T/C:

CUE (product name)

202P1M2... (internal code)

Prod. no: Product number: 12345678

S/N:

Serial number: 123456G234

The last three digits indicate the production

date: 23 is the week, and 4 is the year 2004.

1.5 kW Typical shaft power on the motor

IN:

Supply voltage, frequency and maximum input

current

OUT:

Motor voltage, frequency and maximum output

current. The maximum output frequency

usually depends on the pump type.

CHASSIS/IP20 Enclosure class

Tamb. Maximum ambient temperature

T/C: CUE202P1M2T5E20H1BXCXXXSXXXXAXBXCXXXXDX

Prod. no: 12345678

S/N: 123456G234

IN: 3x380-500 V 50/60Hz 3.7A

OUT: 3x0-Vin 0-100Hz 4.1 A 2.8 kV

A

CHASSIS/IP20 Tamb. 45C/122F

IIIIIIIIIIIBAR CODEIIIIIIIIIII

MADE IN DENMARK

Listed 76X1 E134261 Ind. Contr. Eq.

See manual for prefuse

CAUTION:

SEE MANUAL / VOIR MANUEL

WARNING:

STORED CHARGE DO NOT TOUCH UNTIL

4 MIN AFTER DISCONNECTION

CHARGE RESIDUELLE, ATTENDRE

4 MIN APRES DECONNEXION

1.5 kW (400V)

TM03 9896 4607

Page 5

English (GB)

5

5.3 Space requirements and air circulation

CUE units can be mounted side by side, but as a sufficient air

circulation is required for cooling, these requirements must be

met:

• Sufficient free space above and below the CUE to allow airflow

and cable connection. See fig. 3.

• Ambient temperature up to 45 °C.

Fig. 3 Airflow direction and required space for cooling [mm]

Furthermore, there must be sufficient space in front of the CUE

for opening the door of the CUE. See fig. 4.

Fig. 4 Free space in front of the CUE [mm]

5.4 Mounting

5.4.1 Mounting on the wall

1. Mark the mounting holes on the wall using the drilling

template. See fig. 5.

2. Drill the holes. See fig. 5.

3. Fit the screws at the bottom, but leave loose. Lift the CUE up

on the screws. Move the CUE against the wall, and fit the

screws at the top. Tighten all four screws. See fig. 2.

Fig. 5 Drilling of holes in the wall

TM03 9898 4607TM05 9324 3713

Min. 225

Min. 225

Caution

The user is responsible for mounting the CUE

securely on a firm surface.

Note

See the main dimensions and weights in section

16.2 Main dimensions and weights.

TM03 8860 2607

b

a

a

b

Page 6

English (GB)

6

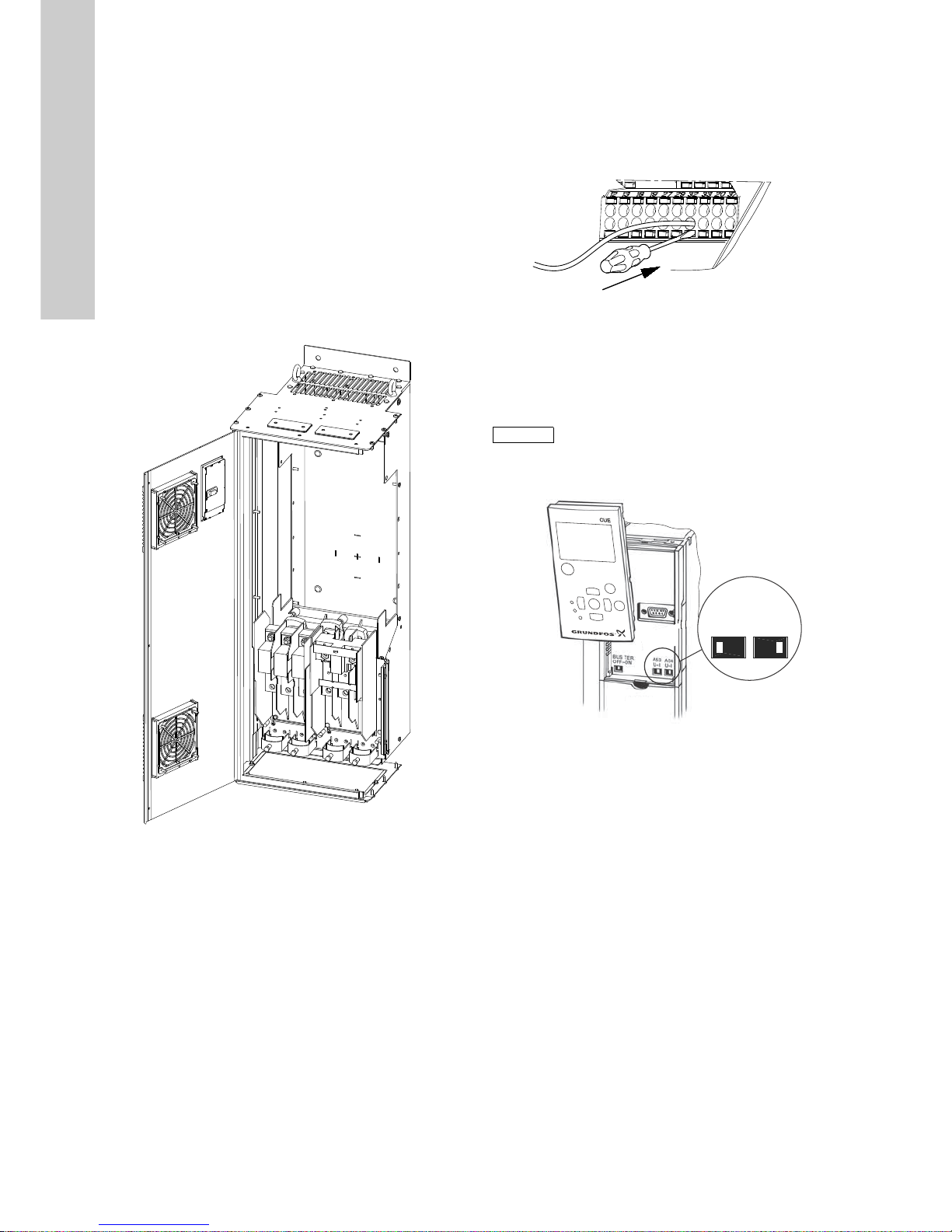

5.4.2 Mounting on the floor

By means of a pedestal (option), the CUE can also be mounted

on the floor.

1. Mark the mounting holes on the floor. See fig. 6.

2. Drill the holes.

3. Mount the pedestal on the floor.

4. Mount the CUE on the pedestal using the enclosed screws.

See fig. 7.

Fig. 6 Drilling template for pedestal

Fig. 7 CUE on a pedestal

Warning

The CUE is top-heavy and may fall over if the

pedestal is not anchored to the floor.

Caution

The user is responsible for mounting the CUE

securely on a firm surface.

Note

See the pedestal kit instructions for further

information.

TM05 9669 4313

Pos.

D1h

[mm]

D2h

[mm]

1 400 400

2 325 420

3 283.8 378.8

4 240 240

5 4 x 14 4 x 14

6 217 317

5

6

3

1

2

4

TM03 9895 4607

Page 7

English (GB)

7

6. Electrical connection

Fig. 8 Example of three-phase mains connection of the CUE

with mains switch, backup fuses and additional

protection

6.1 Electrical protection

6.1.1 Protection against electric shock, indirect contact

Protective conductors must always have a yellow/green (PE) or

yellow/green/blue (PEN) colour marking.

Instructions according to EN IEC 61800-5-1:

• The CUE must be stationary, installed permanently and

connected permanently to the mains supply.

• The earth connection must be carried out with duplicate

protective conductors.

6.1.2 Protection against short-circuit, fuses

The CUE and the supply system must be protected against shortcircuit.

Grundfos demands that the backup fuses mentioned in section

16.6 Fuses and cable cross-section are used for protection

against short-circuit.

The CUE offers complete short-circuit protection in case of a

short-circuit on the motor output.

6.1.3 Additional protection

If the CUE is connected to an electrical installation where an

earth leakage circuit breaker (ELCB) is used as additional

protection, the circuit breaker must be of a type marked with the

following symbols:

The circuit breaker is type B.

The total leakage current of all the electrical equipment in the

installation must be taken into account.

The leakage current of the CUE in normal operation can be seen

in section 16.7.1 Mains supply (L1, L2, L3).

During startup and in asymmetrical supply systems, the leakage

current can be higher than normal and may cause the ELCB to

trip.

6.1.4 Motor protection

The motor requires no external motor protection. The CUE

protects the motor against thermal overloading and blocking.

6.1.5 Protection against overcurrent

The CUE has an internal overcurrent protection for overload

protection on the motor output.

6.1.6 Protection against mains voltage transients

The CUE is protected against mains voltage transients according

to EN 61800-3, second environment.

6.2 Mains and motor connection

The supply voltage and frequency are marked on the CUE

nameplate. Make sure that the CUE is suitable for the power

supply of the installation site.

6.2.1 Mains switch

A mains switch can be installed before the CUE according to local

regulations. See fig. 8.

Warning

The owner or installer is responsible for ensuring

correct earthing and protection according to local

standards.

Warning

Before making any work on the CUE, the mains

supply and other voltage inputs must be switched off

for at least as long as stated in section 3. Safety and

warnings.

TM03 8525 1807

Warning

The CUE must be earthed correctly and protected

against indirect contact according to local

regulations.

Caution

The leakage current to earth exceeds 3.5 mA, and a

reinforced earth connection is required.

ELCB

Caution

The leakage current to earth exceeds 3.5 mA.

ELCB

Page 8

English (GB)

8

6.2.2 Wiring diagram

The wires in the terminal box must be as short as possible.

Excepted from this is the earth conductor which must be so long

that it is the last one to be disconnected in case the cable is

inadvertently pulled out of the cable entry.

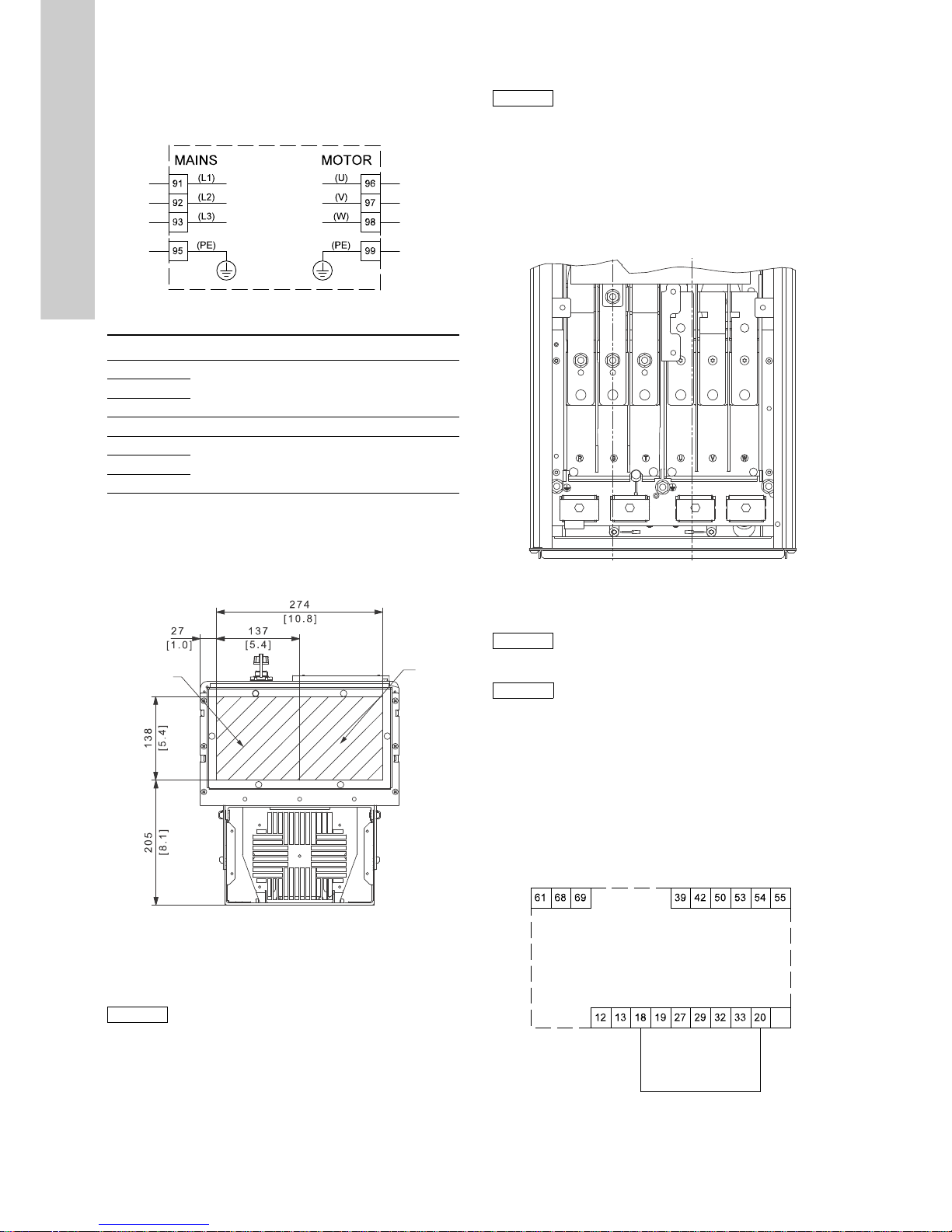

Fig. 9 Wiring diagram, three-phase mains connection

6.2.3 Gland plate

Cables are connected through the gland plate from the bottom.

