Page 1

Conex® DIS-C

Installation and operating instructions

GRUNDFOS INSTRUCTIONS

Page 2

English (GB)

2

English (GB) Installation and operating instructions

Original installation and operating instructions

CONTENTS

Page

1. Symbols used in this document

2. General information

These installation and operating instructions contain

all information important for users of the

Conex

®

DIS-C:

• technical data

• instructions on commissioning, use and

maintenance

• safety information.

Should you require further information or should you

encounter problems that are not handled in sufficient

depth in this manual, please contact Grundfos.

We shall be pleased to support you with our

comprehensive know-how in the fields of measuring

and control technology as well as water treatment.

We always welcome suggestions on how to optimise

our installation and operating instructions to satisfy

our customers.

1. Symbols used in this document

2

2. General information

2

3. Description of the device

3

3.1 Assembly

3

3.2 Principles of conductivity measurement

3

4. Applications

4

4.1 Field of application for measurements

4

5. Safety

4

5.1 Obligations of the owner/operations

manager

4

5.2 Avoidance of danger

4

6. Identification

5

6.1 Nameplate

5

6.2 Type key

5

7. Technical data

6

7.1 Versions

6

7.2 General data

6

7.3 Measuring ranges

6

7.4 Dimensional sketches / drilling diagram

7

8. Installation

8

8.1 Transport and storage

8

8.2 Unpacking

8

8.3 Installation requirements

8

8.4 Assembling the Conex® DIS-C housing

for wall mounting

8

8.5 Assembling the Conex® DIS-C-P, CI

housing for installation in control panel

9

9. Commissioning / electrical

connections

9

9.1 Conex® DIS-C conductive, housing for

wall mounting

10

9.2 Conex® DIS-C inductive, housing for

wall mounting

11

9.3 Conex® DIS-C conductive, housing for

installation in control panel

12

9.4 Important instructions for connecting the

device

13

10. Principles of regulatory function

14

10.1 Regulatory behaviour

14

10.2 Limit values

14

10.3 On-off controller with P behaviour

15

10.4 Parameter settings

16

11. Initial operation and settings

17

11.1 Initial steps for operation

17

12. Operation

17

12.1 Device layout for Conex® DIS-C

17

12.2 Menu control

18

12.3 Navigation in the menus

18

12.4 Setup

19

12.5 Relay menu (S1 S2)

23

12.6 Temperature compensation

23

12.7 Displaying / changing code

24

12.8 Controller settings

24

12.9 Alarm value setting A1/A2

25

12.10 Service

26

13. Disposal

26

Warning

Prior to installation, read these installation

and operating instructions. Installation and

operation must comply with local

regulations and accepted codes of good

practice.

Warning

If these safety instructions are not

observed, it may result in personal injury.

Caution

If these safety instructions are not

observed, it may result in malfunction or

damage to the equipment.

Note

Notes or instructions that make the job

easier and ensure safe operation.

Page 3

English (GB)

3

3. Description of the device

Fig. 1 Conex® DIS-C for wall mounting

Fig. 2 Conex

®

DIS-C for installation in control

panel

3.1 Assembly

The complete measuring system comprises:

• the measuring amplifier Conex

®

DIS-C

• the conductivity measuring cell with temperature

sensor.

3.2 Principles of conductivity

measurement

In metallic conductors, electricity is transported by

freely moving electrons, whereas in electrolytes, the

electrical current is carried by ions.

All water-dissolved components that are in ionogenic

form contribute towards conductivity.

The conductivity is a sum parameter.

Different types of ions vary in their electrical charge

and migration rate. The migration rate is highly

dependent on temperature, which means the

influence of temperature must always be taken into

account when measuring conductivity.

Specific electrolytic conductivity is measured in

Siemens per cm (S/cm). Siemens per cm is the

reciprocal value of electrical resistance.

This measurement is based on a theoretical liquid

cube with sides of a length of 1 cm. In practice, cells

rarely have such an even geometric shape. The cell

constant C is used to specify the correlation between

the actual measured conductivity and the displayed

specific conductivity.

The measuring cell is inserted in a flow armature,

and the water to be measured flows around it.

The Conex

®

DIS-C measuring and regulation device

amplifies the signal from the measuring cell and

calculates the signal (e.g. against cable and

temperature compensation parameters). The result

is displayed digitally and can also be registered

using the analog output. The result is shown as an

actual value.

TM03 6980 3914TM03 6981 4506

Page 4

English (GB)

4

4. Applications

The Conex® DIS-C is a measuring amplifier for

measuring conductivity using a conductive or

inductive measuring cell and for regulation of

disturbance variables using a connected control

element. Two controllers can be set separately as

limit values, intermittent pulse controllers or pulse

frequency controllers.

The Conex

®

DIS-C is available for installation in a

wall-mounted enclosure or for installation in a control

panel (only conductive measuring cell for

conductivity measurement).

4.1 Field of application for measurements

Principal uses:

• waste water treatment

• water purification

• recycling

• in metal processing industries

• in the chemical industry

• in the foodstuff industry.

5. Safety

The owner/operations manager of the system is

responsible for the following:

• compliance with country-specific safety

regulations

• training of operating personnel.

5.1 Obligations of the owner/operations

manager

The owner/operations manager must ensure that

persons working with the device described fulfil

these requirements:

• They are acquainted with the regulations

concerning working safety and accident

prevention.

• They have been trained in use of the device.

• They have read and understood the warning

information and handling symbols.

The owner/operations manager is also responsible

for ensuring that this manual is kept in the immediate

vicinity of the device and is always available for the

operating personnel.

5.2 Avoidance of danger

Warning

Installation and connection of the device

and the associated supplementary

components must only be carried out by

authorised personnel!

The local safety regulations must be

observed!

Switch off the power supply before

connecting the power cable and the relay

contacts!

Warning

Do not dismantle the device!

Cleaning, maintenance and repair must

only be carried out by authorised

personnel!

Warning

Other applications than those described in

section 4. Applications are not approved

and not permitted. Grundfos cannot be

held liable for any damage resulting from

incorrect use.

Caution

The mounting location must be selected so

that the housing is not subjected to

mechanical loading.

Check that all settings are correct before

starting up the device!

Page 5

English (GB)

5

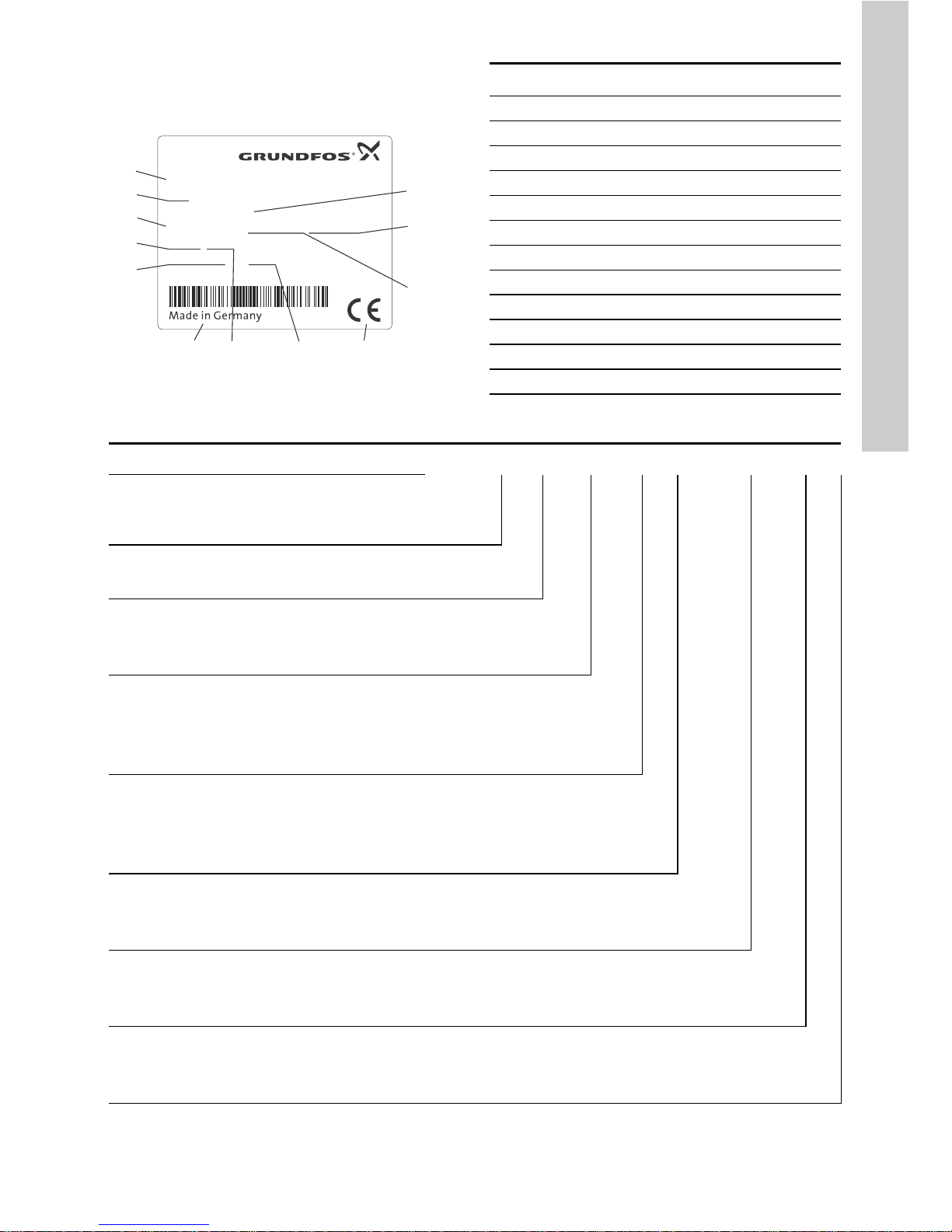

6. Identification

6.1 Nameplate

Fig. 3 Nameplate, Conex® DIS-C

6.2 Type key

TM04 0331 3914

DIS-C 1-CC, W-G

351-2000-10006

S/N: 08/02809

Conex DIS-C, 230/240V 50/60Hz

10 VA, IP 65

96725733P1108030802809

1

2

3

4

5

67 8 9

10

11

12

Pos. D escription

1 Type designation

2 Model

3 Product name

4 Power consumption [VA]

5 Product number

6 Country of origin

7 Enclosure class

8 Year and week of production

9 Marks of approval, CE mark, etc.

10 Voltage [V]

11 Frequency [Hz]

12 Serial number

Example: DIS -C -P CC -R1 -F -PVC W -G

Units for measurement and control

DIS-C

Dosing Instrumentation Standard for

conductivity measurement

Assembly

PPrepacked

Measuring cell

CC Conductivity, conductive

CI Conductivity, inductive

Measuring range

R1 0 to 200 μS/cm

R2 0 to 2000 μS/cm

R3 0 to 20,000 μS/cm

Armature type

FFlow

I Immersion

X No armature

Armature material

PVC Polyvinyl chloride

PP Polypropylene

Controller mounting option

W Wall-mounted

P Panel-mounted (only for conductive measuring cell)

Power supply

G 1 x 230/240 V, 50/60 Hz

H 1 x 115/120 V, 50/60 Hz

Page 6

English (GB)

6

7. Technical data

7.1 Versions

7.2 General data

7.3 Measuring ranges

7.3.1 Measuring ranges and cell constants for

Conex

®

DIS-C with conductive measuring

cell

7.3.2 Measuring ranges for Conex

®

DIS-C with

inductive measuring cell

Power supply

• 230 V (± 10 %), 50/60 Hz

(standard version)

• 115/120 V (± 10 %),

50/60 Hz

Type of measuring

cell

• Conductive

• Inductive

Mounting variants

• For wall mounting

• For installation in control

panel (only Conex

®

DIS-C,

CI devices - with

conductive measuring cell).

