Page 1

CR, CRN 95-155

Vertical, multistage centrifugal pumps

60 Hz

(NEMA)

GRUNDFOS DATA BOOKLET

Page 2

CR, CRN 95-155

Table of contents

1. Product introduction 3

Applications 3

Pumped liquids 3

Performance range 4

Applications 5

Product range 6

Pump 7

Motor 7

Terminal box positions 7

Viscosity 7

2. Construction 8

CR 95, 125 and 155 8

CRN 95, 125 and 155 9

Type keys 10

3. Operating and inlet pressures 11

Max. operating pressure and liquid temperature 11

Operating range of the shaft seal 12

Maximum inlet pressure 13

4. Selection and sizing 14

Selection of pumps 14

How to read the curve charts 17

Guidelines to performance curves 17

5. Performance curves and technical data 18

CR 95 18

CRN 95 20

CR 125 22

CRN 125 24

CR 155 26

CRN 155 28

6. Motor data 30

Standard motors, 60 Hz 30

7. List of pumped liquids 31

8. Accessories 33

9. Grundfos Product Center 34

Grundfos GO 35

2

Page 3

CR, CRN 95-155

1. Product introduction

1

This data booklet covers Grundfos CR and CRN

pumps with these nominal flow sizes:

• CR, CRN 95

• CR, CRN 125

• CR, CRN 155.

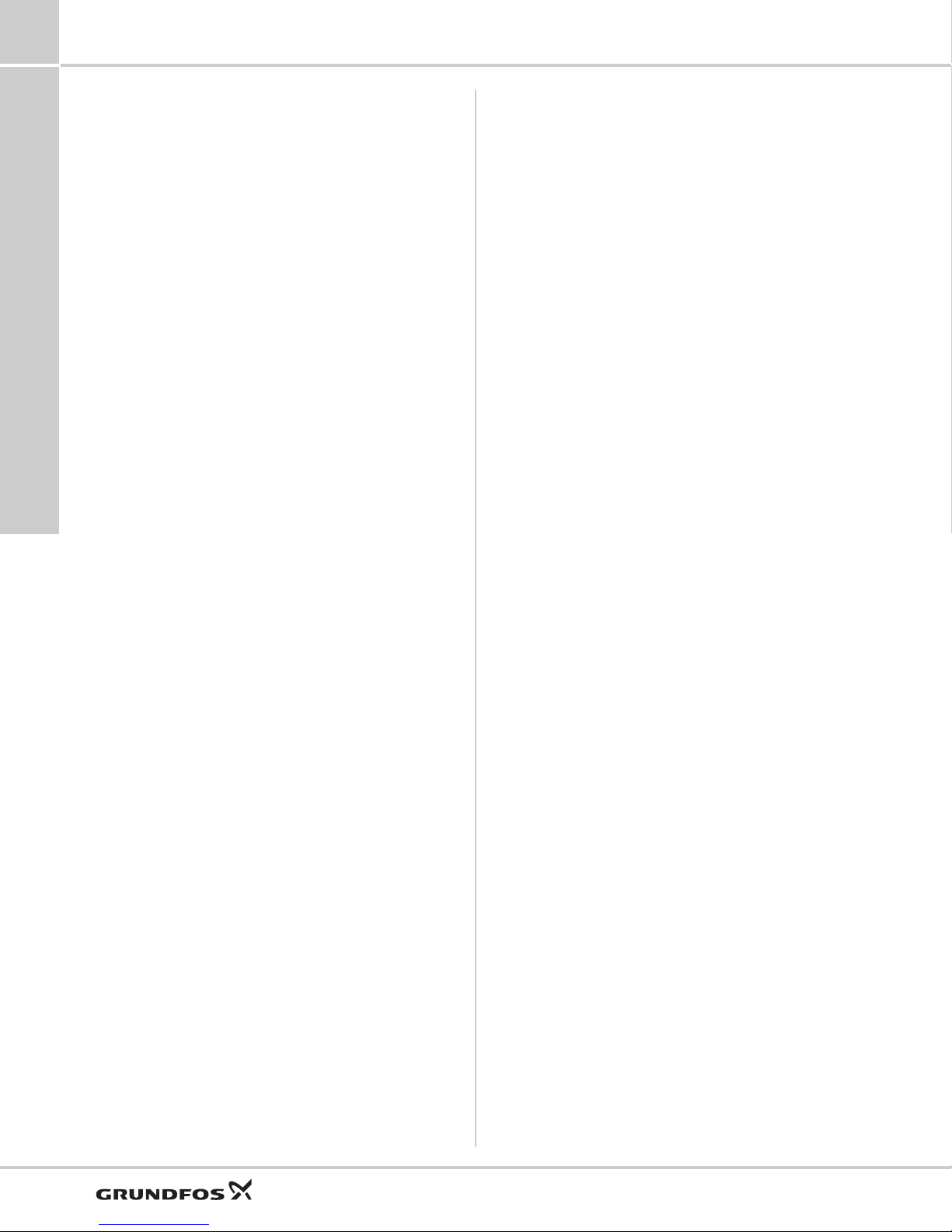

Fig. 1 CR, CRN 95-155

CR, CRN pumps are vertical multistage, centrifugal

pumps. The in-line design of the pumps enables

installation in a horizontal one-pipe system where the

inlet and outlet ports are in the same horizontal level

and have the same pipe dimensions. This design

provides a more compact pump design.

The pumps are available in various sizes and various

numbers of stages to deliver the flow and pressure

required.

CR, CRN pumps are designed for a variety of

applications ranging from the pumping of potable water

to the pumping of chemicals. The pumps are therefore

suitable for a wide diversity of pumping systems where

the performance and material of the pump meet

specific demands.

A CR, CRN pump consists of two main components:

the motor and the pump unit.

The pump unit consists of optimized hydraulics,

various types of connections, a sleeve, a pump head

and various other parts. See Construction, page 8.

CR, CRN pumps are available in various material

versions according to the pumped liquid.

CR pumps with ANSI/NSF 61 and ANSI/NSF 372

listing are available. FKM variants are only available

with ANSI/NSF 372 listing. See UL file MH24600 or

contact Grundfos.

Applications

The new CR, CRN range is suitable for numerous

applications identical to the applications which the

current CR, CRN pumps handle today. The following

applications are some typical examples.

Water supply:

• Filtration and transport water works

• Distribution from water works

• Pressure boosting of mains.

Industrial:

• Pressure boosting

• Process water transfer

• Boiler feed

• Cooling and air conditioning

• Firefighting systems

• District energy systems

• Special liquids transfer.

TM06 9062 1617

Water treatment:

• Filtration

• Brackish water reverse osmosis.

Product introduction

Pumped liquids

Thin, non-explosive liquids, not containing solid

particles or fibers. The liquid must not attack the pump

materials.

CR pumps are suitable for non-corrosive liquids and

are to be used for liquid transfer, circulation and

pressure boosting of cold or hot clean water.

CRN pumps are suitable for industrial liquids and are

to be used in systems where all parts in contact with

the liquid must be made of high-grade stainless steel.

For further details see List of pumped liquids, page 31.

3

Page 4

1

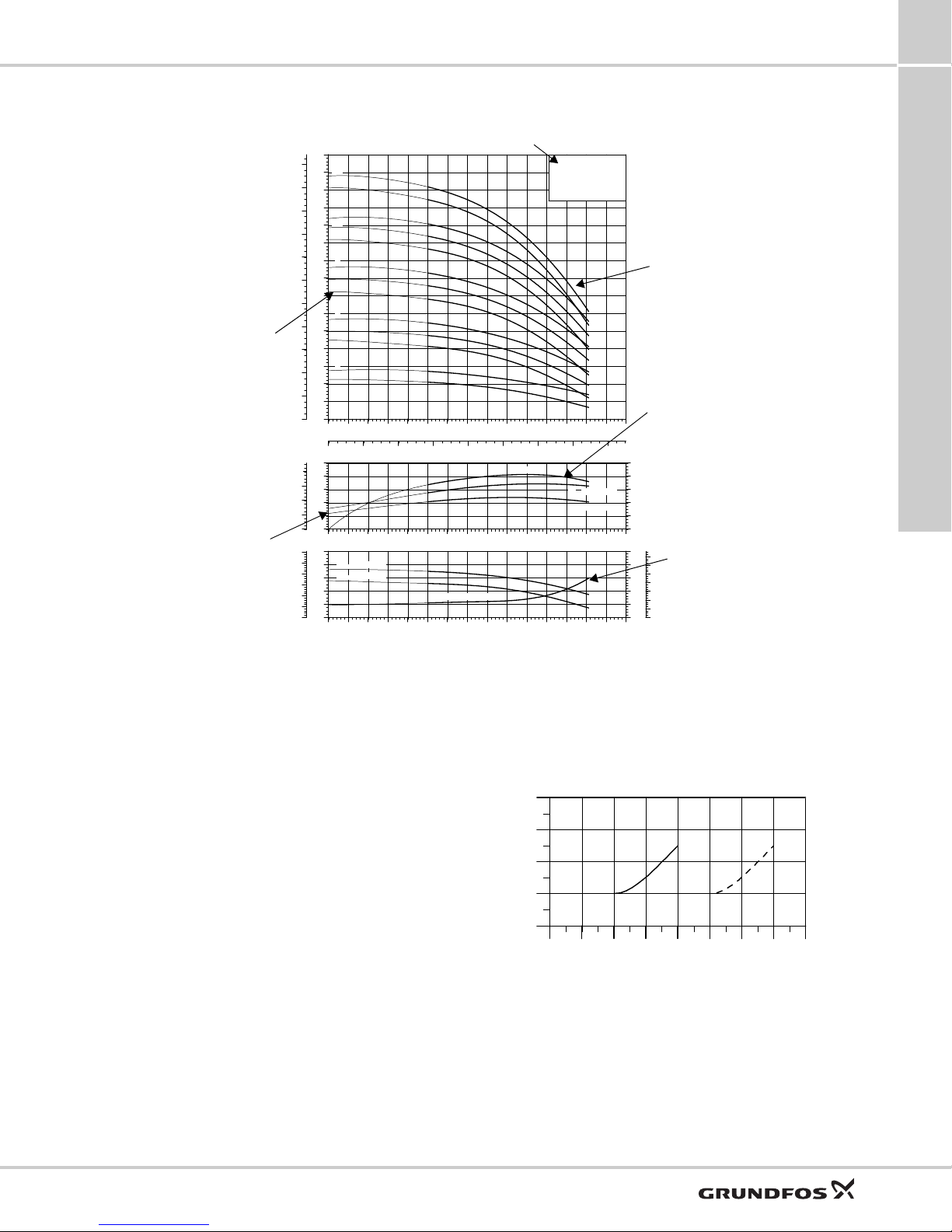

250 300 350 400 500 600 700 800 1000 1200

Q [US GPM]

80

100

150

200

300

400

600

800

1000

[ft]

H

57 60 70 80 90 100100 200

Q [m³/h]

25

30

40

50

60

70

80

100100

200

300

[m]

H

60 Hz

CR(N) 95

CRN 125

CR 125

CRN 155

CR 155

250 300 350 400 500 600 700 800 1000 1200

Q [US GPM]

0

20

40

60

80

[%]

Eff

CR, CRN 95-155

Product introduction

Performance range

Fig. 2 Performance range, CR, CRN

4

TM06 5583 3718

Page 5

CR, CRN 95-155

1

Applications

Application CR CRN

Water supply

Filtration and transfer at waterworks ●

Distribution from waterworks ●

Pressure boosting in mains ●

Pressure boosting in high-rise buildings, hotels, etc. ●

Pressure boosting for industrial water supply ●

Industry

Pressure boosting

Process-water systems ●●

Washing and cleaning systems

Vehicle-washing tunnels ●

Firefighting systems ● -

Liquid transfer

Cooling and air-conditioning systems (refrigerants) ●

Boiler feed and condensate systems ●

Machine tools (cooling lubricants) ●●

Aquafarming ●

Special transfer duties

Oils and alcohols ●●

Acids and alkalis - ●

Glycol and coolants ● -

Water treatment

Ultra-filtration systems - ●

Reverse osmosis systems - ●

Softening, ionizing, demineralizing systems - ●

Distillation systems - ●

Separators ●●

Swimming pools - ●

Irrigation

Field irrigation (flooding) ●

Sprinkler irrigation ●

Drip-feed irrigation ●

● Recommended version.