The gland plate must be fitted to the CUE to ensure the specified

protection degree as well as to ensure sufficient cooling.

Drill holes in the marked areas. See fig. 10.

Fig. 10 CUE viewed from the bottom [mm]

6.2.4 Motor connection

For information about enclosures, see table in section

16.1 Enclosure.

1. Connect the earth conductor to terminal 99 (PE). See fig. 11.

2. Connect the motor conductors to terminals 96 (U), 97 (V), 98

(W).

3. Fix the screened cable with a cable clamp.

6.2.5 Mains connecti on

1. Connect the earth conductor to terminal 95 (PE). See fig. 11.

2. Connect the mains conductors to terminals 91 (L1), 92 (L2),

93 (L3).

3. Fix the mains cable with a cable clamp.

6.2.6 Terminal location

Take the following terminal positions into consideration when you

design the cable connection. See fig. 11.

Fig. 11 Earth, mains and motor connection

6.3 Connecting the signal terminals

Connect the signal cables according to the guidelines for good

practice to ensure EMC-correct installation. See section

6.6 EMC-correct installation.

• Use screened signal cables with a conductor cross-section of

min. 0.5 mm

2

and max. 1.5 mm2.

• Use a 3-conductor screened bus cable in new systems.

6.3.1 Minimum connection, signal terminal

Operation is only possible when terminals 18 and 20 are

connected, for instance by means of an external on/off switch or a

short wire.

Fig. 12 Required minimum connection, signal terminal

TM03 8799 2507

Terminal Function

91 (L1)

Three-phase supply92 (L2)

93 (L3)

95/99 (PE) Earth connection

96 (U)

Three-phase motor connection, 0-100 % of

mains voltage

97 (V)

98 (W)

TM05 9326 3713

Caution

The motor cable must be screened for the CUE to

meet EMC requirements.

Caution

Check that the mains voltage and frequency

correspond to the values on the nameplate of the

CUE and the motor.

TM05 9329 3713

Caution

As a precaution, signal cables must be separated

from other groups by reinforced insulation in their

entire lengths.

Note

If no external on/off switch is connected, short-circuit

terminals 18 and 20 using a short wire.

TM03 9057 3207

Start/stop

GND

Page 9

English (GB)

9

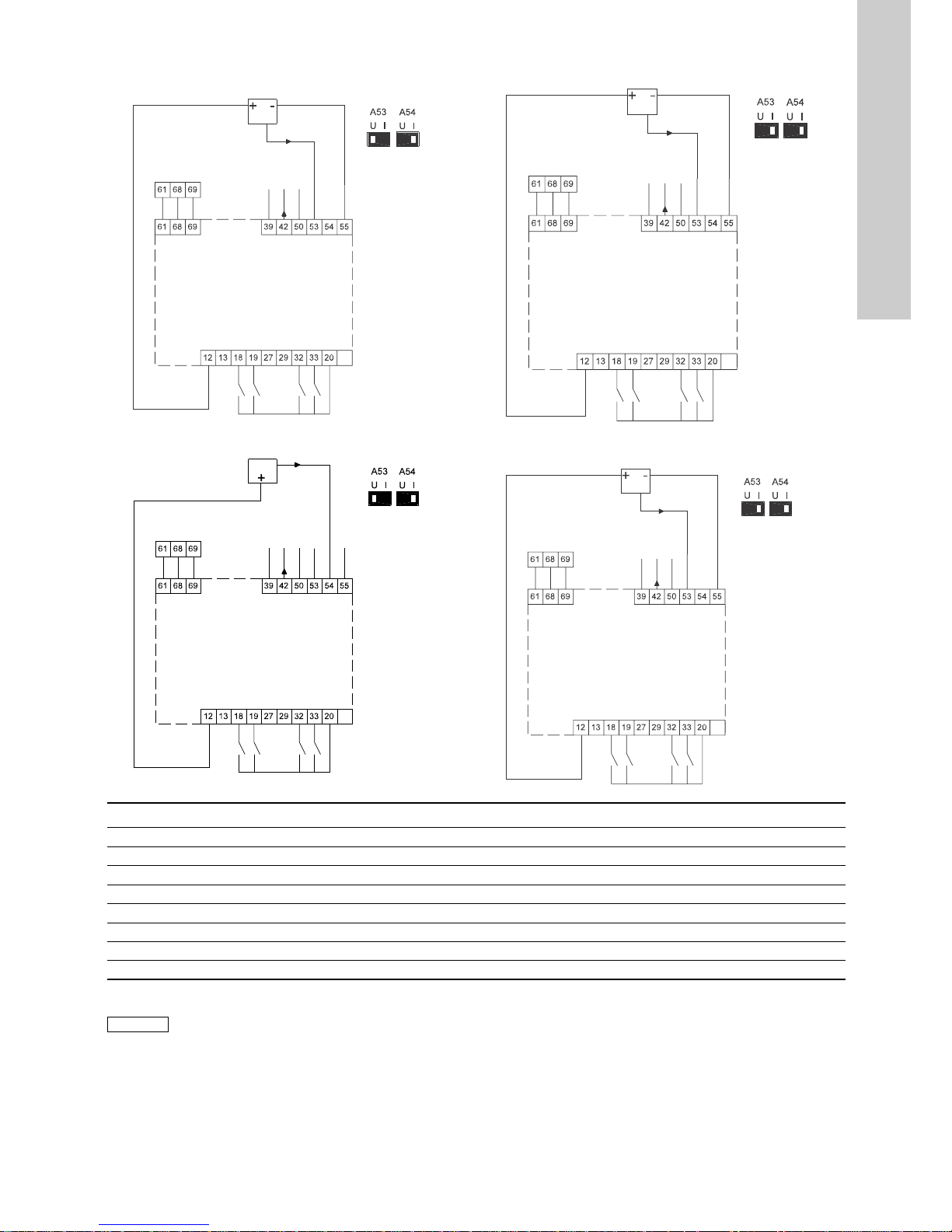

6.3.2 Wiring diagram, signal terminals

Terminals 27 and 29 are not used.

TM05 806 2811

TM05 808 2811

GND

RS-485 B

RS/485 A

RS-485 GND Y

AO 1

+10 V out

AI 1

AI 2

GND

+24 V out

+24 V out

DI 1

DI 2

DI 3

DI 4

GND

External setpoint,

voltage input

0-10 V

Te rm in a ls

U: 0-10 V

I: 0/4-20 mA

GND

AO 1

+10 V out

AI 1

AI

RS-485 GND Y

RS-485 A

RS-485 B

+24 V out

+24 V out

DI 1

DI 2

DI 3

DI 4

GND

GND

Two-wire sensor

0/4-20 mA

Te rm in a ls

U: 0-10 V

I: 0/4-20 mA

TM05 808 2811

TM05 805 2811

GND

AO 1

+10 V out

AI 1

AI 2

RS-485 GND Y

RS-485 A

RS-485 B

+24 V out

+24 V out

DI 1

DI 2

DI 3

DI 4

GND

GND

External setpoint,

current input

0/4-20 mA

Te rm in a ls

U: 0-10 V

I: 0/4-20 mA

GND

AO 1

+10 V out

AI 1

AI 2

RS-485 GND Y

RS-485 A

RS-485 B

GND

DI 4

DI 3

DI 2

DI 1

+24 V out

+24 V out

GND

Three-wire sensor

0/4-20 mA

Te rm in a ls

U: 0-10 V

I: 0/4-20 mA

Terminal Type Function Terminal Type Function

12 +24 V out Supply to sensor 42 AO 1 Analog output, 0-20 mA

13 +24 V out Additional supply 50 +10 V out Supply to potentiometer

18 DI 1 Digital input, start/stop 53 AI 1 External setpoint, 0-10 V, 0/4-20 mA

19 DI 2 Digital input, programmable 54 AI 2 Sensor input, sensor 1, 0/4-20 mA

20 GND Common frame for digital inputs 55 GND Common frame for analog inputs

32 DI 3 Digital input, programmable 61 RS-485 GND Y GENIbus, frame

33 DI 4 Digital input, programmable 68 RS-485 A GENIbus, signal A (+)

39 GND Frame for analog output 69 RS-485 B GENIbus, signal B (-)

Note

The RS-485 screen must be connected to frame.

Page 10

English (GB)

10

6.3.3 Connection of a thermistor (PTC) to the CUE

The connection of a thermistor (PTC) in a motor to the CUE

requires an external PTC relay.

The requirement is based on the fact that the thermistor in the

motor only has one layer of insulation to the windings. The

terminals in the CUE require two layers of insulation since they

are part of a PELV circuit.

A PELV circuit provides protection against electric shock. Special

connection requirements apply to this type of circuit. The

requirements are described in EN 61800-5-1.

In order to maintain PELV, all connections made to the control

terminals must be PELV. For example, the thermistor must have

reinforced or double insulation.

6.3.4 Access to signal terminals

All terminals for signal cables are located beneath the control

panel and can be accessed by opening the door of the CUE. See

fig. 13.

Fig. 13 Signal cable routing

6.3.5 Fitting the conductor

1. Remove the insulation at a length of 9 to 10 mm.

2. Insert a screwdriver with a tip of maximum 0.4 x 2.5 mm into

the square hole.

3. Insert the conductor into the corresponding round hole.

Remove the screwdriver. The conductor is now fixed in the

terminal.

Fig. 14 Fitting the conductor into the signal terminal

6.3.6 Setting the analog inputs, terminals 53 and 54

Contacts A53 and A54 are positioned behind the control panel

and used for setting the signal type of the two analog inputs.

The factory setting of the inputs is voltage signal "U".

Remove the control panel to set the contact. See fig. 15.

Fig. 15 Setting contact A54 to current signal "I"

TM05 9654 4213

TM03 9026 2807

Note

If a 0/4-20 mA sensor is connected to terminal 54,

the input must be set to current signal "I".

Switch off the power supply before setting contact

A54.