Dimensions

(W x H x D)

• 165 x 160 x 80 mm

(for wall mounting)

• 96 x 96 x 127 mm (for

installation in control panel)

Weight

• 1.0 kg (for wall mounting)

• 0.8 kg (for installation in

control panel)

Enclosure class

• IP65 (wall-mounted)

• IP54 (front, installation in

control panel)

Internal fuse

• Yes (wall-mounted)

• No (installation in control

panel)

Display

LCD display, two lines,

2 x 16 characters

Connections

Terminal strips for cable up to

maximum 1.5 mm

2

Power consumption 10 VA

Electrical output

0 (4) to 20 mA galvanically

isolated, maximum load 500 Ω

Switching points

Can be set within the

measuring range

Contact rating for

regulation and alarm

relay

6 A / 250 V, maximum ohm

resistive load 550 VA

(with RC contact protection)

Permissible ambient

temperature

0 °C to +50 °C

Permissible storage

temperature

-20 °C to +65 °C

Maximum relative

humidity

90 % (non-condensing)

Adjustable

temperature

coefficient of

measurement

solution

0 to 8 % / °C

Proportional band Xp 1 to 3000 %

Reset time Tn 0 to 3000 seconds

Measuring range Cell constant

Conductive

measuring

cell

0 to 20 MΩ/cm

C = 0.05 96609150

0 to 2 μS/cm

0 to 20 μS/cm

0 to 200 μS/cm

0 to 2 mS/cm C = 0.2 96609151

0 to 20 mS/cm C = 1 96609152

Measuring range

Inductive measuring

cell

0 to 2.000 mS/cm

95720194

0 to 20.00 mS/cm

0 to 200.0 mS/cm

0 to 2000 mS/cm

Page 7

English (GB)

7

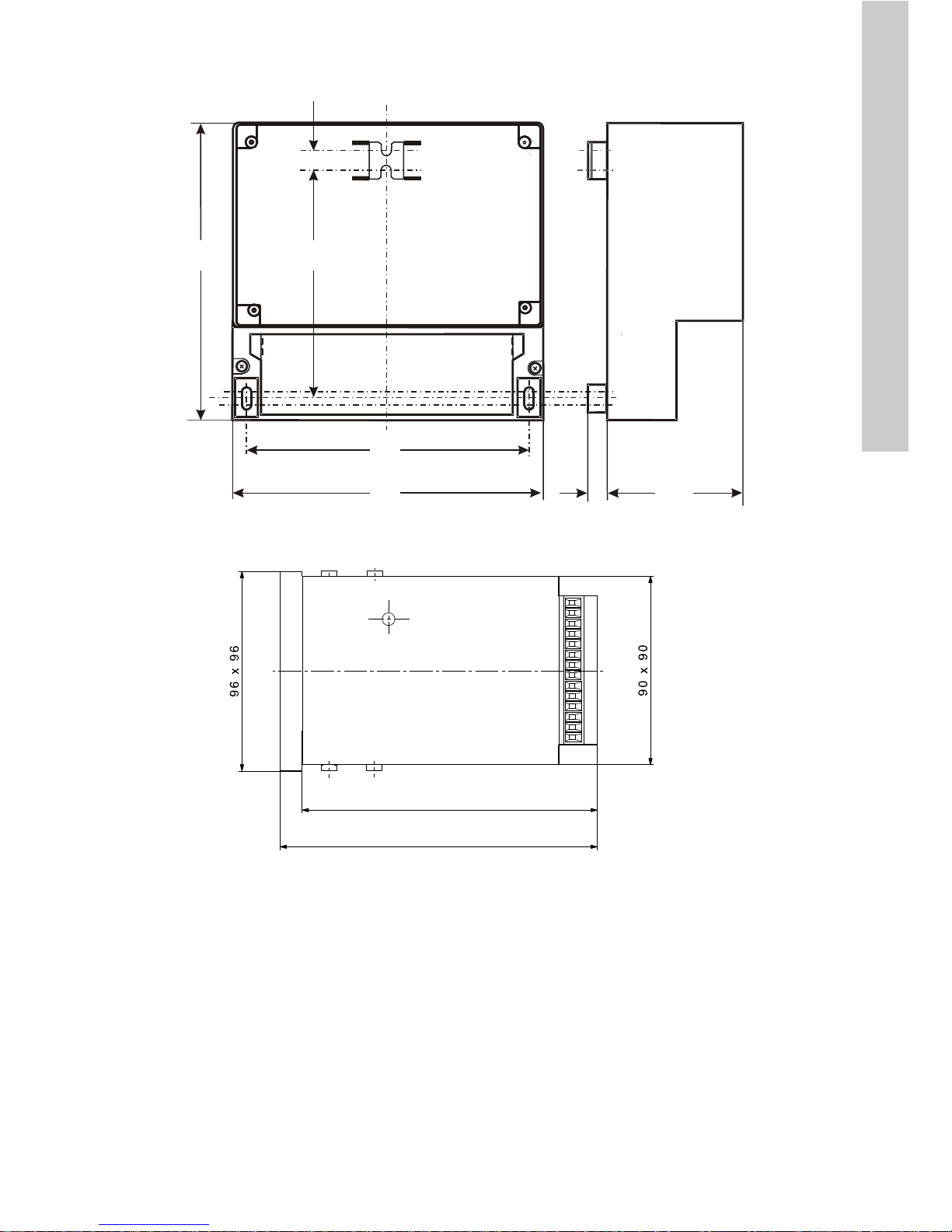

7.4 Dimensional sketches / drilling diagram

Fig. 4 Dimensional sketch / drilling diagram for Conex® DIS-C for wall mounting

Fig. 5 Dimensional sketch / mounting sketch for Conex

®

DIS-C for control-panel wall mounting

TM03 6982 4506TM03 6983 4506

10

72.5

1

6

0

165

151

1

2

0

1

5

approx. 129

approx. 137

Page 8

English (GB)

8

8. Installation

8.1 Transport and storage

• Transport the device carefully, do not drop!

• Store at dry and cool location between -20 °C

and +65 °C.

8.2 Unpacking

• Check the device for damage. Install as soon as

possible after unpacking.

• Do not install or connect damaged devices!

8.3 Installation requirements

• The location must be vibration-free, dry, dust-free

and free of corrosive, pungent fumes or

aggressive solvents.

• Observe the data in section 7. Technical data.

8.4 Assembli ng the C one x® DIS-C housing

for wall mounting

Fig. 6 Installation of Conex® DIS-C for wall mounting

1. Drill three dowel holes with a diameter of 8 mm.

See section 7.4 Dimensional sketches / drilling

diagram.

2. Insert the supplied dowel pins.

3. Unscrew the clamp cover from the device.

4. Screw in the top middle screw.

5. Hang the device onto this screw.

6. Secure the device using the other two screws.

7. Screw the clamp cover back on.

Caution

Do not allow any foreign bodies to enter!

Note

Retain the packing material or dispose of it

according to local regulations.

Caution

If you do not observe the installation

requirements, the device may be

damaged! The measurements may not be

correct!

Warning

Switch off the power supply before

installing!

Enclosure class IP65 is only guaranteed if

the clamp covers and the associated

threaded cable connections and temporary

covers are closed.

TM03 6985 4506

151

120

Caution

Do not damage the gasket.

The gasket must be fitted exactly.

Page 9

English (GB)

9

8.5 Assembling the Conex® DIS-C-P, CI

housing for installation in control panel

1. Make an opening of 92 + 0.8 mm x 92 + 0.8 mm

in the control panel.

2. Slip on the supplied gasket.

3. Insert the device into the opening from the front.

4. Hook the clamps into the tightening cones on the

sides at the top and bottom.

5. Secure the device from the rear using a

screwdriver.

9. Commissioning / electrical

connections

1. Remove the terminal cover on the front of the

device.

2. Use the appropriate cable feedthroughs and

tighten the screws carefully.

3. Connect the cables used to the terminals

according to the Conex

®

DIS-C terminal

assignment.

4. Close the terminal cover again with correctly

positioned gasket.

Caution

Do not damage the gasket.

The gasket must be fitted exactly.

Warning

Switch off the power supply before

installing!

Enclosure class IP65 is only guaranteed

with the front panel of the terminals

enclosure closed and with appropriate

cable glands or dummy caps.

Warning

Switch off the power supply before

connecting the power supply cable and the

relay contacts! For safety reasons, the

protective conductor must be connected

correctly!

Observe the local safety regulations!

Protect the cable connections and plugs

against corrosion and humidity.

Caution

Before connecting the power supply cable,

check that the supply voltage specified on

the nameplate corresponds to the local

conditions!

An incorrect supply voltage may destroy

the device!

To ensure electromagnetic compatibility

(EMC), the input and current output cables

must be screened.

Connect the screening to the screen

ground on one side.

Refer to the wiring diagram! Route the

input, current output and power supply

cables in separate cable channels.

Caution

Enclosure class IP65 is only guaranteed if

the terminal cover is correctly sealed! Do

not damage the gasket on the terminal

cover!

The gasket on the terminal cover must be

positioned precisely!

Do not damage the gasket!

Note

Unused terminals must remain open.