❍ Alternative version.

* For applications involving CIP (cleaning-in-place) and motors above 75 Hp (55 kW,) a bearing flange must be used and a base without thrust

handling device or blind flange.

*

●●

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

❍

Product introduction

5

Page 6

1

CR, CRN 95-155

Product introduction

Product range

Range CR, CRN 95 CR, CRN 125 CR, CRN 155

3

Rated flow rate [US gpm (m

Liquid temperature [°F (°C)] -22 to +248

Maximum pump efficiency [%] 82.5 82.5 82.5

CR, CRN pumps

Flow rate [US gpm] 255-660 330-860 410-1060

Maximum pressure [psi (bar)] 537

Motor power [Hp (kW)]

Version

CR:

Cast iron and stainless steel

EN 1.4301/AISI 304

CRN:

Stainless steel

EN 1.4401/AISI 316

CR pipe connection

Flange 4" ANSI 6" ANSI

CRN pipe connection

Flange 4" ANSI 6" ANSI

PJE coupling (Victaulic type) 4" 6"

1)

CRN 95 to 155 with HQQE shaft seal: -40 to +248 °F (-40 to +120 °C).

2)

CR pumps: Maximum operating pressure is 363 psi (25 bar).

/h)]

500 (114)

2)

(37) 566

20-75 (15-55)

●● ●

●● ●

660 (150) 820 (186)

1)

(-30 to +120)

2)

(39) 580

20-150 (15-111) 25-150 (18-111)

2)

(40)

6

Page 7

CR, CRN 95-155

Impellers

Base

Motor

Coupling

Pump head

Sleeve

Staybolts

Base plate

Shaft seal

(cartridge type)

6 o’clock

position

(standard)

9 o’clock

position

12 o’clock

position

3 o’clock

position

1

Pump

The CR pumps are non-self-priming, vertical

multistage centrifugal pumps.

The pumps are available with a Grundfos or Baldor

standard motor.

The pump consists of a base and a pump head. The

chamber stack and the sleeve are secured between

the base and the pump head by means of staybolts.

The base has inlet and outlet ports on the same level

(in line). All pumps are fitted with a maintenance-free

mechanical shaft seal of the cartridge type.

Grundfos E-motors

We also offer frequency-controlled CRE, CRNE pumps

which are the ideal choice for a number of applications

characterized by a demand for variable flow at

constant pressure. These pumps are suited for water

supply systems and pressure boosting as well as for

industrial applications. Depending on the application,

the pumps offer energy savings, increased comfort and

improved processing.

Optional motors

The Grundfos standard range of motors covers a wide

variety of application demands. However, for special

applications or operating conditions, custom-built

motor solutions can be provided.

For special applications or operating conditions, we

offer custom-built motors such as

• Explosion-proof motors

• Motors with anti-condensation heating unit

• motors with thermal protection.

Motor protection

Single-phase Grundfos motors have a built-in thermal

overload switch (TP 211 according to IEC 34-11).

Three-phase motors must be connected to a

motor-protective circuit breaker according to local

regulations.

Three-phase Grundfos ML motors 5 Hp ( 5 kW) and

larger have a built-in thermistor (PTC) according to

DIN 44082 (TP 211 according to IEC 34-11).

Product introduction

Fig. 3 CR pump

Motor

Grundfos ML standard and Baldor motors

CR, CRN pumps are fitted with a totally enclosed,

fan-cooled, 2-pole Grundfos or Baldor standard motor.

Angular contact bearings are fitted to the drive end on

motors up to 75 Hp (56 kW). This ensures that the

motor bearing life (L10) is extended to match that of

the pump.

Electrical data

Efficiency class NEMA Premium

Insulation class F/B

Enclosure type* TEFC

Rated voltage**

Number of poles 2

Frequency, standard motors 60 Hz

* A different enclosure type is available on request.

** Different voltages are available on request.

3 x 208-230 VΔ / 3 x 380-480 V Y

3 x 575 VΔ (only Canada)

GR5357 - GR3395

Terminal box positions

As standard, the terminal box is fitted on the inlet side

of the pump.

TM03 3658 0606

Fig. 4 Terminal box positions

Viscosity

The pumping of liquids with densities or kinematic

viscosities higher than those of water will cause a

considerable pressure drop, a drop in the hydraulic

performance and a rise in the power consumption.

In such situations, the pump must be fitted with a

larger motor. If in doubt, contact Grundfos.

7

Page 8

2

ANSI flange

1

2

3

4

6

8

9

10

12

11

13

5

7

Construction

2. Construction

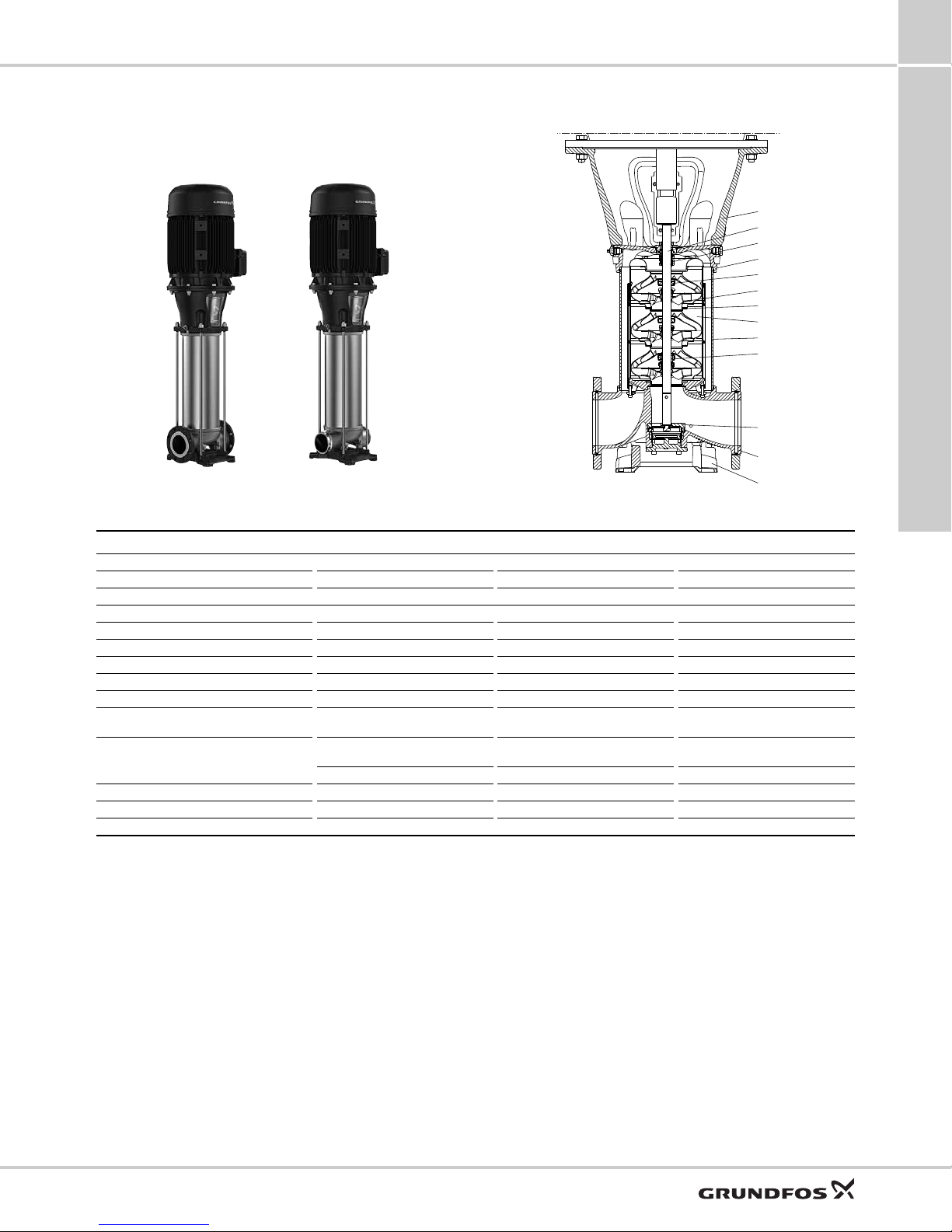

CR 95, 125 and 155

CR, CRN 95-155

TM06 9206 1917

Materials, CR

Pos. Designation Materials DIN/EN ≈ AISI/ASTM

1 Motor stool Ductile cast iron EN-GJS-500-7 ASTM A536-84 70-50-05

2 Shaft Stainless steel

EN10088 1.4057

EN10088 1.4462

3 Shaft seal (seal faces) Silicon carbide/Silicon carbide - -

4 Pump head Ductile cast iron EN-GJS-500-7 ASTM A536-84 70-50-05

5 Support bearing (bush) Carbon-graphite filled PTFE

6 Impeller Stainless steel EN10088 1.4301 AISI 304

7 Neck ring PEEK - -

8 Chamber Stainless steel EN10088 1.4301 AISI 304

9 Sleeve Stainless steel

10 Bearing ring

11 Thrust handling device

3)

Tungsten carbide/Tungsten

carbide

Stainless steel

EN10088 1.4301

EN10088 1.4404

--

EN10088 1.4401

EN10283 1.4408

Silicon carbide/Tungsten carbide - -

12 Base Ductile cast iron EN-GJS-500-7 ASTM A536-84 70-50-05

13 Base plate Ductile cast iron EN-GJS-500-7 ASTM A536-84 70-50-05

Rubber parts EPDM or FKM - -

1)

Applies to CR 95.

2)

Applies to CR 125 to CR 155.

3)

Only fitted on pumps with 100 Hp (75 kW) motors or larger.

1)

2)

1)

2)

EN10088 1.4057=431

EN10088 1.4462=318 LN

AISI 3041)

AISI 316 L

2)

AISI 316/CF 8M

TM06 5161 1917

8

Page 9

CR, CRN 95-155

ANSI flange PJE (Victaulic type)

1

2

3

4

6

8

9

10

12

11

13

5

7

CRN 95, 125 and 155

2

Construction

TM06 9203 1917 - TM06 9208 1917 - TM06 921 01917

Materials, CRN

Pos. Designation Materials DIN/EN ≈ AISI/ASTM

1 Motor stool Ductile cast iron EN-GJS-500-7 ASTM A536-84 70-50-05

2 Shaft Stainless steel EN10088 1.4462 318 LN

3 Shaft seal (seal faces) Silicon carbide/Silicon carbide - -

4 Pump head Stainless steel EN10283 1.4408 CF 8M

5 Support bearing (bush) Carbon-graphite filled PTFE - -

6 Impeller Stainless steel EN10088 1.4401 AISI 316

7 Neck ring PEEK - -

8 Chamber Stainless steel EN10088 1.4401 AISI 316

9 Sleeve Stainless steel EN10088 1.4404 AISI 316 L

10 Bearing ring

11 Thrust handling device

1)

12 Base Stainless steel EN10283 1.4408 CF 8M

13 Base plate Ductile cast iron EN-GJS-500-7 ASTM A536-84 70-50-05

Rubber parts EPDM or FKM - -

1)

Only fitted on pumps with 100 Hp (75 kW) motors or larger.