TM03 9104 3407

UI

A53

UI

A54

Page 11

English (GB)

11

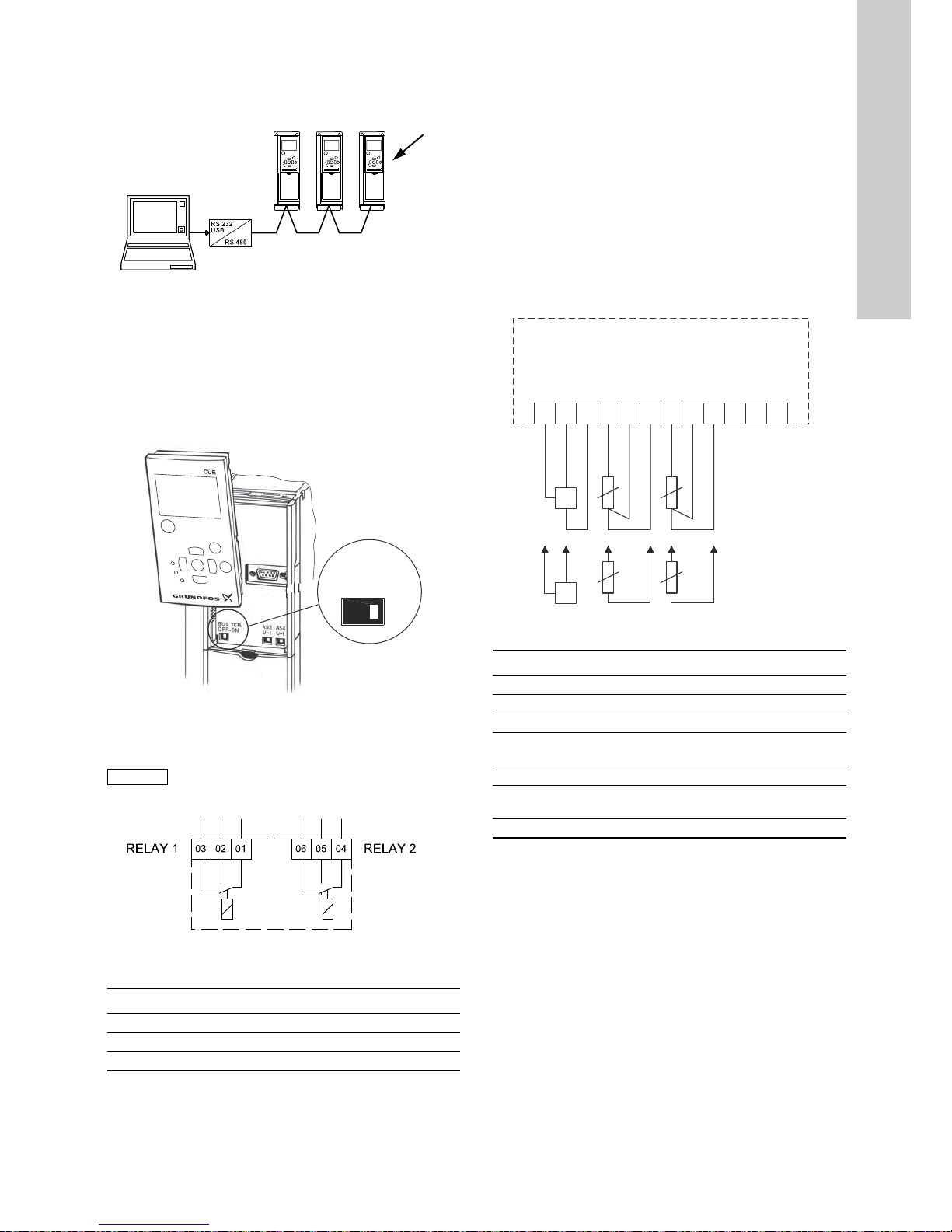

6.3.7 RS-485 GENIbus network connection

One or more CUE units can be connected to a control unit via

GENIbus. See the example in fig. 16.

Fig. 16 Example of an RS-485 GENIbus network

The reference potential, GND, for RS-485 (Y) communication

must be connected to terminal 61.

If more than one CUE unit is connected to a GENIbus network,

the termination contact of the last CUE must be set to "ON"

(termination of the RS-485 port).

The factory setting of the termination contact is "OFF" (not

terminated).

Remove the control panel to set the contact. See fig. 17.

Fig. 17 Setting the termination contact to "ON"

6.4 Connecting the signal relays

Fig. 18 Terminals for signal relays in normal state (not

activated)

6.5 Connecting the MCB 114 sensor input module

The MCB 114 is an option offering additional analog inputs for the

CUE.

6.5.1 Configuration of the MCB 114

The MCB 114 is equipped with three analog inputs for these

sensors:

• One additional sensor 0/4-20 mA. See section 10.8.14 Sensor

2 (3.16).

• Two Pt100/Pt1000 temperature sensors for measurement of

motor bearing temperature or an alternative temperature, such

as liquid temperature. See sections 10.8.19 Temperature

sensor 1 (3.21) and 10.8.20 Temperature sensor 2 (3.22).

When the MCB 114 has been installed, the CUE will automatically

detect if the sensor is Pt100 or Pt1000 when it is switched on.

6.5.2 Wiring diagram, MCB 114

Fig. 19 Wiring diagram, MCB 114

Terminals 10, 11 and 12 are not used.

TM03 9005 2807TM03 9006 2807

Caution

As a precaution, signal cables must be separated

from other groups by reinforced insulation in their

entire lengths.

TM03 8801 2507

Terminal Function

C 1 C 2 Common

NO 1 NO 2 Normally open contact

NC 1 NC 2 Normally closed contact

Bus Ter = ON

OFF ON

BUS TER

C 1

NC 1

NO 1

NC 2

NO 2

C2

TM04 3273 3908

Terminal Type Function

1 (VDO) +24 V out Supply to sensor

2 (I IN) AI 3 Sensor 2, 0/4-20 mA

3 (GND) GND Common frame for analog input

4 (TEMP)

5 (WIRE)

AI 4 Temperature sensor 1, Pt100/Pt1000

6 (GND) GND Common frame for temperature sensor 1

7 (TEMP)

8 (WIRE)

AI 5 Temperature sensor 2, Pt100/Pt1000

9 (GND) GND Common frame for temperature sensor 2

1 98765432

12111

0

VDO

I IN

GND

TEMP

WIRE

GND

TEMP

WIRE

GND

+

-

+

Page 12

English (GB)

12

6.6 EMC-correct installation

This section provides guidelines for good practice when installing

the CUE. Follow these guidelines to meet EN 61800-3, first

environment.

• Use only motor and signal cables with a braided metal screen

in applications without output filter.

• There are no special requirements to supply cables, apart

from local requirements.

• Leave the screen as close to the connecting terminals as

possible. See fig. 20.

• Avoid terminating the screen by twisting the ends. See fig. 21.

Use cable clamps or EMC screwed cable entries instead.

• Connect the screen to frame at both ends for both motor and

signal cables. See fig. 22. If the controller has no cable

clamps, connect only the screen to the CUE. See fig. 23.

• Avoid unscreened motor and signal cables in electrical

cabinets with frequency converters.

• Make the motor cable as short as possible in applications

without output filter to limit the noise level and minimise

leakage currents.

• Screws for frame connections must always be tightened

whether a cable is connected or not.

• Keep main cables, motor cables and signal cables separated

in the installation, if possible.

Other installation methods may give similar EMC results if the

above guidelines for good practice are followed.

Fig. 20 Example of stripped cable with screen

Fig. 21 Do not twist the screen ends

Fig. 22 Example of connection of a 3-conductor bus cable with

screen connected at both ends

Fig. 23 Example of connection of a 3-conductor bus cable with

screen connected at the CUE (controller with no cable

clamps)

6.7 RFI filters

To meet the EMC requirements, the CUE comes with the

following types of built-in radio frequency interference filter (RFI).

Description of RFI filter types

RFI filter types are according to EN 61800-3.

6.7.1 Equipment of c ateg ory C3

• This type of power drive system (PDS) is not intended to be

used on a low-voltage public network which supplies domestic

premises.

• Radio frequency interference is expected if used on such a

network.

TM02 1325 0901TM03 8812 2507

TM03 8732 2407TM03 8731 2407

Voltage

[V]

Typical shaft power P2

[kW]

RFI filter type

3 x 380-500 110-250 C3

3 x 525-690 110-250 C3

C3:

For use in industrial areas with own low-voltage

transformer.

CUEController

CUEController

Page 13

English (GB)

13

6.8 Output filters

Output filters are used for reducing the voltage stress on the

motor windings and the stress on the motor insulation system as

well as for decreasing acoustic noise from the frequency

converter-driven motor.

Two types of output filter are available as accessories for the

CUE:

•dU/dt filters

• sine-wave filters.

Use of output filters

The table below explains in which cases an output filter is

required. From the table it can be seen if a filter is needed, and

which type to use.

The selection depends on:

• pump type

• motor cable length

• the required reduction of the acoustic noise from the motor.

The lengths stated apply to the motor cable.

Motor cable

Fig. 24 Example of installation without filter

Fig. 25 Example of installation with filter. The cable between

the CUE and filter must be short

Fig. 26 Submersible pump without connection box. Frequency

converter and filter installed close to the well

Fig. 27 Submersible pump with connection box and screened

cable. Frequency converter and filter installed far away

from the well and connection box installed close to the

well

Pump type CUE output power dU/dt filter Sine-wave filter

SP, BM, BMB with motor voltage from 380 V and higher All NA 0-300 m

Pumps with MG71 and MG80 up to 1.5 kW < 1.5 kW NA 0-300 m

Reduction of dU/dt, reduced noise emission (Low reduction) All 0-150 m NA

Reduction of dU/dt, Upeak and reduced noice emission (High reduction) All NA 0-300 m

With motors rated 500 V or higher All NA 0-300 m

Note

To meet EN 61800-3, the motor cable must always

be a screened cable, whether an output filter is

installed or not.

The mains cable need not be a screened cable. See

figures 24, 25, 26 and 27.

TM04 4289 1109TM04 4290 1109TM04 4291 1109TM04 4292 1109

Symbol Designation

1 CUE

2Filter

3 Connection box

4 Standard motor

5 Submersible motor

One line Unscreened cable

Double line Screened cable

1

4

124

125

1 32

5

Page 14

English (GB)

14

7. Operating modes

The following operating modes are set on the control panel in the

"OPERATION" menu, display 1.2. See section 10.6.2 Operating

mode (1.2).

Example: Max. curve operation can for instance be used in

connection with venting the pump during installation.

Example: Min. curve operation can for instance be used in

periods with a very small flow requirement.

8. Control modes

The control mode is set on the control panel in the

"INSTALLATION" menu, display 3.1. See section 10.8.1 Control

mode (3.1).

There are two basic control modes:

• Uncontrolled operation (open loop).

• Controlled operation (closed loop) with a sensor connected.

See sections 8.1 Uncontrolled operation (open loop) and

8.2 Controlled operation (closed loop).

8.1 Uncontrolled operation (open loop)

Example: Operation on constant curve can for instance be used

for pumps with no sensor connected.

Example: Typically used in connection with an overall control

system such as the MPC or another external controller.

8.2 Controlled operation (closed loop)

Operating mode Description

Normal

The pump is running in the control mode

selected

Stop

The pump has been stopped (green indicator

light is flashing)

Min. The pump is running at minimum speed

Max. The pump is running at maximum speed

TM03 8813 2507

Min. and max. curves.

The pump speed is kept at a given

set value for minimum and maximum

speed, respectively.

TM03 8479 1607

Constant curve.

The speed is kept at a set value in

the range between the min. and max.

curves.

The setpoint is set in %

corresponding to the required speed.

Min.

Max.

TM03 8475 1607

TM03 8804 2507

Proportional

differential

pressure.

The differential

pressure is reduced

at falling flow rate

and increased at

rising flow rate.

TM03 8476 1607

TM03 8804 2507

Constant

differential

pressure, pump.

The differential

pressure is kept

constant,

independently of

the flow rate.

TM03 8476 1607

TM03 8806 2507

Constant

differential

pressure, system.

The differential

pressure is kept

constant,

independently of

the flow rate.

TM03 8476 1607

TM03 8805 2507

Constant pressure.

The pressure is

kept constant,

independently of

the flow rate.

TM03 8477 1607

TM03 8807 2507

Constant pressure

with stop function.

The outlet pressure

is kept constant at

high flow rate.

On/off operation at

low flow rate.

TM03 8482 1607

TM03 8808 2607

Constant level.

The liquid level is

kept constant,

independently of

the flow rate.

TM03 8482 1607

TM03 8809 2607

Constant level with

stop function.

The liquid level is

kept constant at

high flow rate.

On/off operation at

low flow rate.

TM03 8478 1607

TM03 8810 2507

Constant flow rate.

The flow rate is

kept constant,

independently of

the head.

TM03 8482 1607

TM03 8811 2507

Constant

temperature.

The liquid

temperature is kept

constant,

independently of

the flow rate.

CUE

Δp

CUE

Δp

CUE

Δp

CUE

p

CUE

p

CUE

L

CUE

L

CUE

Q

CUE

t

Page 15

English (GB)

15

9. Menu overview

Fig. 28 Menu overview

Menu structure

The CUE has a startup guide, which is started at the first startup.

After the startup guide, the CUE has a menu structure divided

into four main menus:

1. "GENERAL" gives access to the startup guide for the general

setting of the CUE.

2. "OPERATION" enables the setting of setpoint, selection of

operating mode and resetting of alarms. It is also possible to

see the latest five warnings and alarms.

3. "STATUS" shows the status of the CUE and the pump. It is not

possible to change or set values.

4. "INSTALLATION" gives access to all parameters. Here a

detailed setting of the CUE can be made.

