Page 1

Control MPC

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

Declaration of Conformity

We, Grundfos, declare under our sole responsibility that the products

Control MPC, to which this declaration relates, are in conformity with these

Council directives on the approximation of the laws of the EC member

states:

— Low Voltage Directive (2006/95/EC).

Standards used: EN 60439-1: 2002 and EN 60204-1: 2006.

— EMC Directive (2004/108/EC).

Attestation of conformity: Certificate Control MPC 2: 2009.

These products must not be put into service until the system into which

they are to be incorporated has been declared in conformity with the

provisions of the Machinery Directive (2006/42/EC).

Bjerringbro, 29th December 2009

Svend Aage Kaae

Technical Director

2

Page 3

CONTENTS

Page

1. Symbols used in this document 4

2. Scope of these instructions 4

3. Product description 4

4. Applications 4

4.1 Pumps 4

4.2 Control variant 4

5. Nameplate 5

6. Software label 5

7. Type key 6

8. Overview of control variants, examples 7

9. Installation 9

9.1 Mechanical installation 9

9.2 Electrical installation 9

9.3 Start-up 9

10. Control panel 9

10.1 Display (pos. 1) 10

10.1.1 Menu line 10

10.1.2 Top line 10

10.1.3 Graphical illustration 10

10.1.4 Scroll bar 10

10.1.5 Bottom line 10

10.2 Buttons and indicator lights 10

10.2.1 Arrow to the right (pos. 2) 10

10.2.2 Help (pos. 3) 10

10.2.3 Up and down (pos. 4 and 5) 10

10.2.4 Plus and minus (pos. 6 and 7) 10

10.2.5 Esc (pos. 8) 10

10.2.6 Home (pos. 9) 10

10.2.7 Ok (pos. 10) 10

10.2.8 Indicator lights (pos. 11 and 12) 10

10.2.9 Contrast (pos. 13) 10

10.2.10 Back light 10

11. Functions 11

11.1 Tree of functions 11

11.2 Overview 13

11.3 Description of functions 15

11. 4 Status (1) 1 5

11.4.1 Current alarms (3.1) 15

11.4.2 System (1.2) 15

11.4.3 Operating mode (1.2.1) 16

11.4.4 Setpoint (1.2.2) 16

11.4.5 Setpoint influence (1.2.3) 16

11.4.6 Measured values (1.2.4) 17

11.4.7 Analog inputs (1.2.5) 17

11.4.8 Pump 1...6 (1.3 to 1.8) 17

11.5 Operation (2) 18

11.5.1 Operation (2) 18

11.5.2 System operating mode (2.1.1) 18

11.5.3 Control mode (2.1.2) 19

11.5.4 Setpoints (2.1.3) 21

11.5.5 Individual pump control (2.1.4) 21

11.5.6 Setting of individual operating mode

(2.1.4.1 to 2.1.4.6) 22

11. 6 Al ar m ( 3) 23

11.6.1 Alarm status (3) 23

11.6.2 Current alarms (3.1) 24

11.6.3 Alarm log (3.2) 24

11.7 Settings (4) 25

11.7.1 Primary controller (4.1) 25

11.7.2 PI controller (4.1.1) 26

11.7.3 Alternative setpoints (4.1.2) 27

11.7.4 Alternative setpoints 2 to 7 (4.1.2.1 to 4.1.2.7) 27

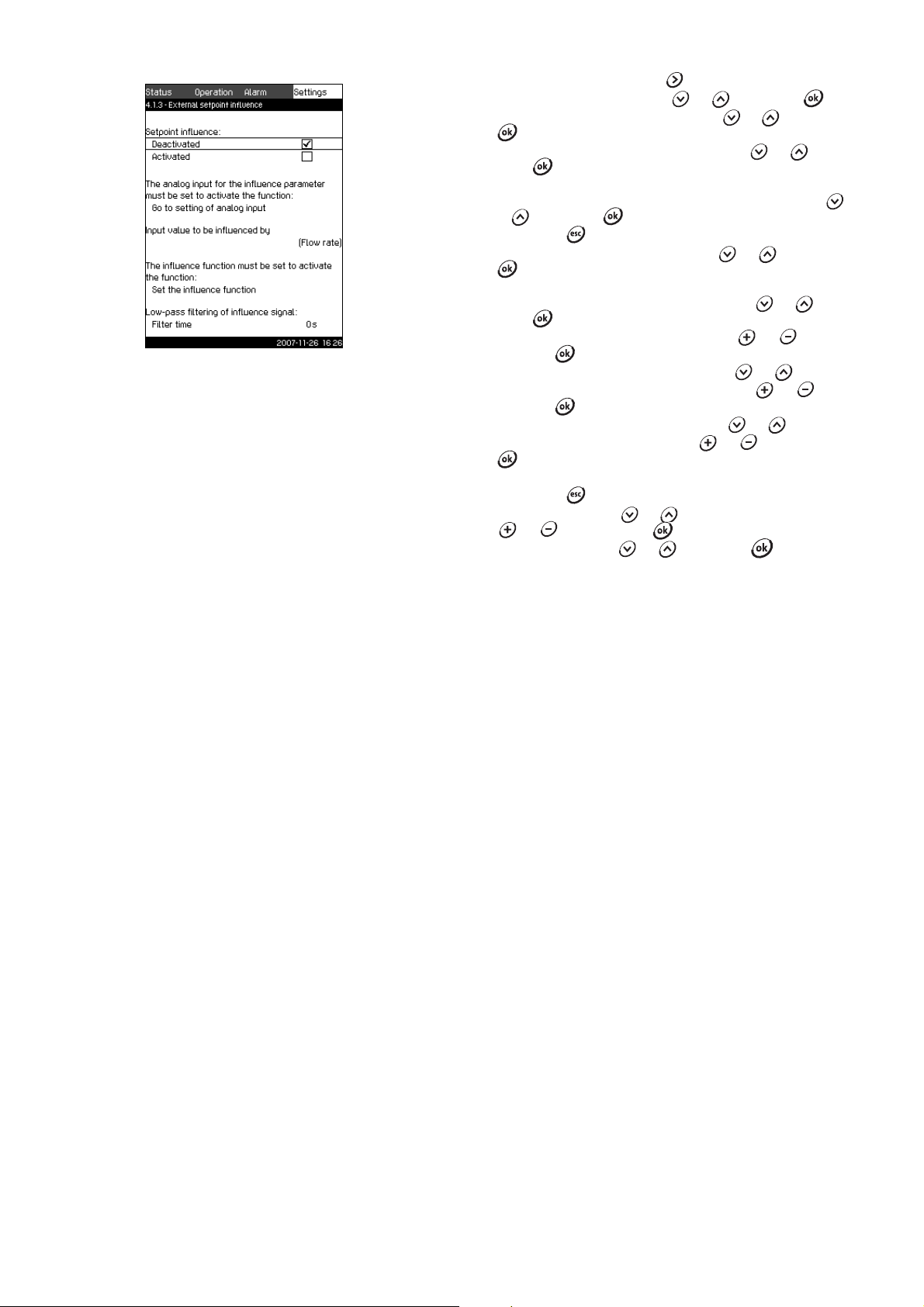

11.7.5 External setpoint influence (4.1.3) 28

11.7.6 Setting of influence function (4.1.3.2) 29

11.7.7 Primary sensor (4.1.4) 29

11.7.8 Clock program (4.1.6) 30

11.7.9 Proportional pressure (4.1.7) 31

