Page 1

GENO-mat duo WE-OSMO-X

Operation manual

GENO-mat duo WE-X

Edition Oktober 2018

Order no. 074 184 046-inter

Page 2

Page 3

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Table of contents

AGeneral notes .......................................................................................................................... 6

1 | Preface .............................................................................................................................................................................. 6

2 | How to use this operation manual ..................................................................................................................................... 6

3 | General safety information ................................................................................................................................................ 7

3.1Symbols and notes .................................................................................................................................................... 7

3.2Operating personnel .................................................................................................................................................. 7

3.3Designated use .......................................................................................................................................................... 7

3.4Protection from water damage .................................................................................................................................. 8

3.5Indication of specific dangers .................................................................................................................................... 8

4 | Shipping and storage ........................................................................................................................................................ 8

5 | Disposal ............................................................................................................................................................................. 9

BBasic information .................................................................................................................. 10

1 | Laws, regulations, standards ........................................................................................................................................... 10

2 | Water, scale, softening .................................................................................................................................................... 10

3 | Ion exchange ................................................................................................................................................................... 11

CProduct description .............................................................................................................. 12

1 | Type designation plate .................................................................................................................................................... 12

2 | Technical specifications .................................................................................................................................................. 12

3 | Designated application .................................................................................................................................................... 15

4 | Application limits .............................................................................................................................................................. 15

5 | Scope of supply ............................................................................................................................................................... 16

5.1Basic configuration .................................................................................................................................................. 16

5.2Optional accessories ............................................................................................................................................... 16

5.3Consumables ........................................................................................................................................................... 17

5.4Wearing parts .......................................................................................................................................................... 18

DInstallation ............................................................................................................................. 19

1 | General installation information ....................................................................................................................................... 19

1.1Water installation ..................................................................................................................................................... 20

1.2Electrical installation ................................................................................................................................................ 21

2 | Preliminary work .............................................................................................................................................................. 23

2.1Filling the exchanger tank ........................................................................................................................................ 24

2.2How to fit the brine line ............................................................................................................................................ 25

3 | How to connect the system ............................................................................................................................................. 25

3.1Water connection ..................................................................................................................................................... 25

3.2How to connect the control unit ............................................................................................................................... 28

EStart-up .................................................................................................................................. 29

1 | How to fill the brine tank .................................................................................................................................................. 29

2 | How to set up the system ................................................................................................................................................ 30

2.1How to set the blending hardness ........................................................................................................................... 30

2.2How to set the control unit ....................................................................................................................................... 31

3 | How to start up the system .............................................................................................................................................. 32

FOperation ............................................................................................................................... 33

GENO-IONO-matic WE-X control unit .................................................................................................................................. 33

1 | Introduction ...................................................................................................................................................................... 33

2 | How to operate the control unit ....................................................................................................................................... 33

2.1Key functions ........................................................................................................................................................... 33

2.2Meaning of the LEDs red / yellow / green ............................................................................................................... 34

2.3Info level – reading the operating status .................................................................................................................. 34

2.4System status display .............................................................................................................................................. 35

2.5Setting operating parameters – operator menu ....................................................................................................... 35

2.6How to release a manual regeneration .................................................................................................................... 36

2.7Changing system parameters – code 290 ............................................................................................................... 37

Control via reverse osmosis system GENO-OSMO-X ......................................................................................................... 38

1 | Introduction ...................................................................................................................................................................... 38

2 | How to operate the control unit ....................................................................................................................................... 40

2.1Change, save, reject parameters ............................................................................................................................ 40

2.2Acknowledgement of errors/signals ......................................................................................................................... 41

2.3Screen saver ........................................................................................................................................................... 42

3| System range ................................................................................................................................................................... 42

3.1System menu I ......................................................................................................................................................... 42

3.2Manual regeneration ................................................................................................................................................ 43

3.3System setting ......................................................................................................................................................... 43

GFaults ..................................................................................................................................... 44

1 | Basic information ............................................................................................................................................................. 44

1.1Warnings ................................................................................................................................................................. 45

1.2Faults ....................................................................................................................................................................... 45

HMaintenance .......................................................................................................................... 46

1 | Basic information ............................................................................................................................................................. 46

2 | Inspection (functional check) ........................................................................................................................................... 46

3 | Maintenance .................................................................................................................................................................... 48

3.1Operating log ........................................................................................................................................................... 49

4 | Spare parts ...................................................................................................................................................................... 49

5 | Operating log ................................................................................................................................................................... 51

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

3

Page 4

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Publisher's information

All rights reserved.

Copyright by Grünbeck Wasseraufbereitung GmbH

Printed in Germany

Effective with the date of edition indicated on the cover sheet.

-We reserve the right to make modifications, especially with

regard to technical progress-

Reprints, translations into foreign languages, electronic storage

or digital copying of this operating manual – even in parts – only

with explicit written approval of Grünbeck Wasseraufbereitung

GmbH.

Any type of duplication not authorised by Grünbeck Wasseraufbereitung is a copyright violation and subject to legal action.

Responsible for contents:

Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Straße 1 89420 Höchstädt/Do., Germany

Phone +49 9074 41-0 Fax +49 9074 41-100

www.gruenbeck.de service@gruenbeck.de

Print: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Straße 1, 89420 Höchstädt/Do., Germany

4

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 5

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

EU Declaration of Conformity

This is to certify that the system designated below meets the safety and health requirements of

the applicable European guidelines in terms of its design, construction and execution.

If the system is modified in a way not approved by us, this certificate is void.

Manufacturer: Grünbeck Wasseraufbereitung GmbH

Josef-Grünbeck-Straße 1

89420 Höchstädt/Do., Germany

Responsible for documentation: Markus Pöpperl

System designation: GENO-mat duo WE-X water softener,

GENO-mat duo WE-OSMO-X water softener

Serial no.: Refer to type designation plate

Applicable directives: Low-Voltage (2014/35/EC)

EMC (2014/35/EC)

Applied harmonised

standards, in particular:

Applied national

standards and technical

specifications,

in particular:

Location, date and signature:

Function of signatory: Head of Technical Systems and Equipment

DIN EN 61000-6-2:2006-03

DIN EN 61000-6-3:2011-09

DIN EN 60335-1:2012-10

Hoechstaedt, 18.10.2018 i. V.

Peter Höß

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

5

Page 6

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

A General notes

1 | Preface

Thank you for opting for a Grünbeck product. Backed by

decades of experience in the area of water treatment, we

provide solutions for all kind of processes.

All Grünbeck systems and devices are made of high-quality

materials. This ensures reliable operation over many years,

provided you treat your water treatment system with the required

care. This operation manual assists you with important information. Therefore, please read the entire operation manual before

installing, operating or maintaining the system.

Customer satisfaction is our prime objective and providing

customers with qualified advice is crucial. If you have any

questions concerning this device, possible extensions or general

water and waste water treatment, our field staff, as well as the

experts at our headquarters in Hoechstaedt, are available to

help you.

Advice and assistance For advice and assistance please contact your local

representative (see www.gruenbeck.de). In case of emergency,

please get in touch with our service hotline at +49 9074 41-444.

We can connect you with the appropriate expert more quickly if

you provide the required system data. To ensure that this

information is always to hand, please keep the precise

equipment data to hand (refer to the type plate in chapter C-1).

2 | How to use this operation manual

This operation manual is intended for the operators of our

systems. It is divided into several chapters (a letter is assigned

to each of them) which are listed in the “Table of contents” on

page 1 in alphabetical order. In order to find the specific

information, you are looking for, check for the corresponding

chapter on page 1.

The headers and page numbers with chapter information make

it easier to find your way around in the operating manual.

6

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 7

y

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

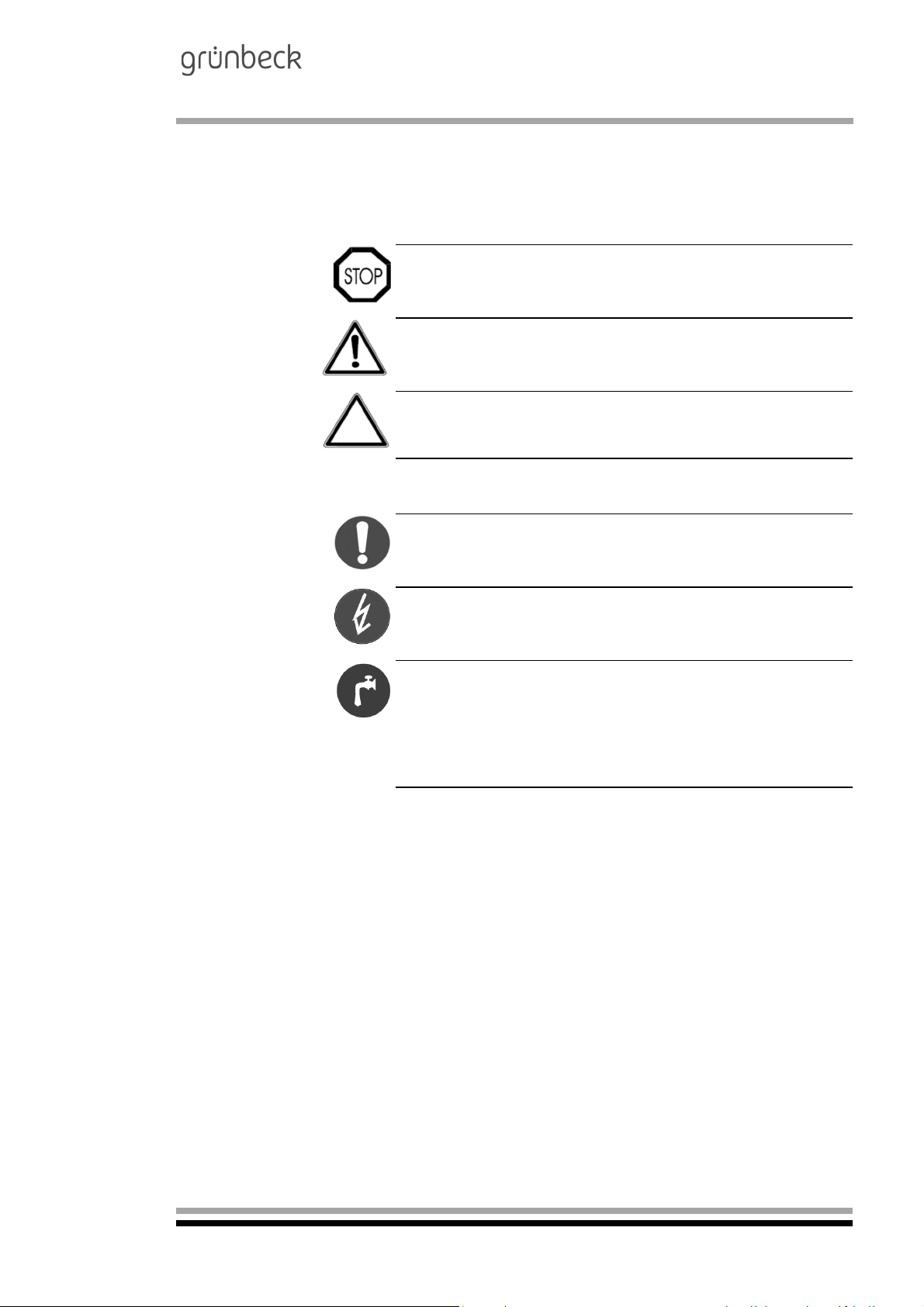

3 | General safety information

3.1 Symbols and notes Important information in this operation manual is characterised

by symbols. Please pay particular attention to this information to

ensure the hazard-free, safe and efficient handling of the

s

stem.