STARTUP GUIDE 0. GENERAL 1. OPERATION

0.1 1.1

1/16 0.2 1.2

2/16 0.24 1.3

3/16 8/16 1.4

4/16 9/16 1.5 - 1.9

5/16 10/16 - 14/16

6/16 8/16 1.10 - 1.14

7/16 16/16

Automatic or manual

setting of the direction

of rotation

Page 16

English (GB)

16

2. STATUS 3. INSTALLATION

2.1 2.10 3.1 3.12 3.24

2.2 2.11 3.2 3.13 3.25

2.3 2.12 3.3 3.14

2.4 2.13 3.3A 3.8

2.5 2.14 3.4 3.16

2.6 2.8 3.5 3.17

2.7 2.16 3.6 3.18

2.8 2.17 3.7 3.19

2.9 3.8 3.20

3.9 3.21

3.10 3.22

3.11 3.23

Page 17

English (GB)

17

10. Setting by means of the control panel

10.1 Control panel

The control panel is used for local setting of the CUE. The

functions available depend on the pump family connected to the

CUE.

Fig. 29 Control panel of the CUE

Editing buttons

Navigating buttons

The editing buttons of the control panel can be set to these

values:

•Active

•Not active.

When set to "Not active" (locked), the editing buttons do not

function. It is only possible to navigate in the menus and read

values.

Activate or deactivate the buttons by pressing the arrow up and

arrow down buttons simultaneously for 3 seconds.

Adjusting the display contrast

Press [OK] and [+] for darker display.

Press [OK] and [-] for brighter display.

Indicator lights

The operating condition of the pump is indicated by the indicator

lights on the front of the control panel. See fig. 29.

The table shows the function of the indicator lights.

Warning

The on/off button on the control panel does not

disconnect the CUE from the power supply and must

therefore not be used as a safety switch.

The on/off button has the highest priority. In "off"

condition, pump operation is not possible.

TM03 8719 2507

Button Function

Makes the pump ready for operation/starts and

stops the pump.

Saves changed values, resets alarms and expands

the value field.

Changes values in the value field.

On/On/

Off

+

-

CUCUE

>

>

>

>

OK

On/On/

Off

OnOn

Off

Alarm

Alarm

On/On/

Off

OK

+

-

Button Function

Navigates from one menu to another. When the

menu is changed, the display shown will always be

the top display of the new menu.

Navigates up and down in the individual menu.

Indicator

light

Function

On (green)

The pump is running or has been stopped by a

stop function.

If flashing, the pump has been stopped by the

user (CUE menu), external start/stop or bus.

Off (orange)

The pump has been stopped with the on/off

button.

Alarm (red) Indicates an alarm or a warning.

>

>

>

>

Page 18

English (GB)

18

Displays, general terms

Figures 30 and 31 show the general terms of the display.

Fig. 30 Example of display in the startup guide

Fig. 31 Example of display in the user menu

10.2 Back to factory settings

Follow this procedure to get back to the factory settings:

1. Switch off the power supply to the CUE.

2. Press [On/Off], [OK] and [+] while switching on the power

supply.

The CUE will reset all parameters to factory settings. The display

will turn on when the reset is completed.

10.3 CUE settings

The startup guide includes all parameters that can be set on the

control panel of the CUE.

The document includes a special table for additional PC Tool

settings and a page where special PC Tool programming details

should be entered.

If you want to download the document, please contact your local

Grundfos company.

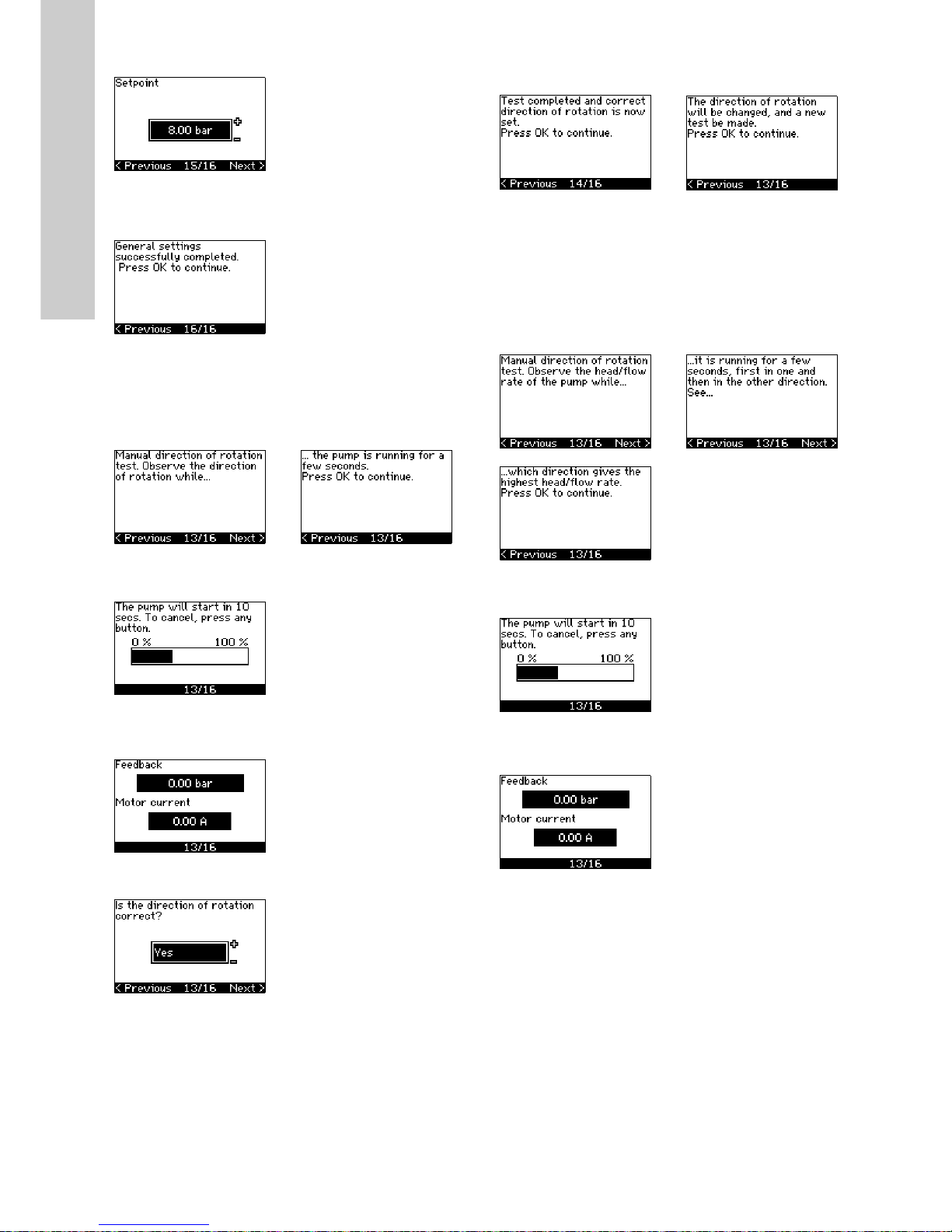

10.4 Startup guide

Use the startup guide for the general setting of the CUE including

the setting of the correct direction of rotation.

The startup guide is started the first time when the CUE is

connected to the power supply. It can be restarted in the

"GENERAL" menu. Please note that in this case all previous

settings will be erased.

Bulleted lists show possible settings. Factory settings are shown

in bold.

10.4.1 Welcoming display

• Press [OK]. You will now be guided through the startup guide.

10.4.2 Language (1/16)

Select the language to be used in the display:

10.4.3 Units (2/16)

Select the units to be used in the display:

• SI: m, kW, bar...

• US: ft, HP, psi...

TM04 7313 1810

Display name

Current display / total number

Value field

Display name

Display number, menu name

Value field

Note

Check that equipment connected is ready for startup,

and that the CUE has been connected to the power

supply.

Have nameplate data for motor, pump and CUE at

hand.

• English UK

•English US

•German

• French

• Italian

• Spanish

• Portuguese

• Greek

•Dutch

•Swedish

• Finnish

•Danish

•Polish

• Russian

• Hungarian

• Czech

• Chinese

• Japanese

• Korean.

Page 19

English (GB)

19

10.4.4 Pump family (3/16)

Select pump family according to the pump nameplate:

• CR, CRI, CRN, CRT

• SP, SP-G, SP-NE

•...

Select "Other" if the pump family is not on the list.

10.4.5 Rated motor power (4/16)

Set the rated motor power, P2, according to the motor nameplate:

• 0.55 - 90 kW.

The setting range is size-related, and the factory setting

corresponds to the rated power of the CUE.

10.4.6 Supply voltage (5/16)

Select supply voltage according to the rated supply voltage of the

installation site.

* Single-phase input - three-phase output.

The setting range depends on the CUE type, and the factory

setting corresponds to the rated supply voltage of the CUE.

10.4.7 Max. motor current (6/16)

Set the maximum motor current according to the motor

nameplate:

• 0-999 A.

The setting range depends on the CUE type, and the factory

setting corresponds to a typical motor current at the motor power

selected.

Max. current will be limited to the value on the CUE nameplate,

even if it is set to a higher value during setup.

10.4.8 Speed (7/16)

Set the rated speed according to the pump nameplate:

• 0-9999 min

-1

.

The factory setting depends on previous selections. Based on the

set rated speed, the CUE will automatically set the motor

frequency to 50 or 60 Hz.

10.4.9 Frequency (7A/16)

This display appears only if manual entry of the frequency is

required.

Set the frequency according to the motor nameplate:

• 40-200 Hz.

The factory setting depends on previous selections.

Unit 1 x 200-240 V:*

• 1 x 200 V

• 1 x 208 V

• 1 x 220 V

• 1 x 230 V

• 1 x 240 V.

Unit 3 x 200-240 V:

• 3 x 200 V

• 3 x 208 V

• 3 x 220 V

• 3 x 230 V

• 3 x 240 V.

Unit 3 x 380-500 V:

• 3 x 380 V

• 3 x 400 V

• 3 x 48 V

• 3 x 440 V

• 3 x 460 V

• 3 x 500 V.

Unit 3 x 525-600 V:

• 3 x 575 V.

Unit 3 x 525-690 V:

• 3 x 575 V

• 3 x 690 V.

Page 20

English (GB)

20

10.4.10 Control mode (8/16)

Select the desired control mode. See section 10.8.1 Control

mode (3.1).

• Open loop

• Constant pressure

• Constant differential pressure

• Proportional differential pressure

• Constant flow rate

• Constant temperature

• Constant level

• Constant other value.

The possible settings and the factory setting depend on the pump

family.

The CUE will give an alarm if the control mode selected requires

a sensor and no sensor has been installed. To continue the

setting without a sensor, select "Open loop", and proceed. When

a sensor has been connected, set the sensor and control mode in

the "INSTALLATION" menu.

10.4.11 Rated flow rate (8A/16)

This display appears only if the control mode selected is

proportional differential pressure.

Set the rated flow rate according to the pump nameplate:

• 1-6550 m

3

/h.

10.4.12 Rated head (8 B/16 )

This display only appears if the control mode selected is

proportional differential pressure.

Set the rated head according to the pump nameplate:

• 1-999 m.

10.4.13 Sensor connected to terminal 54 (9/16)

Set the measuring range of the connected sensor with a signal

range of 4-20 mA. The measuring range depends on the control

mode selected:

If the control mode selected is "Constant other value", or if the

measuring range selected is "Other", the sensor must be set

according to the next section, display 9A/16.

Proportional differential pressure:

• 0-0.6 bar

•0-1 bar

• 0-1.6 bar

• 0-2.5 bar

•0-4 bar

•0-6 bar

• 0-10 bar

•Other.

Constant differential pressure:

• 0-0.6 bar

• 0-1.6 bar

• 0-2.5 bar

•0-4 bar

• 0-6 bar

• 0-10 bar

•Other.

Constant pressure:

• 0-2.5 bar

•0-4 bar

•0-6 bar

• 0-10 bar

• 0-16 bar

• 0-25 bar

•Other.

Constant flow rate:

•1-5 m

3

/h

•2-10 m

3

/h

•6-30 m

3

/h

•8-75 m

3

/h

•Other.

Constant temperature:

• -25 to 25 °C

• 0 to 25 °C

• 50 to 100 °C

• 0 to 80 °C

•Other.

Constant level:

• 0-0.1 bar

• 0-1 bar

• 0-2.5 bar

• 0-6 bar

• 0-10 bar

•Other.

Page 21

English (GB)

21

10.4.14 Another sensor connected to terminal 54 (9A/16)

This display only appears when the control mode "Constant other

value" or the measuring range "Other" has been selected in

display 9/16.

• Sensor output signal:

0-20 mA

4-20 mA.

• Unit of measurement of sensor:

bar, mbar, m, kPa, psi, ft, m

3

/h, m3/min, m3/s, l/h, l/min, l/s,

gal/h, gal/m, gal/s, ft

3

/min, ft3/s, °C, °F, %.

• Sensor measuring range.

The measuring range depends on the sensor connected and the

measuring unit selected.

