Page 1

CU 300

Installation and operating instructions

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction

Overtemperature

Overload

Sensor alarm

GRUNDFOS INSTRUCTIONS

Other languages

www.grundfos.com/CU300-manual

Page 2

English (GB) Installation and operating instructions

English (GB)

Original installation and operating instructions.

CONTENTS

Page

1. Symbols used in this document

2. General

2.1 Expansion possibilities

2.2 On/Off button

3. Mechanical installation

3.1 Location

3.2 Mounting CU 300

4. CU 300 as an alarm unit

4.1 Description

4.2 Electrical installation

4.3 Description of dry-running protection

4.4 Settings

4.5 Description of the dewatering function

5. CU 300 with constant-pressure control 0 to 6 bar

5.1 Description

5.2 Function

5.3 Positioning the pressure sensor

5.4 System sizing

5.5 Electrical installation

5.6 Startup

6. CU 300 with constant-pressure control 0 to 10 bar

6.1 Description

6.2 Function

6.3 Positioning the pressure sensor

6.4 System sizing

6.5 Electrical installation

6.6 Startup

7. CU 300 with constant-pressure control two-pump operation

7.1 Description

7.2 Function

7.3 Positioning the pressure sensor

7.4 System sizing

7.5 Electrical installation

7.6 Startup

8. CU 300 with sensors

8.1 General

8.2 Sensor functioning

8.3 Electrical installation

9. CU 300 connected to potentiometer

9.1 Description

9.2 Electrical installation

10. CU 300 connected to water meter

10.1 Description

10.2 Electrical installation

11. Constant water level

11.1 De scription

11.2 Function

2

11.3 Electrical installation

12. CU 300 connected to RS-485

12.1 Description

12.2 CU 300 connected to a PC directly

12.3 Electrical installation

3

13. Alarm functions

3

13.1 No contact

3

13.2 Overvoltage

3

13.3 Undervoltage

4

13.4 Dry running

4

13.5 Speed reduction

4

13.6 Overtemperature

4

13.7 Overload

4

13.8 Sensor alarm

5

14. CU 300 with Grundfos GO

6

14.1 Menu overview

6

15. Description of functions

7

15.1 Status

15.2 Settings

8

15.3 Alarms and warnings

8

16. Technical data

8

9

17. Disposal

9

10

11

12

12

12

13

13

14

15

16

16

16

17

17

18

19

20

20

21

22

24

24

25

26

26

27

28

28

28

Warning

Prior to installation, read these

installation and operating instructions.

Installation and operation must comply

with local regulations and accepted

codes of good practice.

Warning

This product can be used by children of

eight years and up and persons with

reduced physical, sensory or mental

capabilities or lack of experience and

knowledge if they are under

supervision or have been instructed in

the safe use of the product and

understand the hazards involved.

Children must not play with the

product. Cleaning and maintenance of

the product must not be made by

children without supervision.

29

31

31

31

32

34

34

34

35

35

36

36

37

37

37

38

40

40

40

45

46

47

Page 3

1. Symbols used in this document

Note

Green

Red

Warning

If these safety instructions are not

observed, it may result in personal

injury.

Notes or instructions that make the job

easier and ensure safe operation.

2. General

The control unit CU 300 is developed for the SQE

submersible pumps.

CU 300 covers the voltage range 1 x 100-240 V - 10

%/+ 6 %, 50/60 Hz, PE.

CU 300 has the following functions:

• control of the pump on the basis of sensor

signals

• setting of operating parameters

• monitoring of operation and alarm indication, if

any.

CU 300 indicates the following alarms:

• no contact

• overvoltage

• undervoltage

• dry running

• speed reduction

• overtemperature

• overload

• sensor alarm.

The individual alarms are described in details in

section 13. Alarm functions.

CU 300 receives alarm signals from the motor for the

following parameters:

• dry running

• incipient pump or motor defect

• too high temperature in motor electronics

• supply failure.

As standard, CU 300 incorporates an alarm signal

relay.

2.1 Expansion possibilities

CU 300 enables the use of the following devices:

• Grundfos GO:

Wireless infra-red remote control that enables

change of factory settings and monitoring of the

installation by calling up actual operating data,

e.g. speed, operating hours and power

consumption.

• External sensors:

Reception of data from external sensors and

control according to the data received, e.g. flow

rate, pressure, water level and conductivity.

• External potentiometer SPP 1:

Manual speed control.

2.2 On/Off button

By means of the On/Off button on CU 300, you can

do the following:

• Start or stop the pump.

• Reset alarms.

Fig. 1

The green and red indicator lights in the On/Off

button indicate pump operating condition as follows:

Indication Description

Green indicator light

permanently on

Green indicator light

flashing

Red indicator light

permanently on

Red indicator light

flashing

* If you use the On/Off button to stop the pump,

you must also use this button for restarting the

pump.

If you press the On/Off button for minimum 5

seconds, you start the pump, irrespective of any

active fault or alarm indications. When you

release the On/Off button, the pump will stop.

Pump is operating

Pump has been stopped by

one of the following:

• a sensor

• an external on/off switch

• a stop command from the

Grundfos GO

Pump has been stopped by

means of the On/Off button*

CU 300 is communicating

with the Grundfos GO

English (GB)

TM01 2829 4601

3

Page 4

3. Mechanical installation

104.5

104.5

100

140.5

English (GB)

Warning

Before starting any work on CU 300,

make sure that the power supply has

been switched off and that it cannot be

accidentally switched on.

3.1 Location

You can place CU 300 both indoors and outdoors.

The control unit must not be exposed to direct

sunlight.

3.2 Mounting CU 300

CU 300 is designed for wall mounting.

The box has six mounting holes (∅4). See fig. 2. The

dimensions are in mm.

CU 300 must be mounted as follows:

• Horizontally to allow condensed water, if any, to

escape. See fig. 2.

• On a plane surface to avoid deformation of the

box.

Fig. 2

CU 300 is supplied with a set of gaskets for the Pg

screwed connections.

The gaskets are to be used for the connection of

cables or wires to ensure tight connections, IP55,

and cable relief.

4. CU 300 as an alarm unit

4.1 Description

When CU 300 is connected to an SQE pump, one of

the eight red indicator lights on CU 300 will indicate

any alarm.

The indications are based on signals from the motor

and from sensors, if installed. The individual alarms

are described in details in section 13. Alarm

functions.