Tungsten carbide/Tungsten

carbide

Stainless steel

--

EN10088 1.4401

EN10283 1.4408

Silicon carbide/Tungsten carbide - -

AISI 316/CF 8M

TM06 5161 1917

9

Page 10

2

CR, CRN 95-155

Construction

Type keys

CR, CRN 95-155

Example CR E 95 -4 -2 -A -F -H -E -HQQE

Type range:

CR, CRI, CRN, CRT

Pump with integrated frequency

converter

Flow rate [gpm (m

Number of impellers

Number of reduced-diameter impellers

CR, CRE, CRN, CRNE 95, 125, 155

Code for pump version

Code for pipe connection

Code for materials

Code for rubber parts

Code for shaft seal

Key to codes

Code Description

Pump version

A Basic version

B Oversized motor

3

/h)]

E Pump with certificate

G E-pump without control panel

J E-pump with a different maximum speed

N E-pump with sensor

P Undersized motor

V Cascade function

X Special version

Pipe connection

F DIN flange

FC DIN 11853-2 flange (collar flange)

G ANSI flange

J JIS flange

P PJE coupling (Victaulic type)

X Special version

Materials

A Basic version

H All parts stainless steel, wetted parts EN10088 1.4401 ≈

AISI 316/ASTM 351 - CF8M

R Silicon carbide/Silicon carbide bearing

X Special version

Code for rubber parts in pump

E EPDM

VFKM (Viton

Shaft seal type designation

H Balanced cartridge seal with O-ring

X Special version*

Seal face material

B Carbon, synthetic resin-impregnated

U Cemented tungsten carbide

Q Silicon carbide

X Other ceramics*

Secondary seal material (rubber parts)

E EPDM

V FKM (Viton®)

* Option. See the CR "Custom-built pumps" data booklet available on

Grundfos Product Center. See QR code or link below.

®

)

10

http://net.grundfos.com/qr/i/96486346

Shaft seal

Example -H -Q -Q -E

Shaft seal type designation

Material of rotating seal face

Material of stationary seal face

Material of secondary seal (rubber parts)

Page 11

CR, CRN 95-155

3. Operating and inlet pressures

Max. operating pressure and liquid temperature

ANSI, PJE (Victaulic type)

Pump type

3

Pressure class

CR 95-1-1 → 95-4-1 150

CR 95-4 → 95-5-1 300

CR 125-1-1 → 125-3 150

CR 125-4-2 300

CR 155-1-1 → 155-3-2 150

CRN 95-1-1 → 95-4-1 150

CRN 95-5-2 → 95-5-1 300

CRN 125-1-1 → 125-3 150

CRN 125-4-2 → 125-7-2 300

CRN 155-1-1 → 155-3-2 150

CRN 155-3-1 → 155-5-1 300

* For operating pressures above 435 psi (30 bar) the liquid temperature limits are -40 to 176 °F (-40 to 80 °C).

Maximum permissible operating

pressure in standard configuration

[psi (bar)]

363 (25)

Note: CRN models may be

configured for up to

580 psi (40 bar)

(depending on model).

Please contact Grundfos.

Liquid temperature

[°F (°C)]

-22 to 248 (-30 to 120)

-40 to 248 (-40 to 120)*

TM06 9402 2417

Operating and inlet pressures

11

Page 12

3

-40 -4 32 68 248 284104 140 176 212

0

145

290

435

580

725

HQQE/V

HQBE/V

HQQE/V

HQQE

HQBE

HQQE

(50)

(40)

(30)

(10)

(20)

(-40)(-20) (0) (20) (40) (60) (80) (100)(120)(140)

p [psi (bar)]

t

[°F (°C)]

0

HQQE/V

HQBE/V

HQQE/V

HQQE

HQBE

HQQE

145

290

435

580

725 (50)

(40)

(30)

(10)

(20)

-40 -4 32 68 248 284104 140 176 212

(-40)(-20) (0) (20) (40) (60) (80) (100) (120)(140)

p [psi (bar)]

t

[°F (°C)]

CR, CRN 95-155

Operating and inlet pressures

Operating range of the shaft seal

All pumps will be delivered with a HQQE/V cartridge

shaft seal as standard.

The operating range of the shaft seal depends on

operating pressure, pump type, type of shaft seal and

liquid temperature. The range shown in figs 5 and 6

applies to clean water and water with anti-freeze

liquids. For selection of the right shaft seal, see List of

pumped liquids, page 31. If the operating range is

exceeded, the life of the shaft seal may be reduced.

CR, CRN 95-155

Shaft seals for ∅22 mm shafts (15 to 75 Hp (55 kW))

Fig. 5 Operating range of standard shaft seals for CR,

Standard

shaft seal

HQQE

HQQV

HQBE

HQBV

CRN 95-155

Motor size

[Hp (kW)]

15-75

(11-55)

Description

O-ring (cartridge) (balanced

seal), Silicon carbide/Silicon

carbide, EPDM

O-ring (cartridge) (balanced

seal), Silicon carbide/Silicon

carbide, FKM

O-ring (cartridge) (balanced

seal), Silicon

carbide/carbon, EPDM

O-ring (cartridge) (balanced

seal), Silicon

carbide/carbon, FKM

Liquid

temperature

[°F (°C)]

-40 - +248

(-40 - +120)

-4 - +194

(-20 - +90)

32 - +248

(0 - +120)

32 - +194

(0 - +90)

Shaft seals for ∅28 mm (100-150 Hp (75-110 kW))

and ∅36 mm (200-300 Hp (132-200 kW)) shaft ends

TM07 0325 4917

Fig. 6 Operating range of standard shaft seals for ∅28

mm shaft ends (100-150 Hp (75-110 kW)) and ∅36

mm shaft ends (200-300 Hp) 132-200 kW))

Standard

shaft seal

HQQE

HQQV

TM07 0324 4917

HQBE

HQBV

Motor

size

[Hp (kW)]

100-300

(75-200)

Description

O-ring (cartridge) (balanced

seal), Silicon carbide/Silicon

carbide, EPDM

O-ring (cartridge) (balanced

seal), Silicon carbide/Silicon

carbide, FKM

O-ring (cartridge) (balanced

seal), Silicon carbide/carbon,

EPDM

O-ring (cartridge) (balanced

seal), Silicon carbide/carbon,

FKM

Liquid

temperature

[°F (°C)]

-40 - +248

(-40 - +120)

-4 - +194

(-20 - +90)

32 - +248

(0 - +120)

32 - +194

(0 - +90)

12

Page 13

CR, CRN 95-155

3

Maximum inlet pressure

The following table shows the maximum permissible

inlet pressure. However, the actual inlet pressure plus

the pressure against a closed valve must always be

lower than the maximum permissible operating

pressure.

If the maximum permissible operating pressure is

exceeded, the angular contact bearing in the motor

may be damaged and the life of the shaft seal reduced.

Pump type

CR, CRN 95

CR, CRN 95-1-1 → CR, CRN 95-2-2

CR, CRN 95-2-1 → CR, CRN 95-4-2

CR, CRN 95-4 → CR, CRN 95-8

CR, CRN 125

CR, CRN 125-1-1 → CR, CRN 125-1

CR, CRN 125-2-2 → CR, CRN 125-3-1

CR, CRN 125-3 → CR, CRN 125-9-3

CR, CRN 155

CR, CRN 155-1-1

CR, CRN 155-1 → CR, CRN 155-2

CR, CRN 155-3 → CR, CRN 155-8-3

Maximum inlet pressure

[psi (bar)]

145 (10)

218 (15)

290 (20)

145 (10)

218 (15)

290 (20)

145 (10)

218 (15)

290 (20)

Examples of operating and inlet pressures

The values for operating and inlet pressures shown in

the table must not be considered individually and must

comply with the below statement.

The outlet pressure must be equal to or lower than the

maximum operating pressure.

See the following definitions and examples.

Definitions

Pressure type Definition

Maximum operating pressure

Pump differential pressure

Inlet pressure

Outlet pressure

The maximum pressure is stated on

the nameplate.

The difference between the outlet

pressure and inlet pressure.

The pressure measured at the pump

inlet.

The inlet pressure added to the

pump differential pressure.

Example

The following pump type has been selected: CR 95-3.

Maximum operating pressure: 363 psi (25 bar).

Maximum inlet pressure: 218 psi (15 bar).

Pump differential pressure when operating against a

closed outlet valve (flow = 0 GPM (0 m

3

/h)): 436 ft

head = 190 psi (133 m head = 13.07 bar). See page

18.

This pump is not allowed to start at an inlet pressure of

218 psi (15 bar), but at an inlet pressure of 363 - 190 =

173 psi (25 - 13.07 = 11.93 bar)

Operating and inlet pressures

13

Page 14

4

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

[ft]

H

0 20 40 60 80 100 120 140

Q [m³/h]

0

20

40

60

80

100

120

140

160

180

200

[m]

H

CR 95

60 Hz

ISO 9906:2012 Grade 3B

-5-1

-5-2

-1

-1-1

-2

-2-1

-2-2

-3

-3-1

-4

-3-2

-4-2

-4-1

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

5

10

15

20

[hp]

P2

0

20

40

60

80

[%]

Eff

0

4

8

12

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

40

80

120

160

[ft]

H

0

10

20

30

40

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

[ft]

H

0 20 40 60 80 100 120 140

Q [m³/h]

0

20

40

60

80

100

120

140

160

180

200

[m]

H

CR 95

60 Hz

ISO 9906:2012 Grade 3B

-5-1

-5-2

-1

-1-1

-2

-2-1

-2-2

-3

-3-1

-4

-3-2

-4-2

-4-1

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

5

10

15

20

[hp]

P2

0

20

40

60

80

[%]

Eff

0

4

8

12

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

40

80

120

160

[ft]

H

0

10

20

30

40

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

Duty

point

Best

efficiency

Selection and sizing

CR, CRN 95-155

4. Selection and sizing

Selection of pumps

Selection of pumps must be based on these

parameters:

• the duty point of the pump (see below)

• sizing data such as pressure loss as a result of

height differences, friction loss in the pipes, pump

efficiency (see below)

• pump materials (see page 15)

• pump connections (see page 15)

• shaft seal (see page 15).

Duty point of the pump

From a duty point, you can select a pump on the basis

of the curve charts in section Performance curves and

technical data, page 22.

Sizing data

When sizing a pump, take these parameters into

account:

• Required flow and pressure at the draw-off point.

• Pressure loss as a result of height differences

).

(H

geo

• Friction loss in the pipes (H

).

f

It may be necessary to account for pressure loss in

connection with long pipes, bends or valves, etc.

• Best efficiency at the estimated duty point.

• NPSH value.

For calculation of the NPSH value, see Minimum

inlet pressure, NPSH, page 16.

Pump efficiency

Before determining the best efficiency point, identify

the operation pattern of the pump. If the pump is

expected to operate at the same duty point, select a

CR pump which is operating at a duty point

corresponding to the best efficiency of the pump.

14

Fig. 7 Example of a curve chart

TM06 5537 3718

TM06 5537 3718

Fig. 8 Example of a CR pump’s duty point

Page 15

CR, CRN 95-155

Eta

Q [ m

3

/h ]

NPSH

H

geo

H

f

Required flow, required

pressure

4

As the pump is sized on the basis of the highest

possible flow rate, it is important always to have the

duty point to the right on the efficiency curve (eta) in

order to keep the efficiency high when the flow rate

drops.

Fig. 9 Best efficiency

Fig. 10 Sizing data

Pump material

Select the material variant on the basis of the liquid to

be pumped.

The product range covers the following three basic

types.

•CR

Use CR, CRI pumps for clean, non-aggressive

liquids, such as potable water and oils.

• CRN

Use CRN pumps for industrial liquids and acids.

See List of pumped liquids on page 31, or contact

Grundfos.

Pump connections

Selection of pump connection depends on the rated

pressure and the pipes. To meet any requirement, the

CR, CRN pumps offer a wide range of flexible

connections, such as:

• ANSI flange

• DIN flange

• PJE coupling (Victaulic type)

• other connections on request.