11.7.10 S-system configuration (4.1.8) 31

11.7.11 Pump cascade control (4.2) 32

11.7.12 Min. time between start/stop (4.2.1) 32

11.7.13 Max. number of starts/hour (4.2.1) 32

11.7.14 Standby pumps (4.2.3) 33

11.7.15 Forced pump changeover (4.2.4) 33

11.7.16 Pump test run (4.2.5) 34

11.7.17 Pilot pump (4.2.6) 34

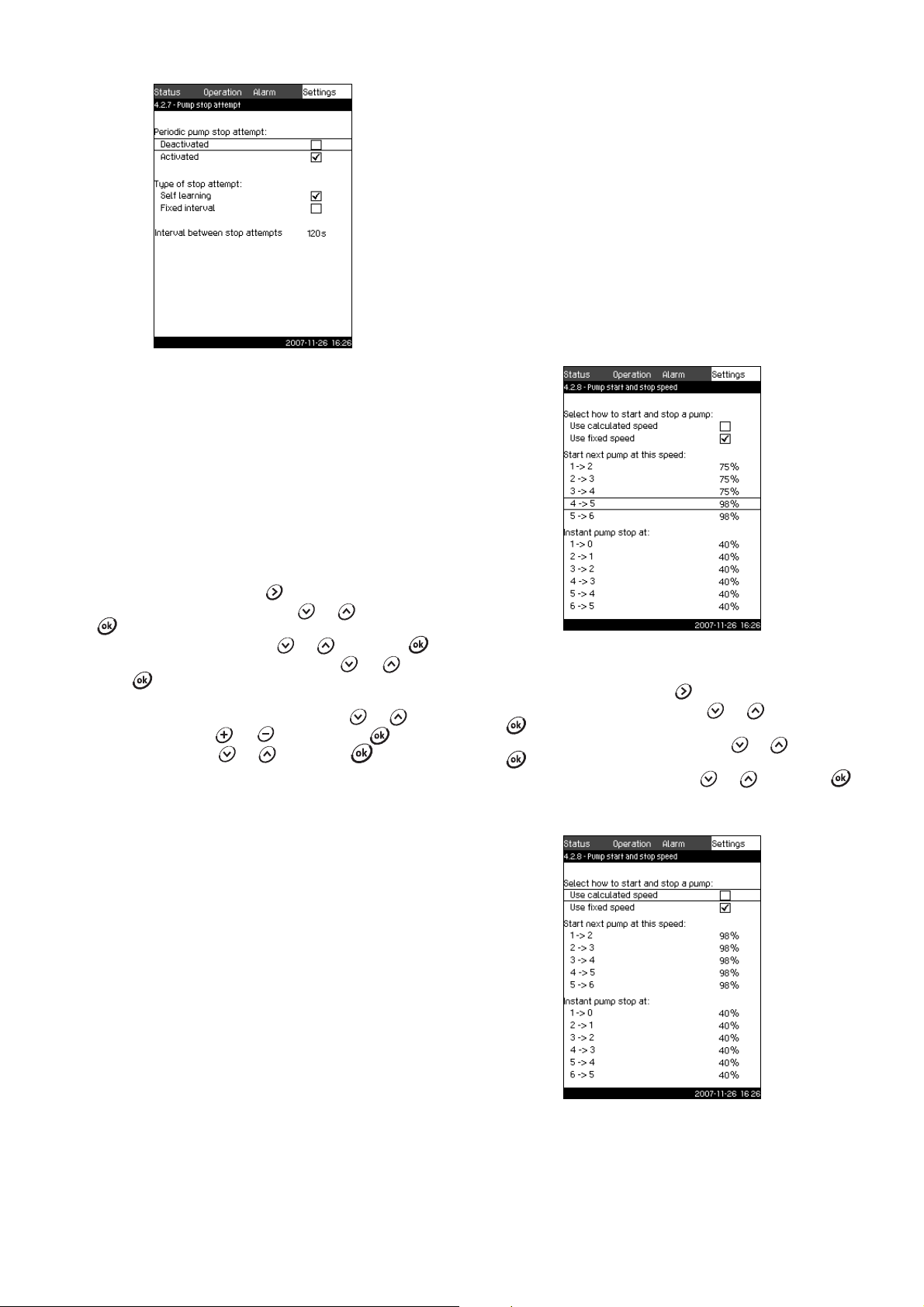

11.7.18 Pump stop attempt (4.2.7) 35

11.7.19 Pump start and stop speed (4.2.8) 35

11.7.20 Min. performance (4.2.9) 36

11.7.21 Compensation for pump start-up time (4.2.10) 36

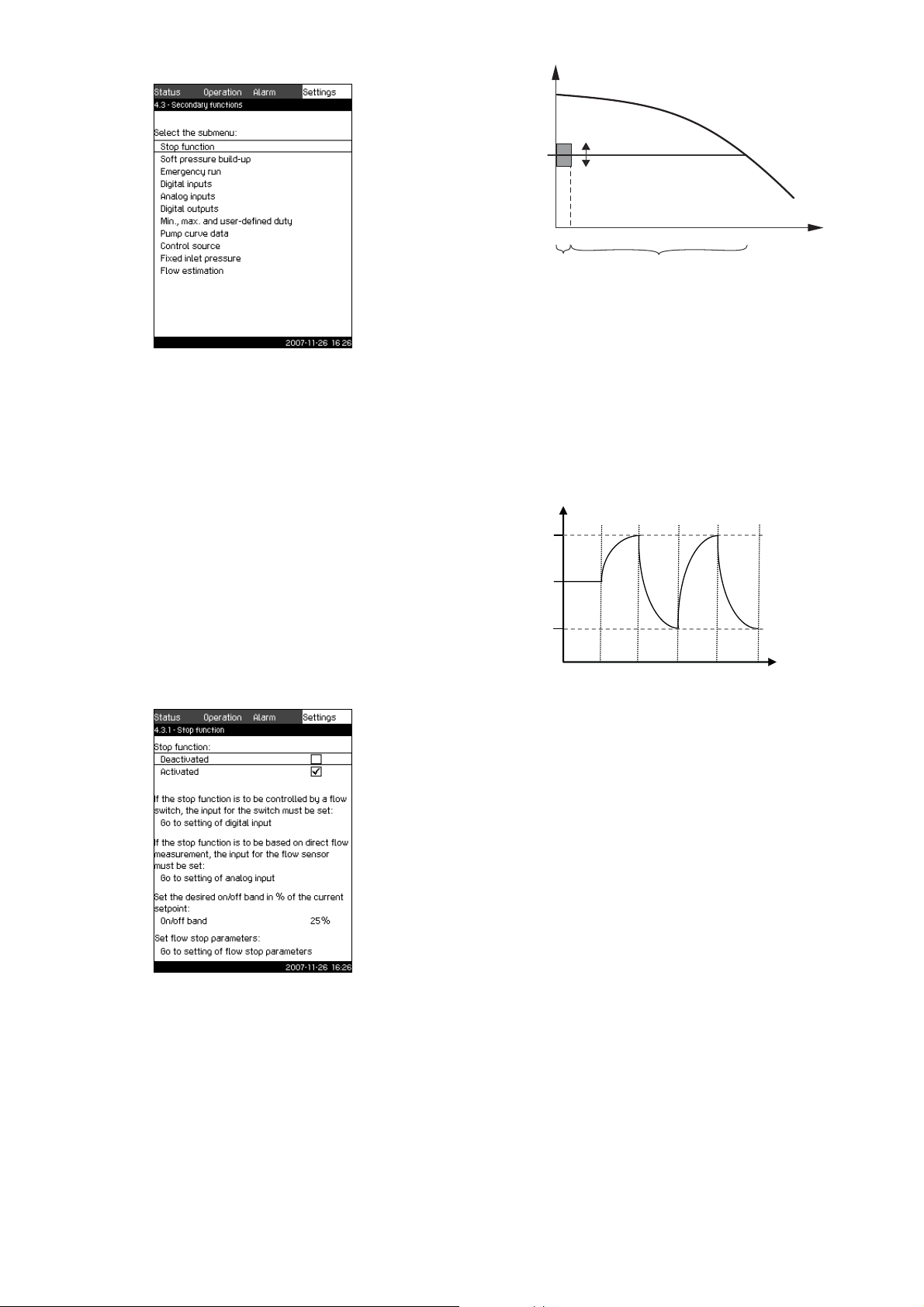

11.7.22 Secondary functions (4.3) 37

11.7.23 Stop function (4.3.1) 37

11.7.24 Soft pressure build-up (4.3.3) 39

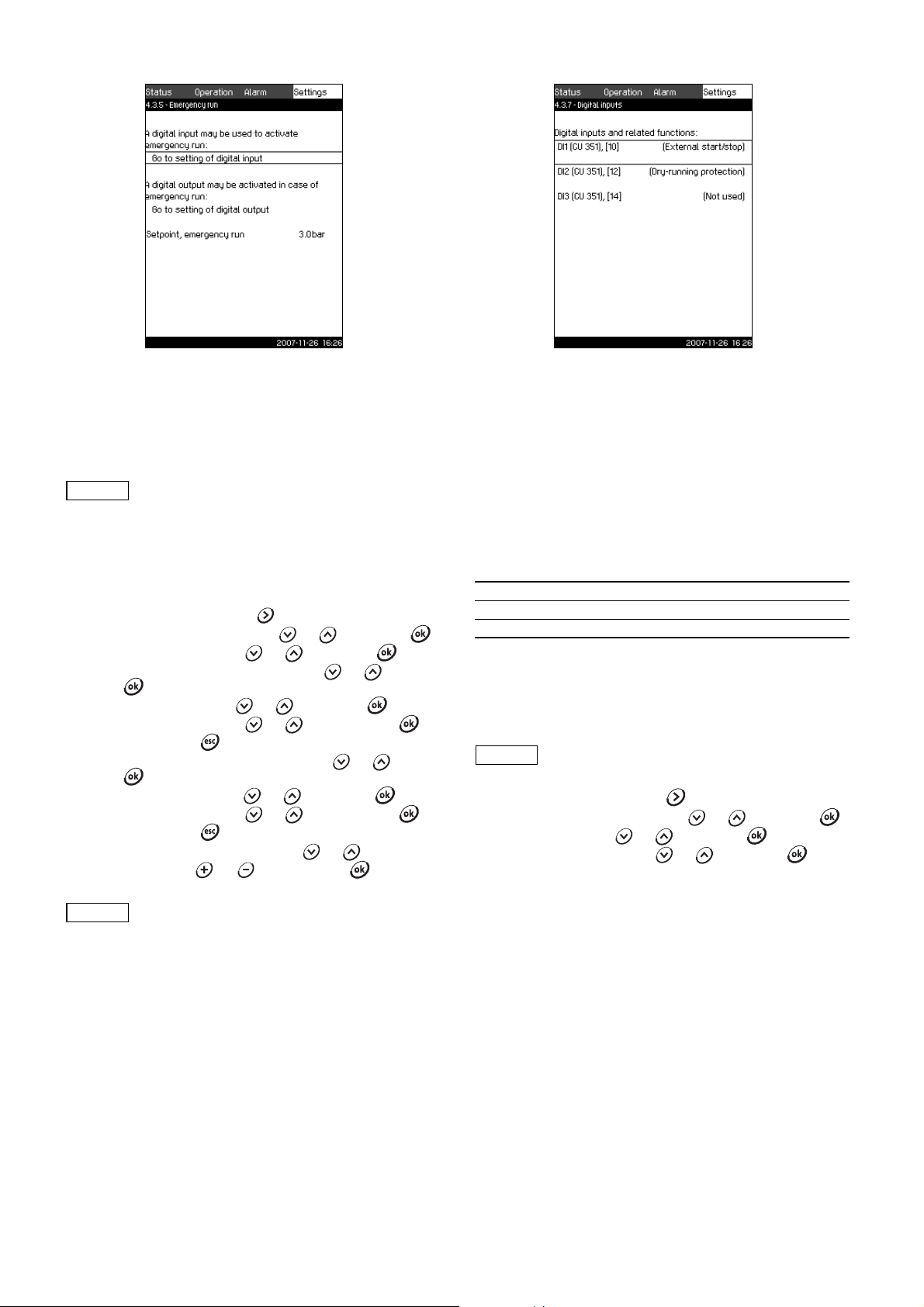

11.7.25 Emergency run (4.3.5) 40

11.7.26 Digital inputs (4.3.7) 40

11.7.27 Functions of digital inputs (4.3.7.1) 41

11.7.28 Analog inputs (4.3.8) 41

11.7.29 Analog inputs (4.3.8.1 to 4.3.8.7) 42

11.7.30 Analog inputs and measured value

(4.3.8.1.1 to 4.3.8.7.1) 42

11.7.31 Digital outputs (4.3.9) 43

11.7.32 Functions of digital outputs (4.3.9.1 to 4.3.9.16) 43

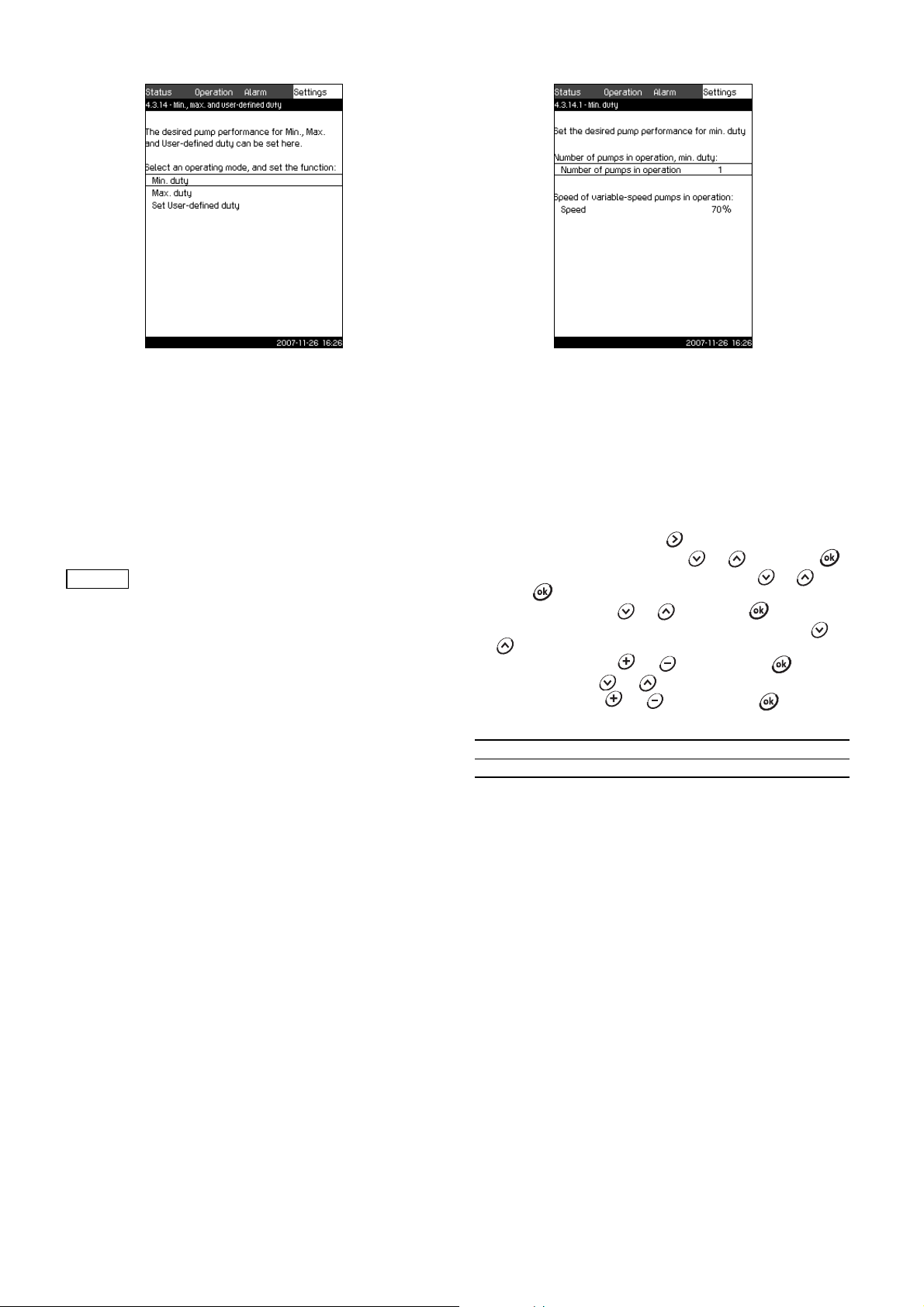

11.7.33 Min., max. and user-defined duty (4.3.14) 44

11.7.34 Min. duty (4.3.14.1) 44

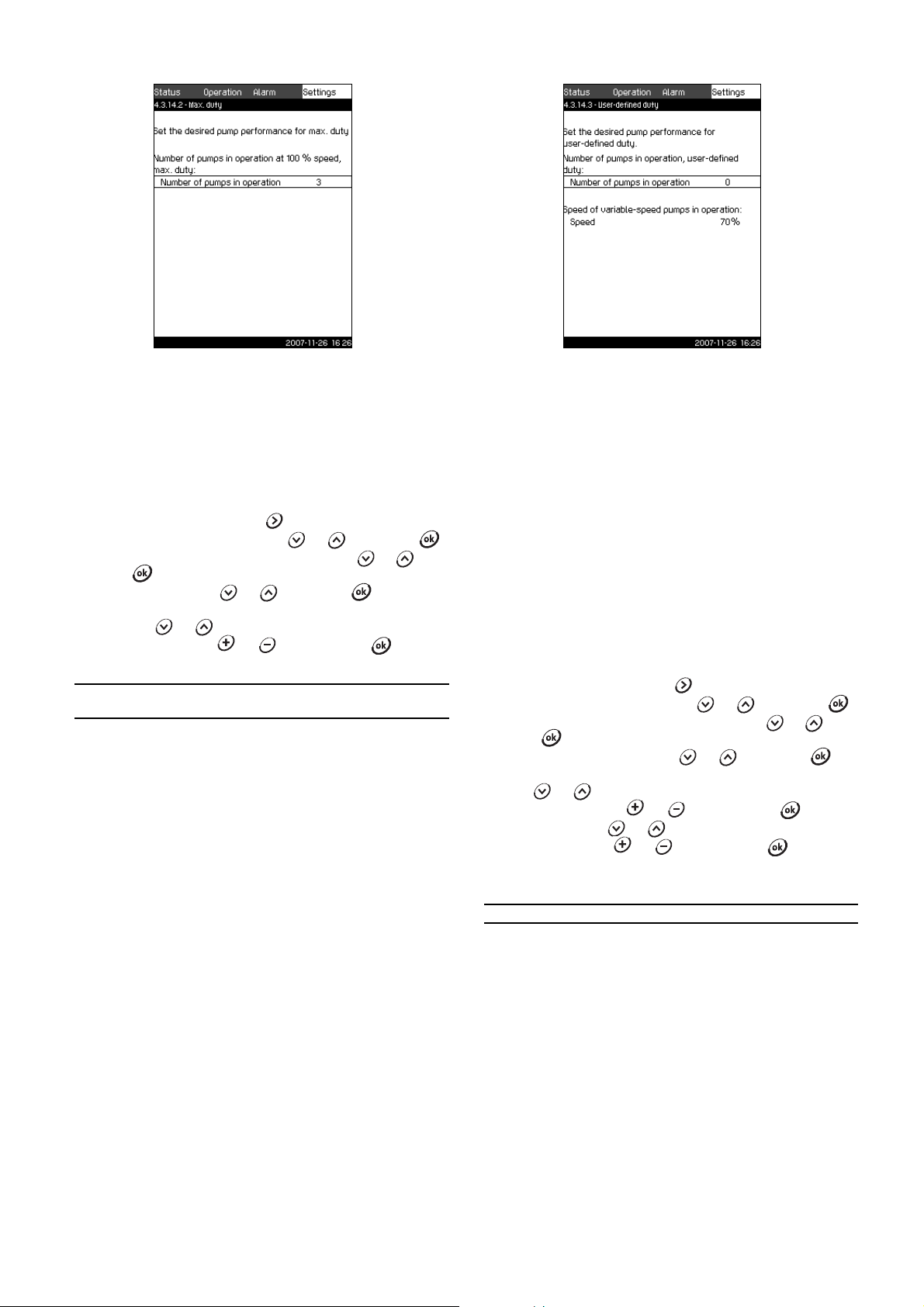

11.7.35 Max. duty (4.3.14.2) 45

11.7.36 User-defined duty (4.3.14.3) 45

11.7.37 Pump curve data (4.3.19) 46

11.7.38 Control source (4.3.20) 47

11.7.39 Fixed inlet pressure (4.3.22) 47

11.7.40 Flow estimation (4.3.23) 48

11.7.41 Monitoring functions (4.4) 48

11.7.42 Dry-running protection (4.4.1) 49

11.7.43 Dry-running protection with pressure/level switch

(4.4.1.1) 49

11.7.44 Dry-running protection with pressure transmitter

(4.4.1.2) 50

11.7.45 Dry-running protection with level transmitter

(4.4.1.3) 50

11.7.46 Min. pressure (4.4.2) 51

11.7.47 Max. pressure (4.4.3) 51

11.7.48 External fault (4.4.4) 52

11.7.49 Limit 1 and 2 exceeded (4.4.5 and 4.4.6) 52

11.7.50 Pumps outside duty range (4.4.7) 53

11.7.51 Pressure relief (4.4.8) 54

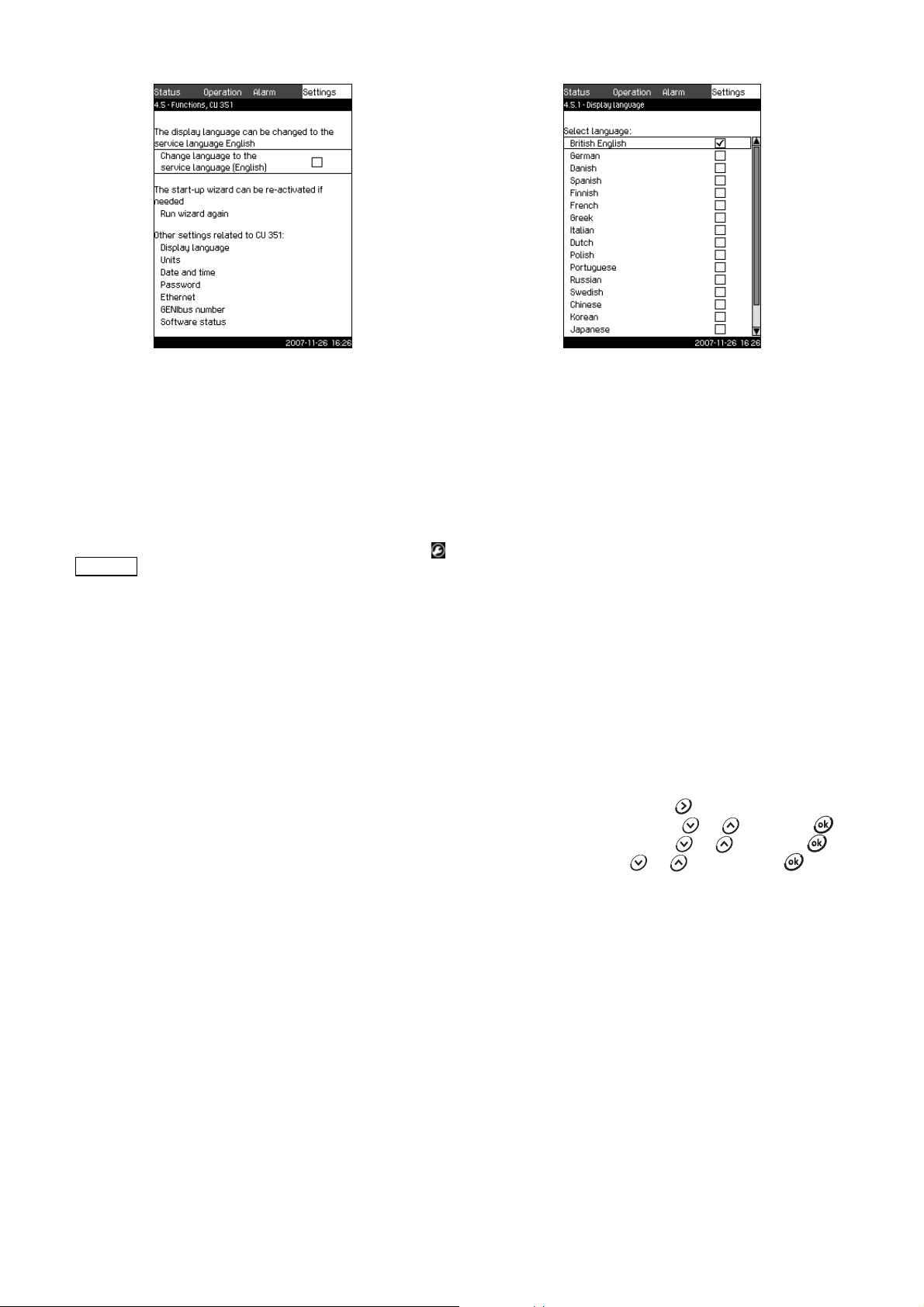

11.7.52 Functions, CU 351 (4.5) 55

11.7.53 Display language (4.5.1) 55

11.7.54 Display units (4.5.2) 56

11.7.55 Date and time (4.5.3) 57

11.7.56 Passwords (4.5.4) 57

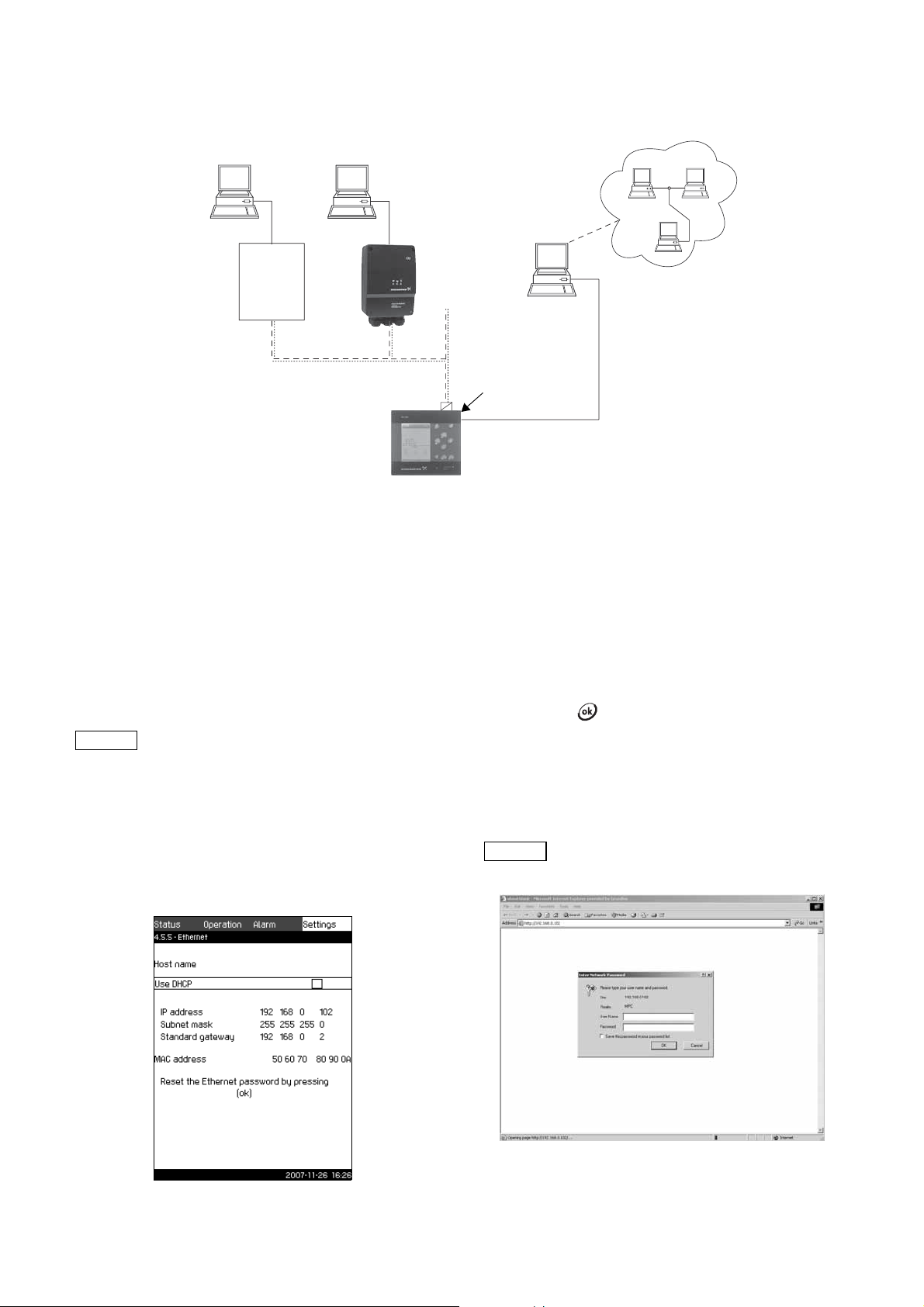

11.7.57 Ethernet (4.5.5) 58

11.7.58 GENIbus number (4.5.6) 58

11.7.59 Software status (4.5.9) 58

11.8 Data communication 59

11.8.1 Ethernet 59

11.8.2 GENIbus 60

12. Measuring parameters 61

12.1 Transmitter types 61

12.2 Parameter list 61

13. Fault finding chart 62

14. Maintenance 63

14.1 CU 351 63

15. Taking out of operation 63

16. Technical data 63

16.1 Temperature 63

16.2 Relative humidity 63

17. Electrical data 63

18. Related documents 63

19. Disposal 63

3

Page 4

Warnin g

Caution

Note

Note

Prior to installation, read these installation and