You can connect an external alarm-signal transmitter

and an external on/off switch. See section

4.2 Electrical installation concerning connection, etc.

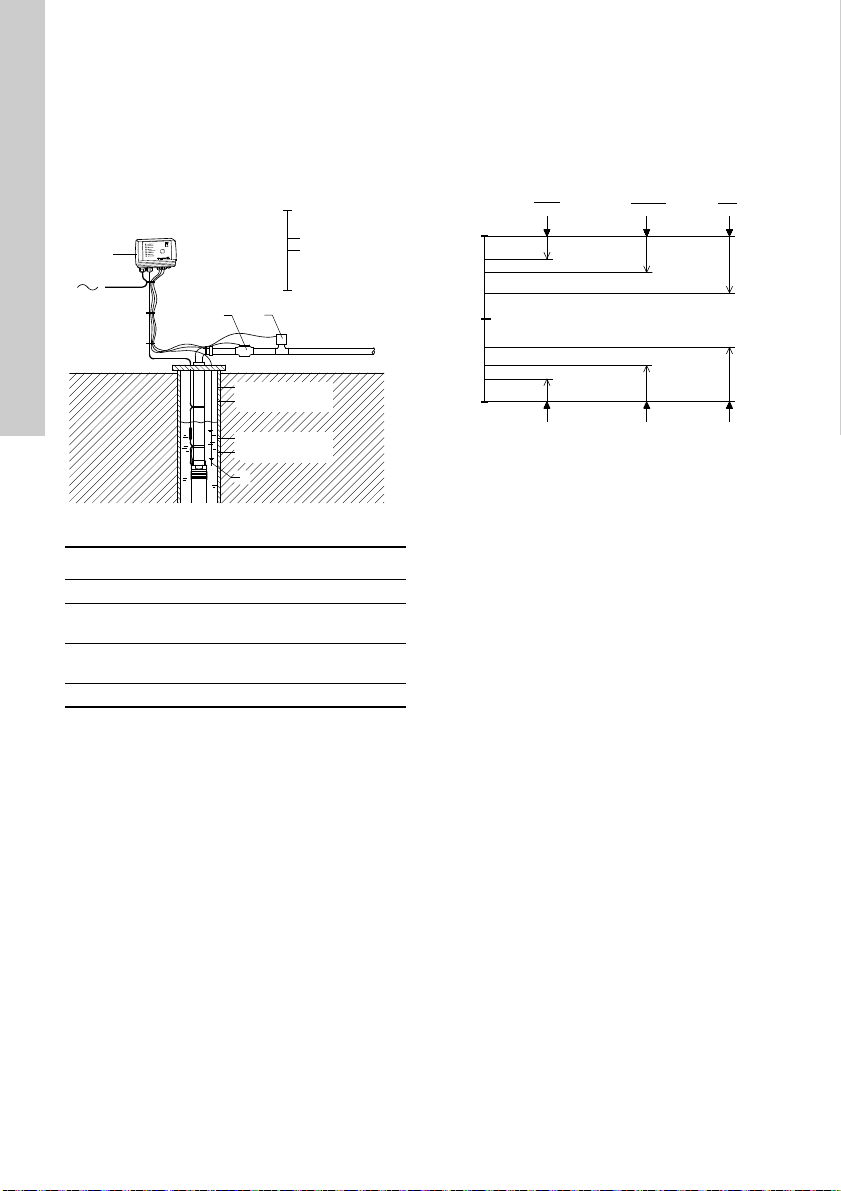

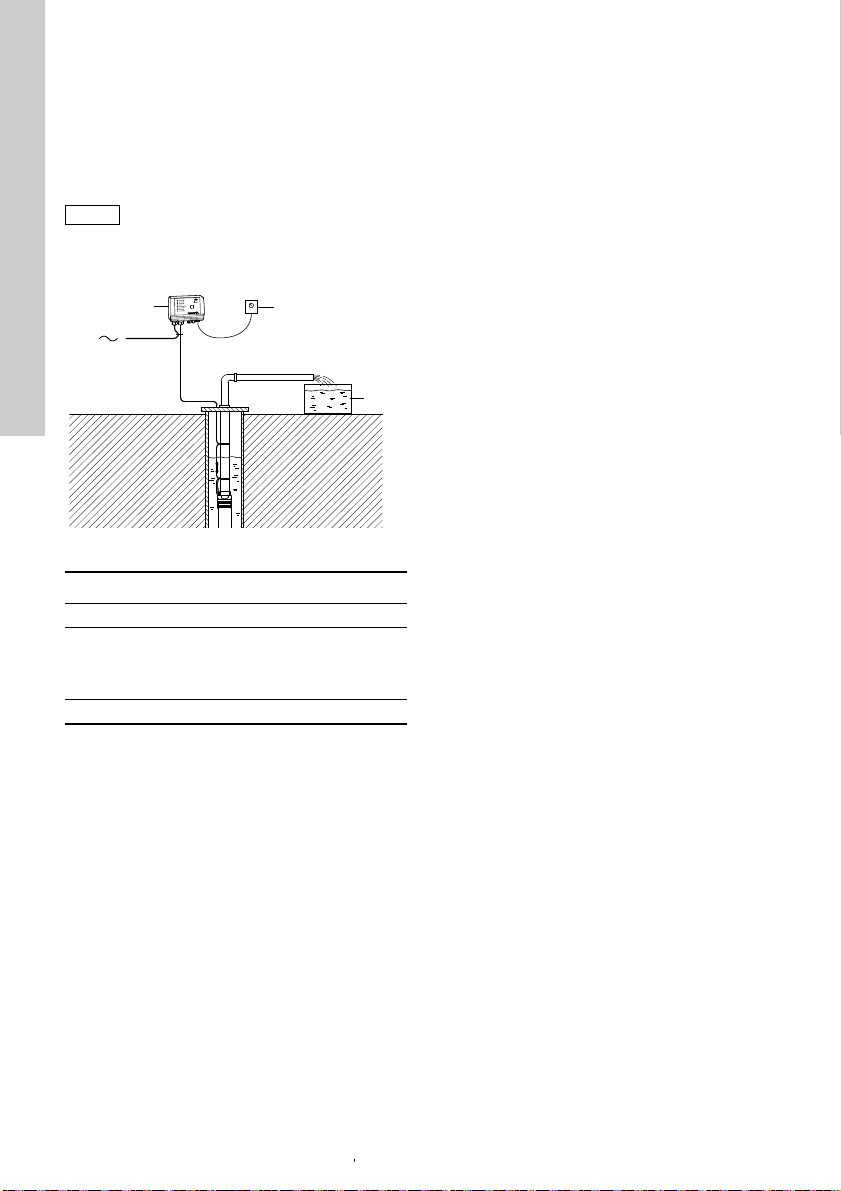

Figure 3 shows an example of an installation with CU

300 as an alarm unit.

Fig. 3

CU 300 functions as an alarm unit for the pump.

Furthermore, you can communicate with the pump

via the remote control Grundfos GO, see also

TM01 2824 2498

section 14. CU 300 with Grundfos GO.

TM01 3150 4601

4

Page 5

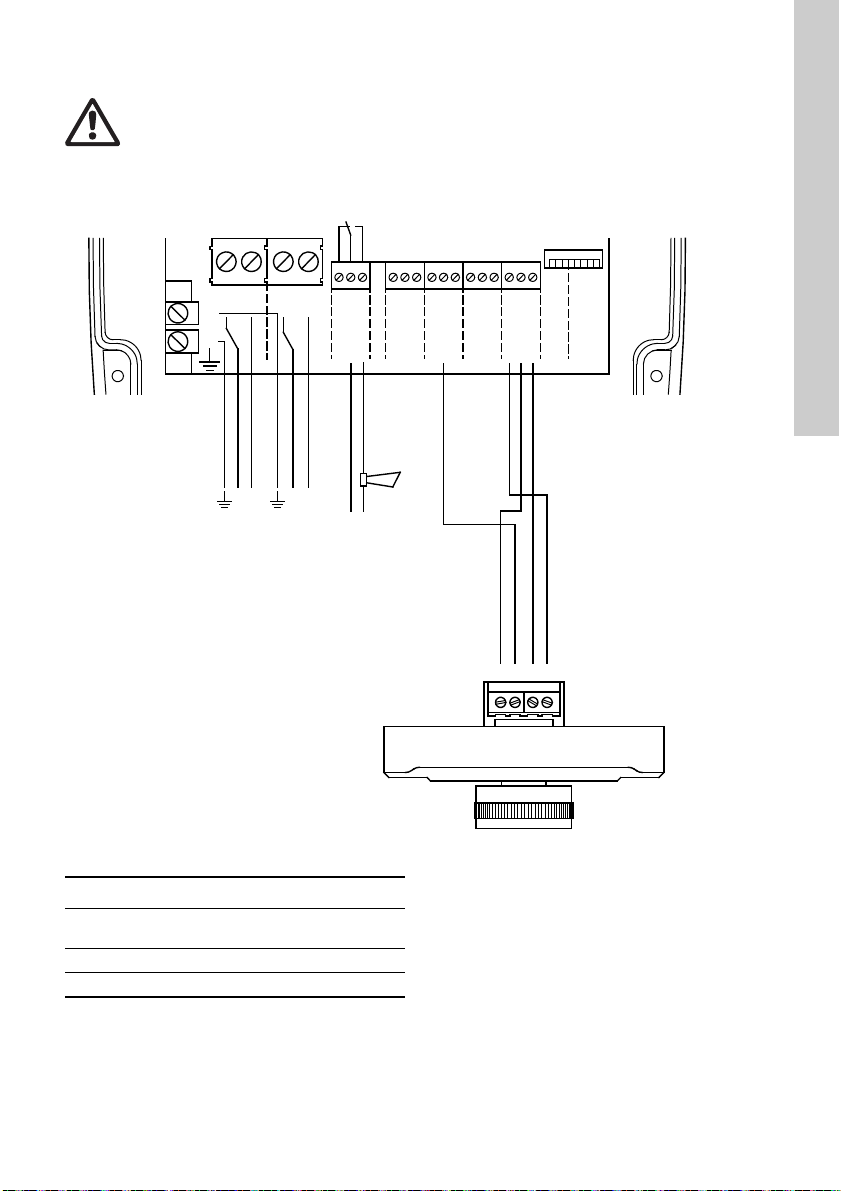

4.2 Electrical installation

K1

POWER

PE

PUMP

RELAY

ALARM

COM

NC

NO

NONCCOM

AUX

RELAY

IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

567

12

1098

34

111213 161514 171819

PE

TXD

LNLN

H

S1

Note

Warning

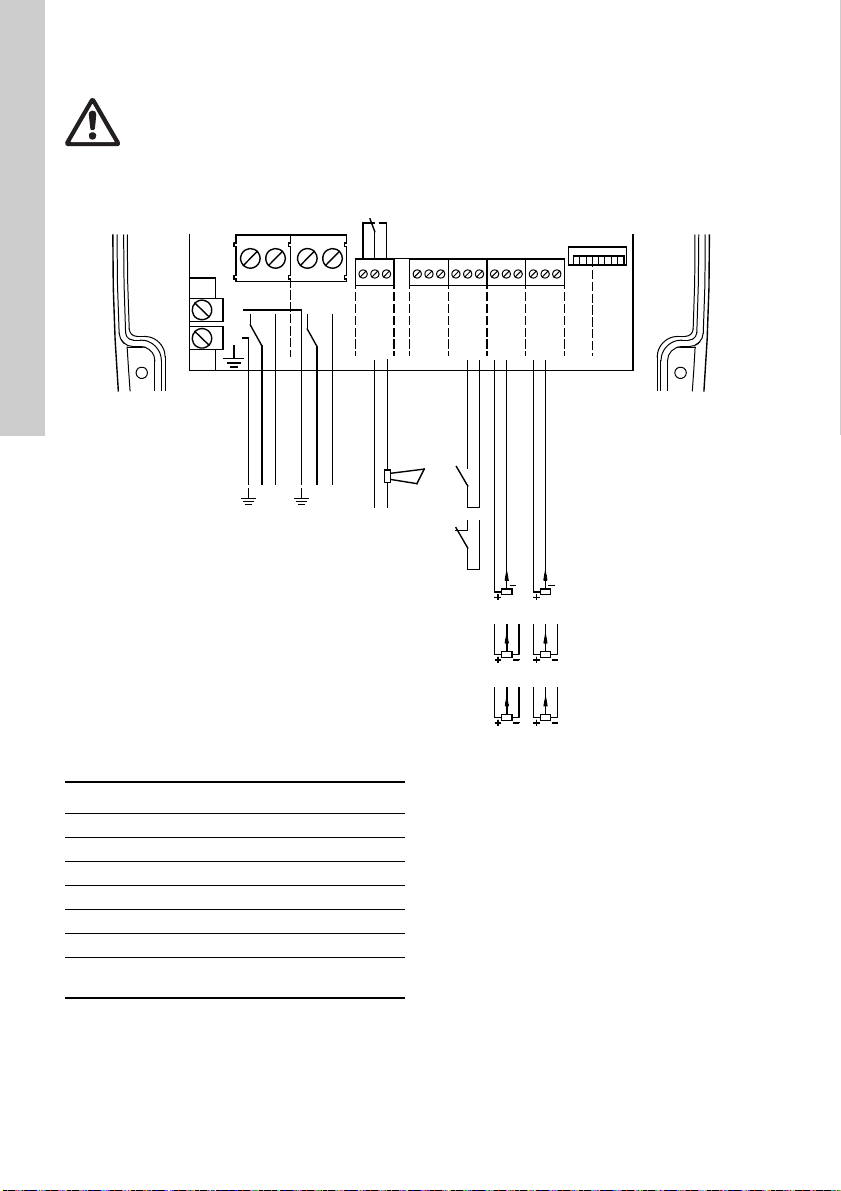

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

Fig. 4

Pos. Description

S1 On/off switch for start or stop of pump

H Alarm signal transmitter (optional)

Internal alarm signal relay

K1

Relay data: 250 VAC, 1 A, AC1

4.2.1 Mains supply

POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. You can connect each

terminal to any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

The maximum cross-section of the leads to be

connected is 6 mm

Backup fuse: Maximum 16 A.

2

.

You must not connect the leads of the

mains supply to terminals 3 and 4.

English (GB)

TM01 3067 3398

5

Page 6

4.2.2 Pump supply

Note

3000 min-1Max. speed

-1000 min

-1

Max.

speed as

set in

section

15.2.22

10,700 min

-1

Motor

speed

Watt

Pump power input

Pump power curve

Dry-running

power limit set

English (GB)

PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. You can connect each terminal to

any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

The maximum cross-section of the leads to be

connected is 6 mm

2

.

4.2.3 Alarm signal relay

ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay is activated when the alarm and warning

limits are exceeded.

You can select manual or automatic restarting in the

Grundfos GO display "Automatic restarting".

Manual restarting is carried out by means of the On/

Off button on CU 300.

4.2.4 Digital input

DIG IN, terminals 11, 12 and 13

In fig. 4, the digital input is used to start and stop the

pump.

You can select the function of the digital input by

means of the Grundfos GO in the display "Digital

input".

4.3 Description of dry-running protection

When the pump sucks air, the pump power input

decreases.

If the pump power input falls below the dry-running

power limit set in the Grundfos GO display "Dryrunning stop", the pump will stop and CU 300 will

indicate the dry-running alarm.