10.4.15 Priming and venting (10/16)

See the installation and operating instructions of the pump.

The general setting of the CUE is now completed, and the startup

guide is ready for setting the direction of rotation:

• Press [OK] to go on to automatic or manual setting of the

direction of rotation.

10.4.16 Automatic setting of the direction of rotation (11/16)

The CUE automatically tests and sets the correct direction of

rotation without changing the cable connections.

This test is not suitable for certain pump types and will in certain

cases not be able to determine with certainty the correct direction

of rotation. In these cases, the CUE changes over to manual

setting where the direction of rotation is determined on the basis

of the installer's observations.

Information displays.

• Press [OK] to continue.

The pump starts after 10 seconds.

It is possible to interrupt the test and return to the previous

display.

The pump runs with both directions of rotation and stops

automatically.

It is possible to interrupt the test, stop the pump and go to manual

setting of the direction of rotation.

Warning

During the test, the pump will run for a short time.

Ensure that no personnel or equipment is in danger!

Note

Before setting the direction of rotation, the CUE will

make an automatic motor adaptation of certain pump

types. This will take a few minutes. The adaptation is

carried out during standstill.

The correct direction of

rotation has now been set.

• Press [OK] to set the

setpoint.

See section

10.4.17 Setpoint (8/16).

The automatic setting of the

direction of rotation has failed.

• Press [OK] to go to manual

setting of the direction of

rotation.

Page 22

English (GB)

22

10.4.17 Setpoint (8/16)

Set the setpoint according to the control mode and sensor

selected.

10.4.18 General settings are completed (16/16)

• Press [OK] to make the pump ready for operation or start the

pump in the "Normal" operating mode. Then display 1.1 of the

"OPERATION" menu will appear.

10.4.19 Manual setting when the direction of rotation is

visible (13/16)

It must be possible to observe the motor fan or shaft.

Information displays.

• Press [OK] to continue.

The pump starts after 10 seconds.

It is possible to interrupt the test and return to the previous

display.

The pressure will be shown during the test if a pressure sensor is

connected. The motor current is always shown during the test.

State if the direction of rotation is correct.

10.4.20 Manual setting when the direction of rotation is not

visible (13/16)

It must be possible to observe the head or flow rate.

Information displays.

• Press [OK] to continue.

The pump starts after 10 seconds.

It is possible to interrupt the test and return to the previous

display.

The pressure will be shown during the test if a pressure sensor is

connected. The motor current is always shown during the test.

•Yes •No

The correct direction of

rotation has now been set.

• Press [OK] to set the

setpoint.

See section

10.4.17 Setpoint (8/16).

The direction of rotation is not

correct.

• Press [OK] to repeat the test

with the opposite direction

of rotation.

Page 23

English (GB)

23

The first test is completed.

• Write down the pressure and/or flow rate, and press OK to

continue the manual test with the opposite direction of

rotation.

The pump starts after 10 seconds.

It is possible to interrupt the test and return to the previous

display.

The pressure will be shown during the test if a pressure sensor is

connected. The motor current is always shown during the test.

The second test is completed.

Write down the pressure and/or flow rate, and state which test

gave the highest pump performance:

•First test

• Second test

• Perform new test.

The correct direction of rotation has now been set.

• Press [OK] to set the setpoint. See section 10.4.17 Setpoint

(8/16).

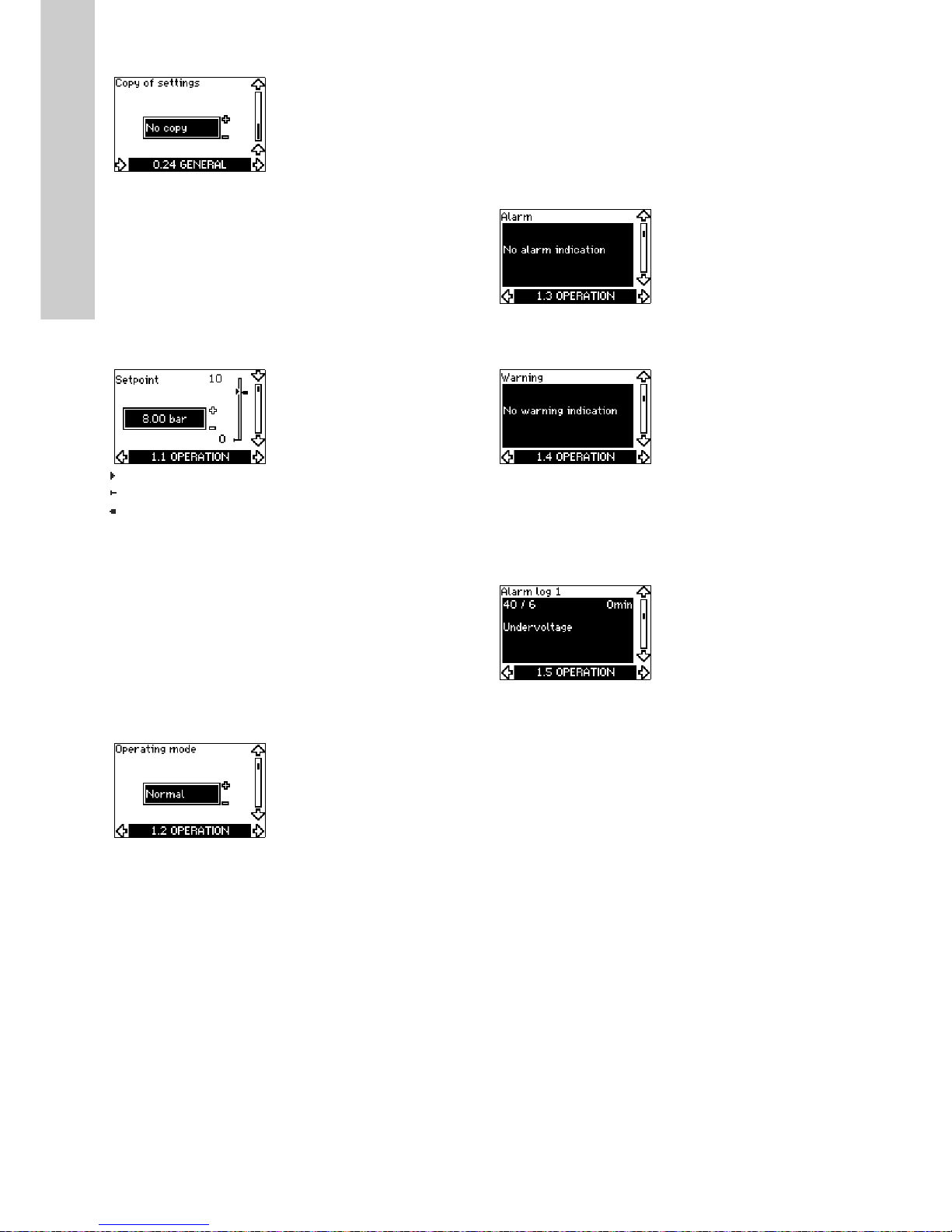

10.5 GENERAL

The menu makes it possible to return to the startup guide, which

is usually only used during the first startup of the CUE.

10.5.1 Return to startup guide (0.1)

State your choice:

•Yes

•No.

If you select "Yes", all settings will be erased, and the entire

startup guide must be completed. The CUE will return to the

startup guide, and new settings can be made. Additional settings

and the settings available in section 10. Setting by means of the

control panel will not require a reset.

Back to factory settings

Press [On/Off], [OK] and [+] for a complete reset to factory

settings.

10.5.2 Type code change (0.2)

This display is for service use only.

Note

If the startup guide is started, all previous settings

will be erased!

Note

The startup guide must be carried out on a cold

motor!

Repeating the startup guide may lead to heating of

the motor.

Page 24

English (GB)

24

10.5.3 Copy of settings

It is possible to copy the settings of a CUE and reuse them in

another one.

Options:

• No copy.

• to CUE (copies the settings of the CUE).

• to control panel (copies the settings to another CUE).

The CUE units must have the same firmware version. See section

10.7.16 Firmware version (2.16).

10.6 OPERATION

10.6.1 Setpoint (1.1)

Setpoint set

Actual setpoint

Actual value

Set the setpoint in the units of the feedback sensor.

In "Open loop" control mode, the setpoint is set in % of the

maximum performance. The setting range will be between the

min. and max. curves. See fig. 38.

In all other control modes except proportional differential

pressure, the setting range is equal to the sensor measuring

range. See fig. 39.

In "Proportional differential pressure" control mode, the setting

range is equal to 25 % to 90 % of max. head. See fig. 40.

If the pump is connected to an external setpoint signal, the value

in this display will be the maximum value of the external setpoint

signal. See section 13.2 External setpoint.

10.6.2 Operating mode (1.2)

Set one of the following operating modes:

• Normal (duty)

•Stop

•Min.

•Max.

The operating modes can be set without changing the setpoint

setting.

10.6.3 Fault indications

Faults may result in two types of indication: Alarm or warning.

An alarm will activate an alarm indication in CUE and cause the

pump to change operating mode, typically to stop. However, for

some faults resulting in alarm, the pump is set to continue

operating even if there is an alarm.

A warning will activate a warning indication in CUE, but the pump

will not change operating or control mode.

Alarm (1.3)

In case of an alarm, the cause will appear in the display. See

section 15.1 Warning and alarm list.

Warning (1.4)

In case of a warning, the cause will appear in the display. See

section 15.1 Warning and alarm list.

10.6.4 Fault log

For both fault types, alarm and warning, the CUE has a log

function.

Alarm log (1.5 - 1 .9)

In case of an alarm, the last five alarm indications will appear in

the alarm log. "Alarm log 1" shows the latest alarm, "Alarm log 2"

shows the latest alarm but one, etc.

The display shows three pieces of information:

• the alarm indication

• the alarm code

• the number of minutes the pump has been connected to the

power supply after the alarm occurred.

Page 25

English (GB)

25

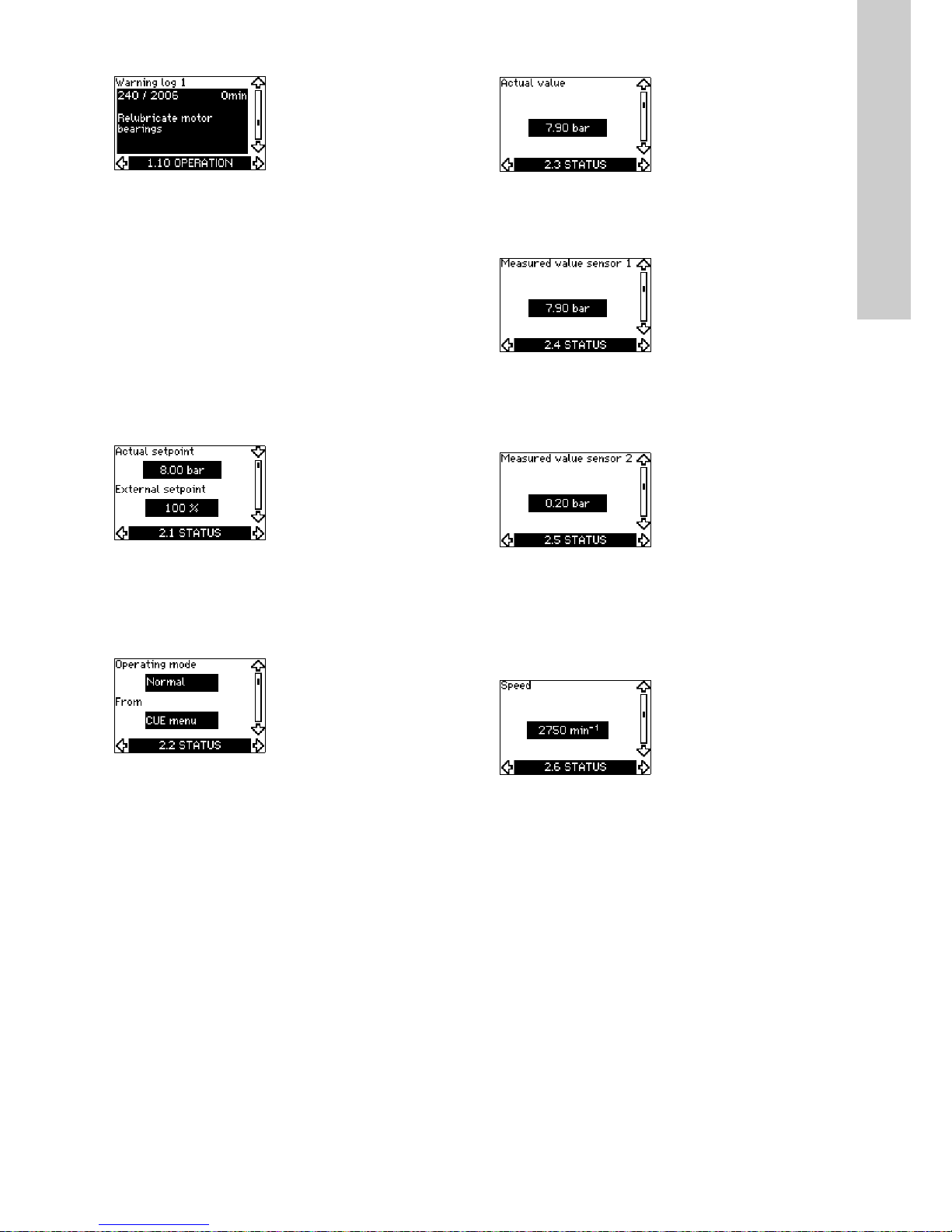

Warning log (1.10 - 1.14)

In case of a warning, the last five warning indications will appear

in the warning log. "Warning log 1" shows the latest fault,

"Warning log 2" shows the latest fault but one, etc.