operating instructions. Installation and operation

must comply with local regulations and accepted

codes of good practice.

4. Applications

Control MPC is used for control and monitoring of pumps in these

applications:

• booster systems

• circulation systems for heating, cooling and air-conditioning.

1. Symbols used in this document

Warnin g

If these safety instructions are not observed, it

may result in personal injury!

If these safety instructions are not observed, it

may result in malfunction or damage to the

equipment!

Notes or instructions that make the job easier

and ensure safe operation.

2. Scope of these instructions

These installation and operating instructions apply to Grundfos

Control MPC.

Grundfos Control MPC is a complete solution for control and

monitoring of up to six identical pumps.

3. Product description

4.1 Pumps

Control MPC is designed for systems with these pumps:

• CR(E), CRI(E), CRN(E), CRIE

• NB(E), NBG(E)

• NK(E), NKG(E)

•TP

• TPE Series 1000

• TPE Series 2000

•HS

•SP

• MAGNA, UPE Series 2000.

The main pumps of the system must be of the

same type and size.

4.2 Control variant

Control MPC is divided into four groups based on control variant:

Control

variant

Series

2000

See also section 8. Overview of control variants.

The Control MPC includes software for booster, heating and

cooling.

Description

Two to six electronically speed-controlled pumps.

From 0,37 to 22 kW, Control MPC-E is equipped with

Grundfos pumps with integrated frequency converter.

-E

As from 30 kW, Control MPC-E is equipped with

mains-operated pumps connected to external

Grundfos CUE frequency converters (one per pump).

Two to six MAGNA, UPE or TPE Series 2000 pumps

Two to six pumps connected to an external Grundfos

-F

CUE frequency converter. The speed-controlled

operation alternates between the pumps.

-S Two to six mains-operated pumps

TM04 0210 0208 - GrA5728

Fig. 1 Control MPC

Grundfos Control MPC is used for control and monitoring of

booster systems and circulation systems.

Control MPC consists of a control cabinet with a built-in controller,

the CU 351. The control cabinet contains all necessary

components such as main switch, contactors, IO modules and

cabling. In systems with external frequency converters, the

frequency converters can be installed in the cabinet.

The control cabinet is for wall or floor mounting.

4

Page 5

5. Nameplate

Type:

Model:

Serial No.:

Order No.:

Options:

IP

Weight: kg

Made in

96778609

1

2

3

4

78 9

16

17

23

24

26

25

Mains supply:

I

n

: A T

AMB.

:

o

C

PU

n

No. kW V

Fixed speed pumps:

E-pumps:

Pilot Pump:

10

11 12

18

20 21

19

22

13 14

15

5

6

Note

The nameplate of the Control MPC is fitted on the base frame.

See position 2 in fig. 2.

6. Software label

The software label is placed on the back of the CU 351 controller.