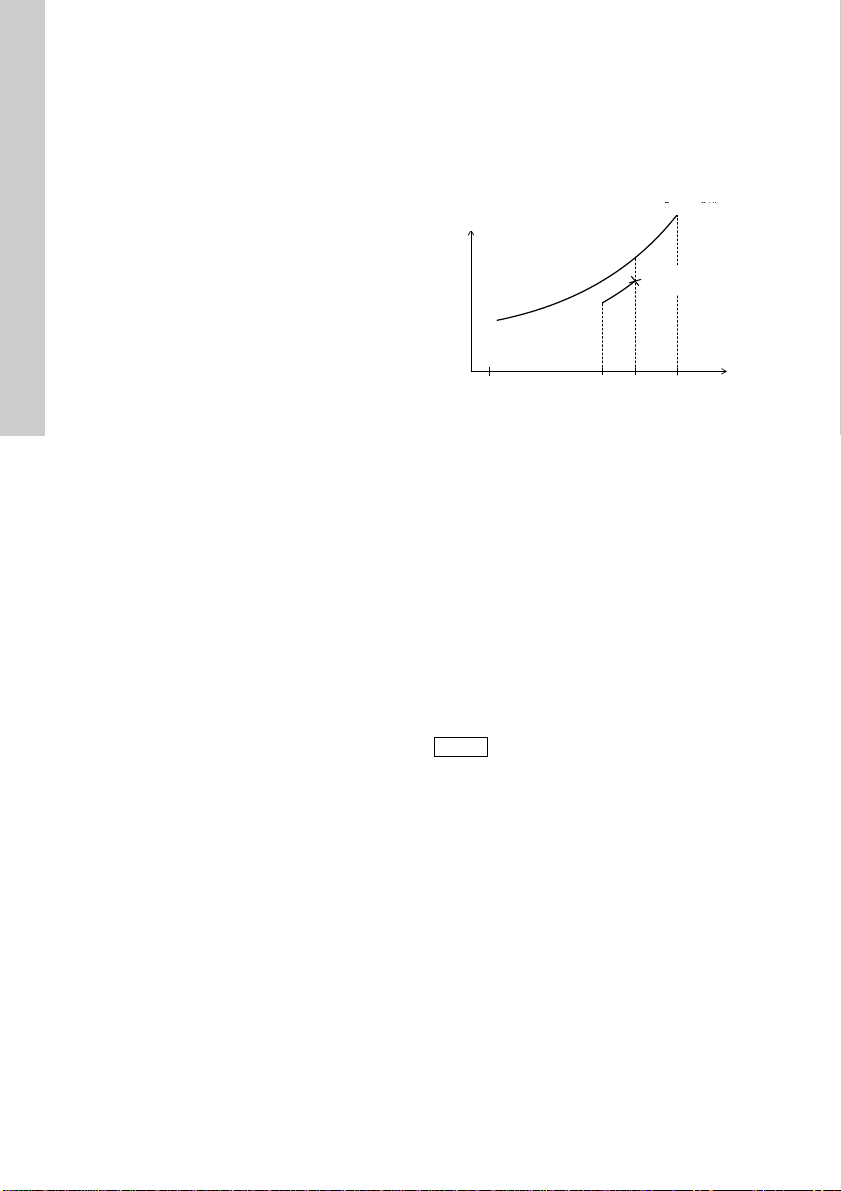

4.3.1 Function

The dry-running protection applies only if the motor

speed lies within the maximum speed range (i.e.

maximum speed less than 1000 min

Normally, maximum speed is 10,700 min

you can reduce the maximum speed in the Grundfos

GO display "Maximum speed". The dry-running

power limit set in the display "Dry-running stop" must

match the speed.

Changing the setpoint:

If you use the Grundfos GO display "Setpoint" or

"External setpoint" to change the setpoint, the pump

can be forced to run at a reduced speed in relation to

the maximum speed. The dry-running protection will

not protect the pump if the reduced speed lies

outside the maximum speed range (i.e. maximum

speed less 1000 min

6

-1

). See fig. 5.

-1

). See fig. 5.

-1

. However,

Constant-pressure control

In constant-pressure control mode, the dry-running

protection is active, as the motor will operate at

maximum speed in connection with dry running.

Pump power input curve

The curve shows the pump power input in relation to

the pump speed.

Fig. 5

4.4 Settings

For a detailed description of the Grundfos GO

displays, see section 14. CU 300 with Grundfos GO.

4.4.1 Required Grundfos GO settings

If the maximum speed of the pump has been

reduced by more than 1000 min

stop value must be changed. In order to change the

dry-running protection function, you must make the

following Grundfos GO settings.

1. Set "Dry-running protection" to "Active".

In certain installations, it may be

necessary to disable the dry-running

protection. The disabling applies to the

dry-running power limit set in the

display 15.2.21 Dry-running stop. See

fig. 5.

Set the dry-running power limit in the display

15.2.21 Dry-running stop by following the

procedure below:

– Start the pump against a closed discharge

pipe.

– Read the input power (P1) in the display

15.1.9 Power consumption.

– Calculate the dry-running power limit: P1 x 0.9

[W].

– Set this value in the display 15.2.21 Dry-

running stop.

-1

, the dry-running

TM01 2689 2598

Page 7

4.5 Description of the dewatering function

Note

35

1

125

60

60

Off time [minutes]

On time [minutes]

When the pump sucks air, the pump power input

decreases.

If the pump power input falls below the dry-running

power limit set in the display 15.2.21 Dry-running

stop, the pump will stop.

During dewatering, the green indicator light in the

On/Off button on CU 300 is flashing to indicate that

the pump has stopped.

4.5.1 Applications

You can use the dewatering function in applications

where the pump often runs dry, e.g.:

• In boreholes with a low yield.

• In boreholes and building sites where the water

table should be lowered.

4.5.2 Function

The dewatering function works as follows:

1. The pump is operating.

2. The pump sucks air due to a drop in the water

level.

3. The load decreases, and consequently the pump

power input does as well.

4. The pump stops when the power input falls to the

dry-running power limit set in the Grundfos GO

display 15.2.21 Dry-running stop.

The length of the stop time depends on

the setting you have made in the

Grundfos GO display "Dewatering max

off time". See section

15.2.19 Dewatering, maximum "On"

and "Off" time.

4.5.3 Required Grundfos GO settings

In order to activate the dewatering function, you

must make the following Grundfos GO settings:

1. Set "Dry-running protection" to "Active".

2. Set the dry-running power limit, i.e. dry-running

stop. See "Setting of dry-running power limit (dryrunning stop)" below.

3. Set the relation between run and stop times.

Indication of operation:

The dry-running alarm indication on CU 300 is

automatically disabled, when you make the

setting in the display 15.2.19 Dewatering,

maximum "On" and "Off" time.

To disable the dewatering function and return to

dry-running protection, simply disable the

"Dewatering" function in the display

15.2.18 Dewatering.

Setting of dry-running power limit (dr y-running

stop):

1. Start the pump against a closed discharge pipe.

2. Read the input power (P1) in the display

15.1.9 Power consumption.

3. Calculate the dry-running power limit: P1 x 0.9

[W].

4. Set this value in the display 15.2.21 Dry-running

stop.

4.5.4 On/off times

The dewatering function means that there is a

dependence between the period of time during which

the pump is running, the on time, and the period of

time during which the pump is stopped, the off time.

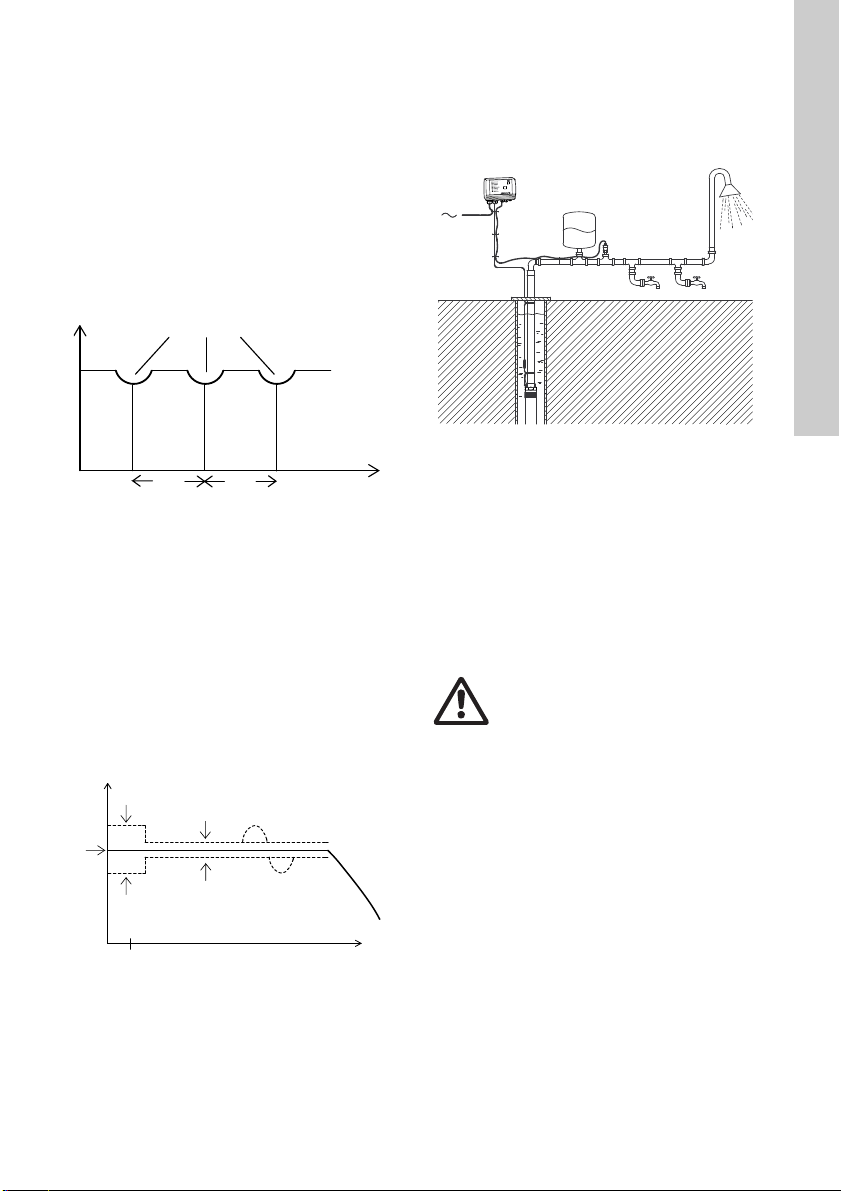

Figure 6 shows an example of on and off times set in

the display 15.2.19 Dewatering, maximum "On" and

"Off" time.