TM00 9190 1303

TM02 6711 1403

Shaft seal

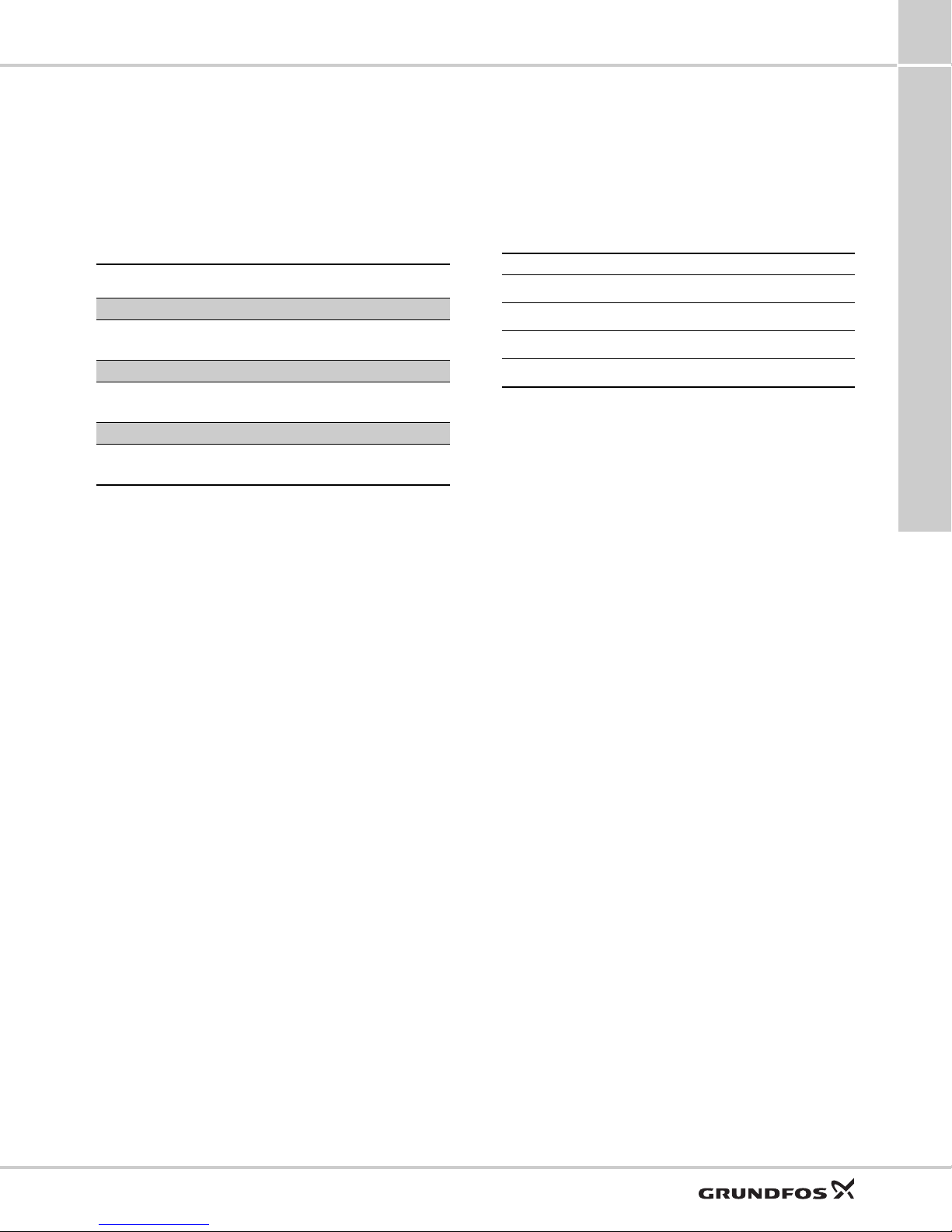

Fig. 11 Shaft seal (cartridge type)

As standard, the CR range is fitted with a Grundfos

shaft seal (cartridge type) suitable for the most

common applications.

These key parameters must be taken into account

when selecting the shaft seal:

• type of pumped liquid

• liquid temperature

• maximum pressure.

We offer a wide range of shaft seal variants to meet

specific demands. See List of pumped liquids, page

31.

Servicing shaft seals

Replacement shaft seals are available as complete

service kits*.

Shaft seals fitted on CR, CRN 95-155 pumps with ∅28

mm or ∅36 mm shaft ends are serviceable. This

means that the wear parts in these shaft seals are

available as service kits* and can be replaced without

having to renew the complete shaft seal.

* All service kits include detailed instructions on how to carry out the

replacement.

GR7386

Selection and sizing

15

Page 16

4

120a

120b

120g

120h

66

49

39

33

26

20

16

13

10

6.6

3.3

2.6

2.0

1.3

0.9

0.7

0.3

4.9

250

230

194

212

176

158

140

122

104

86

68

50

32

Hv

(Ft)

tm

(°F)

300

270

280

82

115

148

131

98

320

340

360

370

203

259

328

413

20

15

12

10

8,0

6,0

5,0

4,0

3,0

2,0

1,0

0,8

0,6

0,4

0,3

0,2

0,1

1,5

120

110

90

100

80

70

60

50

40

30

20

10

0

Hv

(m)

tm

(°C)

150

130

140

25

35

45

40

30

160

170

180

190

62

79

100

126

NPSH

H

v

H

f

p

b

H

CR, CRN 95-155

Selection and sizing

Thrust handling device

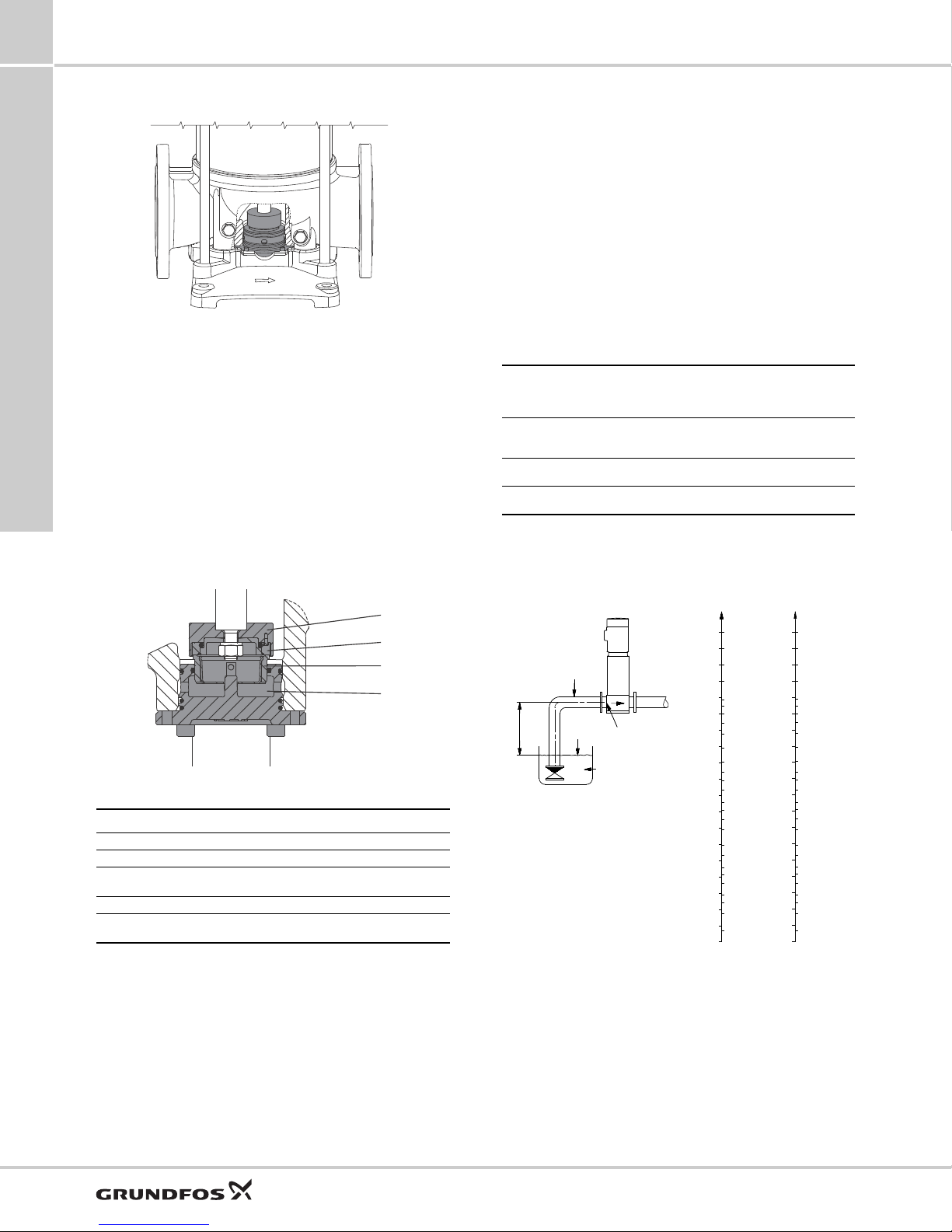

Minimum inlet pressure, NPSH

We recommend that you calculate the inlet pressure

"H" in these situations:

• The liquid temperature is high.

• The flow rate is significantly higher than the rated

flow rate.

• Water is drawn from depths.

• Water is drawn through long pipes.

• Inlet conditions are poor.

To avoid cavitation, make sure that there is a minimum

pressure on the inlet side of the pump.

TM06 9669 2817TM06 9670 2817

Fig. 12 Thrust handling device

A thrust handling device (THD) is factory-fitted on

pumps with 100 Hp (75 kW) motors or larger. The

system consists of two parts. A rotating part mounted

on the shaft end below the first impeller as well as a

non-rotating part mounted in or on the pump base.

The THD absorbs the main part of the thrust force

generated by the impellers and thereby reduces the

resulting axial force the motor bearings must absorb.

This enables the use of standard ball bearings in the

motor instead of special angular contact ball bearings.

Note: For applications involving CIP

(cleaning-in-place) and motors above 75 Hp (55 kW),

use a bearing flange and a base without THD.

Calculate the maximum suction lift "H" in m head as

follows:

x 10.2 - NPSH - Hf - H

H = p

b

p

=

b

NPSH =

H

=

f

H

=

v

Barometric pressure in ft (bar).

Barometric pressure can be set to 39.9 ft (1 bar).

In closed systems, p

feet (bar).

Net Positive Suction Head in ft (m) head, to be read from

the NPSH curve at the highest flow the pump will be

delivering.

Friction loss in inlet pipe in ft (m) head at the highest

flow the pump will be delivering.

Vapor pressure in ft (m) head, to be read from the vapor

pressure scale. H

v

indicates the system pressure in

b

depends on the liquid temperature tm.

v

If the calculated "H" is positive, the pump can operate

at a suction lift of maximum "H" ft (m) head.

If the calculated "H" is negative, an inlet pressure of

minimum "H" ft (m) head is required.

Fig. 13 Position numbers for THD parts

Pos. Description Material

120a Thrust disc Stainless steel

120b Rotating ring Silicon carbide

16

120g Stationary ring

120h Lifting plate Stainless steel

- O-rings

* On request for CRN.

Operating pressure and inlet pressure

Do not exceed the limit values for these pressures:

• maximum operating pressure

• maximum inlet pressure.

Silicon carbide*

Tungsten carbide

EPDM

FKM

TM02 7439 3403 - TM02 7445 3503

Fig. 14 Minimum inlet pressure, NPSH

Note: To avoid cavitation, do not select a pump with a

duty point too far to the right on the NPSH curve.

Always check the NPSH value of the pump at the

highest possible flow rate.