Page 10

English (GB)

10

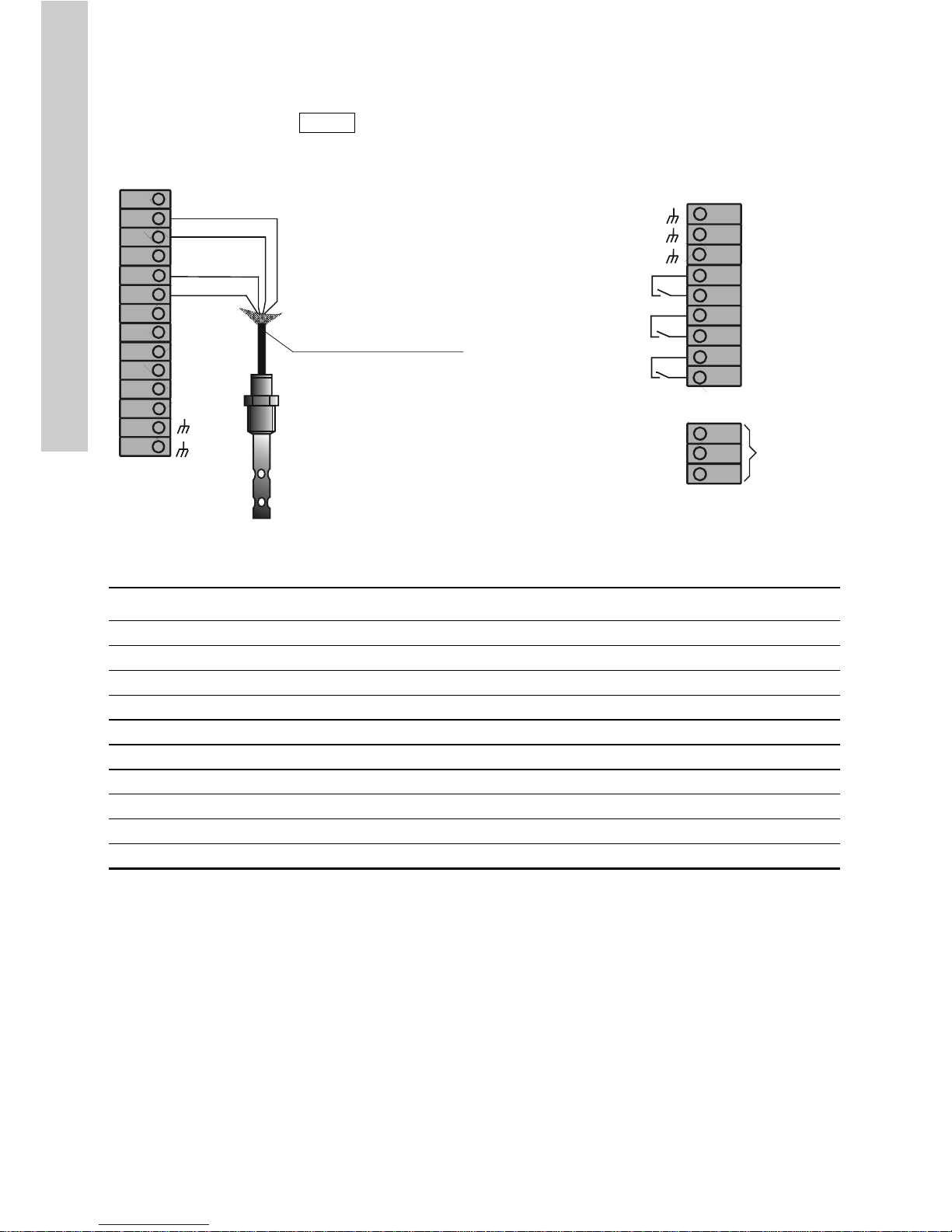

9.1 Conex® DIS-C conductive, housing for wall mounting

Fig. 7 Terminal connection diagram for Conex® DIS-C with conductive measuring cell, housing for wall

mounting

Caution

The measurement input must be screened!

The screen must not be connected to the

Conex

®

DIS-C, but only to the measuring

cell (outer casing of the cell)!

TM03 6986 3914

12

4

5

6

11 12

13

20

21

22

+

L

NPE

14

15 16

17

18 19

A

3

28

27

26

+

29

+

24V

With Pt100, connection with cable:

96611925 (5 m)

96611928 (15 m)

96611929 (25 m)

(maximum cable length: 50 m)

Pos. Description

1 White, inner electrode of measuring cell

2 Brown, outer electrode of measuring cell

4 Yellow, Pt100

5 Green, Pt100

A Trimmer contrast setting

11-12 0/4-20 mA output

14 / 15 Control relay 1 output

16 / 17 Control relay 2 output

18 / 19 Alarm relay 3 output

20 / 21 / 22 For supply voltage, see nameplate

26 / 27 Water sensor

28 Screen

Page 11

English (GB)

11

9.2 Conex® DIS-C inductive, housing for wall mounting

Fig. 8 Terminal connection diagram for Conex® DIS-C with inductive measuring cell, housing for wall

mounting

TM03 6987 4011

12

4

5

61112

13

20

21

22

+

L

N

PE

28

27

26

+

14

15 16

17

18 19

A

29

+

24V

3

3b

Connection with 6 m cable,

extendable with extension cable

95720380

Caution!

Cable length without screen:

maximum 30 mm

Caution!

When extending the cable, the screen

must also be extended!

Pos. Description

1 Green, measurement

2 White, screen

3 Red, voltage supply

3b Black, voltage supply screen

4 Yellow, temperature sensor NTC, screen

5 Brown, temperature sensor NTC

A Trimmer contrast setting

11 / 12 0/4 to 20 mA output

14 / 15 Control relay 1 output

16 / 17 Control relay 2 output

18 / 19 Alarm relay 3 output

20 / 21 / 22 For supply voltage, see nameplate

26 / 27 Water sensor (external controller stop)

28 +24 V

29 Screen

Page 12

English (GB)

12

9.3 Conex® DIS-C conductive, housing for installation in control panel

Fig. 9 Terminal connection diagram for Conex® DIS-C with conductive measuring cell, housing for

installation in control panel

Caution

The screen must not be connected to the

Conex

®

DIS-C, but only to the measuring

cell. See the installation and operating

instructions for the measuring cell!

TM03 6988 4409

L1

N

PE

+

-

+

-

1

24

25

26

3

2

4

5

6

7

8

9

10

11

12

13

14

15

18

21

16

19

22

17

20

23

With Pt100, connection with cable:

96611925 (5 m)

96611928 (15 m)

96611929 (25 m)

(maximum length: 50 m)

Pos. Description

2 White, inner electrode of measuring cell

3 Brown, outer electrode of measuring cell

5 Yellow, Pt100

6 Green, Pt100

9 / 10 0/4 to 20 mA output

11 / 12 Water sensor

18 / 19 Control relay 1 output

20 / 21 Control relay 2 output

22 / 23 Alarm relay 3 output

24 / 25 / 26 For supply voltage, see nameplate

Page 13

English (GB)

13

9.4 Important instructions for connecting

the device

As is common in microprocessor-controlled devices,

certain precautions must be taken during installation

and wiring. In addition to the general guidelines, the

following is of particular importance:

• Input wires and control wires must be laid

separately from one another and from power

supply cables.

• Analog output wires must be screened.

The screen can be connected to the device.

• Relays and protective spools must remain free of

interference.

• If inductive loads are connected, they must either

be screened, or the relay contact must be

protected on the clamping strip of the

Conex

®

DIS-C by an RC protective circuit, in

accordance with the following table and the

switching diagrams.

9.4.1 Power supply

• The device is connected to the power supply at

the clamps (L), (N) and (PE).

• Check the correct supply voltage on the

nameplate.

9.4.2 Connecting the conductivity measuring cell

9.4.3 Relay outputs

If inductive loads (including relay and protective spools)

are connected, they must be screened. If this is not

possible, the relay contact must be protected using a

protection circuit in accordance with the table below.

For AC current

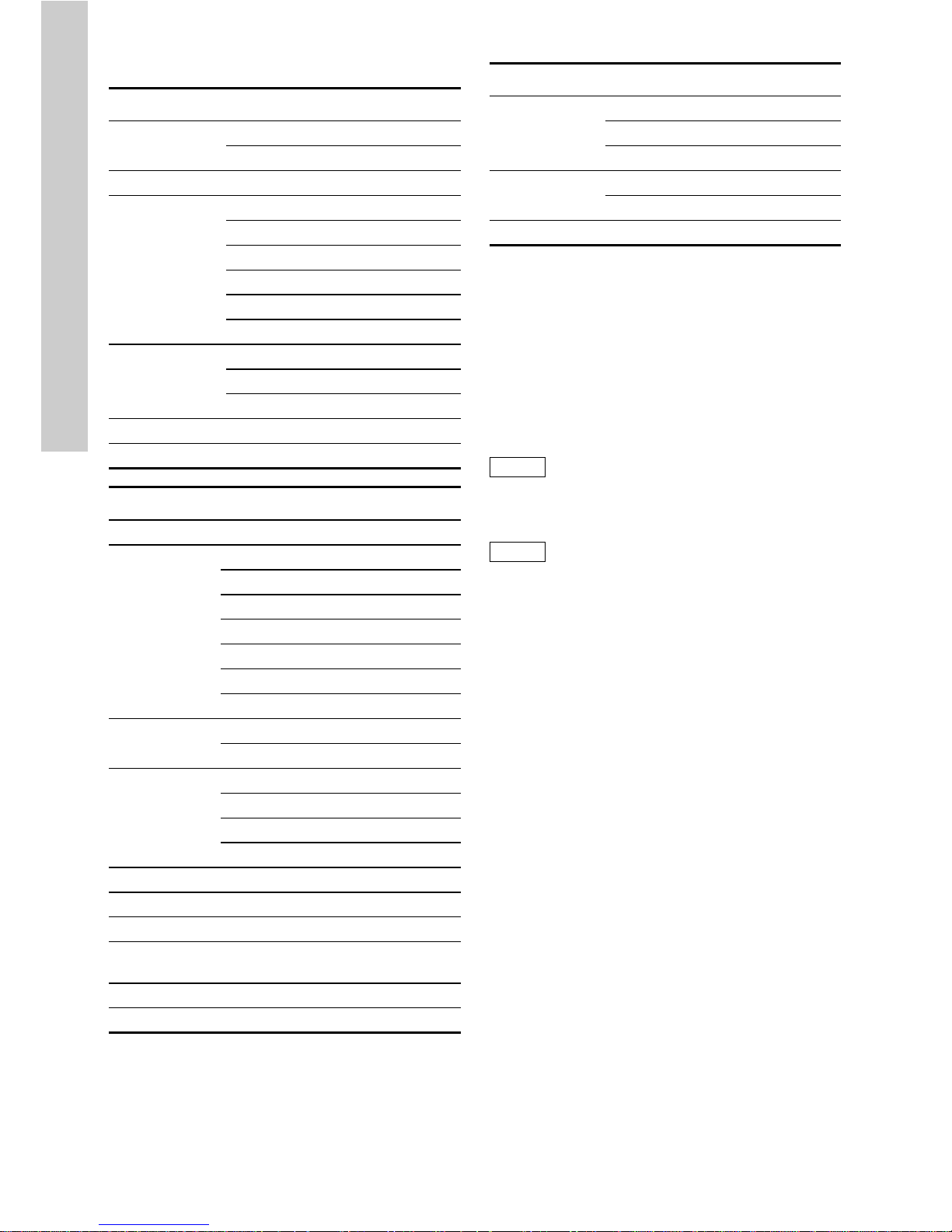

Fig. 10 Protection circuit with AC current

For DC voltage

The relay or protective spool must be screened with

a suppressor diode.