1. Control MPC 3. Hydro MPC

1

2

3

4. H-MPC options2. C-MPC options

4 5

5. Pump data

Fig. 2 Nameplate

Pos. Description

1 Type designation

2 Model

3 Serial number

4 Supply voltage

5 Nominal current [A]

6 Maximum ambient temperature in °C

7 Number of mains-operated pumps

8 Motor power in kW for mains-operated pumps

9 Nominal voltage in volts for mains-operated pumps

10 Number of pumps with frequency converter

11 Motor power in kW for pumps with frequency converter

Nominal voltage in volts for pumps with frequency

12

converter

13 Number of pilot pumps

14 Motor power in kW for pilot pump

15 Nominal voltage in volts for pilot pump

16 Order number

17-22 Options

23 Enclosure class

24 Weight [kg]

25 CE-mark

26 Country of origin

CONFIGURATION STEPS - PLEASE FOLLOW THE NUMBERS

Fig. 3 Software label

Pos. Description

1 Control MPC - GSC file number

2 Control MPC options - GSC file numbers

3 Hydro MPC - GSC file number*

4 Hydro MPC options - GSC file numbers*

5 Pump data - GSC file numbers**

* Applies only to booster systems.

** Applies only to CR, CRI, CRE and CRIE pumps.

A GSC (Grundfos Standard Configuration) file is a

TM03 9956 4707

configuration data file.

96586126

TM03 1742 3105

5

Page 6

7. Type key

Example Control MPC -E 2 x 4 E (* (* (* 3 x 380-415 V, 50/60 Hz, PE

Type range

Subgroups:

E: Pumps with integrated frequency converter (0.37 - 22 kW) - one per pump

E: Pumps with external Grundfos CUE frequency converter (30 kW and above) -

one per pump

F: Pumps with external Grundfos CUE frequency converter

S: Mains-operated pumps (start/stop)

Number of pumps with frequency converter

Power [kW]

Starting method:

E: Electronic soft starter (pumps with integrated frequency converter)

ESS: Electronic soft starter (pumps with external Grundfos CUE frequency converter)

Number of mains-operated pumps

Power [kW]

Starting method:

DOL: Direct-on-line starting

SD: Star-delta starting

Supply voltage, frequency

(* Code for custom-built solution.

6

Page 7

8. Overview of control variants

PTPTPT

Q

H

H

set

H

set

Q

H

H

stop

H

set

Q

H

H

set

H

set

Q

H

H

stop

H

set

The examples below are based on booster systems.

Systems with speed-controlled

pumps

Control MPC-E Control MPC-F Control MPC-S

Control MPC with three E-pumps.

One E-pump in operation.

Systems with pumps connected to

one CUE frequency conve rter

Control MPC with three pumps

connected to an external Grundfos CUE

frequency converter in the control

cabinet. The speed-controlled operation

alternates between the pumps.

TM03 0993 0905

One pump connected to an external

Grundfos CUE frequency converter in

operation.

H

Systems with mains-operated pumps

Control MPC with three mains-operated

pumps.

TM03 1265 1505

One mains-operated pump in operation.

TM03 0999 0905

Three E-pumps in operation.

• Control MPC-E maintains a constant

pressure through continuous adjustment

of the speed of the pumps.

• The system performance is adjusted to

the demand through cutting in/out the

required number of pumps and through

parallel control of the pumps in operation.

• Pump changeover is automatic and

depends on load, operating hours and

fault.

• All pumps in operation will run at equal

speed.

• The number of pumps in operation also

depends on the energy consumption of

the pumps. If only one pump is required,

two pumps will be running at a lower

speed if this results in a lower energy

consumption. This requires that the

differential pressure of the pump is

measured.

TM00 7995 2296

One pump connected to an external

Grundfos CUE frequency converter and

two mains-operated pumps in operation.

H

TM00 7996 2296

• Control MPC-F maintains a constant

pressure through continuous adjustment

of the speed of the pump connected to the

external Grundfos CUE frequency

converter. The speed-controlled operation

alternates between the pumps.

• One pump connected to the external

Grundfos CUE frequency converter

always starts first. If the pressure cannot

be maintained by the pump, one or two

mains-operated pumps will be cut in.

• Pump changeover is automatic and

depends on load, operating hours and

fault.

Q

TM00 7995 2296

Three mains-operated pumps in

operation.

Q

TM00 7998 2296

• Control MPC-S maintains an almost

constant pressure through cutting in/out

the required number of pumps.

• The operating range of the pumps will lie

between H

set

and H

(cut-out pressure).

stop

• Pump changeover is automatic and

depends on load, operating hours and

fault.

TM03 9204 3607

TM03 9203 3607

7

Page 8

The example below is based on a circulation system.

Q

H

H

set

Q

H

H

set

Control MPC Series 2000

Control MPC with three E-pumps.

TM04 0213 5107

One E-pump in operation.

TM04 0211 5107

Three E-pumps in operation.

• Control MPC Series 2000 maintains a

constant pressure through adjustment of

the speed of the pumps connected.

• The performance is adjusted to the demand

through cutting in/out the required number

of pumps and through parallel control of the

pumps in operation.

• Pump changeover is automatic and

depends on load, operating hours and fault.

• All pumps in operation will run at equal

speed.

• The number of pumps in operation is also

depending on the energy consumption of

the pumps. If only one pump is required,

the Control MPC will run with two pumps in

operation at a lower speed if this results in

a lower energy consumption. This requires

that the differential pressure of the pump is

measured.

TM04 0212 5107

8

Page 9

9. Installation

Note

Note

Warning

Installation and operation must comply with local

regulations and accepted codes of good

practice.

Before installation check that

• the Control MPC corresponds to the one ordered

• no visible parts have been damaged.

9.1 Mechanical installation

The Control MPC must be installed in a well ventilated room to

ensure sufficient cooling of the control cabinet.

Install the pumps according to the installation and operating

instructions supplied with the pumps.

Control MPC is not designed for outdoor

installation and must not be exposed to direct

sunlight.

9.2 Electrical installation

Warnin g

The electrical installation should be carried out

by an authorised person in accordance with local

regulations and the relevant wiring diagram.

• The electrical installation of the Control MPC must comply with

enclosure class, IP54.

• Make sure that the Control MPC is suitable for the electricity

supply to which it is connected.

• Make sure that the wire cross-section corresponds to the

specifications in the wiring diagram.

9.3 Start-up

The start-up description presupposes that the selected pumps

have been installed correctly according to the installation and

operating instructions supplied with the pumps.

After having carried out the installation of the Control MPC as

described in section 9. Installation, proceed as follows:

1. Turn on the electricity supply.

2. Wait for the first display to appear.

3. The first time the CU 351 is switched on, a start-up wizard will

guide the user through the basic settings.

4. Follow the instructions in each display.

5. When the wizard is completed, check that all pumps are set to

Auto in the Status menu.

6. Go to the Operation menu (2), select operating mode Normal,

and press .

7. Control MPC is now ready for operation.

Grundfos can supply hydraulic data for CR, CRI,

CRE and CRIE pumps where GSC files can be

downloaded directly to the CU 351. Electrical

data of power must be entered manually.

All other pump types require manual entering of

both hydraulic and electrical pump data.

See section 11.7.37 Pump curve data (4.3.19).

8. The system is now ready for operation.

10. Control panel

The control panel in the front cover of the control cabinet features

a display, a number of buttons and two indicator lights. The

control panel enables manual setting and monitoring of the

performance of the system.

CU 351

1

1213

Fig. 4 Control panel

Key

Pos. Description

1 Display

2 Arrow to the right

3Help

4Up

5Down

6Plus

7 Minus

8Esc

9Home

10 Ok

11 Indicator light, operation (green)

12 Indicator light, fault (red)

13 Contrast

2

3

5

4

6

7

8

9

10

11

TM03 1304 1705

9

Page 10

10.1 Display (pos. 1)

A

B

D

C

Fig. 5 Display design

10.1.1 Menu line

The menu line (A) is illustrated in fig. 5.

The display has four main menus:

Status: Indication of system status

Operation: Change of operating parameters such as setpoint

Alarm: Alarm log for fault finding

Settings: Change of settings (password option)

10.1.2 Top line

The top line (B) is illustrated in fig. 5.

The top line shows

• the display number and title (left side)

• the selected menu (left side)

• the symbol in case of alarm (right side)

• the symbol if the service language has been selected

(right side).

10.1.3 Graphical illustration

The graphical illustration (D) may show a status, an indication or

other elements, depending on the position in the menu structure.

The illustration may show the entire system or part of it as well as

various settings.

10.1.4 Scroll bar

If the list of illustration elements exceeds the display, the symbols

and will appear in the scroll bar to the right. Use the

and buttons to move up and down in the list.

10.1.5 Bottom line

The bottom line (C) shows the date and time.

10.2 Buttons and indicator lights

The buttons (pos. 2 to 10 in fig. 4) on the CU 351 are active when

they are illuminated.

10.2.1 Arrow to the right (pos. 2)

Press the button to move to the next menu in the menu

structure. If you press when the Settings menu is

highlighted, you go to the Status menu.

10.2.2 Help (pos. 3)

When the button is illuminated, a help text applying to the

current display will appear if the button is pressed.

Close the text by pressing the button.

10.2.3 Up and down (pos. 4 and 5)

Press the and buttons to move up and down in lists.

A text can be selected when it is in a box.

If a text is marked and the button is pressed, the text above

TM03 8947 4807

will be marked instead. If the button is pressed, the text

below will be marked.

If the button is pressed in the last line in the list, the first line

will be marked.

If the button is pressed in the first line in the list, the last line

will be marked.

10.2.4 Plus and minus (pos. 6 and 7)

Use the and buttons to increase and reduce values.

A value is activated when the button is pressed.

10.2.5 Esc (pos. 8)

Use the button to go one display back in the menu.

If a value has been changed and the button is pressed, the

new value will not be saved. For further information, see section

10.2.7 Ok (pos. 10).

If the button is pressed before the button, the new

value will be saved. For further information, see section

10.2.7 Ok (pos. 10).

10.2.6 Home (pos. 9) Press the button to return to the Status menu.

10.2.7 Ok (pos. 10)

Use the button as an enter button.

The button is also used to start the setting of a value.

If a value has been changed and the button is pressed, the

new value will be activated.

10.2.8 Indicator lights (pos. 11 and 12)

The control panel incorporates a green and red indicator light.

The green indicator light is on when the Control MPC is in

operation.

The green indicator light is flashing if the Control MPC has been

set to stop.

The red indicator light is on if there is an alarm or a warning.

The fault can be identified from the alarm list.

10.2.9 Contrast (pos. 13)

The contrast in the display can be changed by means of the

button:

1. Press .

2. Adjust the contrast with and .

10.2.10 Back light

If no button is touched for 15 minutes, the back light of the panel

will be dimmed, and the first display in the Status menu will

appear.

Press any button to re-activate the back light.

10

Page 11

11. Functions

11.1 Tree of functions

1. Status 2. Operation 3. Alarm

1 Status 2 Operation 3 Alarm status

3.1

Current alarms

3.1.1 Current alarms

1.2

System

1.2.1 Operating mode

1.2.2 Setpoint

1.2.3 Setpoint influence

1.2.4 Measured values

1.2.5 Analog inputs

1.3

Pump 1

1.4

Pump 2

1.5

Pump 3

1.6

Pump 4

1.7

Pump 5

1.8

Pump 6

2.1 Further settings

2.1.1 System operating mode

2.1.2 Control mode

2.1.3 Setpoints

2.1.4 Individual pump control

2.1.4. Pump 1...6

3.1

Current alarms

3.2

Alarm log

Key to the four main menus, Status, Operation, Alarm and Settings

Continued on page 12

Status

The Status menu shows alarms and the status of system and pumps.

Note: No settings can be made in this menu.

Operation

In the Operation menu, the most basic parameters can be set, such as setpoint,

operating mode, control mode and individual pump control.

Alarm

The Alarm menu gives an overview of alarms and warnings.

Alarms and warnings can be reset in this menu.

Settings

In the Settings menu, it is possible to set various functions:

• Primary controller

Setting of alternative setpoints, external setpoint influence, primary sensor, clock

program, proportional pressure and S-system configuration.

• Pump cascade control

Setting of min. time between start/stop, max. number of starts/hour, number of

standby pumps, forced pump changeover, pump test run, pilot pump, pump stop

attempt, pump start and stop speed, min. performance and compensation for

pump start-up time.

• Secondary functions

Setting of stop function, soft pressure build-up, digital and analog inputs, digital

outputs, emergency run, min., max. and user-defined duty, pump curve data,

flow estimation, control source and fixed inlet pressure.

• Monitoring functions

Setting of dry-running protection, min. and max. pressure, external fault, limit 1

and 2 exceeded, pumps outside duty range and pressure relief.

• Functions, CU 351

Selection of service language, main language and units.

Setting of date and time, passwords, Ethernet connection, GENIbus number and

software status.

11

Page 12

Continued from page 11

4.