Fig. 6

Explanation:

The on and off times are set to 60 minutes each. The

pump has been running for 25 minutes when dry

running occurs. The pump will be stopped for 35

minutes. If the pump has been running for e.g. 120

minutes, the stop time will be 1 minute.

English (GB)

TM06 3501 0415

7

Page 8

5. CU 300 with constant-pressure

Note

Note

Pressure

Low flow

High flow

Time

English (GB)

control - 0 to 6 bar

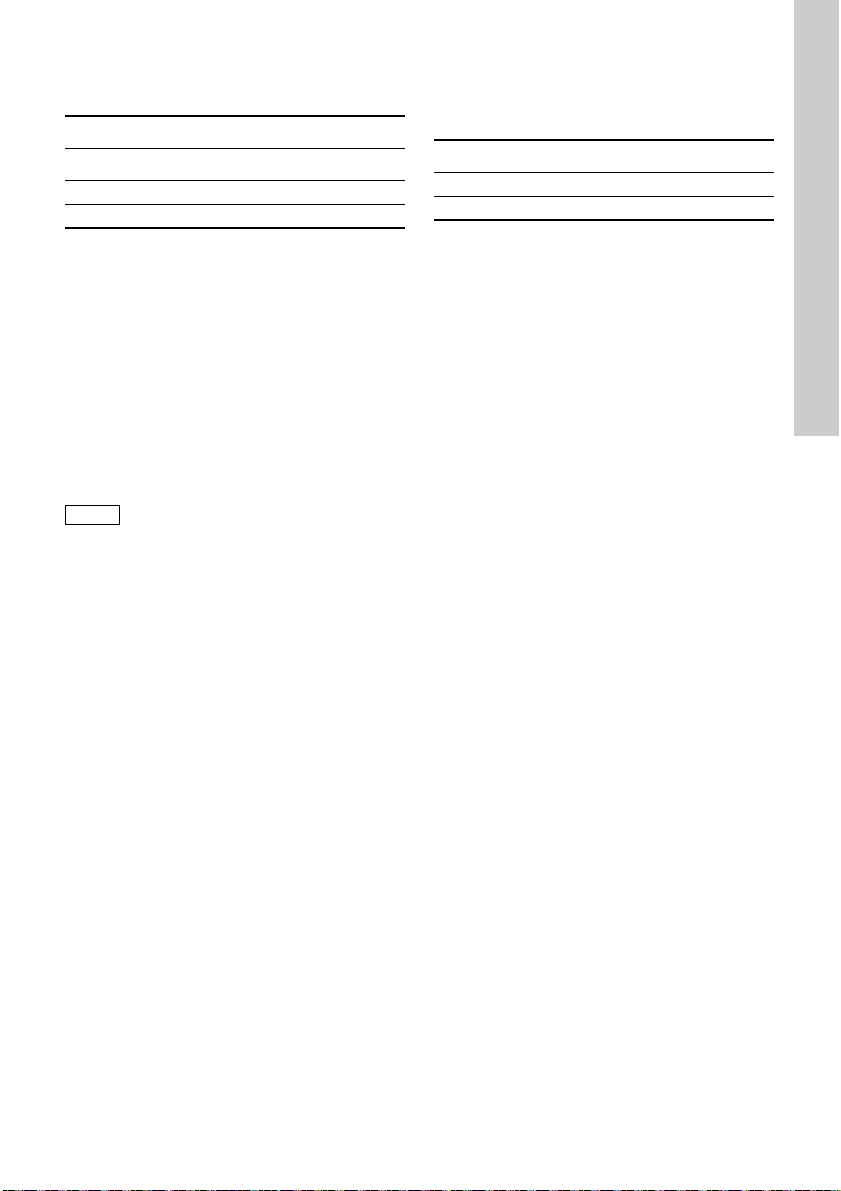

5.1 Description

Using constant-pressure control enables automatic

adjustment of the pump performance according to

consumption. The system maintains a constant

pressure within the maximum pump performance in

spite of a varying water consumption.

Figure 7 shows an example of an installation with

constant-pressure control within the range from 0 to

6 bar.

Fig. 7

Pos. Description

1CU 300

Diaphragm tank

2

Absorbs pressure variations.

Pressure sensor

3

The required pressure is set using the

Grundfos GO.

5.2 Function

The pressure is registered by means of the pressure

sensor, which transmits a signal to CU 300. CU 300

adjusts the pump performance accordingly by

changing the pump speed.

Mains borne signalling

The communication between CU 300 and the pump

is effected via the power supply cable.

This communication principle is called mains borne

signalling or power line communication. Using this

principle means that no additional cables to the

pump are required.

The communication of data is effected by means of a

high-frequency signal transmitted to the power

supply cable and led into the electronics unit by

means of signal coils incorporated in the motor and

CU 300 respectively.

When does the pump start?

The pump starts as a consequence of:

•high flow

• low pressure

• a combination of both.

To ensure that the pump is started when water is

consumed, a flow detection is required. The flow is

detected via pressure changes in the system. When

water is consumed, the pressure will drop

accordingly depending on the size of the diaphragm

tank and the water flow:

• At a low flow, the pressure will drop slowly.

• At a high flow, the pressure will drop quickly.

See fig. 8.

TM01 9649 4601

Fig. 8

When the pressure is dropping 0.1 bar/

s or faster, the pump will start

immediately.

If you use a diaphragm tank of 8 litres, the pump will

start at a flow rate of approx. 0.18 m

If a you use a larger tank, the flow must

be higher before the pump starts.

Consumption up to 0.18 m

The pump will start when the pressure has dropped

to 0.5 bar below the pressure setting.

The pump will run until the pressure is 0.5 bar above

the pressure set.

3

/h.

3

/h

TM01 8545 0400

8

Page 9

Flow detection

Pressure

Flow detection

Time10 s 10 s

A

Stop

Star t

Pressure

Controlling

Dynamic

variation

Flow

m

3

/h

0.18

12

8 l

CU 300

During pump operation, i.e. when water is

consumed, CU 300 will adjust the pump speed to

maintain a constant pressure. In order to stop the

pump when no water is consumed, CU 300 performs

flow detection every 10 seconds.

The pump speed is reduced until a small pressure

drop is registered. This pressure drop indicates that

water is consumed and the pump speed is resumed.

See fig. 9.

If the pump speed can be reduced without any

pressure drop being registered, this indicates that no

water is consumed. The diaphragm tank will be filled

with water and the pump will be stopped.

Fig. 9

System limits

Even though CU 300 is controlling the pressure

within ± 0.2 bar, bigger pressure variations may

occur in the system.

If the consumption is suddenly changed, e.g. if a tap

is opened, the water must start flowing before the

pressure can be made constant again. Such dynamic

variations depend on the pipework, but, typically,

they will lie between 0.5 and 1 bar.

If the desired consumption is higher than the quantity

the pump is able to deliver at the desired pressure,

the pressure follows the pump curve as illustrated in

fig. 10.

5.3 Positioning the pressure sensor

Pressure loss often causes inconvenience to the

user. CU 300 keeps the pressure constant in the

place where the pressure sensor is positioned. See

fig. 11.

Fig. 11

In fig.11, tap 1 is placed close to the pressure

sensor. Therefore, the pressure will be kept nearly

TM01 8546 0400TM01 8634 0500

constant at tap 1, as the friction loss is small. At the

shower and tap 2, the friction loss is bigger. This, of

course, depends on the piping. However, old and

furred-up piping may cause inconvenience due to

friction loss.

Therefore, we recommend that you position the

pressure sensor as close to the places of

consumption as possible.

5.4 System sizing

Warning

The installation must be designed for

the maximum pump pressure.

In normal installations with CU 300 and an SQE

pump set to constant-pressure control, the required

tank size is 8 litres. You can use bigger tanks without

causing any problems.

English (GB)

TM01 9670 4601

Fig. 10

A = Required pressure

9

Page 10

5.5 Electrical installation

K1

POWER

PE

PUMP

RELAY

ALARM

COM

NC

NO

NONCCOM

AUX

RELAY

IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

567

12

1098

34

111213 161514 171819

PE

TXD

LNLN

H

1

3

2

4

English (GB)

Warning

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

Fig. 12

Pos. Description

1 Pressure sensor, brown lead, terminal 14

2 Pressure sensor, black lead, terminal 15

3 Pressure sensor, screen, terminal GND

Pressure sensor

4

Must be connected to analog input 1.

H Alarm signal transmitter (optional).

Internal alarm signal relay

K1

Relay data: 250 VAC, 1 A, AC1

10

TM01 9650 2400

Page 11

5.5.1 Mains supply

Note

POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. You can connect each

terminal to any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

Backup fuse: Maximum 16 A.

You must not connect the leads of the

mains supply to terminals 3 and 4.

5.5.2 Pump supply PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. You can connect each terminal to

any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

5.5.3 Alarm signal relay ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay operates when the alarm and warning

limits are exceeded.

You can select manual or automatic restarting in the

Grundfos GO display "Automatic restarting".

Manual restarting is carried out by means of the On/

Off button on CU 300.

5.5.4 Required Grundfos GO settings

You must make the following Grundfos GO settings:

1. In display "Control mode" select "Closed loop".

2. Set the sensor in the "Analog input 1" or "Analog

input 2" display.

Example:

– sensor output signal (4-20 mA)

– setting range unit (m)

– setting range - head

min.: 0.0

max.: 40

3. Set the stop type in the "Stop type, sensor 1"

display.

– "Fill".

4. Set the digital input.

– "Not active"

5. Set the setpoint

Example: Desired head 35 m.

Rule: The maximum setting of the setpoint

corresponds to the maximum value set in display

15.2.4 Analog inputs less 5 m.

In this case, 40 less 5 = 35 m.

5.6 Startup

Prior to startup, the precharge pressure of the

diaphragm tank must be set to 70 % of the setpoint

set in the Grundfos GO display "Setpoint".

English (GB)

11

Page 12

6. CU 300 with constant-pressure

1

2

3

4

A

Stop (+ 0.5 bar)

Star t

(- 0.5 bar)

Pressure

Controlling

(± 0.2 bar)

Dynamic

(± 0.5 bar)

Flow

m

3

/h

0.18

English (GB)

control - 0 to 10 bar

6.1 Description

Using constant-pressure control enables automatic

adjustment of the pump performance according to

consumption. The system maintains a constant

pressure within the maximum pump performance in

spite of a varying water consumption.