Page 17

CR, CRN 95-155

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

[ft]

H

0 20 40 60 80 100 120 140

Q [m³/h]

0

20

40

60

80

100

120

140

160

180

200

[m]

H

CRN 95

60 Hz

ISO 9906:2012 Grade 3B

-5-2

-5-1

-1

-1-1

-2

-2-1

-2-2

-3

-3-1

-3-2

-4

-4-2

-4-1

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

5

10

15

20

[hp]

P2

0

20

40

60

80

[%]

Eff

0

4

8

12

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

40

80

120

160

[ft]

H

0

10

20

30

40

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

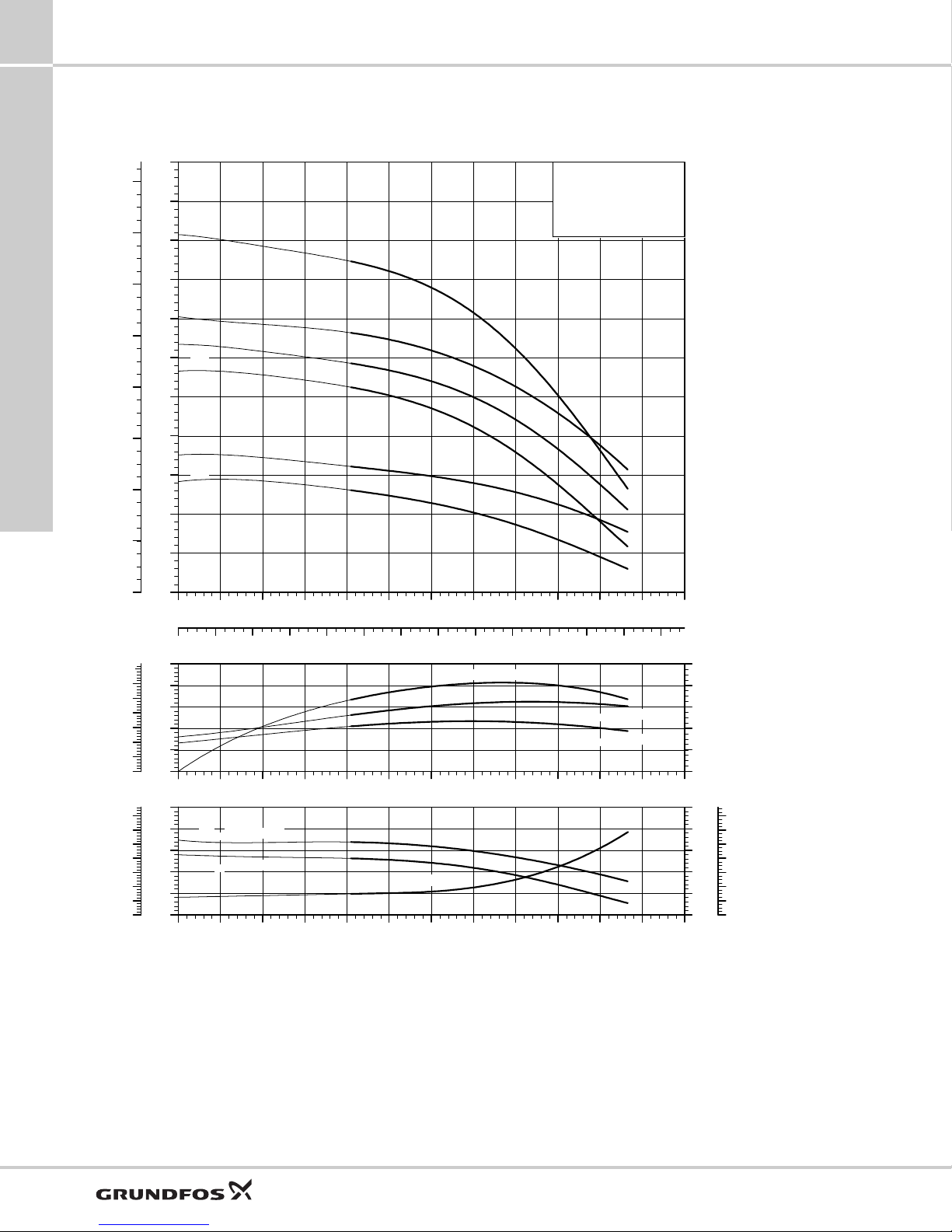

Pump type, frequency and ISO standard.

Number of stages.

First figure: number of stages.

Second figure: number of

reduced-diameter impellers.

The power curves indicate pump

input power per stage.

Curves are shown for complete

(1/1) and for reduced-diameter

(2/3) impellers.

QH curve for the individual pump.

The bold curves indicate the

recommended duty range for

best efficiency.

The eta curve shows the efficiency

of a pump with three full size

impellers.

The efficiency of pumps with

reduced-diameter impellers is

approximately 2 % lower than the

eta curve shown in the chart.

The NPSH curve is a maximum

curve for all the variants shown.

104 140 176 212 248 284 320 356

0

10

20

30

Qmin

(40) (60) (80) (120) (140) (160) (180)(100)

[ % ]

t

[°F]

[(°C)]

How to read the curve charts

4

Selection and sizing

Fig. 15 How to read the curve charts

Guidelines to performance curves

The guidelines below apply to the curves shown on the

following pages:

• Tolerances to ISO 9906:2012, Grade 3B, if

indicated.

• The motors used for the measurements are

standard Grundfos motors.

• Measurements have been made with airless water

at a temperature of 68 °F (20 °C).

• The curves apply to the following kinematic

viscosity: = 1 mm

2

/s (1 cSt).

• Due to the risk of overheating, the pumps must not

be used at a flow rate below the minimum flow rate.

• The QH curves apply to a rated motor speed of a

three-phase mains-operated motor. For realistic

curves, go to Grundfos Product Center

(http://product-selection.grundfos.com/) and insert

data.

The curve below shows the minimum flow rate as a

percentage of the rated flow rate in relation to the

liquid temperature. The dotted line shows a CR pump

fitted with an air-cooled top assembly.

Fig. 16 Minimum flow rate

TM06 5538 3718

TM07 0517 0118

17

Page 18

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

[ft]

H

0 20 40 60 80 100 120 140

Q [m³/h]

0

20

40

60

80

100

120

140

160

180

200

[m]

H

CR 95

60 Hz

ISO 9906:2012 Grade 3B

-5-1

-5-2

-1

-1-1

-2

-2-1

-2-2

-3

-3-1

-4

-3-2

-4-2

-4-1

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

5

10

15

20

[hp]

P2

0

20

40

60

80

[%]

Eff

0

4

8

12

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

40

80

120

160

[ft]

H

0

10

20

30

40

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

5

CR 95

CR 95

5. Performance curves and technical data

CR 95

CR, CRN 95-155Performance curves and technical data

18

The maximum pump efficiency (Eta) is based on a three-stage pump.

TM06 5537 3718

Page 19

CR, CRN 95-155 Performance curves and technical data

B2

D2

D3

D1

G 1/2

G 1/2

G 1/2

G 1/2

B1

8 x ø0.75"

(8 x ø19.1)

(ø100)

ø4"

(225)

8.86"

(275)

10.83"

(380)

14.96"

(350)

13.78"

(419)

16.5"

(ø100)

ø4"

(350)

13.78"

(419)

16.5"

(4 x ø18.5)

4 x ø0.73"

(ø157)

ø6.19"

ø7.5"

(ø190)

ø9"

(ø229)

8 x ø0.88"

(8 x ø22.4)

(4 x ø18.5)

4 x ø0.73"

(ø157)

ø6.19"

ø7.88"

(ø200)

ø10"

(ø254)

(140)

5.51"

Class 300*

4" ANSI

Class 150*

4" ANSI

CR 95

5

CR 95

* CR, CRN 95 pumps with 1 to 4 stages (with 1 reduced diameter impeller) are fitted with 150 lb. (68 kg) flanges as standard. 300 lb.(136 kg) flanges

are available on request.

CR, CRN 95 pumps with 4 or more full diameter impellers are fitted with 300 lb. (136 kg) flanges as standard.

Dimensions and weights

Motor P

Pump type

CR 95-1-1 15 (11) 27.4 (696) 46.2 (1174) 12.4 (314) 8 (204) 8.5 (216) 412 (187)

CR 95-1 20 (15) 27.4 (696) 46.2 (1174) 12.4 (314) 8 (204) 8.5 (216) 412 (187)

CR 95-2-2 25 (18) 31.5 (800) 54.3 (1378) 12.4 (314) 8 (204) 10.5 (267) 452 (205)

CR 95-2-1 30 (22) 31.5 (800) 54.3 (1378) 12.4 (314) 8 (204) 10.5 (267) 478 (217)

CR 95-2 30 (22) 31.5 (800) 54.3 (1378) 12.4 (314) 8 (204) 10.5 (267) 478 (217)

CR 95-3-2 40 (30) 36.4 (925) 64 (1625) 16.9 (429) 14.1 (359) 12.5 (318) 739 (335)

CR 95-3-1 50 (37) 36.4 (925) 64 (1625) 16.9 (429) 14.1 (359) 12.5 (318) 807 (366)

CR 95-3 50 (37) 36.4 (925) 64 (1625) 16.9 (429) 14.1 (359) 12.5 (318) 807 (366)

CR 95-4-2 60 (45) 40.5 (1029) 67.6 (1716) 16.9 (429) 14.1 (359) 12.5 (318) 871 (395)

CR 95-4-1 60 (45) 40.5 (1029) 67.6 (1716) 16.9 (429) 14.1 (359) 12.5 (318) 871 (395)

CR 95-4 75 (56) 40.5 (1029) 68.1 (1729) 19.7 (500) 18.1 (460) 12.5 (318) 1190 (540)

CR 95-5-2 75 (56) 44.6 (1134) 72.2 (1834) 19.7 (500) 18.1 (460) 12.5 (318) 1204 (546)

CR 95-5-1 75 (56) 44.6 (1134) 72.2 (1834) 19.7 (500) 18.1 (460) 12.5 (318) 1204 (546)

[Hp (kW)]

2

B1 B1+B2 D1 D2 D3

Dimension [inch (mm)]

Net weight

[lbs (kg)]

TM06 6059 0218

19

Page 20

5

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

[ft]

H

0 20 40 60 80 100 120 140

Q [m³/h]

0

20

40

60

80

100

120

140

160

180

200

[m]

H

CRN 95

60 Hz

ISO 9906:2012 Grade 3B

-5-2

-5-1

-1

-1-1

-2

-2-1

-2-2

-3

-3-1

-3-2

-4

-4-2

-4-1

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

5

10

15

20

[hp]

P2

0

20

40

60

80

[%]

Eff

0

4

8

12

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 50 100 150 200 250 300 350 400 450 500 550 600

Q [US GPM]

0

40

80

120

160

[ft]

H

0

10

20

30

40

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

CR, CRN 95-155Performance curves and technical data

CRN 95

CRN 95

CRN 95

20

The maximum pump efficiency (Eta) is based on a three-stage pump.

TM06 5538 3718

Page 21

CR, CRN 95-155 Performance curves and technical data

13.78"

16.5"

4 x ø0.73"

G 1/2

G 1/2

8.86"

ø4"

10.83"

14.96"

5.51"

4.49"

B2

D2

D3

D1

G 1/2

G 1/2

G 1/2

G 1/2

B1

8 x ø0.75"

(8 x ø19.1)

(ø100)

ø4"

(225)

(225)

8.86"

(275)

(275)

10.83"

(380)

(380)

14.96"

(350)

13.78"

(419)

16.5"

(ø100)

ø4"

(350) (350)

(ø100)

13.78"

(419)

(419)

16.5"

(4 x ø18.5)

4 x ø0.73"

(ø157)

ø6.19"

ø7.5"

(ø190)

ø9"

(ø229)

8 x ø0.88"

(8 x ø22.4)

(4 x ø18.5)

(4 x ø18.5)

4 x ø0.73"

(ø157)

ø6.19"

ø7.88"

(ø200)

ø10"

(ø254)

(140)

(140)

(114)

5.51"

Class 300*

4" ANSI

Class 150*

4" ANSI

P (PJE) Victaulic type

CRN 95

5

CRN 95

* CR, CRN 95 pumps with 1 to 4 stages (with 1 reduced diameter impeller) are fitted with 150 lb. (68 kg) flanges as standard. 300 lb. (136 kg) flanges

are available on request.