Settings

4.1

Primary controller

4.2

Pump cascade control

4.3

Secondary functions

4.4

Monitoring functions

4.5

Functions, CU 351

4.1.1

4.1.2 Alternative setpoints

4.1.3 External setpoint influence

4.1.4 Primary sensor

4.1.6 Clock program

4.1.7 Proportional pressure

4.1.8 S-system configuration

4.2.1

4.2.3 Standby pumps

4.2.4 Forced pump changeover

4.2.5 Pump test run

4.2.6 Pilot pump

4.2.7 Pump stop attempt

4.2.8 Pump start and stop speed

4.2.9 Min. performance

4.2.10 Compensation for pump start-up time

4.3.1 Stop function

4.3.3 Soft pressure build-up

4.3.5 Emergency run

4.3.7 Digital inputs

4.3.8 Analog inputs

4.3.9 Digital outputs

4.3.14 Min., max. and user-defined duty

4.3.19 Pump curve data

4.3.20 Control source

4.3.22 Fixed inlet pressure

4.3.23 Flow estimation

4.4.1 Dry-running protection

4.4.2 Min. pressure

4.4.3 Max. pressure

4.4.4 External fault

4.4.5 Limit 1 exceeded

4.4.6 Limit 2 exceeded

4.4.7 Pumps outside duty range

4.4.8 Pressure relief

Change language to service language (GB)

Run wizard again

4.5.1

4.5.2 Display units

PI controller

4.1.2.1 Alternative setpoints 2...7

4.1.3.1 Input value to be influenced by

4.1.3.2 Setting of influence function

Min. time between start/stop

Max. number of starts/hour

4.3.1.1 Stop parameters

Function, DI1..DI3 (CU 351), [10, 12, 14]

Function, DI1..DI9 (IO 351-41), [10...46]

Function, DI1..DI9 (IO 351-42), [10...46]

Setting, analog input AI1..AI3 (CU 351), [51, 54, 57]

Function, AI1...AI3 (CU 351), [51, 54, 57]

Setting, AI1..AI2 (IO 351-41), [57, 60]

Function, AI1..AI2 (IO 351-41), [57, 60]

Setting, AI1..AI2 (IO 351-42), [57, 60]

Function, AI1..A2 (IO 351-42), [57, 60]

Function, DO1 and DO2 (CU 351), [71, 74]

Function, DO1...DO7 (IO 351-41), [77...88]

Function, DO1...DO7 (IO 351-42), [77...88]

4.3.14.1 Min. duty

4.3.14.2 Max. duty

4.3.14.3 User-defined duty

4.3.23 Flow estimation

4.4.1.1 Pressure/level switch

4.4.1.2 Measurement, inlet pressure

4.4.1.3 Measurement, tank level

Display language

4.5.2.1 Units for pressure

4.5.2.2 Units for differential pressure 4.5.3 Date and time

4.5.2.3 Units for head 4.5.4 Password

4.5.2.4 Units for level 4.5.5 Ethernet

4.5.2.5 Units for flow rate 4.5.6 GENIbus number

4.5.2.6 Units for volume 4.5.9 Software status

4.5.2.7 Units for specific energy

4.5.2.8 Units for temperature

4.5.2.9 Units for power

4.5.2.10 Units for energy

12

Page 13

11.2 Overview

Section Display and display number See page

11.4 Status (1) 15

11.4.1 Current alarms (3.1) 15

11.4.2 System (1.2) 15

11.4.3 Operating mode (1.2.1) 16

11.4.4 Setpoint (1.2.2) 16

11.4.5 Setpoint influence (1.2.3) 16

11.4.6 Measured values (1.2.4) 17

11.4.7 Analog inputs (1.2.5) 17

11.4.8 Pump 1...6 (1.3 to 1.8) 17

11.5 Operation (2) 18

11.5.1 Operation (2) 18

11.5.2 System operating mode (2.1.1) 18

11.5.3 Control mode (2.1.2) 19

11.5.4 Setpoints (2.1.3) 21

11.5.5 Individual pump control (2.1.4) 21

11.5.6 Setting of individual operating mode (2.1.4.1 to 2.1.4.6) 22

11.6 Alar m (3) 23

11.6.1 Alarm status (3) 23

11.6.2 Current alarms (3.1) 24

11.6.3 Alarm log (3.2) 24

11.7 Settings (4) 25

11.7.1 Primary controller (4.1) 25

11.7.2 PI controller (4.1.1) 26

11.7.3 Alternative setpoints (4.1.2) 27

11.7.4 Alternative setpoints 2 to 7 (4.1.2.1 to 4.1.2.7) 27

11.7.5 External setpoint influence (4.1.3) 28

11.7.6 Setting of influence function (4.1.3.2) 29

11.7.7 Primary sensor (4.1.4) 29

11.7.8 Clock program (4.1.6) 30

11.7.9 Proportional pressure (4.1.7) 31

11.7.10 S-system configuration (4.1.8) 31

11.7.11 Pump cascade control (4.2) 32

11.7.12 Min. time between start/stop (4.2.1) 32

11.7.13 Max. number of starts/hour (4.2.1) 32

11.7.14 Standby pumps (4.2.3) 33

11.7.15 Forced pump changeover (4.2.4) 33

11.7.16 Pump test run (4.2.5) 34

11.7.17 Pilot pump (4.2.6) 34

11.7.18 Pump stop attempt (4.2.7) 35

11.7.19 Pump start and stop speed (4.2.8) 35

11.7.20 Min. performance (4.2.9) 36

11.7.21 Compensation for pump start-up time (4.2.10) 36

11.7.22 Secondary functions (4.3) 37

11.7.23 Stop function (4.3.1) 37

11.7.24 Soft pressure build-up (4.3.3) 39

11.7.25 Emergency run (4.3.5) 40

11.7.26 Digital inputs (4.3.7) 40

11.7.27 Functions of digital inputs (4.3.7.1) 41

11.7.28 Analog inputs (4.3.8) 41

11.7.29 Analog inputs (4.3.8.1 to 4.3.8.7) 42

11.7.30 Analog inputs and measured value (4.3.8.1.1 to 4.3.8.7.1) 42

11.7.31 Digital outputs (4.3.9) 43

11.7.32 Functions of digital outputs (4.3.9.1 to 4.3.9.16) 43

11.7.33 Min., max. and user-defined duty (4.3.14) 44

11.7.34 Min. duty (4.3.14.1) 44

11.7.35 Max. duty (4.3.14.2) 45

11.7.36 User-defined duty (4.3.14.3) 45

11.7.37 Pump curve data (4.3.19) 46

11.7.38 Control source (4.3.20) 47

11.7.39 Fixed inlet pressure (4.3.22) 47

11.7.40 Flow estimation (4.3.23) 48

13

Page 14

Section Display and display number See page

11.7.41 Monitoring functions (4.4) 48

11.7.42 Dry-running protection (4.4.1) 49

11.7.43 Dry-running protection with pressure/level switch (4.4.1.1) 49

11.7.44 Dry-running protection with pressure transmitter (4.4.1.2) 50

11.7.45 Dry-running protection with level transmitter (4.4.1.3) 50

11.7.46 Min. pressure (4.4.2) 51

11.7.47 Max. pressure (4.4.3) 51

11.7.48 External fault (4.4.4) 52

11.7.49 Limit 1 and 2 exceeded (4.4.5 and 4.4.6) 52

11.7.51 Pressure relief (4.4.8) 54

11.7.52 Functions, CU 351 (4.5) 55

11.7.53 Display language (4.5.1) 55

11.7.54 Display units (4.5.2) 56

11.7.55 Date and time (4.5.3) 57

11.7.56 Passwords (4.5.4) 57

11.7.57 Ethernet (4.5.5) 58

11.7.58 GENIbus number (4.5.6) 58

11.7.59 Software status (4.5.9) 58

14

Page 15

11.3 Description of functions

Note

A

B

C

D

E

F

G

H

I

The description of functions is based on the four main menus of

the CU 351 control unit: Status, Operation, Alarm and Settings.

The functions apply to all control variants unless otherwise

stated.

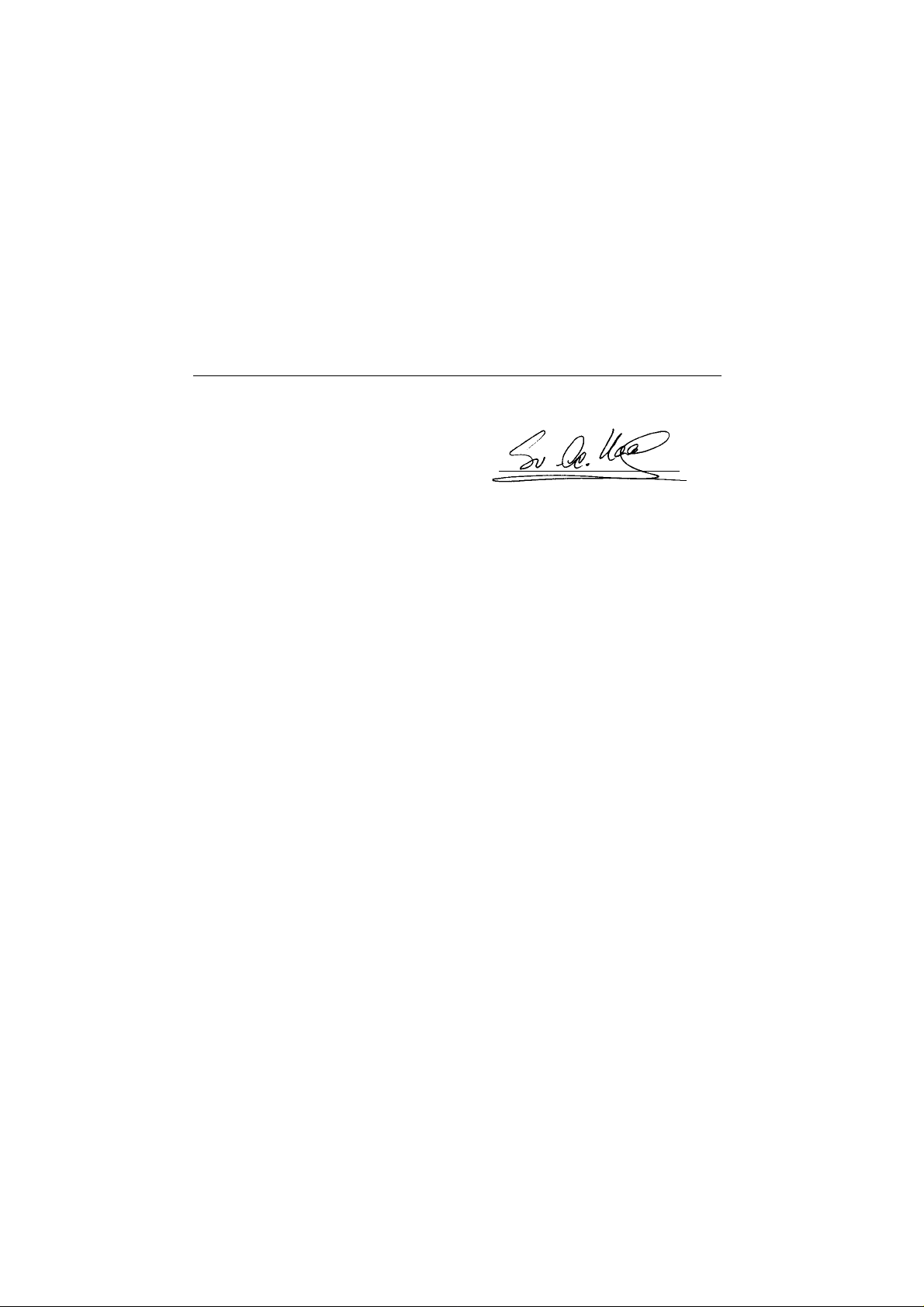

11.4 Status (1)

The first status display is shown below. This display is shown

when the Control MPC is switched on, and it appears when the

buttons of the control panel have not been touched for

15 minutes.

Fig. 6 Status

Description

No settings can be made in this menu.

The current value (process value, PV) of the control parameter,

usually the discharge pressure, is shown in the upper right corner

(G) together with the selected setpoint (SP) (H).

The upper half of the display (A) shows a graphic illustration of

the pump system. The selected measuring parameters are shown

with sensor symbol and current value.

In the middle of the display, an information field (I) will be shown if

any of the following events occur

• limited operation due to standby pump

• proportional pressure influence active

• external setpoint influence active

• alternative setpoint active

• clock program active

• remote-controlled via Ethernet

• remote-controlled via GENI (RS-485).

The lower display half (B) shows

• the latest current alarm, if any, and the fault cause together

with the fault code in brackets

• system status with current operating mode and control source

• pump status with current operating mode and manual/auto.

If a fault has occurred, the symbol will be

shown in the alarm line (C) together with the

cause and fault code, for instance

Overtemperature (64).

If the fault is related to one of the pumps, the symbol will also

be shown in front of the status line (D) of the pump in question.

At the same time, the symbol will be flashing instead of the

pump symbol (E). The symbol will be shown to the right in the

top line of the display (F). As long as a fault is present, this

symbol will be shown in the top line of all displays.

To open a menu line, mark the line with or , and press

.

The display makes it possible to open status displays showing

• current alarms

• system status

• status of each pump.