Fig. 11 Protection circuit with DC voltage

9.4.4 Current outputs

Warning

Before connecting the device, switch off

the power supply!

Caution

Connection of an incorrect supply voltage

may destroy the device!

Caution

For connecting the conductivity cell to the

Conex

®

DIS-C, only use the prescribed

cable. This cable must not be used in the

same cable channel as power supply

cables!

Protect cable connections and plugs

against corrosion and moisture!

Current up to Capacitor C Resistor R

60 mA 10 nF, 260 V 390 Ω, 2 W

70 mA 47 nF, 260 V 22 Ω, 2 W

150 mA 100 nF, 260 V 47 Ω, 2 W

1.0 A 220 nF, 260 V 47 Ω, 2 W

TM03 6990 4506TM03 7007 4506

Warning

If floating relay outputs are used, they

must be supplied with a backup fuse!

Caution

When connecting the electrical outputs, be

aware of the polarity and the maximum

load (500 Ω)!

Caution

Use a screened cable for connecting the

electrical outputs. The screen must be

connected to PE with one end.

R = 47 to 390 Ω

C = 10 nF to 220 nF / 260 V

e.g. Siemens MKC B 81 921

Values can be found in the

above table.

+

-

Page 14

English (GB)

14

10. Principles of regulatory function

Freely selectable control functions mean that the

Conex

®

DIS-C controller can be adapted to a wide

variety of closed-loop control systems.

10.1 Regulatory behaviour

10.1.1 P regulation behaviour

The P controller has a static characteristic curve.

The characteristic proportional band for the P

controller is Xp. Within this range, which is limited to

a maximum or minimum depending on the control

direction, there is a proportional correlation between

the input and output quantities of the controller.

The lower limit is the response threshold of the

controller. This is the smallest regulatory deviation

that leads to a measurable control variable.

The upper limit separates the proportional band from

saturation. Above this limit, no further increase in

output signal is possible, regardless of increases in

the input signal. This range is called the control

range of the controller, and the control variable can

have any value within this range.

Due to the static characteristic curve, the P controller

cannot reach the setpoint in a stationary state.

This results in a consistent regulatory deviation,

which can be reduced by decreasing Xp, but which

cannot be completely eliminated using a P controller.

The controller reacts quicker with small Xp values.

The Xp value cannot, however, be reduced

arbitrarily, as this causes the controller to become

unstable.

10.1.2 I regulation behaviour

The non-delayed relationship between the regulatory

deviation and the control variable in a P controller

results in an undesirable persistent regulatory

deviation. However, if the regulatory deviation is

controlled directly by the regulating speed instead of

the control variable, this fixed assignment of the two

variables no longer applies. The result is an

integrated controller.

With a regulatory deviation of zero, i.e. when the

setpoint is equal to the actual value, the regulating

speed is also zero. Both positive and negative

regulatory deviations can be influenced by positive

or negative regulating speeds. The control variable

covers the whole control range. The control range of

the I controller is the range in which the regulatory

deviation controls the regulating speed in a linear

fashion.

The characteristic value of the I controller is the reset

time Tn. The reset time is the time that must elapse,

due to the integrated mode of action, for the step

response to reach the value that a P controller would

reach immediately.

The control circuit reacts slowly. If a regulatory

deviation results, an I controller can only react by

constantly changing its control variable. For this

reason, regulation with I controllers is always slower

than with controllers that act proportionally. If the

speed of the controller is increased by decreasing

the integration constant, the control circuit has a

slight tendency towards instability.

At Tn = 0, the controller has no I proportion.

In the absence of external influences, a control

circuit with an I controller therefore has no residual

regulatory deviation in a stationary state when the

control variable is constant.

10.2 Limit values

In principle, the limit value only has two switching

states; ON and OFF. Depending on the set control

direction, the controller is deactivated when the

setpoint value is exceeded, or when the value drops

below the setpoint.

10.2.1 Limit values with hysteresis

To prevent constant switching when the setpoint

value is reached, it is possible to specify a hysteresis

for the controller.

Example:

• setpoint 600 μS/cm

• hysteresis 10 μS/cm.

The hysteresis band is arranged symmetrically

around the switching point.

• Switch-off point = measured value + hysteresis / 2

• Switch-on point = measured value - hysteresis / 2.

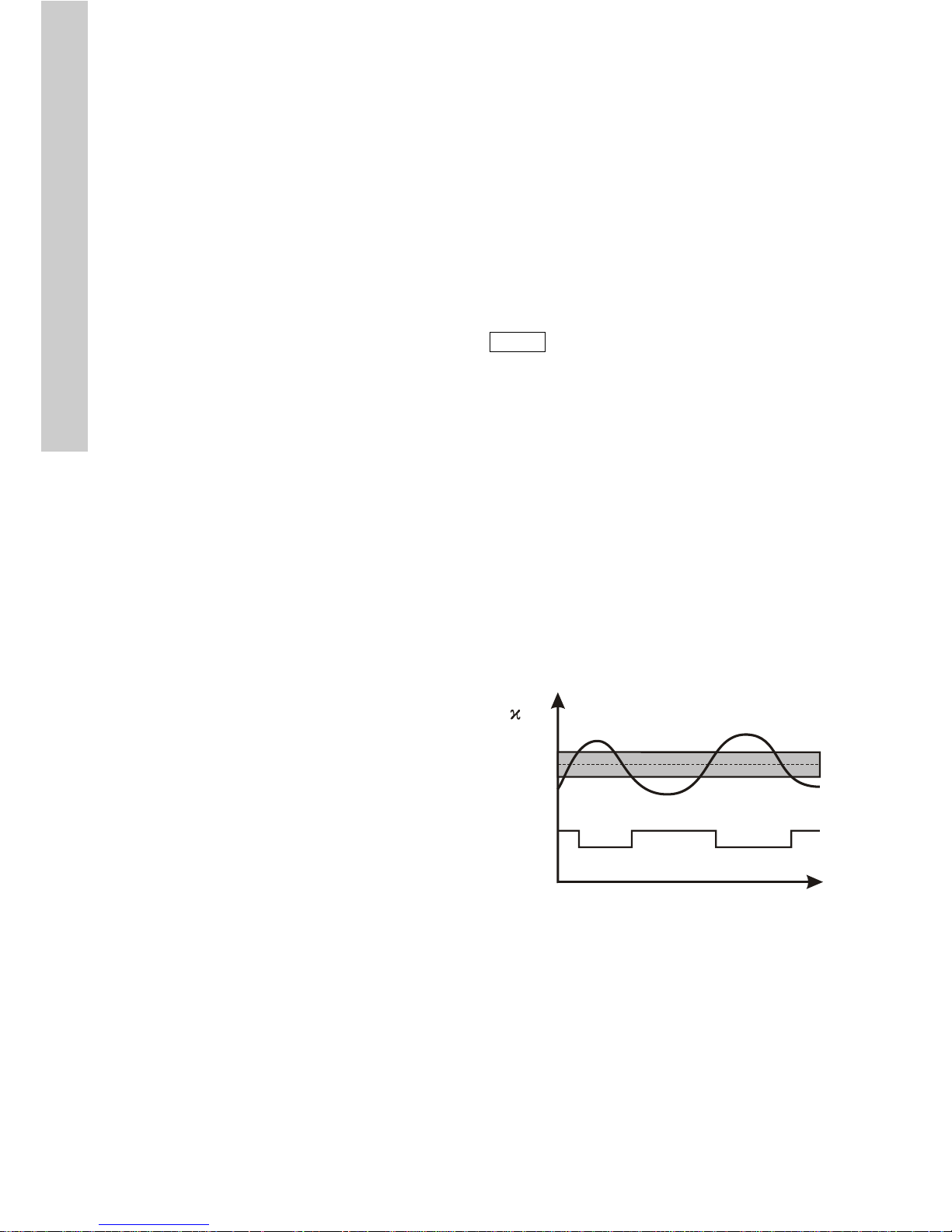

Fig. 12 Limit values with hysteresis

Note

Setting for a limit value: Xp = O.

TM03 6991 4506

605

600

595

µS/cm

µS/cm

µS/cm

1

0

Relay

605 μS/cm

600 μS/cm

595 μS/cm

μS/cm

Page 15

English (GB)

15

10.3 On-off controller with P behaviour

It is possible to use an on-off controller with P

behaviour as an intermittent pulse regulator or as a

pulse frequency regulator.

10.3.1 Intermittent pulse regulator

Example:

• setpoint = 6 mS/cm

• measuring range 0 to 10

• Xp = 30

• control direction = downwards.

Xp determines the size of the proportional band as a

percentage of the measuring range. In the following

example, this means that above 6 mS the relay

switches on, first with a short activation time and

then with an increasing activation time to 9 mS (the

total switching on + off time remains constant).

For greater measured values, the relay remains

constantly switched on.