CR, CRN 95 pumps with 4 or more full diameter impellers are fitted with 300 lb.

(136 kg) flanges as standard.

Dimensions and weights

Motor P

Pump type

CRN 95-1-1 15 (11) 27.4 (696) 46.2 (1174) 12.4 (314) 8 (204) 8.5 (216) 412 (187)

CRN 95-1 20 (15) 27.4 (696) 46.2 (1174) 12.4 (314) 8 (204) 8.5 (216) 412 (187)

CRN 95-2-2 25 (18) 31.5 (800) 54.3 (1378) 12.4 (314) 8 (204) 10.5 (267) 452 (205)

CRN 95-2-1 30 (22) 31.5 (800) 54.3 (1378) 12.4 (314) 8 (204) 10.5 (267) 478 (217)

CRN 95-2 30 (22) 31.5 (800) 54.3 (1378) 12.4 (314) 8 (204) 10.5 (267) 478 (217)

CRN 95-3-2 40 (30) 36.4 (925) 64 (1625) 16.9 (429) 14.1 (359) 12.5 (318) 739 (335)

CRN 95-3-1 50 (37) 36.4 (925) 64 (1625) 16.9 (429) 14.1 (359) 12.5 (318) 807 (366)

CRN 95-3 50 (37) 36.4 (925) 64 (1625) 16.9 (429) 14.1 (359) 12.5 (318) 807 (366)

CRN 95-4-2 60 (45) 40.5 (1029) 67.6 (1716) 16.9 (429) 14.1 (359) 12.5 (318) 871 (395)

CRN 95-4-1 60 (45) 40.5 (1029) 67.6 (1716) 16.9 (429) 14.1 (359) 12.5 (318) 871 (395)

CRN 95-4 75 (56) 40.5 (1029) 68.1 (1729) 19.7 (500) 18.1 (460) 12.5 (318) 1190 (540)

CRN 95-5-2 75 (56) 44.6 (1134) 72.2 (1834) 19.7 (500) 18.1 (460) 12.5 (318) 1204 (546)

CRN 95-5-1 75 (56) 44.6 (1134) 72.2 (1834) 19.7 (500) 18.1 (460) 12.5 (318) 1204 (546)

[Hp (kW)]

2

B1 B1+B2 D1 D2 D3

Dimension [inch (mm)]

Net weight

[lbs (kg)]

TM06 6060 0319

21

Page 22

5

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

550

[ft]

H

0 20 40 60 80 100 120 140 160 180

Q [m³/h]

0

20

40

60

80

100

120

140

160

[m]

H

CR 125

60 Hz

ISO 9906:2012 Grade 3B

-4-2

-1

-1-1

-2

-2-1

-2-2

-3

-3-1

-3-2

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

Q [US GPM]

0

10

20

30

40

[hp]

P2

0

20

40

60

80

[%]

Eff

0

5

10

15

20

25

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

Q [US GPM]

0

40

80

120

160

[ft]

H

0

10

20

30

40

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

CR, CRN 95-155Performance curves and technical data

CR 125

CR 125

CR 125

22

The maximum pump efficiency (Eta) is based on a three-stage pump.

TM06 5539 3718

Page 23

CR, CRN 95-155 Performance curves and technical data

B2

D2

D3

D1

G 1/2

G 1/2

G 1/2

G 1/2

B1

(8 x ø22.2)

(12 x ø22.2)

8 x ø0.88"

12 x ø0.88"

(4 x ø22.6)

(4 x ø22.6)

4 x ø0.89"

4 x ø0.89"

ø6"

(ø150)

ø6"

(425)

16.83"

(499)

19.65"

(275)

10.83"

(332)

13.07"

(485)

19.09"

(425)

16.83"

(499)

19.65"

(ø216)

ø8.5"

ø8.5"

(ø216)

(ø270)

(ø328)

(180)

7.09"

(ø241)

ø9.5"

ø10.62"

ø12.8"

(ø300)

ø12.9"

(ø150)

Class 300*

6" ANSI

Class 150*

6" ANSI

CR 125

5

CR 125

* CR, CRN 125 pumps with 1 to 3 stages are fitted with 150 lb. (68 kg) flanges as standard. 300 lb. (136 kg) flanges are available on request.

CR, CRN 125 pumps with 4 or more stages are fitted with 300 lb.

(136 kg) flanges as standard.

Dimensions and weights

Motor P

Pump type

CR 125-1-1 20 (15) 30.8 (783) 49.6 (1261) 12.4 (314) 8 (204) 8.5 (216) 478 (217)

CR 125-1 25 (18) 30.9 (785) 53.7 (1363) 12.4 (314) 8 (204) 10.5 (267) 518 (235)

CR 125-2-2 30 (22) 35.7 (907) 58.5 (1485) 12.4 (314) 8 (204) 10.5 (267) 569 (258)

CR 125-2-1 40 (30) 36.6 (930) 64.2 (1630) 16.9 (429) 14.1 (359) 12.5 (318) 820 (372)

CR 125-2 50 (37) 36.6 (930) 64.2 (1630) 16.9 (429) 14.1 (359) 12.5 (318) 888 (403)

CR 125-3-2 60 (45) 41.4 (1052) 68.5 (1739) 16.9 (429) 14.1 (359) 12.5 (318) 961 (436)

CR 125-3-1 75 (56) 41.4 (1052) 69 (1752) 19.7 (500) 18.1 (460) 12.5 (318) 1281 (581)

CR 125-3 75 (56) 41.4 (1052) 69 (1752) 19.7 (500) 18.1 (460) 12.5 (318) 1281 (581)

CR 125-4-2 75 (56) 46.2 (1174) 73.8 (1874) 19.7 (500) 18.1 (460) 12.5 (318) 1303 (591)

[Hp (kw)]

2

B1 B1+B2 D1 D2 D3

Dimension [inch (mm)]

Net weight

TM06 6061 0218

[lbs (kg)]

23

Page 24

5

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

900

950

1000

1050

[ft]

H

0 20 40 60 80 100 120 140 160 180

Q [m³/h]

0

20

40

60

80

100

120

140

160

180

200

220

240

260

280

300

320

[m]

H

CRN 125

60 Hz

ISO 9906:2012 Grade 3B

-3-1

-4-1

-5-1

-6-1

-4

-4-2

-5

-5-2

-6

-6-2

-7-2

-1

-1-1

-2

-2-1

-2-2

-3

-3-2

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

Q [US GPM]

0

10

20

30

40

[hp]

P2

0

20

40

60

80

[%]

Eff

0

5

10

15

20

25

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 50 100 150 200 250 300 350 400 450 500 550 600 650 700 750 800

Q [US GPM]

0

40

80

120

160

[ft]

H

0

10

20

30

40

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

CR, CRN 95-155Performance curves and technical data

CRN 125

CRN 125

CRN 125

24

The maximum pump efficiency (Eta) is based on a three-stage pump.

TM06 5540 3718

Page 25

CR, CRN 95-155 Performance curves and technical data

16.83"

19.65"

4 x ø0.89"

G 1/2

G 1/2

10.83"

13.07"

ø6"

19.09"

7.09"

B2

D2

D3

D1

G 1/2

G 1/2

G 1/2

G 1/2

B1

(8 x ø22.2)

(12 x ø22.2)

8 x ø0.87"

12 x ø0.88"

(4 x ø22.6)

(4 x ø22.6)

(4 x ø22.6)

4 x ø0.89"

4 x ø0.89"

ø6"

(ø150)

ø6"

(425)

16.83"

(499)

19.65"

(275)

(275)

10.83"

(332)

(332)

13.07"

(485)

(485)

19.09"

(425)

(425)

16.83"

(499)

(499)

19.65"

(ø216)

ø8.5"

ø8.5"

(ø216)

(ø270)

(ø328)

(180)

(180)

6.63"

(168)

7.09"

(ø241)

ø9.5"

ø10.62"

ø11.8"

(ø300)

ø12.9"

(ø150)

(ø150)

Class 300*

6" ANSI

Class 150*

6" ANSI

P (PJE) Victaulic type

CRN 125

5

CRN 125

* CR, CRN 125 pumps with 1 to 3 stages are fitted with 150 lb. (68 kg) flanges as standard. 300 lb. (136 kg) flanges are available on request.

CR, CRN 125 pumps with 4 or more stages are fitted with 300 lb.

(136 kg) flanges as standard.

Dimensions and weights

Motor P

Pump type

CRN 125-1-1 20 (15) 30.8 (783) 49.6 (1261) 12.4 (314) 8 (204) 8.5 (216) 478 (217)

CRN 125-1 25 (18) 30.9 (785) 53.7 (1363) 12.4 (314) 8 (204) 10.5 (267) 518 (235)

CRN 125-2-2 30 (22) 35.7 (907) 58.5 (1485) 12.4 (314) 8 (204) 10.5 (267) 569 (258)

CRN 125-2-1 40 (30) 36.6 (930) 64.2 (1630) 16.9 (429) 14.1 (359) 12.5 (318) 820 (372)

CRN 125-2 50 (37) 36.6 (930) 64.2 (1630) 16.9 (429) 14.1 (359) 12.5 (318) 888 (403)

CRN 125-3-2 60 (45) 41.4 (1052) 68.5 (1739) 16.9 (429) 14.1 (359) 12.5 (318 ) 961 (436)

CRN 125-3-1 75 (56) 41.4 (1052) 69 (1752) 19.7 (500) 18.1 (460) 12.5 (318) 1281 (581)

CRN 125-3 75 (56) 41.4 (1052) 69 (1752) 19.7 (500) 18.1 (460) 12.5 (318) 1281 (581)

CRN 125-4-2 75 (56) 46.2 (1174) 73.8 (1874) 19.7 (500) 18.1 (460) 12.5 (318) 1303 (591)

CRN 125-4-1 100 (75) 46.1 (1172) 82.2 (2087) 22.2 (565) 19.2 (488) 18 (457) 1781 (808)

CRN 125-4 100 (75) 46.1 (1172) 82.2 (2087) 22.2 (565) 19.2 (488) 18 (457) 1781 (808)

CRN 125-5-2 100 (75) 50.9 (1294) 87 (2209) 22.2 (565) 19.2 (488) 18 (457) 1803 (818)

CRN 125-5-1 125 (93) 50.9 (1294) 90.6 (2300) 26.5 (673) 22.7 (576) 18 (457) 2255 (1023)

CRN 125-5 125 (93) 50.9 (1294) 90.6 (2300) 2 6.5 (673) 22.7 (576) 18 (457) 2255 (1023)

CRN 125-6-2 125 (93) 55.7 (1416) 95.4 (2422) 26.5 (673) 22.7 (576) 18 (457) 2280 (1034)

CRN 125-6-1 150 (112) 55.7 (1416) 95.4 (2422) 26.5 (673) 22.7 (576) 18 (457) 2511 (1139)

CRN 125-6 150 (112) 55.7 (1416) 95.4 (2422) 26.5 (673) 22.7 (576) 18 (457) 2511 (1139)

CRN 125-7-2 150 (112) 60.6 (1538) 100.2 (2544) 26.5 (673) 22.7 (576) 18 (457) 2533 (1149)

[Hp (kW)]

2

B1 B1+B2 D1 D2 D3

Dimension [inch (mm)]

Net weight

[lbs (kg)]

TM06 6062 0218

25

Page 26

5

0 100 200 300 400 500 600 700 800 900 1000

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

[ft]

H

0 20 40 60 80 100 120 140 160 180 200 220 240

Q [m³/h]

0

20

40

60

80

100

120

140

160

[m]

H

CR 155

60 Hz

ISO 9906:2012 Grade 3B

-3-2

-1

-1-1

-2

-2-1

-2-2

0 100 200 300 400 500 600 700 800 900 1000

Q [US GPM]

0

10

20

30

40

[hp]

P2

0

20

40

60

80

[%]

Eff

0

5

10

15

20

25

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 100 200 300 400 500 600 700 800 900 1000

Q [US GPM]

0

50

100

150

200

[ft]

H

0

10

20

30

40

50

60

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

CR, CRN 95-155Performance curves and technical data

CR 155

CR 155

CR 155

26

The maximum pump efficiency (Eta) is based on a three-stage pump.