The display shows three pieces of information:

• the warning indication

• the warning code

• the number of minutes the pump has been connected to the

power supply after the warning occurred.

10.7 STATUS

The displays appearing in this menu are status displays only. It is

not possible to change or set values.

The tolerance of the displayed value is stated under each display.

The tolerances are stated as a guide in % of the maximum values

of the parameters.

10.7.1 Actual setpoint (2.1)

This display shows the actual setpoint and the external setpoint.

The actual setpoint is shown in the units of the feedback sensor.

The external setpoint is shown in a range of 0 to 100 %. If the

external setpoint influence is deactivated, the value 100 % is

shown. See section 13.2 External setpoint.

10.7.2 Operating mode (2.2)

This display shows the actual operating mode (Normal, Stop, Min.

or Max.). Furthermore, it shows where this operating mode was

selected (CUE menu, Bus, External or On/off button).

10.7.3 Actual value (2.3)

This display shows the actual value controlled.

If no sensor is connected to the CUE, "-" will appear in the

display.

10.7.4 Measured value, sensor 1 (2.4)

This display shows the actual value measured by sensor 1

connected to terminal 54.

If no sensor is connected to the CUE, "-" will appear in the

display.

10.7.5 Measured value, sensor 2 (2.5)

This display is only shown if an MCB 114 sensor input module

has been installed.

The display shows the actual value measured by sensor 2

connected to an MCB 114.

If no sensor is connected to the CUE, "-" will appear in the

display.

10.7.6 Speed (2.6)

Tolerance: ± 5 %

This display shows the actual pump speed.

Page 26

English (GB)

26

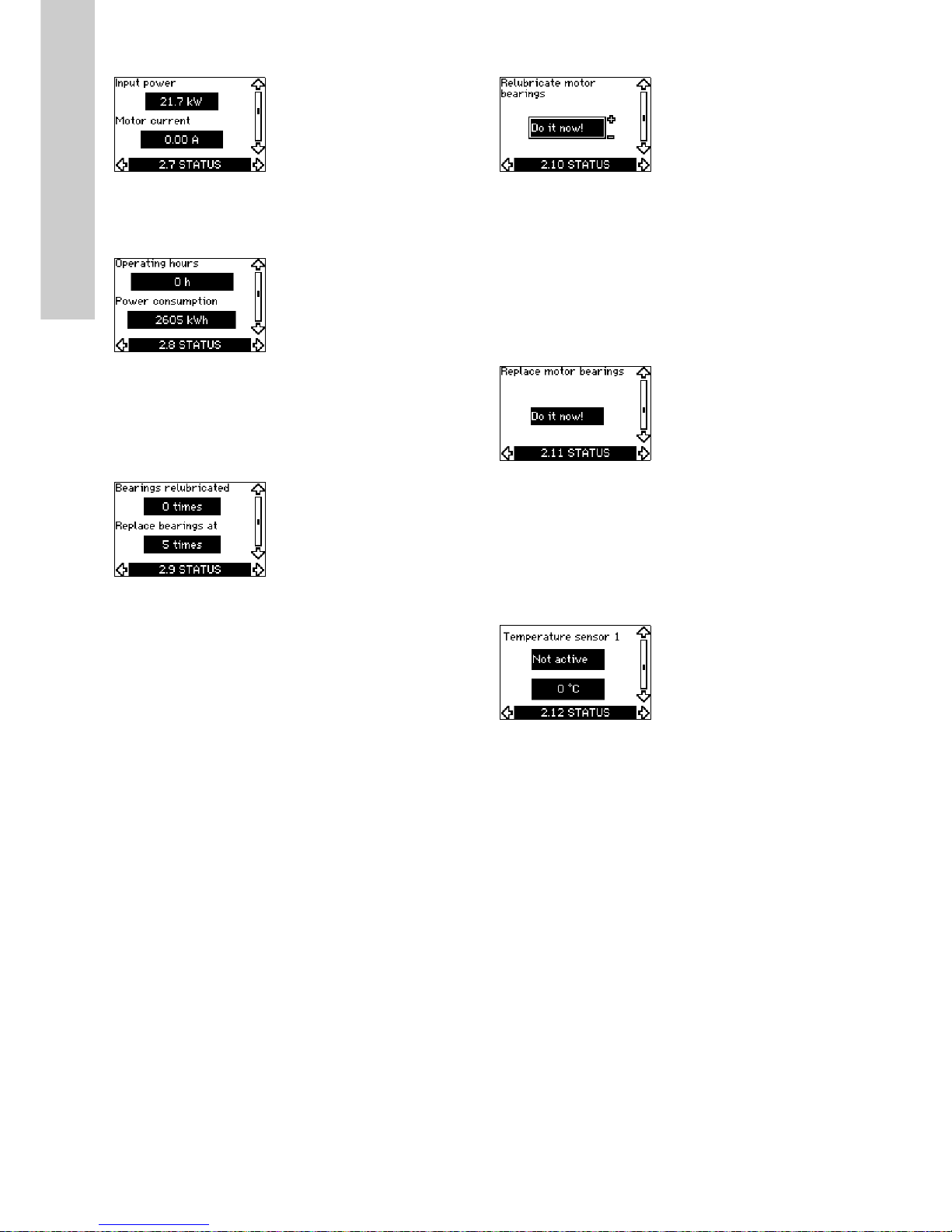

10.7.7 Input power and motor current (2.7)

Tolerance: ± 10 %

This display shows the actual pump input power in W or kW and

the actual motor current in ampere [A].

10.7.8 Operating hours and power consumption (2.8)

Tolerance: ± 2 %

This display shows the number of operating hours and the power

consumption. The value of operating hours is an accumulated

value and cannot be reset. The value of power consumption is an

accumulated value calculated from the unit's birth, and it cannot

be reset.

10.7.9 Lubrication status of motor bearings (2.9)

This display shows how many times the user has given the

lubrication stated and when to replace the motor bearings.

When the motor bearings have been relubricated, confirm this

action in the "INSTALLATION" menu. See section

10.8.18 Confirming relubrication/replacement of motor bearings

(3.20). When relubrication is confirmed, the figure in the above

display will be increased by one.

10.7.10 Time until relubrication of motor bearings (2.10)

This display is only shown if display 2.11 is not shown.

The display shows when to relubricate the motor bearings. The

controller monitors the operating pattern of the pump and

calculates the period between bearing lubrications. If the

operating pattern changes, the calculated time until relubrication

may change as well.

The estimated time until relubrication takes into account if the

pump has been running with reduced speed.

See section 10.8.18 Confirming relubrication/replacement of

motor bearings (3.20).

10.7.11 Time until replacement of motor bearings (2.11)

This display is only shown if display 2.10 is not shown.

The display shows when to replace the motor bearings. The

controller monitors the operating pattern of the pump and

calculates the period between bearing replacements.

The estimated time until replacement of motor bearings takes into

account if the pump has been running with reduced speed.

See section 10.8.18 Confirming relubrication/replacement of

motor bearings (3.20).

10.7.12 Temperature sensor 1 (2.12)

This display is only shown if an MCB 114 sensor input module

has been installed.

The display shows the measuring point and the actual value

measured by a Pt100/Pt1000 temperature sensor 1 connected to

the MCB 114. The measuring point is selected in display 3.21.

If no sensor is connected to the CUE, "-" will appear in the

display.

Page 27

English (GB)

27

10.7.13 Temperature sensor 2 (2.13)

This display is only shown if an MCB 114 sensor input module

has been installed.

The display shows the measuring point and the actual value

measured by a Pt100/Pt1000 temperature sensor 2 connected to

the MCB 114. The measuring point is selected in display 3.22.

If no sensor is connected to the CUE, "-" will appear in the

display.

10.7.14 Flow rate (2.14)

This display is only shown if a flowmeter has been configured.

The display shows the actual value measured by a flowmeter

connected to the digital pulse input (terminal 33) or the analog

input (terminal 54).

10.7.15 Accumulated flow (2.8)

This display is only shown if a flowmeter has been configured.

The display shows the value of the accumulated flow and the

specific energy for the transfer of the pumped liquid.

The flow measurement can be connected to the digital pulse input

(terminal 33) or the analog input (terminal 54).

10.7.16 Firmware version (2.16)

This display shows the version of the software.

10.7.17 Configuration file (2.17)

This display shows the configuration file.

10.8 INSTALLATION

10.8.1 Control mode (3.1)

Select one of the following control modes:

• Open loop

• Constant pressure

• Constant differential pressure

• Proportional differential pressure

• Constant flow rate

• Constant temperature

• Constant level

• Constant other value.

10.8.2 Controller (3.2)

The CUE has a factory setting of gain (K

p

) and integral time (Ti).

However, if the factory setting is not the optimum setting, the gain

and the integral time can be changed in the display.

•The gain (K

p

) can be set within the range from 0.1 to 20.

• The integral time (Ti) can be set within the range from 0.1 to

3600 s. If you select 3600 s, the controller will function as a P

controller.

• Furthermore, it is possible to set the controller to inverse

control, meaning that if the setpoint is increased, the speed

will be reduced. In the case of inverse control, the gain (K

p

)

must be set within the range from -0.1 to -20.

Note

If the pump is connected to a bus, the control mode

cannot be selected via the CUE. See section

13.3 GENIbus signal.

Page 28

English (GB)

28

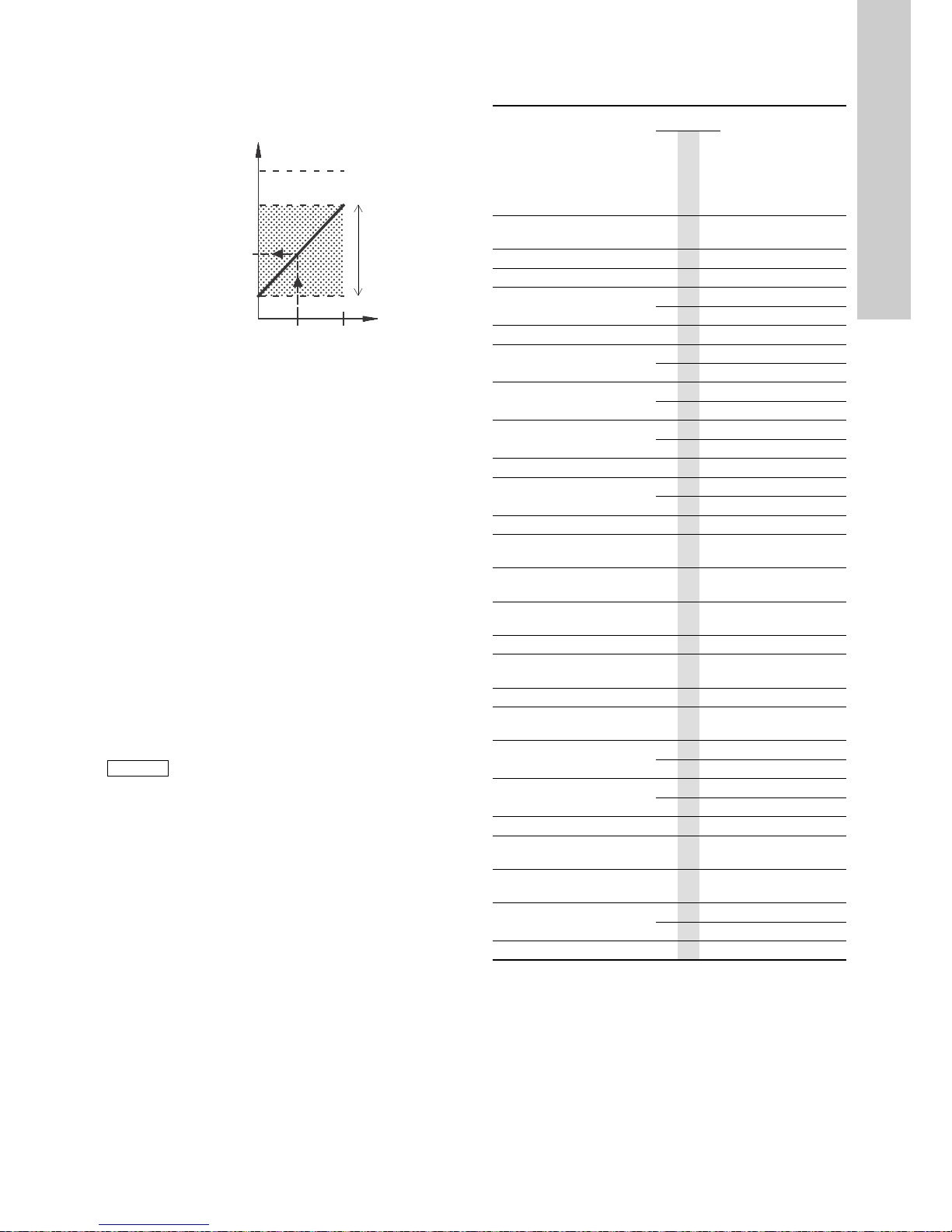

The table below shows the suggested controller settings:

* T

i

= 100 seconds (factory setting).