Danger! Failure to adhere to this information will cause serious

or life-threatening injuries, extreme damage to property or

inadmissible contamination of the drinking water.

Warning! Failure to adhere to this information may cause

injuries, damage to property or contamination of the drinking

water.

Caution! Failure to adhere to this information may result in

damage to the system or other objects.

3.2 Operating personnel Only persons who have read and understood this operation

3.3 Designated use The system may only be used for the purpose outlined in the

Note: This symbol characterises information and tips to make

your work easier.

Tasks with this symbol may only be performed by Grünbeck's

technical service/authorised service company or by persons

expressly authorised by Grünbeck.

Tasks with this symbol may only be performed by trained and

qualified electrical experts according to the VDE guidelines or

according to the guidelines of a similar local institution.

Tasks with this symbol may only be performed by water

companies or approved installation companies. In Germany,

the installation company must be registered in an installation

directory of a water company as per §12(2) AVBWasserV

(German Ordinance on General Conditions for the Supply of

Water).

manual are permitted to work with the system. The safety

guidelines are to be strictly adhered to.

product description (chapter C). The guidelines in this operation

manual as well as the applicable local guidelines concerning the

drinking water protection, accident prevention and occupational

safety must be adhered to.

In addition, appropriate application also implies that the system

may only be operated when it is in proper working order.

Any malfunctions must be repaired at once.

The system exclusively designed for use in the industrial and

commercial field.

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

7

Page 8

Water softener

g

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

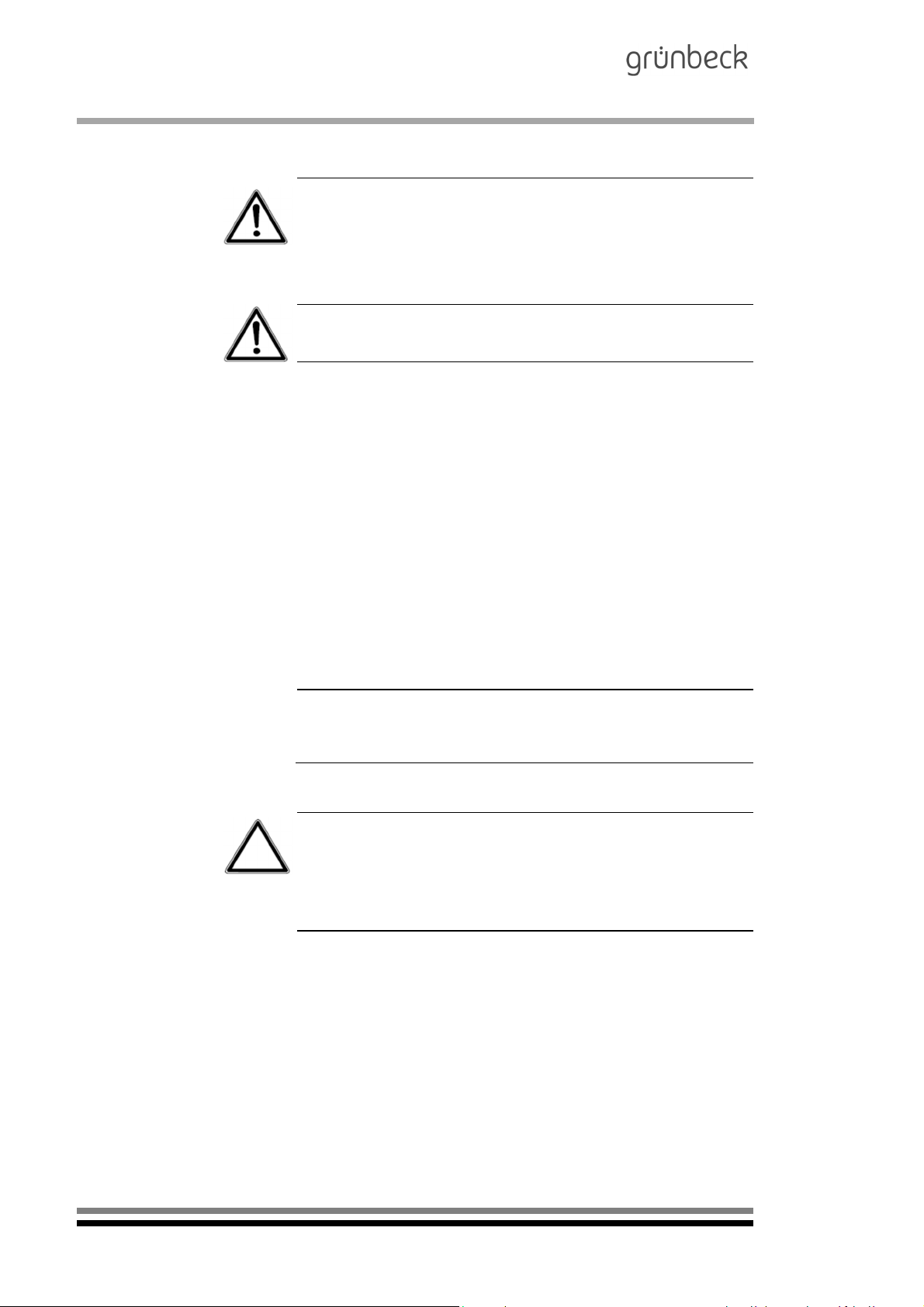

3.4 Protection from water

dama

3.5 Indication of

specific dangers

e

Warning! In order to properly protect the installation site from

water damage:

a sufficient floor drain system must be available or

a water stop device (see chapter C Accessories) must be

installed.

Warning! Floor drains leading to a lifting system do not work in

case of a power failure.

Danger due to electrical energy! Do not touch electrical parts

with wet hands! Disconnect the system from the mains before

starting work on electrical parts of the system. Have qualified

experts replace damaged cables immediately.

Danger due to mechanical energy! System parts may be subject

to overpressure. Danger of injury and damage to property due to

escaping water and unexpected movement of system parts.

Check the pressure pipes at regular intervals. Depressurise

the system before starting repair or maintenance work on the

system.

4 | Shipping and storage

Hazardous to health due to contaminated drinking water!

The system may only be installed by a specialist company.

The operation manual must be strictly adhered to! Ensure that

there is sufficient flow. The pertinent guidelines must be followed

for starting-up after extended periods of standstill. Inspections

and maintenance must be performed at the intervals specified!

Note:By concluding a maintenance contract, you ensure that all

of the required tasks are performed on time. You may perform

the interim inspections yourself.

Caution!The system may be damaged by frost or high

temperatures. In order to avoid damage of this kind:

Protect it from frost during transportation and storage!

Do not install or store system next to objects which radiate a lot

of heat.

The system may only be transported and stored in its original

packing. Ensure that it is handled with care and placed the right

side up (as indicated on the packing).

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

8

Page 9

5 | Disposal

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Comply with the applicable national regulations.

5.1 Packaging

5.2 Product

Dispose of the packaging in an environmentally friendly

manner.

If this symbol (crossed out waste bin) is on the product, this

product is subject to the European Directive 2012/19/EU. This

means that this product or the electrical and electronic

components must not be disposed with household waste.

Dispose of electrical and electronic products or components in

an environmentally friendly manner.

For information on collection points for your product, contact

your municipality, the public waste management authority, an

authorised body for the disposal of electrical and electronic

products or your waste disposal service.

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

9

Page 10

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

B Basic information

1 | Laws, regulations, standards

2 | Water, scale, softening

In the interest of good health, rules cannot be ignored when it

comes to the processing of drinking water (raw water). This

operation manual takes into consideration the current

regulations and stipulates information that you will need for the

safe operation of your water treatment system.

Among other things, the regulations stipulate that

only approved companies are permitted to make major

modifications to water supply facilities

and that tests, inspections and maintenance on installed

devices are to be performed at regular intervals.

The water works provide us with pure water (raw water) that is

suitable for drinking. However, this water is much more often

used for washing machines, heating systems, water heaters,

commercial devices, etc., where it can lead to problems if it is

"hard".

Hard water is generated if water containing carbon dioxide*

flows through layers of calcium. It dissolves the calcium until the

so-called calcium - carbon dioxide - equilibrium has been

reached.

If this equilibrium is unsettled (e.g. by heating CO

more calcium (CaCO

) is precipitated (scale).

3

escapes)

2

Note: Calcium ions and magnesium ions exist side by side in

Hardnessrange °dH °f

1(soft) <8.4 <15.0 <1.50

2(medium) 8.4‐14.0 15.0‐25.0 1.50‐2.50

3(hard) >14.0 >25.0 >2.50

nature, e.g. in the mineral dolomite.

Hardness ranges according to the German Act on Environmental

Sustainability of Detergents and Cleaning Agents (WMRG):

The total hardness of the water is the sum of the concentrations

of calcium ions and magnesium ions.

From hardness range "medium" onwards, it is advisable to

soften the water for usage. Additional measures may be

necessary depending on the original quality of the water and its

intended use.