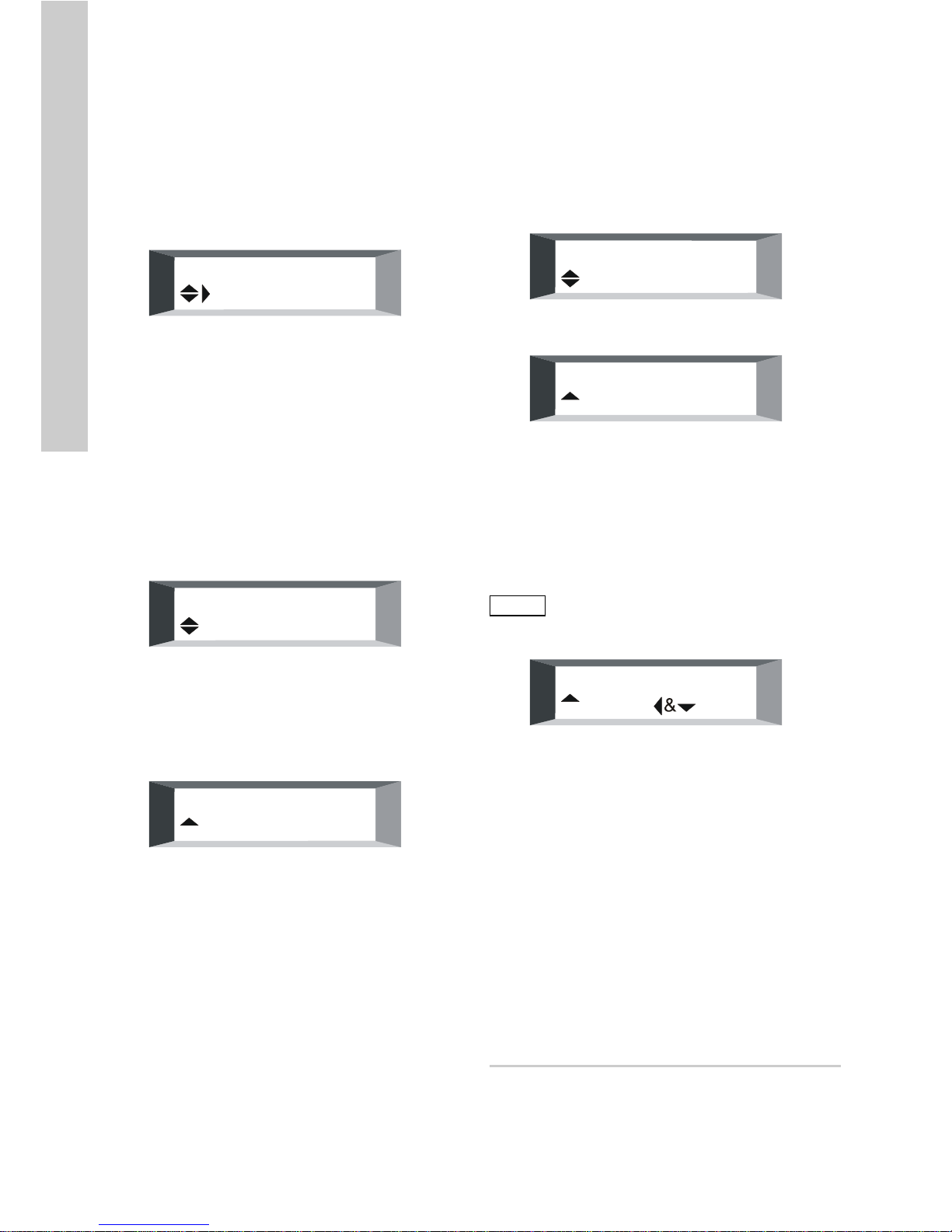

Fig. 13 Intermittent pulse regulator

The intermittent pulse regulation offers the option to

recreate a constant controlling element using very

simple control elements, e.g. a magnetic valve.

Here, the relationship between switching on and off

is changed depending on the calculated control

variable. The total time (ON+OFF) is constant in

intermittent pulse regulation. The total time can be

set to between 1 and 99 seconds depending on the

control system. A setting of 10 seconds leads to a

good result in most cases.

If the calculated control variable is very low, in some

cases it is possible that the control element attached

here does not show a reaction within this short time.

In this case, it is possible to set a minimum drive

pulse. This can be within the range 0.1 to

9.9 seconds.

10.3.2 Pulse-frequency regulator

Example:

• setpoint = 6 mS/cm

• measuring range 0 to 10

• Xp = 20 or 40

• pulse frequency = 120

• control direction = downwards.

Xp determines the size of the proportional band as a

percentage of the measuring range. In the following

example, this means that impulses are output from

6 mS and constantly increase to 8 mS (Xp = 20) or

10 mS (Xp = 40). For higher measured values, the

prespecified maximum number of impulses (here

120/min) is output.

Fig. 14 Pulse-frequency regulator

The pulse frequency regulator in combination with an

appropriate control variable is almost the same as a

continuous controller. The disadvantages of the

impulse-driven control variable only becomes

apparent in the lower control variable range and with

a low maximum pulse frequency. The specification of

the maximum pulse frequency refers to 100 %

dosing flow and can be set within a range from 0 to

180 impulses per minute.

Note

Setting for an on-off controller: Xp > O.

Note

Setting for an intermittent pulse regulator:

Xp > O, pulse frequency = 0.

TM03 6992 4506

SP setpoint

MV measured value

6

7

8

9

T

ON

T

ON

T

[]mS/cm

2 3

0 1

4 5

6 7

8

10

9

[mS ]/cm

SP

MV

MV

[mS/cm]

[mS/cm]

Note

The intermittent pulse period must always

be at least twice as long as the minimum

switch-on time!

Note

Setting for a pulse-frequency regulator:

Xp > O, pulse frequency > 0.

TM03 6993 4506

0

30

60

90

100%

6

789

10

120

Xp = 40

Xp = 20

[1 min]/

Pulse frequency

Measured

value

Setpoint

[1/min]

[mS/cm]

Page 16

English (GB)

16

10.3.3 Continuous action controllers

The control variables calculated by the controller

based on the setpoint S1 or S2 can optionally be

output as a continuous control signal via the analog

output.

See section 12.4.4 Analog output.

Fig. 15 Continuous-action controllers

10.4 Parameter settings

Make a note here of the parameter settings for the

device.

TM03 6994 4506

0

5

10

15

100%

6

789

10

20

Xp = 40

Xp = 20

[mA]

Current output

Measured

value

Setpoint

[m/A]

[mS/cm]

Setup

Controller

Pulse freq. S1 _____ / min

Pulse freq. S2 _____ / min

Ctrl. direction S1

__ downward

__ upward

Ctrl. direction S2

__ downward

__ upward

Hysteresis _____ μS

Int. pulse period _____ s

Min. switch-on _____ s

Delay control

Delay ctrl.

__ off

__ on

Delay ctrl. _____ s

Analog output

Select output

__ 0-20 mA

__ 4-20 mA

Start 0/4 mA _____ μS

End 20 mA _____ μS

Analog output __ measured value

Temper. coeff. _____ % / °C

Cell const. _____

Measur. range _____

Averaging

__ on

__ off

Temperature compensation

Temp. compens.

__ Automat.comp.

__ Manual comp.

Manual temp. _____ °C

Controller settings

Setpoint 1 _____ μS

Prop. band XP S1 _____ μS

Reset time TN S1 _____ s

Setpoint 2 _____ μS

Prop. band XP S2 _____ μS

Reset time TN S2 _____ s

Alarm

Alarm value A1 _____ μS

Alarm value A2 _____ μS

Delay _____ s

Page 17

English (GB)

17

11. Initial operation and settings

11.1 Initial steps for operation

Once the assembly and connection steps have been

completed, carry out the following steps when using

the device for the first time.

1. Switch on the power supply.

2. If required, set the measuring range.

3. Check the entered cell constants.

4. If necessary, perform a cable compensation (for a

conductive measuring cell).

5. Set the parameters for the device function.

Check the outputs and secondary devices.

12. Operation

12.1 Device layout for Conex® DIS-C

12.1.1 Control and display elements

The Conex

®

DIS-C conductivity measuring amplifier

is operated using a touch-sensitive membrane

keypad.

Fig. 16 Control and display elements

Display

Control elements

Display fields

Fig. 17 Display fields

Warning

Before connecting the power supply,

ensure that the supply voltage

corresponds to the power supply specified

on the nameplate!

Note

Notes or instructions that make the job

easier and ensure safe operation.

TM03 6995 4506

Pos. Description

1LCD display

1

2

6

345

Pos. Function Name

2

Menu control button

[Up]

3[Left]

4[Down]

5 [Right]

6

Button for returning to

start menu

[OK]

TM03 6996 4506

Pos. Description

1a

Measuring value display

• Displays the current measured value

in MΩ, μS, mS (depending on the

selected measuring range).

1b

Temperature display

• Displays the temperature used for

compensation. Depending on the

setting, this is either the manually

specified temperature or the

temperature measured using the

temperature sensor.

1c

Relay 1 switching status

• A filled rectangle indicates

switched-on status.

1d

Relay 2 switching status

• A filled rectangle indicates

switched-on status.

1e

Control function

• Displays the preselected regulation

type.

1f Display of active menu control buttons.

Page 18

English (GB)

18

12.2 Menu control

12.3 Navigation in the menus

• To navigate in and between menus, use the [Up]

and [Down] buttons.

• Use the [Right] button to open the menu next to

it. The currently active menu control buttons are

displayed in the corresponding line.

• Use the [Left] button to save values.

• Use [OK] to exit the menu and return to the start

display.

Main menu Default values

Temp. compens.

Temp. compens. Manual comp.

Manual temp. 025 °C

Enter password Enter password Code 086

Controller

Setpoint S1 02.5 μS

Prop. and xp S1 10 %

Reset time TN S1 000 s

Setpoint S2 02.0 μS

Prop. band xp S2 10 %

Reset time TN S2 000 s

Alarm values

Alarm value A1 00.0 μS

Alarm value A2 02.0 μS

Delay 0.05 s

Setup See table below

Service See table below

Setup menu Default values

Corr. temp. Corr. temp. 0 °C

Contr. param.

Pulse freq. S1 0-180 / min

Pulse freq. S2 0-180 / min

Ctrl. direction S1 Downward control

Ctrl. direction S2 Upward control

Hysteresis 00.1 μS

Int. pulse period 10 s

Min. switch-on 0.5 s

Delay ctrl.

Delay ctrl. off

Delay ctrl. 180 s

Analog output

Select output 0-20 mA

Start 0/4 mA 00.0 μS

End 20 mA 200.0 μS

Analog output Measured value

Language Sel. language Deutsch

Temper. coeff. Temper. coeff. 0.0 % / °C

Cell const. Cell const. 0.050

Cable

compens.

Cable compens. 00.0 μS

Measur. range Measur. range 20.00 μS

Averaging Averaging off

Service menu Default values

Product info

Unit No. No. 041

Software date M/Y 1.00

Product. date M/Y 1.00

Analog input

Input 1 -019

Input 2 000 °C

Delete setting Delete setting

Note

Important menu selections and changes to

data are code-protected to prevent

unauthorised access.

Note

The order of the settings in the following

section is different to the order of menu

navigation. This section describes the

basic settings that are made first during

setup.

Page 19

English (GB)

19

12.4 Setup

The "Setup" menu contains settings that need to be

made or checked the first time the Conex

®

DIS-C is

used.

1. Press the [Down] button to navigate to the

"Setup" menu.

2. Press the [Right] button to open the "Setup"

menu.

3. Press the [Down] button to navigate to the

submenus.

In the submenus, it is possible to enter settings

for the following values:

• temperature correction

• control parameters

• switch-on delay

• analog output

• language

• temperature coefficient

• cell constant C

• bus address

• cable compensation/zero point

• measuring range

• averaging on/off.

12.4.1 Temperature correction

Because the temperature sensor is connected using

a 2-conductor method, this can result in deviations in

temperature measurement and display.

These deviations can be corrected within a range of

± 5 °C.

1. Press the [Right] button to open the "Corr. temp."

menu.

2. Press the [Right] button to start value input.

3. Press the [Up] and [Down] buttons to set the

value.

12.4.2 Control parameters

The first time the device is used, the regulatory

functions must be defined.