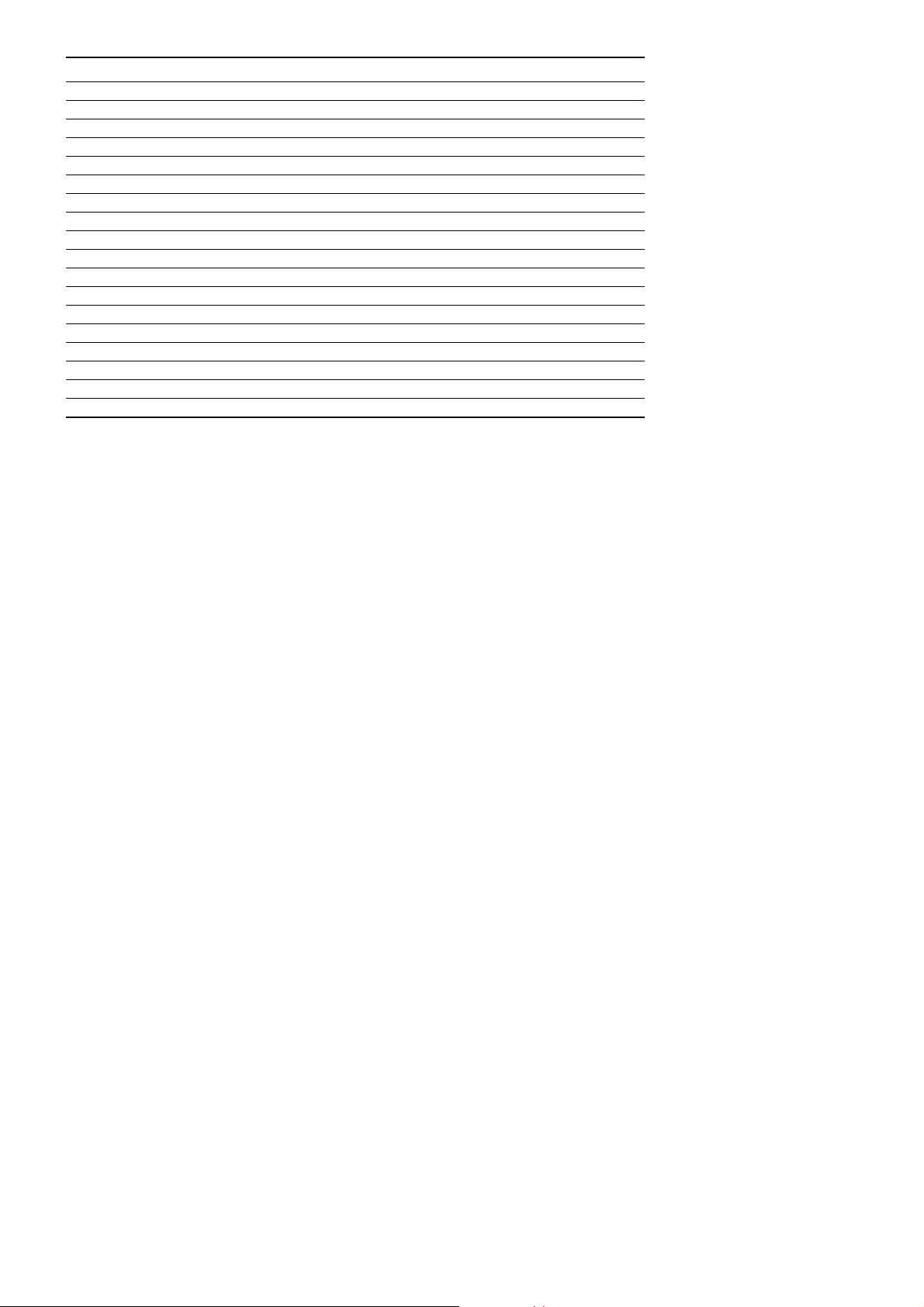

11.4.1 Current alarms (3.1)

Fig. 7 Current alarms

Description

TM03 8947 4707

In this display, current unreset alarms and warnings are shown.

For further information, see sections 11.6.2 Current alarms (3.1)

and 11.6.3 Alarm log (3.2).

11.4.2 System (1.2)

Fig. 8 System

Description

This display shows the current operational state of the system. It

is possible to go to subdisplays showing details.

The display makes it possible to open specific displays about

• operating mode

•setpoint

• setpoint influence

• measured values

• analog inputs.

TM03 2293 4807TM03 8946 4807

15

Page 16

11.4.3 Operating mode (1.2.1)

Setpoint

current SP()

Setpoint

selected

Infl. 1() Infl. 2() ...×××=

11.4.4 Setpoint (1.2.2)

Fig. 9 Operating mode

Description

Here the operating mode of the system is shown as well as from

where the Control MPC is controlled.

Operating modes

Control MPC has six operating modes:

1. Normal

The pumps adapt their performance to the requirement.

2. Max.

The pumps run at a constant high speed. Normally, all pumps

run at maximum speed.

3. User-defined

The pumps run at a constant speed set by the user. Usually, it

is a performance between Max. and Min.

4. Min.

The pumps run at a constant low speed. Normally, one pump

is running at a speed of 70 %.

5. Stop

All pumps have been stopped.

6. Emergency run

The pumps run according to the setting made in the display

Emergency run (4.3.5).

The performance required in the operating modes Max., Min.,

User-defined and Emergency run can be set in the Settings

menu. See sections 11.7.33 Min., max. and user-defined duty

(4.3.14) and 11.7.25 Emergency run (4.3.5).

The current operating mode can be controlled from four different

sources: Fault, External signal, CU 351 and Bus.

Control source

Control MPC can be set to remote control via an external bus

(option). In this case, a setpoint and an operating mode must be

set via the bus.

In the Settings menu, it is possible to select whether the CU 351

or the external bus is to be the control source.

The status of this setting is shown in the display Operating

mode.

TM03 2273 4807

Fig. 10 Setpoint

Description

This display shows the selected setpoint and whether it comes

from the CU 351 or an external bus.

The display also shows all seven possible setpoints from CU 351

(for closed- and open-loop control). At the same time, the

selected setpoint is shown.

As it is a status display, no settings can be made.

Setpoints can be changed in the Operation or Settings menu.

See section 11.7.3 Alternative setpoints (4.1.2).

11.4.5 Setpoint influence (1.2.3)

Fig. 11 Setpoint influence

Description

The selected setpoint can be influenced by parameters. The

parameters are shown as percentage from 0 to 100 % or as a

pressure measured in bar, They can only reduce the setpoint, as

the influence in percentage divided with 100 is multiplied with the

selected setpoint:

TM03 2272 4807TM03 8948 4807

16

The display shows the parameters influencing the selected

setpoint and the percentage or value of influence.

Some of the possible parameters can be set in the display

External setpoint influence (4.1.3). The parameter low flow boost

is set as an on/off band as a percentage of the setpoint set in the

display Stop function (4.3.1). The parameter is set as a

percentage in the display Proportional pressure (4.1.7).

Finally the resulting current setpoint (SP) is shown.

Page 17

11.4.6 Measured values (1.2.4)

Note

11.4.8 Pump 1...6 (1.3 to 1.8)

Fig. 12 Measured values

Description

This display gives a general status of all measured and calculated

parameters.

The lines "Power consumption" and "Energy

consumption" are only shown in Control MPC-E

systems.

11.4.7 Analog inputs (1.2.5)

Fig. 13 Analog inputs

Description

The display shows an overview of the analog inputs and the

current measured values of each input. See sections

11.7.28 Analog inputs (4.3.8), 11.7.29 Analog inputs (4.3.8.1 to

4.3.8.7) and 1 1.7.30 Analog inputs and measured value (4.3.8.1.1

to 4.3.8.7.1).

TM03 2270 4807

Fig. 14 Pump 1

Description

This display shows the operational state of the individual pumps.

The pumps may have different operating modes:

• Au to

Together with the other pumps in automatic operation, the

pump is controlled by the PI controller which ensures that the

system delivers the required performance.

• Manual

The pump is not controlled by the PI controller. In manual

operation, the pump has one of the following operating modes:

– Max.

The pump runs at a set maximum speed. (This operating

mode can only be selected for variable-speed pumps.)

– Normal

The pump runs at a set speed.

– Min.

The pump runs at a set minimum speed. (This operating

mode can only be selected for variable-speed pumps.)

– Stop

The pump has been forced to stop.

Besides information about the operating mode, it is possible to

read various parameters in the status display, such as these:

• current operating mode

• control source

TM03 8949 4807

• speed (only 0 or 100 % are shown for mains-operated pumps)

• power (only Control MPC-E)

• energy consumption (only Control MPC-E)

• operating hours.

TM03 2268 4807

17

Page 18

11.5 Operation (2)

A

C

B

In this menu, the most basic parameters can be set, such as

setpoint, operating mode, control mode and forced control of

pumps.

11.5.1 Operation (2)

Fig. 15 Operation

Description

The column shows the setting range. In closed-loop control, it

corresponds to the range of the primary sensor, here 0-16 bar.

In open-loop control, the setting range is 0-100 %.

At the left hand of the column, the selected setpoint 1 (A) is

shown, i.e. the value set in the display. At the right hand of the

column, the current setpoint (B) is shown, i.e. the setpoint acting

as reference for the PI controller. If no kind of external setpoint

influence has been selected, the two values will be identical. The

current measured value (discharge pressure) is shown as the

grey part of the column (C). See sections 11.7.5 External setpoint

influence (4.1.3) and 11.7.6 Setting of influence function (4.1.3.2).

Below the display is a menu line for setting of setpoint 1 and

selection of operating mode, including the operating modes

Normal and Stop. It is possible to select further settings: system

operating mode, control mode, setpoints for closed and open loop

as well as individual pump control.

Setting range

Setpoint:

Closed-loop control: Measuring range of the primary sensor

Open-loop control: 0-100 %

Setting via control panel

Setpoint:

1. Mark the Operation menu with .

2. Mark Setpoint 1 with or . Set the value with or

.

3. Save with .

Operating mode:

1. Mark the Operation menu with .

2. Mark operating mode Normal or Stop with or .

Save with .

Further settings:

1. Mark the Operation menu with .

2. Mark Further settings with or , and press .

3. Select one of the settings below with or , and press

:

• System operating mode (see section 11.5.2).

• Control mode (see section 11.5.3).

• Setpoints (see section 11.5.4).

• Individual pump control (see section 11.5.6).

Factory setting

The setpoint is a value suitable for the system in question.

Thefactory setting may have been changed in the start-up menu.

11.5.2 System operating mode (2.1.1)

Fig. 16 System operating mode

Description

Control MPC can be set to six different operating modes. Normal

TM03 8950 4707

is the typical setting. See section 11.4.3 Operating mode (1.2.1).

The performance of the operating modes Max., Min., User-

defined and Emergency run can be set in the Settings menu.

In the display shown, it is possible to go directly to the Settings

menu in order to set the pump performance or the setpoint.

Setting range

It is possible to select the operating modes

Normal, Max., Min.,

User-defined, Stop and Emergency run.

Setting via control panel

1. Mark the Operation menu with .

2. Mark Further settings with or , and press .

3. Mark System operating mode with or , and press

.

4. Select the desired operating mode by marking one of the lines

with check boxes with or , and press .

5. In order to set the performance in min., max., user-defined

duty or emergency run, mark the desired line at the bottom of

the display, and press .

See sections 11.7.33 Min., max. and user-defined duty

(4.3.14) and 11.7.25 Emergency run (4.3.5).

Factory setting

Normal.

TM03 8951 4607

18

Page 19

11.5.3 Control mode (2.1.2)

P [bar]

Time [sec]

Setpoint

Input [%] from

external controller

Flow rate [m

3

/h]

10050 70.75

25

50

75

100

86.6

Flow rate [m3/h]

Input [%] from

external controller

Pump 1

Pump 4

Pump 3

Flow rate

Pump 2

Fig. 17 Control mode

Description

There are two control modes, namely closed and open loop.

Examples:

Closed loop

The typical control mode is closed loop where the built-in

PI controller ensures that the system reaches and maintains the

selected setpoint. The performance is based on the setpoint set

for closed loop. See figs 18 and 19.

Open loop

In open-loop control, the pumps run at a fixed speed.

The pump speed is calculated from the performance set by the

user (0-100 %). The pump performance in percentage is

proportional with the flow rate.

Open-loop control is usually used when the system is controlled

by an external controller which controls the performance via an

external signal. The external controller could for instance be a

building management system connected to the Control MPC.

In such cases the Control MPC is like an actuator.

See figs 20 and 21.

TM03 2283 4807TM03 2231 3905TM03 2390 4105

TM03 2232 3905

Fig. 20 Booster system with external controller (open loop)

Setting via control panel

1. Mark the Operation menu with .

2. Mark Further settings with or , and press .

3. Mark Control mode with or , and press .

4. Select Closed loop with or , and press .

5. Set the setpoint. See sections 11.5.4 Setpoints (2.1.3) and

Fig. 18 Booster system controlled by built-in PI controller

(closed loop)

Fig. 19 Regulation curve for closed loop

11.5.1 Operation (2).

0

5

Fig. 21 Regulation curve for open loop

Fig. 22 Regulation curve for Control MPC-E in open loop

TM03 2391 3607TM03 9977 4807

19

Page 20

Fig. 23 Regulation curve for Control MPC-F in open loop

10050 70.75

25

50

75

100

86.6

Input [%] from

external controller

Flow rate [m3/h]

Pump 1

Pump 2

Pump 3

Flow rate

Pump 4

10050 70.75

25

50

75

100

86.6

Flow rate [m3/h]

Input [%] from

external controller

Pump 1

Pump 4

Pump 3

Flow rate

Pump 2

Fig. 24 Regulation curve for Control MPC-S in open loop

Setting range

These settings must be made in connection with open loop:

• Stop of system.

• Selection of control mode Open loop.

• Setting of setpoint 1, open loop.

• Setting of external setpoint influence.

• Selection of operating mode Normal.

Setting via control panel

To set an external control source to control the system, proceed

as follows:

1. Mark the Operation menu with .

2. Mark the operating mode Stop with or , and press

. The check mark in the right box shows that the

operation has been stopped.

3. Mark Further settings with or , and press .

4. Mark Control mode with or , and press .

5. Select Open loop with or , and press .

6. Return by pressing twice.

7. Mark Set setpoint 1, open loop with or .

8. Set the setpoint to 100 % with , and save with .

9. Mark the Settings menu with .

10.Mark Primary controller with or , and press .

11. Mark External setpoint influence with or , and press

TM03 9975 4807TM03 9974 4807

.

12.Mark Go to setting of analog input with or , and

press .

13.Select the analog input with or , and press .

14.Select the range of the analog input with or , and

press . The selection is indicated by a check mark.

15.Mark Measured input value with or , and press .

Now the display 4.3.8.1.1 appears.

16.Select 0-100 % signal with or , and press .