* CO2 from the atmosphere is dissolved in water. In this process, a low

amount of carbon dioxide is generated.

mmol/l=

mol/m

3

10

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 11

3 | Ion exchange

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

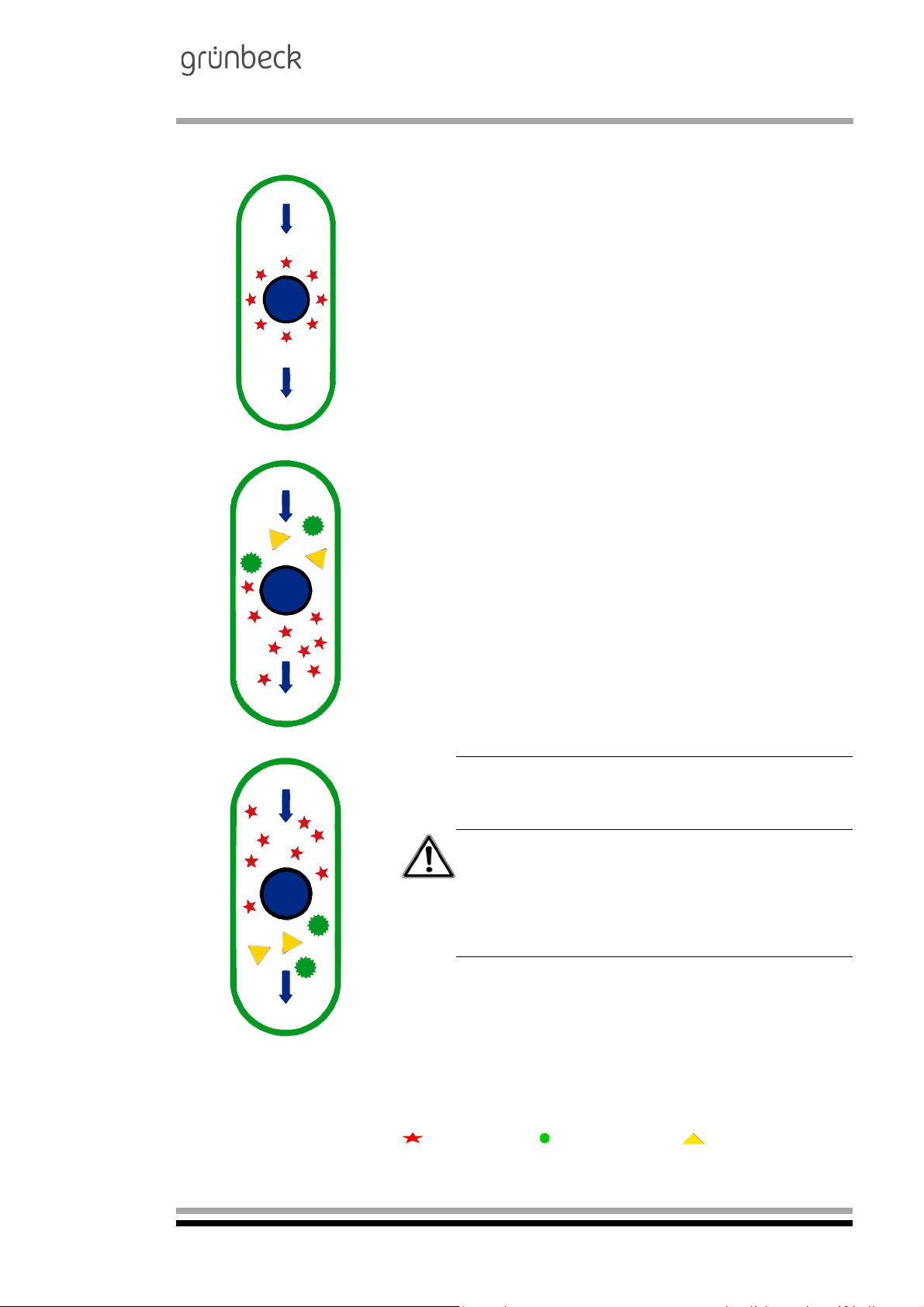

The exchange of calcium and magnesium ions for sodium ions

causes the water to become soft.

Principle

The hard raw water flows through an exchanger. This tank is filled

with a resin, to which sodium ions are bonded (see Fig. B-1).

Resin

Fig. B-1: Initial position

Hard water

Resin

Soft water

Fig. B-2: Operation

Since the bonding positions at the resin prefer calcium and

magnesium ions to sodium ions, these ions are retained while

the resin discharges sodium ions into the water (exchange

reaction). In this way, all substances causing hardness remain

in the exchanger. Soft water loaded with sodium ions leaves the

exchanger (Fig. B-2). This process continues until the sodium

ions are used up.

The exchange reaction can be reversed if a large amount of

sodium ions (salt solution = brine) is added (Fig. B-3).

By their sheer number, the sodium ions displace the calcium

and magnesium ions at the docking positions of the resin.

This process restores the initial state. The resin is regenerated

and is again ready for softening.

Drinking water (raw water)

As protection against corrosion, we recommend a soft water

hardness of at least 3 °dH (5.3 °f, 0.53 mmol/l). According to the

German Drinking Water Ordinance, the limit value for sodium

ions (200 mg/l) must not be exceeded. This hardness is achieved

by adding untreated drinking water (raw water), a process which

is commonly called blending.

Brine solution

Resin

Was t e w a te r

Fig. B-3: Regeneration

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Single/Twin/Triple water softeners

In case of single water softeners, no soft water is available

during the regeneration phase.

Twin water softeners have two exchangers that alternate

operation. As a result, soft water is available at all times.

Triple water softeners consist of three exchangers. Two

exchangers are flown through in parallel while the third is being

regenerated.

Note: Many popular mineral waters contain significantly

more sodium ions. Check for yourself by reading the

analysis results on the labels.

Warning! Risk of infection due to germs in the drinking

water. Germs can reproduce in stagnant water to the

point where they pose a threat. Work with water

softeners requires special hygienic measures. Ensure

that there is sufficient flow. Disinfect the systems if

required.

Sodium ions Calcium ions Magnesium ions

11

Page 12

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

C Product description

1 | Type designation plate

The type designation plate is located at the control valve of the

water softener. In order to speed up the processing of your

inquiries or orders, please specify the data shown on the type

designation plate of your system when contacting Grünbeck.

Please copy the indicated information to the table below in order

to have it handy whenever necessary.

GENO-mat duo WE-X / WE-OSMO-X water softener

duo WE-X

duo WE-OSMO-X

Order no.:

2 | Technical specifications

The GENO-mat duo WE-X water softener is a twin system for

the continuous supply of soft water. The system is equipped with

a central control valve for both exchangers and is volumecontrolled. The regeneration is released when the pre-set water

volume in an exchanger tank has been softened. The system

regenerates with soft water.

All system data is summarised in tables C-1 and C-2. The data

given refers to standard water softeners. Possible deviations

in case of special versions are communicated separately,

if applicable.

Serial number:

Serial number:

The GENO-mat duo WE-OSMO-X water softener is only

available with full salting. The control electronics is not equipped

with an operating and display unit. The system is operated by

means of the control electronics of the OSMO-X reverse

osmosis system.

Warning! Extended periods of idleness may cause bacterial

growth in drinking water. Automatic regeneration counteracts this

effect. Therefore, do not disconnect the system from the water

and power supply when you are absent for longer periods of

time.

Caution! Electrically operated valves. In case of power failure

during the regeneration, water may flow into the drain or brine

tank. In the event of power failure, check the system and shut-off

the water supply, if necessary.