In the "Contr. param." menu, the following values

can be set:

• pulse frequency S1

• pulse frequency S2

• hysteresis

• pulse + pause

• minimum impulse.

1. Press the [Right] button to open the

"Contr. param." menu.

2. Press the [Down] button to navigate to the

submenus.

Pulse frequency S1/S2

1. Press the [Right] button to open the "Pulse

freq. S1" or "Pulse freq. S2" menu.

2. Press the [Up] and [Down] buttons to set the

value.

TM03 6997 4506TM03 6998 4506TM03 6999 4506

Alarm

Setup

Corr. temp.

0.0 °C

TM03 6998 4506

Note

Setting for a limit value: Xp = O.

Setting for an intermittent pulse regulator:

Xp > O, pulse frequency = 0.

Setting for a pulse frequency regulator:

Xp > O, pulse frequency > 0.

Note

Pulse frequency setting = maximum

number of impulses per minute. Set the

appropriate pulse frequency for the

connected control element.

Note

It is possible to make separate control

parameter settings for S1 and S2.

TM03 6998 4506

Corr. temp.

Contr. param.

Corr. temp.

Contr. param.

Page 20

English (GB)

20

Control direction S1/S2

By default, the control direction is set to exceeded (=

downwards) for S1, and for S2 it is set to upwards.

This means that if the value set for setpoint S1 is

exceeded, relay 1 is switched, and if the value drops

below setpoint S2, relay 2 is switched.

It is possible to change the control direction for S1

and S2.

1. Press the [Right] button to open the

"Ctrl. direction S1" or "Ctrl. direction S2" menu.

2. Press the [Up] and [Down] buttons to set the

value.

Hysteresis

The hysteresis setting only takes effect for a limit

value. If a setting is made, the hysteresis band

surrounds the selected setpoint symmetrically. If the

setpoint S1 is set to 0.500 mS and the hysteresis

setting is set to 0.010 mS, the relay switches on or

off (depending on the control direction) at 0.505 mS

and 0.495 mS.

1. Press the [Right] button to open the "Hysteresis"

menu.

2. Press the [Up] and [Down] buttons to set the

value.

Intermittent pulse period

The factory setting for the intermittent pulse period is

10 seconds. This setting has proved ideal for nearly

all applications.

1. Press the [Right] button to open the "Int. pulse

period" menu.

2. Press the [Up] and [Down] buttons to set the

value.

Minimum impulse/minimum switch-on time

The minimum switch-on time determines the shortest

drive pulse in the intermittent pulse period

regulation.

The intermittent pulse period setting must always be

at least twice as long as the minimum switch-on

time.

1. Press the [Right] button to open the

"Min. switch-on" menu.

2. Press the [Up] and [Down] buttons to set the

value.

12.4.3 Switch-on delay

If the switch-on delay of the Conex

®

DIS-C is

activated, the controller is not activated until the

specified time has elapsed after the power supply to

the device has been switched on. This menu can be

used to switch the switch-on delay on and off, and if

the switch-on delay is activated, the delay duration

can be entered.

Activating/deactivating the switch-on delay

1. Press the [Right] button to open the "Delay

control" menu.

2. Press the [Right] button to switch between on

and off.

Setting the switch-on delay time

1. Press the [Right] button to open the value input

display.

2. Press the [Up] and [Down] buttons to set the

value.

TM03 6998 4506TM03 6998 4506TM03 6998 4506

Ctrl. direction

Upward control

Hysteresis

0.010 mS

Int. pulse period

10 sec.

TM03 6999 4506TM03 6998 4506TM03 6998 4506

Min. switch-on

0.5 sec.

Contr. param.

Delay ctrl.

Delay ctrl.

On

Page 21

English (GB)

21

12.4.4 Analog output

Using the analog output, it is possible to choose

whether the measured value is signalled externally

as a registry output, or it is possible to choose the

switching points S1 or S2 as continuous control

outputs. Any range of 0 to 20 mA or 4 to 20 mA

within the measuring range can be assigned to the

analog output. The indicated measuring range is

defined by the start and end values. This also

determines the direction of the analog output.

• Press the [Right] button to open the "Analog

output" menu.

The following settings are made in the "Analog

output" menu:

• switching between 0 to 20 mA and 4 to 20 mA

• analog output start value

• analog output end value

• assigning analog output.

Switching between 0 to 20 mA and 4 to 20 mA

1. Press the [Right] button to choose between

0-20 mA and 4-20 mA.

2. Press the [Down] button to open the

"Start 0/4 mA" submenu.

Analog output start value

1. Press the [Right] button to open the value input

display.

2. Press the [Up] and [Down] buttons to set the

value.

3. Press the [Right] button to save the entry.

4. Press the [Down] button to open the "End 20 mA"

submenu.

Analog output end value

1. Press the [Right] button to open the value input

display.

2. Press the [Up] and [Down] buttons to set the

value.

3. Press the [Left] button to save the entry.

4. Press the [Down] button to open the "Analog

output" submenu.

Assigning analog output

1. Press the [Right] button to choose between the

measured value, continuous controller 1 and

continuous controller 2.

12.4.5 Language

The "Language" menu is used to determine the

language for the Conex

®

DIS-C.

1. Press the [Right] button to open the "Language"

menu.

2. Press the [Right] button to choose between the

languages (German, English, French).

TM03 6998 4506TM03 6998 4506

Select output

0-20 mA

Start 0/4 mA

0.000 mS

TM03 6999 4506TM03 6999 4506TM03 6999 4506TM03 6999 4506TM03 6999 4506

End 20 mA

2.000 mS

Analog output

Measured value

Analog output

Cont. ctrl. S1

Analog output

Cont. ctrl. S2

Sel. language

Deutsch

Page 22

English (GB)

22

12.4.6 Temperature coefficient

This menu is used for displaying and setting the

temperature coefficient.

Because different measuring fluids have different

temperature coefficients, the appropriate coefficient

must be set. The setting range is 0.0 to 8.0 % / °C.

The factory setting is 2.5 % / °C, which is suitable for

many applications.

1. Press the [Right] button to open the

"Temper. coeff." menu.

2. Press the [Right] button to open the value input

display.

3. Press the [Up] and [Down] buttons to set the

value.

12.4.7 Cell constant C

The mechanical dimensions used for the

measurement of active surfaces of the measuring

cell are defined in the cell constant. The measuring

cell is characterised by the cell constant.

1. Press the [Right] button to open the "Cell const."

menu.

2. Press the [Right] button to open the value input

display.

3. Press the [Up] and [Down] buttons to set the

value.

Cable compensation (only for conductive

measurement)

The capacity of the cable can lead to an incorrect

value, particularly for small measuring ranges.

This incorrect value can be corrected as follows:

1. Press the [Right] button to select the "Cable

compens." menu.

2. Hold the connected, dry measuring cell in the air.

– If the top line of the display reads a measured

value, i.e. the value 0.00 is not displayed,

cable compensation must be performed.

3. Simultaneously press the [Left] and [Down]

buttons.

– If the compensation is successful, the value

0.00 is displayed.

12.4.8 Measuring range

In this menu, the required measuring range for the

device can be set (MΩ, μS, mS).

1. Press the [Right] button to open the

"Measur. range" menu.

2. Press the [Right] button (several times) to select

a measuring range.

TM03 6998 4506TM03 6999 4506TM03 6999 4506

Language

Temper. coeff.

Temper. coeff.

0.0 % / °C

Cell const.

0.050

TM03 7000 4506TM03 6999 4506TM03 6999 4506

Note

When setting the measuring range, ensure

that it is suitable for the cell constant of the

measuring cell. See section 7. Technical

data.

0.00 μS

Press

Measur. range

2.000 μS

Measur. range

20.00 MOhm

Page 23

English (GB)

23

12.4.9 Averaging on/off

In this menu, the averaging function can be switched

on or off. If the averaging function is switched on, the

mean of the last 10 measured values is calculated

and displayed as the measured value.

1. Press the [Right] button to open the "Averaging"

menu.

2. Press the [Right] button to select averaging on or

off.

12.5 Relay menu (S1 S2)

In the relay menu (S1 S2), it is possible to choose

between manual and automatic operation. In manual

operation, the relays S1 and S2 can be switched on

and off separately.

12.5.1 Automatic and manual operation

In automatic operation, the relay contacts are

switched by the built-in controller. "Auto" is shown in

the display.

In manual operation, the relay is switched manually.

"Man" is shown in the display.

Switching between automatic and manual

operation:

• Press the [Right] button to switch the controller to

manual or automatic operation.

12.5.2 S1/S2 in manual operation

Switching the relays S1/S2 on and off:

1. Press the [Up] button to select the chosen relay

(S1/S2).

– The corresponding symbol flashes.

2. Press the [Right] button to switch the chosen

relay (S1 or S2) on or off.

– The switch status of the relay is displayed as

follows:

Relay ON = symbol filled

Relay OFF = symbol not filled.

12.6 Temperature compensation

Temperature compensation cancels out the effect of

temperature dependency of the medium. It is based

on a reference temperature of 25 °C.

This temperature compensation can be performed

automatically via a connected temperature sensor or

manually by entering the relevant temperature.

• Select the "Temp. compens." menu.

Switching between manual and automatic

compensation:

• Press the [Right] button to select between

manual and automatic compensation.

Selecting the default temperature for manual

compensation

1. Press the [Down] button to open the "Manual

temp." menu.

2. Press the [Right] button to open the temperature

selection display.

3. Press the [Up] and [Down] buttons to select the

temperature.

TM03 6999 4506

Note

The description of the rest of the menus

now continues in the order of menu

navigation.

TM03 6997 4506TM03 7001 4506

Note

If the relays are switched on manually,

they remain switched on until they are

switched off again, or until control is

switched back to automatic.

Note

Switching to automatic operation is only

possible if the arrow to the right of the

"Man" text is visible.

Averaging

Off

TM03 6998 4506TM03 6999 4506

Temp. compens.

Automat. comp.

Default temp.

25.5 °C

Page 24

English (GB)

24

12.7 Displaying / changing code

The device can be protected against unauthorised or

unintentional changing of the programmed data.

Two release codes are stored:

• Code 086: General access to all functions.

• Code 011: Access to temperature compensation

and controller settings.

In all other code settings, the device is protected

against unintentional changes to data. If a code is

set and a locked menu is selected, the operator is

prompted to enter the code.

Displaying the code

• Press the [Right] button to open the "Enter

password" menu.

– The current code is displayed.

Changing the code

1. Press the [Right] button to open the "Enter

password" menu.

2. Press the [Up] and [Down] buttons to enter the

required code in the range 000 to 2000.

– Pressing the [Up] button once increases the

value by +1. If the button is held down for

longer, the value increases automatically.

– Pressing the [Down] button once decreases the

value by -1. If the button is held down for

longer, the value decreases automatically.