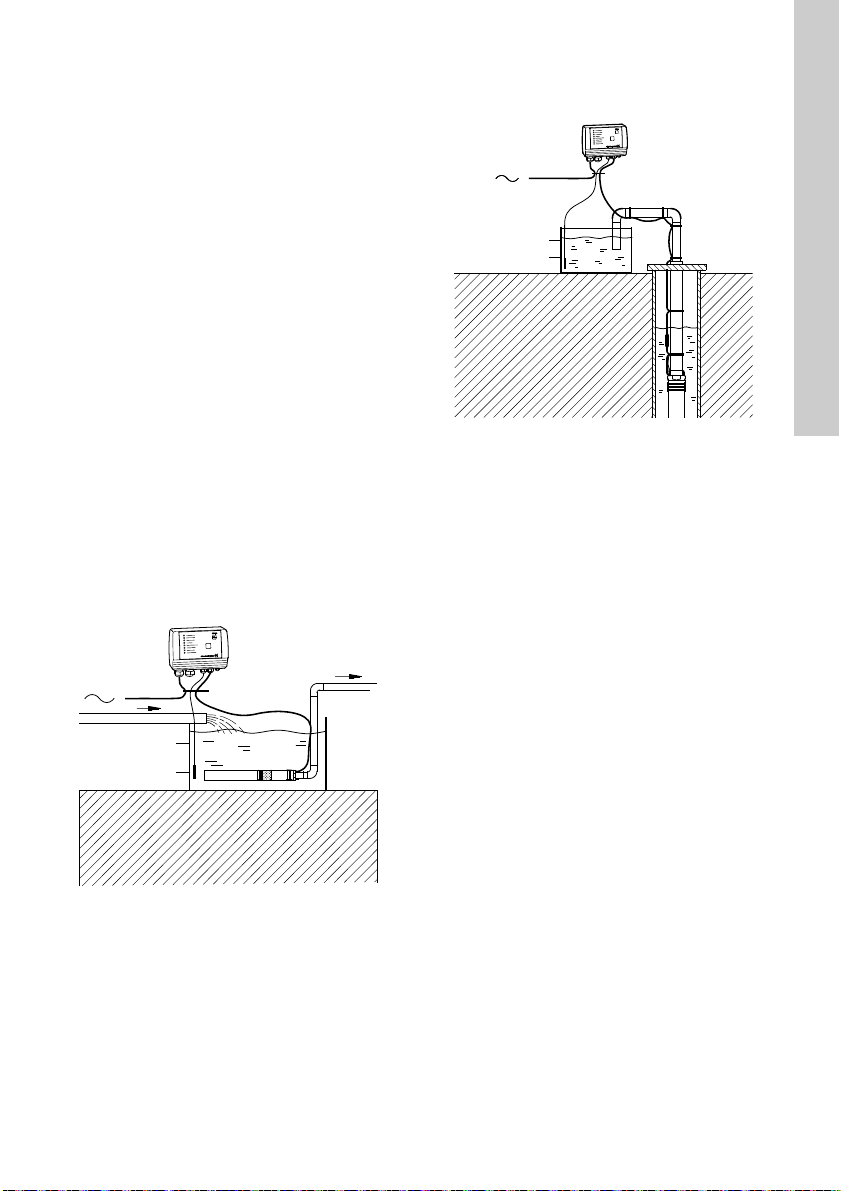

Figure 13 shows an example of an installation with

constant-pressure control within the range from 0 to

10 bar.

Fig. 13

Pos. Description

1CU 300

Diaphragm tank

2

Absorbs pressure variations.

Flow switch

3

The pump starts at once when water is

consumed at the taps.

Pressure sensor

4

The required pressure is set using the

Grundfos GO.

6.2 Function

The pressure is registered by means of the pressure

sensor and transmitted to CU 300. CU 300 adjusts

the pump performance accordingly. To ensure that

the pump is started when water is consumed, include

a flow switch in the system.

The required pressure (setpoint) is set in the

Grundfos GO display "Setpoint".

• Consumption up to 0.18 m

The flow switch contact is open.

The pump starts when the pressure is equal to

the setpoint less 0.5 bar. The pump will fill the

tank and stop when the pressure is equal to the

setpoint plus 0.5 bar. Consequently, the pump

runs on/off operation.

• Consumption above 0.18 m

The flow switch contact is closed.

The pump starts when the flow switch contact

closes and the speed control ensures that the

pressure is kept constant. If the flow is below

3

/h and the flow switch contact is opened,

0.18 m

the tank is filled to a pressure equal to the

setpoint plus 0.5 bar. When this pressure is

reached, the pump stops. Stopping is a

combination of the flow switch contact opening

and the pressure being equal to the setpoint plus

0.5 bar.

If the flow is larger than the quantity the pump is able

to deliver at the desired pressure, the pressure

follows the pump curve as illustrated in fig. 14.

TM01 2653 4601

Fig. 14

A = Required pressure

3

/h.

3

/h.

TM01 8634 0500

12

Page 13

6.3 Positioning the pressure sensor

1

2

CU 300

8 l

Pressure loss often causes inconvenience to the

user. CU 300 keeps the pressure constant in the

place where the pressure sensor is positioned. See

fig. 15.

Fig. 15

In fig. 15, tap 1 is placed close to the pressure

sensor. Therefore, the pressure will be kept nearly

constant at tap 1, as the friction loss is small. At the

shower and tap 2, the friction loss is bigger. This, of

course, depends on the piping. However, old and

furred-up piping may cause inconvenience due to

friction loss.

Therefore, we recommend that you position the

pressure sensor as close to the places of

consumption as possible.

6.4 System sizing

English (GB)

TM01 2834 4601

Warning

The installation must be designed for

the maximum pump pressure.

In normal installations with CU 300 and an SQE

pump set to constant-pressure control, the required

tank size is 8 litres. You can use bigger tanks without

causing any problems.

13

Page 14

6.5 Electrical installation

5

6

4

K1

POWER

PE

PUMP

RELAY

ALARM

COM

NC

NO

NONCCOM

AUX

RELAY

IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

567

12

1098

34

1112 13 161514 17 1819

PE

TXD

LNLN

H

1

3

2

English (GB)

Warning

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

Fig. 16

Pos. Description

1 Pressure sensor, brown lead, terminal 14

2 Pressure sensor, black lead, terminal 15

3 Pressure sensor, screen, terminal GND

Pressure sensor

4

Must be connected to analog input 1.

5 Diaphragm tank connection

Flow switch

Must be connected to the digital input,

6

terminals 12 and 13. Cannot be connected

wrongly.

H Alarm signal transmitter (optional)

Internal alarm signal relay

K1

Relay data: 250 VAC, 1 A, AC1

14

TM01 3089 3398

Page 15

6.5.1 Mains supply

Note

POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. You can connect each

terminal to any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

Backup fuse: Maximum 16 A.

You must not connect the leads of the

mains supply to terminals 3 and 4.

6.5.2 Pump supply PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. You can connect each terminal to

any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

6.5.3 Alarm signal relay ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay operates when the alarm and warning

limits are exceeded.

You can select manual or automatic restarting in the

Grundfos GO display "Automatic restarting".

Manual restarting is carried out by means of the On/

Off button on CU 300.

6.5.4 Required Grundfos GO settings

You must make the following Grundfos GO settings:

1. In display 15.2.2 Control mode" select "Closed

loop".

2. Set the sensor in the "Analog input 1" or "Analog

input 2" display.

Example:

– sensor output signal (4-20 mA)

– setting range unit (m)

– setting range - head

min.: 0.0

max.: 40.

3. Set the stop type in the "Stop type, sensor 1"

display.

– "Fill".

4. Set the digital input.

– "Not active"

5. Set the setpoint

Example: Desired head 35 m.

Rule: The maximum setting of the setpoint

corresponds to the maximum value set in display

"Analog input 1" less 5 m.

In this case, 40 less 5 = 35 m.

6.6 Startup

Prior to startup, the precharge pressure of the

diaphragm tank must be set to 70 % of the setpoint

set in the Grundfos GO display "Setpoint".

English (GB)

15

Page 16

7. CU 300 with constant-pressure

Note

1A

1B

2

3

4

English (GB)

control - two-pump operation

7.1 Description

Using constant-pressure control in connection with

two-pump operation enables automatic adjustment

of the pump performance according to the

consumption in systems where a high flow is

required. The system maintains a constant pressure

within the maximum pump performance in spite of a

varying water consumption.

During two-pump operation, the two

pumps must have the same nominal

flow, e.g. two SQE 2.

Figure 17 shows an example of a two-pump

installation with constant-pressure control.

Fig. 17

7.2 Function

The pressure is registered by means of the pressure

sensor and transmitted to CU 300 (master). CU 300

adjusts the pump speed to ensure that the pressure

is kept constant. To ensure that the pump connected

to CU 300 (master) is started when water is

consumed, a flow switch must be included in the

system.

Set CU 300 (master) to the desired pressure

(setpoint) in the Grundfos GO display "Setpoint".

• Consumption up to 0.18 m

The flow switch contact is open.

The pump connected to CU 300 (master) starts

when the pressure is equal to the setpoint less

0.5 bar. The pump will fill the tank and stop when

the pressure is equal to the setpoint plus 0.5 bar.

Consequently, the pump runs on/off operation.

• Consumption above 0.18 m

The flow switch contact is closed.

The pump connected to CU 300 (master) starts

when the flow switch contact closes and the

speed control ensures that the pressure is kept

constant.

If the flow is lower than 0.18 m

switch contact is opened, the tank is filled to a

pressure equal to the setpoint plus 0.5 bar. When

this pressure is reached, the pump stops.

Stopping is a combination of the flow switch

contact opening and the pressure being equal to

the setpoint plus 0.5 bar.

If the consumption exceeds the quantity the

pump connected to CU 300 (master) is able to

deliver, the pressure in the diaphragm tank will

fall.

TM01 2654 4601

3

/h.

3

/h.

3

/h and the flow

Pos. Description

1A, 1B

1A = CU 300 (master)

1B = CU 300 (slave)

Diaphragm tank, minimum 24 litres

2

Absorbs pressure variations.

Flow switch

3

The pump starts at once when water is

consumed at the taps.

Pressure sensor

4

The required pressure is set using the

Grundfos GO.

16

Page 17

The pump connected to CU 300 (slave) will be

A

Stop (+ 0.5 bar)

Start

(- 0.5 bar)

Pressure

Controlling

(± 0.2 bar)

Dynamic

(± 1.0 bar)

Flow

m

3

/h

0.18

started in the two following situations:

1. If the pressure in the diaphragm tank falls to 1

bar below the setpoint.

2. If the pump connected to CU 300 (master) has

been operating at maximum performance for

more than 5 seconds and the water requirement

has increased.

The pump connected to CU 300 (slave) will be

stopped in the three following situations:

1. If the system pressure is 1 bar higher than the

setpoint.

2. If the pump connected to CU 300 (master) has

been operating at minimum performance for

more than 5 seconds and the water requirement

has fallen.

3. If the flow switch indicates "No flow" and the

system pressure is 0.5 bar higher than the

setpoint.

If the flow is larger than the quantity the pumps are

able to deliver at the desired pressure, the pressure

follows the pump curve. See fig. 18.

7.3 Positioning the pressure sensor

See section 6.3 Positioning the pressure sensor.