12

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 13

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

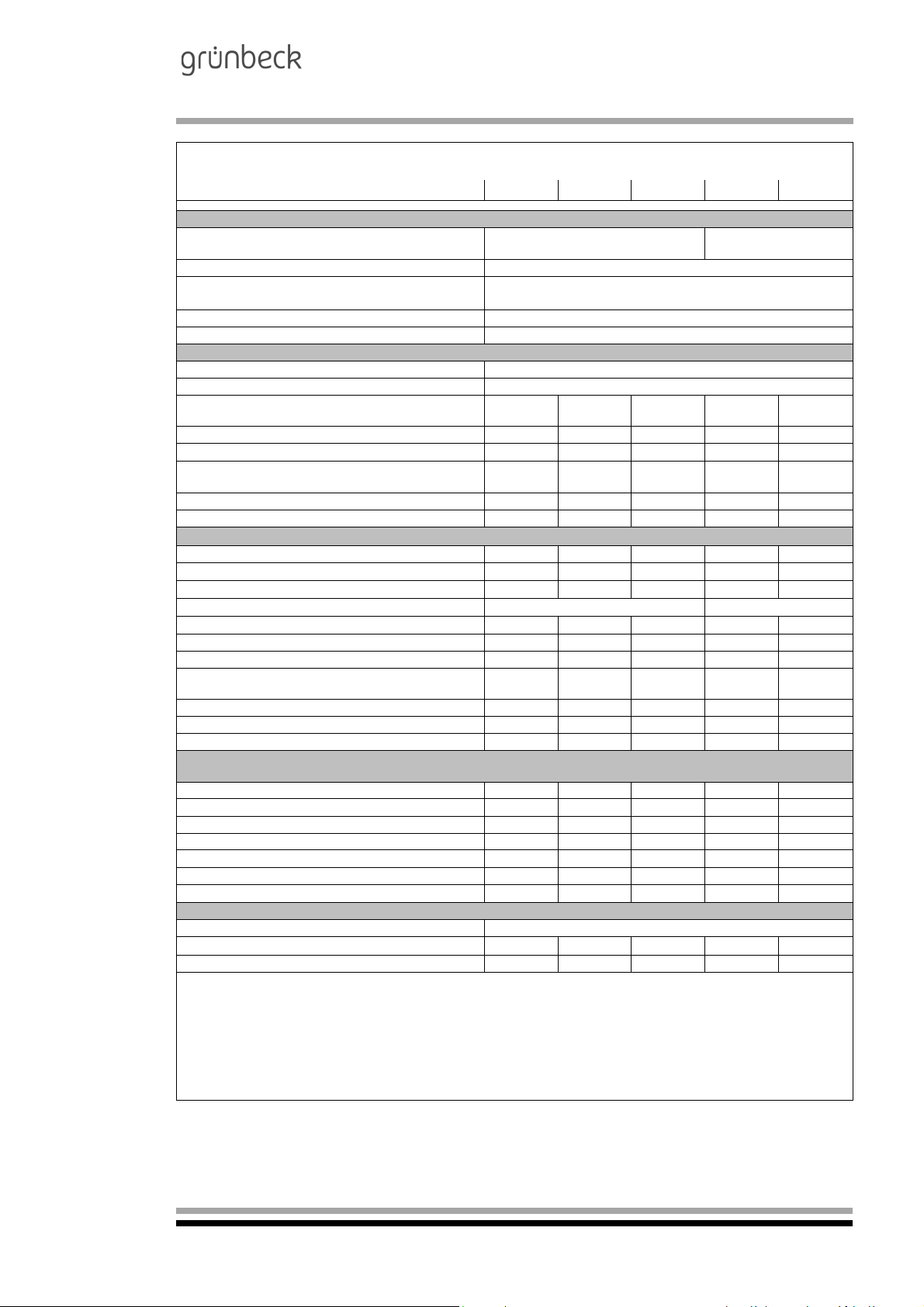

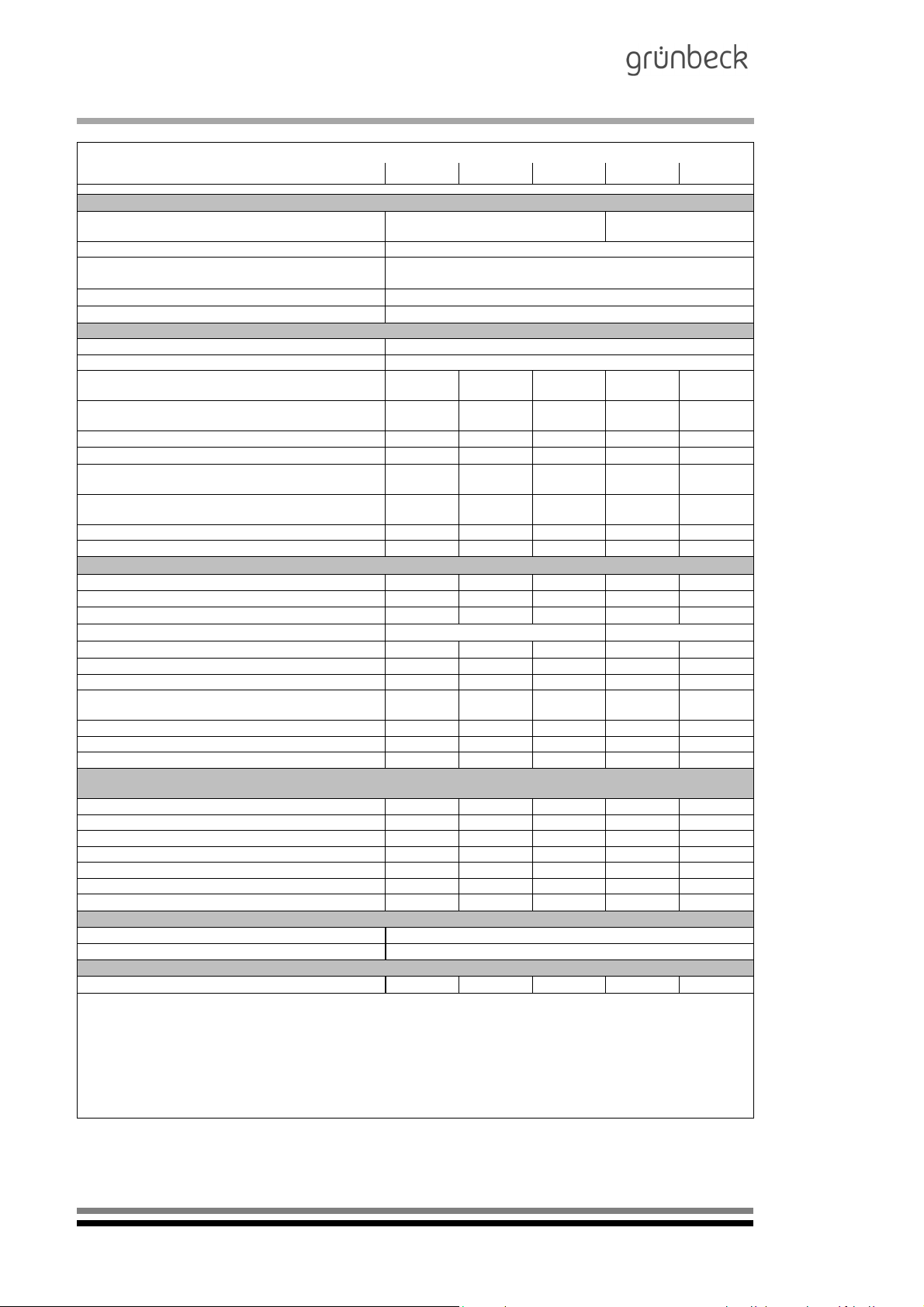

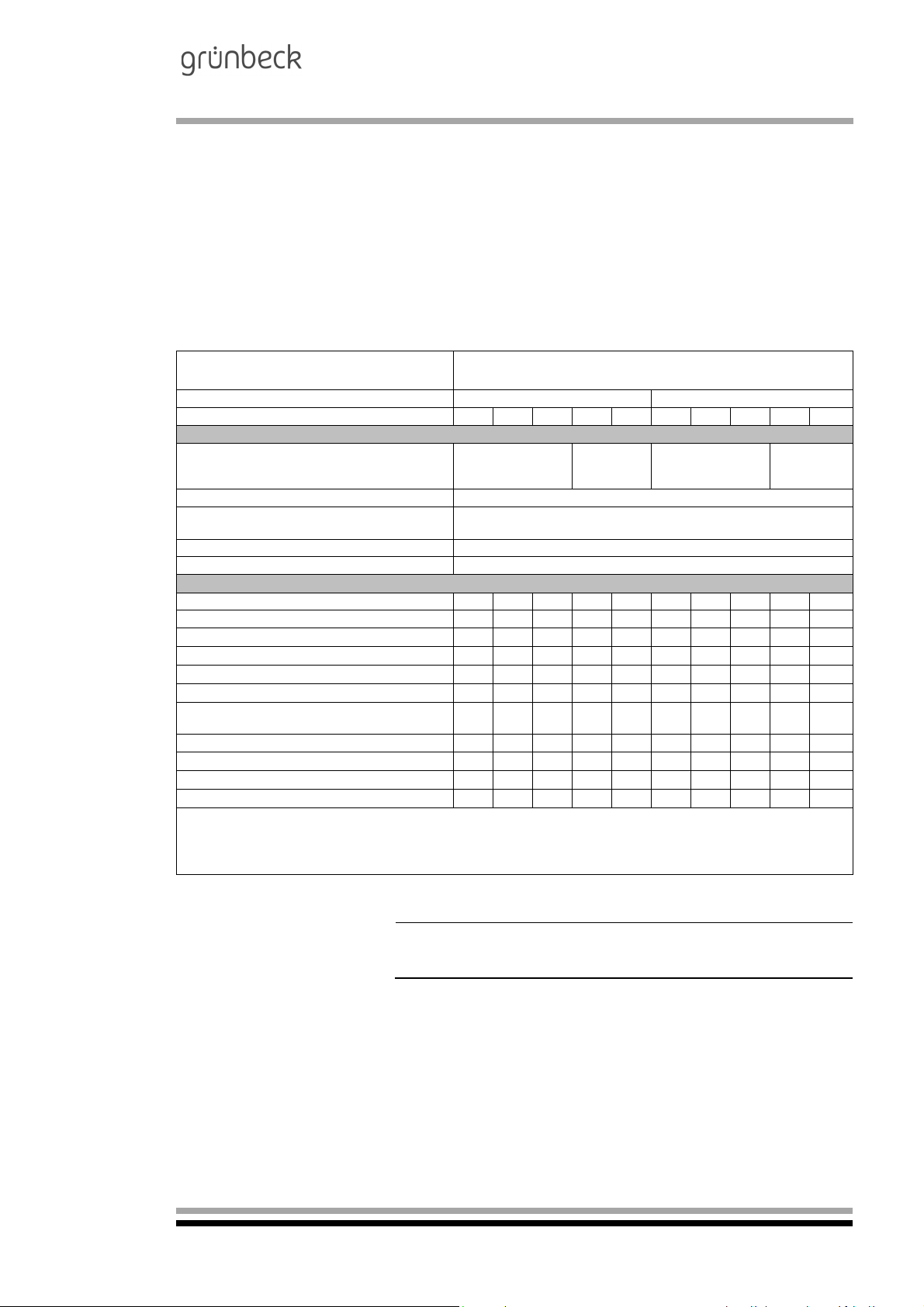

Table C-1: Technical specifications

GENO-mat duo WE-X / WE-OSMO-X

Systems with full salting

Connection data

Nominal connection diameter DN 25

Min. drain connection DN 50

Power supply [V]/[Hz] 85 -250/50-60

Connected load [VA] 10

Protection/protection class IP 54/I

Performance data

Nominal pressure (PN) [bar] 10

Min./max. operating pressure [bar] 2.0/8.0

Max. continuous flow

*** at a residual hardness of < 0.1 °dH

Pressure loss at max. continuous flow [bar] 0.6 1.1 2.1 1.5 2.3

KV-value (at p = 1.0 bar)

Nominal capacity [mol]

Capacity per kg of regeneration salt [mol/kg] 3.33 3.32 3.32 3.16 3.33

Time capacity [m³ x °dH/h] 72 84 145 214 269

Dimensions and weights 1)

Total height [mm] 1310 1530 1790 1840 1970

Overall height (without control unit) **** [mm] 1080 1300 1560

Exchanger tank

Distance between centre of bottles [mm] 400 700

Brine tank *

Overall height of brine tank * [mm] 810 880 870 1100 1250

Height of safety overflow on brine tank * [mm] 700 780 770 980 1120

Connection height of control valve

(raw water)

Min. foundation depth * [mm] 600 700 800 900 1000

Min. length of foundation * [mm] 1460 1500 1700 2100 2400

Approx. operating weight * [kg] 285 435 730 1110 1745

Filling volumes and consumption data

**

Resin quantity [l] 18 40 81 115 200

Freeboard (resin in form of sodium), approx. [mm] 270 230 290 390 300

Salt consumption per regeneration, approx. [kg] 3.6 8.0 16.2 25.3 40.0

Max. regeneration salt supply * [kg] 130 190 285 485 760

Total waste water volume per regen., approx. [l] 112 211 451 693 1020

Operating water volume [l] 10 22 45 70 111

Minimum salt fill level * [mm]

Ambient data

Max. water/ambient temperature [°C] 30/40

Order no. GENO-mat duo WE-X

Order no. GENO-mat duo WE-OSMO-X 186300 186 310 186 320 186 330 186 340

* With standard brine tank

The waste water volume and salt consumption refer to a primary pressure of 3 bar.

**

The indicated values change at different inlet pressures and only serve as a means for a rough determination.

The indicated max. continuous flows may decrease in case of high raw water hardness.

***

In case of systems with a nominal connection diameter of DN 40, the control unit is fastened between the exchanger

****

tanks.

1)

All indicated dimensions and weights are approximate!

[m³/h] 2.0 3.0 5.0 6.0 9.5

[m³/h] 2.6 2.7 3.1 4.5 5.6

[m³ x °dH]

[mm] 208 257 334 369 469

[mm] 500 570 700 780 900

[mm] 940 1160 1420 1710 1830

65 150 300 450 750

(1" female thread)

(system operation with protective low voltage 24V DC)

12.0

67

186 100 186 110 186 120 186 130 186 140

Water softener

26.6

149

53.9

302

DN 40

(1½" female thread)

80.2

449

133.2

746

50

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

13

Page 14

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Table C-2: Technical specifications

Systems with economy salting

Connection data

Nominal connection diameter

Min. drain connection DN 50

Power supply [V]/[Hz] 85 -250/50-60

Connected load [VA] 10

Protection/protection class IP 54/I

Performance data

Nominal pressure (PN) [bar] 10

Min./max. operating pressure [bar] 2.0/8.0

Max. continuous flow

*** at a residual hardness of

Peak flow in case of blending to 8 °dH

and a raw water hardness of 20 °dH

Pressure loss at max. continuous flow [bar] 0.6 1.1 2.1 1.5 2.3

KV value (at p = 1.0 bar)

KV value in case of blending to 8 °dH

and a raw water hardness of 20 ° dH

Nominal capacity

Capacity per kg of regeneration salt [mol/kg] 5.27 5.22 5.22 5.20 5.90

Time capacity [m³ x °dH/h] 68 81 143 207 243

Dimensions and weights 1)

Total height [mm] 1310 1530 1790 1840 1970

Overall height (without control unit) **** [mm] 1080 1300 1560

Exchanger tank

Distance between centre of bottles [mm] 400 700

Brine tank *

Overall height of brine tank * [mm] 670 810 880 870 870

Height of safety overflow on brine tank * [mm] 570 700 780 770 770

Connection height of control valve

(raw water)

Min. foundation depth * [mm] 500 600 700 800 800

Min. length of foundation * [mm] 1300 1500 1600 2100 2200

Approx. operating weight * [kg] 190 340 555 825 1080

Filling volumes and consumption data

**

Resin quantity [l] 18 40 81 115 200

Freeboard (resin in form of sodium), approx. [mm] 270 230 290 390 300

Salt consumption per regeneration, approx. [kg] 1.8 4.0 8.1 11.5 16.0

Max. regeneration salt supply * [kg] 65 130 190 285 285

Total waste water volume per regen., approx. [l] 98 181 376 583 865

Operating water volume [l] 5 11 23 32 44

Minimum salt fill level * [mm]

Ambient data

Max. water temperature [°C] 30

Max. ambient temperature [°C] 40

Control unit

Order no. GENO-mat duo WE-X 186 200 186 210 186 220 186 230 186 240

* With standard brine tank

The waste water volume and salt consumption refer to a primary pressure of 3 bar.