3. Press the [Left] button to save the entry.

12.8 Controller settings

In the "Controller" menu, the following values are

set:

•setpoint S1

• proportional band Xp S1

• reset time Tn (I part) S1

•setpoint S2

• proportional band Xp S2

• reset time Tn (I part) S2.

1. Press the [Right] button to open the "Controller"

menu.

2. Press the [Up] and [Down] buttons to select the

required value.

3. Press the [Right] button to open the value input

display.

12.8.1 Setpoint setting S1/S2

The setpoints S1 and S2 are set separately and can

have different values within the measuring range.

1. Press the [Right] button to open the value input

display.

2. Press the [Up] and [Down] buttons to set the

value.

Note

Important menu selections and changes to

data are code-protected to prevent

unauthorised access.

TM03 6998 4506TM03 6999 4506TM03 7002 4506

Temp. compens.

Enter password

Enter password

011 Code

Enter password

011 Code

Note

This entry is only possible if the

corresponding controller function is

already set in the "Setup" menu.

TM03 6998 4506TM03 6998 4506

Enter password

Controller

Setpoint 2

0.000 mS

Page 25

English (GB)

25

12.8.2 Proportional band Xp S1/S2

The proportional band Xp (P behaviour) is set

separately for both setpoints in the range 1 to

3000 %.

1. Press the [Right] button to open the value input

display.

2. Press the [Up] and [Down] buttons to set the

value.

12.8.3 Reset time Tn (I part) S1/S2

The reset time Tn (I part) is set separately for both

setpoints in the range 0 to 3000 seconds.

If the reset time Tn is 0 seconds, the I part is

deactivated.

1. Press the [Right] button to open the value input

display.

2. Press the [Up] and [Down] buttons to set the

value.

12.9 Alarm value setting A1/A2

For the limit value alarm, the alarm values A1 and A2

are set separately. The switch direction for alarm

value A1 is set to "exceed", and for alarm value A2 it

is set to "drop below". If the alarm value 1 is

exceeded or if the value drops below alarm value 2,

relay 3 is switched after the specified delay time has

elapsed.

The alarm message is delayed by the specified time.

If the delay time is set to 000 seconds, the alarm

message of the limit value alarm is raised

immediately.

Setting the alarm values

1. Press the [Right] button to open the "Alarm

values" menu.

2. Press the [Up] and [Down] buttons to select the

required value (A1, A2).

3. Press the [Right] button to open the value input

display.

4. Press the [Up] and [Down] buttons to set the

value.

Setting the alarm delay time

1. Press the [Up] and [Down] buttons to select

"Delay".

2. Press the [Right] button to open the value input

display.

3. Press the [Up] and [Down] buttons to set the

value.

Note

Setting for a limit value: Xp = O.

Setting for an intermittent pulse controller

or pulse frequency controller: Xp > O.

TM03 6998 4506TM03 6999 4506

Prop. band xp

3000 %

Reset time TN

000 sec.

TM03 6998 4506TM03 6999 4506

Controller

Alarm values

Delay

000 s

Page 26

English (GB)

26

12.10 Service

The "Service" menu contains service information and

utilities.

The "Service" menu contains the following

options:

• device data

• analog inputs

• resetting factory settings.

• Press the [Right] button to open the "Service"

menu.

12.10.1 Device data

1. Press the [Right] button to open the "Product

info" menu.

2. Press the [Up] and [Down] buttons to switch

between the following displays.

Device number

Displays the serial number.

Software status

Displays the latest revision date of the software

(e.g. 1.00: The software revision status is

January 2000).

Production date

Displays the date of manufacture of the device

(e.g. 3.00: The device was produced in March 2000).

12.10.2 Analog inputs/test

In this menu, the analog inputs are tested. The input

signals are displayed in mV (analog input 1) and °C

(analog input 2).

1. Press the [Right] button to open the "Analog

input" menu.

2. Press the [Up] and [Down] buttons to switch

between the following displays:

12.10.3 Deleting data/resetting factory settings

In some circumstances it may be necessary to

restore the device to its delivered status. All values

set by the customer are overwritten with the factory

settings.

The initial settings on the device must then be made

again.

1. Press the [Right] button to open the "Delete

setting" menu.

2. Simultaneously press and hold down the [Left]

and [Down] buttons.

– "Please wait!!!" is displayed.

Deleting the data takes approximately 10 seconds.

When this display disappears, the Conex

®

DIS-C is

restored to the factory settings.

13. Disposal

This product or parts of it must be disposed of in an

environmentally sound way:

1. Use the public or private waste collection service.

2. If this is not possible, contact the nearest

Grundfos company or service workshop.

Subject to alterations.

TM03 6998 4506TM03 7003 4506TM03 7004 4506

Setup

Service

Software date

M/Y 1.00

Product. date

M/Y 3.00

TM03 7003 4506TM03 7004 4506

Note

Before deleting the memory, make a note

of the important parameter settings.

TM03 7000 4506

Analog input

Input 1 056 mV

Analog output

Input 2 023 °C

Delete setting

Press

Page 27

Declaration of conformity

27

Declaration of conformity 1

GB: EC/EU declaration of conformity

We, Grundfos, declare under our sole responsibility that the product

Conex DIS-C, to which the declaration below relates, is in conformity

with the Council Directives listed below on the approximation of the

laws of the EC/EU member states.

DE: EG-/EU-Konformitätserklärung

Wir, Grundfos, erklären in alleiniger Verantwortung, dass das Produkt

Conex DIS-C, auf das sich diese Erklärung bezieht, mit den

folgenden Richtlinien des Rates zur Angleichung der

Rechtsvorschriften der EG-/EU-Mitgliedsstaaten übereinstimmt.

ES: Declaración de conformidad de la CE/UE

Grundfos declara, bajo su exclusiva responsabilidad, que el producto

Conex DIS-C al que hace referencia la siguiente declaración cumple

lo establecido por las siguientes Directivas del Consejo sobre la

aproximación de las legislaciones de los Estados miembros de la

CE/UE.

FR: Déclaration de conformité CE/UE

Nous, Grundfos, déclarons sous notre seule responsabilité, que le

produit Conex DIS-C, auquel se réfère cette déclaration, est

conforme aux Directives du Conseil concernant le rapprochement

des législations des États membres CE/UE relatives aux normes

énoncées ci-dessous.

IT: Dichiarazione di conformità CE/UE

Grundfos dichiara sotto la sua esclusiva responsabilità che il prodotto

Conex DIS-C, al quale si riferisce questa dichiarazione, è conforme

alle seguenti direttive del Consiglio riguardanti il riavvicinamento delle

legislazioni degli Stati membri CE/UE.

NL: EG/EU-conformiteitsverklaring

Wij, Grundfos, verklaren geheel onder eigen verantwoordelijkheid dat

product Conex DIS-C, waarop de onderstaande verklaring betrekking

heeft, in overeenstemming is met de onderstaande Richtlijnen van de

Raad inzake de onderlinge aanpassing van de wetgeving van de

EG-/EU-lidstaten.

PT: Declaração de conformidade CE/UE

A Grundfos declara sob sua única responsabilidade que o produto

Conex DIS-C, ao qual diz respeito a declaração abaixo, está em

conformidade com as Directivas do Conselho sobre a aproximação

das legislações dos Estados Membros da CE/UE.

– EMC Directive (2014/30/EU).

Standards used:

EN 61326-1:2013,

EN 61000-3-2:2015, EN 61000-3-3:2014.

– Low Voltage Directive (2014/35/EU).

Standard used:

EN 61010-1:2011-07.

This EC/EU declaration of conformity is only valid when published as

part of the Grundfos instructions.

Pfinztal, 20th April 2016

Ulrich Stemick

Technical Director

Grundfos Water Treatment GmbH

Reetzstr. 85, D-76327 Pfinztal, Germany

Person authorised to compile the technical file and

empowered to sign the EC/EU declaration of conformity.

Page 28

Grundfos companies

Argentina

Bombas GRUNDFOS de Argentina S.A.

Ruta Panamericana km. 37.500 Centro

Industrial Garin

1619 - Garin Pcia. de B.A.

Phone: +54-3327 414 444

Telefax: +54-3327 411 111

Australia

GRUNDFOS Pumps Pty. Ltd.

P.O. Box 2040

Regency Park

South Australia 5942

Phone: +61-8-8461-4611

Telefax: +61-8-8340 0155

Austria

GRUNDFOS Pumpen Vertrieb

Ges.m.b.H.

Grundfosstraße 2

A-5082 Grödig/Salzburg

Tel.: +43-6246-883-0

Telefax: +43-6246-883-30

Belgium

N.V. GRUNDFOS Bellux S.A.

Boomsesteenweg 81-83

B-2630 Aartselaar

Tél.: +32-3-870 7300

Télécopie: +32-3-870 7301

Belarus

Представительство ГРУНДФОС в

Минске

220125, Минск

ул. Шафарнянская, 11, оф. 56

Тел.: +7 (375 17) 286 39 72, 286 39 73

Факс: +7 (375 17) 286 39 71

E-mail: minsk@grundfos.com

Bosnia/Herzegovina

GRUNDFOS Sarajevo

Trg Heroja 16,

BiH-71000 Sarajevo

Phone: +387 33 713 290

Telefax: +387 33 659 079

e-mail: grundfos@bih.net.ba

Brazil

BOMBAS GRUNDFOS DO BRASIL

Av. Humberto de Alencar Castelo

Branco, 630

CEP 09850 - 300

São Bernardo do Campo - SP

Phone: +55-11 4393 5533

Telefax: +55-11 4343 5015

Bulgaria

Grundfos Bulgaria EOOD

Slatina District

Iztochna Tangenta street no. 100

BG - 1592 Sofia

Tel. +359 2 49 22 200

Fax. +359 2 49 22 201

email: bulgaria@grundfos.bg

Canada

GRUNDFOS Canada Inc.

2941 Brighton Road

Oakville, Ontario

L6H 6C9

Phone: +1-905 829 9533

Telefax: +1-905 829 9512

China

Grundfos Alldos

Dosing & Disinfection

ALLDOS (Shanghai) Water Technology

Co. Ltd.

West Unit, 1 Floor, No. 2 Building (T 4-2)

278 Jinhu Road, Jin Qiao Export

Processing Zone

Pudong New Area

Shanghai, 201206

Phone: +86 21 5055 1012

Telefax: +86 21 5032 0596

E-mail:

grundfosalldos-CN@grundfos.com

China

GRUNDFOS Pumps (Shanghai) Co. Ltd.

10F The Hub, No. 33 Suhong Road

Minhang District

Shanghai 201106

PRC

Phone: +86-21 6122 5222

Telefax: +86-21 6122 5333

Croatia

GRUNDFOS CROATIA d.o.o.