17.Press to return to display 4.3.8.1.

18.Set the minimum sensor value with or , and save with

.

19.Set the maximum sensor value with or , and save

with .

20.Return by pressing twice.

21.Mark Input value to be influenced by with or , and

press .

22.Mark the 0-100 % signal with or , and press .

23. Return with .

24.Mark Set the influence function with or , and press

. For details, see section 11.7.6 Setting of influence

function (4.1.3.2).

25.Mark the menu line for number of points with or , and

press .

26.Select the required number of points with or , and

save with .

27.Mark External input value (point 1) with or .

28.Set the value of the external input value with or , and

save with .

29.Mark Reduce setpoint to (point 1) with or .

30.Set the value as a percentage with or , and save with

.

31.Repeat steps 27 to 31 for all chosen points.

32. Return with .

33.Mark Filter time with or , set the time in seconds with

or , and save with .

34.Mark Activated with or , and press . The check

mark in the right box shows that the function has been

activated.

35.Return by pressing twice.

36.Mark the Operation menu with .

37.Mark the operating mode Normal

with or , and press

. The check mark in the right box shows that the

operation is normal. The booster system can now be

controlled by an external controller.

Factory setting

Closed-loop control.

20

Page 21

11.5.4 Setpoints (2.1.3)

11.5.5 Individual pump control (2.1.4)

Fig. 25 Setpoints

Description

In addition to the primary setpoint 1 (shown in the display 2 in the

Operation menu), six alternative setpoints can be set for closedloop control. It is furthermore possible to set seven setpoints for

open-loop control.

As described in sections 11.7.3 Alternative setpoints (4.1.2) and

11.7.4 Alternative setpoints 2 to 7 (4.1.2.1 to 4.1.2.7), it is

possible to activate one of the alternative setpoints by means of

external contacts.

Setting range

The setting range of setpoints for closed-loop control depends on

the range of the primary sensor. See section 11.7.7 Primary

sensor (4.1.4).

In open loop control, the setting range is 0-100 %.

Setting via control panel

1. Mark the Operation menu with .

2. Mark Further settings with or , and press .

3. Mark Setpoints with or , and press .

4. Select the setpoint with or .

5. Set the setpoint with or , and press .

Factory setting

Setpoint 1 for closed-loop control is a value suitable for the

Control MPC in question.

The alternative setpoints for closed-loop control are 3 bar.

All setpoints for open-loop control are 70 %.

TM03 8952 4807

Fig. 26 Individual pump control

Description

It is possible to change the operating mode from automatic

operation to one of the manual operating modes.

Auto

The pumps are controlled by the PI controller, ensuring that the

system delivers the required performance.

Manual

The pump is not controlled by the PI controller, but set to one of

the following manual operating modes:

• Ma x.

The pump runs at a set maximum speed. (This operating

mode can only be selected for variable-speed pumps.)

• Normal

The pump runs at a set speed.

• Mi n.

The pump runs at a set minimum speed. (This operating mode

can only be selected for variable-speed pumps.)

• Stop

The pump has been forced to stop.

Pumps in manual operation are not part of the normal pump

cascade and speed control. The manual pumps are a

"disturbance" of the normal operation of Control MPC.

If one or more pumps are in manual operation, the system may

not be able to deliver the set performance.

There are two displays for the function. In the first display, the

pump to be set is selected, and in the next display, the operating

mode is selected.

Setting range

All pumps can be selected.

Setting via control panel

1. Mark the Operation menu with .

2. Mark Further settings with or , and press .

3. Mark Individual pump control with or , and press

.

4. Select the pump with or , and press .

TM03 8953 4807

21

Page 22

11.5.6 Setting of individual operating mode (2.1.4.1 to 2.1.4.6)

Fig. 27 Setting of individual operating mode

Description

This display is shown for the individual pumps and makes it

possible to set an operating mode.

Setting range

It is possible to select Auto or Manual as well as the operating

mode of the pump for manual operation - Max., Normal, Min. or

Stop. For mains-operated pumps only Normal or Stop can be

selected.

Setting via control panel

1. Mark the Operation menu with .

2. Mark Individual pump control with or , and press

.

3. Select the pump with or , and press .

4. Mark Auto or Manual with or , and press .

5. Manual: Select the operating mode with or , and

press .

6. Normal: Mark Setpoint with or .

Set the speed of the variable-speed pump with or ,

and press .

Factory setting

Auto.

TM03 8954 4807

22

Page 23

11.6 Alarm (3)

The Alarm menu gives an overview of alarms and warnings.

In this menu, it is possible to reset alarms and to see the alarm

log.

11.6.1 Alarm status (3)

Fault

Warning( ) / alarm( )

Change of operating

mode to

Reset of alarm

Restart

Set in the Settings

menu

Water shortage Man/auto X 206

Water shortage Stop Man/auto X 214

Pressure high Stop Man/auto X 210

Alarm code

Fig. 28 Alarm status

Description

A fault in the system or one of the components monitored can

cause an alarm or a warning . Besides the fault signal via

the alarm/warning signal relay and the red indicator light on the

CU 351, an alarm can also cause a change of operating mode,

for instance from Normal to Stop. A warning only causes a fault

indication.

The table shows the possible causes of fault together with an

alarm code number, and whether they result in an alarm or a

warning. It also shows to what operating mode the system

changes in case of alarm, and whether restart of the system and

reset of the alarm is manual or automatic.

The table also shows that the reaction to some of the fault causes

mentioned can be set in the Settings menu. See sections

11.7.24Soft pressure build-up (4.3.3) and 11.7.41 Monitoring

functions (4.4) to 11.7.51 Pressure relief (4.4.8).

Pressure low

Pressure relief Auto X 219

Alarm, all pumps Stop Auto 203

TM03 2291 4607

External fault

Dissimilar sensor

signals

Fault, primary sensor Stop Auto 89

Fault, sensor Auto 88

Communication fault Auto 10

Phase failure Auto 2

Undervoltage, pump Auto

Overvoltage, pump Auto 32

Overload, pump Auto

Motor temperature too

high

Other fault, pump Auto 76, 83

Internal fault, CU 351 Auto

Internal fault, IO 351 Stop Auto

VFD not ready Auto 213

Fault, Ethernet Auto

Limit 1 exceeded Man/auto X 190

Man/auto

Stop Man/auto

Man/auto

Stop Man/auto

Auto 204

Auto

X211

X3

7, 40,

42, 73

48, 50,

51, 54

64, 65,

67, 70

83,

157

72, 83,

157

231,

232

Limit 2 exceeded Man/auto X 191

Pressure build-up fault Man/auto X 215

Pumps outside duty

range

Pilot pump fault Auto 216

Man/auto X 208

23

Page 24

11.6.2 Current alarms (3.1)

Fig. 29 Current alarms

Description

This submenu shows the following:

• Warnings caused by faults that still exist.

• Warnings caused by faults that have disappeared, but the

warning requires manual reset.

• Alarms caused by faults that still exist.

• Alarms caused by faults that have disappeared, but the

alarm requires manual reset.

All warnings and alarms with automatic reset are automatically

removed from the menu when the fault has disappeared.

Alarms requiring manual reset are reset in this display by

pressing . An alarm cannot be reset until the fault has

disappeared.

For every warning or alarm, the following will be shown:

• Whether it is a warning or an alarm .

• Where the fault occurred: System, Pump 1, Pump 2, etc.

• In case of input-related faults, the input will be shown.

• What the cause of the fault is, and the alarm code in brackets:

Water shortage (214), Max. pressure (210), etc.

• When the fault occurred: Date and time.

• When the fault disappeared: Date and time. If the fault still

exists, date and time are shown as --...--.

The latest warning/alarm is shown at the top of the display.

11.6.3 Alarm log (3.2)

The alarm log can store up to 24 warnings and alarms.

TM03 2293 4607

TM03 2292 4807

Fig. 30 Alarm log

Description

Here warnings and alarms are shown.

For every warning or alarm, the following will be shown:

• Whether it is a warning or an alarm .

• Where the fault occurred. System, Pump 1, Pump 2, etc.

• In case of input-related faults, the input will be shown.

• What the cause of the fault is, and the alarm code in brackets:

Water shortage (214), Max. pressure (210), etc.

• When the fault occurred: Date and time.

• When the fault disappeared: Date and time. If the fault still

exists, date and time are shown as --...--.

The latest warning/alarm is shown at the top of the display.

24

Page 25

11.7 Settings (4)

11.7.1 Primary controller (4.1)

Fig. 31 Settings

In the Settings menu, it is possible to set the following functions:

• Primary controller

Setting of PI controller, alternative setpoints, external setpoint

influence, primary sensor, clock program, proportional pressure

and S-system configuration.

• Pump cascade control

Setting of min. time between start/stop, max. number of starts/

hour, number of standby pumps, forced pump changeover,

pump test run, pilot pump, pump stop attempt, pump start and

stop speed, min. performance and compensation for pump

start-up time.

• Secondary functions

Setting of stop function, soft pressure build-up, digital and

analog inputs, digital outputs, emergency run, min., max. and

user-defined duty, pump curve data, flow estimation, control

source and fixed inlet pressure.

• Monitoring functions

Setting of dry-running protection, min. and max. pressure,

external fault, limit 1 and 2 exceeded, pumps outside duty

range and pressure relief.

• Functions, CU 351

Selection of service language, main language and units.

Setting of time and date, passwords, Ethernet connection,

GENIbus number and software status.

Usually, all these functions are set correctly when the

Control MPC is switched on.

It is only necessary to make settings in this menu if the

functionality is to be expanded with for instance alternative

setpoints or setpoint influence, or if the settings of the CU 351 are

to be adjusted.

TM03 2294 4607

Fig. 32 Primary controller

Description

In this menu section, it is possible to set the functions related to

the primary controller.

It is only necessary to make settings in this menu if the

functionality is to be expanded with for instance alternative

setpoints, external setpoint influence, clock program or

proportional pressure.

The following menus can be selected:

• PI controller

• Alternative setpoints

• External setpoint influence

• Primary sensor

• Clock program

• Proportional pressure

• S-system configuration.

TM03 8955 4807

25

Page 26

11.7.2 PI controller (4.1.1)

ǻS

L [m]

ǻS

1

Q

t

L [m]

2

ǻW

L [m]

2

t

L [m]

2

PI controller settings for heating and cooling

If another application than pressure boosting has been selected

in the start-up wizard, the values of K

and Ti will be set

p

automatically according to the table below. As Control MPC does

not know the pipe length, the default parameters will be set

according to the table to a pipe length (L

System/application

Heating

system

1)

or L2) of 5 metres.

1

K

p

Cooling

system

2)

T

i

[Seconds]

0.5 1

Fig. 33 PI controller

Description

Control MPC includes a standard PI controller which ensures that

the pressure is stable and corresponds to the setpoint.

It is possible to adjust the PI controller if a faster or slower

reaction to changes of consumption is required.

A faster reaction is obtained if K

A slower reaction is obtained if K

is increased and Ti is reduced.

p

is reduced and Ti is increased.

p

Setting range

• Gain K

• Integral time T

: –30 to 30.

p

Note: For inverse control, set K

: 0.1 to 3600 seconds.

i

to a negative value.

p

Setting via control panel

1. Mark the Settings menu with .

2. Mark Primary controller with or , and press .

3. Mark PI controller with or , and press .

4. Select the gain (K

) with or . Set the value with

p

or , and save with .

Note: Usually it is not necessary to adjust K

5. Select the integral time (T

) with or . Set the time with

i

.

p

or , and press .

Factory setting

The setting of K

and Ti depends on the system and application.

p

PI controller settings for pressure boosting

If the application has been set to pressure boosting in the start-up

wizard, the following values of K

: 0.5

•K

p

: 1 second.

•T

i

and Ti will be set automatically:

p

TM03 2387 4607

1)

Heating systems are systems in which an increase in pump

performance will result in a temperature rise at the sensor.

2)

Cooling systems are systems in which an increase in pump

performance will result in a temperature drop at the sensor.

: Distance [m] between pump and sensor.

L

1

: Distance [m] between heat exchanger and sensor.

L

2

ΔP: Measurement of differential pressure.

Q: Measurement of flow rate.

t: Measurement of temperature.

t: Measurement of differential temperature.