**

The indicated values change at different inlet pressures and only serve as a means for a rough determination.

The indicated max. continuous flows may decrease in case of high raw water hardness.

***

In case of systems with a nominal connection diameter of DN 40, the control unit is fastened between the exchanger

****

tanks.

1)

All indicated dimensions and weights are approximate!

>

0.1 °dH

[m³x°dH]

[m³/h] 2.0 3.0 5.0 6.0 9.5

[m³/h] 3.3 5.0 8.3 10.0 15.8

[m³/h] 2.6 2.7 3.1 4.5 5.6

[m³/h] 4.3 4.5 5.2 7.5 9.3

[mol]

[mm] 208 257 334 369 469

[mm] 410 500 570 700 700

[mm] 940 1160 1420 1710 1830

GENO-mat duo WE-X water softener

50 130 230 330 530

DN 25

(1" female thread)

(system operation with protective low voltage 24V DC)

9.5

53

20.9

117

42.3

237

DN 40

(1½" female thread)

60.0

336

95.2

533

14

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 15

3 | Designated application

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

The water to be softened has to be free of iron and manganese

Water softeners of the GENO-mat duo WE-X series are

designed for the softening and partial softening of cold drinking

and process water. As twin systems, they are suitable for the

continuous supply of soft water. There are system types

available with regeneration with full salting or economy salting.

In this case, the type of regeneration is type-specific and is not

allowed to be changed independently.

Note: In order to soften the water to less than 0.1 °dH, only and

exclusively systems with full salting may be applied.

(less than 0.2 mg iron and/or 0.05 mg manganese per litre).

Its temperature must not exceed 30 °C. The maximum ambient

temperature is 40 °C.

The systems are used for the (partial) softening of well, process,

boiler feed, cooling and air-conditioning water.

When softening drinking water, the provisions of the German

Drinking Water Ordinance are binding (residual hardness of

3 °dH - 8 °dH, max. sodium content of 200 mg/l (chapter E-2.1.).

A blending valve for mixing supply water is also needed.

The system is adjusted to the soft water requirements to be

expected at the installation site, it is not suitable for major

deviations. The maximum continuous flow must not be exceeded

under any circumstances.

The system may only be operated if all components are installed

properly. Safety devices and equipment must NEVER be

removed, bridged or tampered with.

Appropriate application of the device also implies that the

information contained in this operation manual and all safety

guidelines applying at the installation site be observed. Furthermore, the maintenance and inspection intervals have to be

observed.

4 | Application limits

The application limit is defined by the maximum continuous flow

corresponding to the data in tables C-1 and C-2 for raw water in

the hardness ranges 1 - 3. With very hard water (from hardness

range 4 onwards), there may be a drop in the continuous flow.

In this case, the application limit of the system is defined by the

formula:

flowcontinuousMaximum

The time capacity is summarised in tables C-1 or C-2.

capacityTime

hardnessBlendinghardnesswaterRaw

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

15

Page 16

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

5 | Scope of supply

5.1 Basic configuration

5.2 Optional accessories

2 double-walled plastic exchanger tanks.

Food-compatible ion exchanger resin

Note: With smaller units (up to GENO-mat duo WE-X 300),

the exchanger tanks are supplied filled with resin.

1 central control valve made of red bronze.

Brine tank made of PE incl. sieve bottom (which separates

the salt supply chamber and the brine chamber) and brine

valve made of PP with safety float (controls the brine flow).

With brine buffer technology.

1 microprocessor controller with LC display (controls all

system functions and indicates operating states and

disturbances).

GENO-mat duo WE-OSMO-X without LCD display. The

operation is carried out via the control electronics of the

reverse osmosis system GENO-OSMO-X.

Turbine water meter (TWZ) (can be replaced by water meter

with counter, refer to Chapter C-4.2.).

Water test kit "total hardness" (refer to Chapter C-4.3).

Operation manual.

Note: It is possible to retrofit existing systems with optional

components. Please contact your local Grünbeck representative

or Grünbeck’s headquarters in Hoechstaedt for details.

Adapter connection 9000 with integrated blending

unit; R 1"

(standard equipment for duo WE-X 50, 130 and

230, available as an option for duo WE-X 65, 150

and 300)

Blending valve (to adjust the residual hardness by

adding raw water)

Connection R 1 ¼"

Water meter with counter

Note: The water meter (163 080 und 163 085) cannot be used

for the control unit of the water softener GENO-mat duo WE-X !

Connection R 1"

Connection R 1½"

125 809

126 003

163 080

163 085

16

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 17

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

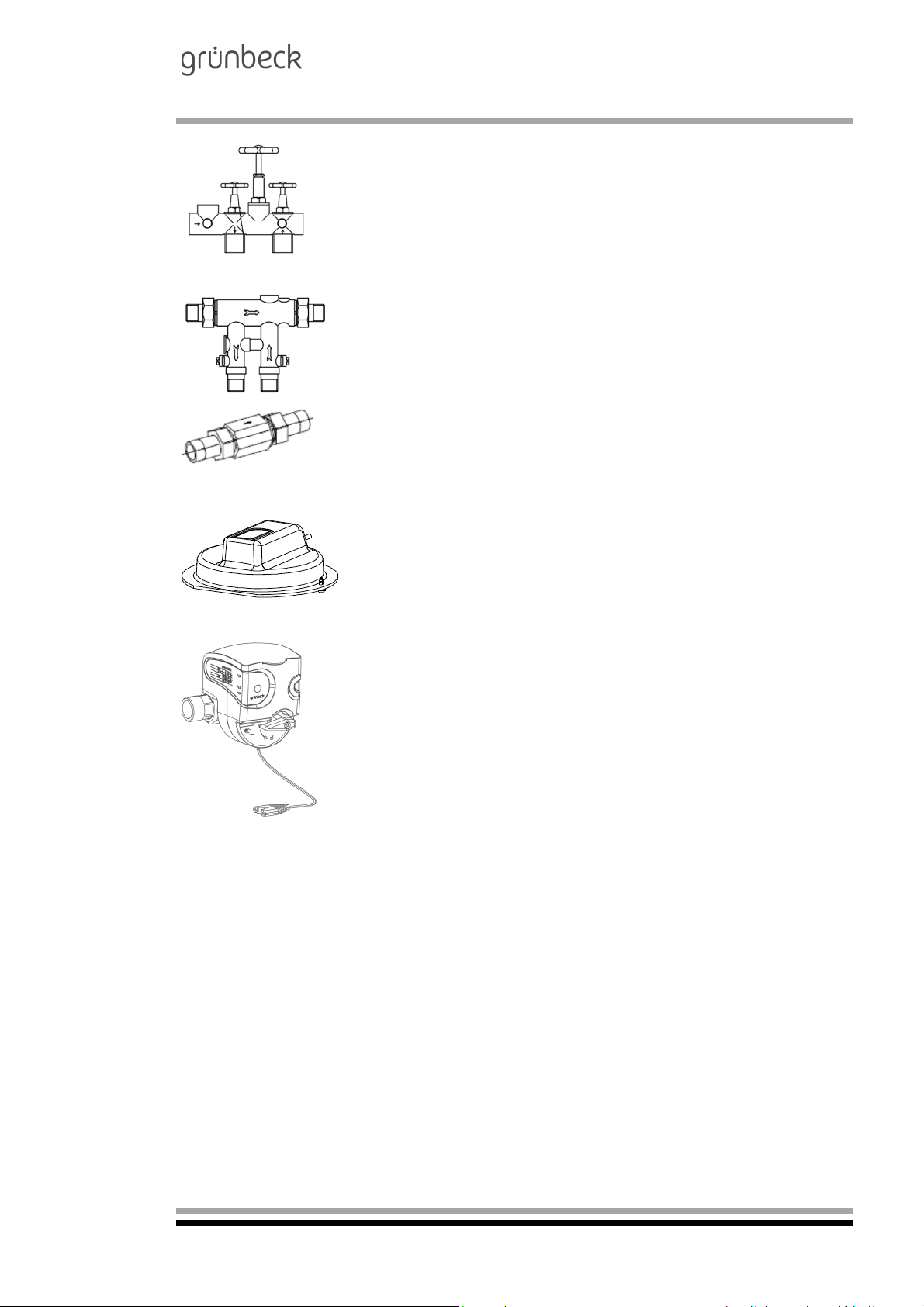

Mounting set 1: (for easy connection to the water

installation)

Compact valve block R 1", female thread,

integrated bypass with shut-off valve, shut-off

valves for hard and soft water, outlet for raw water

(e.g. garden hose), 2 flexible stainless steel fabric

hoses* (connection R 1", female thread, length

600 mm)

Mounting set 2: (for ease of connection to the

water installation) connecting block R 1" male with

threaded connectors, ball shut-off valves for hard

and soft water, non-return valve, overflow valve,

2 flexible stainless steel woven hoses* (connection

R 1" female, length 600 mm)

Overflow valve, connection R 1" male, opening

pressure 0.8 bar (to cover peak demand by adding

raw water, to be installed in the bypass),

Potential-free message (operation and

regeneration message)

Pre-alarm salt supply

Infra-red light sensor to register the minimum salt

filling level in the brine tank. Message via

GENO-IONO-matic-WE control unit

125 845

125 850

125 855

126 890

185 335

Safety device protectliQ

Product for protection against water damage in oneand two-family homes.

5.3 Consumables Only use genuine consumables in order to ensure the reliable

operation of the system.

Regeneration salt (25 kg)

Water test kit for total hardness

°dH and °f

1 piece

10 pieces

126 400

127 001

170 187

170 100

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

17

Page 18

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

5.4 Wearing parts

Seals and control pistons are subject to a certain wear and tear

in the event of heavy duty. Wearing parts are listed below.

Note: Although these are wearing parts, we grant a limited

warranty period of 6 months.