1. Heating systems are systems in which an increase in pump

performance will result in a rise in temperature at the sensor.

2. Cooling systems are systems in which an increase in pump

performance will result in a drop in temperature at the sensor.

L

1

= Distance in [m] between pump and sensor.

L

2

= Distance in [m] between heat exchanger and sensor.

How to set the PI controller

For most applications, the factory setting of the controller

constants K

p

and Ti will ensure optimum pump operation.

However, in some applications an adjustment of the controller

may be needed.

Proceed as follows:

1. Increase the gain (K

p

) until the motor becomes unstable.

Instability can be seen by observing if the measured value

starts to fluctuate. Furthermore, instability is audible as the

motor starts hunting up and down.

As some systems, such as temperature controls, are slowreacting, it may be difficult to observe that the motor is

unstable.

2. Set the gain (K

p

) to half the value of the value which made the

motor unstable. This is the correct setting of the gain.

3. Reduce the integral time (T

i

) until the motor becomes

unstable.

4. Set the integral time (T

i

) to twice the value which made the

motor unstable. This is the correct setting of the integral time.

General rules of thumb:

• If the controller is too slow-reacting, increase K

p

.

• If the controller is hunting or unstable, dampen the system by

reducing K

p

or increasing Ti.

10.8.3 External setpoint (3.3)

The input for external setpoint signal (terminal 53) can be set to

the following types:

•Active

• Not active.

If you select "Active", the actual setpoint is influenced by the

signal connected to the external setpoint input. See section

13.2 External setpoint.

System/application

K

p

T

i

Heating

system

1)

Cooling

system

2)

0.2 0.5

SP, SP-G, SP-NE: 0.5 0.5

0.2 0.5

SP, SP-G, SP-NE: 0.5 0.5

0.2 0.5

- 2.5 100

0.5 - 0.5 10 + 5L

2

0.5 10 + 5L

2

0.5 - 0.5 30 + 5L2*

0.5 0.5*

0.5

L

1

< 5 m: 0.5*

L

1

> 5 m: 3*

L

1

> 10 m: 5*

CUE

p

CUE

p

CUE

Q

CUE

L

t

L

2

CUE

Δt

L

2

CUE

t

L

2

CUE

CUE

Δp

Δp

L

1

CUE

Page 29

English (GB)

29

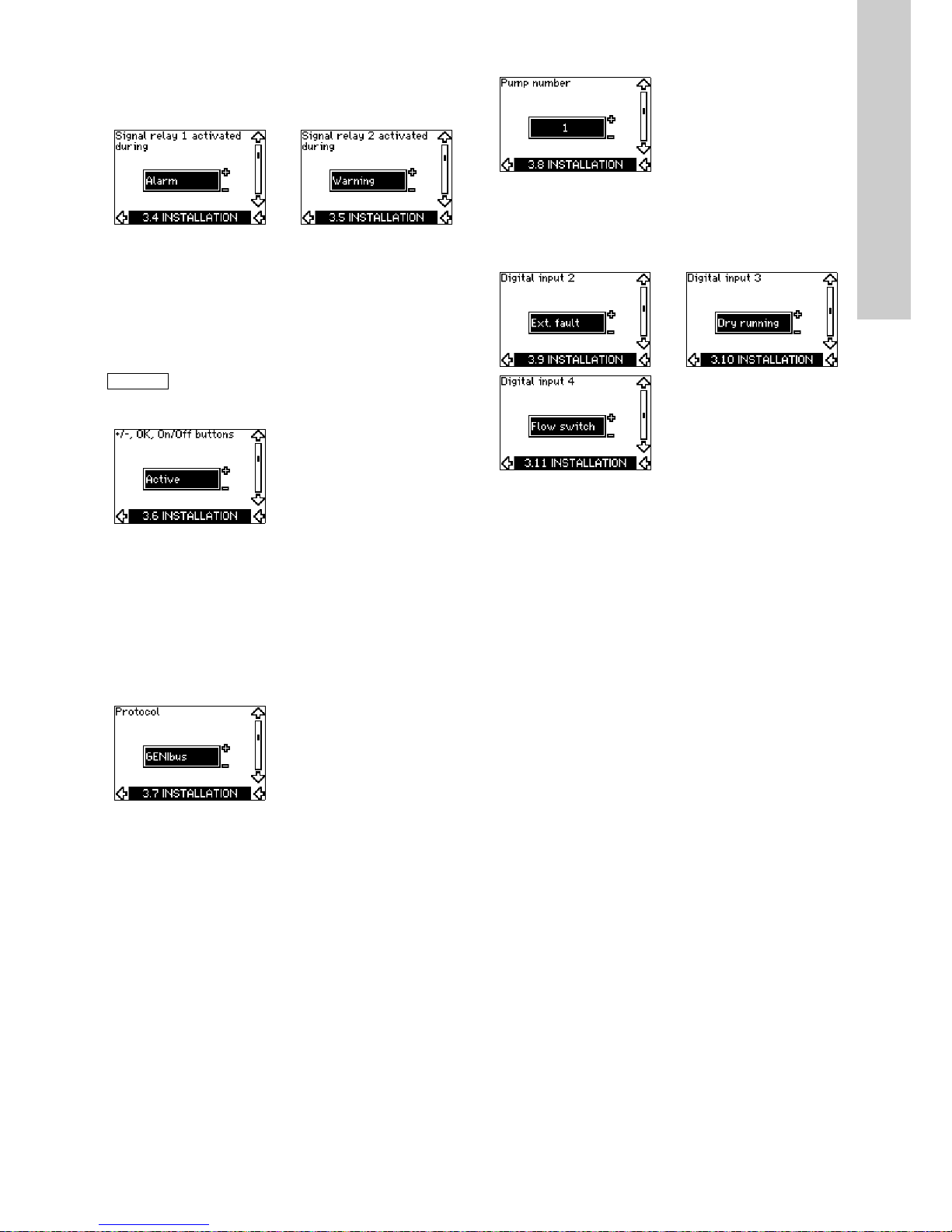

10.8.4 Signal relays 1 and 2 (3.4 and 3.5)

The CUE has two signal relays. In the display below, select in

which operating situations the signal relay should be activated.

10.8.5 Buttons on the CUE (3.6)

The editing buttons (+, -, On/Off, OK) on the control panel can be

set to these values:

•Active

• Not active.

When set to "Not active" (locked), the editing buttons do not

function. Set the buttons to "Not active" if the pump should be

controlled via an external control system.

Activate the buttons by pressing the arrow up and arrow down

buttons simultaneously for 3 seconds.

10.8.6 Protocol (3.7)

This display shows the protocol selection for the RS-485 port of

the CUE. The protocol can be set to these values:

• GENIbus

•FC

•FC MC.

If you select "GENIbus", the communication is set according to

the Grundfos GENIbus standard. FC and FC MC are for service

purposes only.

10.8.7 Pump number (3.8)

This display shows the GENIbus number. A number between 1

and 199 can be allocated to the pump. In the case of bus

communication, a number must be allocated to each pump.

The factory setting is "-".

10.8.8 Digital inputs 2, 3 and 4 (3.9 to 3.11)

The digital inputs of the CUE (terminal 19, 32 and 33) can be set

individually to different functions.

Select one of the following functions:

• Min. (min. curve)

• Max. (max. curve)

• Ext. fault (external fault)

• Flow switch

• Alarm reset

• Dry running (from external sensor)

• Accumulated flow (pulse flow, only terminal 33)

•Not active.

The selected function is active when the digital input is activated

(closed contact). See also section 13.1 Digital inputs.

Min.

When the input is activated, the pump will operate according to

the min. curve.

Max.

When the input is activated, the pump will operate according to

the max. curve.

Ext. fault

When the input is activated, a timer will be started. If the input is

activated for more than 5 seconds, an external fault will be

indicated. If the input is deactivated, the fault condition will cease

and the pump can only be restarted manually by resetting the

fault indication.

Signal relay 1 Signal relay 2

• Ready

•Alarm

• Operation

• Pump running

• Not active

• Warning

• Relubricate.

• Ready

•Alarm

• Operation

• Pump running

• Not active

• Warning

• Relubricate.

Note

For the distinction between alarm and warning, see

section 10.6.3 Fault indications.

Page 30

English (GB)

30

Flow switch

When this function is selected, the pump will be stopped when a

connected flow switch detects low flow.

It is only possible to use this function if the pump is connected to

a pressure sensor or a level sensor, and the stop function is

activated. See sections 10.8.11 Constant pressure with stop

function (3.14) and 10.8.12 Constant level with stop function

(3.14).

Alarm reset

When the input has been activated, the alarm is reset if the cause

of the alarm no longer exists.

Dry running

When this function is selected, lack of inlet pressure or water

shortage can be detected. This requires the use of an accessory,

such as:

• a Grundfos Liqtec

®

dry-running switch

• a pressure switch installed on the suction side of a pump

• a float switch installed on the suction side of a pump.

When lack of inlet pressure or water shortage (dry running) is

detected, the pump will be stopped. The pump cannot restart as

long as the input is activated.

Restarts may be delayed by up to 30 minutes, depending of the

pump family.

Accumulated flow

When this function is set for digital input 4 and a pulse sensor is

connected to terminal 33, the accumulated flow can be

measured.