Cebini 37, Buzin

HR-10010 Zagreb

Phone: +385 1 6595 400

Telefax: +385 1 6595 499

www.hr.grundfos.com

Czech Republic

GRUNDFOS s.r.o.

Čapkovského 21

779 00 Olomouc

Phone: +420-585-716 111

Telefax: +420-585-716 299

Denmark

GRUNDFOS DK A/S

Martin Bachs Vej 3

DK-8850 Bjerringbro

Tlf.: +45-87 50 50 50

Telefax: +45-87 50 51 51

E-mail: info_GDK@grundfos.com

www.grundfos.com/DK

Estonia

GRUNDFOS Pumps Eesti OÜ

Peterburi tee 92G

11415 Tallinn

Tel: + 372 606 1690

Fax: + 372 606 1691

Finland

OY GRUNDFOS Pumput AB

Trukkikuja 1

FI-01360 Vantaa

Phone: +358-(0)207 889 500

Telefax: +358-(0)207 889 550

France

Pompes GRUNDFOS Distribution S.A.

Parc d’Activités de Chesnes

57, rue de Malacombe

F-38290 St. Quentin Fallavier (Lyon)

Tél.: +33-4 74 82 15 15

Télécopie: +33-4 74 94 10 51

Germany

GRUNDFOS Water Treatment GmbH

Reetzstraße 85

D-76327 Pfinztal (Söllingen)

Tel.: +49 7240 61-0

Telefax: +49 7240 61-177

E-mail: gwt@grundfos.com

Germany

GRUNDFOS GMBH

Schlüterstr. 33

40699 Erkrath

Tel.: +49-(0) 211 929 69-0

Telefax: +49-(0) 211 929 69-3799

E-mail: infoservice@grundfos.de

Service in Deutschland:

E-mail: kundendienst@grundfos.de

Greece

GRUNDFOS Hellas A.E.B.E.

20th km. Athinon-Markopoulou Av.

P.O. Box 71

GR-19002 Peania

Phone: +0030-210-66 83 400

Telefax: +0030-210-66 46 273

Hong Kong

GRUNDFOS Pumps (Hong Kong) Ltd.

Unit 1, Ground floor

Siu Wai Industrial Centre

29-33 Wing Hong Street &

68 King Lam Street, Cheung Sha Wan

Kowloon

Phone: +852-27861706 / 27861741

Telefax: +852-27858664

Hungary

GRUNDFOS Hungária Kft.

Park u. 8

H-2045 Törökbálint,

Phone: +36-23 511 110

Telefax: +36-23 511 111

India

GRUNDFOS Pumps India Private

Limited

118 Old Mahabalipuram Road

Thoraipakkam

Chennai 600 097

Phone: +91-44 4596 6800

Indonesia

PT. GRUNDFOS POMPA

Graha Intirub Lt. 2 & 3

Jln. Cililitan Besar No.454. Makasar,

Jakarta Timur

ID-Jakarta 13650

Phone: +62 21-469-51900

Telefax: +62 21-460 6910 / 460 6901

Ireland

GRUNDFOS (Ireland) Ltd.

Unit A, Merrywell Business Park

Ballymount Road Lower

Dublin 12

Phone: +353-1-4089 800

Telefax: +353-1-4089 830

Italy

GRUNDFOS Pompe Italia S.r.l.

Via Gran Sasso 4

I-20060 Truccazzano (Milano)

Tel.: +39-02-95838112

Telefax: +39-02-95309290 / 95838461

Japan

GRUNDFOS Pumps K.K.

Gotanda Metalion Bldg. 5F,

5-21-15, Higashi-gotanda

Shiagawa-ku, Tokyo,

141-0022 Japan

Phone: +81 35 448 1391

Telefax: +81 35 448 9619

Page 29

Grundfos companies

Korea

GRUNDFOS Pumps Korea Ltd.

6th Floor, Aju Building 679-5

Yeoksam-dong, Kangnam-ku, 135-916

Seoul, Korea

Phone: +82-2-5317 600

Telefax: +82-2-5633 725

Latvia

SIA GRUNDFOS Pumps Latvia

Deglava biznesa centrs

Augusta Deglava ielā 60, LV-1035, Rīga,

Tālr.: + 371 714 9640, 7 149 641

Fakss: + 371 914 9646

Lithuania

GRUNDFOS Pumps UAB

Smolensko g. 6

LT-03201 Vilnius

Tel: + 370 52 395 430

Fax: + 370 52 395 431

Malaysia

GRUNDFOS Pumps Sdn. Bhd.

7 Jalan Peguam U1/25

Glenmarie Industrial Park

40150 Shah Alam

Selangor

Phone: +60-3-5569 2922

Telefax: +60-3-5569 2866

Mexico

Bombas GRUNDFOS de México S.A. de

C.V.

Boulevard TLC No. 15

Parque Industrial Stiva Aeropuerto

Apodaca, N.L. 66600

Phone: +52-81-8144 4000

Telefax: +52-81-8144 4010

Netherlands

GRUNDFOS Netherlands

Veluwezoom 35

1326 AE Almere

Postbus 22015

1302 CA ALMERE

Tel.: +31-88-478 6336

Telefax: +31-88-478 6332

E-mail: info_gnl@grundfos.com

New Zealand

GRUNDFOS Pumps NZ Ltd.

17 Beatrice Tinsley Crescent

North Harbour Industrial Estate

Albany, Auckland

Phone: +64-9-415 3240

Telefax: +64-9-415 3250

Norway

GRUNDFOS Pumper A/S

Strømsveien 344

Postboks 235, Leirdal

N-1011 Oslo

Tlf.: +47-22 90 47 00

Telefax: +47-22 32 21 50

Poland

GRUNDFOS Pompy Sp. z o.o.

ul. Klonowa 23

Baranowo k. Poznania

PL-62-081 Przeźmierowo

Tel: (+48-61) 650 13 00

Fax: (+48-61) 650 13 50

Portugal

Bombas GRUNDFOS Portugal, S.A.

Rua Calvet de Magalhães, 241

Apartado 1079

P-2770-153 Paço de Arcos

Tel.: +351-21-440 76 00

Telefax: +351-21-440 76 90

Romania

GRUNDFOS Pompe România SRL

Bd. Biruintei, nr 103

Pantelimon county Ilfov

Phone: +40 21 200 4100

Telefax: +40 21 200 4101

E-mail: romania@grundfos.ro

Russia

ООО Грундфос

Россия, 109544 Москва, ул. Школьная

39

Тел. (+7) 495 737 30 00, 564 88 00

Факс (+7) 495 737 75 36, 564 88 11

E-mail grundfos.moscow@grundfos.com

Serbia

GRUNDFOS Predstavništvo Beograd

Dr. Milutina Ivkovića 2a/29

YU-11000 Beograd

Phone: +381 11 26 47 877 / 11 26 47

496

Telefax: +381 11 26 48 340

Singapore

GRUNDFOS (Singapore) Pte. Ltd.

25 Jalan Tukang

Singapore 619264

Phone: +65-6681 9688

Telefax: +65-6681 9689

Slovakia

GRUNDFOS s.r.o.

Prievozská 4D

821 09 BRATISLAVA

Phona: +421 2 5020 1426

sk.grundfos.com

Slovenia

GRUNDFOS LJUBLJANA, d.o.o.

Leskoškova 9e, 1122 Ljubljana

Phone: +386 (0) 1 568 06 10

Telefax: +386 (0)1 568 0619

E-mail: tehnika-si@grundfos.com

South Africa

Grundfos (PTY) Ltd.

Corner Mountjoy and George Allen

Roads

Wilbart Ext. 2

Bedfordview 2008

Phone: (+27) 11 579 4800

Fax: (+27) 11 455 6066

E-mail: lsmart@grundfos.com

Spain

Bombas GRUNDFOS España S.A.

Camino de la Fuentecilla, s/n

E-28110 Algete (Madrid)

Tel.: +34-91-848 8800

Telefax: +34-91-628 0465

Sweden

GRUNDFOS AB

(Box 333) Lunnagårdsgatan 6

431 24 Mölndal

Tel.: +46 31 332 23 000

Telefax: +46 31-331 94 60

Switzerland

GRUNDFOS ALLDOS International AG

Schönmattstraße 4

CH-4153 Reinach

Tel.: +41-61-717 5555

Telefax: +41-61-717 5500

E-mail:

grundfosalldos-CH@grundfos.com

Switzerland

GRUNDFOS Pumpen AG

Bruggacherstrasse 10

CH-8117 Fällanden/ZH

Tel.: +41-44-806 8111

Telefax: +41-44-806 8115

Taiwan

GRUNDFOS Pumps (Taiwan) Ltd.

7 Floor, 219 Min-Chuan Road

Taichung, Taiwan, R.O.C.

Phone: +886-4-2305 0868

Telefax: +886-4-2305 0878

Thailand

GRUNDFOS (Thailand) Ltd.

92 Chaloem Phrakiat Rama 9 Road,

Dokmai, Pravej, Bangkok 10250

Phone: +66-2-725 8999

Telefax: +66-2-725 8998

Turkey

GRUNDFOS POMPA San. ve Tic. Ltd.

Sti.

Gebze Organize Sanayi Bölgesi

Ihsan dede Caddesi,

2. yol 200. Sokak No. 204

41490 Gebze/ Kocaeli

Phone: +90 - 262-679 7979

Telefax: +90 - 262-679 7905

E-mail: satis@grundfos.com

Ukraine

Бізнес Центр Європа

Столичне шосе, 103

м. Київ, 03131, Україна

Телефон: (+38 044) 237 04 00

Факс.: (+38 044) 237 04 01

E-mail: ukraine@grundfos.com

United Arab Emirates

GRUNDFOS Gulf Distribution

P.O. Box 16768

Jebel Ali Free Zone

Dubai

Phone: +971-4- 8815 166

Telefax: +971-4-8815 136

United Kingdom

GRUNDFOS Pumps Ltd.

Grovebury Road

Leighton Buzzard/Beds. LU7 4TL

Phone: +44-1525-850000

Telefax: +44-1525-850011

U.S.A.

GRUNDFOS Pumps Corporation

17100 West 118th Terrace

Olathe, Kansas 66061

Phone: +1-913-227-3400

Telefax: +1-913-227-3500

Uzbekistan

Grundfos Tashkent, Uzbekistan The

Representative Office of Grundfos

Kazakhstan in Uzbekistan

38a, Oybek street, Tashkent

Телефон: (+998) 71 150 3290 / 71 150

3291

Факс: (+998) 71 150 3292

Addresses revised 25.01.2016

Page 30

www.grundfos.com

96709879 0416

ECM: 1182149

The name Grundfos, the Grundfos logo, and be think innovate are registered trademarks

owned by Grundfos Holding A/S or Grundfos A/S, Denmark. All rights reserved worldwide.

© Copyright Grundfos Holding A/S

Loading...

Loading...