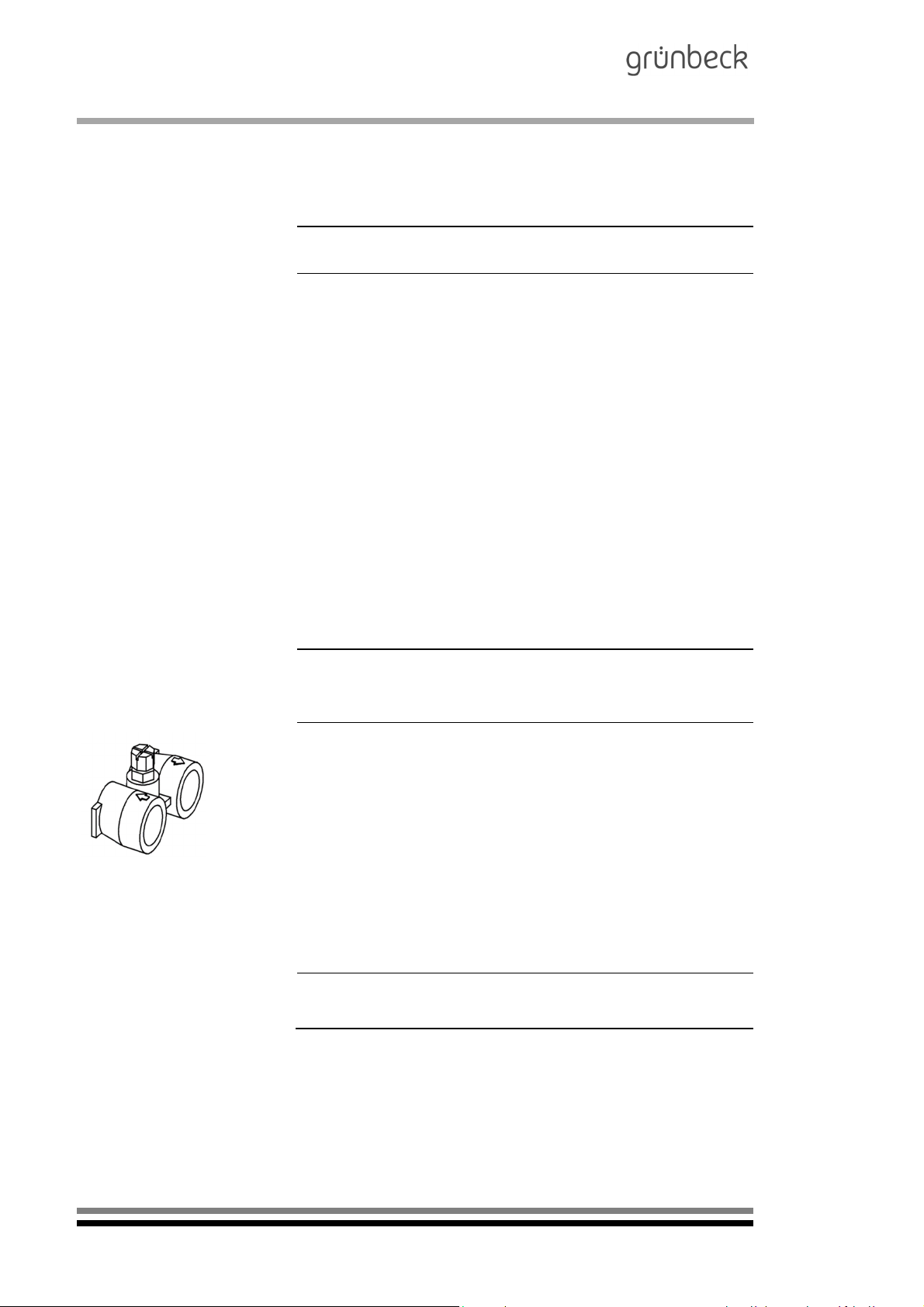

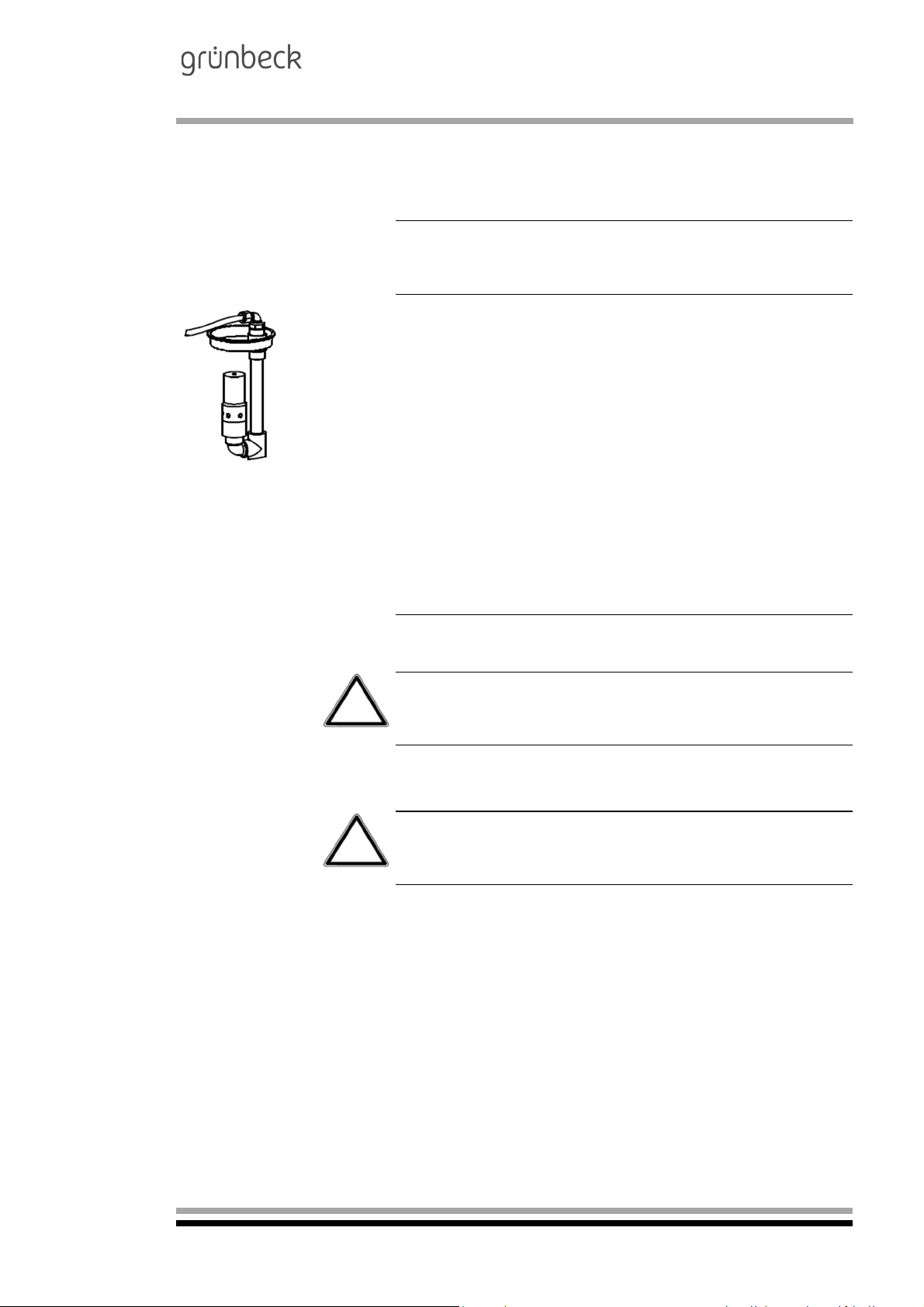

Fig. C-1: Control valve

a) Seals, control pistons, injectors, actuator

nominal connection diameter DN 25

b) Flat seals, backflow preventer

Fig. C-2: Control valve

nominal connection diameter DN 40

Fig. C-3: Brine valve

18

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 19

D Installation

1 | General installation information

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

The installation site must offer adequate space. A foundation of

asufficient size and adequate load carrying capacity must be

provided. The required connections must be provided prior to the

installation. For dimensions and connection data, please refer to

table D-1.

Table D-1: Installation data

Extract from table C-1, C-2

with full salting with economy salting2)

65 150 300 450 750 50 130 230 330 530

Connection data

Nominal connection diameter

Min. drain connection DN 50

Power supply [V]/[Hz]

Connected load [VA]

Protection/protection class IP 54/I

Dimensions and weights1)

Total height** [mm] 1310 1530 1790 1840 1970 1310 1530 1790 1840 1970

Overall height without control unit**** [mm] 1080 1300 1560 1840 1970 1080 1300 1560 1840 1970

Exchanger tank

Distance between centre of bottles [mm] 400 400 400 700 700 400 400 400 700 700

Brine tank *

Overall height of brine tank * [mm] 810 880 870 1100 1250 670 810 880 870 870

Height of safety overflow on brine

tank *

Connection height of control valve [mm] 940 1160 1420 1710 1830 940 1160 1420 1710 1830

Min. foundation depth * [mm] 600 700 800 900 1000 500 600 700 800 800

Min. length of foundation * [mm] 1460 1500 1700 2100 2400 1300 1500 1600 2100 2200

Operating weight, approx. * [kg] 285 435 730 1110 1745 190 340 555 825 1080

* With standard brine tank

**** For systems with a nominal connection diameter of DN 40, the control unit is mounted between the exchanger tanks.

1)

All indicated dimensions and weights are approximate!

2)

not applicable for GENO-mat duo WE-OSMO-X.

GENO-mat duo WE-X / WE-OSMO-X

DN 25

(1" female

thread)

(system operation with protective low voltage 24V DC)

[mm] 208 257 334 369 469 208 257 334 369 469

[mm] 500 570 700 780 900 410 500 570 700 700

[mm] 700 780 770 980 1120 570 700 780 770 770

Water softener

DN 40

(1½" female

thread)

85 -250/50-60

10

DN 25

(1" female

thread)

DN 40

(1½" female

thread)

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Note: Observe the operating manual that have been supplied

with the optional accessories (see chapter C, 4.2) for your unit.

19

Page 20

Water softener

g

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

1.1 Water installation

It is imperative that you comply with certain regulations when

installing the GENO-mat duo WE-X water softener. Additional

recommendations are given in order to facilitate the handling of

the system. The installation instructions described below are

also illustrated in Fig. D-1.

Bindin

The installation of a water softener represents a major

interference with the drinking water system. Therefore,

only authorised experts may install such systems.

Please observe the local installation guidelines and

Install a drinking water filter upstream (e.g. BOXER).

Use corrosion-resistant material for soft water lines

Provide a drain connection (minimum DN 50) to discharge the

Note: If the regeneration water is directed to a lifting system,

said system must be salt water resistant.

The unit does not carry a DVGW test certificate. Provide

additional safety equipment for protection of the drinking water in

line with DIN 1988. Therefore:

Isolate the water softener from the drinking water supply in

Recommendations

Provide a sampling valve immediately downstream of the

rules

the general regulations.

OR

Meter corrosion inhibitor downstream of the water softener.

regeneration water.

line with DIN 1988 part 4 (e.g. by the use of the GENO DK 2

Euro system separator).

softener. This facilitates the sampling for the regular hardness

tests (functional check).