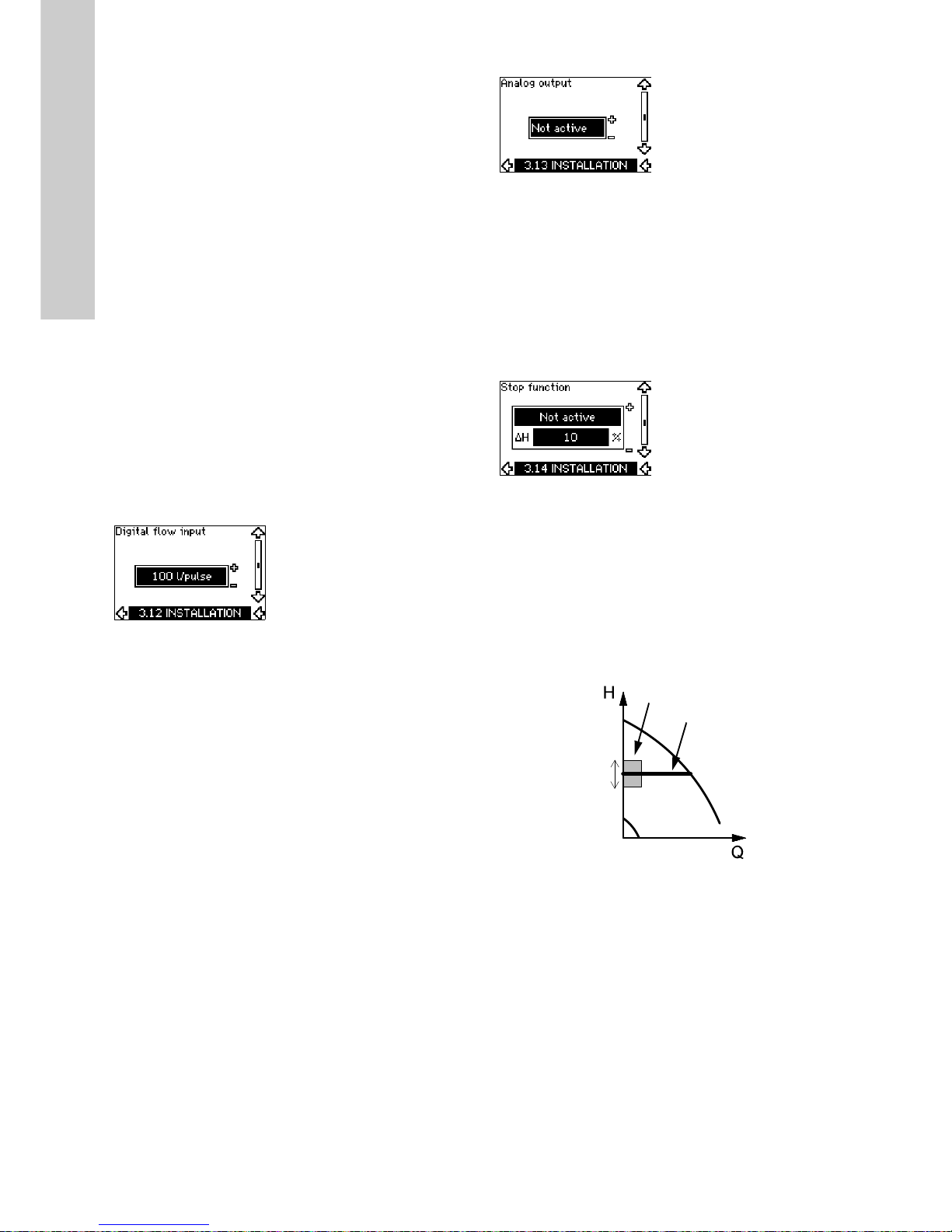

10.8.9 Digital flow input (3.12)

This display appears only if a flowmeter has been configured in

display 3.11.

The display is used for setting the volume for every pulse for the

"Accumulated flow" function with a pulse sensor connected to

terminal 33.

Setting range:

• 0-1000 litres/pulse.

The volume can be set in the unit selected in the startup guide.

10.8.10 Analog output (3.13)

The analog output can be set to show one of the following

options:

• Feedback

• Power input

• Speed

• Output frequency

• External sensor

• Limit 1 exceeded

• Limit 2 exceeded

•Not active.

10.8.11 Constant pressure with stop function (3.14)

Settings

The stop function can be set to these values:

•Active

• Not active.

The on/off band can be set to these values:

• ΔH is factory-set to 10 % of the actual setpoint.

• ΔH can be set within the range from 5 % to 30 % of the actual

setpoint.

Description

The stop function is used for changing between on/off operation

at low flow and continuous operation at high flow.

Fig. 32 Constant pressure with stop function. Difference

between start and stop pressures (ΔH)

Low flow can be detected in two different ways:

1. A built-in "low-flow detection function" which functions if the

digital input is not set up for flow switch.

2. A flow switch connected to the digital input.

TM03 8477 1607

Stop pressure

ΔH

Start pressure

Continuous operation

On/off operation

Page 31

English (GB)

31

1. Low-flow detection function

The pump will check the flow regularly by reducing the speed for

a short time. If there is no or only a small change in pressure, this

means that there is low flow.

The speed will be increased until the stop pressure (actual

setpoint + 0.5 x ΔH) is reached and the pump will stop after a few

seconds. The pump will restart at the latest when the pressure

has fallen to the start pressure (actual setpoint - 0.5 x ΔH).

If the flow in the off period is higher than the low-flow limit, the

pump will restart before the pressure has fallen to the start

pressure.

When restarting, the pump will react in the following way:

1. If the flow is higher than the low-flow limit, the pump will return

to continuous operation at constant pressure.

2. If the flow is lower than the low-flow limit, the pump will

continue in start/stop operation. It will continue in start/stop

operation until the flow is higher than the low-flow limit. When

the flow is higher than the low-flow limit, the pump will return

to continuous operation.

2. Low-flow detection with flow switch

When the digital input is activated because there is low flow, the

speed will be increased until the stop pressure (actual setpoint +

0.5 x ΔH) is reached, and the pump will stop. When the pressure

has fallen to start pressure, the pump will start again. If there is

still no flow, the pump will reach the stop pressure and stop. If

there is flow, the pump will continue operating according to the

setpoint.

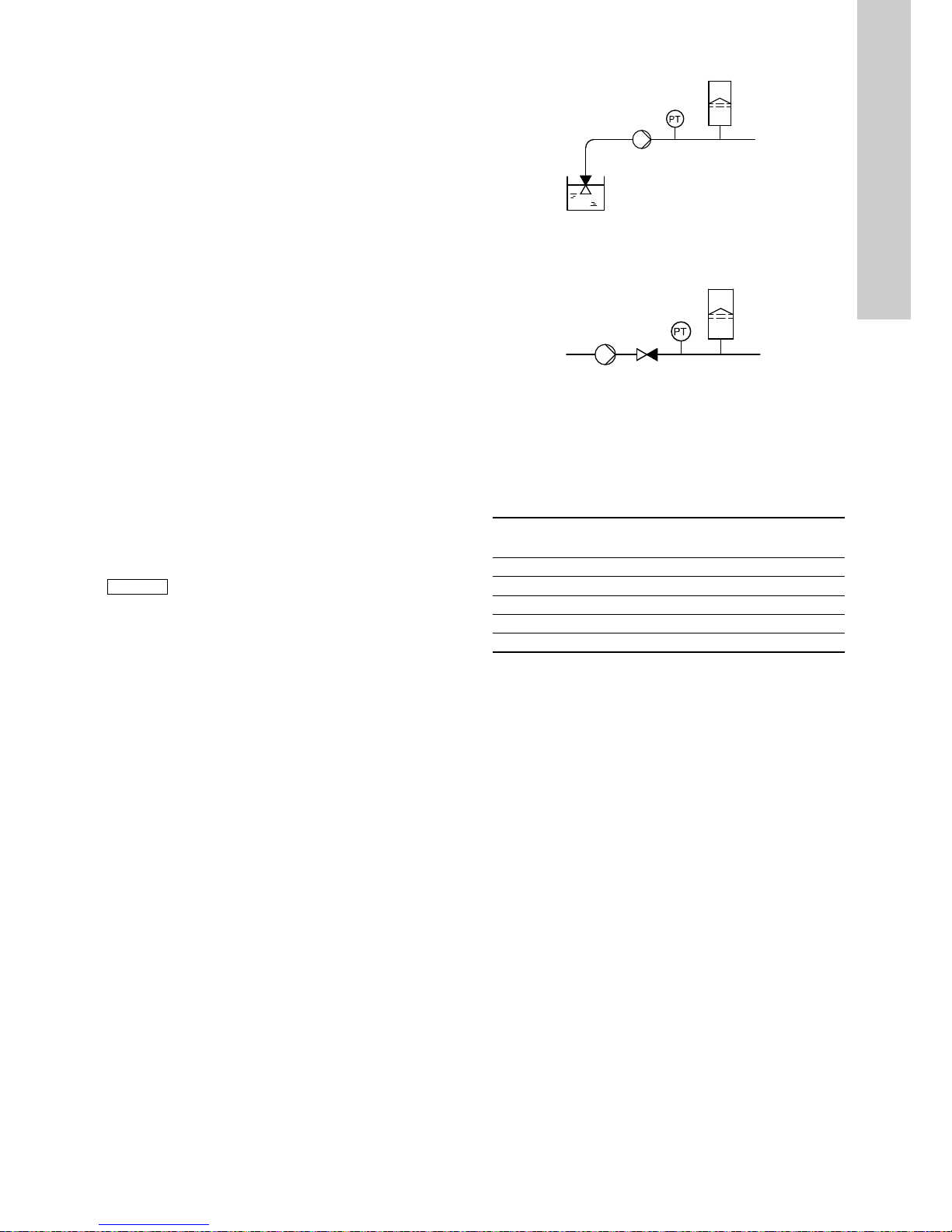

Operating conditions for the stop function

It is only possible to use the stop function if the system

incorporates a pressure sensor, a non-return valve and a

diaphragm tank.

Fig. 33 Position of the non-return valve and pressure sensor in

system with suction lift operation

Fig. 34 Position of the non-return valve and pressure sensor in

system with positive inlet pressure

Diaphragm tank

The stop function requires a diaphragm tank of a certain minimum

size. The tank must be installed as close as possible after the

pump and the precharge pressure must be 0.7 x actual setpoint.

Recommended diaphragm tank size:

If a diaphragm tank of the above size is installed in the system,

the factory setting of ΔH is the correct setting.

If the tank installed is too small, the pump will start and stop too

often. This can be remedied by increasing ΔH.

Caution

The non-return valve must always be installed before

the pressure sensor. See figures 33 and 34.

If a flow switch is used to detect low flow, the switch

must be installed on the system side after the

diaphragm tank.

TM03 8582 1907TM03 8583 1907

Rated flow rate of pump

[m

3

/h]

Typical diaphragm tank size

[litres]

0-6 8

7-24 18

25-40 50

41-70 120

71-100 180

Pressure sensor

Diaphragm tank

Non-return

valve

Pump

Diaphragm tank

Pressure sensor

Pump Non-return valve

Page 32

English (GB)

32

10.8.12 Constant level with stop function (3.14)

Settings

The stop function can be set to these values:

•Active

• Not active.

The on/off band can be set to these values:

• ΔH is factory-set to 10 % of the actual setpoint.

• ΔH can be set within the range from 5 % to 30 % of the actual

setpoint.

A built-in low-flow detection function will automatically measure

and store the power consumption at approx. 50 % and 85 % of

the rated speed.

If you select "Active", proceed as follows:

1. Close the isolating valve to create a no-flow condition.

2. Press [OK] to start the auto-tuning.

Description

The stop function is used for changing between on/off operation

at low flow and continuous operation at high flow.

Fig. 35 Constant level with stop function. Difference between

start and stop levels (ΔH)

Low flow can be detected in two different ways:

1. With the built-in low-flow detection function.

2. With a flow switch connected to a digital input.

1. Low-flow detection function

The built-in low-flow detection is based on the measurement of

speed and power.

When low flow is detected, the pump will stop. When the level has

reached the start level, the pump will start again. If there is still no

flow, the pump will reach the stop level and stop. If there is flow,

the pump will continue operating according to the setpoint.

2. Low-flow detection with flow switch

When the digital input is activated because of low flow, the speed

will be increased until the stop level (actual setpoint - 0.5 x ΔH) is

reached, and the pump will stop. When the level has reached the

start level, the pump will start again. If there is still no flow, the

pump will reach the stop level and stop. If there is flow, the pump

will continue operating according to the setpoint.

Operating conditions for the stop function

It is only possible to use the constant level stop function if the

system incorporates a level sensor, and all valves can be closed.

10.8.13 Sensor 1 (3.8)

Setting of sensor 1 connected to terminal 54. This is the feedback

sensor.

Select among the following values:

• Sensor output signal:

0-20 mA

4-20 mA.

• Sensor unit of measurement:

bar, mbar, m, kPa, psi, ft, m

3

/h, m3/s, l/s, gpm, °C, °F, %.

• Sensor measuring range.

10.8.14 Sensor 2 (3.16)

Setting of sensor 2 connected to an MCB 114 sensor input

module.

Select among the following values:

• Sensor output signal:

0-20 mA

4-20 mA.

• Sensor unit of measurement:

bar, mbar, m, kPa, psi, ft, m

3

/h, m3/s, l/s, gpm, °C, °F, %.

• Sensor measuring range:

0-100 %.

TM03 9099 3307

Star t level

ΔH

Stop level

Page 33

English (GB)

33

10.8.15 Duty/standby (3.17)

Settings

The duty/standby function can be set to these values:

•Active

• Not active.

Activate the duty/standby function as follows:

1. Connect one of the pumps to the mains supply.

Set the duty/standby function to "Not active".

Make the necessary settings in the "OPERATION" and

"INSTALLATION" menus.

2. Set the operating mode to "Stop" in the "OPERATION" menu.

3. Connect the other pump to the mains supply.

Make the necessary settings in the "OPERATION" and

"INSTALLATION" menus.

Set the duty/standby function to "Active".

The running pump will search for the other pump and

automatically set the duty/standby function of this pump to

"Active". If it cannot find the other pump, a fault will be indicated.

The duty/standby function applies to two pumps connected in

parallel and controlled via GENIbus. Each pump must be