7.4 System sizing

Warning

The installation must be designed for

the maximum pump pressure.

In two-pump installations set for constant-pressure

control, the required tank size is 24 litres. You can

use bigger tanks without any problems.

English (GB)

A = Required pressure

Fig. 18

TM01 8634 0500

17

Page 18

7.5 Electrical installation

K1

POWER

PE

PUMP

RELAY

ALARM

COM

NC

NO

NONCCOM

AUX

RELAY

IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

567

12

109834111213 161514 171819

PE

TXD

LNLN

1

3

2

NLNL

TXD

PE

191817141516131211438910

21

765

GND

RXD

DTRRIA

GND

B

232

RS

485

RS

GND

+24VDC

IN

SENSOR

21

SENSOR

IN

+24VDC

GND

GND

+24VDC

IN

DIG

IN

RELAY

AUX

COMNCNO

NO

NC

COM

ALARM

RELAY

PUMP

PE

POWER

A

B

5

6

4

D

C

5

4

7

English (GB)

Warning

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

Fig. 19

TM01 9671 2500

Pos. Description

A CU 300 (master)

B CU 300 (slave)

3

/h

3

/h

3

/h)

3

/h)

C Installation for Q < 5 m

D Installation for Q > 5 m

1 Pressure sensor, brown lead, terminal 14

2 Pressure sensor, black lead, terminal 15

3 Pressure sensor, screen, terminal GND

4

5 Diaphragm tank connection

6

7

K1

Pressure sensor

Must be connected to analog input 1.

Flow switch (Q < 5 m

Must be connected to the digital input,

terminals 12 and 13. Cannot be connected

wrongly.

Flow switch (Q > 5 m

Must be connected to the digital input,

terminals 12 and 13. Cannot be connected

wrongly.

Internal alarm signal relay

Relay data: 250 VAC, 1 A, AC1

18

Page 19

7.5.1 Auxiliary relay

Note

Connect CU 300 (master) to CU 300 (slave) as

follows:

Connections

CU 300 (master) CU 300 (slave)

Terminal 9 (COM) Terminal 12 (IN)

Terminal 10 (NO) Terminal 13 (GND)

See fig. 19.

7.5.2 Mains supply

POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. See fig. 19.

You can connect each terminal to any of the two

leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

Backup fuse: Maximum 16 A.

You must not connect the leads of the

mains supply to terminals 3 and 4.

7.5.3 Pump supply

PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. See fig. 19.

You can connect each terminal to any of the two

leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

7.5.4 Alarm signal relay

ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay operates when the alarm and warning

limits are exceeded.

You can select manual or automatic restarting in the

Grundfos GO display "Automatic restarting".

Manual restarting is carried out by means of the On/

Off button on CU 300.

7.5.5 Flow switch and pressure sensor

Connect the flow switch and the pressure sensor to

the control unit (A = master) as illustrated in fig. 19.

Flow switch:

Pump type Product number

SQE 1 96037332

SQE 2, SQE 3, SQE 5, SQE 7 96037559

7.5.6 Required Grundfos GO settings

You must make the following Grundfos GO settings

on CU 300 (master):

1. In display "Control mode" select "Closed loop".

2. Set the sensor in the "Analog input 1" or "Analog

input 2" display.

Example:

– sensor output signal (4-20 mA)

– setting range unit (m)

– setting range - head

min.: 0.0

max.: 40.

3. Set the stop type in the "Stop type, sensor 1"

display.

– "Fill".

4. Set the digital input in "Digital input 1" display:

– "Start".

5. Set the setpoint

Example: Desired head 35 m.

Rule: The maximum setting of the setpoint

corresponds to the maximum value set in display

15.2.4 Analog inputs less 5 m.

In this case, 40 less 5 = 35 m.

You must make the following Grundfos GO setting on

CU 300 (slave):

6. Set the digital input in "Digital input 1" display:

– "Start"

7.6 Startup

Prior to startup, you must set the precharge pressure

of the diaphragm tank to 70 % of the setpoint set in

the Grundfos GO display "Setpoint".

English (GB)

19

Page 20

8. CU 300 with sensors

pH

100%

0

2

1

3

4

Alarm

Warning

Warning

Warning

Max. (start)

Min. (stop)

Max.

Max.

Max.

Min.

Min.

Min.

Status

100%

Sensor signal

0

Stop

Warning

Alarm

English (GB)

8.1 General

CU 300 can be used in systems with one to three

sensors connected.

Figure 20 shows an example of an installation

incorporating sensors.

Fig. 20

Pos. Description

1 CU 300

pH sensor

2

Detects the water quality.

Pulse flow meter

3

Detects the water quantity.

4 Level sensor

You can set the alarm, warning and stop limits

individually for all sensors connected. The limit

settings do not influence each other, and each

setting offers its own functioning.

Figure 21 shows a schematic presentation of the

setting of maximum and minimum limits for alarm,

warning and stop respectively.

Fig. 21

You must only set the limits applying to the selected

sensor.

TM01 2672 4601

These settings are made in the displays

15.2.4 Analog inputs and 15.2.5 Limits, sensor 1 and

2 to 15.2.5 Limits, sensor 1 and 2.

TM01 2697 2298

20

Page 21

8.2 Sensor functioning

Max. (start)

Min. (stop)

Max. (stop)

Min. (start)

8.2.1 Alarm limits

When an alarm limit is exceeded, the following takes

place:

1. The pump is stopped.

2. The alarm signal relay operates.

3. The "Sensor alarm" indicator light on CU 300 is

on.

4. The alarm appears in the Grundfos GO display

"Alarms and warnings".

If the pump has stopped already or if the alarm

signal relay has operated, this condition is

maintained.

8.2.2 Warning limits

When a warning limit is exceeded, the following

takes place:

1. The alarm signal relay operates.

2. Pump operation is continued. No "Sensor alarm"

indication.

3. The warning appears in the Grundfos GO display

"Alarms and warnings".

8.2.3 Start and stop limits

Start and stop limits must be used in connection with

the emptying and filling of e.g. water tanks.

The start and stop function depends on the

application, i.e. emptying or filling.

• Emptying means that the pump must start at a

given maximum water level and stop at a given

minimum water level. See fig. 22.

• Filling means that the pump must start at a given

minimum water level and stop at a given

maximum water level. See fig. 23.

Fig. 23

English (GB)

TM01 2699 4601

Fig. 22

TM01 2700 4601

21

Page 22

8.3 Electrical installation

K1

POWER

PE

PUMP

RELAY

ALARM

COM

NC

NO

NONCCOM

AUX

RELAY

IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

567

12

1098

34

111213 161514 171819

PE

TXD

LNLN

H

D1

4-20 mA

D1

A1

A2

0-20 mA

0-10V/2-10V

A3

English (GB)

Warning

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

Fig. 24

Pos. Description

A1 Analog sensor, output signal 4-20 mA

A2 Analog sensor, output signal 0-20 mA

A3 Analog sensor, output signal 0-10/2-10 V

D1 Digital sensor, NO (normally open)

D1 Digital sensor, NC (normally closed)

H Alarm signal transmitter (optional)

Internal alarm signal relay

K1

Relay data: 250 VAC, 1 A, AC1

22

TM01 3088 2500

Page 23

8.3.1 Mains supply

Note

POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. You can connect each

terminal to any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

Backup fuse: Maximum 16 A.

You must not connect the leads of the

mains supply to terminals 3 and 4.

8.3.2 Pump supply PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. You can connect each terminal to

any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

8.3.3 Alarm signal relay ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay operates when the alarm and warning

limits are exceeded.

You can select manual or automatic restarting in the

Grundfos GO display "Automatic restarting".

Manual restarting is carried out by means of the On/

Off button on CU 300.

8.3.4 Sensors

SENSOR 1 and SENSOR 2, terminals 14, 15, 16,

17, 18 and 19:

Terminals 14, 15 and 16 (SENSOR 1) and terminals

17, 18 and 19 (SENSOR 2) are used for external

sensors, e.g. a pressure gauge, a flow meter or

another type of sensor.

You set the limits for the signal from an external

sensor in the Grundfos GO in the "Analog input 1"

and "Analog input 2" displays.

You can use the signal to do the following:

• To start and stop the motor.

• To operate the alarm signal relay, without

stopping the motor.

The sensors must give signals within the ranges

0-20 or 4-20 mA, 0-10 or 2-10 VDC. Changeover

between current and voltage signals is carried out by

means of the Grundfos GO.

The total load of terminals 11, 14 and 17 (+24 VDC)

must not exceed 100 mA.

8.3.5 Required Grundfos GO settings

You must make the following Grundfos GO settings:

1. Set "Analog input 1".

– sensor output signal (4-20 mA)

– setting range unit (m)

– setting range - head min.: 0.0

max.: 50.

2. Set "Analog input 2" to "Not active".

3. Set the minimum stop value for sensor 1 in

display "Min. stop value, sensor 1".

4. Set the maximum stop value for sensor 1 in

display "Max. stop value, sensor 1".

5. Set the "Warning limits" and "Alarm limits" for

sensor 1 in display "Limits, sensor 1".

6. Set the desired stop type in display "Stop type,

sensor 1:

Example:

– "Fill".

English (GB)

23

Page 24

9. CU 300 connected to potentiometer

Note

1

2

3

English (GB)

9.1 Description

Using an external potentiometer enables:

• Manual control of the motor speed, and thereby

of pump performance.

Manual starting/stopping of the pump.

To stop the pump, turn the

potentiometer (SPP 1) to "STOP".

Figure 25 shows an example of an installation with a

potentiometer.

Fig. 25

Pos. Description

1CU 300

External Grundfos potentiometer, SPP 1

The required flow is obtained by changing

2

the motor speed manually using the

external potentiometer.

3 Water tank

TM01 2660 4601

24

Page 25

9.2 Electrical installation

K1

POWER

PE

PUMP

RELAY

ALARM

COM

NC

NO

NONCCOM

AUX

RELAY

IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

567

12

1098

34

111213 161514 171819

PE

TXD

LNLN

H

4

3

21

SPP 1

SENSOR IN

GND

DIG IN

+24 VDC

Warning

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

English (GB)

Fig. 26

Pos. Description

Internal alarm signal relay

K1

Relay data: 250 VAC, 1 A, AC1

H Alarm signal transmitter (optional)

SPP 1 External Grundfos potentiometer, SPP 1

TM01 3091 3398

25

Page 26

9.2.1 Mains supply

Note

1

2

English (GB)

POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. You can connect each

terminal to any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

Backup fuse: Maximum 16 A.

You must not connect the leads of the

mains supply to terminals 3 and 4.

9.2.2 Pump supply

PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. You can connect each terminal to

any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

9.2.3 Alarm signal relay

ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay operates when the alarm and warning

limits are exceeded.

You can select manual or automatic restarting in the

Grundfos GO display "Automatic restarting".

Manual restarting is carried out by means of the On/

Off button on CU 300.