Warning! Floor drains leading to a lifting system do not work in

case of a power failure.

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

20

Page 21

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

1.2 Electrical installation

A shock-proof plug is adequate for the electrical connection.

However, it must comply with the specifications given in table

D-1, may not be further away from the softener than 1.20 m and

must carry constant voltage (do not couple with light switch).

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

21

Page 22

Water softener

)

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

1.2.1 Connections to other subsystems within the water softener

The following connections are preset internally at the factory and

must not be modified (cables to be connected by the client are

marked with *

Table D-1:

From IONO-matic

WE control unit

1 Mains cable H05VV-F 3G0.75

2 N BU

PE Earth wire YE-GN

3

4

5

6

PE

7

8

PE

9

10

PE

11 Microswitch

12 S1 Litz wire 2 YE

13 + 24 V=

14 S2 Litz wire 3 OG

Colour of litz wire

20 Step motor control

21 Ph1 BN YE-BK

22 Ph2 GY BK

23 (3 terminals in the

24 Ph3 YE YE

25 Ph4 RS RD

26 Water meter* LiYY 3x0.25 mm² + 12 V= WH

27 pulse GN

28 GND BN

32 Pot.-free contact, closed when

33

34 Pot.-free contact, closed during

35

GND1 Connection to the

40 RS485B GY

41 RS485A GN

GND GND YE

42 + 14 V= BN

to component Line Signal

Reserved terminals

control valve* (3

terminals on the right

on the terminal strip

at the control valve

valve* (3 terminals

on the left)

middle at the control

valve)

exchanger tank 1 in operation.

regeneration.

programming board

.

L BN

mm²

LiYY 3x0.5 mm² + 24 V= Litz wire 1 BK

Line Motor

LiYY 7x0.25 mm² + 24 V= GN BU

+ 24 V= WH BU

Switching capacity

max. 30 V~1A

LiYY 5x0.34 mm² GND-RS WH

22

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 23

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

1.2.2 Connections to external or optional components

From IONO-matic

WE control unit

15 Programmable input + 24 V=

16 IN

17 Option pre-alarm

18 IN BK

19 GND BU

29 Collective fault Max. 250 V~ /

30 Common root

31 Signal contact

1.2.3 Connections to networked GENO-OSMO-X reverse osmosis

From IONO-matic

WE control unit

38 Bus line to

39 94 RS485 B

GND2 95 RS485-GND

(*) With cable length > 20 m: Use LiYcY 3x0.25 mm² and

to component Line Signal

LiYY 4x0.25 mm² + 24 V= BN

salt supply 185335

max. 3 A each

to component Line Signal

OSMO-X

control unit

93 LiYY 3x0.25 mm²

(*)

connect the shielding at one end either in the OSMO-X control

unit or IONO-matic WE/control unit DEA at a free PE terminal.

RS485 A

2 | Preliminary work

1. Unpack all system components.

2. Check for completeness and soundness.

3. Set up both exchanger tanks at the intended site.

Caution! The system only functions if it is set up correctly. Set

up the exchanger tank with control valve on the right (seen from

the front).

Only with small systems (nominal connection diameter 1"):

The connection hoses with pre-installed connection adapters

and coupling pieces are exposed.

4. Plug in coupling pieces.

5. Install hoses between control valve and bottle adapter.

6. Fit connection block for raw water connection.

Note: The connection block is supplied with separate installation

instructions.

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

23

Page 24

Water softener

g

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

2.1 Filling the exchanger

tank

The work described here is only needed with the large systems .

Smaller units are supplied with filled exchanger tanks.

Table D-1: Fillin

Amount of resin per

exchanger container

1. Check whether the riser pipes are covered by protective

caps, plug on protective caps, if necessary.

Protective caps prevent material from entering the riser

pipes.

2. Centre riser pipes in the exchanger containers.

3. Pour ion exchange resin into the tanks. Use the funnel

provided.

Centre riser pipe, fill with resin

4. Centre the riser pipes precisely.

5. On the exchanger containers, clean any adhering ion

exchanger resin off the threads and sealing connections for

the connections of the control valve or bottle adapter.

6. Remove the protective caps from the riser pipes.

7. Guide the control valve from above with its head nozzle over

the riser pipe of the right exchanger tank (as seen from the

front) and secure by turning clockwise.

8. Guide the bottle adapter from above with its head nozzle

over the riser pipe of the left exchanger tank (as seen from

the front) and secure by turning clockwise.

Remove the protective cap,

fix the control valve in place

9. Install connecting pipes between control valve and bottle

adapter.

in resin

450 / 330 750 / 530

115 l 200 l

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

24

Page 25

2.2 How to fit the brine line

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

See Fig. D-1 (b), position 7.

1. Set up the brine tank at its intended site.

2. Remove cover from the brine tank.

Brine valve with transition nipple and

elbow connector

Note: Remove the brine valve to make installing the brine line

easier. To do so, remove the yellow lid and pull the brine valve

upwards.

3. Fit the transition nipple (not needed with 750 (530)) and

elbow connector onto the brine valve.

4. Cut the brine hose to the required length and insert

reinforcing sleeves at both ends.

5. Fit the brine hose onto the brine valve.

6. Only if removed: Insert the brine valve and replace the

yellow cover.

3 | How to connect the system

3.1 Water connection 1. Make the water connection as indicated in the installation

drawing (Fig. D-1 (a)) while observing the guidelines and

recommendations given in section 1.

Note: The supplied water meter must be installed on the soft

water side (after the system) without fail.

Caution! Dirt and corrosion particles may damage the system

(control valve, ion exchanger resin). Flush the supply pipe prior

to start-up.

2. Make the waste water connection: Direct the drain hose to

the outlet and secure it.

Caution! Danger of damage and malfunction due to backflow of

waste water. Therefore, do not bend the hose and do not lead it

higher than the system height.

3. Route the brine tank overflow hose with a gradient to the

channel. Do not connect to the drain hose!

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

25

Page 26

Water softener

X

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Dimensions in Fig. D-1 (a);

Extract from table D-1

with full salting

Dimensions and weights1)

A Total height [mm] 1310 1530 1790 1840 1970 1310 1530 1790 1840 1970

A2 Overall height without control unit [mm] 1080 1300 1560 1840 1970 1080 1300 1560 1840 1970

B Exchanger tank

C Brine tank *

D Total height of brine tank * [mm] 810 880 870 1100 1250 670 810 880 870 870

E Height of safety overflow of brine

F Connection height of control valve [mm] 940 1160 1420 1710 1830 940 1160 1420 1710 1830

* In systems with standard brine tank

1)

All indicated dimensions and weights are approximate!

2)

not for GENO-mat duo WE-OSMO-X.

GENO-mat duo WE-X / WE-OSMO-

65 150 300 450 750 50 130 230 330 530

[mm] 208 257 334 369 469 208 257 334 369 469

[mm] 500 570 700 780 900 410 500 570 700 700

[mm] 700 780 770 980 1120 570 700 780 770 770

Water softener

with economy salting

2)

Fig. D-1 (a): Installation drawing for GENO-mat-duo WE-X water softeners

Fig. D-1 (b): GENO-mat-duo WE-X water softener;

side view right/rear

BOXER drinking water filter

1

GENO DK 2 system separator

2

Control unit

3 7

Water meter

4 8

Control valve

5 9

Exchanger tank

6

Brine tank

Brine line

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

26

Connection of hose to drain

Raw water inlet

10

Soft water outlet

11

Page 27

p

p

See Fig. D-3 for detailed view of the brine line connection

Fig. D-2: GENO-mat-duo WE-X water softener; rear view

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Brinetube

Unionnut3/8“

Fig. D-3: Exploded view of brine line connection

Plastic

pinchring3/8“

PressurelossGENO‐matduoWE

3,00

2,50

2,00

1,50

130/150

1,00

Differenzdruck [bar]

Differentialpressure[bar]

0,50

50/65

Brasssleeve3/8“

Druckverlust GENO-mat duo WE

230/300

330/450

Filterfor

brinevalve

Transition‐

ni

530/750

le

0,00

0,0 1,0 2,0 3,0 4,0 5,0 6,0 7,0 8,0 9,0 10,0 11,0 12,0

Flowrate[m³/h]

Durchfluß [m³/h]

Fig. D-2: Pressure loss curve

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

27

Page 28

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

3.2 How to connect the control unit

The work described here may only be performed by trained

electricians or electronics experts.

The control unit must be connected according to the terminal

diagram shown in Fig. D-2.

2. Route the 7-core cable for the step motor and the 3-core

Note: The corresponding connection diagram is contained in

the electrical circuit diagram of the reverse osmosis system

or the operating instructions for the automatic salt reduction

system/compact air washer.

Note: Small systems (nominal connection diameter 1") are

supplied pre-assembled. This means steps 1 and 2 can be

skipped.

1. Attach the control unit to the connecting pipes using the

supplied fastening kit

Danger due to electrical energy!

Mains voltage is at terminals L, N and PE.

Do not connect system to mains before you have finished this

work.

cable for the micro switch between the control valve and

control unit, and connect according to the terminal diagram

(chapter D-1.2.).

3. Connect the water meter according to the terminal diagram

(chapter D-1.2.1).

4. Connect the mains plug to the socket (chapter D-1.2).

28

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 29

E Start-up

The work described below may only be performed by trained

experts. For safety reasons, the start-up must be performed by

Grünbeck's trained and authorised technical customer

service/authorised service company.

1 | How to fill the brine tank

1. Remove the cover from the brine tank

2. Carefully add water until the water level is about 30 mm

Caution! Insoluble impurities in the salt may cause malfunctions

at the brine valve and at the injector of the control valve.

A defined salt quality is required for the reliable function of the

water softener.

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

above the sieve base.

Only use salt tablets that conform to DIN EN 973 A.

3. Insert salt tablets into the brine tank. The brine tank can be

fully filled.

4. Add the operating water volume (Table E-1).

5. Close the brine tank cover.

Table E-1: Filling of brine tank

Systems with full salting

Max. regeneration salt supply * [kg] 130 190 285 485 760

Operating water volume [l] 10 22 45 70 111

Table E-2: Filling of brine tank

Systems with economy salting

Max. regeneration salt supply * [kg] 65 130 190 285 285

Operating water volume [l] 5 11 23 32 44

* In systems with standard brine tank

Water softener GENO-mat duo WE-X /

GENO-mat duo WE-OSMO-X

65 150 300 450 750

Water softener GENO-mat duo WE-X

50 130 230 330 530

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

29

Page 30

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

2 | How to set up the system

2.1 How to set the blending

hardness

Example

Softening of drinking water

Supply water (22 °dH)

contains sodium (51.6 mg/l)

Possible addition of sodium during

softening:

200 mg/l – 51.6 mg/l = 148.4 mg/l

This means that the maximum

permissible softening is:

Conclusion:

Blend to at least 22 – 18 = 4 °dH!