TM06 5541 3718

Page 27

CR, CRN 95-155 Performance curves and technical data

B2

D2

D3

D1

G 1/2

G 1/2

G 1/2

G 1/2

B1

(8 x ø22.2)

(12 x ø22.2)

8 x ø0.88"

12 x ø0.88"

(4 x ø22.6)

(4 x ø22.6)

4 x ø0.89"

4 x ø0.89"

ø6"

(ø150)

ø6"

(425)

16.83"

(499)

19.65"

(275)

10.83"

(332)

13.07"

(485)

19.09"

(425)

16.83"

(499)

19.65"

(ø216)

ø8.5"

ø8.5"

(ø216)

(ø270)

(ø328)

(180)

7.09"

(ø241)

ø9.5"

ø10.62"

ø12.8"

(ø300)

ø12.9"

(ø150)

Class 300*

6" ANSI

Class 150*

6" ANSI

CR 155

5

CR 155

* CR, CRN 155 pumps with 1 to 3 stages (with 1 reduced diameter impeller) are fitted with 150 lb. (68 kg) flanges as standard. 300 lb. (136 kg) flanges

are available on request.

CR, CRN 155 pumps with 3 or more full diameter impellers are fitted with 300 lb. (136 kg) flanges as standard.

Dimensions and weights

Motor P

Pump type

CR 155-1-1 25 (18) 30.9 (785) 53.7 (1363) 12.4 (314) 8 (204) 10.5 (267) 520 (236)

CR 155-1 40 (30) 31.8 (808) 59.4 (1508) 16.9 (429) 14.1 (359) 12.5 (318) 798 (362)

CR 155-2-2 50 (37) 36.6 (930) 64.2 (1630) 16.9 (429) 14.1 (359) 12.5 (318) 888 (403)

CR 155-2-1 60 (45) 36.6 (930) 63.7 (1617) 16.9 (429) 14.1 (359) 12.5 (318) 939 (426)

CR 155-2 75 (56) 36.6 (930) 64.2 (1630) 19.7 (500) 18.1 (460) 12.5 (318) 1259 (571)

CR 155-3-2 75 (56) 41.4 (1052) 69 (1752) 19.7 (500) 18.1 (460) 12.5 (318) 1283 (582)

[Hp (kW)]

2

B1 B1+B2 D1 D2 D3

Dimension [inch (mm)]

Net weight

[lbs (kg)]

TM06 6061 0218

27

Page 28

5

0 100 200 300 400 500 600 700 800 900 1000

Q [US GPM]

0

50

100

150

200

250

300

350

400

450

500

550

600

650

700

750

800

850

[ft]

H

0 20 40 60 80 100 120 140 160 180 200 220 240

Q [m³/h]

0

20

40

60

80

100

120

140

160

180

200

220

240

260

[m]

H

CRN 155

60 Hz

ISO 9906:2012 Grade 3B

-3-1

-4-1

-5-2

-3

-3-2

-4

-4-2

-5-1

-1

-1-1

-2

-2-1

-2-2

0 100 200 300 400 500 600 700 800 900 1000

Q [US GPM]

0

10

20

30

40

[hp]

P2

0

20

40

60

80

[%]

Eff

0

5

10

15

20

25

[kW]

P2

P2

1/1

IS 3550 rpm

P2

2/3

IS 3550 rpm

Eff 3550 rpm

0 100 200 300 400 500 600 700 800 900 1000

Q [US GPM]

0

50

100

150

200

[ft]

H

0

10

20

30

40

50

60

[m]

H

0

10

20

30

40

[ft]

NPSH

0

2

4

6

8

10

12

[m]

QH

1/1

IS 3550 rpm

QH

2/3

IS 3550 rpm

NPSH 3550 rpm

CR, CRN 95-155Performance curves and technical data

CRN 155

CRN 155

CRN 155

28

The maximum pump efficiency (Eta) is based on a three-stage pump.

TM06 5542 3718

Page 29

CR, CRN 95-155 Performance curves and technical data

16.83"

19.65"

4 x ø0.89"

G 1/2

G 1/2

10.83"

13.07"

ø6"

19.09"

7.09"

B2

D2

D3

D1

G 1/2

G 1/2

G 1/2

G 1/2

B1

(8 x ø22.2)

(12 x ø22.2)

8 x ø0.87"

12 x ø0.88"

(4 x ø22.6)

(4 x ø22.6)

(4 x ø22.6)

4 x ø0.89"

4 x ø0.89"

ø6"

(ø150)

ø6"

(425)

16.83"

(499)

19.65"

(275)

(275)

10.83"

(332)

(332)

13.07"

(485)

(485)

19.09"

(425)

(425)

16.83"

(499)

(499)

19.65"

(ø216)

ø8.5"

ø8.5"

(ø216)

(ø270)

(ø328)

(180)

(180)

6.63"

(168)

7.09"

(ø241)

ø9.5"

ø10.62"

ø11.8"

(ø300)

ø12.9"

(ø150)

(ø150)

Class 150*

6" ANSI

Class 300*

6" ANSI

P (PJE) Victaulic type

CRN 155

5

CRN 155

* CR, CRN 155 pumps with 1 to 3 stages (with 1 reduced diameter impeller) are fitted with 150 lb. (68 kg) flanges as standard. 300 lb. (136 kg) flanges

are available on request.

CR, CRN 155 pumps with 3 or more full diameter impellers are fitted with 300 lb. (136 kg) flanges as standard.

Dimensions and weights

Motor P

Pump type

CRN 155-1-1 25 (18) 30.9 (785) 53.7 (1363) 12.4 (314) 8 (204) 10.5 (267) 520 (236)

CRN 155-1 40 (30) 31.8 (808) 59.4 (1508) 16.9 (429) 14.1 (359) 12.5 (318) 798 (362)

CRN 155-2-2 50 (37) 36.6 (930) 64.2 (1630) 16.9 (429) 14.1 (359) 12.5 (318) 888 (403)

CRN 155-2-1 60 (45) 36.6 (930) 63.7 (1617) 16.9 (429) 14.1 (359) 12.5 (318) 939 (426)

CRN 155-2 75 (56) 36.6 (930) 64.2 (1630) 19.7 (500) 18.1 (460) 12.5 (318) 1259 (571)

CRN 155-3-2 75 (56) 41.4 (1052) 69 (1752) 19.7 (500) 18.1 (460) 12.5 (318) 1283 (582)

CRN 155-3-1 100 (75) 41.3 (1050) 77.4 (1965) 22.2 (565) 19.2 (488) 18 (457) 1761 (799)

CRN 155-3 100 (75) 41.3 (1050) 77.4 (1965) 22.2 (565) 19.2 (488) 18 (457) 1761 (799)

CRN 155-4-2 125 (93) 46.1 (1172) 85.7 (2178) 26.5 (673) 22.7 (576) 18 (457) 2238 (1015)

CRN 155-4-1 125 (93) 46.1 (1172) 85.7 (2178) 26.5 (673) 22.7 (576) 18 (457) 2238 (1015)

CRN 155-4 125 (93) 46.1 (1172) 85.7 (2178) 26.5 (673) 22.7 (576) 18 (457) 2238 (1015)

CRN 155-5-2 150 (112) 50.9 (1294) 90.6 (2300) 26.5 (673) 22.7 (576) 18 (457) 2493 (1131)

CRN 155-5-1 150 (112) 50.9 (1294) 90.6 (2300) 26.5 (673) 22.7 (576) 18 (457) 2493 (1131)

[Hp (kW)]

2

B1 B1+B2 D1 D2 D3

Dimension [inch (mm)]

Net weight

[lbs (kg)]

TM06 6062 0218

29

Page 30

6

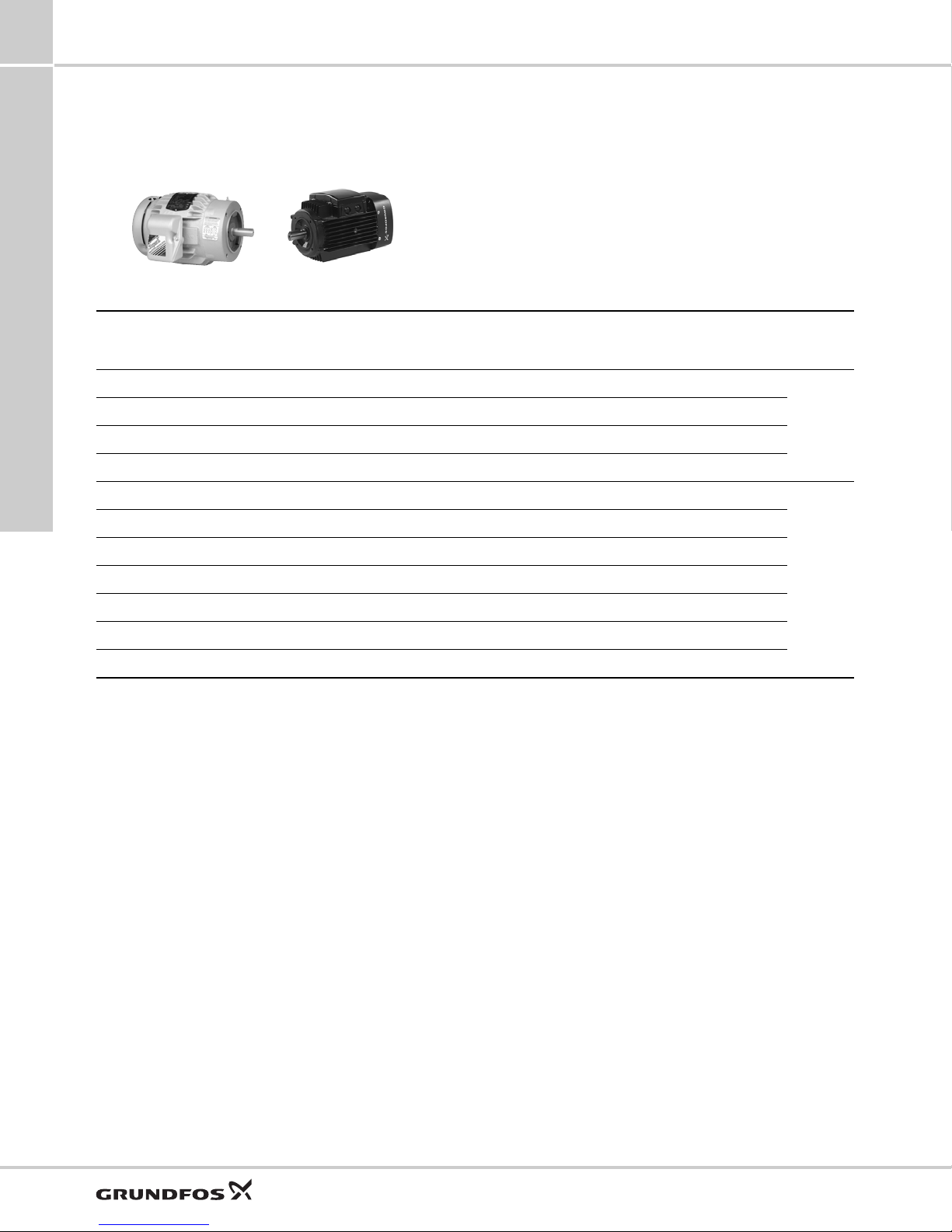

Baldor motor Grundfos motor

Motor data

CR, CRN 95-155

6. Motor data

Standard motors, 60 Hz

TM06 6898 2616 - GR7845

Motor

P2

[Hp

(kW)]