9.2.4 Potentiometer SPP 1

Connections between the SPP 1 and CU 300:

9.2.5 Required Grundfos GO settings

You must make the following Grundfos GO settings:

1. In display "Control mode" select "Open loop".

2. Set the external setpoint to "SPP 1", enabling

speed control using the SPP 1. "Analog input 2"

is set to "SPP 1".

3. Set "Digital input 1" to "Start"

10. CU 300 connected to water meter

10.1 Description

Using a water meter (pulse flow meter) enables:

• Monitoring of the flow.

• Stop of pump after a given quantity of water has

been pumped.

• Indication of accumulated flow and the energy

consumption required to pump 1 m

Figure 27 shows an example of an irrigation system

incorporating a water meter.

Fig. 27

Pos. Description

1CU 300

2 Water meter (pulse flow meter)

3

.

TM01 2659 4601

SPP 1 CU 300

1 17 (SENSOR 2 +24 VDC)

2 19 (SENSOR 2 GND)

3 12 (DIG IN)

4 18 (SENSOR 2 IN)

26

Page 27

10.2 Electrical installation

D1

K1

POWER

PE

PUMP

RELAY

ALARM

COM

NC

NO

NONCCOM

AUX

RELAY

IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

567

12

1098

34

111213 161514 171819

PE

TXD

LNLN

H

Note

Warning

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

Fig. 28

English (GB)

TM01 6223 1899

Pos. Description

D1 Water meter (pulse flow meter)

H Alarm signal transmitter (optional)

Internal alarm signal relay

K1

Relay data: 250 VAC, 1 A, AC1

10.2.1 Mains supply POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. You can connect each

terminal to any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

is 6 mm

2

.

Backup fuse: Maximum 16 A.

You must not connect the leads of the

mains supply to terminals 3 and 4.

27

Page 28

10.2.2 Pump supply

1

2

Warning

Desired level

Warning

English (GB)

PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. You can connect each terminal to

any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

10.2.3 Alarm signal relay ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay operates when the alarm and warning

limits are exceeded.

You can select manual or automatic restarting in the

Grundfos GO display "Automatic restarting".

Manual restarting is carried out by means of the On/

Off button on CU 300.

10.2.4 Water meter (pulse flow meter) DIG IN, terminals 12 and 13

Connect terminals 12 and 13 to the water meter:

• Terminal 12 IN (signal input).

• Terminal 13 GND (earth).

10.2.5 Required Grundfos GO settings

You must make the following Grundfos GO settings:

1. Set "Digital input 1".

– Function: "Pulse-flow meas."

2. Set "Flow per pulse":

Example: "10 l/pulse".

When you have set a value in this display, the actual

flow will appear in status display "Digital input".

You must only set a value in the display "Stop limit,

accum. flow" if stop of pump after a given quantity of

water has been pumped is required.

Example:

• Stop limit, accum. flow: "7.5 m

3

".

• Sensor, accum. flow stop: "Digital input".

When you have set a value in this display, the

"Accumulated flow" and "Energy per m

in the status displays "Accumulated flow" and

"Specific energy".

3

" will appear

11. Constant water level

11.1 Description

The water level can be kept constant by connecting

an analog level sensor.

Figure 29 shows an example of an installation

designed for maintaining a constant water level in

the borehole.

Fig. 29

Pos. Description

1CU 300

2 Level sensor

11.2 Function

CU 300 controls the pump speed and consequently

adjusts the pump performance to the borehole yield.

1. When the water level is much higher than the

desired level (setpoint), the pump is running at

maximum performance.

2. When the level is coming closer to the desired

level, the pump performance will be reduced.

3. When the desired level is reached, the pump

speed will be so low that the pump performance

is zero. After further 60 seconds, the pump will

stop.

TM01 2671 4601

28

Page 29

11.3 Electrical installation

POWERPEPUMP

RELAY

ALARM

COMNCNO

NONCCOM

AUX

RELAY IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

A

RI

DTR

RXD

GND

567

12

1098

34

111213 161514 171819

PE

TXD

+24VDC

4-20 mA / IN

1

1

Warning

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

Fig. 30

English (GB)

TM01 6213 2400

Pos. Description

Connection of level sensor:

1

• Terminal 14, 24 VDC supply

• Terminal 15, signal input

29

Page 30

11.3.1 Mains supply

Note

English (GB)

POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. You can connect each

terminal to any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

Backup fuse: Maximum 16 A.

You must not connect the leads of the

mains supply to terminals 3 and 4.

11.3.2 Pump supply PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. You can connect each terminal to

any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

11.3.3 Alarm signal relay ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay operates when the alarm and warning

limits are exceeded. See section 15.2.5 Limits,

sensor 1 and 2.

11.3.4 Digital input

Connect terminals 12 and 13 with a short piece of

wire to create a short circuit between them.

11.3.5 Level sensor

Connect terminals 14 and 15 to the level sensor:

• Terminal 14, 24 VDC (voltage supply).

• Terminal 15, IN (signal input).

11.3.6 Required Grundfos GO settings

You must make the following Grundfos GO settings:

1. In display "Control mode" select "Closed loop".

2. Set "Analog input 1".

Example:

– sensor output signal (4-20 mA),

– setting range unit (m)

– setting range - head

Min.: 0.0

Max.: 60.

Set the stop type.

– Sensor 1: "Empty".

3. Set the "Setpoint" e.g. desired water level (m).

Example: 55 m.

– Rule: The maximum setting of the setpoint

corresponds to the maximum value set in

display "Analog input 1" less 5 m.

In this case, 60 less 5 = 55 m.

The water level can be kept within a tolerance

of ± 1 % of the setting range.

4. Set "Digital input 1".

– "Start".

30

Page 31

12. CU 300 connected to RS-485

5

1

1

3

2

WWW

CIU 27X

12.1 Description

Using the RS-485 input enables:

• communication via Grundfos fieldbus GENIbus

• connection to the Grundfos Remote Management

(CIU 270) gateway for communication over long

distances.

12.2 CU 300 connected to a PC directly

Figure 31 shows an example of an installation which

is connected to a PC directly via the PC Tool link and

GENIbus.

The installation shown in the example enables

configuration, fault finding and servicing of the

installation by means of a PC with a PC Tool CU 300

software. See fig. 31.

Fig. 31

CU 300 connected to GENIbus network:

Figure 32 shows an example of an installation

connected to a GENIbus network with two CU 300

installations via the RS-485 input. The GENIbus

network is connected to Grundfos Remote

Management (CIU 270) through a PC with internet

access.

The installation shown in the example enables

configuration, fault finding, servicing, data logging of

the connected installations over long distances. See

fig. 32.

You can connect and communicate with up to 32

GENIbus units on one network.

The units can be:

• CU 300 units only

• CU 300 units in combination with other Grundfos

products with GENIbus connection.

Contact Grundfos for further details.

TM06 3619 0715

English (GB)

Pos. Description

1CU 300

E.g. a pH sensor for monitoring of water

2

quality

Fig. 32

TM06 3618 0715

3 Level sensor

4PC

5 PC Tool Link

Pos. Description

1CU 300

2 CIU 270

3PC

31

Page 32

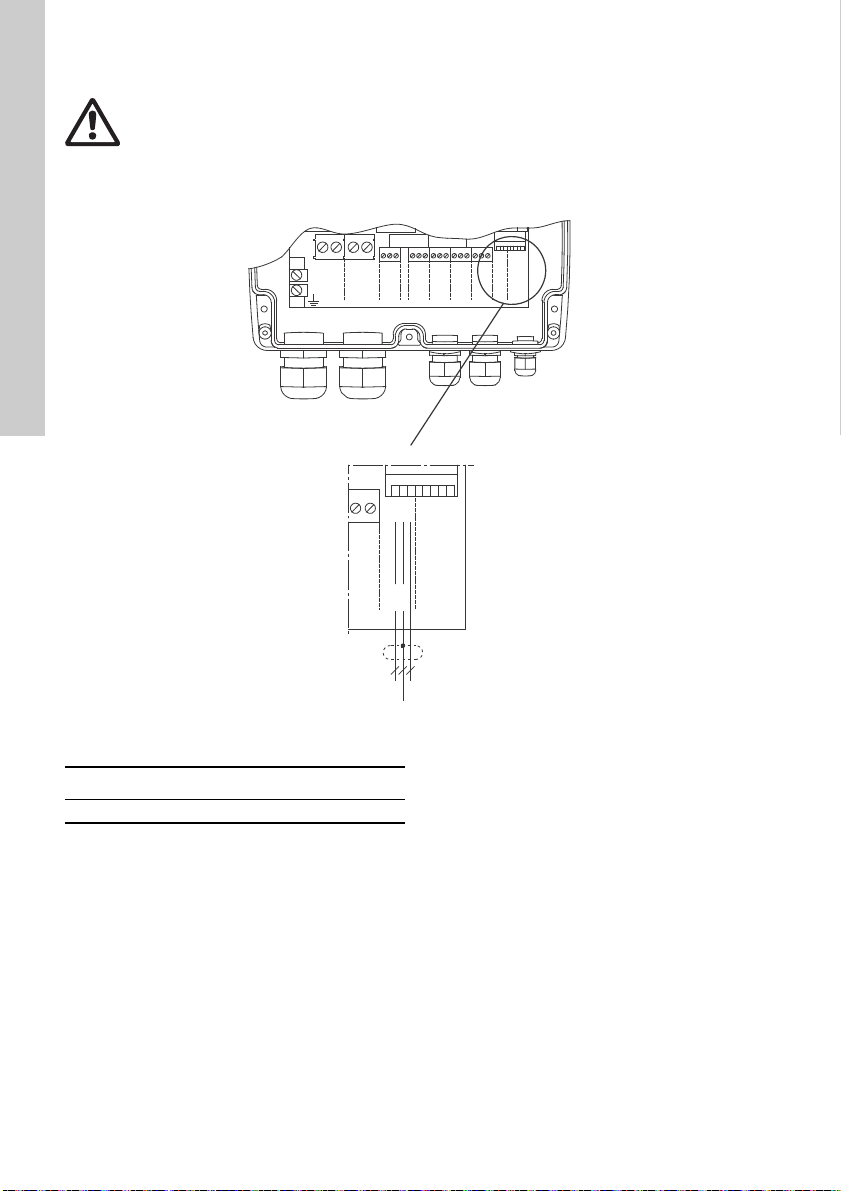

12.3 Electrical installation

POWER

PE

PUMP

RELAY

ALARM

COMNCNO

NONCCOM

AUX

RELAY IN

DIG

IN

+24VDC

GND

GND

+24VDC

IN

SENSOR

12

SENSOR

IN

+24VDC

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

56712109834111213 161514 171819

PE

TXD

RS-485 BRS-485-A

IN

GND

RS

485

RS

232

B

GND

ARIDTR

RXD

GND

18 19

TXD

Y

RS-485

English (GB)

Warning

Never make any connections in the CU 300 unit unless the power supply has been switched off.