2.1.1 Recommendations

Blending hardness

The small systems with economic salting (GENO-mat duo

WE-X 50, WE-X 130, WE-X 230) are equipped with a blending

unit as standard.

This blending unit is available as additional equipment for the

GENO-mat duo WE-X 65, WE-X 150, WE-X 300 systems.

Larger systems can be fitted with a blending valve R 1¼" as

additional equipment. If both soft water with 0 °dH and blended

water are needed, this blending valve is also recommended for

small systems. Refer to the operating manual for the blending

valve in systems with this equipment.

Caution! If the water softener is installed before a reverse

osmosis system, the feed line to the reverse osmosis system is

not allowed to be configured as a blending water line.

Note: The provisions of the German Drinking Water Ordinance

are binding when softening drinking water.

Sodium content (max:) 200 mg/l Note point 3.1 with regard to the

blending hardness!

Sodium content

Obtain the sodium content of the supply water from your water

supply provider. The sodium content increases by approx. 8.2

mg/l when softening water by 1 °dH. The water cannot be

softened unrestrictedly if the provisions of the German Drinking

Water Ordinance are to be adhered to. The permissible blending

hardness results from the limit value for the sodium content and

the supply water hardness.

200 mg/l (limit value according to the Drinking Water

Ordinance)

– x mg/l (sodium content in the supply water)

y mg/l (permissible addition of sodium during softening)

y

The supply can be softened to a maximum of Z °dH. Depending

on the sodium content of the supply water, a blending hardness

needs to be selected which is below the admissible maximum of

200 mg/l.

Blending

hardness

= Z °dH (maximum possible softening)

82,

Result

3 – 5 °dH Very soft water – ideal for thermal equipment

– possible problems when washing off soap

6 – 8 °dH Optimum soft water

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

30

Page 31

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Setting the blending unit

In the GENO-mat duo WE-X 50, duo WE-X 130 and duo

WE-X 230 systems, the blending unit described here is mounted

on the control valve. Optionally, small systems with full salting

can be equipped with it. In all other cases, the operating manual

for the installed blending valve applies.

1. Open the valve on the raw water inlet.

2. Open the valve on the soft water outlet.

5. Perform a hardness test using the "Total hardness" water

3. Set the adjusting cap (1) to a mean scale value.

4. Take a water sample at the sampling valve downstream of

the system.

inspection device.

6. Set the blending hardness as required.

In order to do so:

Turn the adjusting cap to the left (close) so as to reduce

the blending hardness.

Turn the adjusting cap to the right (open) so as to increase

the blending hardness.

7. Repeat steps 4. and 5. until the desired blending hardness is

reached.

2.2 How to set the control

unit

2.2.1 Setting the time and

raw water hardness

Press and hold key P for > 1 second. The parameters can be

The GENO-mat duo WE-X water softener is volume-controlled.

The operating parameters are already stored in the GENOIONO-matic WE-X control unit. During start-up, all parameters

must be entered which are required for the automatic calculation

of the regeneration interval.

Note: For detailed information on the handling of the

GENO-IONO-matic WE-X control unit, please refer to chapter F.

Starting from the basic display

accessed there.

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

31

Page 32

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

3 | How to start up the system

1. Open the valve on the raw water inlet.

2. Release a manual regeneration (chapter F). Starting from

the basic display, press and hold key for 5 seconds.

An exchanger is now regenerated.

3. When the first manual regeneration has finished: Start a

manual regeneration again, the second exchanger is now

regenerated.

Note: All systems with low-salt alarm have a delay time set between 2 regenerations (factory setting: 0.2 hours = 12 minutes).

At the end of the regeneration, it is necessary to wait for this

time to elapse before a manual regeneration can be triggered

again.

4. Open the valve on the soft water outlet after regeneration has

finished.

5. Perform a visual check.

Ensure that no water leaks from the system at any point.

6. Take a water sample at the sampling valve downstream of

the system.

7. Perform a hardness test using the "Total hardness" water

inspection device.

The system is working correctly if the analysis of the water

taken just downstream of the exchanger tank gives 0 °dH.

8. Complete the cover sheet and check list / column 1 of the

operating log. To do this, carry out the necessary measurements and tests.

32

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 33

F Operation

GENO-IONO-matic WE-X control unit

1 | Introduction

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Fig. F-1: Display of control unit GENO-IONO-matic WE-X

The GENO-mat duo WE-X water softeners are volumecontrolled. They are operated and monitored by means of the

control unit.

2 | How to operate the control unit

2.1 Key functions

Accesses parameters for editing (cursor flashing).

Save the modified parameters (cursor stops flashing).

Starting from the basic display (time/residual capacity/time

since last regeneration): Press and hold for > 1 sec. = access

to the operator menu.

Acknowledge of errors/warnings.

Within a menu: Switch to the next parameter.

+

+

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Opened parameters: Reduce the set value.

Starting from the basic display (time/residual capacity/time

since last regeneration): Press and hold for > 5 sec. = trigger

manual regeneration.

Within a menu: Return to the previous parameter.

Opened parameters: Increase the set value.

Starting from the basic display (time/residual capacity/time

since last regeneration): Access to the code request for menu

levels with code protection.

Jump back to the basic display (time/residual capacity/time

since last regeneration) from any menu level.

Close the opened parameter without saving, the previously set

value is maintained.

33

Page 34

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

5 minutes after the last key was pressed, the system jumps back

to the basic display (time/residual capacity/time since last

regeneration) from any opened menu. Parameter changes which

have not been saved are lost.

The display backlighting is switched off 10 minutes after the last

key was pressed. Each new key press activates the backlighting

again.

2.2 Meaning of the LEDs

red / yellow / green

2.3 Info level – reading the

operating status

Green LED is illuminated = everything OK

Yellow LED is illuminated = message (service due, low salt, time

incorrect after power failure > 24 hours)

Red LED is illuminated = fault

Also refer to chapter G Faults.

The info level offers the following information about operation of

the system:

Current time

Residual capacity of the exchanger in operation

Time since last regeneration

Press the key to continue or the key to go

back.

Remaining duration of the service interval

Press the key to continue or the key to go

back

Current regeneration step

Remaining duration of the current regeneration step

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

34

Page 35

y

2.4 System status display

2.5 Setting operating

parameters – operator

menu

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

The residual capacity of the exchanger bottle in operation is

displayed in %.

For the exchanger bottle that is undergoing regeneration, the

current flow direction is indicated by arrow symbols.

In addition to the water meter symbol, the 0 °dH flow rate

currently coming from the system is displayed in m³/h.

If the pre-alarm salt supply (Order no.185335) option is fitted,

the brine tank is shown as empty when salt tablets need to be

refilled.

On start-up, at least the time and raw water hardness must be

programmed (see table below, printed in bold). The raw water

hardness must be set to the highest hardness that is

encountered, if there are fluctuations in the water quality.

Starting point: Basic display (time/residual capacity/time since

last regeneration)

Press and hold P key for > 1 sec. >>

Operator menu appears.

Parameters Factor

Raw water

hardness

Data logging (*)

Interval

Time

Date

(*) The Yes setting means the following information is recorded in the set interval:

[°dH] 25 1…250

No No/Yes On internal SD-card (*),

[Min] 60 1…999

XX:XX 00:00…23:59

XX.XX.XX

setting Setting range Comment

Residual capacity of the exchanger in operation

(C XX.XX m³).

Current flow (Q XX.XX m³/h).

Card slot for SD-card on

operating board

Time since last regeneration (T XXX h).

Current regeneration step

0 = No regeneration

1 = Backwashing

2 = Salting

3 = Slow rinsing

4 = Washing out

5 = Filling brine tank

Time until service is due (S XXX d).

Regeneration counter (XXXXXX).

Soft water meter (XXXXXX m³).

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

35

Page 36

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

The data is stored on the SD card as a *.txt file, the values are

separated from one another by semicolons. This means the file

can be imported into MS Excel, for example, without difficulty.

2.6 How to release a

manual regeneration

Press and hold the key > 5 sec.: The exchanger bottle that is

Note: Prior to removing the SD card, make sure that the data

logging was terminated with "No"!

Note: The SD card used must be formatted FAT32. We

recommend proper formatting instead of quick formatting.

Starting point: Basic display (time/residual capacity/time since

last regeneration).

in operation is regenerated.

The function is not possible

If a regeneration is already in progress (the key command is

not stored).

If a regeneration lock is active (either via programmable input

or in the form of an interval between two regenerations).

36

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 37

y

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

2.7 Changing system

parameters – code 290

Press and hold P and keys simultaneously,

In this menu, it is possible to set various hardness units and

operating languages.

Starting point: Basic display (time/residual capacity/time since

last regeneration).

the code request appears

Water softener

Use the or keys to set code 290 and confirm with the P key.

Parameters Factor

Hardness unit °dH °dH / °f / mol/m³

Data record Depending on system

size

Capacity [m³ x °dH]

Water meter

pulse rate

Release time 00:00

[l/Imp]

Indication only

setting Setting range Comment

Applies to raw water

hardness and capacity

rate

Set value is not allowed

to be changed!

Display values cannot

be changed

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

37

Page 38

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Control via reverse osmosis system GENO-OSMO-X

1 | Introduction

The GENO-mat duo WE-Osmo-X water softeners are volumecontrolled. The systems are operated and monitored by means

of the control electronics of the GENO-WE-OSMO-Xreverse

osmosis system.

Drinking water filter BOXER K 1“

1

GENO-DK 2 system separator

2

3

Water softener Delta-p

4

GENO-softwatch Komfort

5

Active carbon filter AKF

Fig. F-2: Installation drawing

Reverse osmosis system GENO-OSMO-X

6

Permeate tank with sterile air filter and level probe

7

Pressure booster system GENO-FU-X 2/40-1 N

8

38

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 39

A

GENO

ccess to the

®

-OSMO-Xmenu

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

Home-button

Operating mode, current measuring values

The following information is stored in the OSMO-X control unit.

This can be found in the subsystem range of the INFO level (can

be called up using the or keys).

Residual capacity AT * [m³]

Flow rate Q [m³/h]

Time since last regeneration [h]

Current regeneration step [X]

Time to service due [d]

Regeneration counter [XXX]

Counter soft water [m³]

Software version [X.XX]

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

39

Page 40

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

2 | How to operate the control unit

2.1 Change, save, reject parameters

In a menu with permanently stored selections,

any choice (line) can be selected by tapping on it.

The middle line is in slightly larger print, however.

Save your selection with this button.

Quit the menu with this button without changing

the prior selection.

The numerical and the alpha-numerical menu each

feature the same operating logic:

Save your selection with this button.

Quit the menu with this button without changing

the prior selection.

Save your selection with this button.

Quit the menu with this button without changing

the prior selection.

40

Order no. 074 184 046-inter Edited by: phar/mrie G:\BA-184046-inter_074_GENO-mat duo_WE-X.docx

Page 41

Water softener

GENO-mat duo WE-X,

GENO-mat duo WE-OSMO-X

2.2 Acknowledgement of errors/signals