Δ

L

< 5 m: 1

0.5

1

L

> 5 m: 3

1

L

> 10 m: 5

1

0.5 1

0.5 -0.5 10 + 5L

0.5 10 + 5L

0.5 -0.5 30 + 5L

2

2

2

26

Page 27

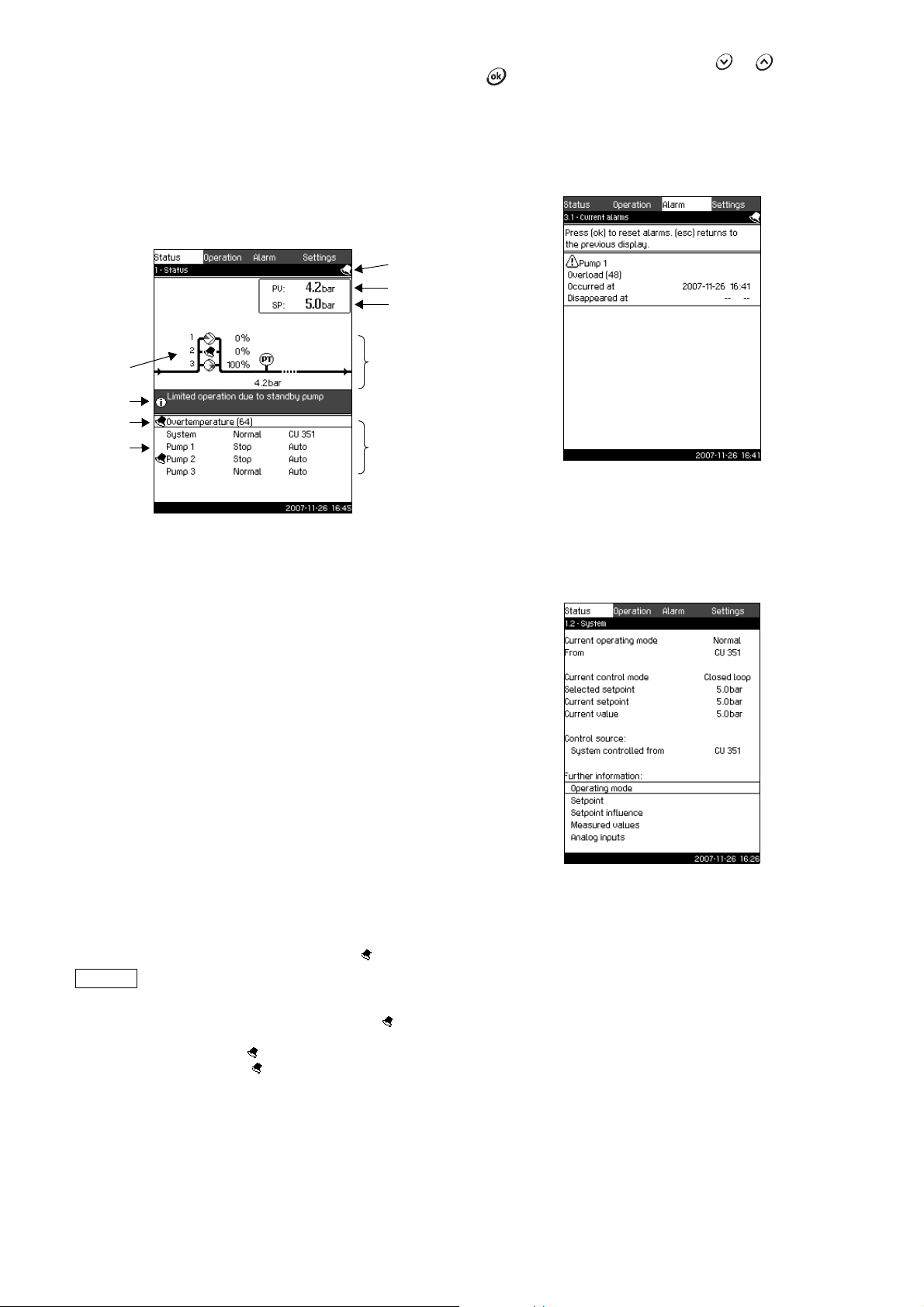

11.7.3 Alternative setpoints (4.1.2)

11.7.4 Alternative setpoints 2 to 7 (4.1.2.1 to 4.1.2.7)

Fig. 34 Alternative setpoints

Description

This function makes it possible to select up to six setpoints (No 2

to 7) as alternatives to the primary setpoint (No 1). The primary

setpoint (No 1) is set in the Operation menu.

Every alternative setpoint can be addressed manually to a

separate digital input (DI). When the contact of the input is

closed, the alternative setpoint applies.

If more than one alternative setpoint has been selected and they

are activated at the same time, the CU 351 selects the setpoint

with the lowest number.

Setting range

• Six setpoints, No 2 to 7.

Factory setting

No alternative setpoints have been selected.

TM03 2383 4607

Fig. 35 Alternative setpoints 2 to 7

For each alternative setpoint, select the digital input to activate

the setpoint.

It is possible to set a setpoint for closed loop and for open loop.

Setting via control panel

1. Mark the Settings menu with .

2. Mark Primary controller with or , and press .

3. Mark Alternative setpoints with or , and press .

4. Select the alternative setpoint with or , and press

.

5. Mark Go to setting of digital input with or , and

press .

Now the display Digital inputs (4.3.7) appears. Set the input

and return with .

6. Mark the menu line of the setpoint (closed or open loop) with

or .

7. Set the required setpoint with or , and save with .

Set both setpoints if the system is to be controlled both in

open and closed loop.

Factory setting

No alternative setpoints have been set.

TM03 2384 4607

27

Page 28

11.7.5 External setpoint influence (4.1.3)

Setpoint

current SP()

Setpoint

selected

Infl. 1() Infl. 2() ...×××=

Fig. 36 External setpoint influence

Description

This function makes it possible to adapt the setpoint by letting

measuring parameters influence the setpoint. Typically an analog

signal from a flow or temperature transmitter, or a similar

transmitter. Section 12. Measuring parameters shows an

overview of transmitter types and possible positions.

As an example, the setpoint can be adapted to parameters that

can influence the discharge pressure or temperature of the

system. The parameters which influence the performance of the

system are shown as a percentage from 0 to 100 %. They can

only reduce the setpoint, as the influence as a percentage divided

with 100 is multiplied with the setpoint:

The influence values can be set individually.

A low-pass filter ensures smoothing of the measured value which

influences the setpoint. This results in stable setpoint changes.

Setting range

The following parameters can be selected.

• 0-100 % signal

• Inlet pressure

• Discharge pressure

• External pressure

• Differential pressure, pump

• Differential pressure, external

•Flow rate

• Tank level, discharge side

• Tank level, suction side

• Flow pipe temperature

• Return pipe temperature

• Ambient temperature

• Return pipe temperature, external

• Differential temperature.

Setting via control panel

1. Mark the Settings menu with .

2. Mark Primary controller with or , and press .

3. Mark External setpoint influence with or , and press

.

4. Mark Input value to be influenced by with or , and

press .

Now a list of available parameters appear.

5. Mark the parameter which is to influence the setpoint with

or , and press .

6. Return with .

7. Mark Set the influence function with or , and press

. For details, see section 11.7.6 Setting of influence

function (4.1.3.2).

8. Mark the menu line for number of points with or , and

press .

9. Select the required number of points with or , and

TM03 8956 4807

save with .

10.Mark External input value (point 1) with or .

11.Set the value of the external input value with or , and

save with .

12.Mark Reduce setpoint to (point 1) with or .

13.Set the value as a percentage with or , and save with

.

14.Repeat steps 8 to 13 for all desired parameters.

15. Return with .

16.Mark Filter time with or , set the time in seconds with

or , and save with .

17.Mark Activated with or , and press . The check

mark in the right box shows that the function has been

activated.

Factory setting

Setpoint influence is not activated.

28

Page 29

11.7.6 Setting of influence function (4.1.3.2)

0

140

10

100

100

25

Temperature [°C]

Setpoint influence [%]

Fig. 37 Setting of influence function

Description

In this menu, you select the relation between the measuring

parameter which is to influence the setpoint and the desired

influence as a percentage.

The relation is set by entering values in a table with maximum

eight points by means of the control panel.

Example:

Setting via control panel

1. Mark the Settings menu with .

2. Mark Primary controller with or , and press .

3. Mark External setpoint influence with or , and press

.

4. Mark Set the influence function with or , and press

.

5. Mark the menu line for number of points with or , and

press .

6. Select the required number of points with or , and

save with .

7. Mark External input value (point 1) with or .

8. Set the value of the external input value with or , and

save with .

9. Mark Reduce setpoint to (point 1) with or .

10. Set the value as a percentage with or , and save with

TM03 9963 4707TM03 9978 4707

.

11. Repeat steps 7 to 10 for all desired parameters.

Factory setting

External setpoint influence is not activated.

11.7.7 Primary sensor (4.1.4)

Fig. 38 Relation between setpoint influence and flow rate

The control unit draws straight lines between the points. A

horizontal line is drawn from the minimum value of the relevant

sensor (0 m

case from the last point to the sensor's maximum value (example

3

50 m

/h).

Setting range

Two to eight points can be selected. Each point contains the

relation between the value of the parameter which is to influence

the setpoint and the influence of the value.

3

/h in the example) to the first point. This is also the

TM03 8958 4807

Fig. 39 Primary sensor

Description

In this display, select the control parameter of the system and set

the sensor to measure the value.

For booster systems, the control parameter is usually the

discharge pressure which is measured by a sensor fitted on the

discharge manifold. In heating and cooling systems, the control

parameter is typically a differential pressure or a temperature.

See section 12. Measuring parameters.

Setting range

• Discharge pressure

• Differential pressure, external

• Differential pressure, pump

• Series 2000, differential pressure

• External pressure

• Differential pressure, inlet

• Differential pressure, outlet

•Flow rate

• Series 2000, flow rate

• Flow pipe temperature

• Return pipe temperature

• Differential temperature

• Ambient temperature

• Return pipe temperature, external

• 0-100 % signal

• Not used.

29

Page 30

Setting via control panel

Note

1. Mark the Settings menu with .

2. Mark Primary controller with or , and press .

3. Mark Primary sensor with or , and press .

4. Mark Go to setting of analog input with or , and

press .

Now the display Analog inputs (4.3.8) appears. Select the

analog input (AI) for the primary sensor, and set the

parameters for this sensor. Return to display Primary sensor

(4.1.4) with .

5. Select the control parameter for the primary sensor with

or , and press .

Factory setting

The primary parameter is discharge pressure. The sensor is

connected to AI1 (CU 351). Other primary parameters can be

selected in the start-up wizard.

11.7.8 Clock program (4.1.6)

Setting range

• Activation of the function.

• Activation and setting of event.

Setting via control panel

1. Mark the Settings menu with .

2. Mark Primary controller with or , and press .

3. Mark Clock program with or , and press .

4. Mark Event 1 with or , and press .

TM03 8959 4807

Fig. 41 Event 1

Fig. 40 Clock program

Description

With this function, it is possible to set setpoints and day and time

for their activation. It is also possible to set day and time for stop

of the system.

If the clock program is deactivated, the setpoint of the program

will remain active.

Minimum 2 events are required when activating

the clock program; one to start the system and

one to stop the system.

5. Mark operating mode Normal or Stop with or , and

press . (If Stop is selected, step 6 will be skipped.)

6. Mark Setpoint, closed loop with or .

Set the pressure with or , and save with .

7. Mark Time (hours, minutes) with or .

8. Set the time with or , and save with .

TM03 8990 4807

9. Mark day of week on which the settings are to be activated

with or , and press .

10.Mark Activated with or , and press .

11.Repeat steps 4 to 10 if several events are to be activated.

Note: Up to ten events can be set.

12. Return with .

13.Mark Activated with or , and press . The check

mark in the right box shows that the function has been

activated.

Factory setting

The function is deactivated.

30

Page 31

11.7.9 Proportional pressure (4.1.7)

Setpoint

Resultant setpoint, linear

Pump curve

Starting point of proportional pressure control

(Influence at 0 flow = x % of H

set

)

Resultant setpoint, square

H

set

Start/stop band

H

set

Time [sec]

H [m]

Pump stops

Pump starts

Normal control

Start/stop band

H

set

Time [sec]

H [m]

Pump starts

Pump stops

Inverse control

11.7.10 S-system configuration (4.1.8)

Description

The function can only be activated in pressure-controlled systems

and automatically adapts the setpoint set to the current flow rate.

The adaptation can be linear or square. See fig. 43.

The function has these purposes:

• to compensate for pressure losses

• to reduce the energy consumption

• to increase the comfort for the user.

Setting range

• Activation of the function.

• Selection of control mode.

• Setting of setpoint influence.

Setting via control panel

1. Mark the Settings menu with .

2. Mark Primary controller with or , and press .

3. Mark Proportional pressure with or , and press

4. Mark Activated with or , and press . The check

5. Mark Adaptation, linear or square with or , and

6. Mark Influence at 0 flow with or . Set the value with

Factory setting

The function is deactivated.

Fig. 42 Proportional pressure

Fig. 43 Proportional pressure

.

mark in the right box shows that the function has been

activated.

press .

or , and save with .

TM03 8960 4807TM03 8524 1807

Fig. 44 S-system configuration

Description

The function makes it possible to invert the control of mainsoperated pumps (Control MPC-S). That is to set whether pumps

are to be started or stopped depending on the current value.

A start/stop band must be set in order to use this function.

See fig. 45.

Normal control: A pump is stopped when the current value

becomes higher than H

+ start/stop band. And a pump is

set

started when the current value becomes lower than H

See fig. 45.

Inverse control: A pump is started when the current value

becomes higher than H

+ start/stop band. And a pump is

set

stopped when the current value becomes lower than H

See fig. 45.

Fig. 45 Normal and inverse control

Setting range

• Selection of configuration (normal or inverse control).

• Setting of start/stop band.

Setting via control panel

1. Mark the Settings menu with .

2. Mark Primary controller with or , and press .

3. Mark S-system configuration with or , and press

.

4. Mark Inverse with or , and press .

5. Mark Start/stop band with or . Set the value

with or , and save with .

Factory setting

Normal.

set

set

TM03 8961 4807TM03 9205 3607 - TM03 9205 3607

.

.

31

Page 32

11.7.11 Pump cascade control (4.2)

Note

Fig. 46 Pump cascade control

Factory setting

The setting is done in the start-up wizard and depends on the

application.

11.7.13 Max. number of starts/hour (4.2.1)

TM03 8962 4807TM03 2367 4607

In this menu section, it is possible to set the functions connected

to pump cascade control.

The following menus can be selected:

• Min. time between start/stop

• Max. number of starts/hour

• Standby pumps

• Forced pump changeover

• Pump test run

• Pilot pump

• Pump stop attempt

• Pump start and stop speed

• Min. performance

• Compensation for pump start-up time.