CU 300 must be connected in accordance with the rules and standards in force for the

application in question.

The supply voltage and frequency are marked on the nameplate. Make sure that CU 300 is suitable for the

power supply on which it will be used.

Fig. 33

Pos. Description

RS-485 Connection of RS-485, GENIbus

32

TM06 3600 0615

Page 33

12.3.1 Mains supply

Note

POWER, terminals 1, 2 and PE

Connect terminals 1 and 2 to the phase and neutral

leads of the mains supply. You can connect each

terminal to any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

Backup fuse: Maximum 16 A.

You must not connect the leads of the

mains supply to terminals 3 and 4.

12.3.2 Pump supply PUMP, terminals 3, 4 and PE

Connect terminals 3 and 4 to the phase and neutral

leads of the pump. You can connect each terminal to

any of the two leads.

Connect the PE terminal to the green/yellow earth

lead. You must connect each PE terminal to an earth

lead of its own.

Maximum cross-section of the leads to be connected

2

.

is 6 mm

12.3.3 Alarm signal relay ALARM RELAY, terminals 5, 6 and 7

Connect terminals 5, 6 and 7 to the internal alarm

signal relay as follows:

• Terminal 5 NC (normally closed).

• Terminal 6 COM (common).

• Terminal 7 NO (normally open).

The relay operates when the alarm and warning

limits are exceeded.

You can select manual or automatic restarting in the

Grundfos GO display "Automatic restarting".

Manual restarting is carried out by means of the On/

Off button on CU 300.

12.3.4 RS-485 input

The RS-485 input, terminals A, Y (GND) and B, is for

external bus communication.

The communication is effected according to the

Grundfos bus protocol, GENIbus, and is two-way

communication.

CU 300 can communicate with a PC with the PC Tool

CU 300 installed.

You need a PC Tool link adapter to communicate

with a PC. Connect the adaptor to CU 300, terminals

A, Y (GND) and B, for direct communication with a

PC on a GENIbus network.

The PC Tool CU 300 enables configuration,

monitoring and fault finding of the actual installation.

The RS-485 input is a low-voltage circuit. Therefore,

you must separate all connections to terminals A, Y

(GND) and B from network circuits by means of

double or reinforced insulation.

A screened, twisted-pair cable is required. The

maximum cable length is 1200 m.

English (GB)

33

Page 34

13. Alarm functions

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction

Overtemperature

Overload

Sensor alarm

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction

Overtemperature

Overload

Sensor alarm

English (GB)

13.1 No contact

The connection and/or communication between CU

300 and the motor is not established.

"No contact"

is permanently on. See fig. 34.

13.2 Overvoltage

The supply voltage to the motor exceeds the

maximum value allowed.

For more information about factory settings, see

section 16. Technical data.

The motor is stopped and "Overvoltage" is

permanently on. See fig. 35.

Fig. 34

Possible cause Remedy

Motor is not an MSE 3

motor.

Motor is not connected. Check connections.

Cable breakage. Check cable.

Poor or no connection. Check connections.

The cable length

exceeds 200 m.

CU 300 is defective. Replace CU 300.

The motor is defective. Replace motor.

Important:

The alarm indication "No contact" will also appear if

the pump and CU 300 do not have the same number

(allocated by the Grundfos GO). The problem may

occur e.g. in connection with replacing a motor or a

CU 300.

Solution:

The pump and CU 300 must be allocated the same

number via the Grundfos GO display "Number".

The alarm "No contact" makes the On/Off button on

CU 300 inactive, and actual operating parameters

cannot be called up. However, installation

parameters can be called up.

"No contact" does not cause a pump stop.

Install an MSE 3 motor.

Reduce cable length.

TM01 2782 0415

Fig. 35

Possible cause Remedy

Unstable power supply.

Too high supply voltage.

Supply voltage outside

voltage range of motor.

Restarting

When the supply voltage lies within the voltage

range of the motor, the motor will restart

automatically.

Contact the power

supply authorities.

Contact the power

supply authorities.

Check installation.

Check installation.

TM01 2783 0415

34

Page 35

13.3 Undervoltage

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction

Overtemperature

Overload

Sensor alarm

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction

Overtemperature

Overload

Sensor alarm

The supply voltage to the motor is lower than the

minimum value allowed.

For more information about the factory setting, see

section 16. Technical data.

The motor is stopped and "Undervoltage" is

permanently on. See fig. 36.

Fig. 36

13.4 Dry running

The purpose of the dry-running protection is to

protect the pump in case of insufficient water flow.

The dry-running protection makes the conventional

dry-running protection unnecessary.

No additional cables to the motor are required.

The dry-running alarm is activated when the load has

been below the dry-running power limit for an

accumulated time of 5 seconds.

The motor is stopped and "Dry running" is

permanently on. See fig. 37.

TM01 2784 0415

English (GB)

Possible cause Remedy

Unstable power supply.

Supply voltage outside

voltage range of motor.

Voltage drop in mains is

too big.

Restarting

When the supply voltage lies within the voltage

range of the motor, the motor will restart

automatically.

Contact the power

supply authorities.

Check installation.

Increase wire crosssection.

Fig. 37

Possible cause Remedy

Replace pump with a

The pump performance

is too high compared to

the borehole yield.

Borehole filter is

blocked.

Restarting

After 5 minutes (factory setting), or the period set by

means of the Grundfos GO display "Automatic

restarting", the motor will restart automatically.

smaller one.

Reduce pump

performance using the

Grundfos GO display

"Maximum speed".

Borehole service is

required.

35

TM01 2785 0415

Page 36

13.5 Speed reduction

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction

Overtemperature

Overload

Sensor alarm

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction

Overtemperature

Overload

Sensor alarm

English (GB)

At a moderate undervoltage or overload of the motor,

the speed is reduced, but the motor is not stopped.

The speed reduction indicator light is on, and at the

same time the undervoltage or overload light is on.

"Speed reduction" and "Undervoltage" or "Overload"

are permanently on.

In fig. 38, the "Speed reduction" alarm was caused

by undervoltage.

Fig. 38

Possible cause Remedy

Pump is worn, causing

overload.

Wrong combination of

pump and motor,

causing overload.

Unstable power supply,

causing undervoltage.

Too big voltage drop

over the cable, causing

undervoltage.

Speed resuming

When the supply voltage lies within the voltage

range of the motor again and the cause of the

overload has disappeared, the motor resumes

normal speed.

Pump must be serviced.

Replace pump or motor.

Contact the power

supply authorities.

Size cable to avoid too

big voltage drop.

13.6 Overtemperature

The motor temperature is monitored continuously

during operation.

The motor is factory-set to a maximum value. See

section 16. Technical data.

The motor temperature has exceeded the maximum

temperature limit. If the temperature is too high,

there is a risk that the motor electronics will be

damaged.

The motor is stopped and "Overtemperature" is

permanently on. See fig. 39.

TM01 2786 0415

Fig. 39

A too high operating temperature may indicate that

the installation needs service.

Possible cause Remedy

Insufficient cooling or

flow velocity along

motor.

Insufficient cooling due

to incrustation of the

motor.

Restarting

When the motor electronics has cooled sufficiently,

the motor will restart automatically. See section

16. Technical data.

Take out pump and

install flow sleeve.

Clean motor. Install flow

sleeve.

TM01 2787 0415

36

Page 37

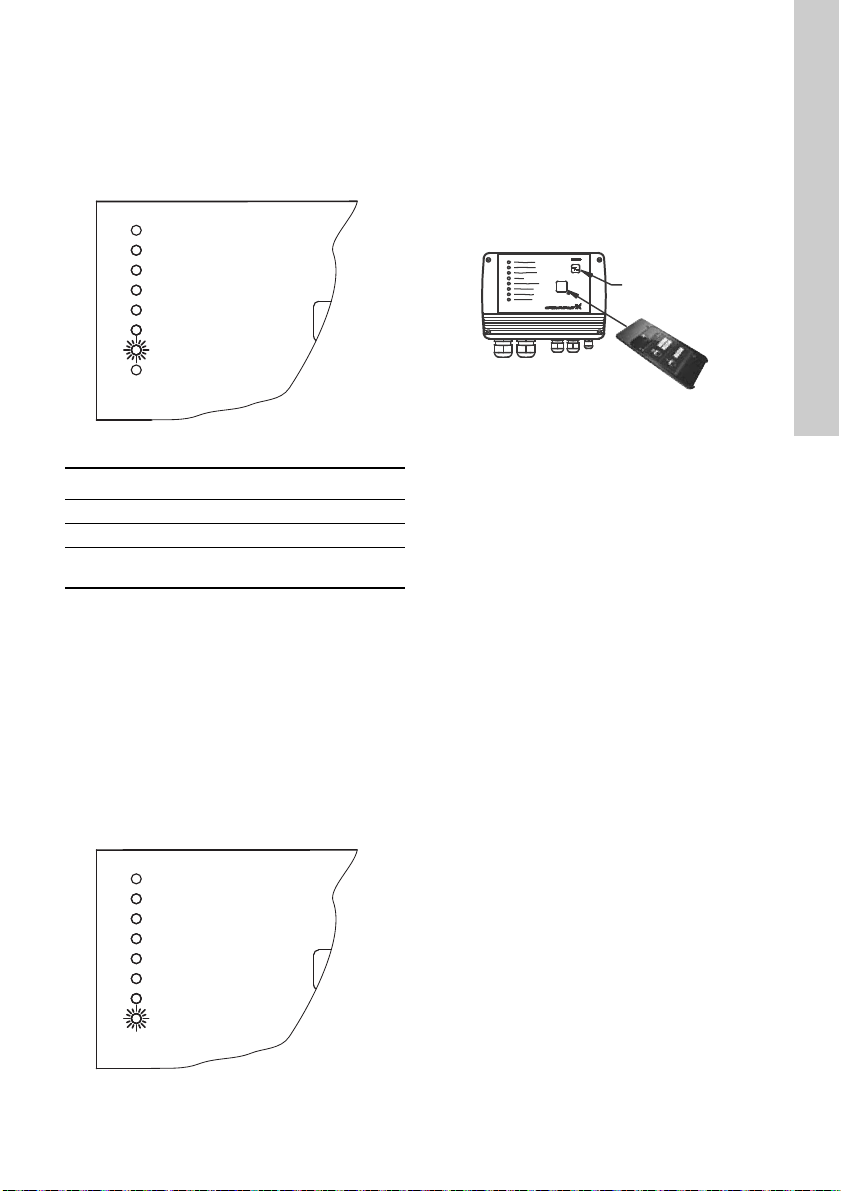

13.7 Overload

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction

Overtemperature

Overload

Sensor alarm

No contact

Overvoltage

Undervoltage

Dry running

Speed reduction