15 (11) 254TC

20 (15) 254TC

25 (19) 284TSC

30 (22) 286TSC

40 (30) 324TSC 230/460 90/45 1.15 0.86

50 (37) 326TSC 230/460 112/56 1.15 0.87

60 (45) 364TSC 230/460 132/66 1.15 0.87

75 (56) 365TSC 230/460 166/83 1.15 0.87

100 (75) 405TSD 460 110 1.15 0.90

125 (93) 444TSD 460 137 1.15 0.90

150 (112) 445TSD 460 166 1.15 0.89

Frame

size

Standard

voltage

[V]

208-230DD/

460D

208-230DD/

460D

208-230DD/

460D

208-230DD/

460D

I

Service

1/1

[A]

37.5-34/17 1.15 0.91-0.89

50.5-46/23 1.15 0.92-0.90

62-56/28 1.15 0.92-0.91

74-67/33.5 1.15 0.92-0.91

factor

Cos φ

Efficiency class

1/1

NEMA Premium /

NEMA Premium /

NEMA Premium /

NEMA Premium /

NEMA Premium /

NEMA Premium /

NEMA Premium /

NEMA Premium /

NEMA Premium /

NEMA Premium /

NEMA Premium /

IE3 60Hz

IE3 60Hz

IE3 60Hz

IE3 60Hz

IE3 60Hz

IE3 60Hz

IE3 60Hz

IE3 60Hz

IE3 60Hz

IE3 60Hz

IE3 60Hz

η

[%]

IE3 91.0% 255-306/153 3490-3530

IE3 91.0% 308-373/186 3490-3530

IE3 91.7% 341-420/210 3490-3530

IE3 91.7% 400-489/245 3490-3530

IE3 92.4% 564/326 3540

IE3 93.0% 688/398 3540

IE3 93.6% 989/572 3550

IE3 93.6% 1210/700 3550

IE3 94.1% 695 3565

IE3 95.0% 848 3565

IE3 95.0% 978 3575

I

start

[A]

Speed

[rpm]

Motor

brand

Grundfos

Baldor

30

Page 31

CR, CRN 95-155

7. List of pumped liquids

A number of typical liquids are listed below.

Other pump versions may be applicable, but those

stated in the list are considered to be the best choices.

The table is intended as a general guide only and

cannot replace actual testing of the pumped liquids

and pump materials under specific working conditions.

Therefore, use the list with some caution. Factors such

as those mentioned below may affect the chemical

resistance of a specific pump version:

• concentration of the pumped liquid

• liquid temperature

• pressure.

Take safety precautions when pumping dangerous

liquids.

Notes

D Often with additives.

The density and/or viscosity differ from that/those of water.

E

Take this factor into account when calculating motor output and

pump performance.

F Pump selection depends on many factors. Contact Grundfos.

H Risk of crystallization/precipitation in shaft seal.

1 Highly flammable liquid.

2 Combustible liquid.

3 Insoluble in water.

4 Low self-ignition point.

7

List of pumped liquids

31

Page 32

7

List of pumped liquids

Pumped liquid Chemical formula Note

Acetic acid CH

Acetone CH

Alkaline degreasing agent D, F - HQQE Ammonium bicarbonate NH

Ammonium hydroxide NH

Aviation fuel 1, 3, 4, F 100 %, 68 °F (20 °C) HQBV Benzoic acid C

Boiler water

Calcareous water - < 194 °F (90 °C) HQQE Calcium acetate (as coolant with inhibitor) Ca(CH

Calcium hydroxide Ca (OH)

Chloride-containing water F

Chromic acid H

Citric acid HOC(CH

Completely desalinated water (demineralized

water)

Condensate - 248 °F (120 °C) HQQE Copper sulphate CuSO

Corn oil D, E, 3 100 %, 176 °F (80 °C) HQQV Diesel oil 2, 3, 4, F 100 %, 68 °F (20 °C) HQBV Domestic hot water (potable water) - < 248 °F (120 °C) HQQE Ethanol (ethyl alcohol) C

Ethylene glycol HOCH

Formic acid HCOOH - 5 %, 68 °F (20 °C) - HQQE

Glycerine (glycerol) OHCH

Hydraulic oil (mineral) E, 2, 3 100 %, 212 °F (100 °C) HQQV Hydraulic oil (synthetic) E, 2, 3 100 %, 212 °F (100 °C) HQQV Isopropyl alcohol CH

Lactic acid CH

Linoleic acid C

Methanol (methyl alcohol) CH

Motor oil E, 2, 3 100 %, 176 °F (80 °C) HQQV Naphthalene C

Nitric acid HNO

Oil-containing water - < 212 °F (100 °C) HQQV Olive oil D, E, 3 100 %, 176 °F (80 °C) HQQV Oxalic acid (COOH)

Ozone-containing water (O

Peanut oil D, E, 3 100 %, 176 °F (80 °C) HQQV Petrol 1, 3, 4, F 100 %, 68 °F (20 °C) HQBV Phosphoric acid H

Propanol C

Propylene glycol CH

Potassium carbonate K

Potassium formate (as coolant with inhibitor) KOOCH D, E 30 %, 122 °F (50 °C) HQQE Potassium hydroxide KOH E 20 %, 122 °F (50 °C) - HQQE

Potassium permanganate KMnO

Rape seed oil D, E, 3 100 %, 176 °F (80 °C) HQQV Salicylic acid C

Silicone oil E, 3 100 % HQQV Sodium bicarbonate NaHCO

Sodium chloride (as coolant) NaCl D, E 30 %, < 41 °F (5 °C), pH > 8 HQQE Sodium hydroxide NaOH E 20 %, 122 °F (50 °C) - HQQE

Sodium hypochlorite NaOCl F 0.1 %, 68 °F (20 °C) - HQQV

Sodium nitrate NaNO

Sodium phosphate Na

Sodium sulphate Na

Softened water - < 248 °F (120 °C) - HQQE

Soya oil D, E, 3 100 %, 176 °F (80 °C) HQQV Sulphuric acid H

Sulphurous acid H

Unsalted swimming-pool water - Approx. 2 ppm free chlorine (Cl

CR, CRN 95-155

Liquid concentration, liquid

temperature

COOH - 5 %, 68 °F (20 °C) - HQQE

3

COCH

3

3

HCO

4

3

OH - 20 %, 104 °F (40 °C) HQQE -

4

COOH H 0.5 %, 68 °F (20 °C) - HQQV

6H5

1, F 100 %, 68 °F (20 °C) - HQQE

E 20 %, 86 °F (86 °F (30 °C)) - HQQE

- < 248 °F (120 °C) HQQE -

F 248-356 °F (120-180 °C) - -

COO)

3

2

2

CrO

2

4

COOH H 5 %, 104 °F (40 °C) - HQQE

2CO2H)2

D, E 30 %, 122 °F (50 °C) HQQE -

E

Saturated solution, 122 °F (50

< 86 °F (30 °C), maximum 500

°C)

ppm

H 1 %, 68 °F (20 °C) - HQQV

- 248 °F (120 °C) - HQQE

4

OH 1, F 100 %, 68 °F (20 °C) HQQE -

2H5

OH D, E 50 %, 122 °F (50 °C) HQQE -

2CH2

CH(OH)CH2OH D, E 50 %, 122 °F (50 °C) HQQE -

2

CHOHCH

3

CH(OH)COOH E, H 10 %, 68 °F (20 °C) - HQQV

3

17H31

CH(OH)CH2OH D, E 50 %, 194 °F (90 °C) HQQE -

3

(OH)COOH H 0.1 %, 68 °F (20 °C) - HQQE

6H4

3

COOH E, 3 100 %, 68 °F (20 °C) HQQV OH 1, F 100 %, 68 °F (20 °C) HQQE -

3

10H8

3

2

) - < 212 °F (100 °C) - HQQE

3

3PO4

OH 1, F 100 %, 68 °F (20 °C) HQQE -

3H7

2CO3

4

3

3

3PO4

2SO4

2SO4

2SO3

E 10 %, 122 °F (50 °C) - HQQE

1, F 100 %, 68 °F (20 °C) HQQE -

E, H 100 %, 176 °F (80 °C) HQQV -

F 1 %, 68 °F (20 °C) - HQQE

H 1 %, 68 °F (20 °C) - HQQE

E 20 %, 68 °F (20 °C) - HQQE

E 20 %, 122 °F (50 °C) HQQE -

- 5 %, 68 °F (20 °C) - HQQE

E 10 %, 140 °F (60 °C) - HQQE

E 10 %, 140 °F (60 °C) - HQQE

E, H 10 %, 140 °F (60 °C) - HQQE

E, H 10 %, 140 °F (60 °C) - HQQE

F 1 %, 68 °F (20 °C) - HQQV

- 1 %, 68 °F (20 °C) - HQQE

CR CRN

HQQE -

- HQQE

) HQQE -

2

32

Page 33

CR, CRN 95-155

8. Accessories

PJE couplings for CRN

Materials in contact with the pumped liquid are made of stainless steel AISI 316 and rubber.

A set consists of two coupling halves (Victaulic

and nuts.

®

type 77), one gasket, one pipe stub (for welding or threaded), bolts

8

Accessories

Coupling Pump type Pipe stub

CRN 95 For welding 800 (55) 4"

CRN 125

CRN 155

For welding 800 (55) 6"

Max. pressure

[psi (bar)]

Pipe connection

Rubber

parts

EPDM

FKM

EPDM

FKM

Number of

coupling sets

required

2

2

33

Page 34

9

"REPLACEMENT" enables you to find a

replacement product. Search results will

include information on the following:

• the lowest purchase price

• the lowest energy consumption

• the lowest total life cycle cost.

"CATALOGUE" gives you

access to the Grundfos

product catalogue.

"LIQUIDS" enables you to find

pumps designed for aggressive,

flammable or other special

liquids.

Grundfos Product Center

9. Grundfos Product Center

Online search and sizing tool to help you

make the right choice.

http://product-selection.grundfos.com

This drop-down menu enables you to set the

search function to "Products" or "Literature".

"SIZING" enables you to size a

pump based on entered data and

selection choices.

CR, CRN 95-155

All the information you need in one place Downloads

Performance curves, technical specifications, pictures, dimensional drawings, motor

curves, wiring diagrams, spare parts, service kits, 3D drawings, documents, system parts.

The Product Center displays any recent and saved items - including complete projects right on the main page.

34

On the product pages, you can download

installation and operating instructions, data

booklets, service instructions, etc. in PDF format.

Page 35

CR, CRN 95-155

GET IT ON

Grundfos GO

Mobile solution for professionals on the GO!

Grundfos GO is the mobile tool box for professional

users on the go. It is the most comprehensive platform

for mobile pump control and pump selection including

sizing, replacement and documentation. It offers

intuitive, handheld assistance and access to Grundfos

online tools, and it saves valuable time for reporting

and data collection.

9

Grundfos Product Center

35

Page 36

99407996 0419

ECM: 1257564

Grundfos Kansas City

9300 Loiret Boulevard

Lenexa, Kansas 66219

Phone: 913-227-3400

Fax: 913-227-3500

www.grundfos.us

Grundfos Canada

2941 Brighton Road

Oakville, Ontario L6H 6C9 Canada

Phone: +1-905-829-9533

Fax: +1-905-829-9512

www.grundfos.ca

Grundfos México

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

C.P. 66600 Apodaca, N.L. Mexico

Phone: 011-52-81-8144 4000

Fax: 011-52-81-8144 4010

www.grundfos.mx

Trademarks displayed in this material, including but not limited to Grundfos, the Grundfos logo and “be think innovate” are registered trademarks owned by The Grundfos Group. All rights reserved. © 2019 Grundfos Holding A/S, all rights reserved.

Loading...

Loading...